Winding system of winding machine

A winding machine and winding technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of low work efficiency, unreliable finished product pass rate, high production cost, etc., to improve production efficiency and simple structure Novel, Consistency-Enhancing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

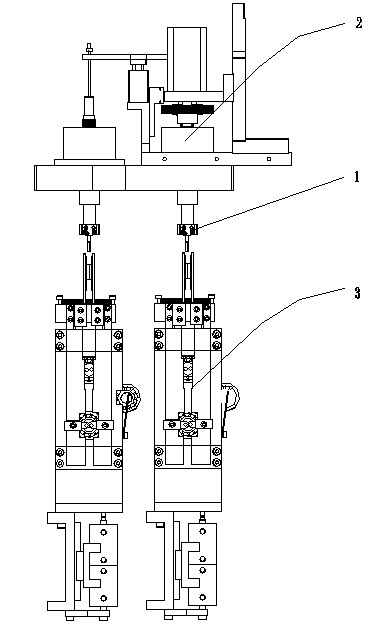

[0043] See Figure 1 to Figure 18 : The winding system of the winding machine shown, which includes a frame, a demoulding mechanism 1, a demoulding power mechanism 2 and a coil winding mechanism 3, wherein the demoulding mechanism 1 and the coil twisting mechanism 3 are fixed on the frame ,in:

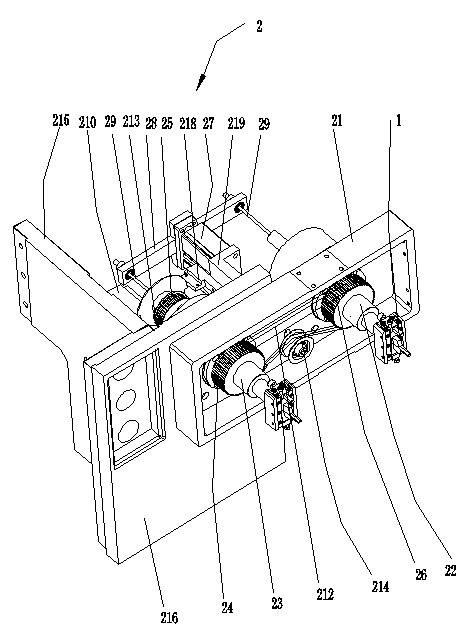

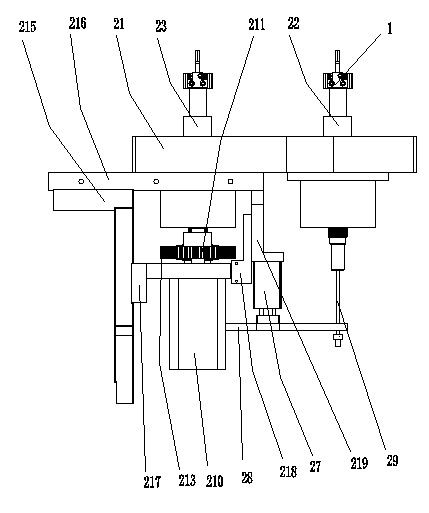

[0044] combine Figure 1 to Figure 6 It can be seen that: A, the demoulding power mechanism 2 includes a support frame and a mounting box 21 fixed on the support frame, and the first winding mold clamp main shaft 23 and the second winding mold clamp main shaft 23 are installed on the mounting box 21 through bearings. Winding die clamp main shaft 22, the first winding die clamp main shaft 23 and the second winding die clamp main shaft 22 pass through the installation box 21, and the first winding die clamp main shaft 23 and the second winding die clamp main shaft 22 pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com