Detection device of laser damage threshold of optical crystal element

A technology of laser damage threshold and optical crystal, which is used in measurement devices, material analysis by optical means, scientific instruments, etc., can solve the problem of accurate measurement of laser damage threshold without optical crystal components, and achieve reliable clamping and accurate damage point. The effect of accurate observation and precise movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

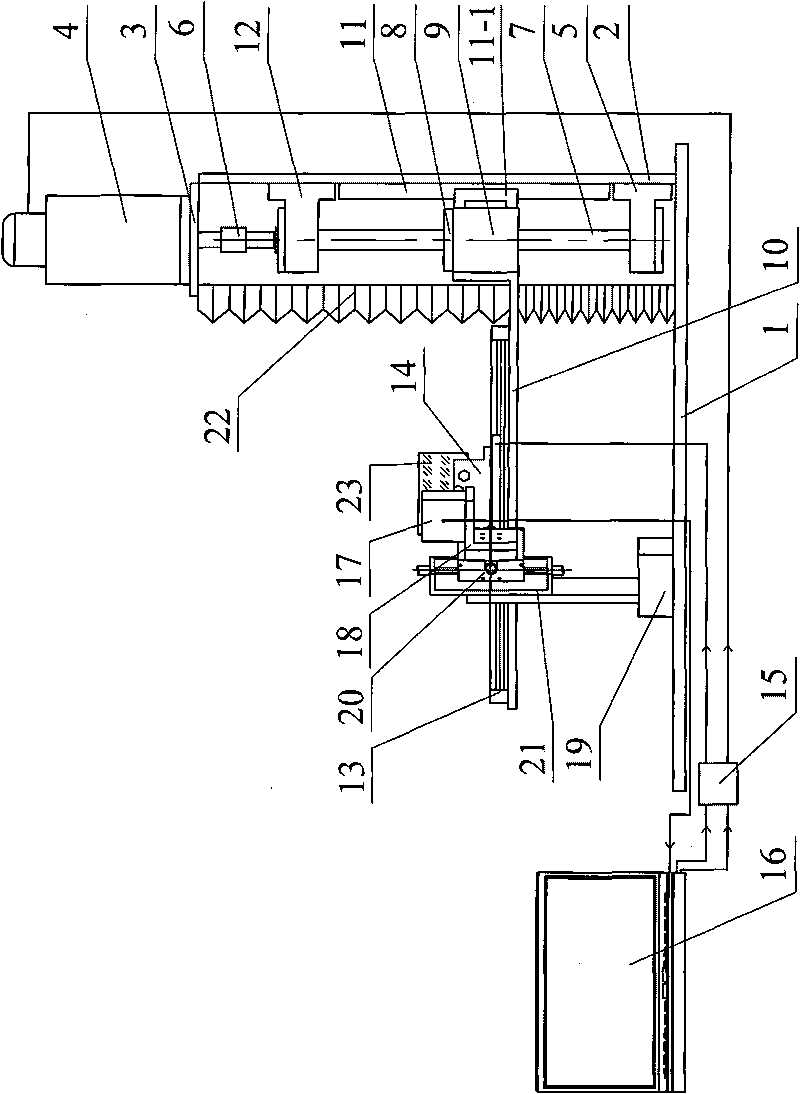

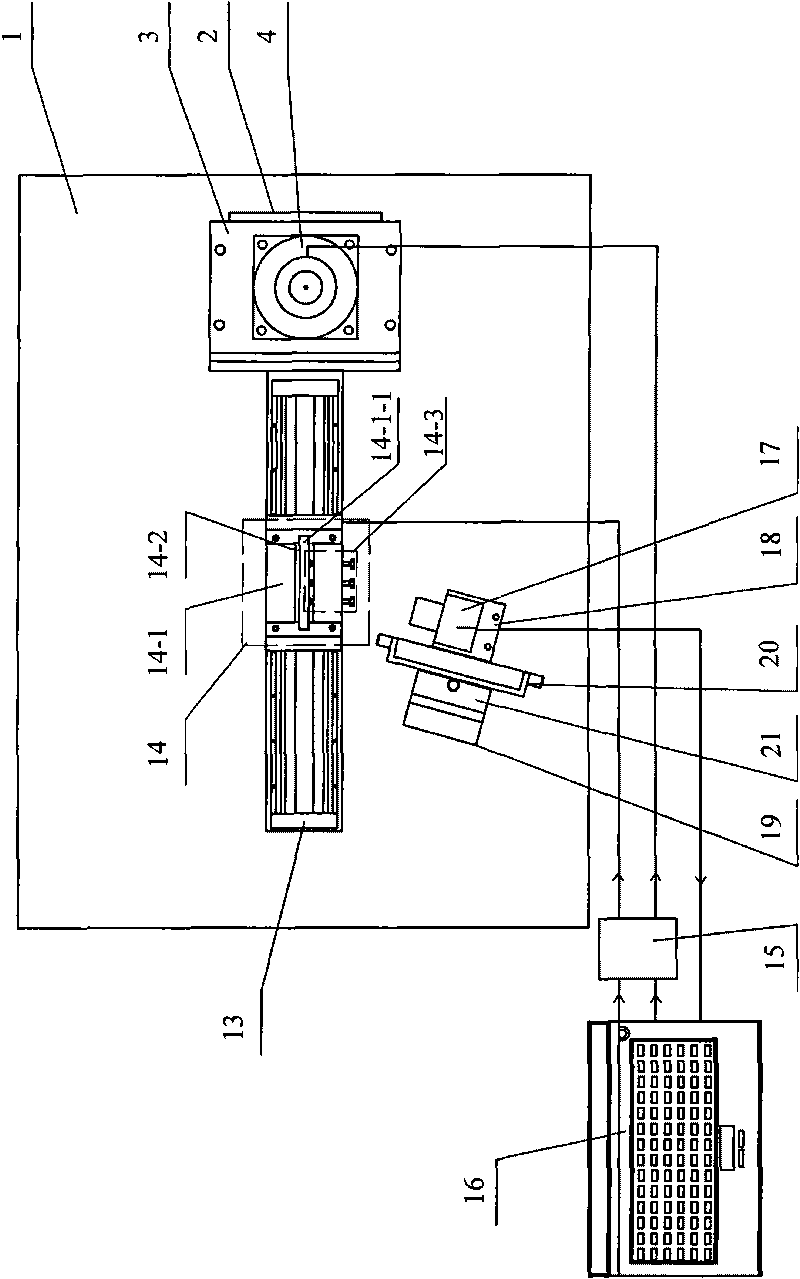

[0012] Specific implementation mode one: the following combination figure 1 , figure 2 , Figure 5-Figure 8 and Figure 17-Figure 21 To illustrate this embodiment, this embodiment includes a horizontal table 1, a motor support frame 2, a motor connecting plate 3, a servo motor 4, a lower bearing assembly 5, a shaft coupling 6, a ball screw 7, a ball screw nut 8, a wire Female slider 9, L-shaped linear motor support plate 10, linear guide rail 11, upper bearing assembly 12, flat linear motor 13, optical element clamp body 14, two-axis motion control card 15, control computer 16, CCD camera 17, L-shaped CCD connection plate 18, CCD support frame 19, horizontal micro-displacement workbench 20 and vertical micro-displacement workbench 21,

[0013] The bottom end of the motor support frame 2 is centered and fixed on one side of the upper surface of the horizontal workbench 1, the top end of the motor support frame 2 is fixedly connected with the motor connection plate 3, the se...

specific Embodiment approach 2

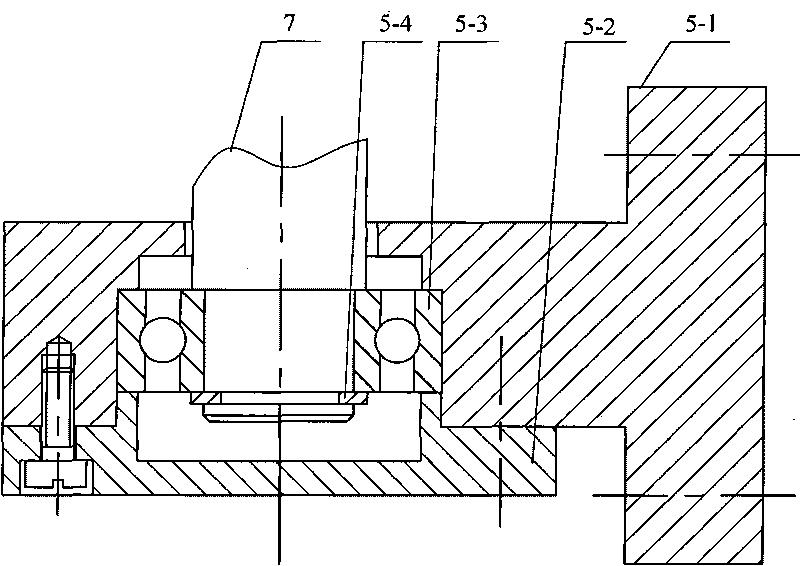

[0038] Specific implementation mode two: the following combination image 3 and Figure 4 To illustrate this embodiment, the difference between this embodiment and Embodiment 1 is that the lower bearing assembly 5 consists of a lower bearing seat 5-1, a lower bearing cover 5-2, a sealed angular contact thrust ball bearing 5-3 and a shaft The end retaining ring is composed of 5-4,

