Patents

Literature

115results about How to "Guaranteed clamping accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

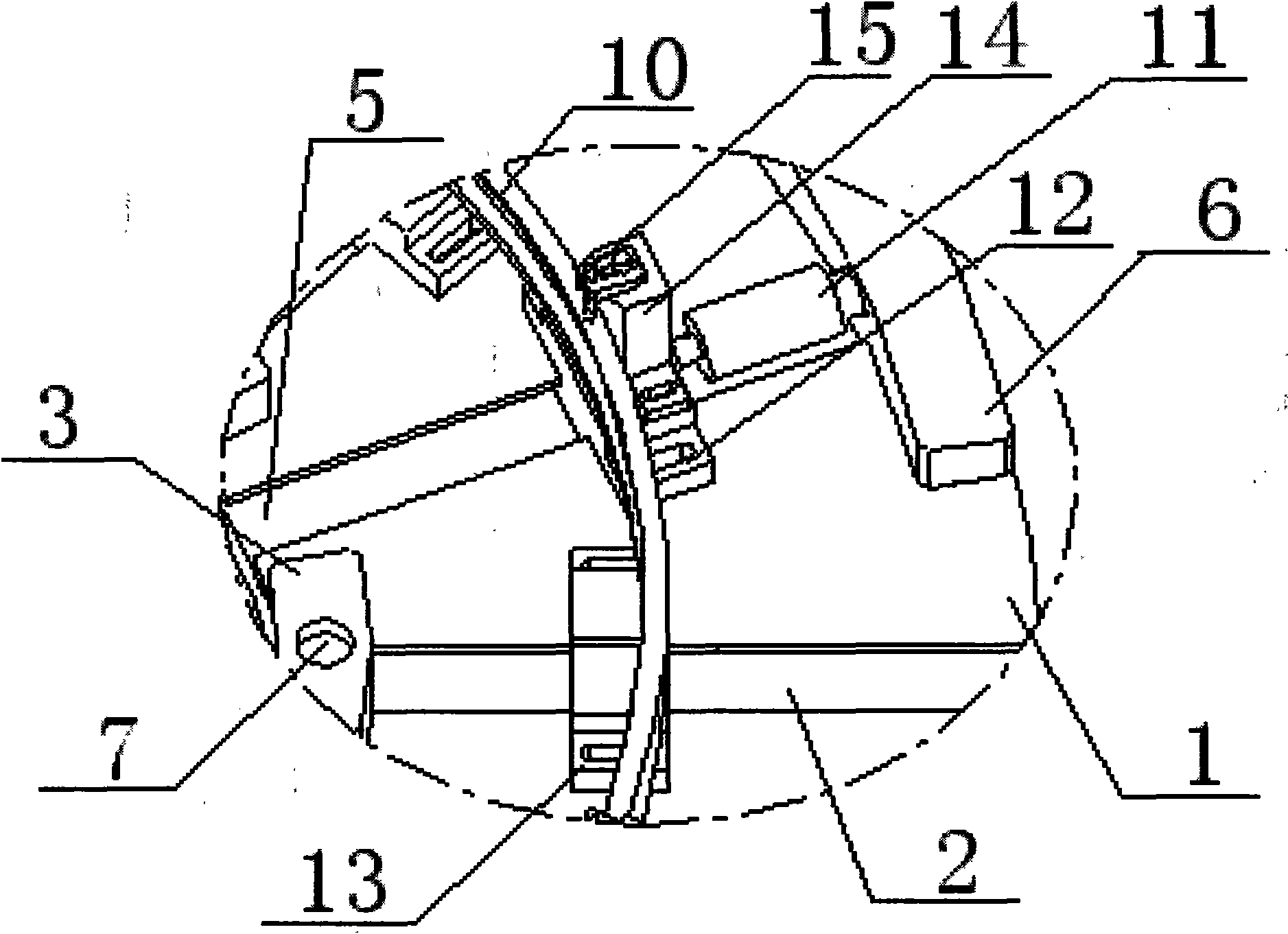

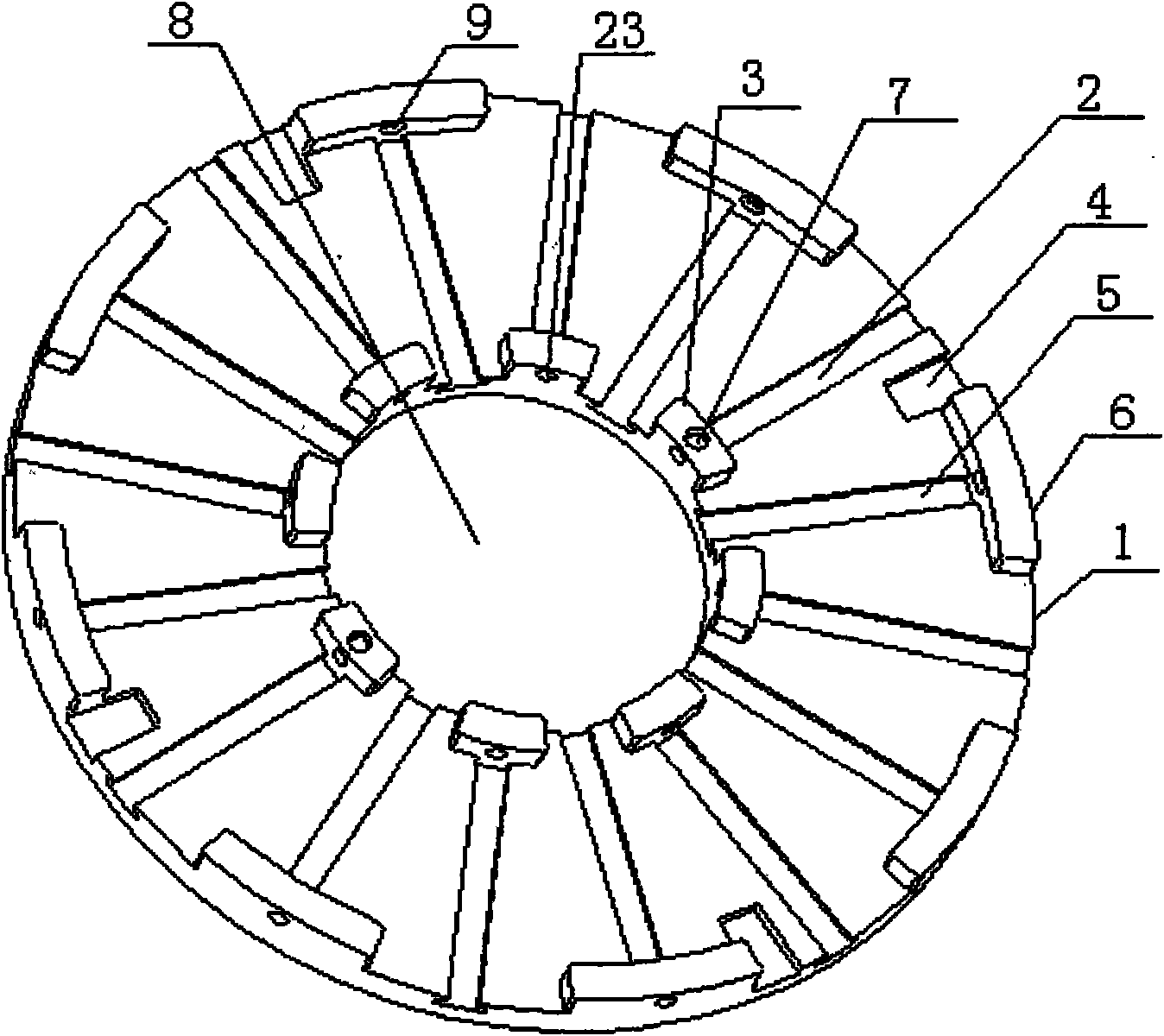

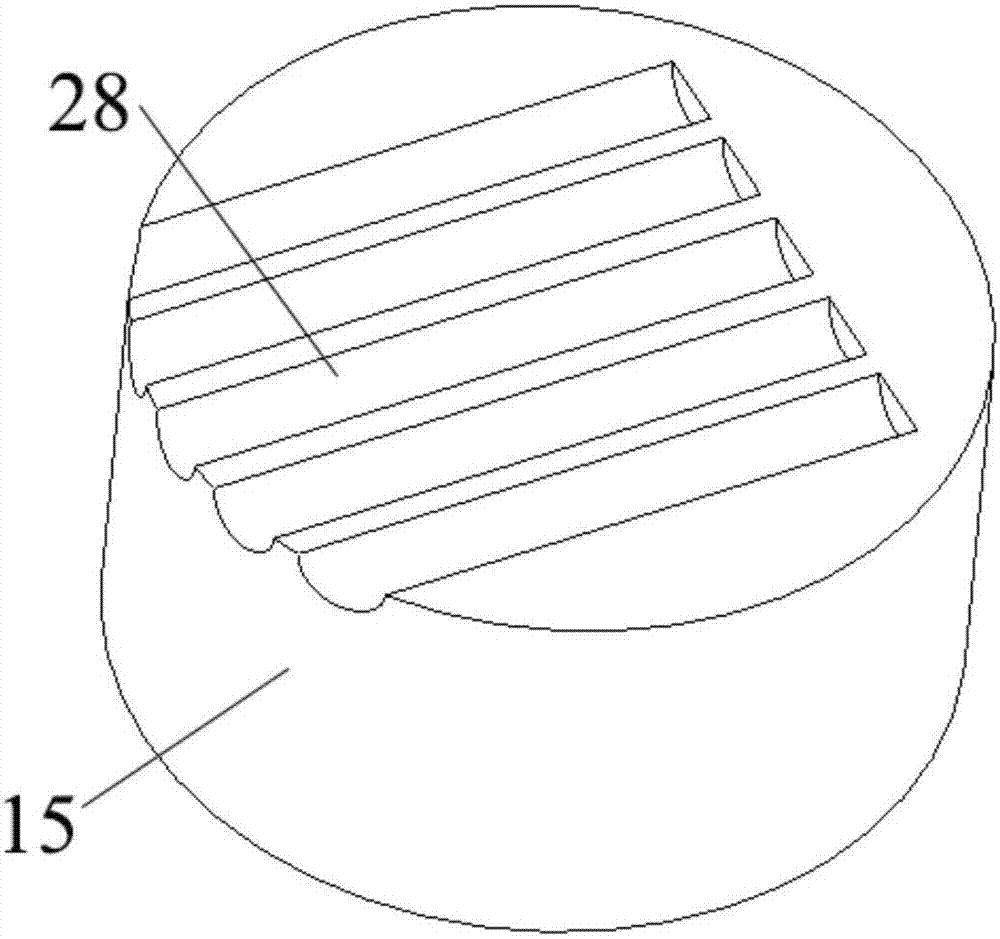

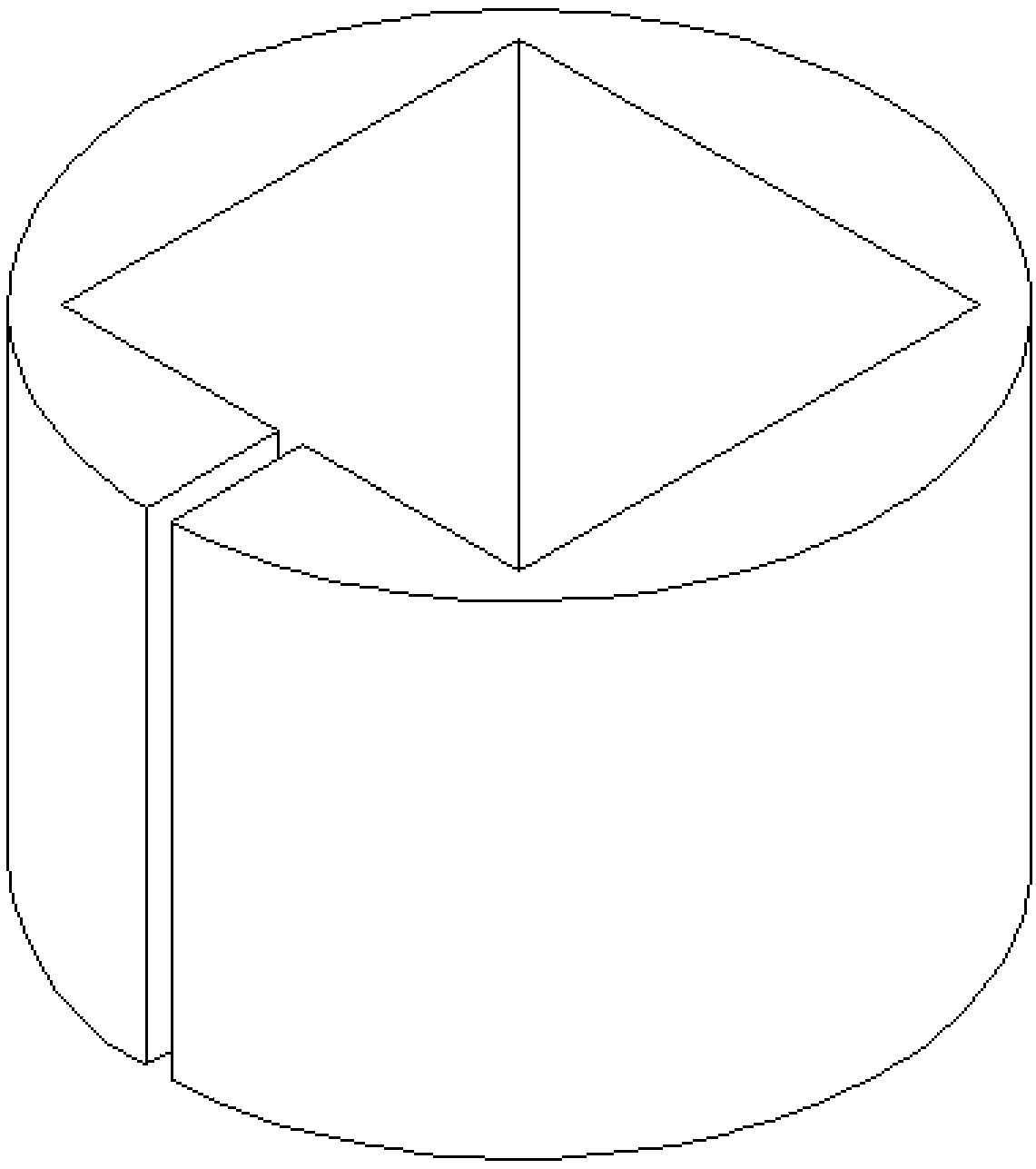

Annular thin-wall article clamping device and using method thereof

ActiveCN101954604AGuaranteed accuracyReduce labor intensityAutomatic conveying/guiding stockPositioning apparatusEngineeringThin walled

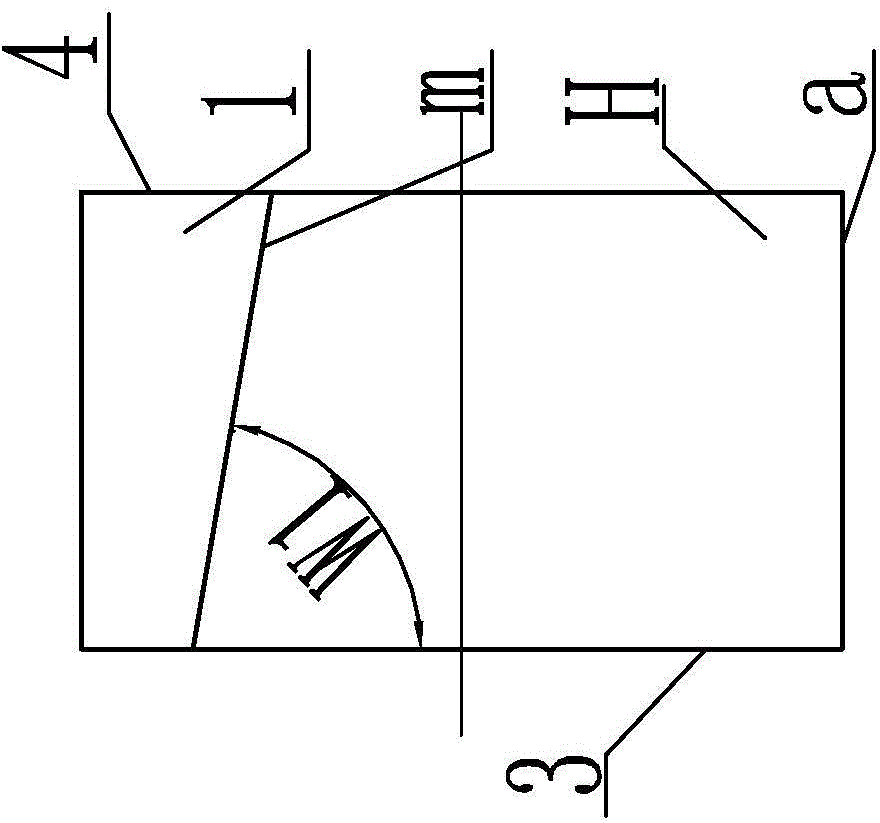

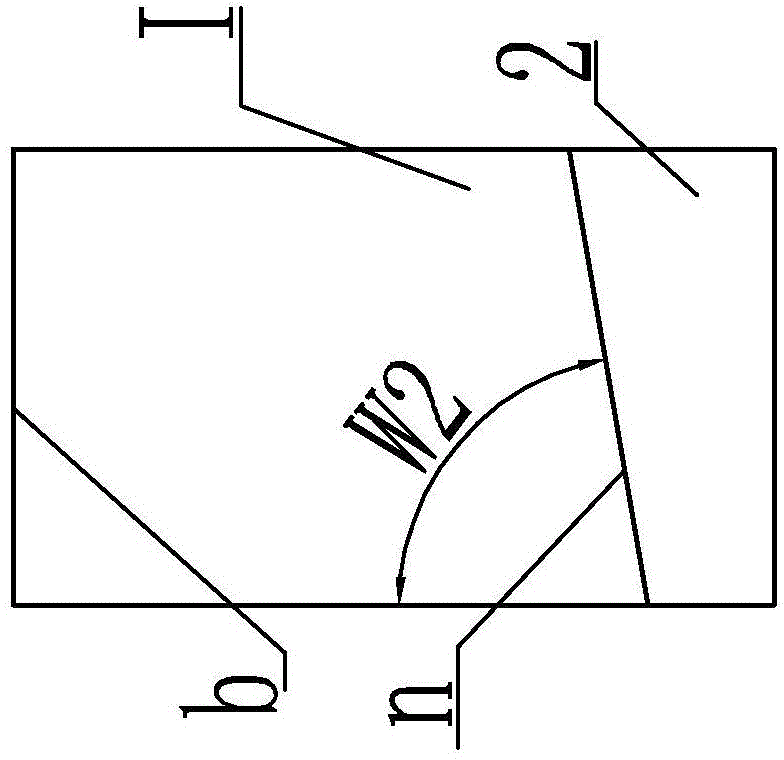

The invention provides an annular thin-wall article clamping device and a using method of the device. The clamping device comprises an annular chassis; the chassis is provided with a radial regulation mechanism of a locating workpiece; the radial regulation mechanism is divided into an inner radial regulation mechanism and an outer radial mechanism; two radial regulation mechanisms position workpiece respectively from the inner side or the outer side of the workpiece; the chassis is respectively provided with track-directed sliding grooves for the two radial adjustment mechanisms; the inner end of the sliding groove of the inner radial regulation mechanism is provided with a stopping block; the outer end of the sliding groove of the outer radial regulation mechanism is provided with the stopping block; the sliding grooves of the two groups of radial regulation mechanisms are disposed at intervals; one of the two groups of radial regulation mechanisms is provided with an axial compacting mechanism for fixing the workpiece; and the axial compacting mechanism is displaced alternatively between the two groups of radial regulation mechanisms when turning the workpiece. The clamping device can realize the processing of two side walls of the workpiece by clamping the workpiece once, and is fit for the clamping of the workpieces with different specifications. The device has the characteristics of high use rate, strong practical applicability, good generality, time saving and labor saving, light labor intensity, high production efficiency and the like.

