Patents

Literature

119results about How to "Control the amount of feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

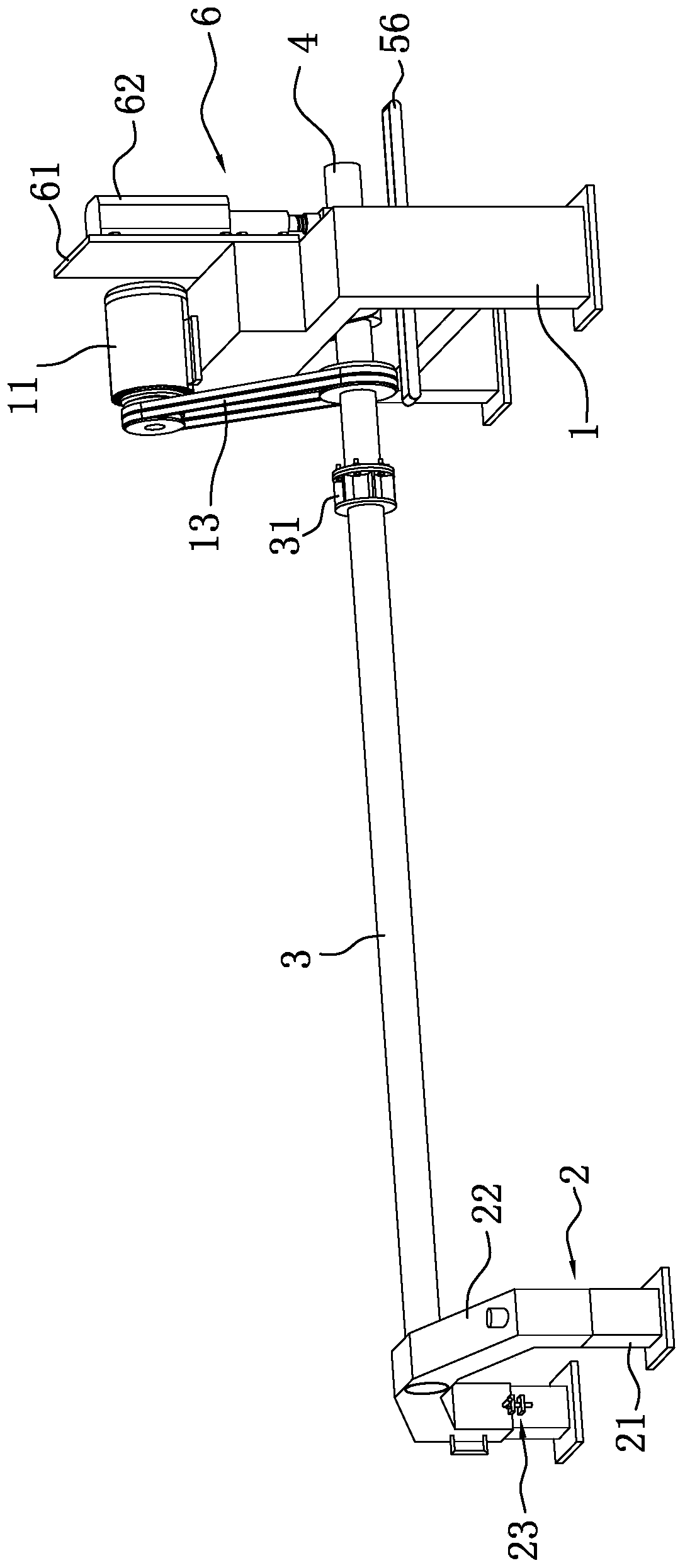

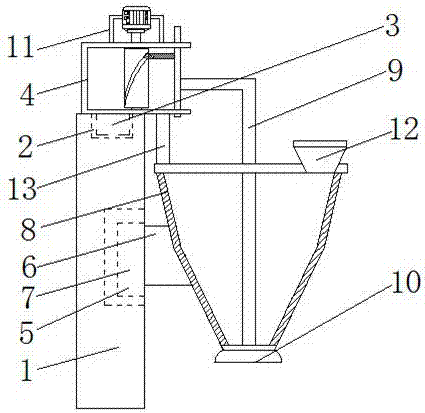

Intelligent food feeder and program control method for intelligent food feeder

ActiveCN104488748AEasy to operateSmall footprintAnimal watering devicesAnimal feeding devicesAutomatic controlElectric machinery

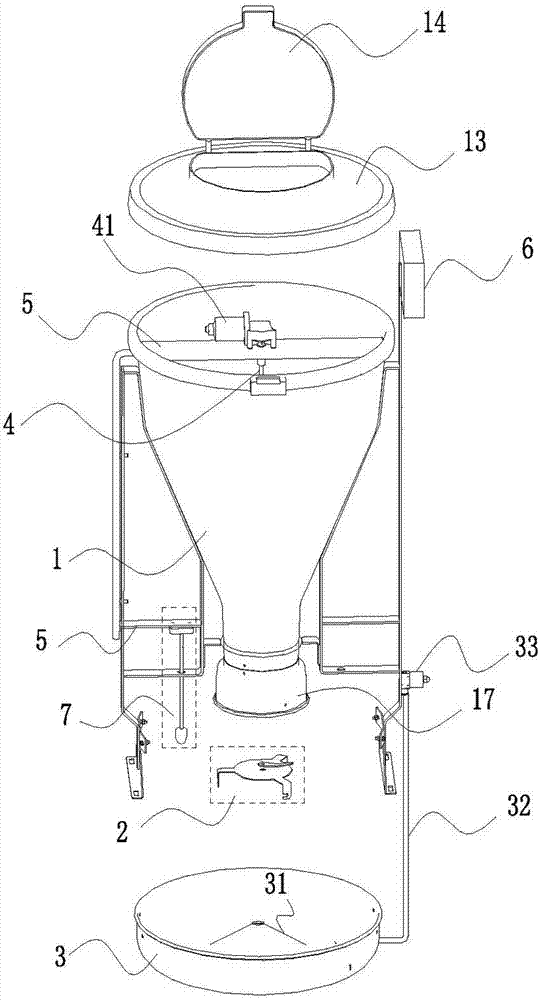

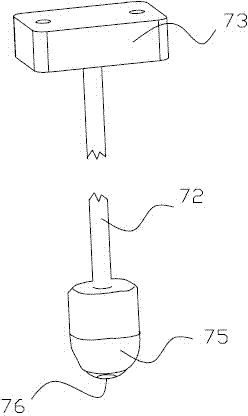

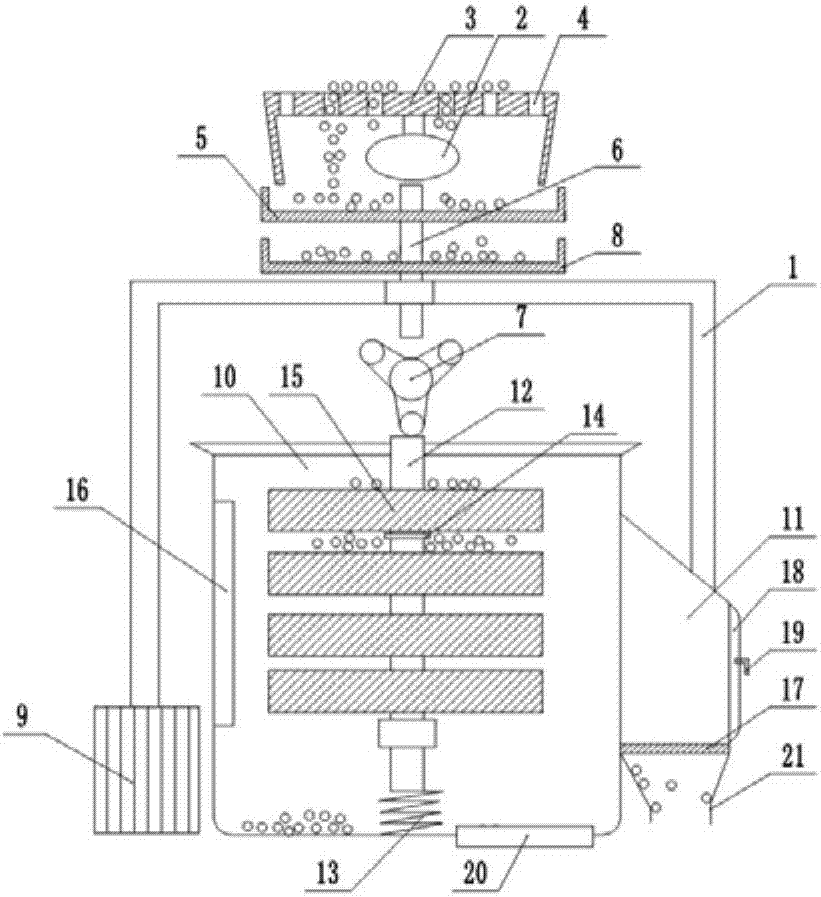

The invention relates to an intelligent food feeder and a program control method for the intelligent food feeder. A push device is arranged at a first discharge hole of a food bucket; the bottom end of a rotating shaft is connected with the push device; the top end of the rotating shaft is linked with the output shaft of a motor; a water pipe is provided with a water valve; the water valve and the motor are connected with the control device; a support is fixedly provided with a touch device; the touch device comprises a discharge switching device and a level detection device; the top end of an oscillating bar of the discharge switching device is provided with a travel switch; the bottom end of the oscillating bar is provided with a gravity touch end; the discharge switching device is connected with the control device; a probe of the level detection device is arranged in the gravity touch end and is used for detecting food amount on a manger and sending a detection signal to the control device. The signal is transmitted to the control device through a sensor, so that an automatic control function is realized; the intelligent food feeder is simple in structure, space-saving, convenience to use and convenient to install and detach.

