Patents

Literature

204results about How to "Easy to shake off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

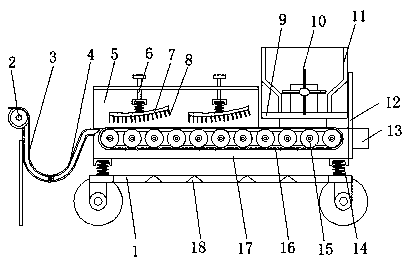

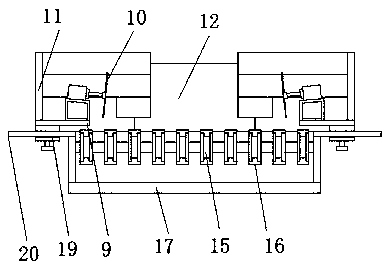

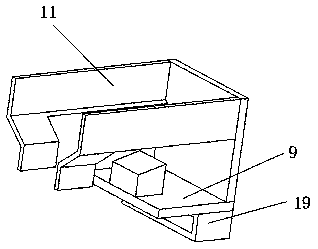

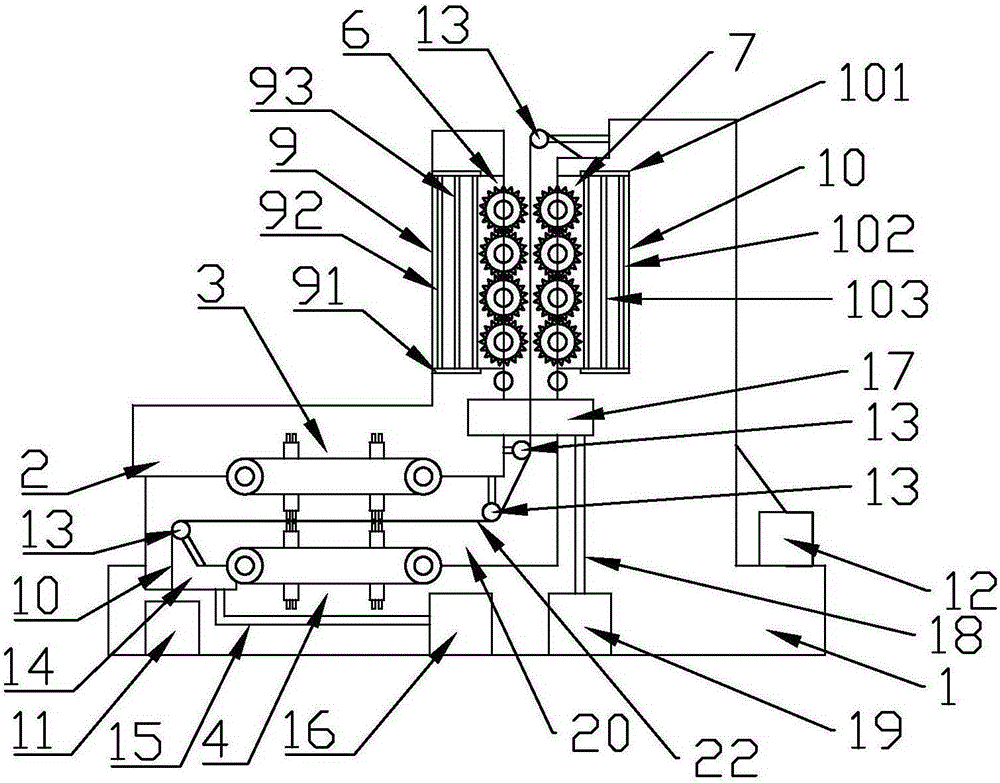

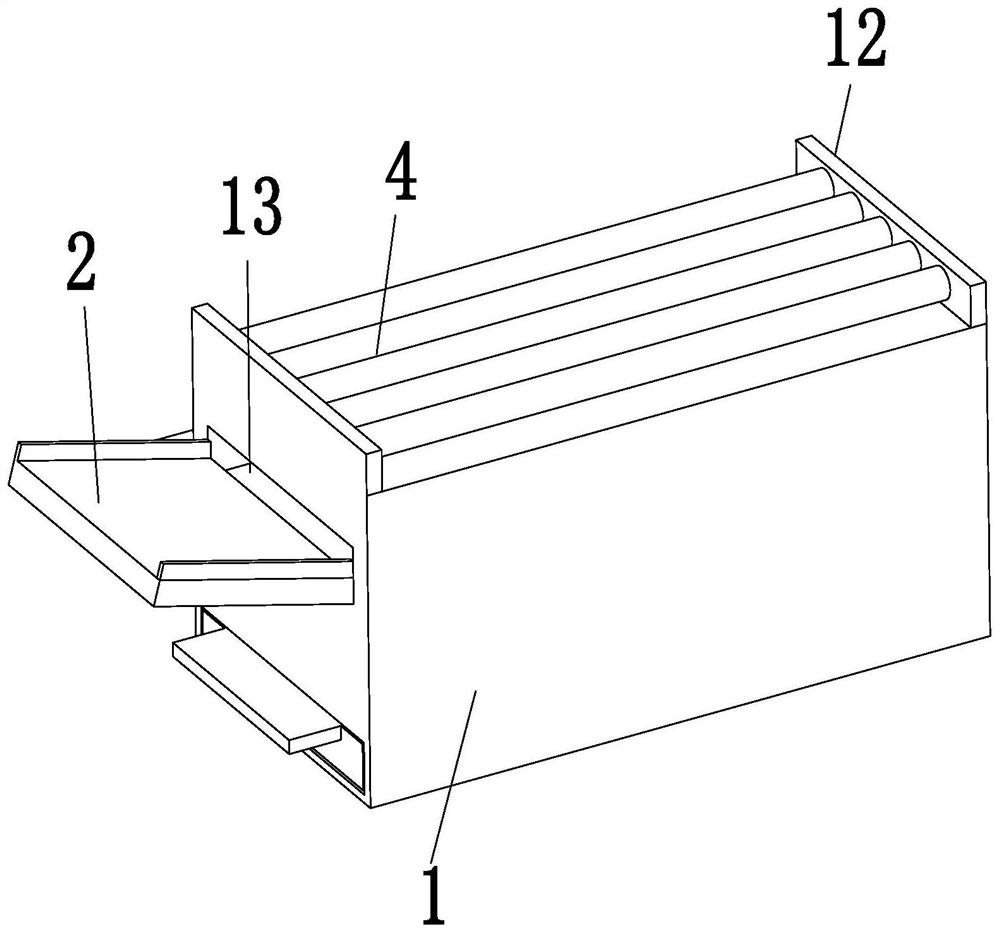

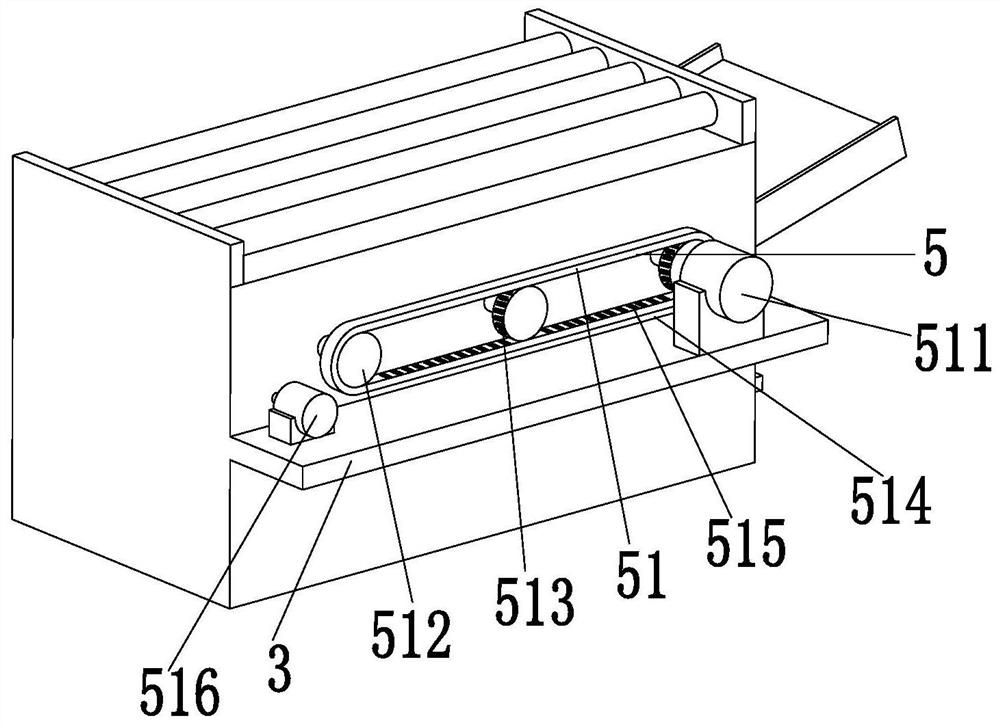

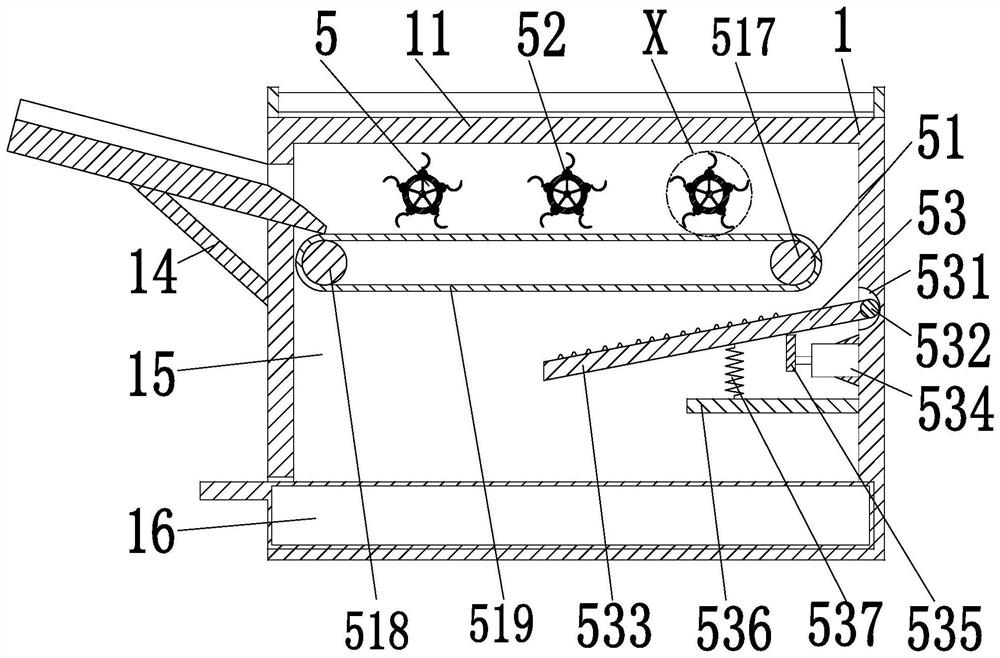

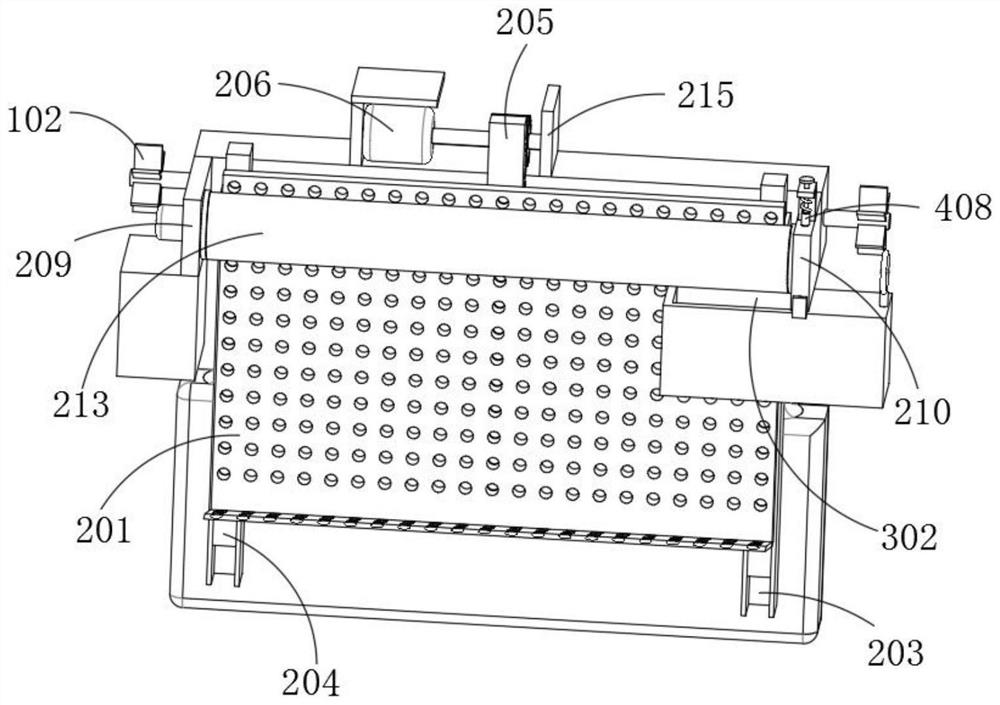

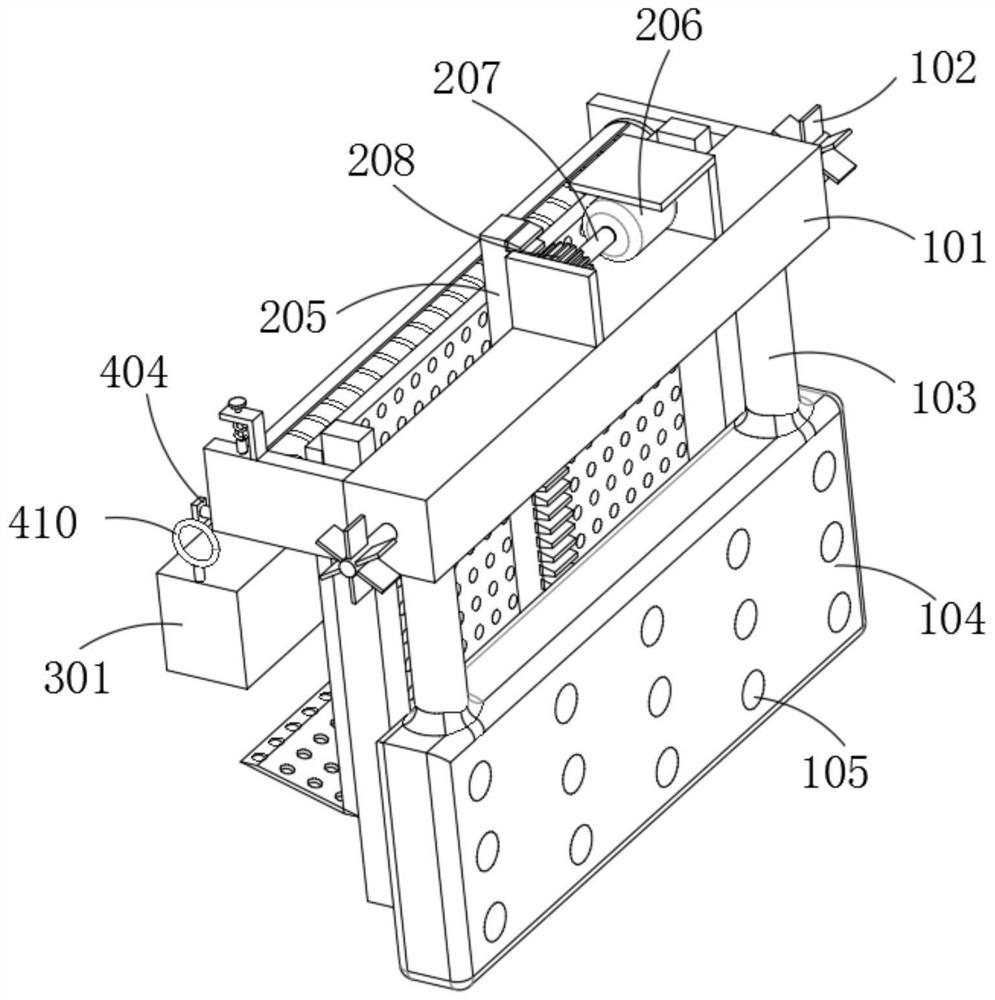

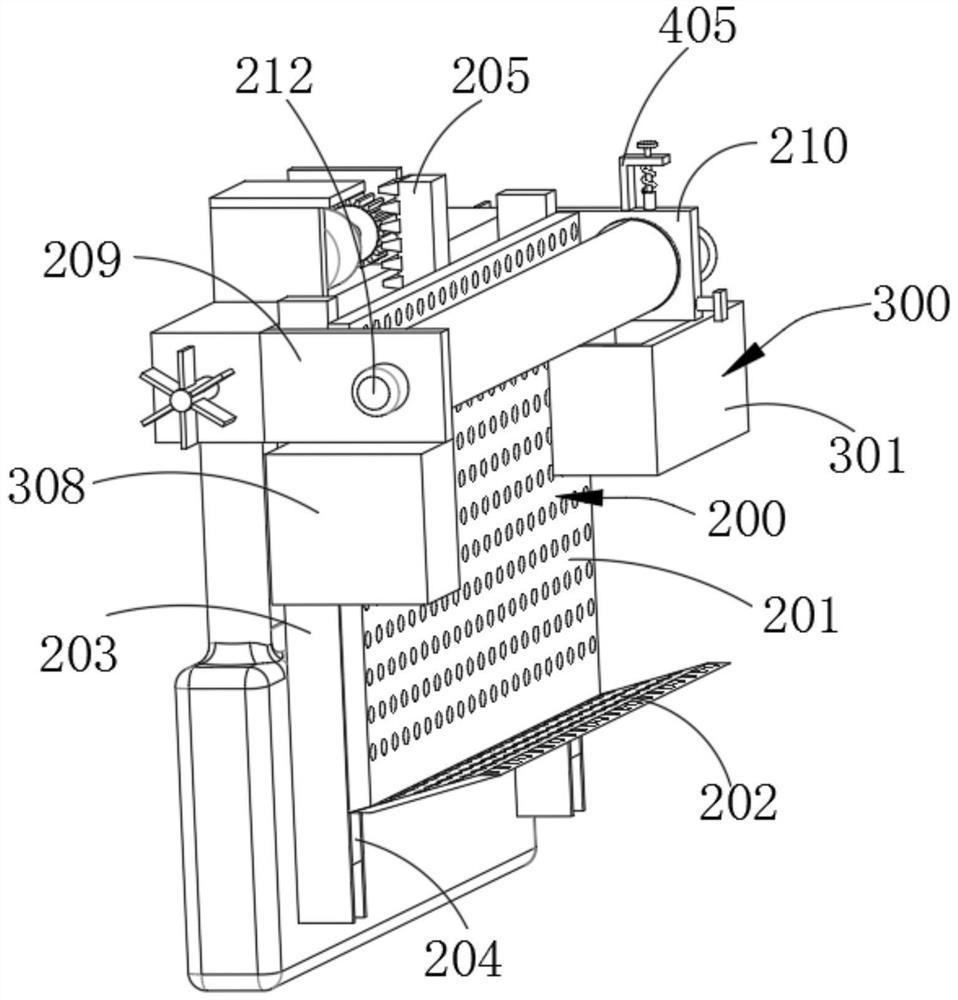

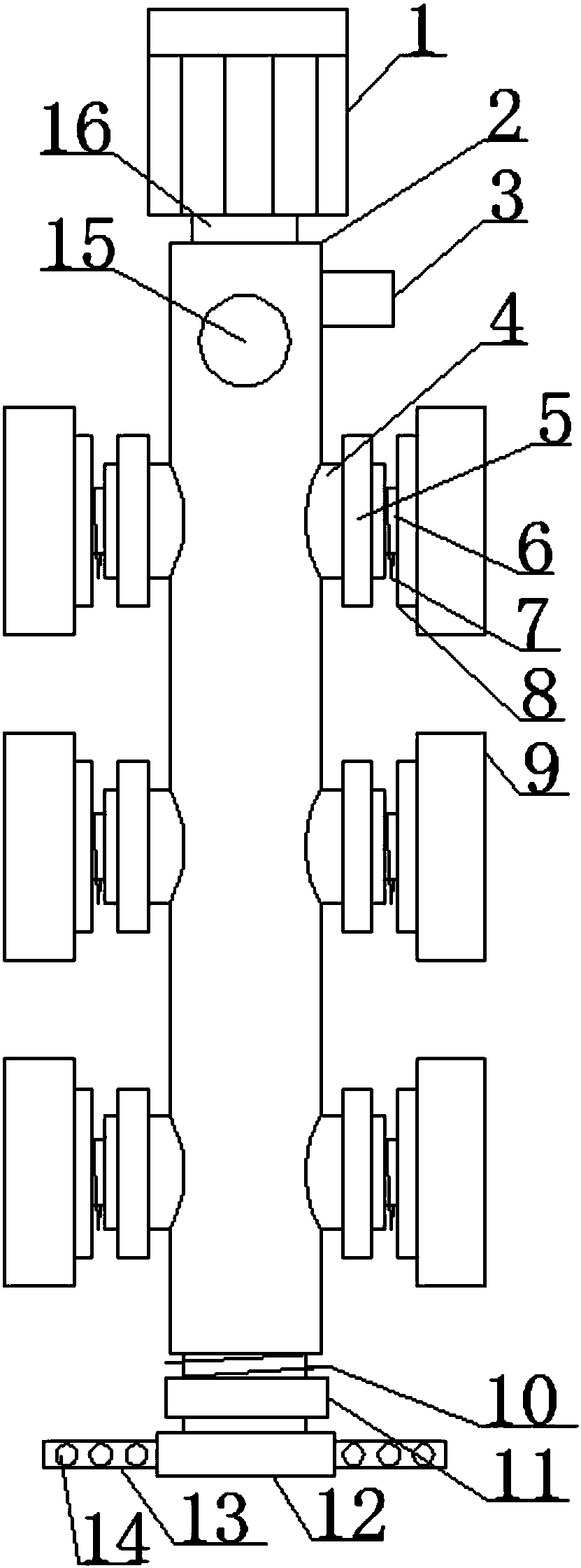

Impurity-removing cleaning machine

ActiveCN108035133AEasy to changeEasy to cut offMechanical cleaningPressure cleaningPulp and paper industryHearing perception