[0039] The lower bearing seat 5-1 of the lower bearing assembly 5 is fixed at the middle position of the lower end of an inner surface of the motor support frame 2, the lower bearing cover 5-2 is fixedly connected with the lower bearing seat 5-1, and the sealed angular contact thrust ball bearing 5 The inner ring of -3 is matched and fixed with the lower end of the ball screw 7 through the shaft end retaining ring 5-4, and the outer ring of the sealed angular contact thrust ball bearing 5-3 is passed through the lower bearing seat 5-1 and the lower bearing cover 5-2 Cooperate and fix, there is a g...

specific Embodiment approach 3

[0040] Specific implementation mode three: the following combination Figure 9 and Figure 10 To illustrate this embodiment, the difference between this embodiment and Embodiment 2 is that the upper bearing assembly 12 is composed of an upper bearing housing 12-1, an upper bearing cover 12-2, and two sealed angular contact thrust balls dedicated to ball screws. Bearing 12-3 and round nut 12-4 are formed,

[0041] The upper bearing seat 12-1 of the upper bearing assembly 12 is fixed on the middle position of the upper end of one inner surface of the motor support frame 2, the upper bearing seat 12-1 is fixedly connected with the upper bearing cover 12-2, and the two ball screws are specially sealed Angular contact thrust ball bearings 12-3 are set facing to each other and are connected and fixed. The inner rings of the two ball screw special-purpose sealed angular contact thrust ball bearings 12-3 are fixed by the ball screw 7 and the round nut 12-4. The two ball screws The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com