Owner:DONGFANG TURBINE CO LTD

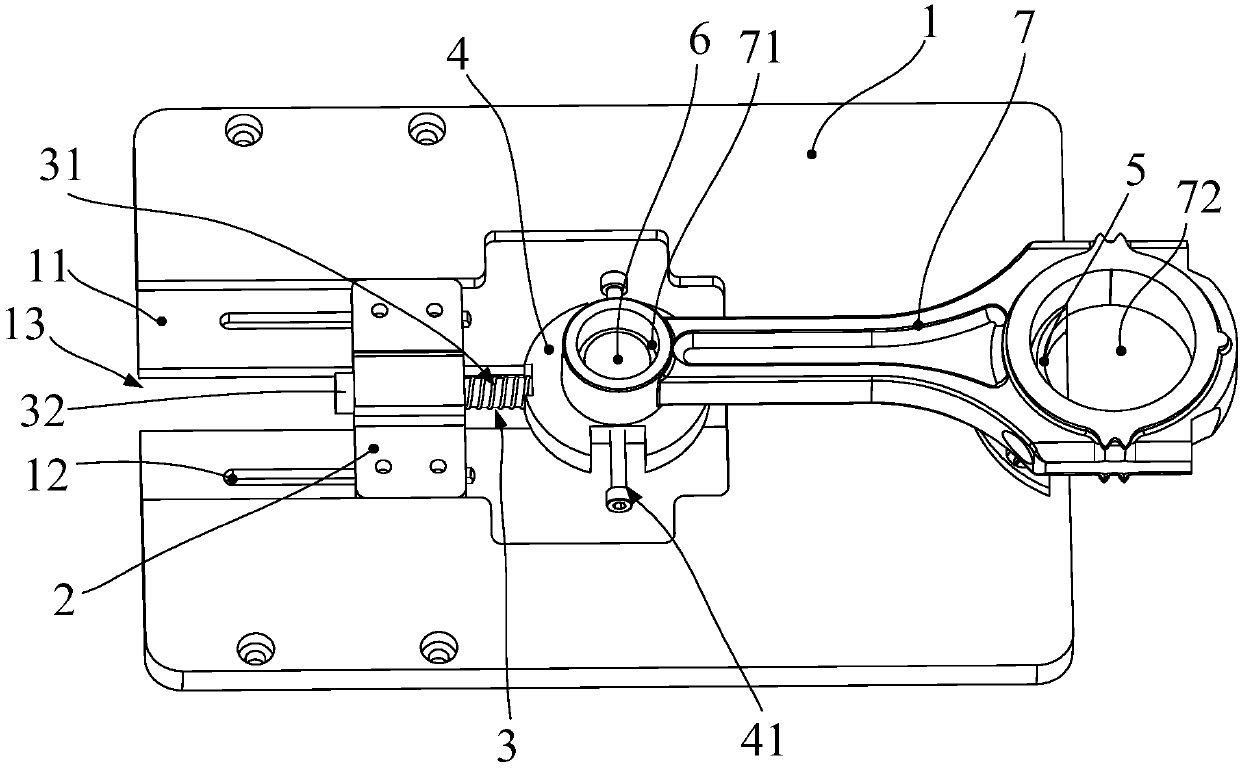

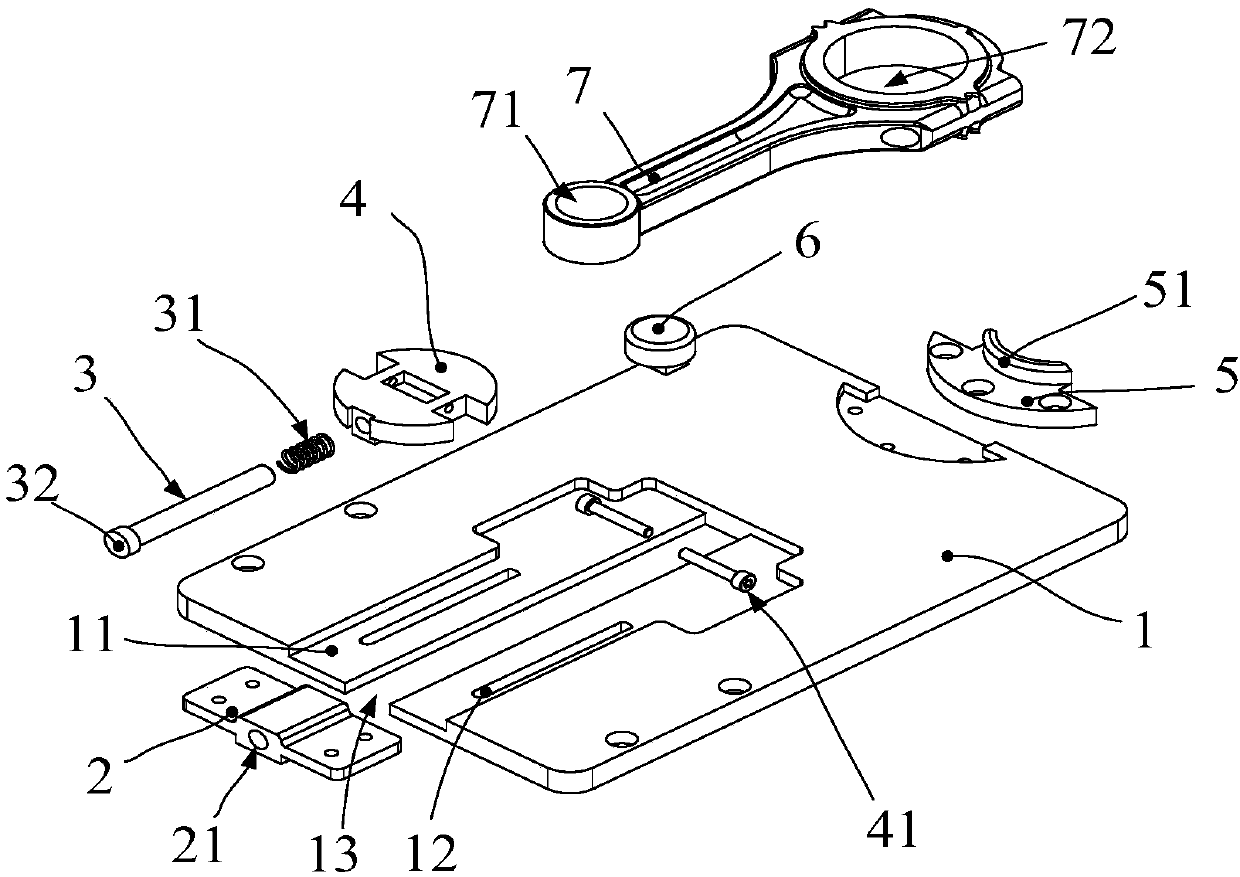

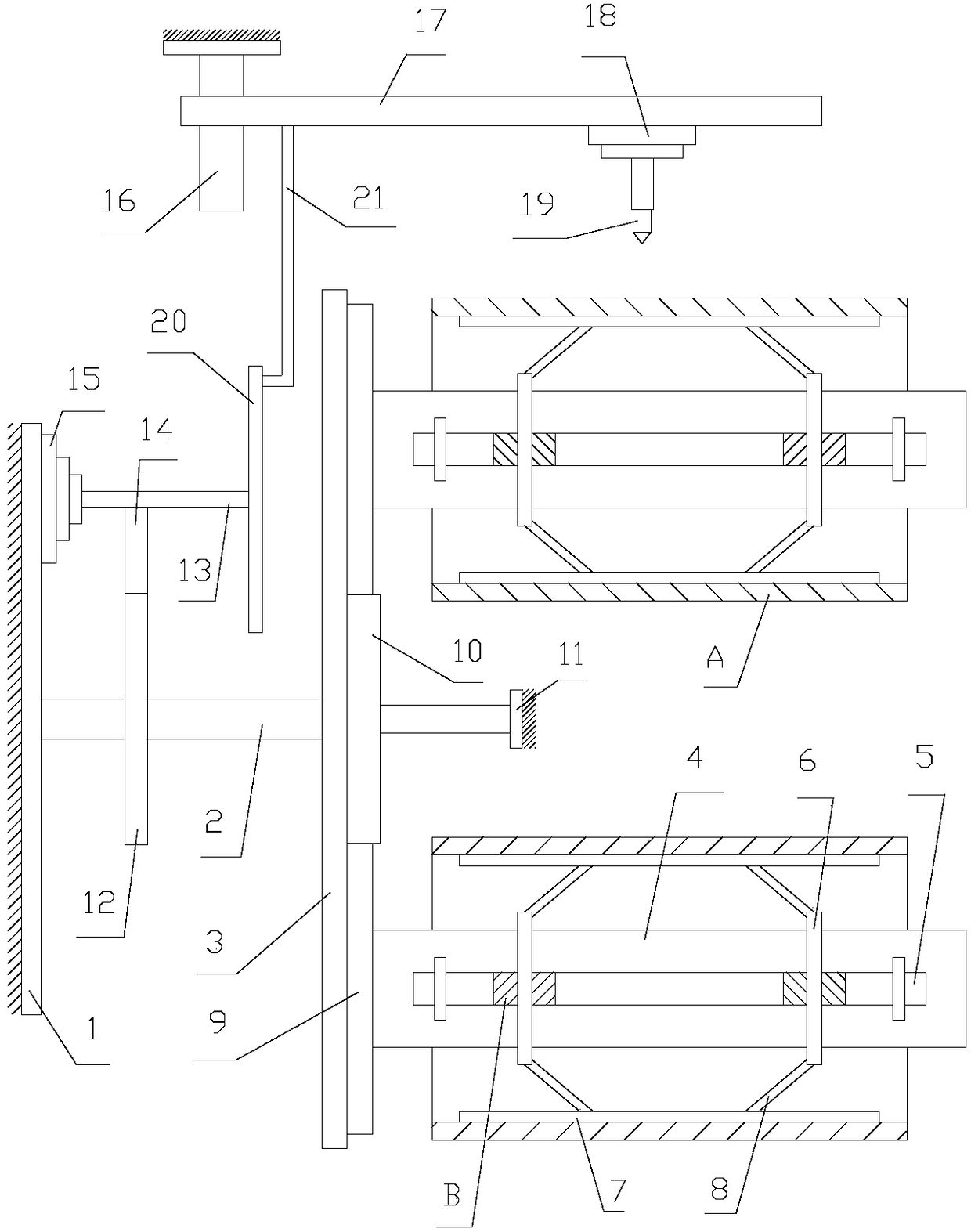

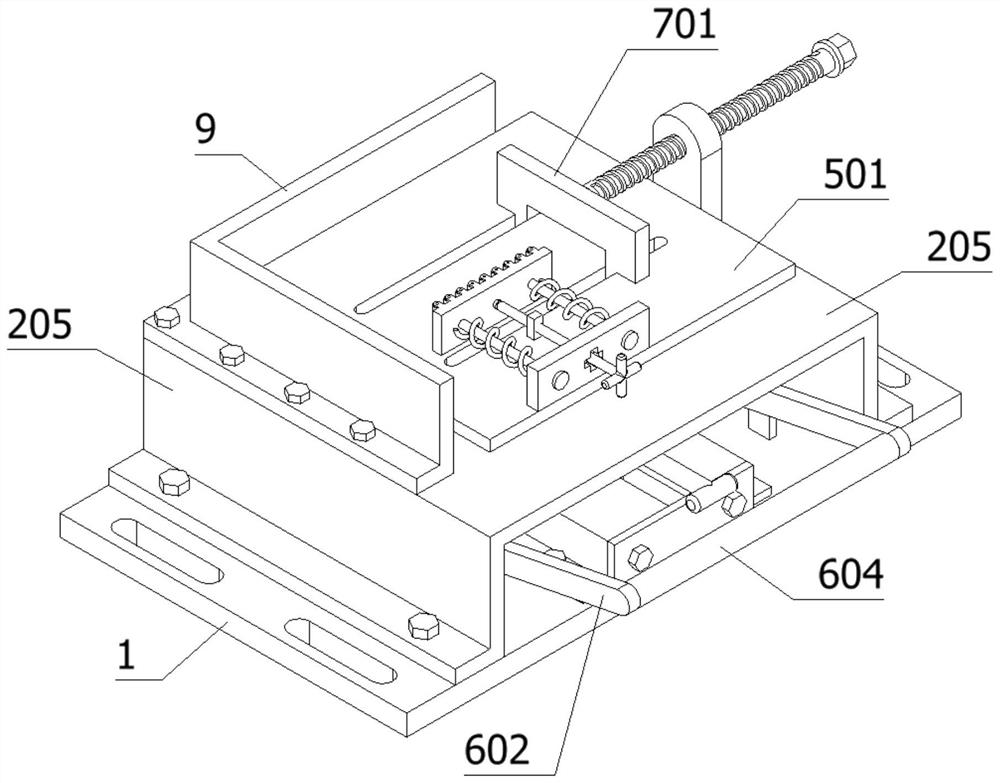

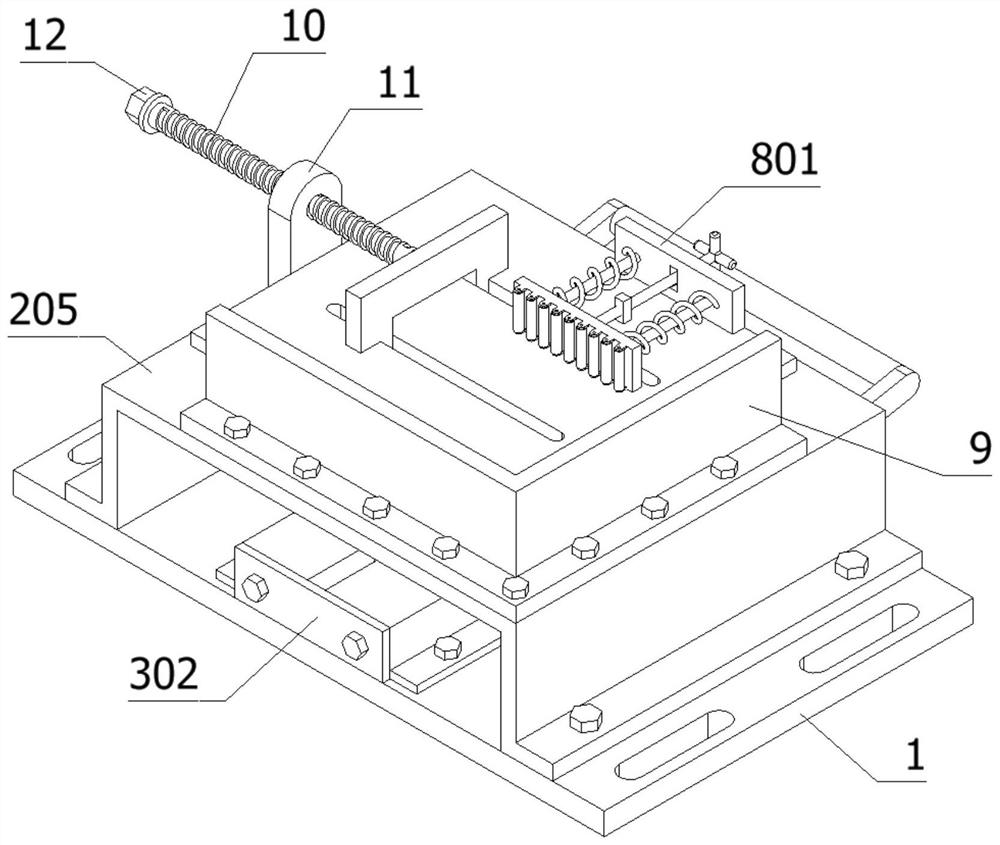

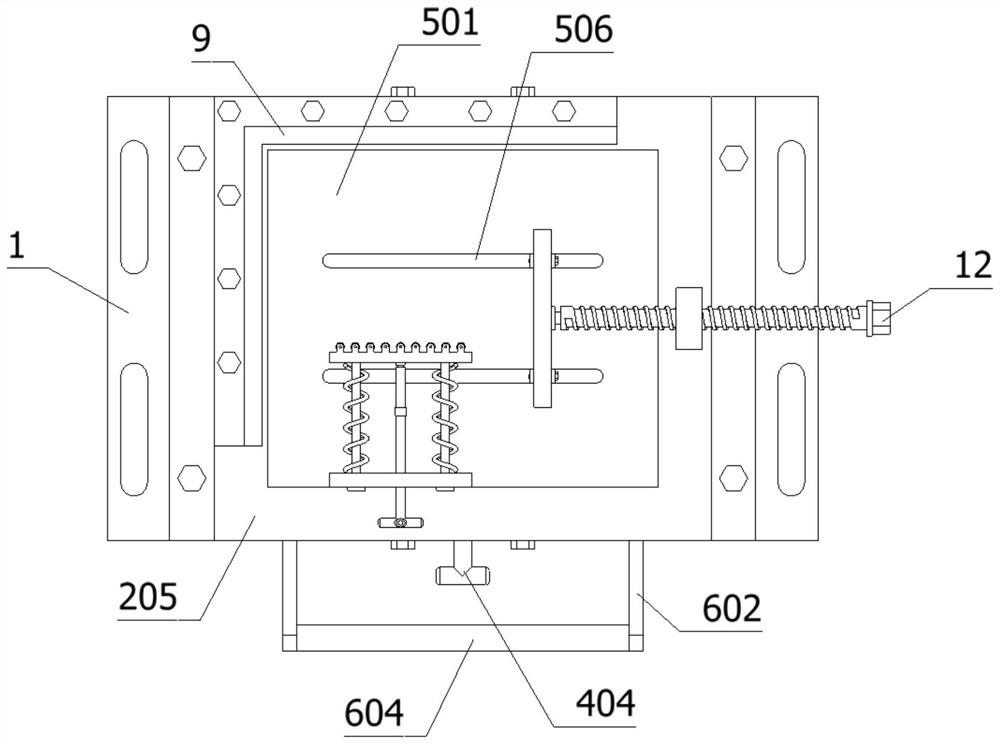

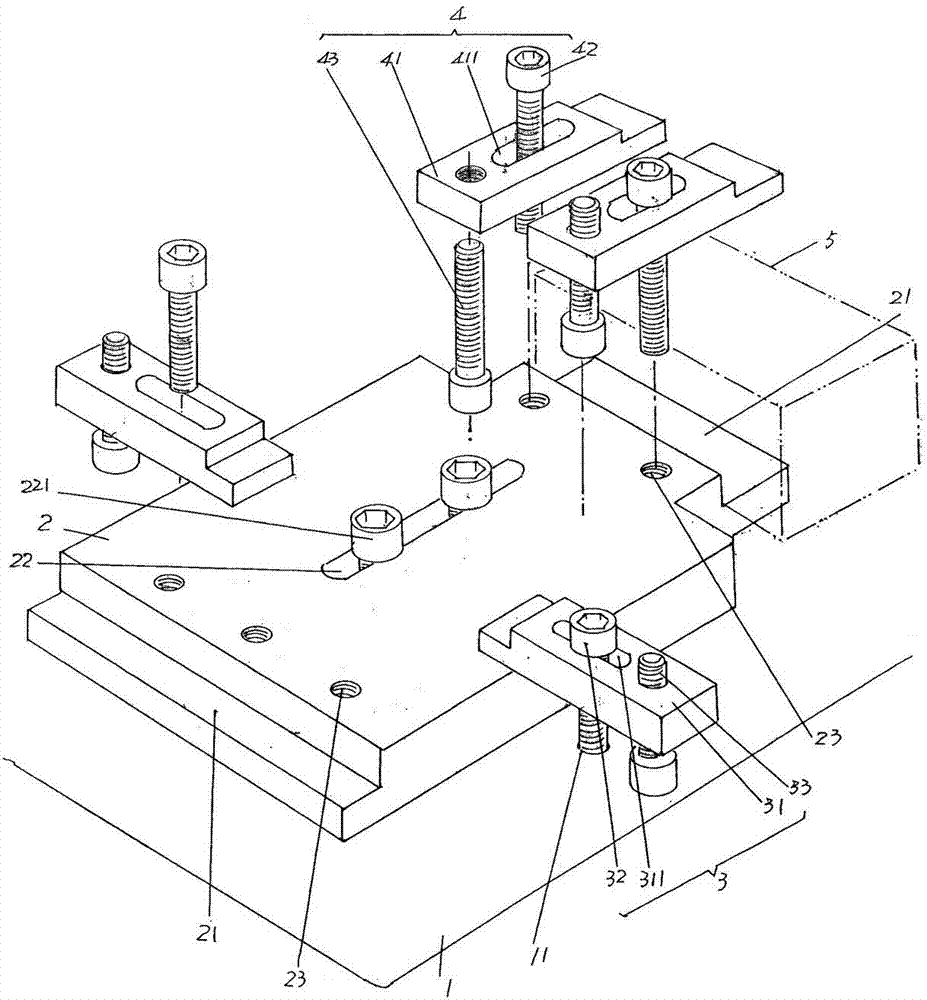

Adjustable simple clamping device and method for automobile connecting rod cracking groove machining

ActiveCN107838703AReduce the difficulty of clampingReduce wearPositioning apparatusElectrical-based auxillary apparatusEngineeringMachining

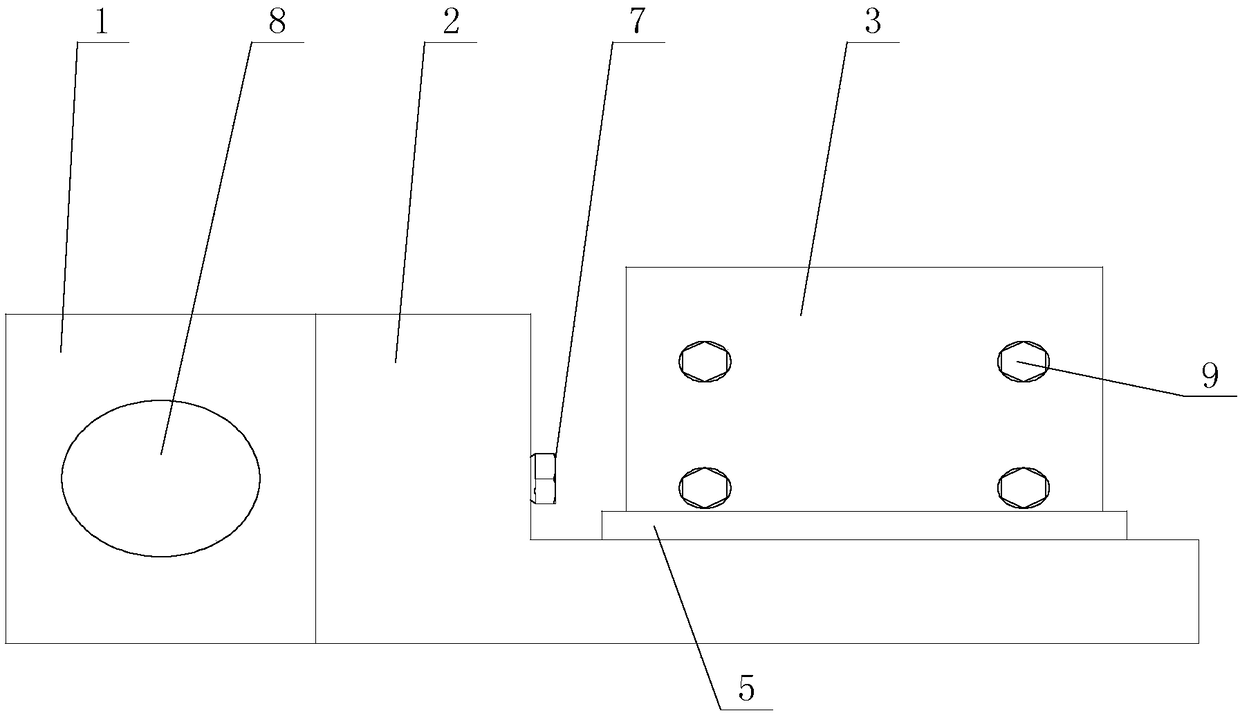

The invention discloses an adjustable simple clamping device for automobile connecting rod cracking groove machining. The adjustable simple clamping device comprises a base, the top face of the base is connected with a guide rod seat and a connecting rod big-end hole positioning seat, and a connecting rod small-end hole positioning seat is arranged between the guide rod seat and the connecting rodbig-end hole positioning seat. The guide rod seat is connected with the connecting rod small-end hole positioning seat through a guide rod arranged horizontally, the middle of the guide rod is sleeved with a spring, one end of the spring props against the other side face of the guide rod seat, and the other end of the spring props against the side face of the connecting rod small-end hole positioning seat. The top face of the connecting rod small-end hole positioning seat is further connected with a connecting rod small-end hole positioning pin, the top face of the connecting rod big-end holepositioning seat is provided with a cambered surface positioning block with a cambered surface, the connecting rod small-end hole positioning pin is inserted into a connecting rod small-end hole, andthe cambered surface positioning block is inserted into a connecting rod big-end hole, and the outer hook face props against the inner wall face of the connecting rod big-end hole and clamps and positions a connecting rod. The invention further provides a method for using the adjustable simple clamping device for automobile connecting rod cracking groove machining, and the adjustable simple clamping device and method aim to improve the automobile connecting rod clamping precision and machining efficiency.