Owner:GUANGDONG PROVINCE MODERN AGRI EQUIP RES INST +1

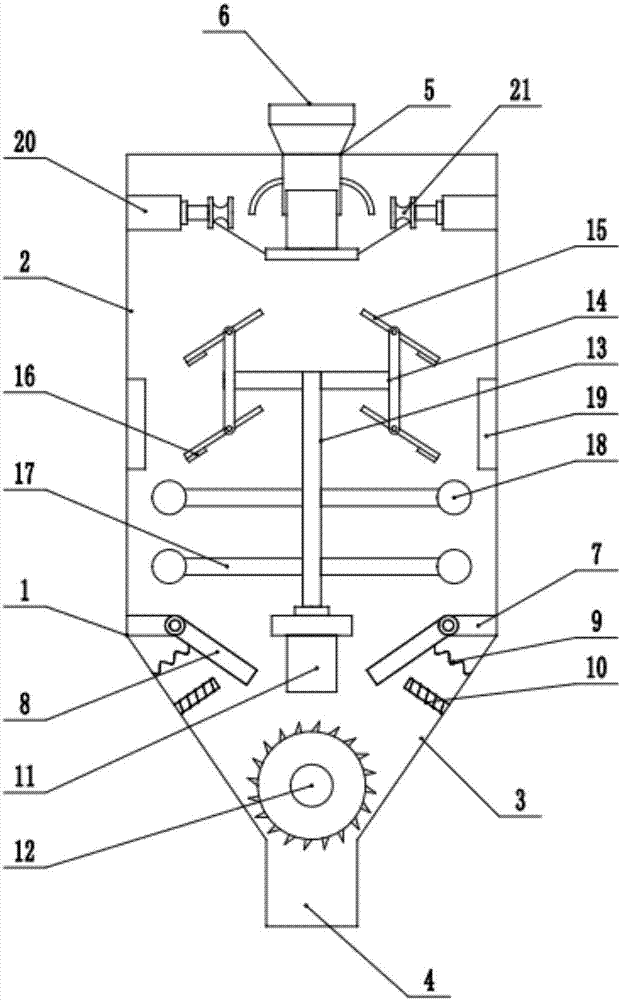

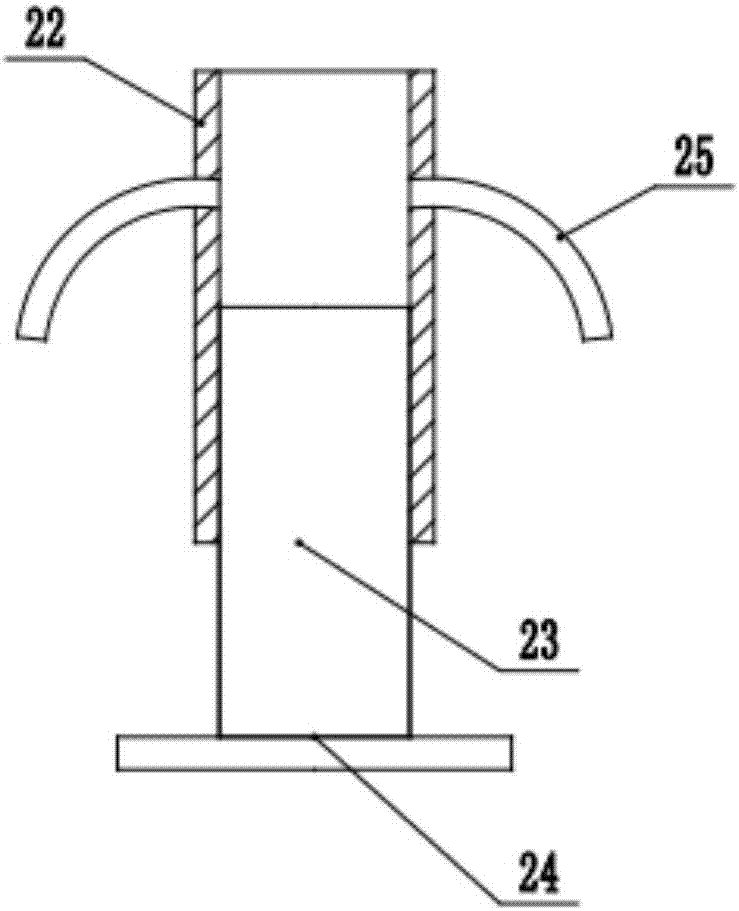

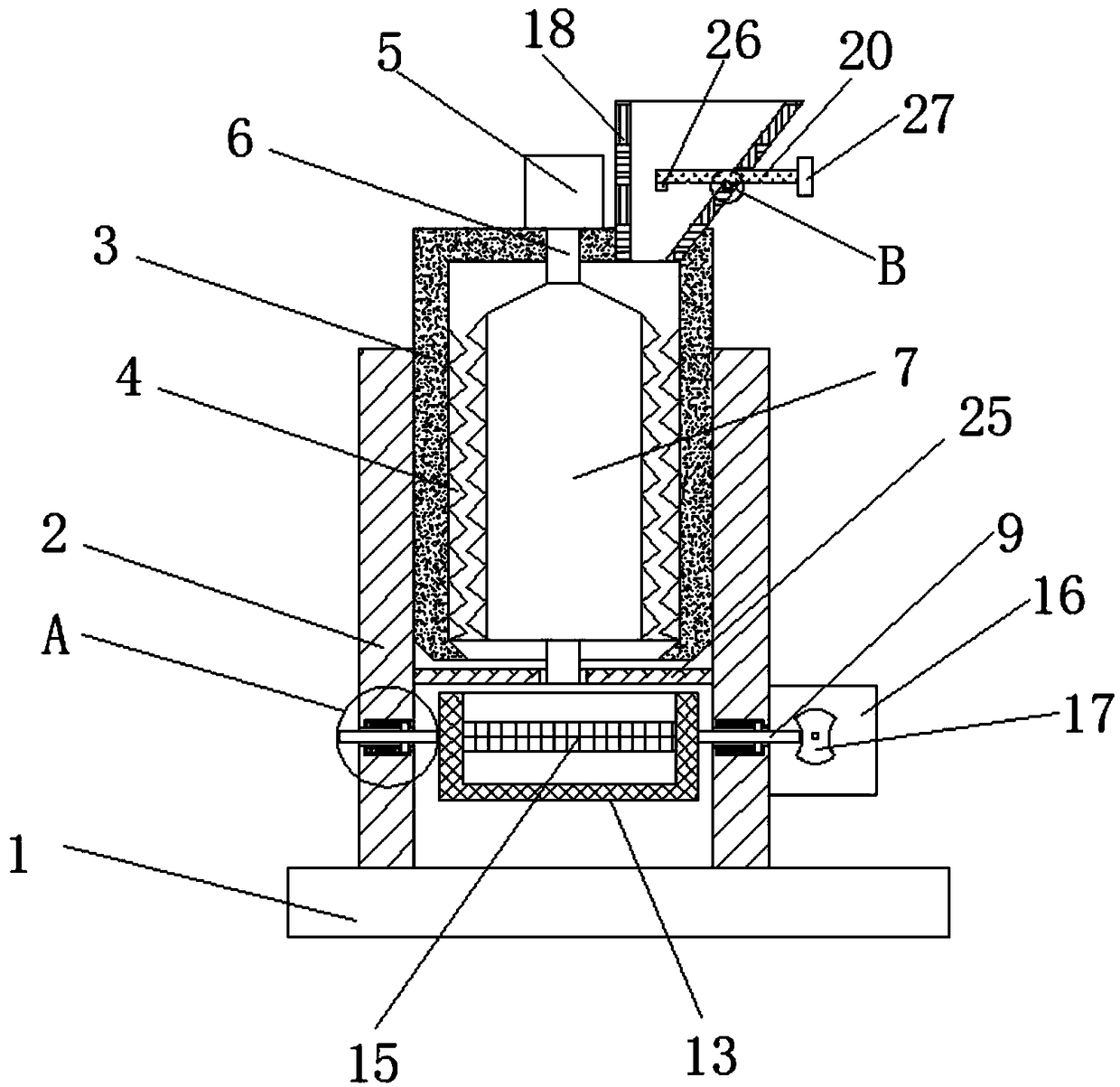

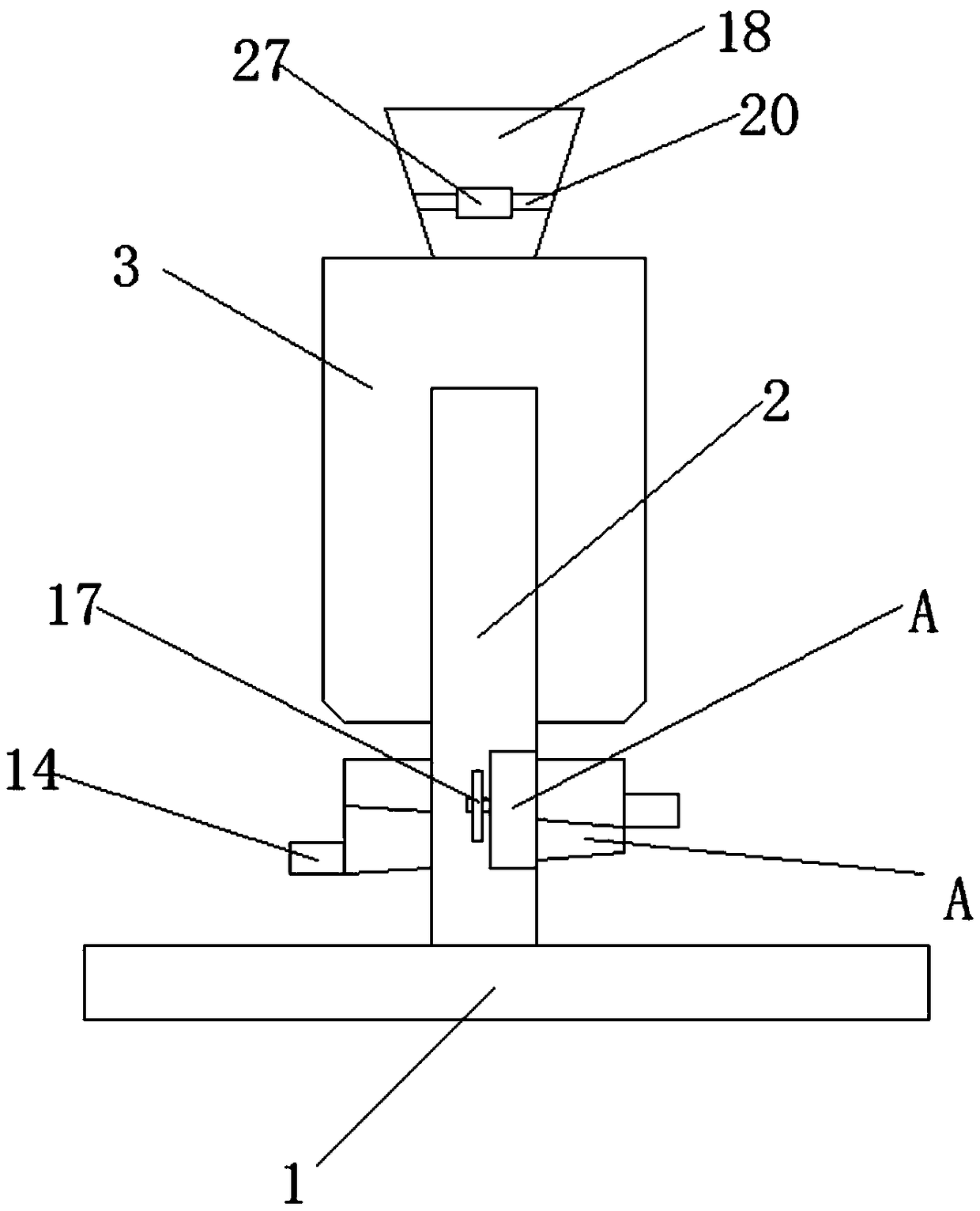

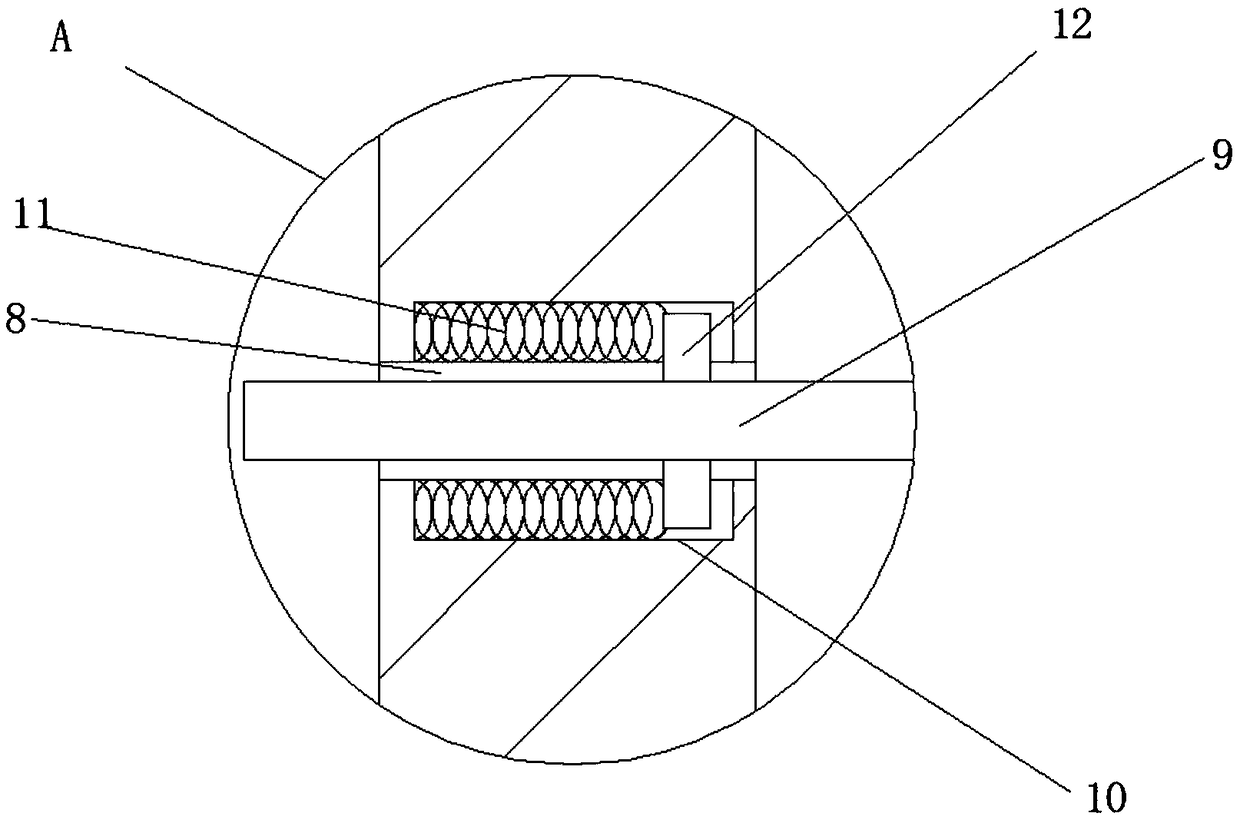

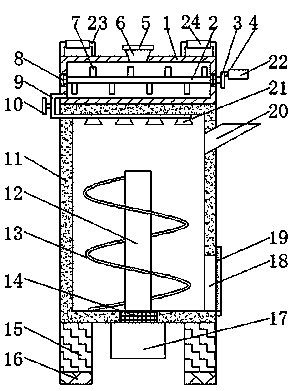

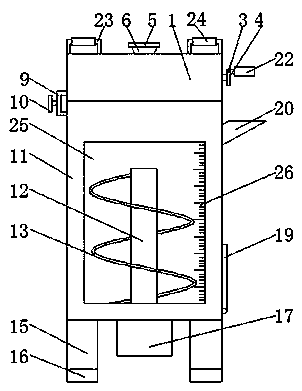

Damping smashing device for traditional Chinese medicine processing

InactiveCN107469969AAvoid corrosionExtended service lifeGrain treatmentsEngineeringEnergy consumption

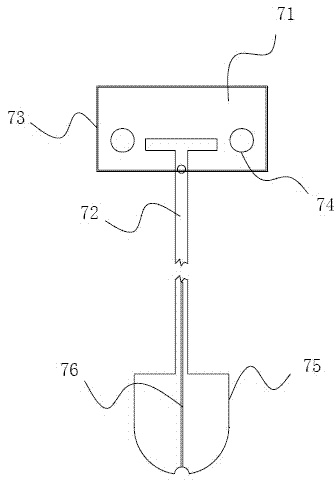

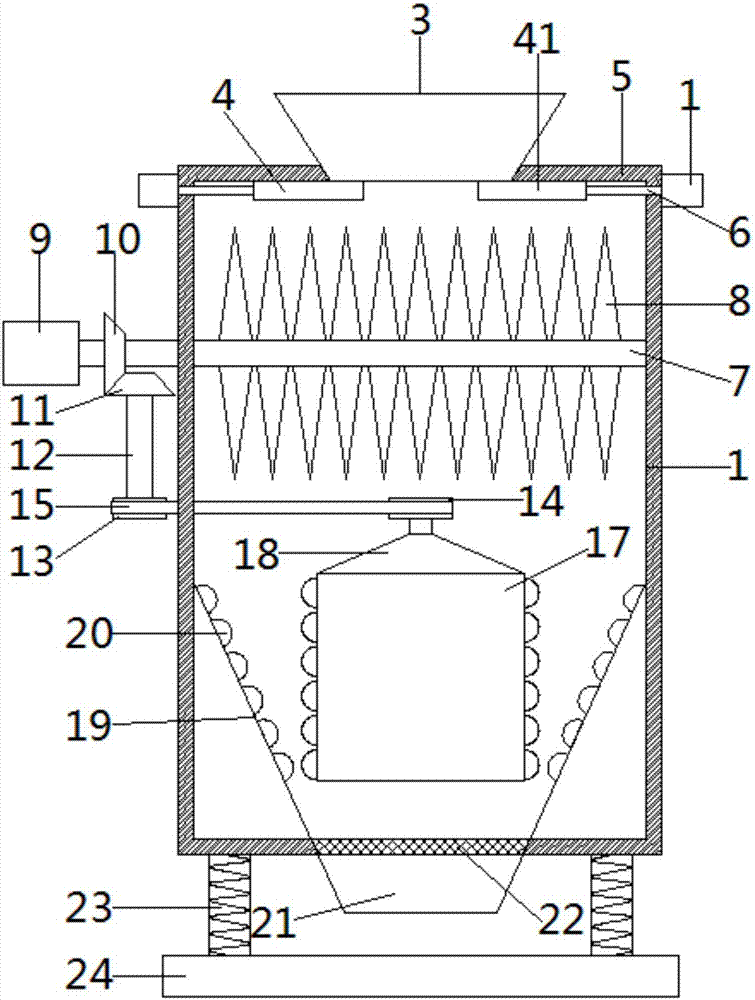

The invention discloses a shock-absorbing crushing device for traditional Chinese medicine processing, which comprises a machine body, the outer wall of which is covered with a ceramic layer, a circular feeding port is opened on the upper side of the machine body, and a feeding hopper is connected to the feeding port , the bottom of the feed hopper matches the size of the feed port, and the left and right feed baffles are respectively arranged at the left and right ends of the lower side of the feed port, and the left feed baffle and the right feed The baffle is a semicircular baffle arranged symmetrically. This invention is a shock-absorbing crushing device for processing traditional Chinese medicine, which can control the feeding amount and feeding speed, and effectively improve work efficiency. Two crushing mechanisms are arranged inside the machine body. The material is fully crushed, and the two crushing mechanisms are driven by one motor, which effectively reduces energy consumption, greatly improves the crushing efficiency, and makes the medicinal materials crushed more fully. In addition, it can effectively reduce the vibration generated during the operation of the device and improve the operation of the device. stability.

Owner:单开禹

Polishing device for plastic particle production and processing

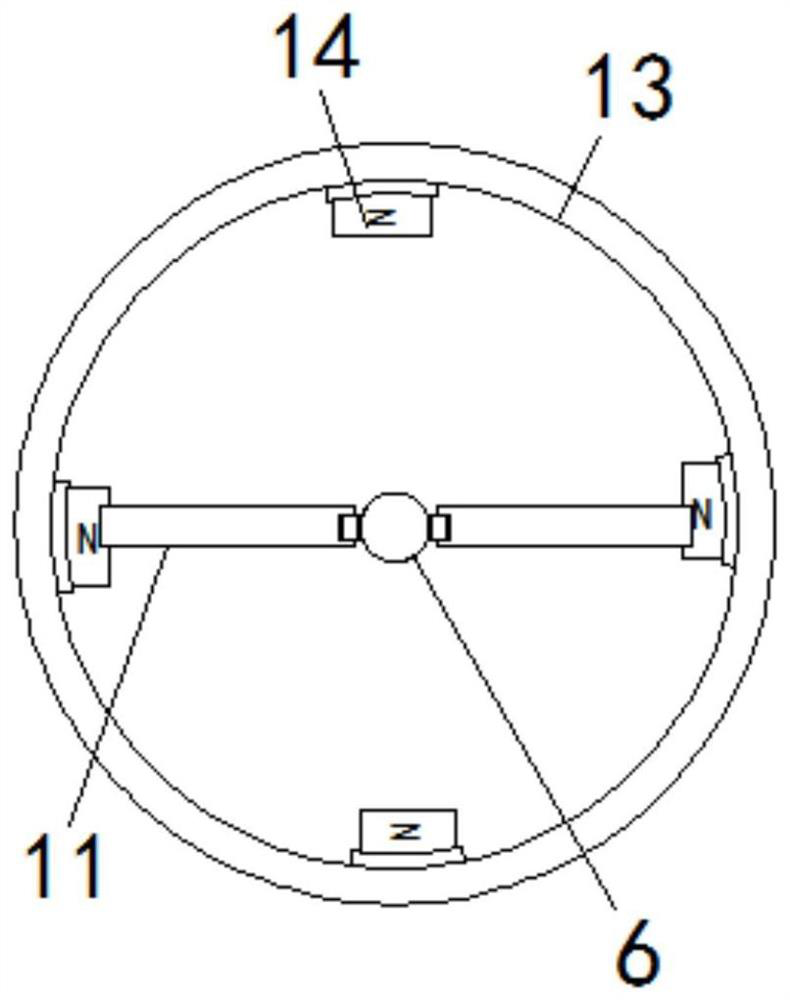

InactiveCN107234539AImprove stirring efficiencyStir wellEdge grinding machinesPolishing machinesDrive motorEngineering

The invention discloses a polishing device for plastic particle production and processing. The polishing device comprises a device body. The device body is mainly composed of a polishing barrel and a discharging hopper. A bottom plate is arranged on the inner bottom of the polishing barrel and provided with an opening, and a rotating plate is hinged to the bottom plate. The lower surface of the rotating plate is fixedly connected with a spring, and the tail end of the spring is fixedly connected with the inner wall of the discharging hopper. The bottom plate is fixedly connected with a drive motor, the top of the drive motor is connected with a rotating shaft, and the top of the rotating shaft is fixedly connected with a supporting frame. The upper end and the lower end of the supporting frame are connected with stirring rods in a hinged manner correspondingly. The top of the polishing barrel is provided with a feeding port, the polishing barrel is internally provided with a distributing cylinder, and the feeding port communicates with the interior of the distributing cylinder. By means of the polishing device, the stirring efficiency of plastic particles is improved, polishing is facilitated, and the polishing load of the plastic particles is reduced by controlling the feeding amount of the plastic particles; and according to the polishing device, through cooperation of the rotating plate and a discharging wheel, the situation that the plastic particles block a discharging port is avoided, discharging is facilitated, and convenience is brought to people for use.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

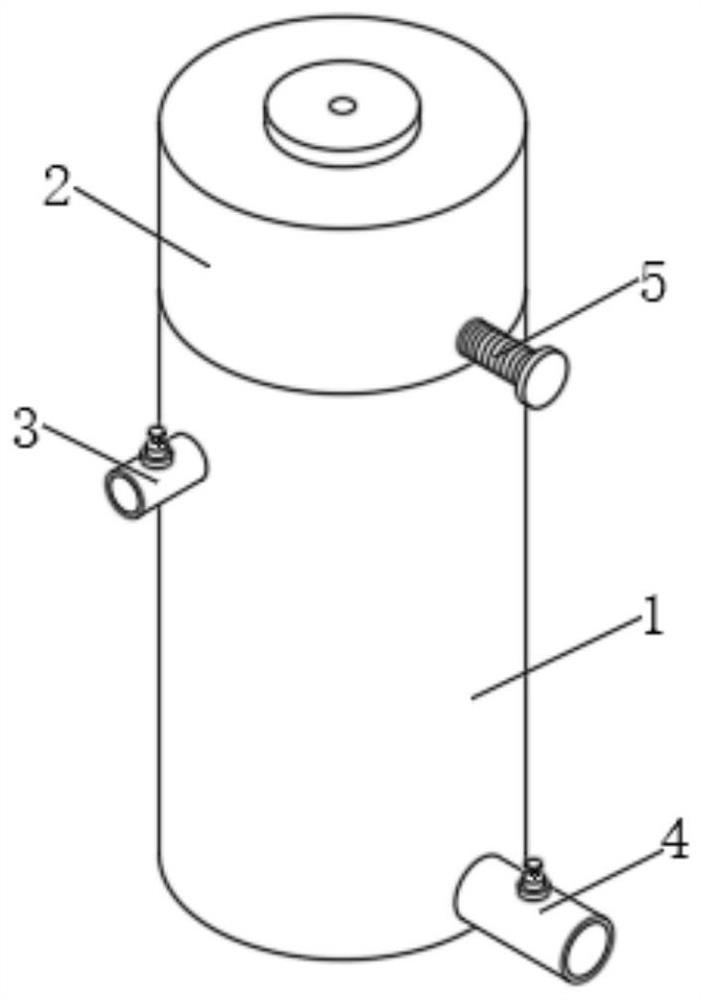

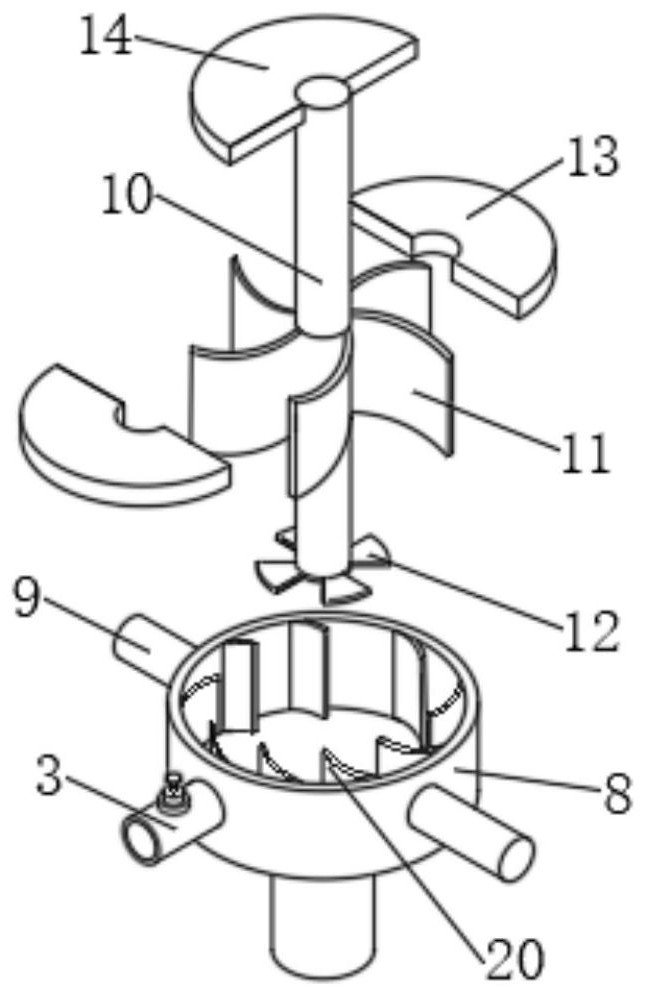

Chemical dissolving tank for sewage treatment and using method thereof

InactiveCN111729521AAvoid cloggingControl the amount of feedRotary stirring mixersTransportation and packagingWater flowEngineering

The invention discloses a chemical dissolving tank for sewage treatment, and relates to the field of sewage treatment. According to the chemical dissolving tank for sewage treatment, the upper surfaceof a mixing box is fixedly connected with a chemical bin, a shell is arranged in the mixing box, a rotating shaft is connected to a bearing in the shell, an impeller sleeves the outer surface of therotating shaft, a stirring wheel is fixedly connected to the outer surface of the bottom end of the rotating shaft, a fan-shaped plate is fixedly connected to the outer surface of the top end of the rotating shaft, and a water outlet is formed in the bottom of the mixing box. According to the chemical dissolving tank for sewage treatment, water flow enters the shell through a water inlet pipe anddrives the rotating shaft to rotate through the impeller in the flowing process, a sector plate rotates with the rotating shaft as the axis in the lower part of a discharge port, and the discharge port is used for intermittent discharge. Meanwhile, a chemical which is not dissolved in time is precipitated to the bottom of the mixing box, is positioned on the upper surface of the filter plate and is stirred through the stirring wheel, so that the chemical and the water flow are synchronously added and stirred to be dissolved, and the blockage of the water outlet caused by accumulation of the chemical at the bottom is avoided.

Owner:陈燕娜

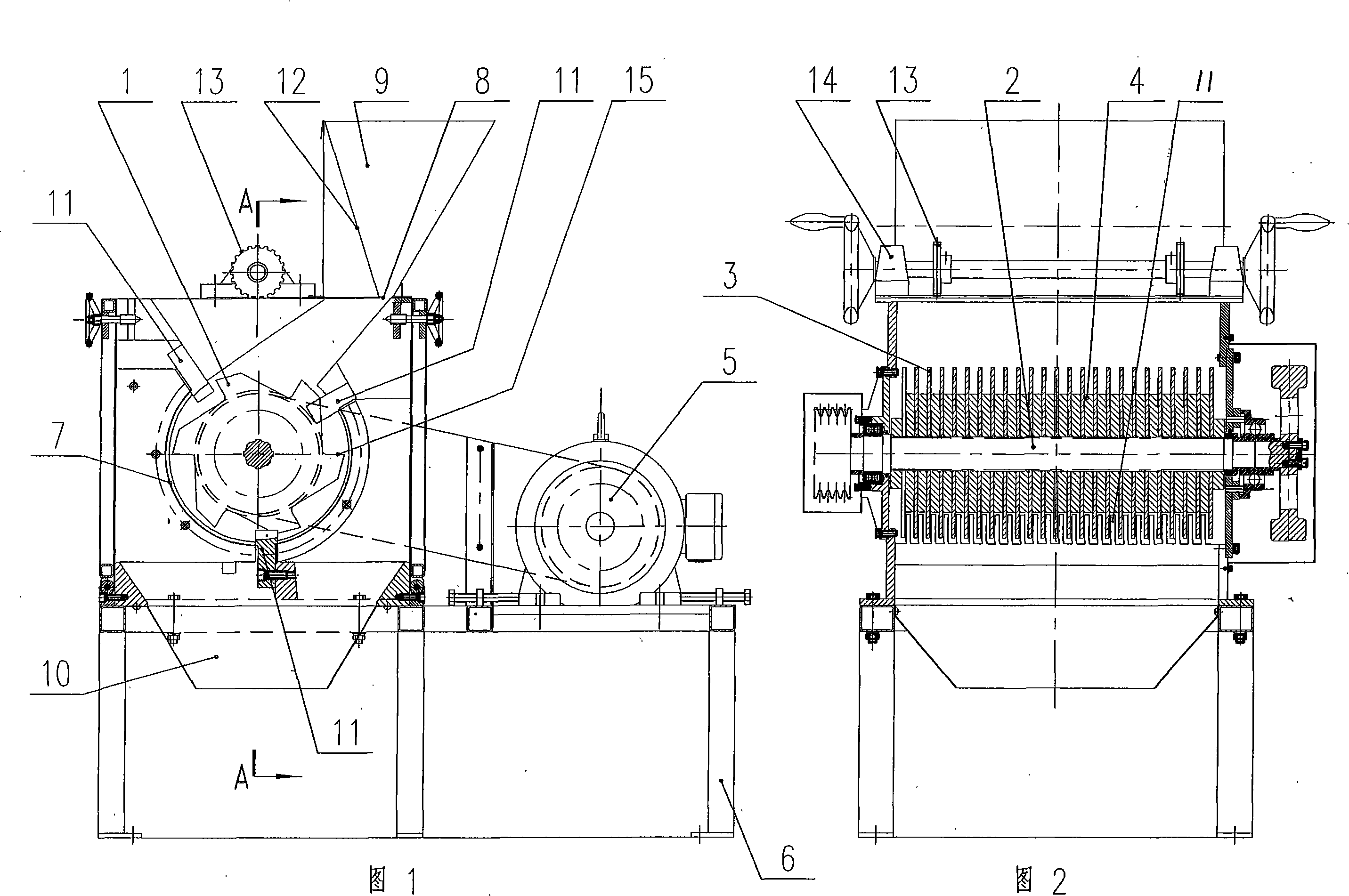

Rolling cutter grinder

InactiveCN101214458AEffective shreddingAvoid cloggingTobacco treatmentGrain treatmentsEngineeringKnife blades

A hob pulverizing machine comprises a stander (6) and a hob mounted on the stander. The hob comprises a horizontal rotating shaft (2) and a moveable knife tackle (1) installed on the rotating shaft. The moveable knife tackle has a subassembly of blades with cutting edge (15). The blades are separated by a range spacer (4). The rotating shaft of the moveable knife tackle is connected with a gear (5). A meshed cylinder (7) is arranged outside the moveable knife tackle. One or more than one comb-shape stationary knives (11) are arranged on the inner wall of the cylinder along the direction of circumference. The comb of the stationary knife and the blades of the moveable knife tackle alternate with each other and match. The top of the cylinder is provided with a feed opening (8). The bottom of the cylinder is provided with a discharge opening (10). The utility model provides the hob pulverizing machines that can pulverize wet and cellulosic materials. The particle size of the wet and cellulosic materials is consistent. The utility model has high efficiency and simple structure. And caulking materials do not stick easily and inlet amount can be adjusted.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

