Patents

Literature

433results about How to "Improve the excellent rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

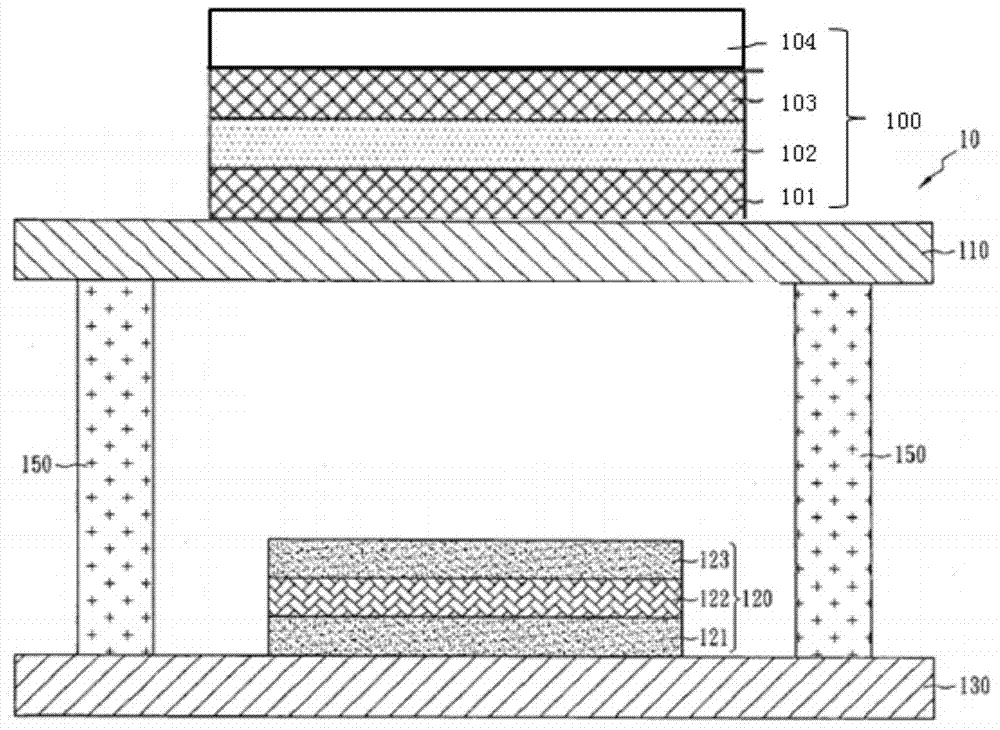

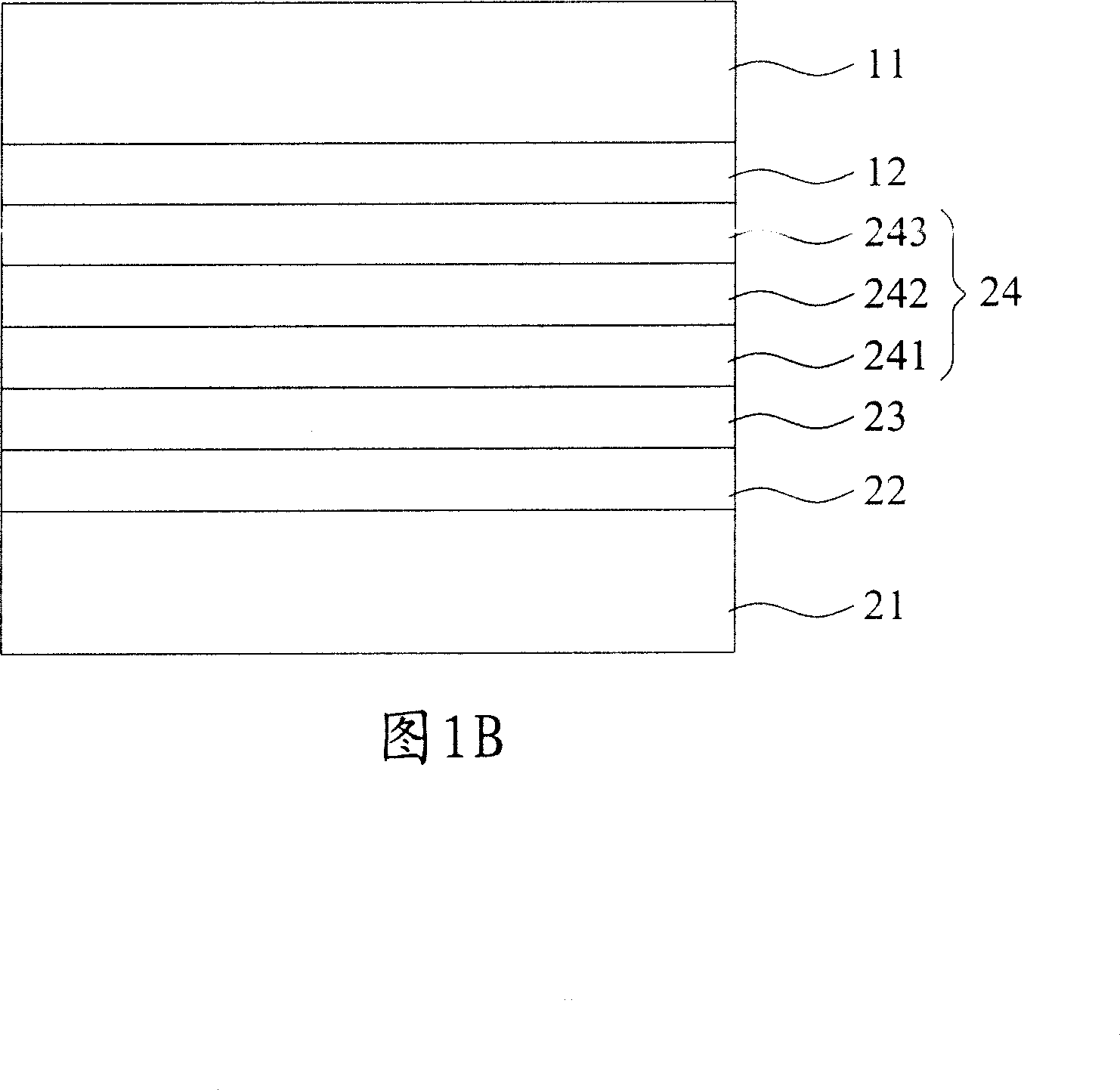

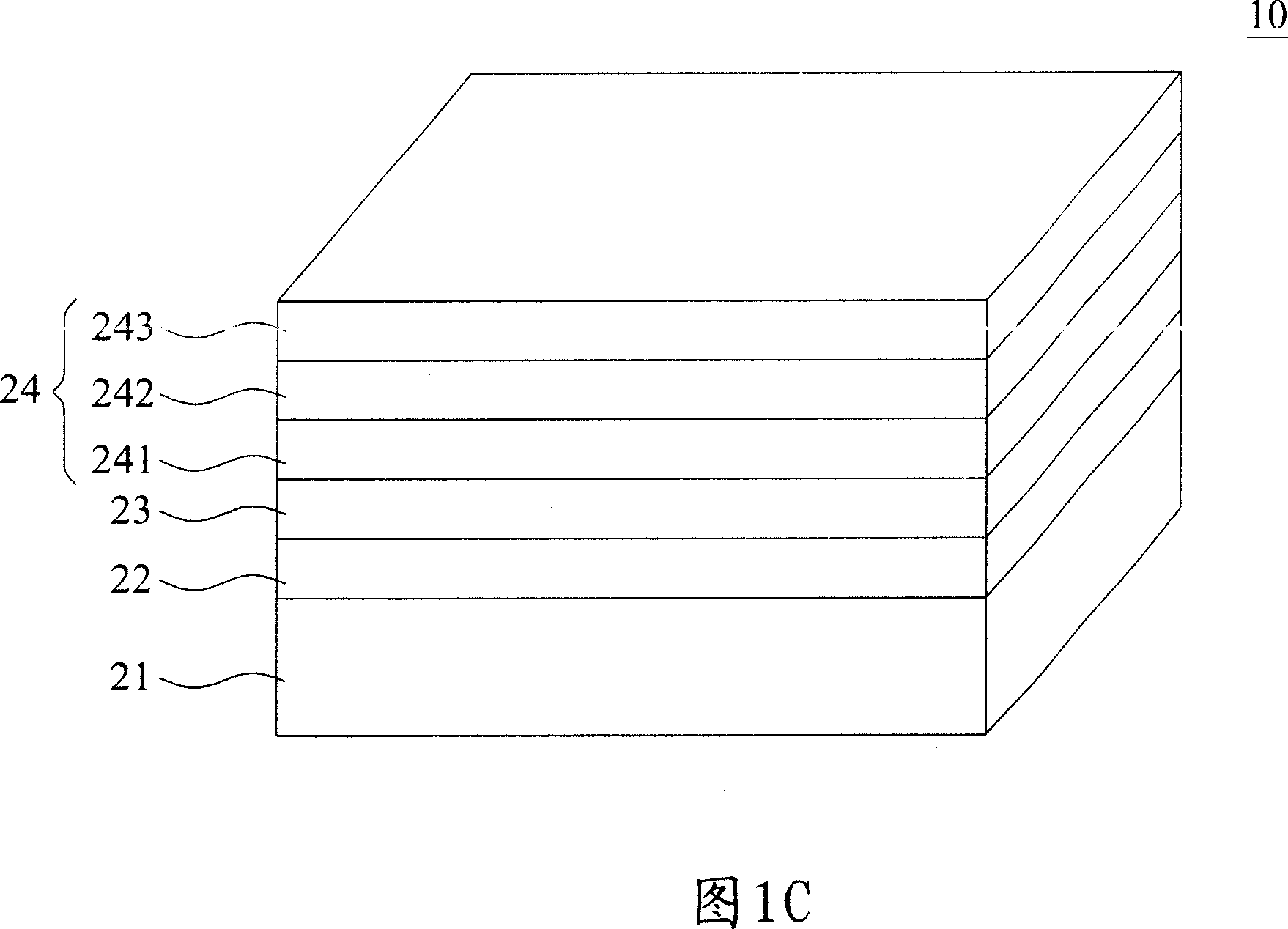

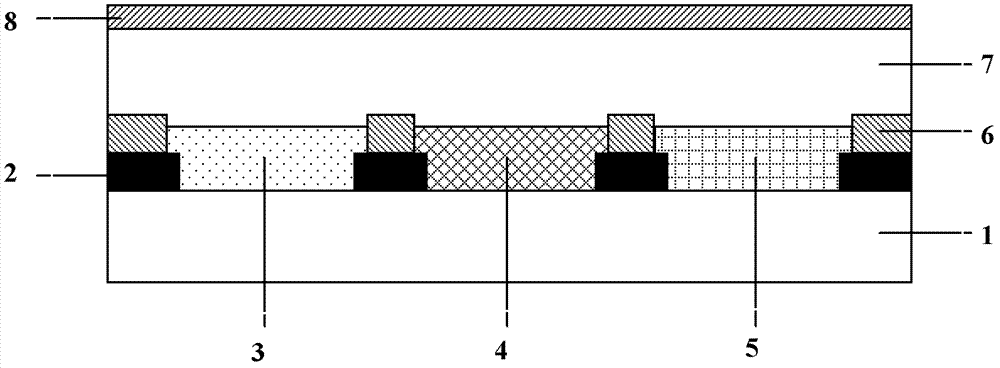

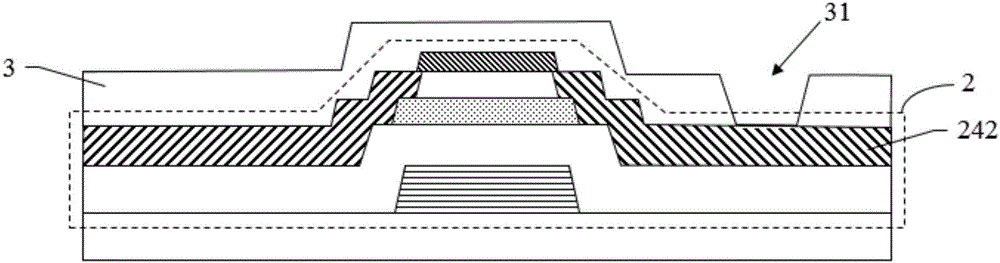

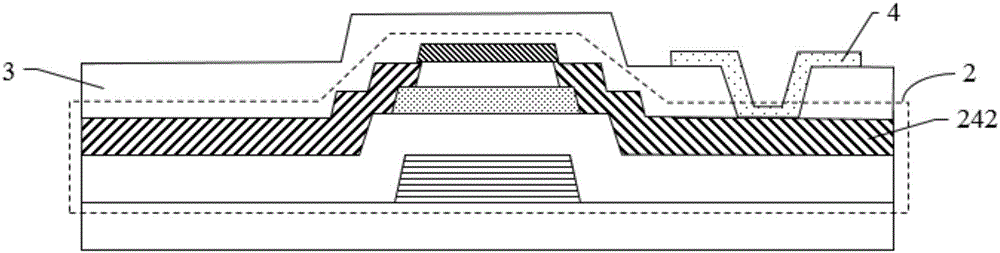

Organic light emitting display device with touch screen function and manufacturing method thereof

ActiveCN104752466AEasy to useSimple structureSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceDisplay device

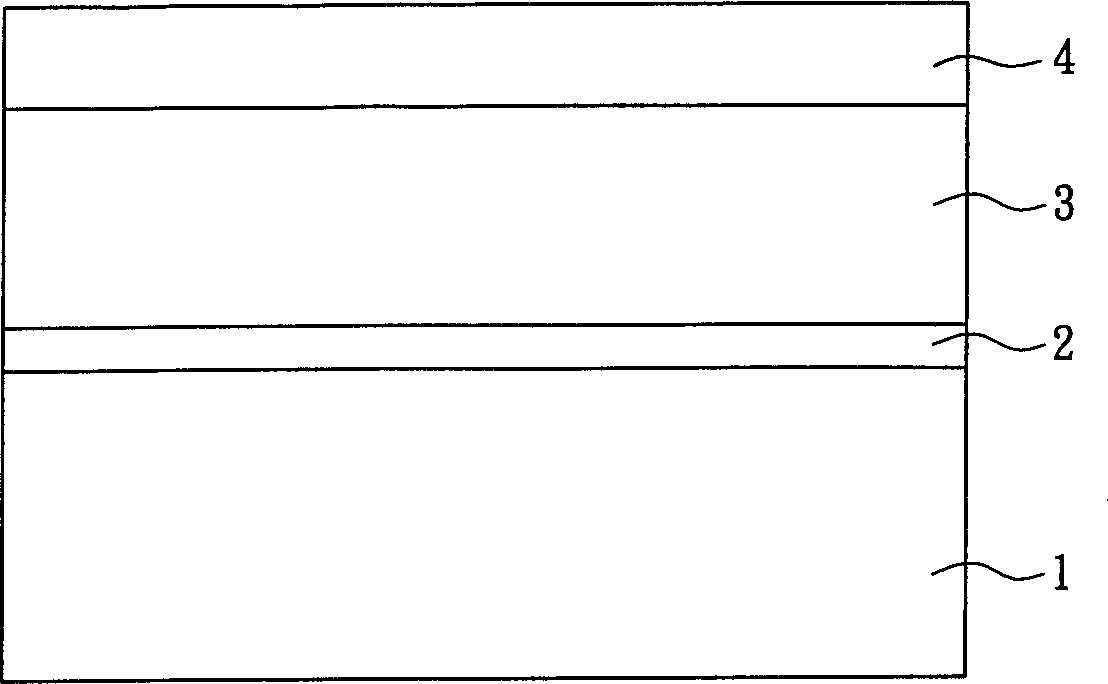

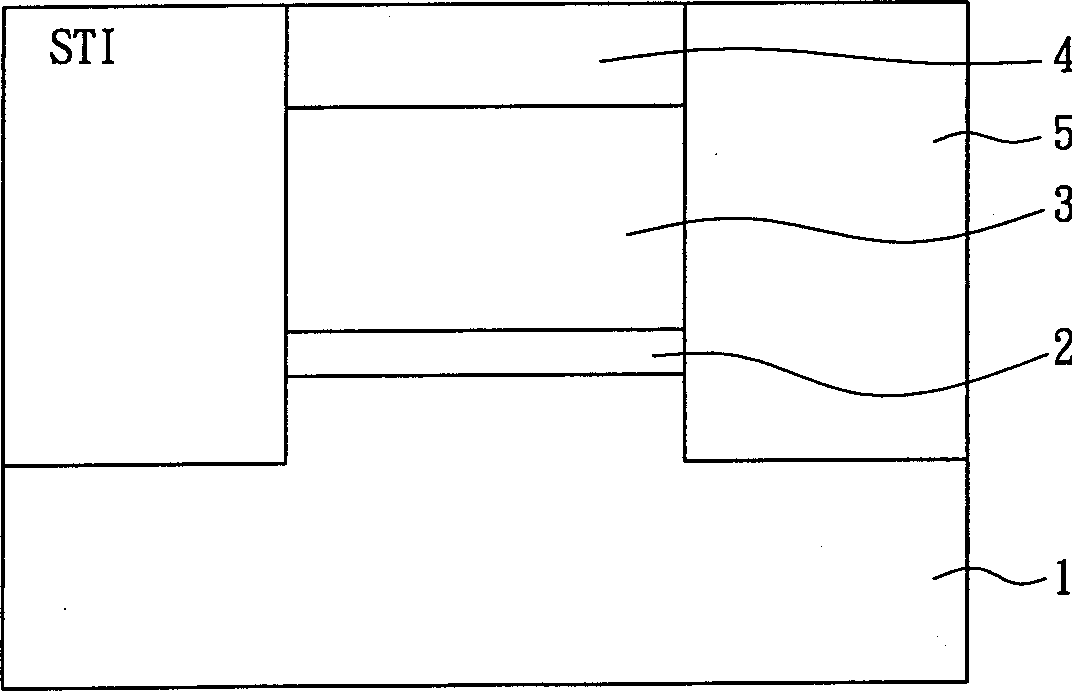

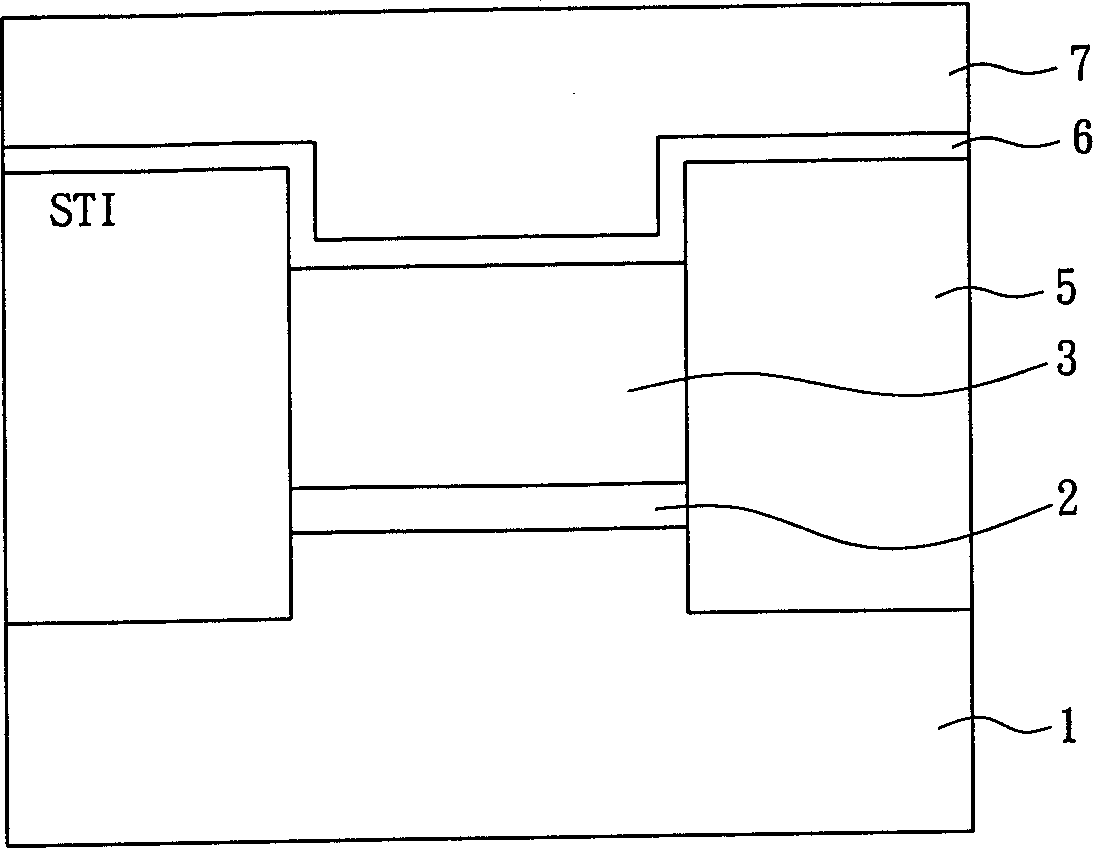

The invention discloses an organic light emitting display device with a touch screen function and a manufacturing method thereof. The organic light emitting display device comprises a touch screen sensing layer and an organic light emitting layer, wherein a sensing electrode and an organic light emitting electrode share a composite layer. A capacitance type touch control sensing layer comprises an insulating layer, a first transparent conducting layer and a first touch control sensing layer, and an OLED light emitting layer comprises an anode layer, an organic light emitting layer and a cathode layer. The composite layer combines the first touch control sensing layer of the capacitance type touch control sensing layer and the cathode layer of the OLED light emitting layer. The organic light emitting display device with the touch screen function enables the overall thickness to be lowered, the manufacturing program to be reduced, and the cost to be lowered.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

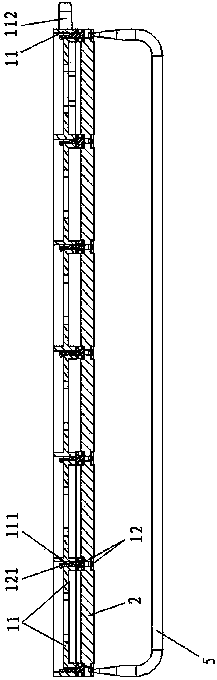

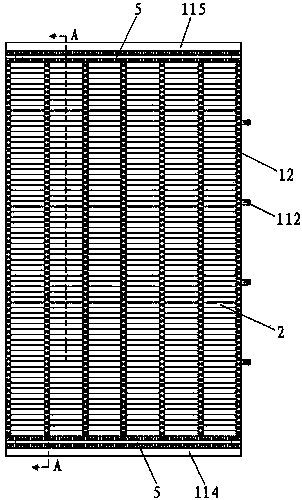

Rare earth thick film circuit electrical heating element based on aluminum nitride minicrystal ceramic substrates and its preparation technique

