Patents

Literature

68results about How to "Reduce the difficulty of clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

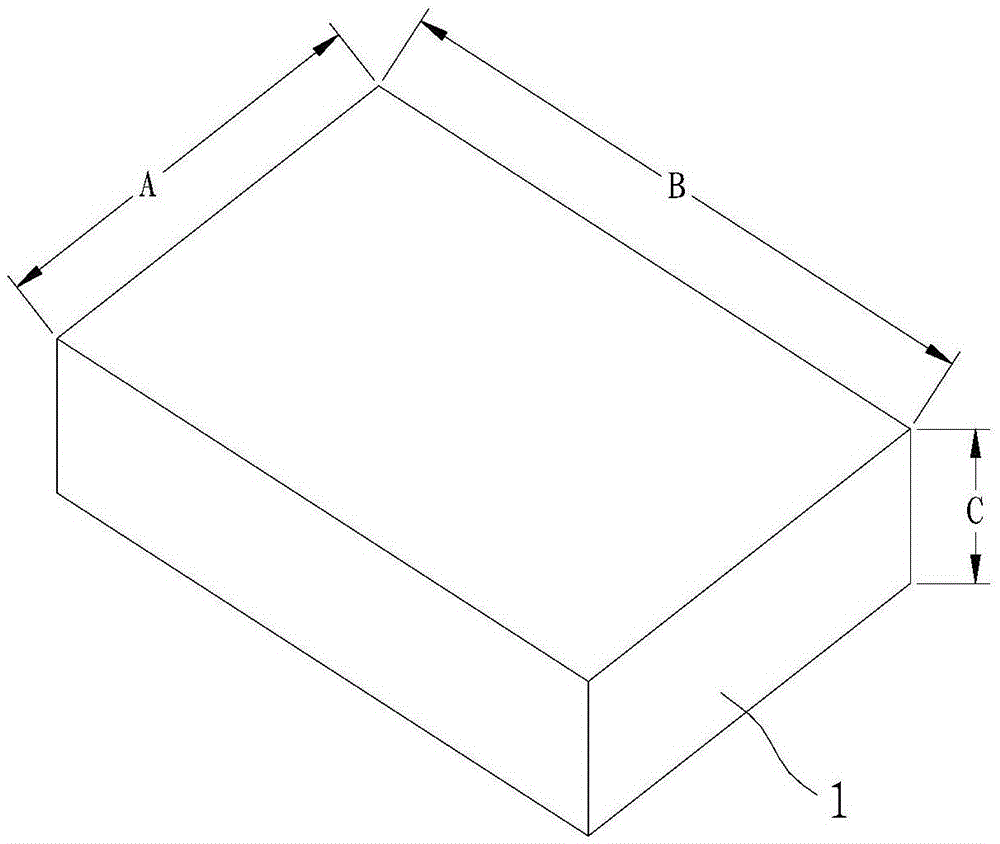

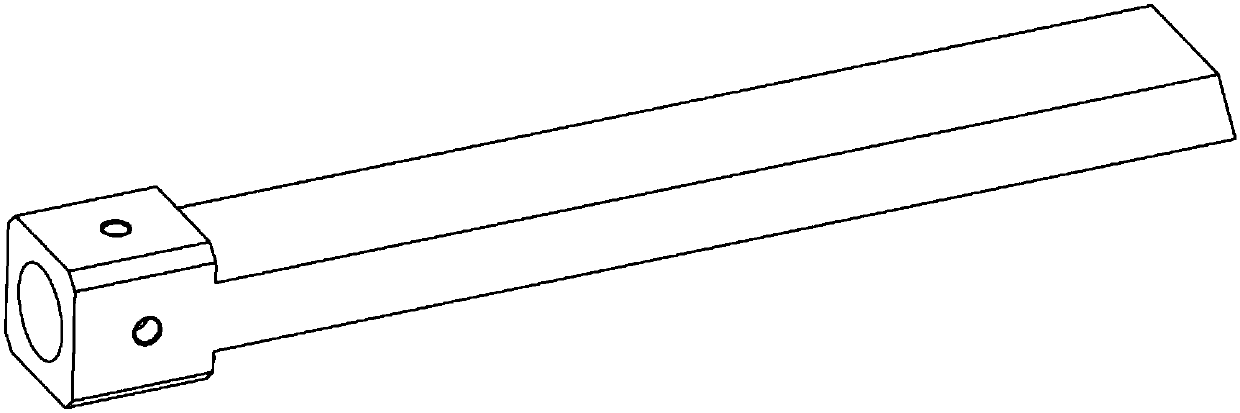

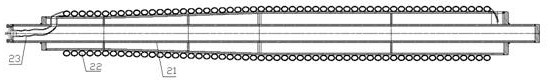

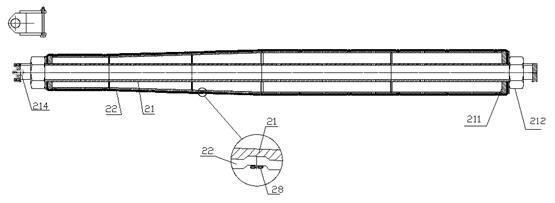

Processing method of parts with long shaft and thin wall and processing clamp thereof

InactiveCN102079045AReduce the difficulty of clampingReduce processing difficultyOther manufacturing equipments/toolsPositioning apparatusMetallic materialsMachining