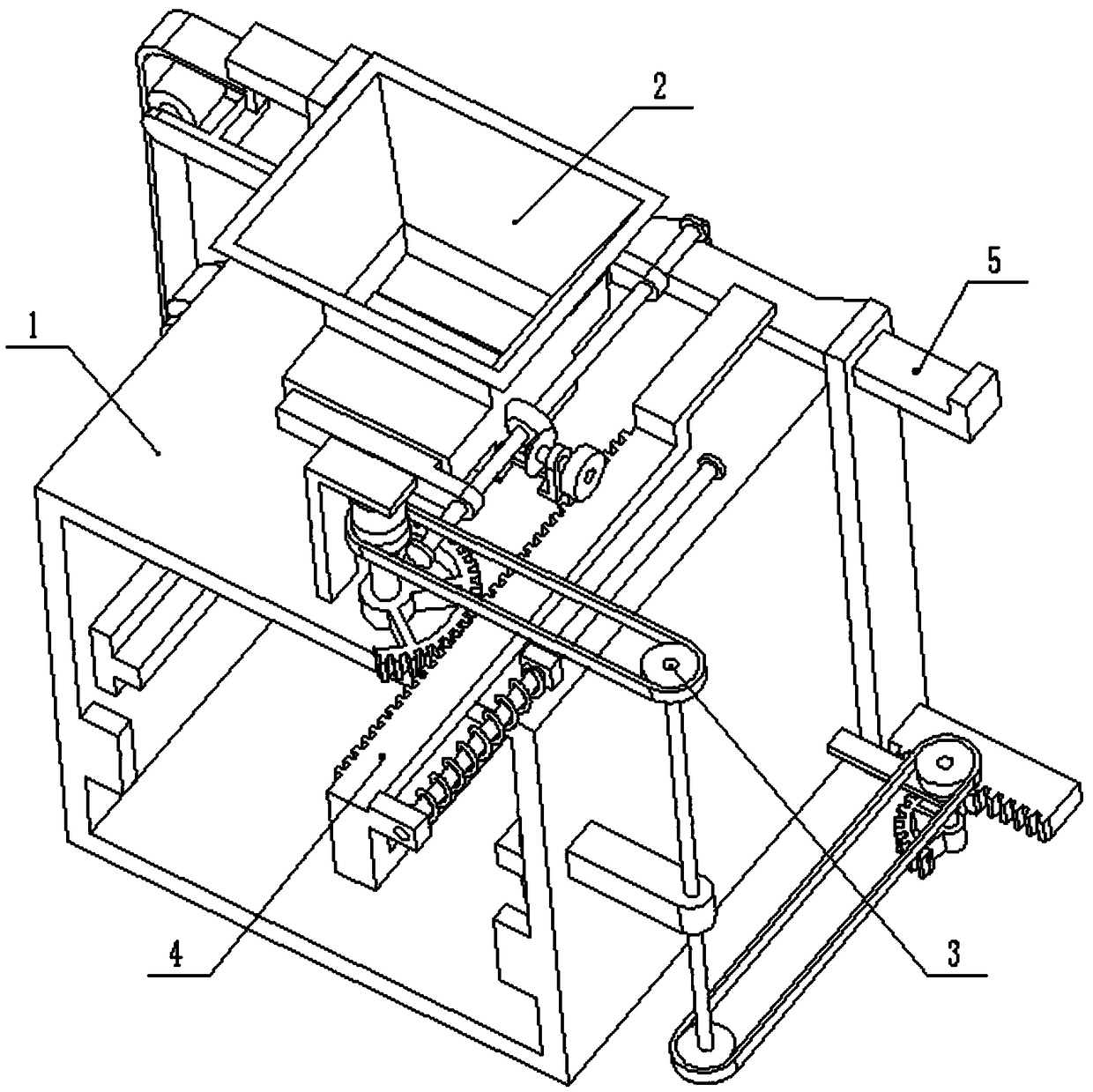

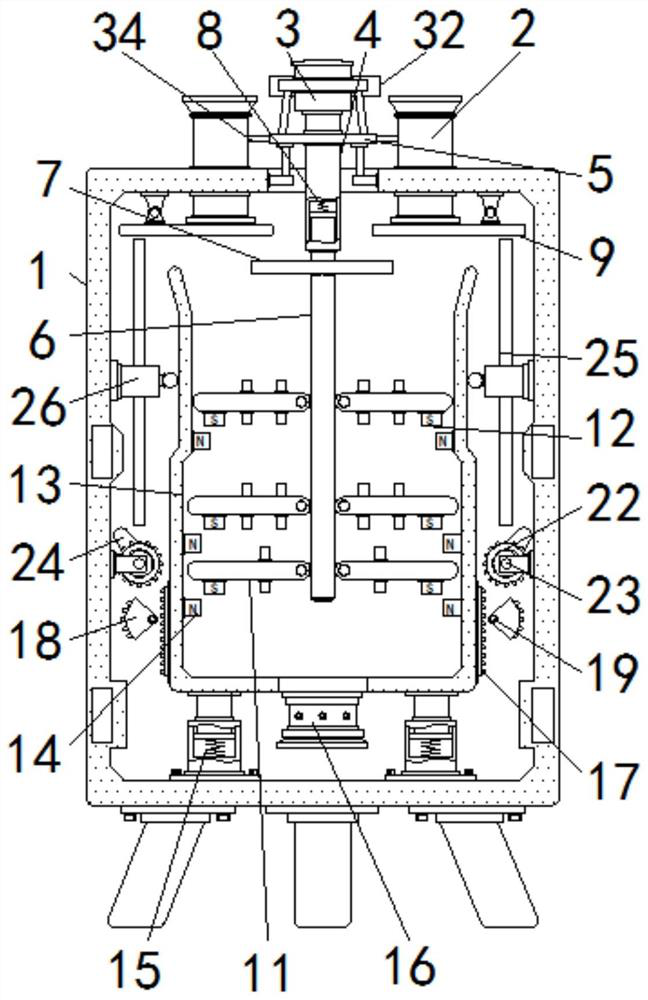

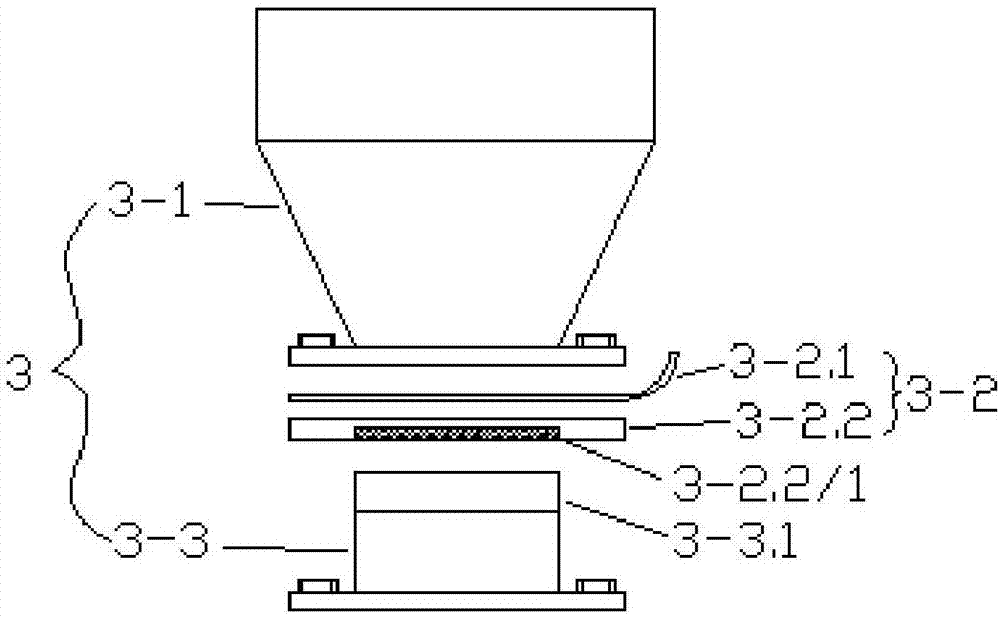

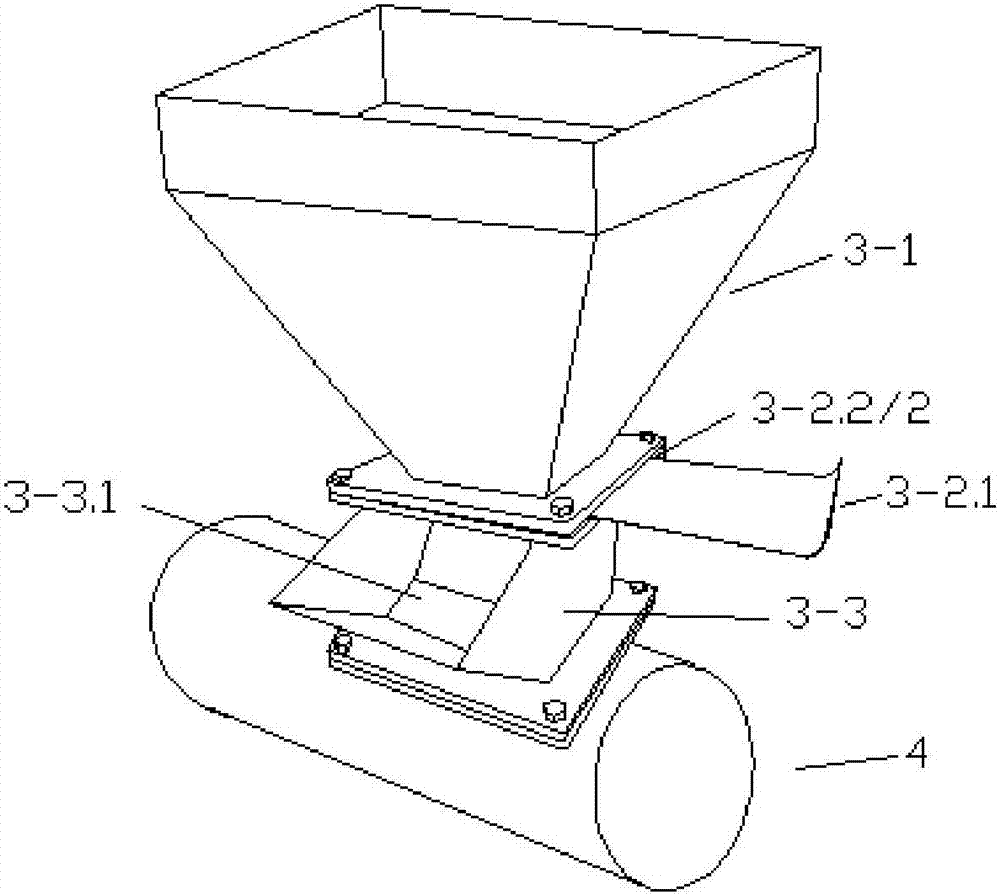

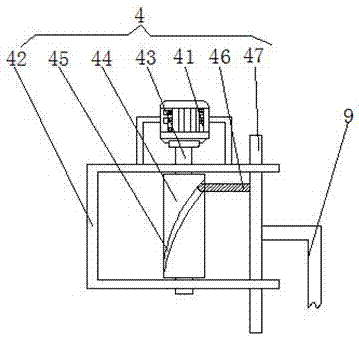

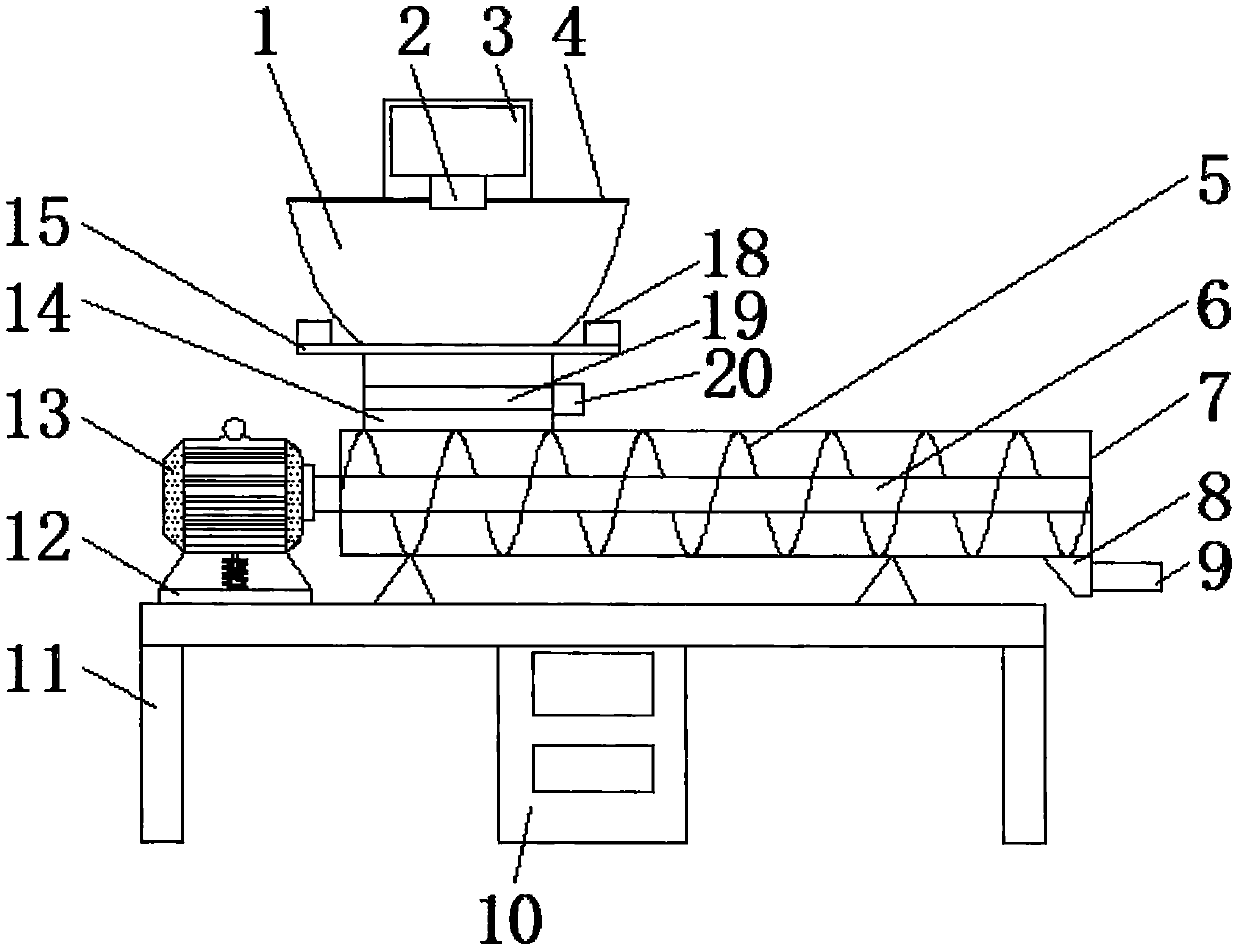

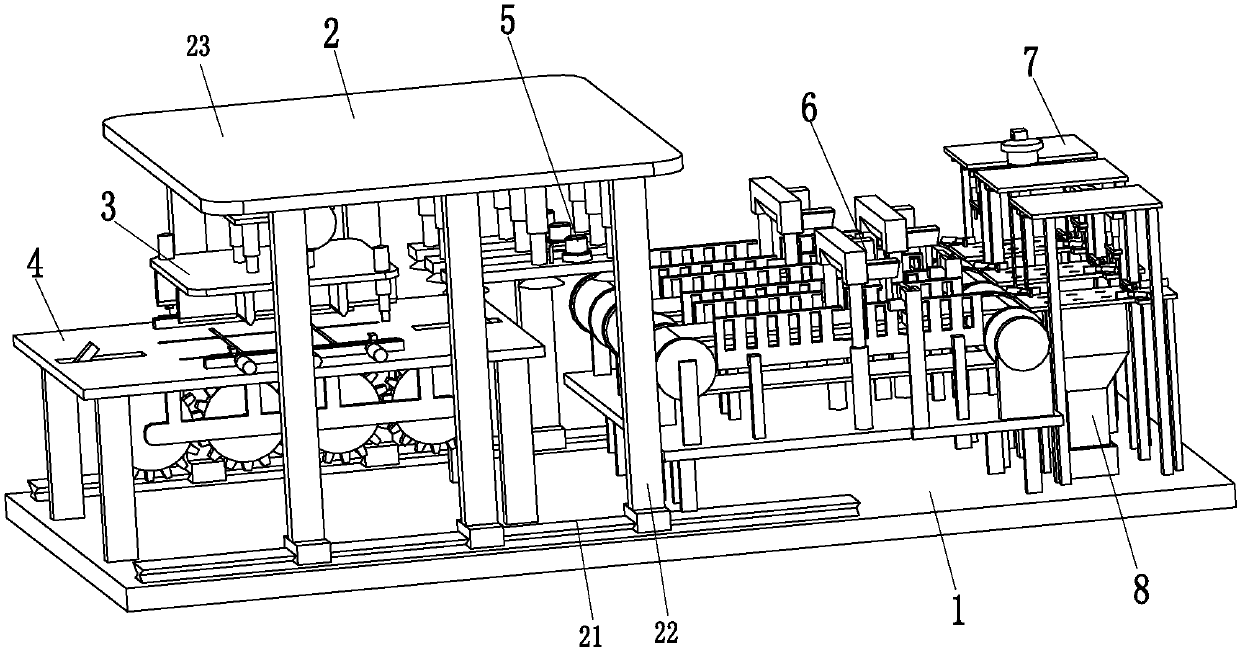

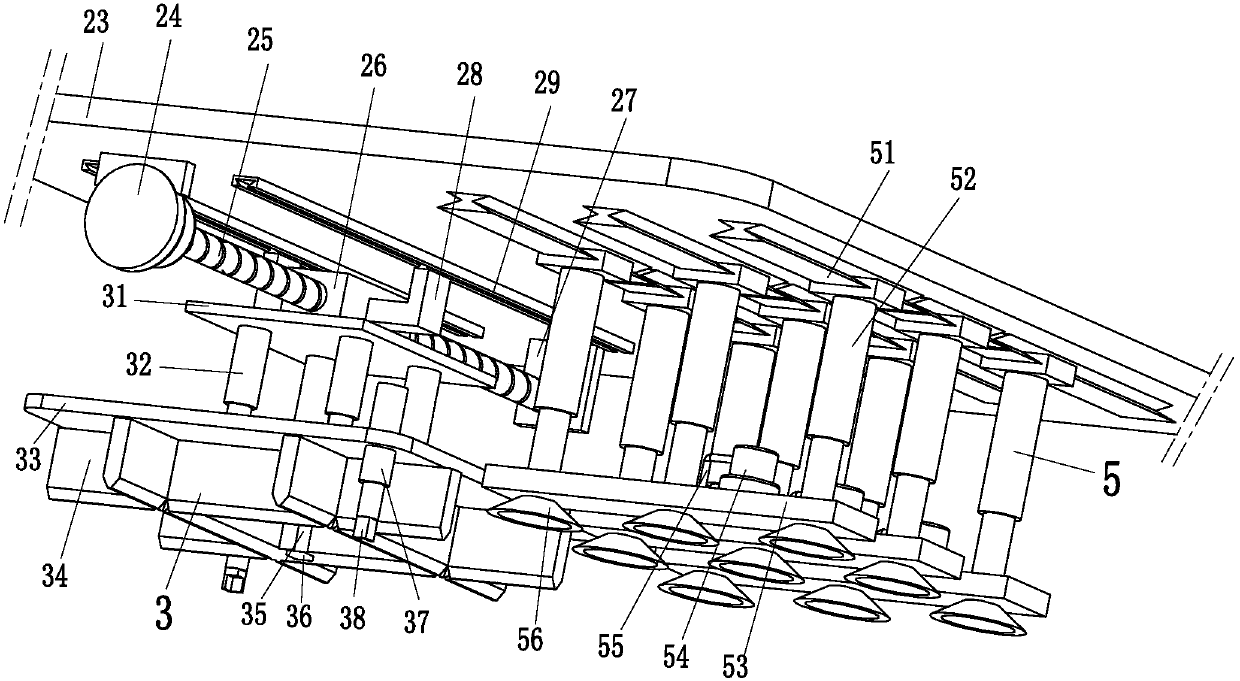

Automatic fuel particle moulding and processing device

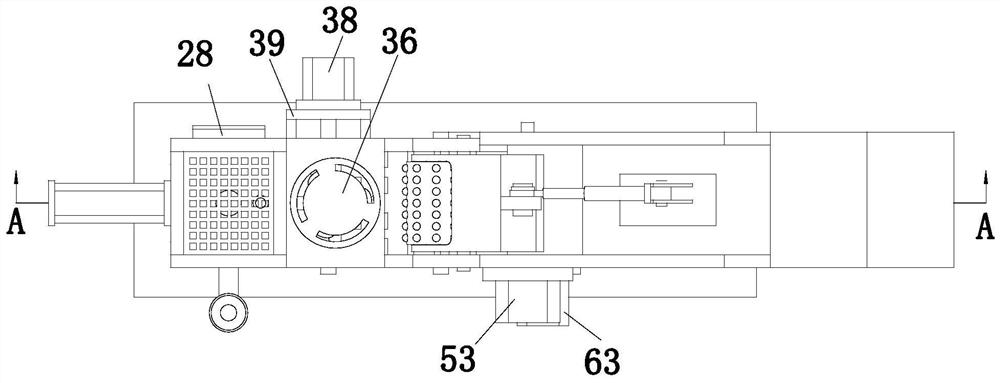

ActiveCN108929739APrevent overloadPrevent the phenomenon of overloading the machineBiofuelsSolid fuelsUltimate tensile strengthRaw material

The invention relates to the technical field of biomass particle production, and specifically relates to an automatic fuel particle moulding and processing device. An intermittent feeding seat is arranged on the upper end of a fuel extrusion box; the intermittent feeding seat is communicated with the interior of the fuel extrusion box; a power driving member is arranged on the fuel extrusion box;an extrusion plate is arranged on the fuel extrusion box; the power driving member is connected to the extrusion plate in a transmission mode; a cut-off tool is arranged on the front end of the fuel extrusion box, and the power driving member is connected to the cut-off tool in a transmission mode. The provided device can control a reasonable feeding amount, when the materials reach a certain amount, the materials can be baffled in the raw material inlet automatically, the overload of the device is prevented, the crash of the device caused by overload is avoided, the work efficiency is improved, the work labor and production cost are reduced, and the service life is prolonged.

