Patents

Literature

543 results about "Laser damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

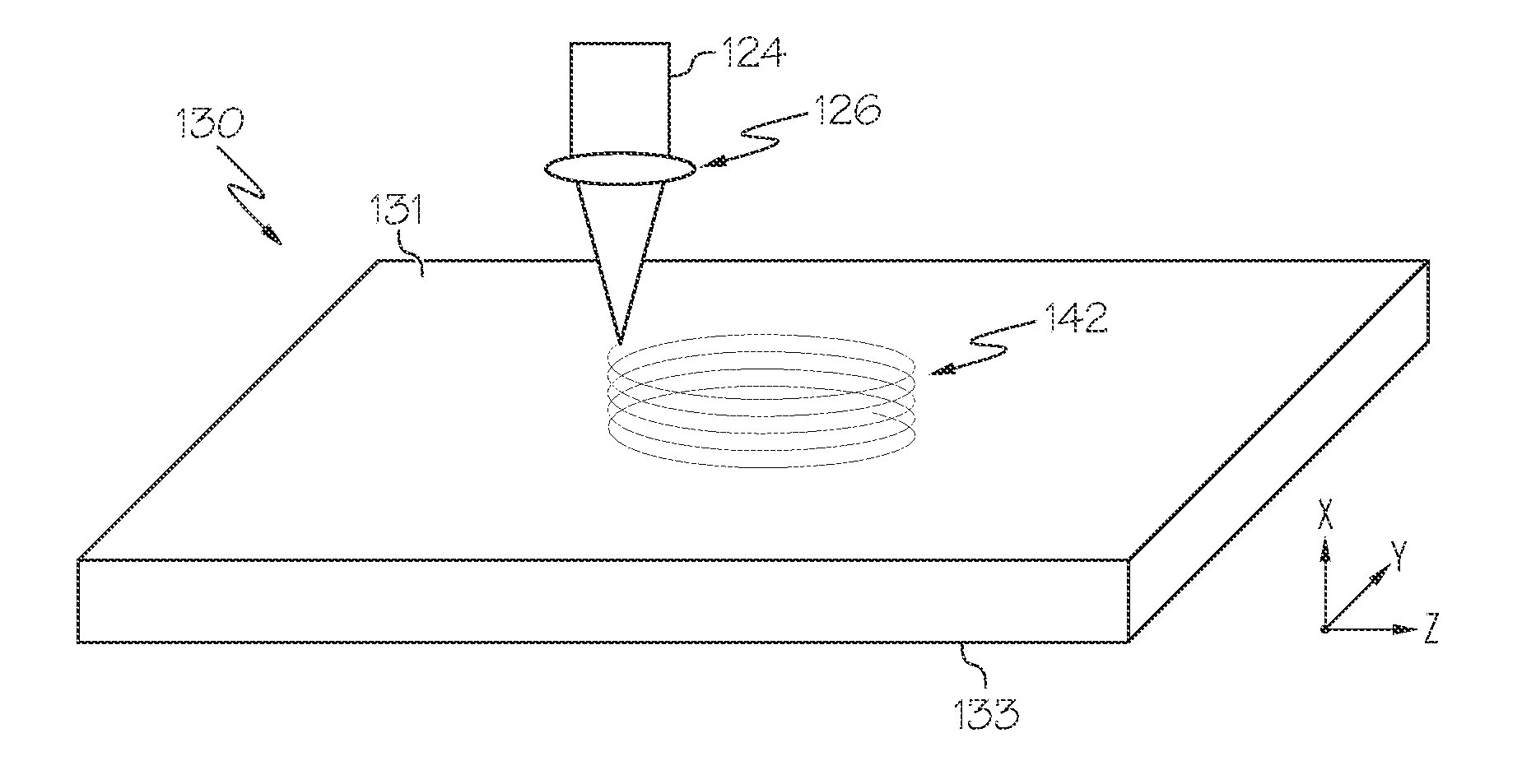

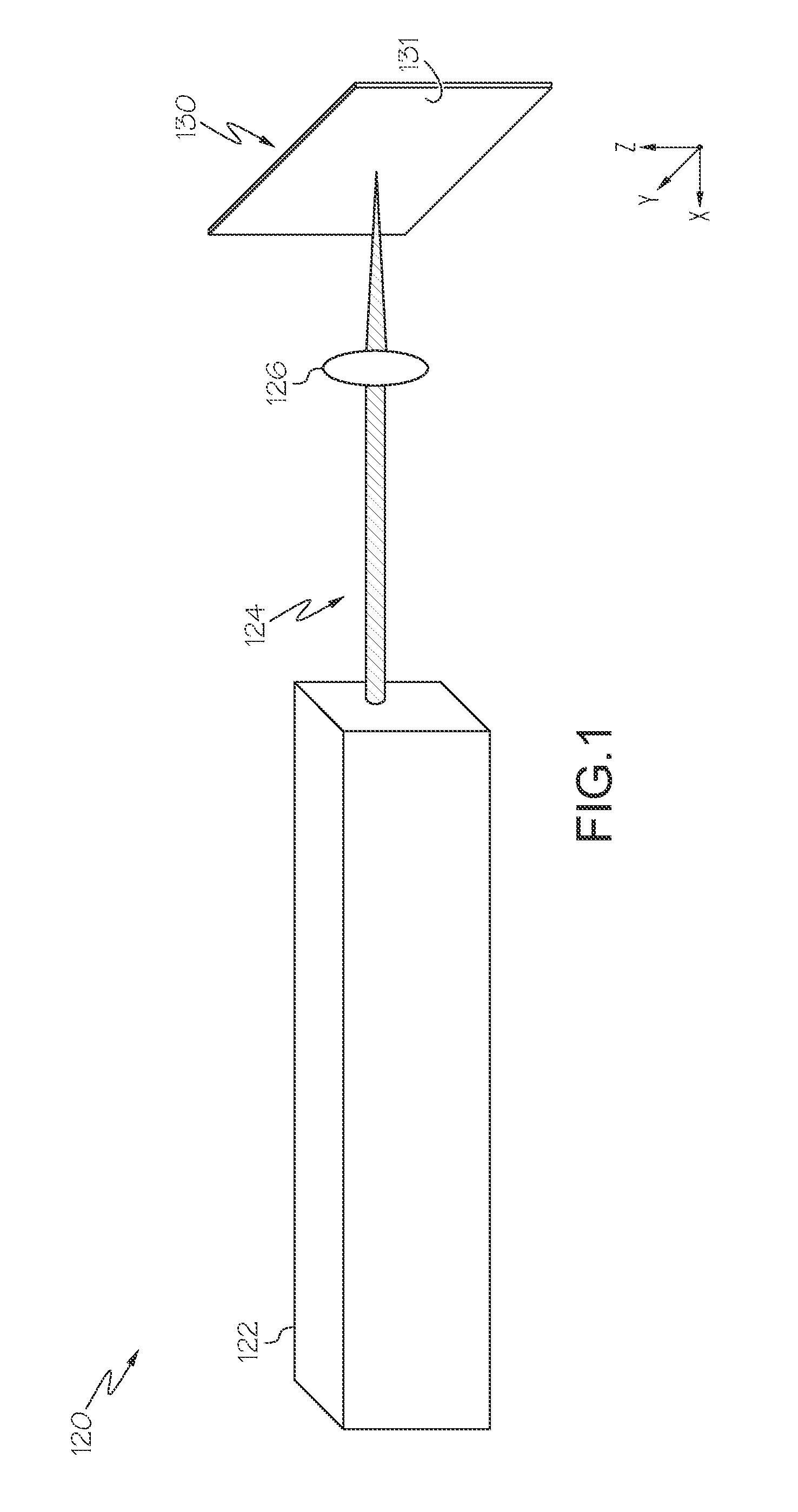

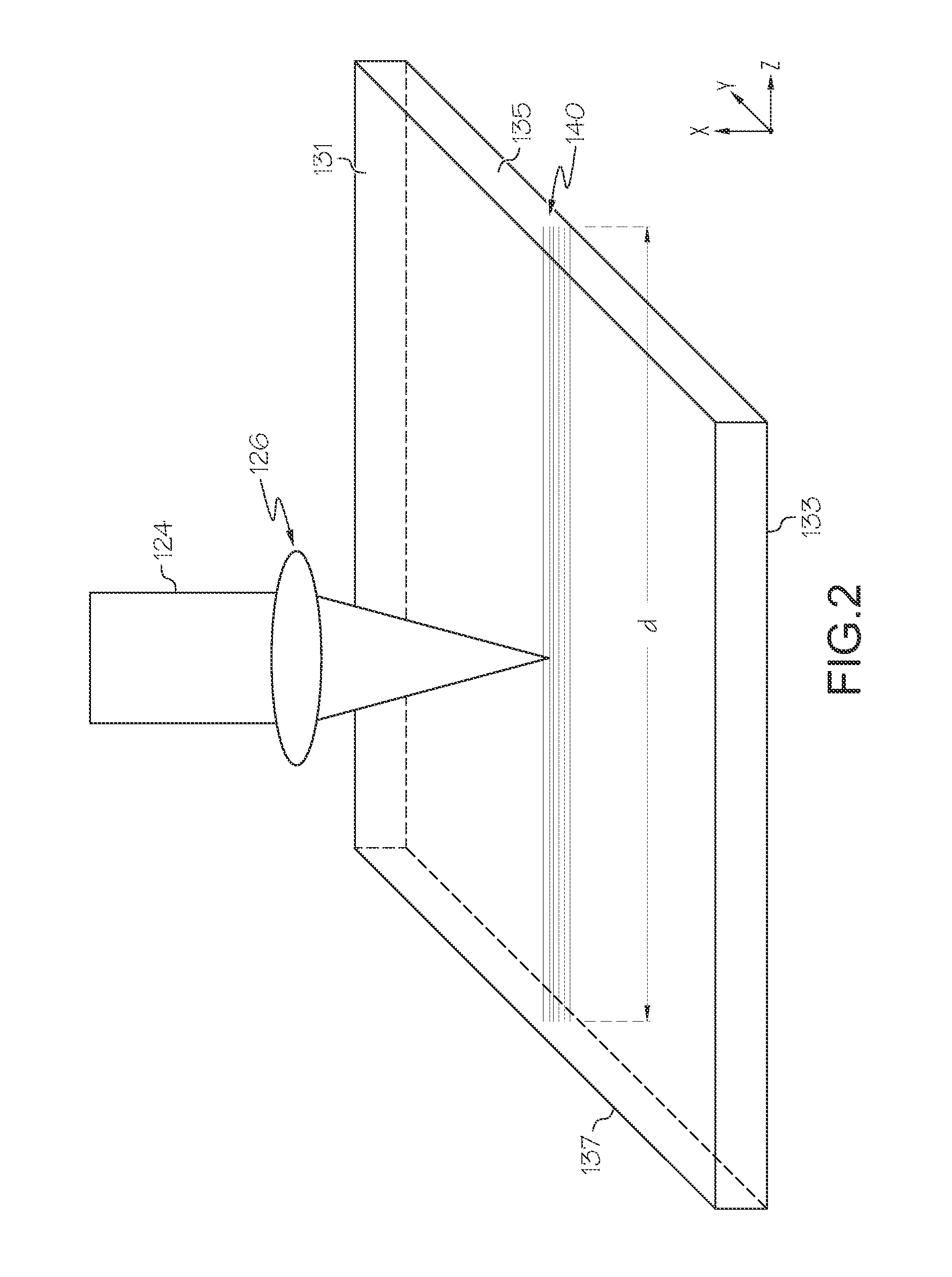

Methods of Fabricating Glass Articles by Laser Damage and Etching

Methods of forming a glass article are disclosed. In one embodiment, a method of forming a glass article includes translating a pulsed laser beam on a glass substrate sheet to form a laser damage region between a first surface and a second surface of the glass substrate sheet. The method further includes applying an etchant solution to the glass substrate sheet to remove a portion of the glass substrate sheet about the laser damage region. The method may further include strengthening the glass substrate sheet by an ion-exchange strengthening process, and coating the glass substrate sheet with an acid-resistant coating. Also disclosed are methods where the laser damage region has an initial geometry that changes to a desired geometry following the reforming of the glass substrate sheet such that the initial geometry of the laser damage region compensates for the bending of the glass substrate sheet.