Owner:GUANGDONG UNIV OF TECH

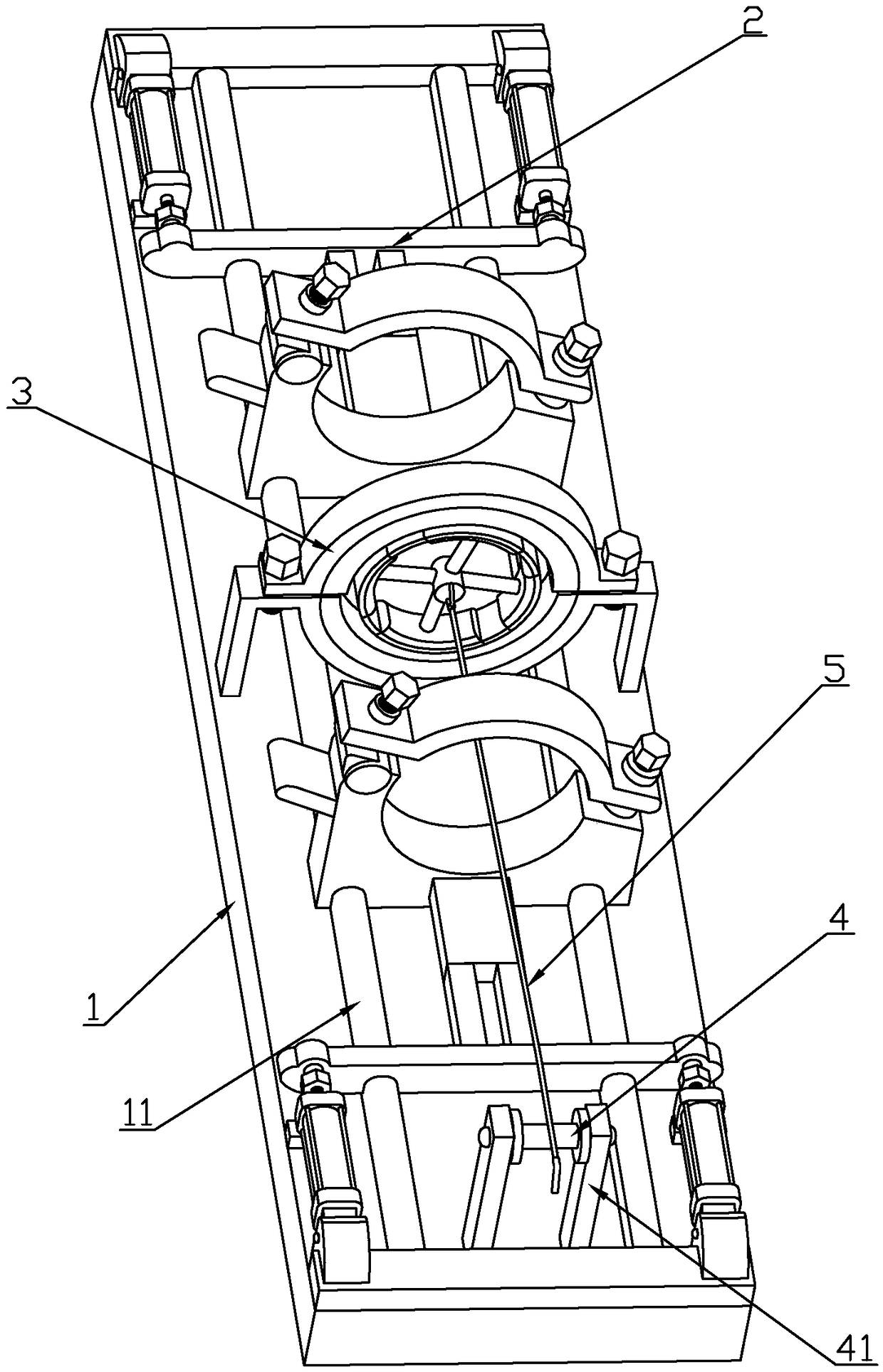

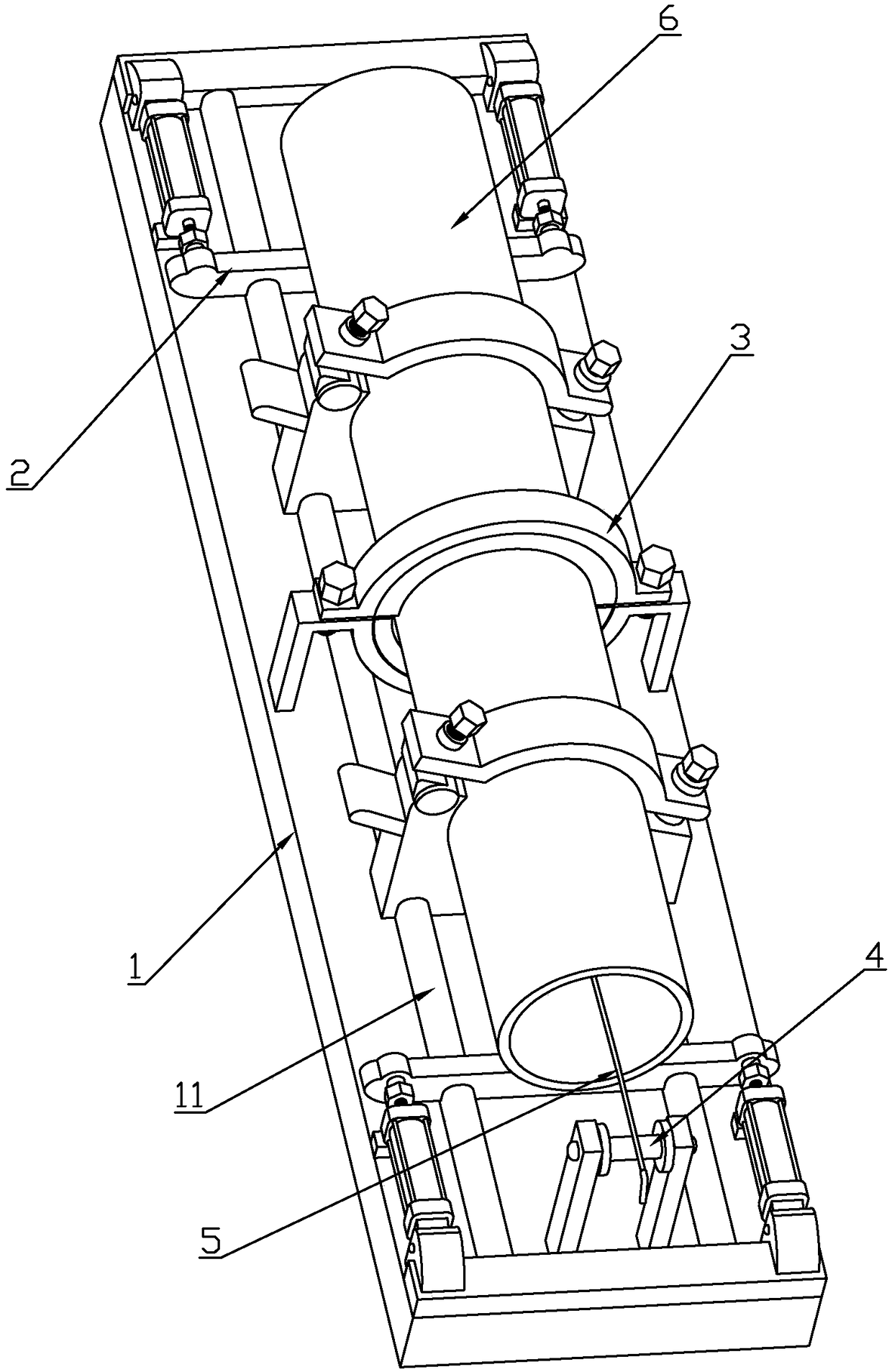

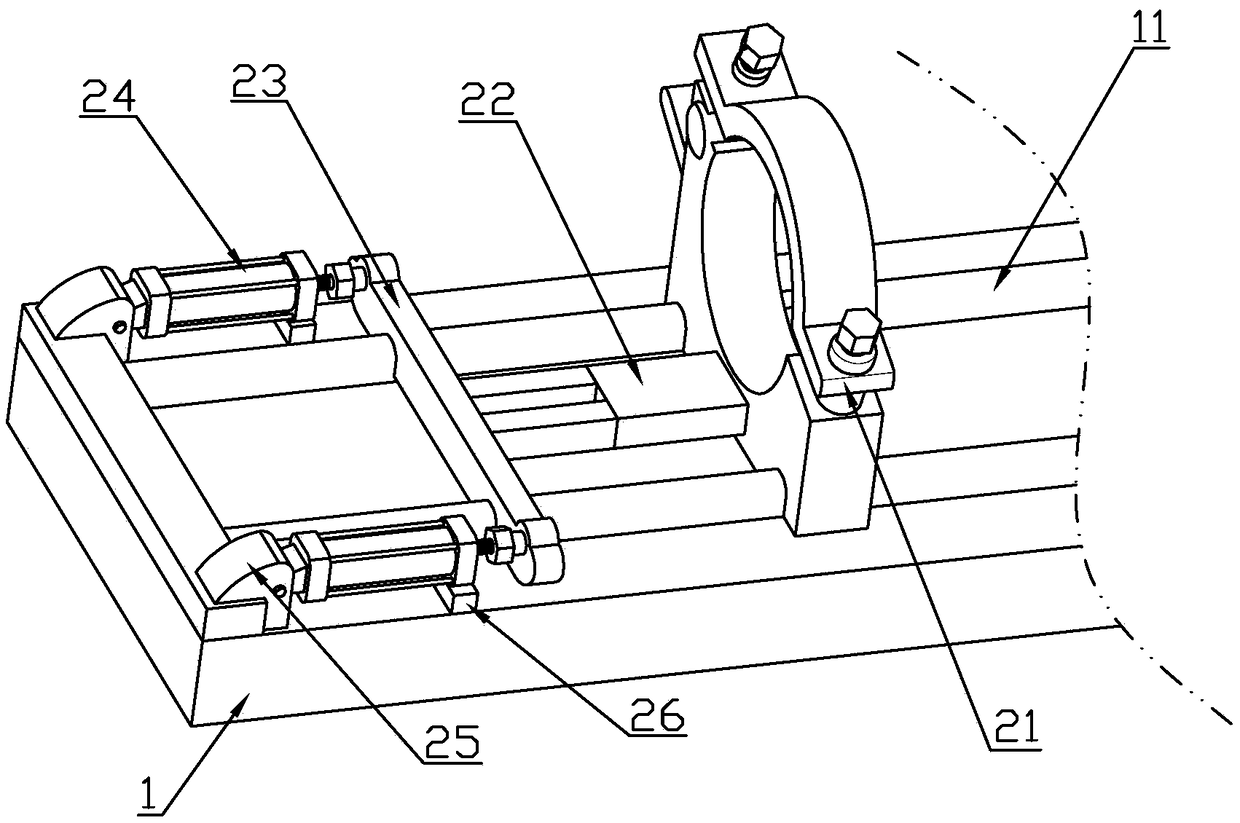

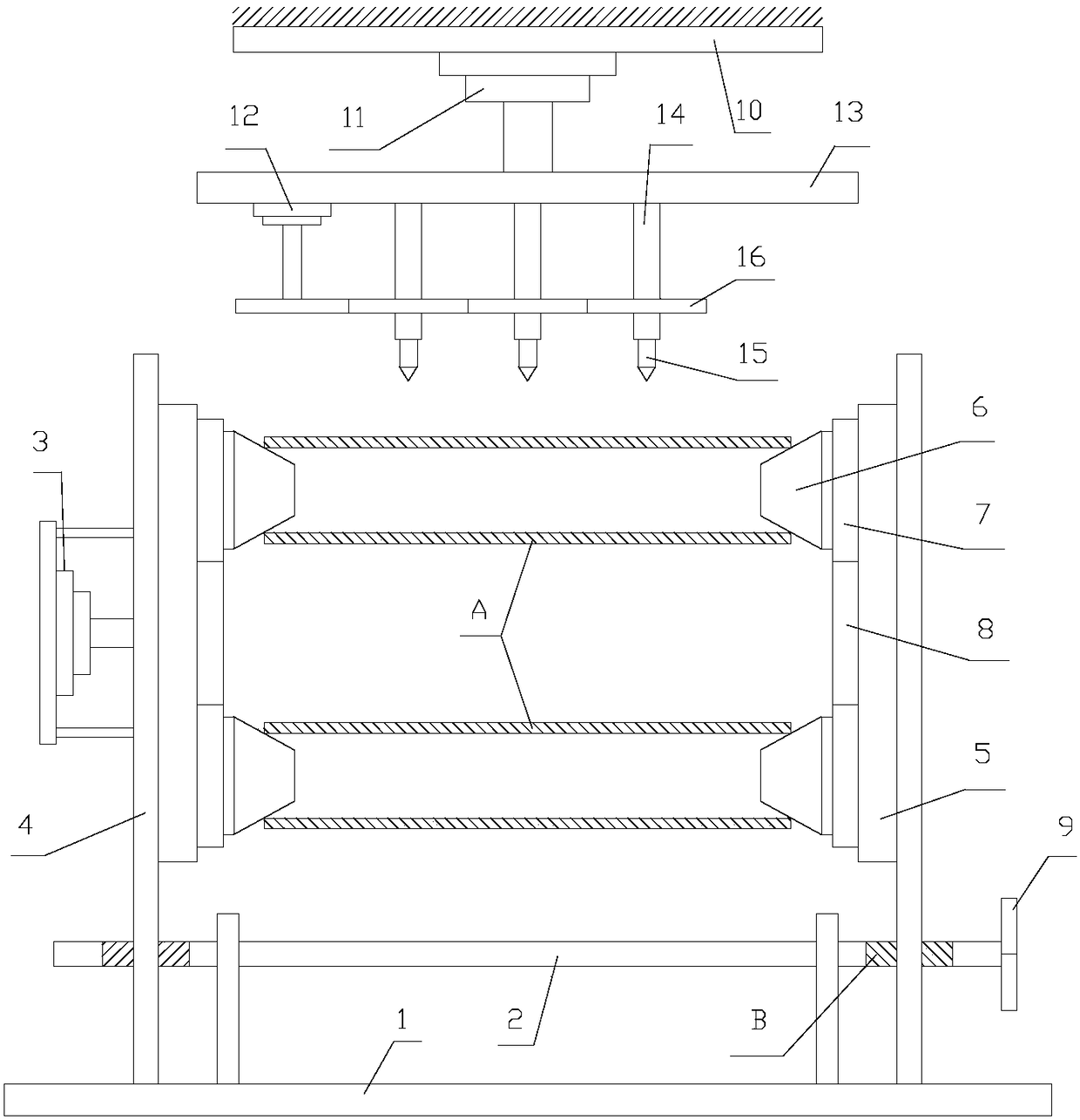

Hot melting and butt joint equipment of plastic pipeline

InactiveCN109367029AGuaranteed clamping accuracyAvoid Lost Component SituationsButt jointEngineering

The invention discloses hot melting and butt joint equipment of a plastic pipeline. The equipment comprises a base, pushing mechanisms, a butt joint mechanism, and a traction rope; the base is provided with two slide rails; the middle of the top side of the base is provided with the butt joint mechanism, the two sides of the butt joint mechanism are each provided with one pushing mechanism, the pushing mechanisms are connected to the outer sides of the sliding rails in sliding and sleeving modes respectively; each pushing mechanism comprises a fixing support, the fixing support is mainly composed of a fixing base, a pressing cover and a retaining shoulder, the fixing base is arranged on one side of the base, and the two sides of the bottom end of the fixing base are slidably connected withtwo sliding rails respectively; and the butt joint mechanism comprises a lining assembly, the inner lining assembly is mainly composed of an inner heating ring, a connecting shaft, connecting rods, and arc plates, wherein the lining assembly is arranged on the inner side of a pipeline joint, the plurality of connecting rods are uniformly arranged on the outer side wall of the connecting shaft, and one end of each connecting rod is connected with one arc plate. The equipment is simple in structure, and the accuracy of pipeline clamping and the flatness of the joint of the inner side wall of the pipeline can be guaranteed.

Owner:黄力华

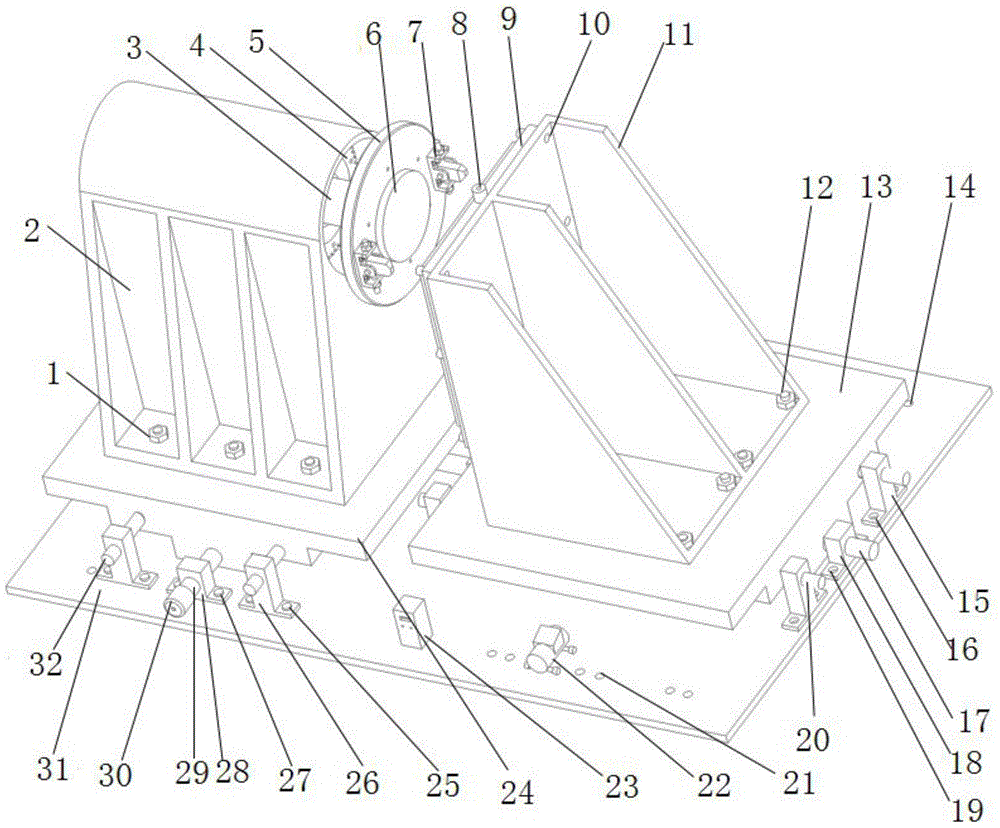

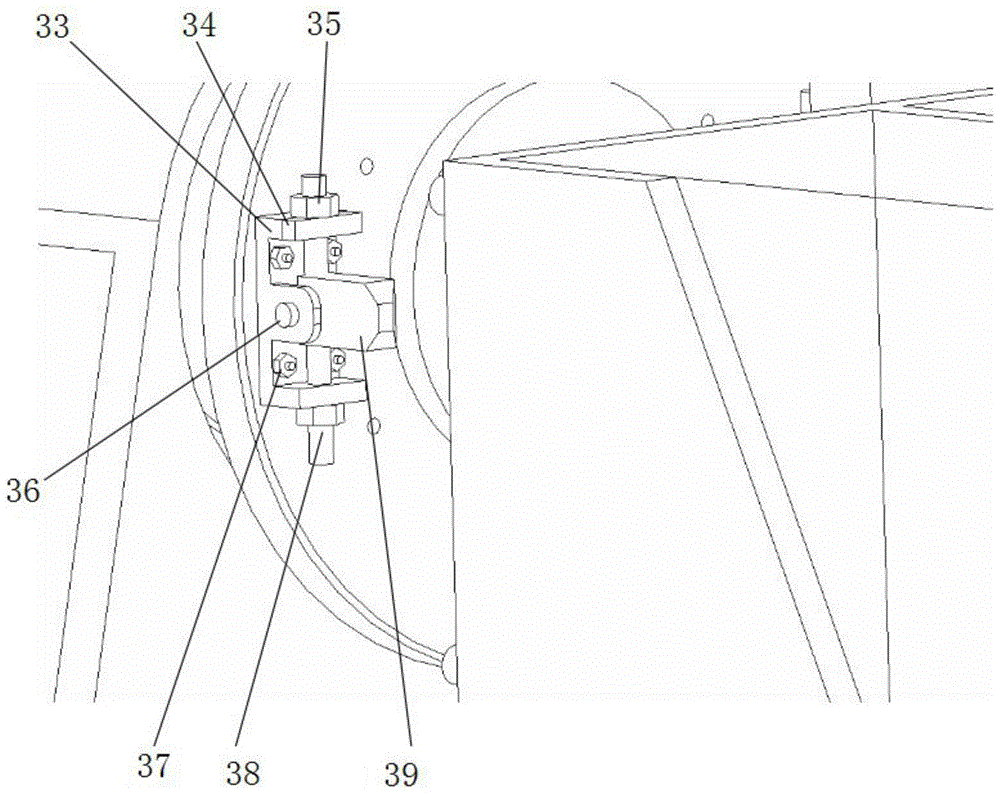

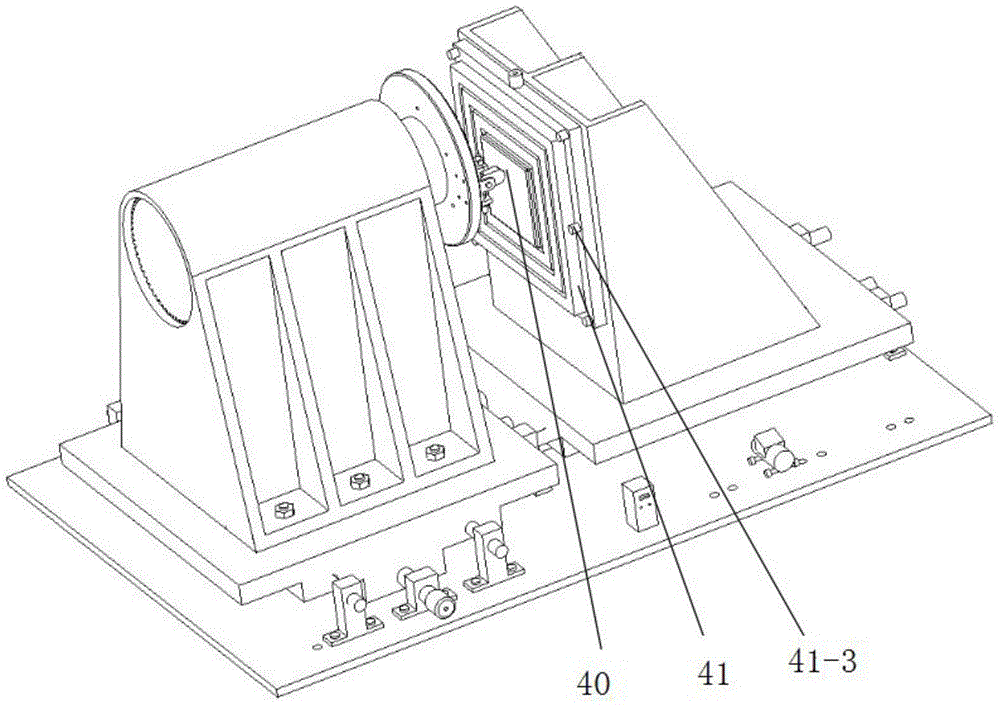

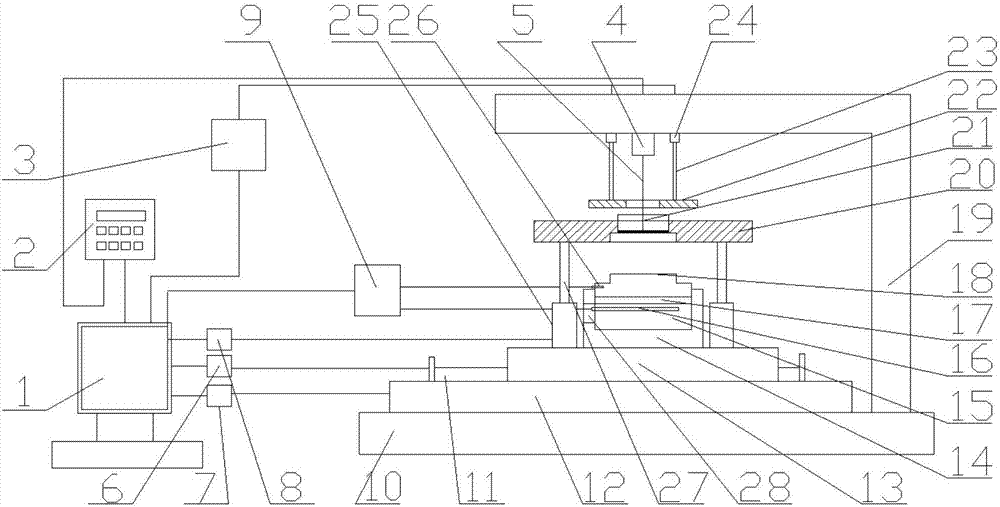

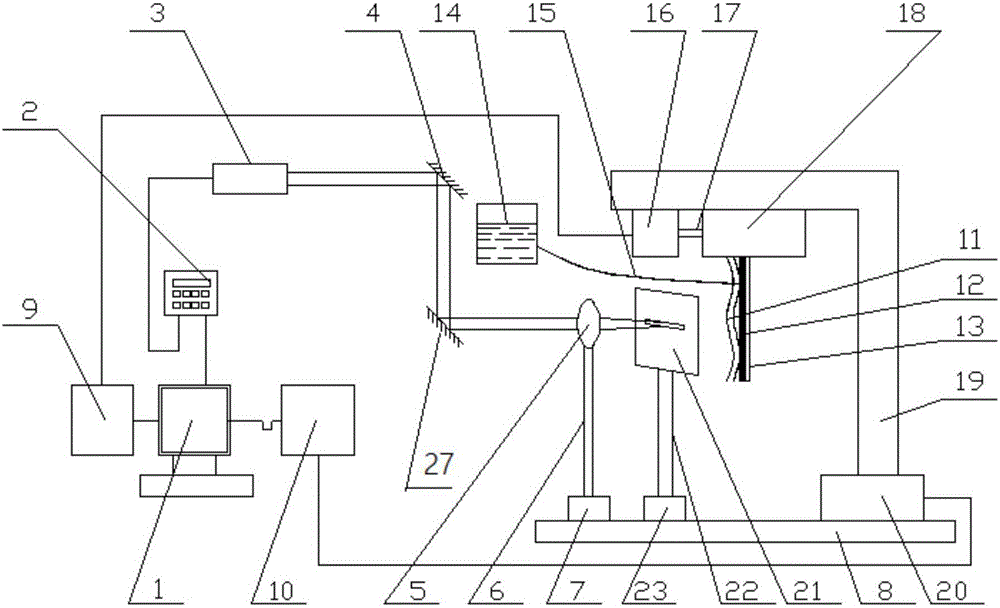

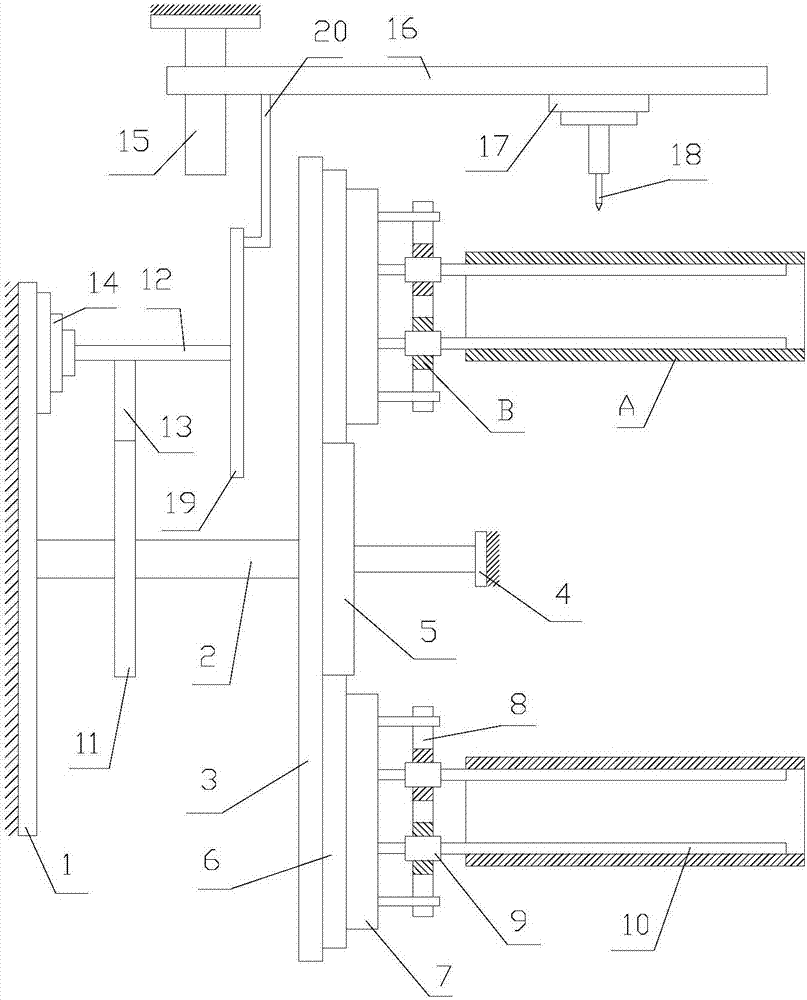

KDP crystal material single point diamond fly cutting device

ActiveCN105666711AReduce precisionHigh precisionFine working devicesMaterials processingMachine tool

The invention relates to a KDP crystal material single point diamond fly cutting device. The KDP crystal material single point diamond fly cutting device consists of eight parts, namely a support mechanism, a spindle motor fixing mechanism, a spindle motor working table part, an arc-edge diamond cutter clamping mechanism, a KDP crystal part fixing mechanism, a KDP crystal part clamping working table part, a power part and a control part. A unique horizontal tool machine structure is adopted by the device; the spindle of the motor is connected with a cutterhead and participates in cutting of a KDP crystal material directly, so that no transmission error exists, and the problem that small-size ripples are generated during KDP crystal material processing is avoided; furthermore, the special single point diamond fly cutterhead and a cutter angle adjusting device are arranged on the device, so that the increasing and decreasing of the number of teeth of the diamond cutter and adjustment on the cutter working radius and the cutter cutting angle can be realized according to practical machining requirement; and a special fixture is arranged on the device, so that high-precision, high-efficient and low-cost precise machining on the KDP crystal material is truly realized.