ActiveCN101321415AHigh thermal conductivityImprove electrical performanceHeating element materialsRare earthHigh power density

The invention provides a controllable electrical heating element of rare-earth thick-film circuit based on aluminum nitride microcrystal ceramic base plate and manufacturing method thereof, comprising base pieces and serial electronic sizing agents which are manufactured on the base pieces. The serial electronic sizing agents comprise package sizing agent and electronic sizing agent, and are all composed of three parts including a functional phase, an inorganic bonding phase and an organic carrier. The serial electronic sizing agents further comprise rare-earth resistance sizing agent. The base piece is ALN aluminum nitride microcrystal ceramic base piece. The serial electronic sizing agents are manufactured on the base piece by means of thick film circuit. The invention synchronously further provides formulations of ALN aluminum nitride microcrystal ceramic base piece, rare-earth envelopment sizing agent, rare-earth resistance sizing agent and rare-earth electrode sizing agent. The invention is environment-friendly, safe and reliable by providing with equal and controllable heating temperature field, large power, high power density, high efficiency of heat conduction, high speed of response, high efficiency for saving energy, strong capability of thermal-shock resistance, small volume and wide application range.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

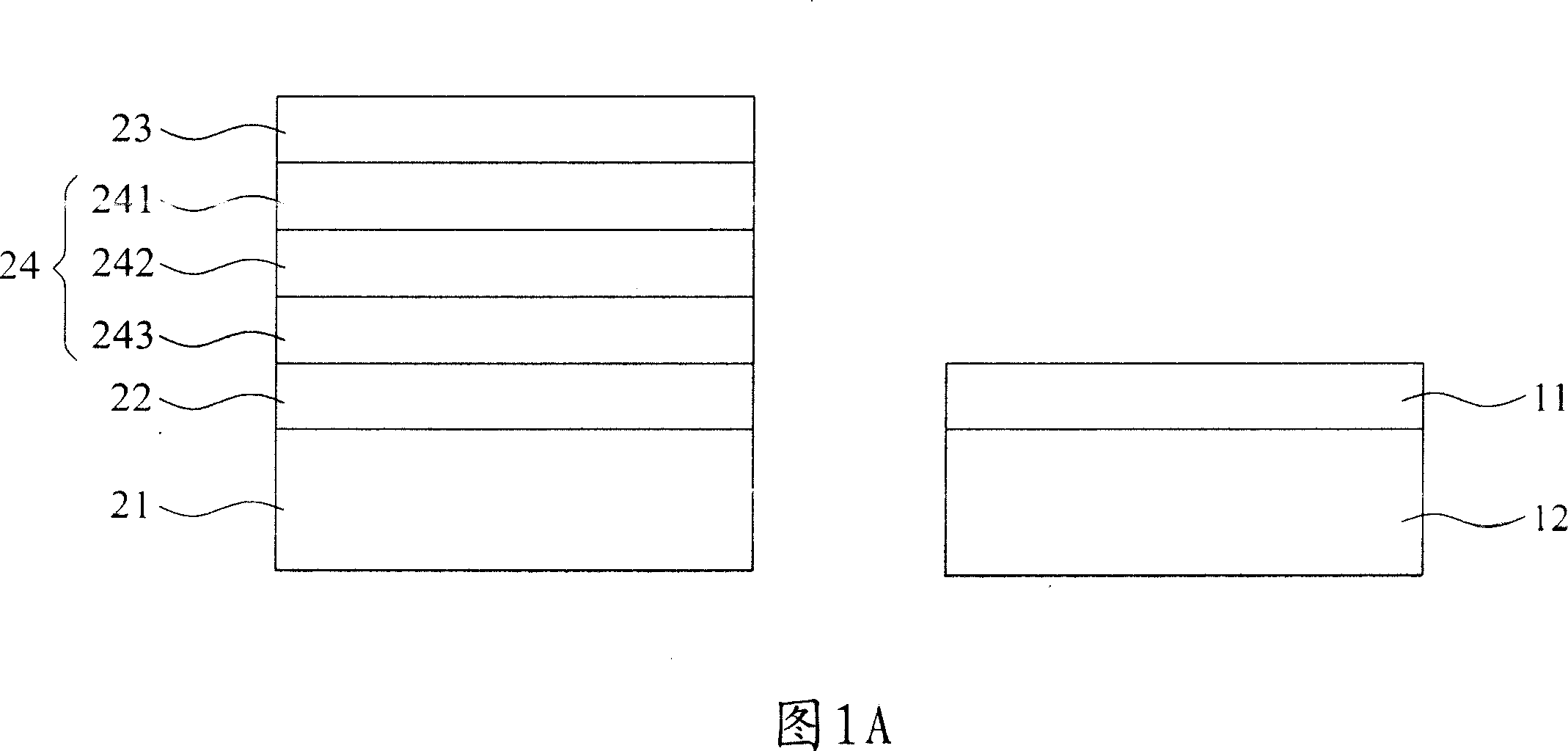

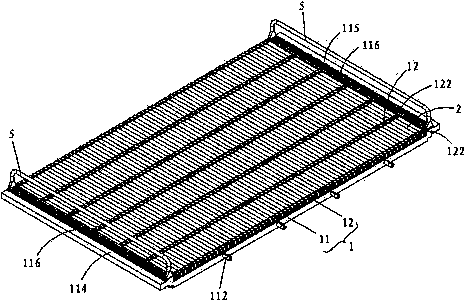

LED structure

InactiveCN101145570AConvenient series/parallel circuit connectionSimplify the linkSolid-state devicesSemiconductor devicesHigh pressureBare surface

The invention relates to a light-emitting diode structure which comprises a first substrate, an adhesive layer formed on the first substrate, a first ohmic connection layer formed on the adhesive layer, an epitaxial layer formed on the first ohmic connection layer, a first insulating layer covered on the exposed surfaces of the first ohmic connection layer and the epitaxial layer, a first current-conducting plate and a second current-conducting plate both formed inside the first insulating layer and electrically connected with the one end of the first ohmic connection layer and the epitaxial layer. With the arrangement of a first groove and a second groove, the complicated series / parallel circuit connection of the light-emitting diode structure can be performed conveniently, and thus the light-emitting diode structure, in a monomer form, is adapted to various operations in high pressure environment.

Owner:HELIO OPTOELECTRONICS

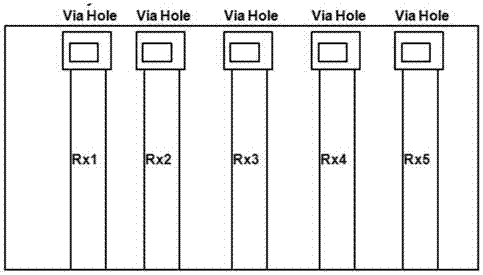

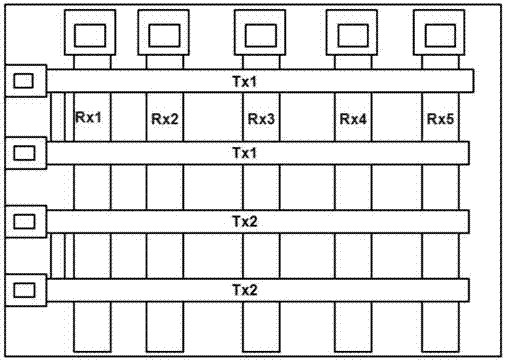

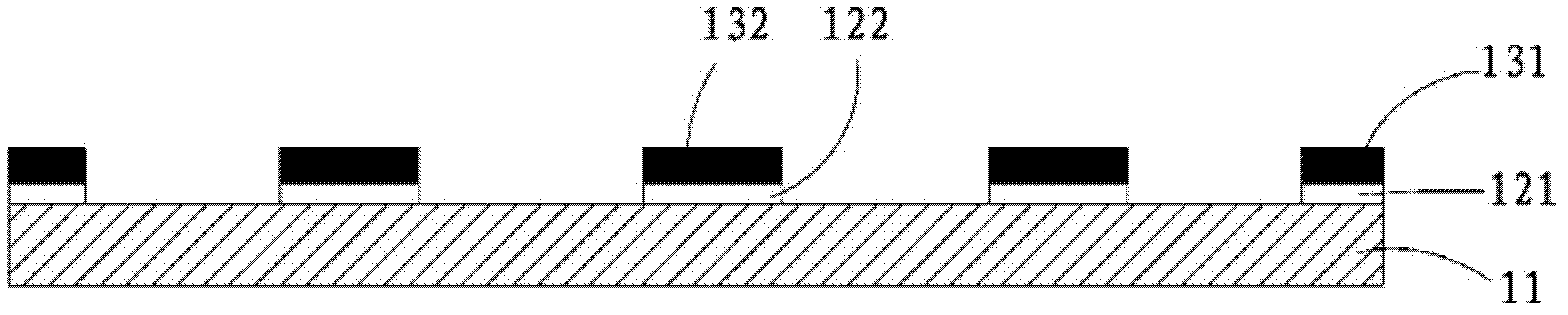

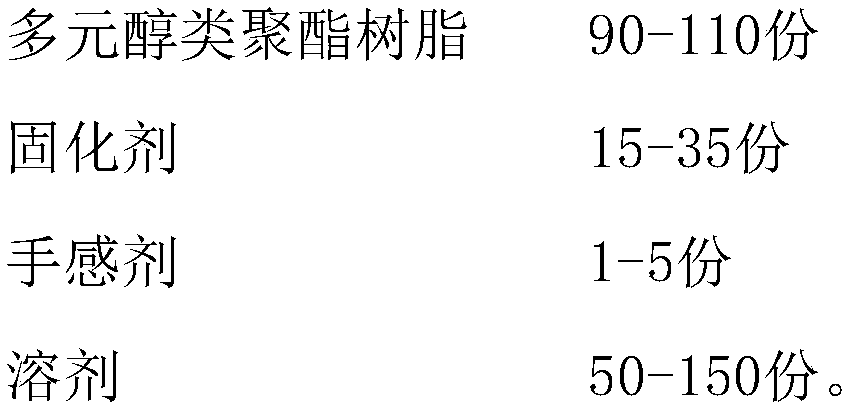

Novel electrode lead capacitive screen manufacturing method and its product and touch screen terminal

ActiveCN102279684AThere will be no disconnectionPrecise thickness controlInput/output processes for data processingPolyesterCapacitance

The invention is applicable to the technical field of touch screen production and provides a method for manufacturing a novel electrode lead capacitive screen, the novel electrode lead capacitive screen and a touch screen terminal. The method comprises the following steps of: (1) preparing an indium tin oxide (ITO) conductive film on a polyester (PET) base film; (2) preparing a copper film on the ITO conductive film by using a magnetically-controlled splutter coating method; (3) manufacturing ITO patterns, and forming an edge copper electrode lead at one time; (4) selectively etching the copper film on the middle ITO pattern, and reserving the ITO pattern to obtain PET thin film structures; and (5) sequentially adhering two PET thin film structures which are obtained in the step (4) and a piece of panel glass by using an optical adhesive to obtain the novel electrode lead capacitive screen. In the method for manufacturing the novel electrode lead capacitive screen provided by the invention, the magnetically-controlled splutter coating method is adopted to replace a silk-screening silver paste process to manufacture an electrode lead of a capacitive screen with mature technical means; and by the method, the good rate for manufacturing the capacitive screen having a film-film structure can be greatly improved, so that the manufacturing cost of the capacitive screen is saved.