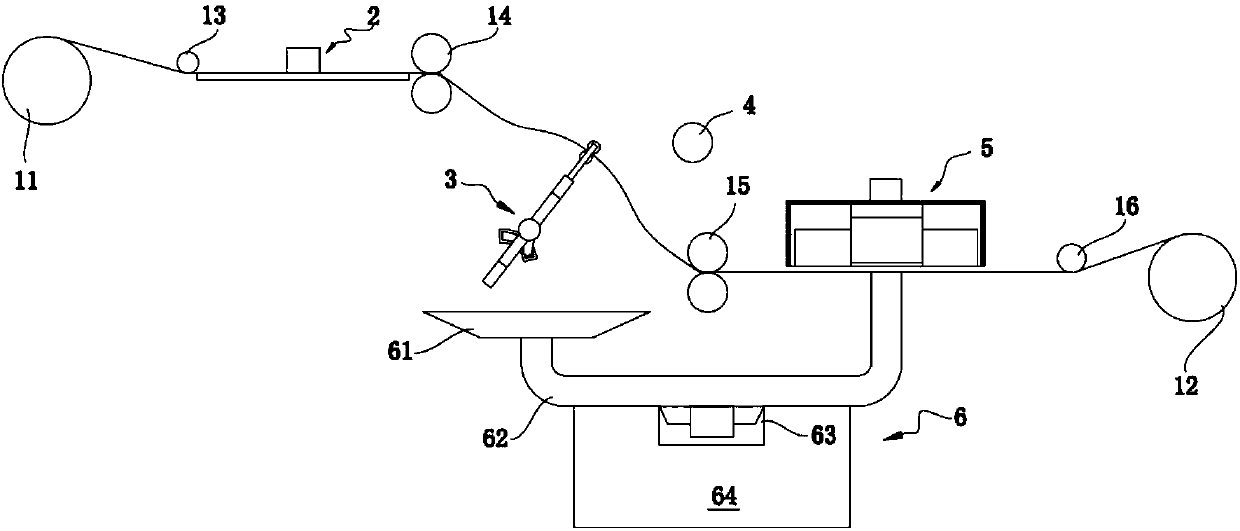

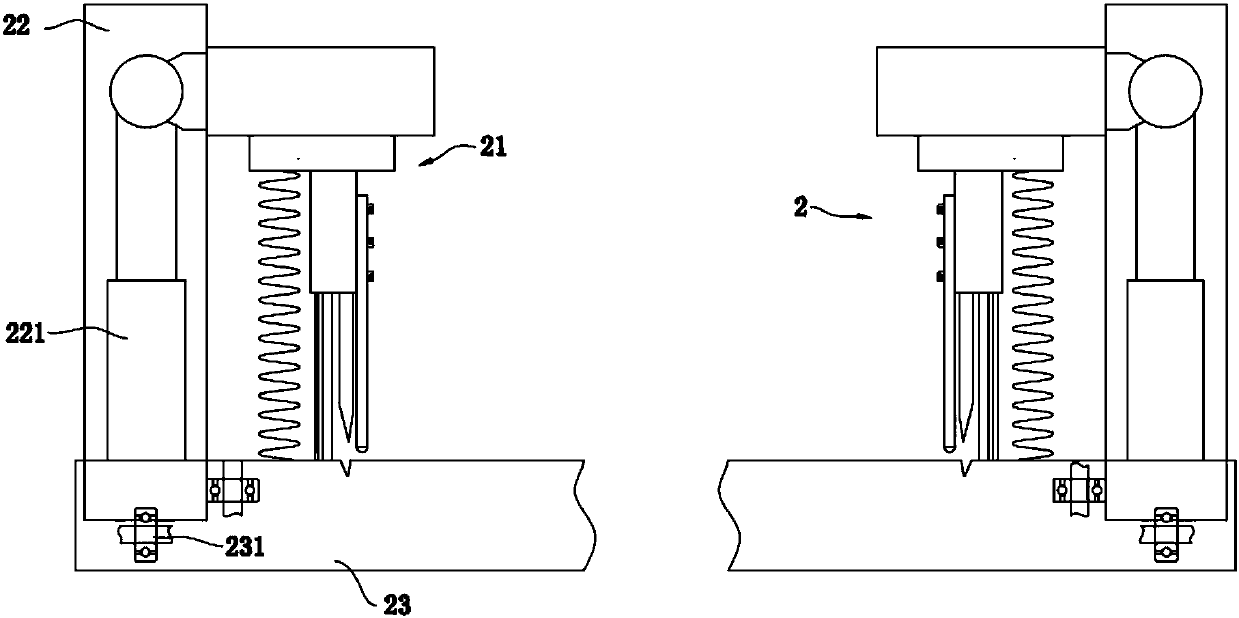

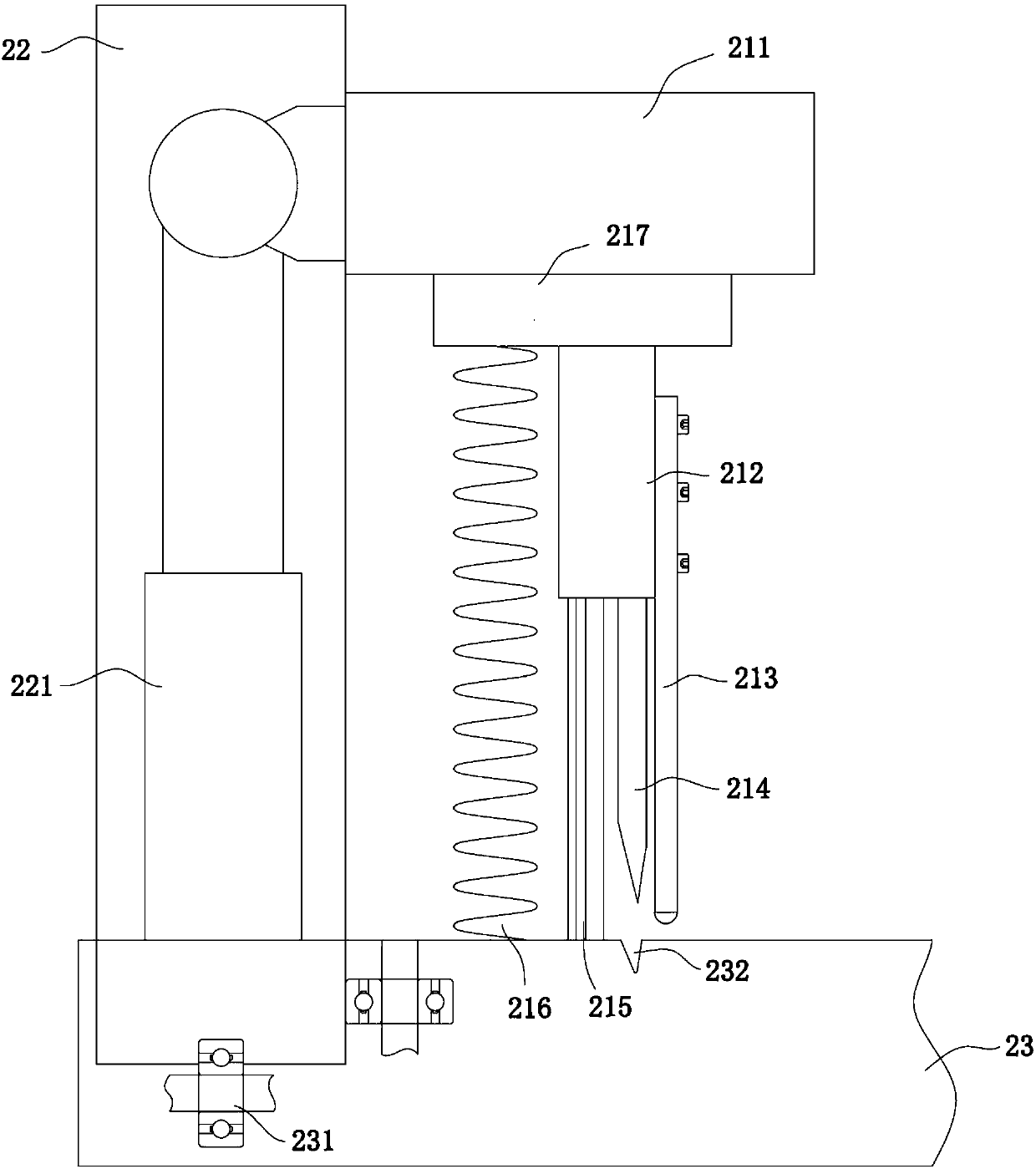

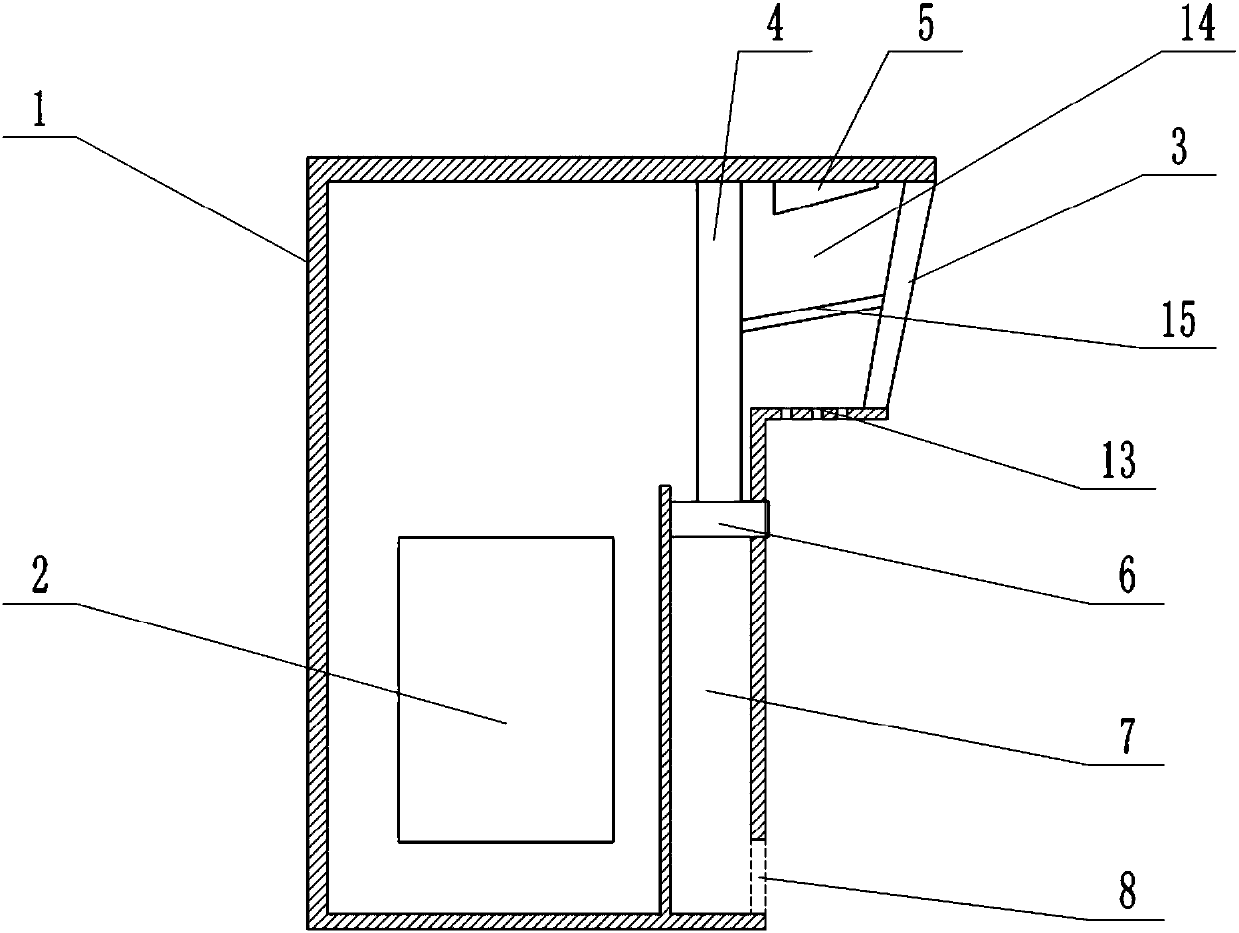

The invention provides an impurity-removing cleaning machine. The impurity-removing cleaning machine comprises a rack, a thread residue removing device, a cloth shaking mechanism, a static eliminator,a cleaning device and a dust collecting device; the thread residue removing device includes a thread cutting mechanism, a mobile frame and a supporting platform; the cloth shaking mechanism and the static eliminator are disposed between a first support roller and a second support roller; the cleaning device includes a housing, a first fan blade, a second fan blade, a third fan blade and a first suction fan; and the dust collecting device includes an air suction opening, an air suction tube, a second air suction fan and a dust collecting box. According to the impurity-removing cleaning machineof the present invention, the thread residue removing device can remove redundant thread residues at two sides of a textile; the cloth shaking mechanism and the static eliminator are used in cooperation, so that impurities attached onto the textile can be shacked off more easily; the cleaning device is provided with a dust removal fan and a dust removal brush, and hearing rollers can dry the textile, and therefore, dust can fall off more easily, and dust removal is more thorough; and therefore, the quality of the textile can be ensured, and the health of staff can be ensured.

Owner:青岛凯尊帽业有限公司

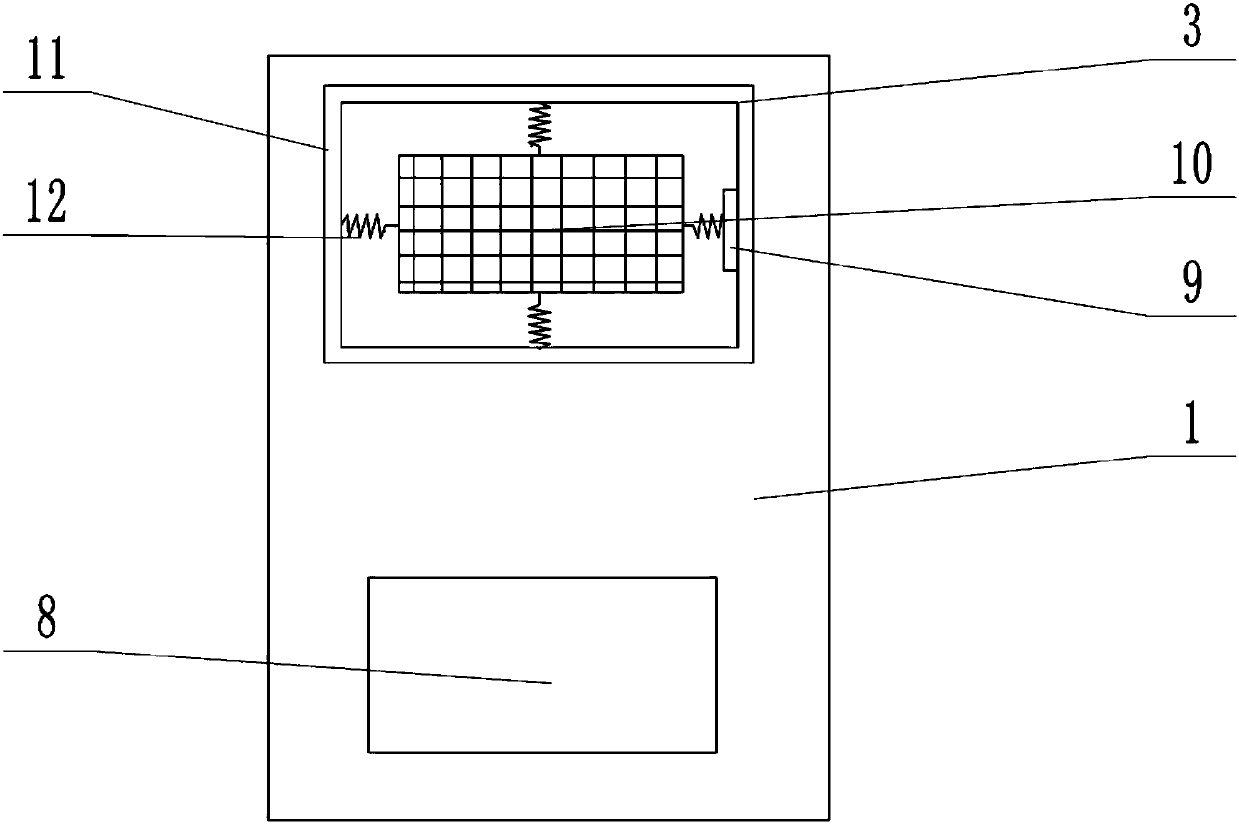

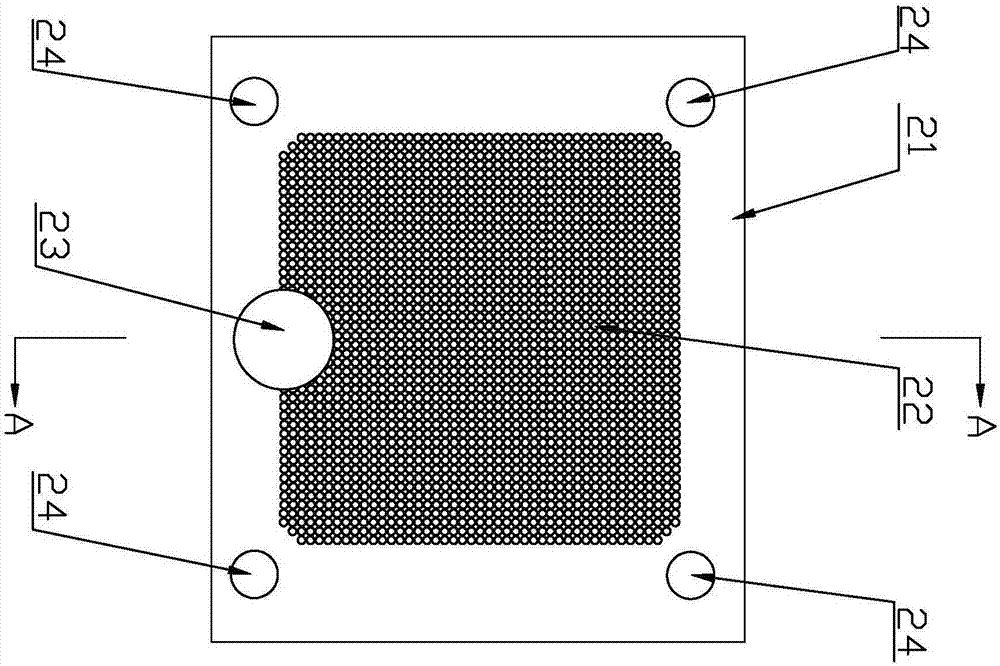

Dust collection device of distribution box

ActiveCN107800045AIncrease the time to move back and forthAchieve clearingSubstation/switching arrangement casingsElectrodes cleaningElectrical controlEngineering

The present invention belongs to the field of electrical control, and especially discloses a dust collection device of a distribution box. The device comprises an insulation frame arranged at a blow-off nozzle of a distribution box; the insulation frame is internally provided with a jittered metal net and an electrostatic generator connected with the metal net; the insulation frame has four side walls, and one spring is connected between each side wall and the metal net; one side wall of the insulation frame is provided with an electromagnet configured to absorb the metal net; and the electromagnet and the electrostatic generator are connected with the same electric circuit. Compared to the prior art, the dust collection device of the distribution box is simple in structure and convenientto use and can perform cleaning of dust in the distribution box through the metal net, a circuit board cannot be touched in the cleaning process, and therefore, faults of the circuit board caused by manual cleaning can be effectively avoided.

Owner:宁波南顿电力科技有限公司

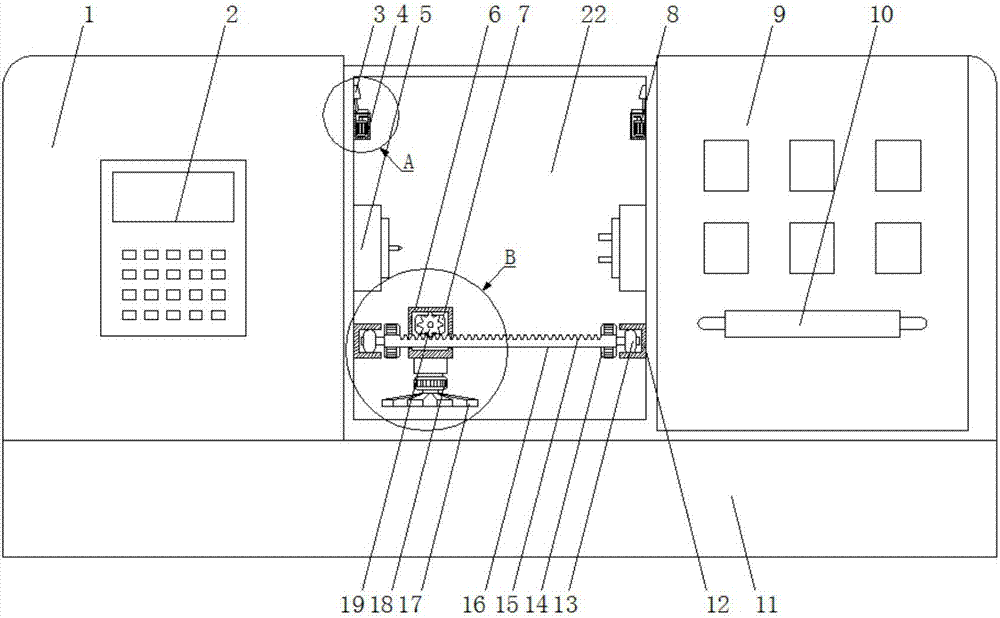

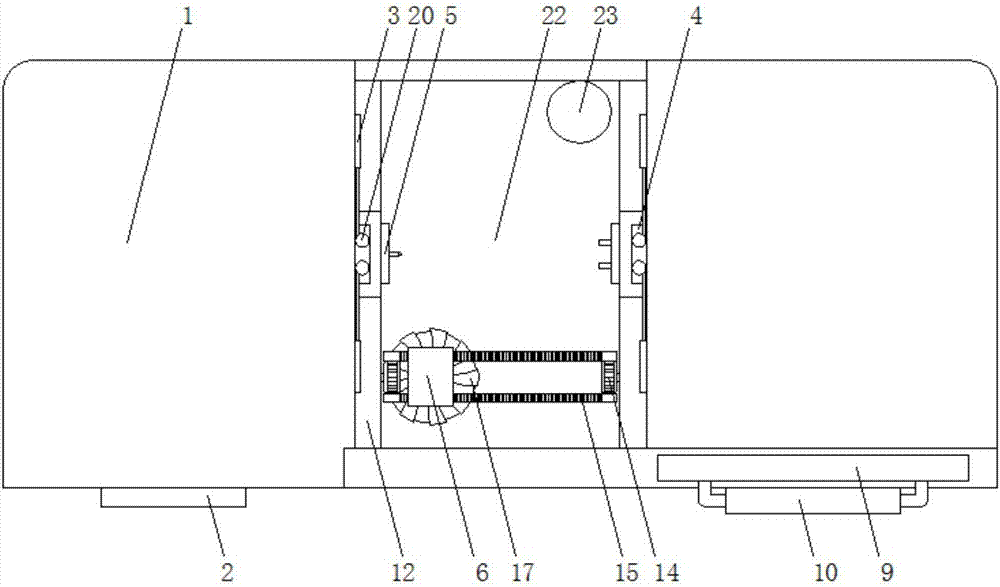

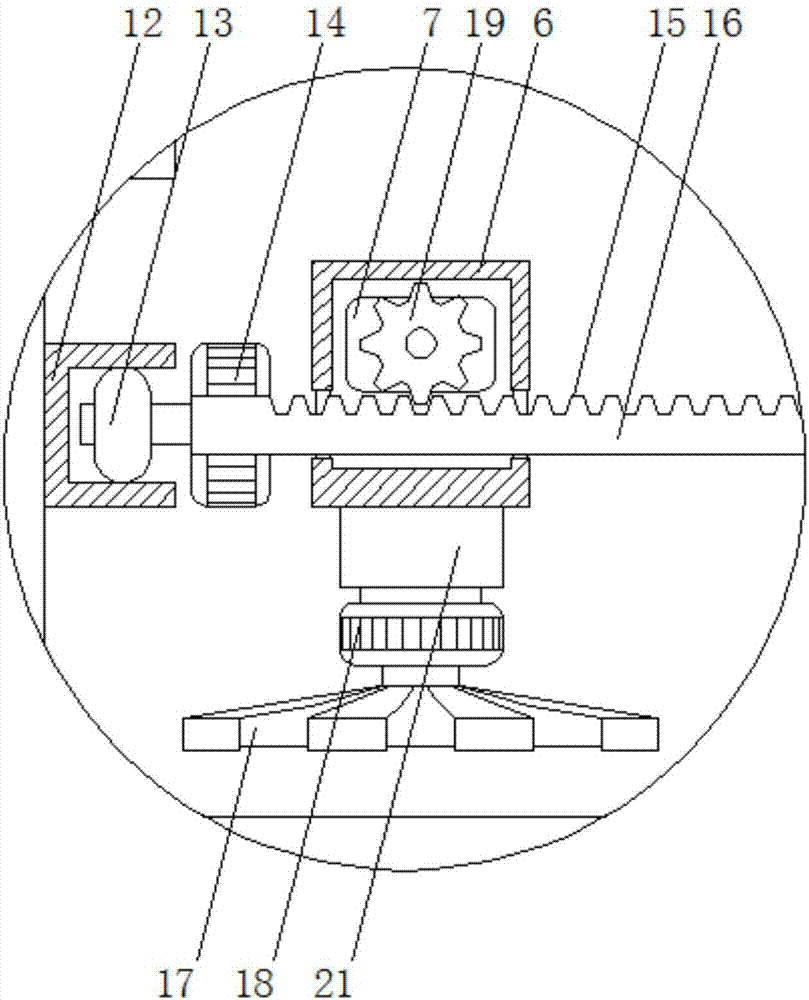

Numerical-control machine tool cleaning device

InactiveCN107378625AEasy to shake offEasy to blowMaintainance and safety accessoriesMachine toolMechanical equipment

The invention discloses a cleaning device for a numerically controlled machine tool, which comprises a numerically controlled machine tool, a vibrating motor box, a machine base and a slide rail. A numerically controlled machine tool is fixedly installed on the top of the machine tool base, and a control panel is fixedly installed on the outer wall of one end side of the numerically controlled machine tool. A sliding door is slidably installed on the outer wall of the other end of the CNC machine tool, and a processing room is fixed in the middle of the CNC machine tool, and the sliding door is matched with the processing room, and the center of the inner wall on both sides of the processing room is respectively movably installed with a processing tool; The inner walls on both sides of the processing chamber are located on the top of the processing tool and are fixed with a vibrating motor box by screws. The vibrating motor box is fixed with a vibrating motor inside. The present invention cleans the CNC machine tool by using the cleaning method of electromagnet adsorption, avoiding the traditional The damage caused to the mechanical equipment by using the flushing cleaning method, and the invention can clean the equipment when the equipment is working, without affecting the production efficiency of the numerical control machine tool.

Owner:苏州圣凡自动化科技有限公司

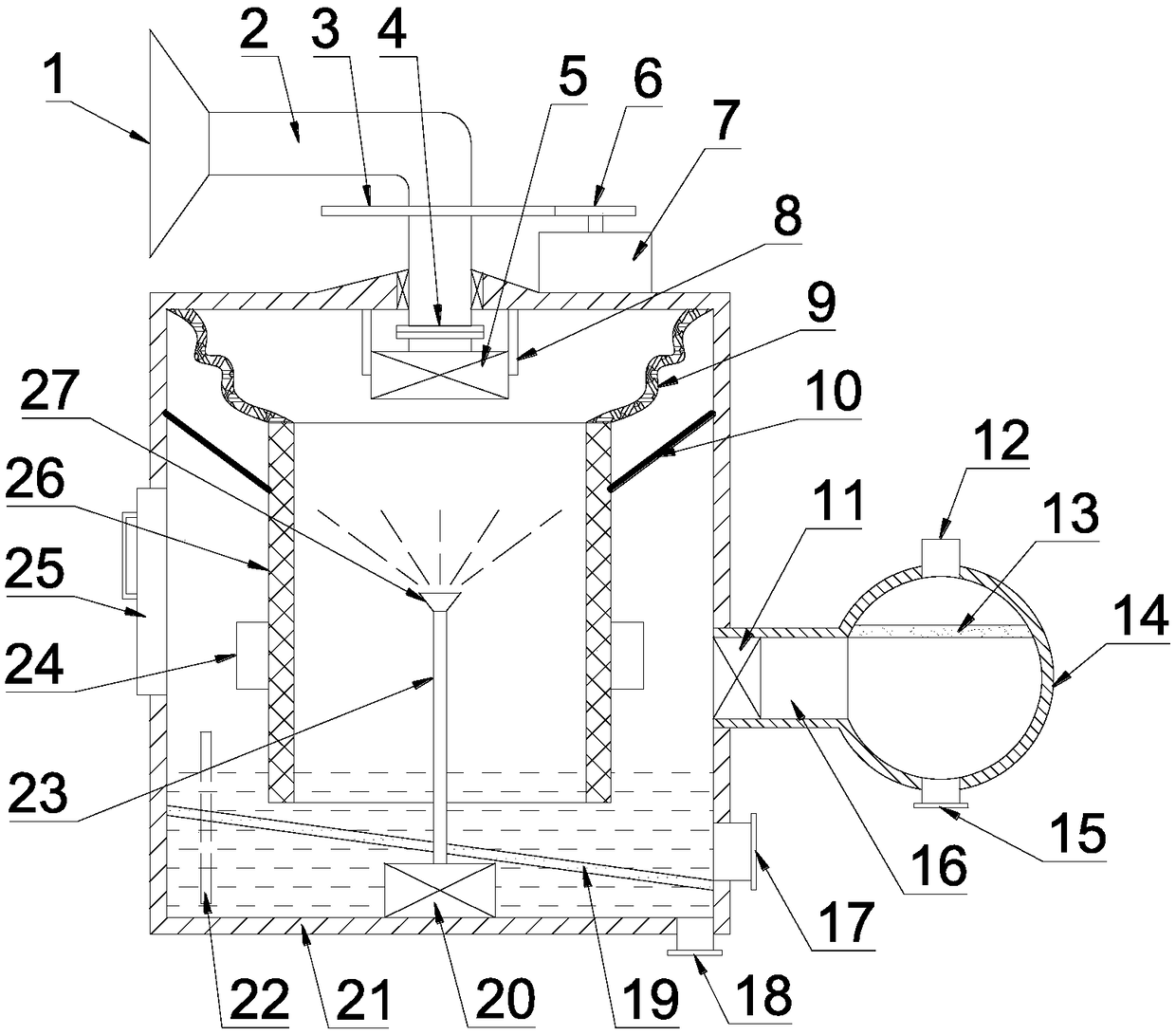

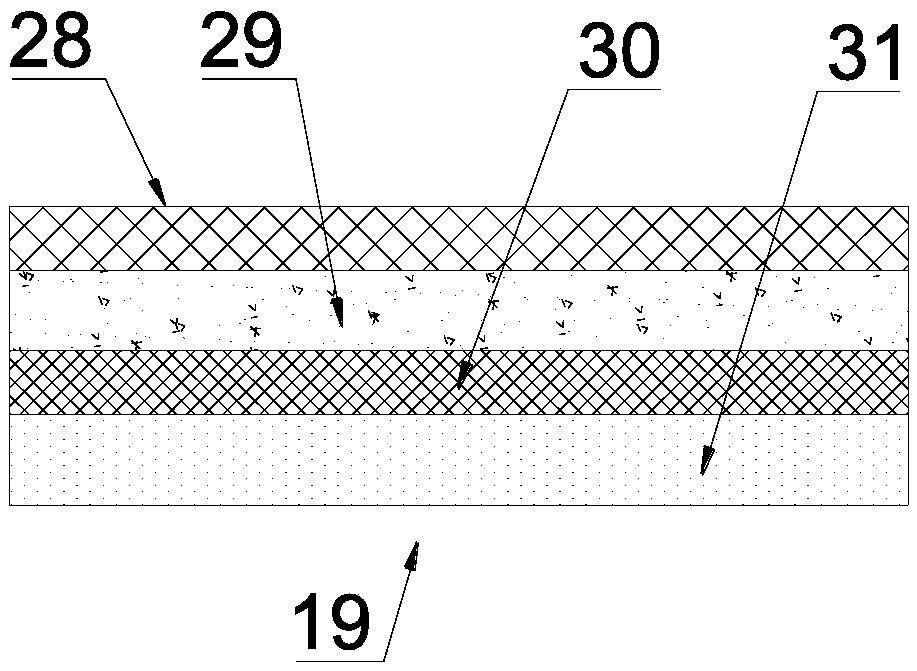

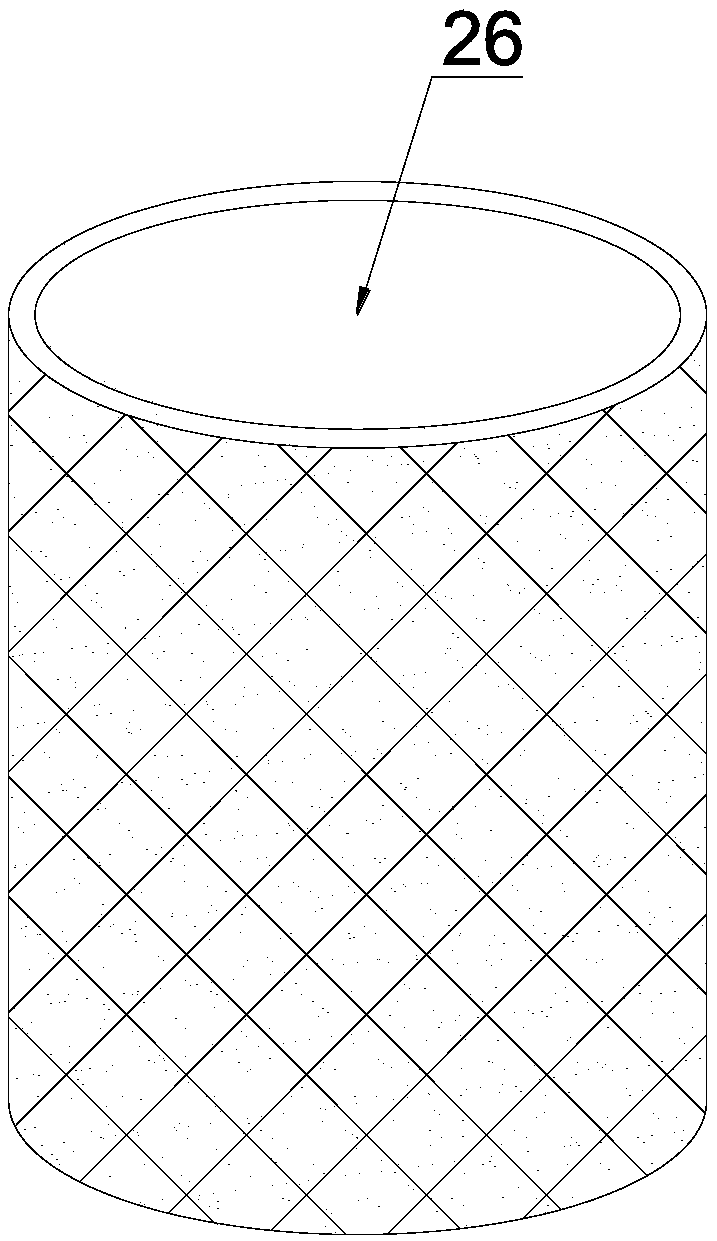

Environment-friendly dust removal device for producing and processing coating

InactiveCN108722083ADoes not hinder dischargeEasy to interceptCombination devicesSeparation devicesEngineeringCoating