Owner:BEIJING UNIV OF TECH

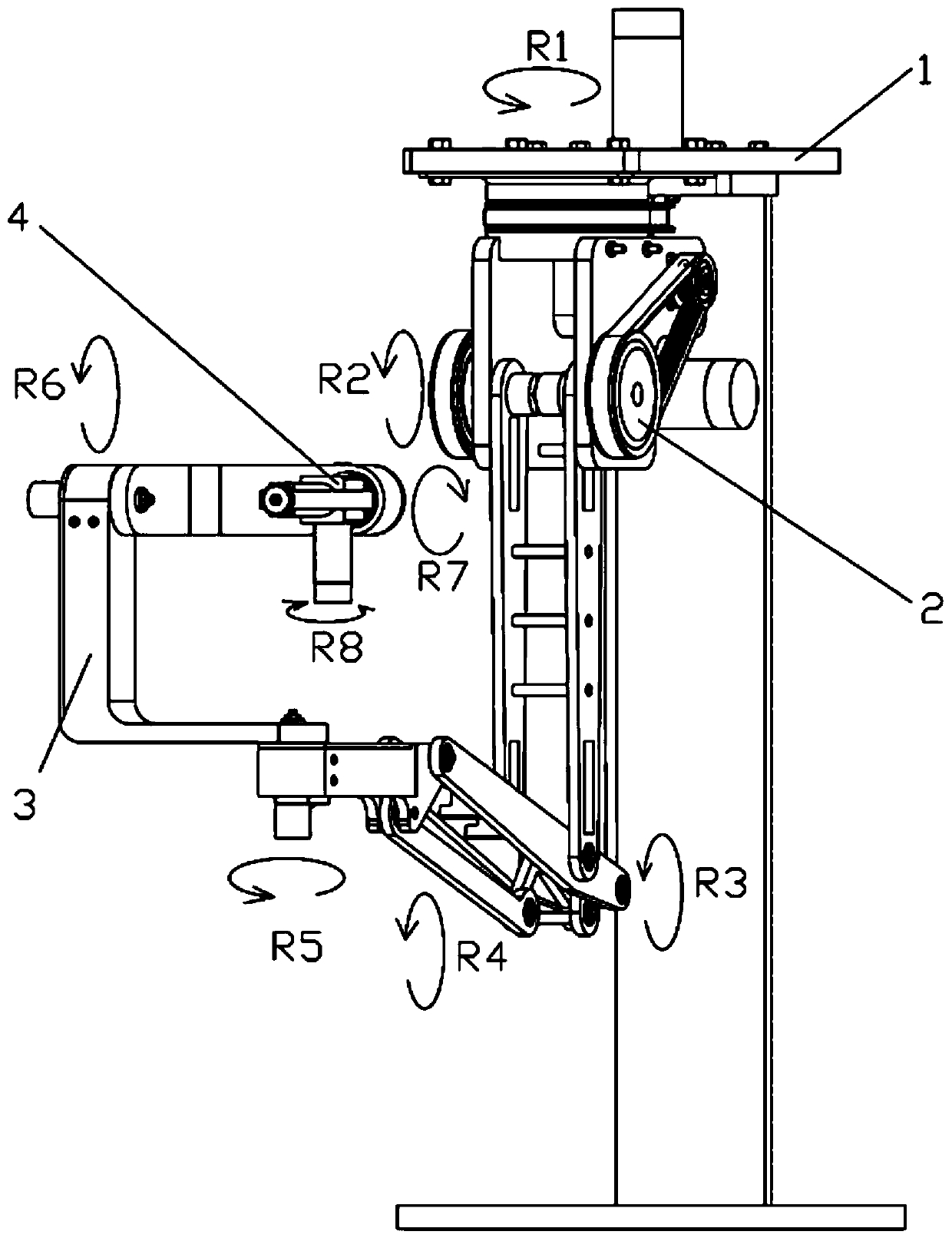

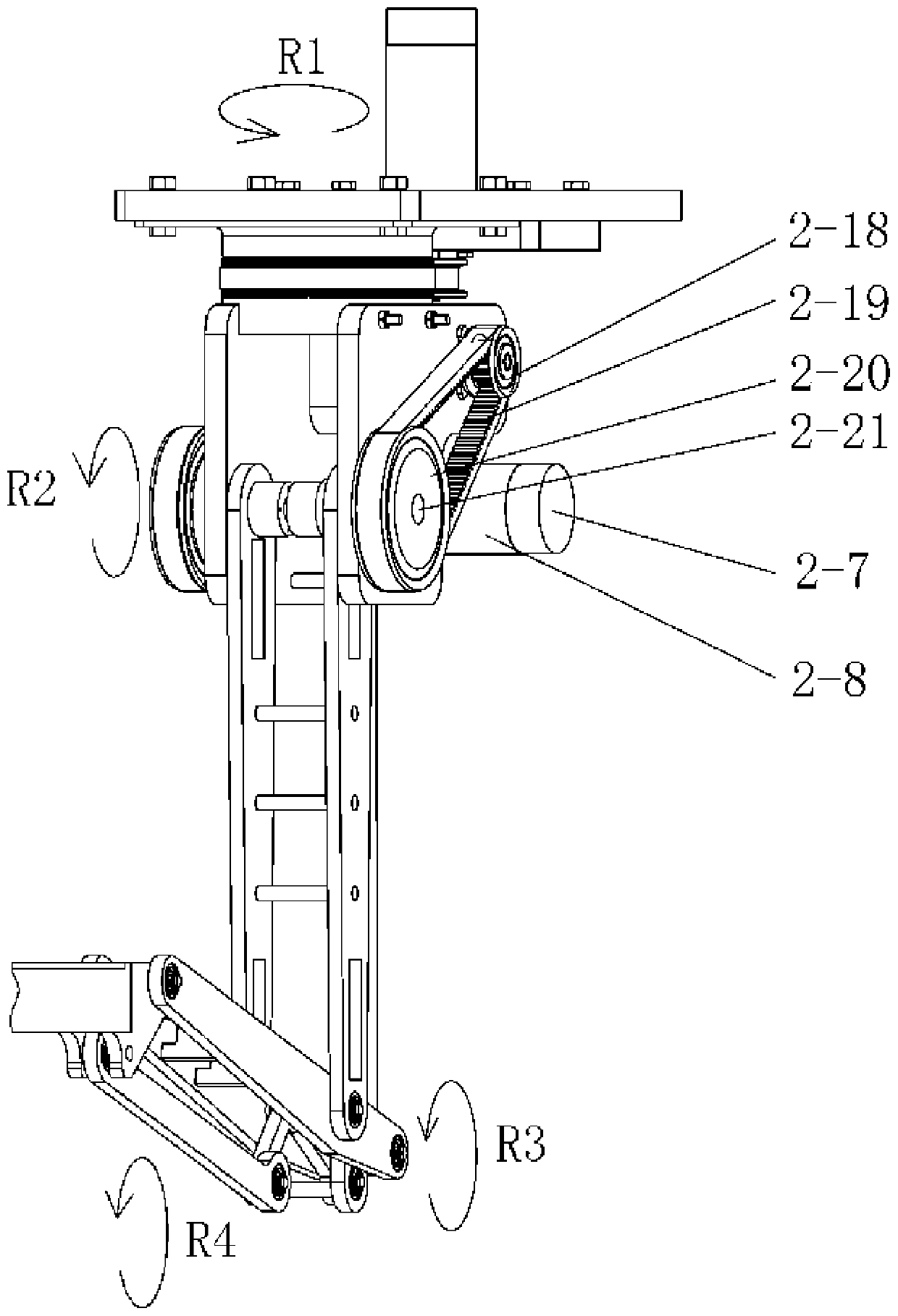

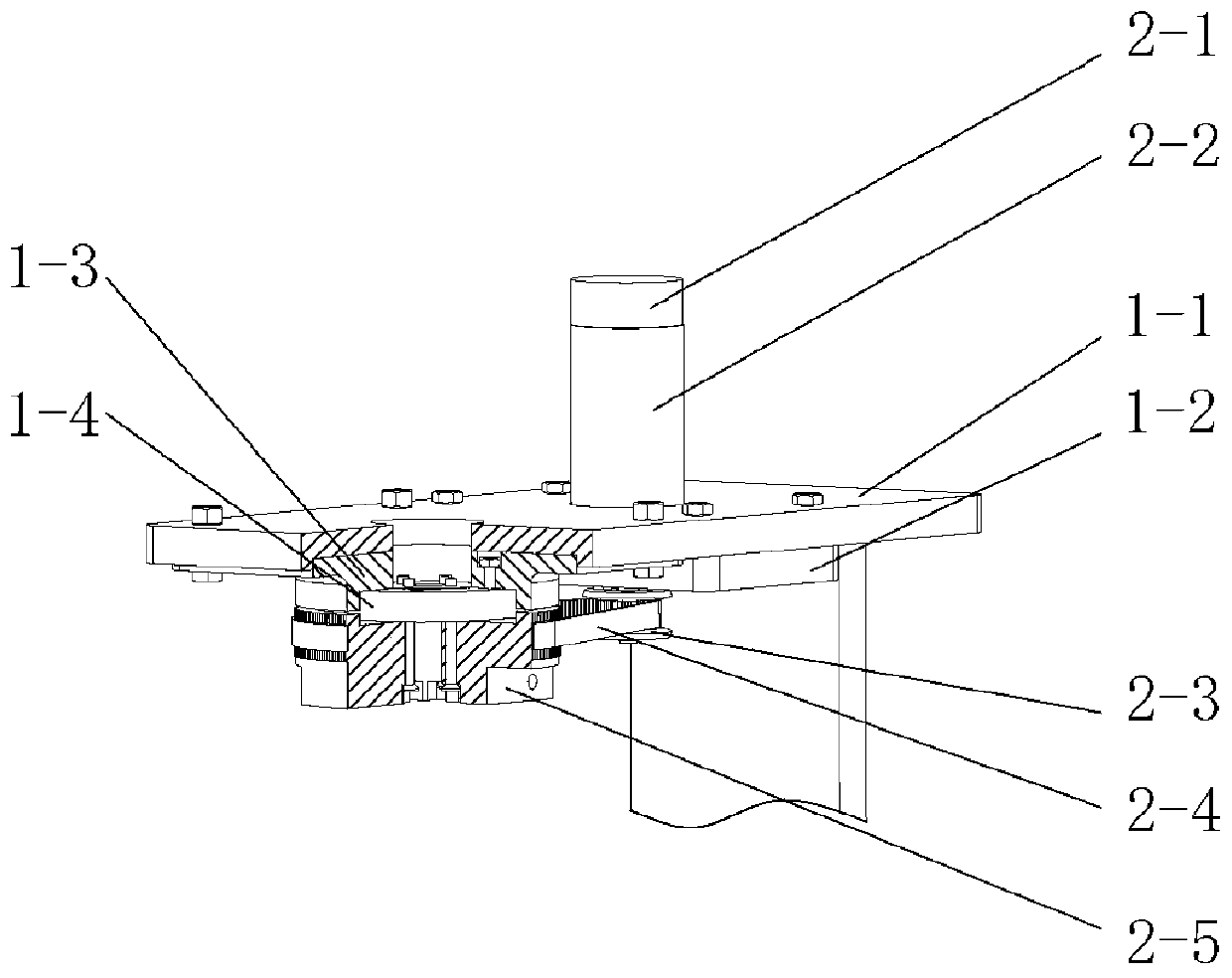

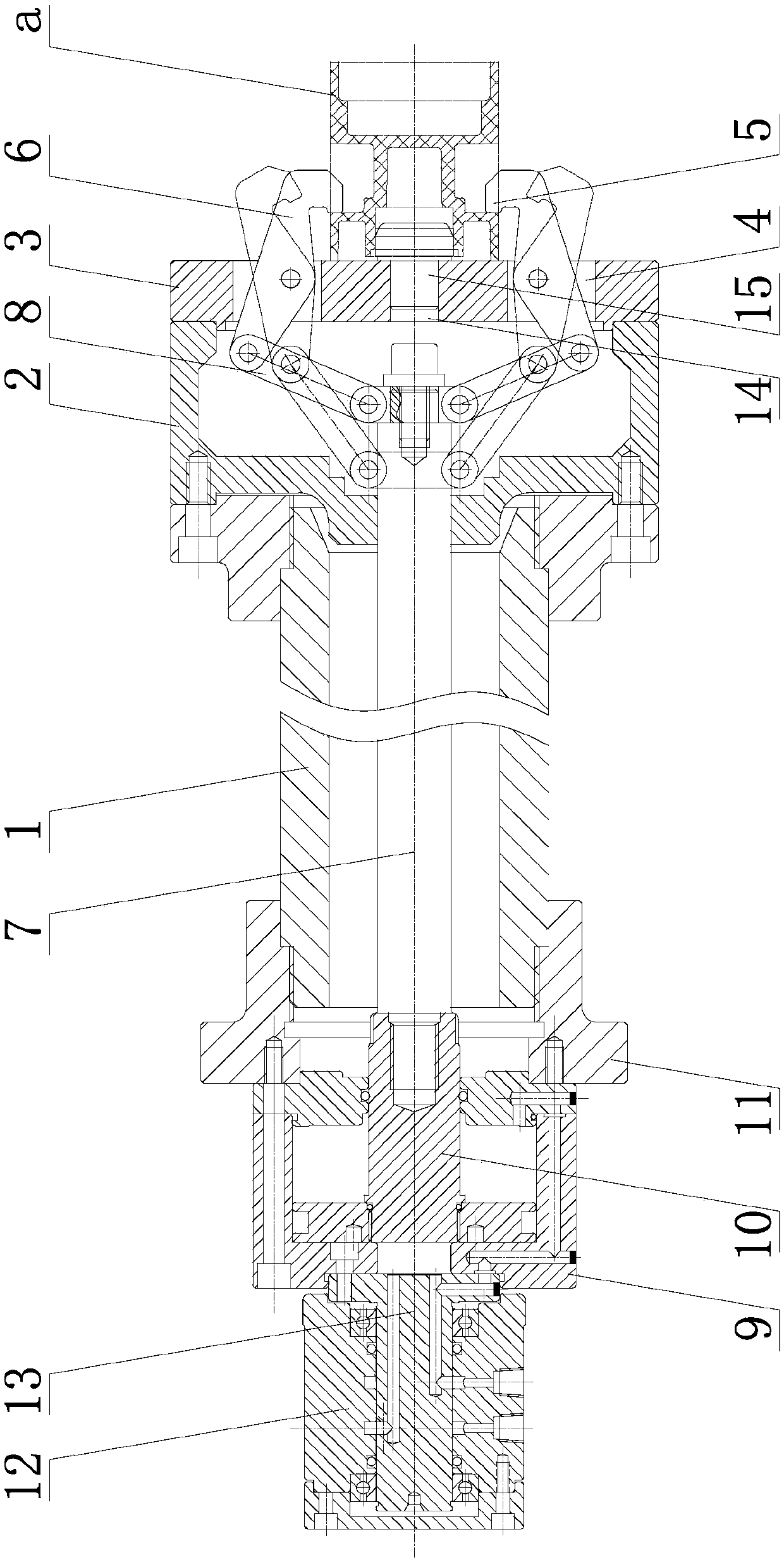

Force feedback main manipulator for minimally invasive surgery

ActiveCN110811843AReduce moment of inertiaMinus moment of inertiaDiagnosticsSurgical manipulatorsLess invasive surgeryEngineering

The invention discloses a force feedback main manipulator for minimally invasive surgery. The force feedback main manipulator comprises a first parallelogram structure, a second parallelogram structure, an attitude adjusting mechanism and a clamping mechanism; the first parallelogram structure and the second parallelogram structure are both formed by a plurality of rod pieces which are sequentially hinged end to end; a first hinging point of the first parallelogram structure is coaxial with a first hinging point of the second parallelogram structure; a second hinging point of the first parallelogram structure is connected with a second hinging point of the second parallelogram structure through a connecting rod; the tail end of the second parallelogram structure is a wrist part, wherein the wrist part can be keep horizontal under connection of the first parallelogram structure and the second parallelogram structure; the wrist part is hinged with the attitude adjusting mechanism; and the attitude adjusting mechanism is hinged with the clamping mechanism. The force feedback main manipulator provided by the invention can meet the requirements of minimally invasive surgery, conforms toergonomics, has a force feedback function and is low in cost.

Owner:SHANDONG UNIV

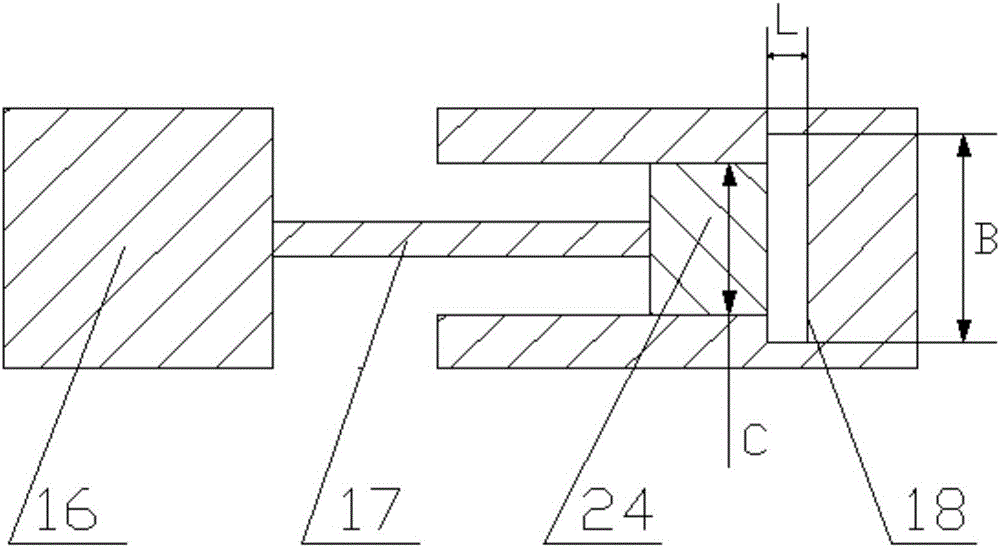

Device and method of laser impact welding in warm state

InactiveCN107252975AFor precise clampingGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesControl systemEngineering

The invention discloses a device and method of laser impact welding in a warm state. The device comprises a laser emitting system, a control system and a workpiece warm welding operation system. The workpiece warm welding operation system comprises a workpiece warm device, a base plate pressing device and a workpiece pressing device. Before-welding preheating of a workpiece is achieved through the workpiece warm device, the plasticity of the to-be-welded workpiece is improved, and the welding performance of the workpiece is improved; by means of the base plate pressing device and the workpiece pressing device, the precise clamping of the workpiece in the warm state is achieved. The device is high in precision and automation degree and wire in application range, and warm welding of various different materials can be conducted.

Owner:JIANGSU UNIV

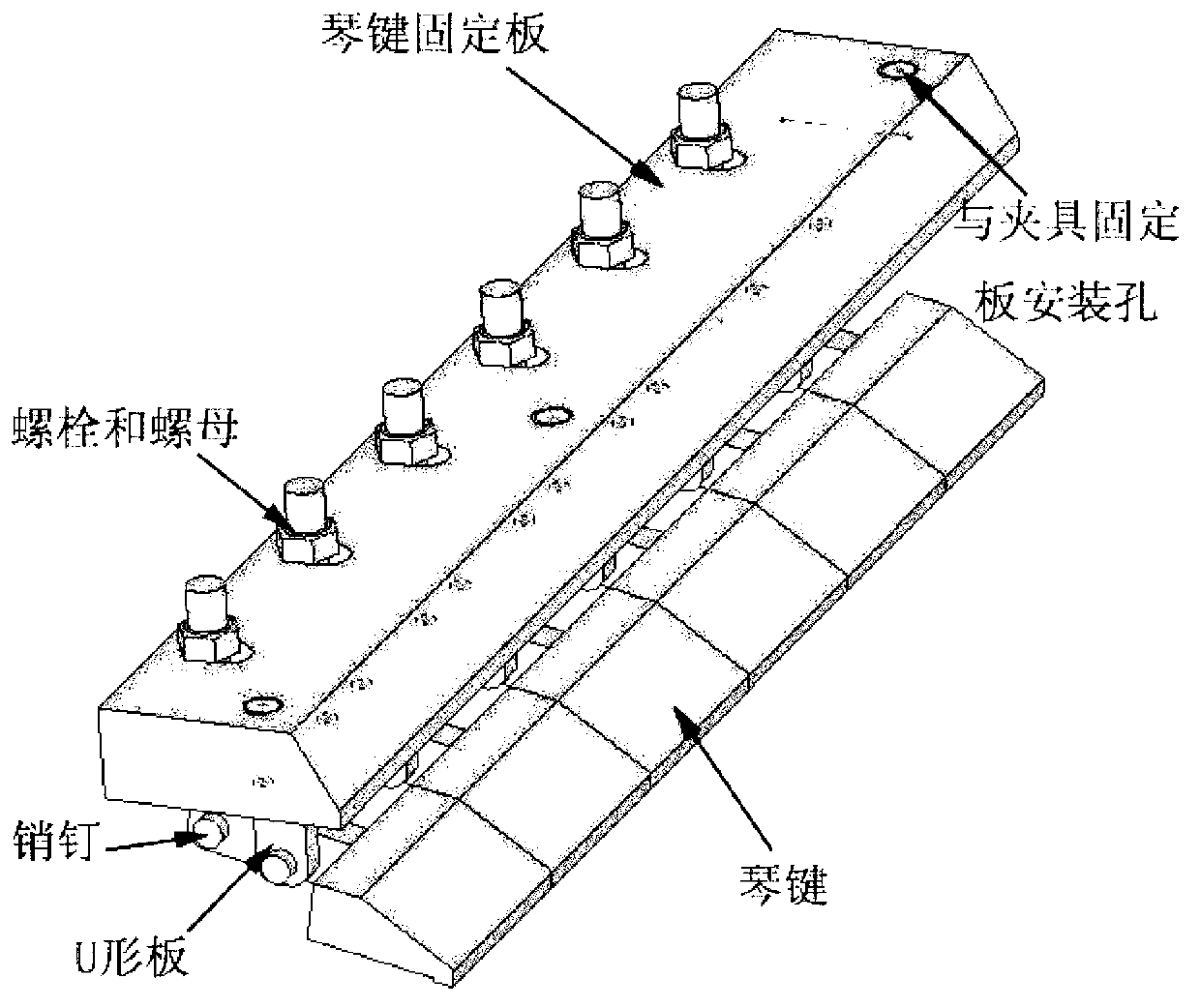

Argon tungsten-arc welding clamp for butt joint of thin steel strips and using method

InactiveCN102990266AEasy to put inEasy to take outWelding/cutting auxillary devicesArc welding apparatusButt jointEngineering

The invention discloses an argon tungsten-arc welding clamp for butt joint of thin steel strips and a using method. A clamp pressing block is based on a piano keyboard clamp and still adopts a piano keyboard pressure block by utilizing the characteristics of even clamping force and high reliability of the piano keyboard clamp, and meanwhile, a movement mechanism of the clamp is designed. Therefore, the clamp can move in a clamping process of a test specimen, so that the steel strips can be conveniently fed, clamped and taken out after being weld, so as to finish taking out of the test specimen. The defect that the traditional piano keyboard clamp cannot be used for welding long steel strips and has complicated clamping procedure is overcome, and meanwhile, the disadvantages of uneven stress of the test specimen caused in a pressing process of a lifting clamp are also overcome, and the argon tungsten-arc welding clamp has high use value.

Owner:TIANJIN UNIV

Equipment for oil pipe drilling

ActiveCN108188439AGood effectImprove efficiencyPositioning apparatusMetal-working holdersScrew threadMachining

The invention discloses equipment for oil pipe drilling. The equipment comprises a support, a supporting shaft, a drive mechanism, a supporting plate, multiple clamping portions and a drilling portion. The supporting shaft is rotationally connected with the support. The drive mechanism is used for driving the supporting shaft to rotate. The supporting plate is mounted on the supporting shaft. Themultiple clamping portions are evenly distributed with the supporting shaft as the center. Each clamping portion comprises a mounting plate, a screw, two sliding blocks and multiple clamping units, and each mounting plate is connected with the supporting plate and is provided with a sliding groove. Each screw and the corresponding mounting plate are rotationally connected, and the length directionof each screw is parallel to that of the corresponding sliding groove. Each screw is provided with two thread areas, and the rotating directions of threads of the two thread areas of each screw are opposite. The two sliding blocks of each clamping portion are in threaded connection with the two corresponding thread areas correspondingly and are in sliding connection with the corresponding slidinggroove. The multiple clamping units of each clamping portion surround the periphery of the corresponding screw. Each clamping unit comprises a clamping plate and two connecting rods, and each clamping plate is hinged to the two corresponding sliding blocks through the two corresponding connecting rods. The drilling portion is used for oil pipe drilling machining.

