Self-centering chuck

A self-centering chuck and chuck frame technology, which is applied to chucks, turning equipment, tool holder accessories, etc., can solve the problems of affecting sealing performance, unstable holding force, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

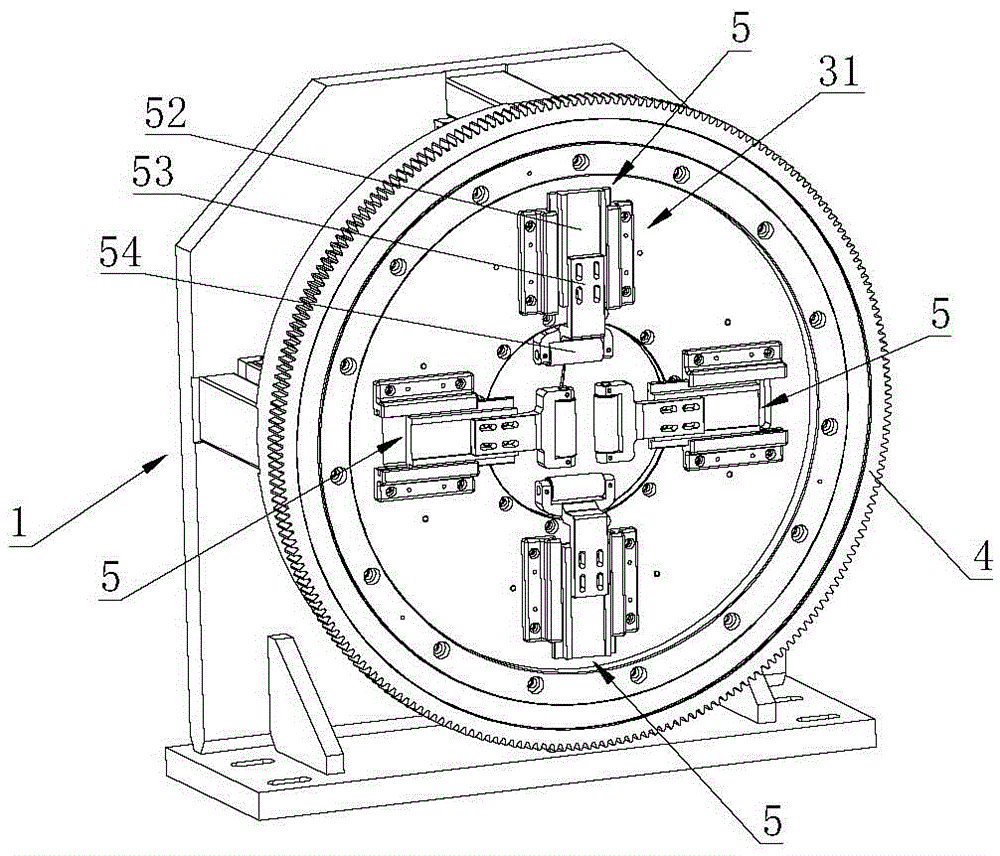

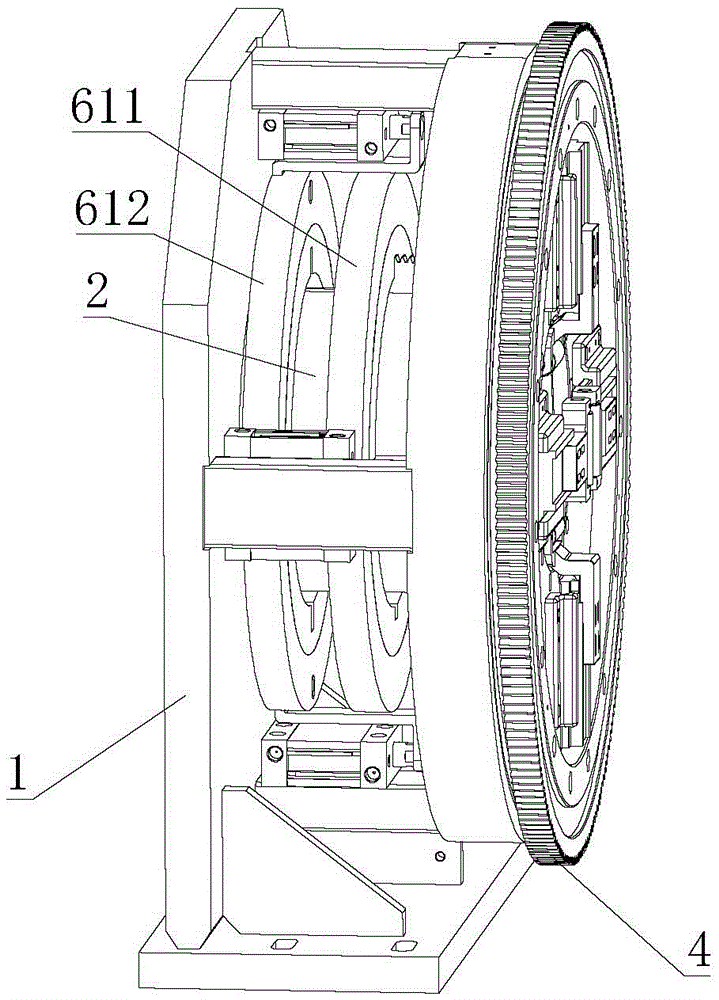

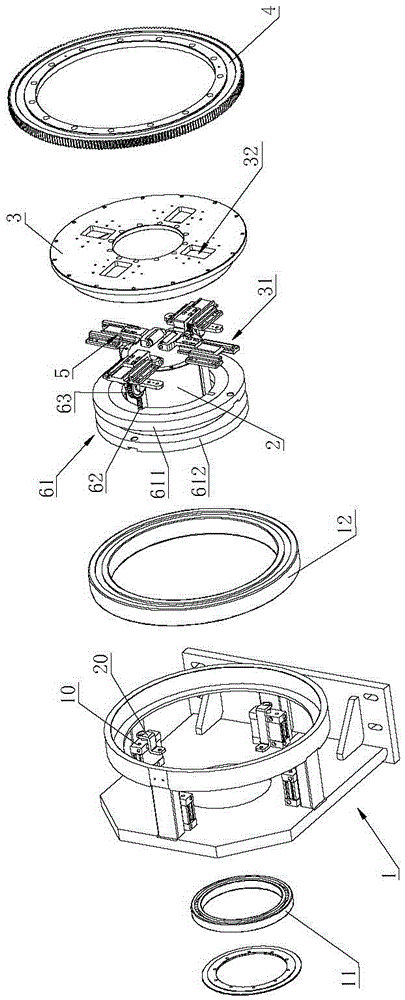

[0023] Such as Figure 1 to Figure 5 As shown, a self-centering chuck includes a chuck frame 1, a rotary sleeve 2 rotatably arranged on the chuck frame 1, a jaw plate 3 connected to one end of the rotary sleeve 2, and a jaw plate 3 installed on the The driving wheel 4, at least two jaws 5 oppositely arranged on the jaw plate 3, and the jaw driving mechanism 6 for driving the jaws 5 to clamp materials, the jaw driving mechanism 6 includes a drive mounted on the rotary sleeve 2 Bearing 61, the linear drive mechanism that is connected with the outer ring of drive bearing 61, the first rack 62 that is connected with the inner ring of drive bearing 61 and the gear 63 that meshes with the first ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com