Manufacture of flash memory

A manufacturing method and memory technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increasing flash memory, poor reliability, and backwardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

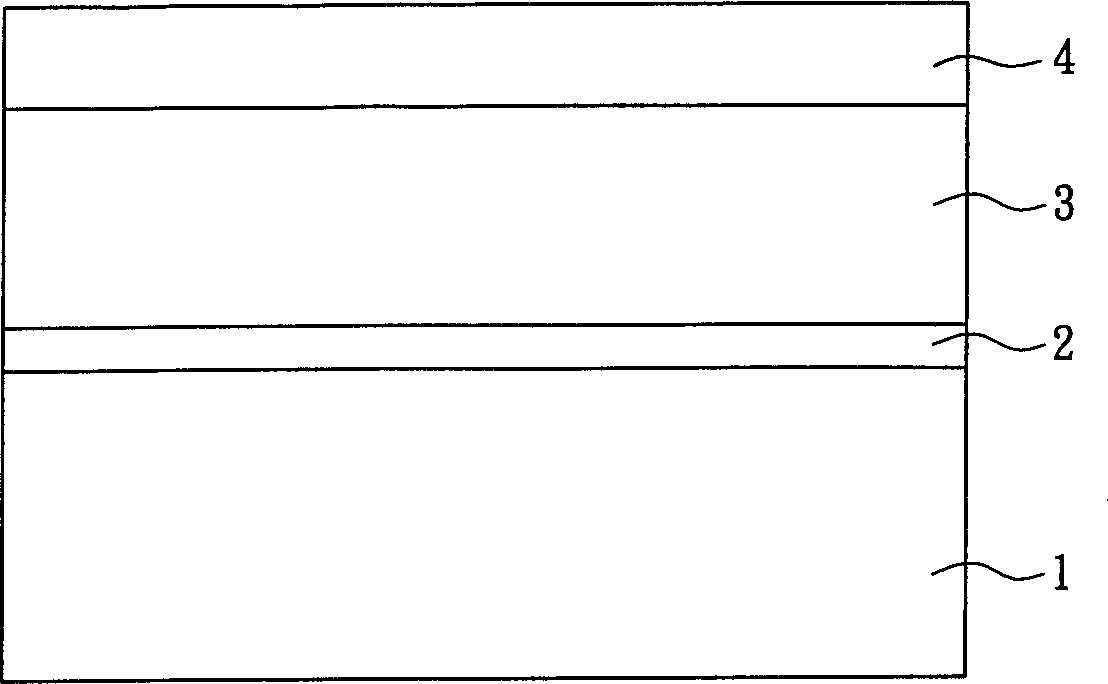

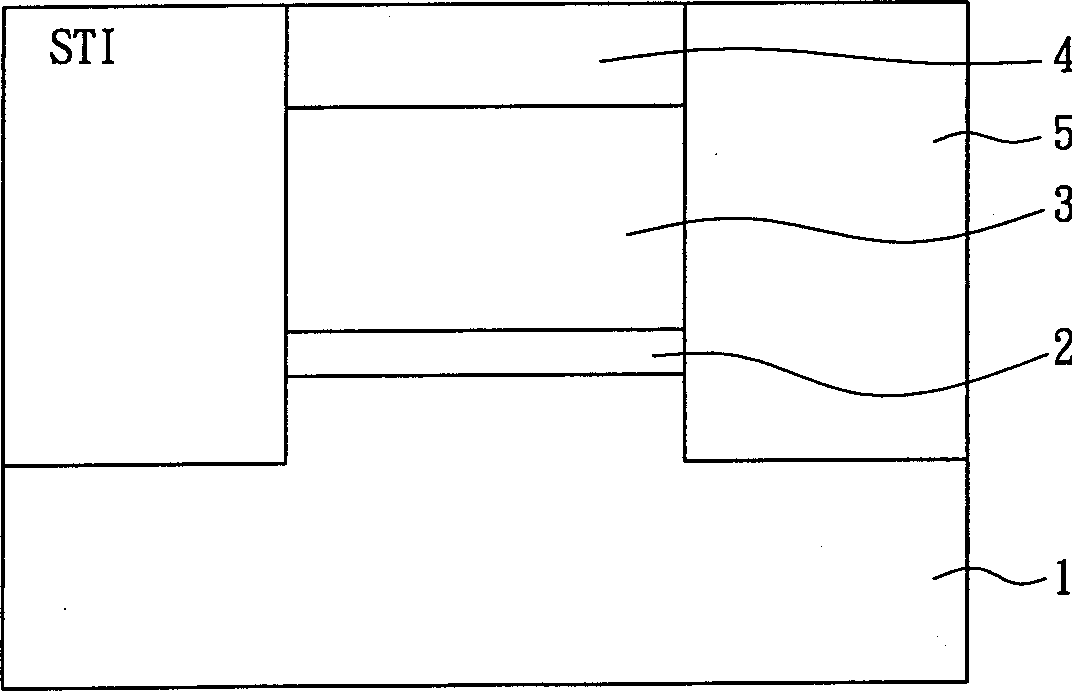

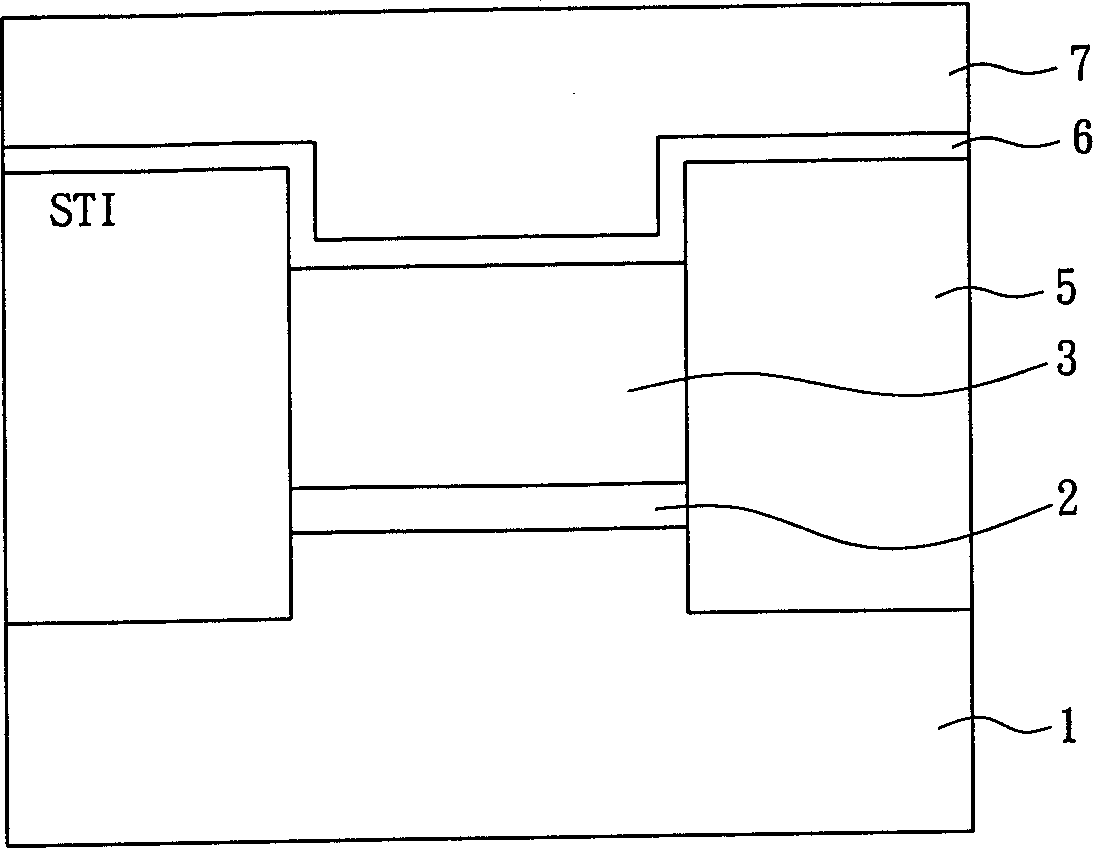

[0013] A method for manufacturing a flash memory, the steps are as follows: provide a semiconductor substrate 8, sequentially form a tunnel oxide layer 9 and a first conductive layer 10, and then form shallow trench isolation 11 (Shallow trench isolation; ST1), In this way, the front-end process has been completed, wherein the first conductive layer 10 is one of polysilicon, metal silicide or amorphous silicon, and its thickness is between 1000 Å and 5000 Å. Of course, as is well known in the industry, the front-end process can also be implemented in a different sequence, for example: first forming shallow trench isolation (STI) on the semiconductor substrate, and then sequentially depositing a tunnel oxide layer 9 and the first conductive layer 10 .

[0014] The key point of the present invention is to remove part of the first conductive layer 10, so that the shallow trench isolation 11 (STI) is higher than the first conductive layer 10, to facilitate subsequent process requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com