Owner:许恩明

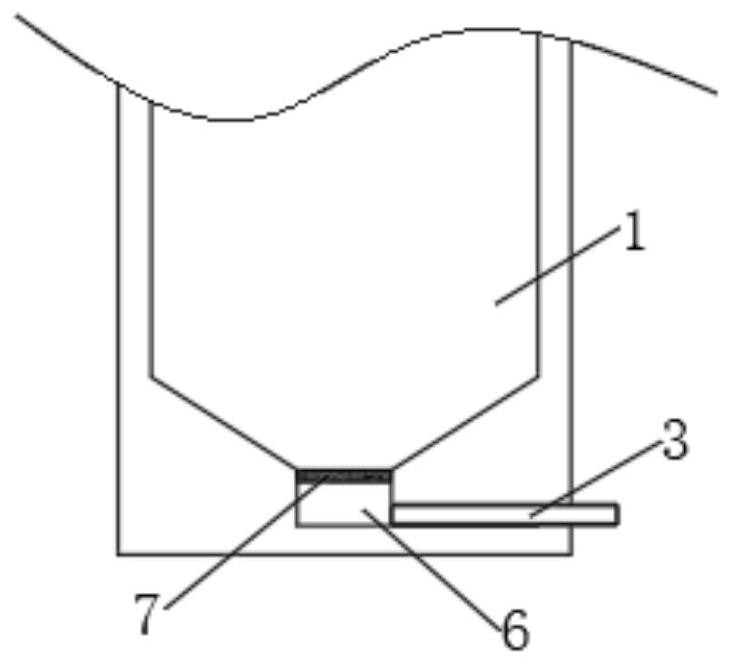

Dehydration device of figs

InactiveCN107087804AEasy to dehydrateEasy to control feed volumeFood treatmentFixed frameEngineering

The invention discloses a fig dehydration device, which comprises a device body, the device body is a cavity structure, a feeding hopper is arranged on one side of the top end of the device body, and the bottom end of the feeding hopper is connected with a vertically arranged The material guide tube is located in the device body, fixed openings are set on both sides of the material guide tube, and horizontally arranged baffles are arranged in the material guide tube, and the two ends of the baffle extend to the guide material through the fixed openings respectively. On the outside of the pipe, a push rod motor is installed on the outer wall of the device body close to the side of the feed hopper, and the output shaft of the push rod motor is connected to the baffle plate, and a fixing frame is installed on the inner wall of the bottom end of the device body. The fixed frame is provided with a conveying mechanism, wherein the conveying mechanism includes a conveyor belt, a rotating shaft and a rotating motor, and the rotating motor is fixedly installed on one side of the fixing frame. The invention has reasonable design, realizes automatic production, conveniently controls the feed amount of figs, reduces manual management costs, and improves the production efficiency of figs.

Owner:滨海康之源生态农业科技有限公司

Lime slaking and chemical feeding device

InactiveCN105084786ASpeed up the flowAchieving the purpose of continuous fuelPulp and paper industry

The invention discloses a lime slaking and medical feeding device which comprises a lime transporting unit, a lime slaking unit, a lime milk separating unit and a lime chemical feeding unit. The lime slaking unit comprises a barrel body, a feed hole and a discharge hole are formed in the barrel body, and the interior of the barrel body is sequentially divided into a buffer area, a homogeneity area, a milk-residue separation area, a residue salvaging area and a residue discharging area from the feed hole to the discharge hole; unslaked lime is slaked into lime milk and sand water mixtures through the lime slaking unit, and the lime milk and sand water mixtures flow out from the discharge hole; the lime milk and sand water mixtures flowing in the lime milk separating unit from the discharge hole are separated to lime milk and lime residues by the lime milk separating unit; the lime feeding device can push lime and is installed under a fine lime tank, and a lime outlet of the lime feeding device is located over a feed hole of the lime slaking unit. By adopting the feeding device, automatic feeding can be performed, the working efficiency is improved, and labor force is saved.

Owner:SHENYANG POLYTECHNIC UNIV

Camellia seed stripping machine

PendingCN108851102AEasy to separateControl the amount of feedSievingScreeningCamellia oleiferaCoupling

The invention discloses a camellia seed stripping machine which comprises a base. The upper side of the base is fixedly connected with symmetric supporting plates, and a stripping barrel is arranged above the base and arranged between the two supporting plates. The outer barrel wall of the stripping barrel is fixedly connected with the opposite side walls of the two supporting plates, the ends, away from the base, of the supporting plates are fixedly connected with the stripping barrel, the inner barrel wall of the stripping barrel is fixedly connected with annular first crushing teeth, and the top center of the outer side of the stripping barrel is fixedly connected with a first driving motor. The output end of the first driving motor is fixedly connected with a rotary shaft through a coupler. The end, away from the first driving motor, of the rotary shaft penetrates through the top of the stripping barrel and extends inwards, the position, located in the stripping barrel, of the rotary shaft is fixedly sleeved with a rotary barrel, and the outer barrel wall of the rotary barrel is fixedly connected with second crushing teeth. According to the camellia seed stripping machine, camellia shucks and camellia seeds can be separated well, and the feeding amount can be controlled to be increased or reduced.

Owner:贵州布依仁农业科技有限公司

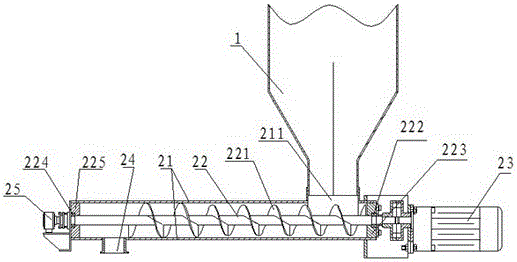

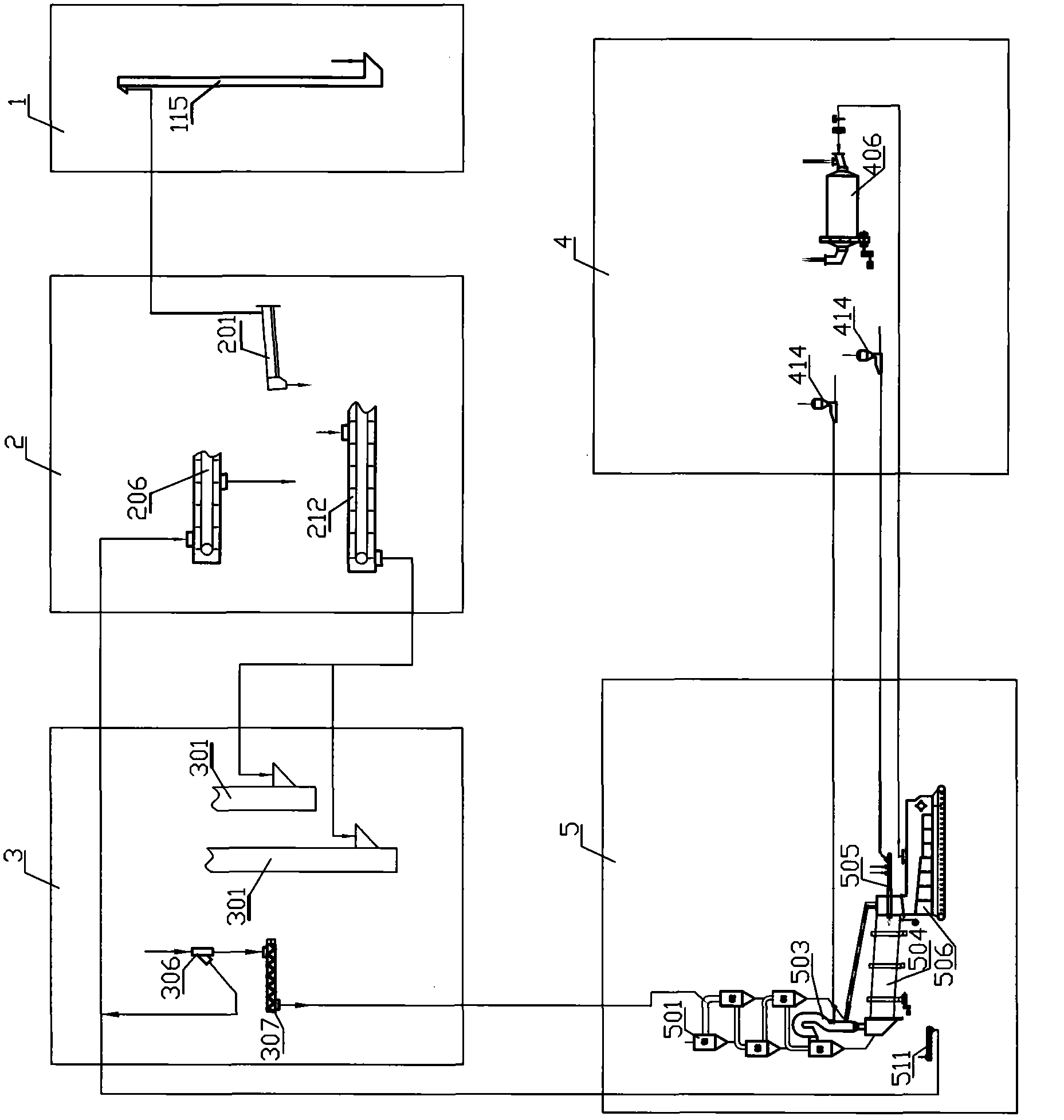

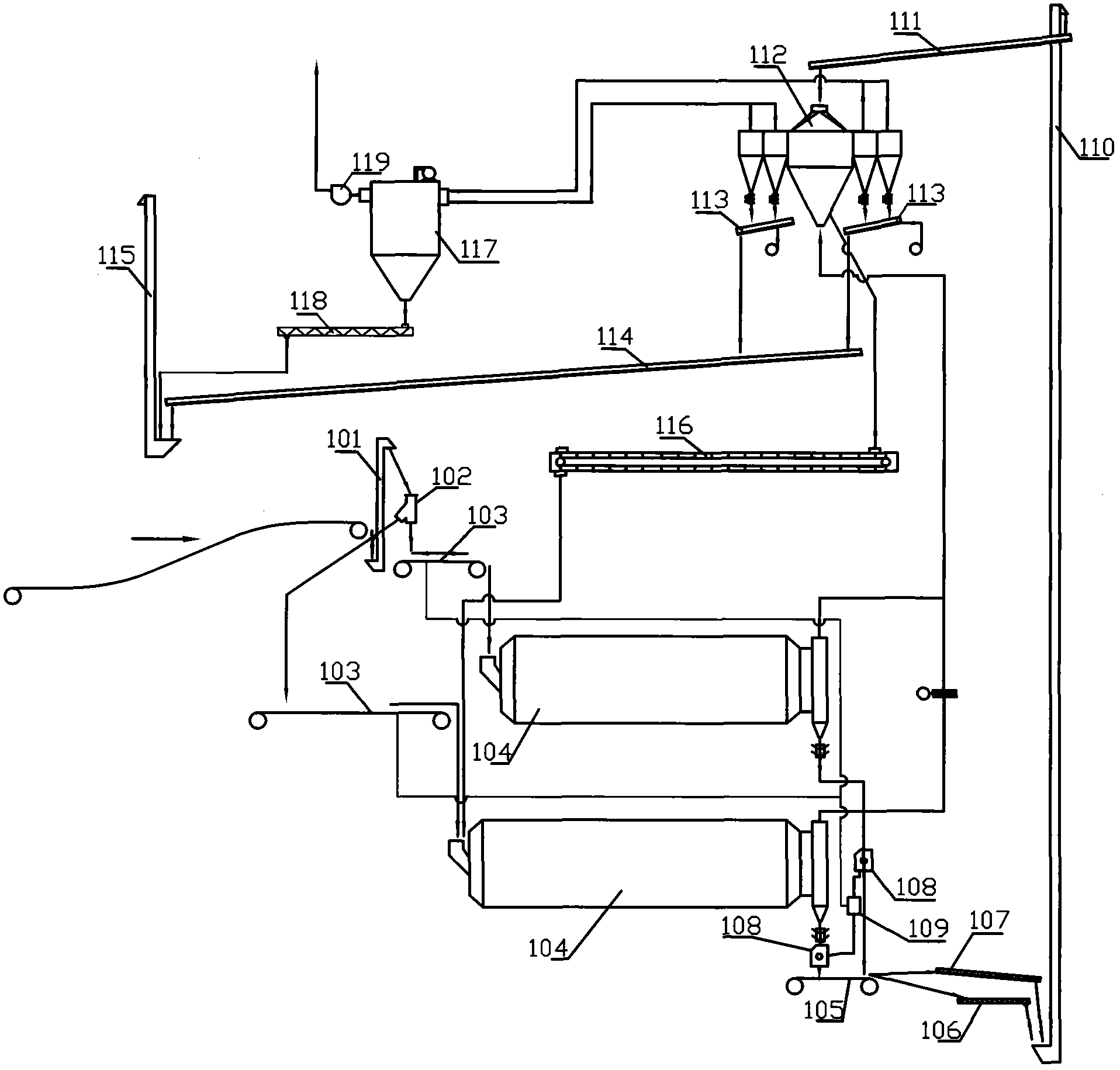

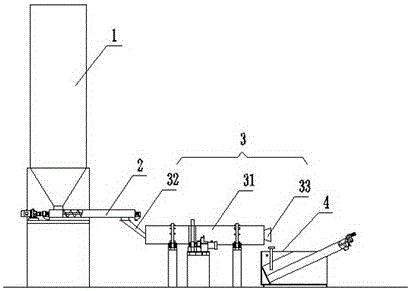

Energy-saving and environment-friendly cement clinker preparation system

ActiveCN103351106AUniform and stable qualityQuality improvementClinker productionDecompositionScrew conveyor

The invention discloses an energy-saving and environment-friendly cement clinker preparation system, which includes a raw material preparation system, a raw material homogenization system, a fed raw material conveying system, a cement and pulverized coal preparation system and a cement clinker calcination system, wherein a material outlet of a loading bucket elevator is connected with a material inlet of a raw material homogenization air conveying chute; a material outlet of an unloading chain conveyer is connected with material inlets of two unloading bucket elevators respectively; a material outlet of a raw material feeding spiral conveyer is connected with a material inlet of a preheater; a material outlet of a spiral pneumatic conveying pump is connected with a material inlet of a decomposition furnace; a material outlet of another spiral pneumatic conveying pump is connected with a material inlet of a four-passage pulverized coal combustion device; a hot air outlet of an air-beam type grate cooler is connected with an air inlet of an air-swept coal mill; one material outlet of an electric tee scraper-trough conveyer and a material outlet of a kiln tail dust collection spiral conveyer are both connected with a material inlet of a re-homogenization loading chain conveyer. The system has the advantages as follows: the yield of the clinker is increased, the energy consumption is lowered, the emission is reduced, the quality of the clinker is improved, and the quality of the cement is stable.

Owner:INNER MONGOLIA MENGXI CEMENT CO LTD

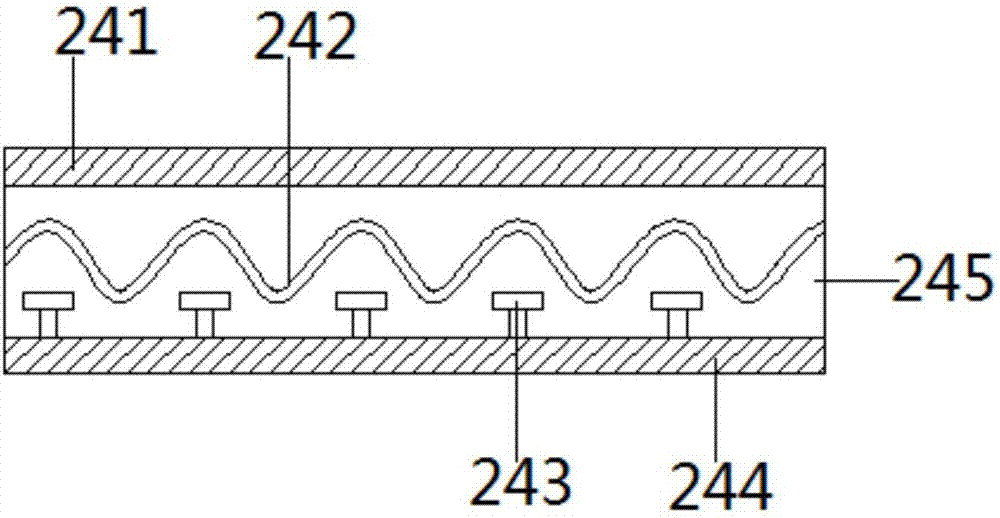

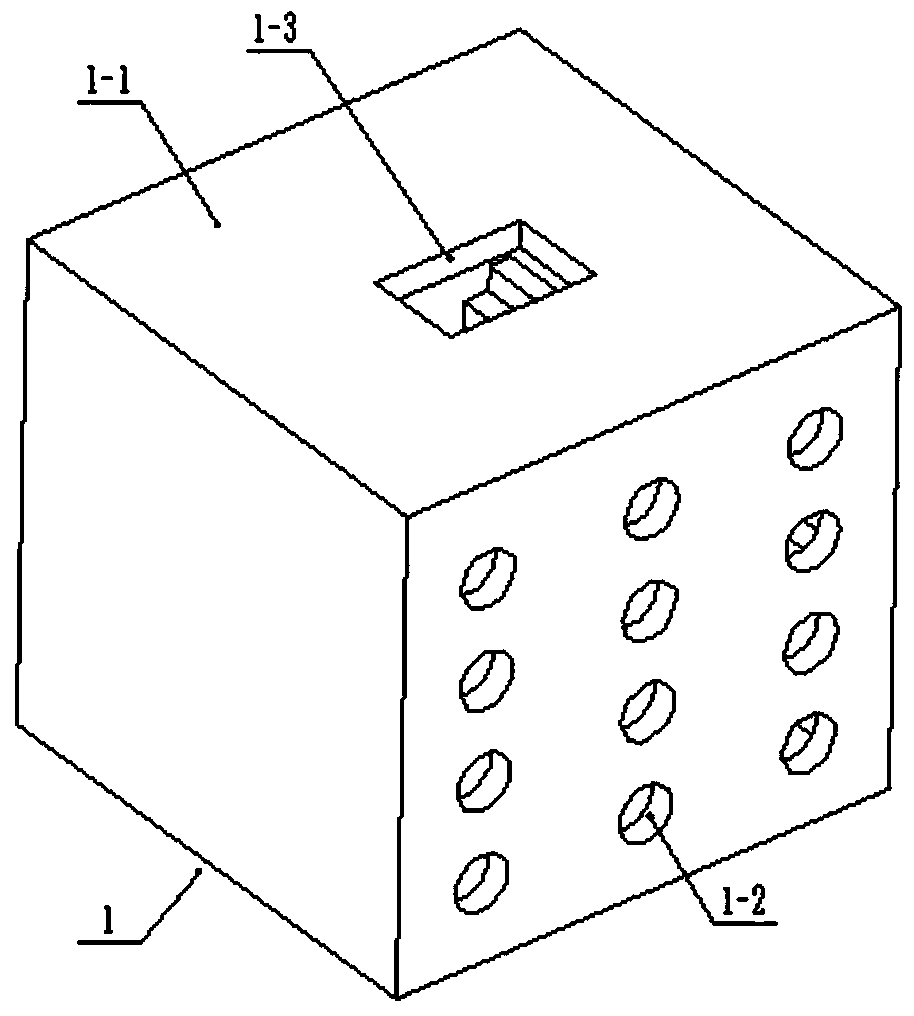

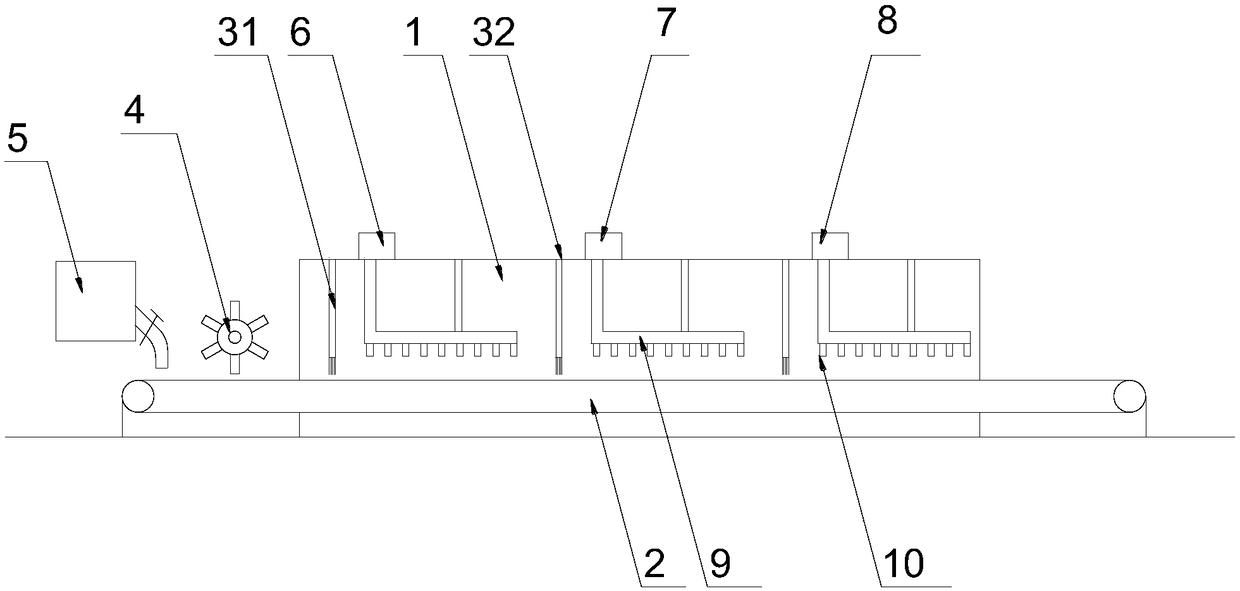

Rice drying equipment

InactiveCN108562155AInto a stableControl the amount of feedDrying gas arrangementsDrying solid materialsEngineeringPulp and paper industry

The invention discloses rice drying equipment which comprises a drying bin, a conveying belt, a baffle, a rotating roller, a feeder, a fan, a first hot air blower, a second hot air blower, air pipes and jet heads. The baffle comprises a first baffle, a second baffle and a third baffle. The conveying belt is arranged inside the drying bin, the rotating roller is arranged above the conveying belt, the top of the baffle is fixedly connected with the top of the drying bin, the baffle divides the drying bin into multiple drying cavities, the fan, the first hot air blower and the second hot air blower are connected with the mutually-independent air pipes correspondingly, the air pipes are provided with the multiple jet heads, and the jet direction of the jet heads faces towards the surface of the conveying belt. Rice stably enters the drying bin in an equivalent mode, the drying effect is good, the rice water content is low, and rice can be stored for a long time.

