Back pull type cylinder clamp and planet carrier machining equipment

A collet and collet technology, used in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of poor alignment accuracy, poor axial positioning, easy entry of impurities, etc., and achieve high precision , Easy to disassemble, increase the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

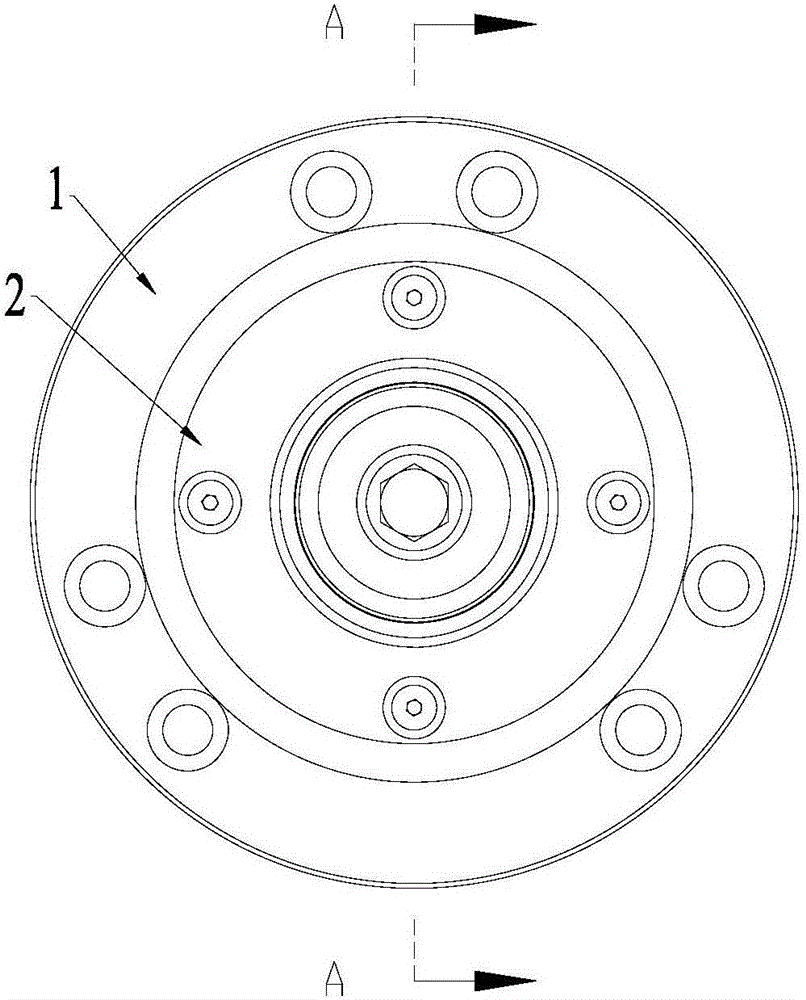

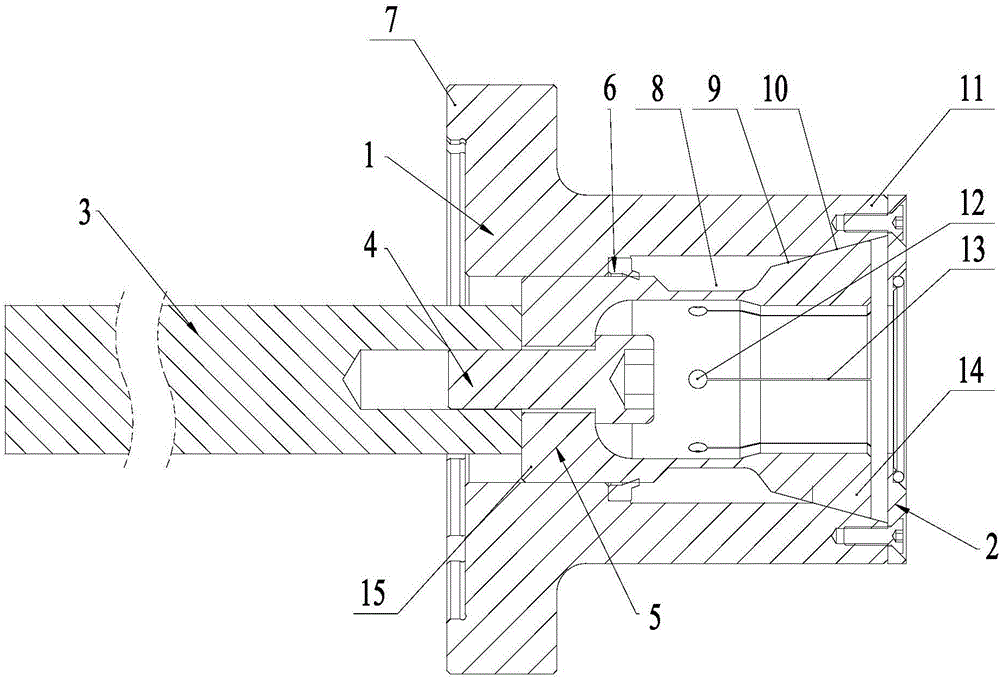

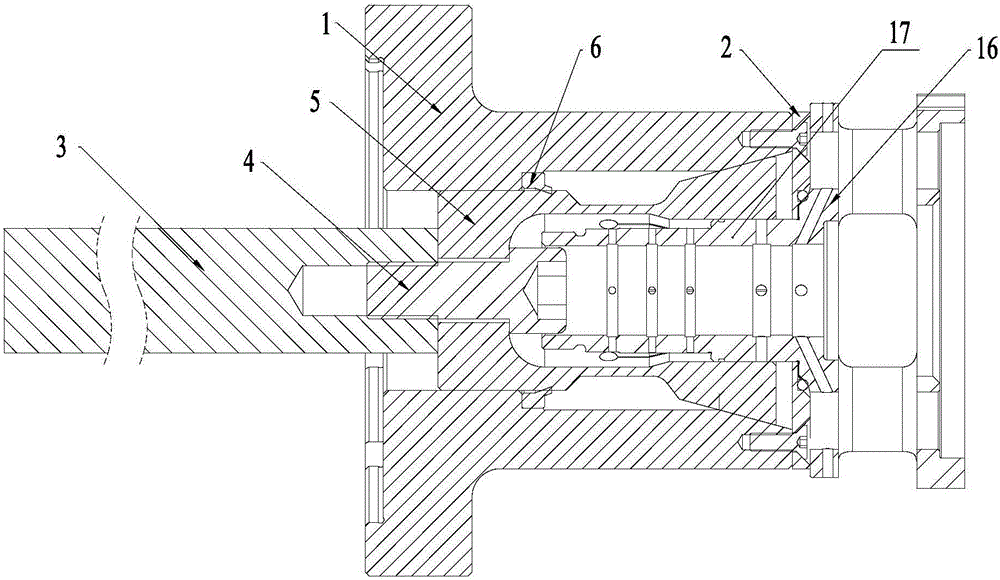

[0056] Such as figure 1 , 2 and 4, a pull-back collet comprising:

[0057] Hollow chuck seat 1, one end of the chuck seat is a fixed end 7, the other end is a mating end 11, and the inner side wall of the chuck seat includes a tapered side wall 10 at the mating end;

[0058] The hollow collet 5 is set inside the collet seat 1 and is slidably matched with the collet seat. The collet 5 includes a connecting end 15 and a clamping end 14 for clamping the workpiece. The outer wall 9 of the clamping end is a cone shape, the outer wall 9 of the clamping end cooperates with the tapered side wall 10 of the chuck seat, and the side wall of the clamping end is provided with a plurality of slits 13 in the axial direction, and each slit is evenly distributed around the axis of the chuck;

[0059] The pull rod 3 is fixed to the connecting end 5 of the chuck through the fastener 4, and the pull rod is used to drive the chuck to move along the axis of the chuck seat, so that the clamping en...

Embodiment 2

[0072] This embodiment discloses a rear pull type collet, such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the collet includes a detachable connecting part 24 and a clamping part 25, the connecting end is located at the connecting part, the clamping end is located at the clamping part, and the connecting part and the clamping part The thread fits, and the connecting part and the clamping part have mating surfaces that fit against each other, and at least one mating surface has a concave-convex pattern 26 .

[0073] The detachable matching method of this embodiment can realize the replacement of clamping parts of different specifications, so as to adapt to workpieces of different sizes, and when the clamping part is damaged, only the clamping part needs to be replaced, and the connecting part does not need to be scrapped. The detachable fit can save costs; the connecting part and the clamping part are threaded and at least one mating s...

Embodiment 3

[0075] This embodiment discloses a rear pull type collet, such as Figure 10 and 11 As shown, the difference between this embodiment and Embodiment 1 is that the inner wall of the elastic part 27 (each slit 13 divides the clamping end into several elastic parts 27) has a mounting groove 29, and the rear pull collet also includes a The clamping block 28 on the mounting groove, the clamping block 28 is magnetically attracted to the mounting groove 29, and one end of the clamping block 28 passes through the mounting groove. The quick installation of the clamping block can be realized through magnetic attraction, and by changing the clamping block of different sizes (the distance between the clamping block and the installation groove is different), the clamping range of the chuck can be changed, so that it can adapt to workpieces of different sizes; In actual use, at least one of the mounting groove and the clamping block has a magnetic medium, so that the two can be magnetically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com