The invention discloses an environment-friendly dust removal device for producing and processing coating. The environment-friendly dust removal device comprises a box body, wherein a dust collection pipe is mounted in the middle of the top of the box body; a dust collection cover is mounted at the end part of a horizontal part of the dust collection pipe; the lower end of a vertical part of the dust collection pipe is connected with a first exhaust fan through a rotary connector in the box body; a wet curtain water barrel is arranged at the inner side of the box body; a plurality of vibrationmotors are arranged in the peripheral direction of the lower part of the outer side of the wet curtain water barrel; the upper end of the wet curtain water barrel is further connected with corrugatedpipes; a dirt filtering screen is arranged at the lower part of the inner side of the box body; the dirt filtering screen is fixedly connected with an inner wall of the box body; a lifting pump is arranged at a part, located at the bottom in the box body, of the lower side of the dirt filtering screen; a water conveying pipe is arranged on a water outlet of the lifting pump; a spraying nozzle is mounted at the upper end of the water conveying pipe; a communication pipe is mounted at the right side of the box body; a second exhaust fan is mounted in the communication pipe; a dust removal ball is arranged at the right end of the communication pipe. The environment-friendly dust removal device disclosed by the invention has the advantages of good dust removal effect, high efficiency and widerange; a water body can be circularly utilized, energy saving and environment protection are realized and the device is easy to popularize and apply.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

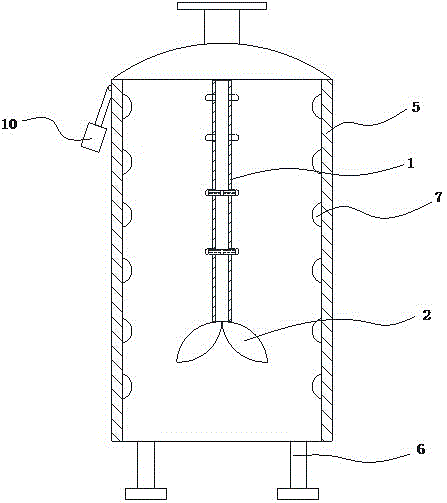

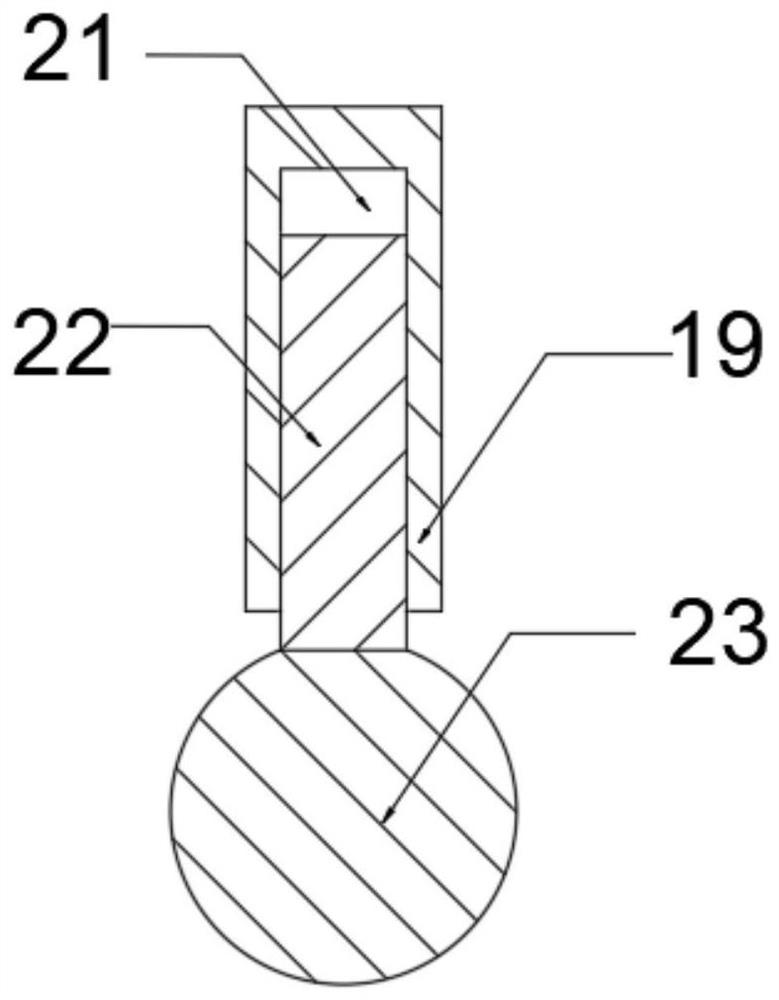

Powder stirring tank

Provided is a powder stirring tank with a simple structure and raising the stirring efficiency. The powder stirring tank comprises a stirring tank, a stirring shaft and stirring blades. The stirring shaft is arranged in the center of the stirring tank vertically. The stirring blades are arranged at the lower end of the stirring shaft. Elastic projections are distributed on the inner wall uniformly. A heavy bob is movably arranged on the surface of the stirring tank. The stirring shaft has a hollow holding cavity. A plurality of telescopic elastomers are distributed on the surface of the stirring shaft uniformly. Through holes communicated with the elastomers are arranged in the side wall of the stirring shaft. The upper end of the stirring shaft is communicated with a gas source. The stirring quality is raised greatly, powder is mixed uniformly after stirring, the quality is fine, the structure is simple and usage is convenient.

Owner:DEQING WEIKANG BIOTECH

Part processing waste separation treatment device

InactiveCN108580280ASimple structureImprove dithering efficiencySievingScreeningElectricityElectric conductance

The invention discloses a part processing waste separation treatment device. The part processing waste separation treatment device comprises a separation box, and is simple in structure, a rotating motor is used for driving a rotating disc to rotate, a second magnet intermittently and leftwards repels a first magnet, under the effect of a third spring, a screen horizontally moves back and forth, fine waste scrap iron on the screen is shaken off, the rotating disc drives a third electric conductance piece to rotate so as to make contact with a fourth electric conductance piece intermittently, an electromagnet intermittently and magnetically repels the third magnet downwards, under the effect of a sixth spring, a scraping plate moves back and forth vertically, fine waste scrap iron attachedto the inner side wall of the separation box is scraped down, when the weight on the screen tends to be balanced, a first electric conductance piece and a second electric conductance piece make contact, , an alarm device sends out sounds, a worker is reminded of receiving, two screws are manually rotated in an opposite manner, under the effect of a first spring, the screen ascends to the top of the separation box, and remaining large waste iron blocks are manually collected away.

Owner:成超宇

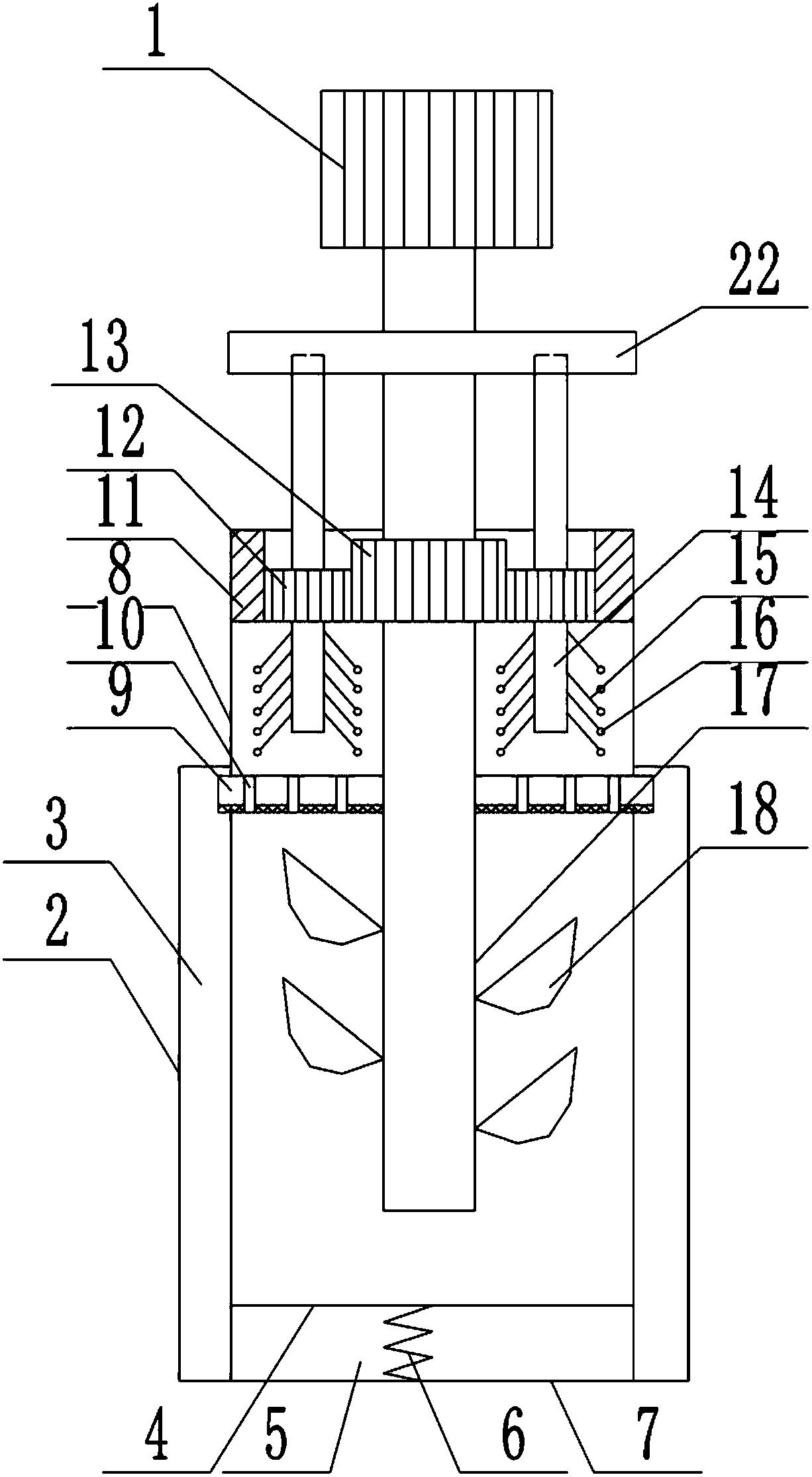

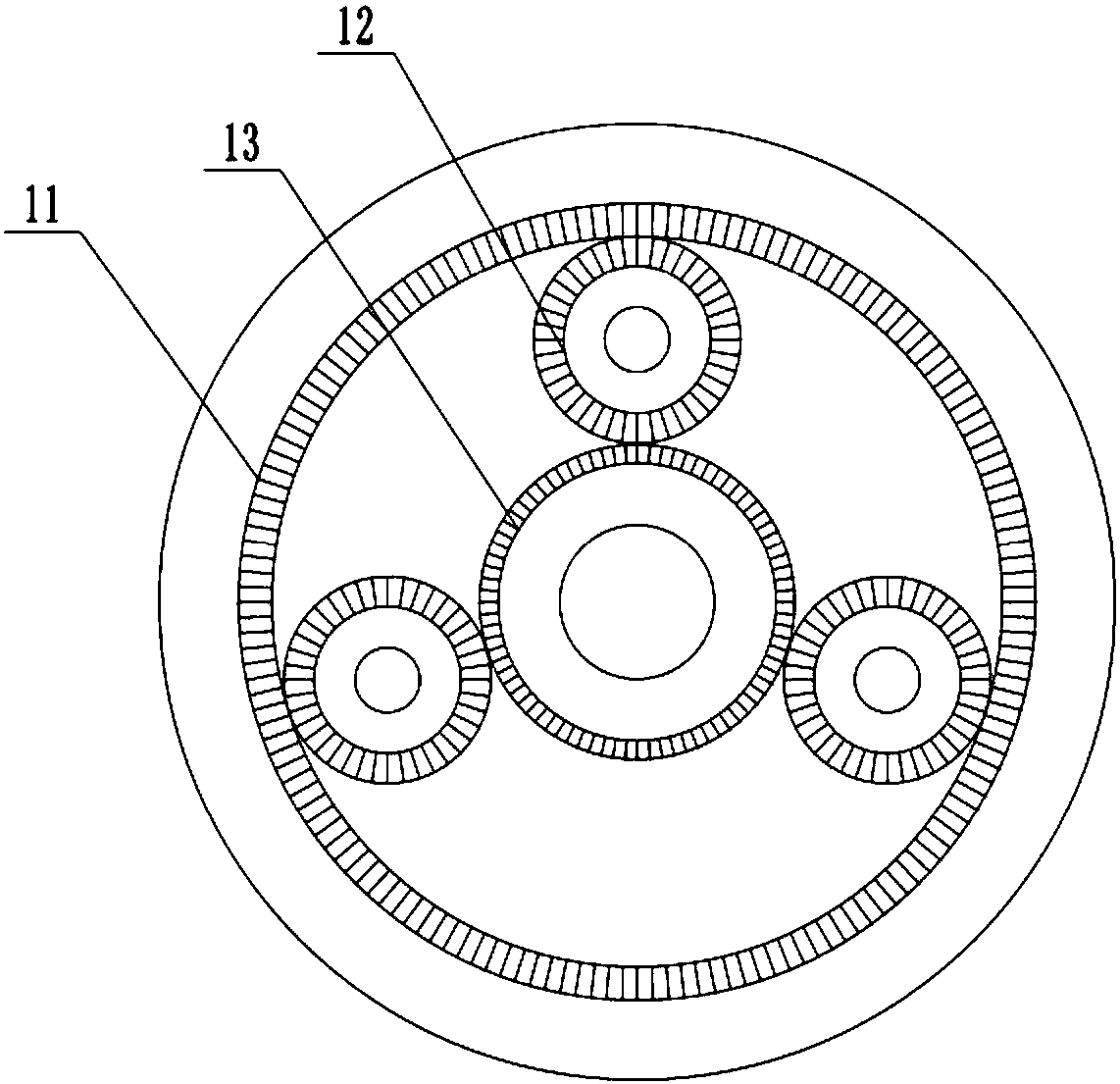

Meat mincing device used for can production

ActiveCN107912516AEasy to shake offWell mixedMeat mixing apparatusMeat processing devicesAgricultural engineering

The invention relates to the technical field of can production, and particularly relates to a meat mincing device used for can production. The meat mincing device comprises a meat mincing cylinder anda meat mincing shaft, wherein a blade is arranged at the bottom end of the meat mincing shaft, the bottom end of the meat mincing shaft is located in the meat mincing cylinder, a motor is connected to the top end of the meat mincing shaft, and a feed box is arranged at the top of the meat mincing cylinder; a gear set is arranged at the top of the feed box and comprises a main gear, an inner gearand an outer gear; and the main gear is fixedly connected to the meat mincing shaft and sleeves the middle of the inner gear, the outer gear is meshed with the inner gear and the main gear, the lowerend face of the inner gear is fixedly connected with the feed box, a stirring shaft is fixedly connected to the lower end face of the outer gear, a draw cord is fixedly connected to the stirring shaft, a pendulum bob is fixed on the draw cord, a discharge part is arranged at the bottom of the feed box, a discharge hole is formed in the discharge part, and the meat mincing shaft penetrates throughthe feed box. The scheme disclosed by the invention reduces the stirring time of seasonings and meat, and increases the stirring efficiency of the meat and the seasonings.

