Composite steel pan and manufacturing process thereof

A steel pot and pot body technology, applied in the field of composite steel pot and its manufacturing process, can solve the problems of pot body deformation, affecting product appearance quality, failure to pass the bottom concave test, etc., and achieves reduced thermal deformation and multi-layer structure connection Densification and the effect of improving the good rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

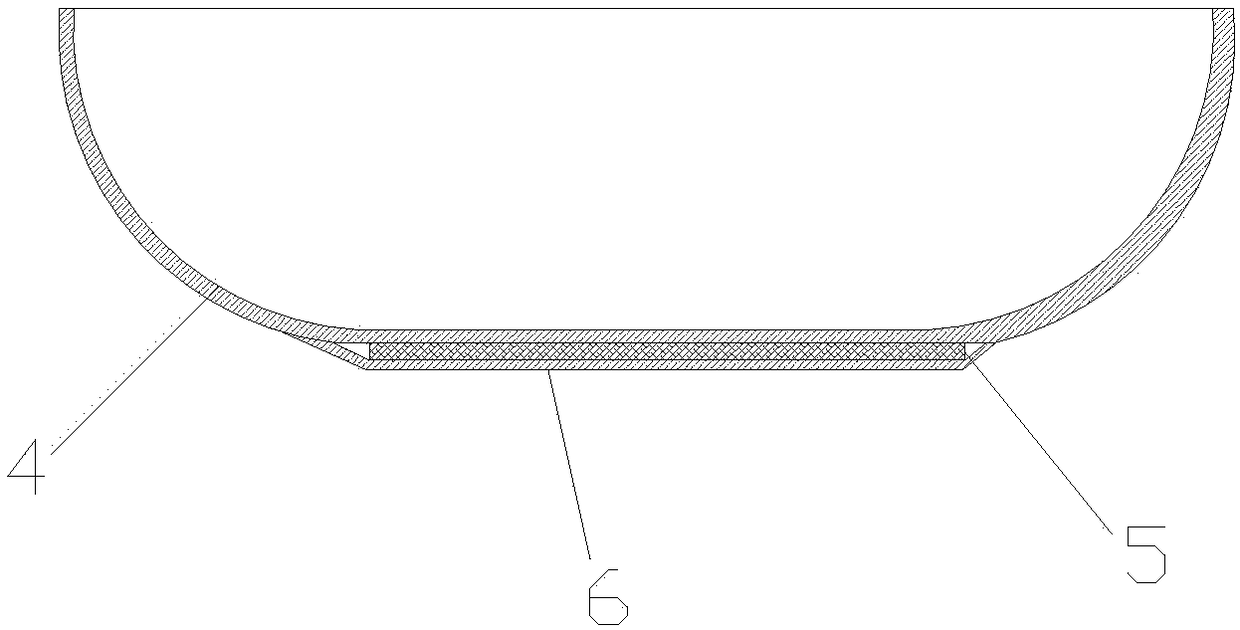

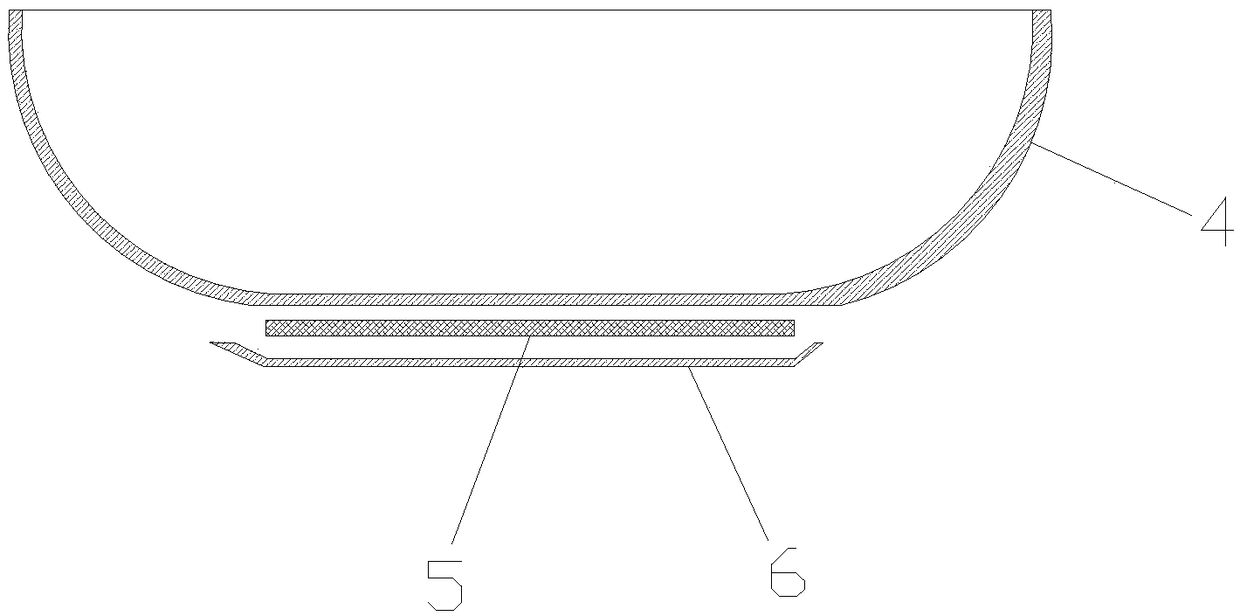

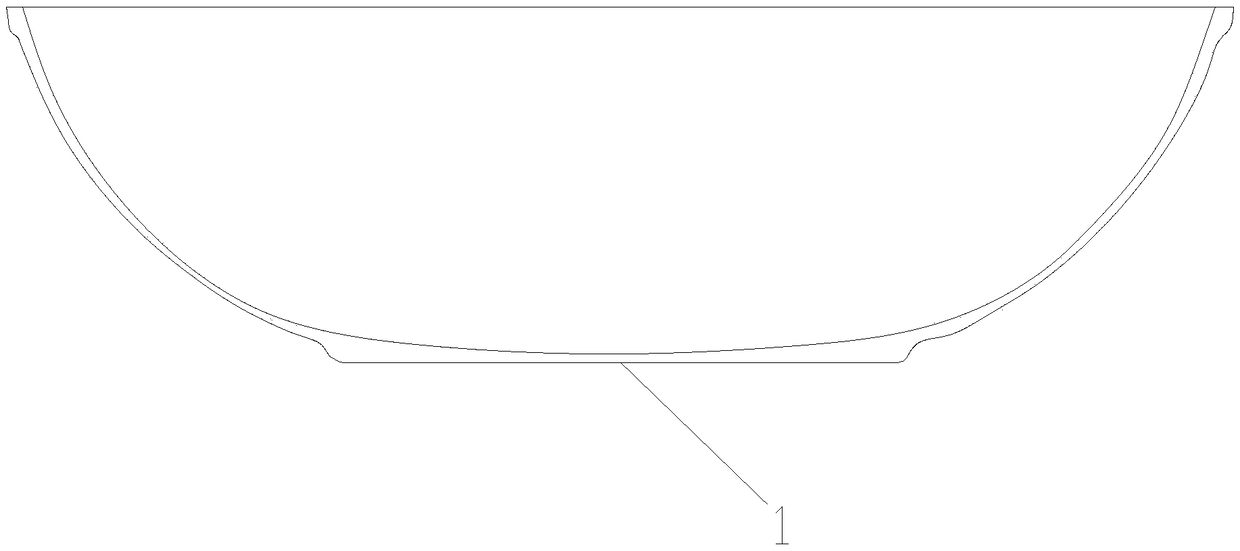

[0025] A composite steel pan and, as Figure 3-5 As shown, it includes a pot body 1, and the pot body 1 includes an inner working layer 11 and an outer heating layer 12 made of a magnetically permeable material, and the bottom of the inner working layer 11 protrudes downward to form a pot bottom boss 3, The bottom of the outer heating layer 12 protrudes downwards to form a base 121, and the base 121 is provided with a first groove 1211; the outer wall of the inner working layer 11 is provided with an inner annular boss 4 near the mouth of the pot, and the outer heating layer The outer wall of 12 is provided with an outer annular boss 122 near the mouth of the pot, and the inner side of the outer annular boss 122 is provided with a second groove 1221; In the first groove 1211 , the inner annular boss 4 is accommodated in the second groove 1221 .

[0026] The material of the inner layer working layer 11 is a stainless steel inner layer working layer or an aluminum inner layer w...

Embodiment 2

[0038] Ordinary full double bottom (non-porous double bottom) test results:

[0039] LGA-test sample bottom concave value

[0040]

Embodiment 3

[0042] Multi-layer steel imitation pressure cooker test results:

[0043] LGA-test sample bottom concave value

[0044]

[0045] Wherein, embodiment 2 and embodiment 3 are the test data of common full compound bottom (non-porous compound bottom) pan and multi-layer steel imitation pressure cooker respectively.

[0046] According to the above data, it can be known that the present invention is compared with the double-bottom pan applicable to ordinary induction cooker: the bottom of the multi-layer composite steel pan is not easily deformed after being heated, the magnetic conduction area is large, and the heat conduction is more uniform. Compared with ordinary full-bottom pots, it will not lose thermal efficiency due to the reduction of the magnetic conduction area of the raised bottom due to heating. The process of the present invention simultaneously covers: making other materials, aluminum alloy and stainless steel or the material of the magnetic conduction layer clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com