Electrostatic dust removal capsule polishing and drying device and using method

A technology of electrostatic dust removal and drying device, which is used in grinding/polishing safety devices, capsule conveying, grinding/polishing equipment, etc., to achieve the effect of low residual rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

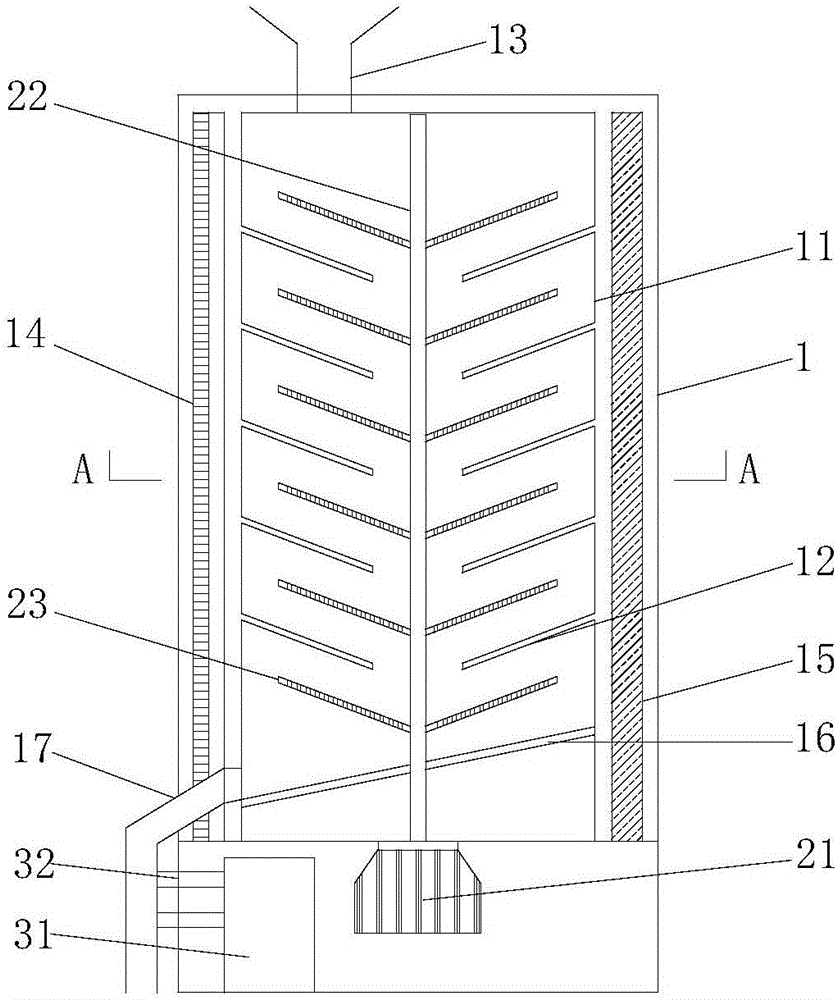

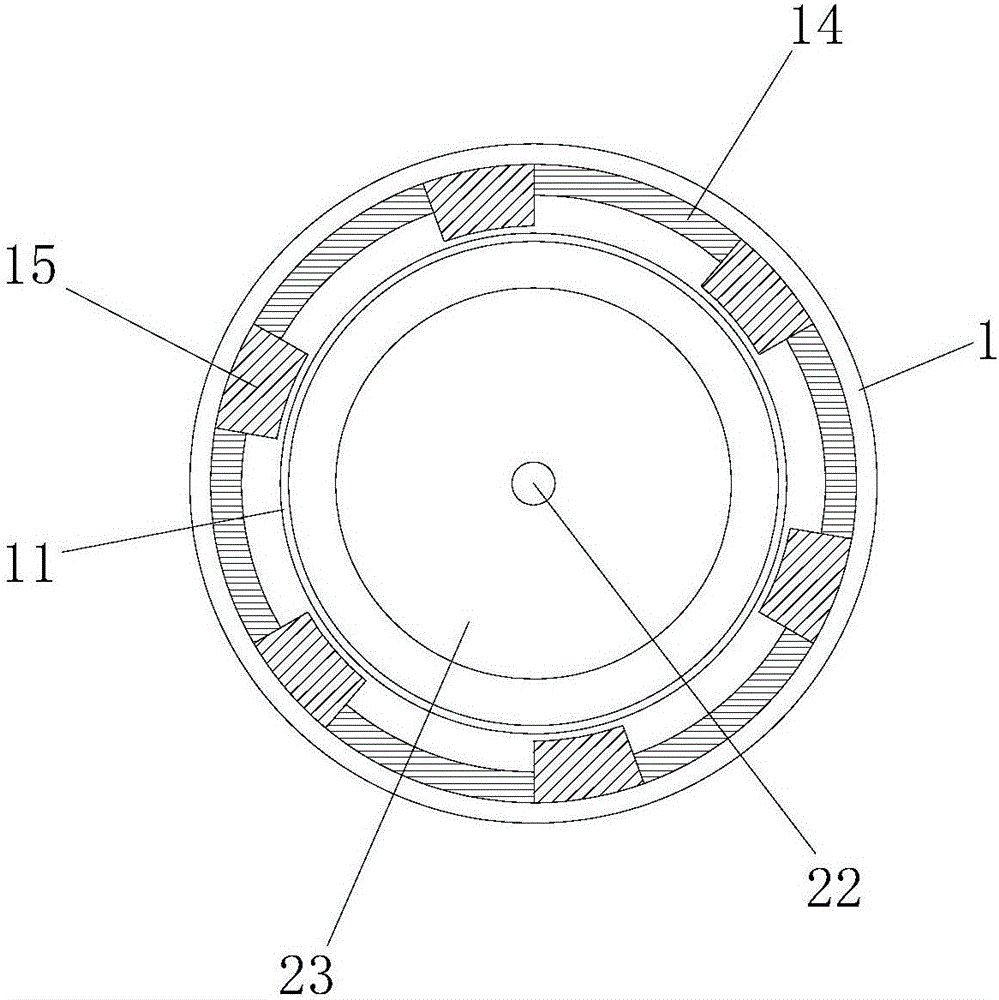

[0030] combined with figure 1 And attached figure 2 As shown, the electrostatic dust removal capsule polishing and drying device in this embodiment includes a polishing cylinder 1, a polishing device and a dust removal and drying device. The elastic steel wire mesh 11 arranged in a ring is arranged in the described polishing cylinder 1, and the elastic steel wire mesh 11 It is coaxial with the polishing cylinder 1, and its upper and lower ends are respectively welded to the top and bottom surfaces of the polishing cylinder. The surface of the elastic steel mesh 11 is provided with numerous through holes with different apertures. The inner side of the wire mesh 11 is provided with an annular baffle 12 inclined downward from the outside to the inside, the inclination angle of the baffle is 25°, and the distance between the baffle and the center of the polishing cylinder is 30 mm, so that the capsule can pass through the baffle and the axis of the polishing cylinder The gap bet...

Embodiment 2

[0054] The electrostatic dust removal capsule polishing and drying device in the present embodiment includes a polishing cylinder 1, a polishing device and a dust removal and drying device. The elastic steel wire mesh 11 arranged in a ring is arranged in the described polishing cylinder 1, and the elastic steel wire mesh 11 is connected with the polishing cylinder. 1 is coaxial, its upper and lower ends are respectively welded to the top and bottom of the polishing cylinder, the surface of the elastic steel mesh 11 is provided with countless through holes with different apertures, the distance between the elastic steel mesh 11 and the inner wall of the polishing cylinder is 500mm, and the elastic steel mesh 11 There are 5 layers of annular baffles 12 inclined downwards from the outside to the inside at the inner interval of the baffle. The inclination angles of the baffles are 25°, 27°, 29°, 31° and 33° respectively. 30mm, to ensure that the capsule can pass through the gap bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com