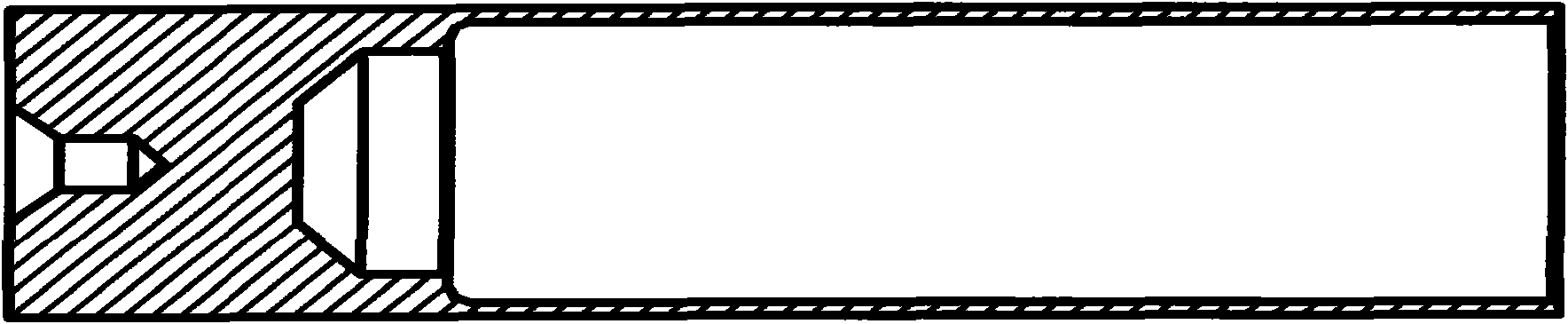

The invention discloses a machining processing method of parts with a long shaft and a thin wall, belonging to the technical field of mechanical machining. The processing method comprises the following steps: firstly selecting the required metal material, then performing baiting, thermal refining, roughly machining, ageing at high and low temperatures, half precisely machining and precisely machining, and finishing the machining after the passed inspection; during the half precise machining, the outer circle of the part with the long shaft and thin wall is preserved with the machining residue; during the precisely machining, an expandable shoulder plunger piston clamp is used for matching with the part to machine; the other end of the part is reserved with a technical handle and provided with a central hole so as to locate through the outer diameter of the clamp and the inner hole of the part; and the outer diameter of the clamp is regulated so that the outer diameter is properly matched with the inner hole of the part. By using the processing method, the problems that the part with the long shaft and thin wall is easy to deform during the mechanical machining, is incapable of reaching the requirement of the technical parameter, and is low in machining yield are solved.

