KDP crystal material single point diamond fly cutting device

A single-point diamond and cutting device technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., to achieve low-cost precision machining, ensure clamping accuracy, and reduce machining residual stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

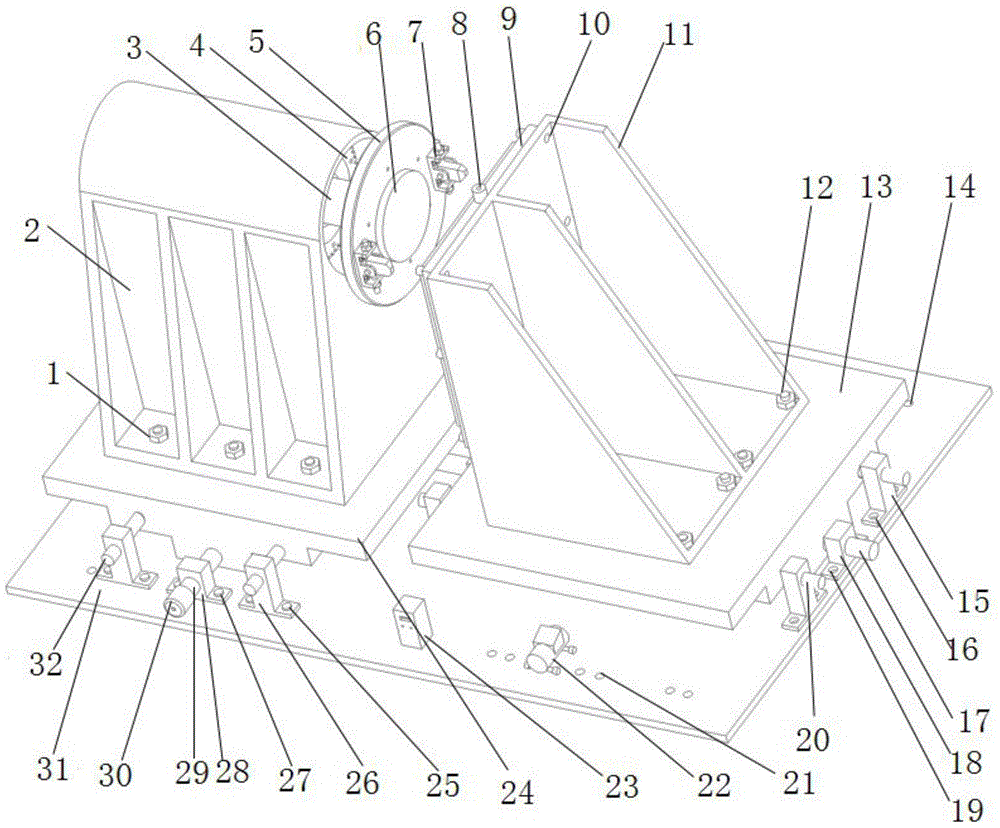

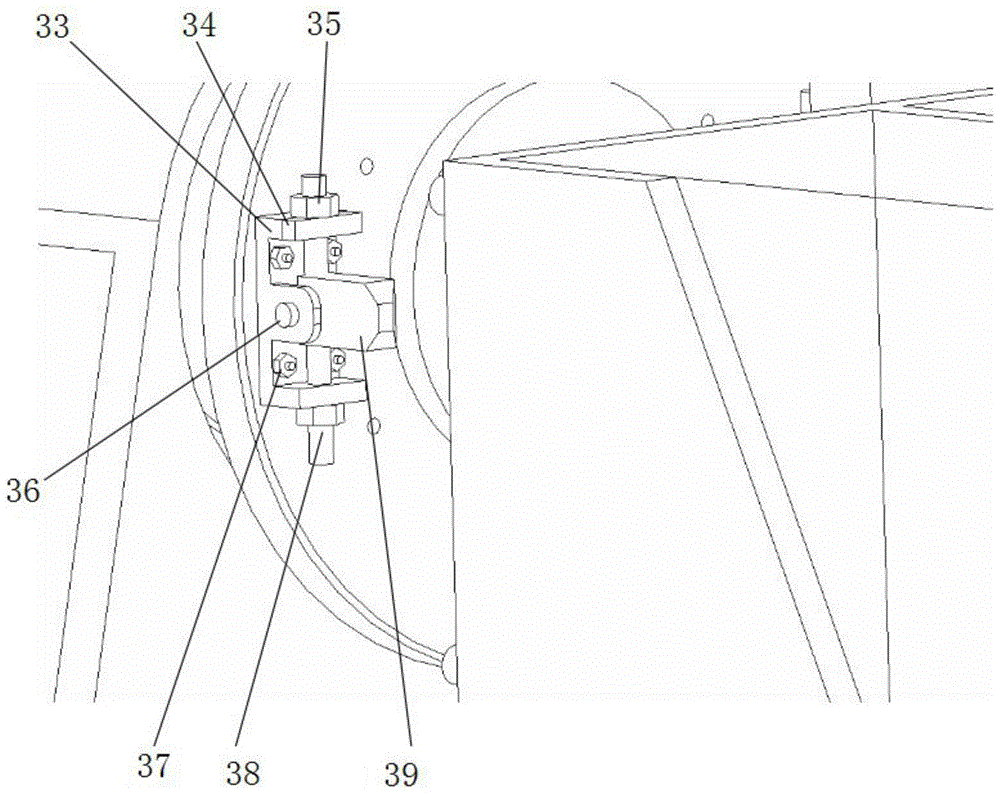

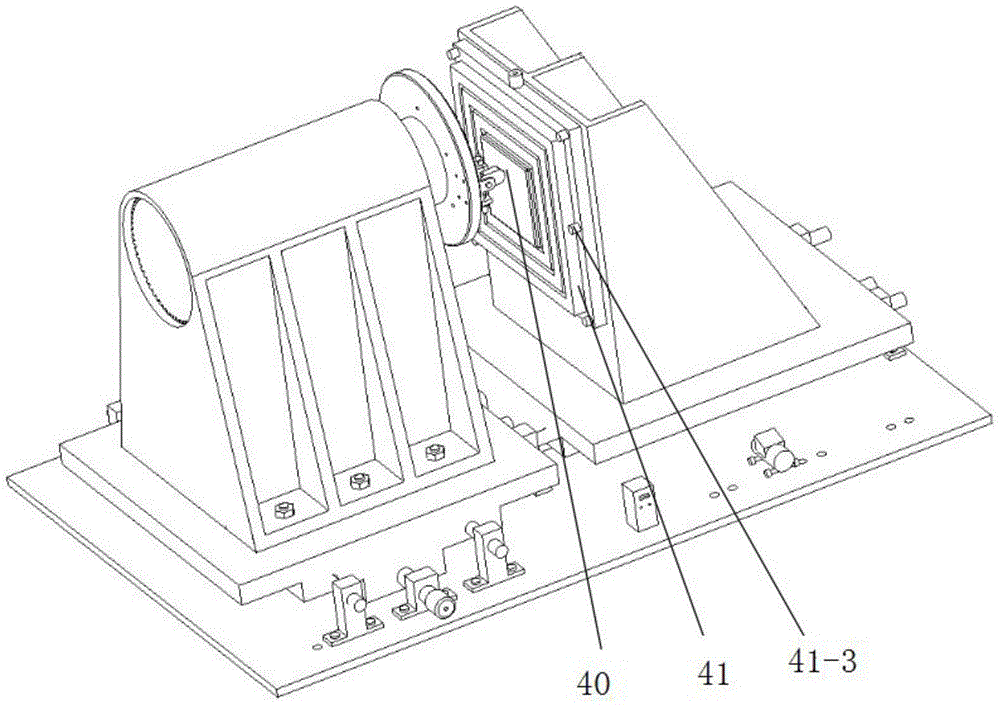

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0041] like Figure 1-5 Shown, preparation work before processing. Before processing the KDP crystal part (40), adjust the balance degree of the device through the shock pad, the base balance adjuster and its clamping hole (14), and then use the special vacuum suction cup to fix the plate with the built-in bolt assembly (10) and the special vacuum suction cup for balance. Regulator (41-3) adjusts the height and verticality of special-purpose vacuum sucker (41). At the same time, set the corresponding processing parameters according to the processing requirements, and then set the spindle motor (4) speed, radial feed speed and stroke, KDP crystal part (40) lateral feed speed through the computer and electronic control system components (23) and itinerary. According to corresponding processing requirement again, adjust the quantity, protruding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com