Dead weight conveying platform and goods shelf

A conveying platform and integrated technology, applied in the field of conveying platforms and shelves, can solve the problems of reducing the product quality rate, the roller rotation is not smooth, increasing labor costs, etc., and achieving the effect of saving labor costs, high product quality rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

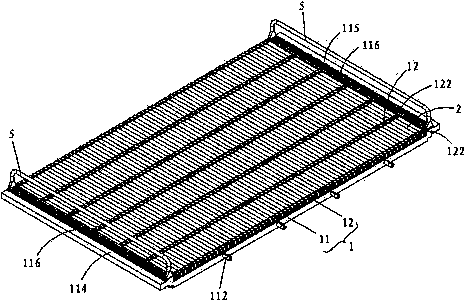

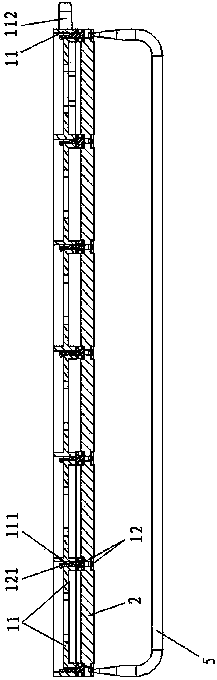

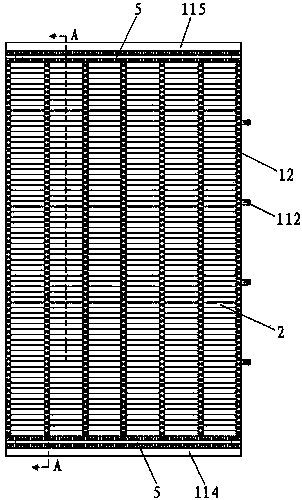

[0031] Such as Figure 1 to Figure 6 As shown in , the self-weight conveying platform described in Embodiment 1 of the present invention includes a roller seat 1 and several rollers 2 , and the rollers 2 are rotatably mounted on the roller seat 1 . The specific structure can be: the roller seat 1 is mainly composed of a base 11 and at least two support bars 12, and the base 11, the support bars 12 and the roller 3 can all be made of plastic materials; wherein, the The bottom of the support bar 12 is provided with a clamping foot 121, and the base 11 is provided with a clamping hole 111; the opposite upper ends of two adjacent support bars 12 are provided with mounting grooves 122, and the upper ends of the mounting grooves 122 are clamped into the entrance. Locking protruding blocks 123 are provided on the left and right sides, and the locking protruding blocks 123 are arc-shaped and integrally formed with the support bars 12; when assembled, the support bars 12 are installed ...

Embodiment 2

[0036] Such as Figure 7 with Figure 8 As shown in , the self-weight conveying platform described in the second embodiment of the present invention has basically the same structure as the first embodiment, including a roller seat 1 and several rollers 2, and the rollers 2 are rotatably installed on the roller Seat 1. The roller seat 1 is mainly composed of a base 11 and at least two support bars 12, and the base 11, the support bars 12 and the roller 3 can all be made of plastic materials; the bottom of the support bars 12 is provided with Clipping feet 121, the base 11 is provided with clipping holes 111, the support bars 12 are installed on the base 11 in parallel with each other, and the clipping feet 121 pass through the clipping holes 111 to fasten the bottom of the base 11; the difference The only difference is that two adjacent supporting bars 12 are provided with protruding rotating bearing shafts 124 on the opposite side walls. The roller shaft 2 is a hollow tube, ...

Embodiment 3

[0038] Such as Figure 9 with Figure 10As shown in , the self-weight conveying platform described in Embodiment 3 of the present invention is basically the same in structure as Embodiments 1 and 2, including a roller seat 1 and several rollers 2, and the rollers 2 are rotatably installed on Roller seat 1. The roller seat 1 is mainly composed of a base 11 and at least two support bars 12, and the base 11, the support bars 12 and the roller 3 can all be made of plastic materials; the bottom of the support bars 12 is provided with Clipping feet 121, the base 11 is provided with clipping holes 111, the support bars 12 are installed on the base 11 in parallel with each other, and the clipping feet 121 pass through the clipping holes 111 to fasten the bottom of the base 11; the difference The only thing is: the roller 2 is a hollow tube, the support bar 12 is provided with a shaft hole 125, and the hollow tube is installed in the adjacent shaft 3 through the shaft 3 pierced insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com