Rice milling equipment

A kind of equipment and grinding technology, which is applied in grain processing, application, grain pod removal, etc., can solve the problems of uncontrollable feeding amount, insufficient grinding, high broken rice rate, etc., so as to avoid uneven grinding and prolong the use Longevity and the effect of reducing work stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further detailed explanation through specific implementation mode below:

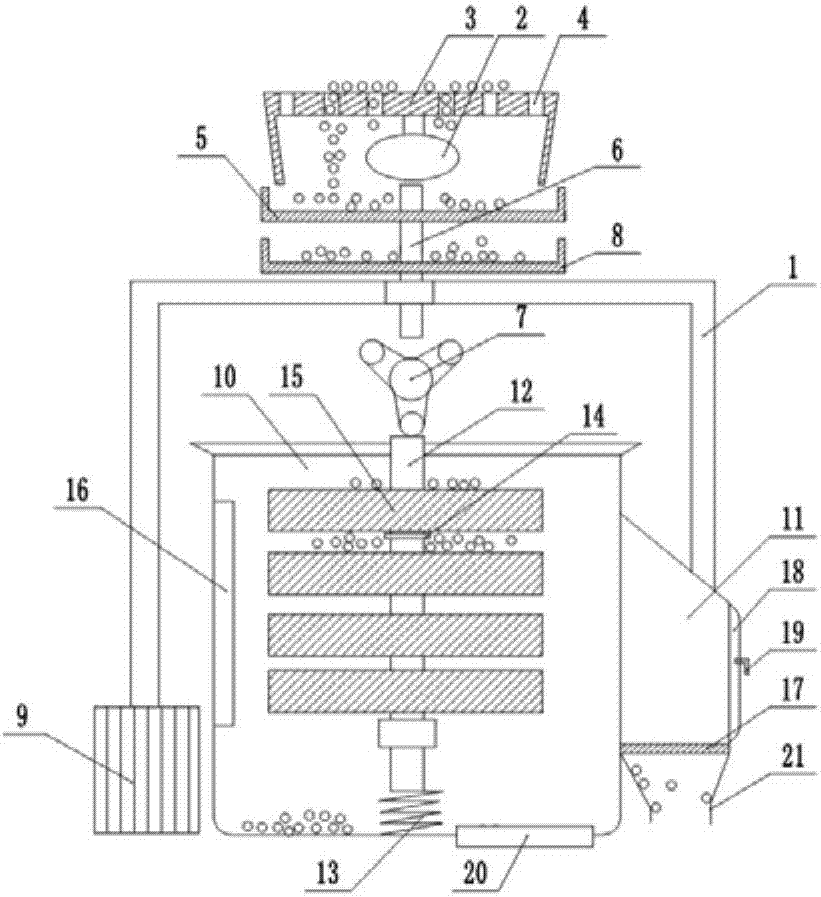

[0018] The reference signs in the accompanying drawings of the description include: frame 1, main airbag 2, feed airbag 3, feed inlet 4, filter screen 5, push rod 6, cam 7, baffle plate 8, motor 9, grinding box 10 , bran collection box 11, threaded rod 12, spring 13, support block 14, milling disc 15, blower 16, filter layer 17, warehouse door 18, handle 19, discharge port 20, broken rice collection port 21.

[0019] The embodiment is basically as attached figure 1 Shown: a rice milling device, including a frame 1, a feeding mechanism, a filtering mechanism and a grinding mechanism, the feeding mechanism includes a feeding air bag 3 and a main air bag 2, the main air bag 2 communicates with the feeding air bag 3, and the feeding The airbag 3 is made of rubber material, and the feeding airbag 3 is provided with a plurality of feeding ports 4; the filter mechanism is located at the bottom of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com