Owner:CORNING INC

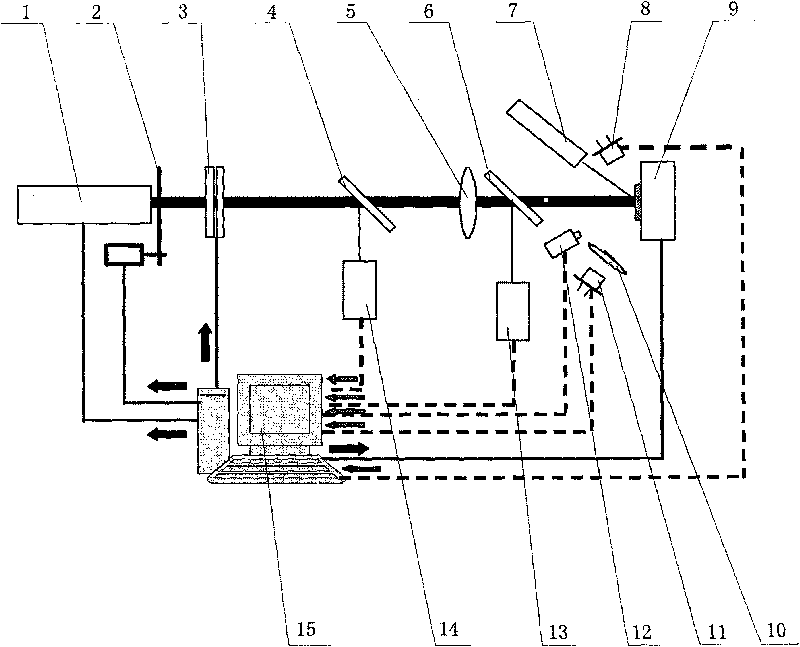

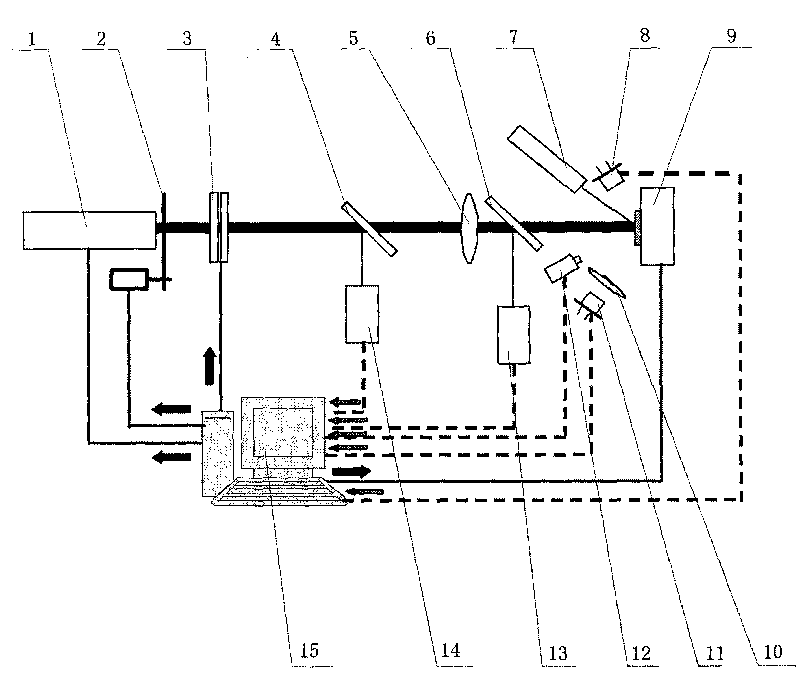

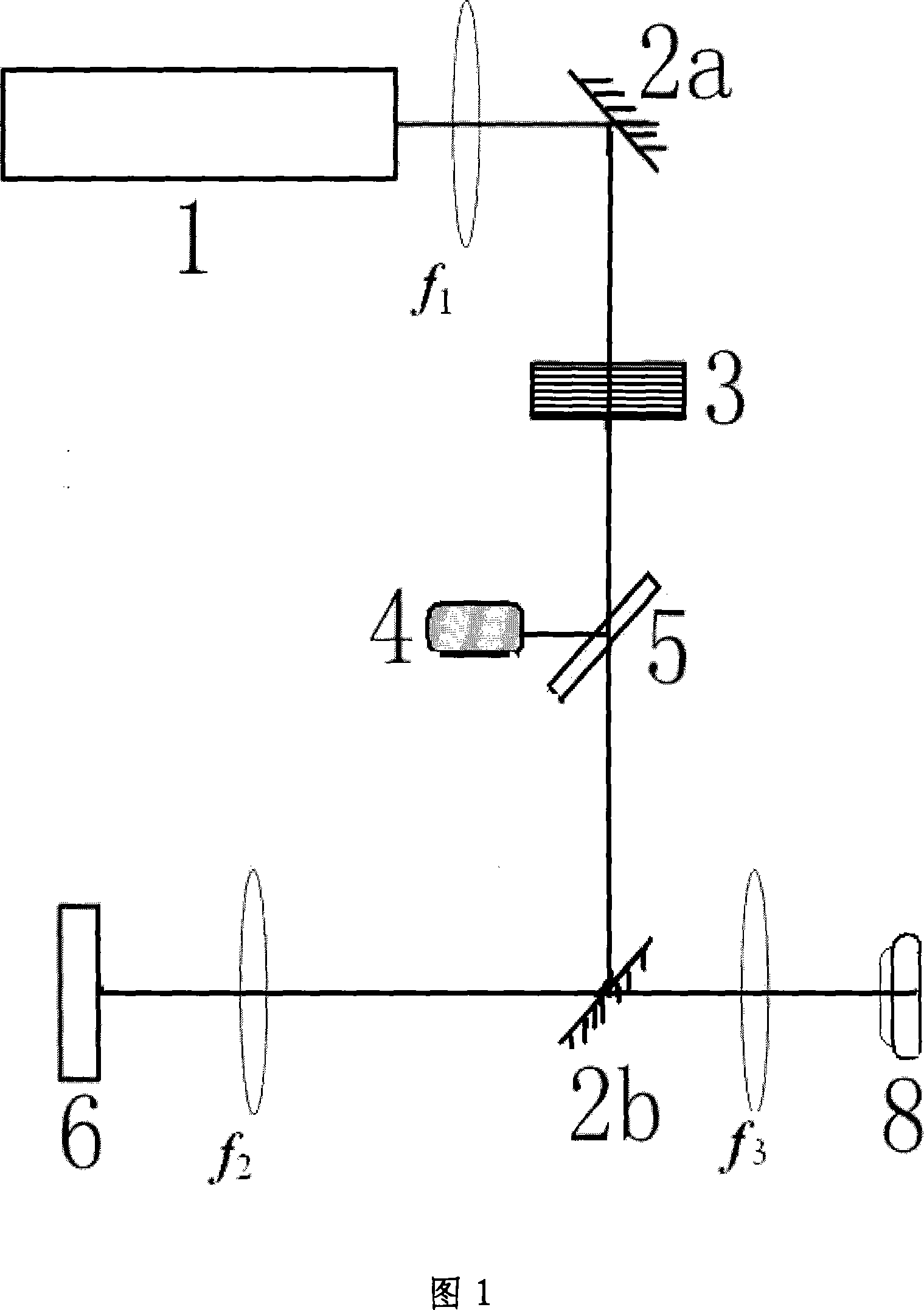

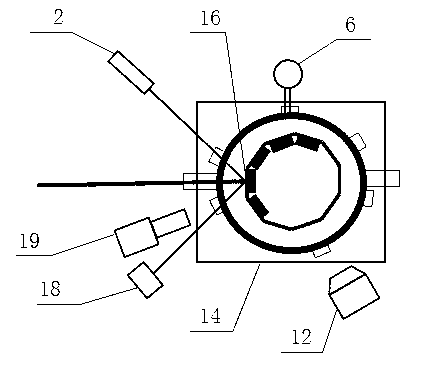

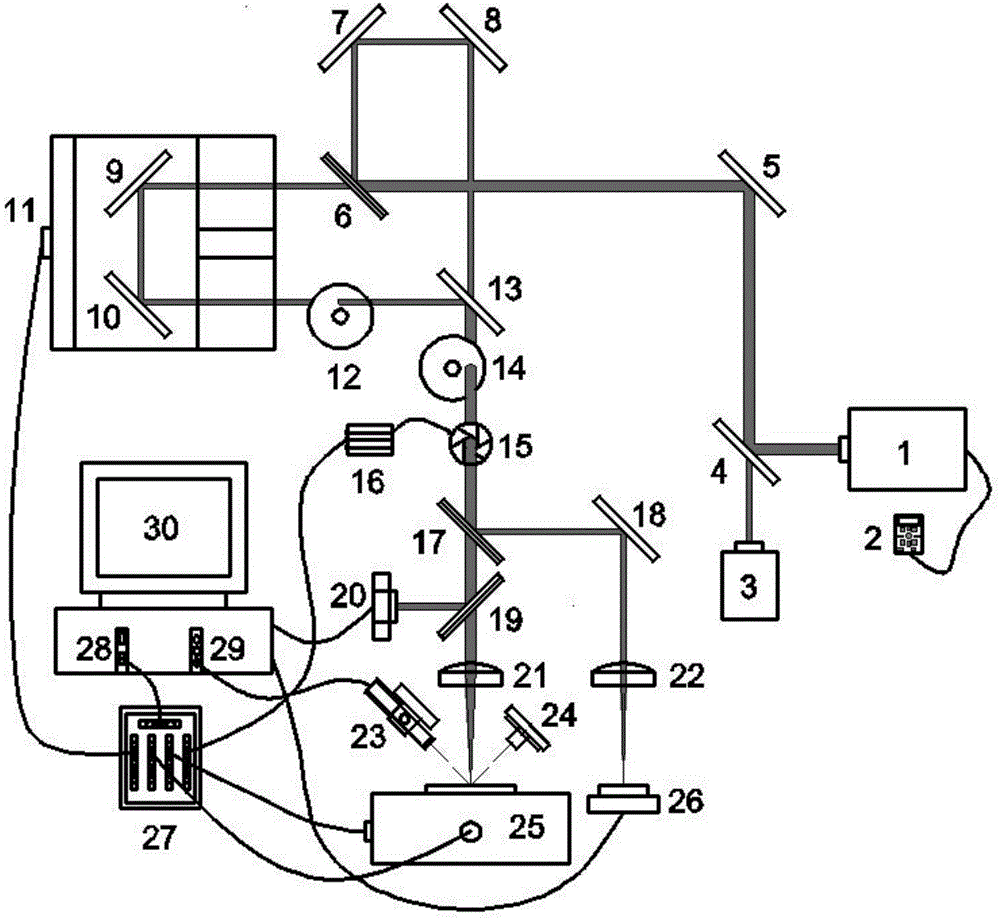

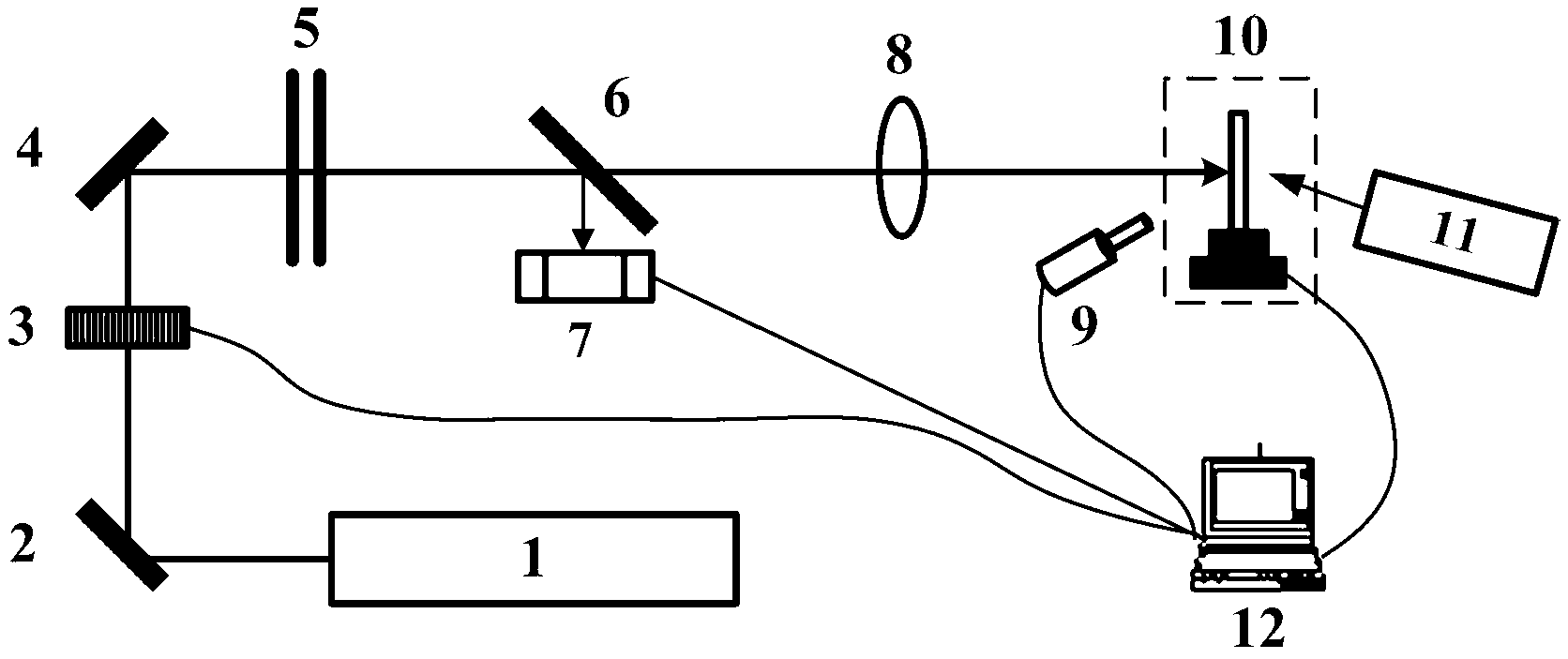

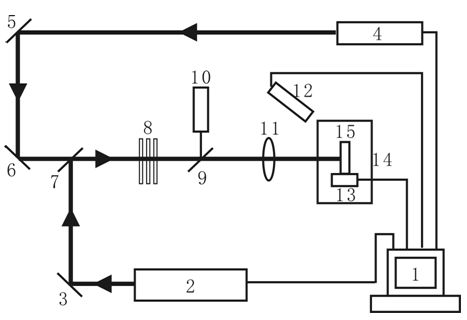

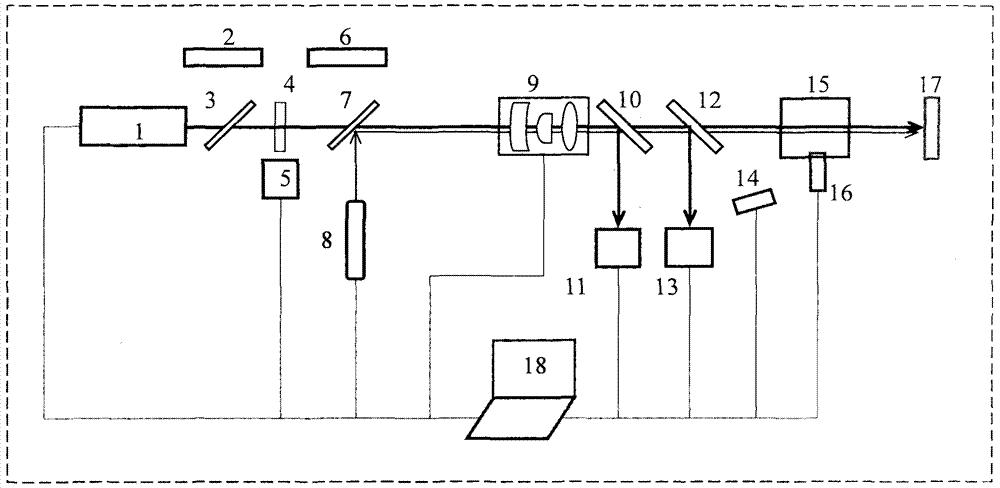

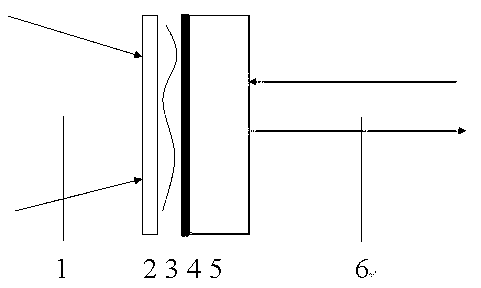

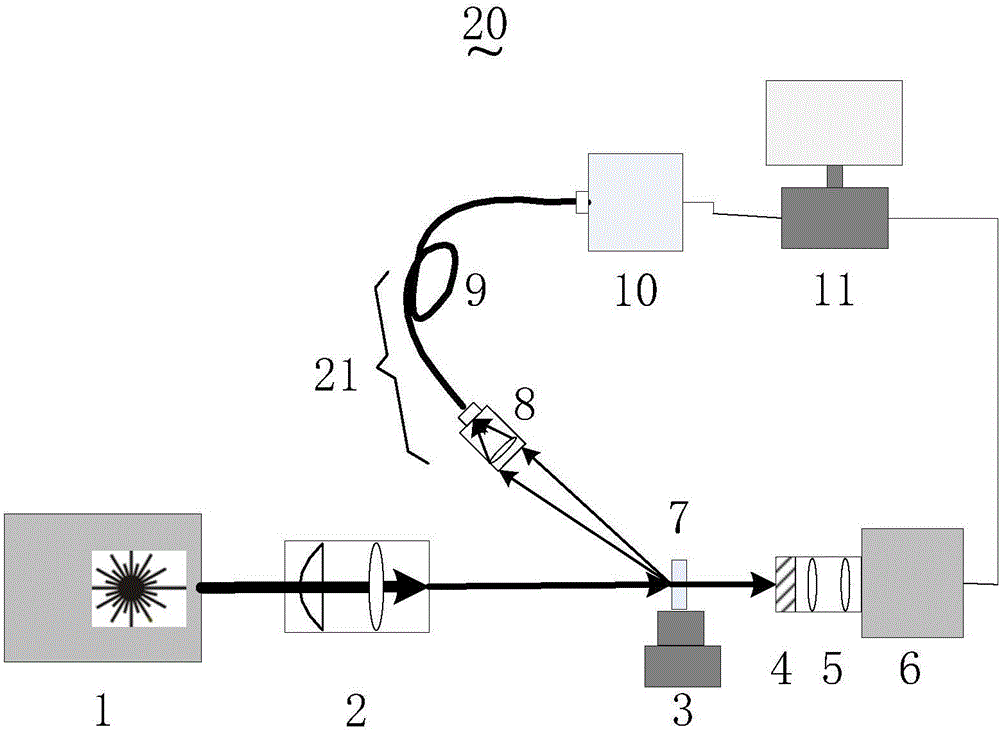

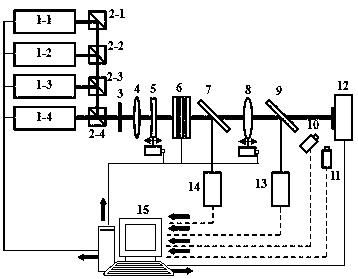

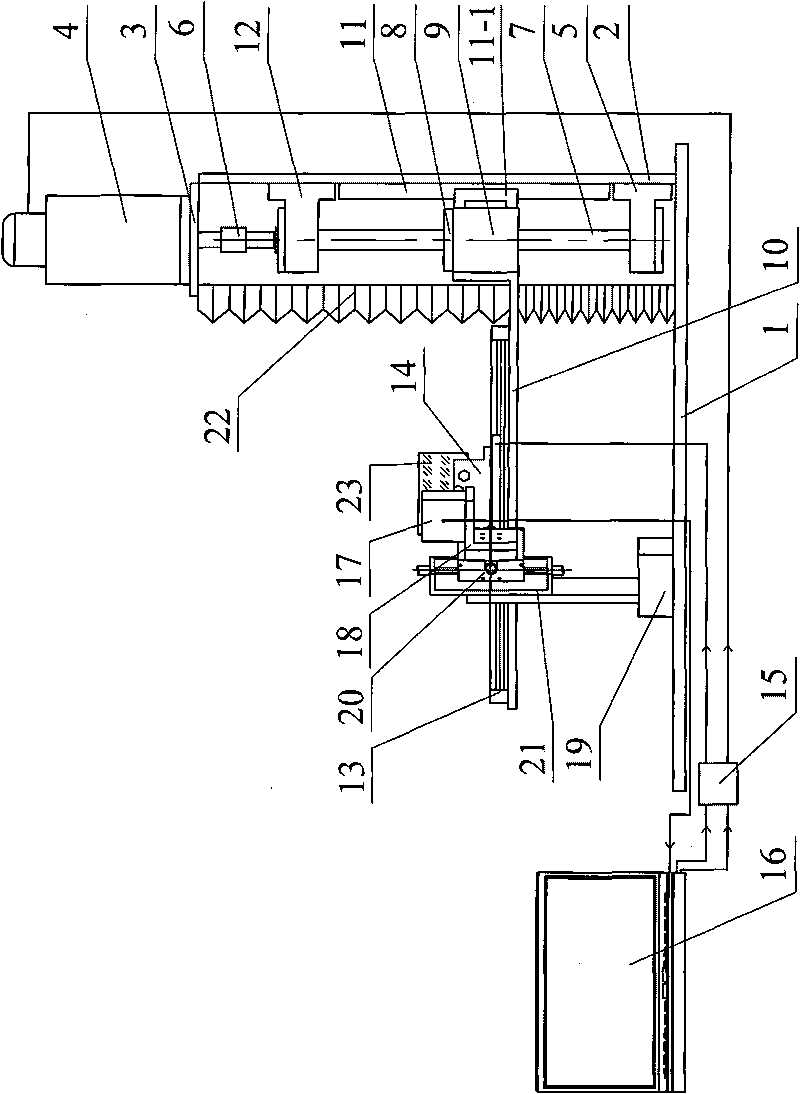

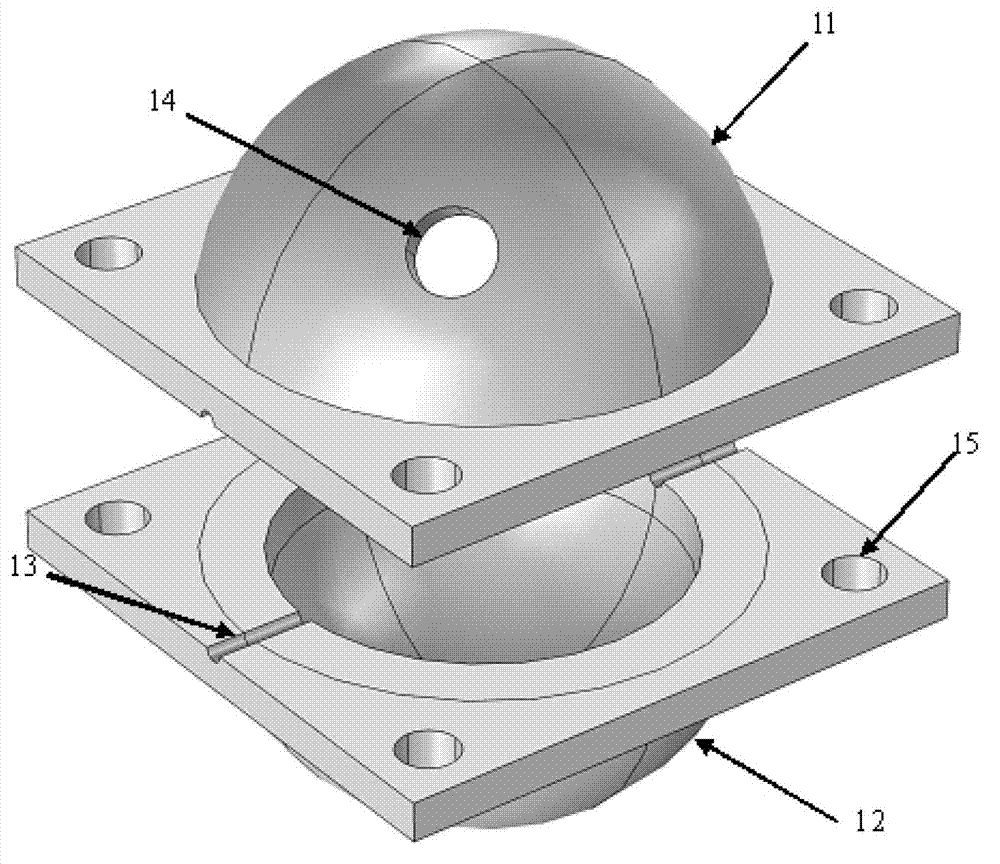

Combined testing device and testing method of laser damage thresholds of film and optical element

ActiveCN101718712AReduce mistakesWide varietyScattering properties measurementsOptically investigating flaws/contaminationPhotovoltaic detectorsBeam splitter

The invention relates to a combined testing device of the laser damage thresholds of a film and an optical element and a testing method utilizing the device. The traditional testing device and testing method have greater error and poor suitability for various film materials. The combined testing device of the laser damage thresholds of a film and an optical element comprises a testing assembly and a processing assembly, wherein the testing assembly comprises a Nd:YAG laser, a switch baffle, a first beam splitter, a focusing lens, a second beam splitter, a sample platform, a photodiode array, a convergent lens, an optoelectronic detector, a CCD camera, and the like; and the processing assembly comprises a computer. The testing method comprises the step of: conveying a testing result to judge whether various types of film samples are damaged or not by a CCD video microscopy judging method and a plasma flashing method according to a judgment criterion that one displayed damage is conformed The structure and the testing method of the invention has minimum testing error without error judgments and strong suitability and practicability.