Owner:深圳豪威显示科技有限公司

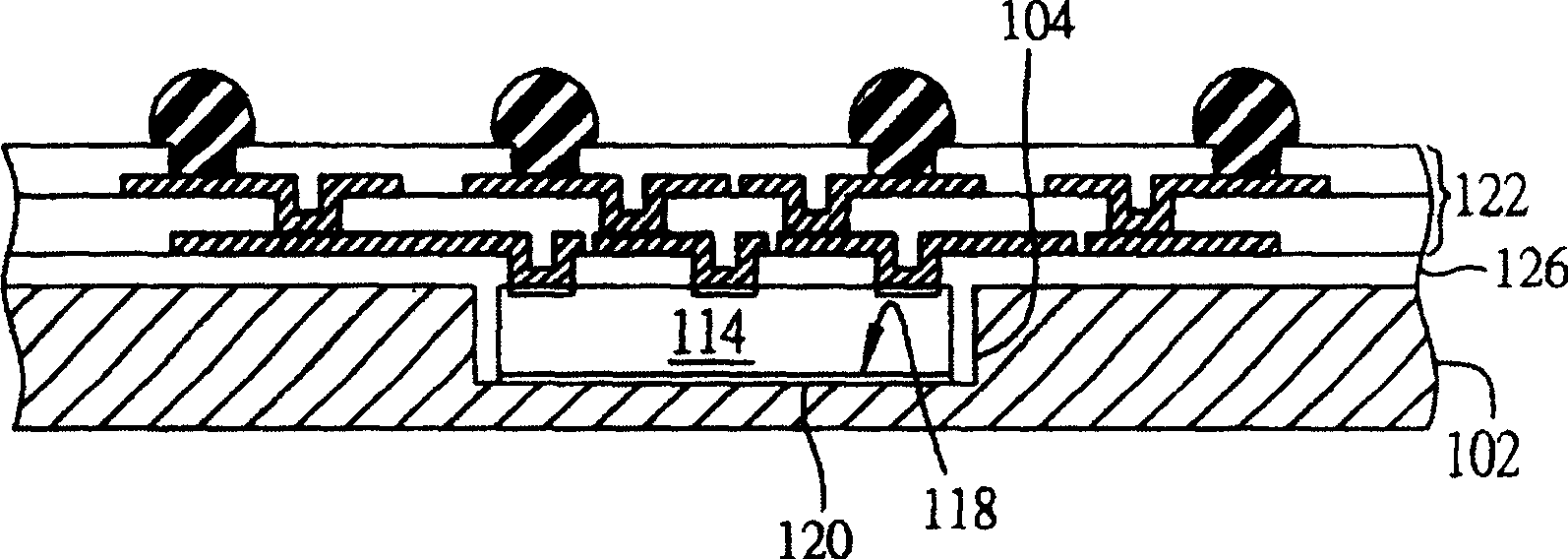

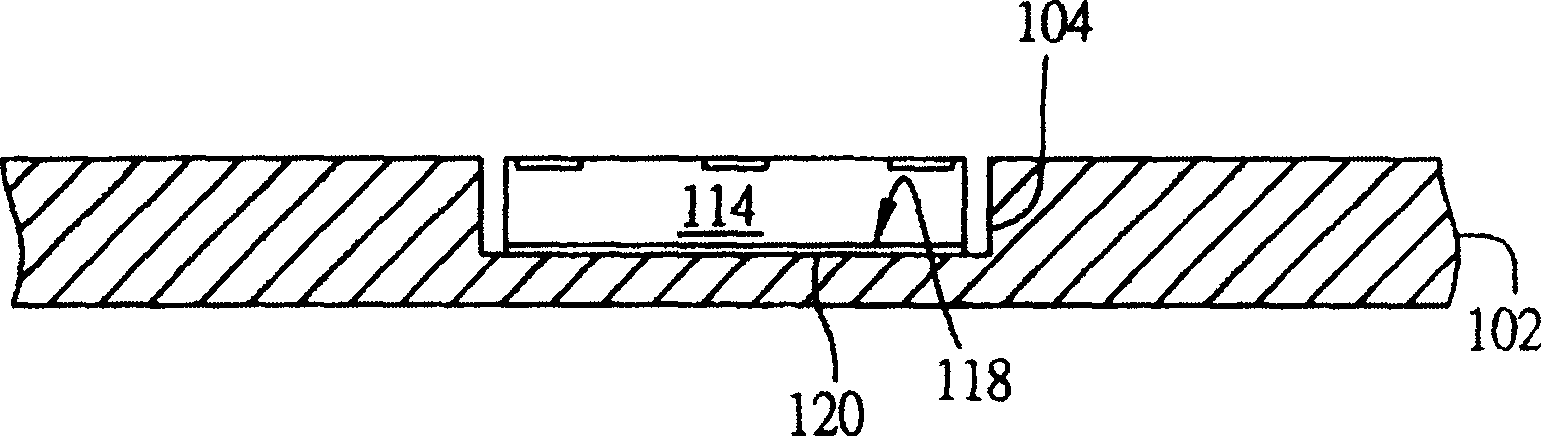

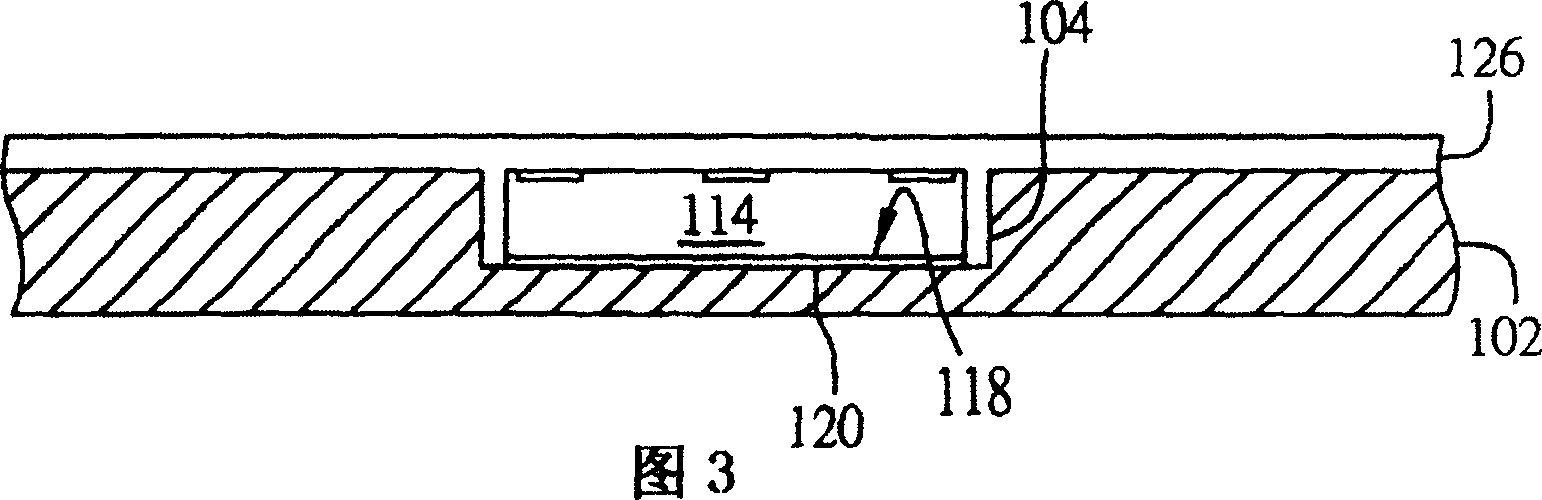

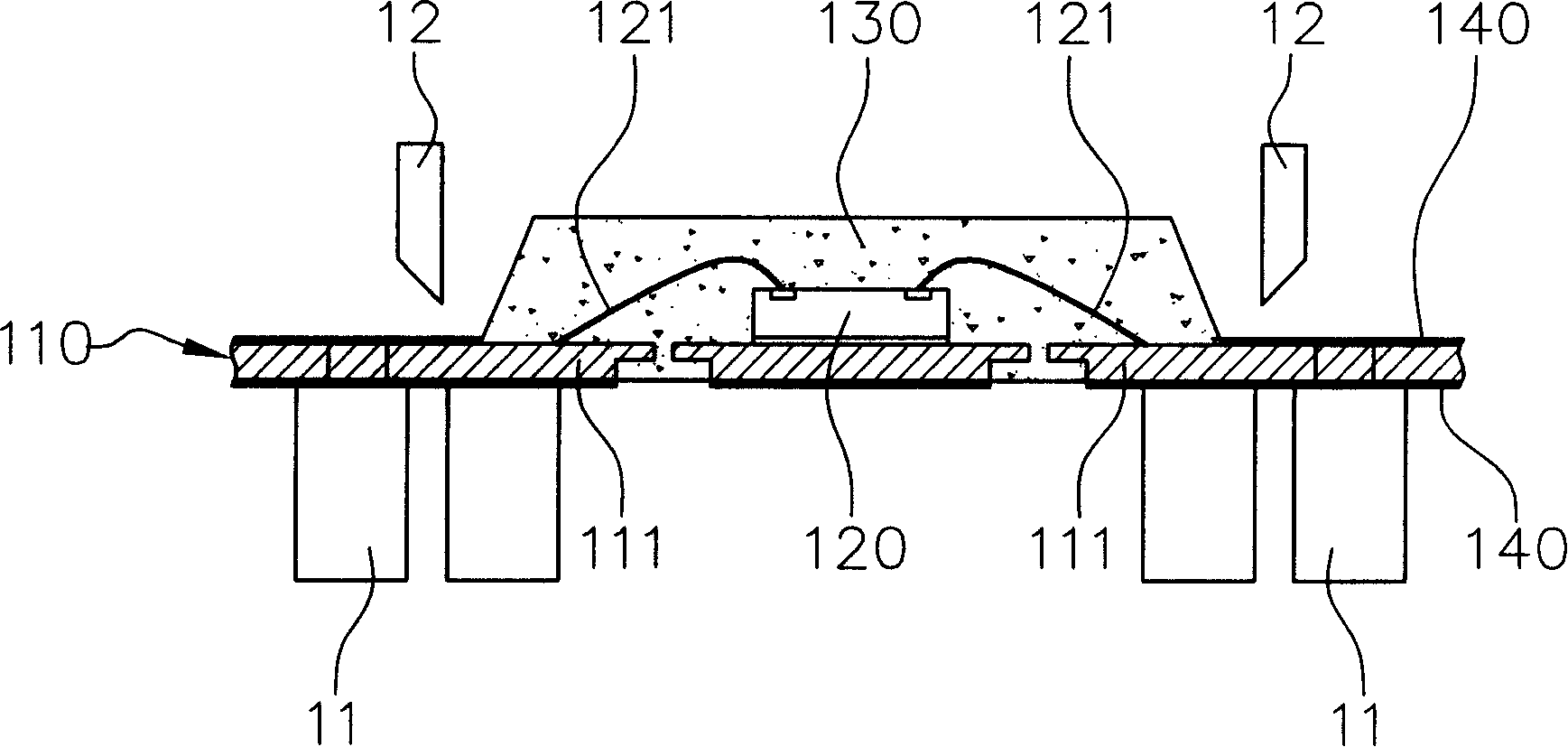

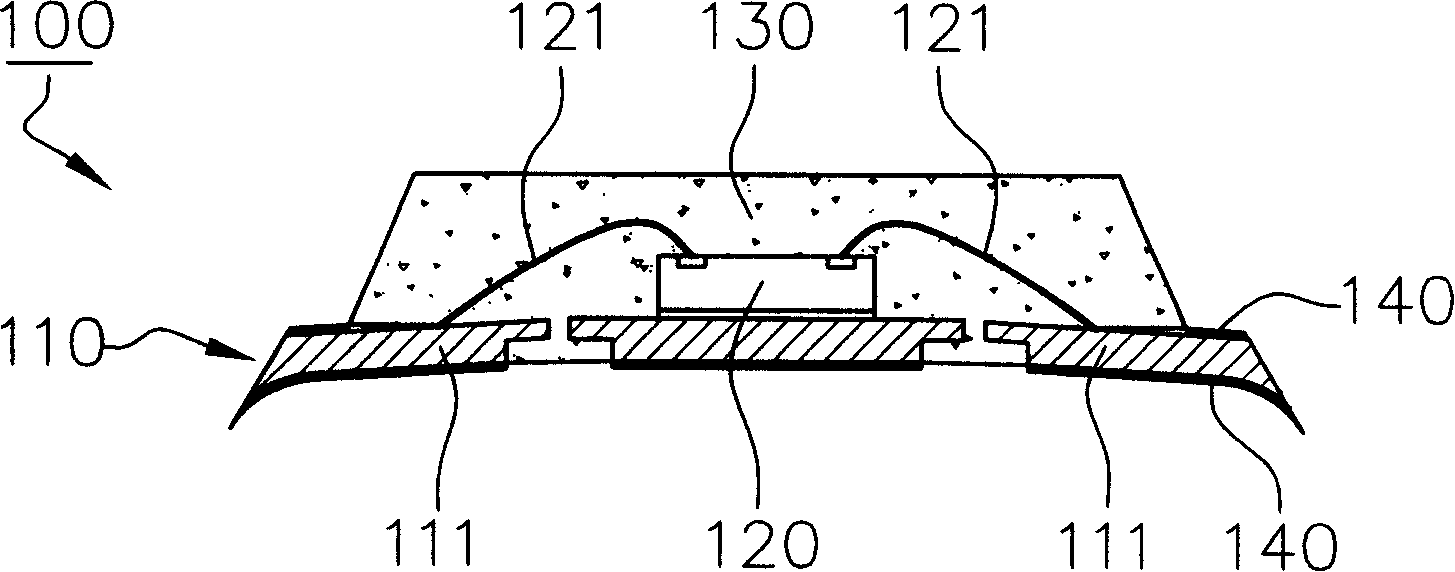

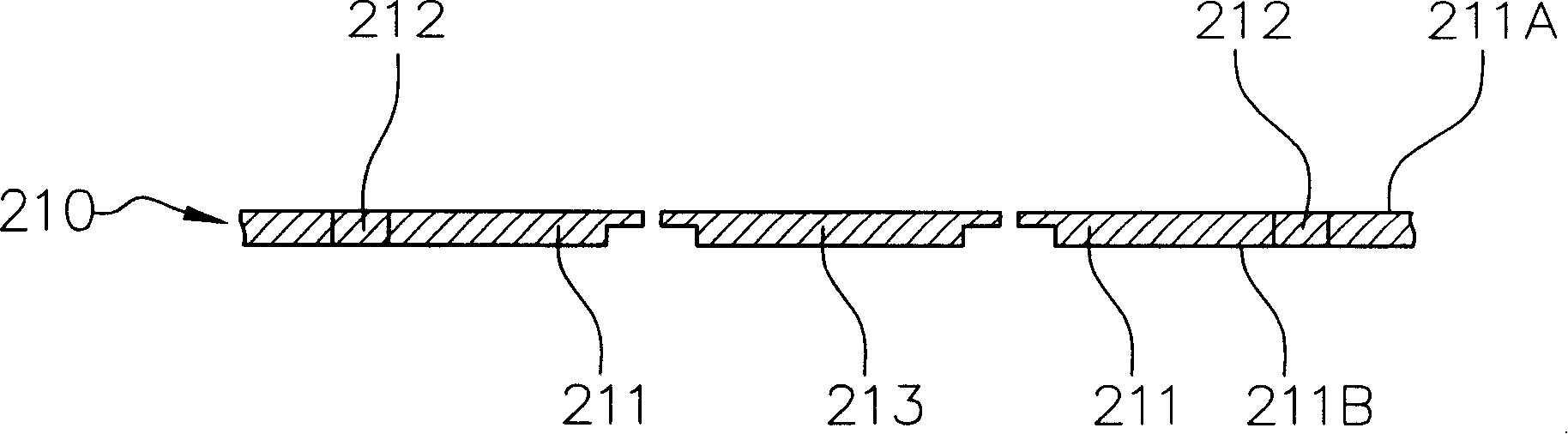

Semiconductor chip buried base plate 3D construction and its manufacturing method

ActiveCN100463128CWon't pushEasy to pushSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

This invention relates to semiconductor chip imbed baseboard three dimensional seal structure and its process method, which comprises the following steps: connecting load parts with at least one hole to first insulation layer and at least one conductor chip onto first insulation contained in the load holes; then forming second insulation layer onto load part and chips for adhesion and filling insulation resin into gap between load board and chip to form electricity connection to chip circuit layer; forming chip dissipation blind hole on first insulation layer to aid semiconductor chip to dissipate heat outside.

Owner:PHOENIX PRECISION TECH CORP

Method for processing silicon polished section with low-roughness concentration

ActiveCN101352829AIncrease roughnessReduce defectsPolishing machinesSemiconductor/solid-state device manufacturingSurface roughnessSingle crystal

The invention relates to a processing method of low roughness silicon polished wafers, which comprises a process during which polishing treatment is carried out for silicon single crystal wafers by utilizing a polisher, and the process sequentially comprises a rough polishing process, a moderate polishing process and a fine polishing process. In the fine polishing process, the polish finish is carried out for the silicon single crystal wafers by utilizing polishing cloth and fine polishing slurries are introduced between the polishing cloth and the silicon single crystal wafer surface, and the fine polishing slurry consists of pure water and activators. The surface roughness of the silicon wafer processed by the processing method can be raised to 3 to 5 degree, the performance is steady and the resistivity is uniform.

Owner:无锡光炜电子材料有限公司

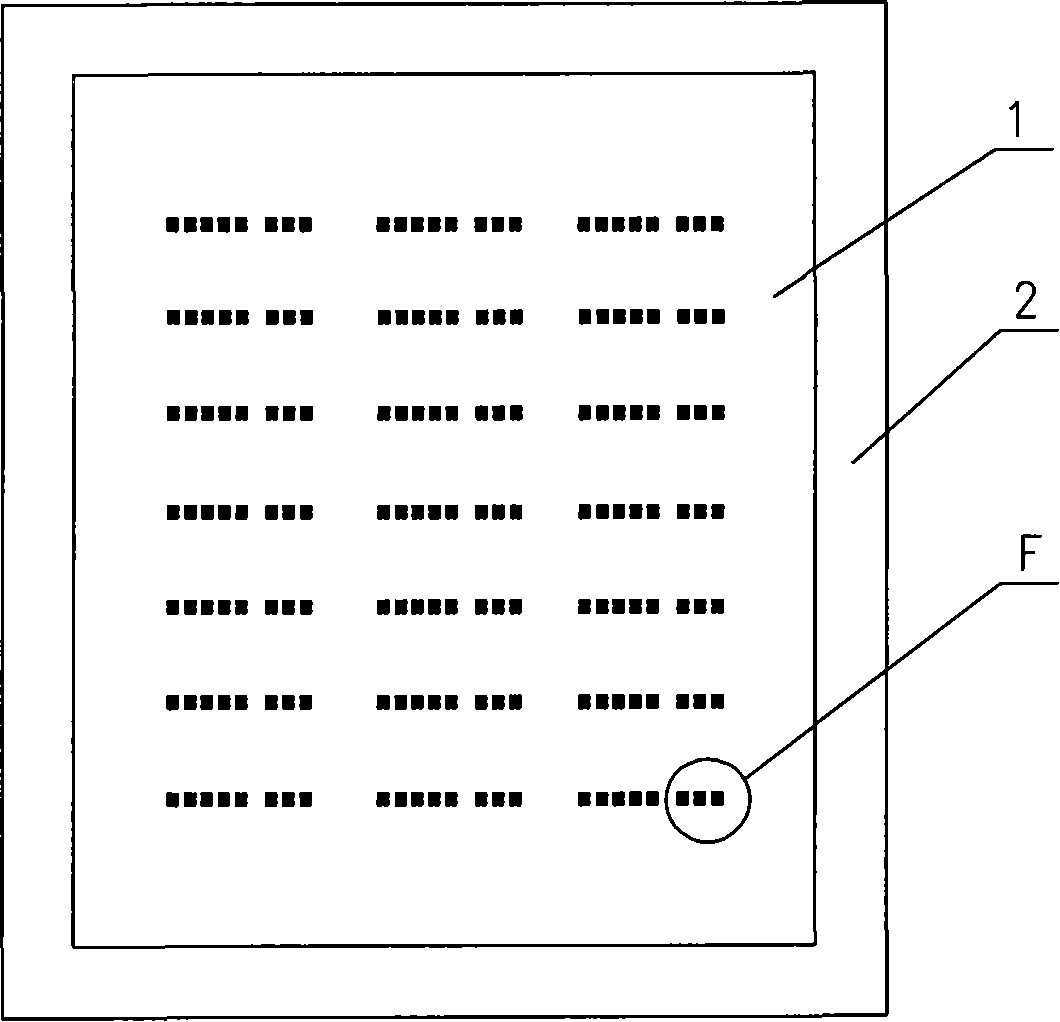

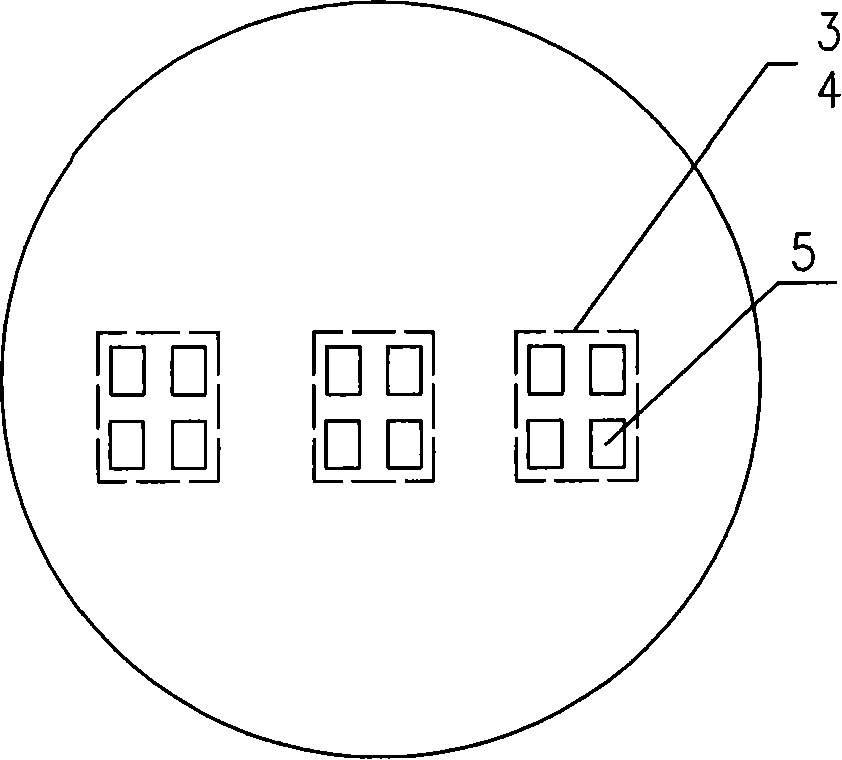

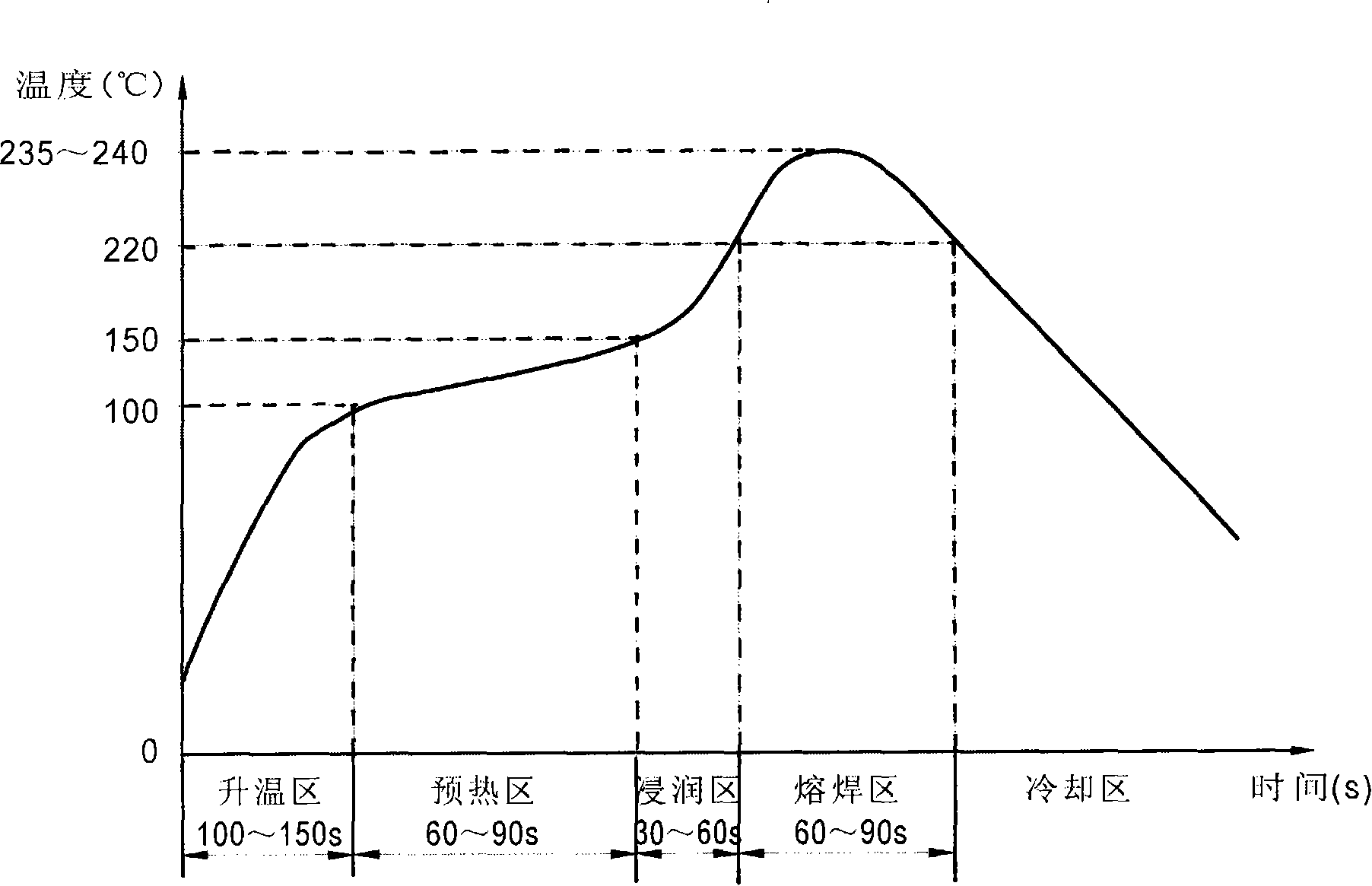

Solder tray local tin plating method on circuit board

InactiveCN101252815AImprove mechanizationReduce manufacturing costPrinted circuit assemblingTinningEngineering

The invention discloses a method for local tinning to the bonding pad on a circuit substrate, which enables lead-free tin plasma to be brushed to the spot welding position bonding pad of the circuit substrate through a steel mesh; the circuit substrate brushed with the lead-free tin plasma passes through the five areas of a reflow soldering machine for operating parameters in sequence, to form liquid tin coating covered in the entire spot welding position bonding pad, and after the circuit substrate cools, solid tin coating is formed in the spot welding position bonding pad. The invention utilizes the steel mesh to brush the lead-free tin plasma to the bonding pad of a common substrate, and utilizes the reflow soldering machine and depends on the wetting property of soldering flux, and the diffusion and the self positioning effect of the tin plasma to accomplish the tinning process of the bonding pad, the tin coating meets the process requirements of the thickness and the smoothness, and provides good basic conditions for the subsequent spot welding working procedure, and the manufacturer does not require to purchase special substrates for the substrate supplier, therefore, the production efficiency can be greatly improved, the qualified rate of the product can be increased, and the production cost of the enterprise can be reduced.

Owner:MORNSUN GUANGZHOU SCI & TECH

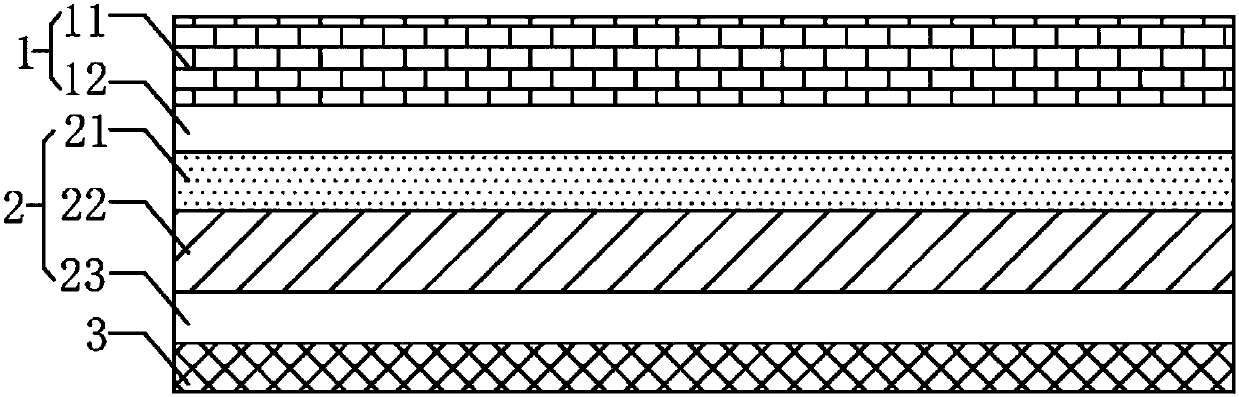

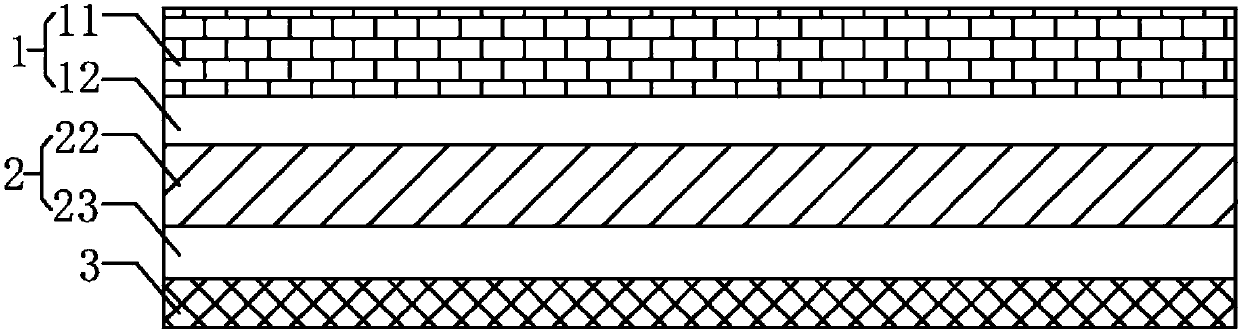

Flexible all-coating soft film and preparation method thereof

ActiveCN107936860AEvenlyGood flexibilityPolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesTectorial membraneEngineering

The invention relates to the technical field of protective films, and particularly relates to a flexible all-coating soft film and a preparation method thereof. The flexible all-coating soft film comprises a film protecting layer, a using layer and a stripping layer which are sequentially adhered from top to bottom; the protecting film layer comprises a base material layer and a film protecting glue layer which are sequentially adhered from top to bottom; the using layer comprises a self-repairing layer, a flexible soft film layer and a using glue layer which are sequentially adhered from topto bottom; the lower surface of the film protecting glue layer is adhered to the upper surface of the self-repairing layer; and the lower surface of the using layer is adhered to the upper surface ofthe stripping layer. The flexible all-coating soft film provided by the invention has smooth hand feeling and large stripping force, a curved screen can be all coated, relatively good resilience and self-repairing effect can be achieved, scratch marks can be repaired automatically, and the service life of the flexible all-coating soft film is prolonged. The preparation method provided by the invention is simple, the operation control is convenient, conventional production processes are simplified, the production efficiency is high, the production cost is low, the prepared product is high in yield and stable in quality, and the preparation method is suitable for large-scale industrial production.

Owner:NALI OPTICAL MATERIAL DONGGUAN

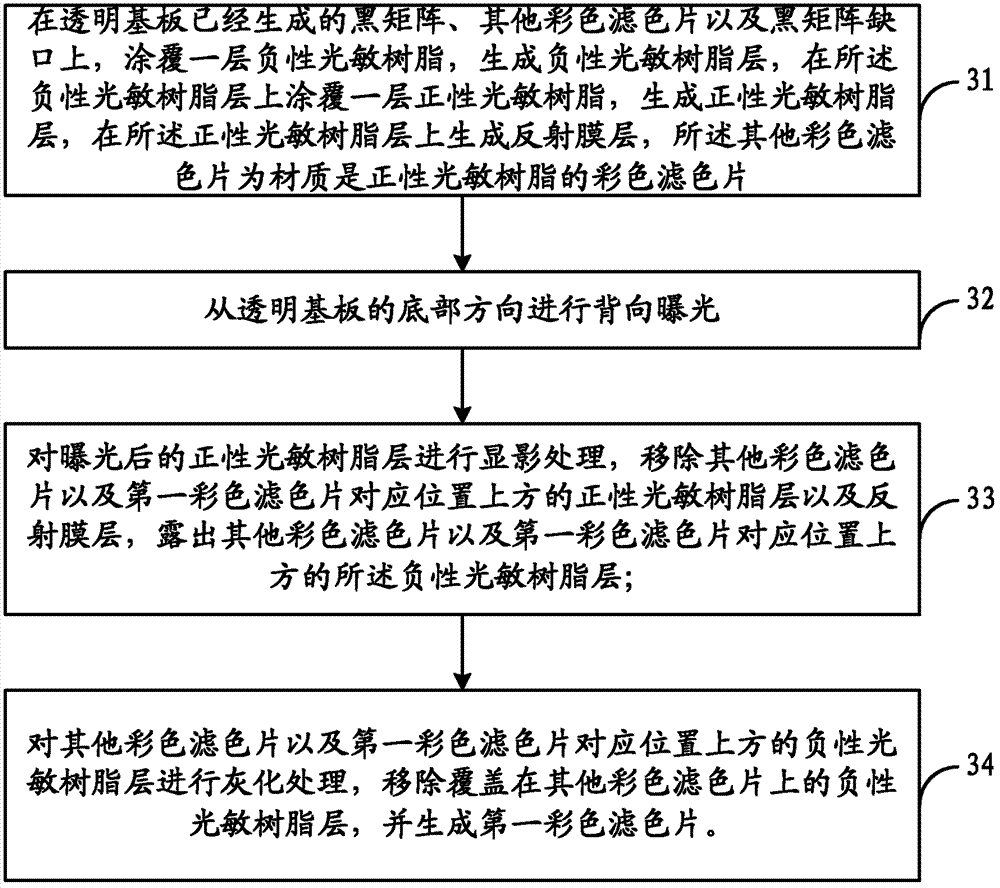

Semi-transmission and semi-reflection color-film substrate and manufacturing method thereof as well as liquid crystal display device

InactiveCN102707484ASimple production processImprove product quality rateNon-linear opticsOptical elementsLiquid-crystal displayEngineering

The invention provides a semi-transmission and semi-reflection color-film substrate and a manufacturing method thereof as well as a liquid crystal display device. The semi-transmission and semi-reflection color-film substrate is arranged in a notch of a black matrix on a transparent substrate and is provided with a plurality of color filters for presenting different primary colors, wherein backward exposure is carried out from a direction of the bottom of the transparent substrate to finally manufacture a first color filter which is made of negative photosensitive resin; and in front of the first color filter, forward mask exposure is carried out from a top direction of the transparent substrate to generate other color filters which are made of positive photosensitive resin, so that a picture layer which can be generated by two times of the forward mask exposure in the prior art can be realized through one time of the backward exposure; and therefore, a production process of the semi-transmission and semi-reflection color-film substrate is simplified and the product yield is effectively improved.