Owner:CHONGQING YUANXIANG FOOD

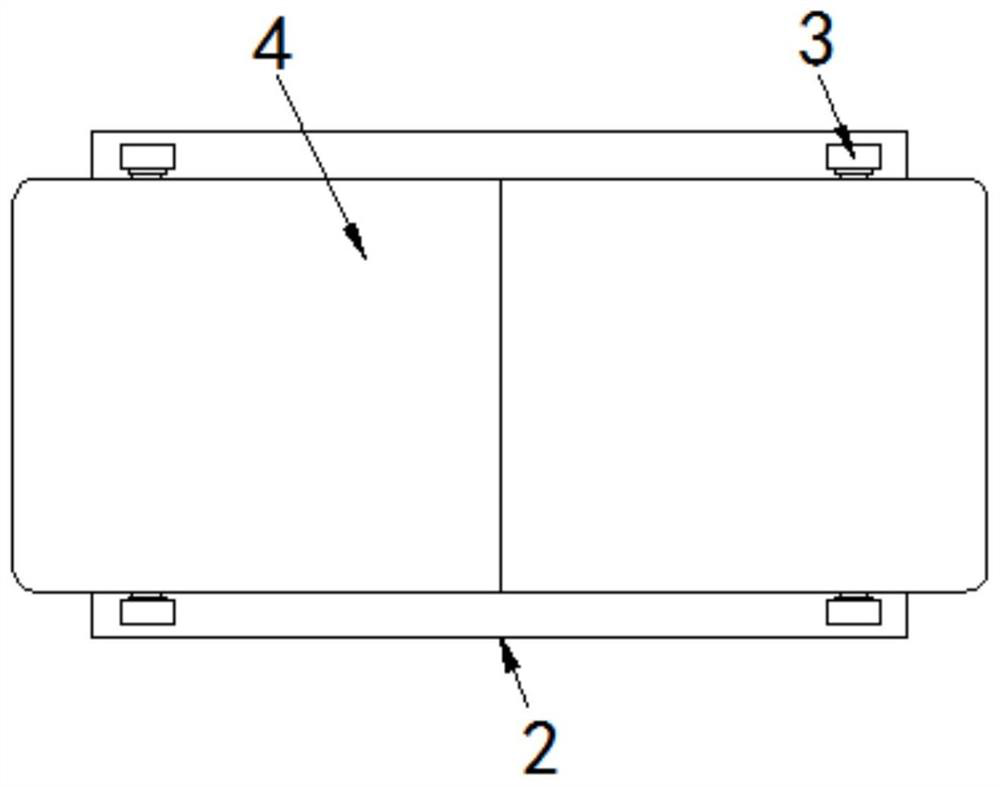

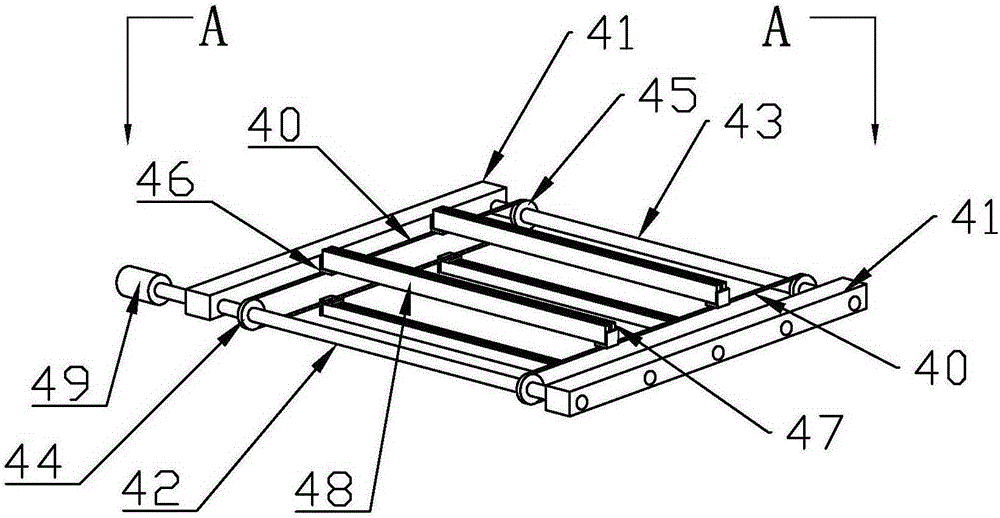

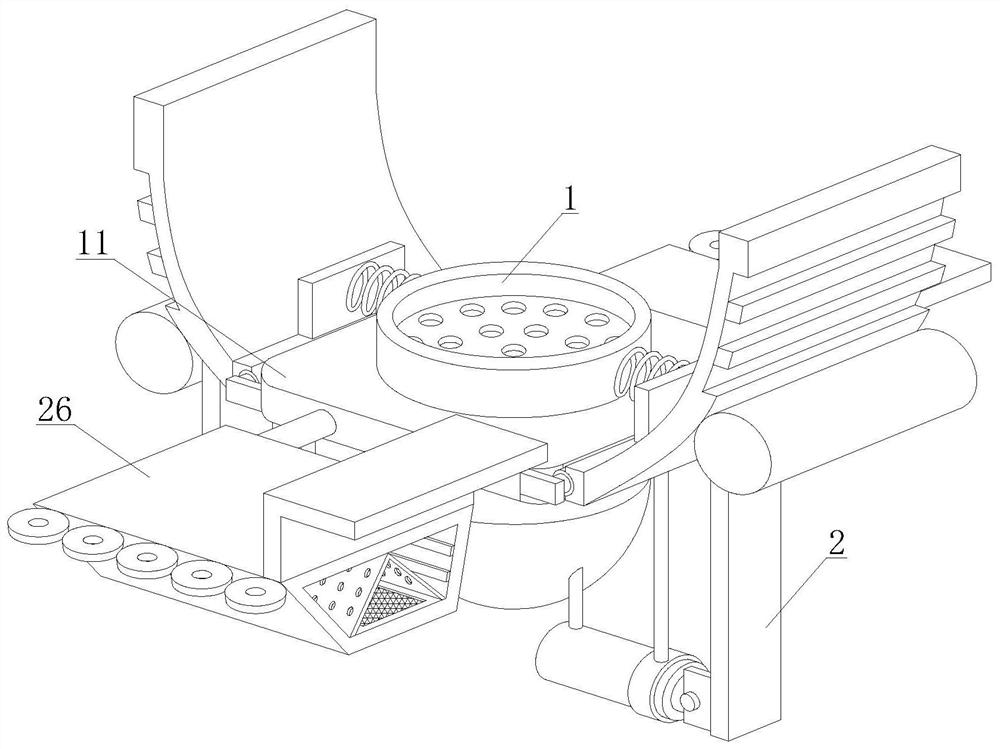

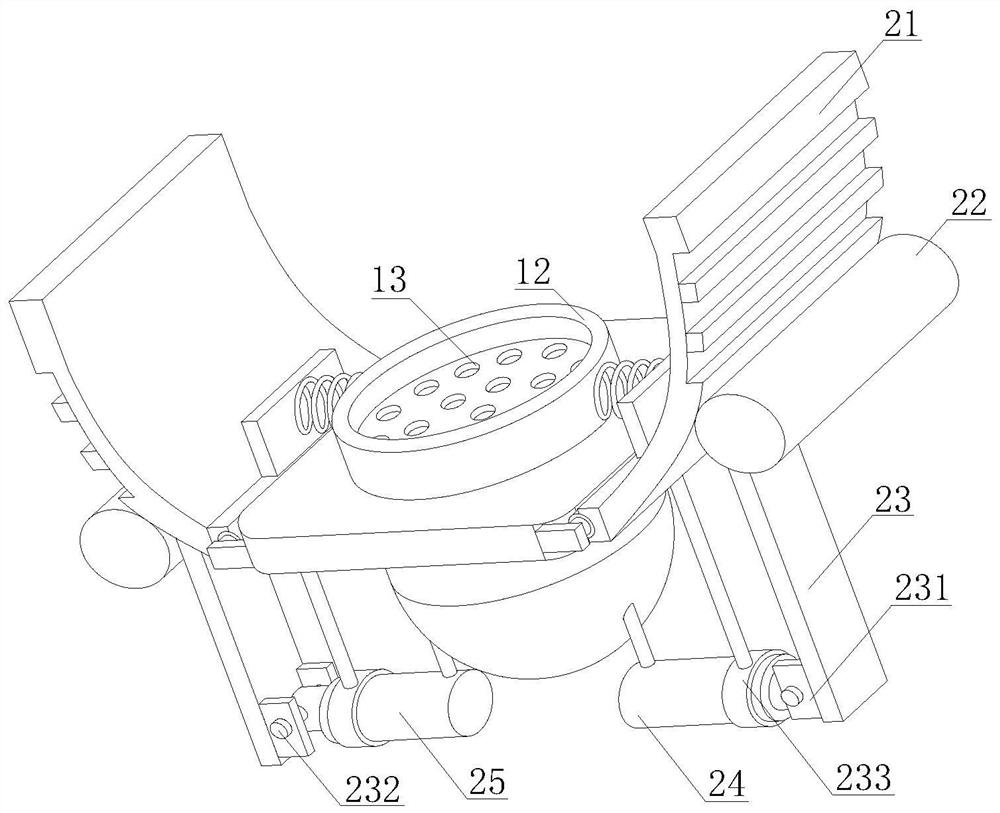

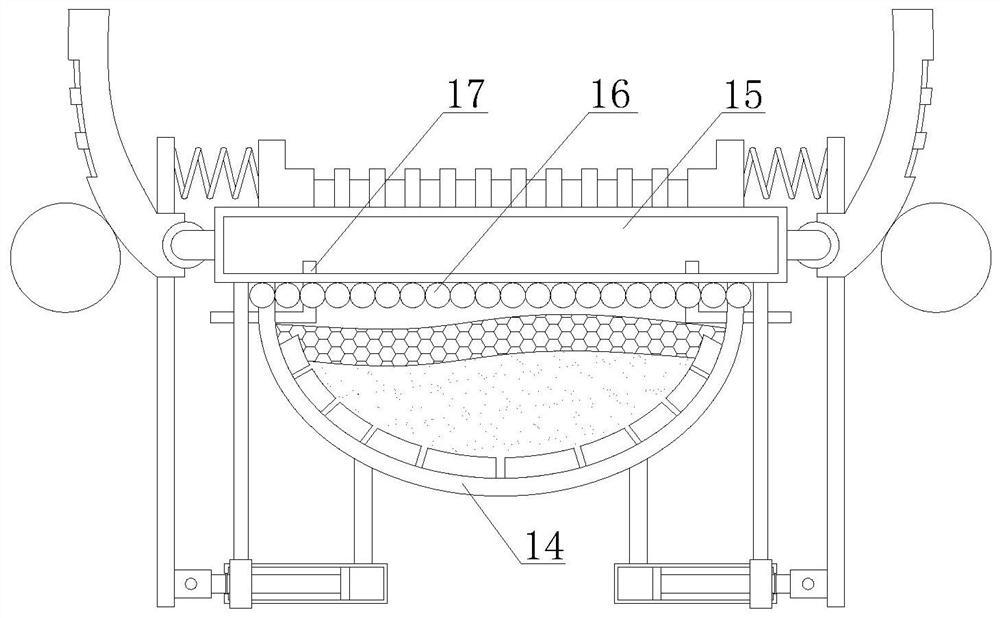

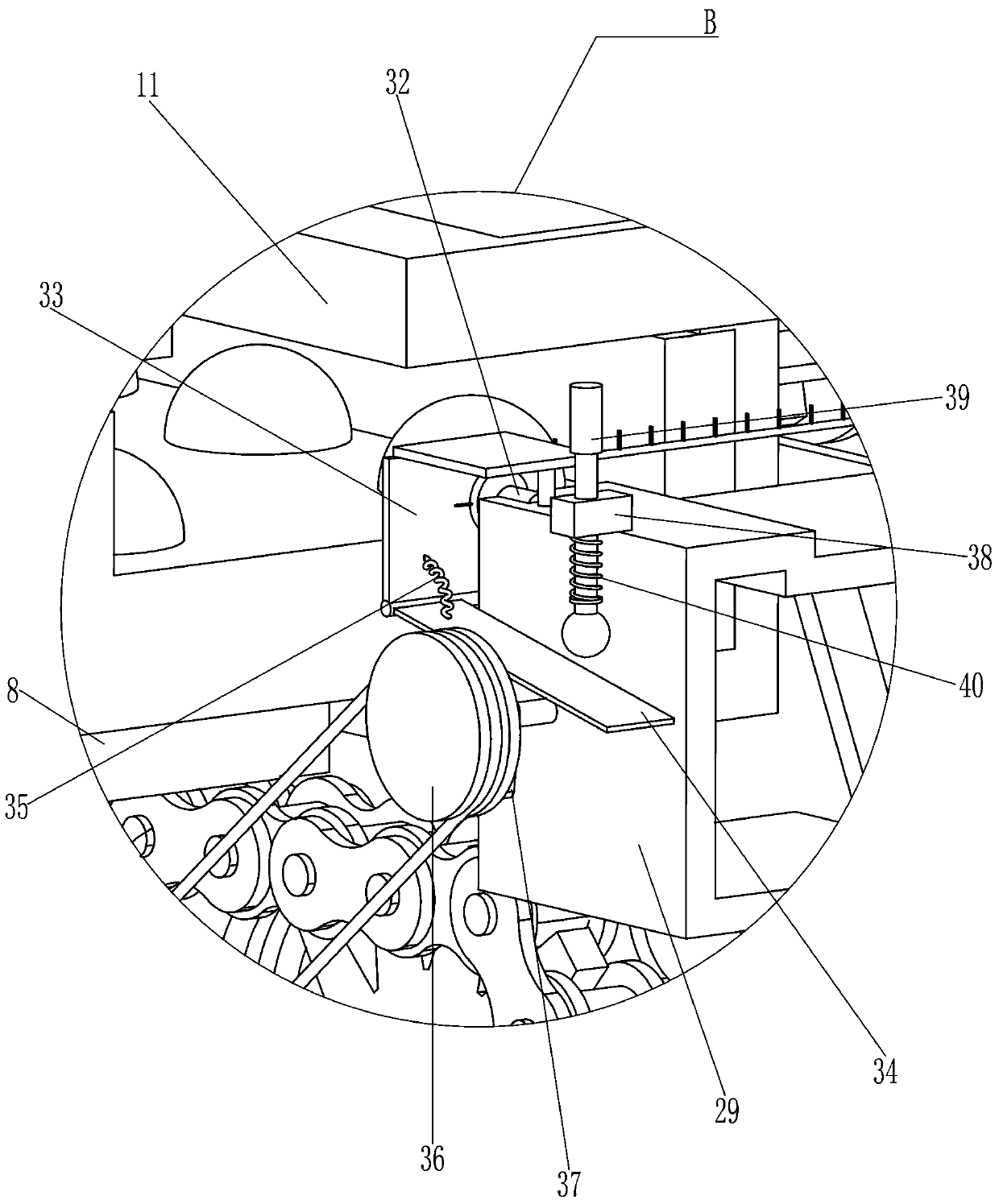

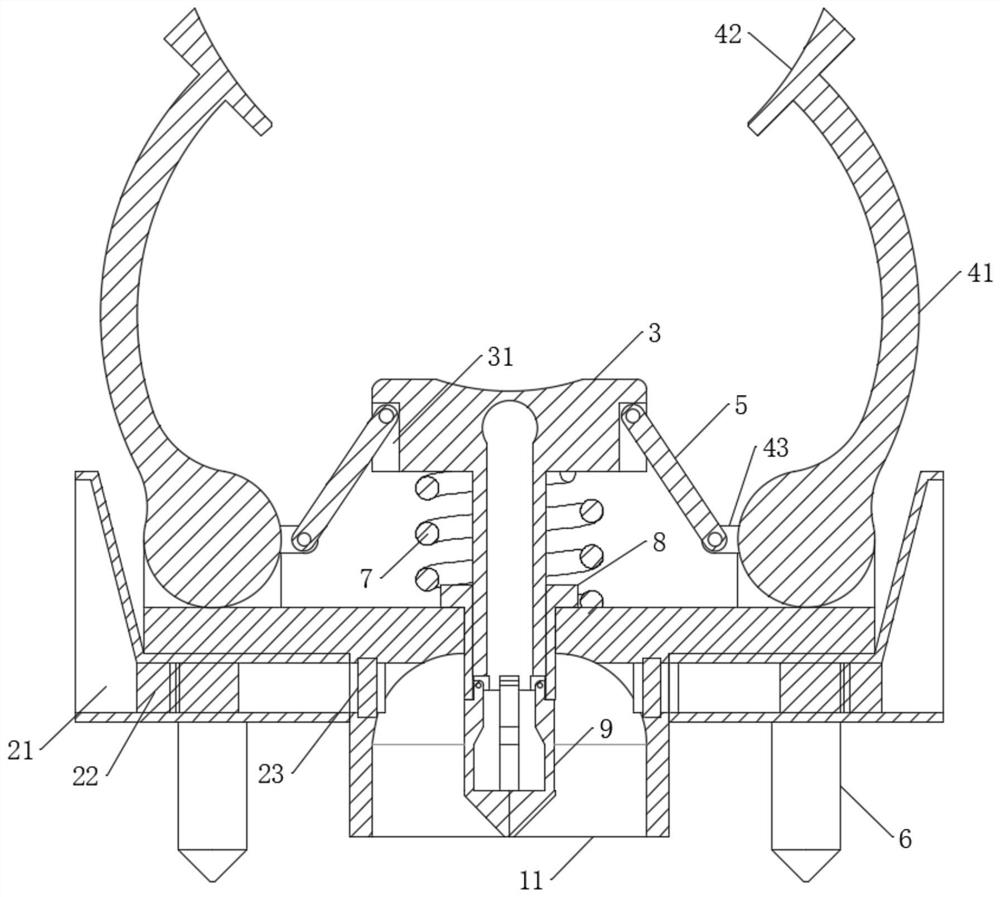

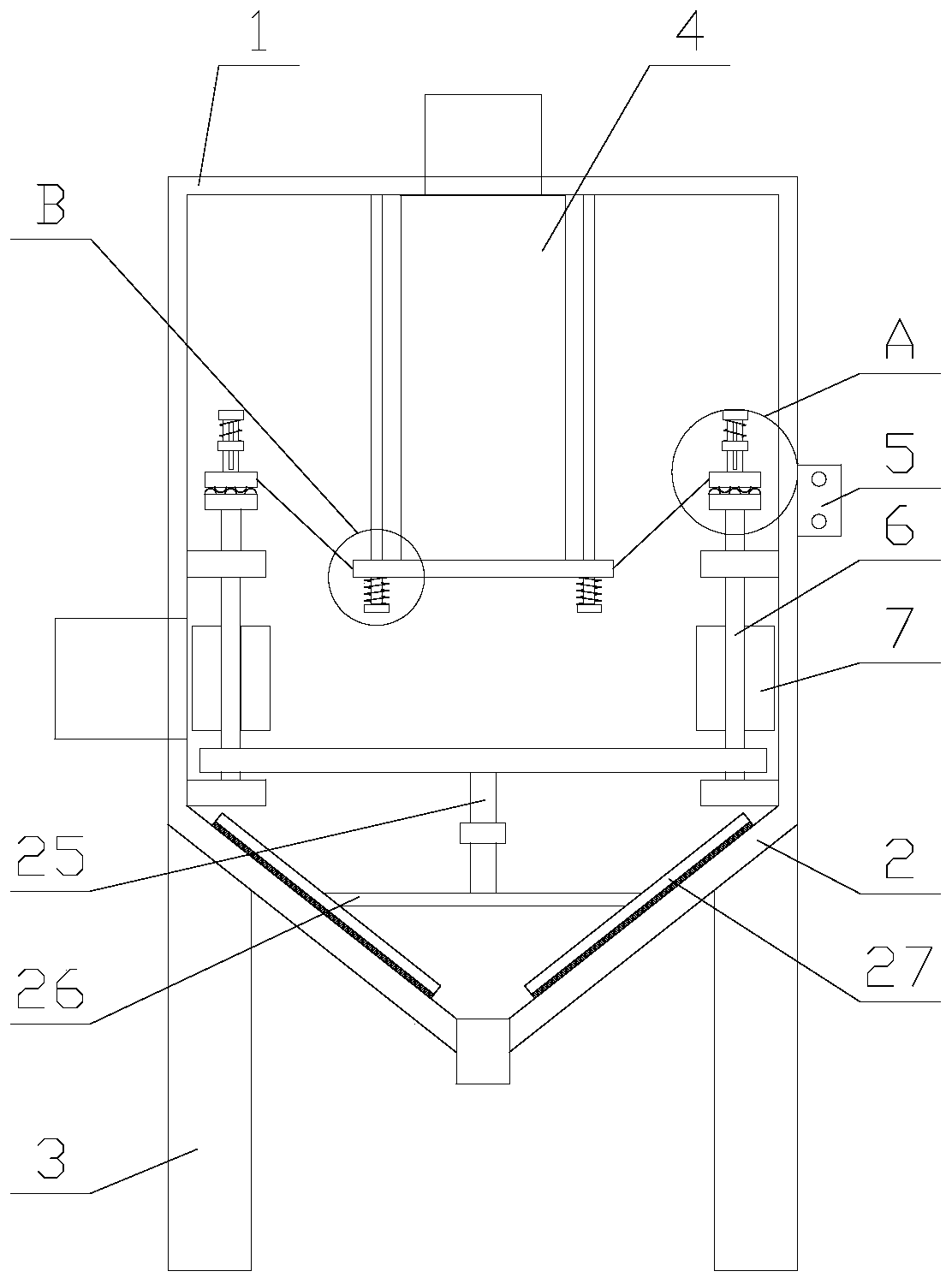

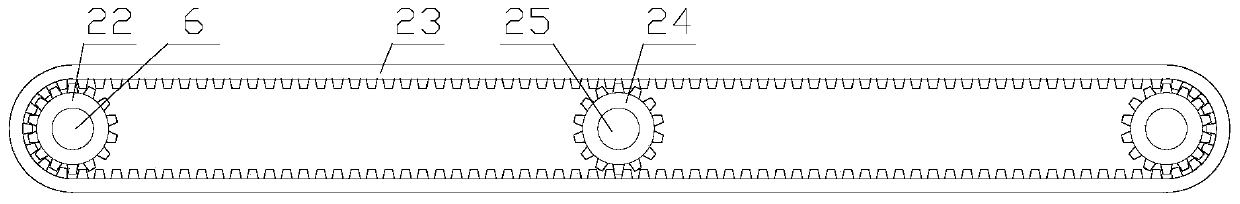

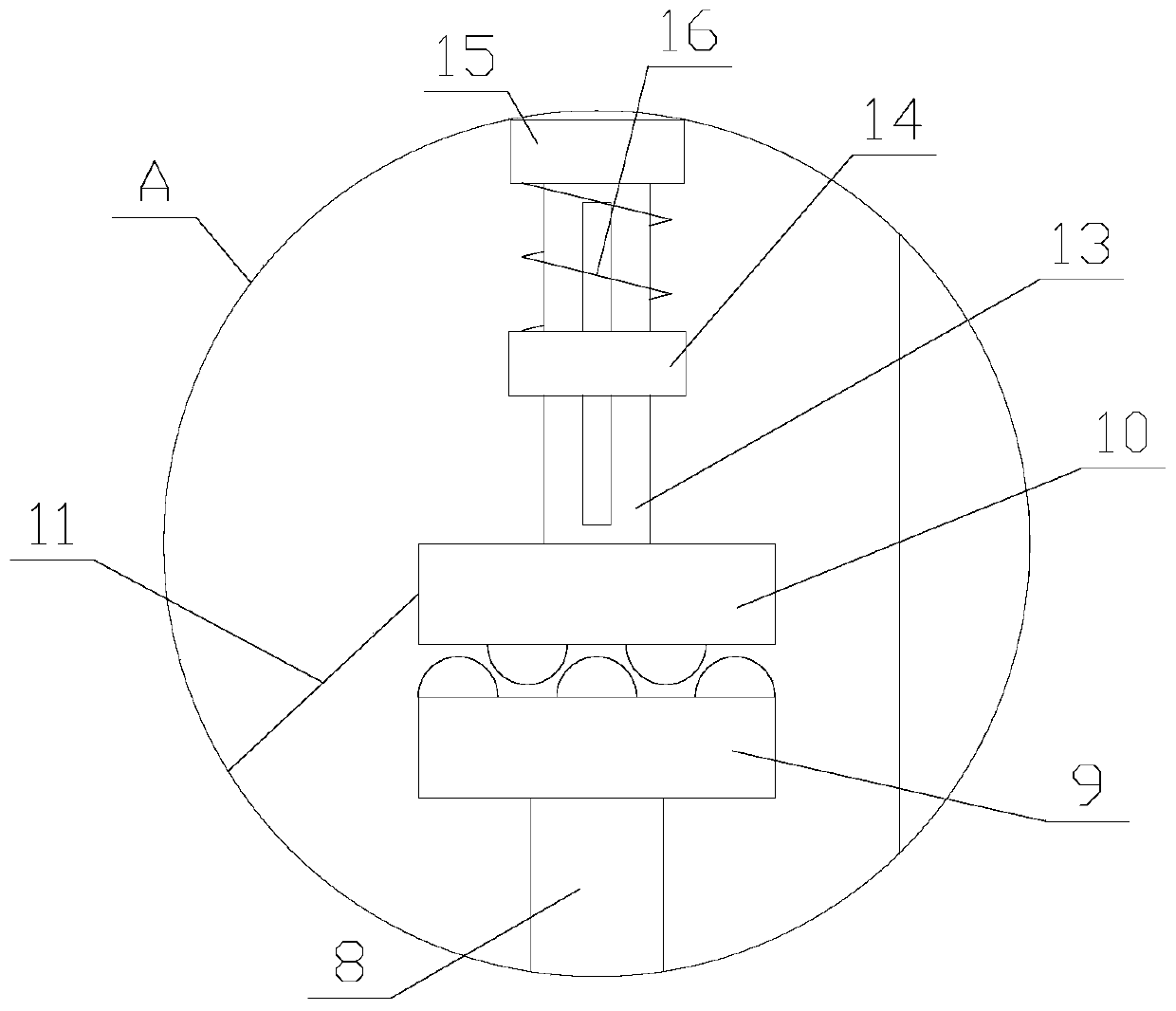

Mud removing and packaging device for harvesting dioscorea opposita Thunb

ActiveCN111439423ATo achieve the effect of clean mudEasy to shake offMetal working apparatusPackaging fruits/vegetablesEngineeringConveyor belt

The invention discloses a mud removing and packaging device for harvesting dioscorea opposita Thunb, relates to the technical field of planting of dioscorea opposita Thunb, and aims at solving the problems that generally, mud clods on the surface of dioscorea opposita Thunb need to be cleaned manually, the amount of labor is large, and juice of dioscorea opposita Thunb is very likely to itch the hands of workers. The mud removing and packaging device specifically comprises a base, wherein a plurality of idler wheels are fixedly installed at the bottom of the base, two rows of springs are fixedly installed at the top of the base, a supporting frame is fixedly installed between the top ends of the two rows of springs, and a cover body is fixedly installed at the top end of the supporting frame. According to the mud removing and packaging device, the dioscorea opposita Thunb turns over under the friction between the surfaces of scrubbing mechanisms and conveyor belt mechanisms in the movement process, then the mud clods attached to the surface of the dioscorea opposita Thunb are removed, then the dioscorea opposita Thunb with the uniform size is collected to the interiors of feeding mechanisms, convenience is brought for harvesters to conduct packaging and bundling, and the efficiency of harvesting the dioscorea opposita Thunb is improved. Through vibration generated during running of the device, the mud clods can conveniently shake off from gaps of the conveyor belt mechanism, and stacking of the mud clods is avoided.

Owner:四川金林药业有限公司

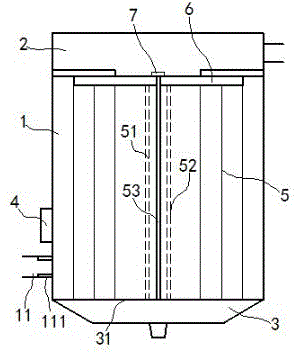

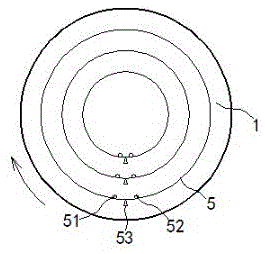

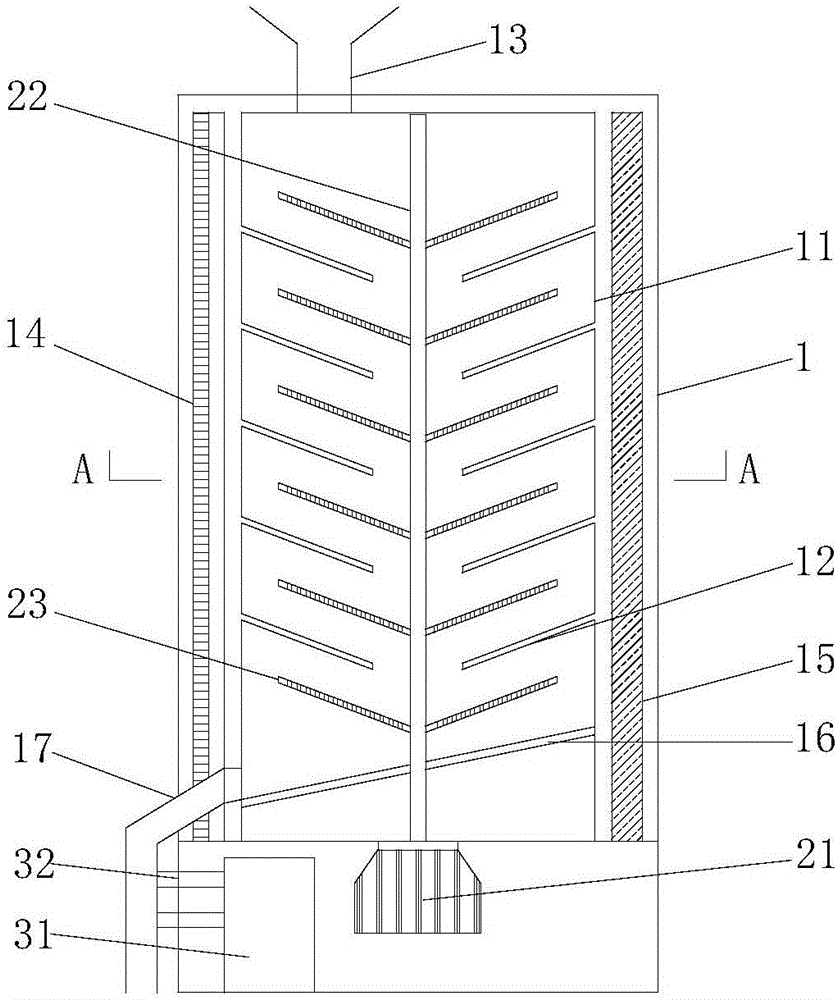

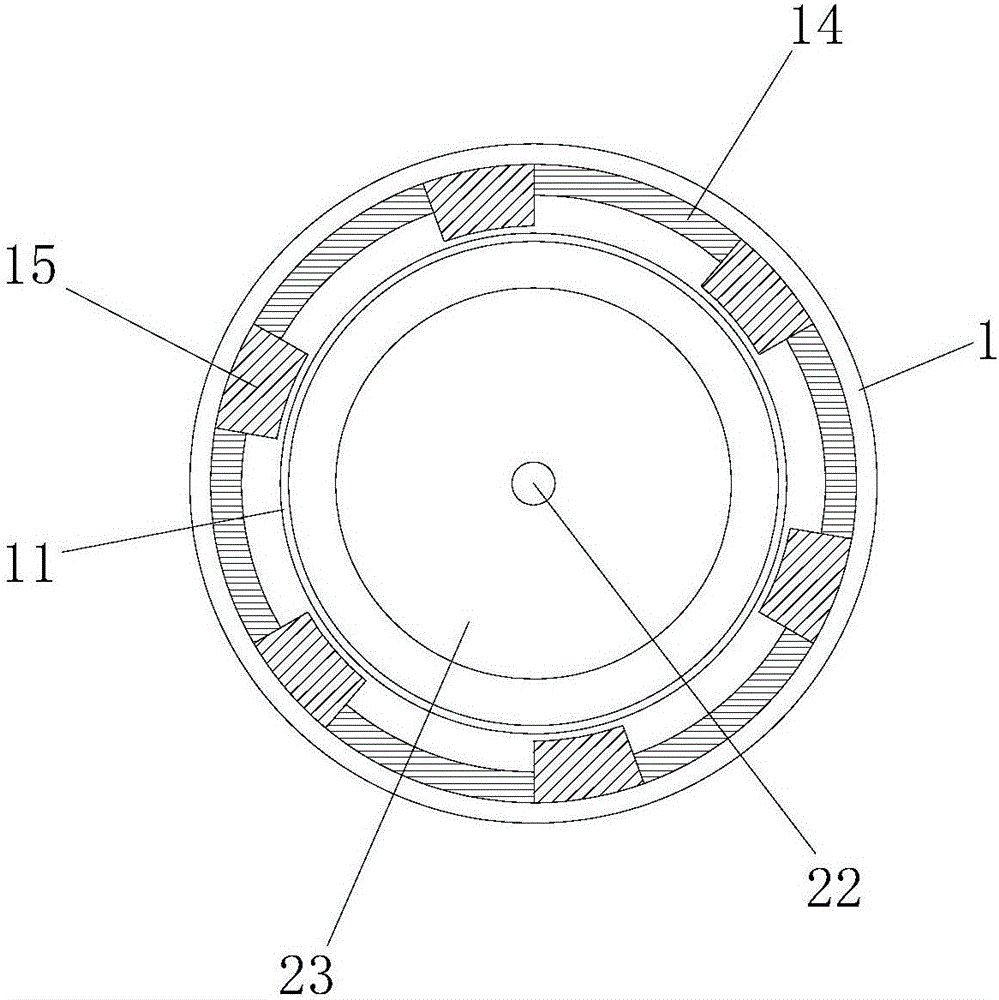

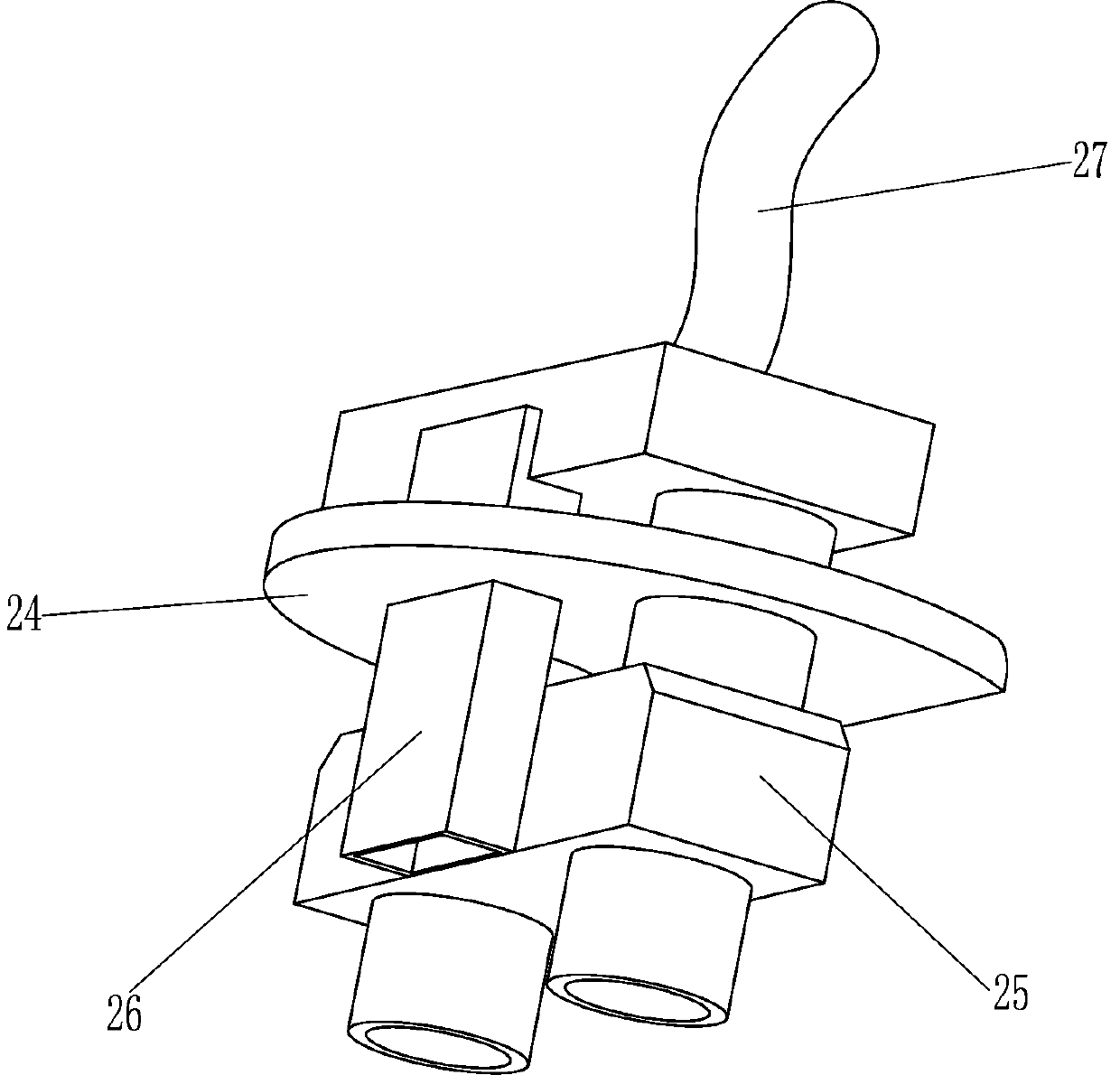

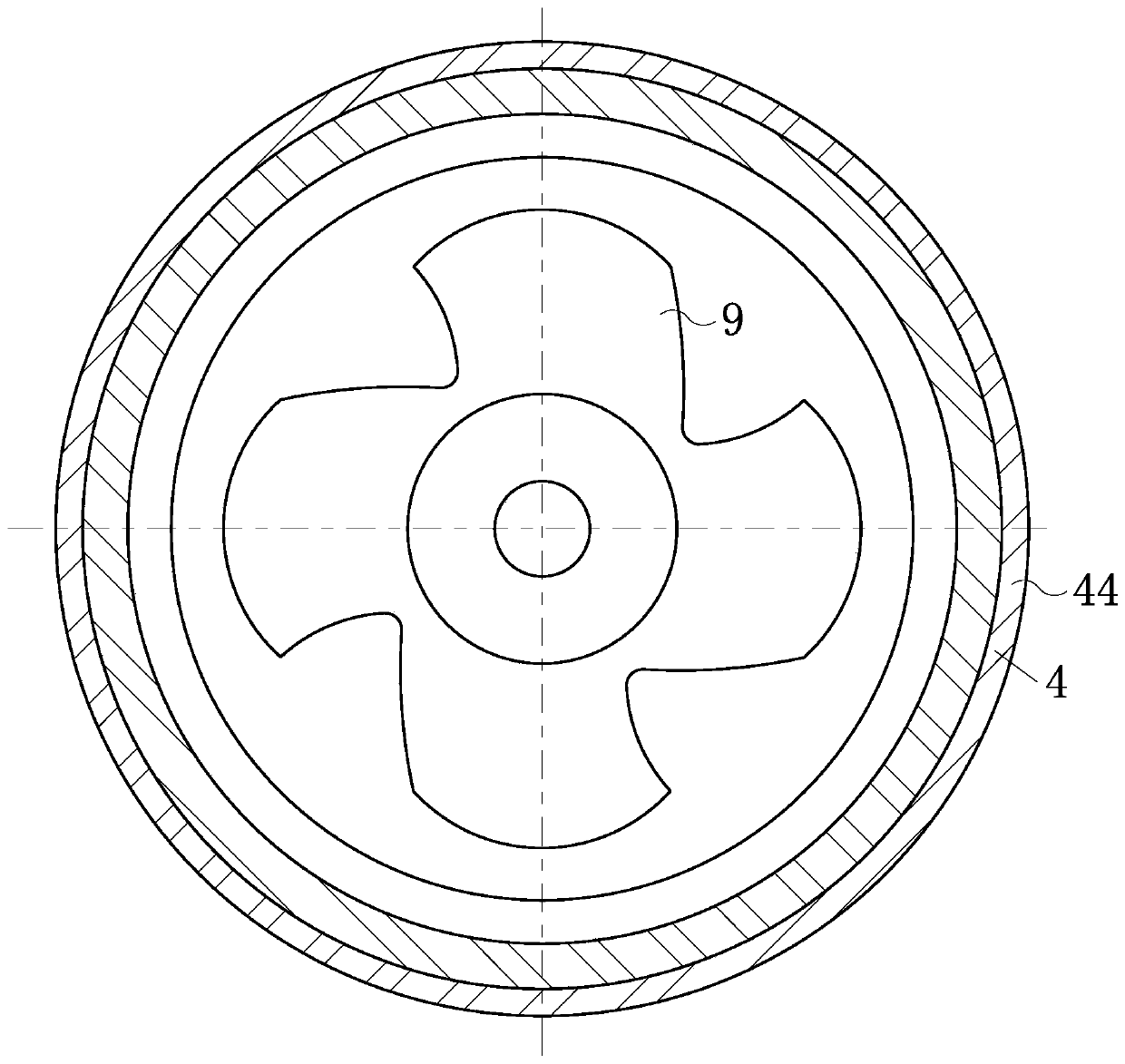

Brush type electrostatic dust remover

ActiveCN105665143AReduce adsorptionImprove adsorption capacityExternal electric electrostatic seperatorElectrode constructionsElectricityEngineering

