Patents

Literature

191results about How to "Easy to fall off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

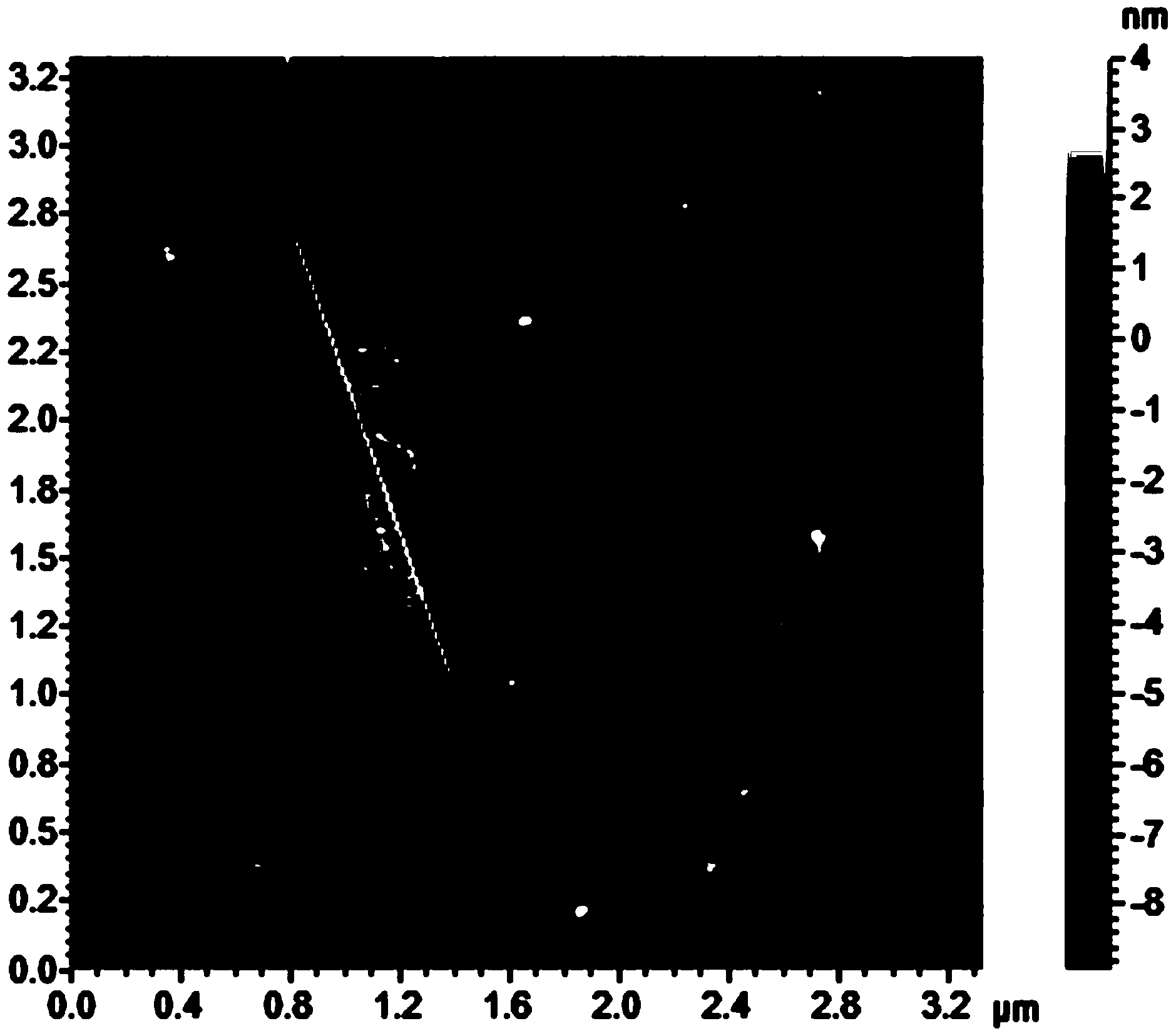

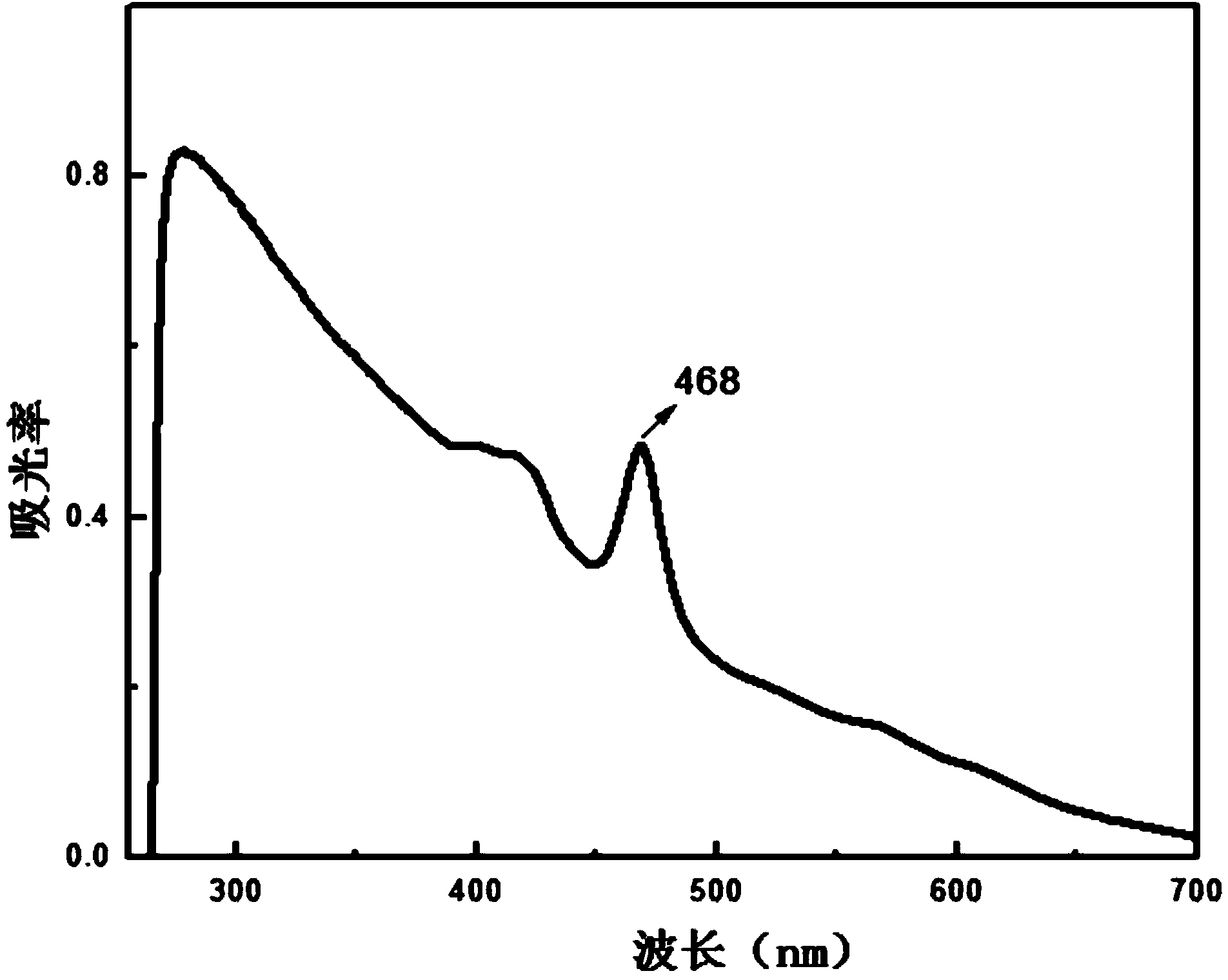

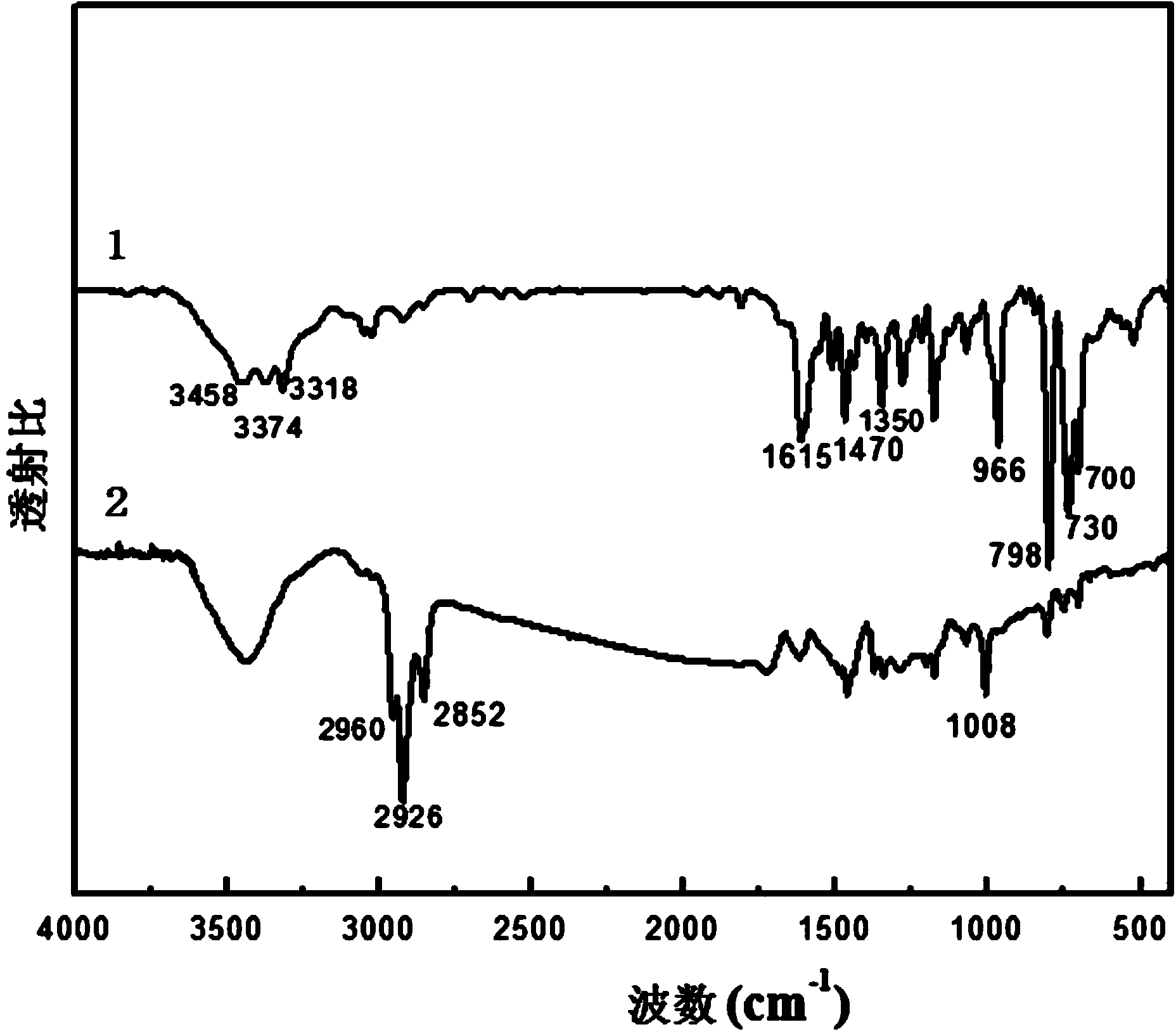

Manufacturing method of graphene-porphyrin modified electrode and application of electrode

InactiveCN103852505ASensitive detectionStable detectionMaterial electrochemical variablesManganese porphyrinCoordination complex

The invention relates to a manufacturing method of a graphene-porphyrin modified electrode and application of the electrode, aiming to solve the problems of complex operation, long time and relatively high price in the conventional method for detecting the content of ascorbic acid in a living body. The method comprises the following steps: I, preparing pre-oxidized graphene; II, preparing a graphene oxide solid; III, preparing acyl-chlorinated graphene; IV, preparing tetraphenylporphyrin; V, preparing 5-(4-nitro)-10,15,20-triphenyl porphyrin; VI, preparing 5-(4-amino)phenyl-10,15-20-triphenyl porphyrin; VII, preparing a pure manganese porphyrin coordination compound; VIII, preparing a functional composite material of graphene oxide and porphyrin; IX, modifying a glassy carbon electrode. The modified electrode has excellent interference resistance, stability and reproducibility, and can be taken as a biosensor for detecting ascorbic acid in practical samples.

Owner:HARBIN INST OF TECH

Modified polyester fiber and preparation process thereof

InactiveCN103898628ACompatibility is reasonableUnique preparation methodMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterTitanium dioxide

The invention belongs to the technical field of chemical fiber products, and discloses a modified polyester fiber which is prepared by PET slices, glyceryl monostearate, hydroxyethyl cellulose, Chinese medical extract, chitosan and titanium dioxide powder. The invention also provides a preparation process of the modified polyester fiber. The preparation process mainly comprises the following steps of 1) preparing the Chinese medical extract, 2) preparing a modifier and 3) preparing the modified polyester fiber. The modified polyester fiber is unique in preparation process and reasonable in compatibility of materials; at the same time, the physicochemical properties of the materials do not change, so that the market requirements can be satisfied.

Owner:LINYI YUCHENG TEXTILE

Film-coating fresh-keeping fruit wax for fruits and vegetables and preparation method thereof

InactiveCN101642159AEasy to fall offFast dryingFruits/vegetable preservation by coatingRevolutions per minuteWax

The invention relates to a method for preparing a film-coating fresh-keeping fruit wax for fruits and vegetables, which mixes red lac, morpholine, propanediol and ammonia according to weight ratio, and comprises the following steps: emulsifying the mixture for 20 to 40 minutes at an emulsifying temperature of between 113 and 117 DEG C, and stirring the mixture at a speed of between 750 and 1,050 revolutions per minute; when the temperature of the solution is reduced to 60 DEG C, adding natamycin, sec-butylamine and thiabendazole L according to the following proportions; and after dispersing the mixture, reducing the temperature to 30 DEG C, taking the mixture out, and performing high-pressure homogenization on the mixture to obtain the film-coating fresh-keeping fruit wax for fruits and vegetables. The fresh-keeping fruit wax is a dark brown semi-transparent water-soluble emulsion, cannot be hardened after coating, is easy to fall off, has a quick drying speed and moderate viscosity, can perform fruit waxing through a full automatic wax-polishing machine, is bright in color and beautiful, and has lasting brightness. The concentration of the natamycin used by the fresh-keeping fruitwax has only 10<-6> order of magnitude and is in accordance with the standard of the maximum residual quantity in food stated by the national 'use sanitation standard of food additives'; therefore, the film-coating fresh-keeping fruit wax for fruits and vegetables is a safe and environment-friendly fresh-keeping material.

Owner:天津市赛奥农产品保鲜科技有限公司 +1

Cerium basis composite oxides doped precious metal integer catalyzer and method of manufacturing the same

InactiveCN101108345AOvercoming easy fall offSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsComposite oxideOxide

The invention is a ceric pyridyl compound oxide mixing with precious metal whole catalyst used for organic waste gas catalyzing burning purifying process and the preparation method, which aims to the defects of existing Pt / Ce0.68Zr0.32O2 whole catalyst preparation method with complicate preparation technique and chap on coating under high temperature, to provide a ceric pyridyl compound oxide mixing with precious metal whole catalyst with high catalyzing activity, heat stability and integration intensity and the preparation method. The catalyst comprises honeycomb ceramics carrier, addition agent and active component, wherein, the honeycomb ceramics carrier is cordierite honeycomb ceramics, the addition agent is ceric pyridyl compound oxide with the chemical formula CexM1-xO Delta, the active component is one or two of precious metal Pd and Pt. The preparation method comprises preparing soakage solution and the coating of the soakage solution on the honeycomb ceramics carrier two procedures.

Owner:ZHEJIANG NORMAL UNIVERSITY

Nanometer reinforced, non-transition-layer, organosilicone and low-surface-energy type antifouling paint and preparation method thereof

ActiveCN104231919AEasy to buyEasy to synthesizeAntifouling/underwater paintsPaints with biocidesMaricultureSlurry

The invention discloses a novel nanometer reinforced, non-transition-layer, organosilicone and low-surface-energy type antifouling paint which can be directly coated to a base material and an epoxy primer without an intermediate transition layer. The antifouling paint comprises the following components in parts by weight: 10 to 20 parts of A, 2 to 10 parts of B, and 0.1 to 2 parts of C, wherein the component A comprises the following materials in parts by weight: 25.0 to 50.0 parts of nanometer pre-dispersed slurry, and 0.5 to 5.0 parts of silicone oil; the component B comprises the following materials in parts by weight: 3.0 to 50.0 parts of crosslinking curing agent, and 1.0 to 10.0 parts of silane coupling agent; the component C comprises the following materials in parts by weight: 0.1 to 3.0 parts of catalyst. The coating has the advantages of being high in intensity, high in attaching force, easy to be constructed, and high in recoatability, and can be applied to various ships, offshore oil platforms, ocean structures and facilities, and mariculture nets and the like.

Owner:DALIAN MARITIME UNIVERSITY

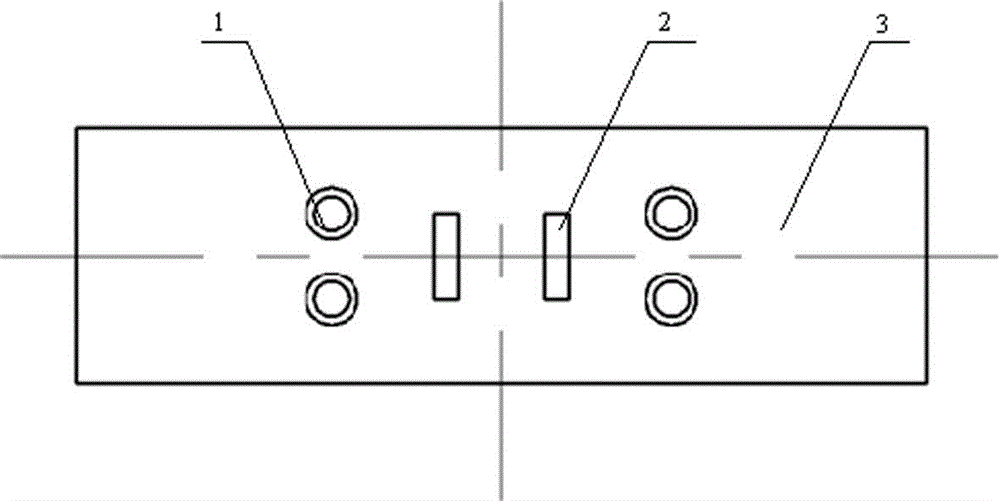

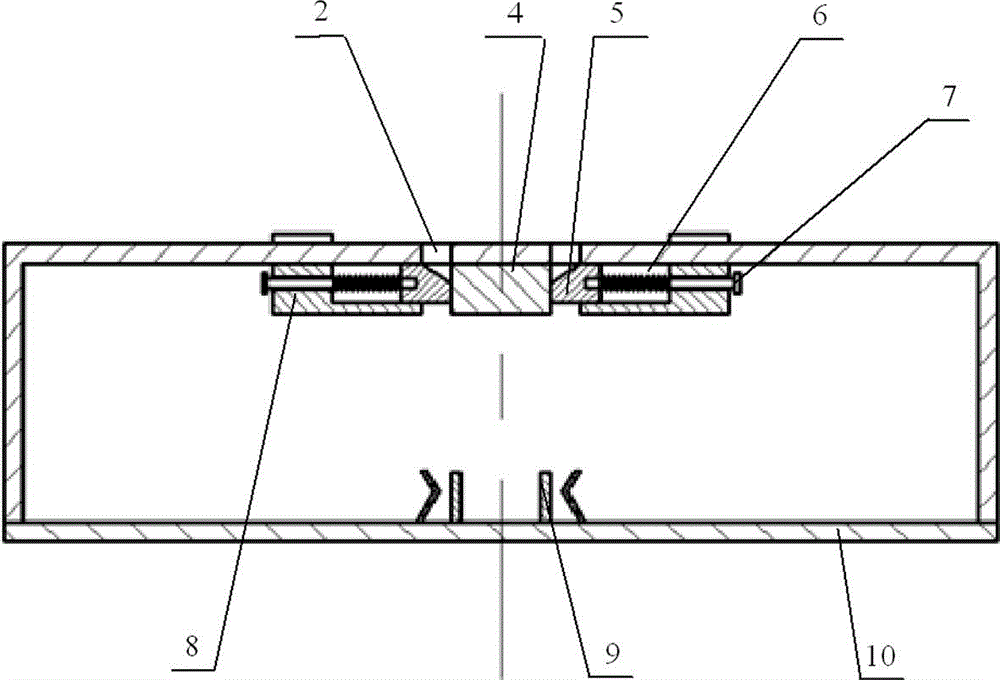

Novel safety protection power strip

A novel safety protection power strip comprises a power strip shell (3). The lower part of the power strip shell (3) is connected in a buckling mode with a bottom plate (10). The outer wall of the power strip shell (3) is provided with a jack (2). A limiting block (4) is fixed to the inner wall of the power strip shell (3). Connection supporting blocks (8) are fixed to the power strip shell (3) through screws (1). The connection supporting blocks (8) are connected with a sliding block (5) through sliding rods (7). A compression spring (6) is sheathed on each sliding rod (7). Binding posts (9) are arranged on the inner wall of the bottom plate (10). The novel safety protection power strip has the advantages that improvement is made on the basis of the existing power strip structure, and a safety protection device is added; when the power strip is not in use, electric shock can be effectively prevented; when the power strip is in use, potential security problems, for example, a plug is easy to fall off, can be effectively avoided; and the slope design of the sliding block enables a plug to be easily plugged into the jack, and the power strip has good usability.