Owner:BOE TECH GRP CO LTD

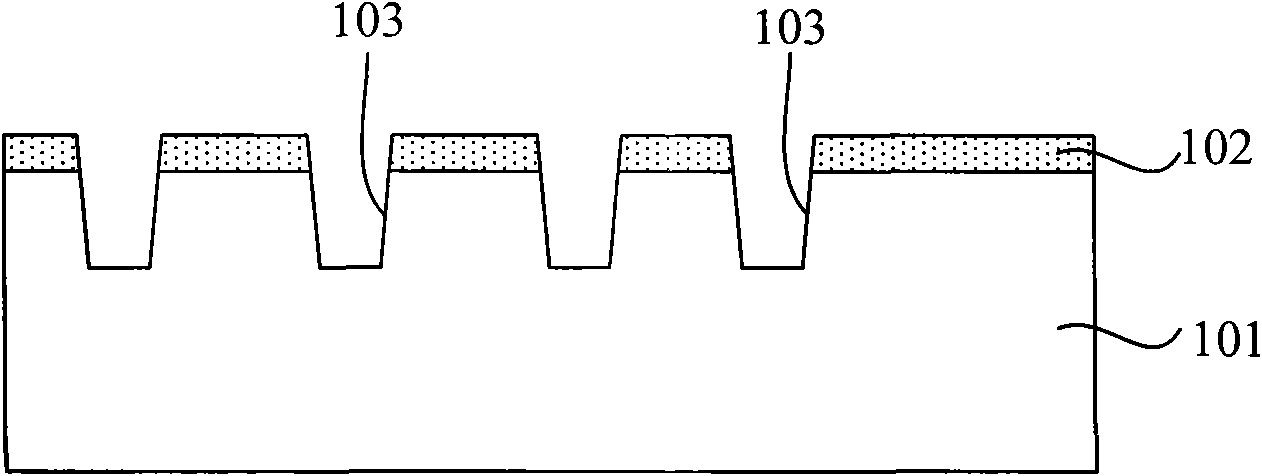

Production method for sapphire pattern substrate

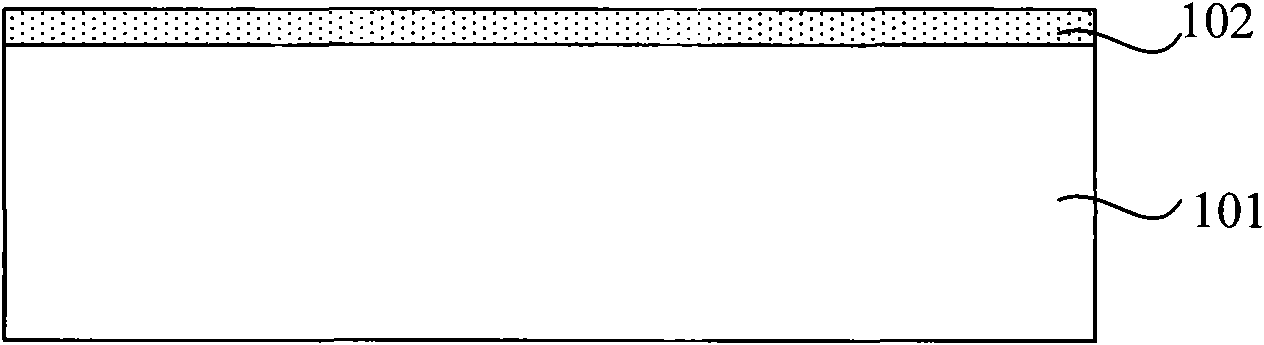

InactiveCN101814426ALow refractive indexReduce hardnessSemiconductor/solid-state device manufacturingRefractive indexPhotoresist

The invention discloses a production method for a sapphire pattern substrate, comprising the following particular steps of (1) depositing a layer of thin film on the upper surface of a sapphire which has a low refractive index material and 1AA-999AA thickness; (2) preparing a mask pattern on the thin film with photoresistance; (3) transferring the pattern masked with photoresist to the thin film through etching to obtain a protuberance with the 1AA-999AA thickness, wherein the lower substrate of the pattern of the protuberance has a width of 0.5-3 mu m and a gap of 0.5-3 mu m; and (4) cleaning the sapphire to remove the residual photoresistance. The invention has the advantages that PSS cost can be greatly reduced and total reflection angles are increased for light, thereby being more favorable for emergent light, improving emergent light efficiency, being favor of laser peeling and increasing excellent rate of the finished product LED chip.

Owner:NANCHANG UNIV

Rare earth electrode slurry of rare earth thick film circuit based on metal plate and its preparation technology

ActiveCN1909748AIntermolecular bonding strength and improved manufacturabilitySolid combinationOhmic-resistance electrodesNon-conductive material with dispersed conductive materialSolid phasesYttrium

The invention relates to a rare-earth electrode slurry of rare-earth circuit, based on the metal base board and a relative production, wherein it is characterized in that: said slurry is formed by solid material and organic solvent carrier, while their mass ratio is 70-90:30-10; the solid component comprises: silver, palladium, and yttrium composite power and micro-crystal glass powder, while their mass percentage is 99.4-94:0.6-6; said composite power is formed by silver, palladium, and yttrium powders at the ratio as 0.6-10:99-82:0.4-8; said micro-crystal glass is the one in SiO2-Al2O3-CaO-B2O3-Bi2O3-La2O3 group. And the production comprises: (1), preparing rare-earth micro-crystal glass powder; (2), preparing silver, palladium, and yttrium composite powder; (3), preparing organic solvent carrier; (4), mixing material in three-dimension and rolling with three rollers; (5), preparing the rare-earth slurry; (6), bottling. The invention is environment friendly and better humidity compatibility.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

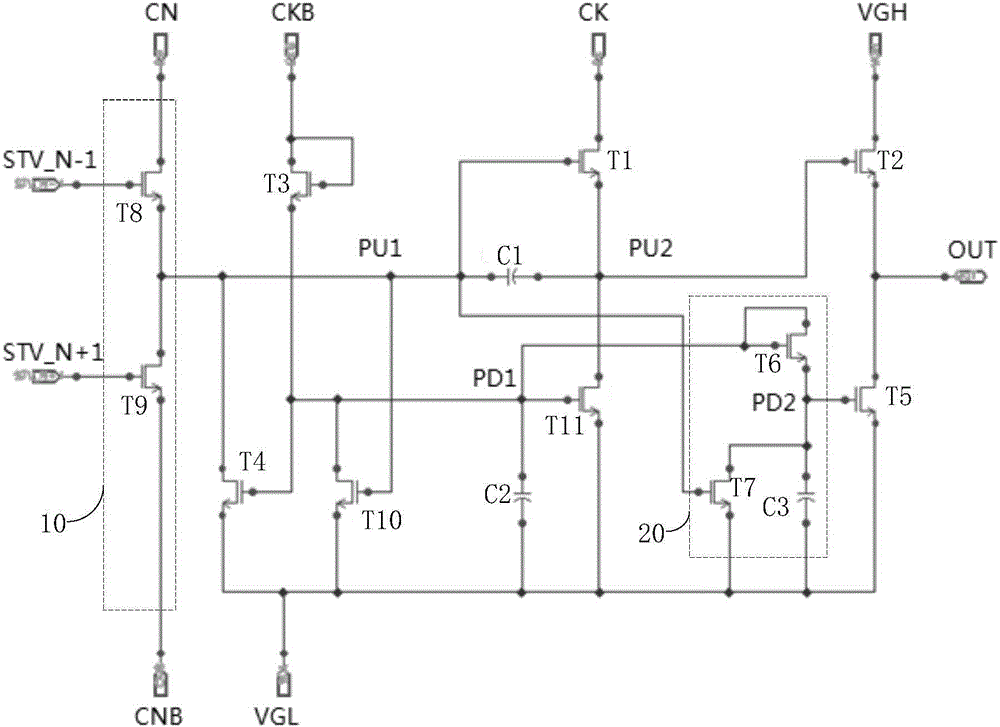

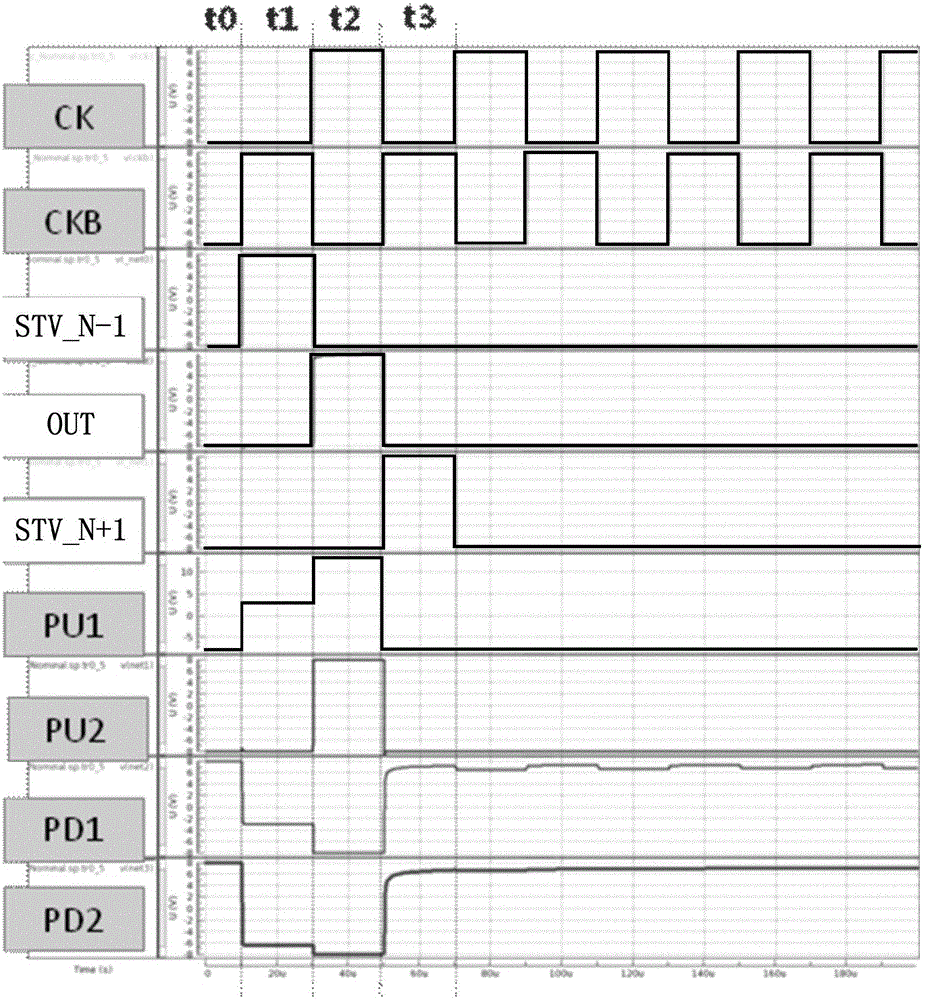

Touch control electronic equipment, touch control display device and grid drive circuit of array baseplate

ActiveCN106814911AStable outputReduce the effect of the outputStatic indicating devicesDigital storageCapacitanceDisplay device