The invention relates to a brush type electrostatic dust remover. The brush type electrostatic dust remover comprises a dust removal cavity, a purification cavity and a dust hopper. A dust collection screen plate is installed between the dust hopper and the dust removal cavity. A discharging piece is installed at an air inlet. The discharging piece is electrically connected with one electrode of an electrostatic generator. Electrostatic grid cylinders are vertically installed in the dust removal cavity. The electrostatic grid cylinders are driven by a driving turntable to rotate, and the driving turntable is installed at the top of the dust removal cavity. The upper end of each electrostatic grid cylinder communicates with the purification cavity. The lower end of each electrostatic grid cylinder is installed on the dust collection screen plate. Discharging brushes and electricity eliminating brushes are vertically installed on the inner circumferential surfaces of the electrostatic grid cylinders. The discharging brushes are electrically connected the other electrode of the electrostatic generator. The electricity eliminating brushes are electrically connected with a ground wire. Dust removal brushes are further vertically installed on the outer circumferential surfaces of the electrostatic grid cylinders. The dust removal brushes are located between the discharging brushes and the electricity eliminating brushes. The brush type electrostatic dust remover is simple in structure and can efficiently remove dust for a long time; and dust collection is convenient, and meanwhile ash removal is convenient.

Owner:盐城市欧蓝森布业有限公司

Gingko pollen collecting method

The invention relates to an arbor pollen collecting technology, in particular to a ginko pollen collecting method. The invention adopts the following technical scheme that aiming at a mature male gingko tree with a trunk chest diameter of not greater than 30cm, at the non-wind time interval during the flowering period of the male tree, a thin film of which the radius is equal to that of the crown of the male tree in the horizontal direction is laid by using the buttress of the gingko male tree as the center; then a rod-type concrete vibrator with power of 1.8KW is taken; a vibrating head of the rod-type concrete vibrator is pressed against the trunk to vibrate for 5 to 10 minutes; then the thin film on the ground is put away; obtained pollen is sieved by a 120-mesh sieve so as to obtain pure gingko pollen. According to the scheme, not only can the gingko pollen be shaken out, but also the tree bark cannot be damaged.

Owner:NINGBO YINZHOU YUNFAN ENG CONSULTING

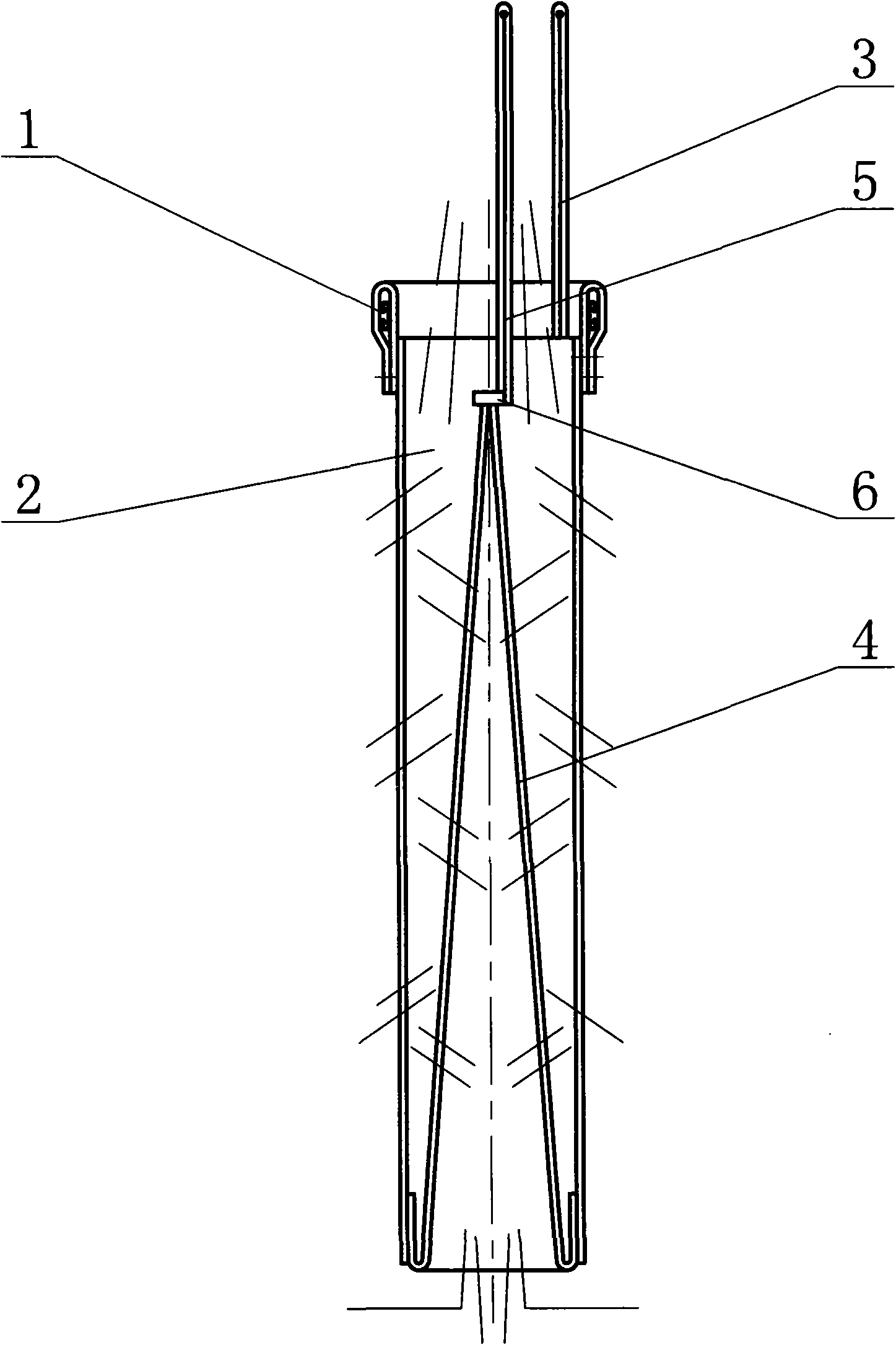

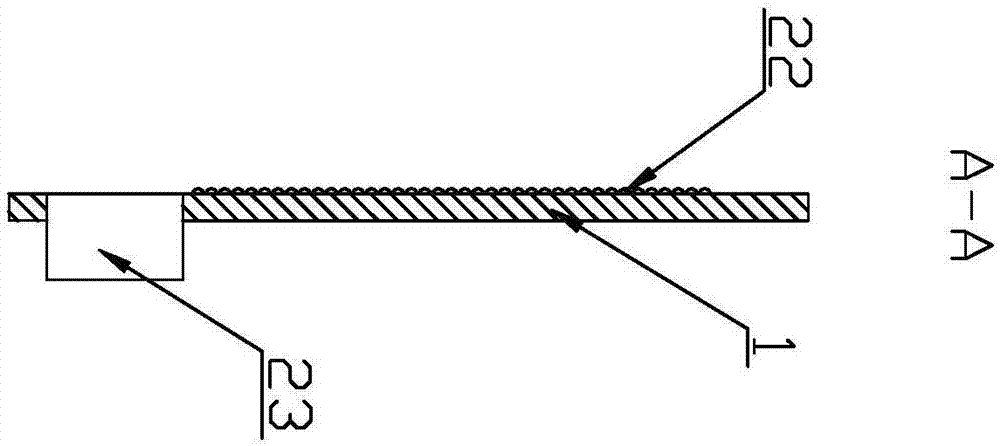

Built-in cone type filter bag

InactiveCN101564626ASolve the gas problemReduce volumeDispersed particle filtrationEngineeringOperating cost

The invention relates to a built-in cone type filter bag which comprises a bag mouth, a straight pocket and an outer drawing strip, wherein the outer drawing strip is sewed at the inner side of the bag mouth, the bag mouth is sewed at one end of the straight pocket, the straight pocket is an empty opening without a bottom, a conical bag is arranged in the straight pocket, the empty opening without a bottom is arranged at the lower end of the conical bag, the lower end of the straight pocket is sewed with the edge of the heavy caliber end of the conical bag, the top of the conical bag is sewed with a conical bag buckle, and the conical bag buckle is sewed with an inner drawing strip. The invention solves the problem that the filtering area is increased on the basis without changing the appearance of the original filter bag, and simultaneously solves the problem of reducing the compressed gas quantity required for ash removal; and the invention cancels the bag bottom, increases the conical bag and utilizes the empty opening formed after the bag bottom is eliminated as the inlet for the dusty gas to enter in the conical bag, thereby not only increasing the filtering area, but also reducing the volume of filling the compressed gas during the ash removal, reducing the manufacturing cost of the device as well as the occupied land due to the increase of the appearance of the device and meanwhile, and reducing the operating cost as well.

Owner:杨东明 +1

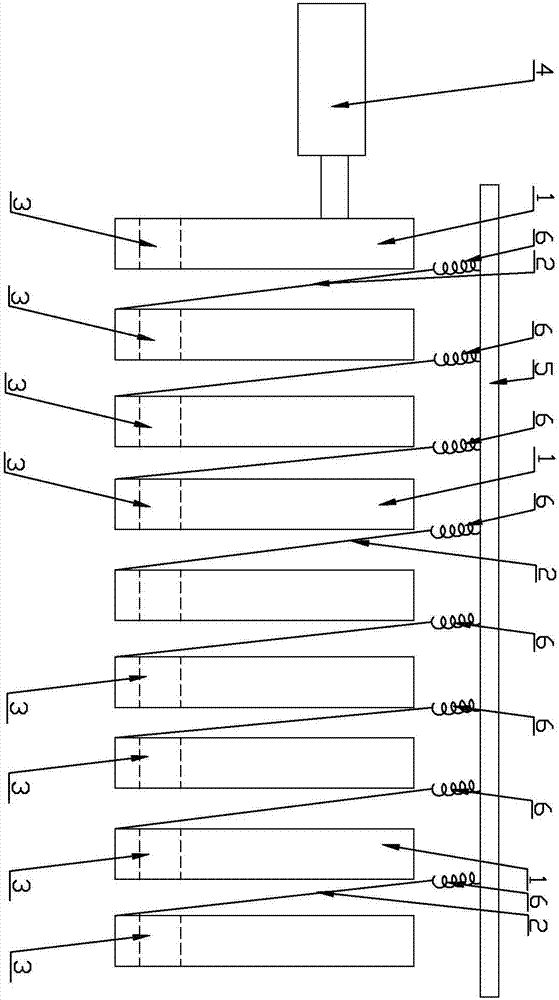

Sludge dewatering and press-filtering device

InactiveCN106955514AEasy to shake offGood effect of desliming technologySludge treatment by de-watering/drying/thickeningFiltration separationPush and pullSludge cake

The invention discloses a sludge dewatering and press-filtering device, which comprises a press-filter box, a plurality of drumhead plates arranged on the press-filter box in parallel, a drive motor for pushing and pulling each drumhead plate to move, a fixedly arranged fixed rack, and a vibrator arranged on the fixed rack and used for vibrating and pulling each filter membrane. A filter membrane is arranged between each two adjacent drumhead plates; a water through hole penetrating through each drumhead plate is also formed in the lower end of each drumhead plate; the upper end of each filter membrane is connected with the vibrator; the lower end of each filter membrane is fixedly arranged on each drumhead plate on the lower part of each water through hole. Through the arrangement of the vibrator and the water through hole, when each drumhead plate squeeze sludge to separate, the vibrator pulls or vibrates each filter membrane so as to shake off a squeezed sludge cake on each filter membrane; since the water through hole is formed in the lower part, compared with a traditional water through hole formed in the middle, the sludge on the lower part of the filter membrane can be more easily shaken off, so that a better desliming technical effect is achieved; the sludge dewatering and press-filtering device is simple in structure, low in cost and applied to the field of press-filtering equipment.

Owner:广州福之源环保科技有限公司

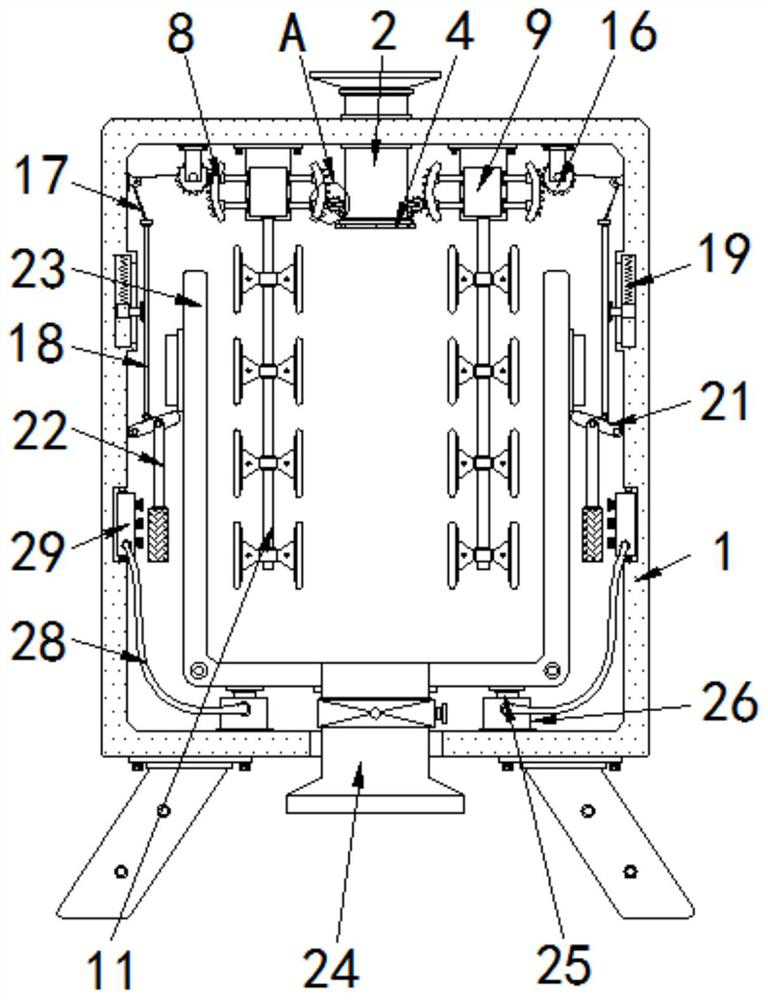

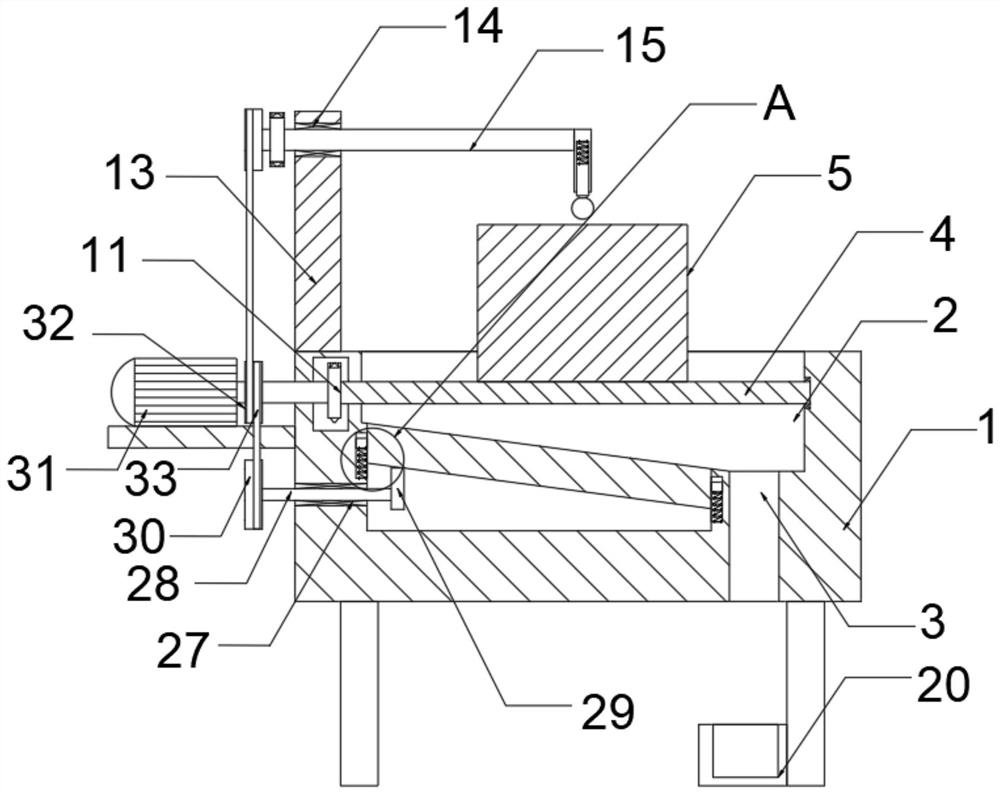

Electrostatic dust removal capsule polishing and drying device and using method

ActiveCN106363514AEasy to dropEasy to shake offGrinding machine componentsPolishing machinesEngineeringElectromagnetic heating

The invention relates to an electrostatic dust removal capsule polishing and drying device and a using method and belongs to the technical field of capsule polishing equipment. An elastic steel wire mesh is arranged in a polishing cylinder. A gap is formed between the elastic steel wire mesh and the inner wall of the polishing cylinder. Baffles which incline downwards are arranged on the inner side of the elastic steel wire mesh from outside to inside at intervals. A polishing device comprises a motor, a rotary shaft and polishing discs. The motor is arranged at the bottom of the polishing cylinder. The rotary shaft penetrates through the bottom of the polishing cylinder and extends into the polishing cylinder. The polishing discs are arranged obliquely from inside to outside. The inner ring of each polishing disc is fixedly connected with the rotary shaft. The polishing discs and the baffles are arranged alternately. A dust removal and drying device comprises an electromagnetic heating device and an electrostatic dust removal device. The electromagnetic heating device and the electrostatic dust removal device are arranged in the gap between the elastic steel wire mesh and the inner wall of the polishing cylinder in a spaced mode. According to the electrostatic dust removal capsule polishing and drying device and the using method, dust falling in the polishing process is adsorbed through the electrostatic dust removal device, and residual quantity of the dust is reduced.

Owner:ZHEJIANG HUAGUANG CAPSULE

Bubble mixed light soil foaming preparation process and mixing preparation device