Owner:XIAN TECHNOLOGICAL UNIV

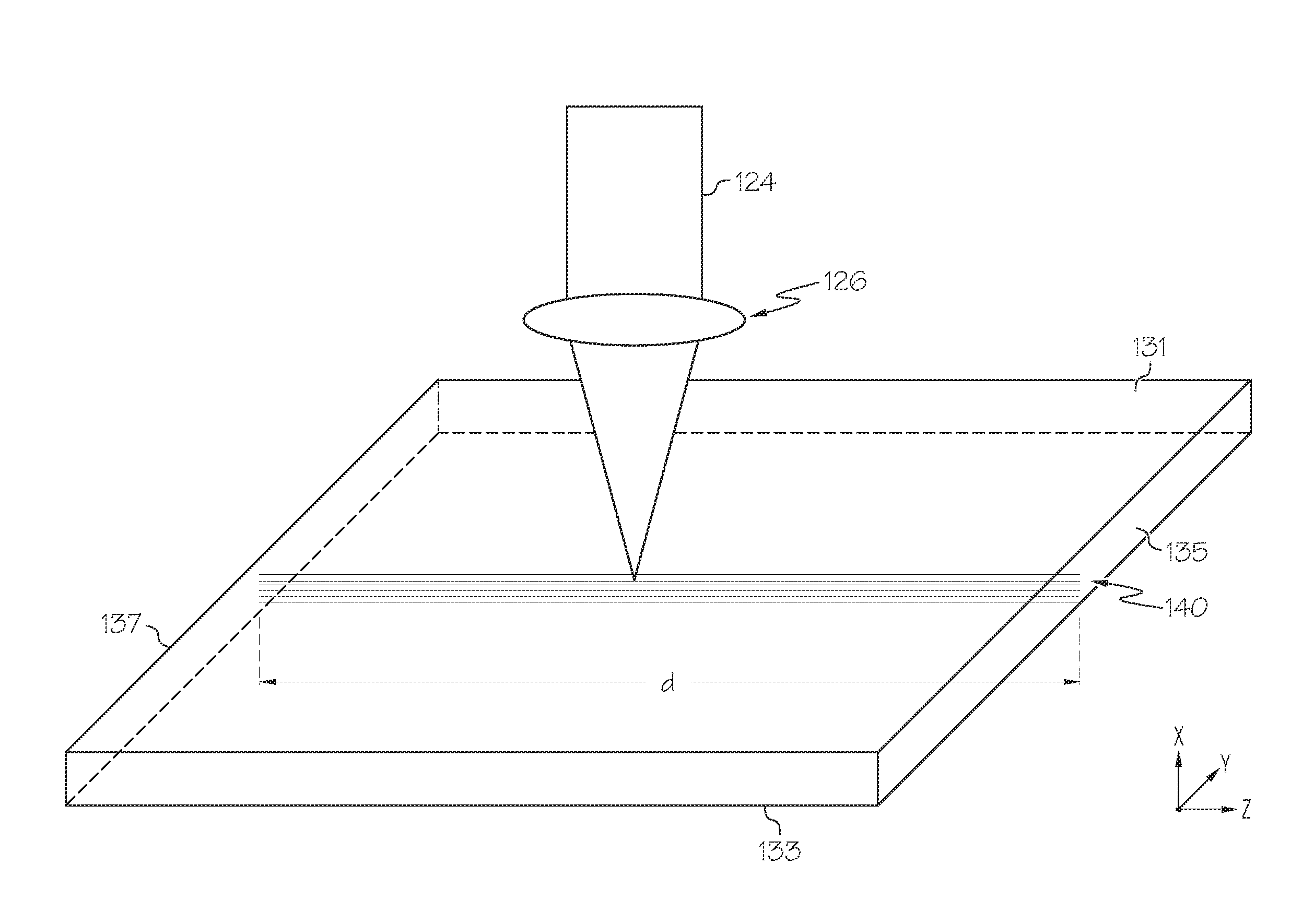

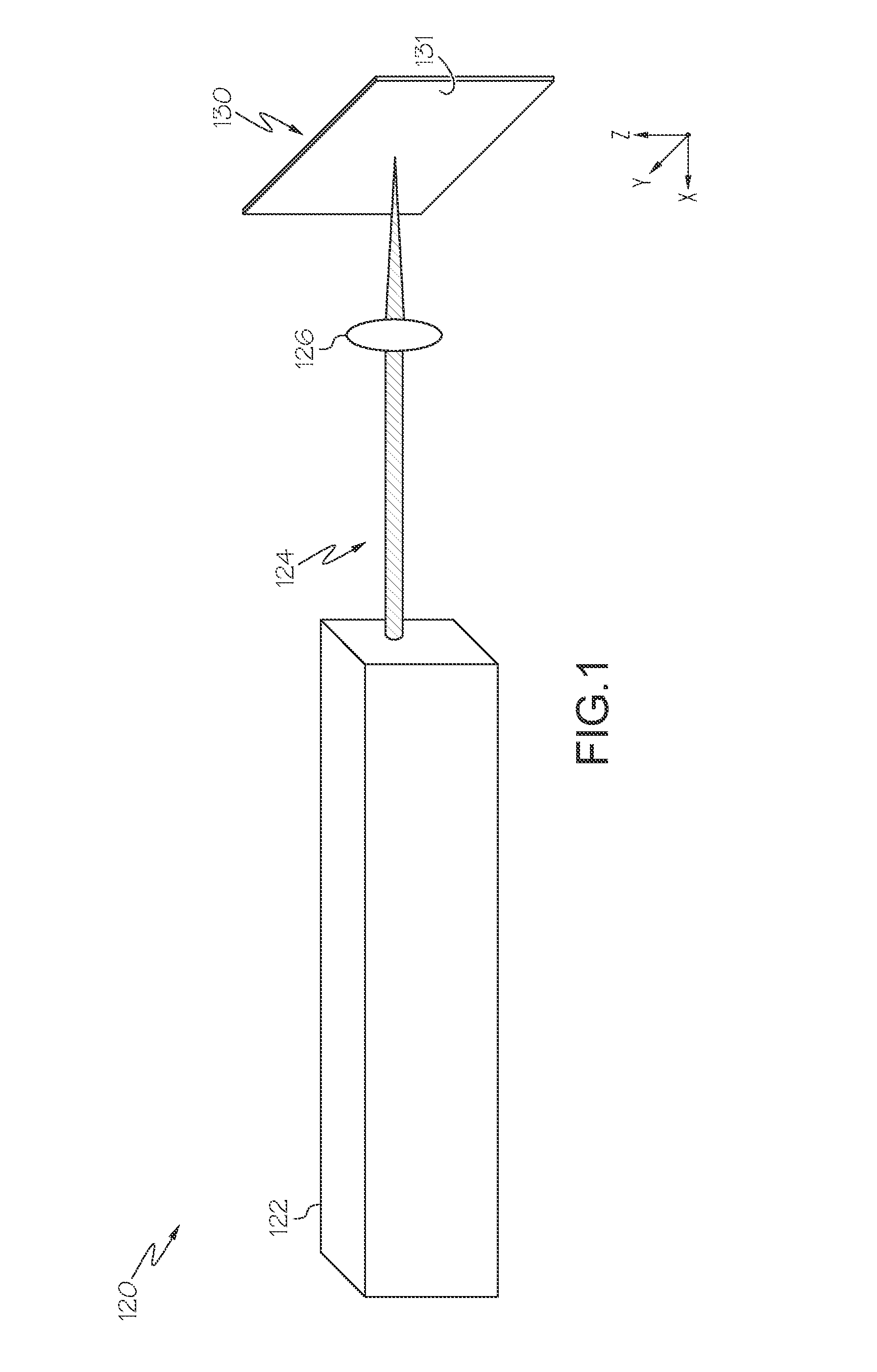

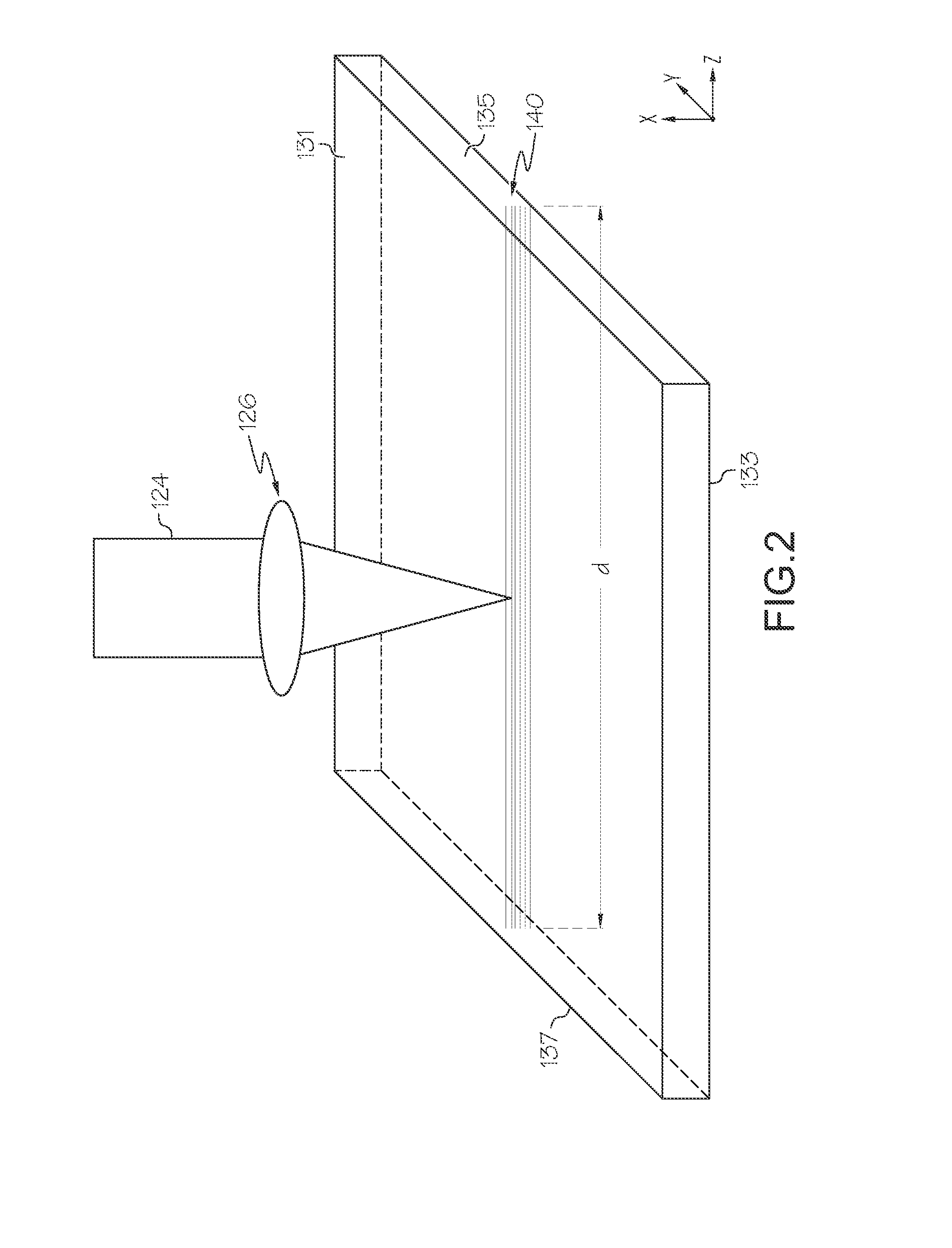

Methods of fabricating glass articles by laser damage and etching

Methods of forming a glass article are disclosed. In one embodiment, a method of forming a glass article includes translating a pulsed laser beam on a glass substrate sheet to form a laser damage region between a first surface and a second surface of the glass substrate sheet. The method further includes applying an etchant solution to the glass substrate sheet to remove a portion of the glass substrate sheet about the laser damage region. The method may further include strengthening the glass substrate sheet by an ion-exchange strengthening process, and coating the glass substrate sheet with an acid-resistant coating. Also disclosed are methods where the laser damage region has an initial geometry that changes to a desired geometry following the reforming of the glass substrate sheet such that the initial geometry of the laser damage region compensates for the bending of the glass substrate sheet.

Owner:CORNING INC

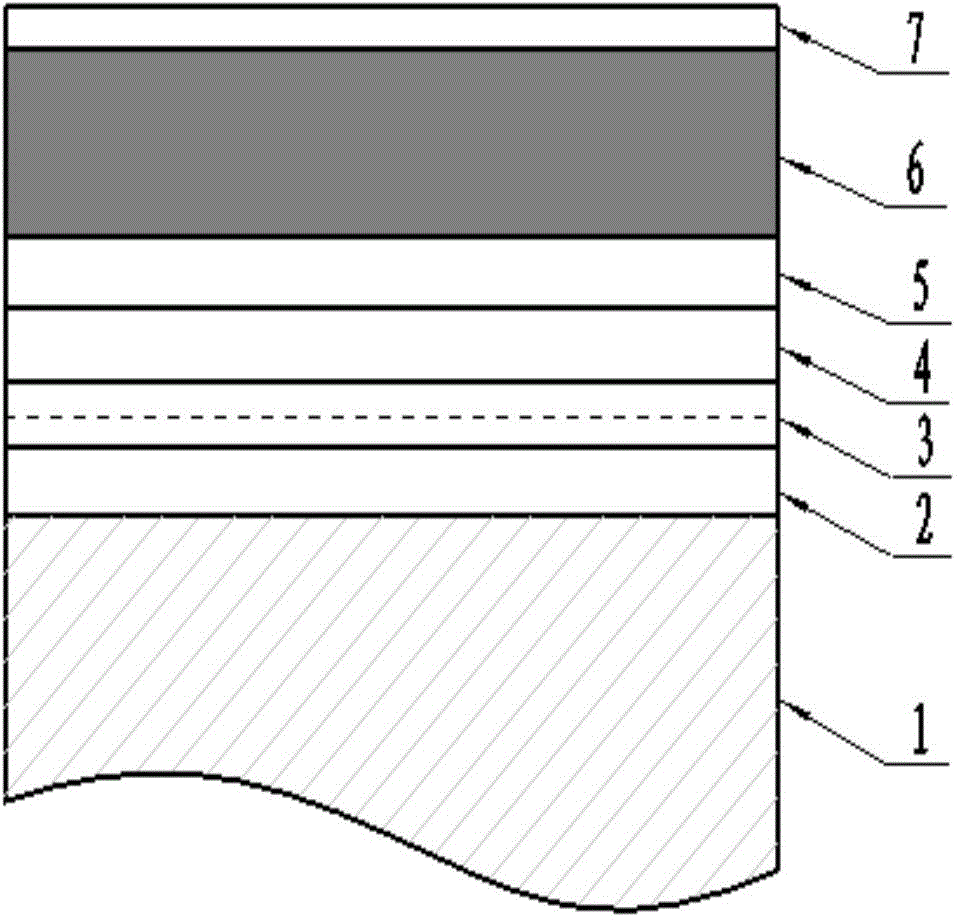

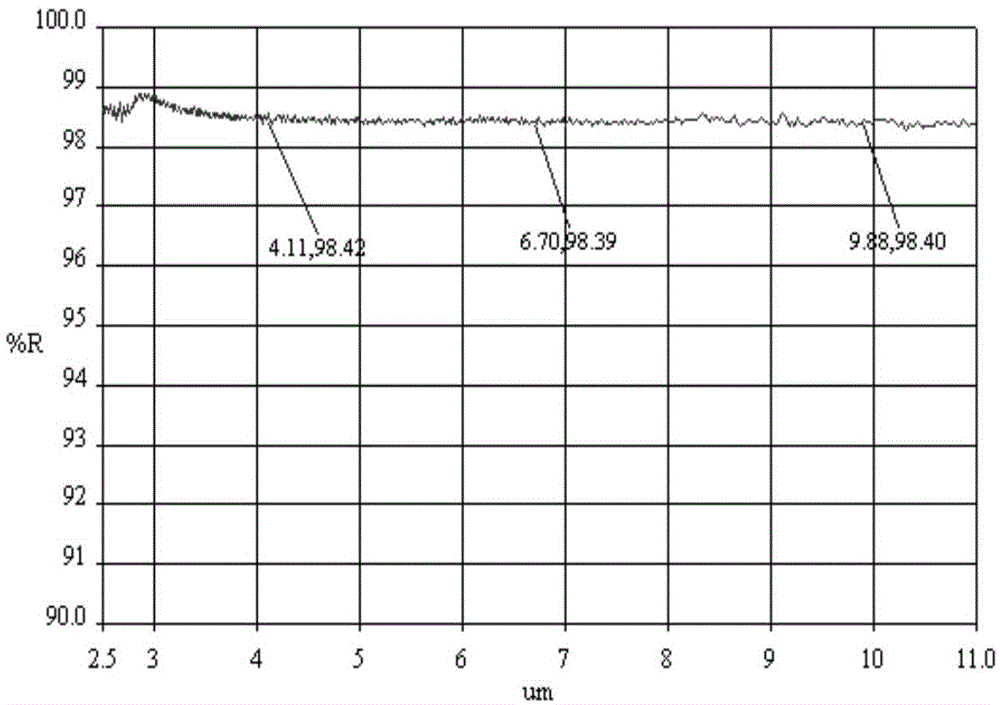

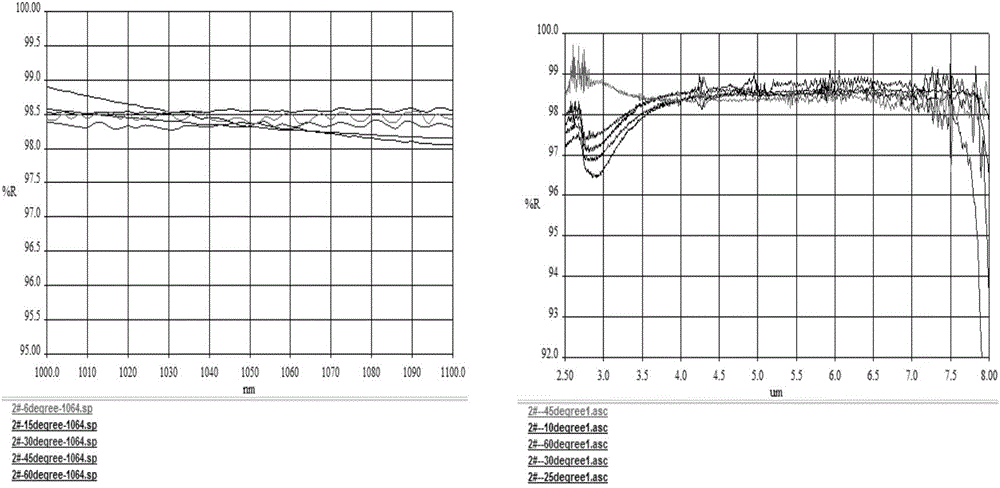

Infrared metal reflecting film with high adhesive force and manufacturing method thereof

ActiveCN104090312AGood physical occlusionImprove adhesionVacuum evaporation coatingSputtering coatingAdhesiveWear resistant

The invention provides an infrared metal reflecting film with high adhesive force and a manufacturing method thereof, wherein the infrared metal reflecting film with high adhesive force is plated on substrates of optical components such as glass, metal and silicon crystals. The infrared metal reflecting film with high adhesive force comprises a substrate, and is characterized in that a first transition layer, a holding-on bonding layer, a metal layer, a stress matching layer, a dielectric enhancement protecting layer and a hard wear-resistant layer are sequentially arranged on the substrate in an evaporation mode. The infrared metal reflecting film has the advantages of being good in film adhesive force, high in reflectivity, resistant to wear and high in environmental suitability, has a high laser damage resistance threshold value level, and can be widely applied to military and civilian photoelectron technical fields such as infrared lasers, refraction-reflection type optical systems and laser / infrared universal photoelectric equipment.

Owner:NO 717 INST CHINA MARINE HEAVY IND GRP

Method and device for detecting optical element laser damage threshold

ActiveCN101226148ASuitable for online testingHigh sensitivityFluorescence/phosphorescenceOnline testOptoelectronics

The invention provides a laser damage threshold detection method of optical component and a relative device, which utilizes the laser generated by a laser device to radiate on the surface of an object optical component to generate fluorescent light, to detect the surface morphology change of the optical component, wherein the laser device is KrF laser, and the invention detects the distortion of surface fluorescent light strength distribution on the optical surface to detect the surface morphology change of the optical component. The invention can directly detect damage generation and develop, with wide application for surface damage online tests on ultraviolet optical component and high sensitivity.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

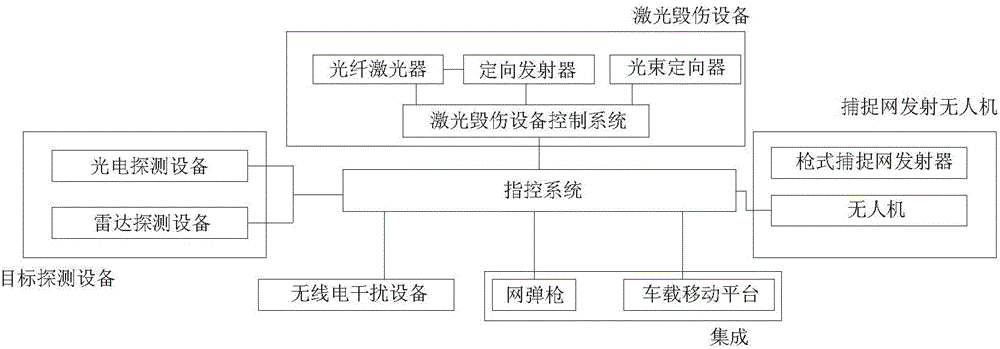

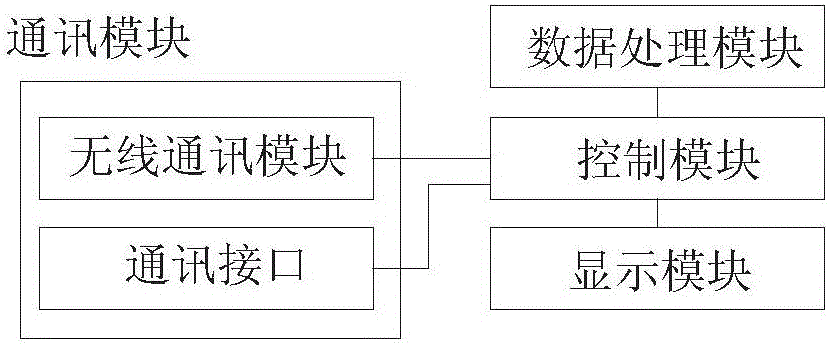

Anti-LSS-aircraft defensive system

InactiveCN106288964AHandlingWith auxiliary decision-makingDefence devicesCommand and controlModular design

The invention discloses an anti-LSS-aircraft defensive system which comprises a command and control system, a target detection device, a laser damage device, a radio interference device, a catching net launch unmanned aerial vehicle and a net gun. The command and control system is in communication connection with the target detection device, the laser damage device, the radio interference device, the catching net launch unmanned aerial vehicle and the net gun. According to the anti-LSS-aircraft defensive system, signals can be processed to generate intelligence, and then situation awareness display is conducted for providing aid decision making; the laser damage device, the radio interference device, the catching net launch unmanned aerial vehicle and the net gun and other firing units are commanded and controlled to operate through the command and control system, the multi-batch multi-target processing capacity is achieved, and a modular design concept is adopted for the command and control system, so that compatibility of multiple detection means and processing means is achieved; and the utilization rate of weapons can be increased, the effectiveness of the processing means and the environmental suitability of the system can be improved, and diversification demands of anti-LSS-aircraft tactical application can be met.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

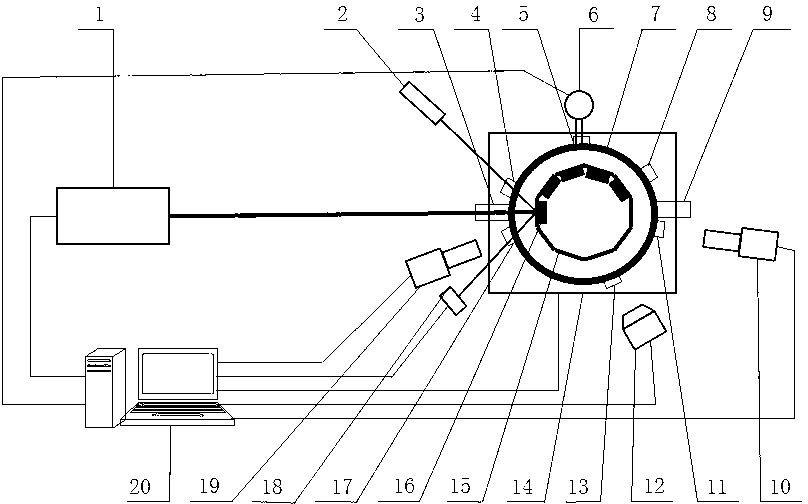

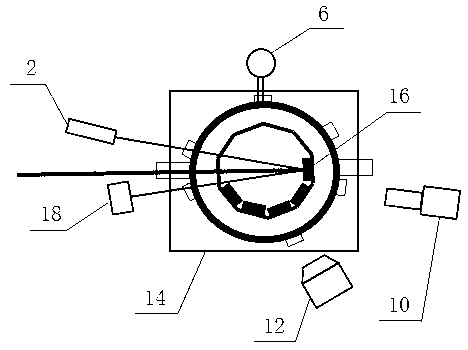

Multifunctional high-efficiency laser damage test device and method in vacuum environment

ActiveCN103226057AImprove efficiencyShorten the timeTesting optical propertiesSample rotationEngineering

The invention relates to a multifunctional high-efficiency laser damage test device and method in a vacuum environment. Five samples can be placed on a sample stage in a vacuum chamber at one time; the samples can be sequentially rotated to the laser irradiation position for testing laser damage by rotating the sample stage; online monitoring and judgment of damage conditions can be realized by using an online imaging and scattered light detection device of a CCD (Charge Coupled Device) camera and a pressure detection element; and the samples can also be rotated to an observation window and then the damage morphology of the samples is observed in an off-line manner and analyzed. Meanwhile, the function that front sides and back sides of the samples are respectively irradiated by laser can be achieved by using the rotation of the sample stage. The device is simple and easy to operate; according to the device, the data test time in the vacuum environment is greatly saved and the efficiency of damage test is increased; and meanwhile, test method and functions are diversified and comprehensive damage information can be obtained.