Owner:WUHAN SHUTAI TECH

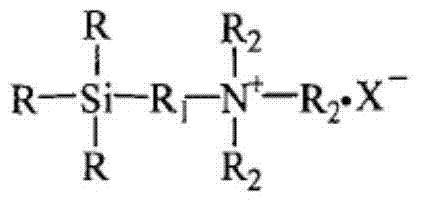

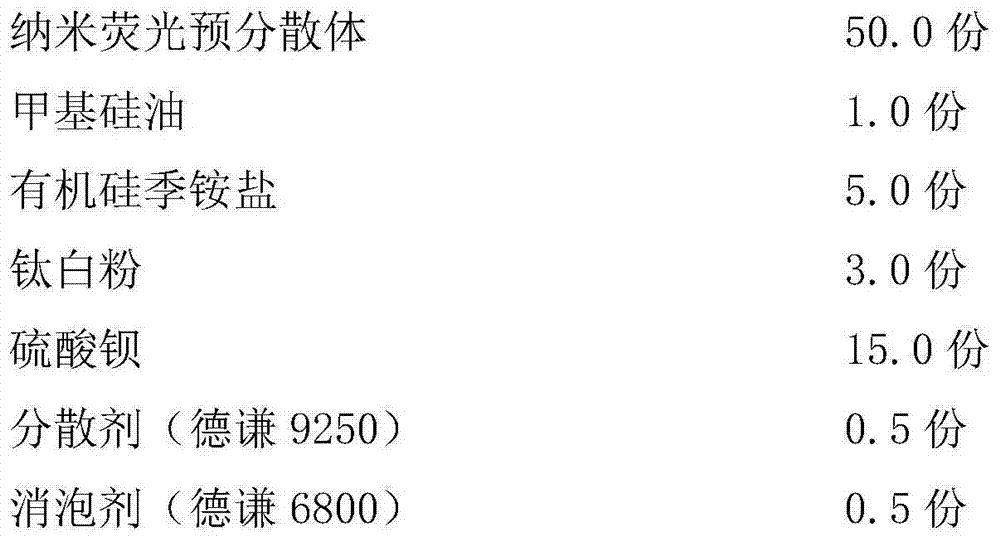

Nano-antibacterial low-surface energy organosilicon luminescence anti-fouling paint and preparation method thereof

ActiveCN104327721AEasy to buyEasy to synthesizeAntifouling/underwater paintsLuminescent paintsMarine aquacultureFluorescence

The invention discloses a nano-antibacterial low-surface energy organosilicon luminescence anti-fouling paint, which comprises the following components by weight: 25-35 parts of component A, 2-5 parts of component B and 1 part of component C; the component A comprises 25.0-50.0 parts of nano fluorescence pre-dispersion, 5-25.0 parts of organosilicon quaternary ammonium salt and 0.5-5.0 parts of silicone oil; the component B comprises 3.0-50.0 parts of crosslinking curing agent and 1.0-10.0 parts of silane coupling agent; The component C comprises 0.1-3.0 parts of catalyst; and the catalyst is at least one of stannous octoate, dibutyl tin diacetate and dibutyltin dilaurate. The paint has long persistence luminescent performance, has can prevent pollution by depending on fluorescence and enables contact sterilization, and has advantages of excellent antifouling performance, high strength and high adhesive force, can be used for various ships, sea petroleum platforms, marine structure and facility, marine aquaculture nets.

Owner:DALIAN MARITIME UNIVERSITY

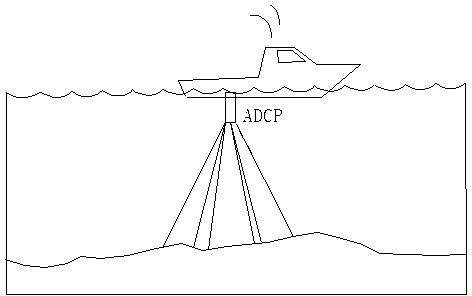

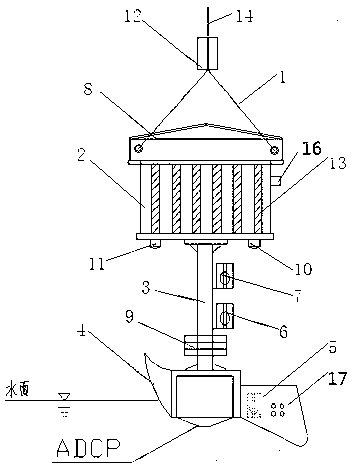

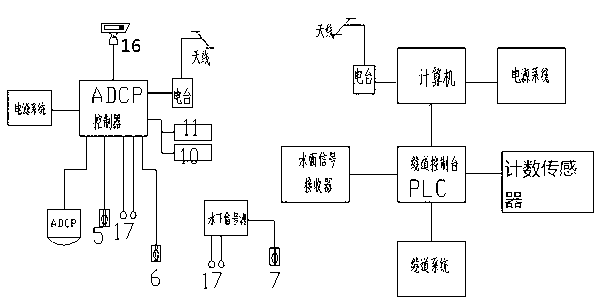

Hydrometric station cableway type flow velocity automatic measurement device

ActiveCN103197093ASolve the problem of on-site controlSolving the challenge of winding test equipmentFluid speed measurementElectricityMeasurement device

The invention discloses a hydrometric station cableway type flow velocity automatic measurement device. The hydrometric station cableway type flow velocity automatic measurement device comprises a plurality of fixing cables, wherein top ends of the fixing cables are hung on a cableway system, and an instrument container with an acoustic doppler current profiler (ADCP) controller arranged inside is connected with lower ends of the fixing cables. A flow guiding structure is fixed below the instrument container through a connecting rod, and an ADCP which is electrically connected with the ADCP controller is fixed at the bottom end of the flow guiding structure. The ADCP controller communicates with a control system installed in a control chamber of a hydrometric station, and a motor of the cableway system is controlled by the control system. The hydrometric station cableway type flow velocity automatic measurement device is high in reliability, the problem that an existing device needs to be operated by a test worker on the spot is solved, and the aim of being guarded by nobody is achieved.

Owner:POWERCHINA ZHONGNAN ENG

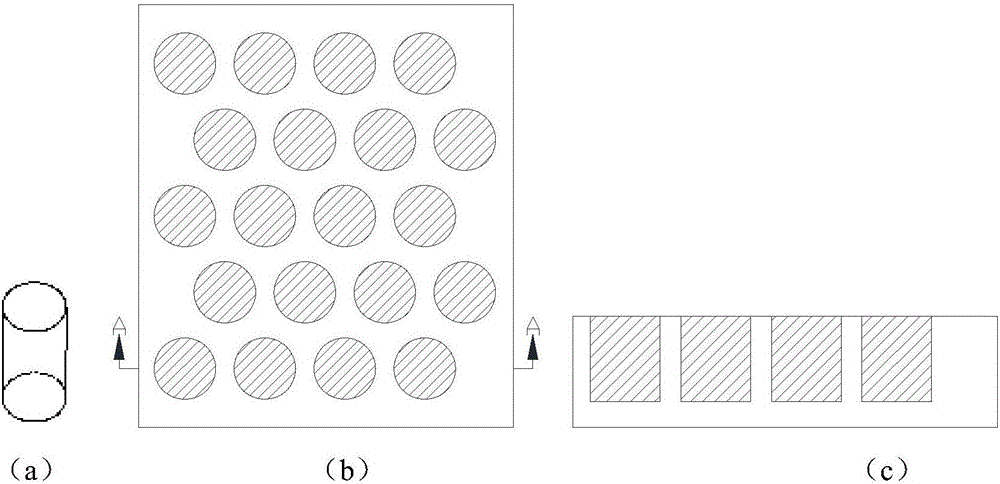

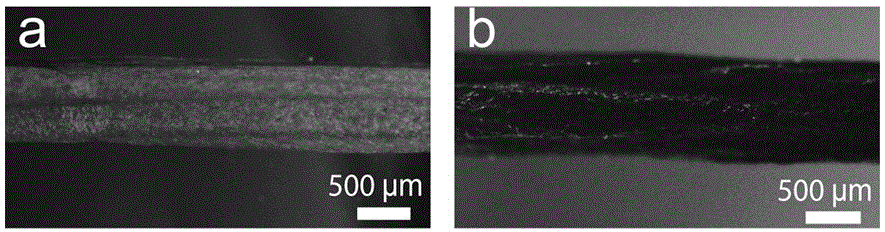

Flexible cell based on metallic oxide/graphene composite macroscopic fibers and preparation method

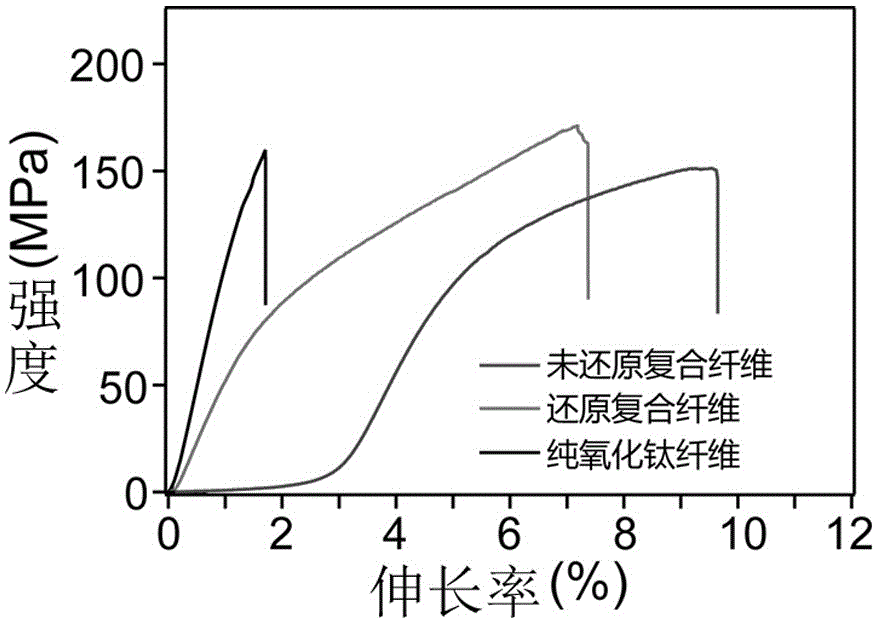

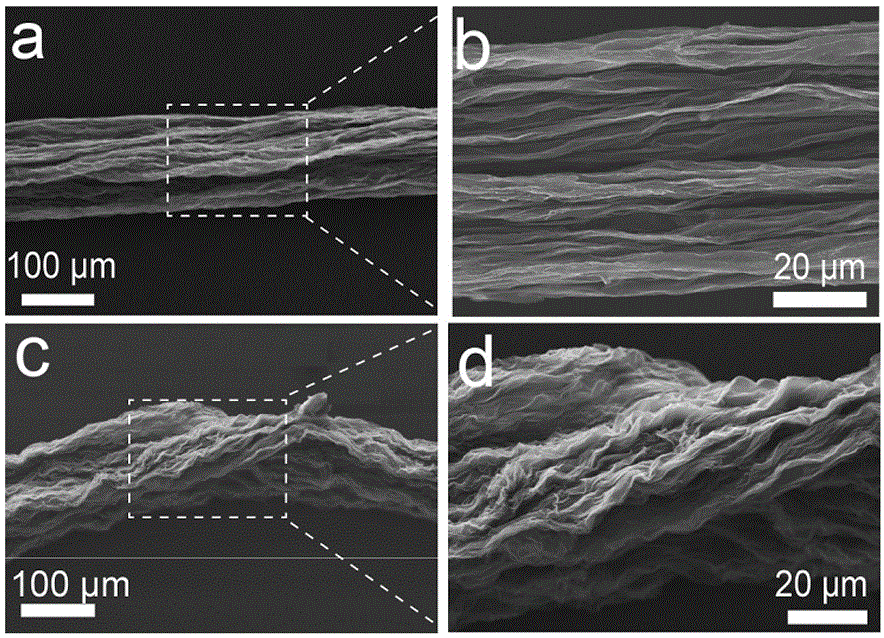

ActiveCN107180947AGood mechanical propertiesExcellent electrochemical performanceFinal product manufactureCell electrodesCvd grapheneHydroiodic acid

The invention relates to a flexible cell based on metallic oxide / graphene composite macroscopic fibers and a preparation method. The preparation method comprises the following steps: after mixing an anionic metal oxide aqueous solution with graphene oxide to obtain a spinning solution, adding the spinning solution in wet spinning equipment to obtain nascent fibers; repeatedly washing the obtained nascent fibers with deionized water, and drying the nascent fibers to obtain metallic oxide and graphene oxide composite fibers; reducing the metallic oxide and graphene oxide composite fibers with hydroiodic acid, and then washing and drying the metallic oxide and graphene oxide composite fibers to obtain the metallic oxide and graphene composite fibers; placing the composite fibers, lithium lines and lithium manganate loaded carbon cloth fibers in a shrinkable tube in parallel; and adding diaphragms and electrolyte so that half cells and total cells can be assembled respectively. The preparation process is simple and controllable, and large-scale production is facilitated. The metallic oxide and graphene composite fibers which are prepared by the preparation method for the first time have unlimited prospects in the field of energy storage of flexible cells.

Owner:SUZHOU UNIV

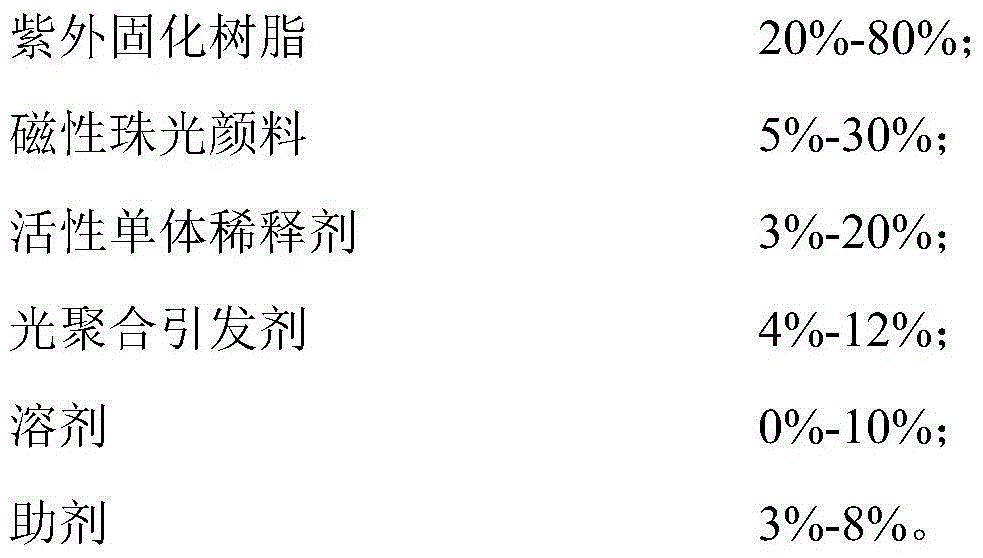

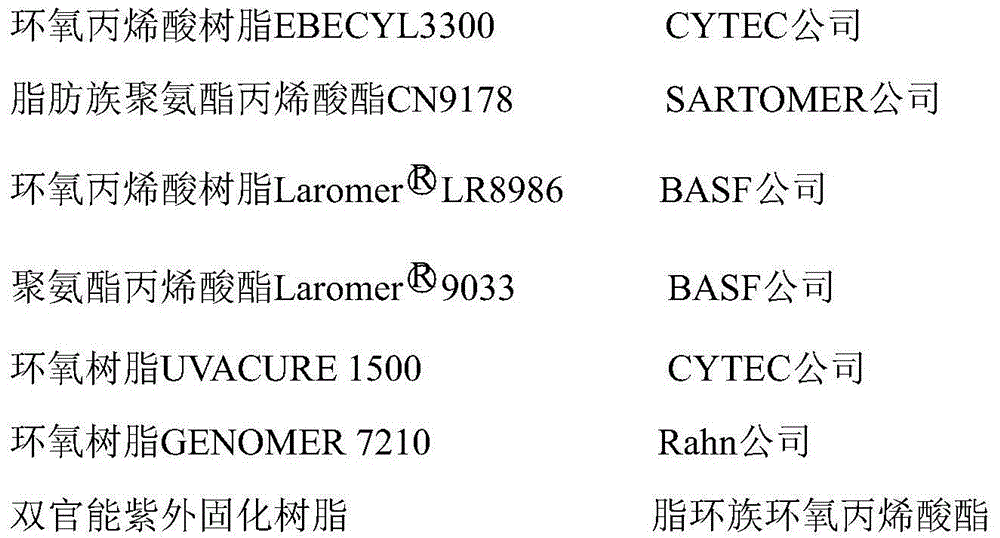

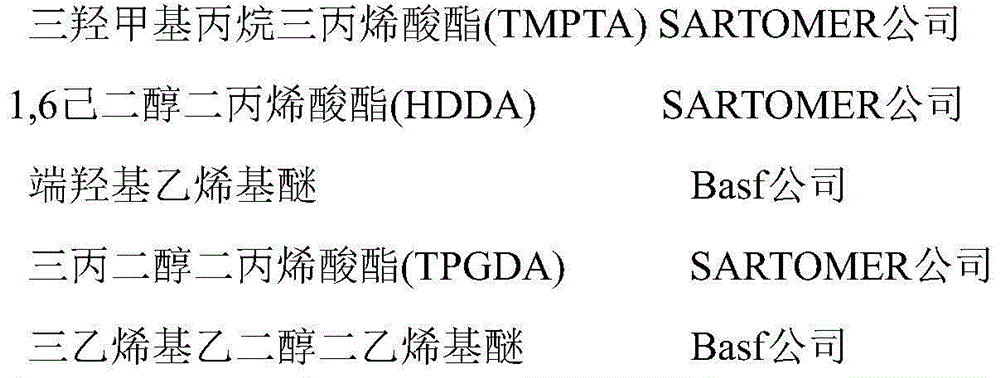

Cationic-radical UV (Ultraviolet)-cured magnetic pearly-luster silk screen ink and preparation method thereof

The invention discloses a cationic-radical UV (Ultraviolet)-cured pearly-luster silk screen ink and a preparation method thereof. The ink is prepared from the following components in percentage by weight: 20 to 80% of UV-cured resin, 5 to 30% of magnetic pearly-luster pigment, 3 to 20% of active monomer diluents, 4 to 12% of photoplymerization, 0 to 10% of solvent, and 3 to 8% of additive. The cationic-radical UV-cured magnetic pearly-luster silk screen ink has a dynamic optical effect that pear luster changes as the change changes and is easily recognized by the public; in addition, the ink has a post-curing characteristic through which the problem of easy falling and bubbling of the surface of an ink film at the part in which sheet-shaped magnetic pigments are vertically arranged can be solved.