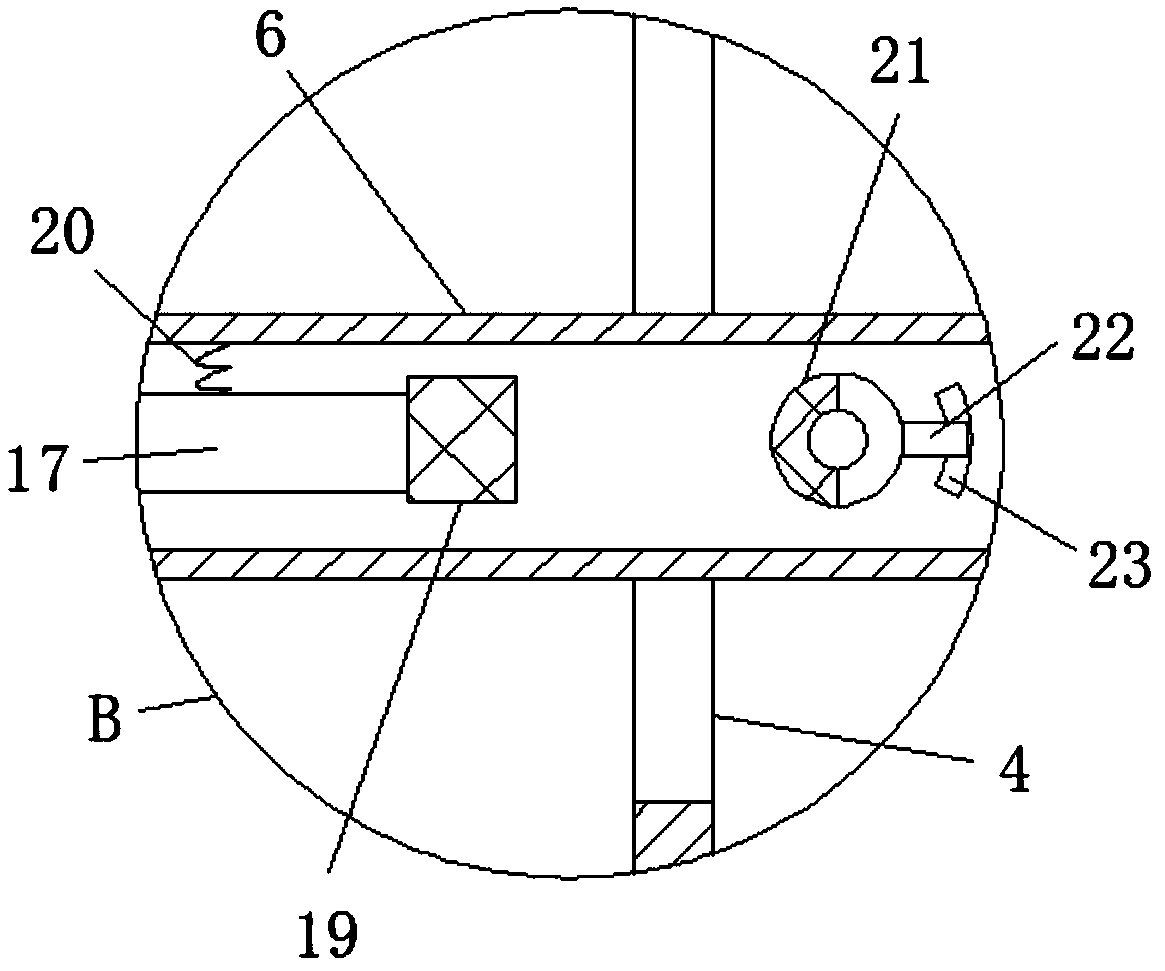

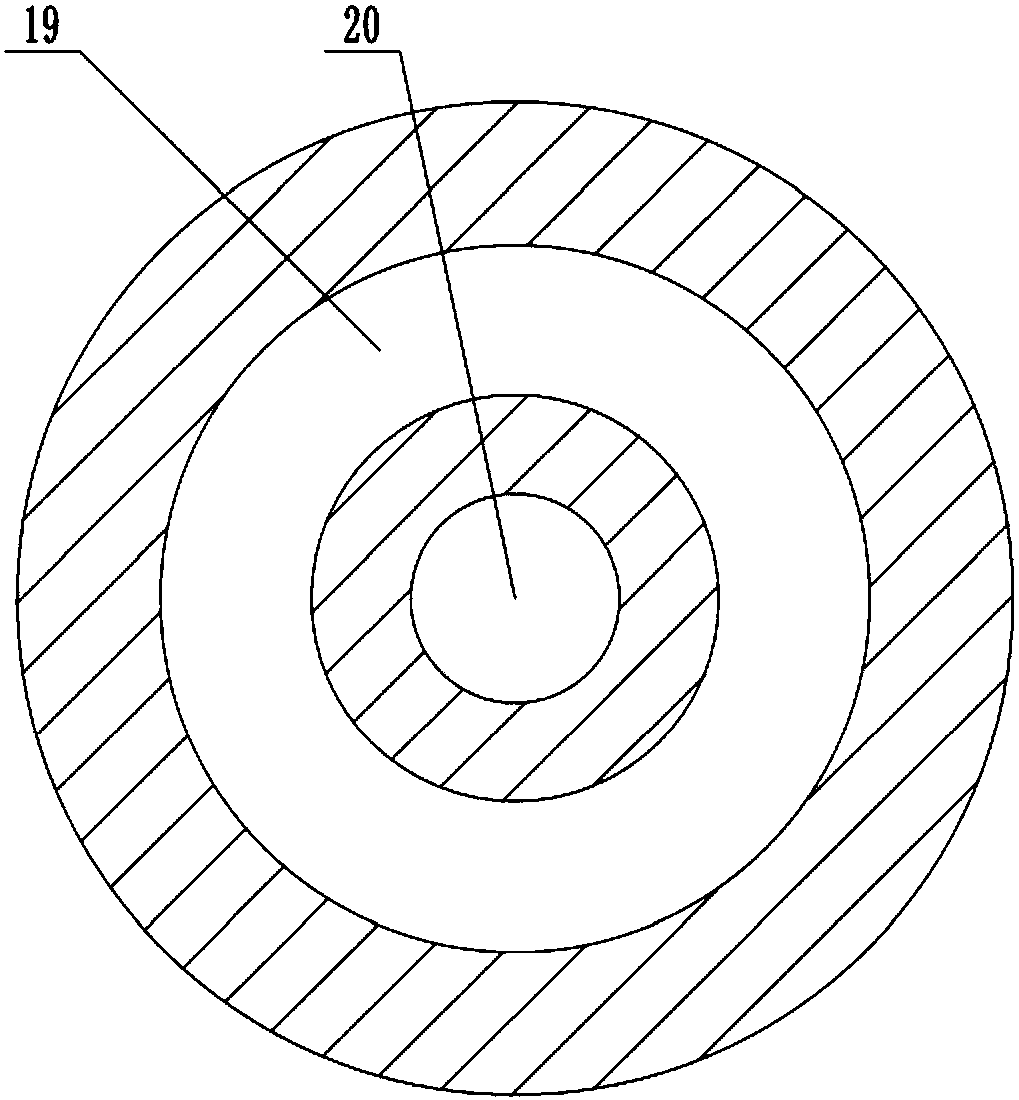

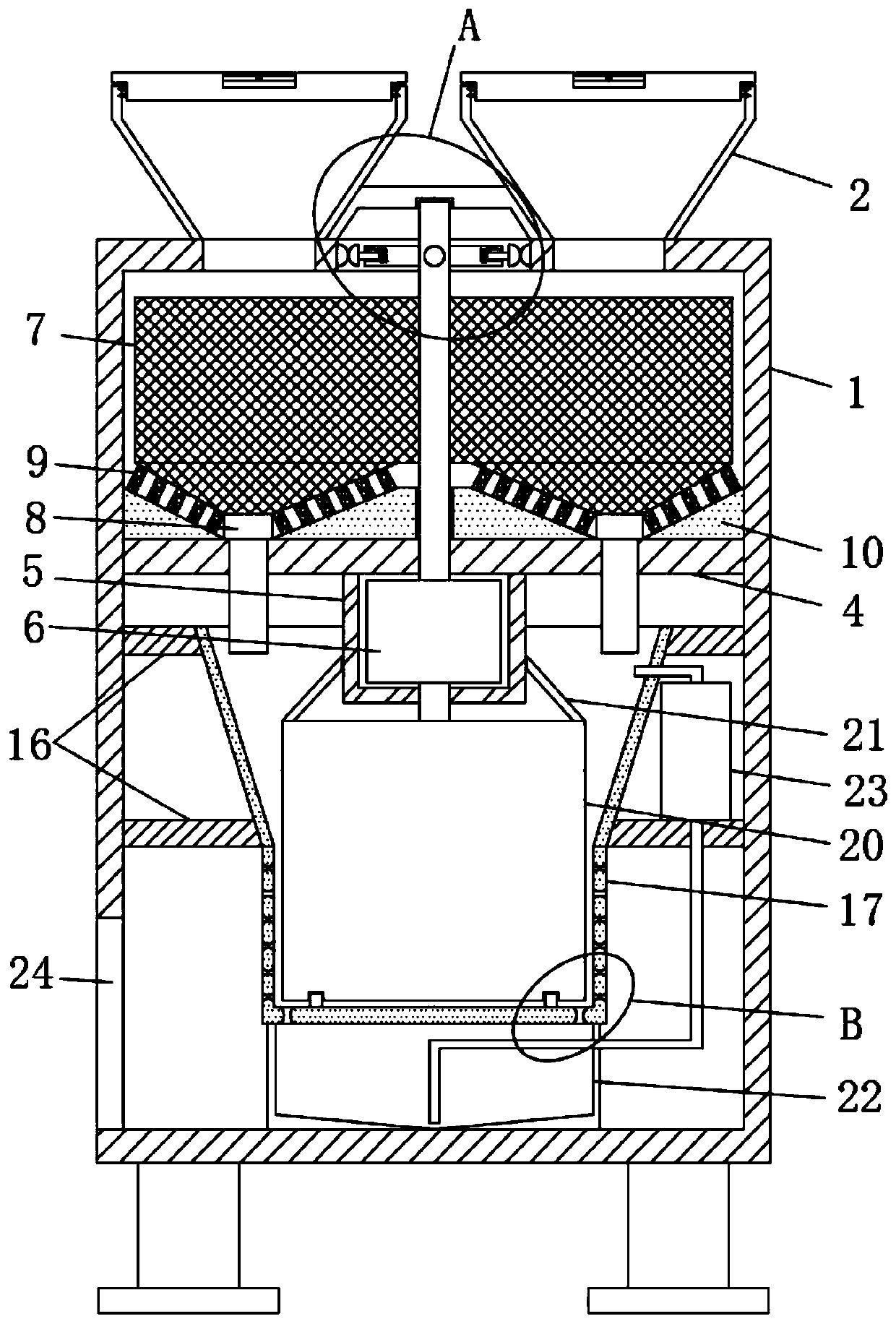

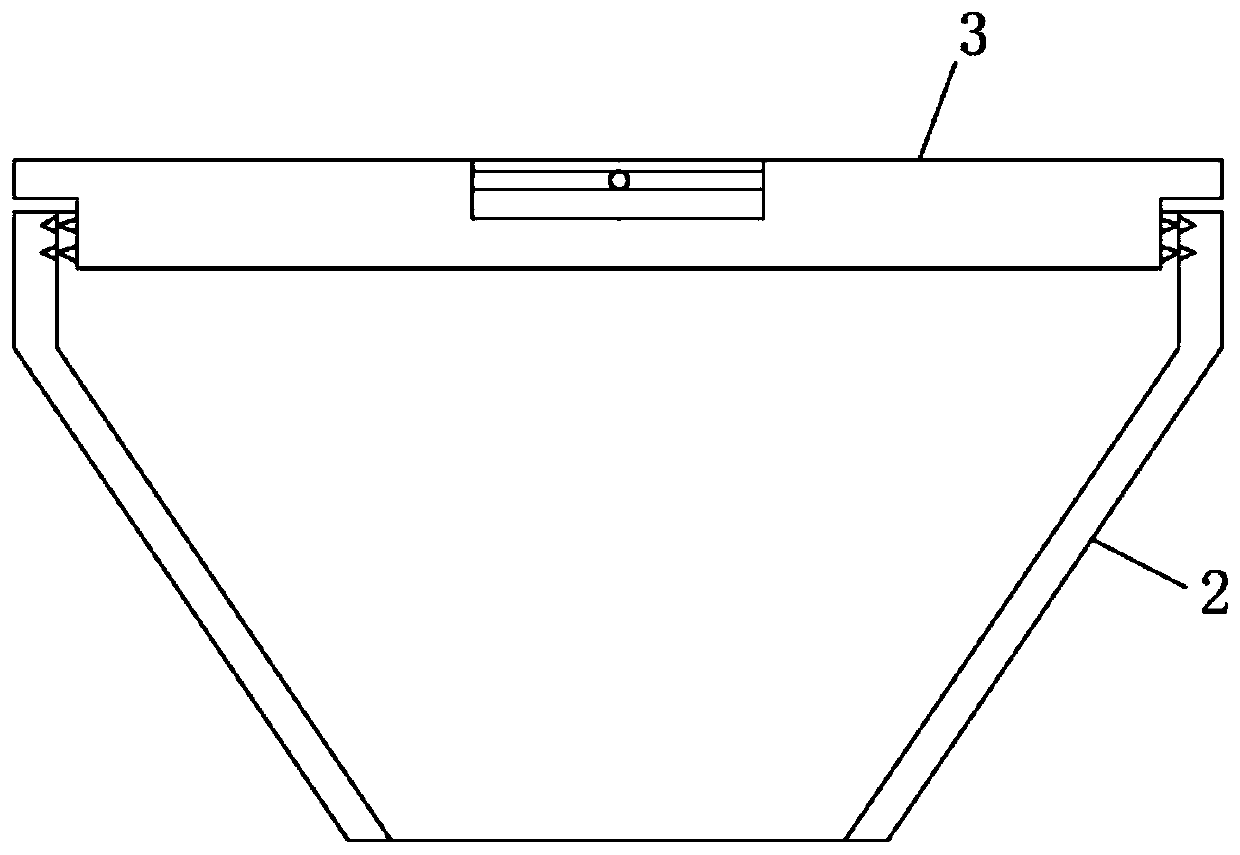

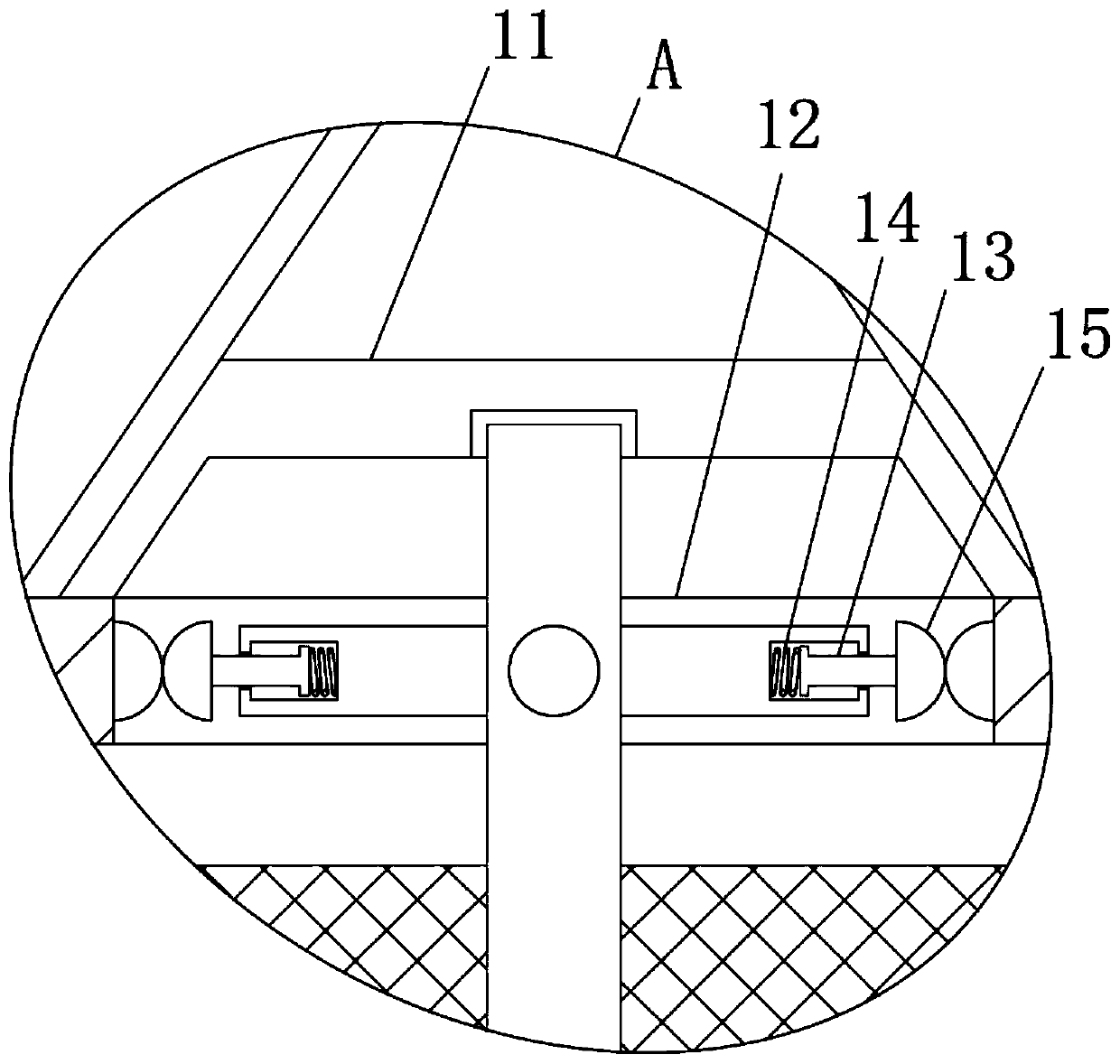

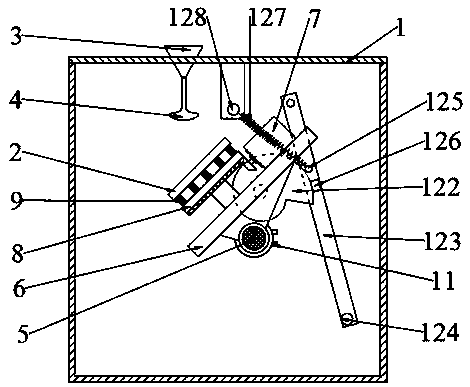

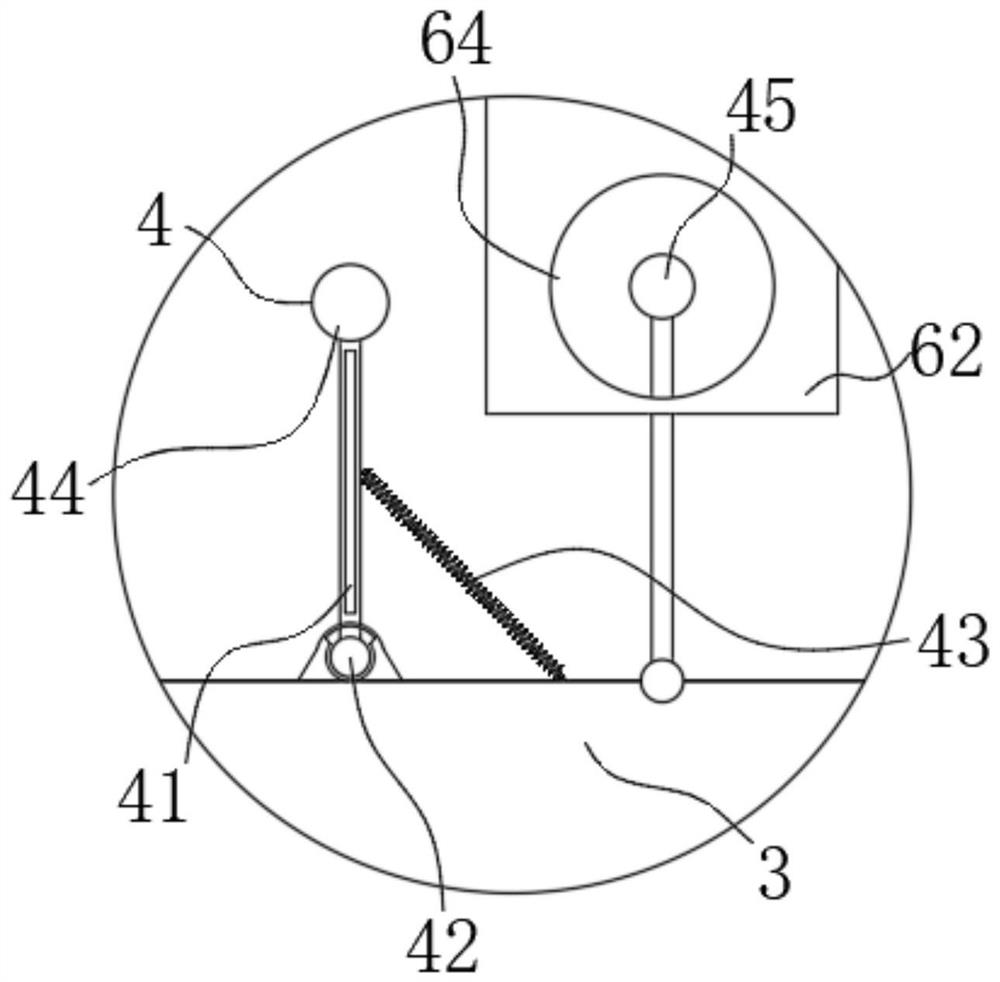

InactiveCN113146848AEasy to shake offControl the amount of feedHollow article cleaningCement mixing apparatusElectric machineEnvironmental engineering

The invention discloses a bubble mixed light soil foaming preparation process and a mixing preparation device. The bubble mixed light soil foaming and mixing preparation device comprises a feeding hopper, wherein the feeding hopper is fixedly mounted in a device body through a bolt for maintaining stability, a fixed shaft for limiting, supporting and rotating is mounted at the lower end of the feeding hopper, and a vortex spring for providing recovery elasticity is mounted on the side of the fixed shaft; a driving motor, wherein the driving motor is fixedly installed in a protective cover for protecting the driving motor; a servo motor, wherein the servo motor is fixedly installed on the back surface of the device body through bolts, a linkage rod is installed at the end of the servo motor; and an inner barrel, wherein the inner barrel is installed in the device body, and the middle of the lower end of the inner barrel is fixedly connected with a discharging port facilitating follow-up discharging. According to the bubble mixed light soil foaming preparation process and the mixing preparation device, the feeding amount can be effectively controlled, the situation that too many raw materials are added at a time, and consequently the mixing quality of a final product is reduced is avoided, and meanwhile, the overall stirring effect can be improved, and the raw materials adhering to the inner wall of the device can be conveniently shaken off.

Owner:重庆泰恒建筑科技有限公司

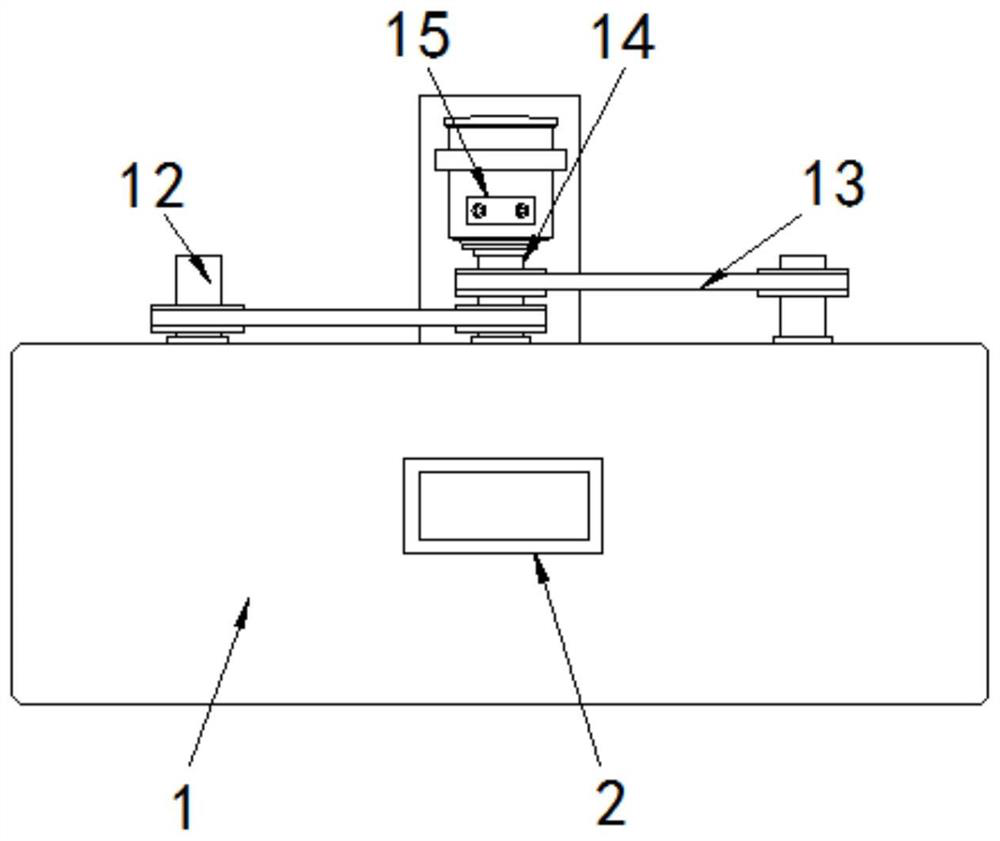

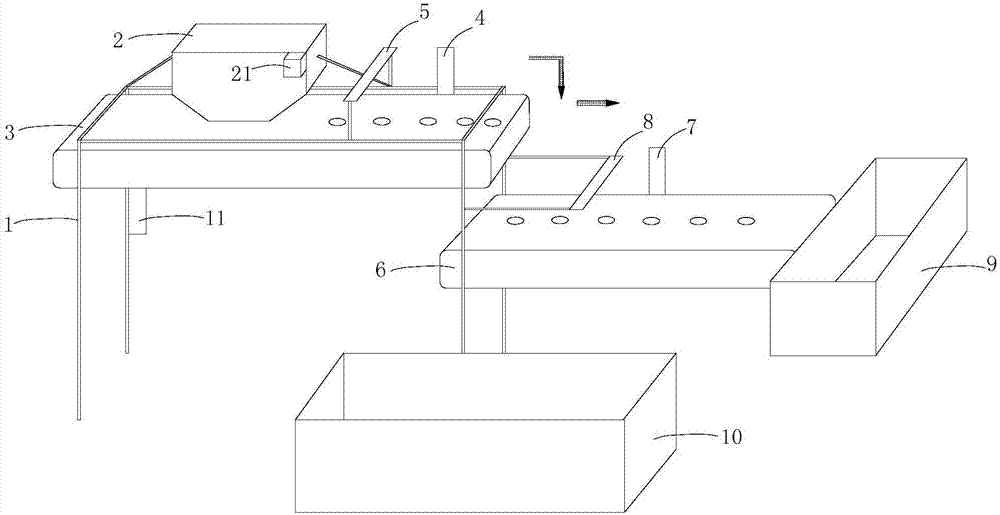

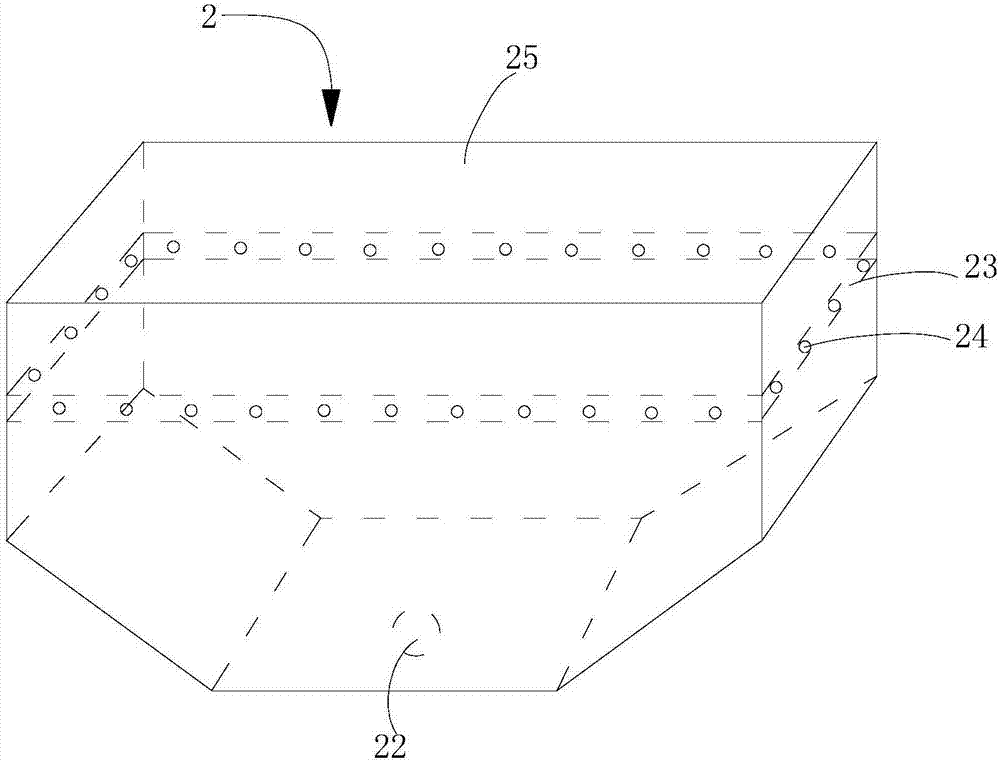

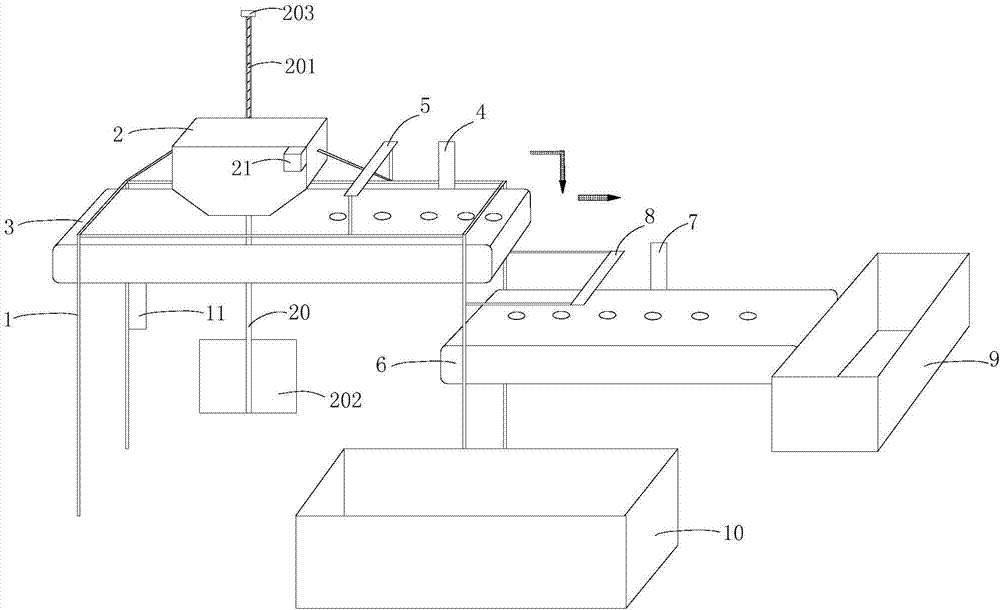

Cloth inspecting dust removing system applied to clothing production

ActiveCN105170499ASimple structureTargetedCleaning using toolsElectrostatic chargesEngineeringTextile

The invention discloses a cloth inspecting dust removing system applied to clothing production. The cloth inspecting dust removing system applied to clothing production comprises a cloth inspecting rack and a dust removing rack. A dust removing channel is formed between the cloth inspecting rack and the dust removing rack and is internally provided with dust removing cloth and dust removing devices. The dust removing devices comprise the horizontal dust removing device and the vertical dust removing device. The horizontal dust removing device comprises an upper dust removing mechanism, a lower dust removing mechanism and a horizontal driving mechanism. The upper dust removing mechanism and the lower dust removing mechanism are both connected with the horizontal driving mechanism. The vertical dust removing device comprises a left dust removing mechanism, a right dust removing mechanism and a vertical driving mechanism. The left dust removing mechanism and the right dust removing mechanism are both connected with the vertical driving mechanism. The horizontal dust removing device and the vertical dust removing device are used for performing dust removal on the upper surface and the lower surface of the dust removing cloth two times respectively, the dirt, dust and electrostatic effect of the cloth is eliminated, the eliminating rate can reach up to 98%, and therefore the purposes that a cloth cover is clean and tidy, product quality is improved, the product yield rate is increased, the reject ratio is reduced, and product cost is reduced can be achieved.

Owner:HAIAN RUNDE CLOTHING CO LTD

Solid waste drying treatment system and treatment process

ActiveCN111750660AIncrease drynessNot easy to agglomerateDrying machines with progressive movementsDrying solid materialsHeater RodProcess engineering

The invention relates to a solid waste drying processing treatment system and a treatment process. The solid waste drying processing treatment system comprises a mounting frame, a feeding plate, a mounting plate, heating rods and a drying device, wherein the feeding plate is fixed to the outer wall of the left end of the mounting frame, the mounting plate is installed on the outer wall of the middle of the rear end of the mounting frame, the heating rods are evenly arranged at the upper end of the mounting frame, and the drying device is arranged in the mounting frame. According to the solid waste drying processing treatment system and the treatment process, the problems that a traditional solid waste drying processing mode usually adopts a natural airing or direct drying mode, the naturalairing time is long, only the surface of the solid waste is usually dried through direct drying, the interior of the solid waste is still in a wet state, and the interior of the dried solid waste isprone to caking can be solved; and according to the traditional solid waste drying processing mode, when solid waste is dried and processed through a machine, the problems that wet solid waste in themachine adheres to the machine and is difficult to remove often occur.