Owner:TONGJI UNIV

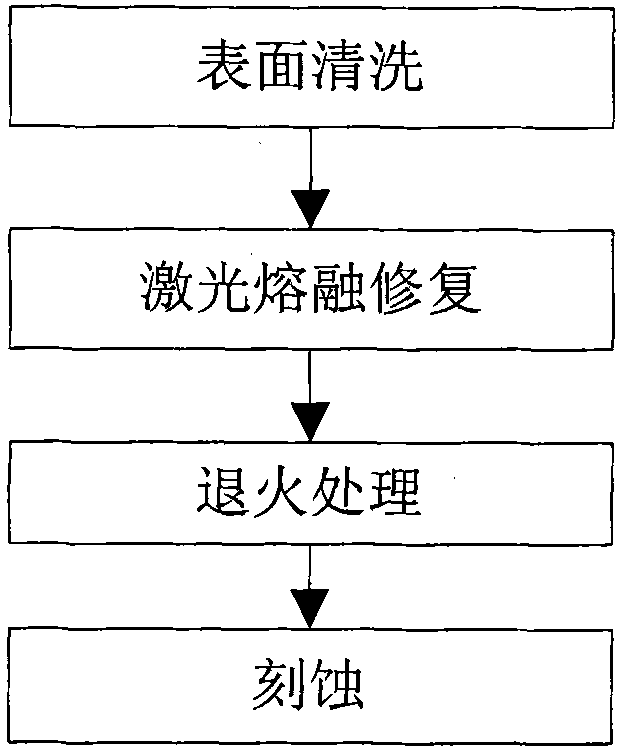

Method for repairing fused quartz optical damage component

The invention discloses a method for repairing a fused quartz optical damage component, which belongs to the technical field of the optical material and the optical component, in particular to a method for repairing and processing laser damage of a fused quartz optical component. The method comprises the following steps: firstly adopting infrared carbon dioxide laser to carry out laser fusion repair on the damage part of the fused quartz optical damage component; and then carrying out annealing treatment on the fused quartz optical damage component subjected to laser fusion repair. The method can carry out complete repair on the fused quartz optical damage component and eliminate residual stress caused by the laser fusion repairing process. The fused quartz optical component repaired by the method can revert to the state of the ideal fused quartz optical component. And the method also can inhibit the increase of the damage points of the fused quartz optical component. The method can prolong the service life of the fused quartz optical component, greatly reduces operation cost and has the characteristics of strong process controllability, high repetitiveness and stable performance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