Owner:滁州广洋湖米业有限公司

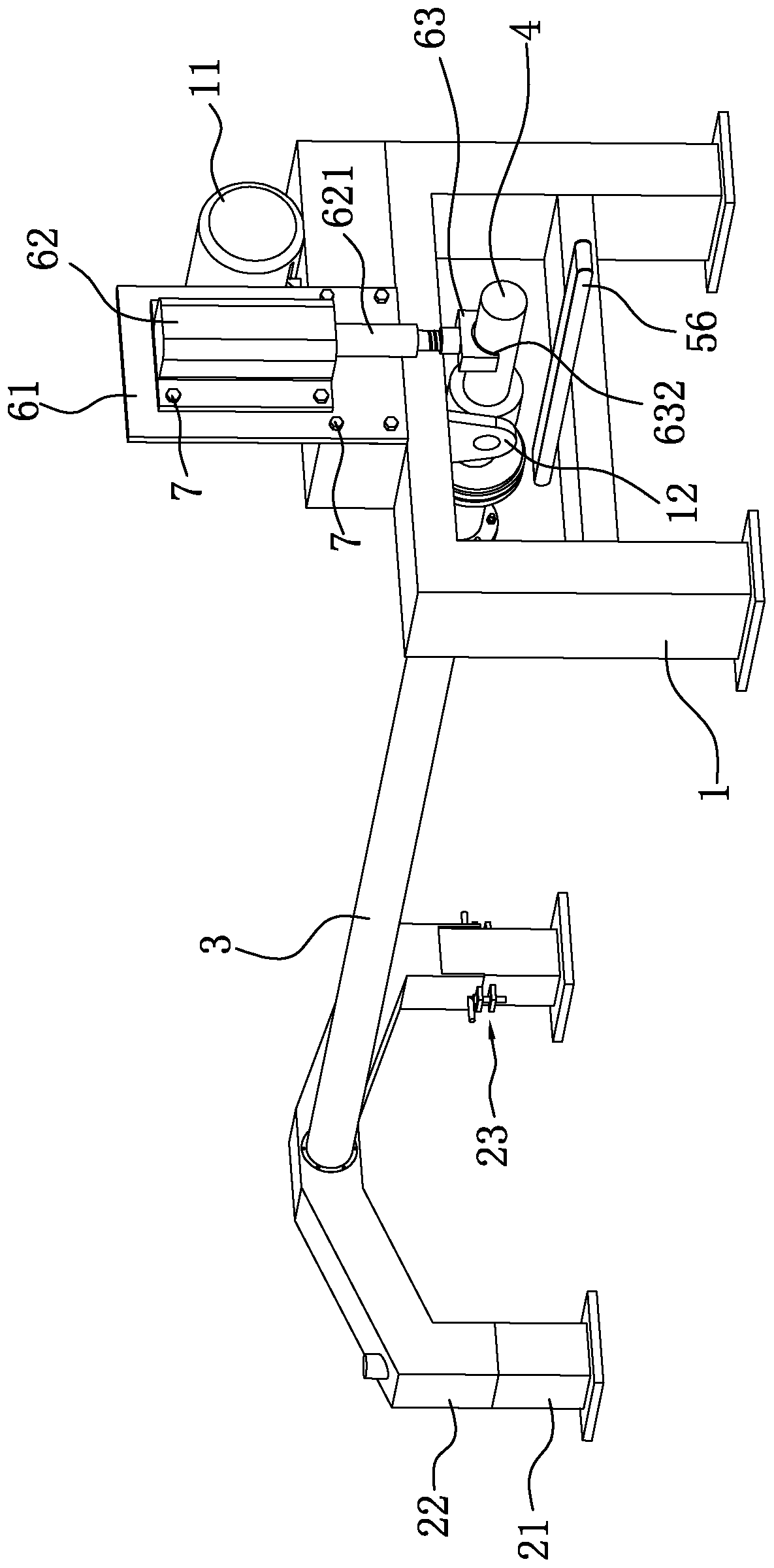

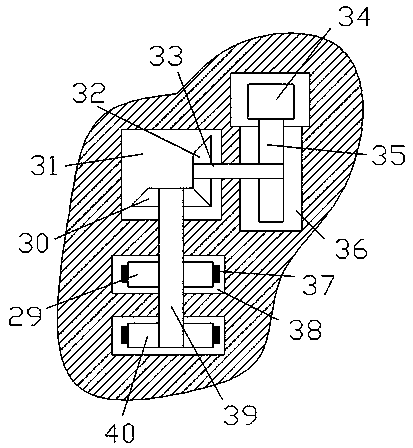

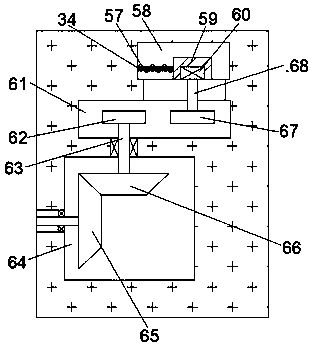

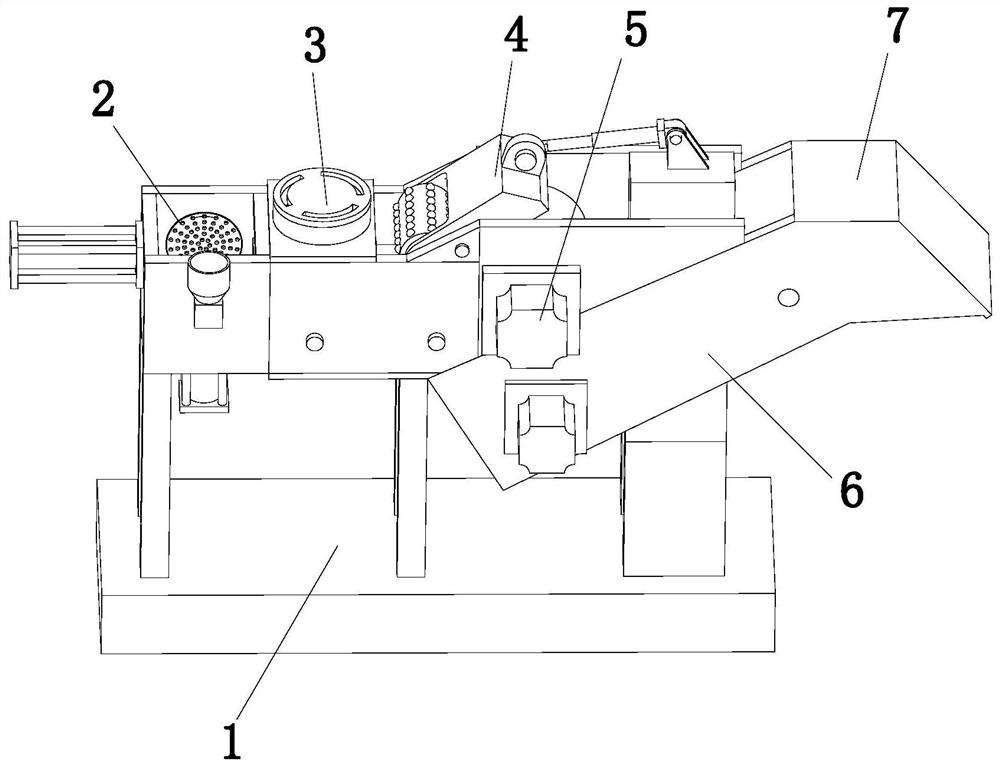

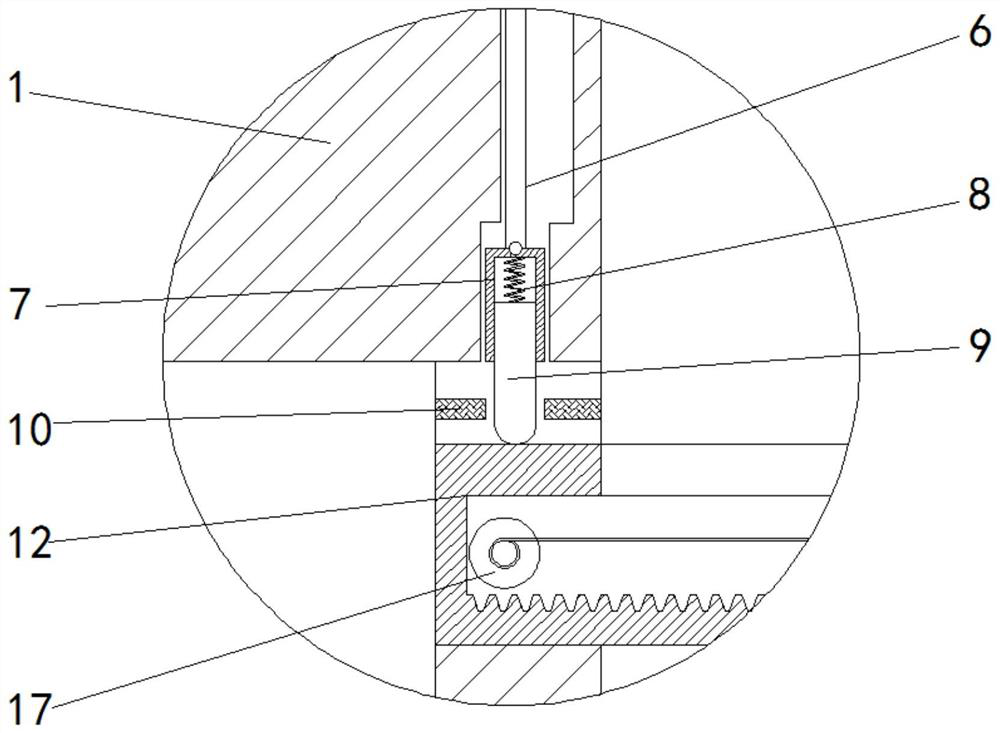

Rice milling equipment

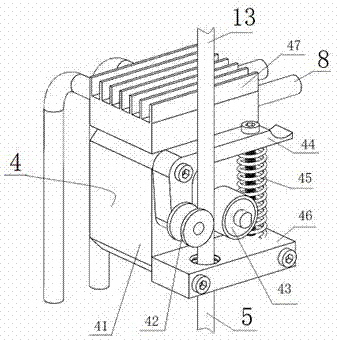

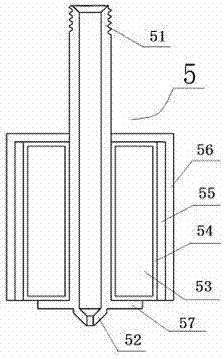

ActiveCN107999164AAffects the effect of grindingControl the amount of feedGrain huskingGrain polishingEngineeringCam

The invention relates to the field of grain processing machinery and particularly discloses rice milling equipment. The rice milling equipment comprises a rack, a feeding mechanism, a filtering mechanism and a milling mechanism, wherein the feeding mechanism comprises a feeding air bag and a main air bag which communicates with the feeding air bag, and the feeding air bag is made of an elastic material and provided with a plurality of feeding inlets; the filtering mechanism is located below the feeding mechanism and comprises filtering sieves, a push rod and a cam; the milling mechanism is located below the cam and comprises a milling box and a bran collecting box, a threaded rod is disposed in the milling box, a spring is connected between the lower end of the threaded rod and the lower wall of the milling box, a supporting block is disposed on the threaded rod, and a plurality of milling discs are in threaded connection with the threaded rods; and an air blower is disposed on one side of the milling box, and the other side of the milling box communicates with the bran collecting box. By means of the rice milling equipment, the problems that milling is incomplete due to the fact that the feeding amount cannot be controlled in the rice milling process of coarse rice, and the rice breaking ratio is high due to too high temperature in the milling process are solved.

Owner:重庆市合川区云天食品科技有限公司

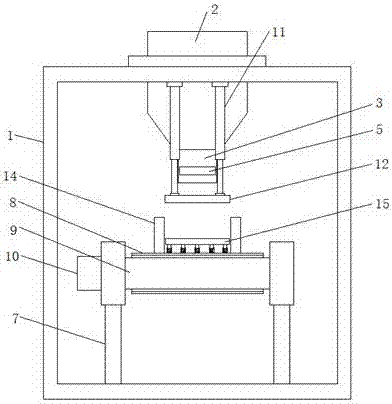

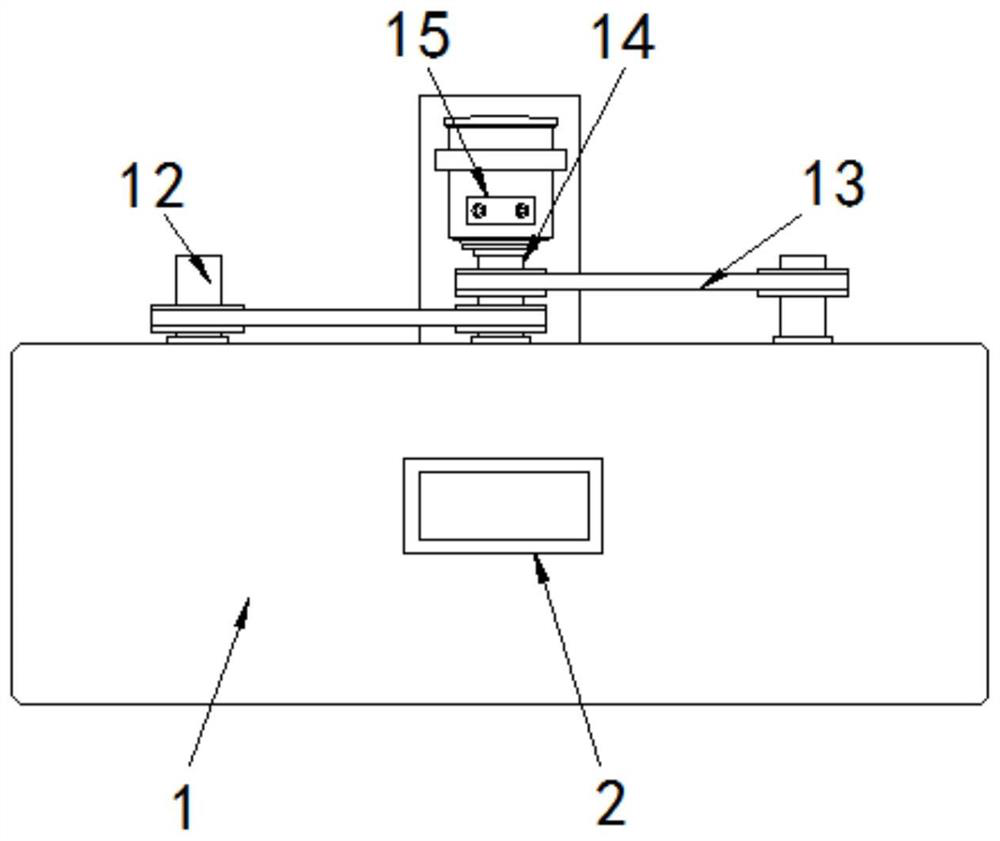

3D (three-dimension) printer for printing vitreous body and printing method

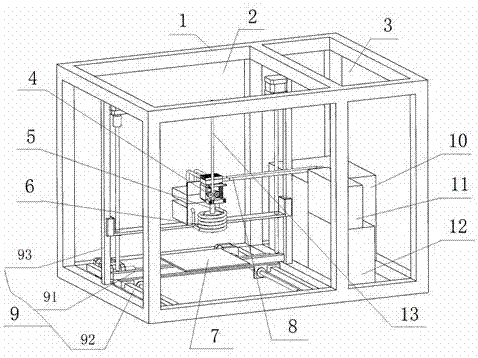

InactiveCN107285609ABroaden your optionsControl feedAdditive manufacturing apparatusGlass shaping apparatusHigh energyControl system

The invention relates to a 3D (three-dimension) printer for printing a vitreous body and a printing method. The 3D printer is composed of a frame, a printing silo and a control cooling silo; the printing silo is connected with the control cooling silo and arranged in the frame; the inner part of the printing silo is provided with a delivering mechanism, a nozzle printing mechanism, a sensing heating device, a printing bottom plate, a cooling medium guide flow pipe and a three-dimensional movement mechanism; the inner part of the control cooling silo is provided with a cooling device, a control system and a power supply. By applying the 3D printer for printing the vitreous body and the printing method, the selection scale of the printing raw material is enlarged; the sensing heating method has the significant advantages of high working efficiency, high energy utilization rate, quick temperature rise, control easiness, small equipment volume, pollution free and others; besides, the printer and the printing device have the advantages of simple and reliable structure, high automatic degree, control easiness, strong practicability and others.

Owner:贵州云上左岸科技有限公司

Stirring device for vegetable seeds

InactiveCN108465425AStir wellImprove stirring efficiencyRotary stirring mixersTransportation and packagingSpiral bladeEngineering

The invention discloses a stirring device for vegetable seeds. The device comprises a first stirring box, the bottom surface of the first stirring box is fixedly connected with two symmetrical supporting legs, the upper part of the right side surface of the first stirring box fixedly communicates with a first material inlet, the lower part of the right side surface of the first stirring box is provided with a material outlet, the lower part of the right side surface of the first stirring box is fixedly hinged with a material outlet door matched with the material outlet through hinges, and themiddle part of the inner bottom wall of the first stirring box is fixedly inlaid with a first bearing. According to the stirring device for the vegetable seeds disclosed by the invention, through arrangement of a second stirring rod, under action of a hand wheel and stirring blades, different pesticides in a second stirring box can be fully mixed, and drug properties of pesticides are played in amaximization manner; and through arrangement of spraying heads and a spiral blade, under action of a pipeline, a stirring motor and a first stirring rod, the vegetable seeds in the first stirring boxcan be sprayed while being turned up and down, so that the vegetable seeds are in full contact with the pesticides, stirring efficiency is high, and stirring is uniform.

Owner:WUXI IGROWTHS TECH CO LTD

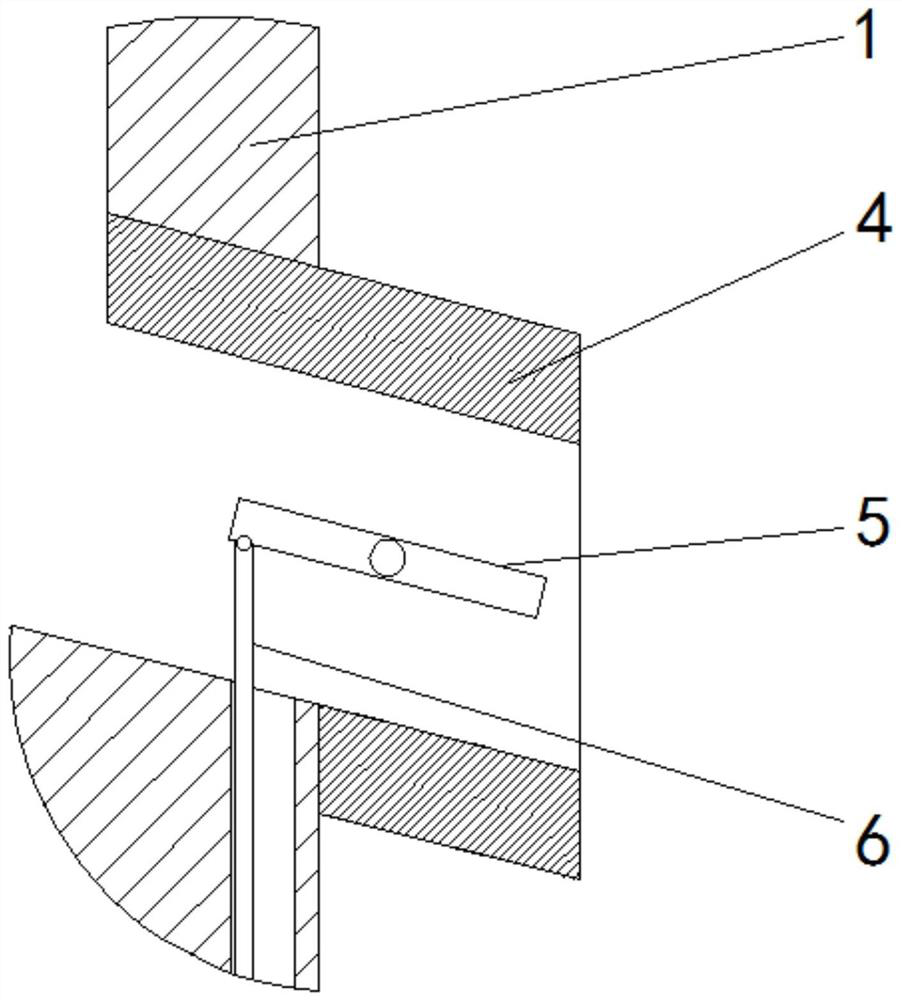

Bubble mixed light soil foaming preparation process and mixing preparation device

InactiveCN113146848AEasy to shake offControl the amount of feedHollow article cleaningCement mixing apparatusElectric machineEnvironmental engineering

The invention discloses a bubble mixed light soil foaming preparation process and a mixing preparation device. The bubble mixed light soil foaming and mixing preparation device comprises a feeding hopper, wherein the feeding hopper is fixedly mounted in a device body through a bolt for maintaining stability, a fixed shaft for limiting, supporting and rotating is mounted at the lower end of the feeding hopper, and a vortex spring for providing recovery elasticity is mounted on the side of the fixed shaft; a driving motor, wherein the driving motor is fixedly installed in a protective cover for protecting the driving motor; a servo motor, wherein the servo motor is fixedly installed on the back surface of the device body through bolts, a linkage rod is installed at the end of the servo motor; and an inner barrel, wherein the inner barrel is installed in the device body, and the middle of the lower end of the inner barrel is fixedly connected with a discharging port facilitating follow-up discharging. According to the bubble mixed light soil foaming preparation process and the mixing preparation device, the feeding amount can be effectively controlled, the situation that too many raw materials are added at a time, and consequently the mixing quality of a final product is reduced is avoided, and meanwhile, the overall stirring effect can be improved, and the raw materials adhering to the inner wall of the device can be conveniently shaken off.