Owner:CHINA BANKNOTE INK +1

Electric kettle

The invention provides an electric kettle which comprises an inner container, a noise reduction layer, a heat conduction plate and a heating device; the inner container comprises a bottom plate and side enclosing plates; the bottom plate is connected with the side enclosing plates to form an accommodating cavity for accommodating liquid; the noise reduction layer is arranged on the bottom plate and is positioned in the accommodating cavity, and the upper surface of the noise reduction layer is uneven microscopically; the heat conduction plate is arranged under the bottom plate; the heating device is arranged on the heat conduction plate; when the electric kettle heats the liquid, the upper surface of the noise reduction layer is uneven to accelerate the generation and the aggregation of air bubbles. The electric kettle provided by the invention has the benefits that through the noise reduction layer, different areas on the bottom plate are uniformly heated, so that the rate when the air bubbles are separated from the noise reduction layer is reduced; meanwhile, the generation and the aggregation of the air bubbles are accelerated, so that the plurality of small air bubbles are aggregated into big air bubbles, the problem of large noise caused by implosion, namely disappearance after a large amount of single small air bubbles is changed into the big air bubbles in the rising process is solved, ,the noise generated when the electric kettle heats the liquid is reduced, and the use conform of the product is improved.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

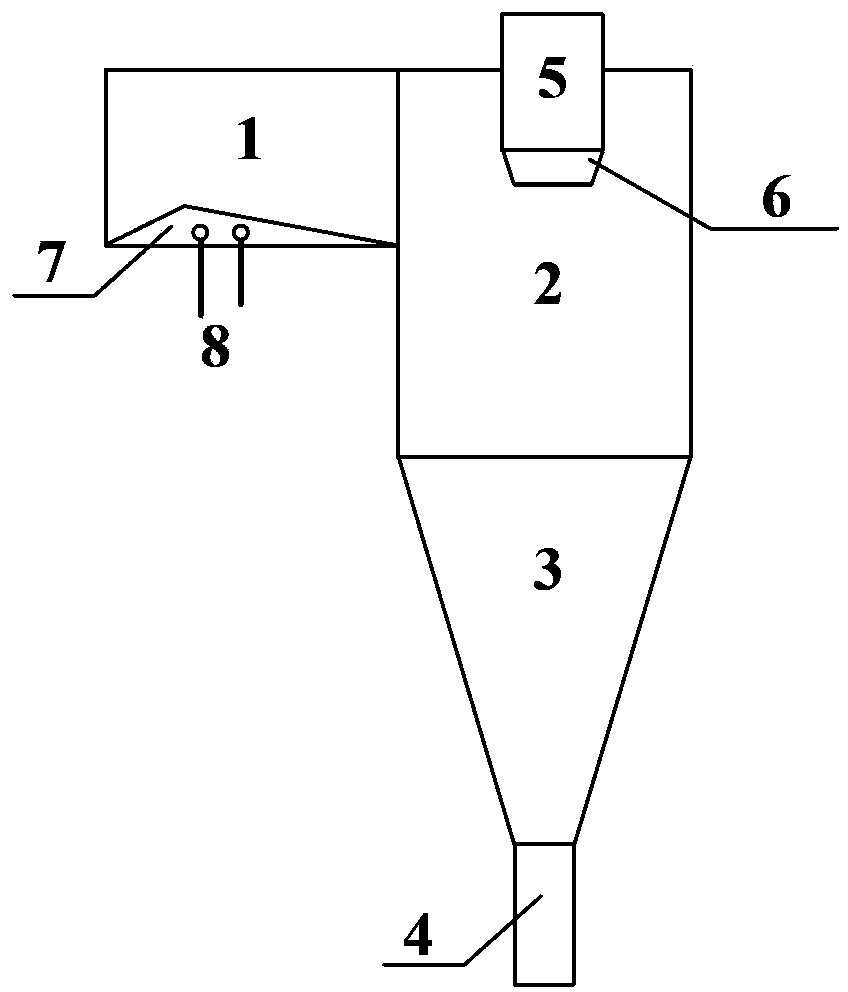

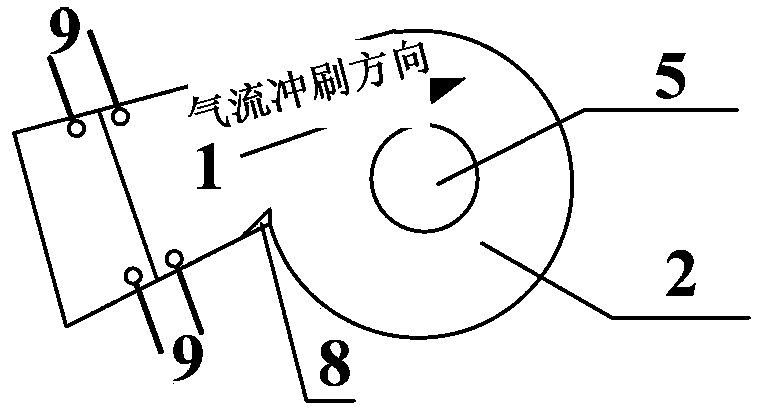

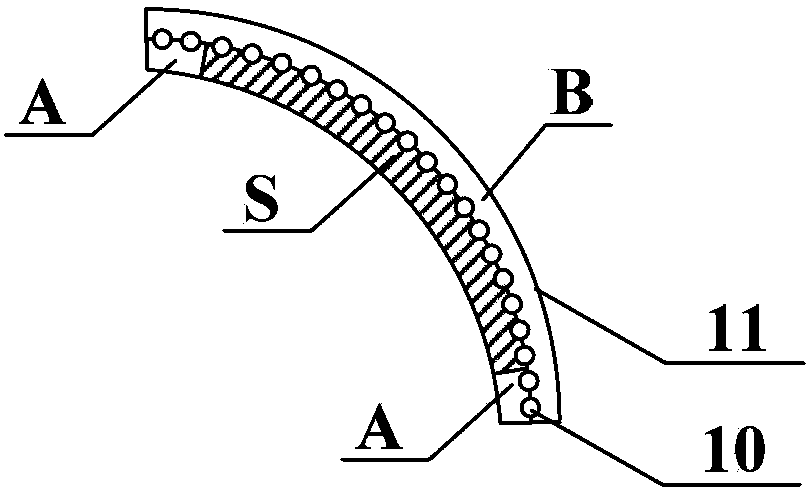

Cyclone separator with wear-resistant target section and guiding device for circulating fluidized bed boiler

ActiveCN103398375AIncreased flow velocityIncrease flow rateFluidized bed combustionApparatus for fluidised bed combustionRefractory wearCyclone

A cyclone separator with a wear-resisting target section and a guiding device for a circulating fluidized bed boiler. The cyclone separator comprises a separator inlet flue, a separator barrel body connected with an outlet of the separator inlet flue, a separator cone and a separator standpipe, which are successively connected below the separator cylinder body, and a separator central cylinder inserted into the upper part of the separator barrel body. The lower part of the separator central cylinder is provided with a central cylinder necking; the separator inlet flue is a tapered inlet flue, which is provided inside with a smoke guiding boss, and a smoke diversion part at the outlet; the smoke guiding boss and the smoke diversion part are covered with a high-strength refractory wear-resistant material layer; and one or a plurality of soot blowing mouths are arranged surrounding the smoke guiding boss. Optimization on the flow field in the cyclone separator reduces the direct impact of airflow and wear on the refractory wear-resistant material in the target section, and can improve the continuous operation cycle of the circulating fluidized bed boiler.

Owner:HUANENG CLEAN ENERGY RES INST

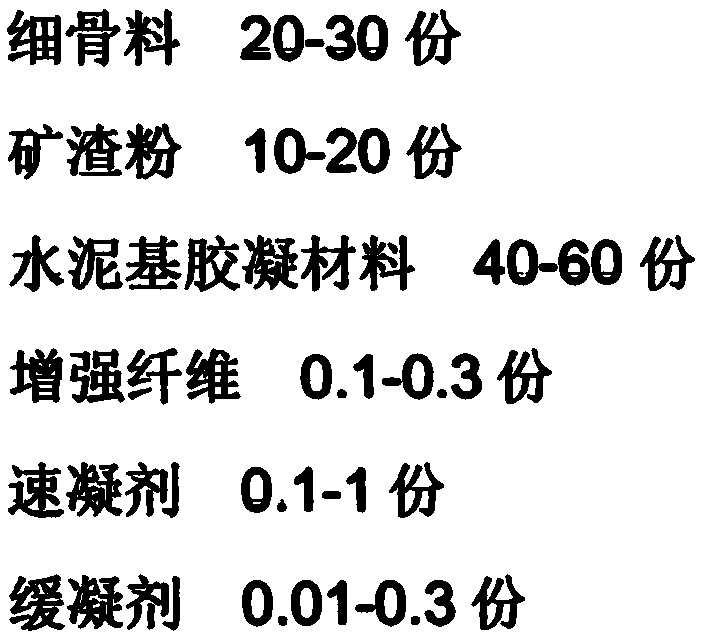

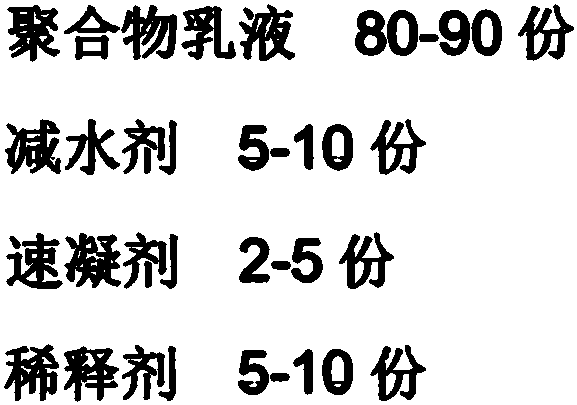

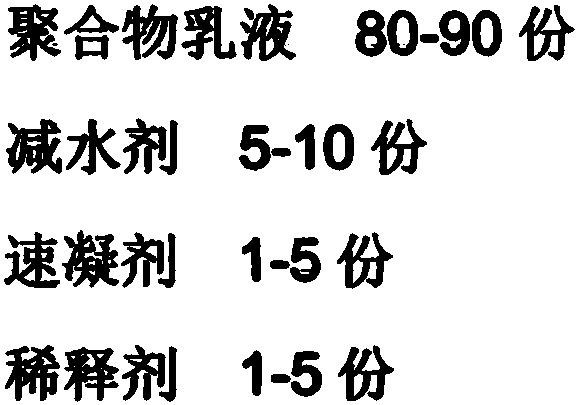

Flexible spraying material for mine laneway supporting and preparation method and application of flexible spraying material

ActiveCN111533518ANon-volatileEfficient use ofUnderground chambersTunnel liningSlagHazardous substance

The invention relates to a flexible spraying material for mine roadway support and a preparation method and application of the flexible spraying material, and belongs to the technical field of mine roadway supporting. The slag-based anchoring and shotcreting support guniting material prepared by the method is an organic-inorganic hybrid material and does not volatilize harmful substances and is safe and environment-friendly; a slag doped guniting material is adopted so that effective utilization of slag is developed, secondary pollution is relieved, and the cost is reduced; vertical face and top face spraying construction does not flow, the construction environment is friendly, and any springback and dust pollution problems are avoided; the curing temperature is low, and the flame-retardant property is realized.

Owner:赣州创可通科技有限公司

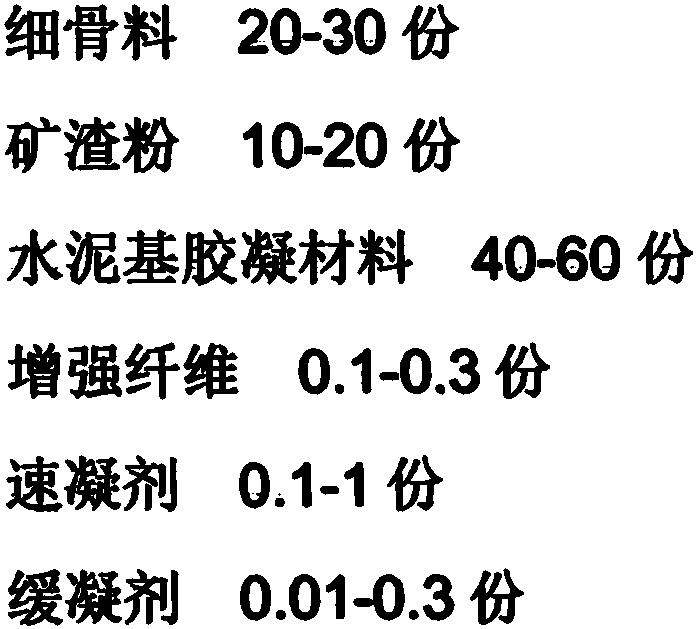

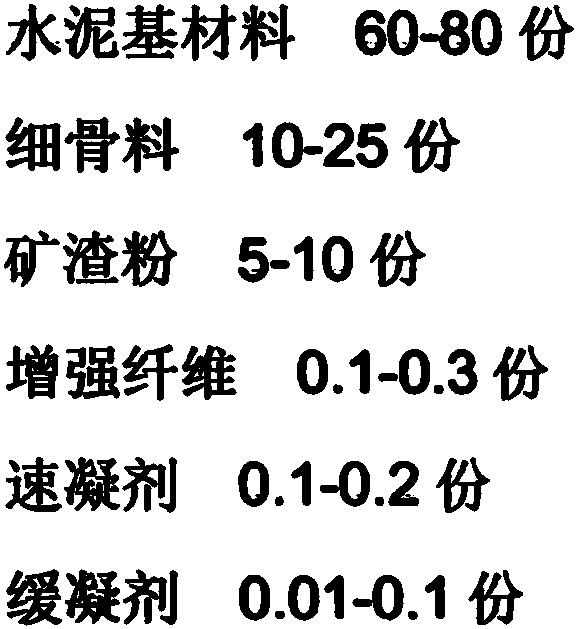

Flexible spraying material for tunnel roadway support and preparation method and application thereof

The invention relates to a flexible spraying material for tunnel roadway support and a preparation method and application thereof, and belongs to the technical field of tunnel roadway support. Vertical face and top face spraying construction does not flow, the construction speed is high, the construction environment is friendly, and any springback and environmental pollution problems are avoided;a spraying material can be subjected to long-distance spraying construction through conventional spraying equipment, the safety distance of manual operation is long, the time is short, and the construction process is safer and more reliable; and the material curing speed is high, the tensile strength and the bonding strength are increased rapidly, the problems that a guniting layer is large in thickness, prone to falling off and cracking and needing to be maintained repeatedly are solved, and the technology is particularly suitable for supporting and reinforcing, air leakage preventing and water leakage preventing treatment of key positions of tunnels or positions where surrounding rock is seriously broken.

Owner:赣州创可通科技有限公司

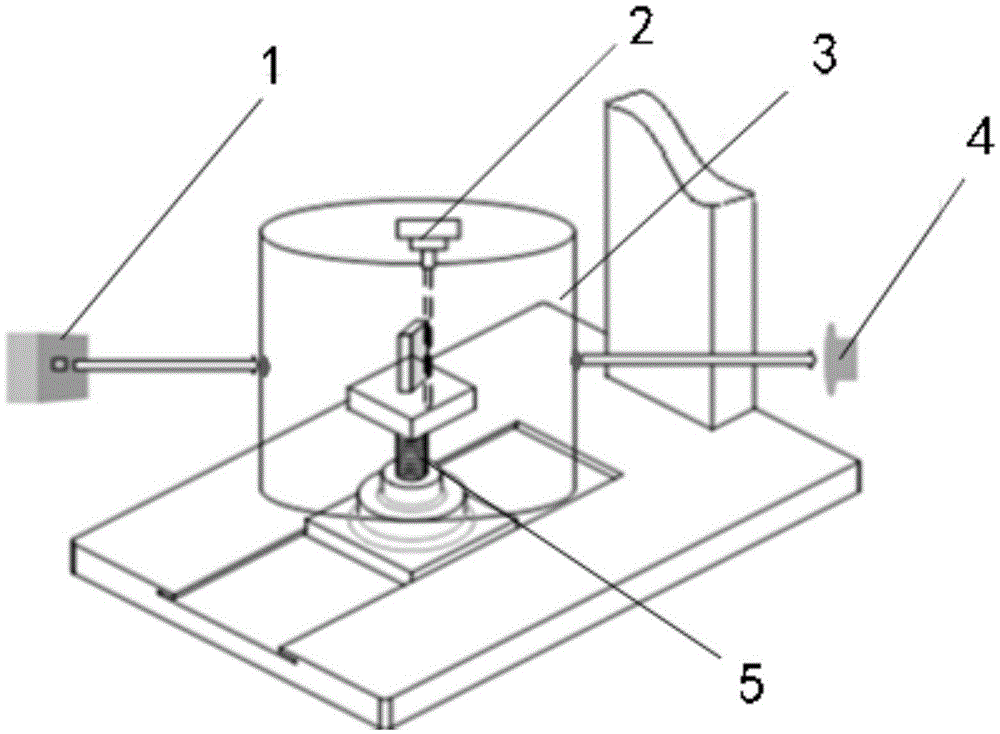

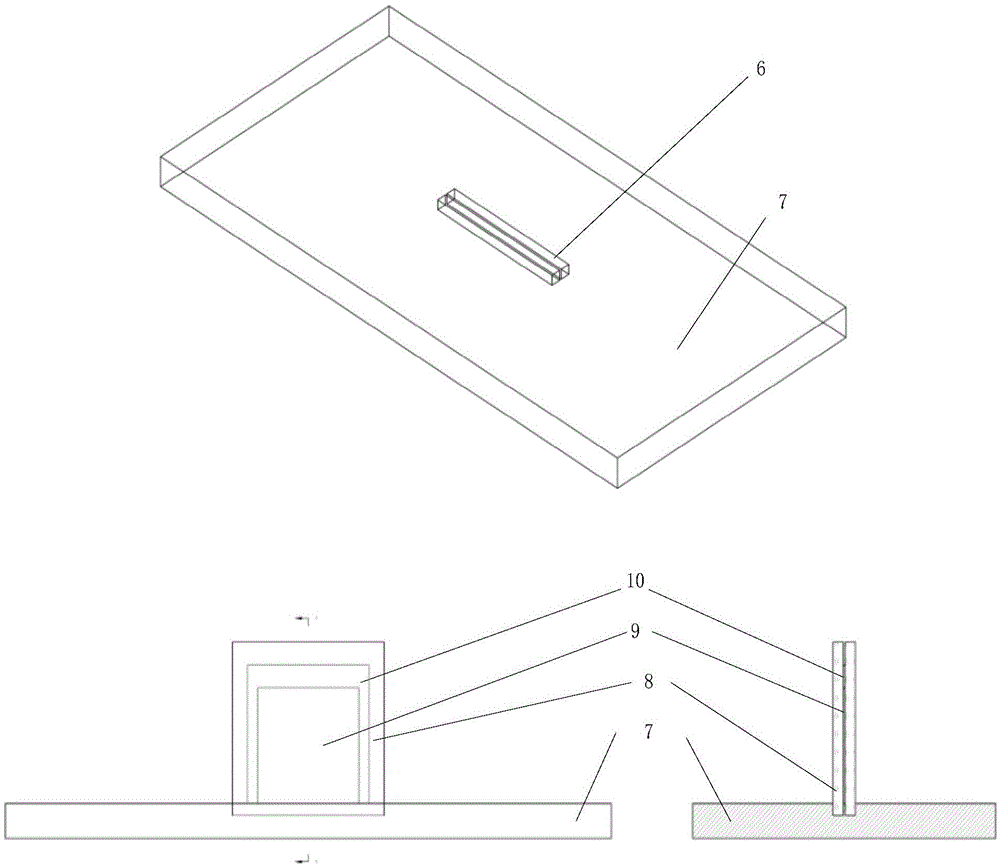

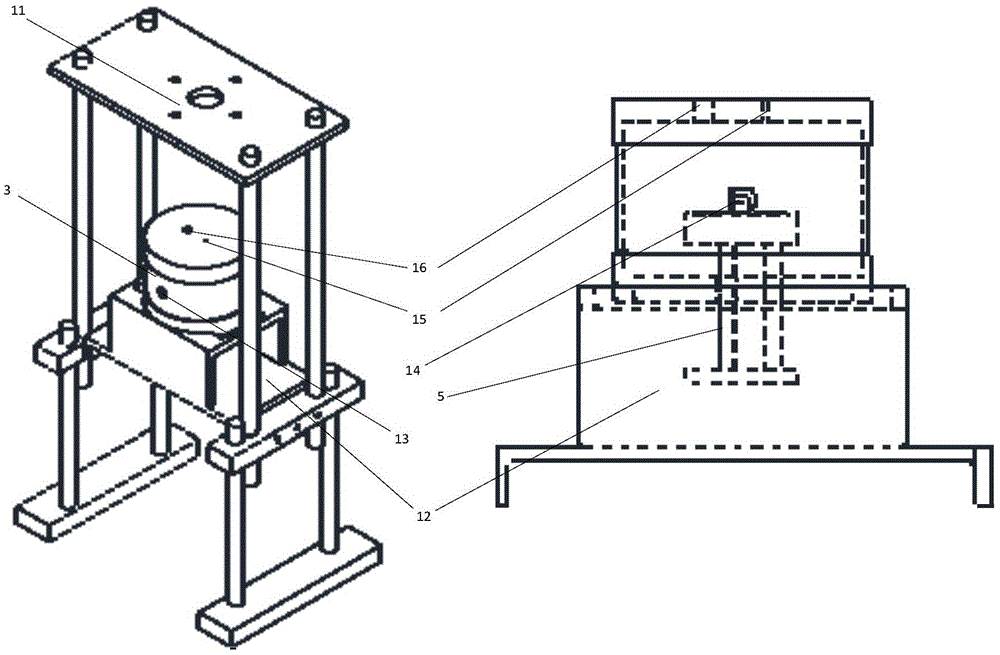

In-situ visualization method for cavitation behavior of fused brazing filler metal in solid liquid interface in ultrasonic-assisted brazing

The invention relates to an in-situ visualization method for the cavitation behavior of fused brazing filler metal in a solid liquid interface in ultrasonic-assisted brazing. The in-situ visualization method is suitable for the sizes of the brazing filler metal and base metal for synchrotron radiation imaging and the sandwiched coupled mode, and an ultrasonic field is applied through a high temperature-resistant ultrasonic vibration system capable of resisting 800 DEG C. The method comprises the steps of sample preparation; ultrasonic field application preparation; integral imaging equipment assembly; and visualization measurement of synchrotron radiation imaging of the cavitation behavior of the fused brazing filler metal. The method especially comprises the steps of ultrasonic field application in the high temperature environment, selection of the coupled mode of the sample base metal and the brazing filler metal and high temperature anti-oxidation treatment. The method is widely applied to the brazing filler metal of different temperatures and plays an important role in understanding and improving breaking oxidation films of the cavitation effect of ultrasonic-assisted brazing, promoting the moistening and spreading process of the brazing filler metal, revealing the acoustic-induced moistening physical mechanism of the brazing process of the brazing filler metal and the base metal (such as aluminum alloy and titanium alloy) and promoting industrial application of the ultrasonic-assisted brazing technology.