Owner:全椒县新华机械有限责任公司

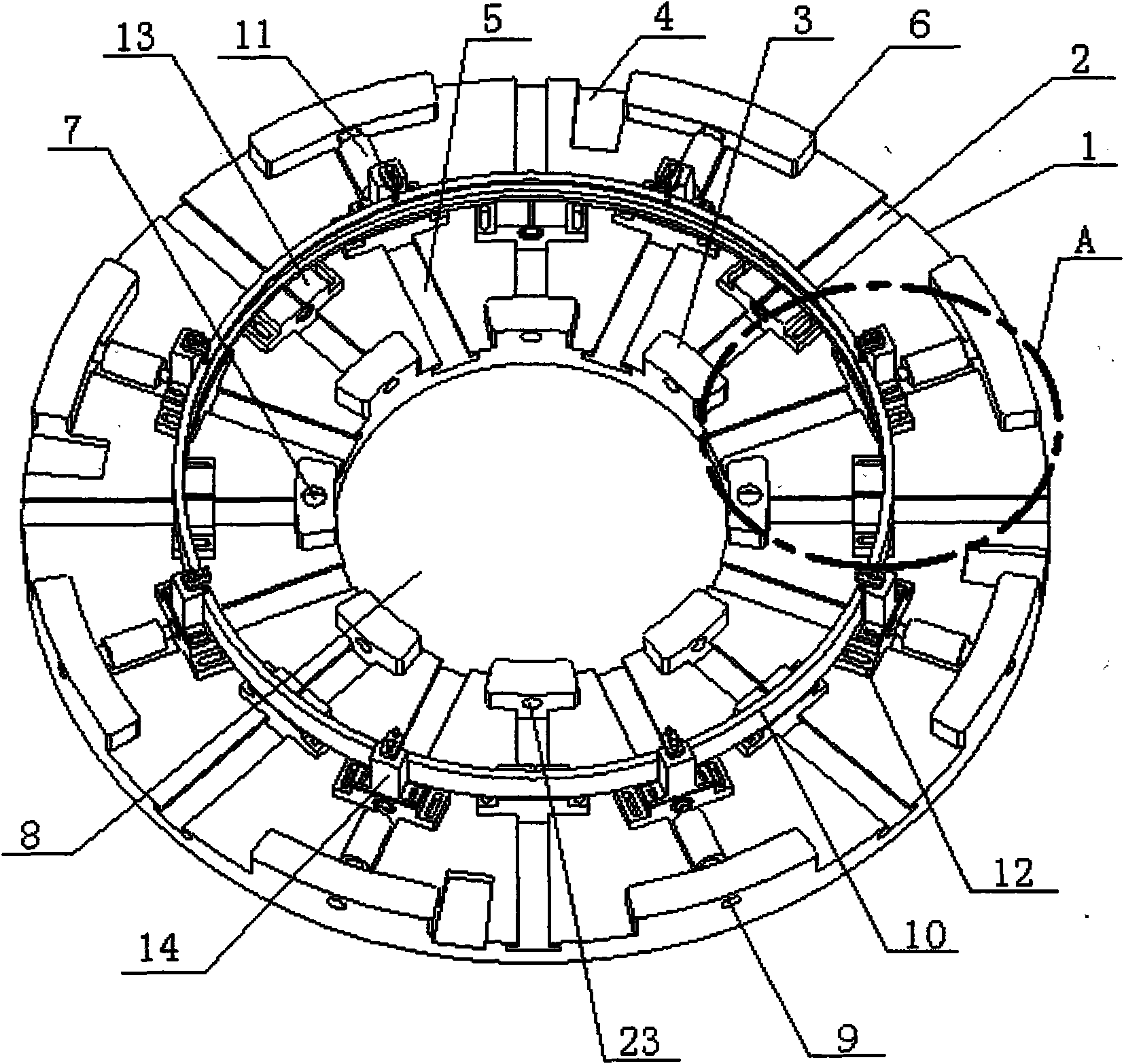

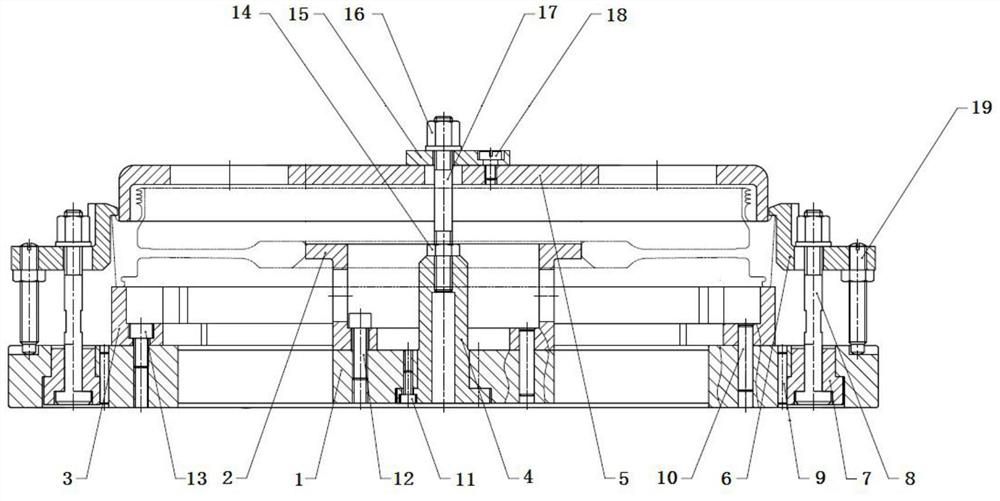

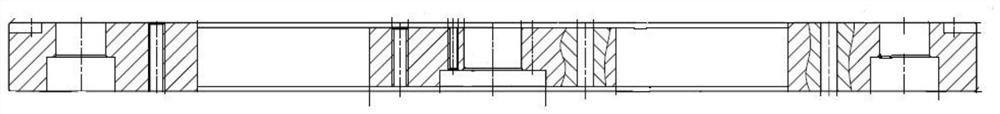

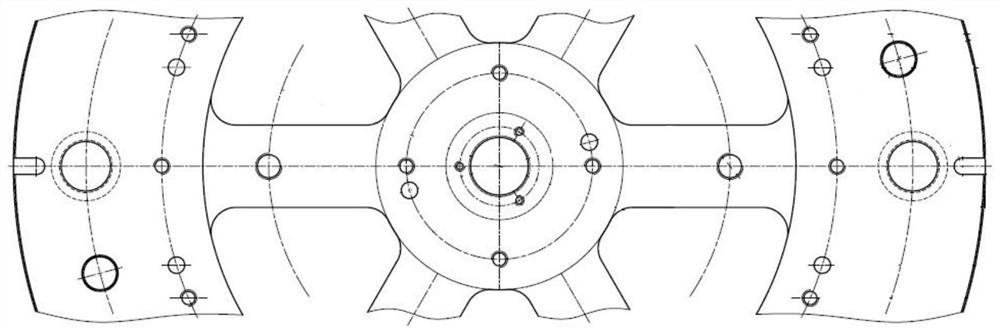

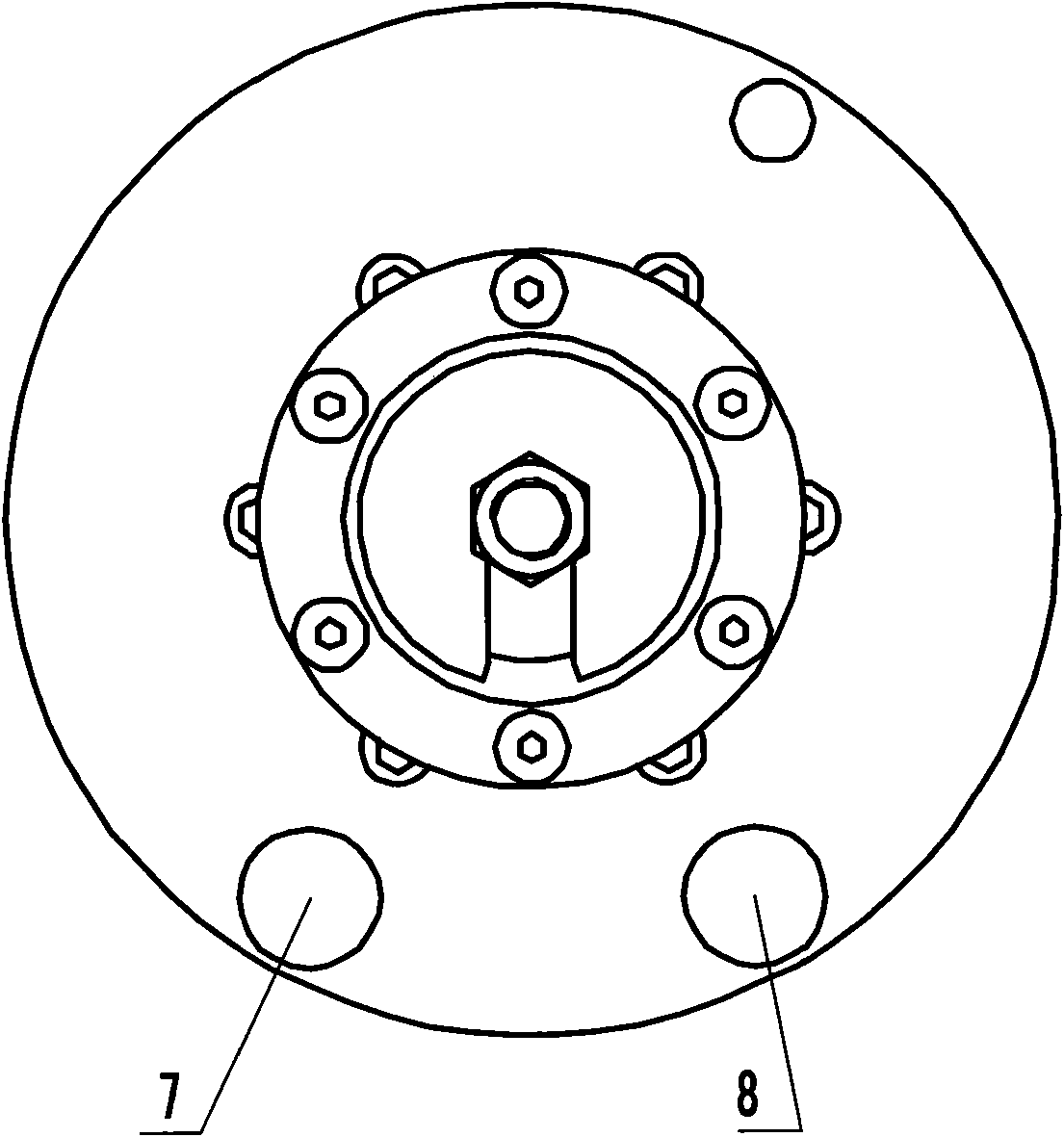

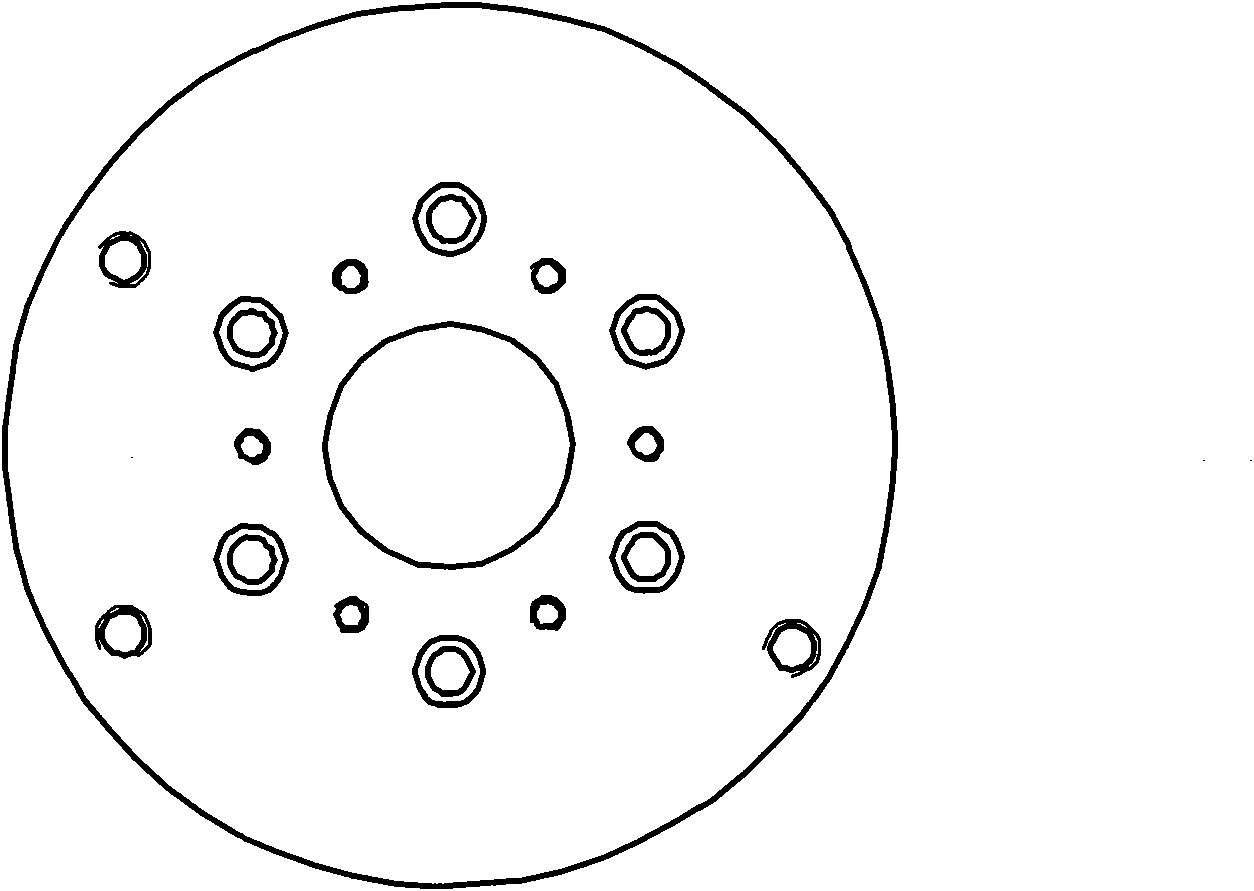

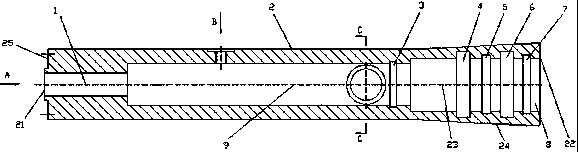

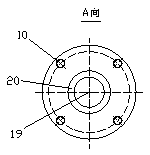

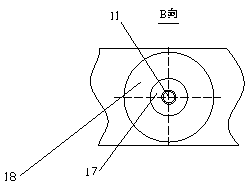

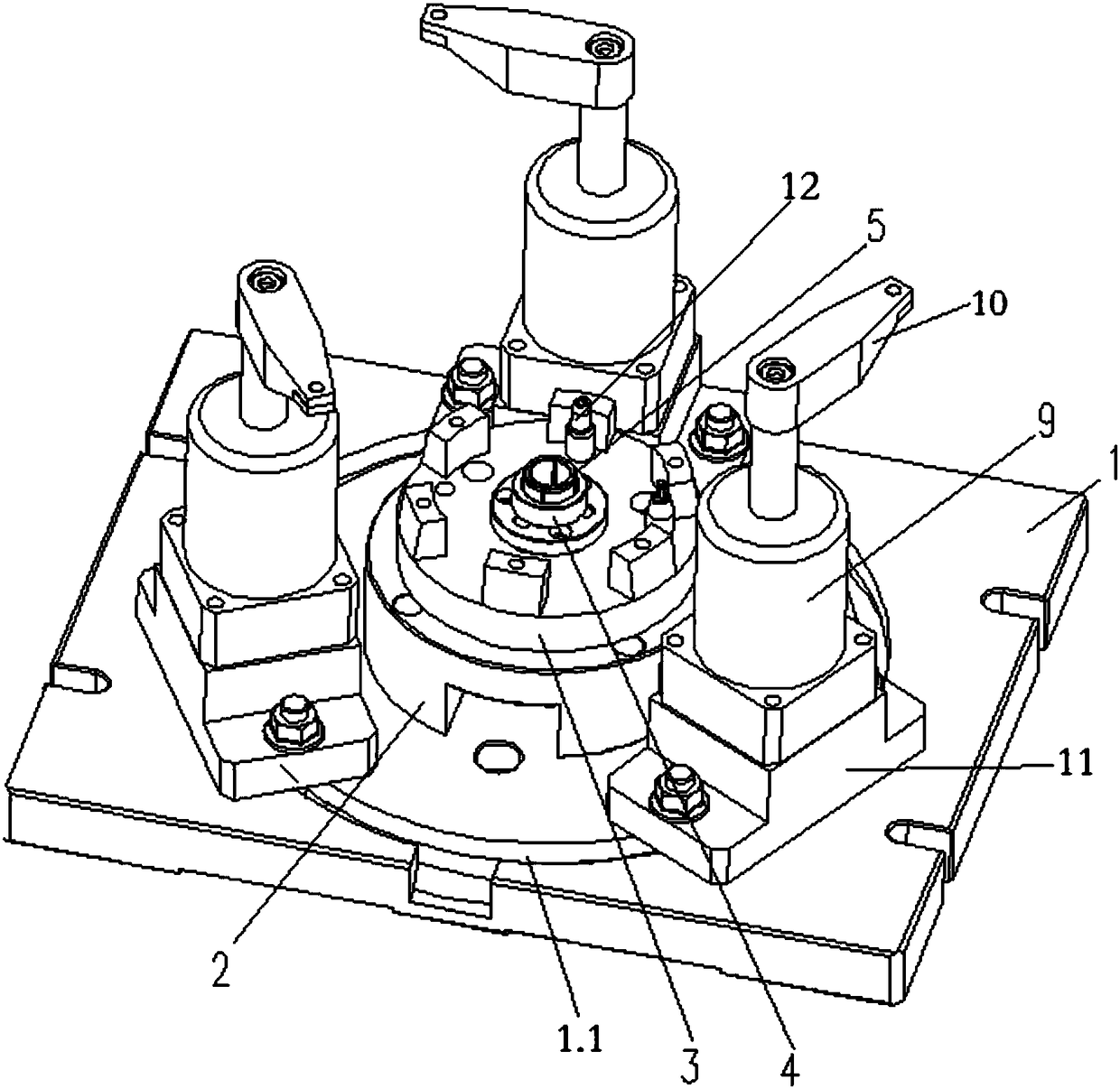

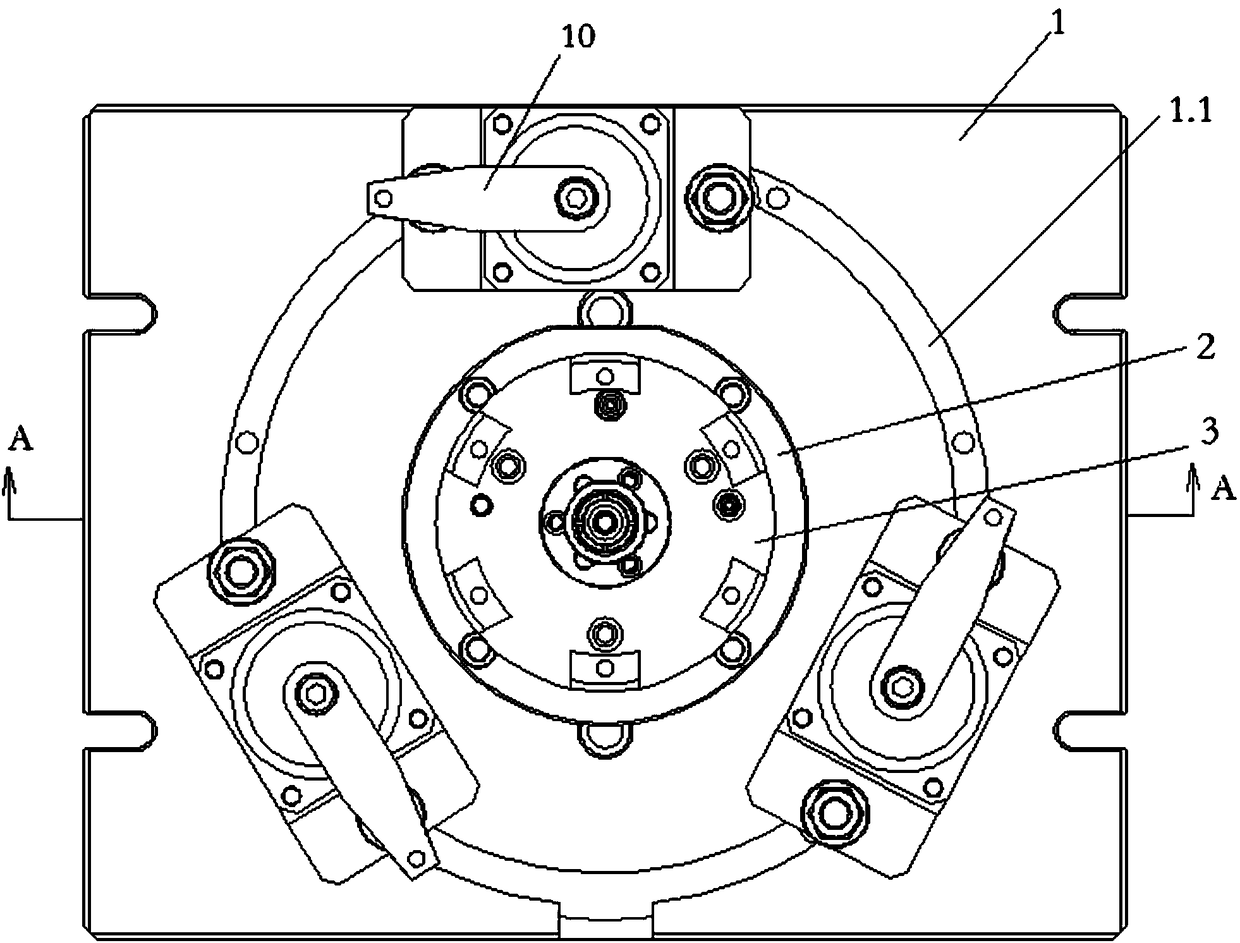

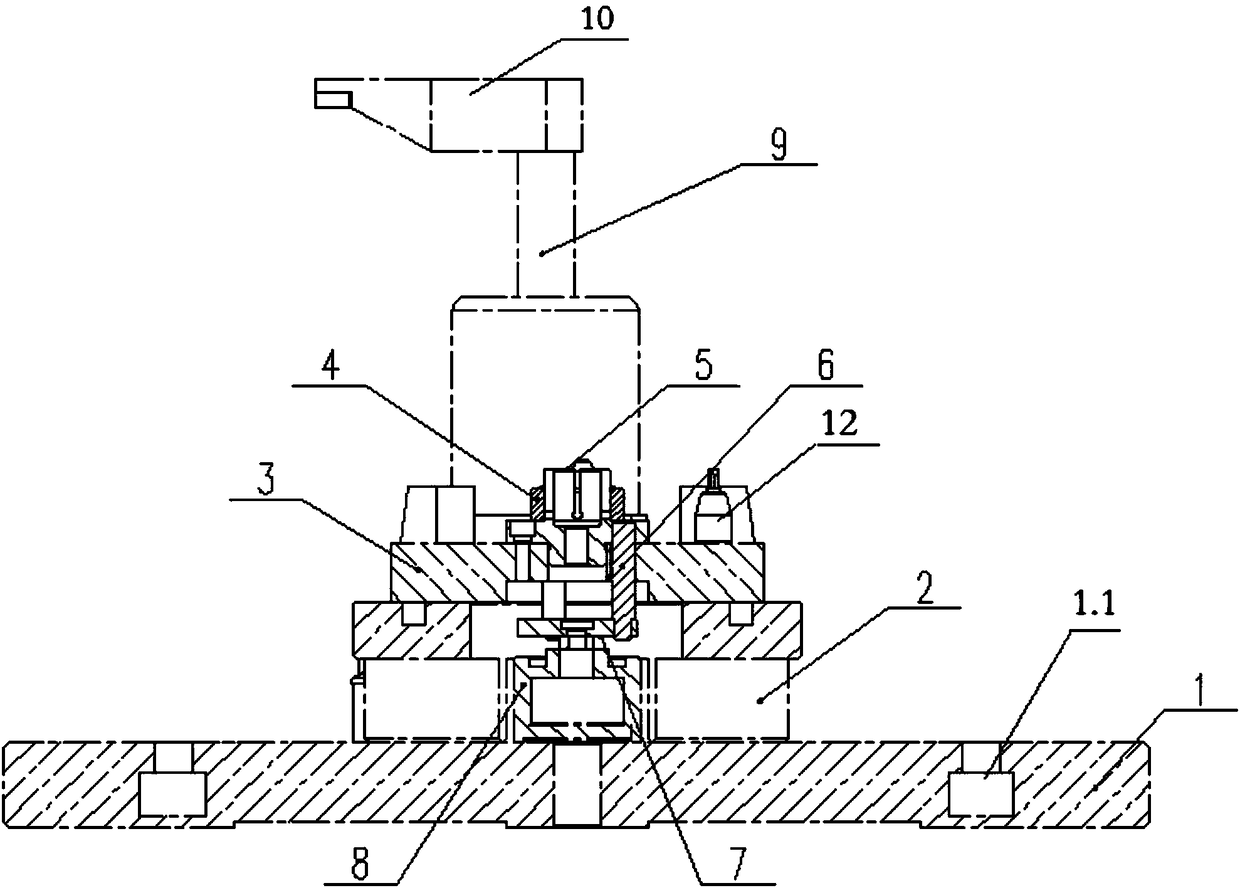

Tool for machining thin-walled disc-shaped part of aero-engine

InactiveCN112276620AReduce manufacturing costGuaranteed clamping accuracyPositioning apparatusMetal-working holdersMachine partsEngineering

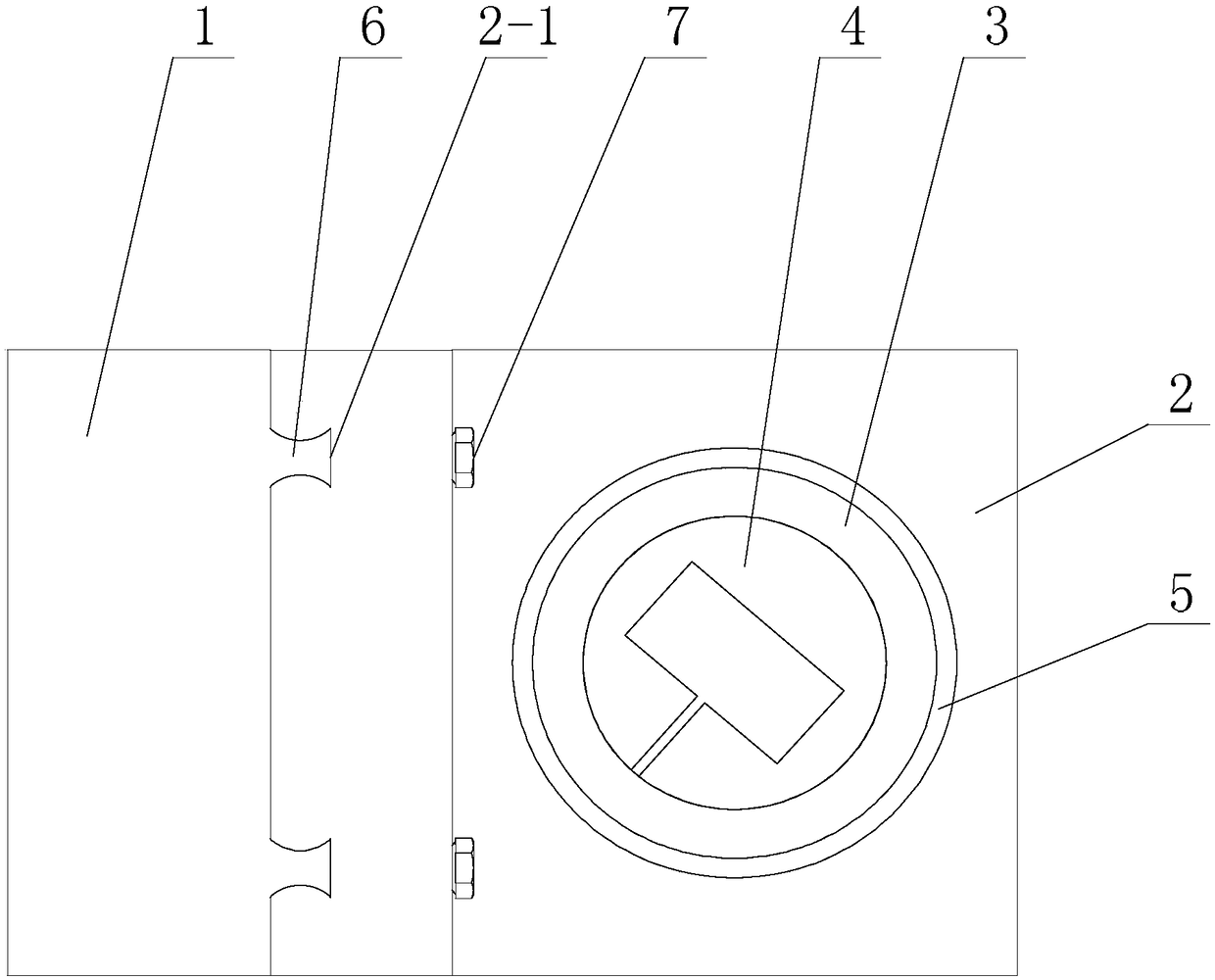

The invention discloses a tool for machining a thin-walled disc-shaped part of an aero-engine. The tool mainly comprises a C-shaped circular base, a positioning ring, a support block, a shaft, a gland, a pressing plate, bushes, bolts, second screws, third screws, a second nut and a stud. Inner hole positioning of a to-be-machined part is formed after the part is connected, so that clamping precision is guaranteed; meanwhile, when the interior of the part is turned, the gland can be removed and the pressing plate can be installed; when the excircle of the part is turned, the gland can be installed and the pressing plate can be removed; and the same clamp can be applied to two machining procedures, so that the machining precision of the part is guaranteed, and the manufacturing cost of the part clamp is reduced.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Lathe pneumatic fixture

InactiveCN108032122AGuaranteed clamping accuracyEasy to holdWork clamping meansPositioning apparatusEngineeringMechanical engineering

Owner:浙江升宏机械有限公司

Oil pipe drilling machining device

InactiveCN108188433AGuaranteed clamping accuracyGood processing effectFeeding apparatusMetal working apparatusIndustrial engineeringMachining

The invention discloses an oil pipe drilling machining device. The oil pipe drilling machining device comprises a base, a screw, two clamping parts, a drive mechanism and a drilling part. The base isprovided with a sliding groove, and the screw and the base are rotationally connected. The length direction of the screw is parallel to the length direction of the sliding groove. The screw is provided with two thread areas, and the rotation directions of threads of the two thread areas are opposite. The two clamping parts correspond to the two thread areas in a one-to-one manner. Each clamping part comprises a movable plate, an installing plate and a plurality of clamping units, wherein the movable plate is provided with a threaded hole, the movable plate and the corresponding thread area arein threaded connection through the threaded hole, the movable plate and the sliding groove are in sliding connection, the installing plate and the movable plate are rotationally connected, and the multiple clamping units are evenly distributed around the rotation center of the installing plate. Each clamping unit comprises a clamping block arranged on the corresponding installing plate. Each clamping block is in a circular platform shape, and the diameters of the clamping blocks are gradually reduced along with increasing of the distance between the clamping blocks and the installing plate. The drive mechanism is used for driving the installing plates to rotate, and the drilling part is used for oil pipe drilling machining.

Owner:全椒县新华机械有限责任公司

Device for clamping eccentric parts

InactiveCN102107367AGuaranteed clamping accuracyEasy and fast clampingAuxillary equipmentPositioning apparatusHigh volume manufacturingCoupling

The invention discloses a device for clamping eccentric parts, which relates to the field of machinery. In the existing mechanical working, when eccentric parts are processed, the operation of clamping the eccentric parts is difficult, the working accuracy is not easy to guarantee, and the qualification rate of finished products is low, therefore, the existing eccentric-part clamp device is not suitable for batch production. The device disclosed by the invention comprises a coupling disk, a mandrel, a clamp bolt, a stop pin, a counter-weight block, an open washer and a nut, wherein the mandrel is embedded in a hollow cavity of the coupling disk, the clamp bolt is in threaded connection with the mandrel, the open washer is used for adjusting the position of the mandrel relative to the coupling disk, the nut is used for fixing the coupling disk, the counter-weight block is used for balancing workpieces, and the stop pin is used for positioning. The device disclosed by the invention is an eccentric-part clamp device with a simple structure and easily-guaranteed working accuracy, and has the advantages of wide application scope, high operating efficiency, simplicity in installation, capability of being applied in batch production, and the like.

