Pulverized coal low temperature carbonization system and method and coal low temperature carbonization system

A pulverized coal and low-temperature technology, which is applied in the field of coal low-temperature carbonization system and pulverized coal low-temperature carbonization system, can solve the problems of pollution, waste of human resources, waste of resources, etc., and achieve the goals of saving human resources, good economic benefits, and increasing production rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

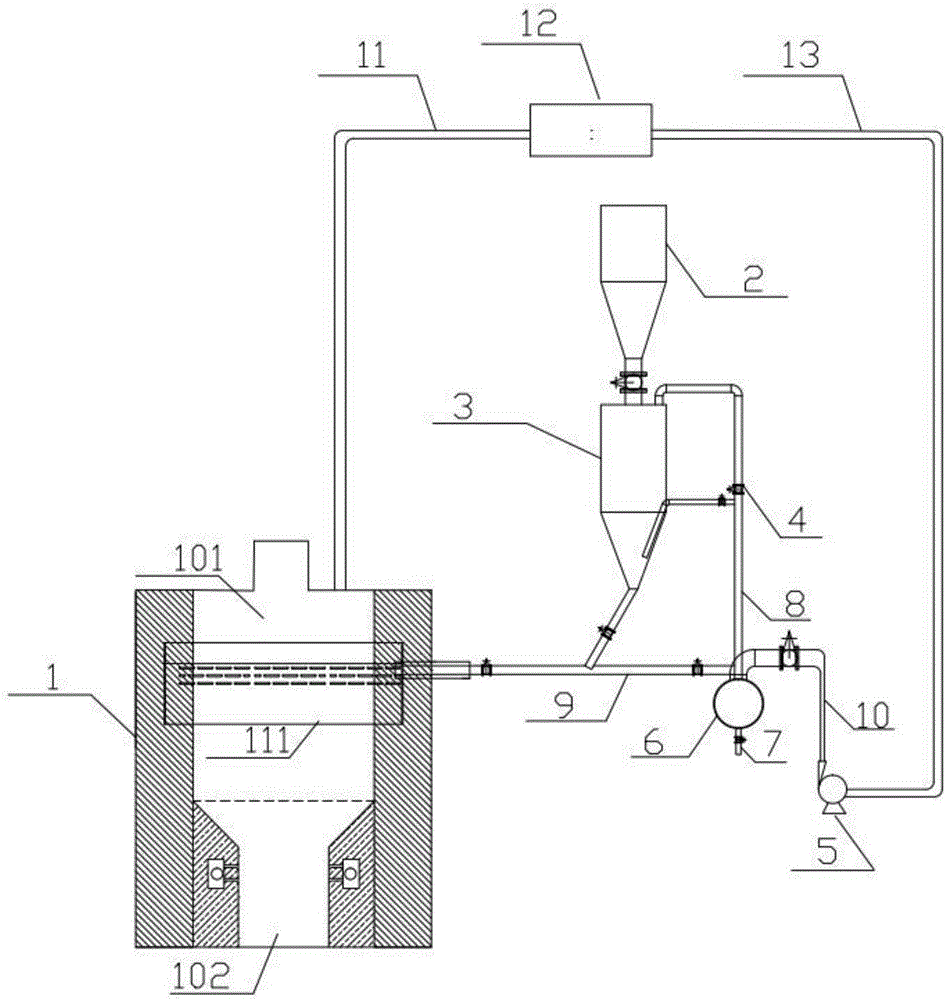

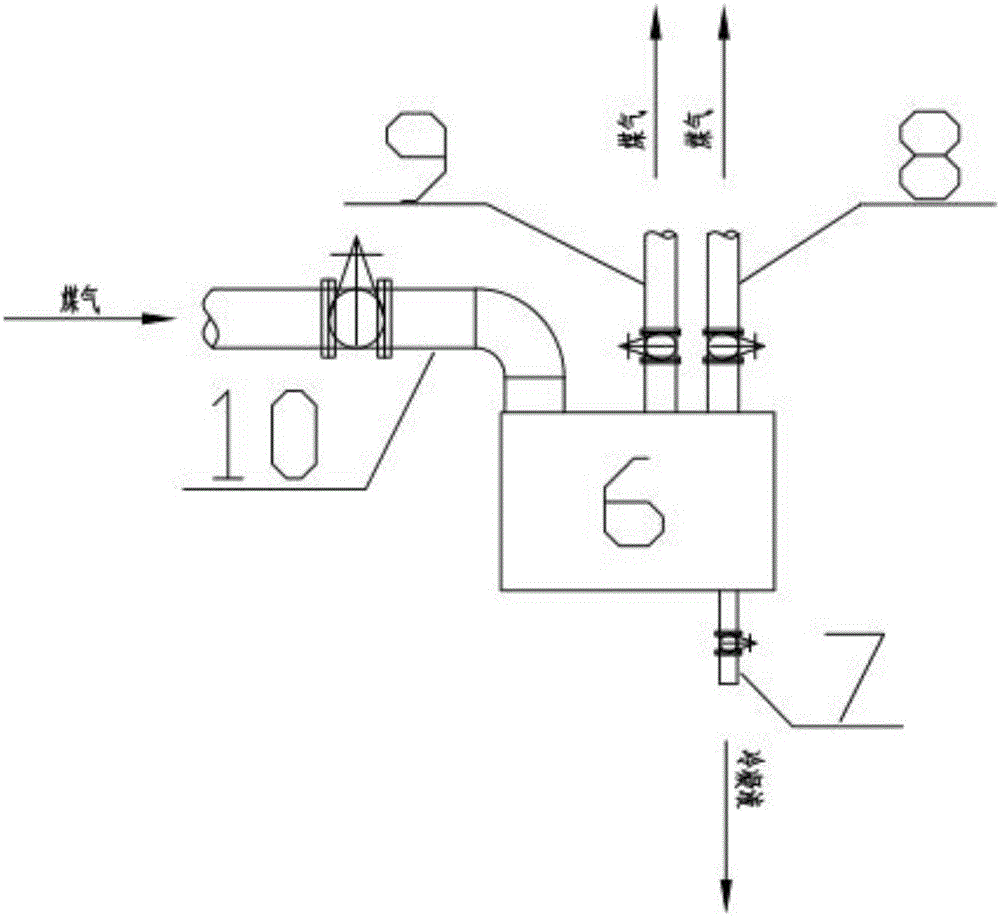

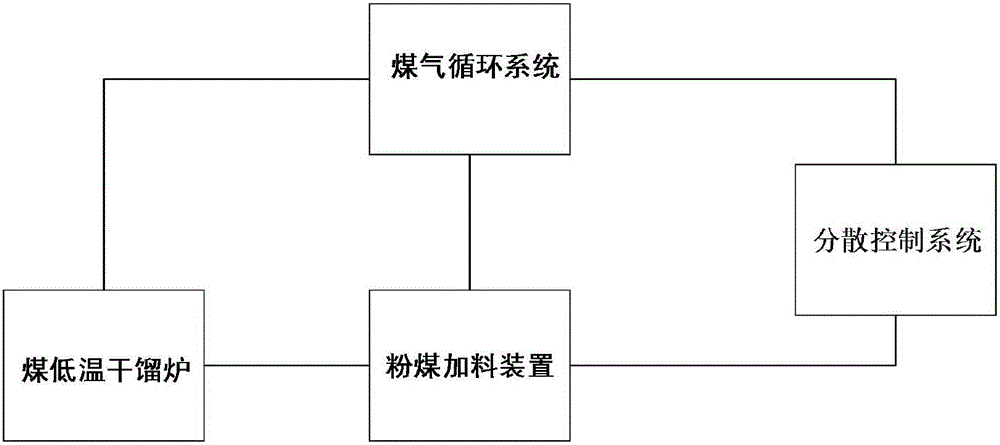

[0043] Such as figure 1 As shown, a pulverized coal low-temperature carbonization system includes a pulverized coal feeding device, a low-temperature carbonization furnace 1, and a gas circulation system. The low-temperature carbonization furnace 1 includes a carbonization section 101 and a cooling section 102 located at the lower end of the carbonization section 101, The top of the low-temperature carbonization furnace 1 is connected to the gas circulation system, the gas circulation system is connected to the pulverized coal feeding device, and the gas circulation system and the pulverized coal feeding device are connected to the low-temperature carbonization furnace through the injector 9 The dry distillation section 101 of 1 is connected in phase.

[0044] Using the above system, the pulverized coal low-temperature carbonization method includes a pulverized coal low-temperature carbonization process and a gas circulation process, and the pulverized coal low-temperature car...

Embodiment 2