Owner:BEIJING UNIV OF TECH

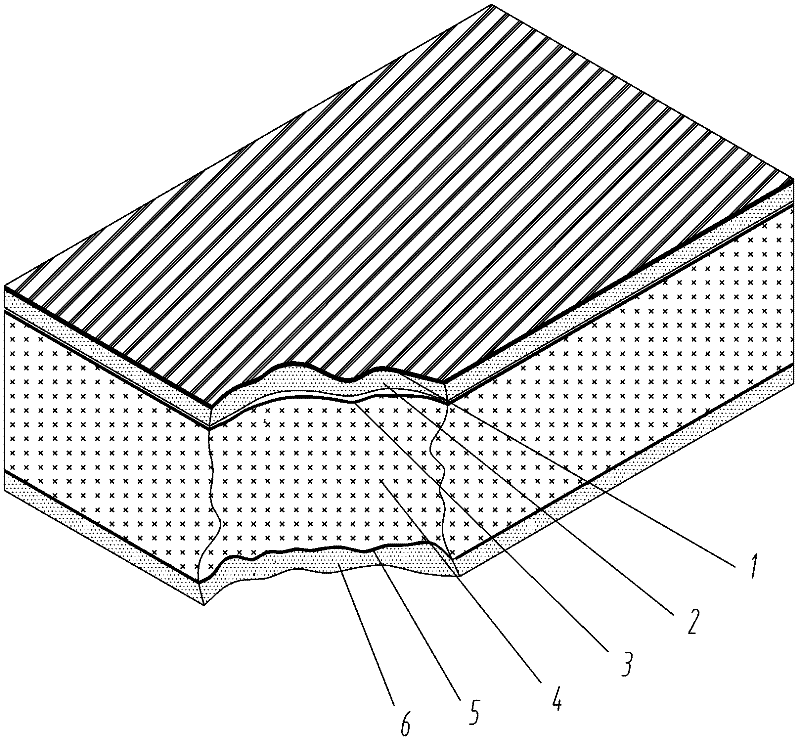

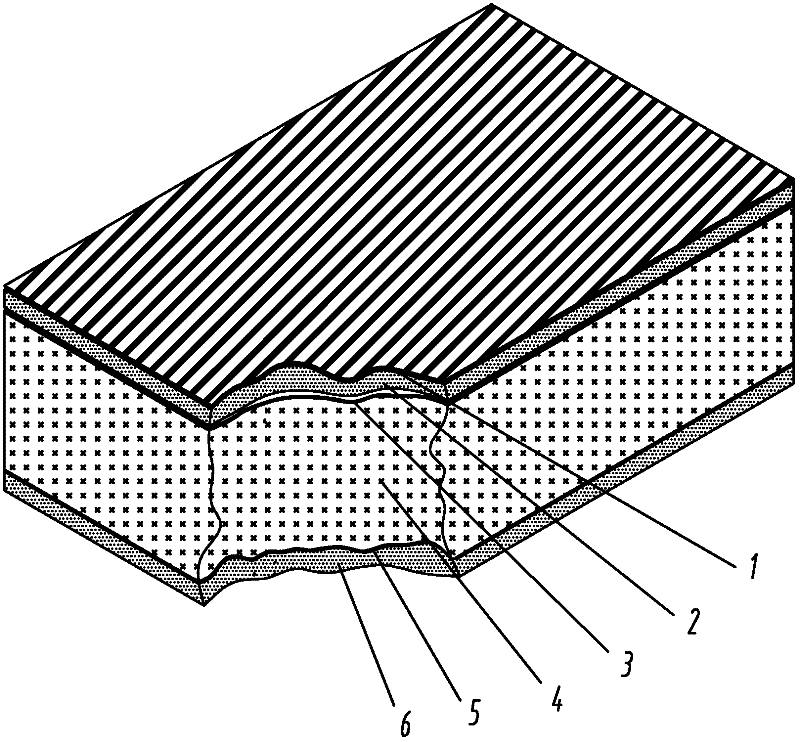

Low-carbon fireproof thermal insulation decoration integrated board and preparation method thereof

InactiveCN102400530ASolve the consumption problemEasy to crackCovering/liningsSynthetic resin layered productsFiberThermal insulation

The invention relates to a low-carbon fireproof thermal insulation decoration integrated board and a preparation method thereof. The board is characterized by comprising a finish coat, an inorganic mineral tailing surface layer, a first inorganic structure fiber net layer, an inorganic / organic composite thermal insulation core layer, a lower inorganic structure fiber net layer and an inorganic mineral tailing bottom layer which are connected from top to bottom in turn. The preparation method comprises the following steps of: preparing the inorganic mineral tailing surface layer; paving the first inorganic structure fiber net layer; paving the inorganic / organic composite thermal insulation core layer; paving the lower inorganic structure fiber net layer; preparing and paving the inorganic mineral tailing bottom layer; and coating the finish coat to prepare the fireproof thermal insulation decoration integrated board. The board has the advantages of high thermal insulation property, decoration property, mechanical property and flame retardant property and the like.

Owner:易科美德(天津)环保建材有限公司

Flame-retardant inorganic interior wall coating and preparation method thereof

PendingCN110396311AIncrease flame retardancyReduce surface temperatureFireproof paintsAntifouling/underwater paintsCrack resistanceHydroxyethyl cellulose

The invention provides a flame-retardant inorganic interior wall coating and a preparation method thereof. The coating is prepared by mixing the following components comprising, by weight, 250-315 parts of deionized water, 3-5 parts of hydroxyethyl cellulose, 0.5-2 parts of bentonite, 3-8 parts of a stabilizer, 1-5 parts of a defoaming agent, 1-2 parts of a preservative, 100-250 parts of magnesiumhydroxide, 90-190 parts of titanium dioxide, 30-80 parts of calcined kaolin, 50-80 parts of 800# heavy calcium carbonate, 150-230 parts of inorganic potassium silicate, 50-100 parts of a styrene-acrylic emulsion and 2-5 parts of a thickener. The paint has the characteristics of flame retardancy, compactness, multicolor, scratch resistance, cracking resistance, dew formation resistance, mildew resistance, stain resistance, easiness in scrubbing and good storage stability.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

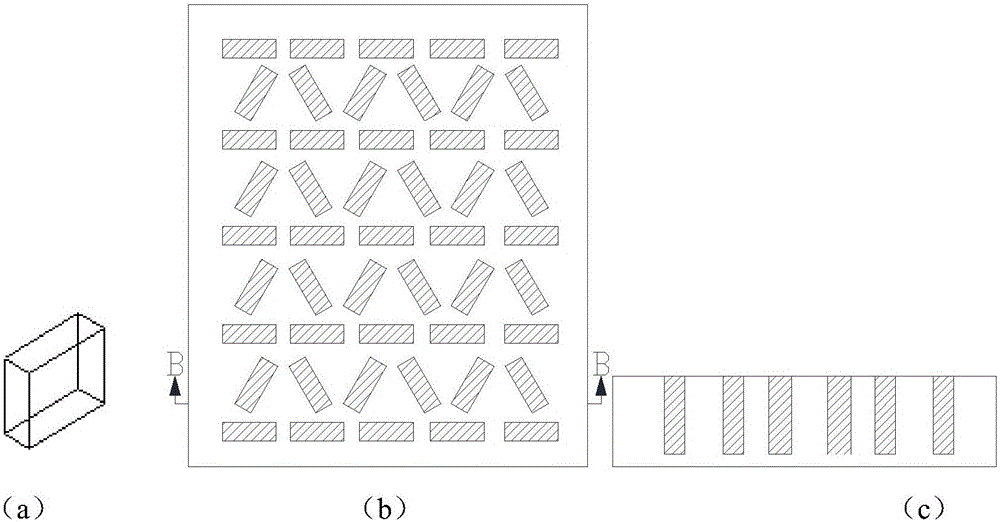

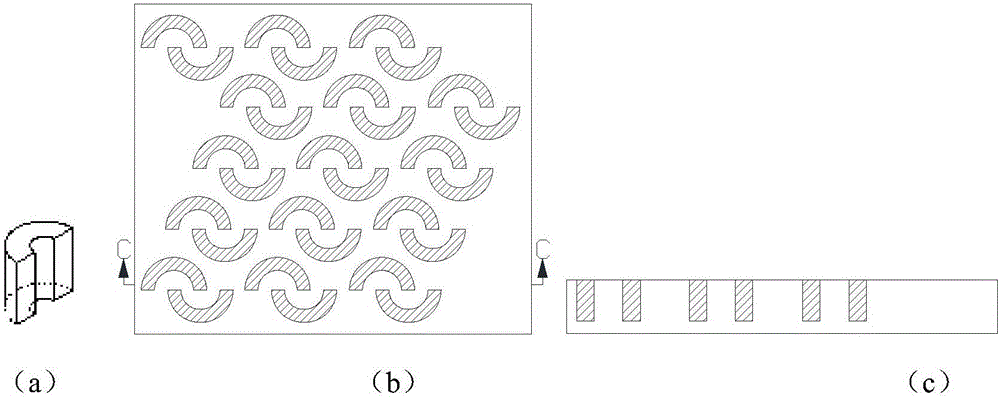

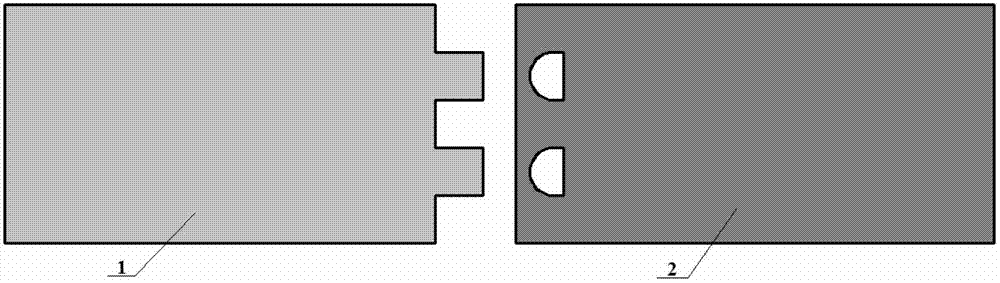

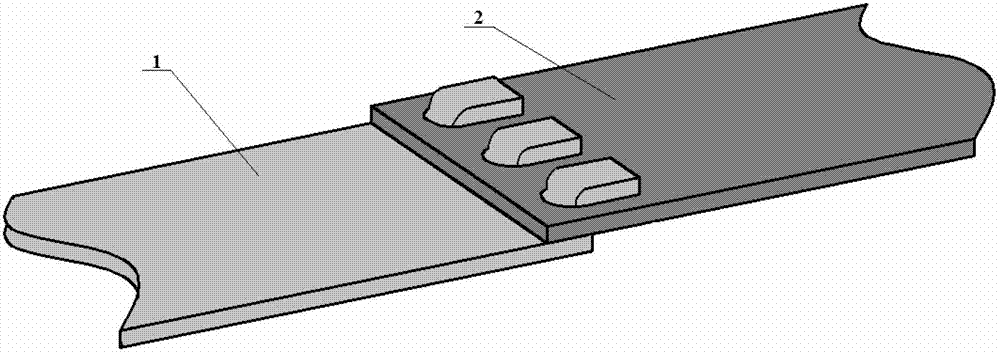

Metal plate deforming, connecting and forming method

The invention provides a metal plate deforming, connecting and forming method, belongs to the technical field of metal plate connection and aims at solving various bottleneck problem that existing metal plates have poor bearing capacity in the thickness direction in connection and forming, dropping occurs easily, and the like. The metal plate deforming, connecting and forming method comprises the steps of pre-designing structural style of end portions of plates to be connected, pre-processing convex teeth, holes or grooves with certain shapes at the end portions of the plates, performing matched lap joint of the connecting end portions of two processed plates, arranging a manufactured sample on a work table of press machine, loading connecting positions with a moving-down punch to enable the sample to be subjected to plastic deformation, then maintaining pressure for a certain period of time, enabling the punch to return, taking out connected plates and finishing the connection. By means of the method, the bearing capacity and the reliability in the thickness direction of the connecting positions are improved, and the connection failure defects including dropping and the like can be avoided.