Owner:杨元昌

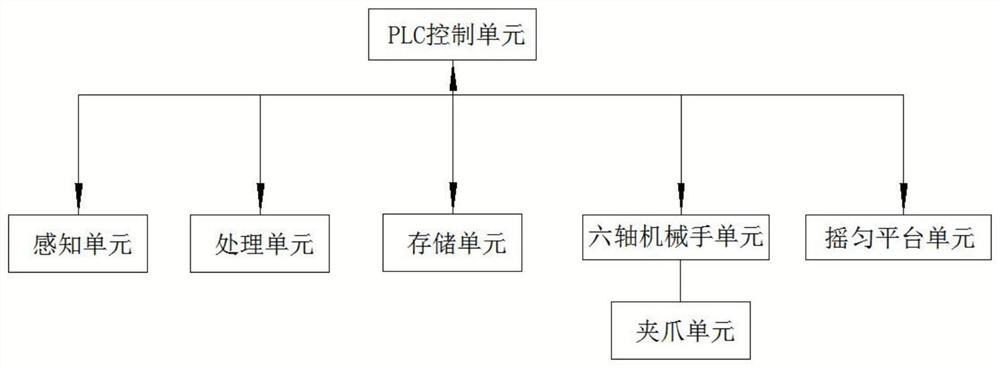

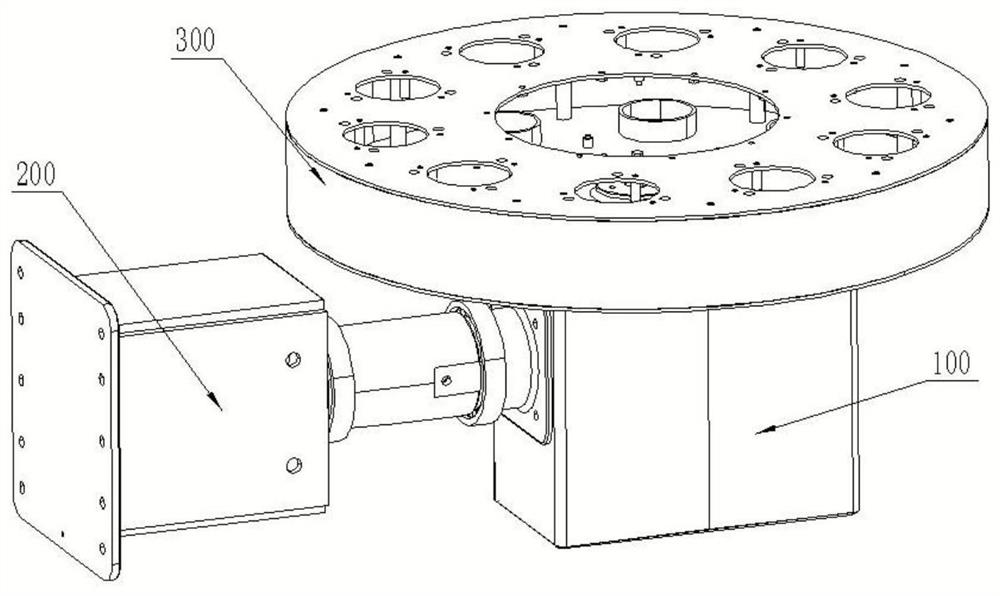

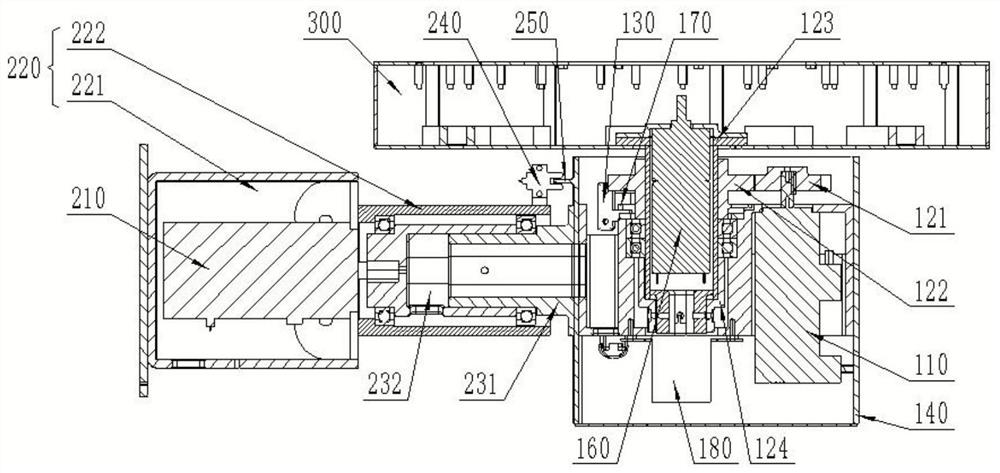

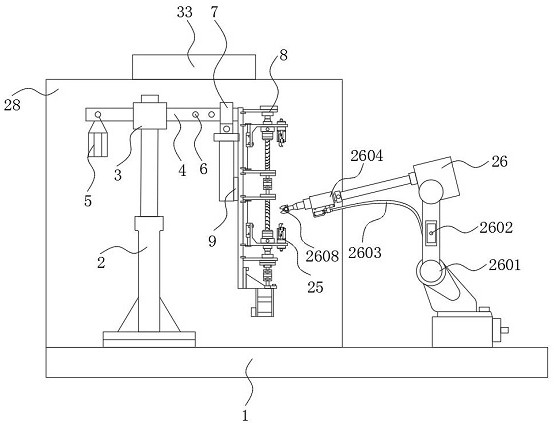

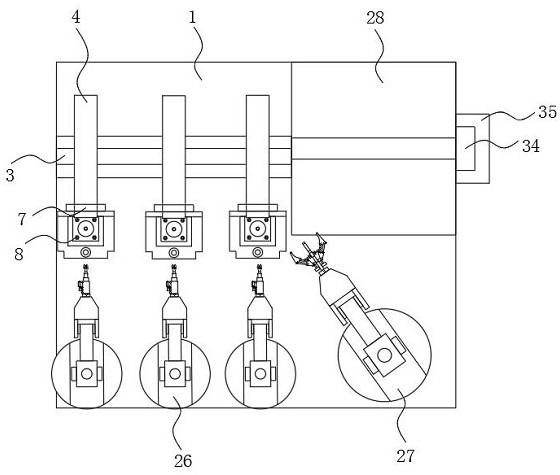

Automatic liquid preparation system and method based on industrial robot

ActiveCN113001564ARelieve stressImprove dosing efficiencyProgramme-controlled manipulatorGripping headsMedical equipmentPenicillin

The invention belongs to the technical field of medical equipment, particularly relates to an automatic liquid preparation system and method based on an industrial robot, and aims at solving the problems that an existing liquid preparation system is low in automation degree and poor in precision. The system comprises a sensing unit, a storage unit, a processing unit, a PLC control unit, a six-axis mechanical arm unit, a shaking platform unit and a clamping jaw unit arranged at the end of the six-axis mechanical arm unit. The six-axis mechanical arm unit drives the clamping jaw unit to extract liquid in a liquid bag; the sensing unit is used for detecting the types of penicillin bottles and transmitting information to the processing unit; the processing unit is matched with a preset instruction in the storage unit based on the acquired information; and the PLC control unit issues an instruction of whether to start the six-axis mechanical arm unit to extract liquid or prepare liquid and issues an instruction of whether to start the shaking platform unit based on the matching information acquired by the processing unit. According to the automatic liquid preparation system and method based on the industrial robot, automatic and accurate liquid preparation of the penicillin bottles can be realized, manual participation is effectively reduced, and the working efficiency is improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

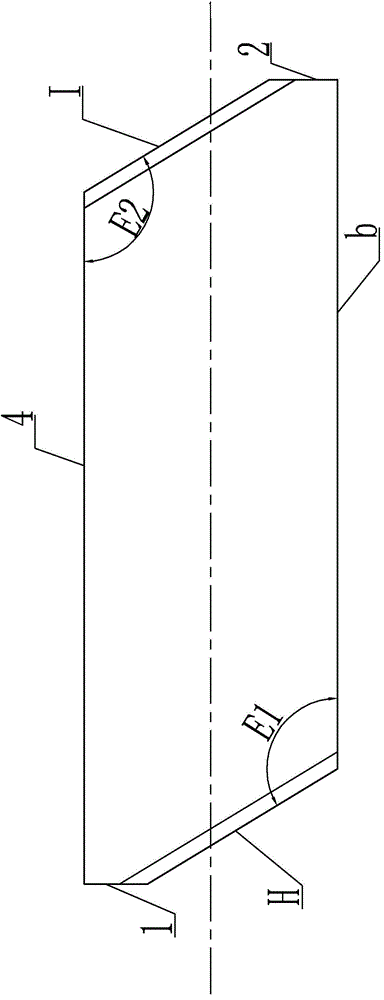

Machining technology for batch production of thin and long deep-hole complex parts

The invention discloses a machining technology for batch production of thin and long deep-hole complex parts. The machining technology is characterized by sequentially comprising the following steps that 1, a blank is prepared; 2, the small end of each part is clamped, and the middle section of the part is turned as a technological external circle (2), the large-diameter end face is turned as a technological positioning face (22), and a positioning sleeve is used for positioning during clamping; 3, the technological positioning face (22) is used as a benchmark, the large-diameter end of the part is clamped, the end face and external circle of the small-diameter end are turned, and an inner hole of the small-diameter end is drilled; 4, the small-diameter end of the part is clamped, the steps that the large-diameter end external circle is turned, an inner hole is roughly turned, the inner hole is finely turned and an inner-side groove is turned are sequentially executed, and the positioning sleeve is used for positioning during clamping; 5, the technological positioning face (22) is used as the benchmark, the large-diameter end of the part is clamped, a machining center is used for milling all end faces, a polished hole and a screw hole are formed in the part, and a positioning block is used for positioning during clamping. During workpiece clamping, a special tool is used for clamping and positioning, and therefore the clamping precision and efficiency are improved.

Owner:CHINA UNIV OF MINING & TECH

Positioning and clamping tool for aircraft part machining

The invention provides a positioning and clamping tool for aircraft part machining. The positioning and clamping tool comprises a bottom plate, wherein a mounting structure is fixedly arranged at the top of the bottom plate through screws; the mounting structure further comprises through grooves, limiting holes, sliding grooves, a through hole and a mounting plate; four limiting holes are formed in the mounting plate in a penetrating mode, and the through hole is formed in the center of the mounting plate in a penetrating mode; the through grooves are formed in the mounting plate in a left-right symmetrical penetrating mode, and the sliding grooves are formed in the mounting plate in a front-back symmetrical mode; a fixing plate is fixedly arranged at the top of the mounting plate through screws; and a fixing device is fixedly arranged at the center position of the top of the bottom plate through screws. According to the positioning and clamping tool, a top plate is mounted more firmly through the through grooves and the limiting holes, so that aircraft parts are prevented from shaking during machining, and the machining precision of the parts is guaranteed. A sliding block slides by pulling a handle I, and a worker can adjust according to the heights of different parts, so that the device can machine the parts with different heights.

Owner:哈尔滨安宇迪航空工业有限公司

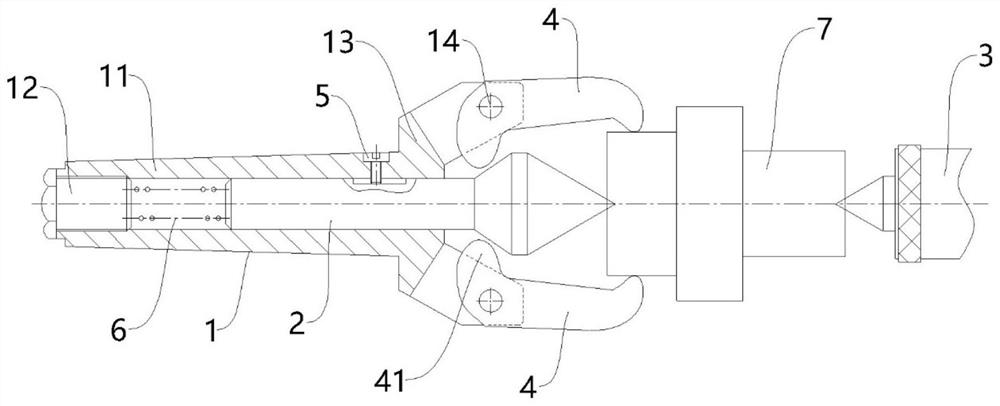

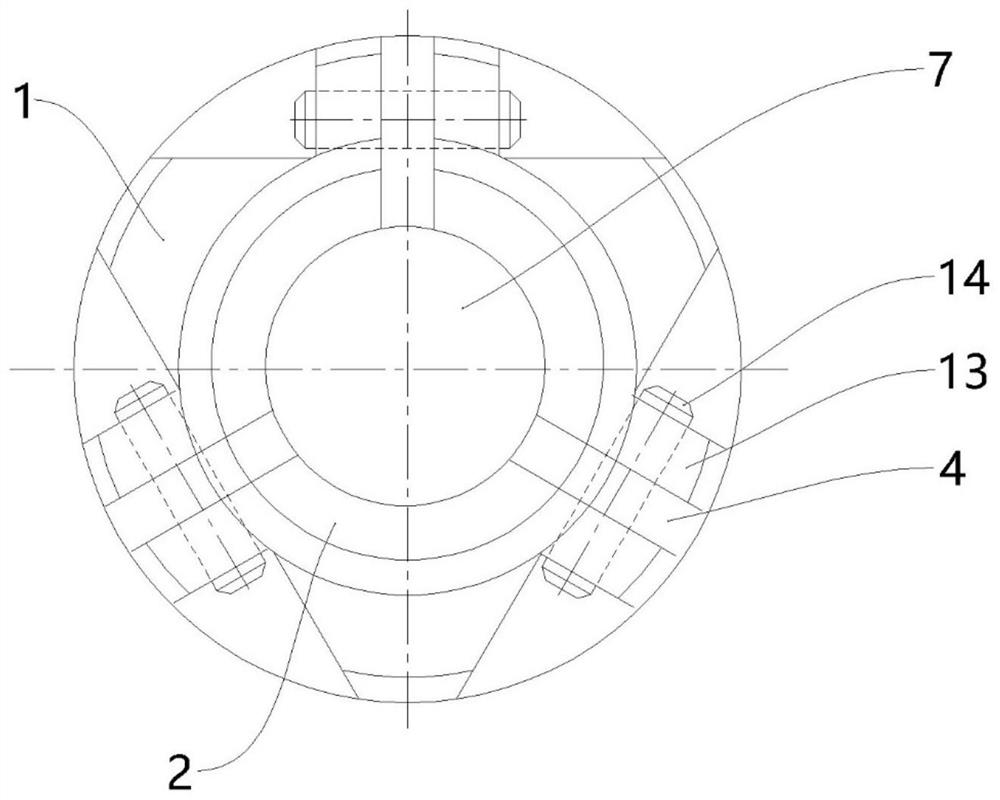

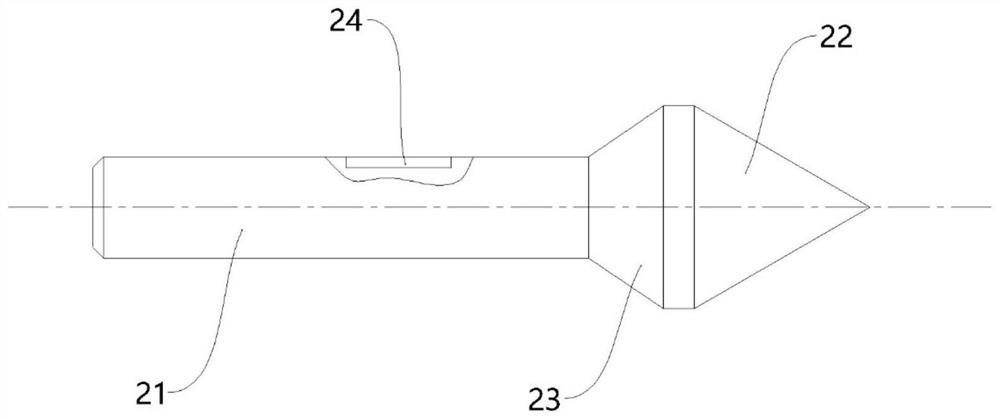

Novel cutting fixture

PendingCN112570741AEasy to disassembleGuaranteed clamping forceTailstocks/centresChucksEngineeringCam

The invention relates to the technical field of machining, and discloses a novel cutting fixture. The fixture comprises a fixture body, a centering centre and a live centre; the centering centre and the live centre are coaxially arranged; the centering centre is axially and movably inserted into the fixture body; an elastic piece for elastically supporting the centering centre is arranged at the tail end of the fixture body; a clamping jaw is further rotationally assembled on the fixture body; the front end of the clamping jaw is defined as a clamping end, and the tail end is defined as a driving end; a cam is formed at the driving end; the centering centre is provided with a jacking slope for jacking the cam during axial movement; the clamping jaw is provided with a clamping position forenabling the jacking inclined surface to jack the cam to enable the clamping end to clamp the workpiece and a releasing position for enabling the jacking inclined surface to be separated from the camto enable the clamping end to release the workpiece in the rotating stroke. When the workpiece is machined, the jacking inclined surface of the centering centre jacks the cam, the clamping end of theclamping jaw clamps the workpiece in the radial direction, the larger the movement amount of the centering centre is, the larger the clamping force of the clamping jaw is, clamping is completed whilethe clamping force is guaranteed, the clamping speed and efficiency are improved, and meanwhile, the clamping precision is guaranteed.

Owner:GUANGZHOU CITY POLYTECHNIC

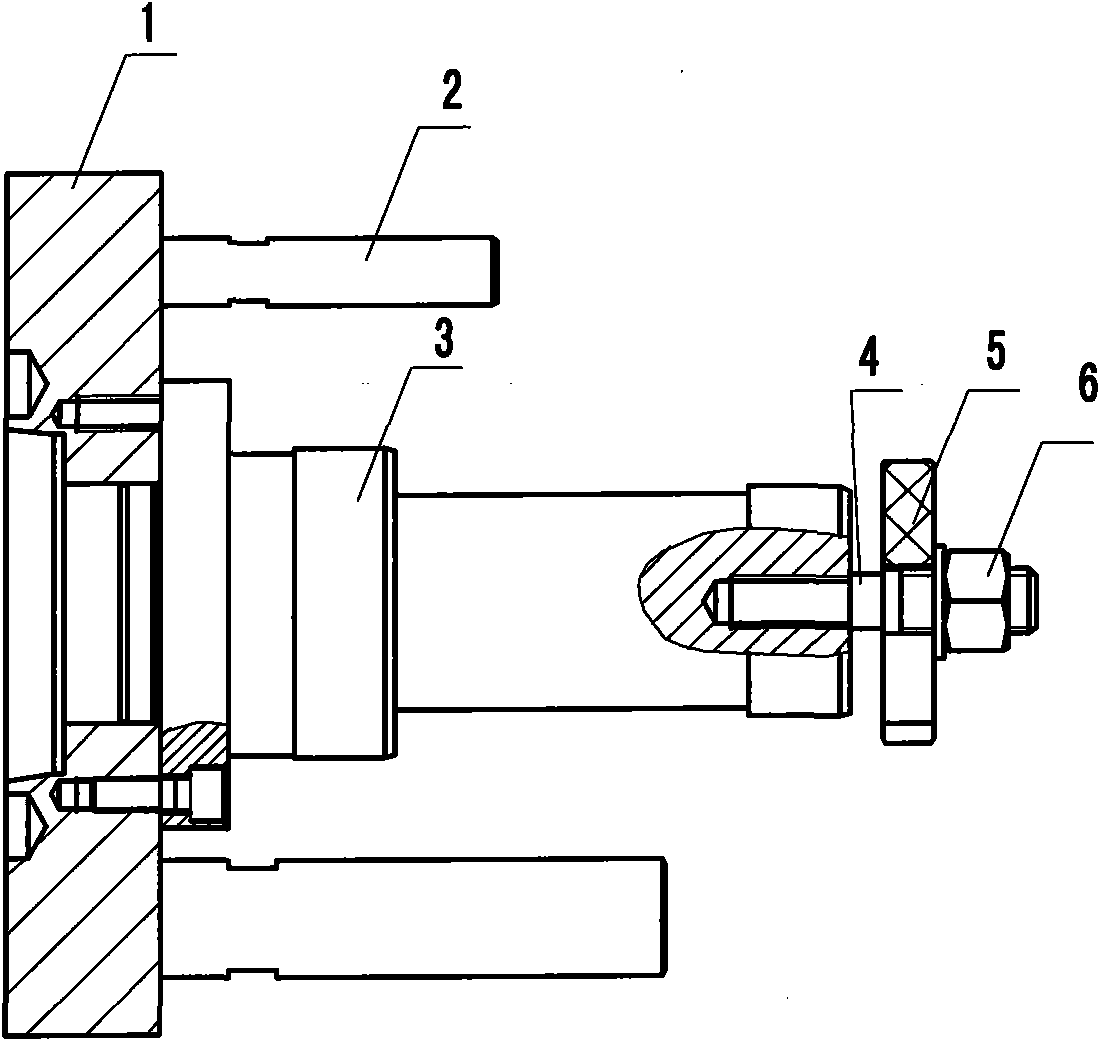

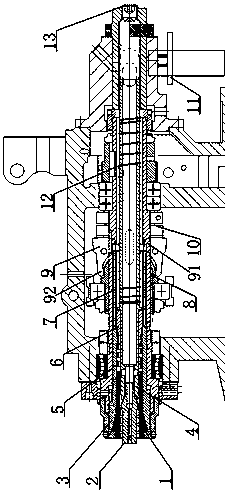

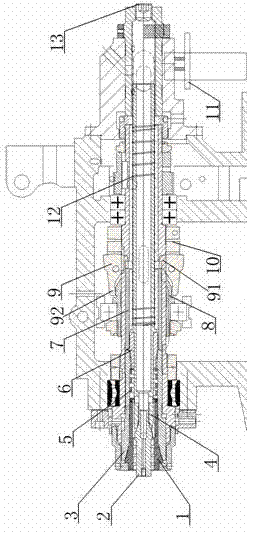

Automatic discharge device for back spindle

InactiveCN108788838ARealize automatic nestingSimple and fast operationPositioning apparatusMetal working apparatusProcess efficiencyEngineering

The invention discloses an automatic discharge device for a back spindle. The automatic discharge device comprises an elastic chuck, an ejector pin, a chuck sleeve and a bar charge hole, wherein the ejector pin is positioned in the elastic chuck; the elastic chuck is positioned in the chuck sleeve; the ejector pin is in threaded connection with a pushing rod I; the chuck sleeve is in threaded connection with a limiting sleeve; a return spring is arranged between the elastic chuck and the limiting sleeve; one end, close to the bar charge hole, of the chuck sleeve is in contact with a pushing rod II; the other end of the pushing rod II is in contact with a short arm of an opening-closing claw; a long arm of the opening-closing claw is in contact with a pneumatic performer; an ejecting springis arranged between the elastic chuck and the bar charge hole; and one side of the bar charge hole is equipped with an inducting switch. The automatic discharge device realizes an automatic chargingfunction and an automatic discharge function of the back spindle, is simpler and more convenient to operate, and is higher in processing efficiency.

Owner:HUBEI YIXING INTELLIGENT EQUIP CO LTD

Back spindle automatic discharging device

InactiveCN103028988ARealize automatic nestingSimple and fast operationPositioning apparatusMetal working apparatusEngineeringShort arms

The invention relates to a back spindle automatic discharging device which comprises an elastic chuck, an ejector pin, a chuck sleeve and a bar feed inlet. The ejector pin is positioned in the elastic chuck; the elastic chuck is positioned in the chuck sleeve; the ejector pin is in threaded connection with a first push rod; the chuck sleeve is in threaded connection with a limiting sleeve; a return spring is arranged between the elastic chuck and the limiting sleeve; one end of the chuck sleeve, which is close to the bar feed inlet, is in contact with a second push rod; the other end of the second push rod is in contact with a short arm of an opening and closing jaw; a long arm of the opening and closing jaw is in contact with a pneumatic actuator; an ejector spring is arranged between the elastic chuck and the bar feed inlet; and one side of the bar feed inlet is provided with an inductive switch. According to the invention, functions of automatically clamping and discharging a back spindle are implemented; and the back spindle automatic discharging device is simpler and more convenient to operate and has higher processing efficiency.

Owner:陈胜喜

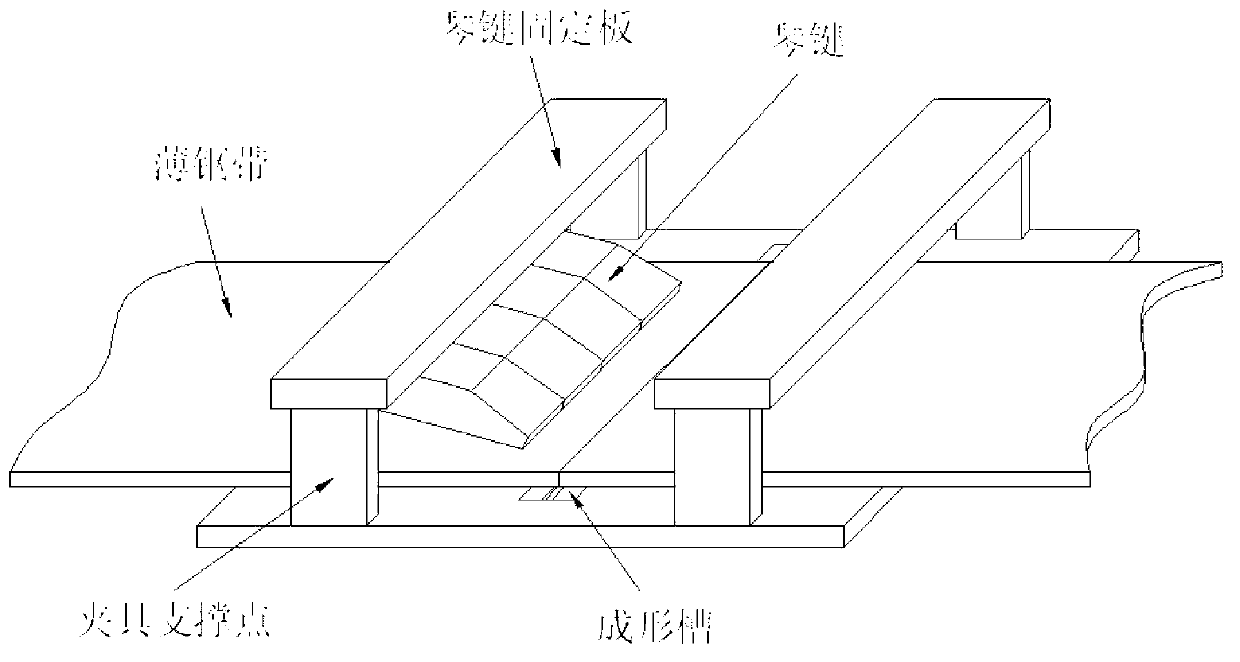

Device for incremental bending forming of metal foil plate based on laser shocks and method of device

The invention discloses a device for incremental bending forming of a metal foil plate based on laser shocks and a method of the device. The device comprises a laser emission system, a control system and a workpiece deformation operation system. The workpiece deformation operation system comprises a workpiece system, a workpiece clamping device, a mask system and a water supply system. According to the device, accurate clamping of workpieces is achieved through the workpiece clamping device, the laser incremental shock forming accuracy is guaranteed, and masks in different shapes are used for changing the shapes of laser spots so as to adapt to workpiece shock incremental forming of any shape or requirement. The device is high in accuracy and automation degree and wide in application range, and accurate shock forming of the multiple workpieces can be achieved.