Owner:重庆泰恒建筑科技有限公司

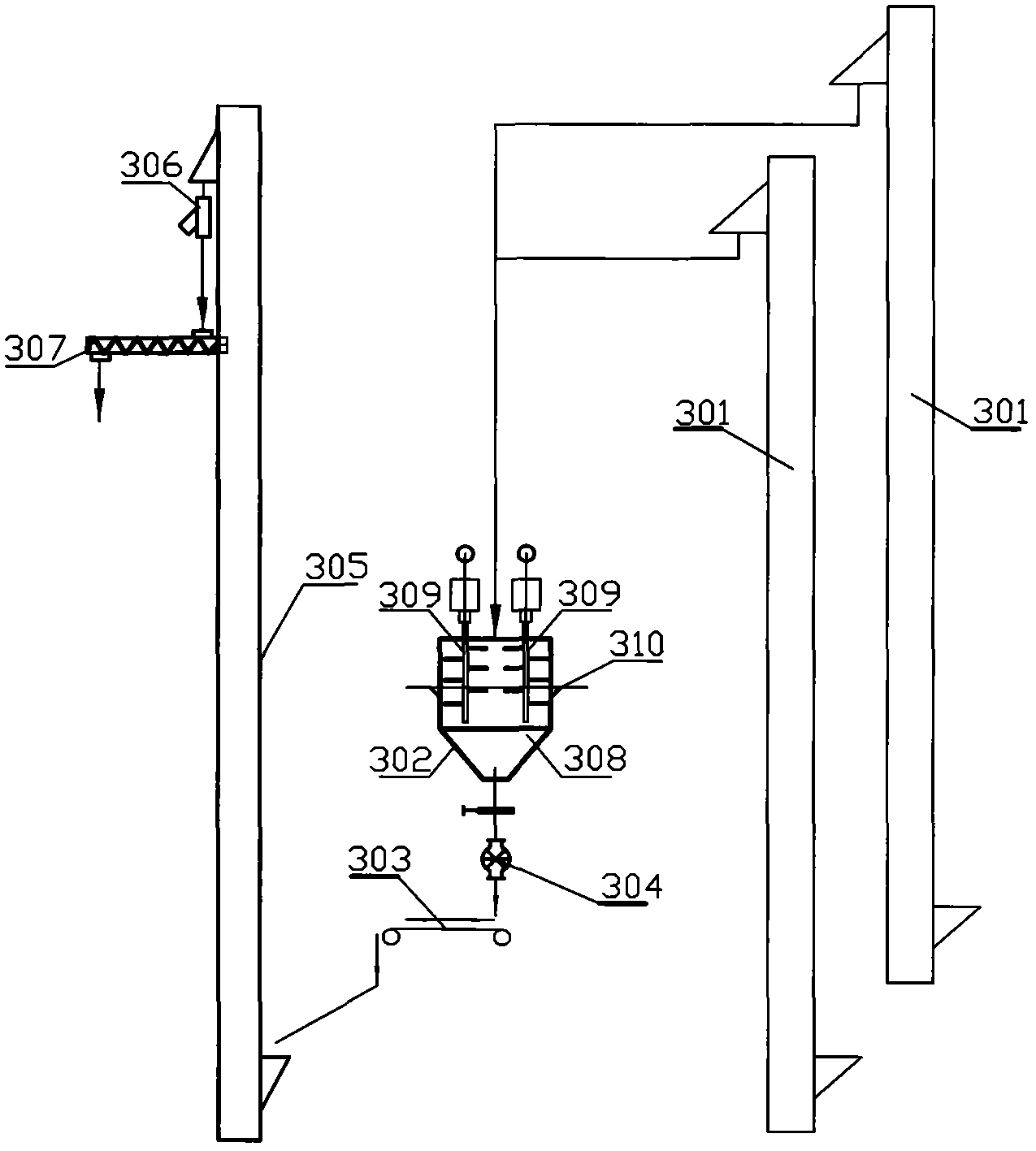

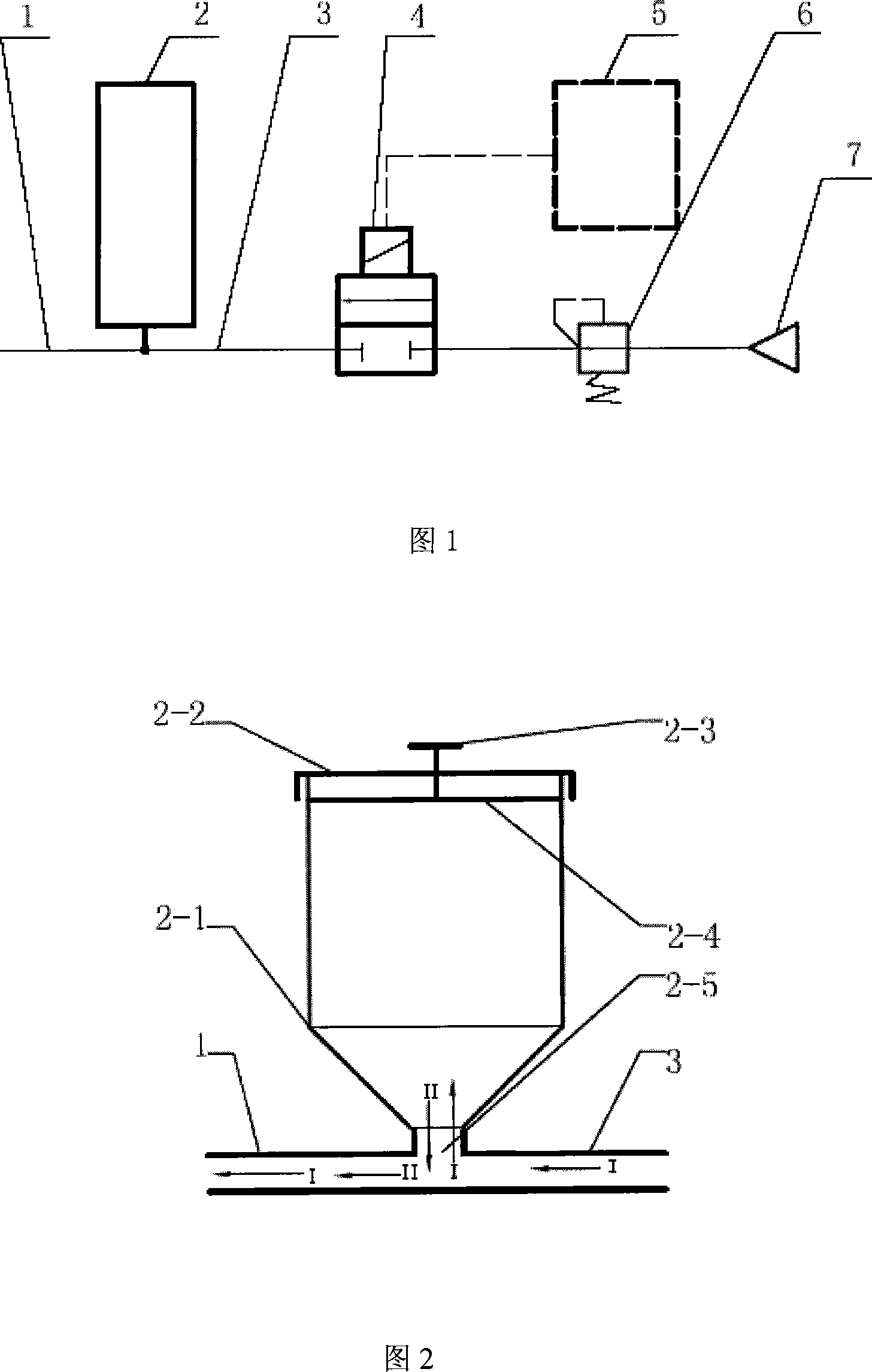

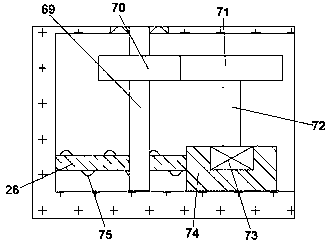

Energy accumulating pulse micro feeding system for precise fine abrasive water jet

ActiveCN101020301AEliminate feed interruptionsEliminate cloggingGrinding/polishing apparatusEngineeringControl circuit

The present invention belongs to the field of special machining technology, and is especially energy accumulating pulse micro feeding system for precise fine abrasive water jet machining apparatus. The energy accumulating pulse micro feeding system consists of gas source, pressure regulating valve, high frequency switch valve and its frequency varying control circuit, gas inlet pipe, energy accumulating material bin and material pipe connected together. The present invention has intermittent material feeding gas flow matching with the energy accumulating material bin, no material pipe blocking and high machining precision.

Owner:SHANDONG UNIV

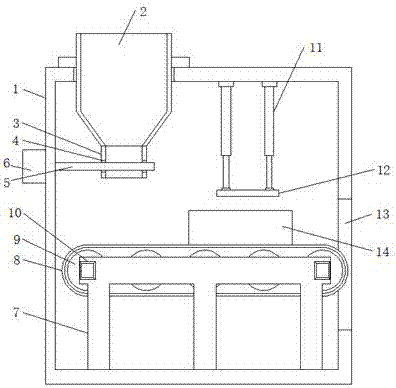

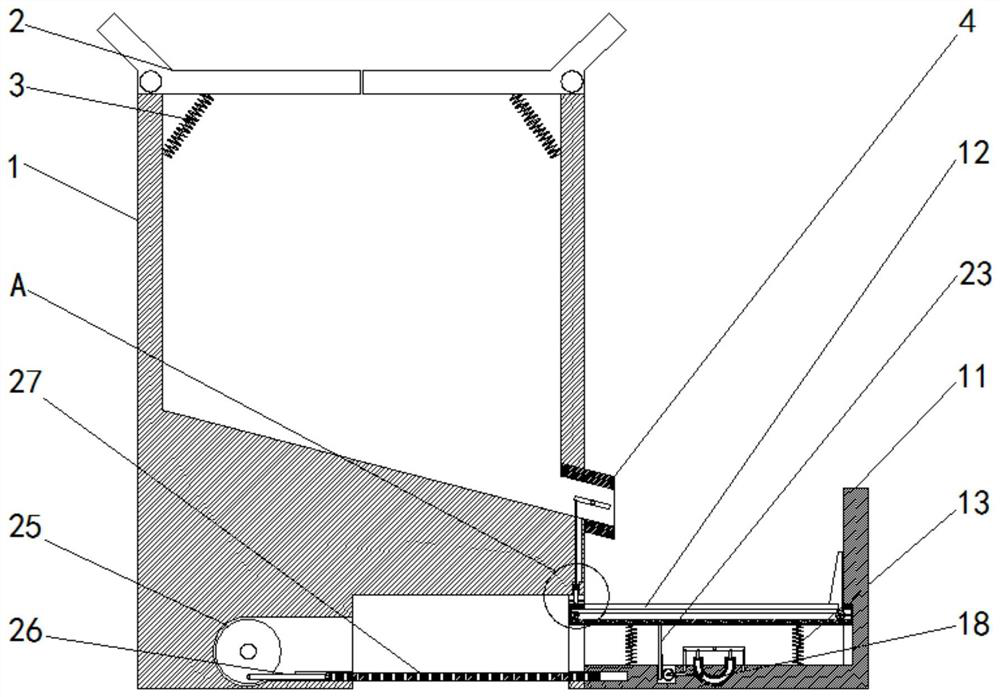

Production equipment and production process of skincare lotion

InactiveCN112844165AImprove the mixing effectControl the amount of feedShaking/oscillating/vibrating mixersTransportation and packagingGear wheelElectric machinery

The invention relates to production equipment of a skincare lotion, which comprises a device body, a feeding hopper, a driving motor, a stirring barrel and a servo motor, the feeding hopper is fixedly installed on the edge side of the upper end of the device body, the driving motor is installed in the middle of the upper end of the device body, and the lower end of the driving motor is connected with a transmission rod; the transmission rod is mounted in the middle of a carrying plate in a penetrating manner, a movable rod is mounted at the lower end of the transmission rod, a mixing rod is mounted on the side of the movable rod, a rack is fixedly connected to the lower end of the side of the stirring barrel, a main gear is mounted on the side of the carrying plate, and a swing rod is fixedly mounted at the upper end of the main gear. According to the production equipment of the skincare lotion and the production process thereof, the raw material mixing effect can be improved during processing, meanwhile, bubbles generated in the mixing process can be removed, the feeding amount can be effectively controlled, and raw materials adhering to the inner wall of the feeding hopper can be cleaned.

Owner:平世粉

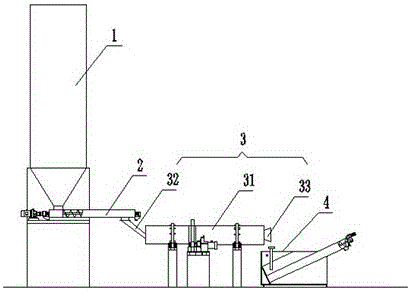

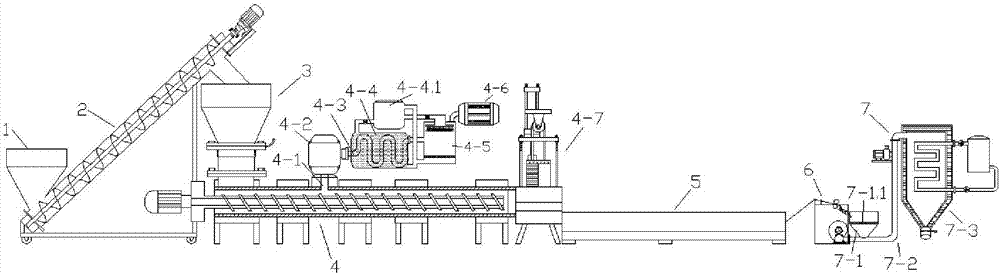

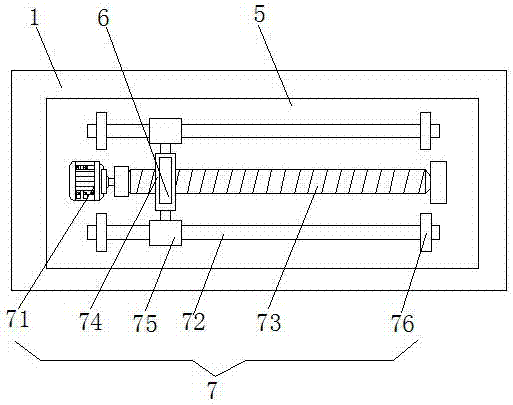

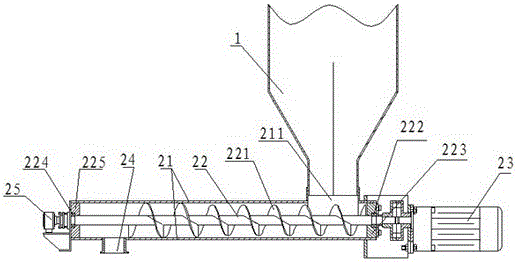

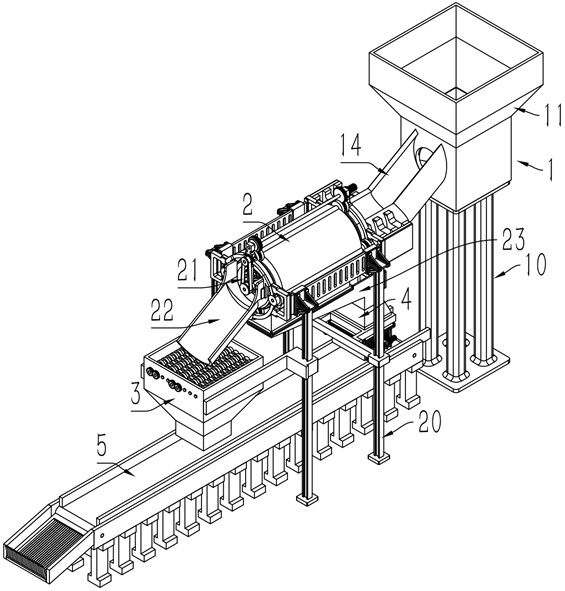

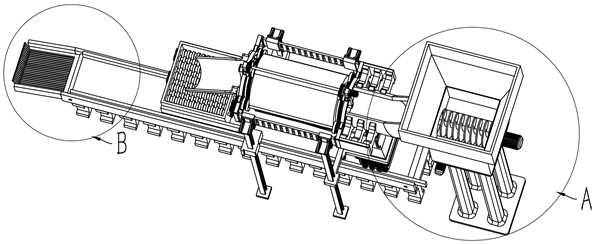

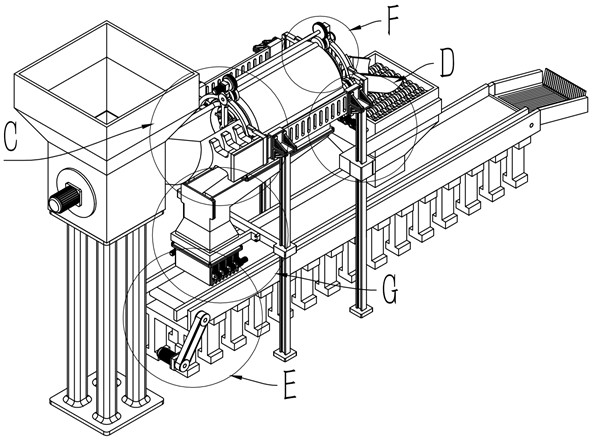

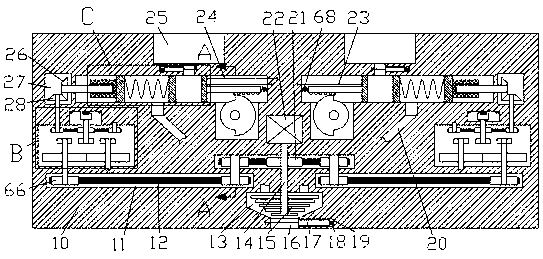

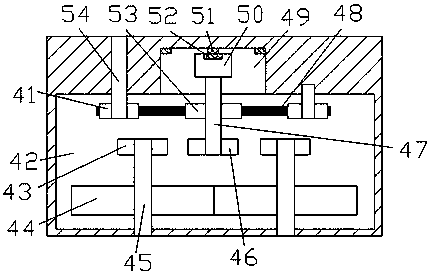

Waste plastic pelleting unit

InactiveCN107150418AControl the amount of feedFeed Quantity ObservationCoatingsEngineeringMechanical engineering

The invention discloses a waste plastic pelleting unit and relates to the technical field of plastic processing equipment. The waste plastic pelleting unit comprises a storage box, a transmission auger, a feeding device, a screw extruder, a cooling device, a granulator and a receiving device which are connected in sequence, wherein the feeding device comprises a first feeding hopper and a second feeding hopper; a flow intercepting assembly for controlling material flow rate is arranged under the first feeding hopper and comprises a flow intercepting plate and a connecting plate; the middle of the connecting plate is hollow; a groove allowing the flow intercepting plate to slide is formed in the connecting plate; the flow intercepting plate can control the material flow rate through sliding along the groove; a feeding filter screen is detachably arranged in the middle hollow part of the connecting plate; the second feeding hopper is connected with the flow intercepting assembly; a remainder viewport is formed in the second feeding hopper; the second feeding hopper is connected with a machine barrel of the screw extruder; and the material quantity in the machine barrel can be observed in real time through the remainder viewport. The waste plastic pelleting unit transmits material through the transmission auger to realize uniform feeding and ensure that the obtained finished plastic product is high in quality.