Owner:BOE TECH GRP CO LTD +1

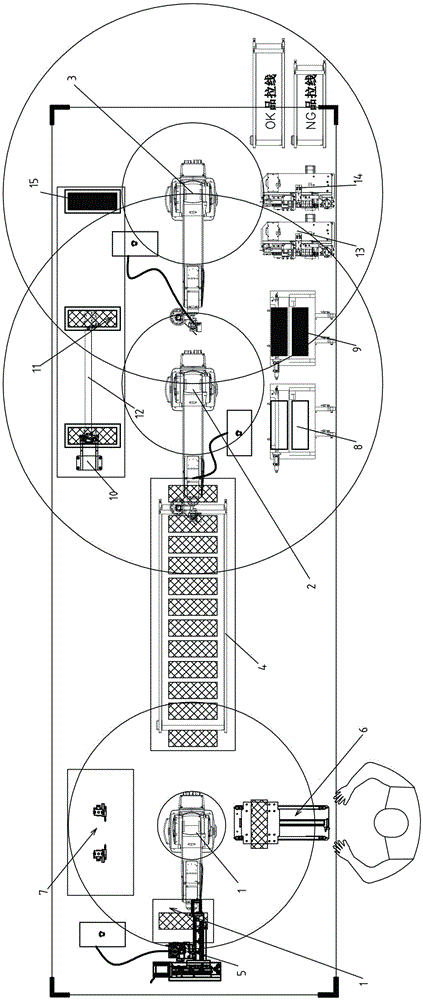

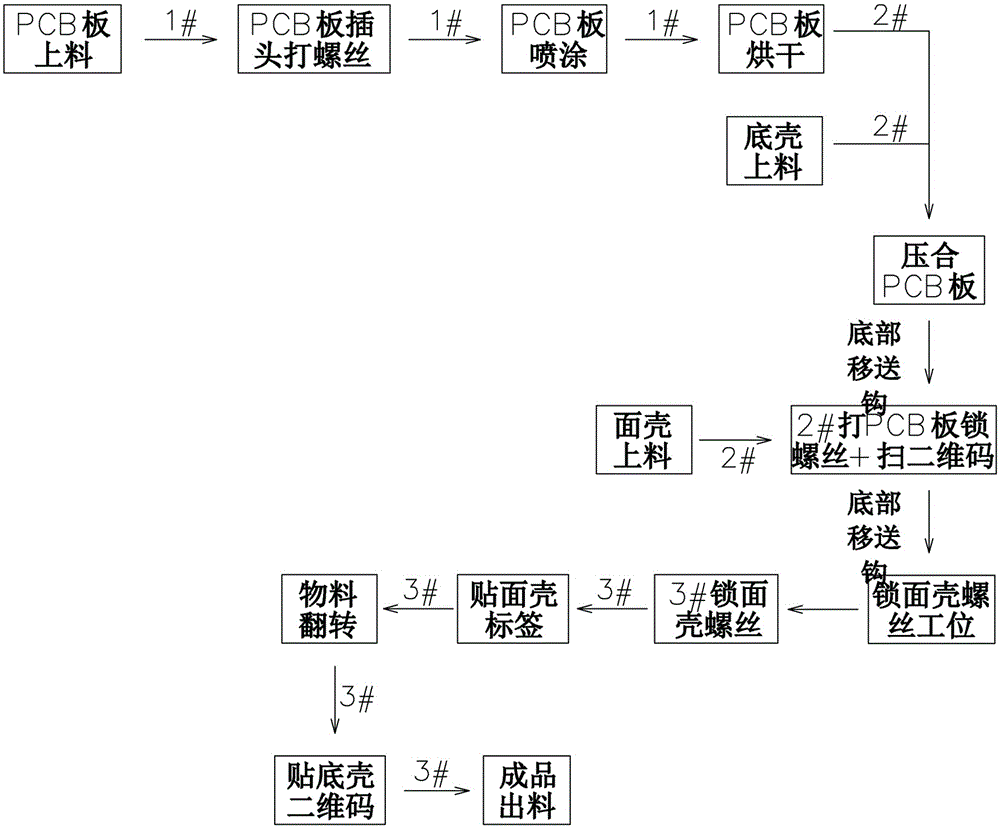

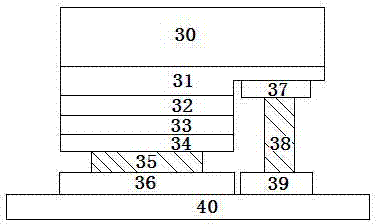

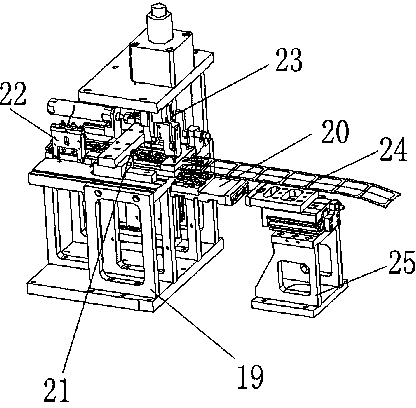

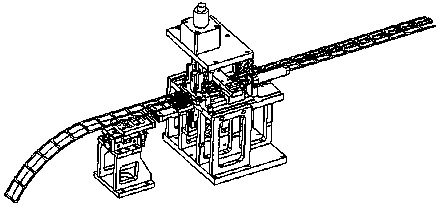

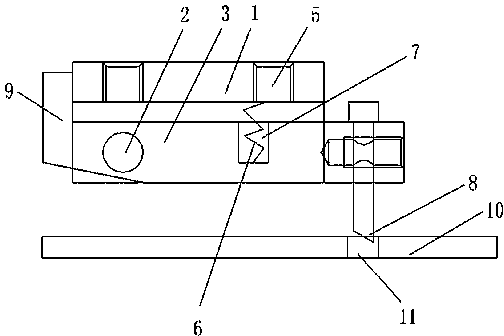

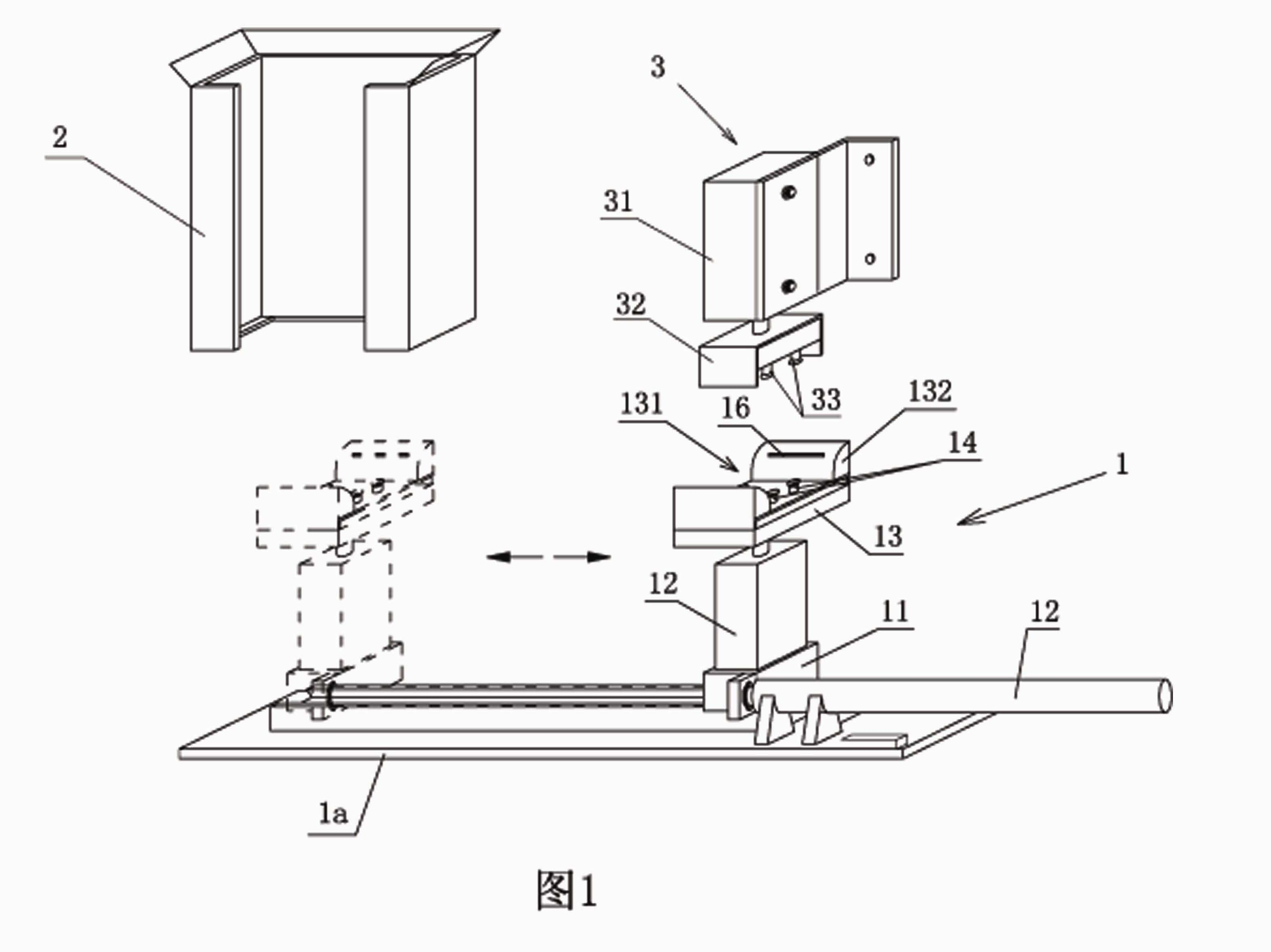

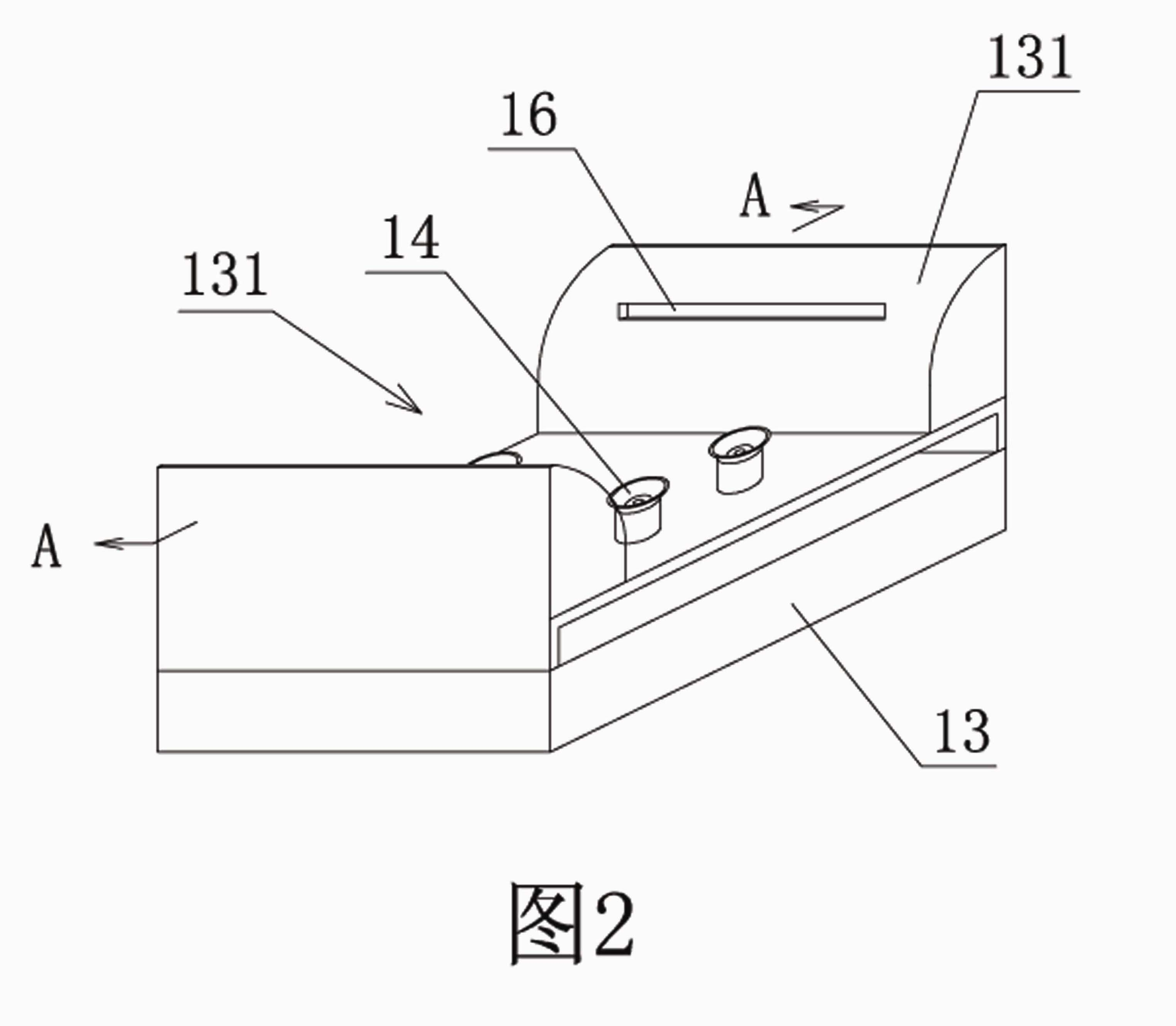

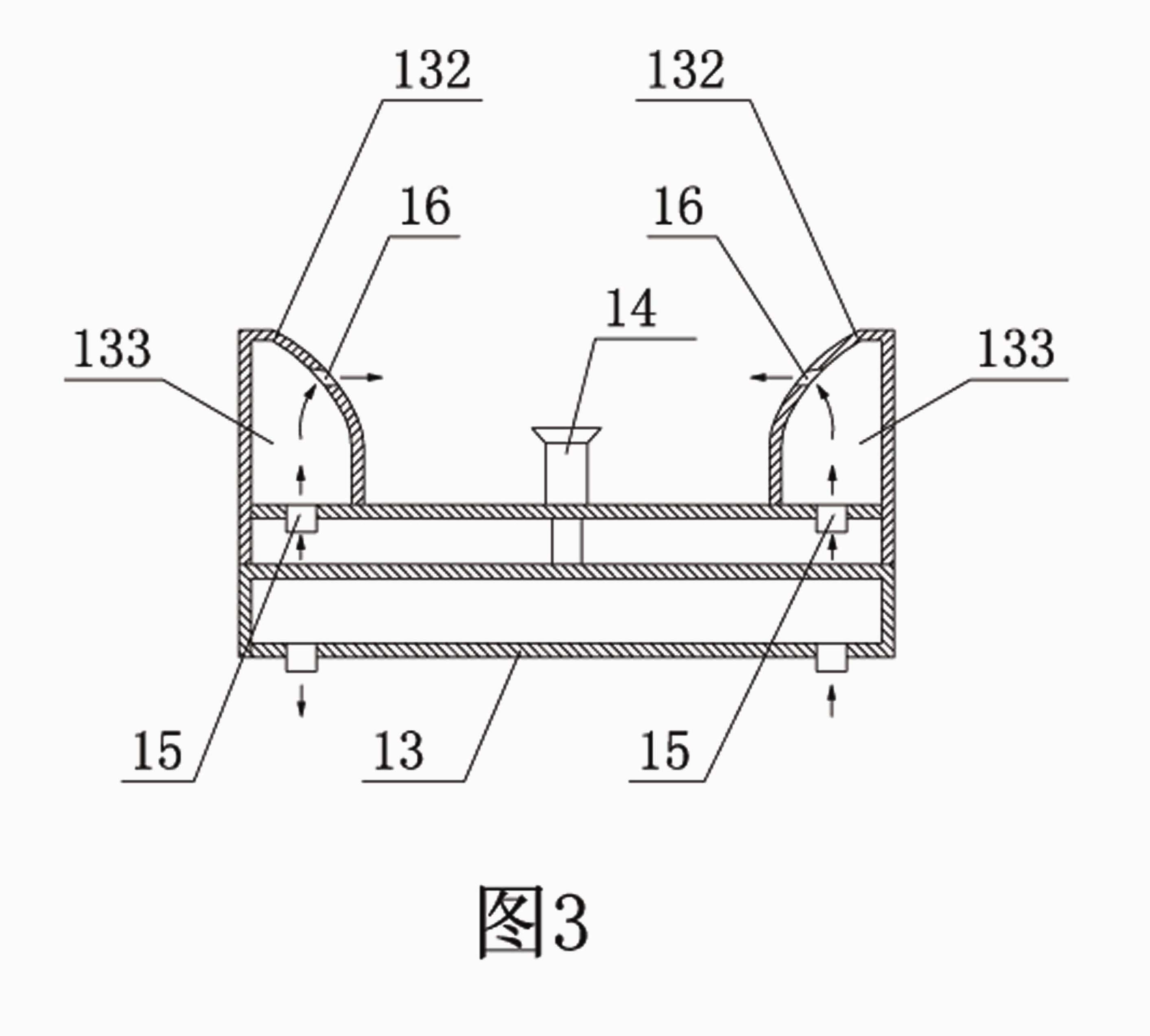

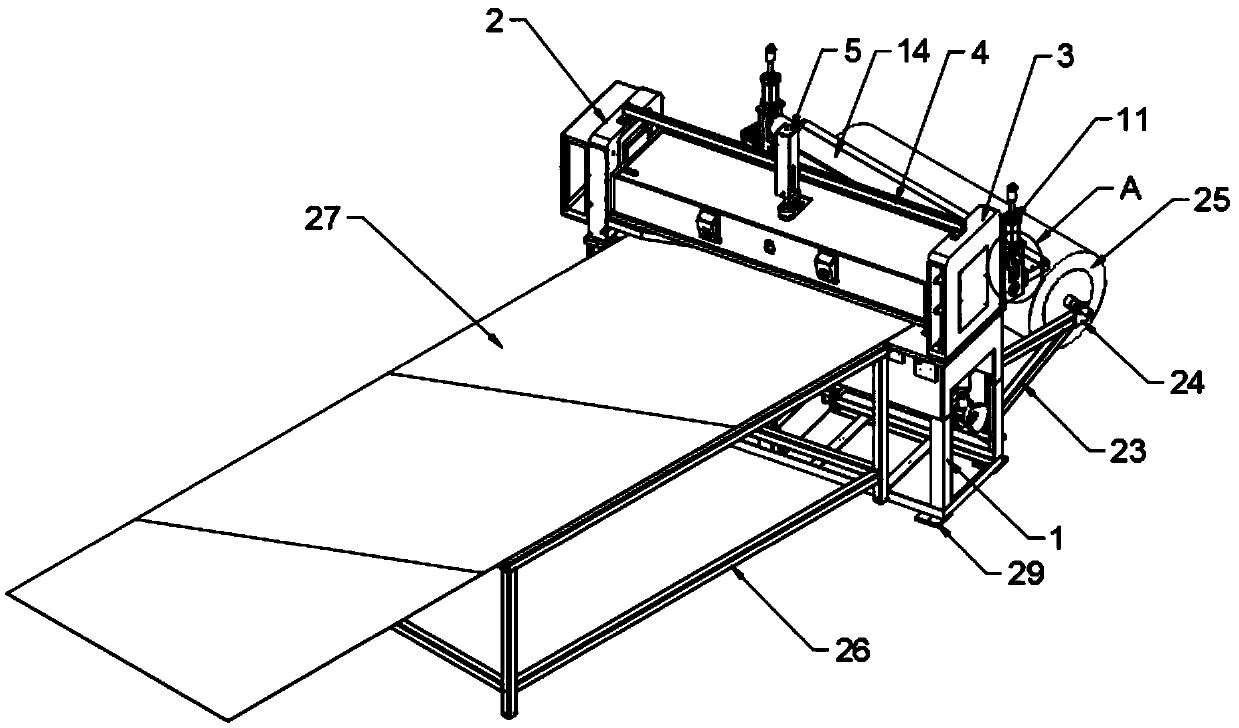

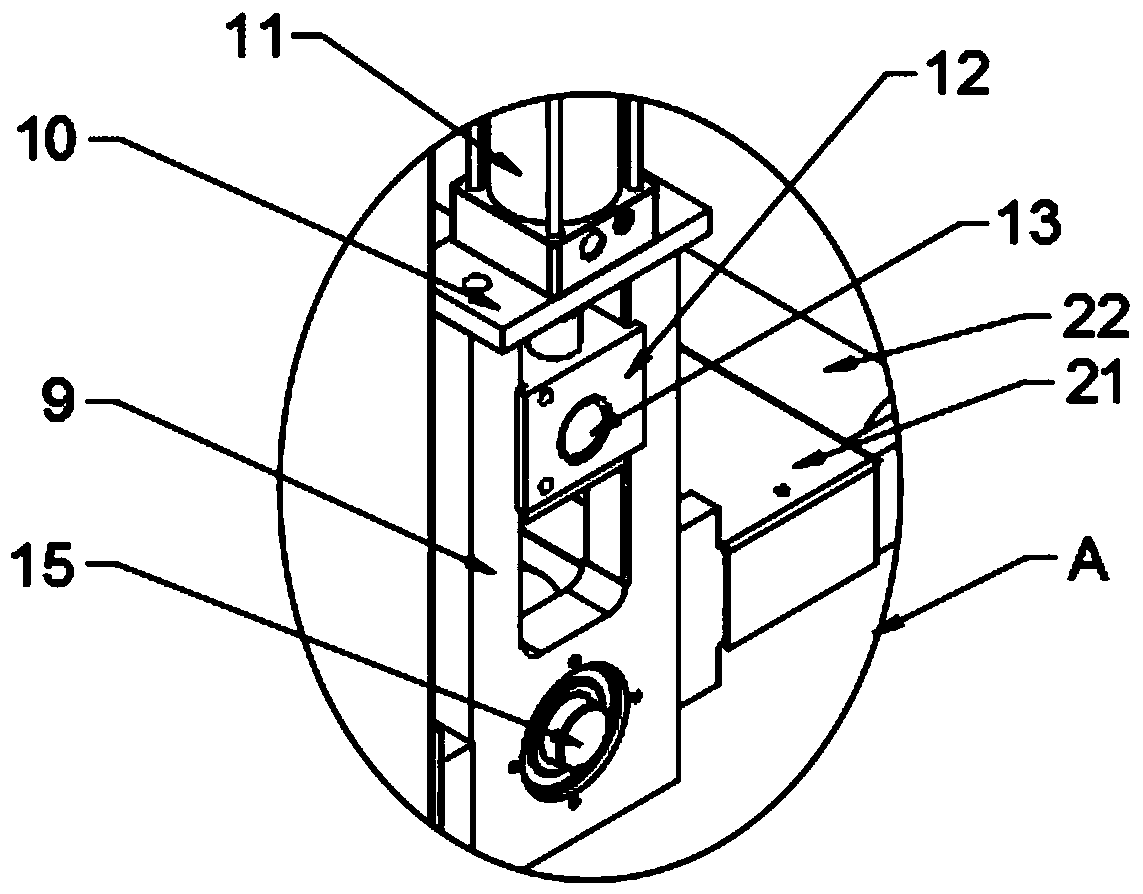

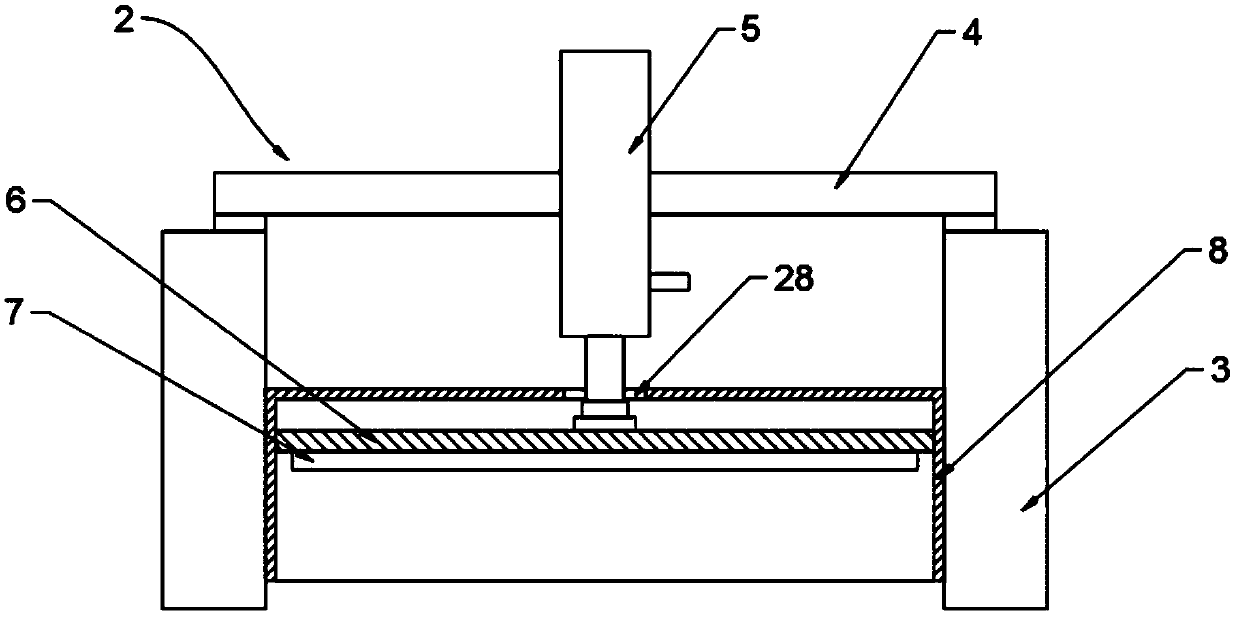

PCB and shell assembling machine and assembling process thereof

ActiveCN105127736AIncrease production capacityImprove the excellent rateAssembly machinesRobot handStructural engineering

The invention discloses a PCB and shell assembling machine. A drying box is arranged between a first six-axis mechanical arm and a second six-axis mechanical arm. The second six-axis mechanical arm corresponds to a third six-axis mechanical arm. The left end of the first six-axis mechanical arm is provided with a screw supplier and a screw hitting machine. A PCB feeding sliding table is arranged in front of the first six-axis mechanical arm, and a spraying box is arranged behind the first six-axis mechanical arm. The first six-axis mechanical arm corresponds to the spraying box, the screw hitting machine, the PCB feeding sliding table and the drying box. A bottom shell material bin and a face shell material bin are arranged in front of the second six-axis mechanical arm. A pressing mechanism and a PCB screw locking mechanism are arranged behind the second six-axis mechanical arm. A bottom transferring hook is arranged between the pressing mechanism and the PCB screw locking mechanism. A glue tearing mechanism and a two-dimension code labeling storage bin are arranged in front of the third six-axis mechanical arm. The third six-axis mechanical arm corresponds to the glue tearing mechanism, the two-dimension code labeling storage bin and a face shell screw locking and labeling mechanism. The invention further discloses a process for assembling a PCBA bard and a shell through the assembling machine. By means of the PCB and shell assembling machine, a PCB and shell assembling production line is achieved intelligently, the PCB and shell assembling machine is high in efficiency and yield, and manpower is saved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Method for manufacturing inverted LED chip

InactiveCN102403425AImprove packaging yieldAvoid WeldingSemiconductor devicesOhmic contactLight reflection

Owner:俞国宏

Method for controlling laser welding

ActiveCN105108338AFull flowLower weld stayWelding/soldering/cutting articlesLaser beam welding apparatusHelical lineWeld seam

The invention discloses a method for controlling laser welding. The method comprises the following steps that 1, the weld seam width w of a workpiece to be welded is measured; 2, the locus of laser welding is controlled as x0=x1+delta*cos beta, y0=y1+delta*sin beta, x=x0+R*cos alpha, y=y0+R*sin alpha, wherein w=2R+phi, x0 and y0 serve as coordinates of a point on a straight line, x1 and y1 serve as starting point coordinates of the straight line, delta serves as a point distance of the straight line, beta serves as an inclination angle of the straight line, R serves as a shaking radius, alpha serves as a polar angle, x and y serve as coordinates of a point on a circle (that is a helical line locus), phi serves as a welding point diameter, and delta is smaller than phi. According to the method for controlling laser welding, the locus of a welding helical line is adjusted by adjusting the shaking radius and the point distance for changes of the weld seam width, therefore, a molten pool can flow more fully, the problems of weld seam depression, undercut, point burst and needle holes which are brought by traditional laser welding can be effectively solved, the welding performance is improved, and the quality rate of products is improved.

Owner:UNITED WINNERS LASER CO LTD

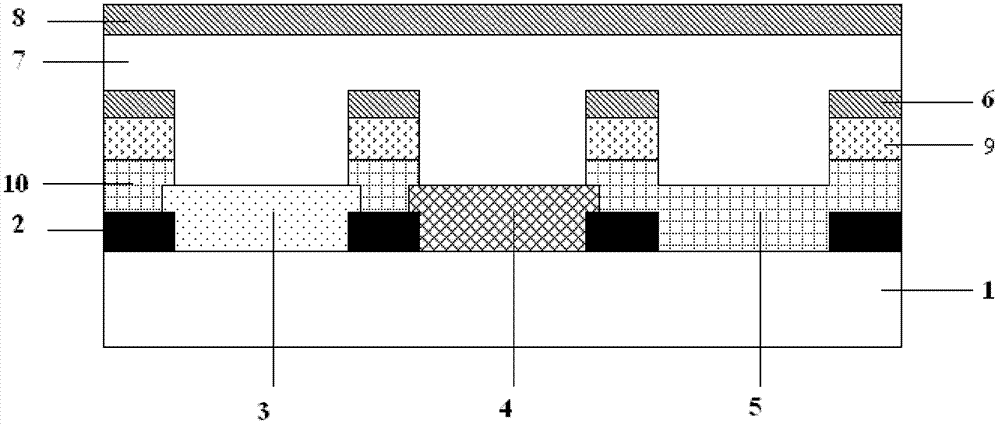

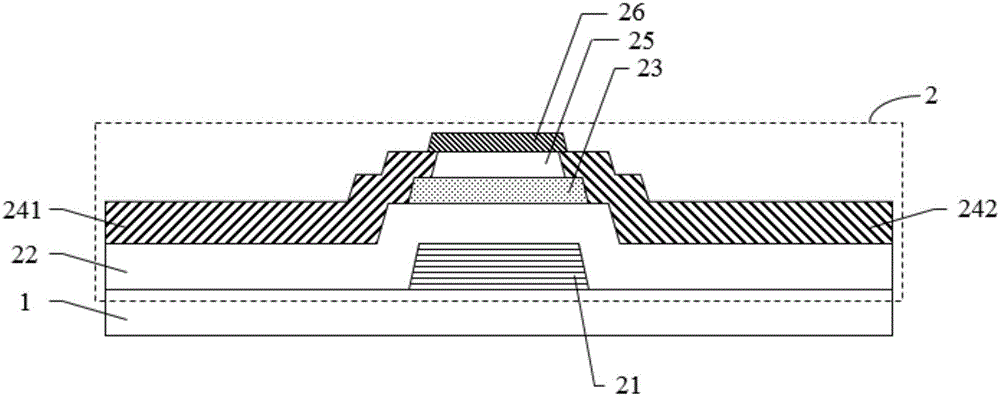

Thin film transistor array substrate and preparation method thereof, and display device

InactiveCN106601754AAddressing Threshold Voltage DriftAvoid electrical failureSolid-state devicesSemiconductor devicesSemiconductor materialsDisplay device

The invention discloses a thin film transistor array substrate. In a thin film transistor of the array substrate, the material of an active layer is a metal oxide semiconductor material, an etching barrier layer is also arranged on the active layer, the etching barrier layer covers a channel region, and a light shielding layer is also arranged on the etching barrier layer. The method for preparing the abovementioned thin film transistor array substrate includes preparing and obtaining the etching barrier layer and the light shielding layer in a same photomask process. In addition, the invention also discloses a display device including the abovementioned thin film transistor array substrate. In the thin film transistor array substrate provided by the invention, through additional arrangement of the light shielding layer, influence of illumination on the active layer of the thin film transistor in a manufacture process is avoided, and the problems of threshold voltage drifting and electrical property failure of the thin film transistor due to illumination influence are prevented, thereby improving product quality.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Automatic steel casing cutting device with positioning function

InactiveCN103752948ASimple structureRun smoothlyMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic steel casing cutting device with a positioning function. The automatic steel casing cutting device with the positioning function comprises a work table and a carrier plate, and is characterized by further comprising a material stirring mechanism, a material overlapping induction mechanism, a cutting mechanism and a position limiting mechanism, wherein a slide rail used for material feeding of a steel casing material belt is arranged on the work table, the material overlapping induction mechanism is arranged at the rear of the work table and above the steel casing material belt, the material stirring mechanism which drives the steel casing material belt to advance is arranged at the front end of the material overlapping induction mechanism, the cutting mechanism is arranged at the front end of the material stirring mechanism, and the carrier plate is arranged beside the cutting mechanism. The automatic steel casing cutting device with the positioning function is simple in structure, convenient to use, high in machining precision and convenient in material feeding, can rapidly locate the material belt and the carrier plate, and facilitates induction of material overlapping of the material belt, and then can send an alarm.