Owner:JIANGSU UNIV

High-efficiency oil tube machining device

InactiveCN107999819AImprove efficiencyGood effectLarge fixed membersPositioning apparatusGear wheelFixed frame

The invention discloses a high-efficiency oil tube machining device which comprises a support, a supporting shaft, a drive mechanism, a supporting plate, a fixed frame, a driving gear, multiple clamping portions and a drilling portion. The supporting shaft is rotationally connected with the support. The drive mechanism is used for driving the supporting shaft to rotate. The supporting plate is mounted on the supporting shaft. The driving gear is located on the side, away from the supporting shaft, of the supporting plate and is connected with the fixed frame, and the center line of the drivinggear coincides with the axis of the supporting shaft. The multiple clamping portions surround the periphery of the driving gear, each clamping portion comprises a driven gear and a clamping unit, andthe driven gears are rotationally mounted on the supporting plate and are engaged with the driving gear. The clamping units are connected with the driven gears and used for clamping oil tubes. The drilling portion is used for carrying out drilling machining on the oil tubes.

Owner:全椒县新华机械有限责任公司

Machining method of wedge-groove gauge

ActiveCN104827248AGuaranteed clamping accuracyGuaranteed accuracy requirementsMechanical measuring arrangementsNumerical controlCircular cone

Provided is a machining method of a wedge-groove gauge. The invention relates to the machining method of the wedge-groove gauge with the purpose of solving problems in the prior art such as complicated operation for measuring machining precision of a wheel disc dovetail groove and inaccurate measurement. In order to solve such problems, the method is realized by adopting following steps: firstly, discharging: selecting rectangular workblank 230 mm long, 80 mm wide and 50 mm high; secondly, rough mill and precision grinding; thirdly, milling end surfaces including a first oblique plane and a second oblique plane; fourthly, machining a circular conical surface by utilization of a numerical control milling machine; fifthly, machining a workpiece. The operation for machining the workpiece further comprises following steps of installing workblank onto a wire cutting machine and machining the bottom surface of the workpiece. Therefore, two vertical surfaces are machined between the bottom surface of the workpiece and the circular conical surface. A protrusion is machined between each one of the two vertical surfaces and the bottom of the workpiece and comprises a first protruding oblique plane and a second protruding oblique plane, by means of which each vertical surface is connected with the bottom surface of the workpiece in order. The machining method of the wedge-groove gauge is used for the machining field of wedge-groove gauges.

Owner:HARBIN TURBINE +1

Adjustable clamp for high-speed friction and and wear testing machine

InactiveCN108152126AHigh positioning accuracyImprove accuracyStrength propertiesWear testingEngineering

The invention provides an adjustable clamp for a high-speed friction and wear testing machine, relates to a clamp for a wear testing machine, and particularly relates to an adjustable clamp for the ahigh-speed friction and wear testing machine. The invention aims to solve the problems that an existing clamp for thea friction and wear testing machine can not realize horizontal movement and can notrealize friction and wear test clamping of a machining cutter at any angle. The clamp provided by the invention comprises a connecting block, a mobile station, a clamp sleeve and a friction model sleeve, wherein the connecting block is connected with one end of the mobile station, the clamp sleeve is vertically mounted on the mobile station, and the friction model sleeve is inserted in the clampsleeve. The clamp provided by the invention belongs to the field of machinery.

Owner:HARBIN UNIV OF SCI & TECH

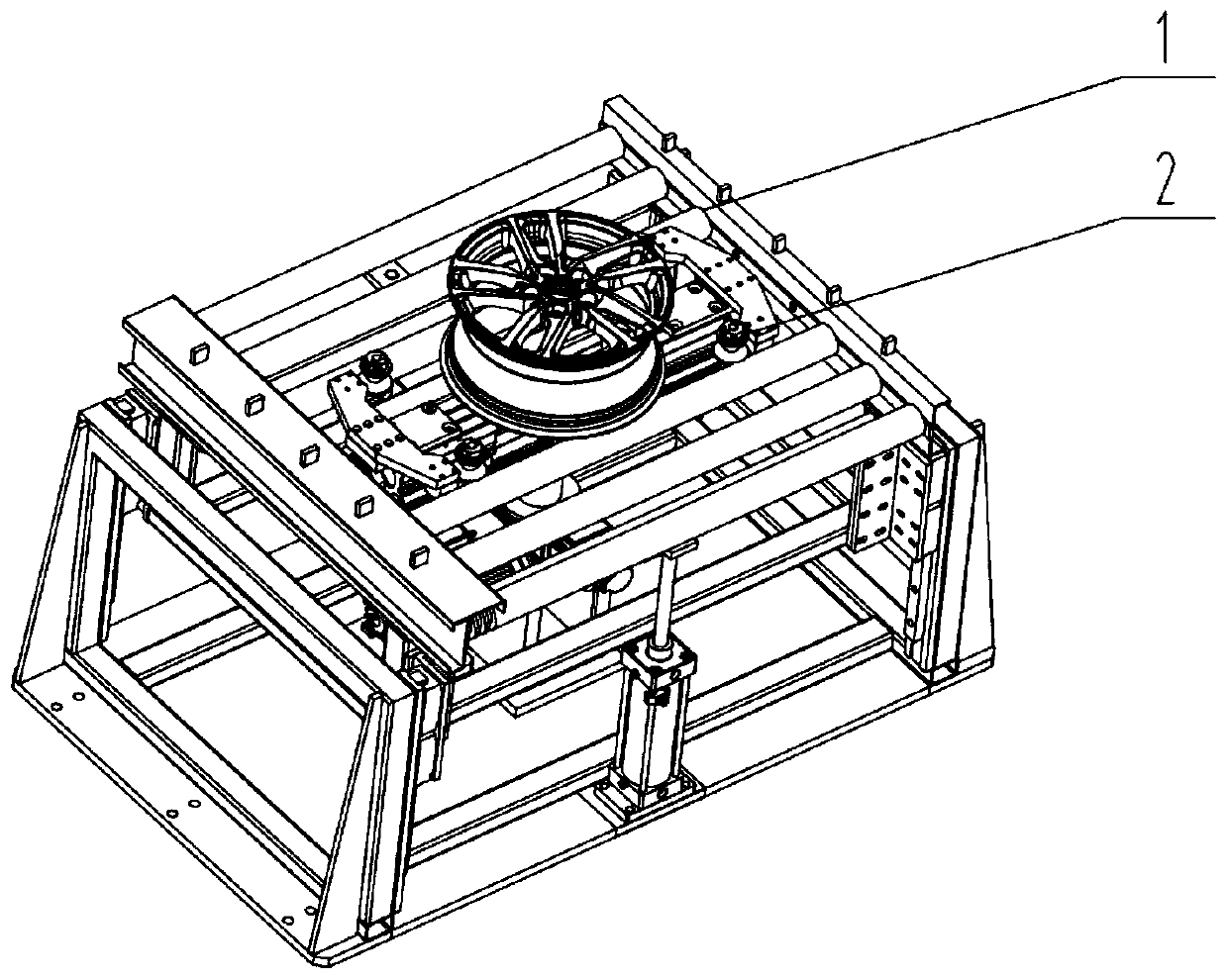

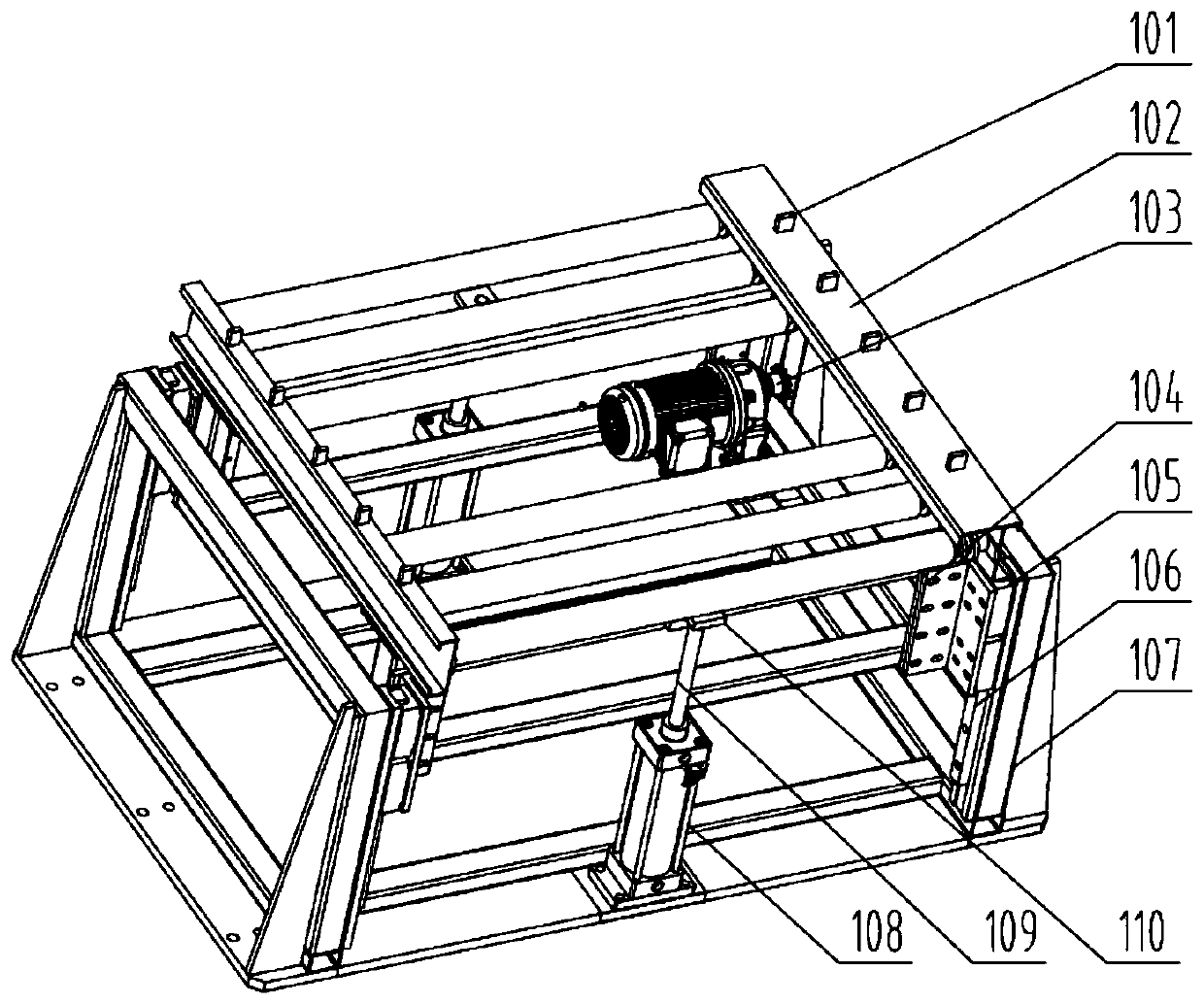

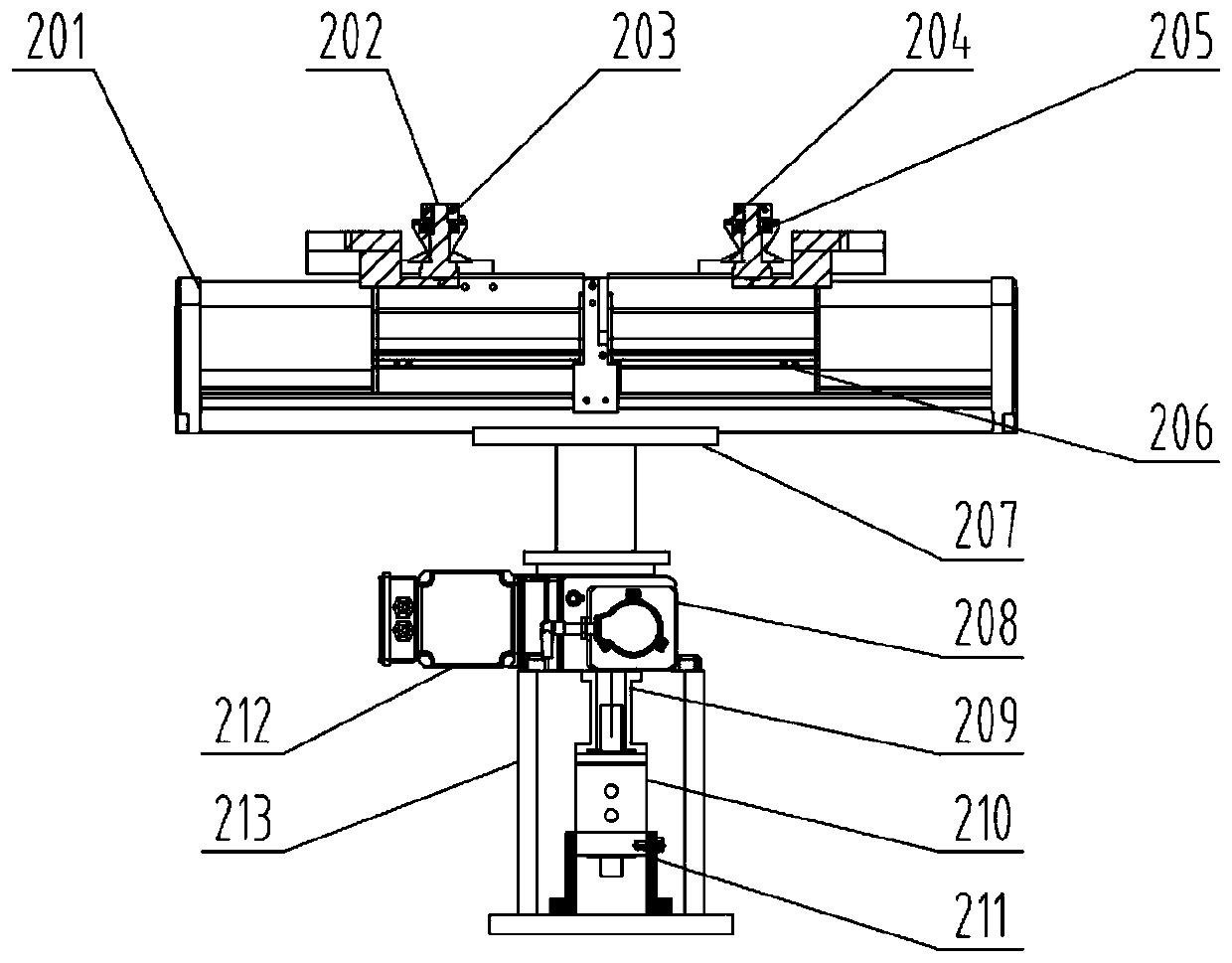

Through type arbitrary-angle rotating clamp for aluminum wheel

PendingCN111069952AGuaranteed to be in balanceMaintain balancePositioning apparatusMetal-working holdersElectric machineryEngineering

The invention discloses a through type arbitrary-angle rotating clamp for an aluminum wheel. The through type arbitrary-angle rotating clamp for the aluminum wheel is composed of a conveying assemblyand a positioning assembly, wherein a roller path in the conveying assembly conveys a wheel to a designated position detected by a photoelectric switch; a V wheel in the positioning assembly positionsand supports the wheel; the roller path is pulled to the lower position along a linear guide rail through a piston rod; a motor B drives a cam divider and the V wheel on the cam divider to position the wheel to rotate to an arbitrary angle for machining operation; and after machining is completed, the piston rod pushes the roller path to the upper position along the linear guide rail, the V wheelin the positioning assembly loosens the wheel, the roller path conveys the wheel out, and the next working cycle is started. The through type arbitrary-angle rotating clamp for the aluminum wheel aims at achieving the positive effects that the deburring design is adopted for an aluminum wheel window, the labor cost is saved, the labor intensity is relieved, the automation degree is improved, andthe positive effects are achieved in the hub machining work.

Owner:QINHUANGDAO XINYUE INTELLIGENT EQUIP CO LTD

Automobile air conditioner compressor cylinder block boring machining tool

PendingCN108188797AAvoid destructionGuaranteed push out point of actionPositioning apparatusMaintainance and safety accessoriesAutomobile air conditioningEngineering

The invention provides an automobile air conditioner compressor cylinder block boring machining tool. The automobile air conditioner compressor cylinder block boring machining tool comprises a bottomplate. A base is fixedly arranged in the middle of the bottom plate. A pressing air cylinder is fixedly arranged on the part, located on the periphery of the base, of the bottom plate. A pressing plate is connected with a piston rod of the pressing air cylinder. A positioning ring is fixedly arranged at the top end of the base. An elastic mandrel is fixedly arranged in the center of the positioning ring. A pushout ring is movably arranged on the periphery of the elastic mandrel in a sleeving mode. A lifting air cylinder is fixedly arranged in a center hole of the base. A mounting plate is horizontally and fixedly arranged at the piston end of the lifting air cylinder. A plurality of connecting rods are fixedly arranged on the mounting plate. The top ends of the connecting rods penetrate through the positioning ring and then make contact with the bottom end of the pushout ring. Through the tool, the compressor cylinder block boring machining precision and machining efficiency can be improved, the production cost is reduced, operation is simple, rapid and convenient, the product quality can be improved, and the actual application effect is good.

Owner:合肥达因汽车空调有限公司

Spraying device with quick drying function for production of steel sheets of windscreen wipers

InactiveCN112191431APrevent leakageEvenly distributedLiquid spraying apparatusSpray boothsMotor vehicle partStructural engineering

The invention discloses a spraying device with a quick drying function for production of steel sheets of windscreen wipers, and relates to the technical field of production of automobile parts. The spraying device specifically comprises a base, a screw rod chuck mechanism, a wedge clamping mechanism, a spraying mechanism and a quick drying mechanism, wherein a supporting column is arranged at oneend of the top end of the base; and the screw rod chuck mechanism is arranged at the bottom end of a lifting ring. According to the spraying device with the quick drying function for production of thesteel sheets of the windscreen wipers, the quick drying mechanism is arranged, a circulating mechanism is arranged, so that uniform distribution of the temperature in a cavity of a rack is guaranteed; a sliding groove which is shaped like a Chinese character 'jing (well)' is formed in the surface of a drying layer, so that a magnetic base can freely move on the surface of the sliding groove conveniently, and the adaptability to to-be-dried materials of different types and specifications is high; the magnetic base guarantees effective adsorption, and meanwhile, the contact between the magneticbase and the to-be-processed materials is reduced, so that the drying effect is guaranteed; and the drying layer and a heating layer can run at different rates due to the arrangement of a differential mechanism, so that the to-be-dried materials are uniformly heated, the drying rates of different parts are consistent, and the applicability is higher.

Owner:东莞市龙飞数控科技有限公司

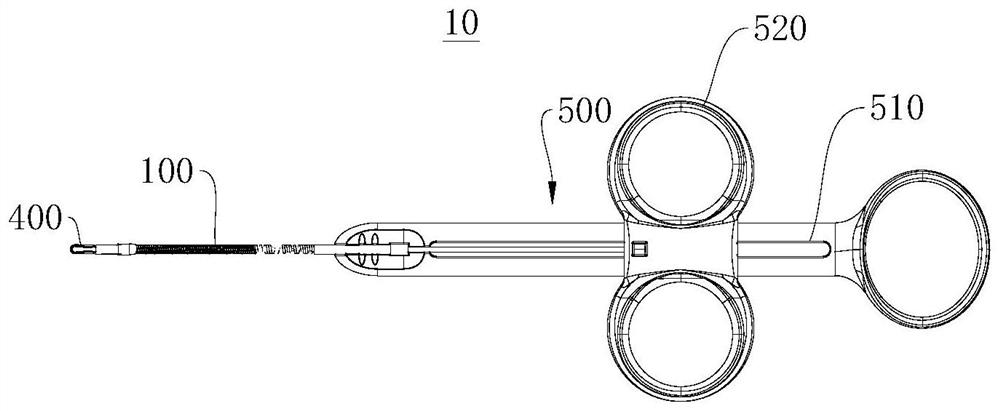

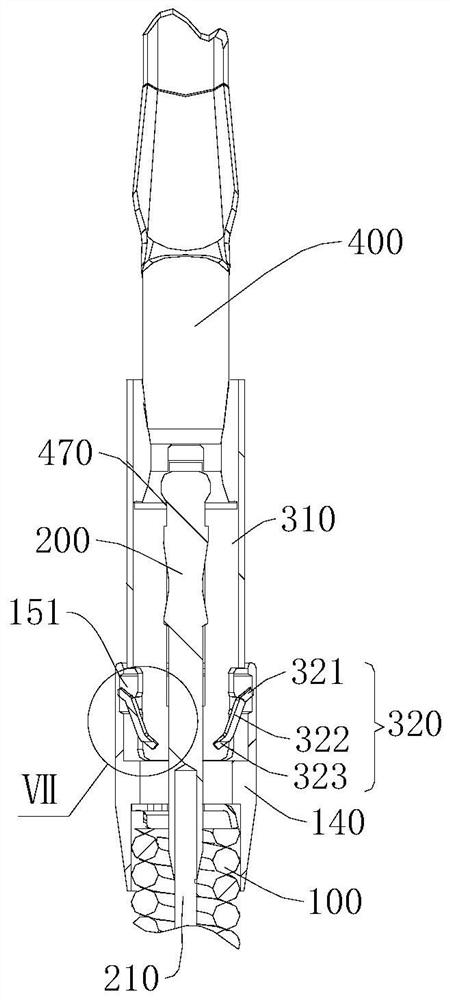

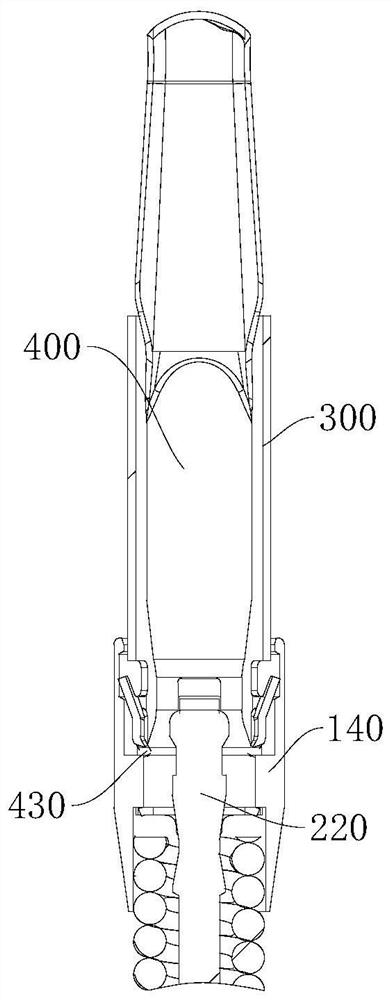

Tissue traction device and using method thereof

PendingCN112603396AGuaranteed clamping accuracyGuaranteed clamping stabilityInstruments for stereotaxic surgerySurgical forcepsMedicineEngineering

The embodiment of the invention provides a tissue traction device and a using method of the tissue traction device, and relates to the technical field of medical instruments. The tissue traction device provided by the embodiment of the invention comprises an outer tube assembly, a clamping seat, a clamping body and an inhaul cable assembly. The clamping base is connected to the far end of the outer tube assembly, and the clamping body is used for clamping tissue and movably matched with the clamping base. A first connecting structure is arranged on the clamp body, a second connecting structure is arranged on the clamp base, and the first connecting structure is used for being connected with the second connecting structure so that the clamp body can be in a clamping and locking state. The inhaul cable assembly penetrates through the outer pipe assembly, and the far end of the inhaul cable assembly is connected with the clamp body so that the clamp body can be operated through the inhaul cable assembly. When the clamp body is in a clamping and locking state, the outer tube assembly is connected with the clamp seat, so the clamp body in the body can be pushed and pulled by operating the near end of the outer tube assembly extending out of the body during use, tissue traction is further realized, and the surgical field can be better improved.