Owner:哈尔滨松花江汽车内饰件有限责任公司

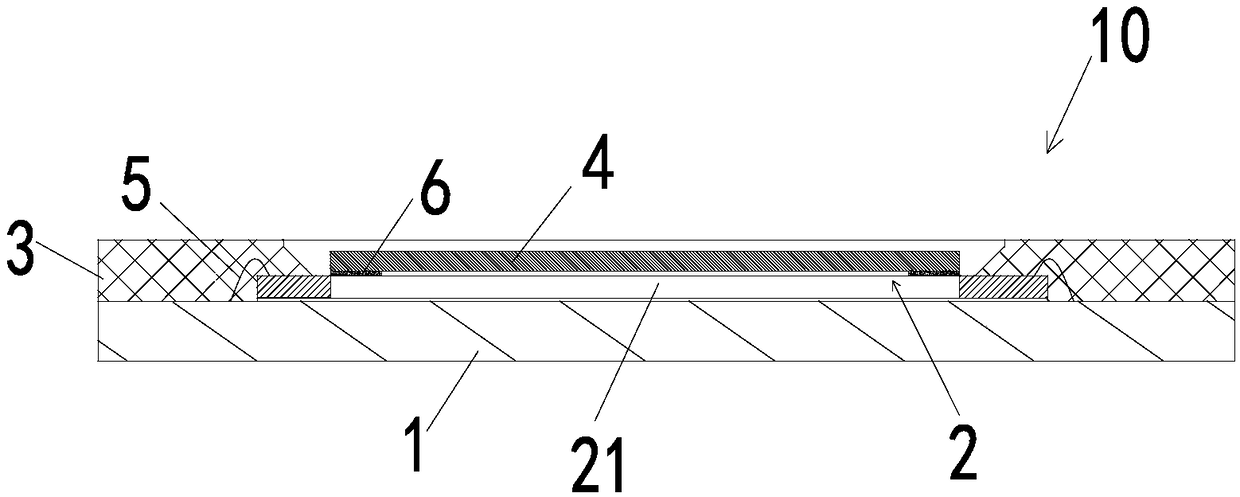

Gold finger and touch screen

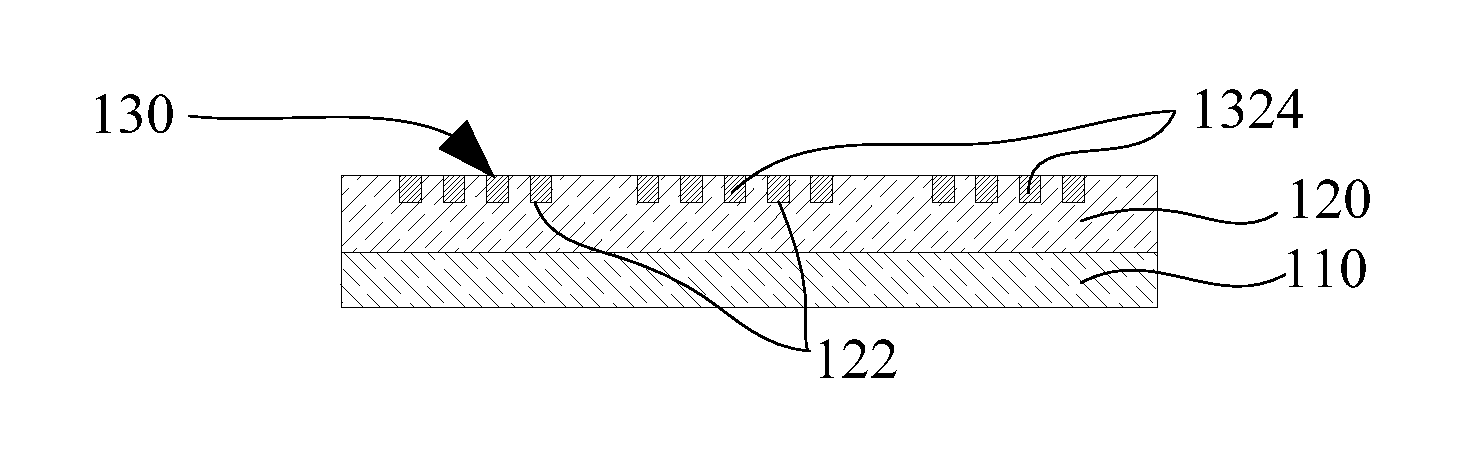

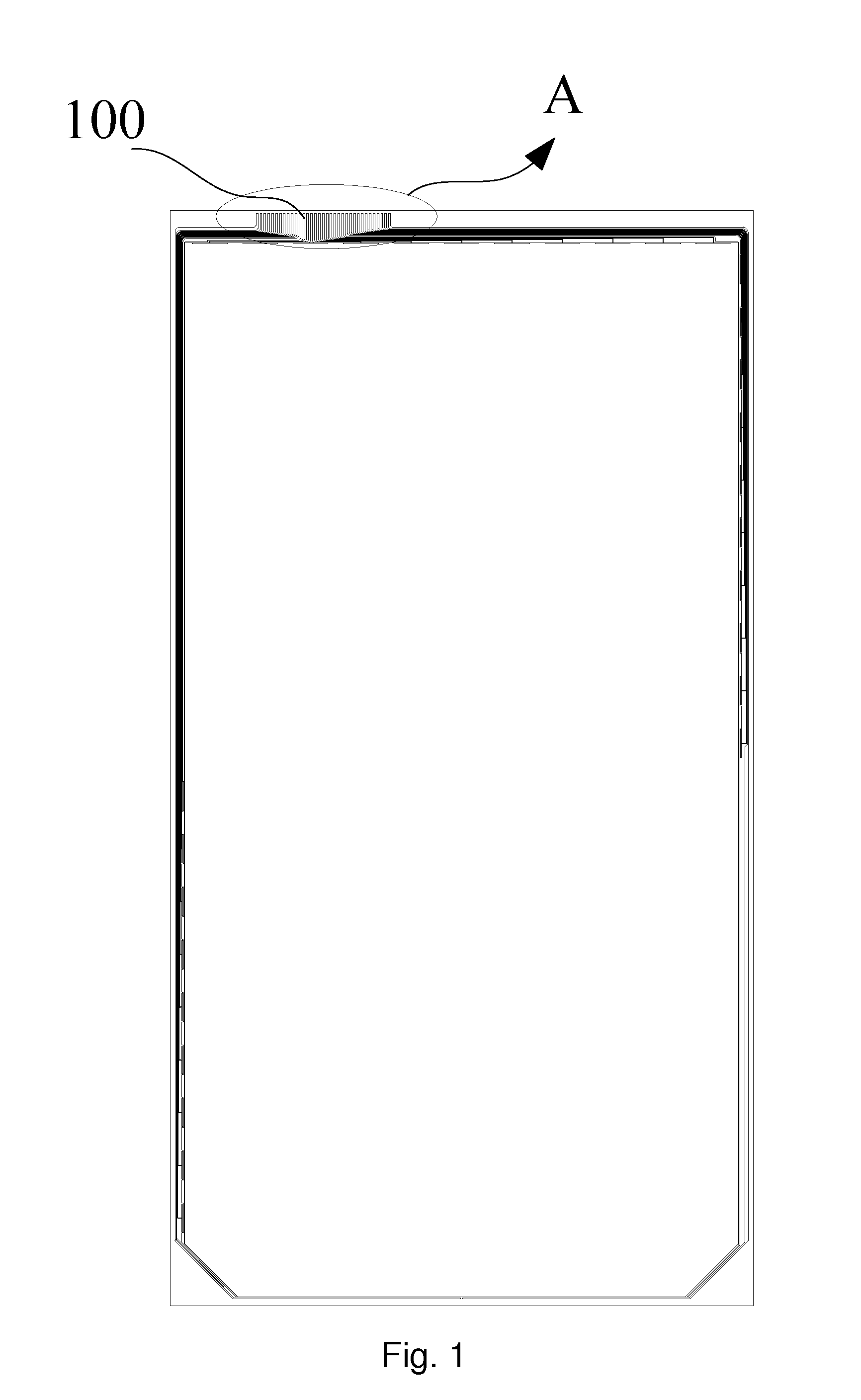

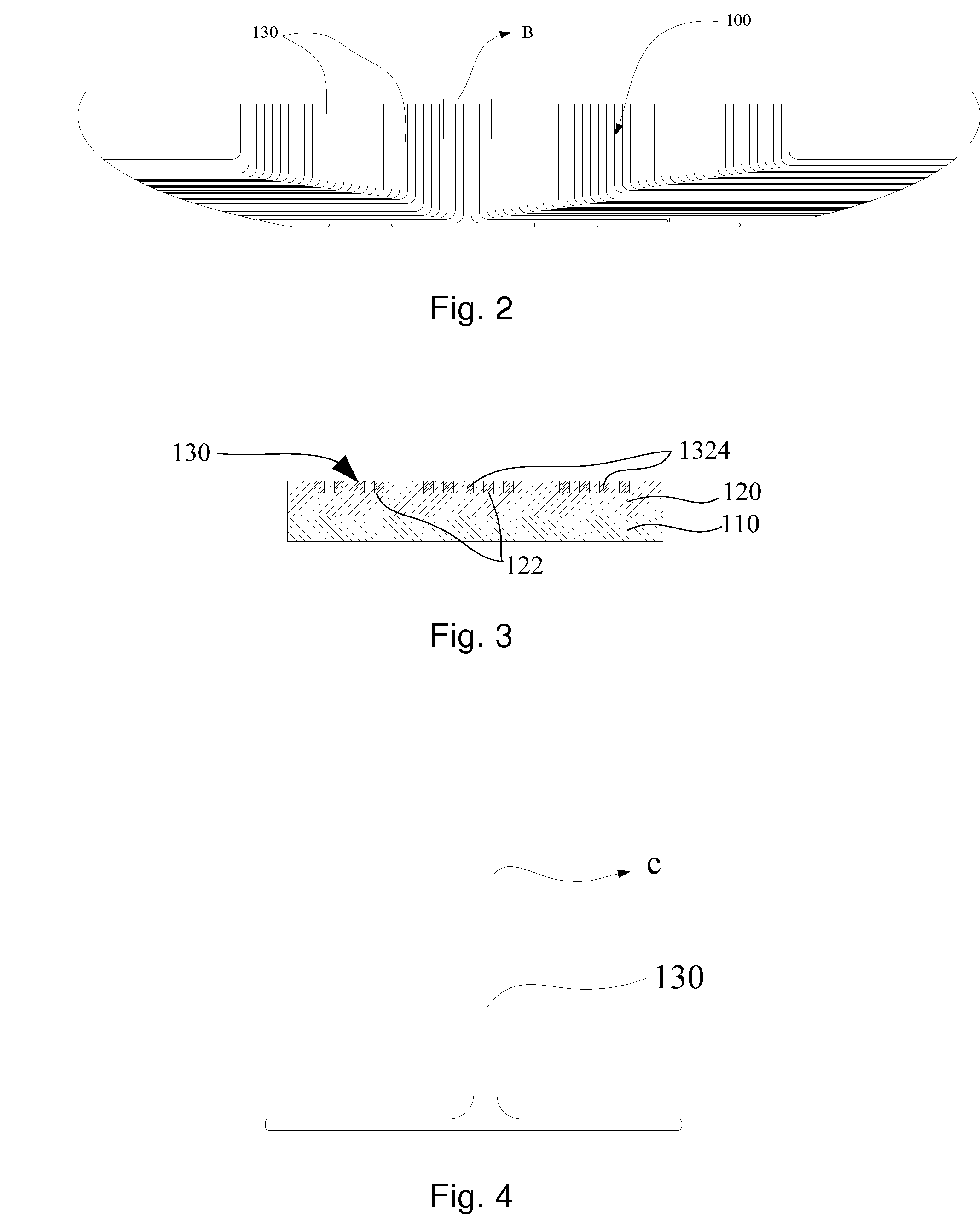

ActiveUS20140290991A1Easy to fall offEnsure conductivityTransparent dielectricsPrinted circuit manufactureAnisotropic conductive adhesiveEngineering

A gold finger, includes a substrate, an embossable adhesive layer and a plurality of wires. The gold finger is achieved through adhering an embossable adhesive layer to a side of the substrate, providing grid-shaped grooves on a side of the embossable adhesive layer away from the substrate, embedding conductive grids of the wires in the grooves to form the wires. The gold finger is disposed on a sensing component, the wires of the gold finger are electrically connected with a circuit board through an anisotropic conductive adhesive. The contact area of the wire and the embossable adhesive layer is increased through embedding the conductive grid of the wire, which is grid-shaped structure, in the grooves such that the wires are tightly combined to the embossable adhesive layer and not easy to fall off or be scratched. The present invention further provides a touch screen containing the gold finger.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

Novel industrialized synthesis technique for preparing cinnamic acid from cinnamic aldehyde by catalytic oxidation

InactiveCN102826992AExtended service lifeSolve poisoningOrganic compound preparationCarboxylic compound preparationPtru catalystCatalytic oxidation

The invention belongs to the technical field of intermediate synthesis in fine chemical engineering, and particularly relates to a novel industrialized synthesis technique for preparing cinnamic acid from cinnamic aldehyde by catalytic oxidation. The technique comprises the following steps: (A) adding sodium hydroxide, pure water and catalyst mixed solution in a mass ratio of (8-40):180:(1.1-2.2) into a reaction kettle, stirring, introducing pure oxygen, dropwisely adding cinnamic aldehyde into the mixed solution at proper rate to generate sodium cinnamate, and standing for 10-40 minutes to deposit the catalyst; and (B) leading out the sodium cinnamate solution obtained in the step (A), carrying out acid precipitation at 70-80 DEG C, keeping the reaction for 15-40 minutes, and naturally cooling to room temperature, thereby obtaining the cinnamic acid. The catalyst is nano silver particles. By adopting the supporter-free nano silver particles as the catalyst for the first time, the invention solves the problems of catalyst poisoning, high shedding tendency, high loss and the like, simplifies the production technique, greatly lowers the production cost, has the advantage of high yield, and implements industrialized mass production.

Owner:湖北远成赛创科技有限公司

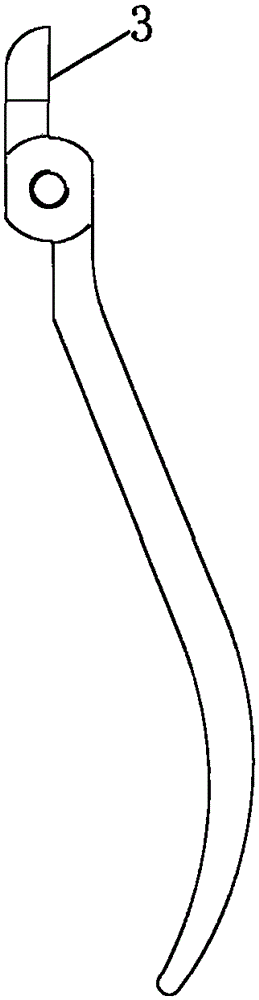

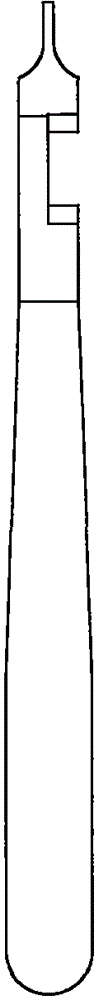

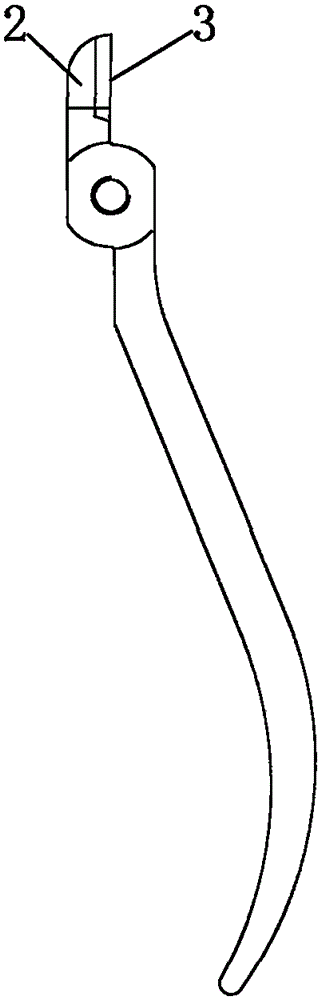

Medical clamp and processing method thereof

InactiveCN105149886AFulfil requirementsIncrease soldering temperatureSurgical scissorsSurgical forcepsProduct gasHardness

The invention discloses a medical clamp and a processing method thereof. The medical clamp comprises a clamp head, a jaw and soldering flux, wherein the clamp head is made of a medium-low hardness stainless steel material; the jaw is made of a higher hardness stainless steel material; the soldering flux is used for splicing the clamp head and the jaw; and when the clamp head and the jaw are quenched, the soldering flux is melted to weld the clamp head and the jaw integrally. The processing method comprises the following steps: the clamp head and the jaw are clamped together to form a combination, the combination is coated with the soldering flux, the combination coated with the soldering flux is placed in a vacuum furnace or a tracked furnace with the gas protection function to be quenched, and at the same time, the soldering flux is melted to weld the clamp head and the jaw, so as to connect the clamp head with the jaw integrally, and at last, after excess materials of the clamp head and the jaw are cut with a wire or cut off by a grinding machine, a finished product is manufactured. The jaw is made of the higher hardness stainless steel, and a handle and a clamp body are made of the medium-low hardness stainless steel material, so that the problems of blackening and rusting of the jaw are solved well.

Owner:王光良

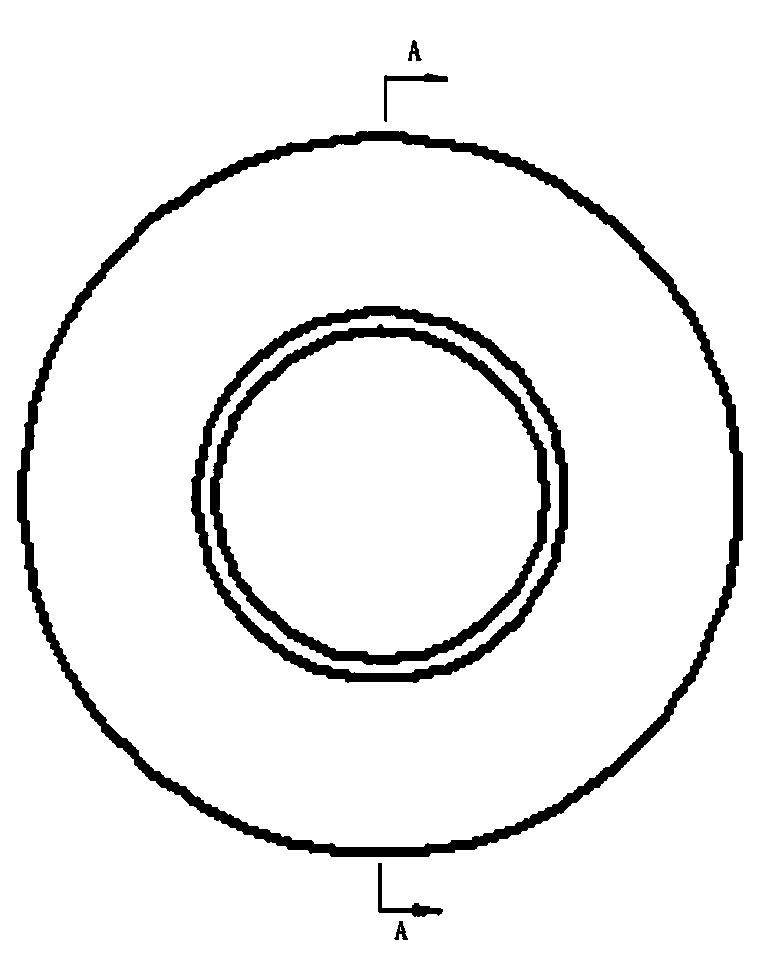

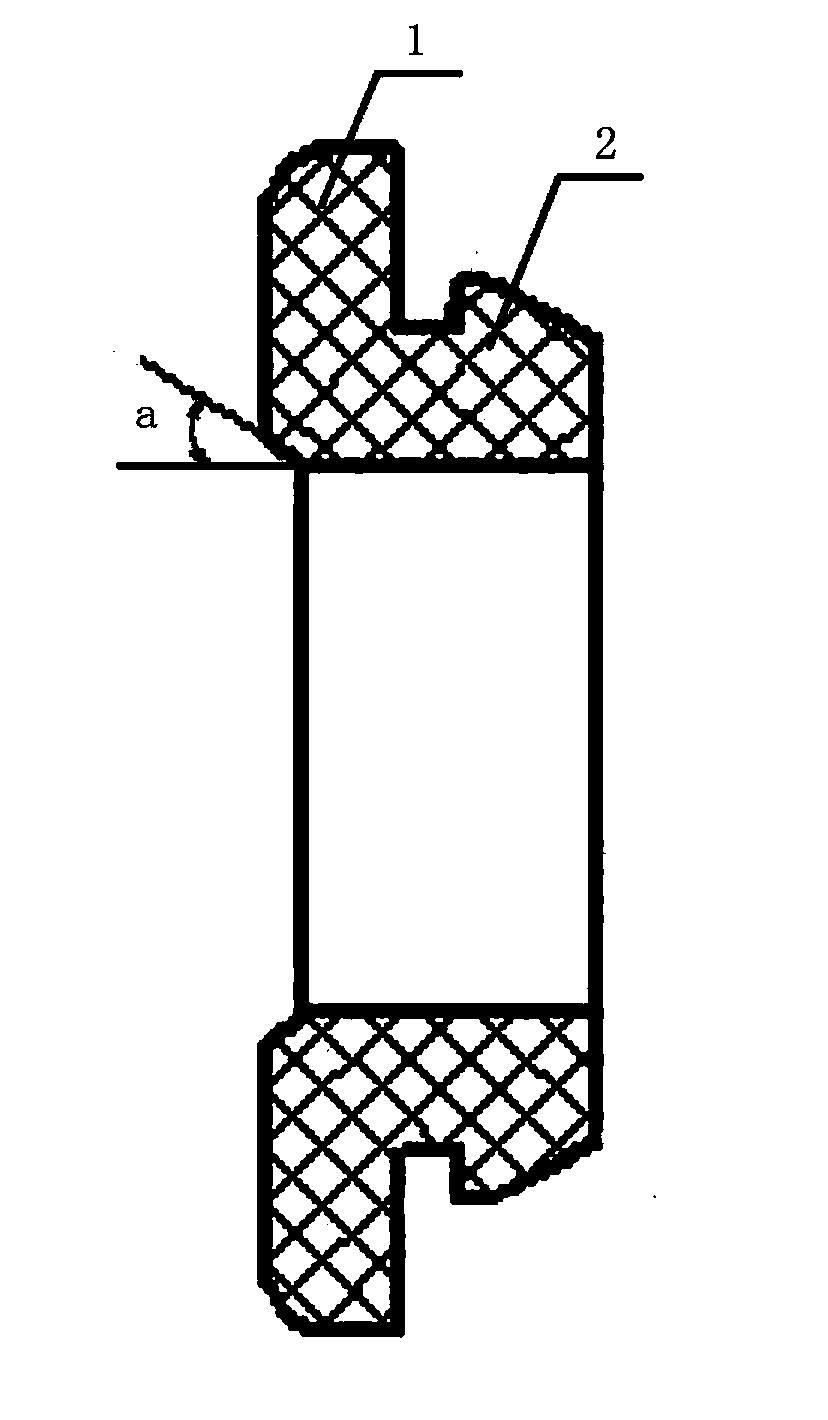

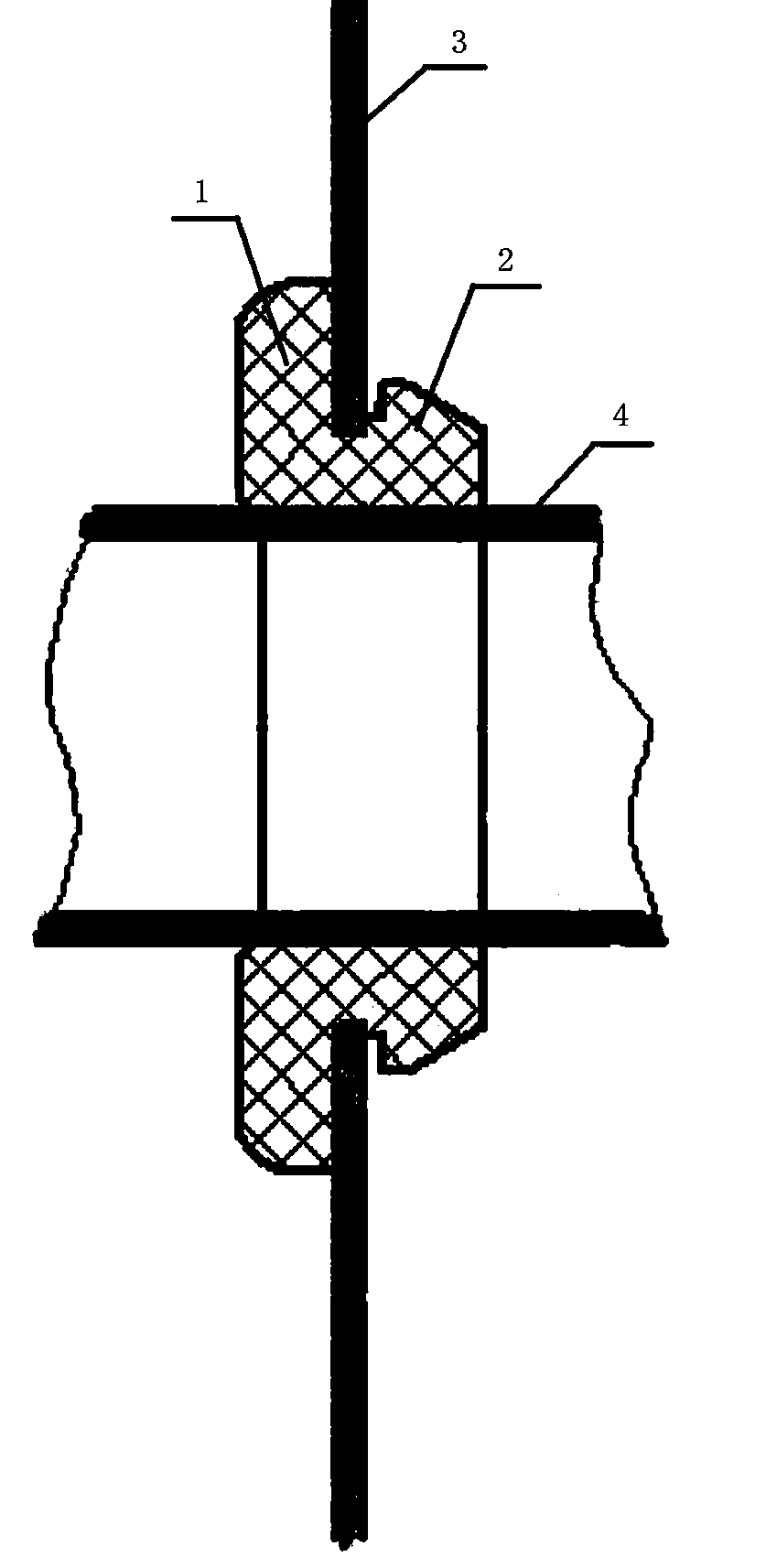

Automotive air conditioner drainage pipe sealing ring

The invention discloses an automotive air conditioner drainage pipe sealing ring, and belongs to the technical field of automobile making. A first boss stretching out in the radial direction is arranged at one end of the automotive air conditioner drainage pipe sealing ring, a chamfer forming an included angle alpha with the horizontal direction is formed on the inner wall, corresponding to the end of the first boss, of the sealing ring, a second boss stretching out in the radial direction is arranged at the other end of the sealing ring, the outer wall surface of the second boss is a conical surface, a groove vertical to a plane is formed between the first boss and the second boss, the inner diameter of the through hole of the sealing ring is smaller than the outer diameter of a drainage pipe, and the width of the groove is smaller than the thickness of automobile metal plates. According to the automotive air conditioner drainage pipe sealing ring, the problems that the drainage pipe is difficult to mount, and the sealing ring is prone to falling off and difficult to assemble are solved.