Owner:KUNSHAN FOR EASIER AUTOMATION TECH

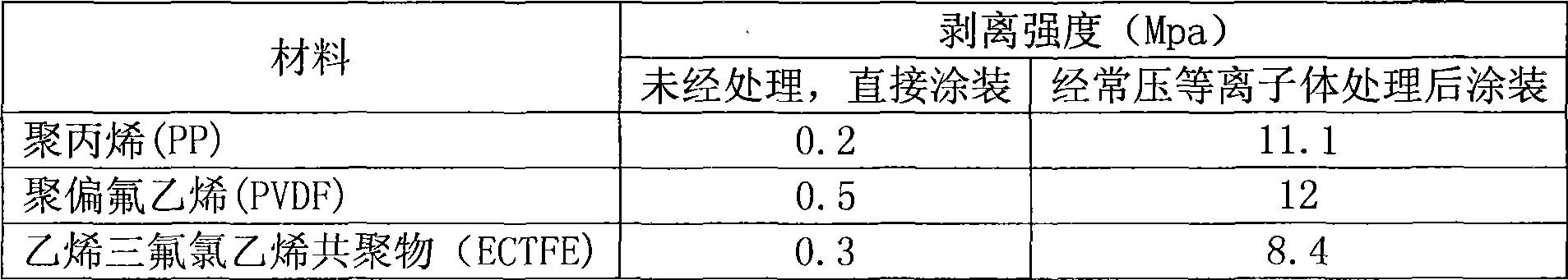

Pretreatment method of atmospheric plasma on surface of automobile accessory

ActiveCN101462106AImprove adhesionReduce tensionPretreated surfacesCoatingsPretreatment methodNitrogen

The invention relates to the technical field of surface treatment of automobile parts, in particular to a normal-pressure plasma surface pretreatment method for the automobile parts, which comprises: putting a workpiece on a work top of a normal-pressure plasma treatment device; moving a spray gun at uniform velocity on a position which is 3 to 40 millimeters away from the surface of the workpiece to spray plasma beams dissociated by the air at normal pressure to the surface of the workpiece for normal-pressure plasma treatment; and removing pollutant and dust after treating the surface of the workpiece. The normal-pressure plasma surface pretreatment method for the automobile parts saves the procedures of grinding, high-pressure flushing and the like, and simplifies the technological flow; and energy of plasma can drive molecules on the surface of the workpiece to react with oxygen and nitrogen in the air to form new active functional groups, so that the normal-pressure plasma surface pretreatment method for the automobile parts obviously improves the adhesive force on coating materials, does not need primary coat, reduces the cost, and improves the excellent rate of products.

Owner:DONGGUAN HIROSAWA AUTOMOTIVE TRIM

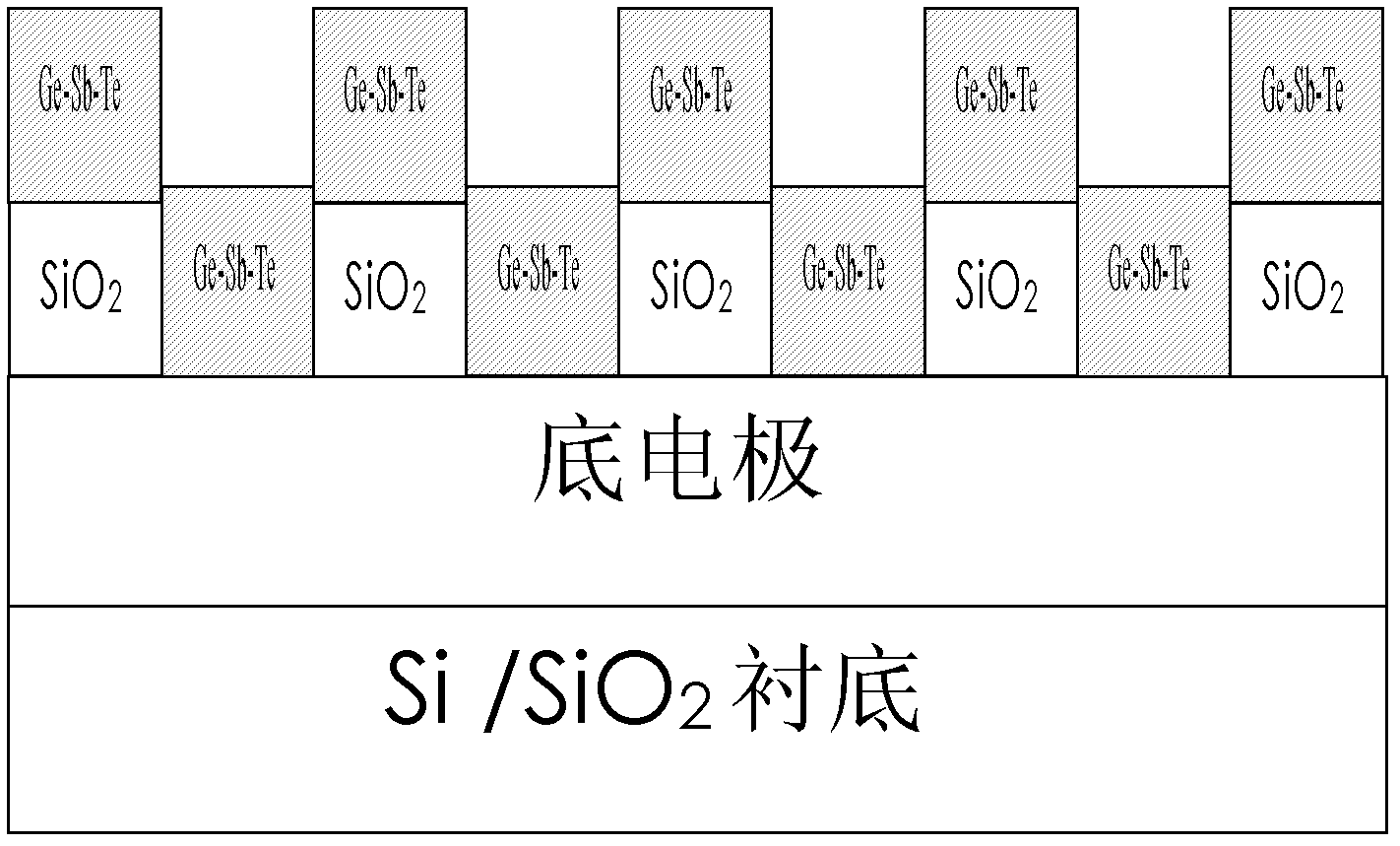

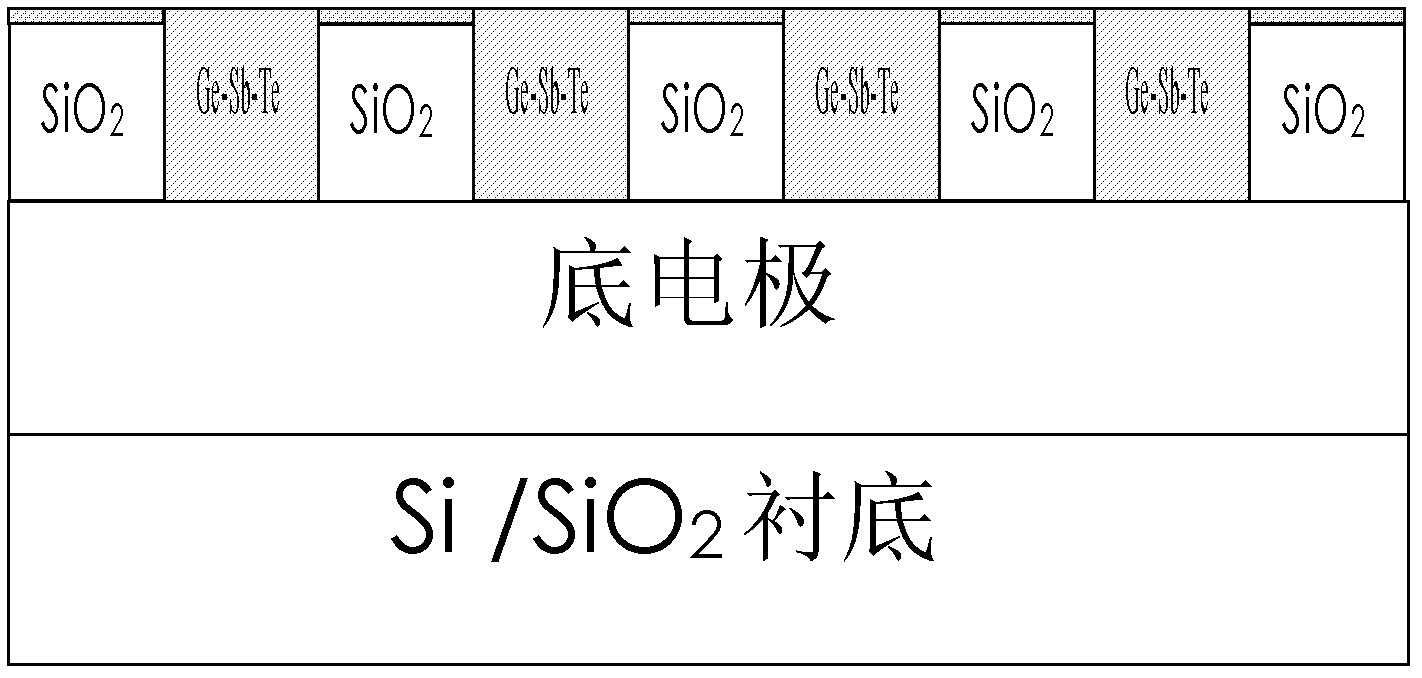

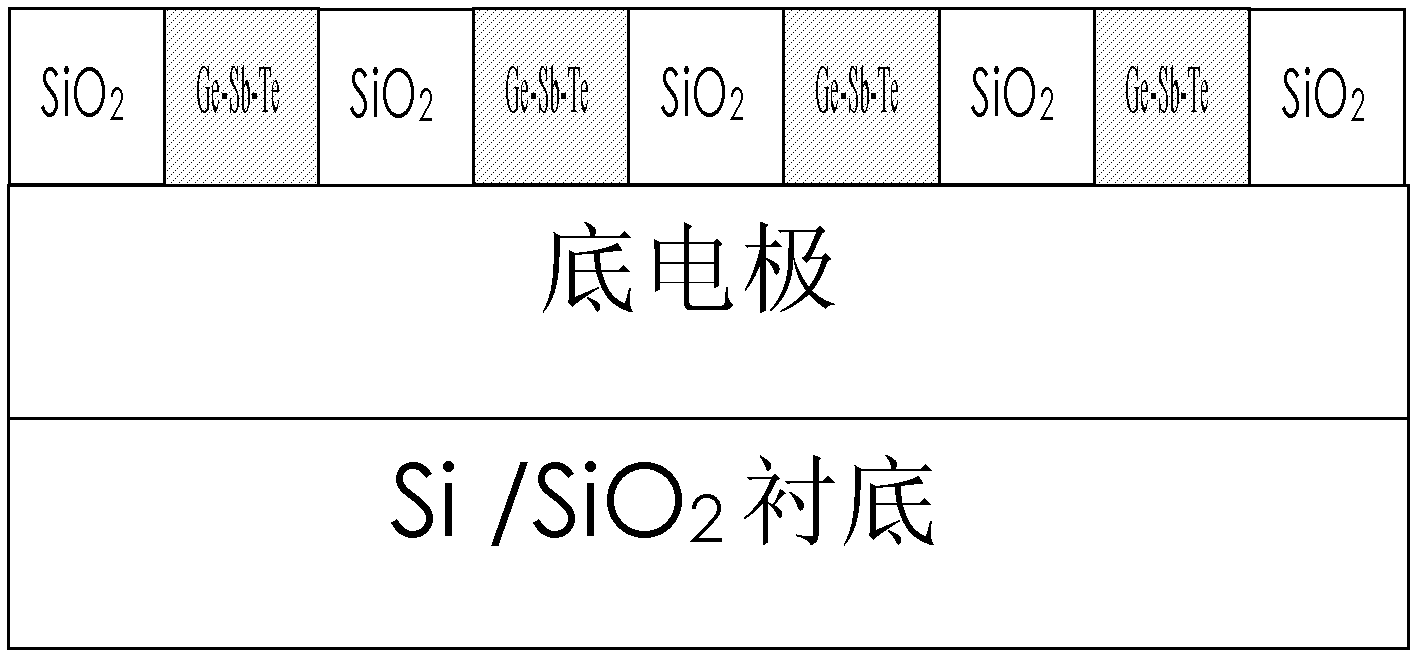

Chemical and mechanical polishing method and solution for sulfur phase-change material

ActiveCN102441819AAvoid damageEasy to cleanPolishing compositions with abrasivesPhase-change memorySulfur

A chemical and mechanical polishing method for a sulfur phase-change material comprises the following steps: 1) roughly polishing the sulfur phase-change material to quickly remove most of sulfur compound outside through holes in an inlaid structure; and 2) performing ultrafine polishing on the sulfur phase-change material which is roughly polished to remove the rest sulfur compound outside the through holes and expose a final through hole array structure. A polishing solution used in the polishing method comprises a polishing solution A for rough polishing and a polishing solution B for ultrafine polishing, and is prepared by mixing a nano grinding agent, a pH regulating agent, a surfactant, a defoaming agent, a bactericide, an assistant cleaning agent and a solvent. The chemical and mechanical polishing method for the sulfur phase-change material has the advantages of high polishing efficiency and simple and feasible process; a polished surface is smooth and has no scratch; over polishing can be prevented well, so that the stability of the performance of a phase-change memory which is manufactured on the base of the inlaid structure and the good rate of products are improved, and the cost is reduced.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

External bag opening shaping method of automatic vacuum packaging machine for tea and apparatus thereof

InactiveCN101804874ASimple structureWork reliablyPackaging under special atmospheric conditionsTea leafEngineering

The invention provides an external bag opening shaping method of an automatic vacuum packaging machine for tea and an apparatus thereof. The apparatus comprises an empty external bag absorbing and sending mechanism, which is capable of reciprocating between an empty external bag holding device and an empty external bag expanding mechanism and is provided with a bag-fetching sucker holder with a bag-fetching sucker; a through groove is arranged at the middle of the top surface of the bag-fetching sucker holder; the bag-fetching sucker is installed on the bottom surface of the groove; the opposite sides of two side walls of the groove are correspondingly provided with a shaping and blowing opening; the bag-fetching sucker holder is provided with an air inlet for connecting an external air source and an air passage for communicating with the shaping and blowing opening and the air inlet. After the empty external bag is charged, in the process that the bag expanding sucker and the bag-fetching sucker are close to each other again, the shaping and blowing opening aims at the middle part of the foldable side of the empty external bag and blows continuously; the continuous blowing forcibly makes the middle part of the foldable side of the empty external bag fold inwards and ensures that the external bag opening recovers the folded shape of the side after the bag expanding sucker and the bag-fetching sucker are compacted with each other. The invention has the advantages of simple structure, reliable work, automatic shaping of the external bag opening and improvement of the excellent rate of the finished product to the maximum.

Owner:李文峰

Manufacture of flash memory

InactiveCN1332474AReduce complexityImprove reliabilitySemiconductor/solid-state device manufacturingForms ControlOxide

The manufacture of flash memory includes providing a prefabricated semiconductor substrate with tunnel oxide layer and the first conductor layer on the oxide layer; removing partial first conductor layer to make the separating part in the shallow ditch higher than the first conductor layer; depositing one dielectric layer and etchbacking in the first conductor layer to form spacer as etching shield and etching the first conductor layer to form one channel; removing partial shallow ditch isolation to expose the outer side of the ditch; removing the spacer to form one floating gate; depositing a thin dielectric layer and the second conductor layer; and making pattern in the second conductor layer of form control gate.

Owner:VANGUARD INTERNATIONAL SEMICONDUCTOR CORPORATION

Method for controlling critical size of graph on uneven silicon slice surface

ActiveCN102339733AMeet the process requirementsImprove the excellent rateSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingResistGraphics

The invention relates to a method for controlling a critical size of a graph on an uneven silicon slice surface, which comprises the following steps that: establishing a relation curve of a step height and the critical size, and the step height is a distance between a highest point and a lowest point on the surface of a silicon slice; measuring a real step height; judging whether the real step height is equal to a setup value, if the real step height is equal to the setup value, exposing photosensitive resist according to a setup exposure energy, and if the real step height is not equal to the setup value, executing a next step; utilizing a formula Esplit= Ebaseline + (CDsplit - CDBASELINE) * Slop to calculate the exposure energy, exposing the photosensitive resist according to the calculated exposure energy Esplit, wherein the Esplit indicates the real exposure energy, Ebaseline indicates the setup exposure energy, CDsplit is a critical size corresponding to the real step height in the relation curve of the step height and the critical size, CDbaseline is a critical size corresponding to the step height setup value in the relation curve of the step height and the critical size, and Slop is a constant.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

Method for preparing samming board

InactiveCN101116886AImprove the excellent rateTightly boundHeat exchange apparatusEngineeringMechanical engineering