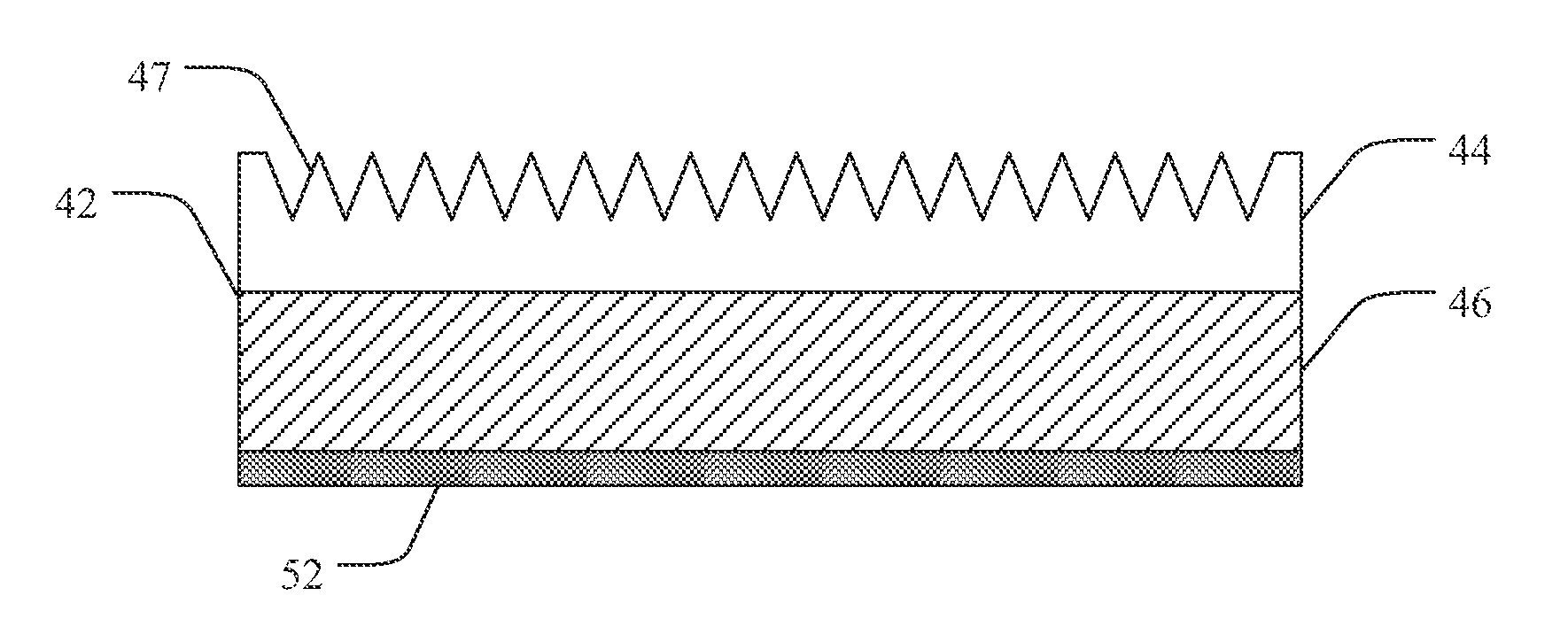

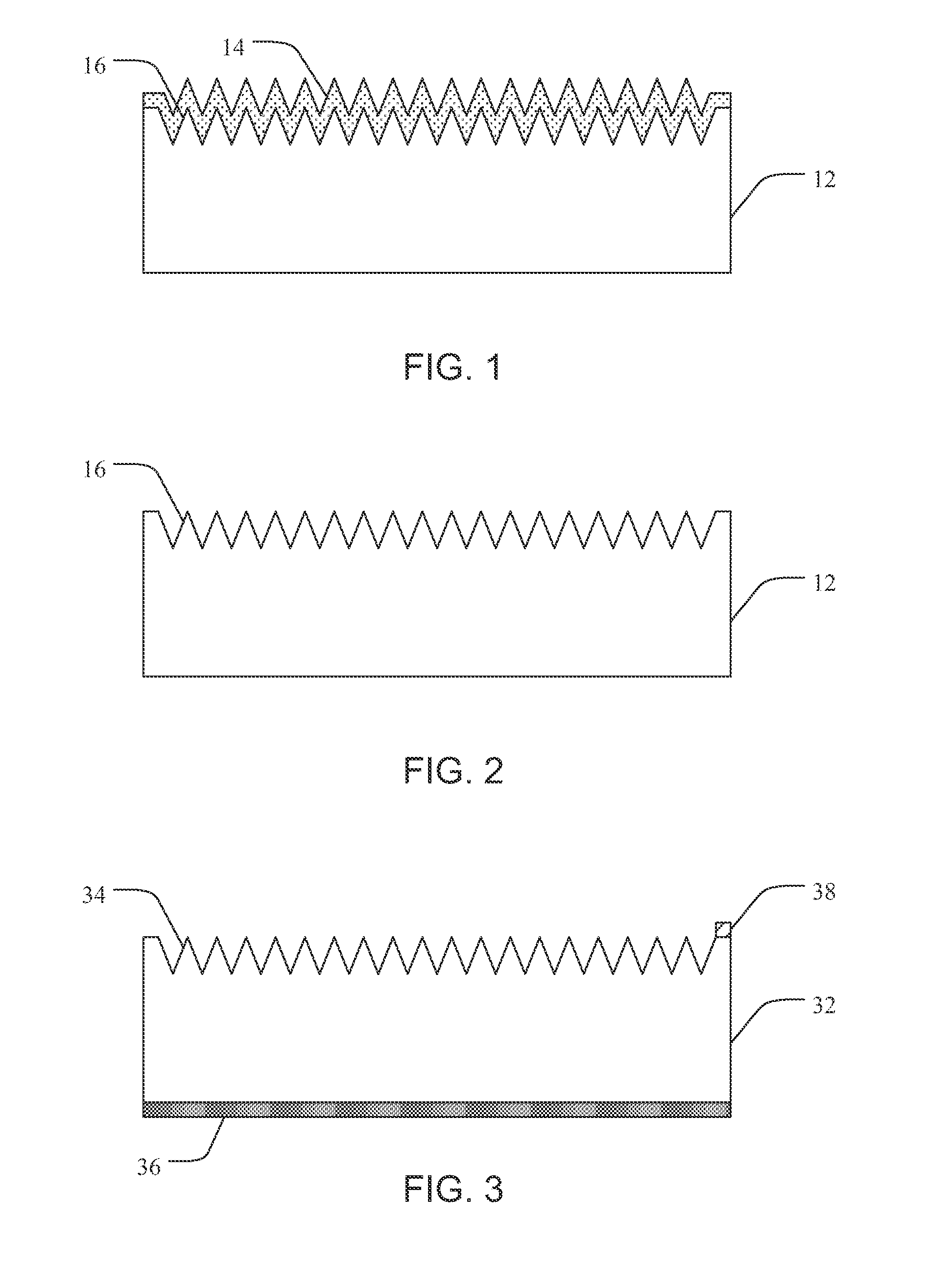

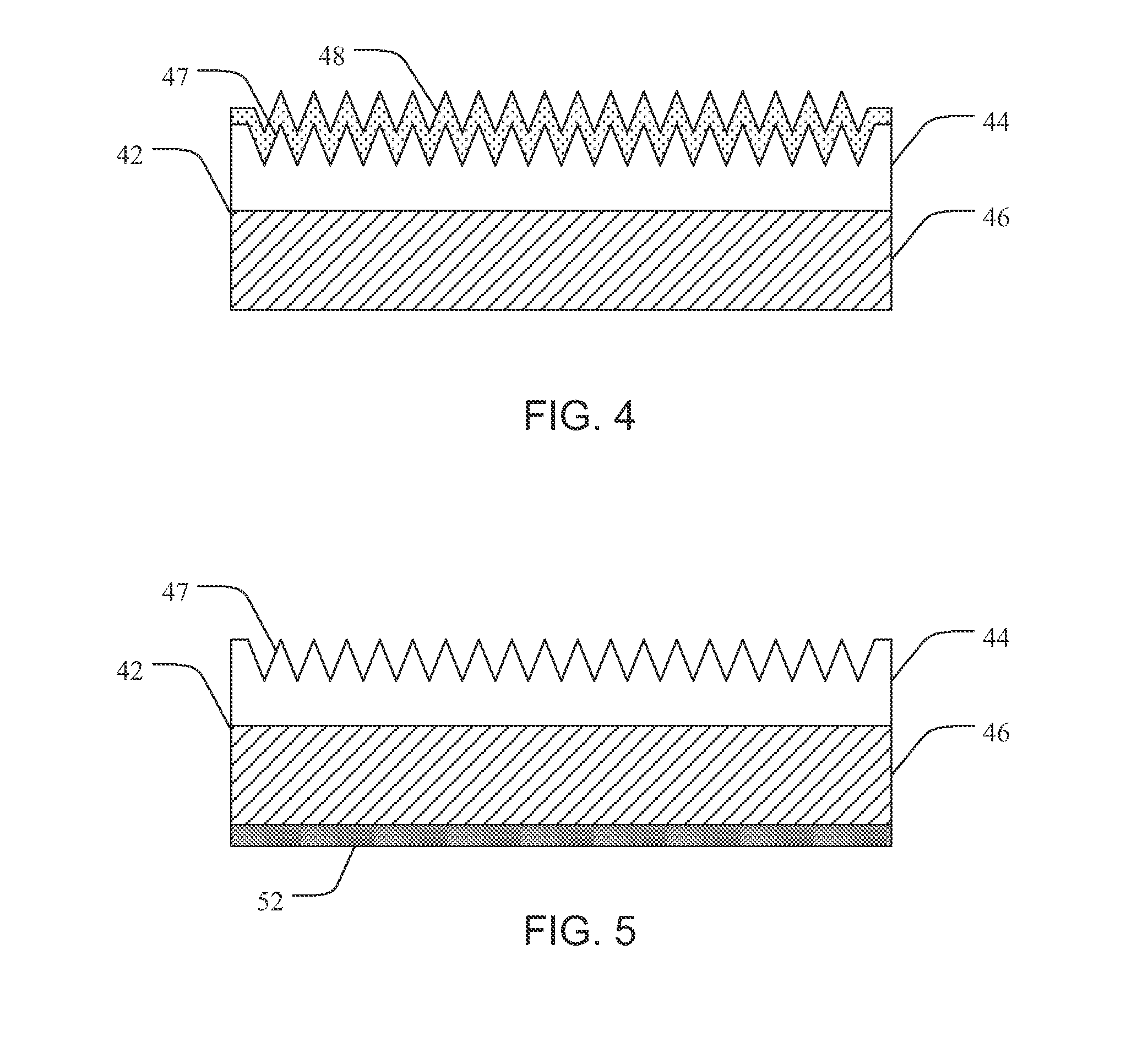

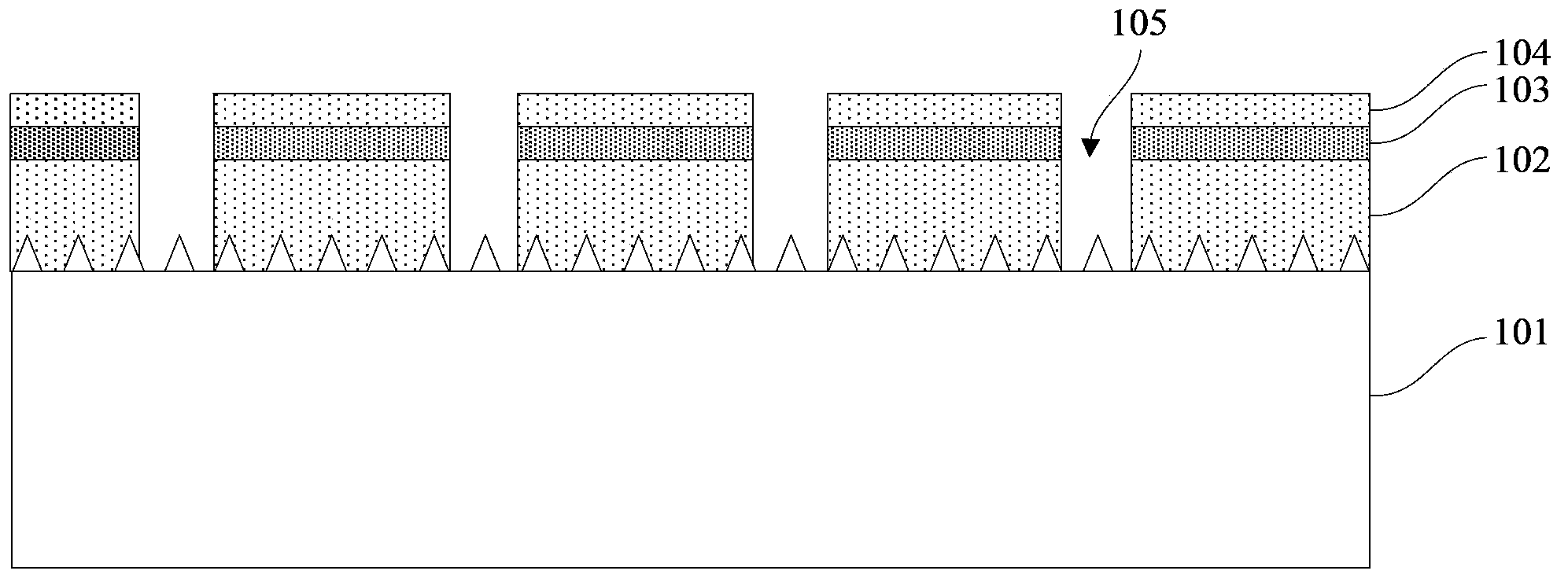

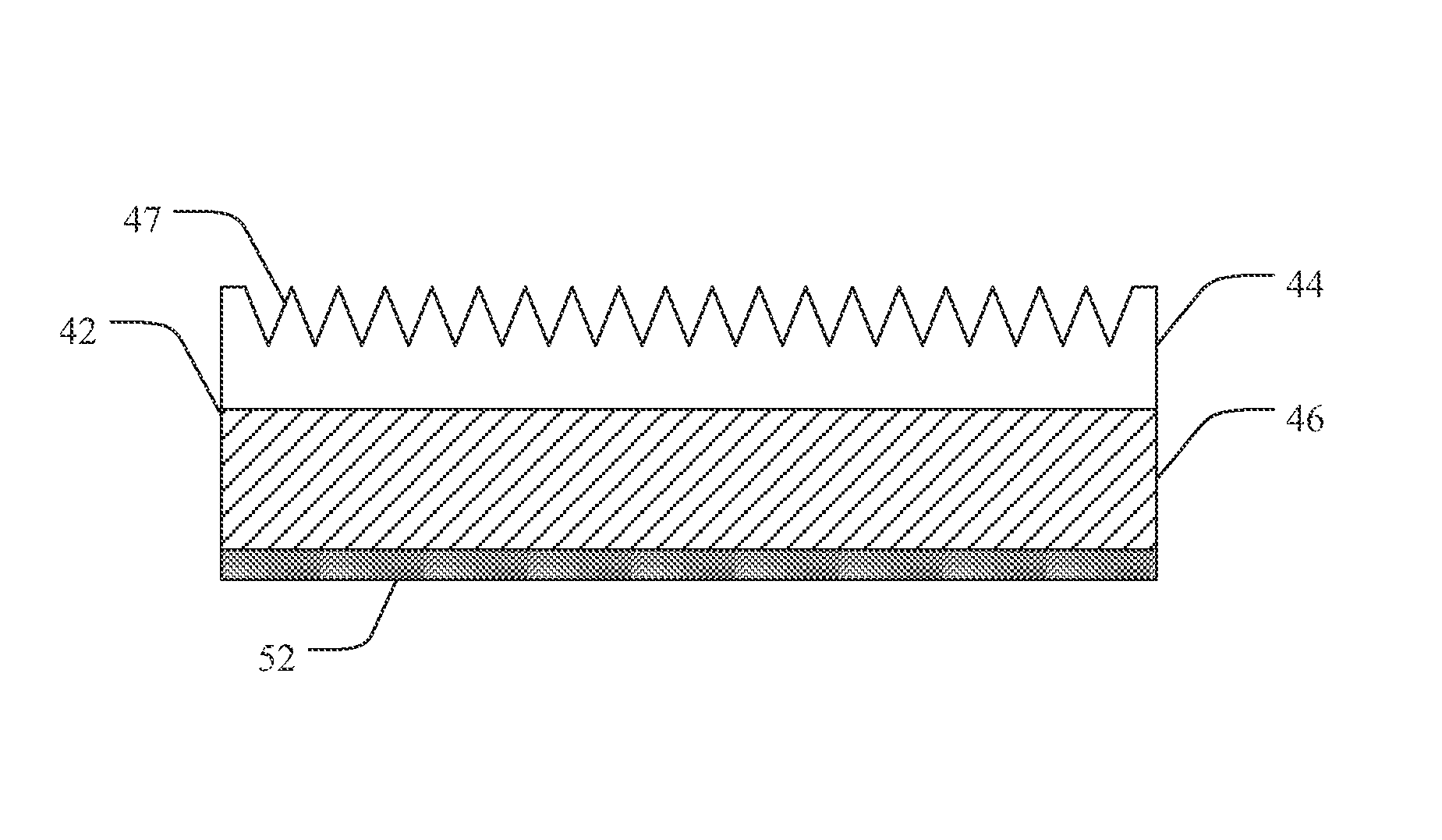

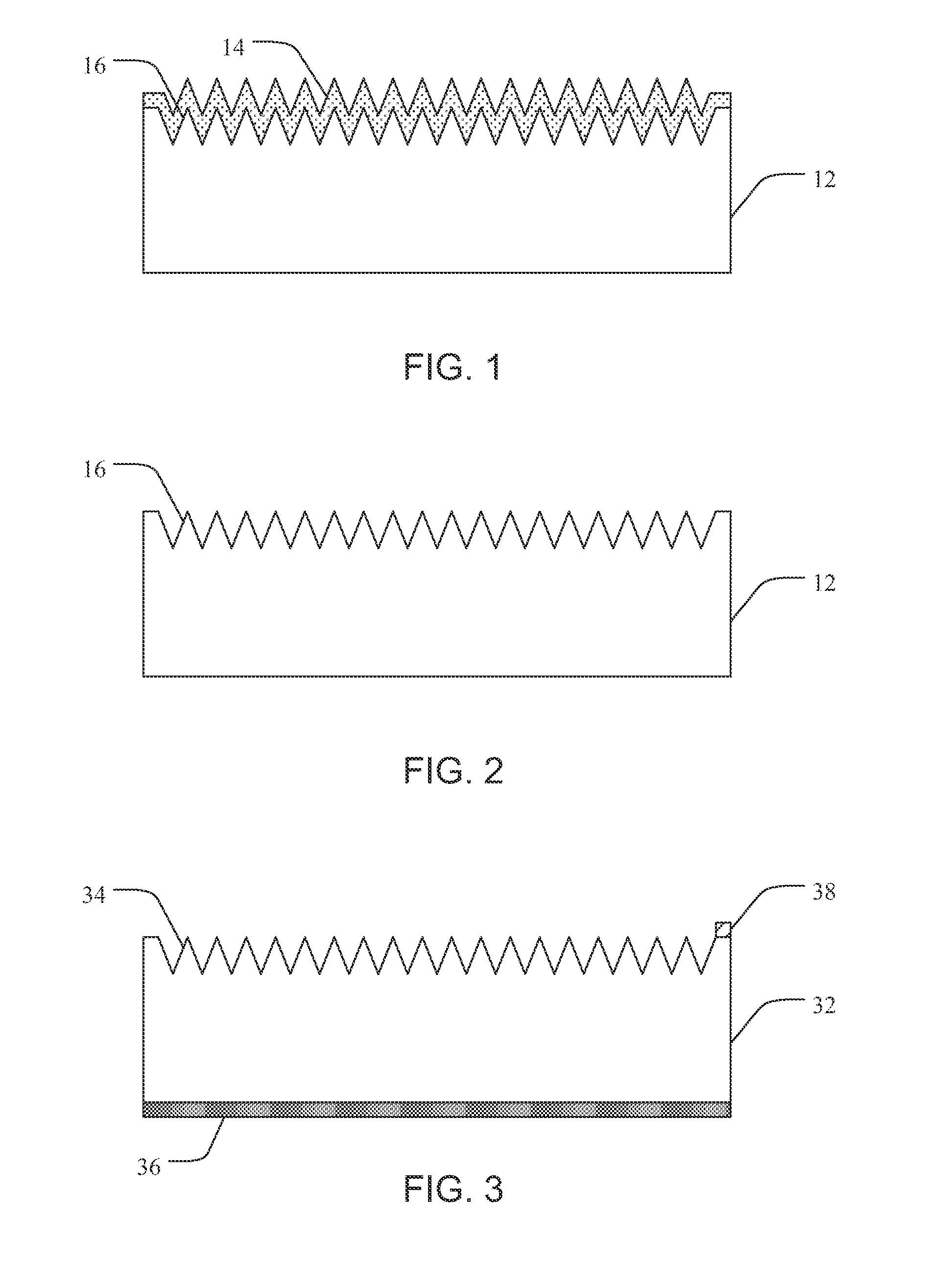

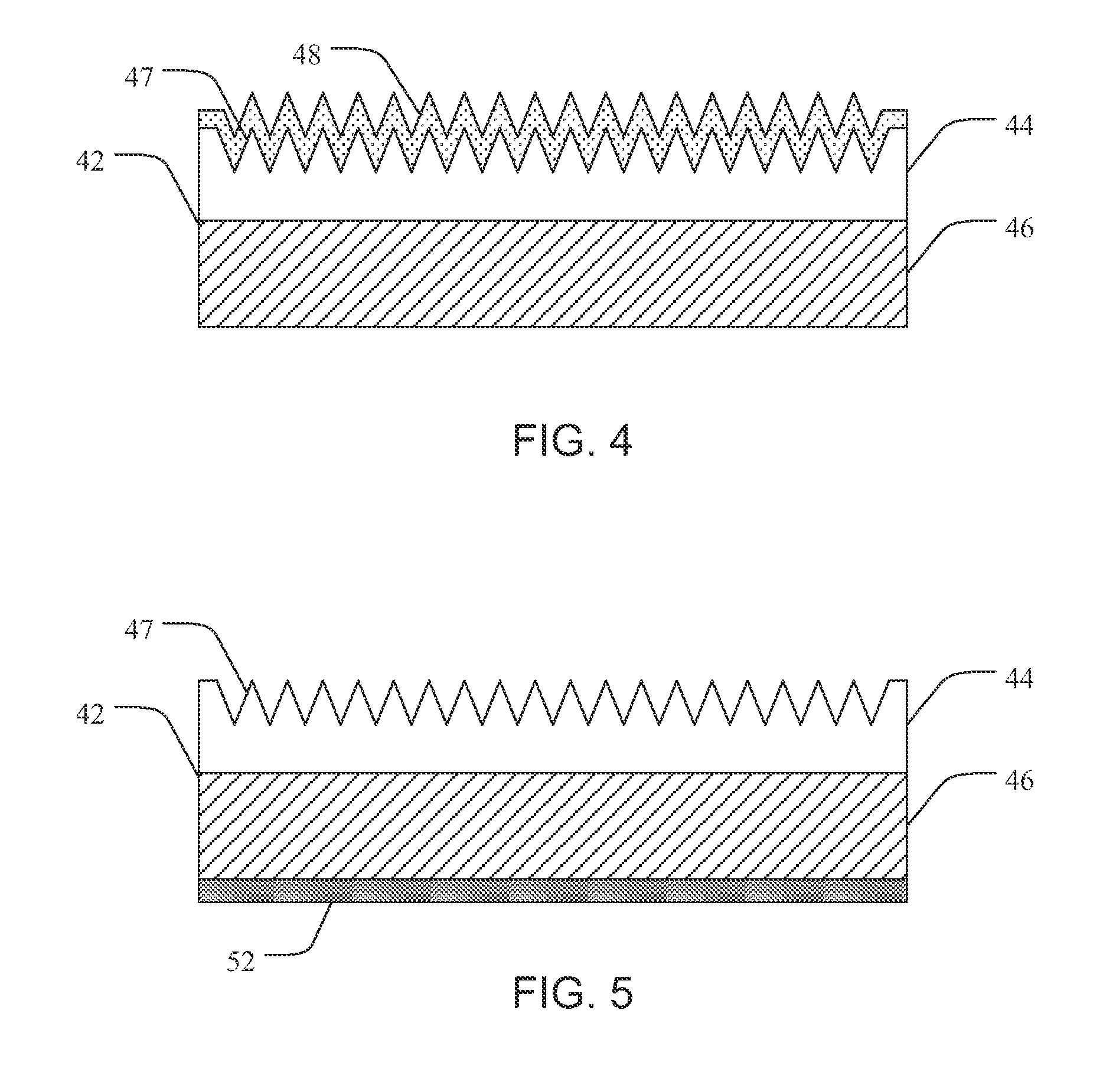

Semiconductor devices having reduced substrate damage and associated methods

ActiveUS20130001553A1Improve business performanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsProcess region

Optoelectronic devices, materials, and associated methods having increased operating performance are provided. In one aspect, for example, an optoelectronic device can include a semiconductor material, a first doped region in the semiconductor material, a second doped region in the semiconductor material forming a junction with the first doped region, and a laser processed region associated with the junction. The laser processed region is positioned to interact with electromagnetic radiation. Additionally, at least a portion of a region of laser damage from the laser processed region has been removed such that the optoelectronic device has an open circuit voltage of from about 500 mV to about 800 mV.

Owner:SIONYX

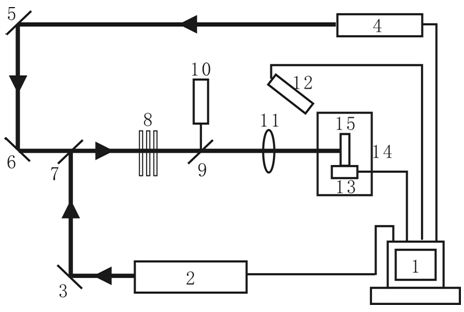

Double-beam delayed laser damage testing system

ActiveCN104101486AMeet laser damage test requirementsTesting optical propertiesElectronic shutterAutomatic control

The invention discloses a double-beam delayed laser damage testing system. The system is composed of a pulse laser, a laser controller, seven reflecting mirrors, four light splitters, two annular changeable neutral-density filtering sheets, an electrically controlled translation platform, a motor driver, a main control computer, an electronic shutter, two plano-convex lenses, a three-dimensional electrically controlled sample platform, a beam quality analyzer, an energy detector, a high-resolution color CCD imaging device and a white light source. With the utilization of the computer, the double-beam delayed laser damage testing system realizes automatic control by utilizing the computer, and can perform laser damage threshold testing of lasers in different pulse widths on the surface of an optical element.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

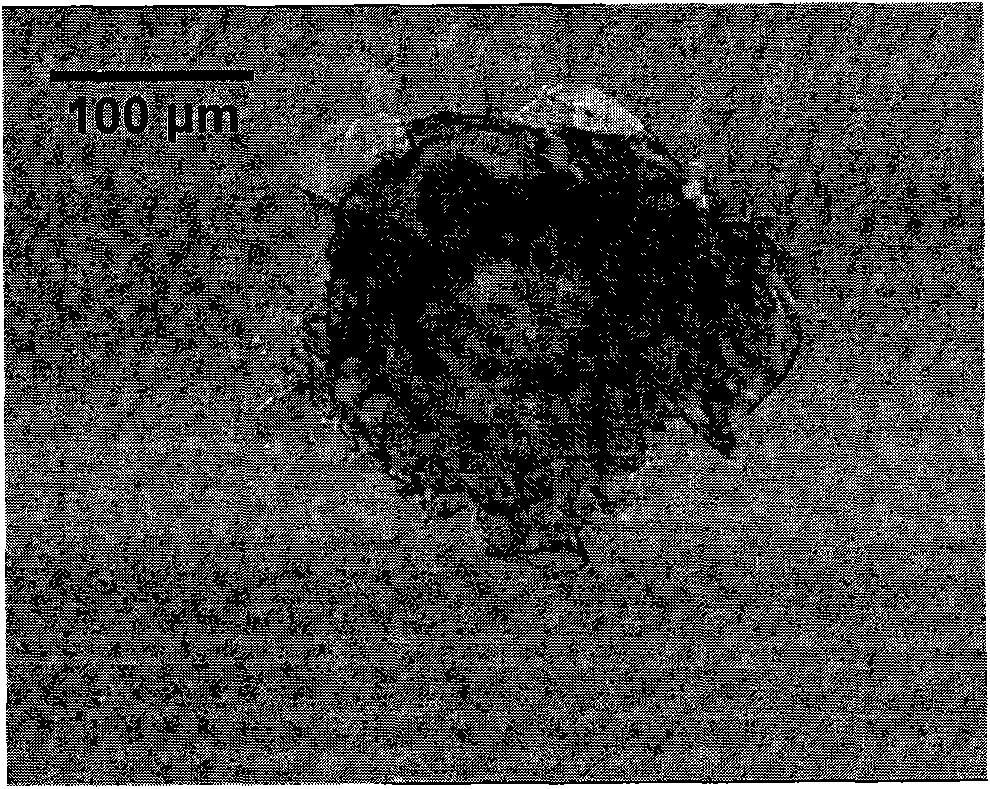

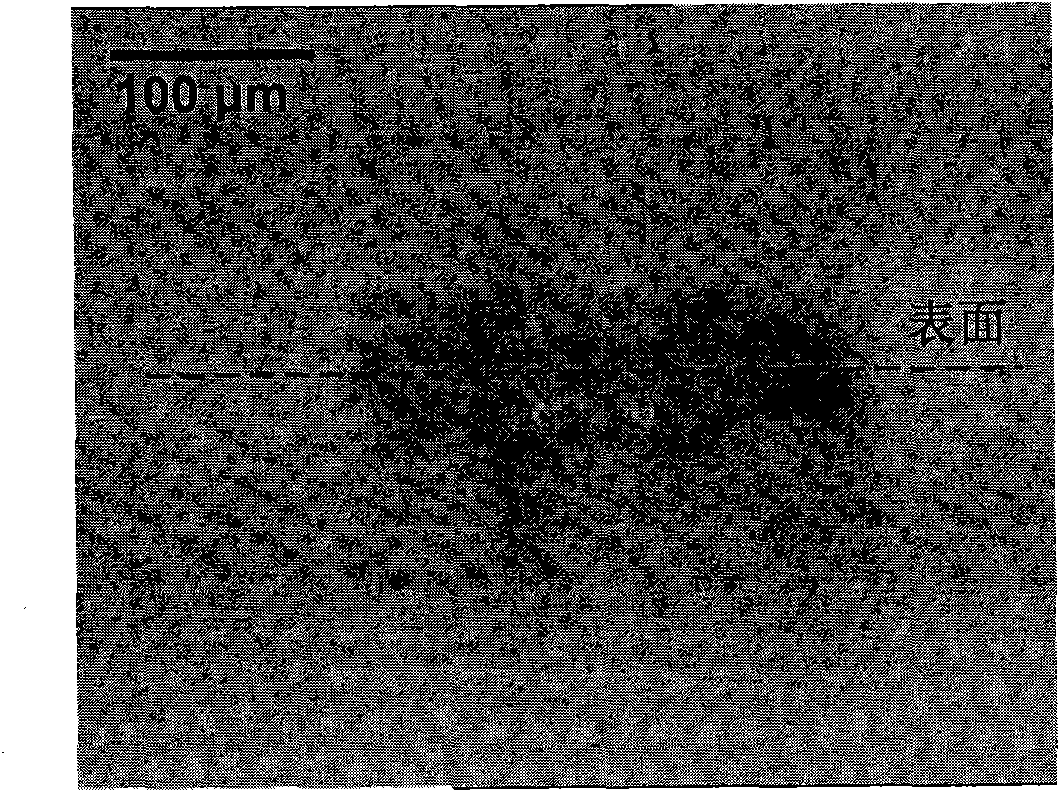

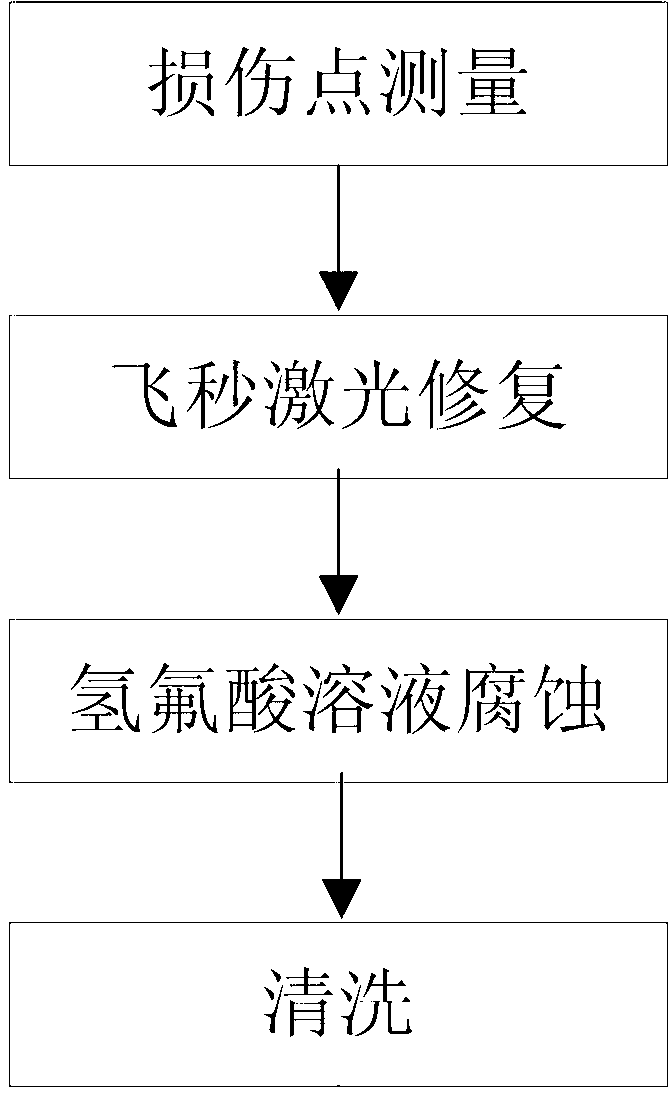

Repair method for surface-damaged growth point of melted quartz element

The invention relates to a repair method for a surface-damaged growth point of a melted quartz element. The method comprises the following steps of: measuring the surface-damaged growth point of melted quartz; repairing the damaged point by femtosecond laser; corroding by using a hydrofluoric acid liquid; and cleaning. Thermal stress can be avoided through adoption of femtosecond laser for repairing the damaged point. The step of hydrofluoric acid liquid corrosion is used for removing re-sediment left after femtosecond laser treatment. Experimental test shows that the laser damage growth threshold value of the melted quartz element which is repaired according to the method is greatly enhanced, the service life of the element is prolonged, and the method has the characteristics of good repeatability and high stability.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

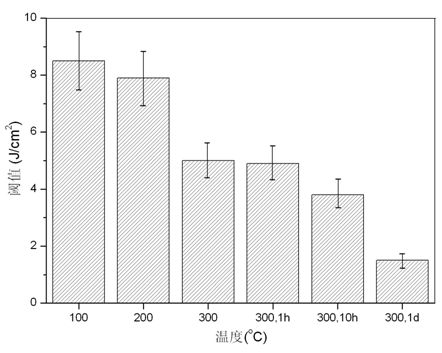

Device and method for measuring laser irradiation optical thin film damage threshold in high-temperature environment

InactiveCN102608019AEvaluation DurabilityEasy to measureWeather/light/corrosion resistanceTemperature controlTest sample

The invention relates to a device and a method for measuring a laser irradiation optical thin film damage threshold in a high-temperature environment. The measuring device comprises a first laser, a second laser for collimating a light path and assisting detection damage, a temperature control box for heating a sample and realizing temperature control, a high temperature resistance movable platform located in the temperature control box, and a test sample on the high temperature resistance movable platform. Different temperatures and holing time are set through the temperature control box, so that an instant damage threshold and damage durability of the thin film are evaluated. The measuring device has the advantages that: 1, the problem that in the prior art, only the laser irradiation optical thin film damage threshold in a normal temperature condition is solved, and the device capable of measuring the laser irradiation optical thin film damage threshold in the high-temperature environment is provided; and 2, the device has the measuring method being simple and easy to realize, and can be used for measuring the instant damage threshold of the laser irradiation optical thin film in the high-temperature environment, measuring the damage threshold of samples with different insulation time, and evaluating the durability of laser damage in the high-temperature environment of the thin film.

Owner:CHINA UNIV OF MINING & TECH

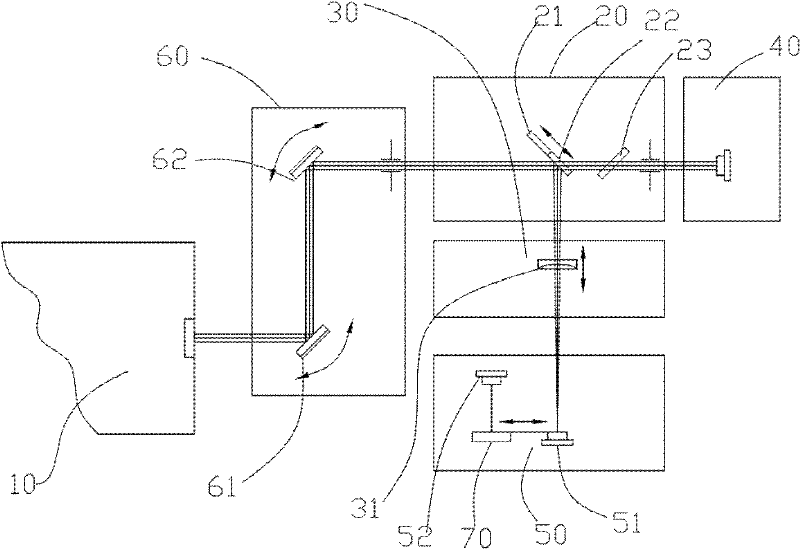

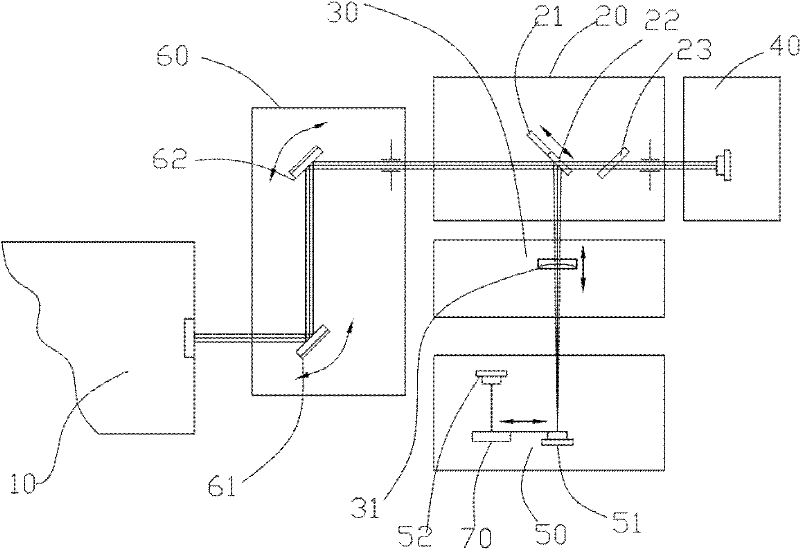

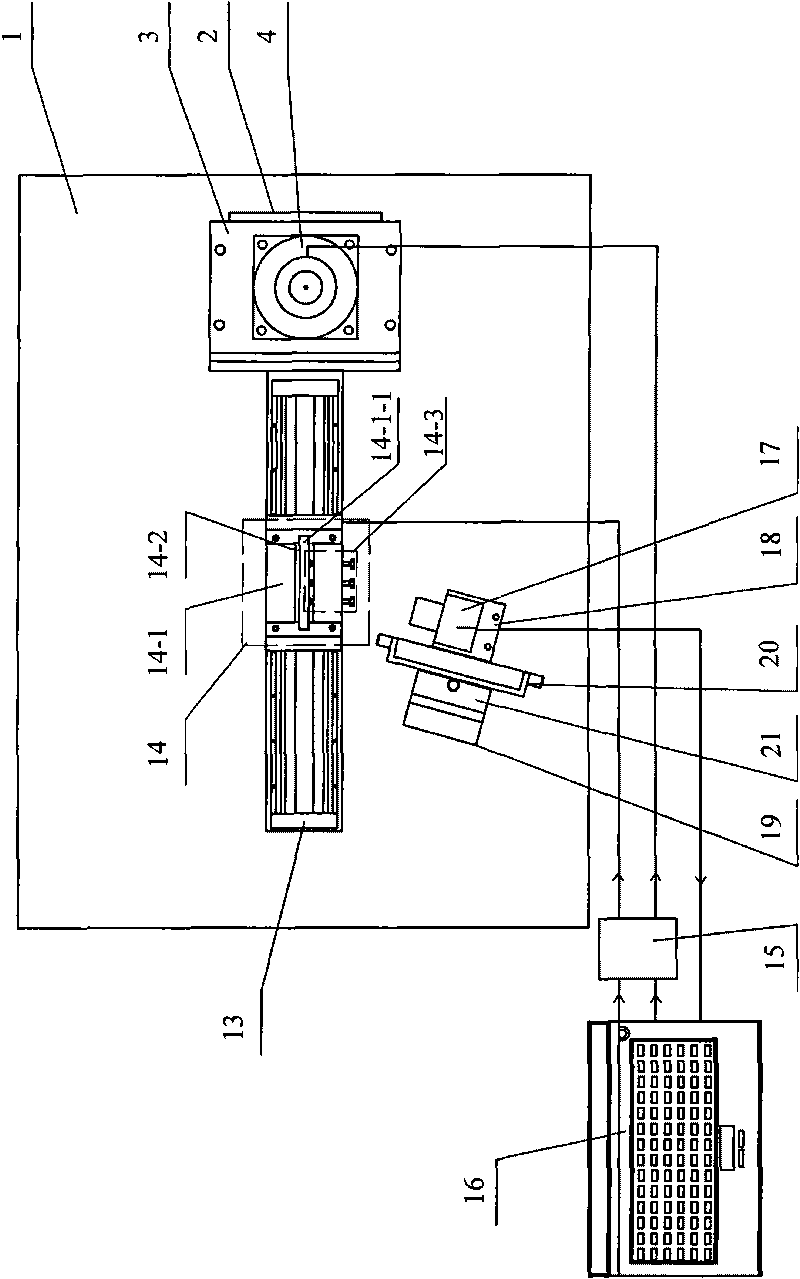

Laser preprocessing and restoring method and device having on-line detection function and used for optical elements