Owner:绵阳立新科技发展有限公司

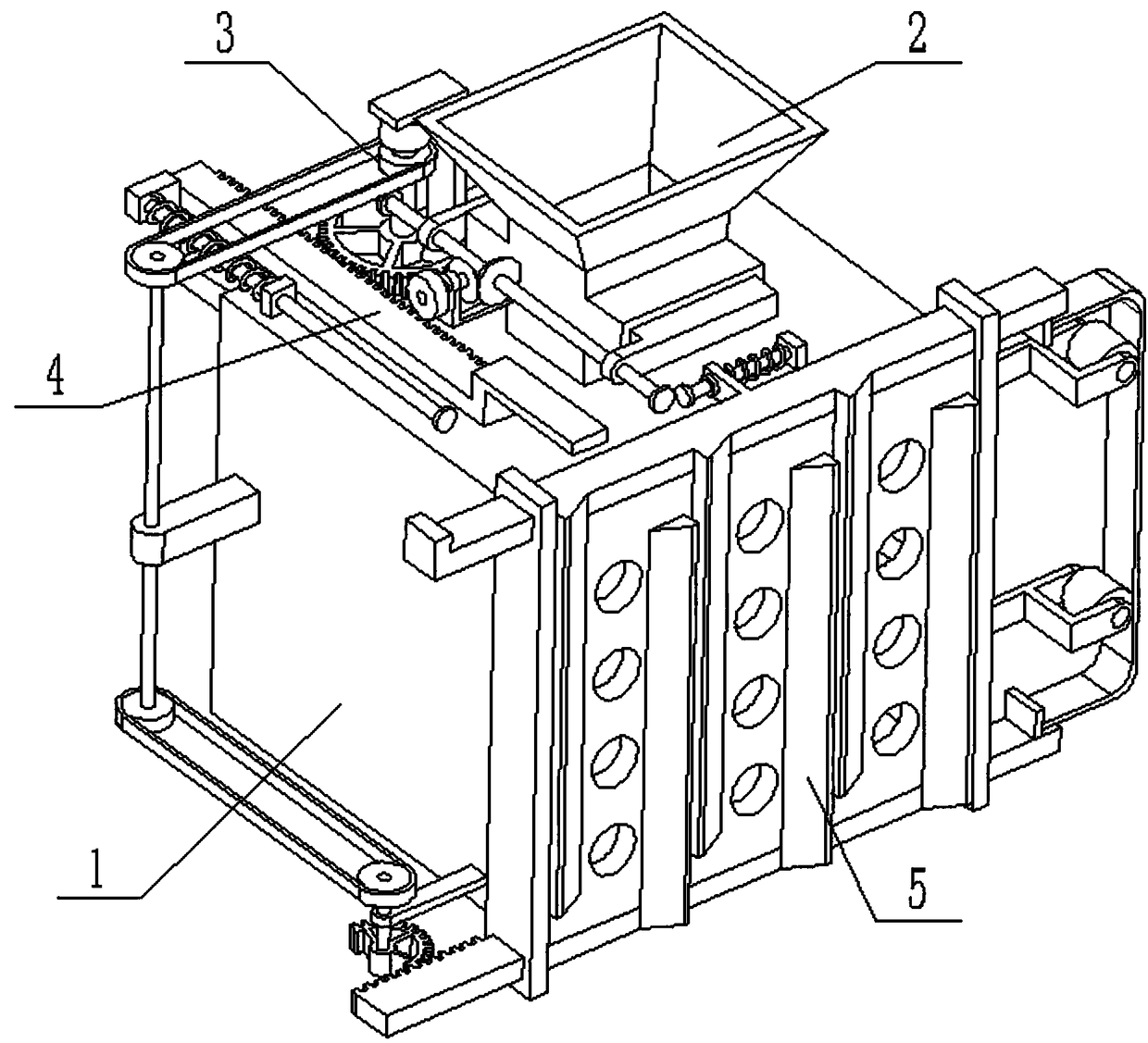

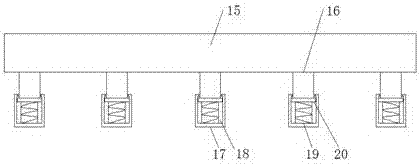

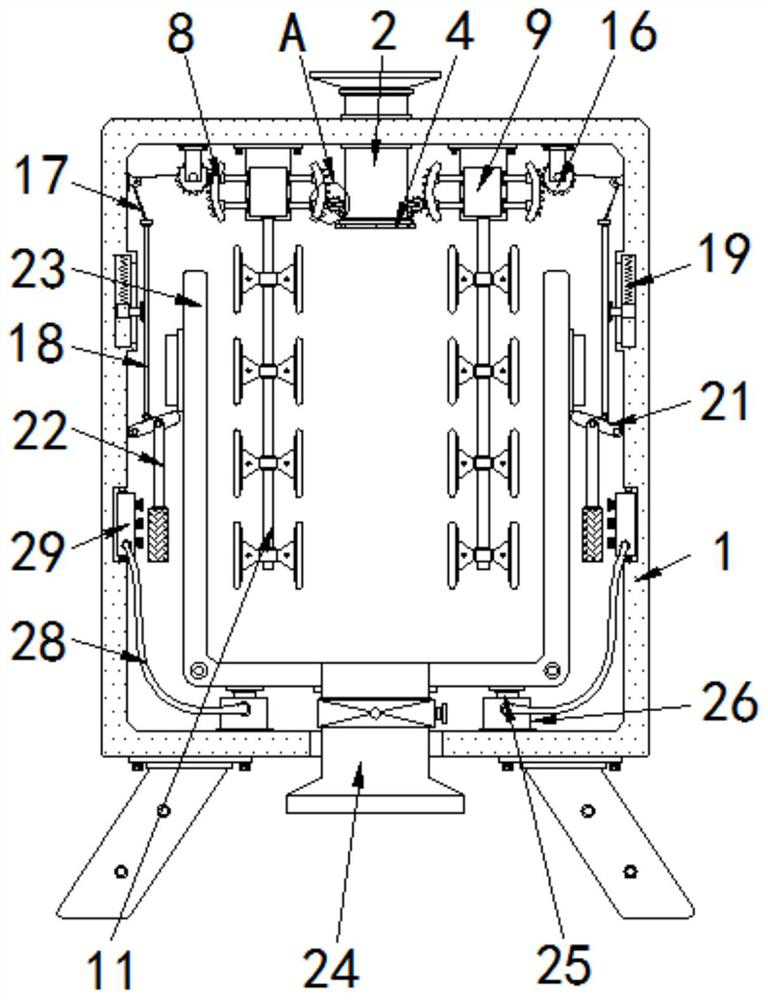

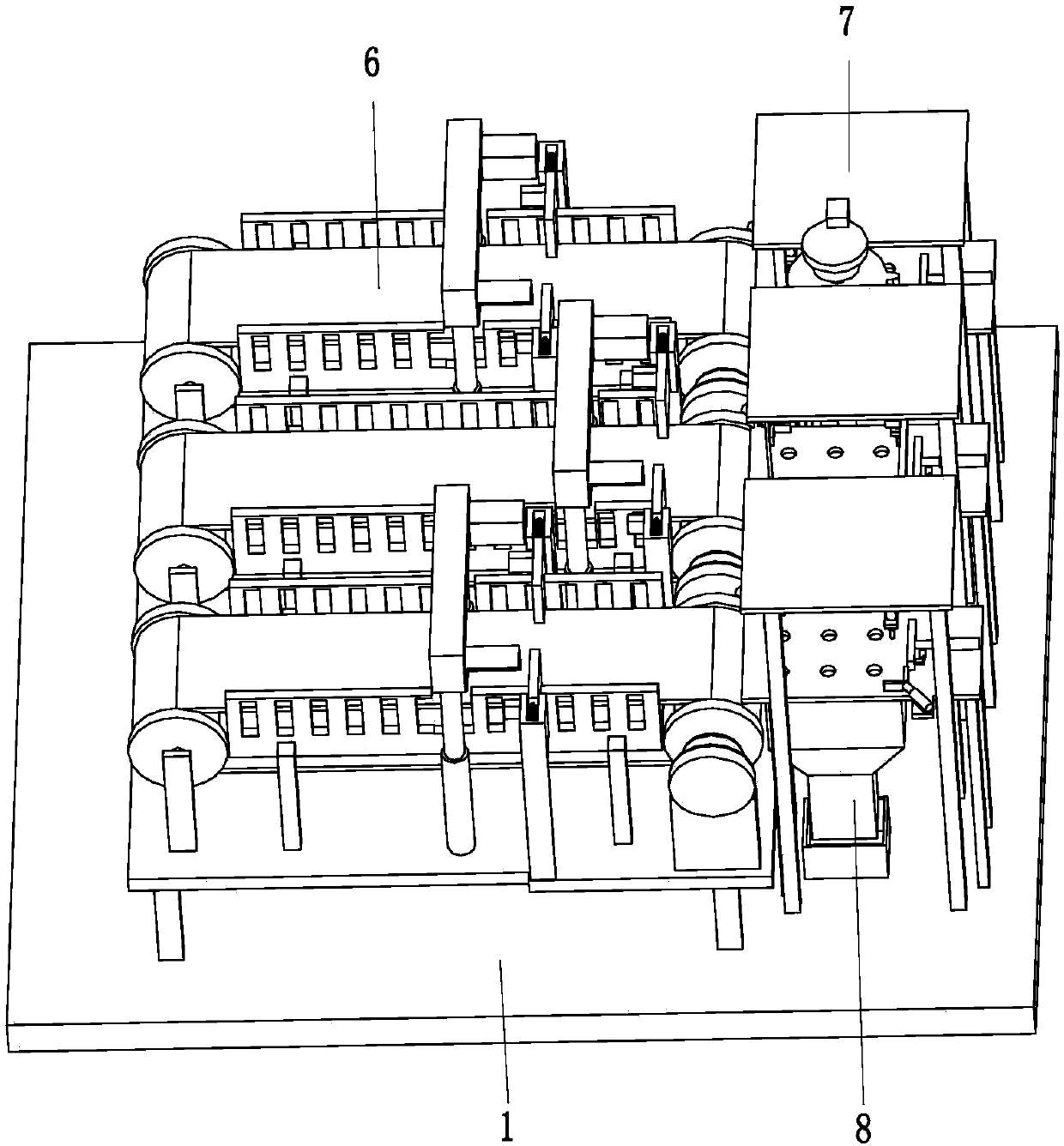

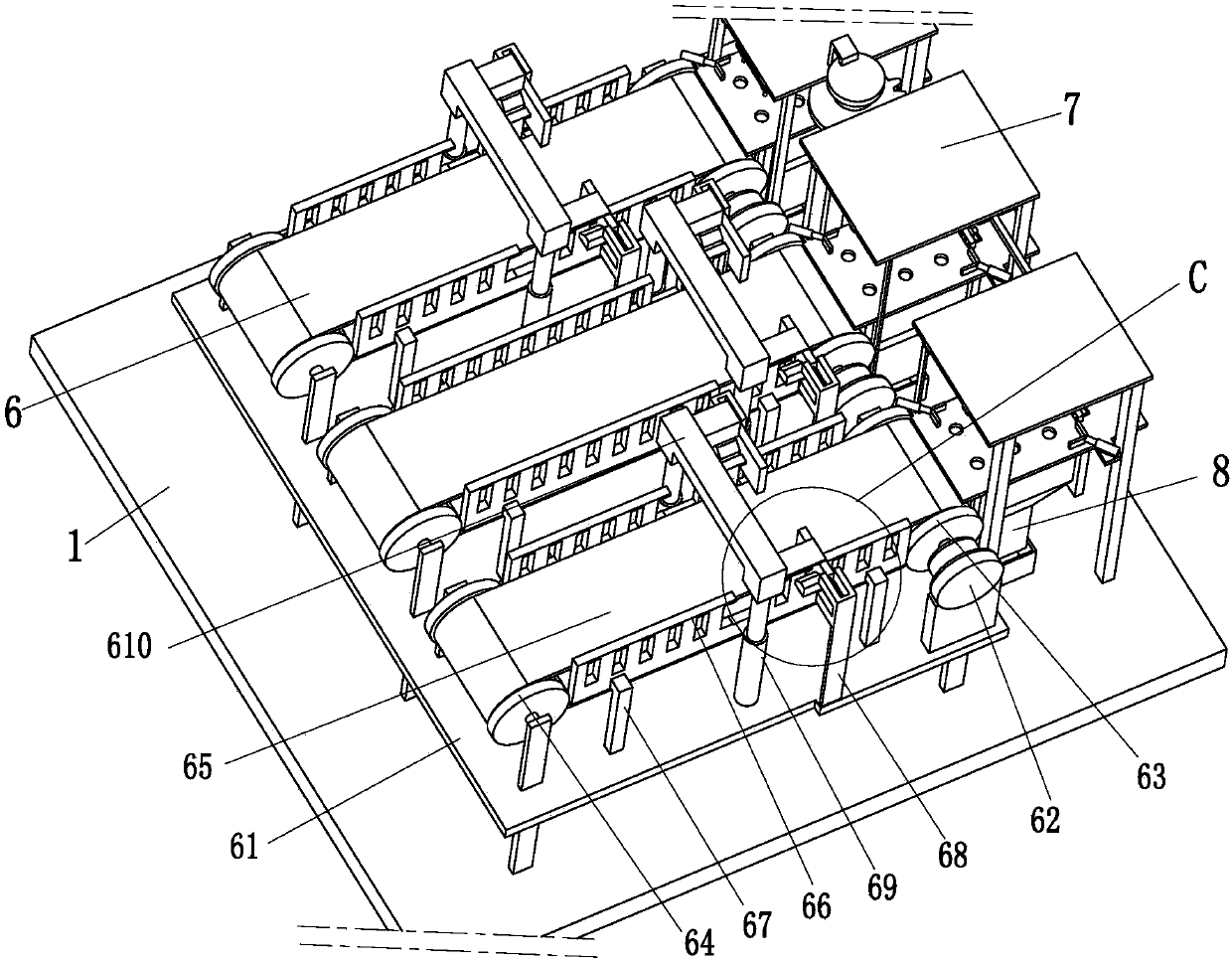

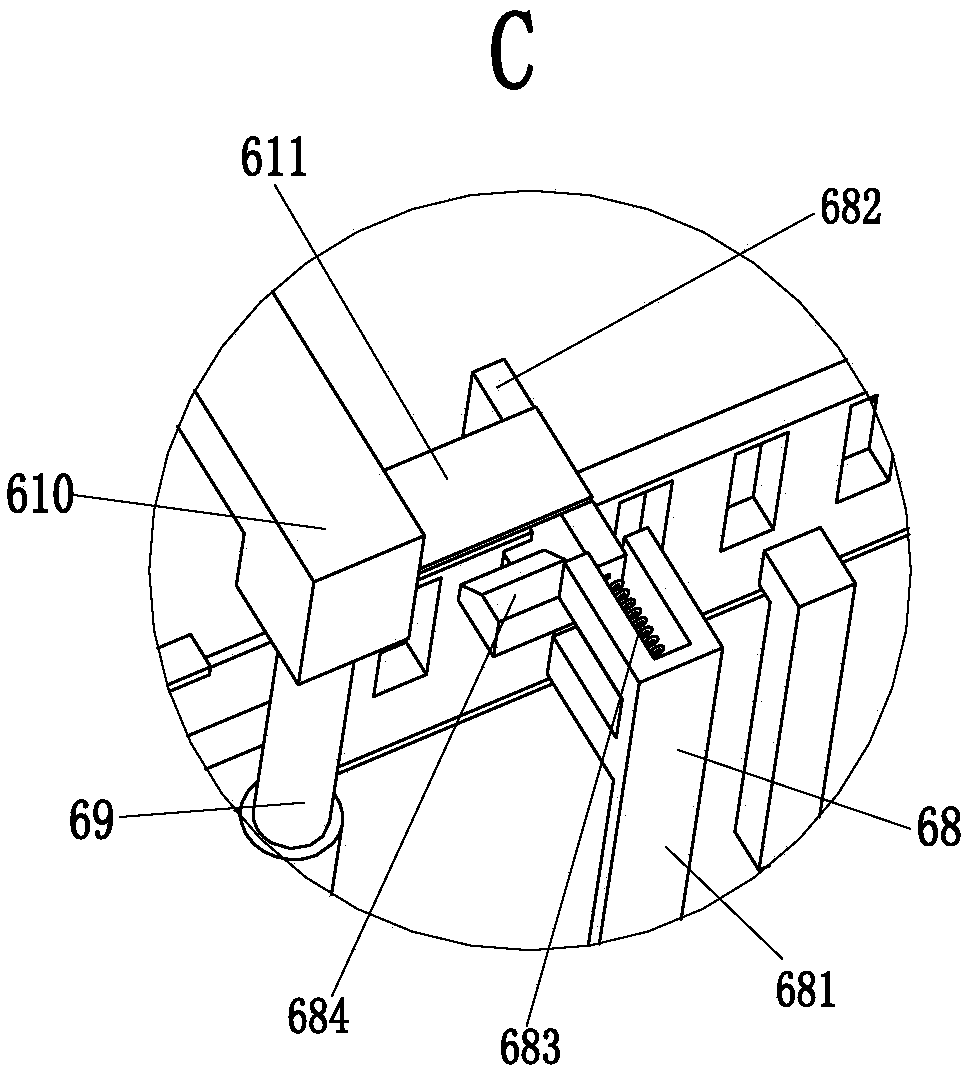

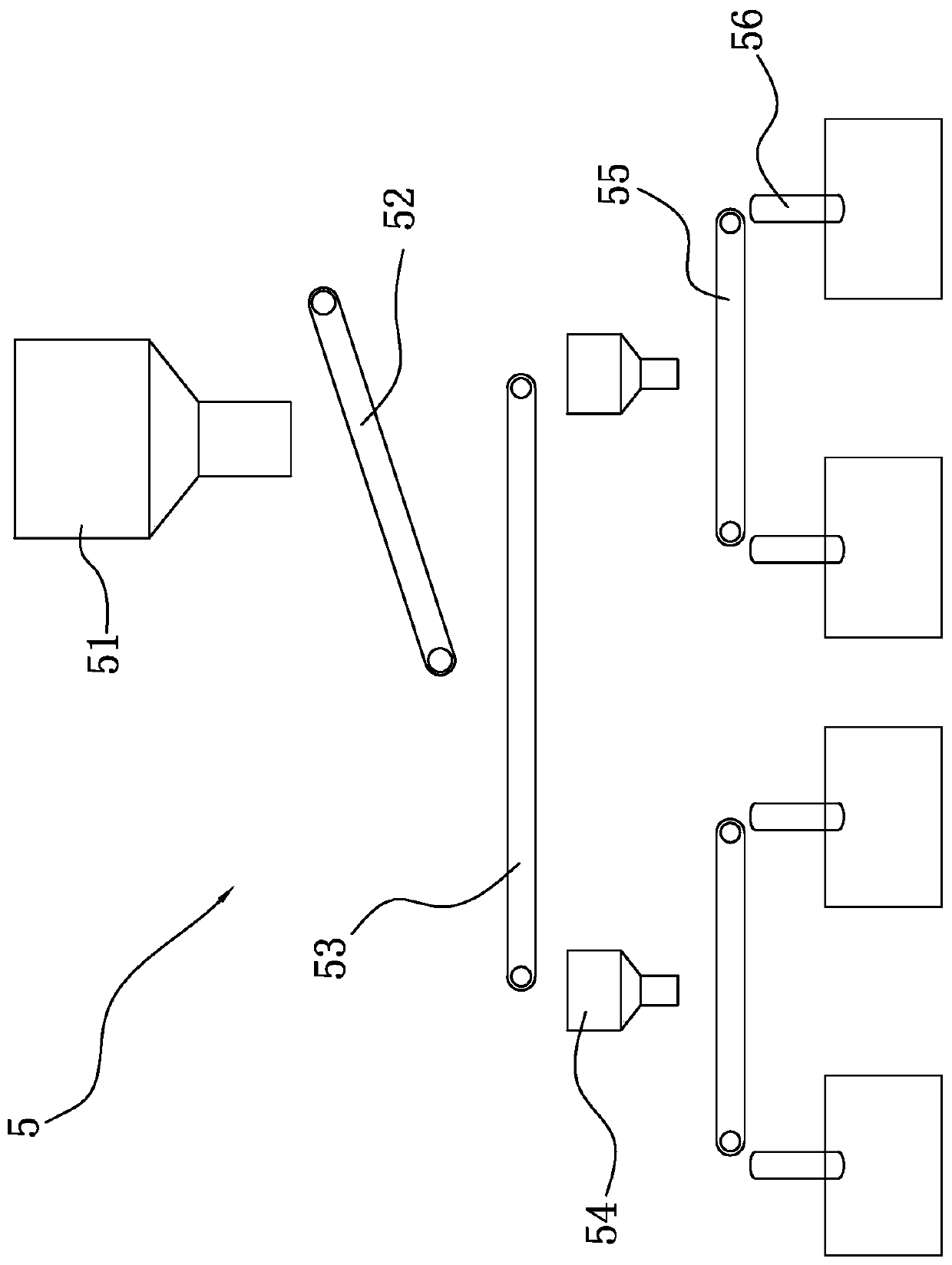

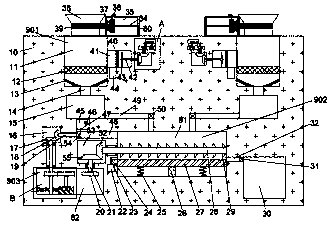

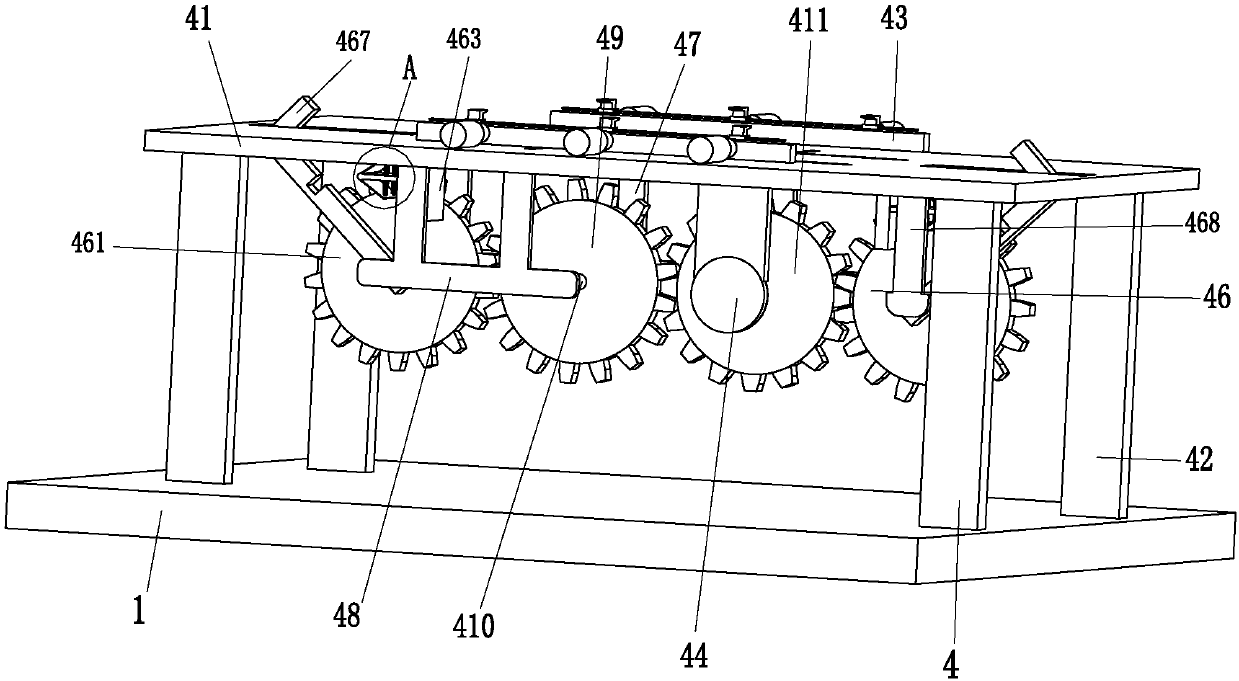

Automatic punching equipment of polystyrene foam plate for construction wall decoration

InactiveCN108044694AAutomatic control of feed quantityImprove work efficiencyMetal working apparatusPunchingAutomatic control

The invention relates to automatic punching equipment of a polystyrene foam plate for construction wall decoration. The automatic punching equipment comprises a supporting bottom plate, three transmission devices, a punching device and three recovery devices; the three transmission devices are uniformly arranged on the supporting bottom plate; the punching device is connected with the right end ofthe supporting bottom plate; the three recovery devices are located below the punching device; and the three recovery devices are uniformly arranged on the supporting bottom plate. The problems thatthe degree of mechanization is low, the feeding quantity of foam blocks cannot be controlled, and punching work on the multiple foam blocks at one time cannot be realized, and foam chippings cannot berecovered when existing punching equipment punches the polystyrene foam plate can be solved. The automatic punching equipment has the advantages that the feeding quantity of the foam blocks can be controlled automatically, the punching work on the multiple foam blocks can be carried out at one time, and the foam chippings can be recovered.