[0058]A pulverized coal low-temperature carbonization system is shown in Embodiment 1, wherein the low-temperature carbonization furnace 1 further includes a distribution umbrella 111, and the distribution umbrella 111 is arranged in the carbonization section, and the pulverized coal feeding device passes through the injector 9 and The cloth umbrella 111 communicates.

[0059] The beneficial effect of this embodiment is as shown in Embodiment 1, wherein the coal gas blows the pulverized coal from the injector 9 into the distribution umbrella 111, so that the pulverized coal is evenly distributed to the distribution umbrella of the low-temperature carbonization furnace for sufficient carbonization, and the pulverized coal is prevented from entering the low-temperature carbonization The furnace cannot be fully calcined, which further increases the yield of pulverized coal carbonization, which has good economic benefits.

Embodiment 3

[0061] A pulverized coal low-temperature carbonization system is shown in Embodiment 2, wherein the pulverized coal feed device includes a pulverized coal feed tank 2 and a pulverized coal storage tank 3, and the outlet of the pulverized coal feed tank 2 and the pulverized coal storage tank The inlet of 3 communicates, and the outlet of pulverized coal storage tank 3 communicates with cloth umbrella 111 through injector 9.

[0062] In this embodiment, the pulverized coal feeding device is composed of the pulverized coal feed tank 2 and the pulverized coal storage tank 3, which can control the feeding amount of pulverized coal, and spray the pulverized coal to the place with the highest temperature in the carbonization section of the low temperature carbonization furnace through the distribution umbrella , to further fully and effectively utilize pulverized coal, increase the yield of pulverized coal dry distillation, and have good economic benefits;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com