Thin film transistor array substrate and preparation method thereof, and display device

A technology for thin film transistors and array substrates, applied in the field of display manufacturing, can solve problems such as electrical failure, thin film transistor threshold voltage drift, and reduce product yield, and achieve the effects of preventing threshold voltage drift and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

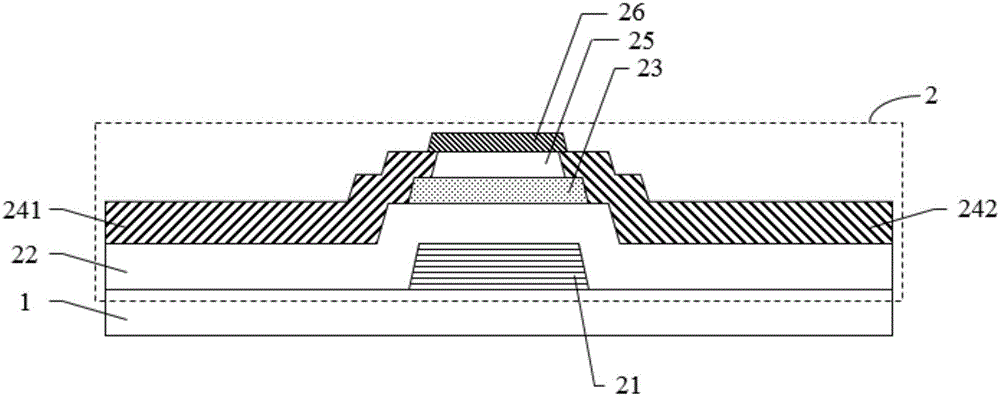

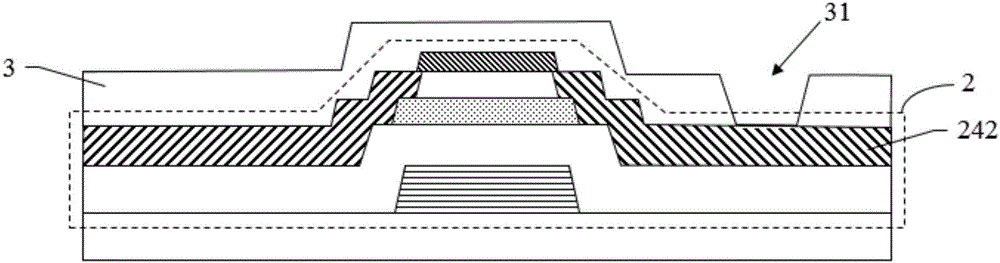

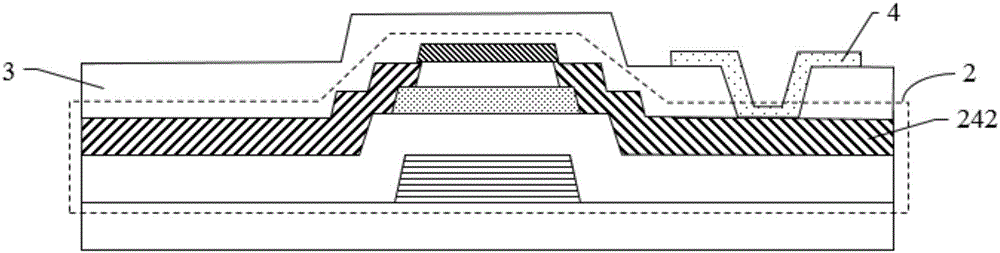

[0025] Such as figure 1 As shown, this embodiment provides a thin film transistor array substrate, which includes a plurality of thin film transistors 2 arranged in an array on a glass substrate 1, and only one thin film transistor 2 is shown here as an example to more clearly describe the The structure of the thin film transistor.

[0026] The thin film transistor 2 includes: a gate electrode 21, a gate insulating layer 22 covering the gate electrode 21, an active layer 23 formed on the gate insulating layer 22, a source electrode 241 and a drain electrode 242 , the source electrode 241 and the drain electrode 242 are spaced from each other and part of the structure is overlapped on the active layer 23, and the active layer 23 corresponds to the distance between the source electrode 241 and the drain electrode 242. region forms the channel region.

[0027] Specifically, the material of the active layer 23 is a metal oxide semiconductor material. Compared with amorphous sil...

Embodiment 2

[0048] Embodiment 2 provides a display device, wherein the thin film transistor array substrate provided in Embodiment 1 is used. By adopting the thin film transistor array substrate as provided in Embodiment 1, the display device can have the advantages brought by the above thin film transistor array substrate.

[0049] Specifically, a thin film transistor liquid crystal display device is used as an example showing the application of the above thin film transistor array substrate to a display device, see Figure 4 The liquid crystal display device includes a liquid crystal panel 100 and a backlight module 200, the liquid crystal panel 100 is arranged opposite to the backlight module 200, and the backlight module 200 provides a display light source to the liquid crystal panel 100, so that the The liquid crystal panel 100 displays images. Wherein, the liquid crystal panel 100 includes an array substrate 101 and a filter substrate 102 disposed opposite to each other, and furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com