Owner:DONGFENG LIUZHOU MOTOR

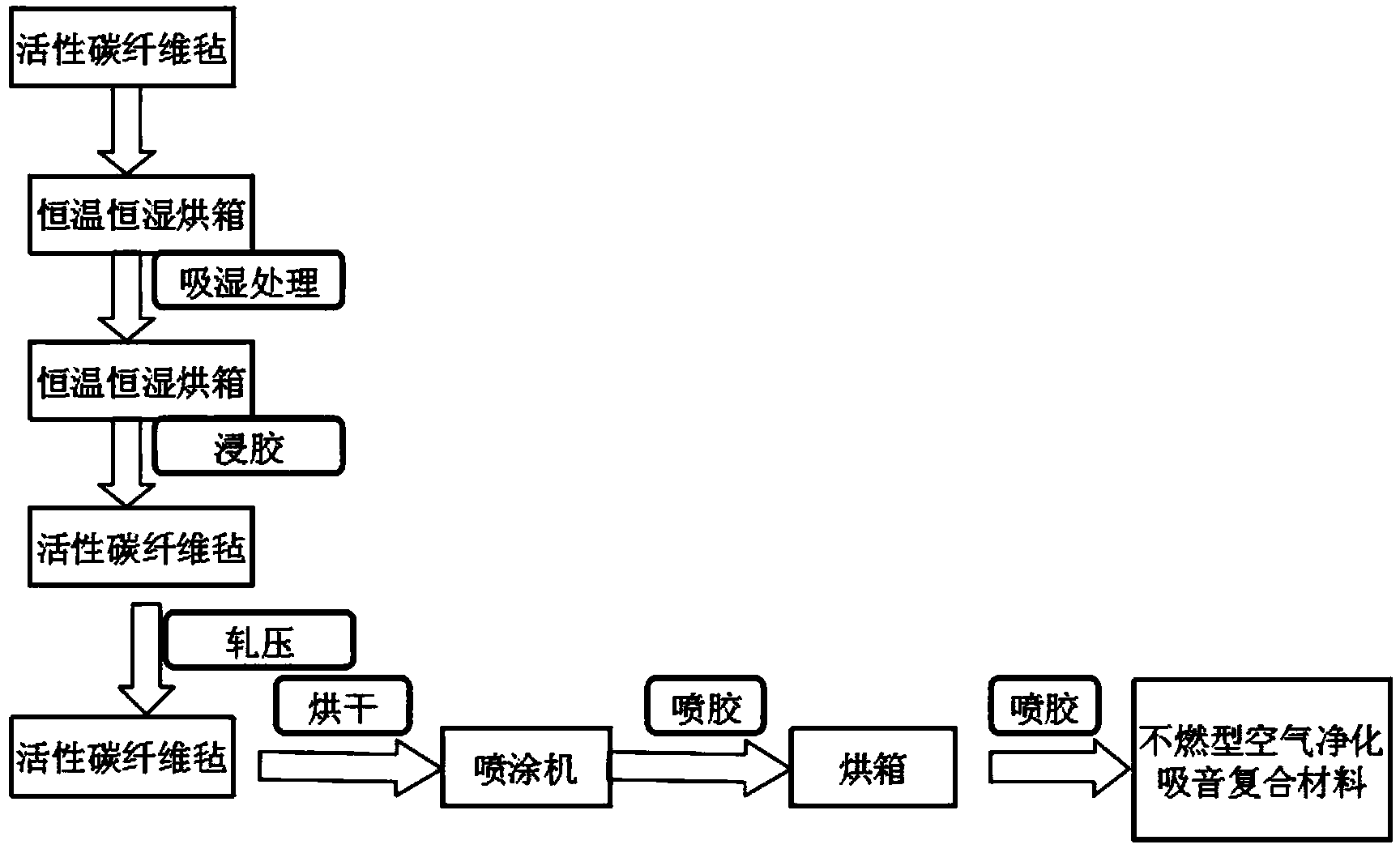

Non-combustible air purification acoustic absorption composite material as well as preparation method thereof

ActiveCN103879097AGood effectHigh strengthSynthetic resin layered productsLaminationActivated carbonFiber

The invention provides a non-combustible air purification acoustic absorption composite material as well as a preparation method thereof. The preparation method comprises the following steps: (1) impregnating, carrying out roll compacting on and drying an activated carbon fiber felt so as to obtain an impregnation treatment felt; (2) carrying out waterproof treatment on the single surface of the impregnation treatment felt, drying, and spraying glue on the surface so as to obtain a glue spraying treatment felt; (3) compounding the glue spraying treatment felt directly along the glue spraying surface or compounding by inserting a layer of barbed wire into the glue spraying treatment felt, applying certain pressure, drying and forming, or carrying out quilting enhancement on the impregnation treatment felt directly by adopting a quilting machine so as to obtain the non-combustible air purification acoustic absorption composite material. The acoustic absorption composite material obtained by the invention has the characteristics of no smoke or naked flame in catching fire, flexible hand feel, good acoustic absorption, indoor air purification, no falling fiber in knocking and the like, also can be combined with other decoration materials to prepare acoustic absorption flame-retardant decoration materials, and is especially suitable for public places with condense people and high fire fighting requirements, such as KTV, bars, theaters and auditoriums.

Owner:陈植民 +2

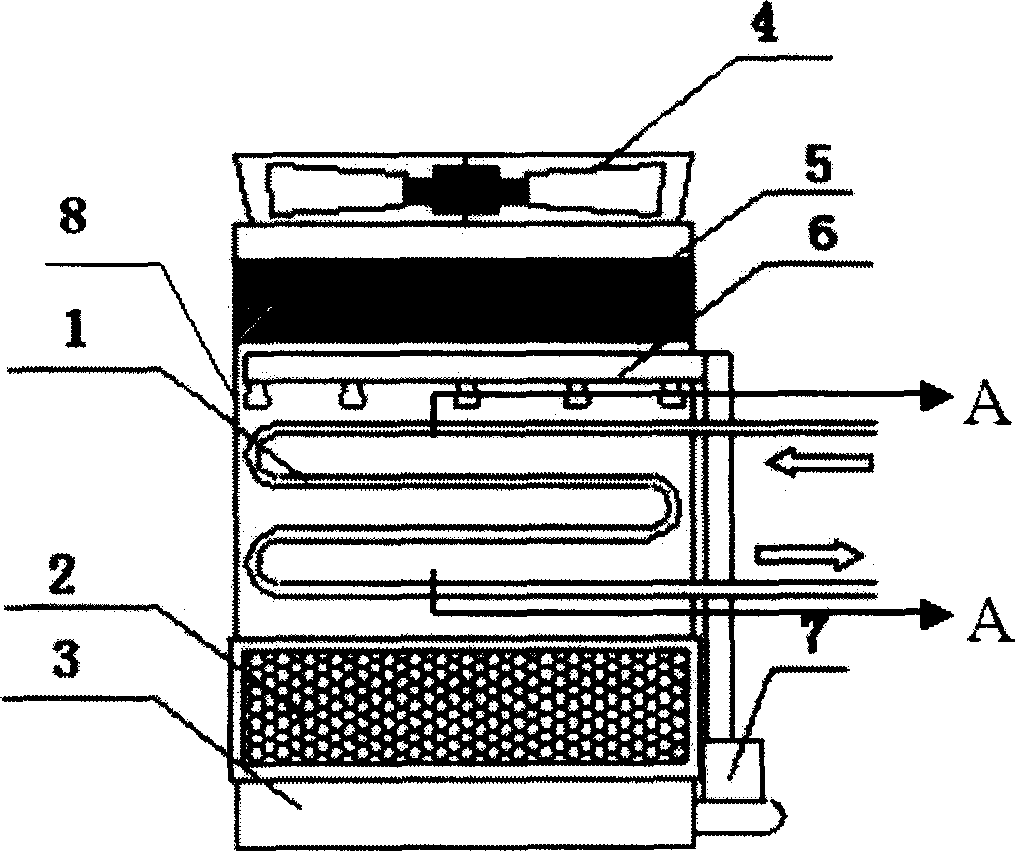

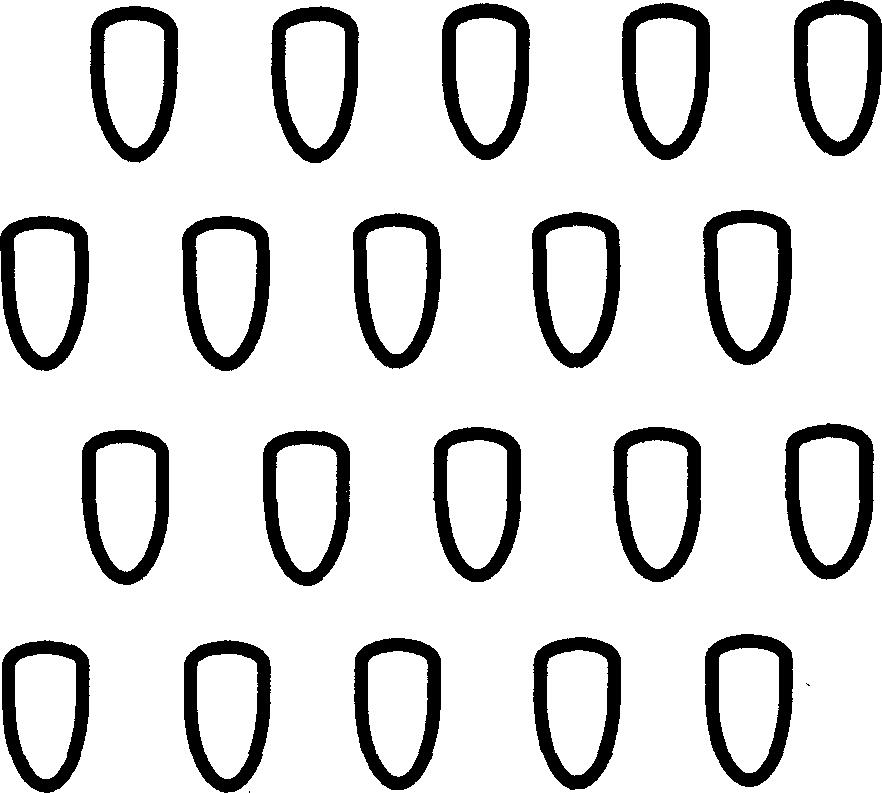

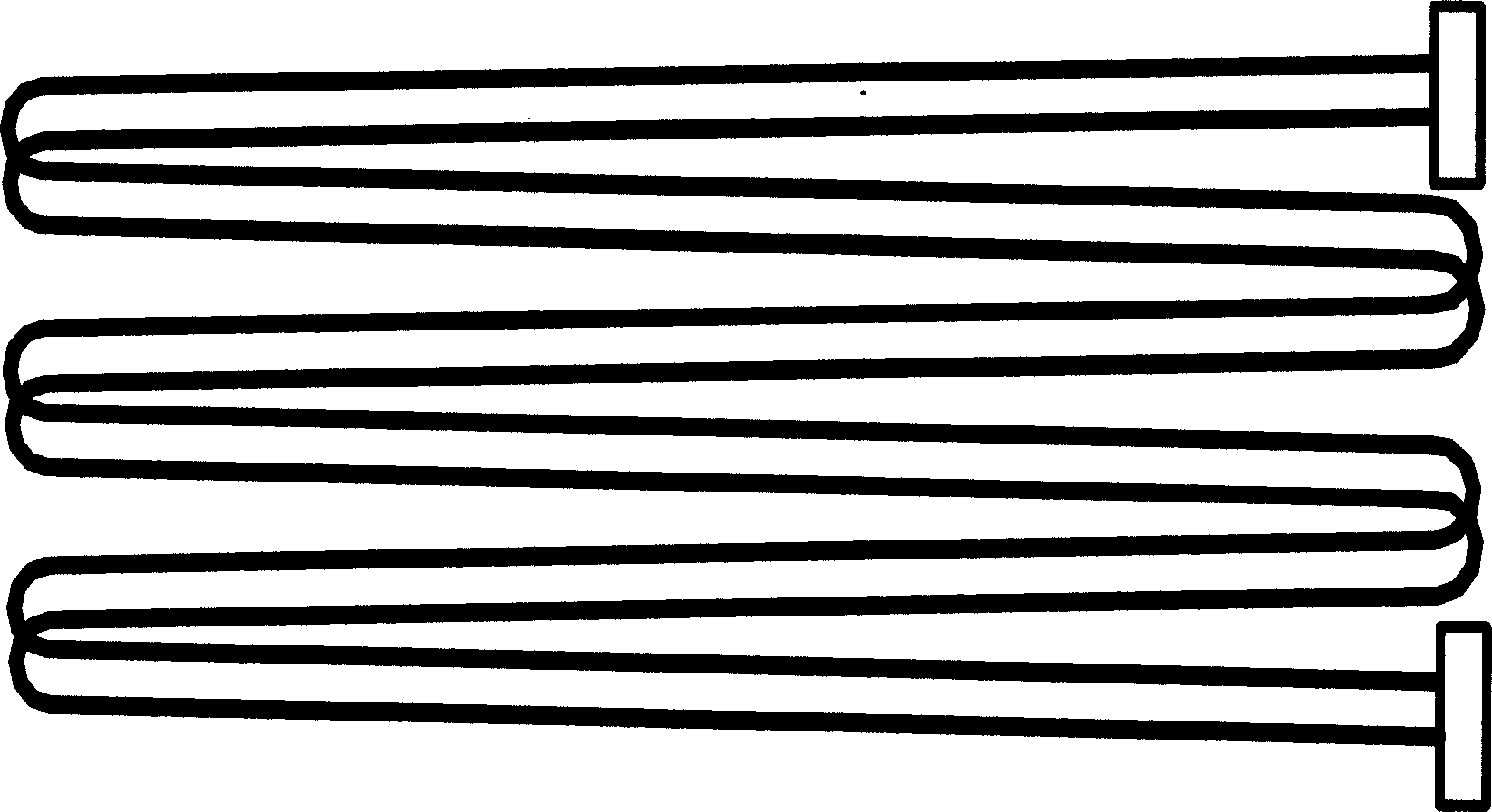

Spring tube evaporation type cold exchange device

InactiveCN1648589ALarge heat capacityIncrease the heat exchange areaStationary conduit assembliesTubular elementsStraight tubeEvaporation

The present invention relates to a elastic distortion tube evaporation type heat exchange device comprising heat exchange coiled tube, case, blower, intake grille, water blocking grate, spraying unit, water pump and water collecting sump. It features that the coiled tube consists of straight tube and bent tube, the straight tube is elastic distortion tube and in an angle of 0-15 deg to the horizontal plane; and the bent tube is circular tube. The present invention has more heat transferring coiled tubes and great heat capacity in unit, high water film forming capacity in heat transferring tube, high water film covering rate, fast water film updating course, powerful heat exchange capacity and less flow resistance.