The invention discloses a laser preprocessing and restoring method and device having on-line detection function and used for optical elements. A non-contact on-line detection system is introduced into a laser processing or laser restoring system for detecting a laser processing region or a laser restoring region of an optical element on line, so that processing and restoring effects reach desired effects, and the processing and restoring effects do not need to be checked through a subsequent damage experiment; the processing and manufacturing process of the large-aperture optical element is greatly simplified; and the cost is greatly saved. The laser preprocessing and restoring method and the laser preprocessing and restoring device can be used in the fields of laser preprocessing and laser damage point restoring of smelted quartz, potassium dihydrogen phosphate (KDP) crystal, BK7 glass and various types of other laser materials and thin films, and is particularly suitable for laser preprocessing of defect points on the surface and the subsurface of the large-aperture optical element in an ultra-large-size laser system and laser restoring of laser damage points on the surface and the subsurface.

Owner:HEFEI ZHICHANG PHOTOELECTRIC TECH

Laser damage resistance testing system

The invention provides a laser damage resistance testing system which comprises a pulse laser, a first light barrier, a first polaroid, a first half wave plate, a first electronic control rotating table, a second light barrier, a second polaroid, an indicating light source, an electronic control zoom system, a first 45-degree partial reflecting mirror, a CCD facula analysis meter, a second 45-degree partial reflecting mirror, an energy meter, a photoelectric detector, a sample room, a monitoring camera, a third light barrier and a control system. Lasers are focused in the sample room, focused faculae can be adjusted continually through the control system, damage strength is formed, video real-time monitoring is available in the sample room so that a tester can monitor a threshold value point when a sample is damaged, the size of the faculae at the position of the sample is monitored in real time by the CCD facula analysis meter, a three-dimensional strength distribution diagram of the faculae is given, pulse energy is monitored in real time by the energy meter, the pulse width of the lasers is detected by the photoelectric detector in real time, real-time peak value power density is provided after detection data are processed through software, and the damage threshold value of the sample is detected accurately.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Preparation method for tantalum oxide film with high laser damage threshold under high-temperature environment

InactiveCN102605333AImprove the characteristics of easy moisture absorptionImprove stabilityVacuum evaporation coatingSputtering coatingCombined methodRoom temperature

The invention relates to a preparation method for a tantalum oxide film with a high laser damage threshold under a high-temperature environment and belongs to the preparation method for an optical film. The preparation method comprises the following steps: plating a tantalum oxide film on a clean substrate according to a double ion beam sputtering method; performing post-processing on a prepared film in laser pre-processing and annealing manner, thereby achieving better functions of repairing film defect and relieving film stress; and preparing a laser film capable of being applied to high-temperature environment. The preparation method provided by the invention has the advantages that: 1) the film prepared according to the double ion beam sputtering method is compact, the characteristic of easiness in moisture absorption of a loosened film prepared according to an electronic beam preparation method is improved, and the stability is better; 2) the laser pre-processing and annealing combined method is adopted, thereby overcoming the limitation caused by traditionally adopting a single method, and being beneficial to greatly increasing the threshold; and 3) the film prepared according to the method can be used under a high-temperature environment with the highest temperature at 350 DEG C, and the problem of the prior art that only the laser film used under room temperature can be prepared is solved.

Owner:CHINA UNIV OF MINING & TECH

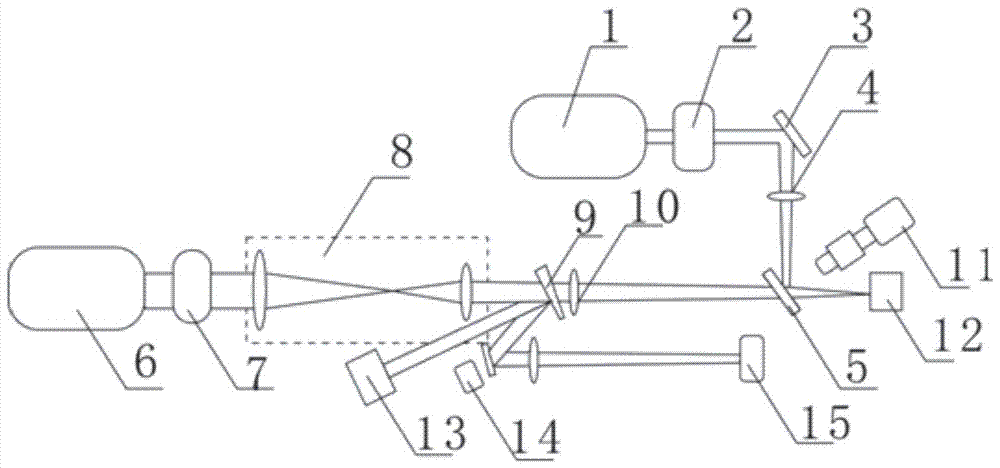

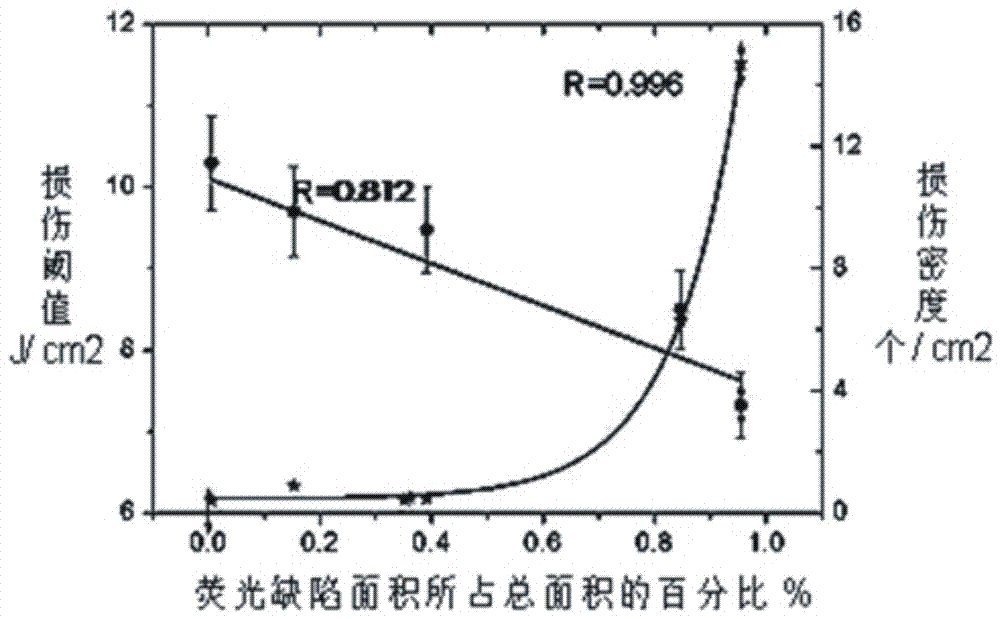

Method for realizing lossless evaluation for damage performance of optical element

InactiveCN107063641AAchieve non-destructive evaluationFluorescence/phosphorescenceTesting optical propertiesTest sampleFluorescence

The invention discloses a method for realizing lossless evaluation for damage performance of an optical element. A continuous laser device can transmit continuous laser. After a first energy regulator, a first lens, a reflector and the front surface of a sample, the continuous laser is irradiated to the back surface of the sample. The reflecting direction of the continuous laser after reflection by the sample is provided with a residual laser collector. The pulse laser can transmit pulse laser. After a second energy regulator, a beam compressing system, a split board and a second lens, the pulse laser is irradiated to the back surface of the sample. According to the method of the invention, multiple-sample and multiple-position testing is performed on the elements which are same with a to-be-tested optical element for obtaining a correlation relation between fluorescent defect data and a laser damage threshold and a damage density in the optical elements of this kind, thereby calculating the damage threshold and the damage density in measurement of the to-be-tested sample through measuring the fluorescent defect data. According to the method of the invention, a damage performance level of the optical element can be obtained through lossless testing for the fluorescent defect of the optical element, thereby realizing lossless evaluation to the damage performance of the optical element.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

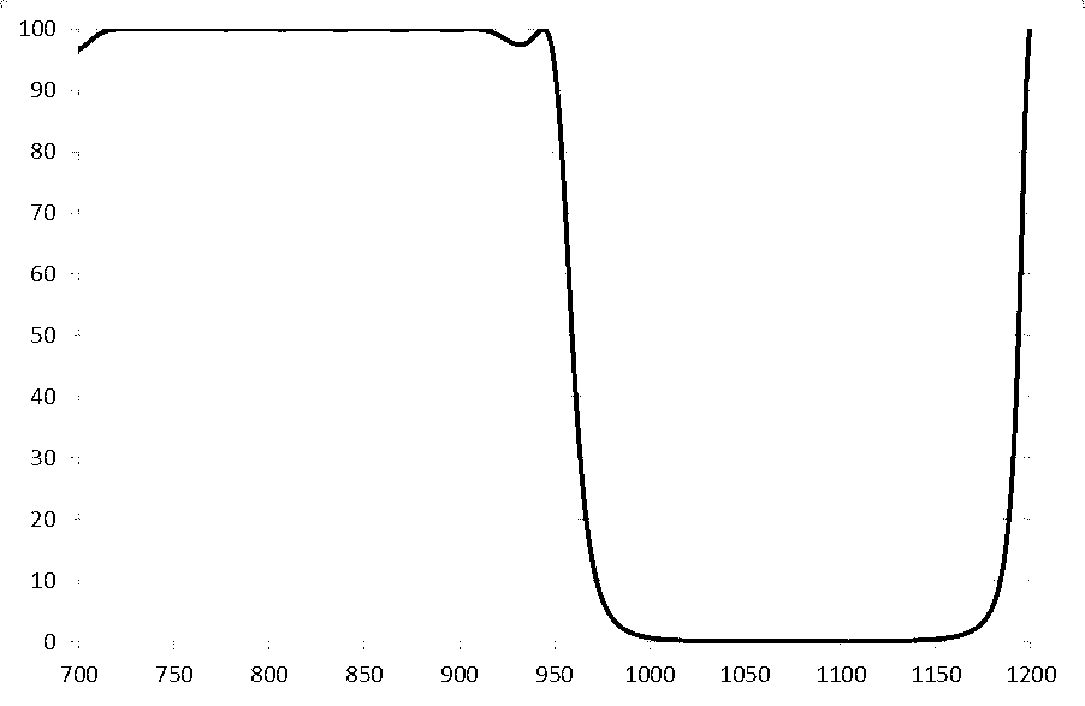

Preparation method for waterproof laser film

ActiveCN103173720AImprove transmittanceImprove reflectivityVacuum evaporation coatingSputtering coatingDiode-pumped solid-state laserRefractive index

The invention relates to a preparation method for a waterproof laser film. According to the requirement in practical application of normal incidence 800nm pumping transmission and back incidence 1064nm fundamental frequency light reflection, an HfO2 and SiO2 film is prepared by a vacuum electron beam evaporation sedimentation technology and is taken as the film which has a large electric filed and is easy to damage due to being close to a base plate when being used as the back incidence, so as to obtain higher laser damage resistance threshold; aiming at the working condition of a water cooling system, for the films close to the water side and easy to be permeated and corroded, Ta2O5 and SiO2 films are prepared by an ion beam auxiliary sedimentation technology, so that the microstructure of the film is improved, higher stacking density is obtained, and good waterproof performance is realized; HfO2, Ta2O5 and SiO2 of high or low refractive index are deposited alternately so as to form a multi-layer film, and the optical thickness of each layer is controlled so as to obtain the needed spectral characteristic. The preparation method can well take advantages of the three characteristics and can apply the characteristics to a neodymium glass substrate of a diode pumping solid laser system, so that the diode pumping solid laser system can work in a water cooing system normally, and has good laser damage resistance performance and the spectral characteristic needed by the system.

Owner:润坤(上海)光学科技有限公司

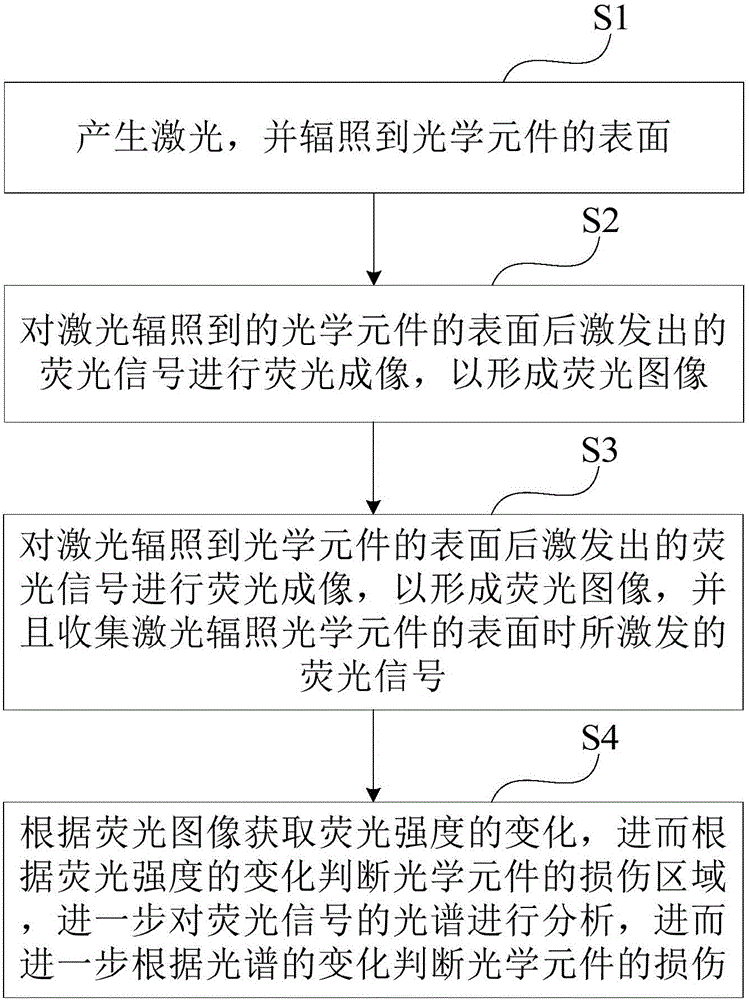

Method and apparatus for online test of laser damages of optical element

InactiveCN106066318AImprove efficiencyFluorescence/phosphorescenceFluoroscopic imageResearch efficiency

The invention discloses a method and apparatus for online test of laser damages of an optical element. The method comprises the following steps: generating laser, and irradiating the surface of the optical element with the laser; carrying out fluorescence imaging on fluorescence signals excited after the irradiation of the surface of the optical element with the laser in order to form a fluoroscopic image, and collecting the fluorescence signals excited after the irradiation of the surface of the optical element with the laser; and obtaining the fluorescence intensity change according to the fluoroscopic images, judging the damage area of the optical element according to the fluorescence intensity change, analyzing the spectra of the fluorescence signals, and judging the damages of the optical element according to the spectrum change. The method and the apparatus, adopting the above mode, realize real-time online continuous monitoring of the irradiated area of the optical element, improve the damage evolution and the mechanism research efficiency of the optical element under the laser irritation condition, and are helpful for effectively researching the damage evolution and the mechanism of the optical element.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

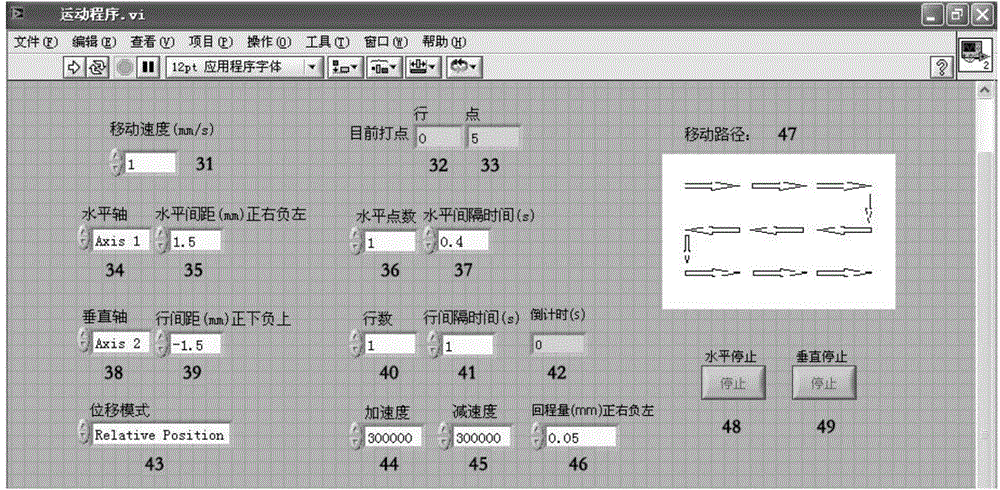

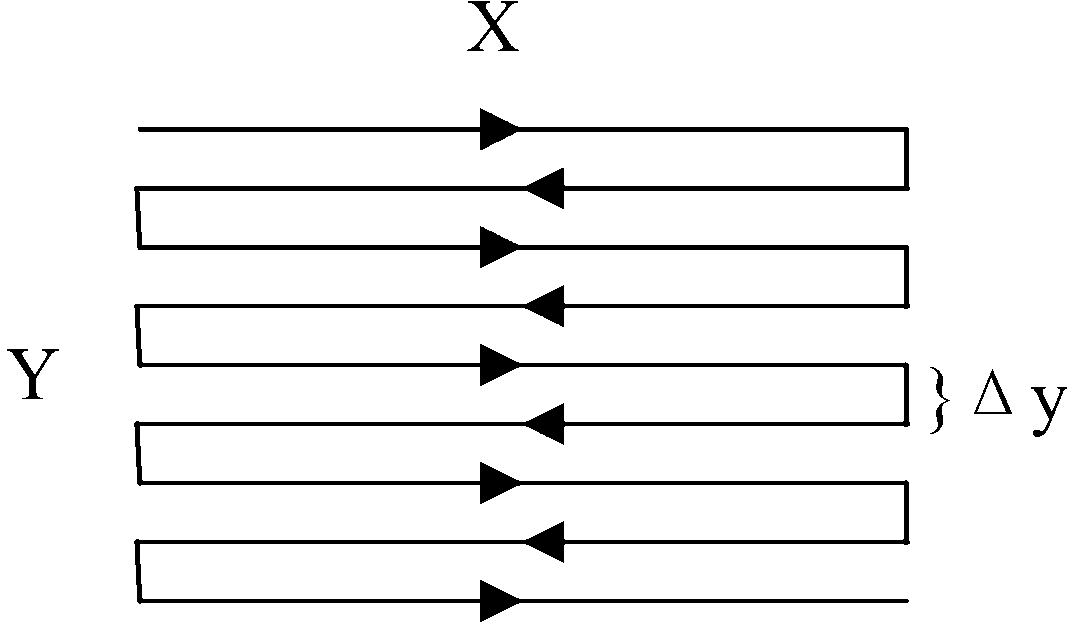

Automatic testing device and testing method for laser damage threshold value

InactiveCN102564734AEasy to useEasy to adjust lightTesting optical propertiesUltrasound attenuationData acquisition

The invention discloses an automatic testing device and an automatic testing method for a laser damage threshold value. The automatic testing device comprises a laser, a light splitting attenuation system, a focusing system, an energy acquisition system, a beam acquisition system and a processing system, wherein the light splitting attenuation system comprises a high reflective mirror, a high transmitting mirror, a linkage mechanism and a splay compensation high transmitting mirror; and the high reflective mirror and the high transmitting mirror are transposed under the action of the linkage mechanism, and in the transposition process, the front mirror surfaces of the high reflective mirror and the high transmitting mirror are positioned on the same plane. The testing method comprises the following steps of: a) calculating damage energy on the unit area of a laser beam; b) dotting a lens to be tested to form a plurality of test dots by using the laser beam, and observing the damage condition of the surface of the lens to be tested by using the beam acquisition system; and c) regulating the energy of the laser beam, and repeating the steps a and b until the damage threshold value is measured. The structure and the testing method provided by the invention are low in test errors and high in applicability and accuracy.