Owner:宋当建

Suspension roller type cement pipe making machine

ActiveCN110497518AControl is levelControl level statusAuxillary shaping apparatusDrive shaftPulp and paper industry

The invention relates to a suspension roller type cement pipe making machine, and relates to the technical field of cement pipe making machines. The suspension roller type cement pipe making machine comprises a rack, a door frame, a suspension roller shaft and a driving shaft, wherein one end of the suspension roller shaft is connected with the driving shaft through a flange plate, the other end of the suspension roller shaft is connected with the door frame in a rotating mode, and the driving shaft is installed on the rack through a shaft supporting seat; and the suspension roller type cementpipe making machine further comprises a downward pressing device fixedly installed on the rack, wherein the downward pressing device comprises a bottom plate, a driving mechanism and a pressing platearranged on the driving mechanism, the pressing plate is arranged above the end, far away from the suspension roller shaft, of the driving shaft, the driving mechanism is arranged on the bottom plate, and the bottom plate is arranged on the rack. The machine has the effect of controlling the suspension roller shaft to be in a horizontal state.

Owner:唐山市丰南区利源水泥制品有限公司

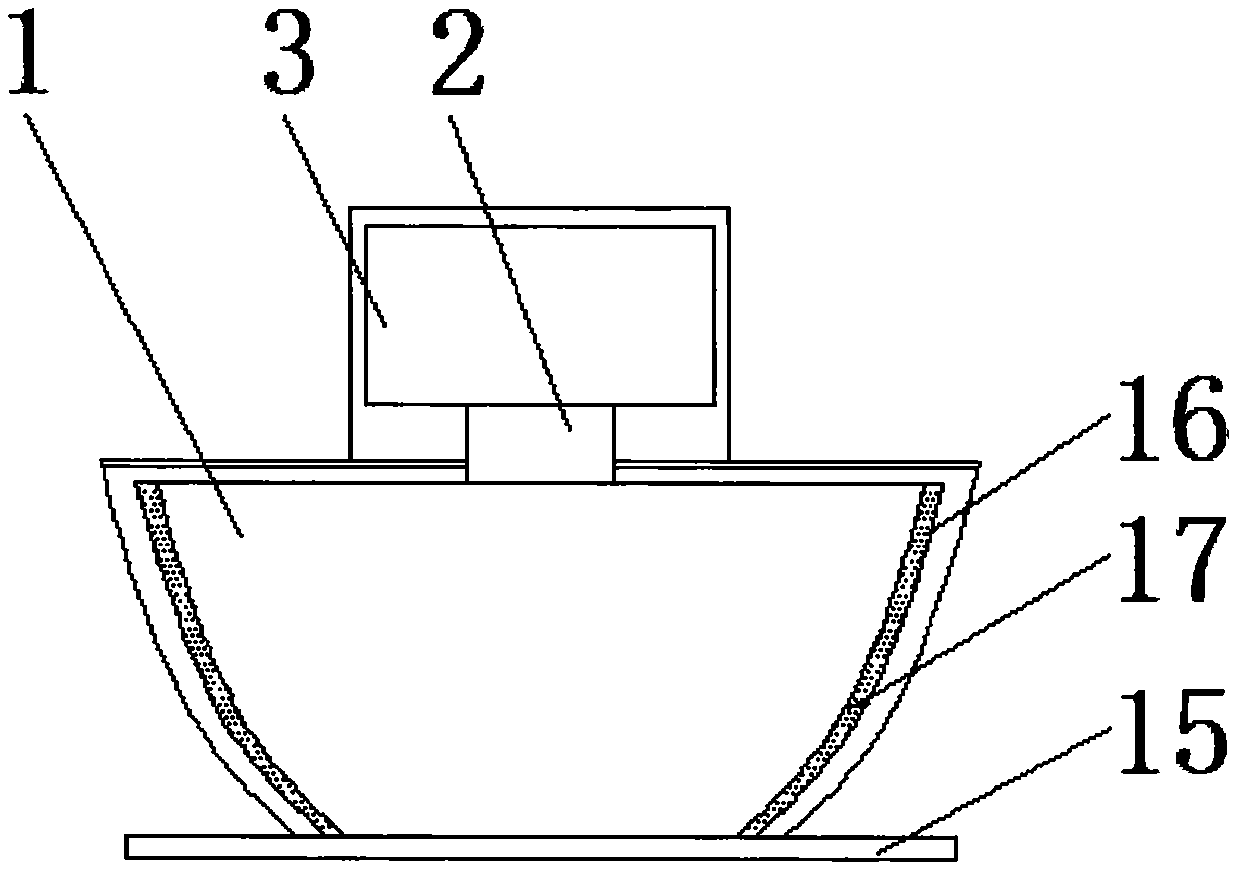

Feeding device for cattle and sheep breeding

InactiveCN106857281AIncrease automation and efficiencySave human effortAnimal feeding devicesFixed frameEngineering

The invention discloses a feeding device for cattle and sheep breeding, which comprises a wall body, a chute is opened on the top of the wall body, a slider 1 is movably connected to the bottom of the inner wall of the chute, and the top of the slider 1 is fixed. A discharge device is connected, a groove is provided on one side of the wall, a mobile device is fixedly connected to the bottom of the inner wall of the groove, a fixed seat is fixedly connected to the top of the mobile device, and one side of the fixed seat A feed barrel is fixedly connected, and the feeding device includes a motor one and a fixed frame, and the output shaft of the motor one is fixedly connected with a rotating shaft through a coupling. The present invention relates to the technical field of farming equipment. The feeding device for cattle and sheep breeding solves the problem of manual feeding for most cattle and sheep breeding, solves the complexity and inconvenient operation of the existing feeding device, improves the efficiency and automation of breeding feeding, and saves a lot of manpower , to reduce the pressure of people when feeding.

Owner:盐城市牧龙养殖有限公司

A lime digestion dosing and feeding device

InactiveCN105084786BSpeed up the flowAchieving the purpose of continuous fuelPulp and paper industry

Owner:SHENYANG POLYTECHNIC UNIV

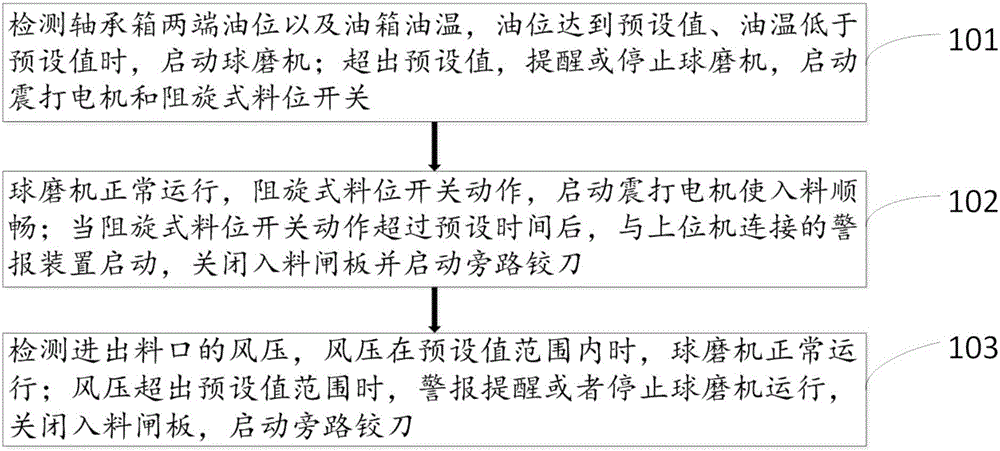

Control method of ball mill

InactiveCN106732985AControl the amount of feedAvoid blockingGrain treatmentsElectric machineryFuel tank

The invention discloses a control method of a ball mill. The control method can prevent problems generated in a production process of the ball mill to affect production, so that the loss of the ball mill is reduced and the production efficiency is improved. The control method comprises the steps: detecting the oil levels at two ends of a bearing box and the oil temperature of an oil tank, and starting the ball mill when the oil level achieves a predetermined value and the oil temperature is lower than a predetermined value; if the oil level exceeds the predetermined value, reminding or stopping the ball mill, and starting a vibrating motor and an impeding material level switch; normally operating the ball mill, acting the impeding material level switch and starting the vibrating motor to charge the material smoothly; when the impeding material level switch acts over the predetermined time, starting an alarm device connected to an upper computer, closing a charging gate and starting a bypass reamer; detecting the air pressure of a feed inlet / out, wherein when the air pressure is in a predetermined value range, the ball mill is operated normally; when the air pressure exceeds the predetermined value range, alarming and reminding or stopping the ball mill to operate, closing the charging gate and starting the bypass reamer.

Owner:BEIJING NEW BUILDING MATERIALS PLC

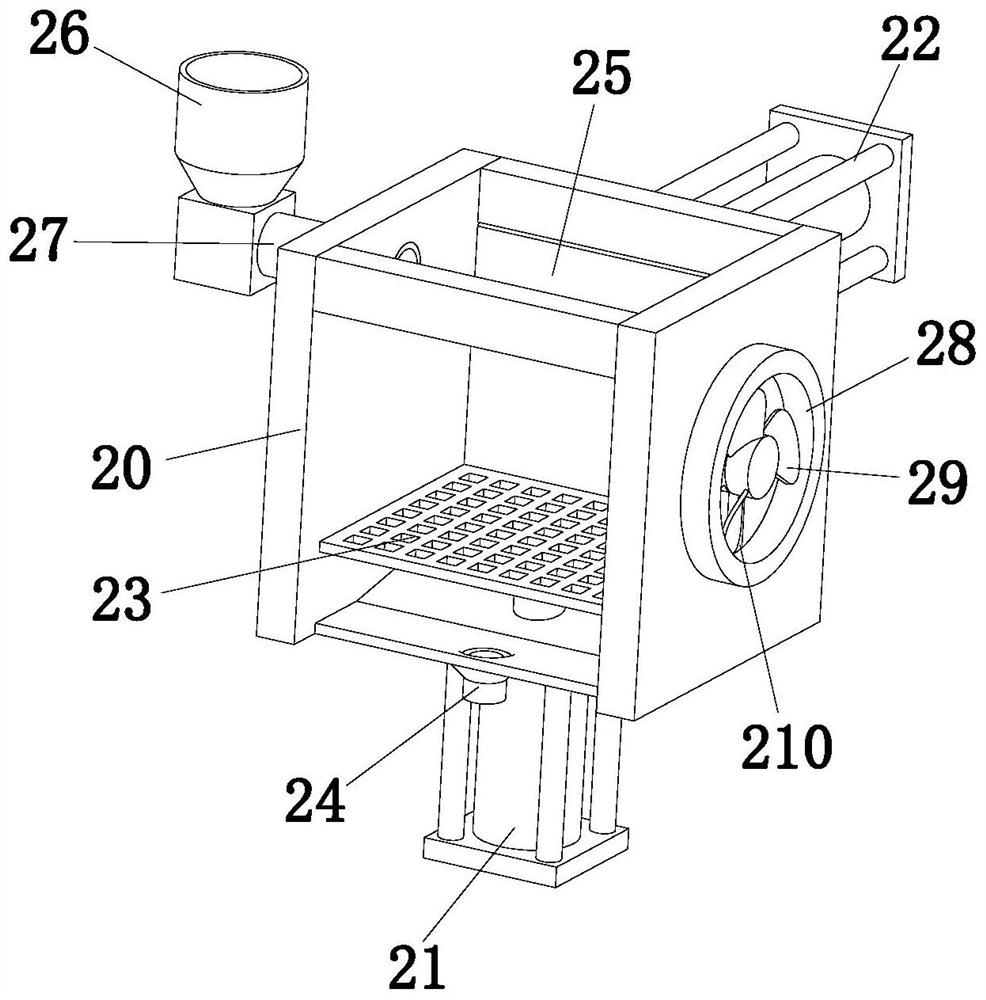

Bio-organic fertilizer screening device

ActiveCN113477363AEasy to sieveControl the amount of feedGas current separationGrain treatmentsAgricultural engineeringOrganic fertilizer

A bio-organic fertilizer screening device comprises a feeding assembly, a screening assembly, a first crushing mechanism, a second crushing mechanism and a conveying mechanism, the screening assembly is arranged on the feeding assembly, and the first crushing mechanism is arranged below one end of the screening assembly; the second crushing mechanism is arranged below the other end of the screening assembly; and the conveying mechanism is arranged under the first crushing mechanism and the second crushing mechanism. In the preparation process of a bio-organic fertilizer, screening operation of the bio-organic fertilizer is facilitated, primary crushing of the bio-organic fertilizer can be conducted during the screening operation, refined secondary grinding and crushing can be conducted according to the size of bio-organic fertilizer blocks, the feeding amount of the bio-organic fertilizer can be conveniently controlled, the preparation efficiency of the bio-organic fertilizer is improved, meanwhile, the refining degree of the bio-organic fertilizer is improved, then the quality of the bio-organic fertilizer is improved, and high practicability is achieved.

Owner:四川沃野好土科技有限公司

Alloy powder mixing device capable of adjusting mixing proportion in real time

InactiveCN111013446AControl the amount of single feedReal-time adjustment of mixing ratioRotary stirring mixersTransportation and packagingReciprocating motionElectric machine

The invention discloses an alloy powder mixing device capable of adjusting the mixing proportion in real time. The alloy powder mixing device comprises a main box body, wherein a motor is fixedly connected in the main box body, a power distribution cavity is formed on the lower side of the motor, a stirring cavity is formed in the lower side of a power distribution cavity, the lower side of the stirring cavity is communicated with a discharging cavity with a downward opening, the right side of the discharging cavity communicates with a discharging baffle cavity, and a discharging baffle is connected into the discharging baffle cavity in a sliding fit mode. According to the invention, powder feeding is completed through the reciprocating motion of the push plate while the stirring rod rotates to finish the mixing and stirring of the powder; and when the push plate pushes, the feeding baffle and the discharging baffle are closed to discharge and completely mix, and the fixed plate and the sliding plate can be controlled to move towards the two sides by poking the poking rod so as to control the single-time feeding amount of the powder, so that the real-time adjustment of the powder mixing proportion is completed, and the situation that the device is frequently started and stopped to adjust the mixing proportion is avoided.

Owner:YIWU ZIYING MASCH TECH CO LTD

Adjustable feed adding device

InactiveCN107772519AReduce labor intensityControl the amount of feedFeeding-stuffEngineeringFeed additive

The invention discloses a controllable feed adding device, which comprises a feeding bin, a stirring bin and a base, the base is fixed with a base and a mixing bin, and the second motor is rotationally connected with a spiral stirring rod through a second rotating shaft , the bottom of one side of the mixing bin is provided with a discharge port, one side of the top of the mixing bin is fixed with a delivery bin, one side of the electromagnetic valve is provided with a switch, and the feeding bin passes through the sieve plate and the delivery bin connection, the feed bin is provided with a friction plate, and the first motor is rotationally connected with the friction plate through the first rotating shaft, the first motor is fixed on the top of the feed bin, and the top of the feed bin is provided with a cover plate , the bottom of the base is provided with a control cabinet. The invention can effectively control the feeding amount, is not easy to be blocked, absorbs the dust raised when the feed is poured through the electrostatic adsorption film, reduces the impact on the environment and the staff, improves the work efficiency, and reduces the labor intensity of the staff.

Owner:TIANJIN ZHONGRUI PHARMA

Paint mixing, stirring and collecting device

InactiveCN111085128AWell mixedStir wellRotary stirring mixersTransportation and packagingMechanical engineeringEngineering

Owner:YUYAO FEIGE AUTOMATION TECH CO LTD

Automatic clipping and punching equipment of polystyrene foam boards for logistic express packing boxes

InactiveCN107718697AAutomatic control of feed quantityImprove work efficiencyBox making operationsPaper-makingAutomatic controlPunching

The invention relates to automatic clipping and punching equipment of polystyrene foam boards for logistic express packing boxes. The automatic clipping and punching equipment comprises a supporting bottom plate, a hoisting frame device, a cutting device, a fixing device, a sucking device, three conveying devices, a punching device and three recovering devices. According to the automatic clippingand punching equipment, the difficult problems that in existing foam board processing, the work efficiency is low, the labor intensity is high, the foam boards cannot be positioned and fixed, cut foamblocks are easily clamped in cutters, the feeding quantity of the foam blocks cannot be automatically controlled, and the multiple foam blocks cannot be punched at a time are solved. The functions that the foam boards can be automatically finely cut, and the cut foam boards are automatically punched at a time are achieved, and the automatic clipping and punching equipment has the advantages thatthe work efficiency is high, the labor intensity is small, the foam boards can be positioned and fixed, the cut foam blocks cannot be clamped in the cutters, the feeding quantity of the foam blocks can be automatically controlled, and the multiple foam blocks can be punched at a time.

Owner:宋当建

Medical waste wood stick treatment device for department of stomatology

InactiveCN112474713AGood effectThe efficiency of disinfection and sterilization is fastSolid waste disposalTransportation and packagingMedical wasteMechanical engineering

The invention discloses a medical waste wood stick treatment device for the department of stomatology, and belongs to the technical field of medical waste treatment. The medical waste wood stick treatment device comprises a supporting leg structure, a soaking disinfection area, a first transportation area, a clamping fixing device, a crushing device, a second transportation area and a dischargingopening, wherein the supporting leg structure is arranged on the horizontal plane; the soaking disinfection area is arranged on the top of one end of the supporting leg structure; the first transportation area is arranged at the other end of the soaking disinfection area and is fixedly mounted on the top of the middle of the supporting leg structure; the crushing device is fixedly mounted on the side face of the other end of the first transportation area; the second transportation area is arranged at the lower end of the crushing device and the lower end of the first transportation area and isobliquely mounted on the top of the supporting leg structure; the two ends of the clamping fixing device are mounted at the upper end of the first transportation area and the upper end of the secondtransportation area correspondingly and located above the crushing device; and the discharging opening is formed in an outlet in the upper end of the second transportation area. According to the medical waste wood stick treatment device, waste wood sticks are disinfected and sterilized and then dried and crushed, and the medical waste wood stick treatment device is very safe, capable of saving energy and environmentally friendly.

Owner:陈志湘

Poultry feeding device capable of automatically feeding and preventing pollution

InactiveCN112167105AControl the amount of feedFree from pollutionHollow article cleaningAvicultureCrankControl theory

The invention relates to the technical field of poultry feeding, and discloses a poultry feeding device capable of automatically feeding and preventing pollution. The feeding device comprises a storage tank, wherein a blocking cover is movably connected to the top of the storage tank, supporting springs are fixedly connected to the bottom of the blocking cover, a hopper is fixedly connected to theright side of the storage tank, a bottom plate is slidably connected to the interior of the hopper, gravity springs are fixedly connected to the bottom of the bottom plate, a crank wheel is fixedly connected to the interior of the storage tank, a transmission rod is movably connected to the front face of the crank wheel, and a sieve plate is movably connected to the right side of the transmissionrod. According to the poultry feeding device capable of automatically feeding and preventing pollution, the bottom plate ascends to drive an ejector rod to ascend, the ejector rod drives a buffer spring to ascend, the buffer spring drives a sliding rod to ascend, the sliding rod drives a connecting rod to ascend, the connecting rod drives a valve to swing, and then the valve and a discharging port are used in cooperation, so that the effect of automatically feeding and controlling the feed amount is achieved.

Owner:朱合松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com