Owner:JIEFEI

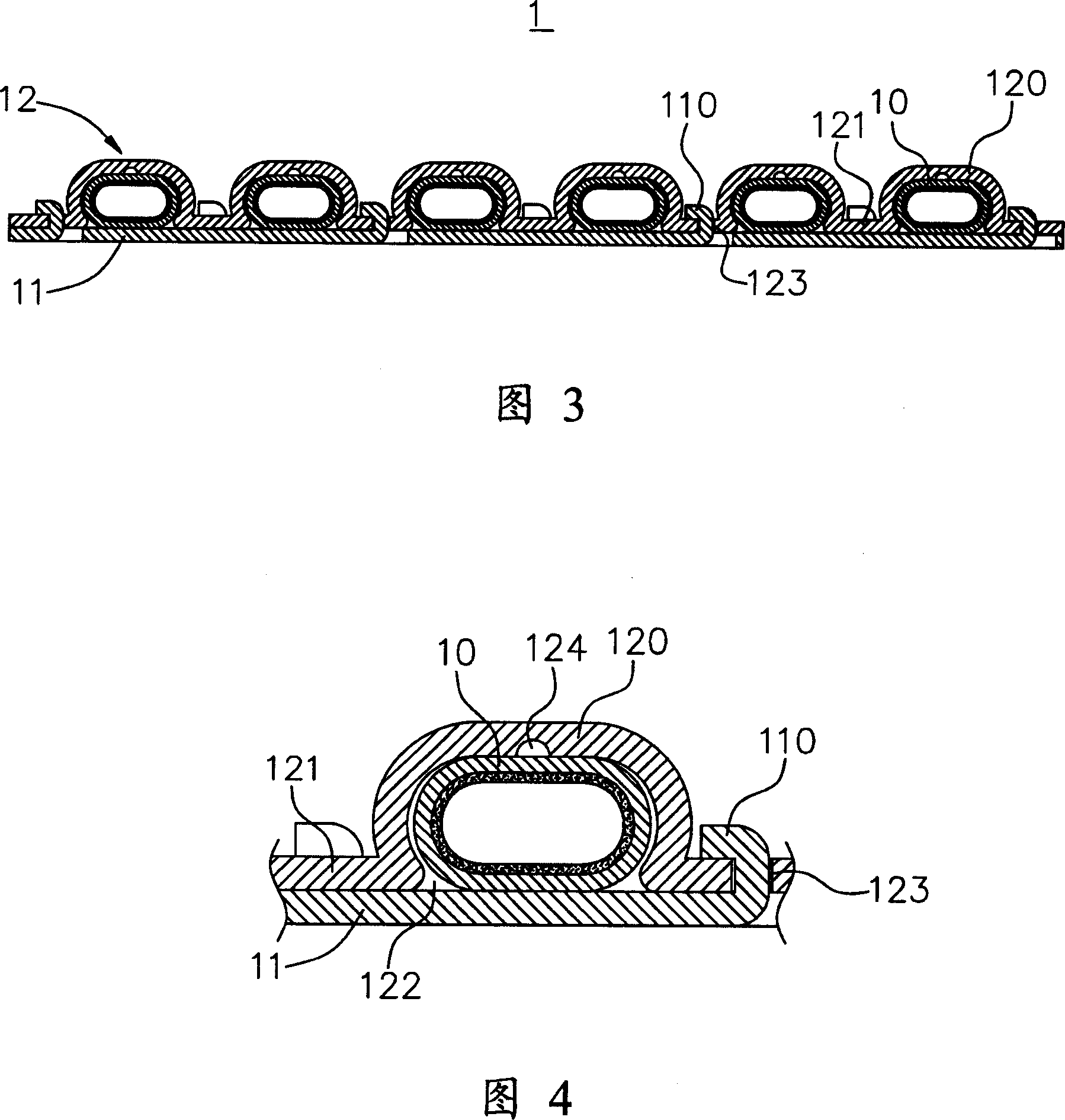

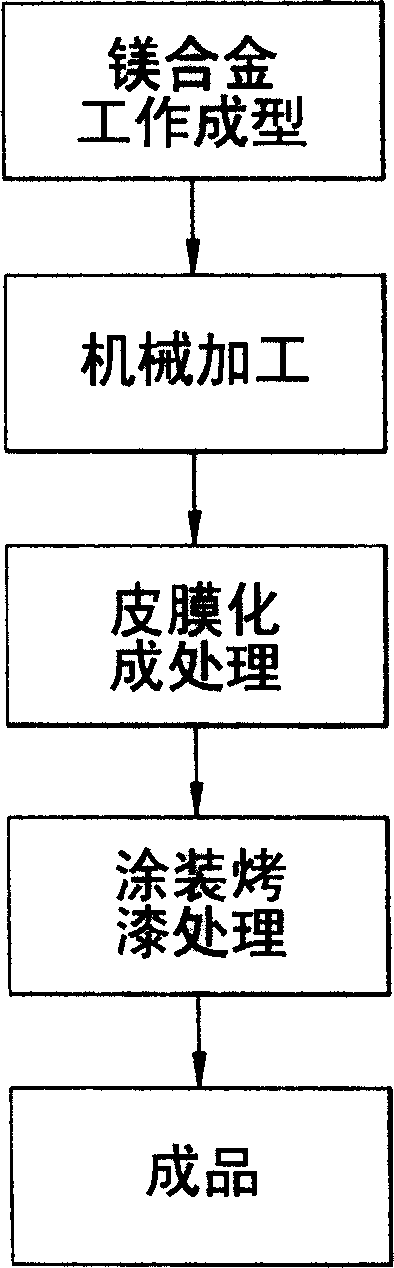

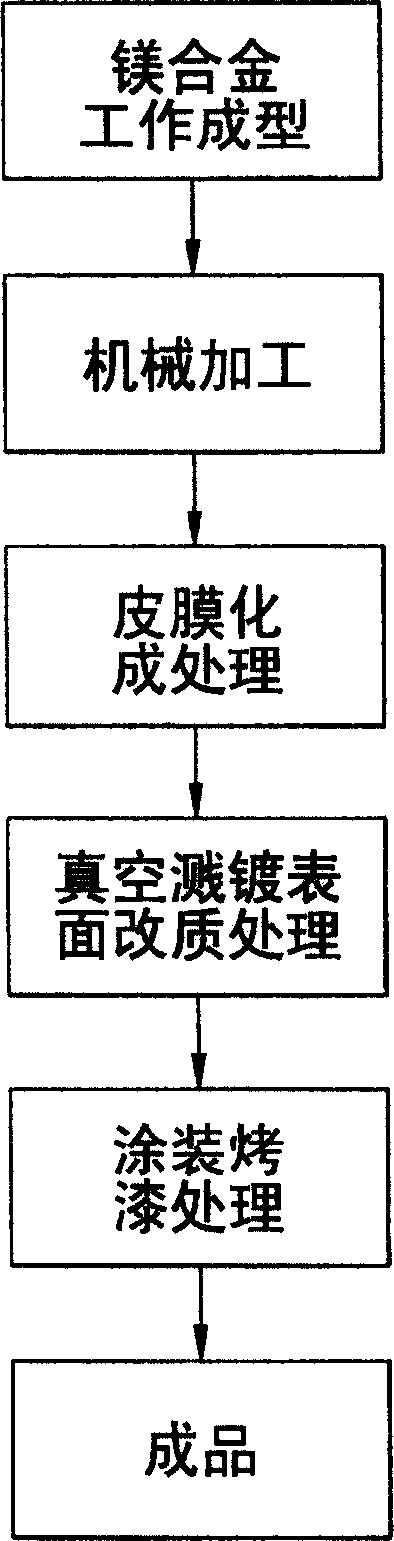

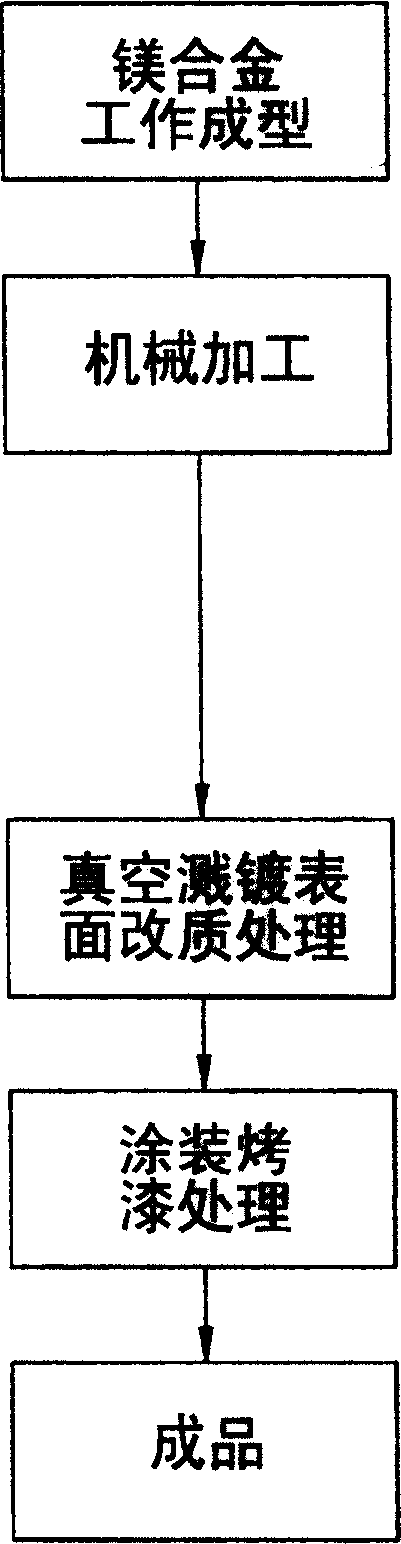

Method for manufacturing metallic products and production

InactiveCN1660510AReduced burst defectsImprove the excellent rateVacuum evaporation coatingPretreated surfacesSputteringMaterials science

A method for preparing the product of the soft metal difficult to machine, such as Mg-alloy or MgAl-alloy, features a vacuum sputtering method is used for modifying the surface of said product. Said Mg-alloy product has high surface quality.

Owner:SILITECH TECH CORP

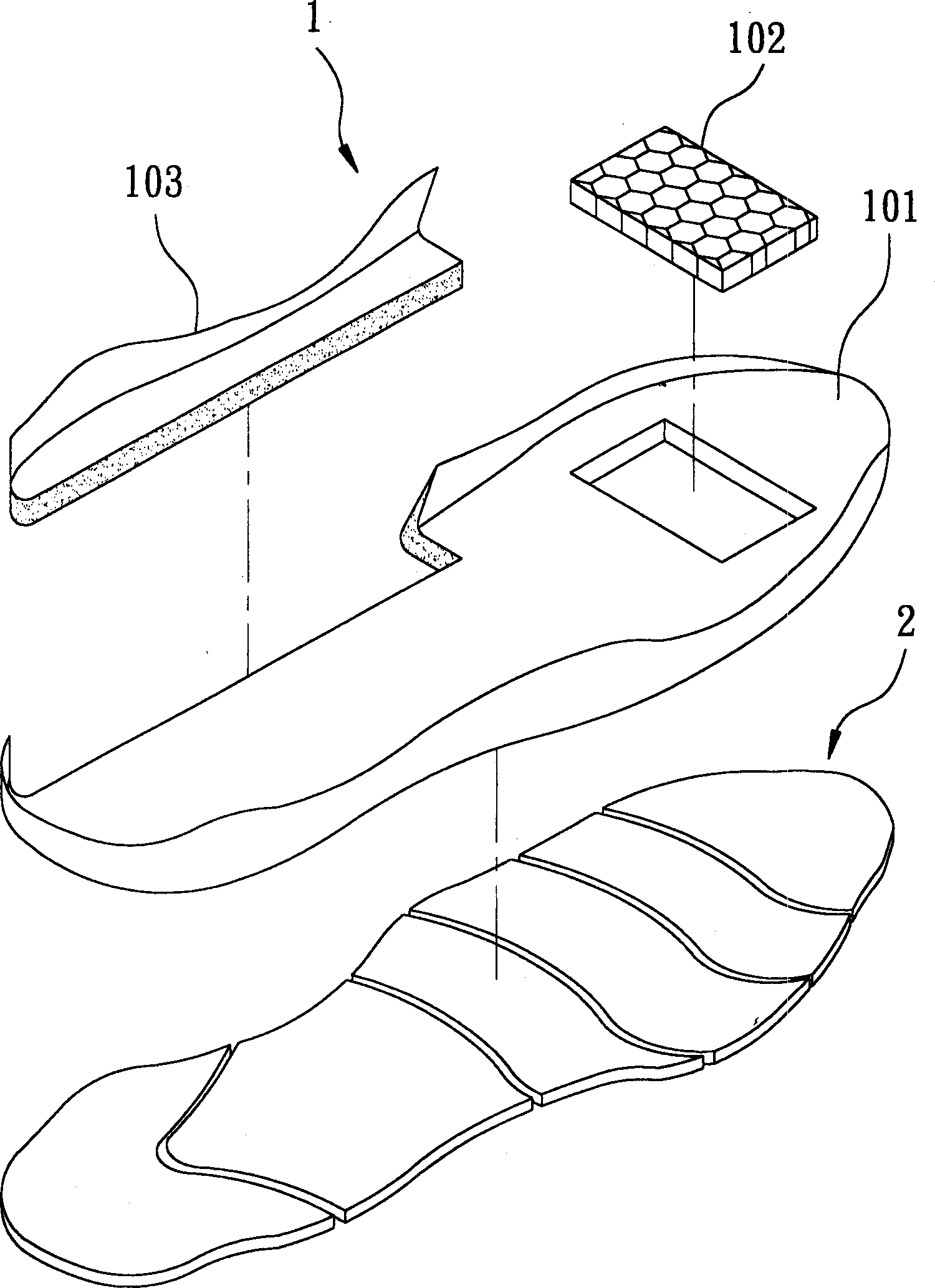

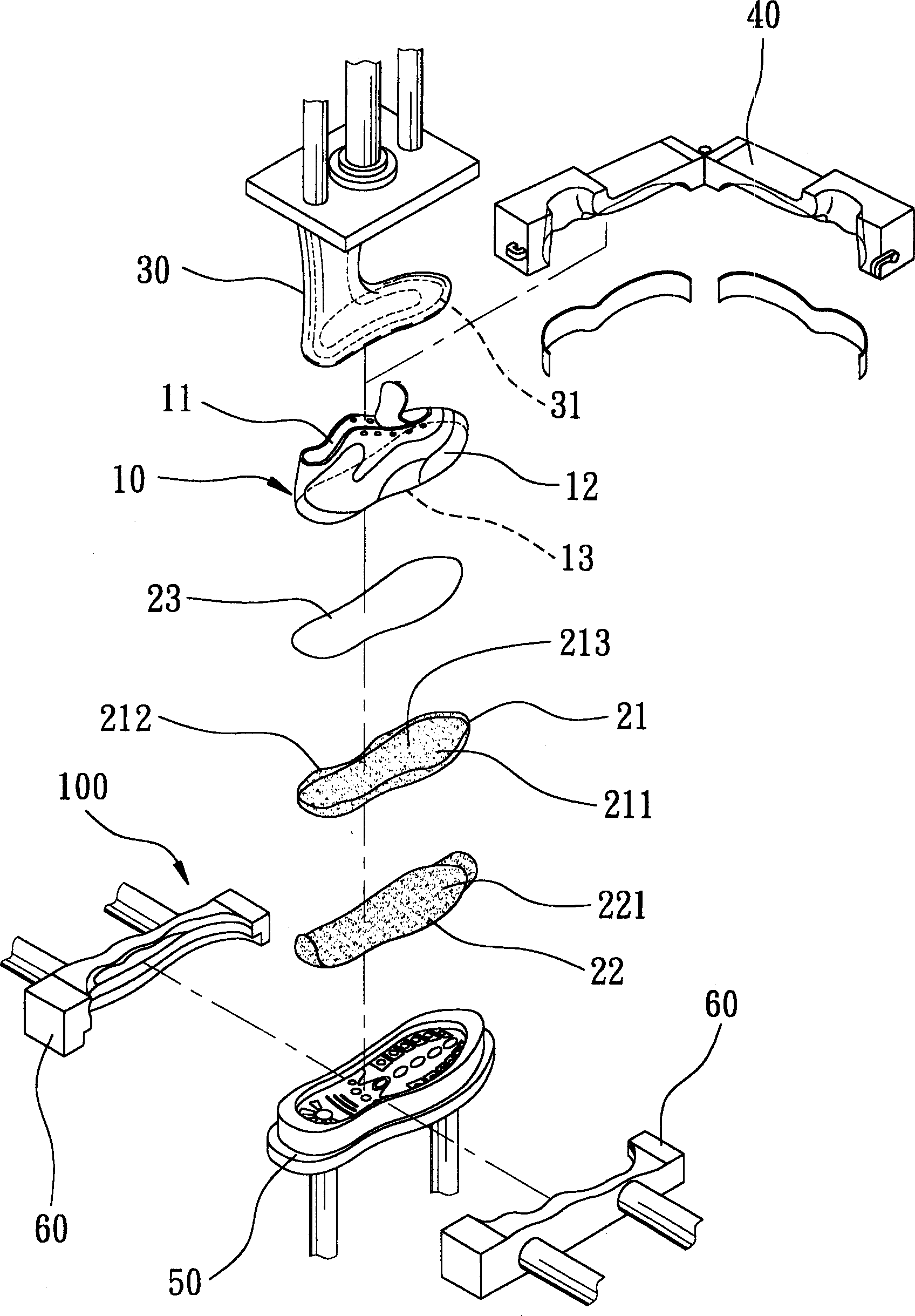

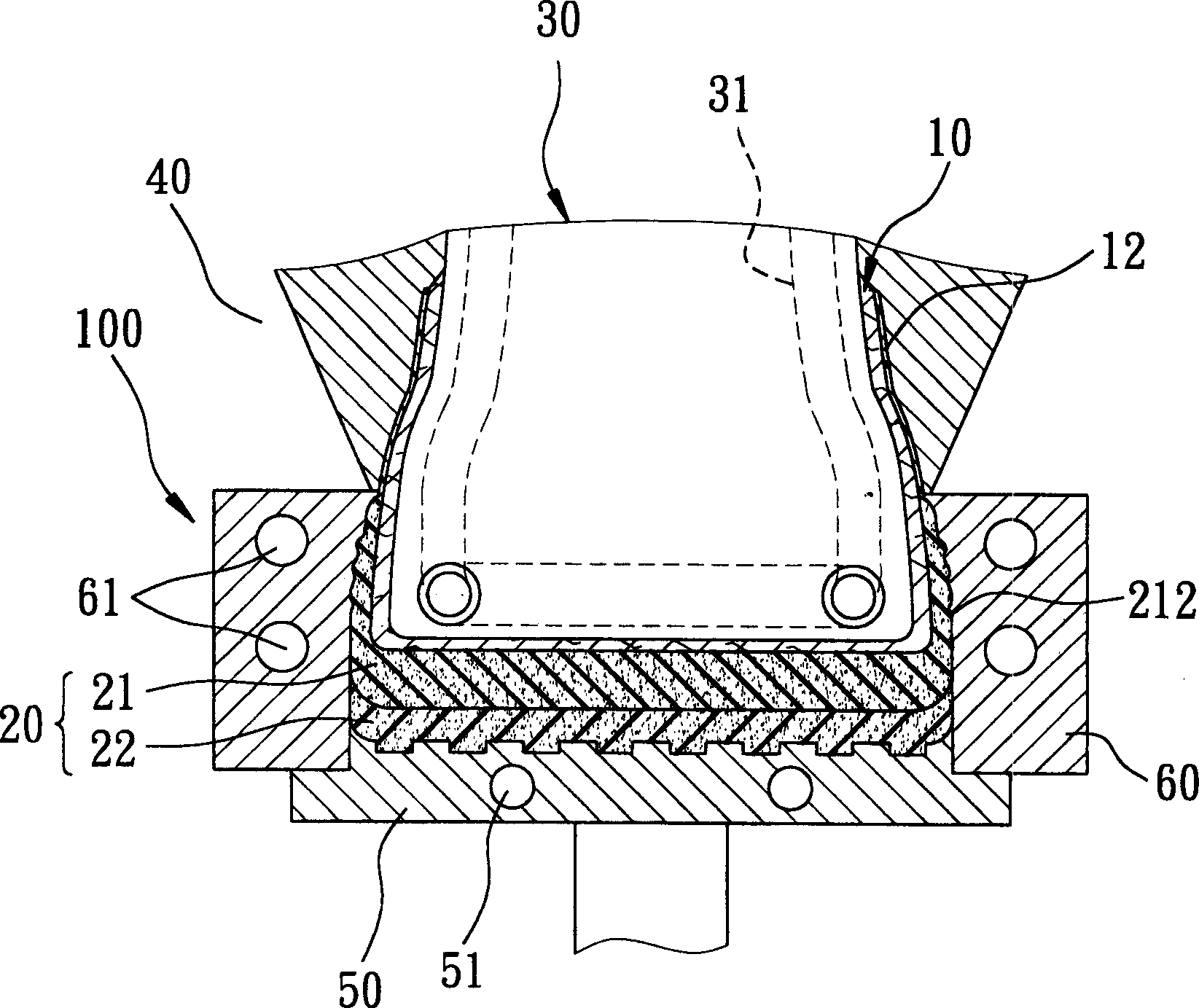

Method for making foam shoe body by integral forming

InactiveCN1401473AEasy to manufactureImprove the excellent rateDomestic footwearHeat flowEngineering

A method for integrally forming the foamed shoe body includes such steps as putting an upper assembly and a sole unit with foamed insole in a die, introducing the heat flow in the circulating channel in the die for raising its temp. and hot pressing. Its advantages are low cost and high productivity.