Owner:贵州航天控制技术有限公司

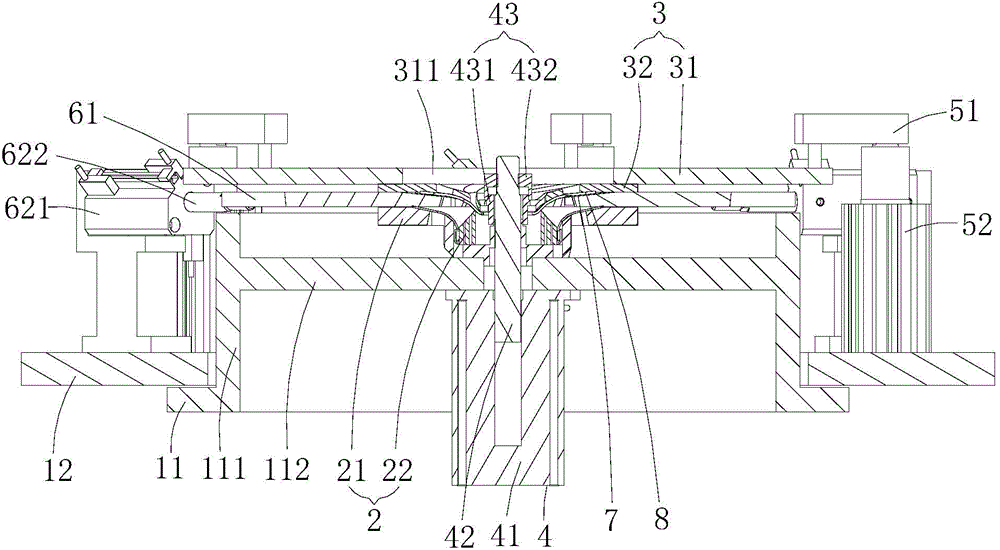

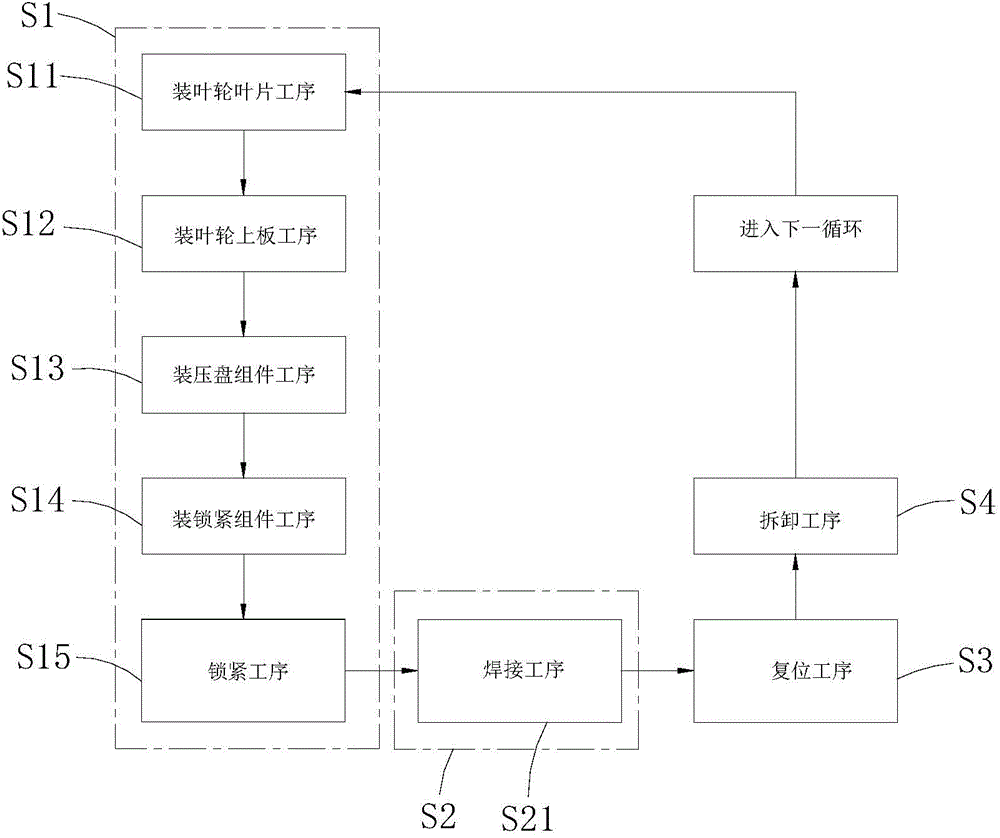

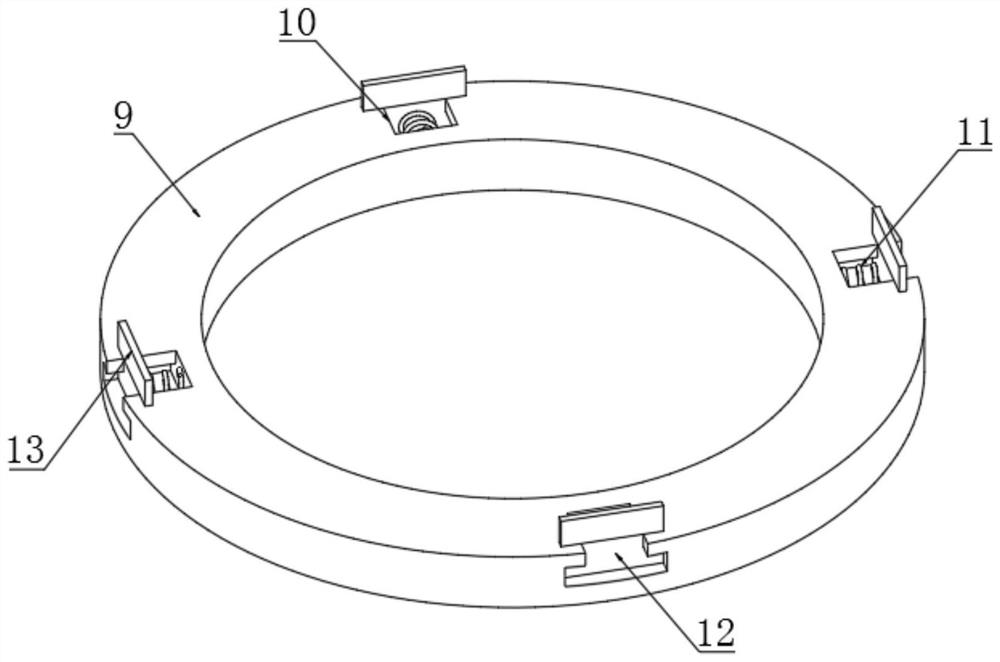

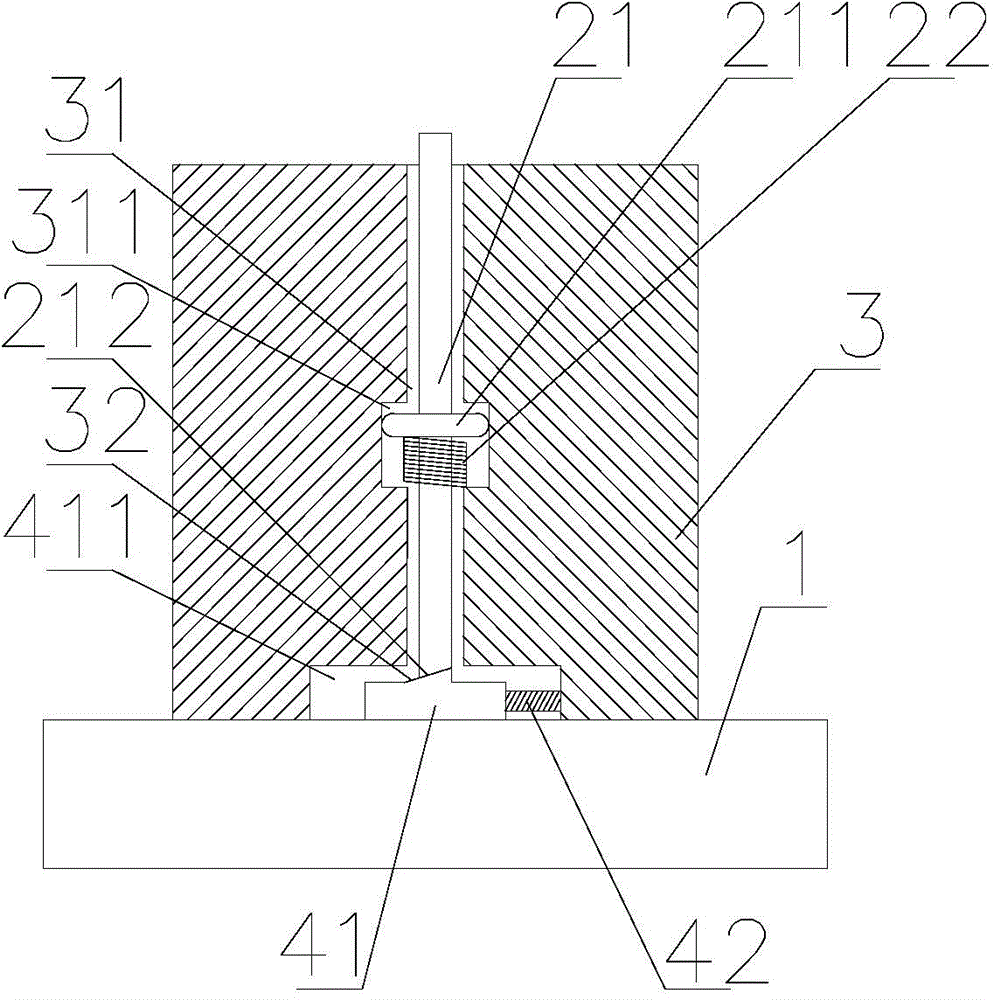

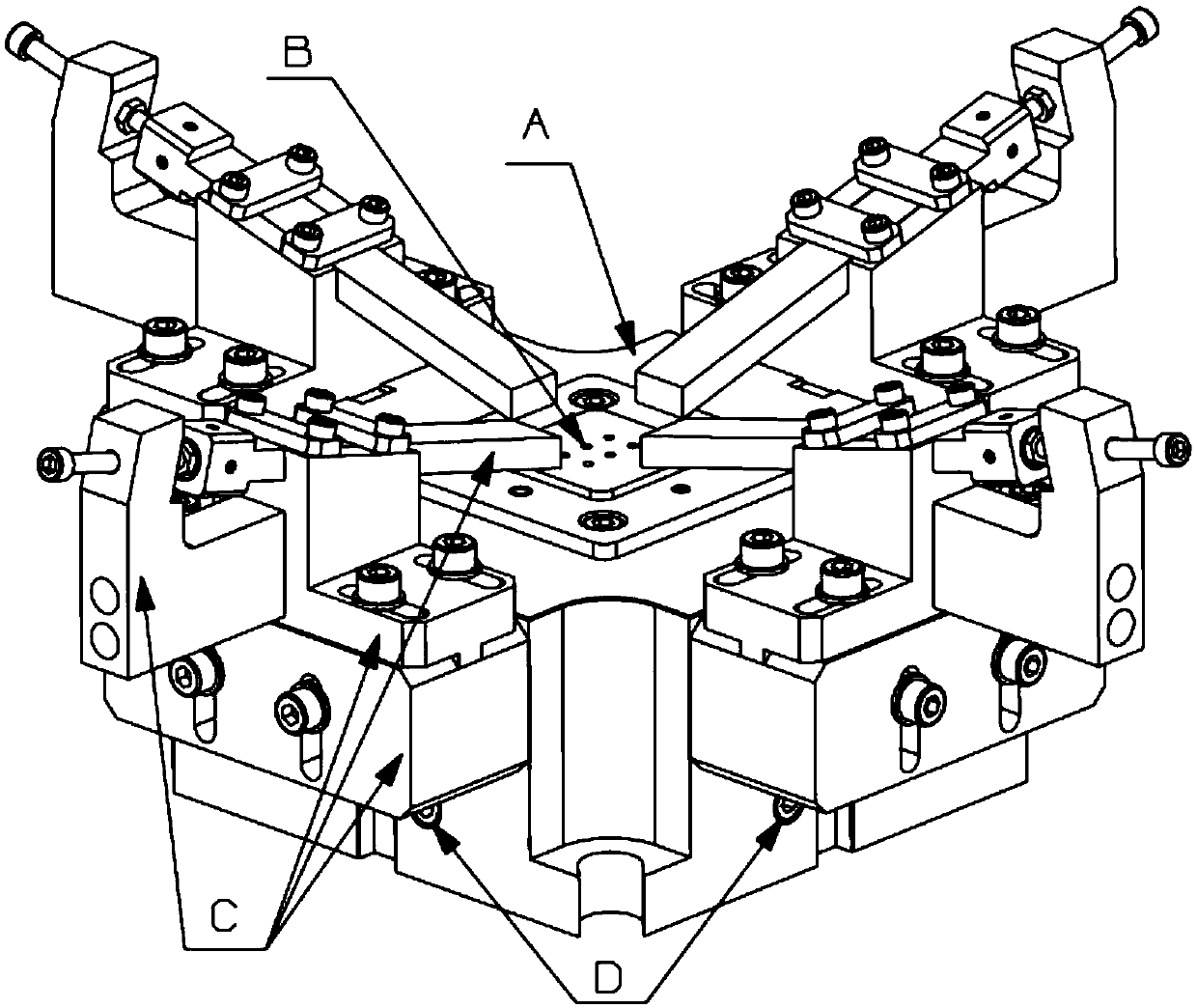

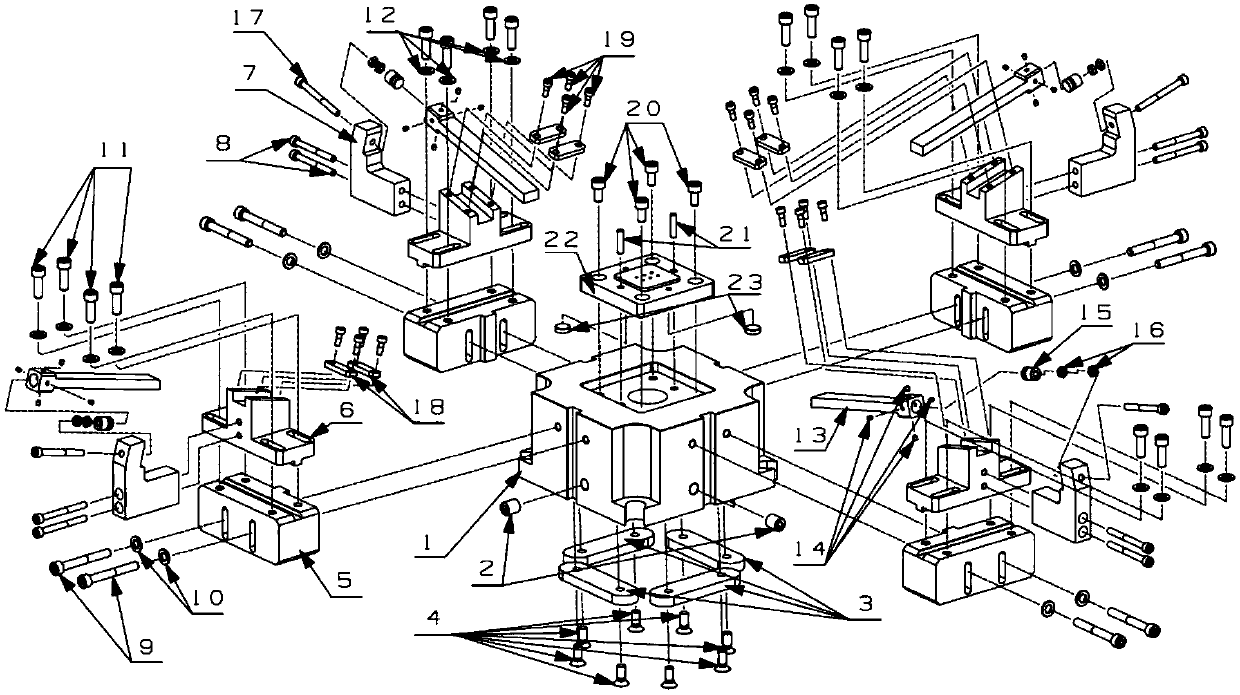