Owner:MICRO TECH (NANJING) CO LTD +1

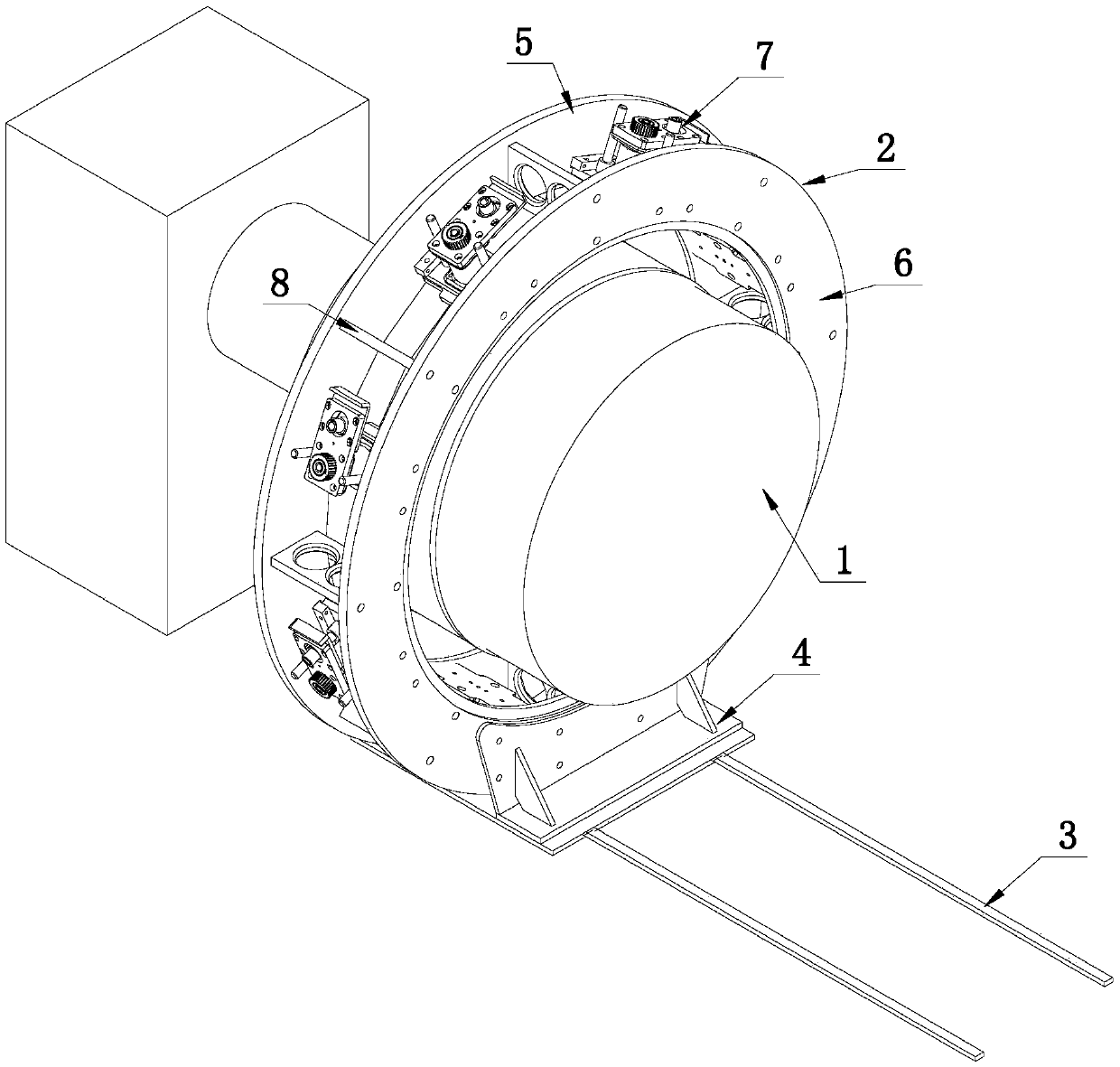

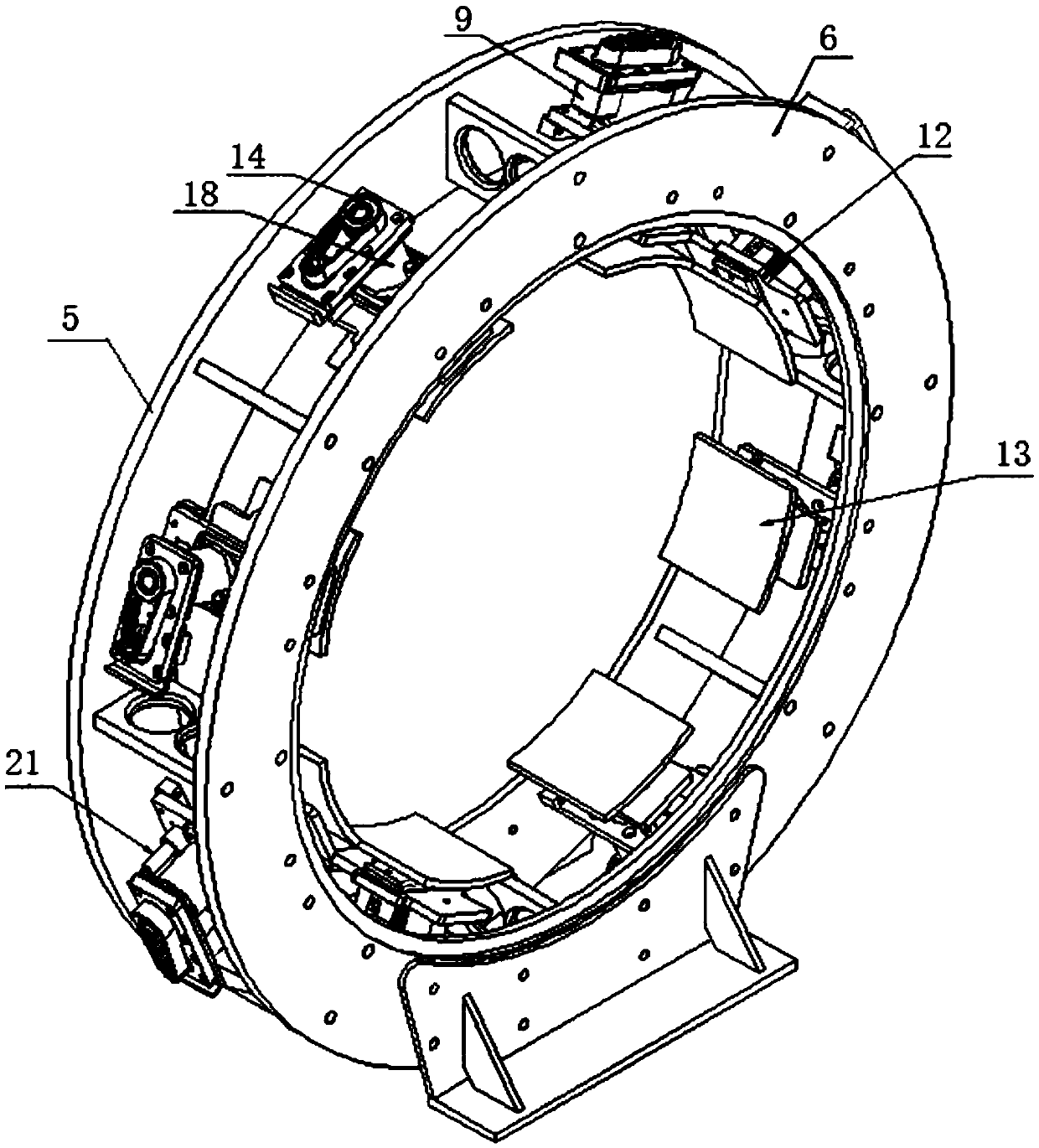

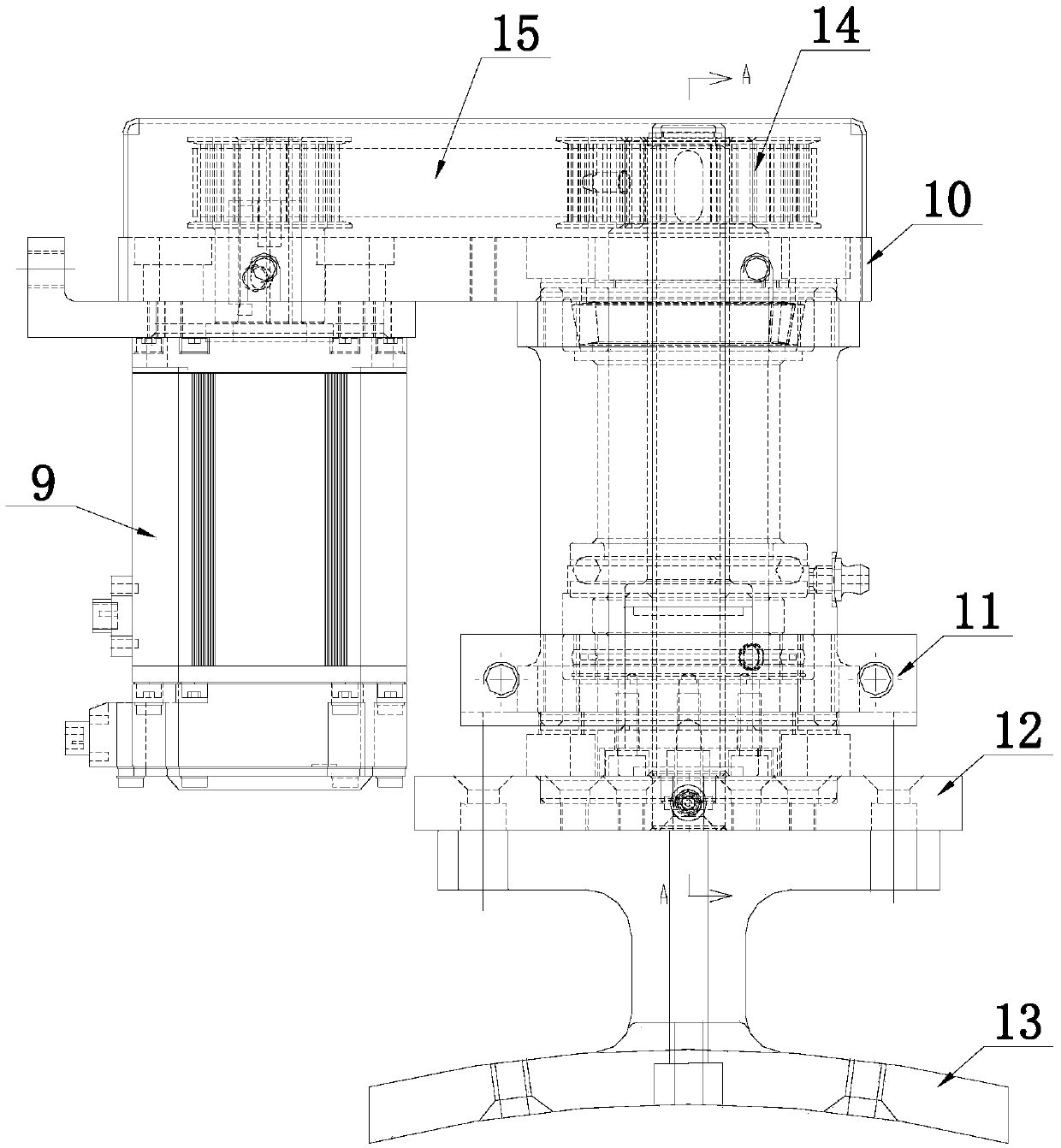

Forming and transmitting device of semi-steel radial tires

The invention relates to a tire forming device, in particular to a forming and transmitting device of semi-steel radial tires. The device comprises a forming drum device, a transmitting ring device and rails. The transmitting ring device comprises 6-10 clamping devices. Bearing housings are arranged between upper plates and middle plates of the clamping devices. Transmission shafts are arranged in the bearing housings. The upper ends of the transmission shafts are connected with servo motors through gears and synchronous belts in a transmission mode. Middle holes are formed in the middles of the transmission shafts. Nuts are fixedly arranged at the bottoms of the middle holes. Lead screws are arranged in the middle holes and connected with the nuts through threads. The bottoms of the lead screws are fixedly connected with lower plates. Guide shafts are fixedly arranged on the lower plates. Shaft sleeves are arranged on the middle plates. The guide shafts are arranged in the shaft sleeves in a penetrating mode. Clamping plates are fixedly arranged on the lower plates. Circle centers of circles formed by clamping parts of the clamping plates coincide with circle centers of the circle of a forming drum. The whole mechanism is simple in structure and complete in function, and the requirements of on-site complex production links are met.

Owner:ZHONGCE RUBBER GRP CO LTD

Clamp structure arranged on linear cutting machine

InactiveCN103785910AReduce setup timeImprove work efficiencyElectrical-based auxillary apparatusMechanical engineeringEngineering

The invention relates to a clamp structure arranged on a linear cutting machine, and belongs to the technical field of tool clamps. The linear cutting machine comprises a linear cutting operation platform, the clamp structure comprises a clamp plate, clamp plate limiting mechanisms and a workpiece limiting mechanism, wherein the clamp plate is arranged on the linear cutting operation platform, and the two ends of the clamp plate respectively extends to form a workpiece bracket; the pair of clamp plate limiting mechanism is connected with the linear cutting operation platform at the edge portions corresponding to the two sides in the length direction of the clamp plate respectively; the workpiece limiting mechanism is arranged on the clamp plate and corresponds to the upside of the workpiece brackets in the state of rising to the sky. The clamp structure is simple wholly, and not only facilitates manufacturing, but also is beneficial for facilitating operation; when a workpiece is clamped, it is only required that the workpiece is placed on the workpiece brackets, and the workpiece limiting mechanism is operated, so that the time for clamping the workpiece is shortened substantially, and the working efficiency of the linear cutting machine is improved; due to the fact that the clamp structure clamps the workpiece conveniently, rapidly and efficiently, operation intensity of an operator can be reduced substantially.

Owner:金牌模具(常熟)有限公司

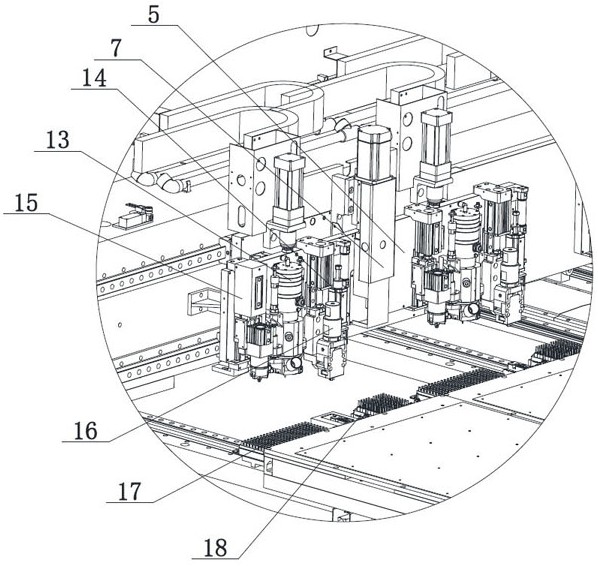

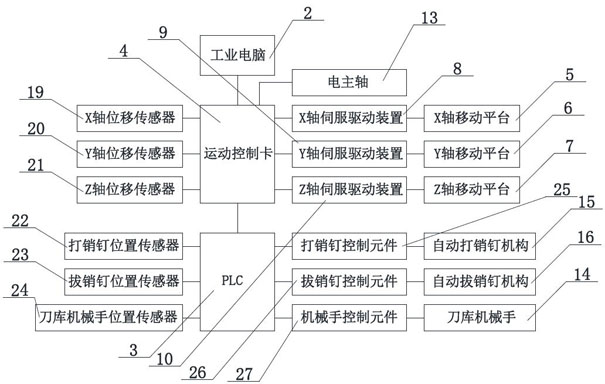

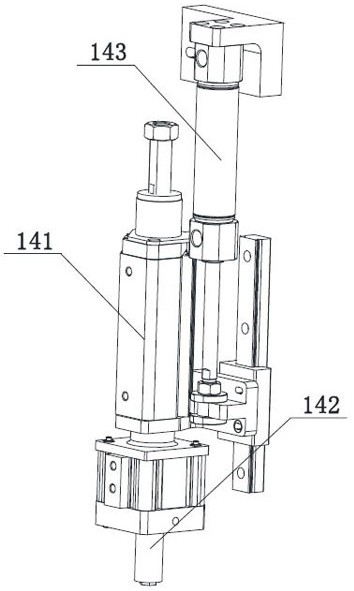

PCB automatic machining device and automatic machining process with automatic pin driving and pulling function

ActiveCN112296392ARealize three-axis linkageMobile location is accuratePrinted circuit manufactureMetal working apparatusRobot handControl engineering

The invention discloses a PCB automatic machining device with an automatic pin driving and pulling function. The PCB automatic machining device comprises a device body, an industrial computer, a motion control card, a PLC, an X-axis moving platform, a Y-axis moving platform, a Z-axis moving platform, an X-axis servo driving device, a Y-axis servo driving device and a Z-axis servo driving device. An electric main shaft, a tool magazine mechanical hand, an automatic pin driving mechanism and an automatic pin pulling mechanism are arranged on the Z-axis moving platform. A pin magazine and a toolmagazine are arranged at the end, close to the X-axis moving platform, of a work table. The industrial computer is connected with the motion control card, and the PLC is connected with the motion control card. The PLC is connected with the automatic pin driving mechanism, the automatic pin pulling mechanism and the tool magazine mechanical hand, and the electric main shaft is connected with the motion control card. By means of the PCB automatic machining device, automation and precision of the whole process of pin driving and pulling are achieved, and the automation degree of the PCB machiningdevice can be greatly improved.

Owner:CHENGDU JINDALI TECH

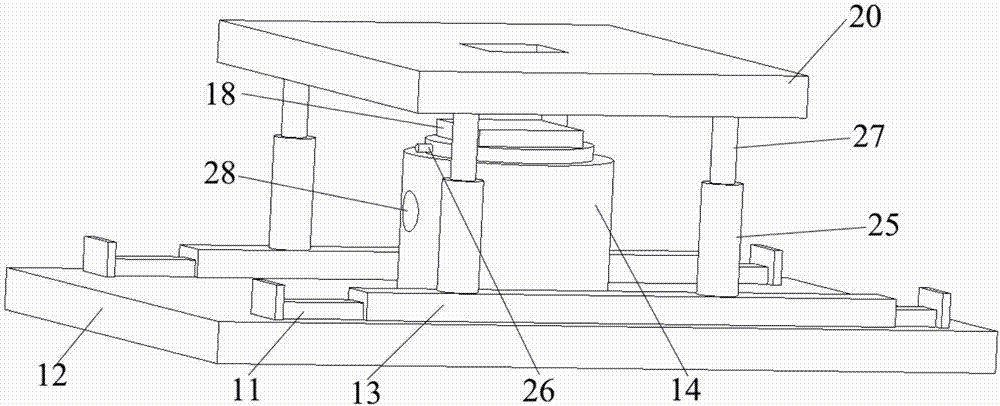

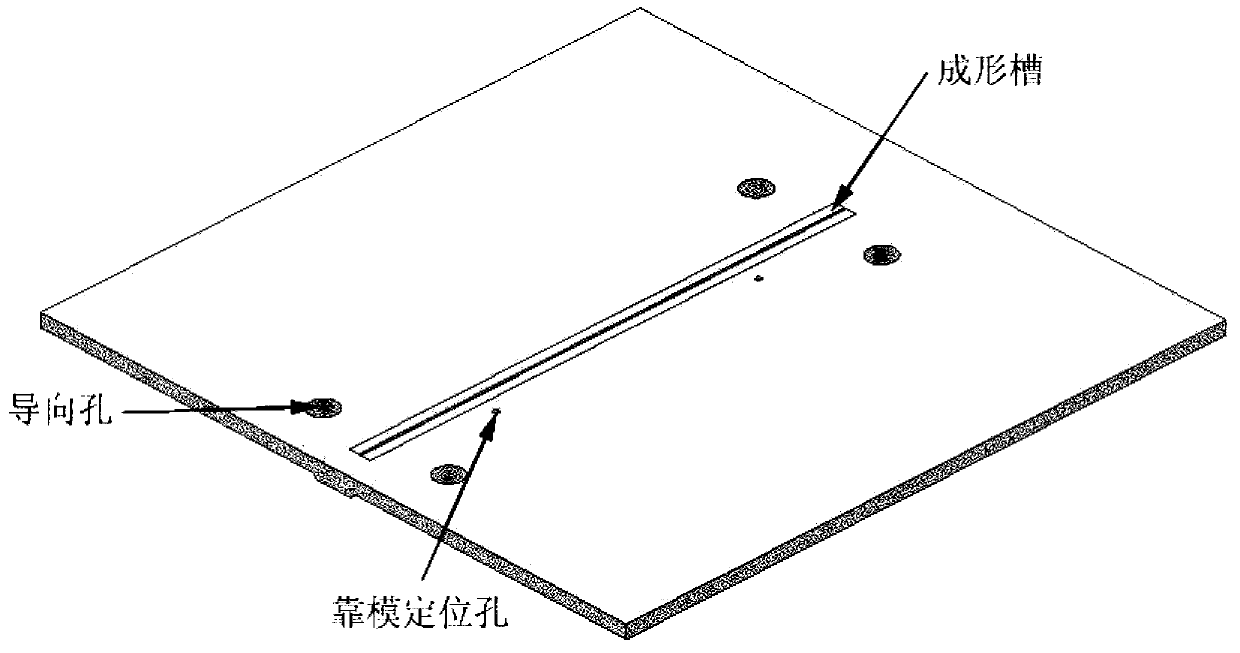

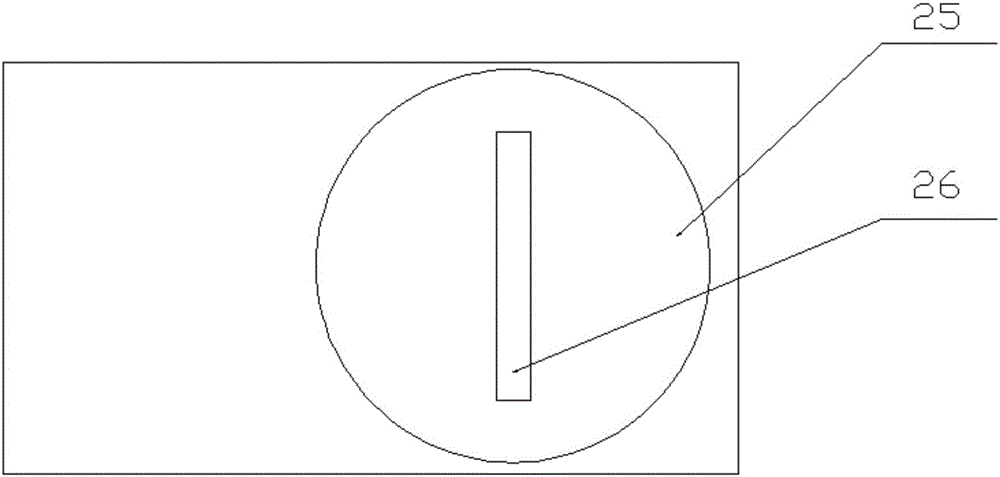

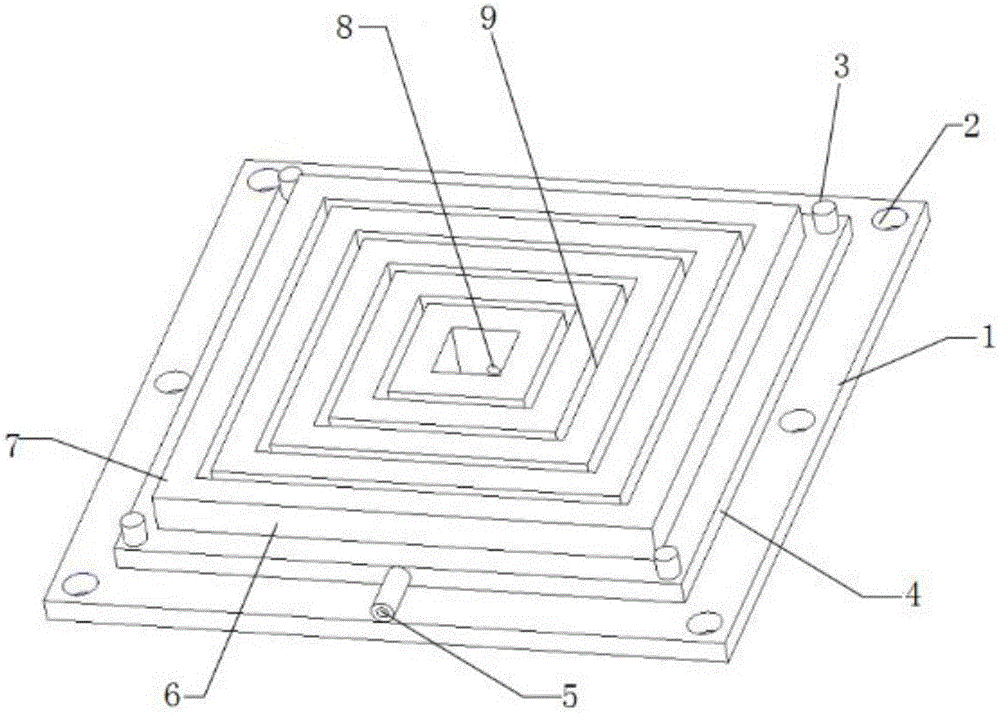

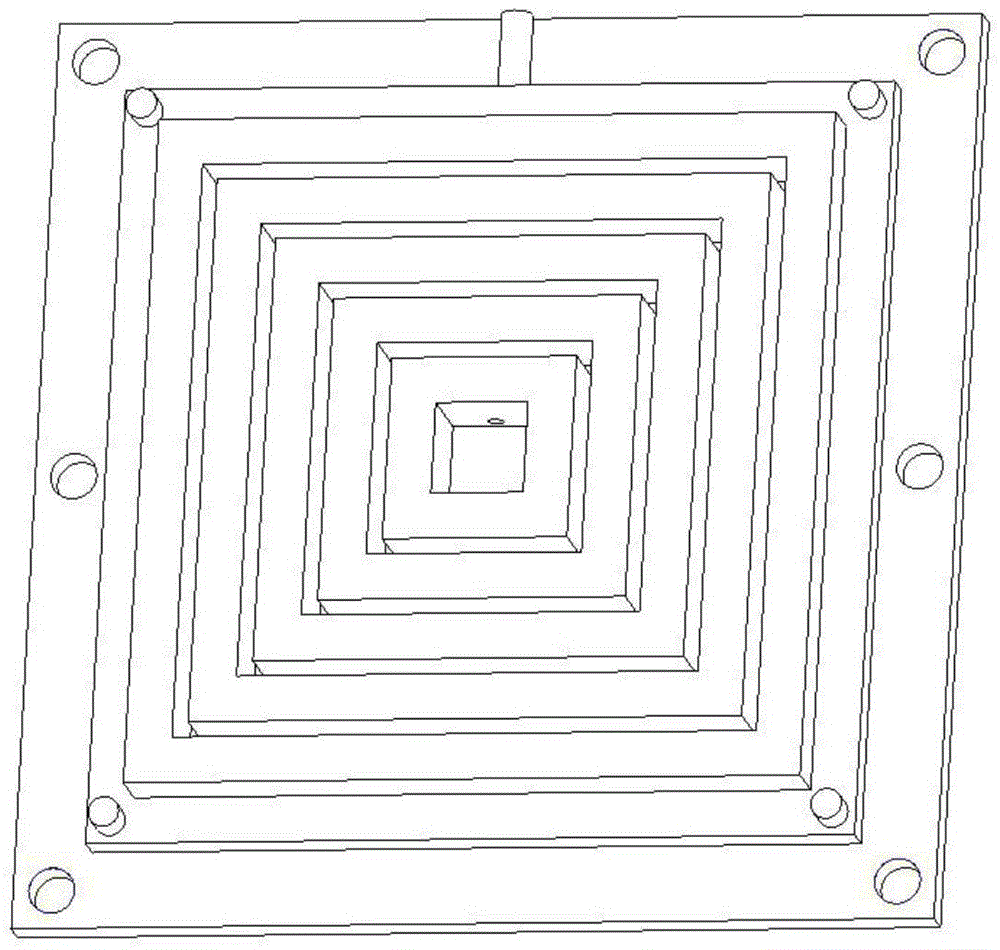

Vacuum chuck for KDP crystalline material

ActiveCN105485144AGuaranteed clamping accuracyReduce machining residual stressSuction cupsCrystalline materialsEngineering

The invention relates to a vacuum chuck for a KDP crystalline material. A special vacuum chuck high-strength fixed support is mounted on a high-flatness workbench and a liquid hydrostatic guideway support plate assembly through a special vacuum chuck high-strength fixed support fixing nut and bolt assembly; vacuum chuck balance adjusters are distributed at four corners of a vacuum chuck balance adjusting plate, grooves shaped like dual nested rectangles have consistent width and depth, each groove is communicated through a vent hole connected with a special vacuum chuck air-guide pipe, and the special vacuum chuck air-guide pipe is connected with an air pump and a vacuum generator assembly. When the air pump and the vacuum generator assembly operate, the grooves shaped like dual nested rectangles in the surface of the vacuum chuck are in a vacuum state, so that the vacuum chuck has suction to fix KDP crystalline parts. The vacuum chuck is also applicable to all parts with non-machining surfaces being planes, and the clamping accuracy is guaranteed; non-uniform force clamping deformation does not exist, so that the machining residual stress of the parts is greatly reduced.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com