Owner:SOUTH CHINA UNIV OF TECH

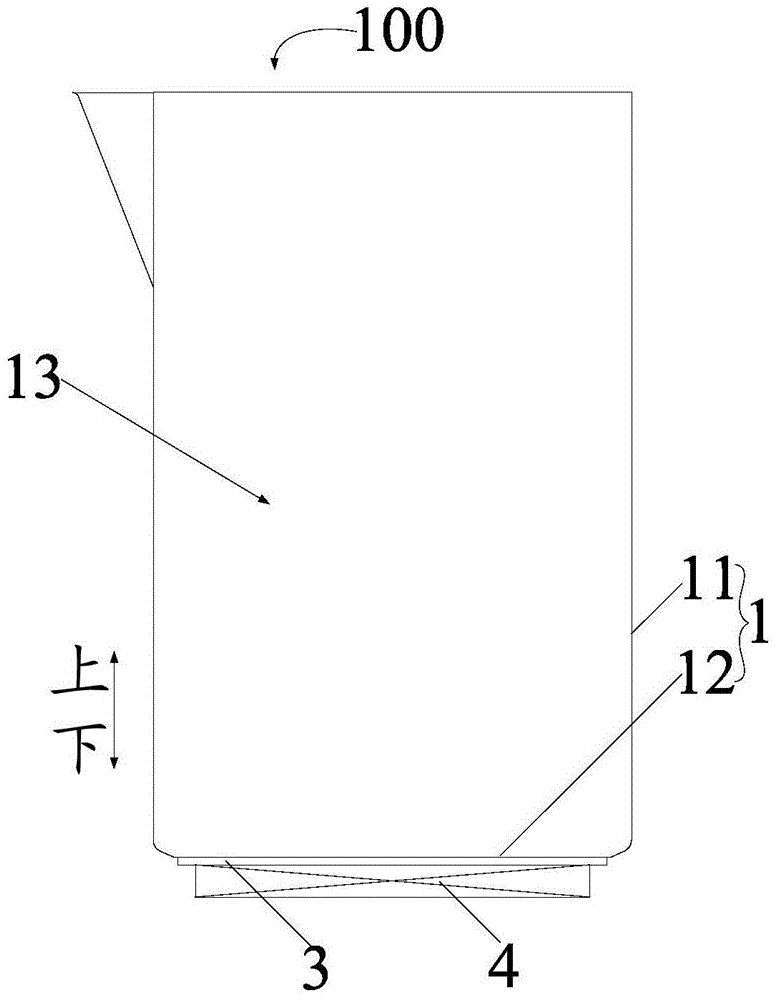

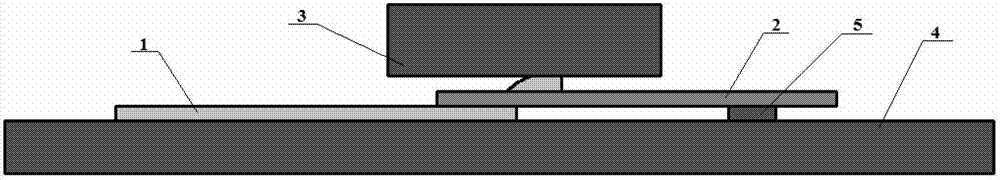

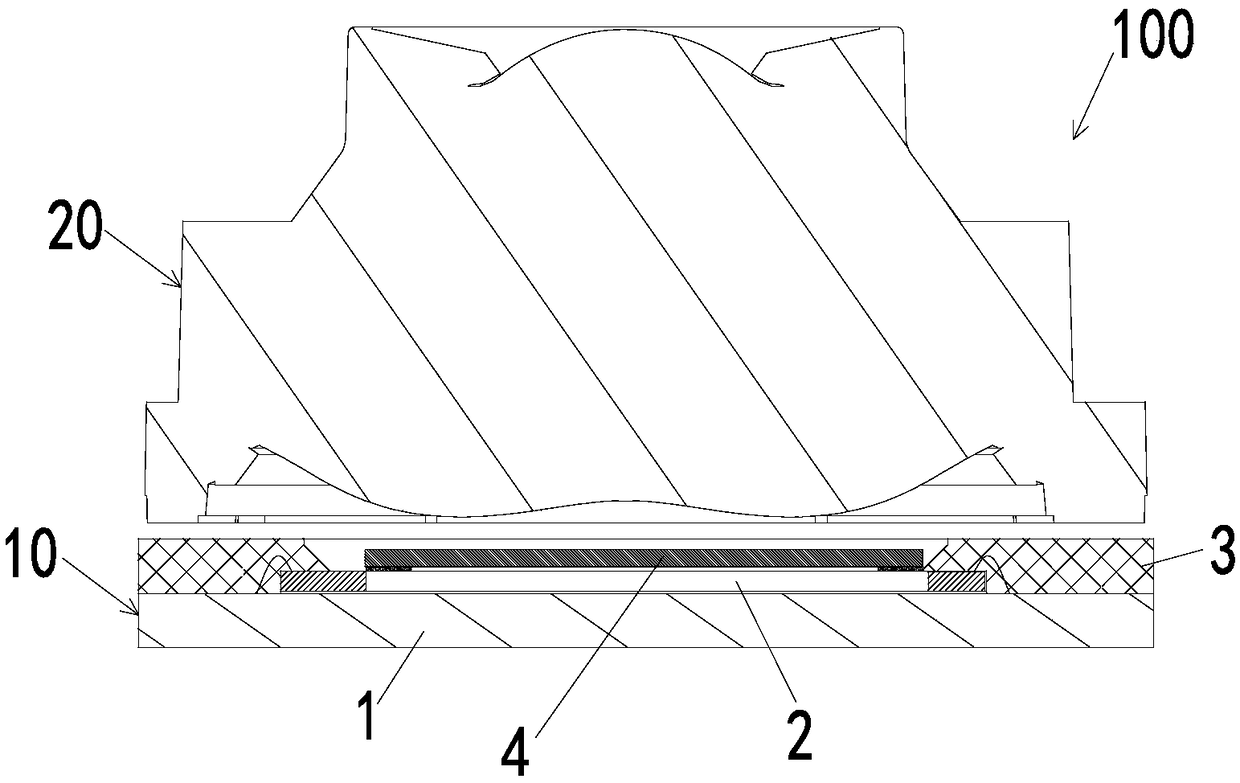

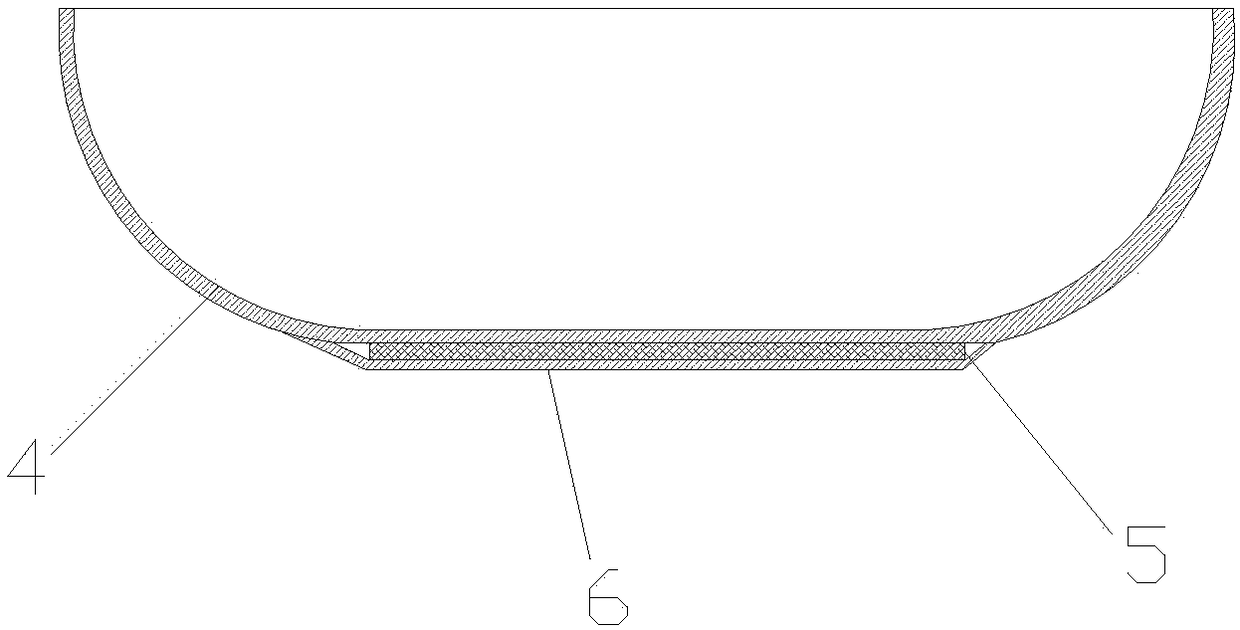

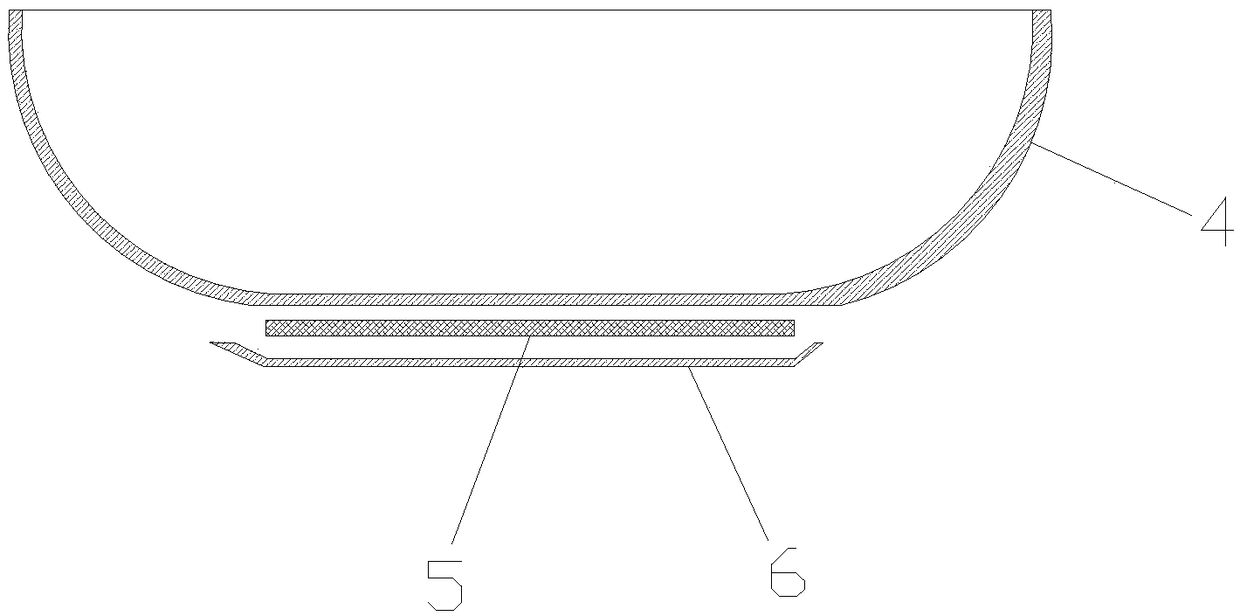

Module, manufacturing method thereof, camera and electronic device

InactiveCN109218582AEasy to fall offResolve fragmentationTelevision system detailsColor television detailsEngineeringUltimate tensile strength

The invention is applicable to the technical field of a camera, and provides a lightweight and thin module and a manufacturing method thereof, a camera and an electronic device. The module comprises acircuit board, an image sensor, a middleware and an optical filter, wherein the optical filter is directly fixed on the top surface of the photosensitive area of the image sensor. The embodiment eliminates the base in the prior art and directly fixes the filter on the top surface of the photosensitive area of the image sensor, thereby saving components and reducing the filter attaching process, and avoiding the problem of tilting the base and the middleware in the installation process. As for that module design, since there is no base, the space of the module in the vertical direction is saveby 0.3 to 0.5 mm, so that the module is lighter and thin. In addition, since the image sensor itself is fixed on the circuit board, the image sensor can provide sufficient bearing strength to the filter, thereby improving the bearing capacity of the module when impacted by external forces, and making the filter not easy to fall off or break.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

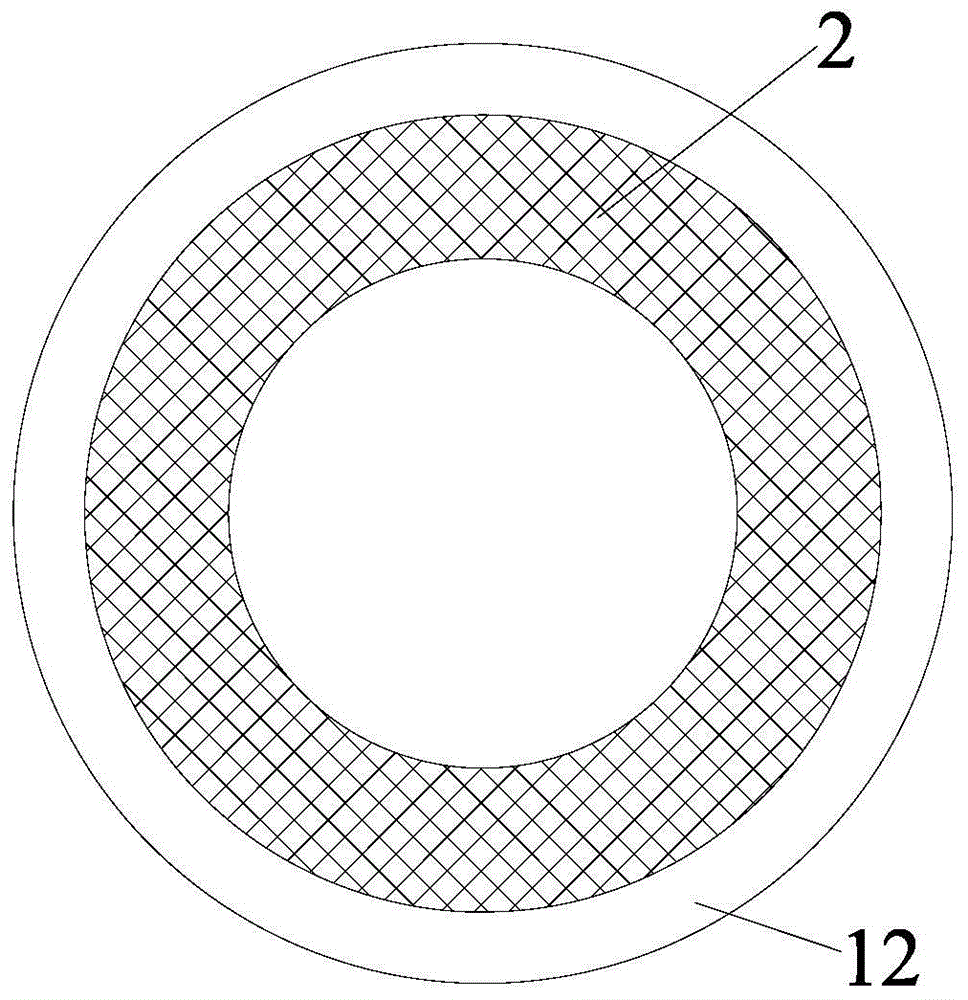

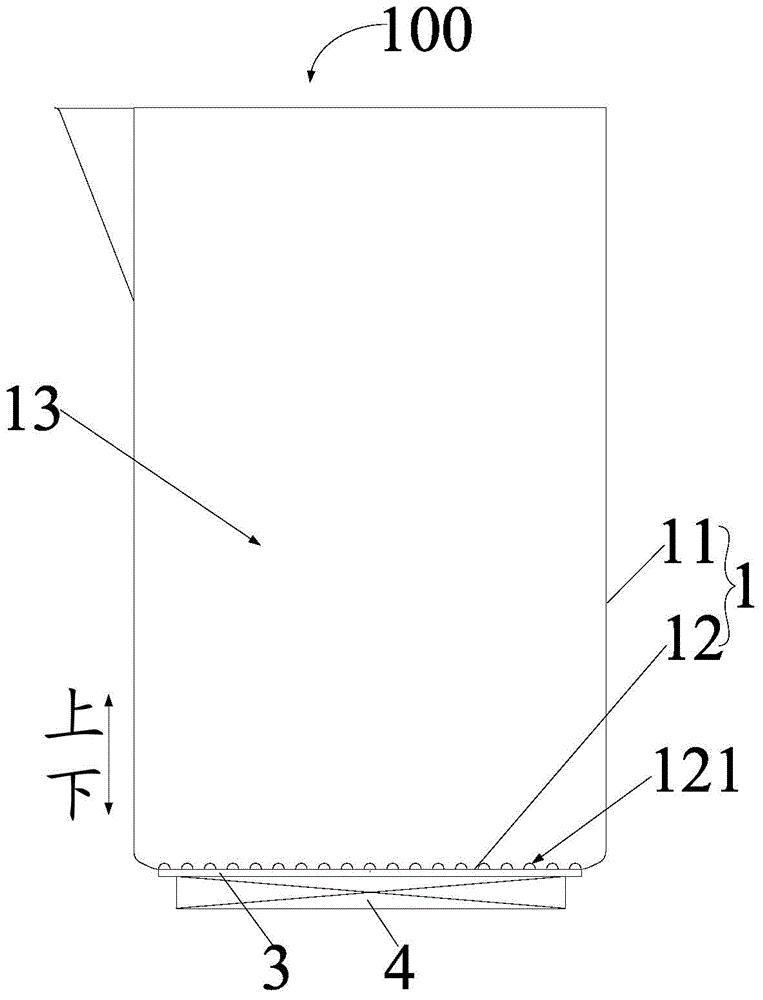

Composite steel pan and manufacturing process thereof

InactiveCN108903595AHigh strengthReduce deformation rateCooking-vessel materialsHollow articlesVolumetric Mass DensityMaterials science

The invention relates to a steel pan and a manufacturing process thereof, and discloses a composite steel pan and a manufacturing process thereof. The composite steel pan comprises a pan body (1), wherein the pan body (1) comprises an inner working layer (11) and an outer heated layer (12); the inner working layer (11) is covered by the outer heated layer (12); bosses, which are used for increasing structural intensity, are arranged at the bottom of the pan body (1) and the outer edge of a pan opening; and during manufacturing, sheet stocks are applied with oil, and multiple layers of structures undergo imitated pressing and molding, so that the multiple layers of structures are combined through imitated pressing. According to the manufacturing process provided by the invention, the various layers are closely bonded under high-tonnage pressure; under the effect of the high-tonnage pressure, a material of the pan body flows under a cold-solid state or a heated state, so that density isimproved, a molecular structure is distributed more closely and adhesive force between aluminum alloy and stainless steel or a magnetic-conductive layer material is increased; in addition, the multiple layers of composite steel materials of the pan body are integrally molded, and through a stepped-form strengthening effect between the opening and the bottom of the pan body, the pan body is prevented from getting deformed easily when sprayed and roasted at high temperature.