Owner:BEIJING GK LASER TECH

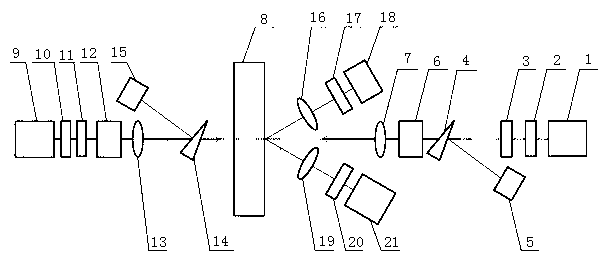

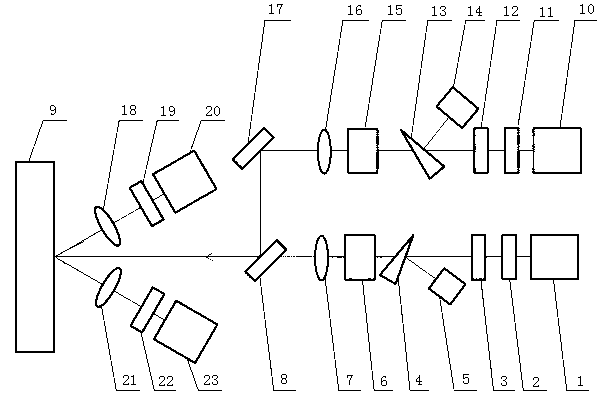

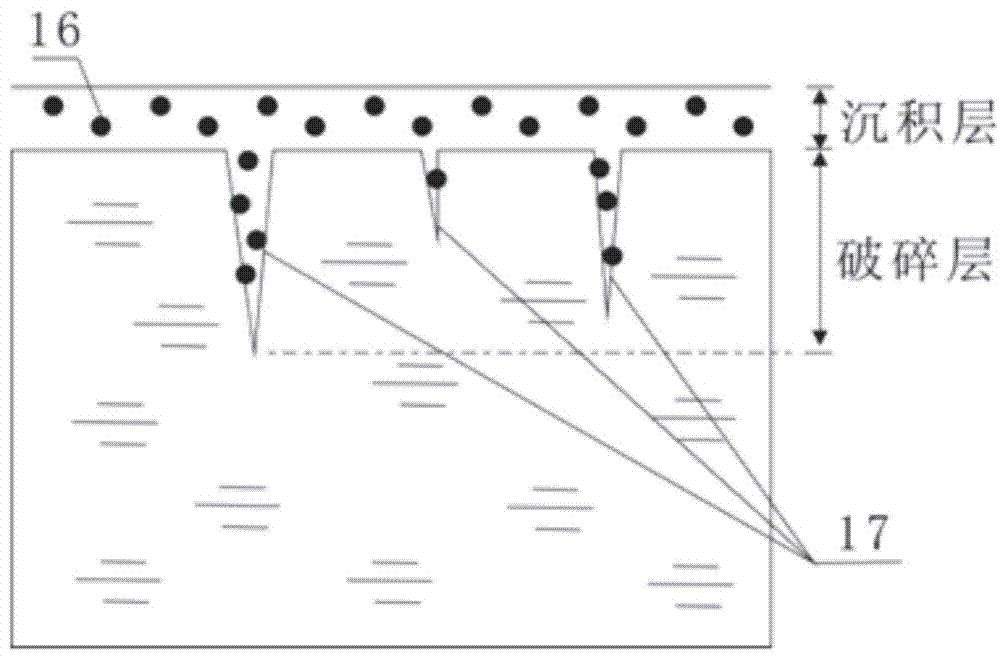

Multi-beam coaxial laser damage threshold test device and realization method

The invention discloses a multi-beam coaxial laser damage threshold test device and a realization method. According to the multi-beam coaxial laser damage threshold test device, four high-energy pulsed lasers are adopted, reflected by corresponding prisms and then enter a coaxial optical system, four light beams use one set of system and a computer control processing system, a variable-interval positive lens and a variable-interval negative lens are utilized to constitute a beam expanding system, the optical interval of the beam expanding system is adjusted, and thus collimated beam expandingof laser beams with different wavelengths can be achieved; and a stepper motor is adopted to precisely control the position of a focusing lens, and focal lengths of the different laser wavelengths arecompensated, so that it is ensured that laser is transmitted to the test surface, and the size and defocusing amount of a light spot are constant. According to the multi-beam coaxial laser damage threshold test device, integration, automation and intellectualization of a test system are achieved, thin film damage can be judged quickly and accurately in real time online, and laser damage thresholds of the various different wavelengths can be measured through the same test device.

Owner:XIAN TECH UNIV

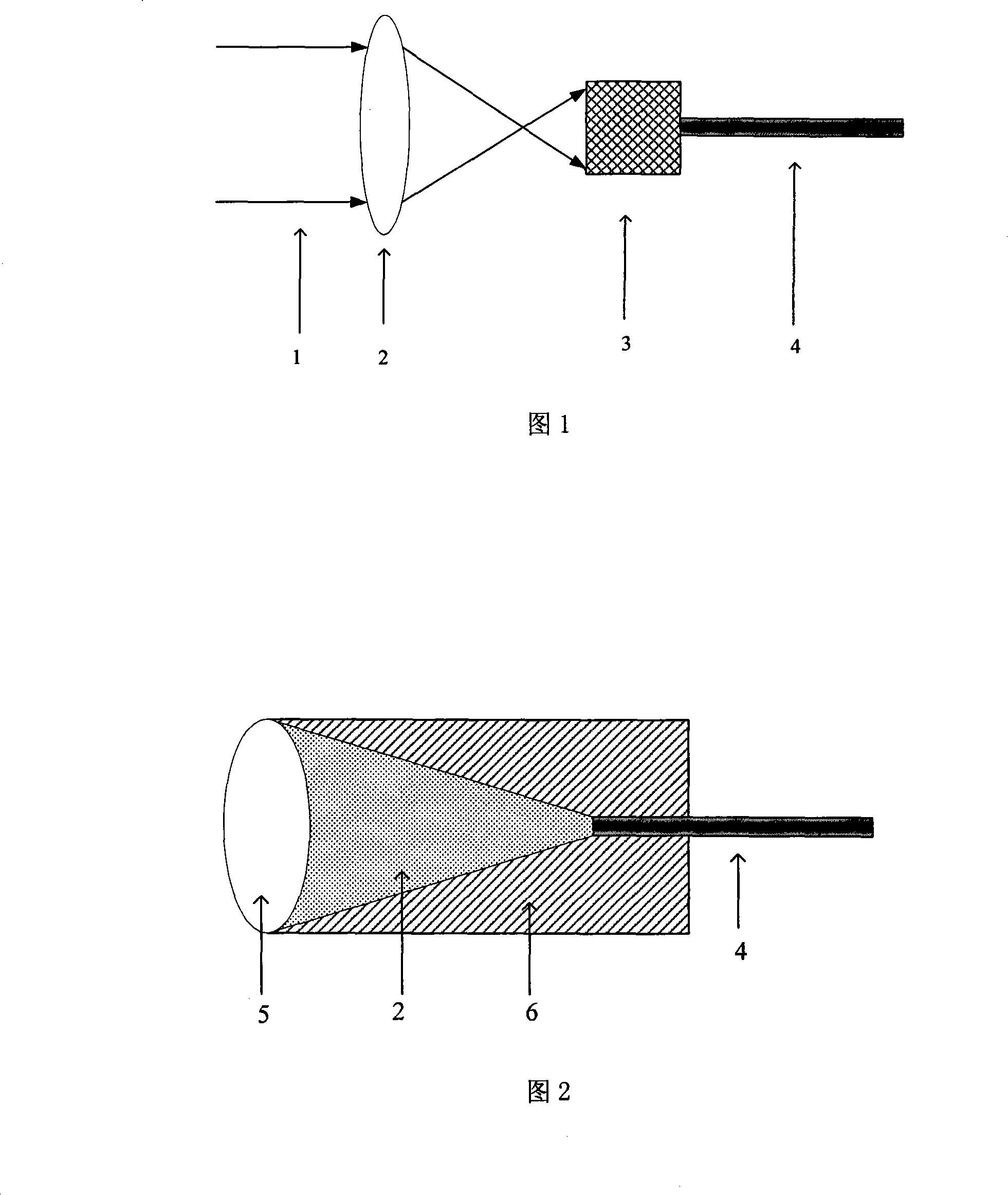

Hollow light guiding cone coupling vacuum transmission laser device

InactiveCN101241209AReduce damage rateReduce nonlinear lossCoupling light guidesLight spotLaser power density

An optical fiber transmission device based on hollow light guiding cone coupling for vacuum-transmitting high-capacity laser is provided. A hollow light guiding cone is connected to the input end of the optical fiber, and small injection light spots are obtained by the hollow light guide cone to implement laser optical fiber coupling transmission. The hollow light guiding cone and the interior of the optical fiber are vacuumed or injected with inert gas to enlarge laser capacity of the optical fiber transmission system and enhance output beam quality. The invented device enlarges the lighted area on the laser input end surface effectively, reduces laser power density of the input end surface, and lowers laser damage probability. Linear and nonlinear wastage is decreased by vacuuming the laser transmission path, and the transmission efficiency of the optical fiber transmission system is increased. The invented device is provided with a simple structure, strong innovation and an evident effect.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

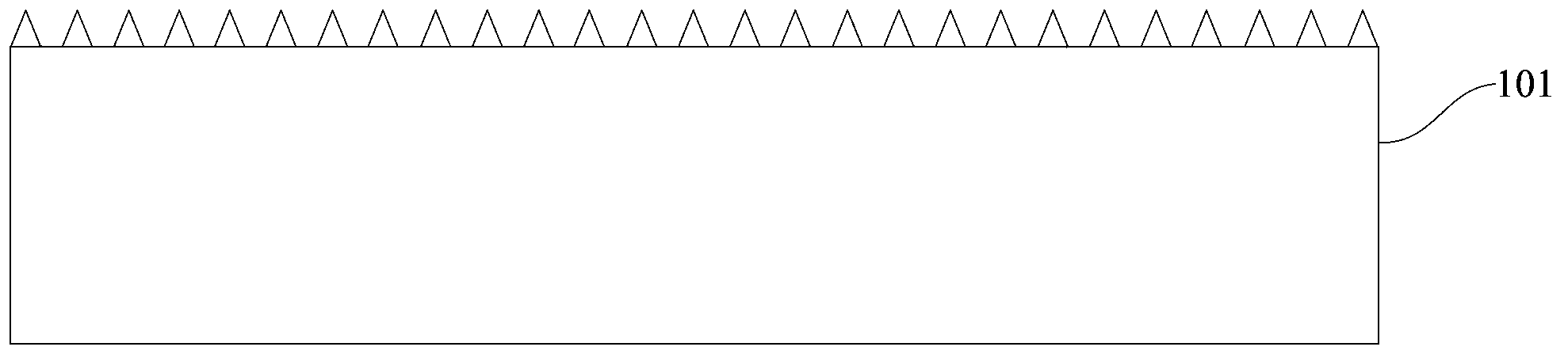

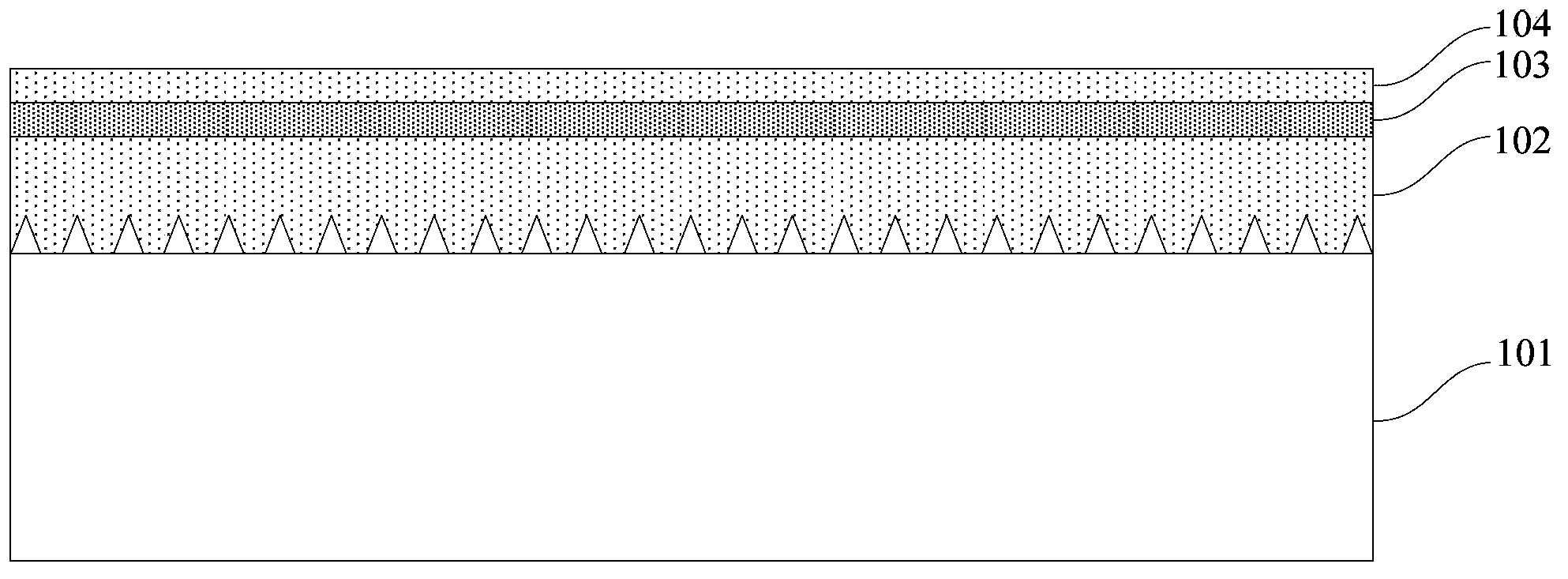

Front cutting technology of light emitting diode

ActiveCN104078534AAvoid damageIncrease brightnessSemiconductor/solid-state device manufacturingLaser beam welding apparatusQuantum wellLaser damage

The invention provides a front cutting technology of a light emitting diode. The technology comprises the steps of 1) forming a light emitting epitaxy structure at least comprising N-type layers, quantum well layers and P-type layers on the surface of a semiconductor substrate, 2) defining a plurality of light emitting units and etching a plurality of passages up to the semiconductor substrate among the light emitting units, 3) forming N electrode preparation areas in the light emitting units, 4), forming transparent conductive layers on the surfaces of the P-type layers of the light emitting units, preparing P electrodes on the surfaces of the transparent conductive layers and preparing N electrodes in the N electrode preparation areas, 5) performing laser front cutting technologies on the passages and forming a plurality of cutting marks corresponding to the light emitting units in the semiconductor substrate, and 6) splitting according to the cutting marks. The invention provides a laser front cutting method of the light emitting diode. The method can effectively avoid laser damage to the light emitting diode; the brightness and the yield of the light emitting diode are improved and increased; and the method is simple in technology and is suitable for technology production.

Owner:EPILIGHT TECH

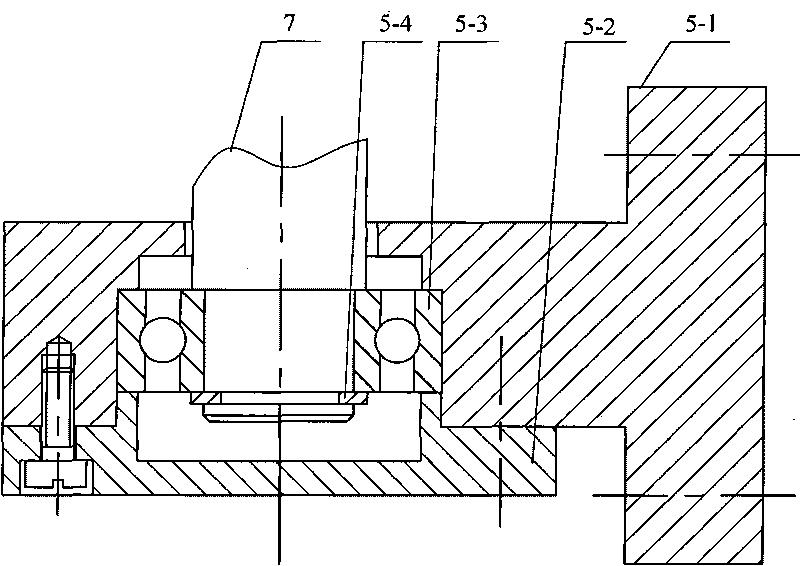

Detection device of laser damage threshold of optical crystal element

InactiveCN101706444AReliable clampingAccurate observationMaterial analysis by optical meansLinear motionBall screw

The invention relates to a detection device of a laser damage threshold of an optical crystal element, belonging to the technical field of laser damage threshold detection of optical crystal elements and solving the problem that no special detection device realizes the accurate testing of the laser damage threshold of the optical crystal element at present. The detection device controls the motion of a servo motor and a flat linear motor by controlling computer programming so that an initial testing area of the optical crystal element is positioned on a path of a laser beam; the relative position between a CCD camera and the optical crystal element is adjusted through a vertical micro-displacement work table and a horizontal micro-displacement work table; the rotation motion of the servo motor is transformed into the linear motion of a ball nut through a ball screw, and the ball nut drives a nut slide block to move up and down so as to drive a support plate of an L-shaped linear motor to move up and down, thus the flat linear motor can adjust the height of a clamp body of the optical crystal element up and down. The invention is used for the detection of the laser damage threshold of the optical crystal element.