Owner:福建国为联华实业有限责任公司

Anti-rollover biological floating bed for river regulation and implementation method of anti-rollover biological floating bed

InactiveCN113135617AStable floatingDecrease the tilt angleBiological treatment apparatusRiver routingRiver regulation

The invention discloses an anti-rollover biological floating bed for river regulation and an implementation method thereof. The anti-rollover biological floating bed for river regulation comprises a floating mechanism and a protection mechanism, arc-shaped baffles are installed on the two sides of a floating bed body, and air inducing grooves are formed in the upper ends of the sides, away from the floating bed body, of the arc-shaped baffles; and the arc-shaped baffles can shield the floating bed body and planting baskets, the air inducing grooves enable shielded wind power or wave water to flow out through the air inducing grooves, a balancing weight and a gravel layer are arranged at the bottom end of the inner cavity of a semicircular base, and a foam filling layer and a sealing hollow layer are arranged at the upper end of the inner cavity of the semicircular base. Therefore, the lower end of the semicircular base is heavy, and the upper end of the semicircular base is light. According to the principle of a tumbler, the semicircular base and the floating bed body cannot be blown over, so that the floating bed body keeps stable on a river channel, an impurity collecting box collects floating garbage on the water surface through a collecting empty groove, and a limiting baffle can block the floating garbage on the river channel, so that the floating garbage moves downwards to enter the inner side of the collecting empty groove.

Owner:王泽亮

Glue filling auxiliary equipment for LED guardrail pipe

ActiveCN110976215AEfficient collectionAvoid drippingLiquid surface applicatorsCoatingsAdhesive glueMechanical engineering

The invention relates to glue filling auxiliary equipment, in particular to glue filling auxiliary equipment for an LED guardrail pipe. The invention aims to provide the glue filling auxiliary equipment for the LED guardrail pipe, wherein the equipment can synchronously perform glue filling operation on a guardrail pipe lamp holder and can prevent a glue layer from being too high. The glue fillingauxiliary equipment for the LED guardrail pipe comprises a bottom plate, a first mounting seat, a second mounting seat and the like, wherein one side of the top of the bottom plate is provided with the first mounting seat, and the other side of the top of the bottom plate is provided with the second mounting seat. According to the equipment, by adopting a concave plate with an opening, after theoperation of the equipment is finished, redundant glue in a double-head spray pipe and a strip-shaped spray head can be effectively collected, and thus the situation that the redundant glue drips on the top of the bottom plate, and the subsequent clearing is inconvenient is prevented.

Owner:张存存

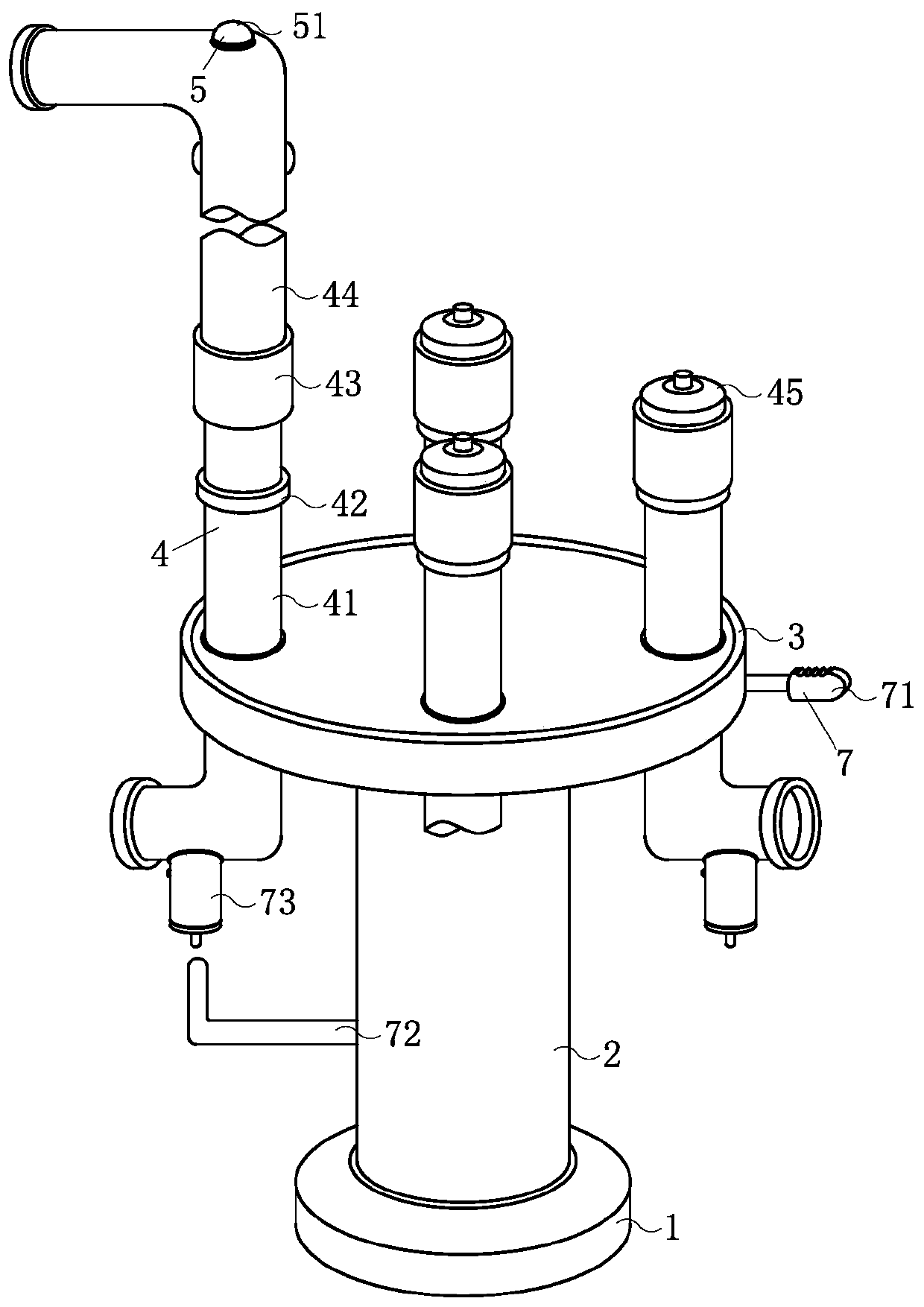

Air purification equipment for factories

ActiveCN111365777AImprove the use effectEasy to collectDucting arrangementsMechanical apparatusAir cleaningProcess engineering

The invention relates to the field of air purification, in particular to air purification equipment for factories. The air purification equipment comprises a base, a supporting rod, an installation table, a through pipe mechanism, a purification mechanism, a feeding mechanism, a humidifying mechanism, a filter element mechanism and a fan main body. According to the air purification equipment, thepurification mechanism rotates inside the through pipe mechanism, and a large amount of impurities adsorbed for the first time can be conveniently shaken off, so that the purification mechanism can beprevented from being blocked; under the rotation of the purification mechanism, the feeding mechanism can automatically and continuously add decomposition agents of harmful substances to a filter element inside the through pipe mechanism in the use process, so that the equipment has a better purification effect on harmful components in gas; the humidifying mechanism is rotated, the humidity of the filtered gas is conveniently adjusted under the matching of the through pipe mechanism, and the influence of the dry air on production is avoided; and the filter element mechanism is arranged in themiddle of an inner cavity of the through pipe mechanism, and through the matched operation with the humidifying mechanism, the rapid replacement of the filter element in the equipment is convenientlyrealized.

Owner:南通安强工程科技有限公司

Garbage collecting and cleaning device for river regulation

PendingCN114197419AImprove cleaning efficiencyEasy to shake offWater cleaningFiltration circuitsRefuse collectionRiver routing

The invention provides a garbage collecting and cleaning device for river regulation, and belongs to the technical field of river regulation equipment. A garbage collecting and cleaning device for river regulation comprises a supporting frame, and power paddles are rotationally connected to the two sides of the supporting frame; and the garbage intercepting and collecting mechanism comprises an intercepting steel wire mesh plate, the intercepting steel wire mesh plate is arranged on the front side of the supporting frame in a sliding mode, and the bottom of the intercepting steel wire mesh plate is fixedly connected with an inclined mesh plate. According to the device, the garbage intercepting and collecting mechanism is arranged, garbage floating in a river can be intercepted through an intercepting steel wire mesh plate, and when the garbage collected by the intercepting steel wire mesh plate needs to be cleaned, the intercepting steel wire mesh plate moves upwards; and the spiral conveyor rotates to convey the garbage collected on the intercepting steel wire mesh plate into the garbage collecting box and then collect the garbage in a centralized manner, so that the cleaning efficiency of the river garbage is improved.

Owner:清远市南清环保有限公司

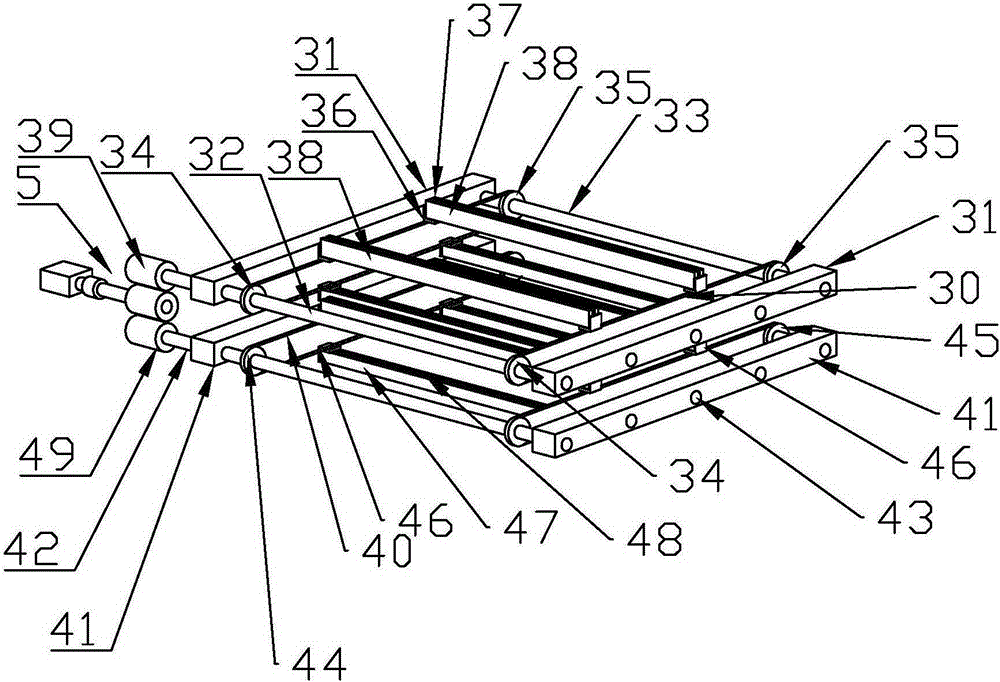

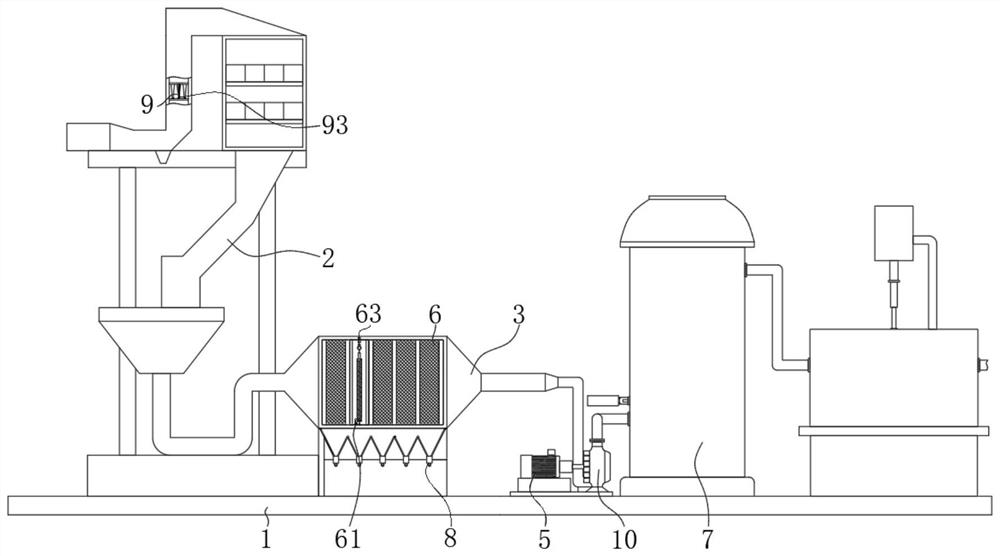

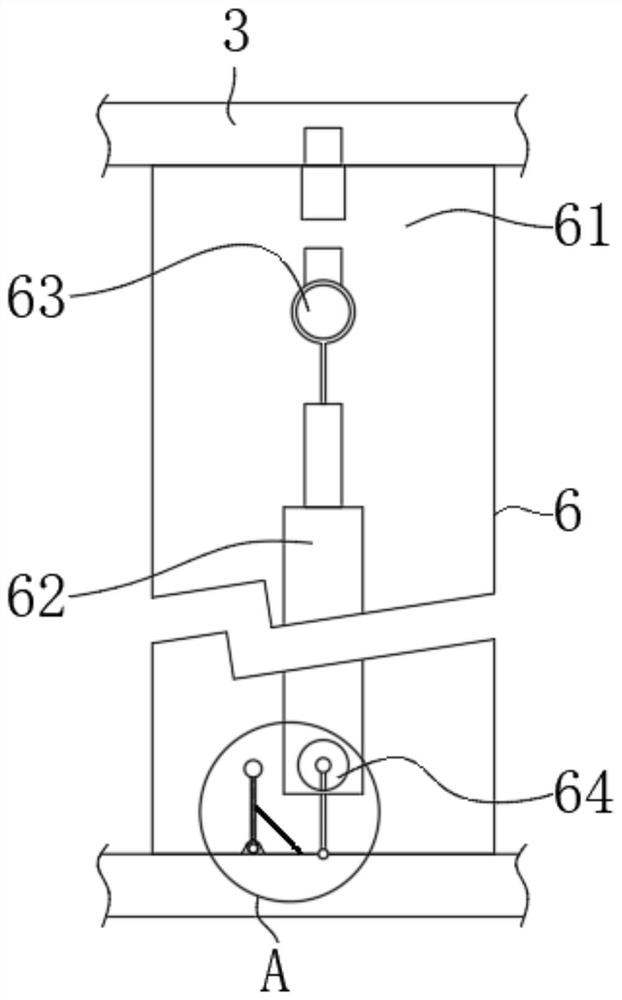

Automatic pupa screening device

PendingCN107185847ASolve the speed problemSolve quality problemsSortingClimate change adaptationEngineeringStructural engineering

The invention relates to the field of machining equipment for by-products in the cocoon silk industry, in particular to an automatic pupa screening device. The automatic pupa screening device comprises a supporting frame, a discharging bin, a vibrator, a first conveying belt assembly, a first high-pressure impact water device, first high-speed shooting equipment, a good pupa collecting box and a bad pupa collecting box; the discharging bin is mounted above the supporting frame; a discharging port is formed in the bottom surface of the discharging bin; the vibrator is mounted on the discharging bin and is connected with the discharging bin; the first conveying belt assembly is arranged below the discharging port and is connected with the supporting frame; the first high-speed shooting equipment is mounted above the first conveying belt assembly; the first high-pressure impact water device is mounted on one side of the first conveying belt assembly; a lens and the spray direction face the conveying surface of the first conveying belt assembly; the good pupa collecting box is mounted at the conveying tail end of the first conveying belt assembly; and the bad pupa collecting box is mounted on one side of the first conveying belt assembly and is located on the opposite side of the first high-pressure impact water device. The automatic pupa screening device is high in pupa screening efficiency.

Owner:广西上林县斯尔顿丝绸有限公司

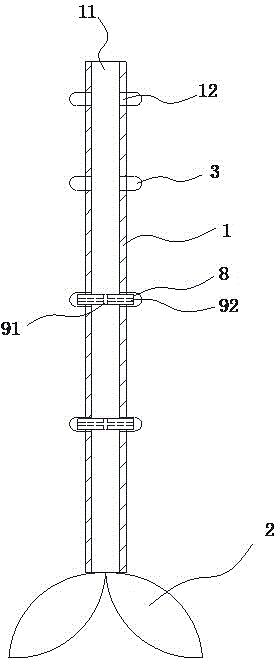

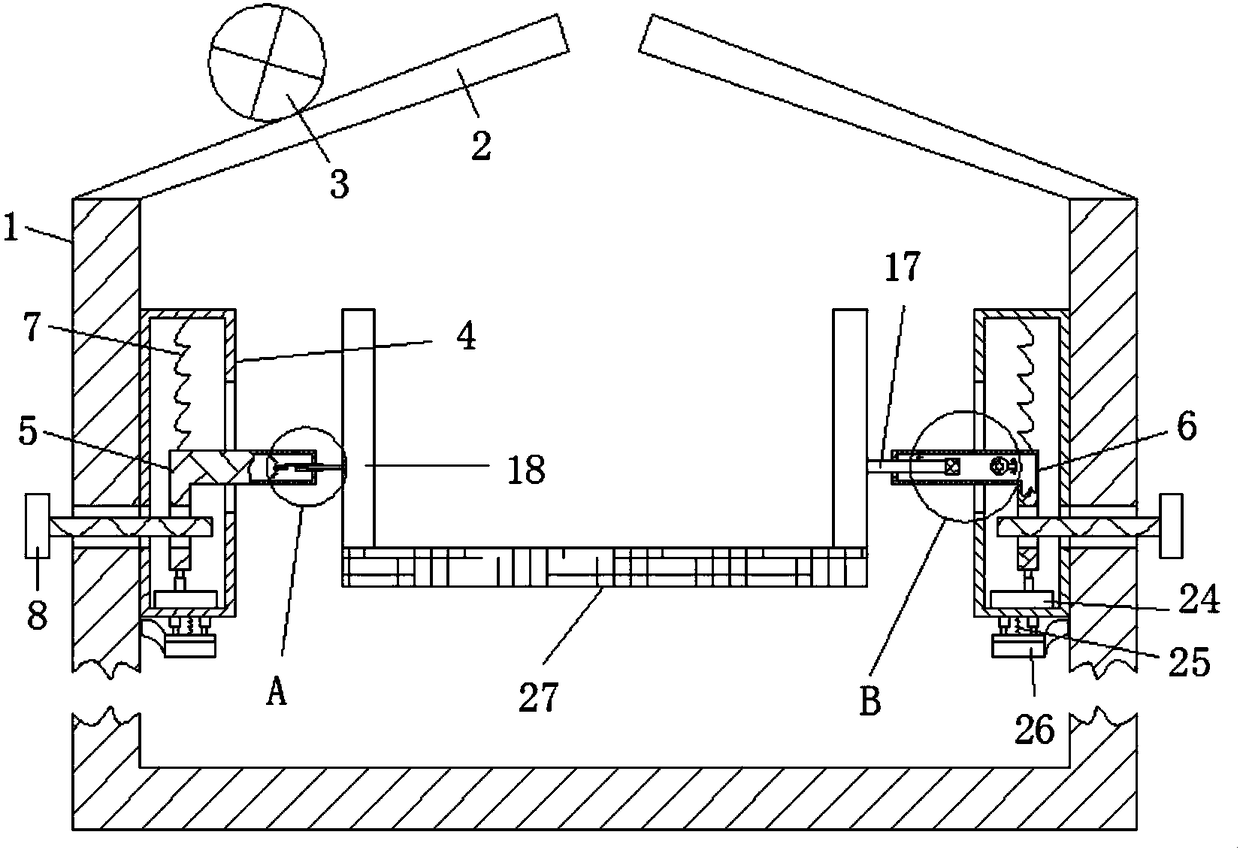

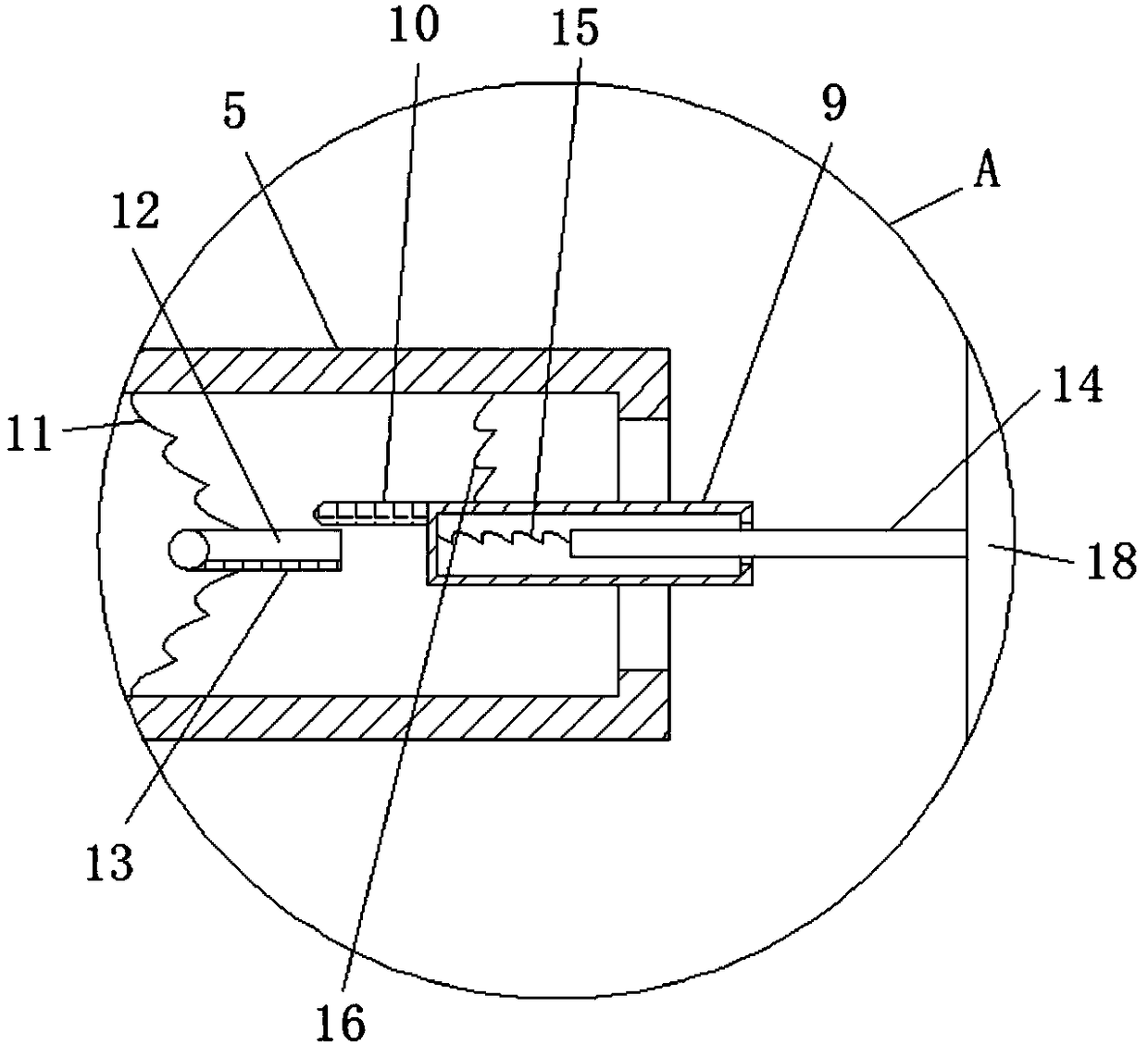

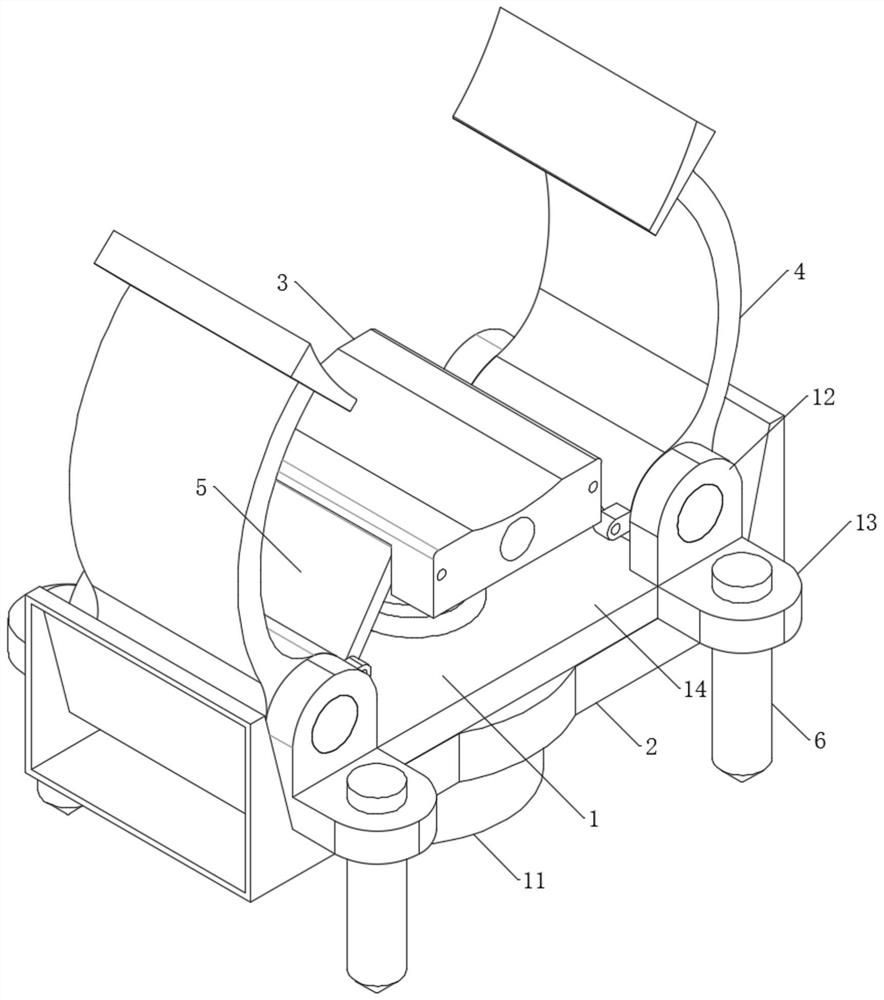

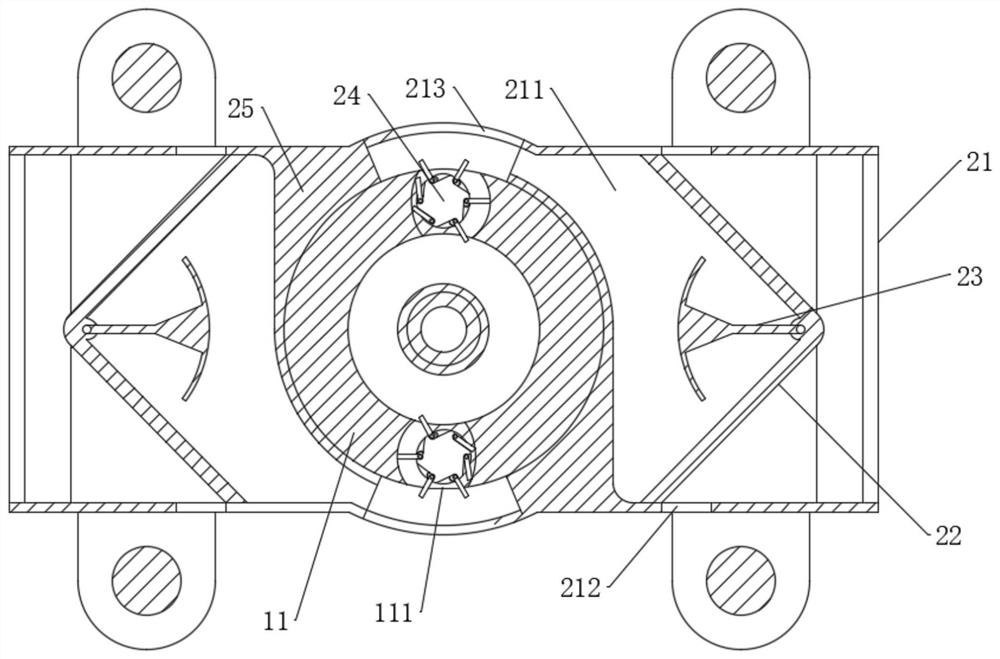

Pipeline erecting device used for ocean engineering

InactiveCN113685615AAchieve clampingImprove reliabilityPipe supportsPipe laying and repairStructural engineeringMechanical engineering

The invention discloses a pipeline erecting device used for ocean engineering, and relates to the technical field of ocean engineering. The pipeline erecting device used for ocean engineering comprises a bottom plate, wherein the bottom plate comprises a flat plate and a columnar shell vertically distributed on the flat plate; two sets of connecting seats I are fixed onto the flat plate, and the connecting seats I and the columnar shell are distributed oppositely; a corresponding fixing arm is rotatably installed on each set of connecting seat I, telescopic assemblies are further installed on the flat plate, and the telescopic assemblies are connected with the fixing arms through connecting plates; a water inlet part is further installed on the side surface, provided with the columnar shell, of the flat plate; and the water inlet part comprises a square pipe, rotating parts and a partition plate, the columnar shell is sleeved with the partition plate arranged in the square pipe, groove holes which communicate with channels of the square pipe are formed in the columnar shell, and the rotating parts are rotatably installed in the groove holes. According to the pipeline erecting device used for ocean engineering, trumpet-shaped openings are formed in end portions of the water inlet part, and undercurrent of seabed can conveniently drive the installed rotating parts through the openings, so that water in the columnar shell is discharged, and the columnar shell is adsorbed to the seabed.