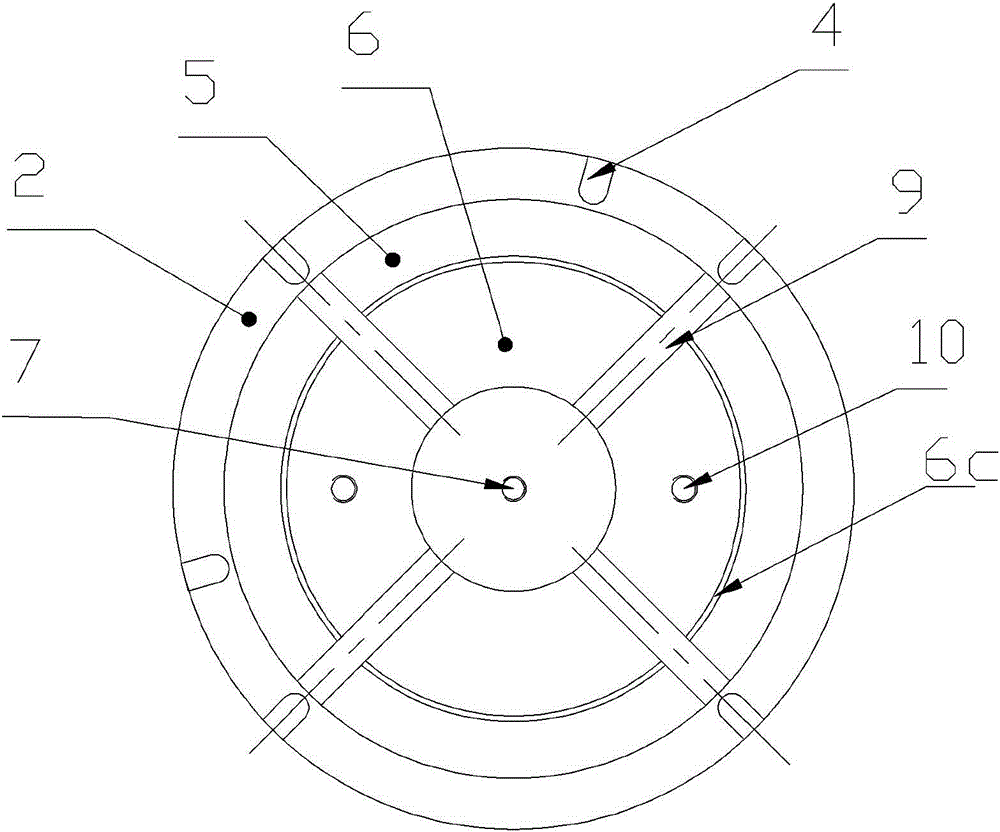

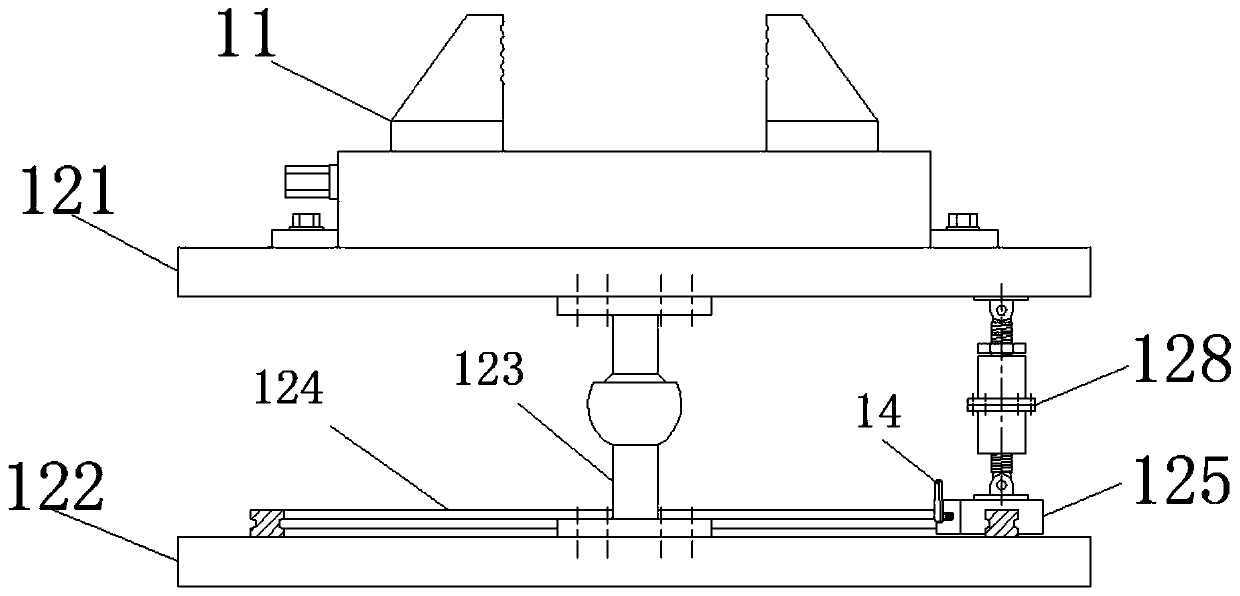

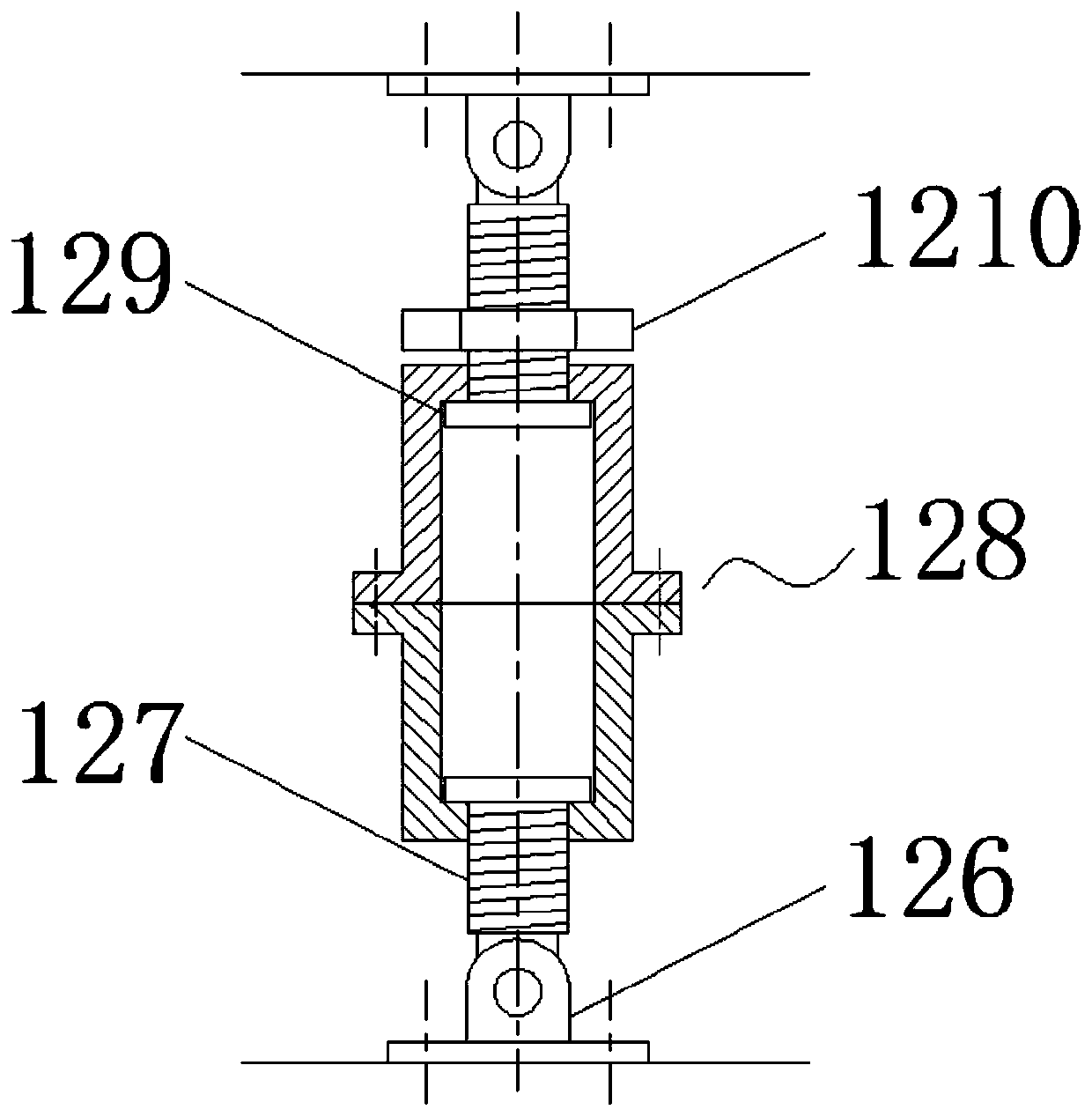

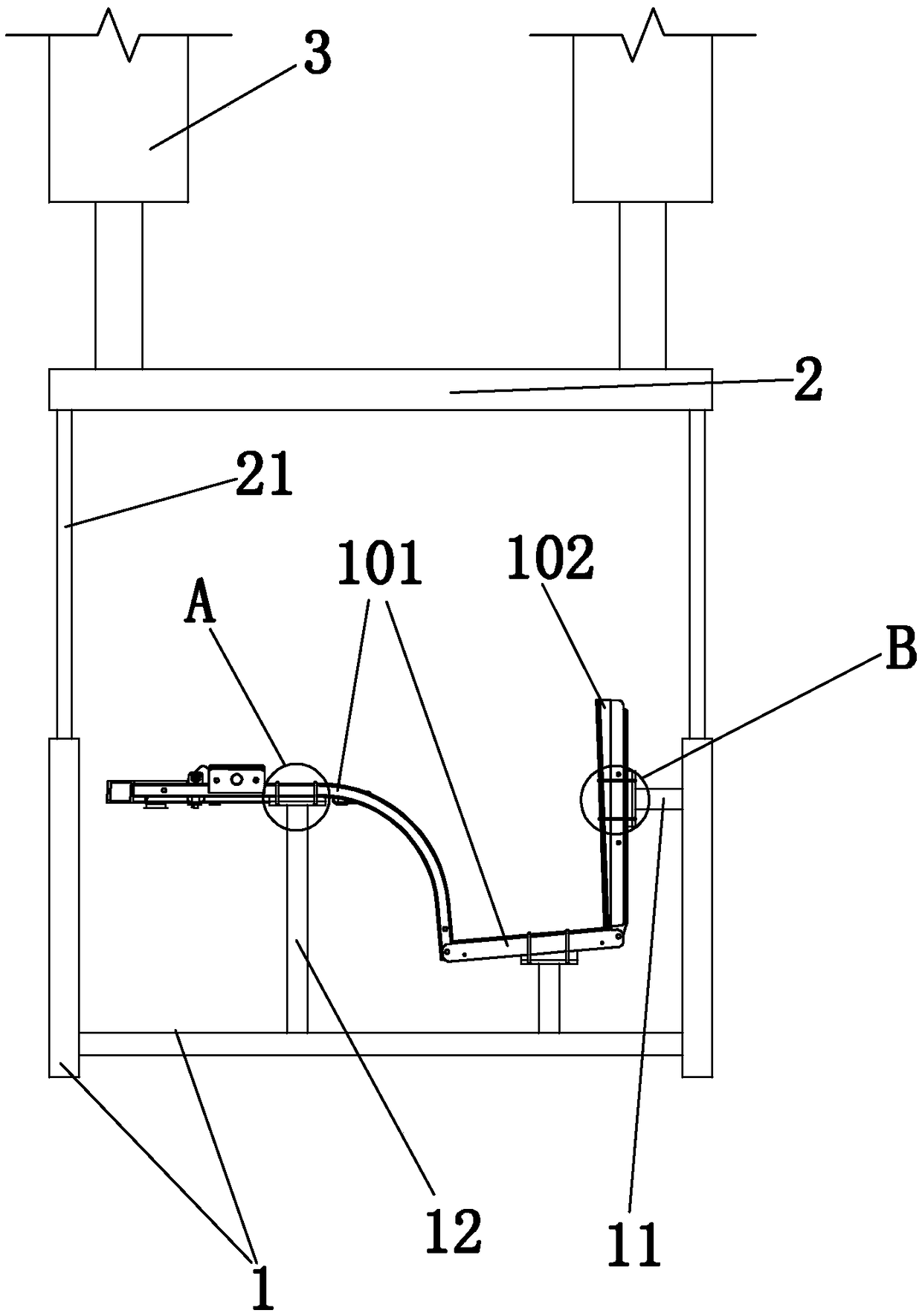

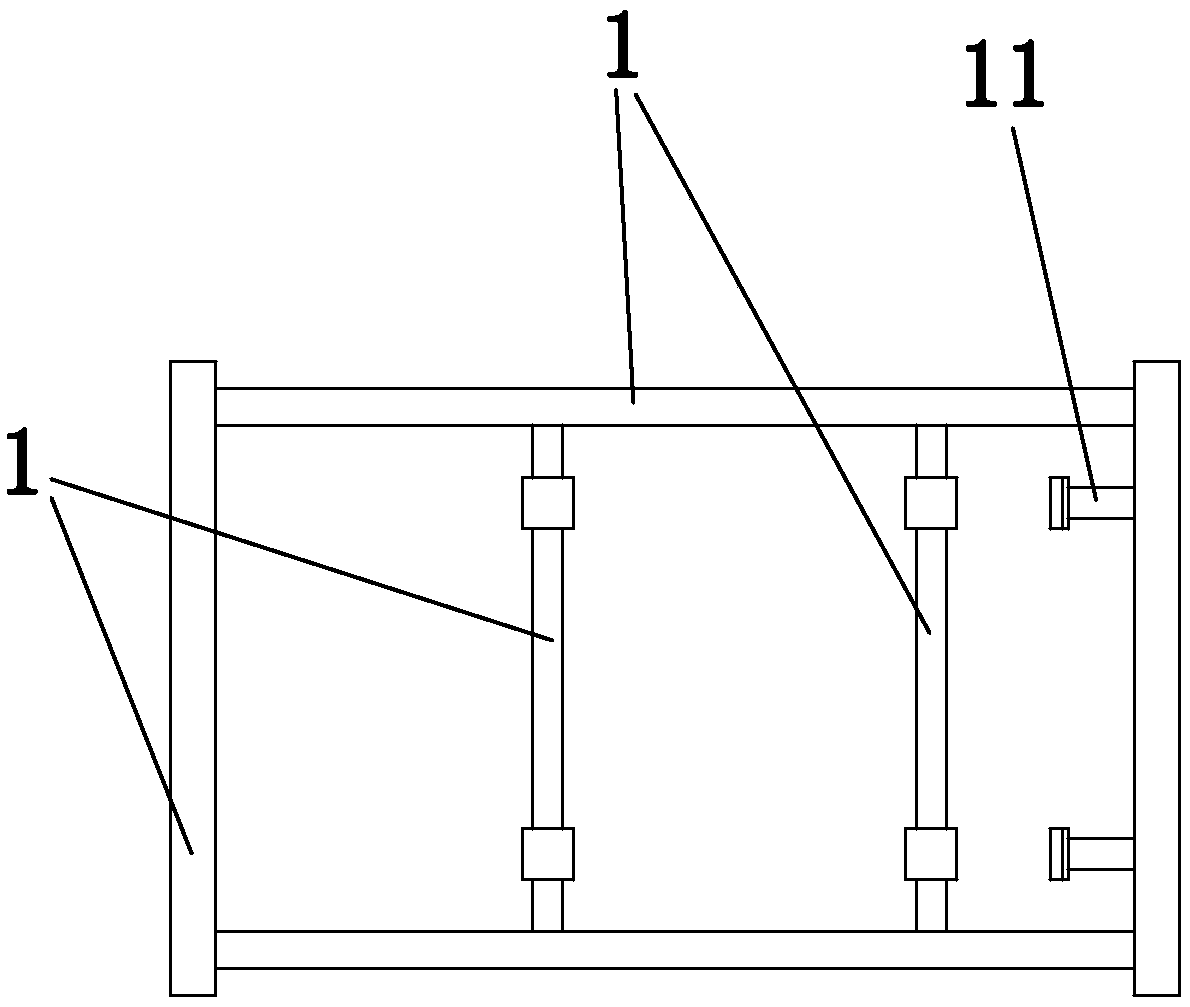

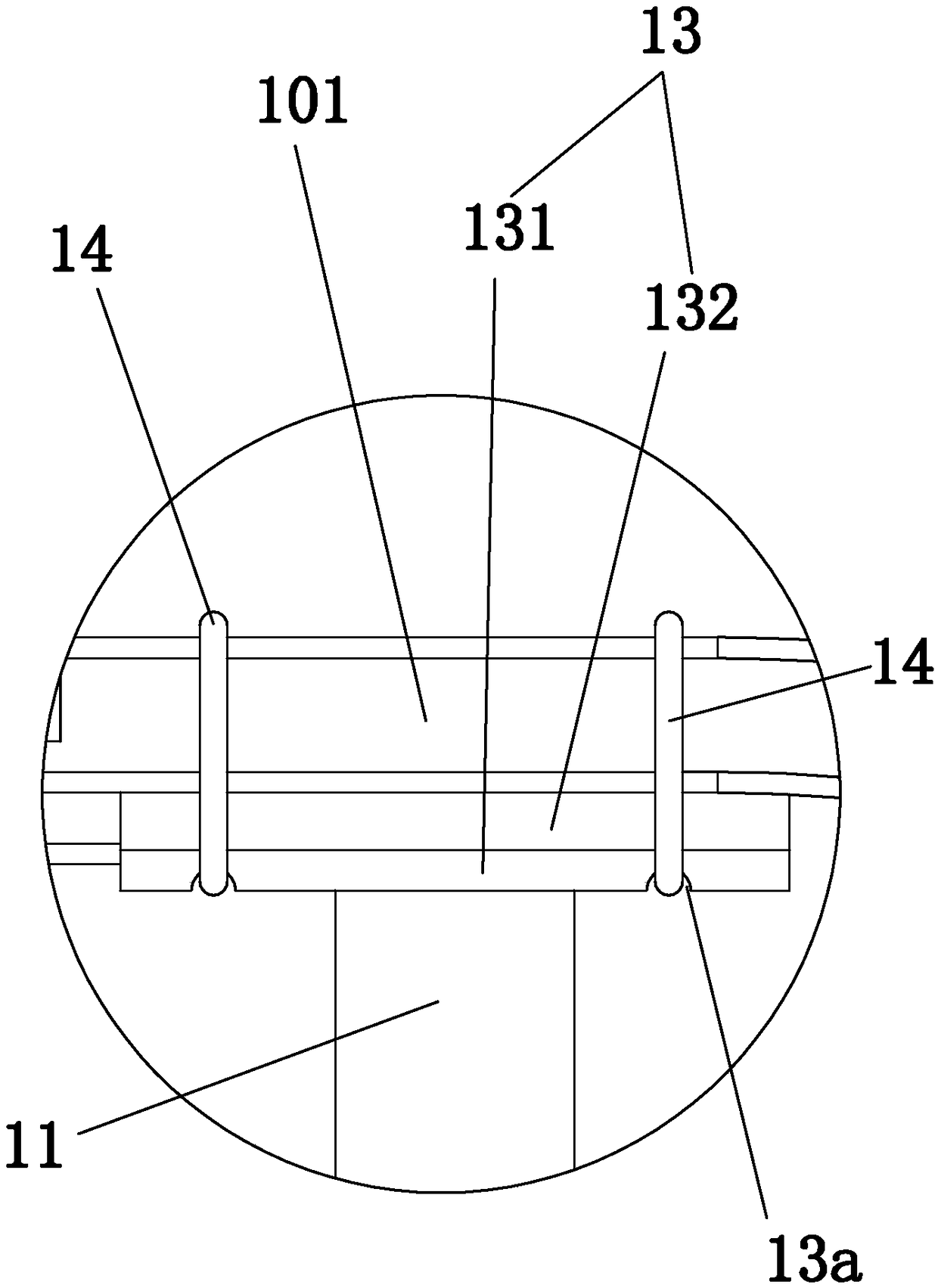

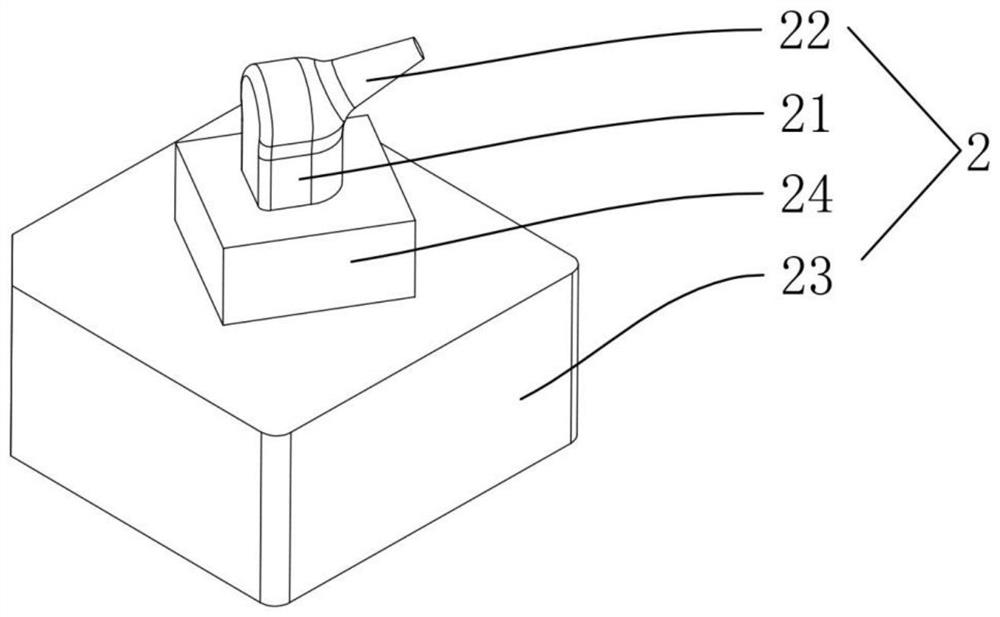