Owner:HARBIN INST OF TECH

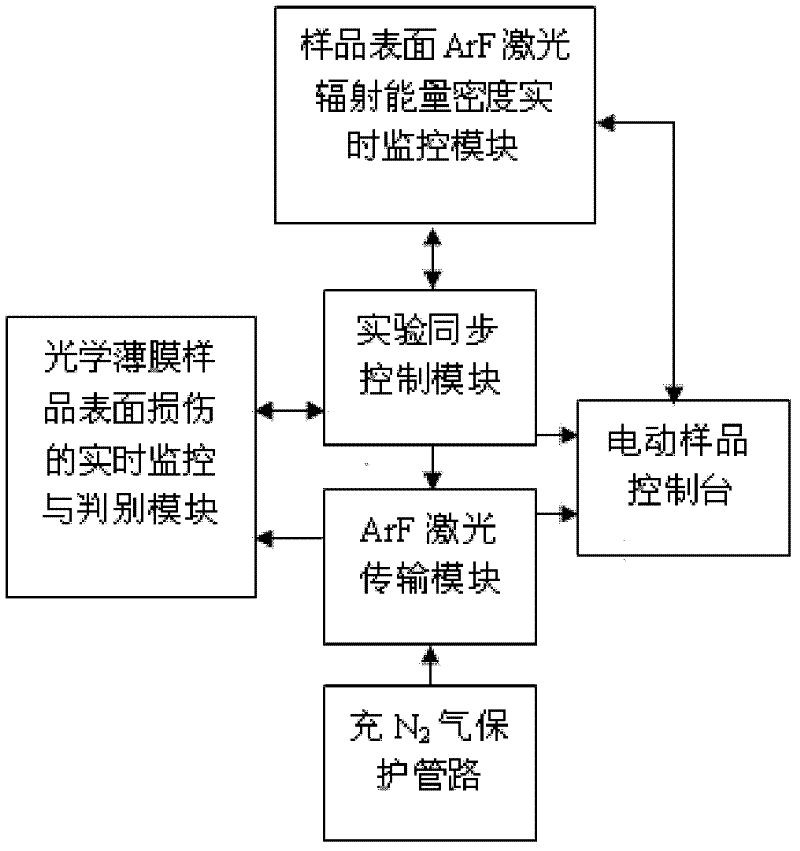

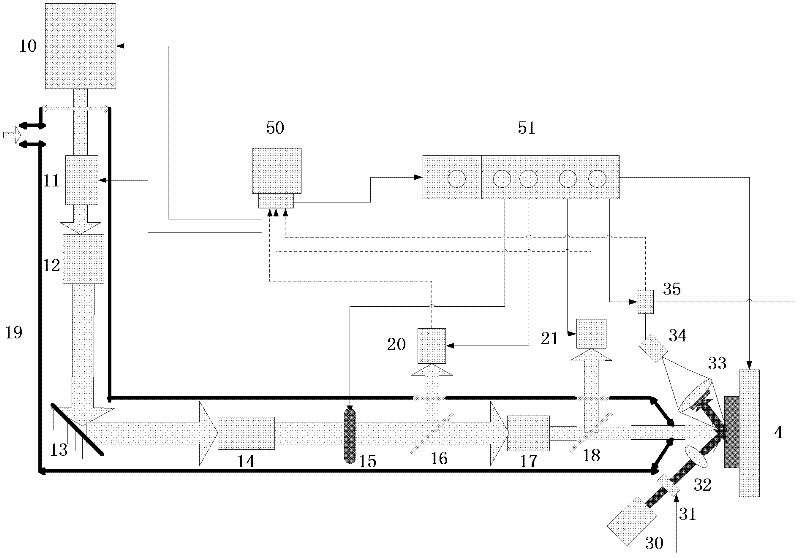

ArF laser film element irradiation damage test device with high irradiation density uniformity

InactiveCN102393383AReduce uncertaintyHigh precisionScattering properties measurementsRadiant energy densityLight spot

An ArF laser film element irradiation damage test device with high irradiation density uniformity relates to the technical field of ArF excimer laser film element application. The device comprises an ArF laser transmission module, a real-time sample surface laser irradiation energy density monitoring module, a real-time optical film sample surface damage monitoring and judging module, an electricsample control platform and a synchronous experiment control and data collection module. The device has the following obvious characteristics: the sample surface ArF laser irradiation energy density has extremely high uniformity, the accuracy, reliability and comparability of the optical film element laser damage threshold testing result can be improved effectively, the measurement on the damage of the ArF laser optical film elements with different irradiated light spot sizes and different irradiated energy densities can be realized, and the demands on different types of ArF laser optical film element damage tests and damage mechanism researching can be met.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

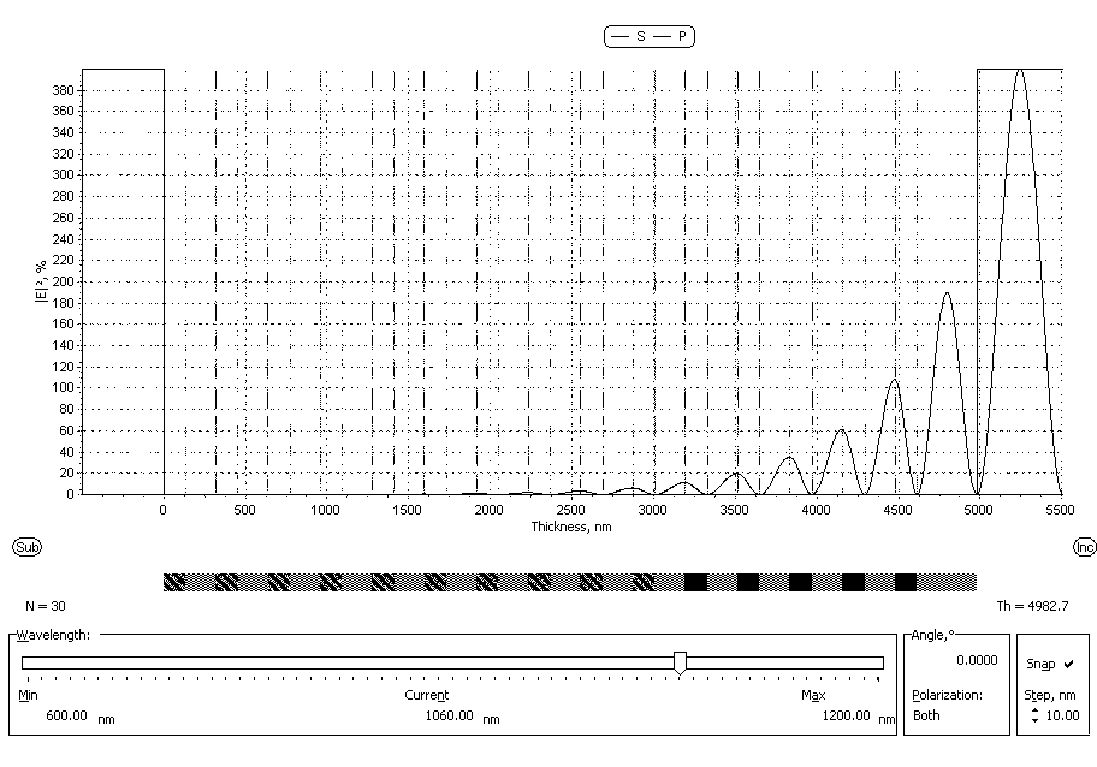

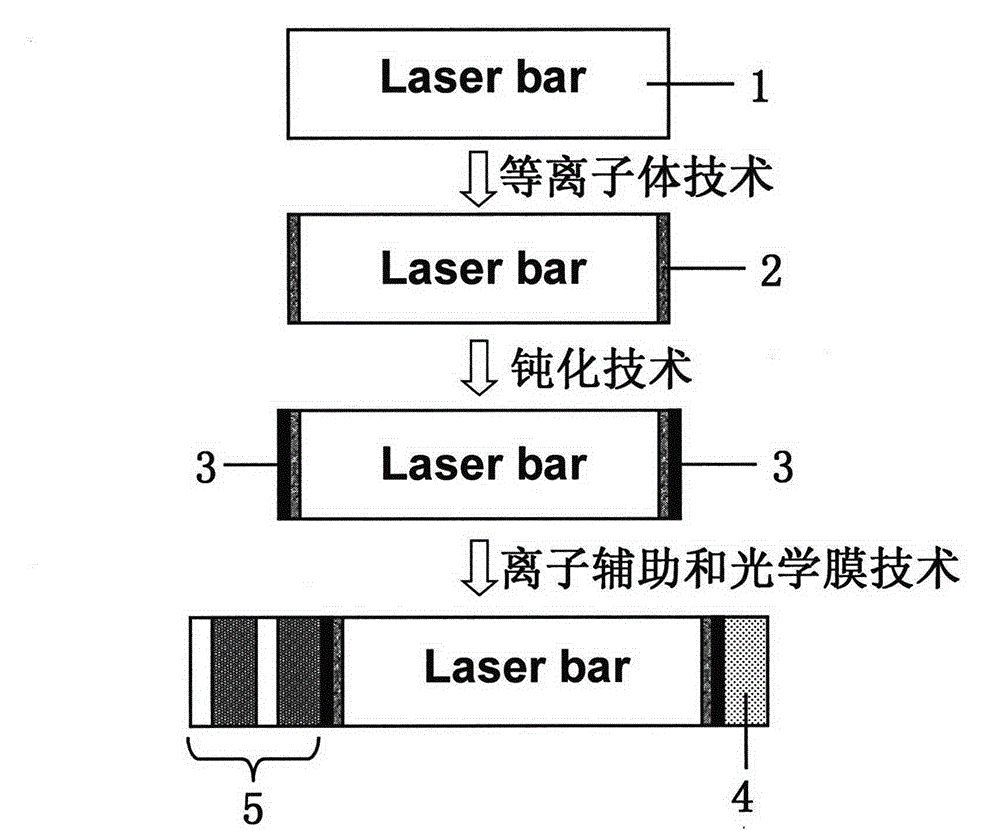

Method for prolonging service life of semiconductor laser device

InactiveCN102882120AExtend your lifeEfficient removalLaser detailsSemiconductor lasersPlasma technologyLaser damage

The invention belongs to the technical field of an optoelectronics technology of a semiconductor and relates to a method for prolonging the service life of a semiconductor laser device, namely an integrated technology of plasma technology, passivation technology, ion auxiliary technology and optical film technology. The method comprises a semiconductor laser device bar 1, a semiconductor laser device bar 2 processed by the plasma technology, a passivation film 3, a front cavity surface film 4 and a rear cavity surface film 5. The method comprises the following steps of: orderly stacking the sorted semiconductor laser device bar 1 on a special bar clamp; putting into a vacuum coating machine; and extracting vacuum. When a pre-set vacuum degree is realized, the plasma technology is firstly adopted to carry out cavity surface washing to wash cavity surface oxides and an unstable surface state to form the semiconductor laser device bar 2 processed by the plasma technology; then the passivation technology is adopted to deposit one layer of the passivation film 3 on the cavity surface to inhibit the cavity surface from being oxidized; and finally, the ion auxiliary technology and the optical film technology are adopted to prepare the front cavity surface film 4 and the rear cavity surface film 5, which have high-laser damage threshold values, so as to improve a cavity surface damage threshold value of the semiconductor laser device. With the adoption of the method disclosed by the invention, the service life of the semiconductor laser device can be effectively prolonged.

Owner:CHANGCHUN UNIV OF SCI & TECH

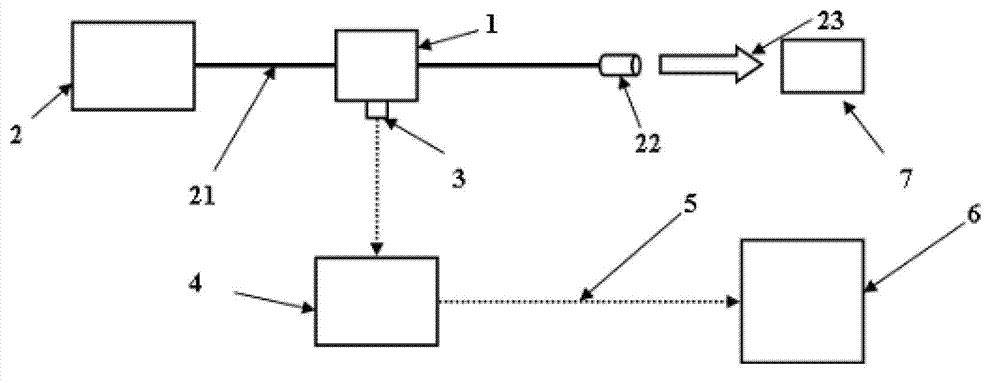

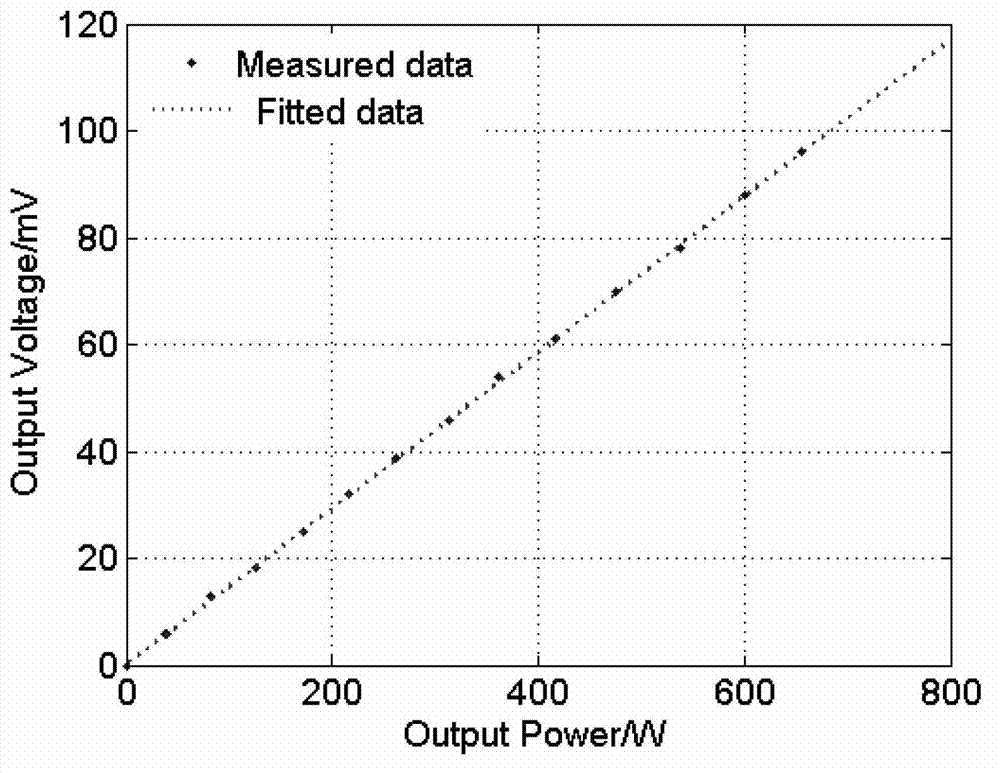

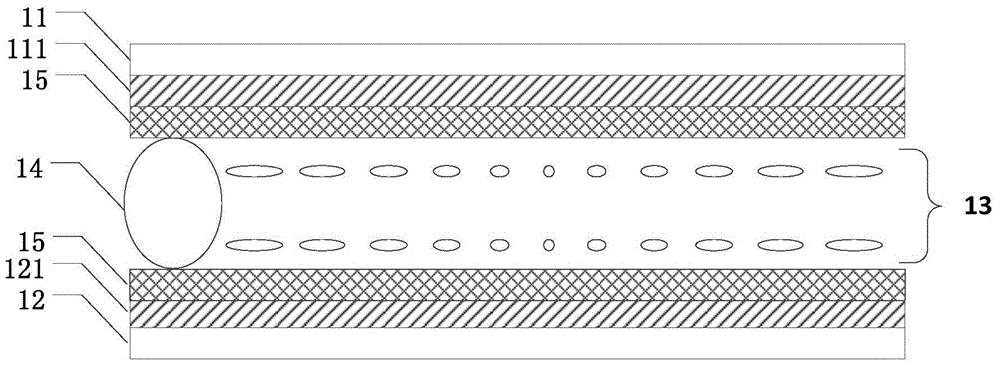

Online monitoring system of optical fiber laser output power based on integrating sphere

InactiveCN103162822ACompact structureHigh energyPhotometry using electric radiation detectorsSignal processing circuitsPhotovoltaic detectors

The invention relates to an online monitoring system of an optical fiber laser output power based on an integrating sphere. The system comprises a high-energy optical fiber laser output power sampler and a detecting unit, wherein the detecting unit comprises a photoelectric detector, a signal processing circuit and a data collecting and processing unit, the photoelectric detector is put into an output window of the high-energy optical fiber laser output power sampler, and a signal generated by the photoelectric detector is sent to the data collecting and processing unit after being processed by the signal processing circuit. The system is used for optical laser energy monitoring with different wavelengths by exchanging different sizes of the detectors, is capable of keeping an all-fiber compact structure of a high-energy optical fiber laser system without bearing strong laser irradiation and without the problem of laser damage threshold, is used for high-efficiency and high-energy optical fiber laser sampling and online monitoring, and is simple in structure, low in cost and easy to operate.

Owner:NAT UNIV OF DEFENSE TECH

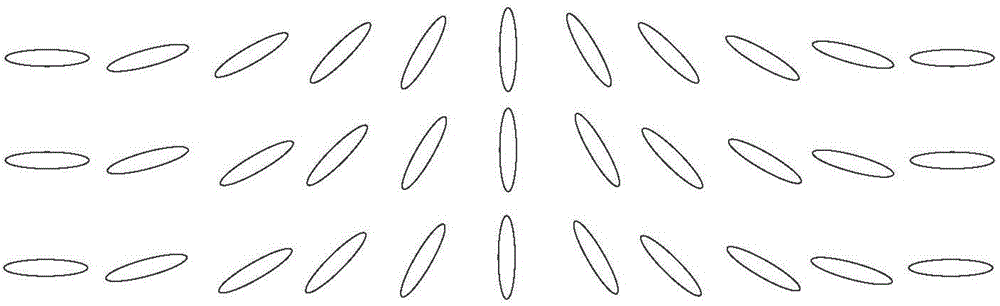

Polarized Airy liquid crystal formwork, preparation method and generating system

The invention discloses a polarized Airy liquid crystal formwork, a preparation method and a generating system. The polarized Airy liquid crystal formwork comprises a first substrate, a second substrate and a liquid crystal layer located between the first substrate and the second substrate, wherein the first substrate and the second substrate are oppositely arranged. Interval particles are arranged between the first substrate and the second substrate so as to support the liquid crystal layer. Light-controlled orientation films are arranged on the sides of the first substrate and the second substrate adjacent to the liquid crystal layer and are provided with cubic phase control graphs with molecular director directions in periodic gradual change distribution, the widths in each period of the cubic phase control graphs are gradually reduced from the center areas of the control graphs to two sides, the control graphs of the light-controlled orientation films control liquid crystal molecular directors in the liquid crystal layer to be in periodic 0-180-degree gradual change distribution, so that incident light shining the polarized Airy liquid crystal formwork is converted into Airy light beams, and the laser-damaged threshold of the polarized Airy liquid crystal formwork and the stability of the polarized Airy liquid crystal formwork in the presence of hard light are improved.

Owner:NANJING UNIV

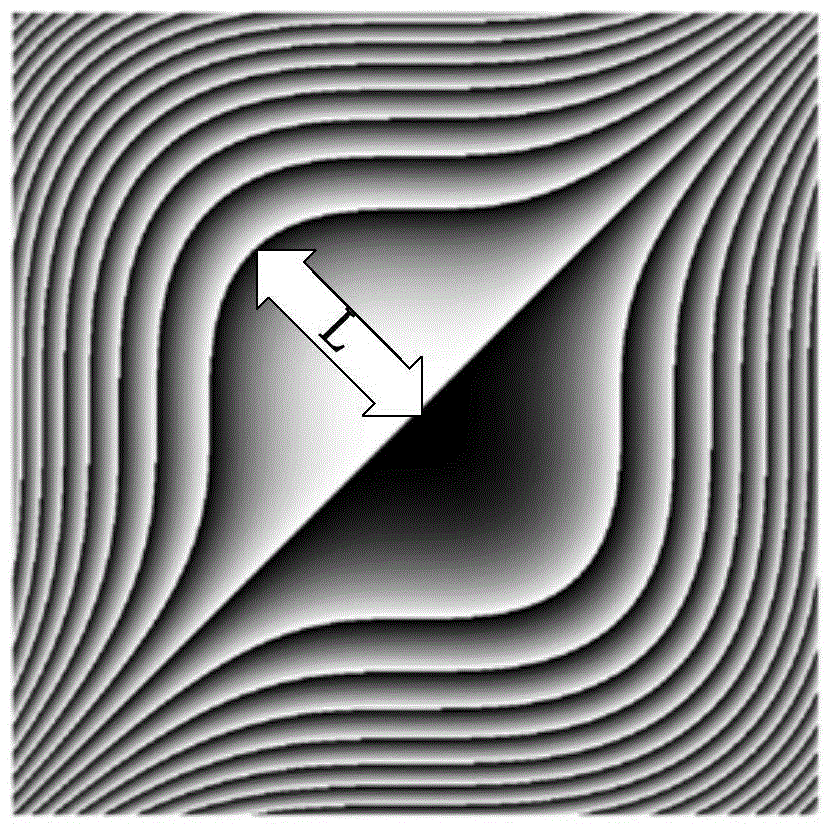

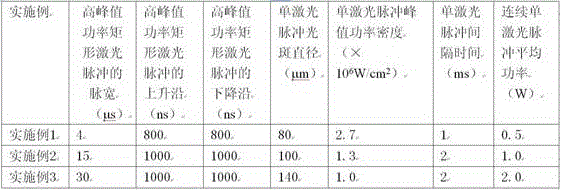

Method for repairing laser damage of fused quartz without thermal residual stress

ActiveCN105948519AControlling High Temperature Structural RelaxationThermal Residual Stress SuppressionRepair timeOptoelectronics

The invention provides a method for repairing laser damage of fused quartz without thermal residual stress. According to the method, rectangular laser pulses with high-peak power are acquired by intercepting peak segments of pulses output from a laser device; the rectangular laser pulses with high-peak power are focused, and single laser pulses with super-high-peak power density are acquired; the single laser pulses are used for peeling a material at a single point of a damaged part on a fused quartz substrate through transient gasification; the interval of the single laser pulses is controlled, so that the substrate is cooled sufficiently; gasification peeling is performed repeatedly through the single laser pulses until the material at the whole damaged part is removed. With the adoption of the method, high-temperature structural relaxation of the fused quartz substrate is effectively controlled, the damage of the fused quartz is repaired without thermal residual stress, the anti-damage capacity of damage points of a fused quartz optical element is improved, surface damage and development of surface damage of the fused quartz optical element are inhibited, the service life of the fused quartz optical element is prolonged, and the method has the advantages of short repair time, simple and efficient process, good process stability, high controllability and high repeatability.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Film coating method for improving optical thin-film laser injure threshold

InactiveCN1614082AIncreased Laser Damage ThresholdReduce defect densityVacuum evaporation coatingSputtering coatingOptoelectronicsPetroleum benzin

The invention was involved in one coated method of improving laser damage threshold of optical thin-film. The process consist of the following steps: a) The substrate was put into petroleum benzin or de-ionized water for ultrasonic cleaning. b) The substrate was evaporated to dryness under highly pure nitrogen stream after cleaning was over. c) The substrate was coated in the vacuum chamber. d) After treatment of the deposited thin-film was done by using plasma (oxygen). The method could improve the laser damage threshold of optical thin-film obviously and was found to be effective, rapid, simple and cheap.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Semiconductor devices having reduced substrate damage and associated methods

ActiveUS8698272B2Improve business performanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor materialsProcess region

Optoelectronic devices, materials, and associated methods having increased operating performance are provided. In one aspect, for example, an optoelectronic device can include a semiconductor material, a first doped region in the semiconductor material, a second doped region in the semiconductor material forming a junction with the first doped region, and a laser processed region associated with the junction. The laser processed region is positioned to interact with electromagnetic radiation. Additionally, at least a portion of a region of laser damage from the laser processed region has been removed such that the optoelectronic device has an open circuit voltage of from about 500 mV to about 800 mV.

Owner:SIONYX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com