Owner:谢勇伟

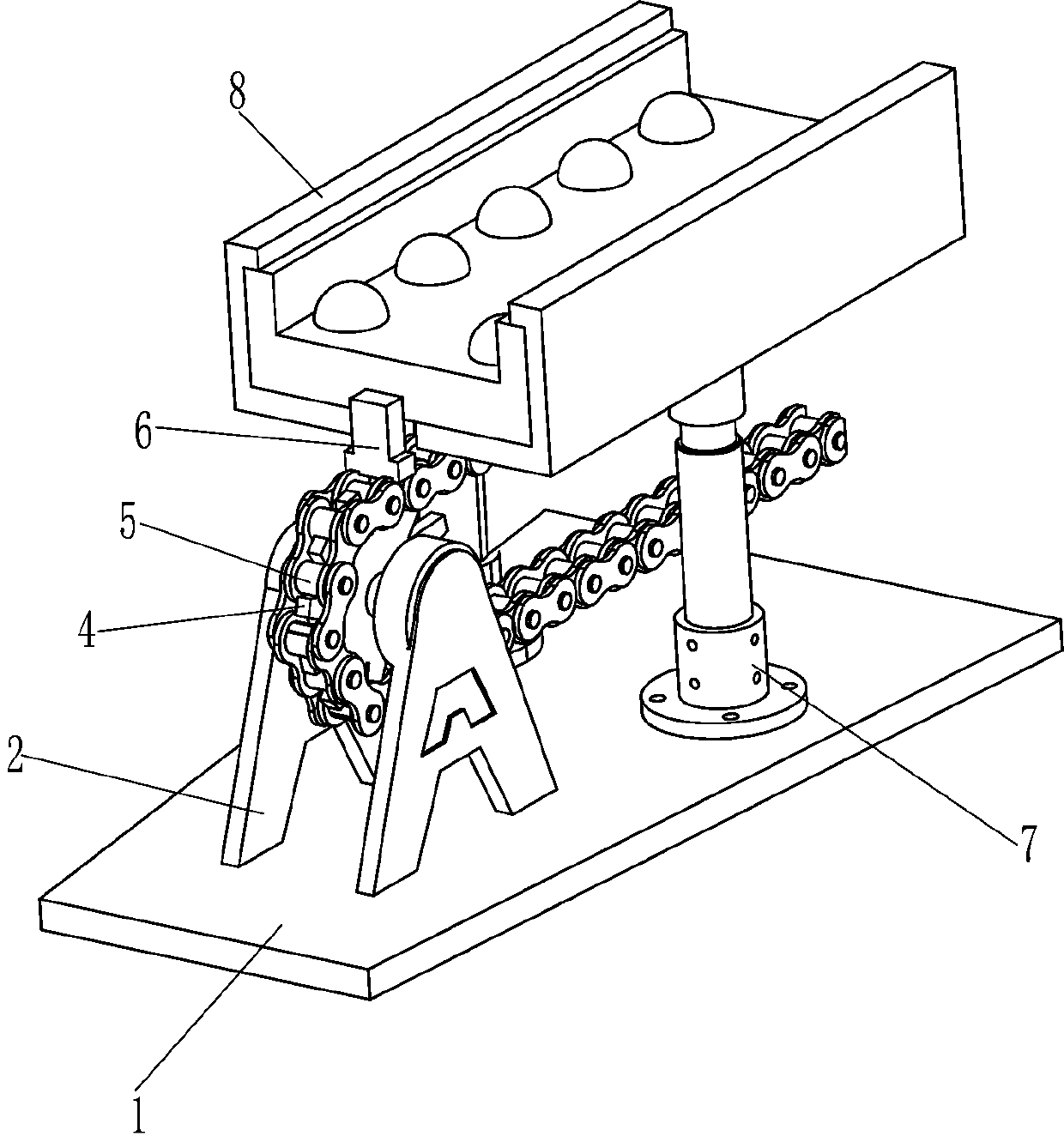

Shakeout equipment facilitating uniform feeding and used for casting machining and dredging technology

The invention relates to the technical field of iron casting equipment, in particular to casting machining shakeout equipment facilitating uniform feeding and a dredging technology. The casting machining shakeout equipment comprises a workbench, a groove is formed in the upper surface of the workbench, a strip-shaped through opening is formed in the lower wall of the groove, and a plurality of cylinders are rotationally connected to the right wall of the groove; a casting is placed at the upper end of the cylinder, a plurality of through holes are formed in the side wall of the supporting plate, vibrating mechanisms are arranged in the through holes, a driving mechanism is arranged on the side wall of the groove, and a linkage mechanism is arranged on the side wall of the groove. The vibration mechanism can be arranged to be matched with the cylinder so that the vibration mechanism can conveniently expand a casting on the cylinder, molding sand on the casting can be conveniently crushed through vibration generated by collision, the cylinder rotates to transport the casting, an assembly line can be formed, and the production efficiency is improved. And secondary vibration can be conducted on the castings through jolt generated when the castings are conveyed through the cylinders, and the shakeout effect is improved.

Owner:泰兴市启泰机械铸造有限公司

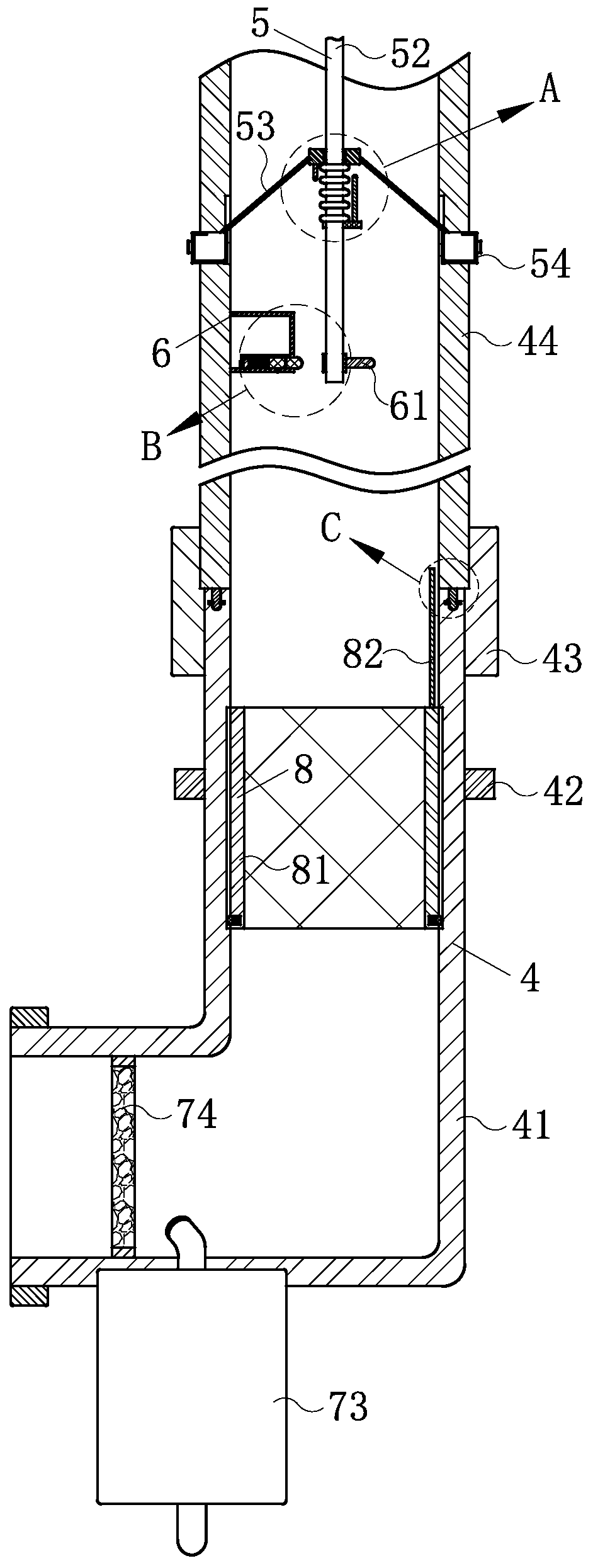

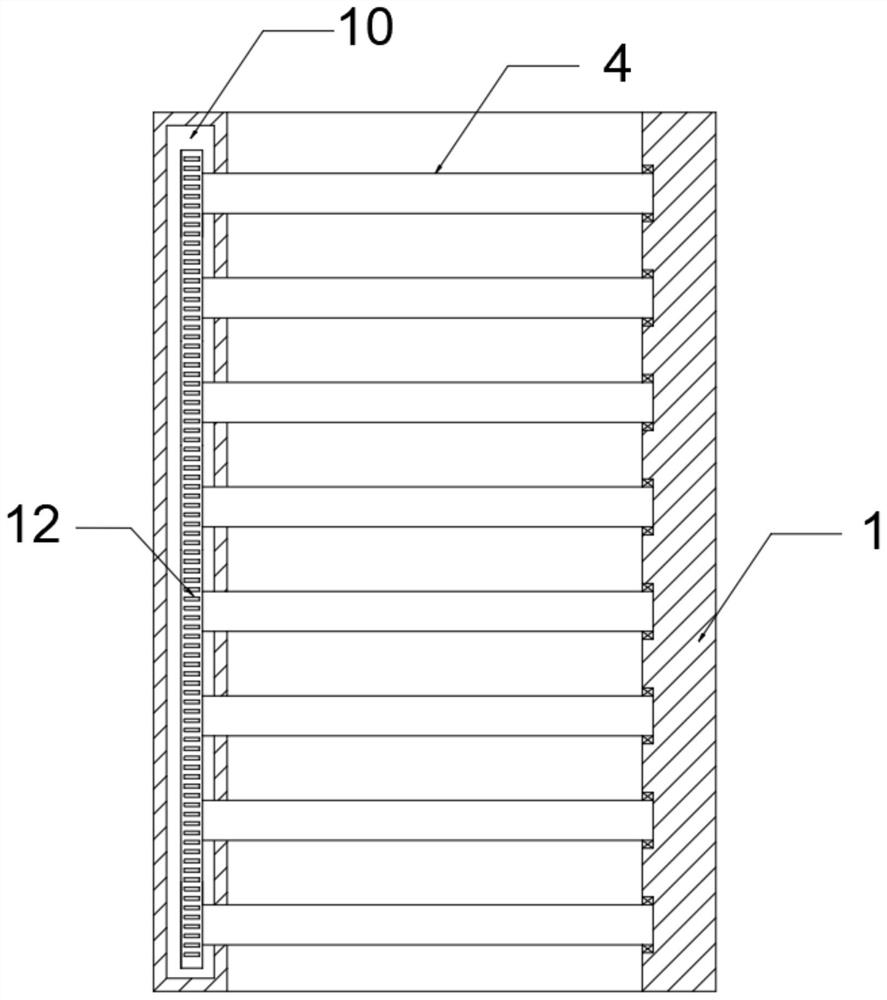

Anti-blocking bag type dust removal equipment for waste gas treatment

InactiveCN111437664AEasy to shake offAffect the circulation effectDispersed particle filtrationDust controlEnvironmental engineering

The invention relates to anti-blocking bag type dust removal equipment for waste gas treatment. The equipment comprises a main body, an ash discharge hopper, an ash discharge pipe, a dust removal bag,an air inlet pipe, an air outlet pipe and two supporting columns. The equipment further comprises a dust shaking mechanism and a cleaning mechanism. The ash shaking mechanism comprises a moving rod,a transmission assembly and two ash shaking assemblies; each ash shaking assembly comprises a rotating shaft, a connecting shaft, a pull wire, a first rotating plate, a second rotating plate, a lifting rod, a limiting plate, a limiting ring, a first spring, two first bearings and a plurality of paddles; the cleaning mechanism comprises a second bearing, a transmission shaft, a first gear, a supporting rod and two scraping plates. According to the anti-blocking bag type dust removal equipment for waste gas treatment, the dust shaking mechanism is arranged, the dust removal bag shakes, dust adhering to the dust removal bag can be shaken off conveniently, the dust is prevented from blocking the dust removal bag, the circulation effect of the dust removal bag is prevented from being affected,the function of cleaning the dust discharging hopper is achieved through the cleaning mechanism, manual cleaning is not needed, and the convenience of cleaning the dust discharging hopper is improved.

Owner:南京昕知环保科技有限公司

Granulator for preventing pig feed from being clamped in gaps and operation method thereof

The invention discloses a granulator for preventing pig feed from being clamped in gaps. The granulator comprises a granulator body, wherein the top face of the granulator body is provided with a feeding port, the upper side of the feeding port is provided with a feeding hopper, an opening of the feeding hopper is provided with a cover plate, the inner wall of the granulator body is provided witha partition plate, and the bottom face of the partition plate is provided with a motor frame. The invention further discloses an operation method of the granulator for preventing the pig feed from being clamped in the gaps. The operation method comprises the following steps of feeding, mixing of materials, conveying of the materials, granulation, circulation of remaining materials and taking of the materials. The granulator and the operation method thereof have the advantages that a telescopic rod body is additionally arranged on the surface of a driving shaft at the upper end of the providedgranulator for preventing the pig feed from being clamped in the gaps, when a beating head at the end of the telescopic rod body and a beating head on the inner wall of a through port are out of position during rotating, knocking of the inner wall of the through port is achieved, and materials in the feeding port are shaken off conveniently during knocking, thereby avoiding the blockage of the feeding port.

Owner:黄颖

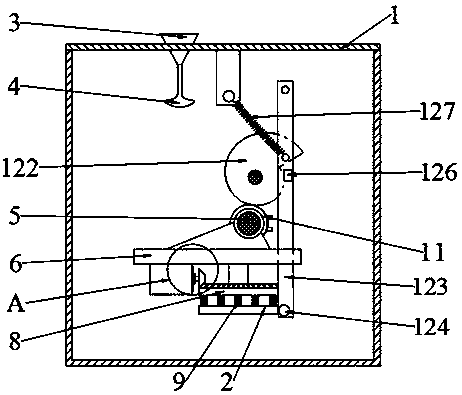

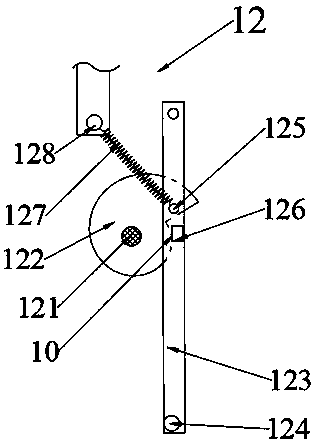

Improved textile waterproof performance detection device and detection method

PendingCN109827887ARealize automatic operationEasy to shake offPermeability/surface area analysisSpray nozzleEngineering

The invention discloses an improved textile waterproof performance detection device. The device comprises a box body and a holder positioning substrate; a funnel is arranged in the through hole of thetop surface of the box body; the bottom end of the funnel is connected with a nozzle; a rotating shaft is disposed between the opposite side walls of the box body; the rotating shaft is fixedly provided with a base; a rotation driving component, a rotation support plate, an elastic connecting component and the holder positioning substrate are sequentially stacked on the surface of the base; a rotating shaft driving component is arranged between the box body and the rotating shaft; and the side surface of the rotating shaft is provided with a positioning substrate striking mechanism. The improved textile waterproof performance detection device is provided with the rotating shaft and the positioning substrate striking mechanism; the holder positioning substrate on the rotating shaft is usedfor positioning a fabric holder; the positioning substrate striking mechanism is used for striking the holder positioning substrate; the elastic connecting component can enhance the vibration of thestruck holder positioning substrate so as to shake off test water retained on the surface of the fabric. The invention also discloses a detection device-based textile waterproof performance detectionmethod.

Owner:江苏创标检测技术服务有限公司

Desulfurization and denitrification integrated flue gas purification device

InactiveCN112452146AImprove purification effectImprove timelinessGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention relates to the technical field of flue gas purification devices, and discloses a desulfurization and denitrification integrated flue gas purification device, which comprises a fixed seat, the left side of the upper surface of the fixed seat is fixedly connected with a denitrification cylinder, the middle part of the inner cavity of the denitrification cylinder is fixedly connected with an ammonia gas release device, and the ammonia gas release device comprises a stabilizing frame. According to the desulfurization and denitrification integrated flue gas purification device, flue gas blows the hollow ball to drive the hollow ball to move rightwards, the elastic contraction part is in an extrusion state at the moment, and then the hollow ball is driven to swing leftwards and rightwards, so that the anode plate is knocked; dust collected by the anode plates and dust adhering to the hollow balls can be conveniently shaken off into the dust collecting hopper, the anode plates can be conveniently cleaned, part of wind power in flue gas is effectively converted into kinetic energy for cleaning the electrostatic dust collection device, energy is effectively utilized, and the timeliness of cleaning the electrostatic dust collection device by the desulfurization and denitrification integrated flue gas purification device is improved.

Owner:马鞍山市方正机械制造有限责任公司

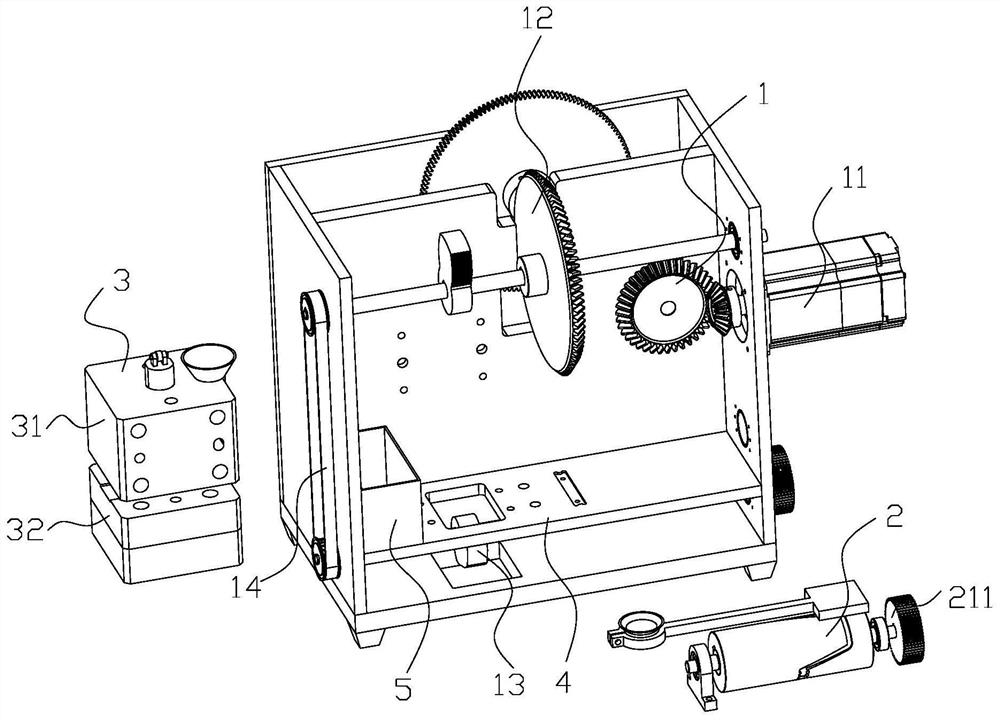

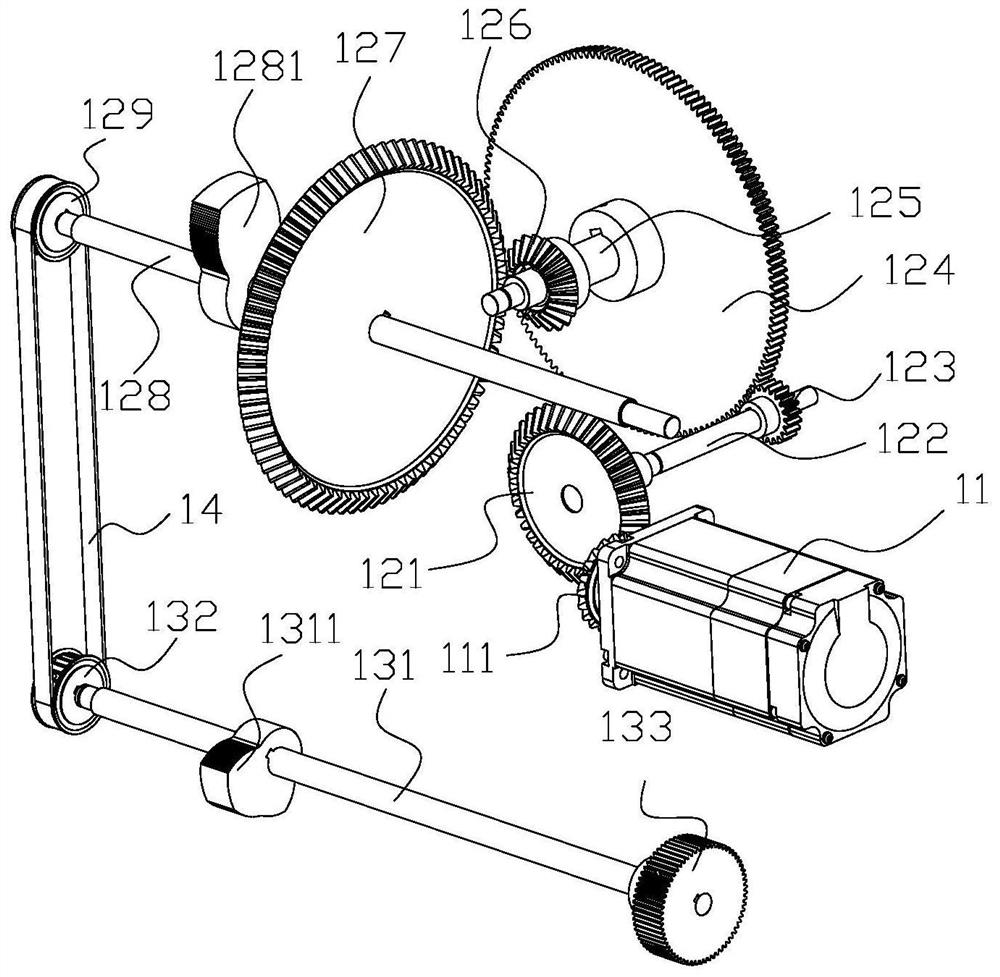

Traditional Chinese medicine tablet stamping mechanism and method

InactiveCN112238644AConsistent rotation speedGuaranteed uniformityPharmaceutical product form changePress ramElectric machineryDrive motor

The invention belongs to the technical field of traditional Chinese medicine pharmaceutical production, and relates to a traditional Chinese medicine tablet stamping mechanism and method. The mechanism comprises a driving device and a stamping device; the driving device comprises a driving motor, an upper driving module and a lower driving module; the driving motor is connected with the upper driving module and used for driving the upper driving module to rotate, and the upper driving module and the lower driving module are connected through a conveying belt; the stamping device comprises a downward pressing module at the upper part and a jacking module at the lower part; and the upper driving module is matched with the downward pressing module, and the lower driving module is matched withthe jacking module, so that traditional Chinese medicine tablets are stamped and formed by pressing the downward pressing module and the jacking module towards the middle. The mechanism has the advantages that the traditional Chinese medicine tablets are directly stamped and formed through cooperation of downward pressing and jacking, and the stamping quality of the stamped traditional Chinese medicine tablets is improved.

Owner:魏乃淳

Toaster liner rust removal device

InactiveCN107662150AEasy to separateEasy to closeDirt cleaningGrinding machinesCoil springEngineering

The invention aims at solving the problem that rust removal is uneasy to conduct by existing toaster liner rust removal devices, and discloses a toaster liner rust removal device. The device includesa sleeve, a second spiral spring, a rotating shaft, a stirring pipe, a conduit, a first spiral spring and an irony sheet; the conduit is fixedly installed at the top end of the right surface of the sleeve, a handle is fixedly installed at the upper side of the surface of the sleeve, a stop block is fixedly connected to the lower side of the second spiral spring, a chassis is fixedly installed at the lower end of the rotating shaft, through holes are evenly formed in the surface of the stirring pipe, a motor is installed at the upper side of the rotating shaft, a spiral coil is fixedly installed on the surface of the conduit, a guide rod is sleeved with the first spiral spring, and a pushing plate is fixedly installed at the outer side of the irony sheet. By powering on or powering off thespiral coil, the irony sheet can be separated from the spiral coil or connected with the spiral coil conveniently, the pushing plate can be pushed to move back and forth conveniently, and therefore the pushing plate can push a toaster liner so that rust impurities of the toaster liner can be shaken off conveniently.

Owner:梁健飞

Production process of medical nanofiber with sterilization and waterproof functions

PendingCN111364124AHigh fatality rateMeet medical standardsConjugated synthetic polymer artificial filamentsArtifical filament manufactureFiberMaterials science

The invention discloses a medical nanofiber with sterilization and waterproof functions. The medical nanofiber comprises the following components of, in parts by weight, 60-70 parts of chitosan, 25-30parts of polylactic acid, 20-25 parts of titanium dioxide, 10-15 parts of nano-silver, 30-40 parts of sterilization liquid, 10-14 parts of formic acid, 10-12 parts of distilled water and 2-5 parts ofsilane coupling agent. According to a production process of the medical nanofiber with the sterilization and waterproof functions, bacteria attached to a nanofiber woven product are killed by using traditional Chinese medicines, so that the medical nanofiber is harmless to a human body and meets the medical standard, meanwhile, the woven product is formed by weaving nanofibers, water cannot be attached and can be easily shaken off, and the fatality rate of escherichia coli, staphylococcus aureus, candida albicans and salmonella attached to the woven surface is high.

Owner:河北康鹤居安科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com