Impeller blade and impeller upper plate laser welding method and clamping method and jig

ActiveCN104384804AGuaranteed reliabilityEnsure positioning reliabilityTurbinesWelding/cutting auxillary devicesImpellerEngineering

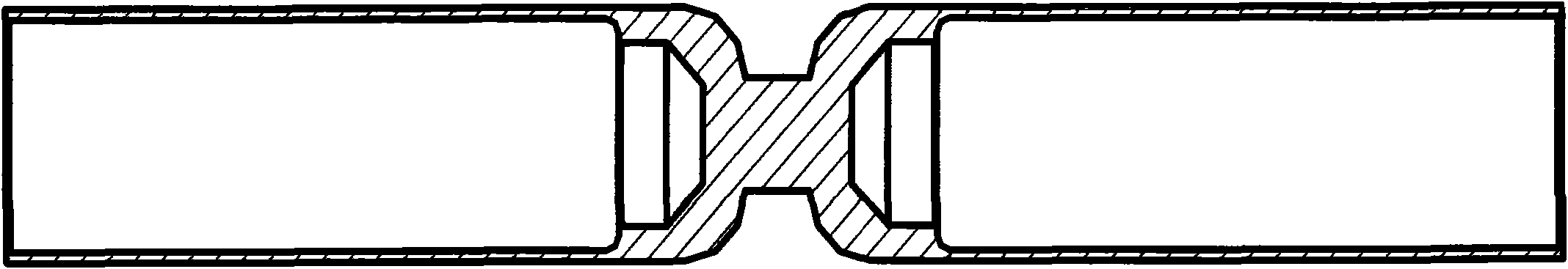