Owner:JH LEICAST COOKWARE CO LTD

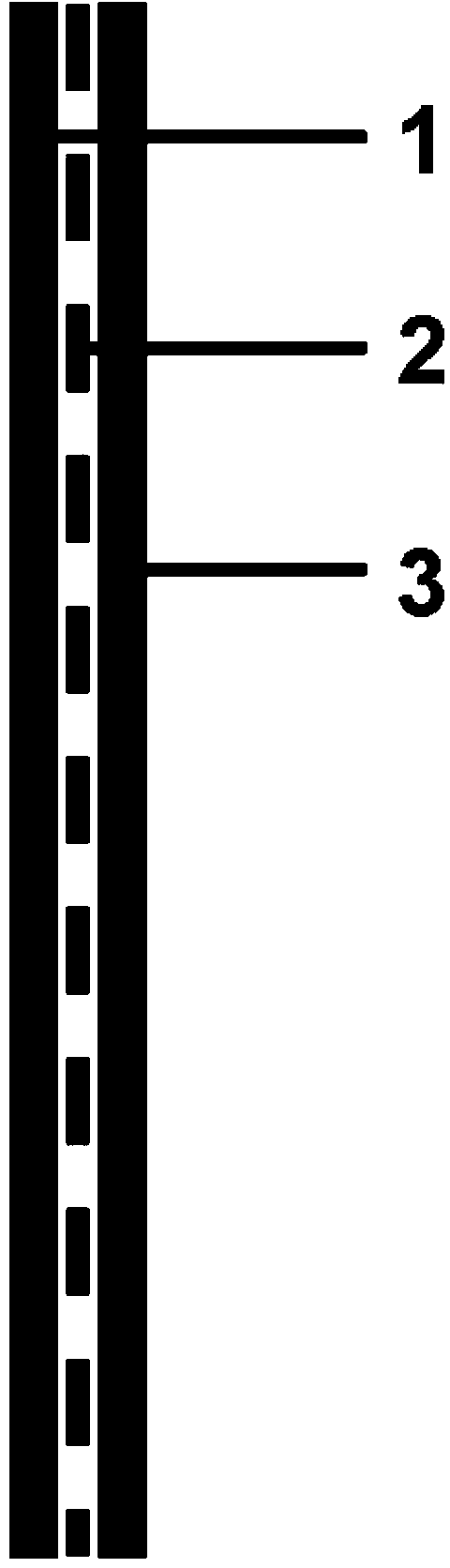

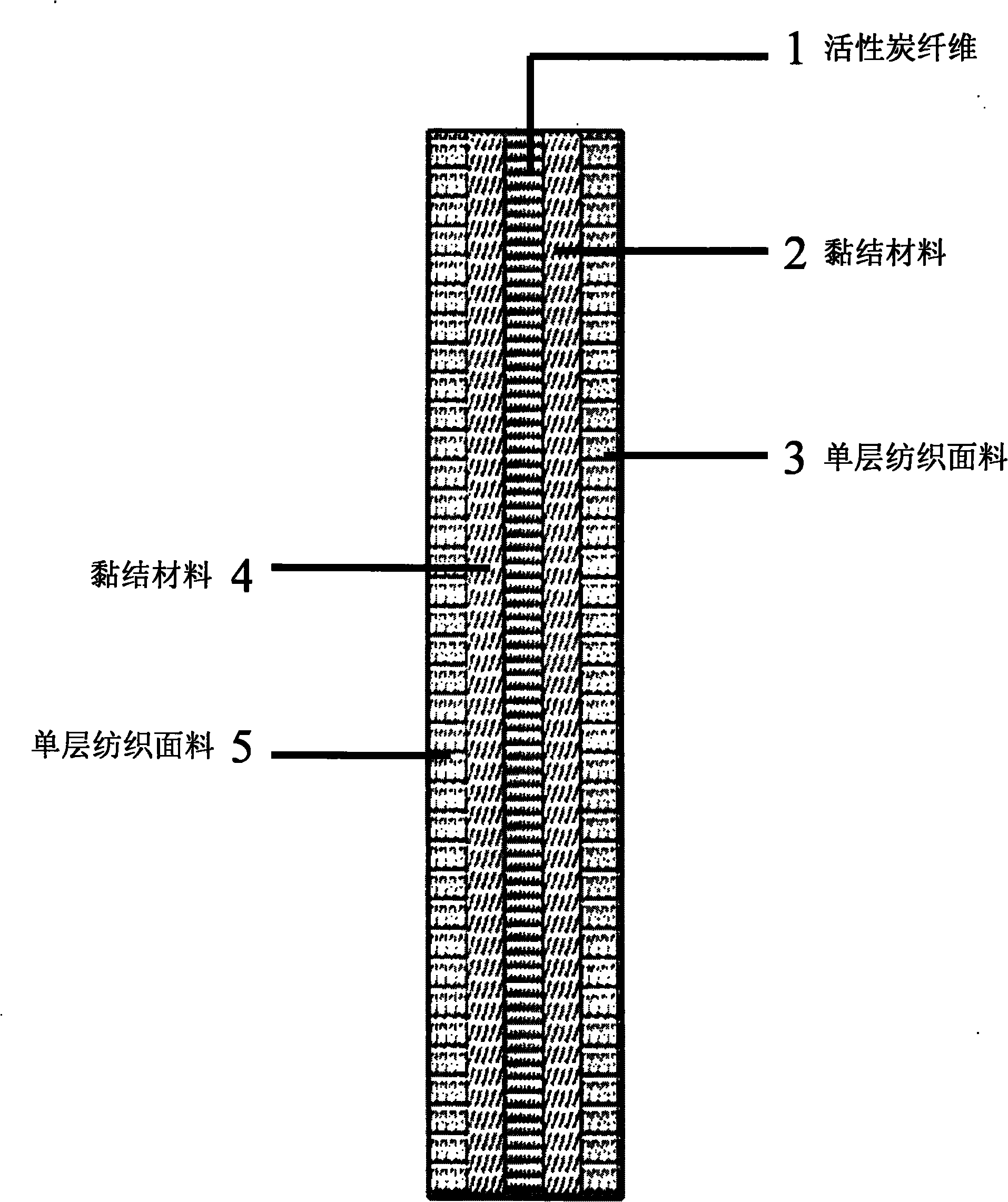

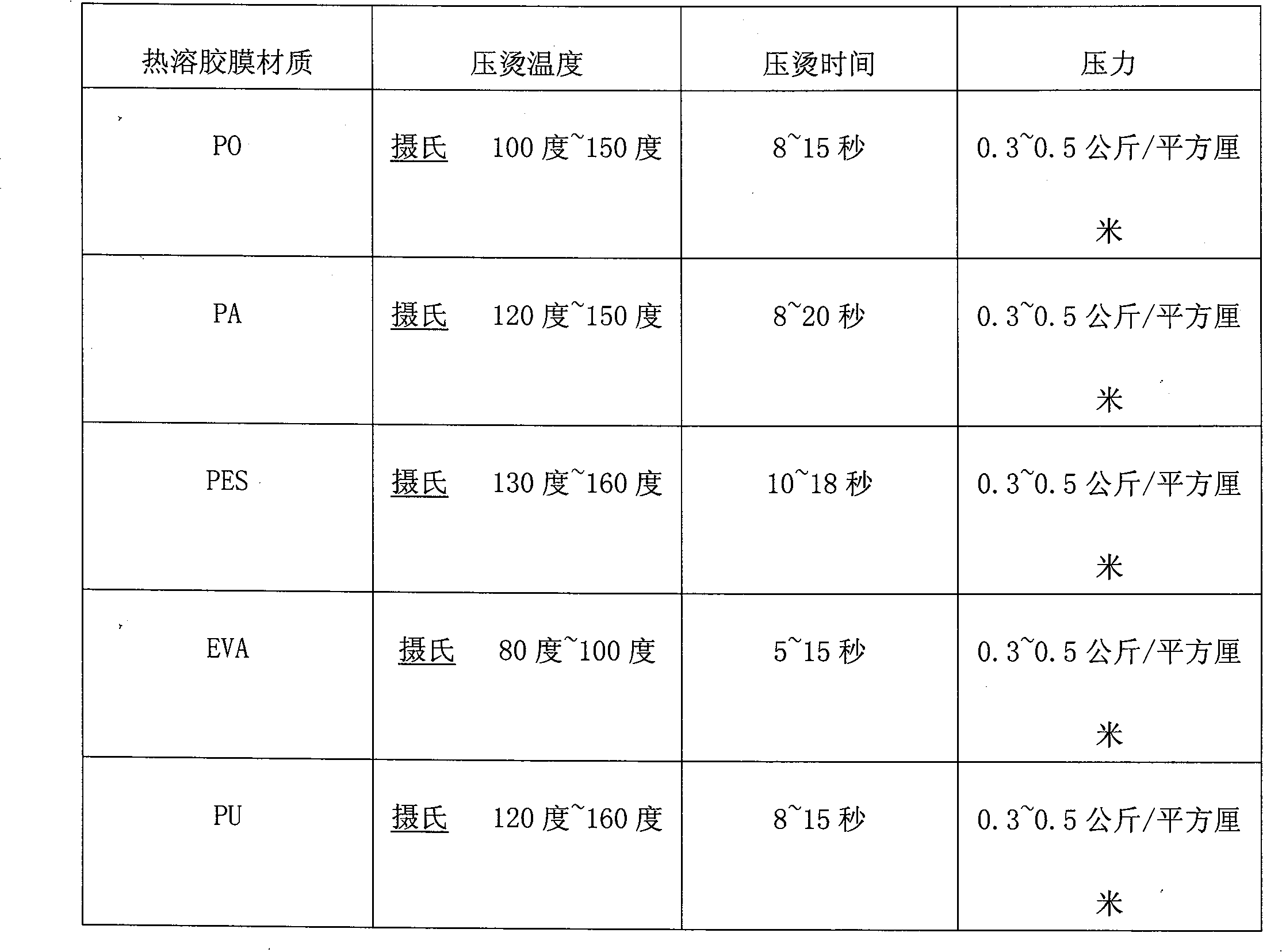

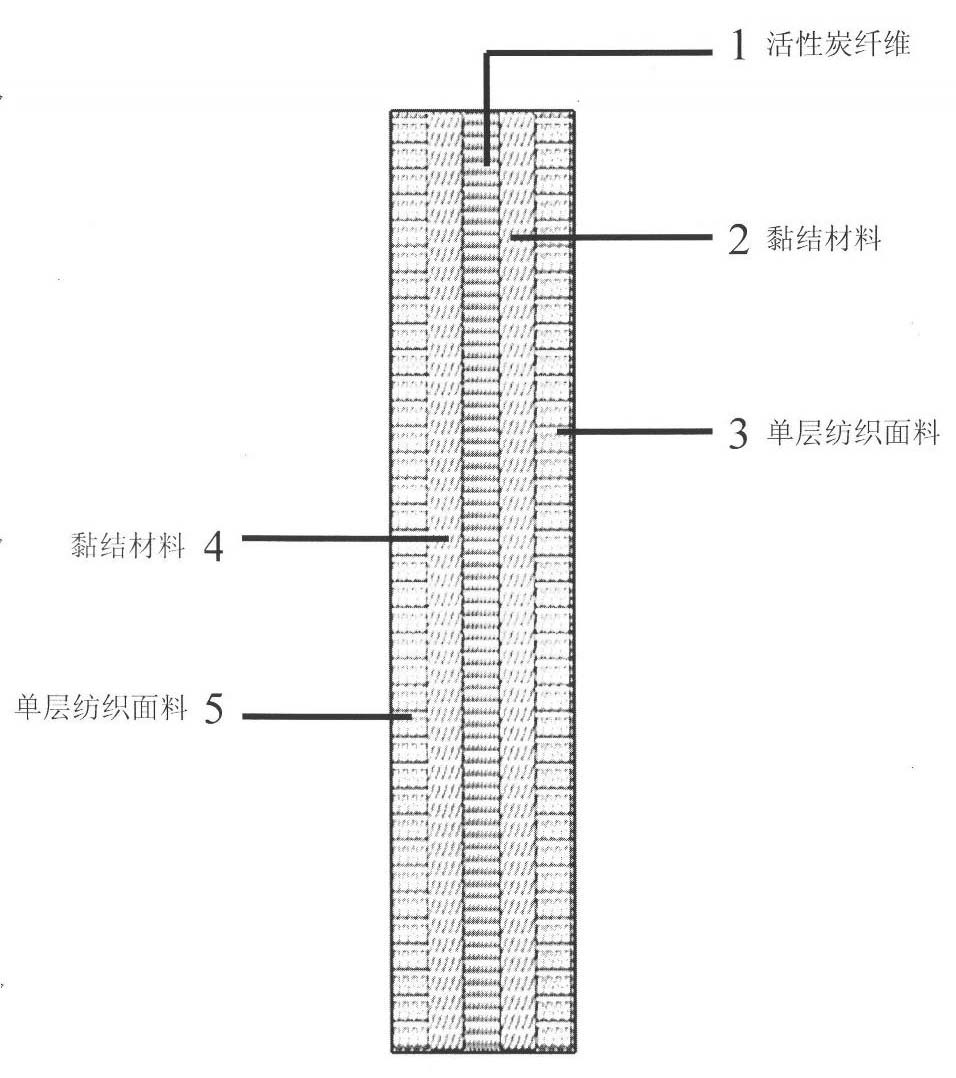

Preparation method of multi-layered textile fabric capable of purifying air

The invention relates to a preparation method of a multi-layered textile fabric capable of purifying air. The method comprises the following steps that: activated carbon fiber is adopted as the middle layer of the fabric, bonding material layers are respectively covered on the upper surface and the lower surface of the activated carbon fiber, single-layered textile fabric layers are singly added on the surface of the upper layered bonding material and the lower layered bonding material, and finally the textile fabric in a five-layered structure is formed. The fabric in the structure can not only prevent the defects of low activated carbon fiber strength, easy fall-off, no wear resistance, poor spinning property and easy external drilling of activated carbon fiber yarn, but also keeps the absorption property of harmful gases, and embodies the characteristics of practicality, durability, aesthetics, permeability, wear resistance and large contact area with the air of the textile fabric. The preparation method is as follows: solid bonding material is combined with the single-layered textile fabric and the activated carbon fiber to prepare the fabric by hot melting after a certain pressure is applied, or liquid bonding material is combined with the single-layered textile fabric and the activated carbon fiber to prepare the fabric by glue transfer after a certain pressure is applied.

Owner:沈靖

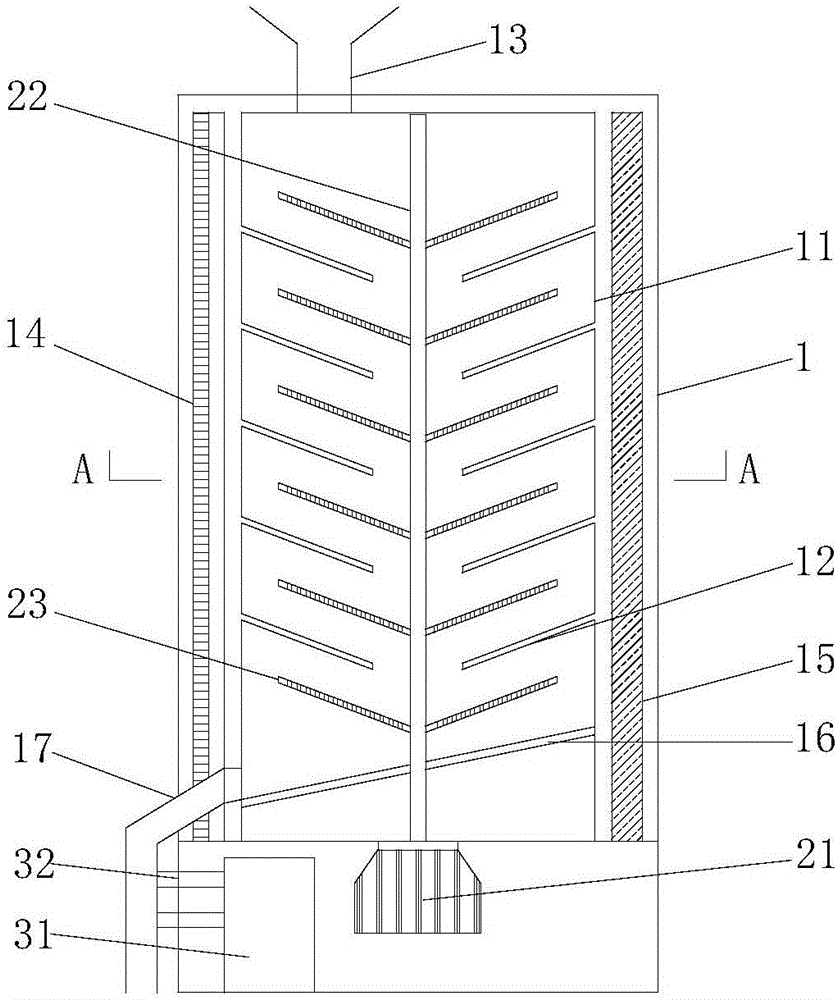

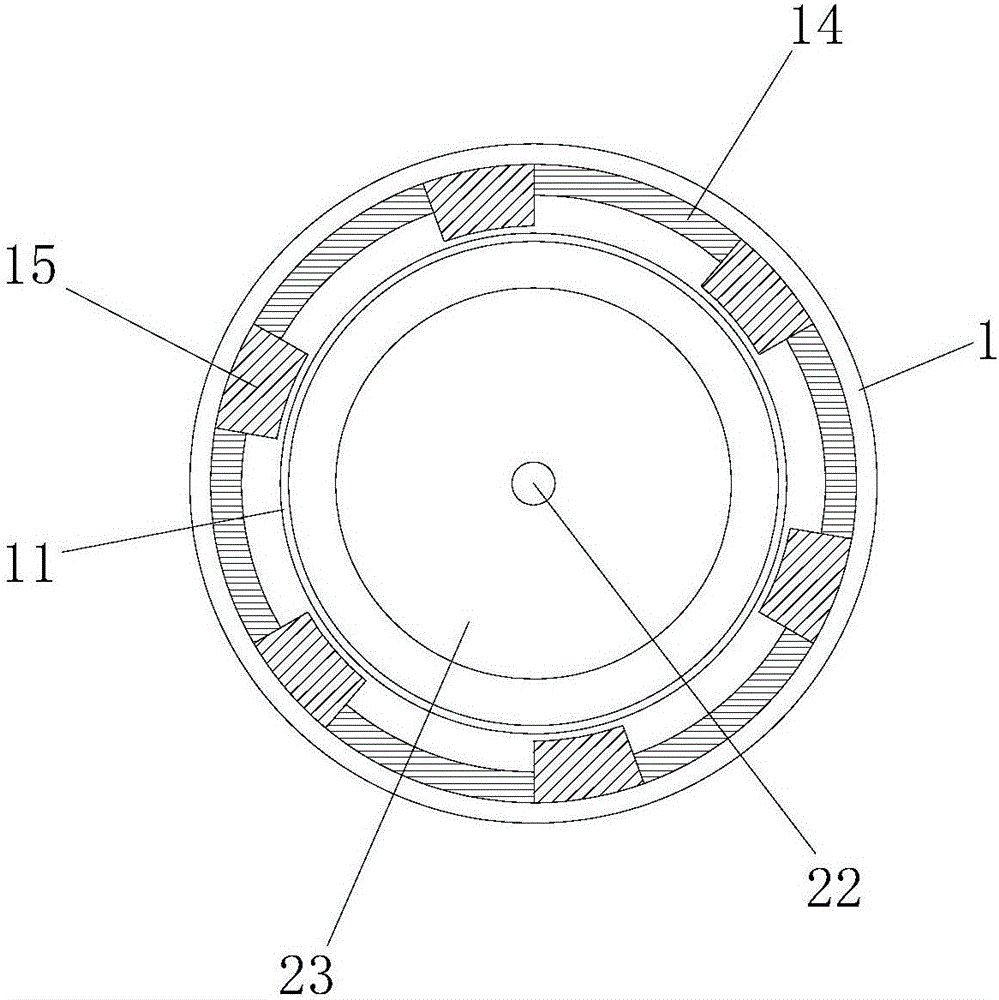

Electrostatic dust removal capsule polishing and drying device and using method

ActiveCN106363514AEasy to dropEasy to shake offGrinding machine componentsPolishing machinesEngineeringElectromagnetic heating

The invention relates to an electrostatic dust removal capsule polishing and drying device and a using method and belongs to the technical field of capsule polishing equipment. An elastic steel wire mesh is arranged in a polishing cylinder. A gap is formed between the elastic steel wire mesh and the inner wall of the polishing cylinder. Baffles which incline downwards are arranged on the inner side of the elastic steel wire mesh from outside to inside at intervals. A polishing device comprises a motor, a rotary shaft and polishing discs. The motor is arranged at the bottom of the polishing cylinder. The rotary shaft penetrates through the bottom of the polishing cylinder and extends into the polishing cylinder. The polishing discs are arranged obliquely from inside to outside. The inner ring of each polishing disc is fixedly connected with the rotary shaft. The polishing discs and the baffles are arranged alternately. A dust removal and drying device comprises an electromagnetic heating device and an electrostatic dust removal device. The electromagnetic heating device and the electrostatic dust removal device are arranged in the gap between the elastic steel wire mesh and the inner wall of the polishing cylinder in a spaced mode. According to the electrostatic dust removal capsule polishing and drying device and the using method, dust falling in the polishing process is adsorbed through the electrostatic dust removal device, and residual quantity of the dust is reduced.

Owner:ZHEJIANG HUAGUANG CAPSULE

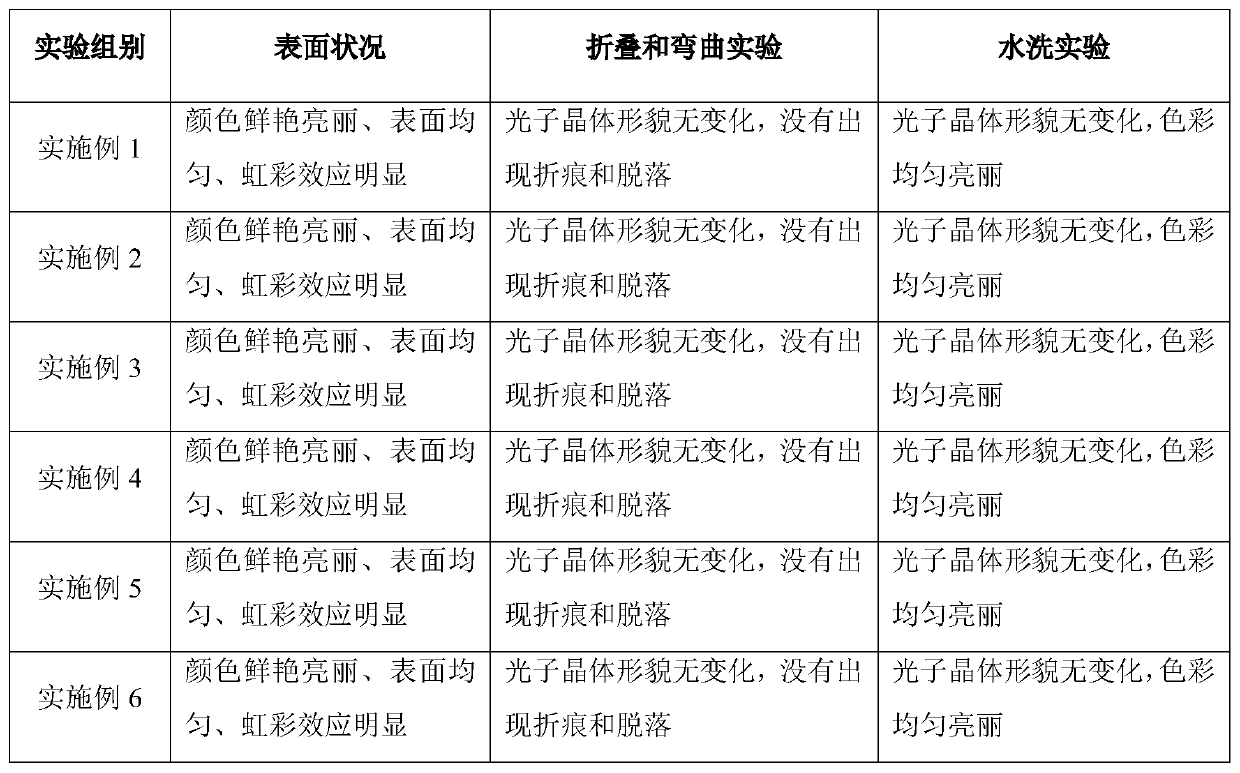

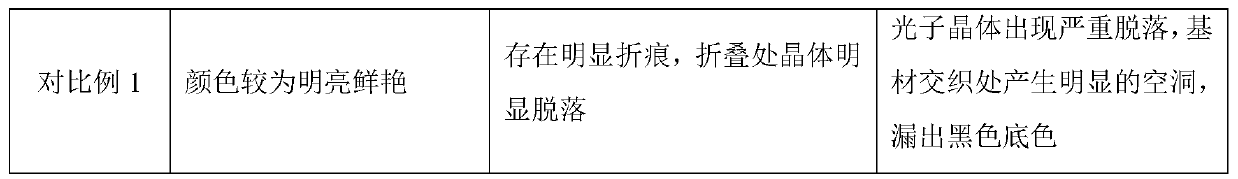

Structural chromogenic finishing liquid for preparing high-stability photonic crystal, and application of structural chromogenic finishing liquid

PendingCN111379174AThe iridescent effect is obviousEasy to fall offDyeing processPhotonic crystalMicrosphere

The invention belongs to the technical field of photonic crystal preparation, and particularly provides structural chromogenic finishing liquid for preparing a high-stability photonic crystal and application of the structural chromogenic finishing liquid in preparation of a patterned high-stability photonic crystal chromogenic structure on a textile substrate. By preparing the structural chromogenic finishing liquid composed of colloidal microspheres, a structural stabilizer, a surfactant and the thickener, the structural chromogenic textile which is bright in color, obvious in iridescence effect and good in durability can be rapidly obtained. The novel-structure chromogenic finishing liquid effectively overcomes the defects that existing photonic crystals are prone to falling off and unstable, can guarantee the durability of the structural color of a fabric, and has the advantages of being easy to implement, low in cost, environmentally friendly and good in universality.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com