Owner:纪正贤

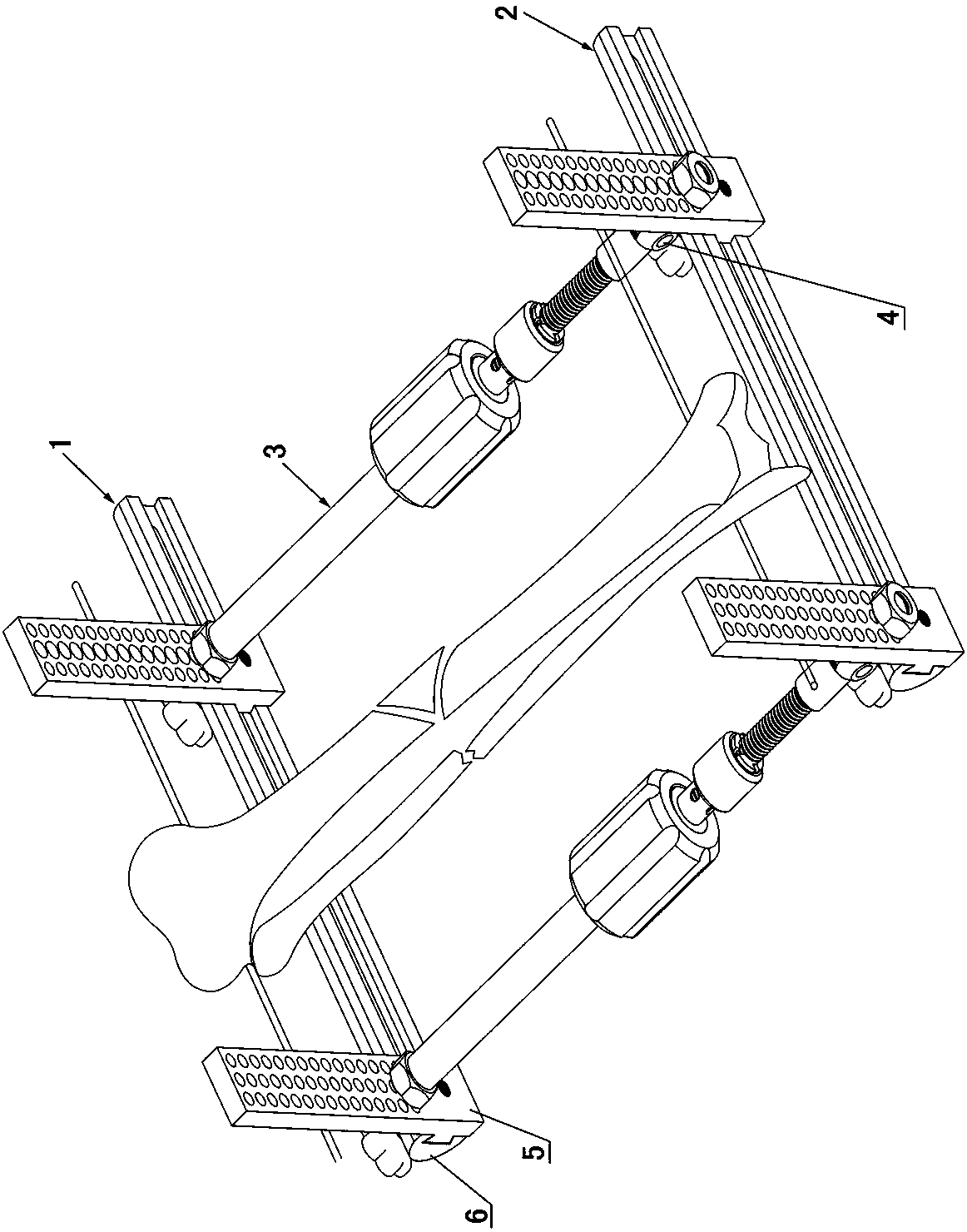

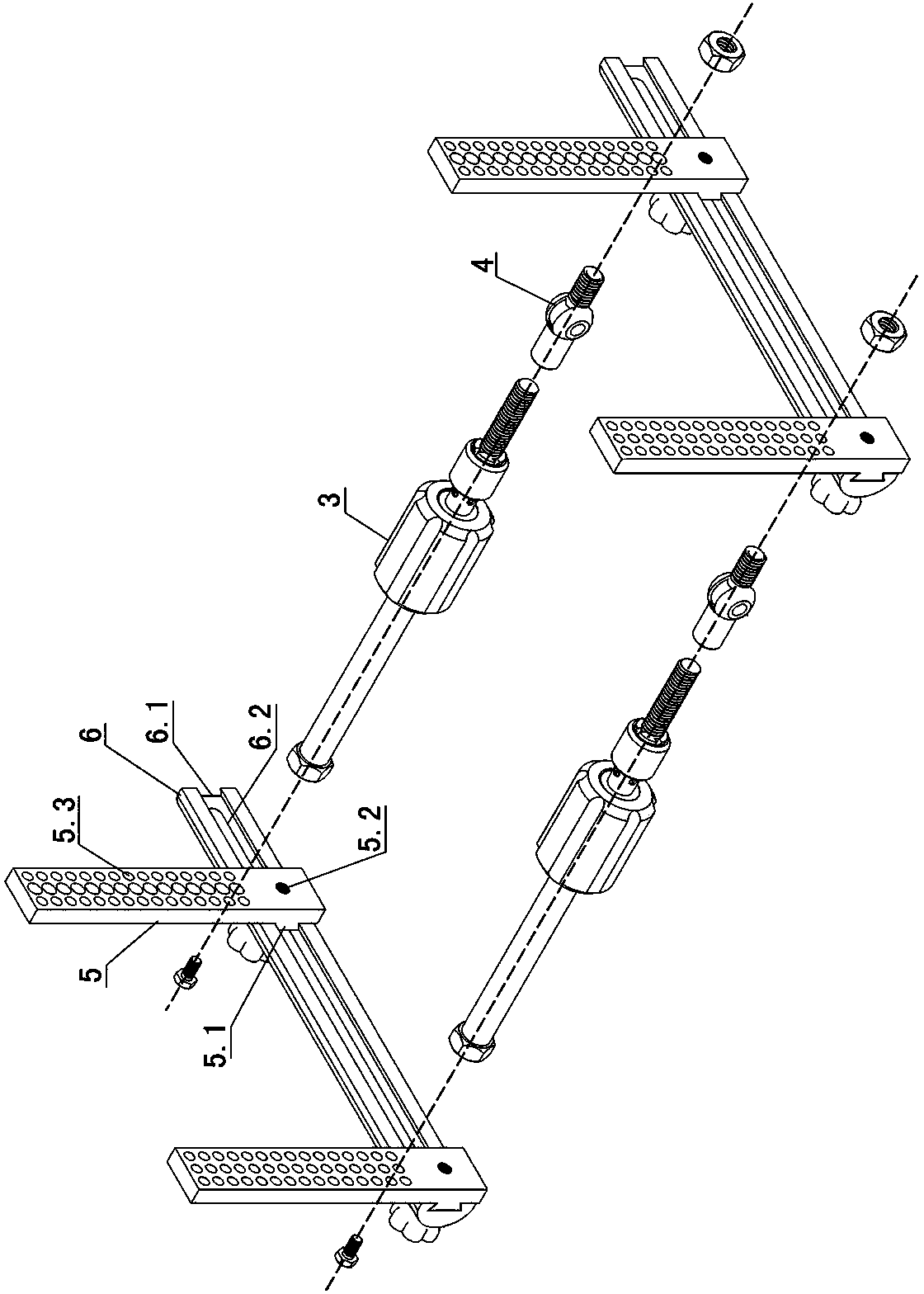

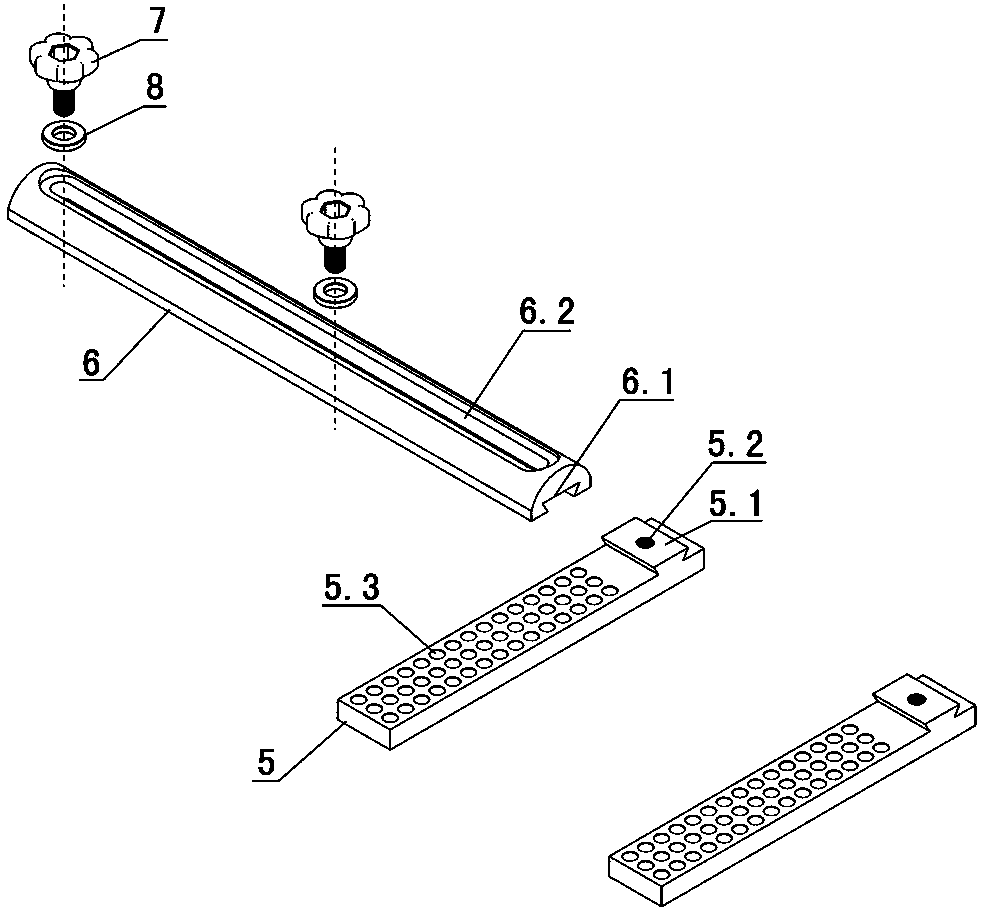

Long bone fracture repositioning device

ActiveCN103445838ASimple structureReasonable configurationExternal osteosynthesisLONG BONE FRACTUREEngineering

The invention discloses a long bone fracture repositioning device, which comprises a proximal end support frame, a distal end support frame, quick drawing extension rods, steel needle fixing clamps and steel needles, wherein the quick drawing extension rods are connected between the proximal end support frame and the distal end support frame, the steel needle fixing clamps are connected to the proximal end support frame and the distal end support frame, the steel needles are clamped by the steel needle fixing clamps, the proximal end support frame and the distal end support frame are same in structure and respectively comprise a transverse chute type repositioning slide plate and two fixed gliding hole plates which are connected to the chute type repositioning slide plate, one surface of each chute type repositioning slide plate is provided with a transverse guide sliding chute, a transverse guide long hole is formed between the bottom of the guide sliding chute and the other surface of the chute type repositioning slide plate, the fixed gliding hole plates are provided with holes for connecting the steel needle fixing clamps, the fixed gliding hole plates are further provided with positioning bulges which are matched with the guide sliding chutes and can slide along the guide sliding chutes. The long bone fracture repositioning device disclosed by the invention is simple in structure, the minimally invasive idea is enhanced, the excellent rate of repositioning is improved, and requirements of fracture repositioning and various malformation correcting can be met to the maximum extent.

Owner:JIANGSU GUANGJI MEDICAL TECH

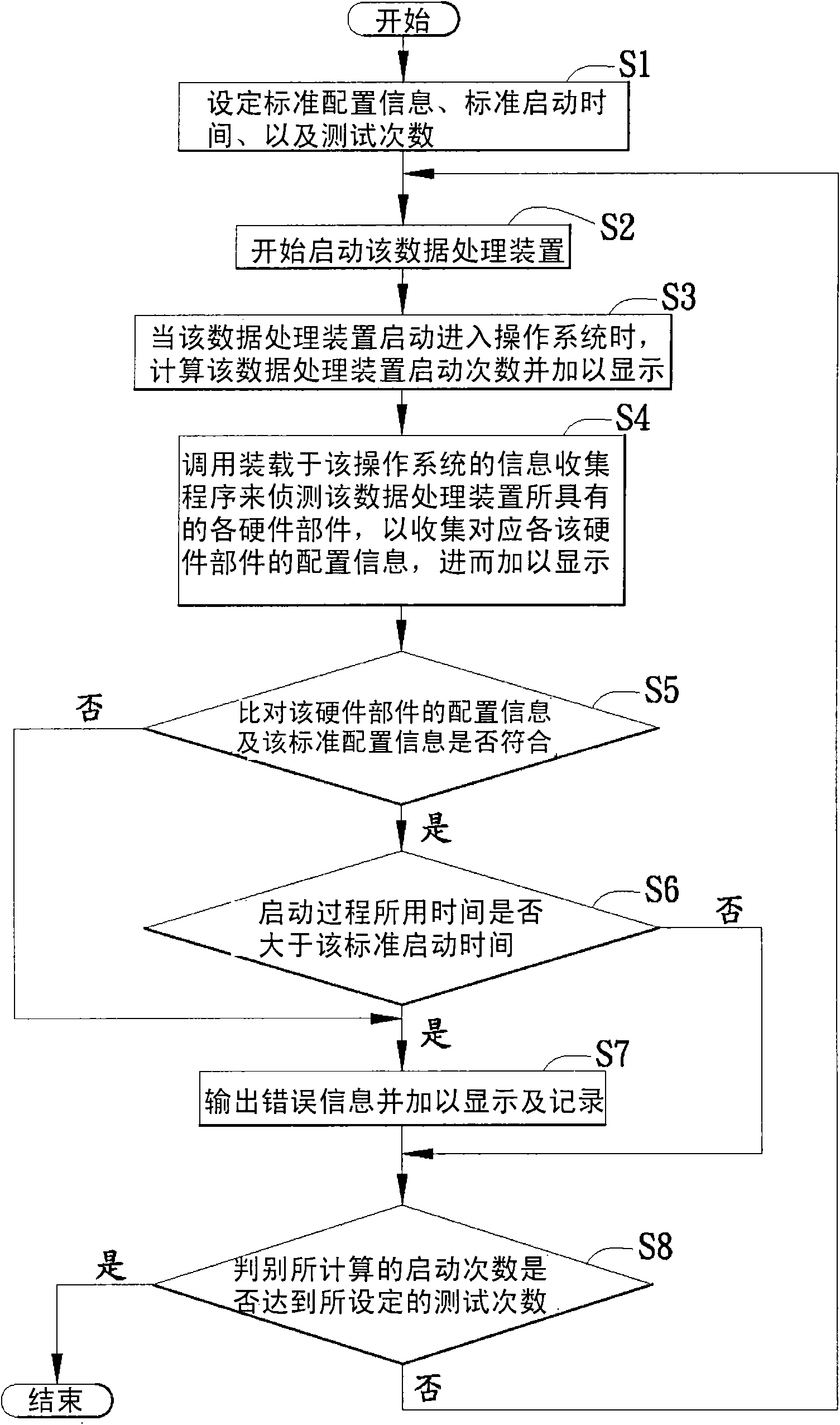

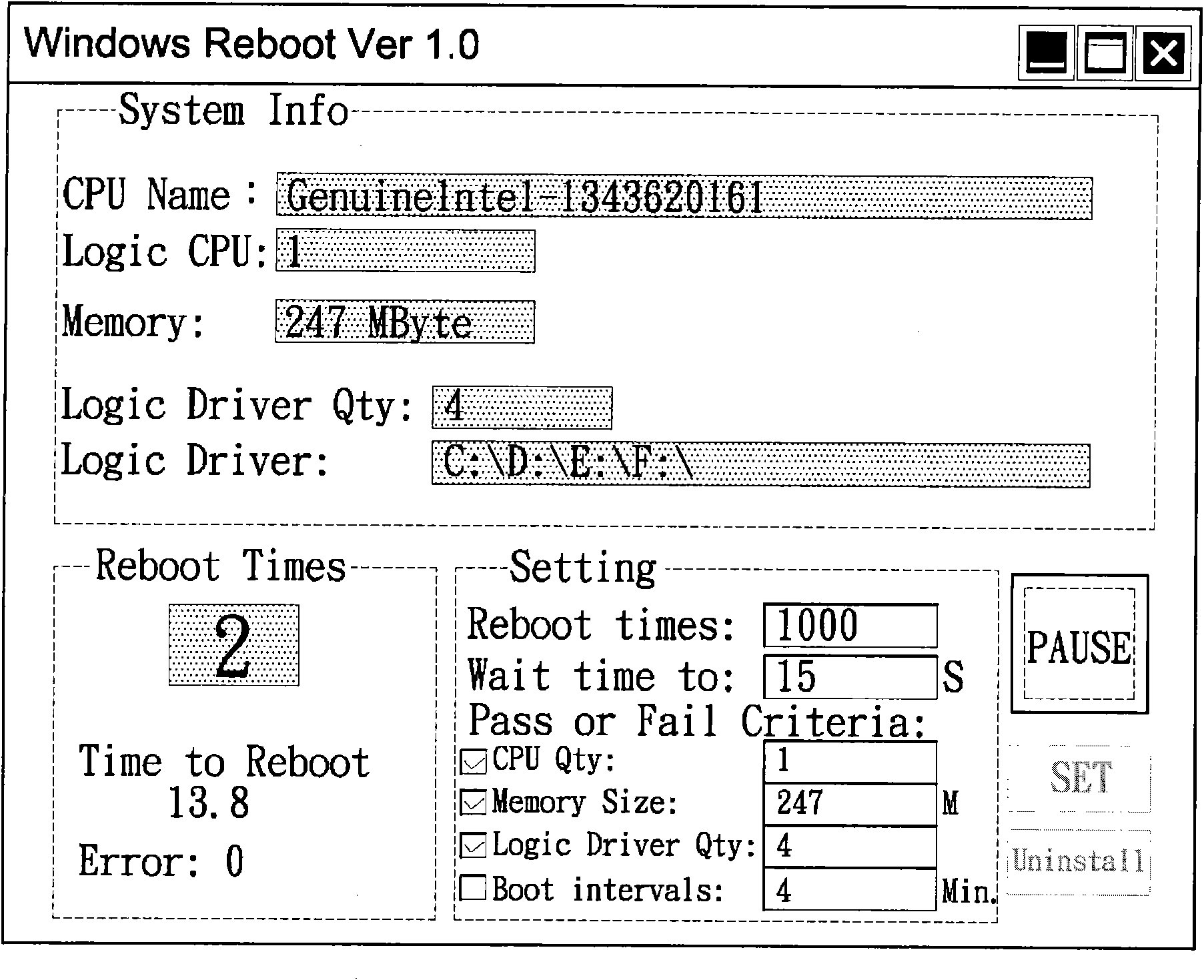

Error-detecting method

InactiveCN101593137AImprove test qualityImprove the excellent rateDetecting faulty computer hardwareOperational systemEmbedded system

The invention relates to an error-detecting method for testing the state of a data-processing device starting and entering an operating system and setting standard configuration information, standard startup time and a test number so that the data-processing device executes startup operation according to the test number. The data-processing device starts up and enters the operating system, calculates and displays the startup number of the data-processing device, calls an information-collecting program loaded on the operating system so as to sense various hardware parts on the data-processing device and collect configuration information which corresponds to the hardware parts while calculating consumed time for the data-processing device to start and enter the operating system so as to respectively compare the collected configuration information of the hardware parts with the standard configuration information and compare the calculated consumed time with the standard startup time to judge and record whether the startup process has errors.

Owner:INVENTEC CORP

Blanking type encapsulation constitution without external pin and manufacturing method thereof

InactiveCN101226890AIncrease plating areaSolve pin strippingSemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

The invention relates to a blanking-type packaging structure without outer pins and a manufacturing method thereof. The manufacturing method of the blanking-type packaging structure without outer pins comprises the following steps: providing a lead frame with a plurality of carrier units, wherein each carrier unit internally forms a plurality of pins, disposing a plurality of wafers to the lead frame, wherein the wafers are electrically connected to the pins, forming a plurality of glue sealing bodies on the carrier units and combining the pins, performing one step of semi-blanking to form a plurality of half-concave nicks on the pins along the outer periphery of the glue sealing bodies, performing one step of electric plating to form an electric plating layer on the exposed surface of the half-concave nicks of the pins and performing one step of complete plating for cutting off the pins along the half-concave nicks to be divided into individual glue sealing bodies. The invention can resolve the problems that the pins of the blanking-type packaging structure without outer pins are torn off, dropped down with rough edges and the like in the single planking process, and the invention can increase the excellent rate of the process and even increase the plating area of the pins, thereby being quite suitable for utility.

Owner:CHIPMOS TECH INC

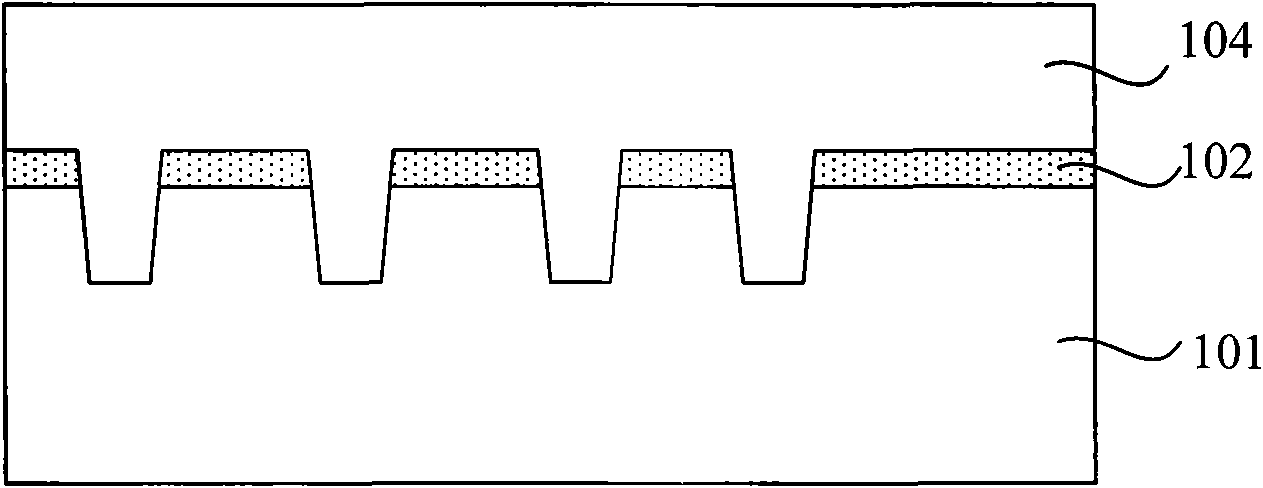

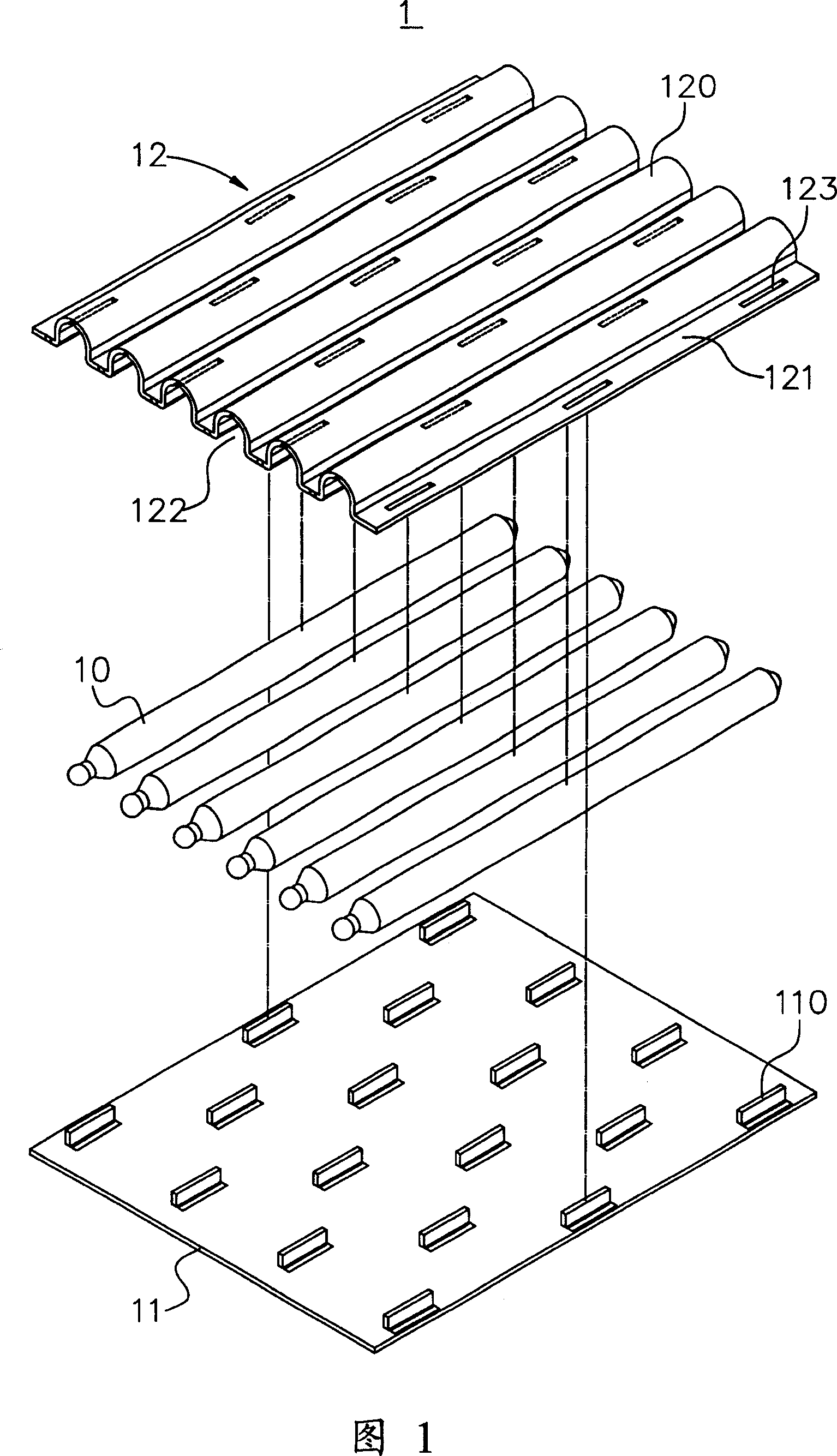

Dead weight conveying platform and goods shelf

ActiveCN103738656AEasy to upgradeReduce labor costsStorage devicesChutesMechanical engineeringIndustrial engineering

The invention relates to a dead weight conveying platform and a goods shelf. The dead weight conveying platform comprises a roller seat and a plurality of rollers, wherein the rollers can be rotatably installed on the roller seat, the roller seat mainly comprises a base and at least two support bars, snapping feet are arranged at the bottoms of the support bars, snapping holes are formed in the base, the support bars are parellelly installed on the base, and the snapping feet penetrate the snapping holes to fasten the bottom of the base. The conveying platform is inclined a certain angle to be laid on the goods shelf, so that dead weight of goods can be used as power to automatically achieve conveying of goods without additional tally clerks, energy is saved, environment protection is achieved, labor costs are saved, upgrading of existing goods shelves is facilitated, upgrading costs are low, engineering is simple, the time limit for a projection is short, affections on production and sales are absent, market competitiveness is high, and popularization and application are facilitated; besides, the roller seat is formed by assembling the individually processed base and the support bars, so that production difficulties are reduced, a good rate of products is high, and the dead weight conveying platform is simple in structure, and easy, convenient, and fast to assemble.

Owner:珠海微准科技有限公司

Feeding mechanism of roller pair cutting machine

InactiveCN109551041AAvoid indentation wearImprove the excellent rateShearing machinesMetal working apparatusDrive wheelEngineering

The invention discloses a feeding mechanism of a roller pair cutting machine. The feeding mechanism of the roller pair cutting machine comprises a frame, a cutting mechanism, an U-shaped frame, a topplate, a second cylinder, a slide block, a first rotating shaft, an upper guide roller, a second rotating shaft, a lower guide roller, a driven wheel, a belt, a driving wheel, a motor, a transition plate, a spring roller, an emptying frame, a support block, an emptying roller, a bracket, a collecting table, a through hole and a fixed block; the cutting mechanism is arranged at the upper end of theframe; the cutting mechanism comprises a support base, a cross beam, a first cylinder, a mounting plate, a cutter mold and a protective cover; through extension of the second cylinder, the slide block is driven to slide on the inner wall of the U-shaped frame up and down to drive the upper guide roller to move up and down; according to the material thickness, the upper guide roller is adjusted toa proper position for coacting with the lower guide roller to press materials; and through structural arrangement, the cutting machine can adjust the pressing gap according to the material thicknessto effectively prevent indentation and wear of the materials so as to improve the product yield.

Owner:YANCHENG HUASEN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com