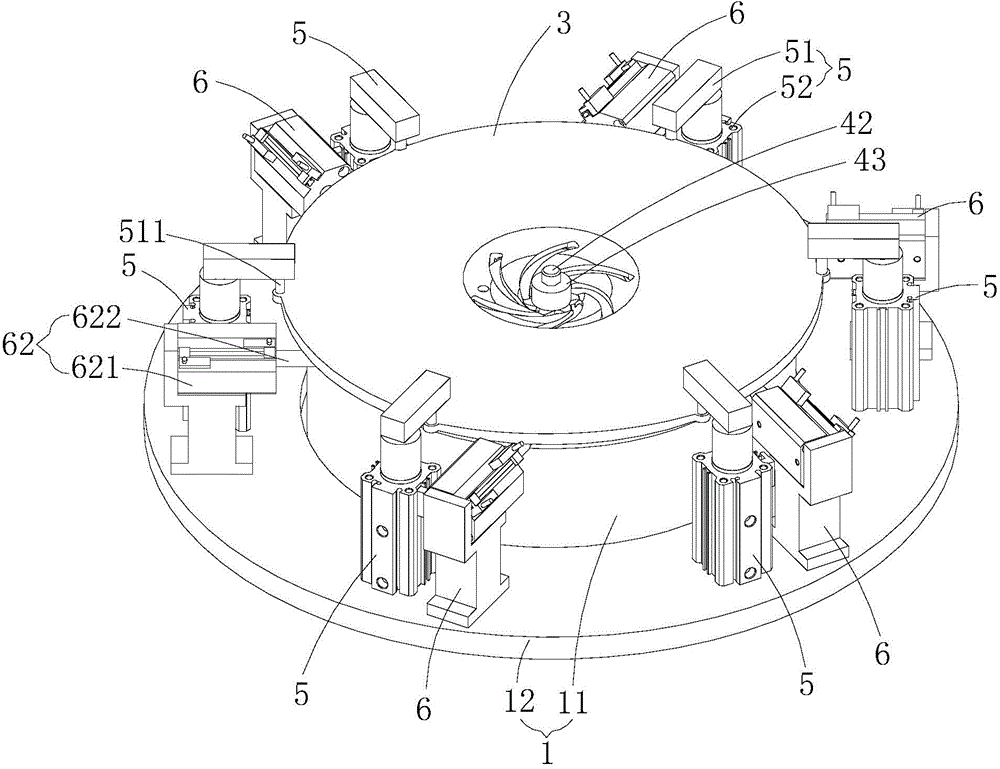

The invention is applicable to the field of impeller laser welding and discloses an impeller blade and impeller upper plate laser welding jig, an impeller blade and impeller upper plate clamping method with the jig and an impeller blade and impeller upper plate laser welding method through the clamping method. The impeller blade and impeller upper plate laser welding jig comprises a base assembly, a support assembly mounted on the base assembly for placing and positioning an impeller blade and an impeller upper plate, a pressing plate assembly arranged above the support assembly for pressing the impeller blade and the impeller upper plate to the support assembly, a first telescoping assembly mounted on the base assembly for pressing the pressing plate assembly in the axial direction of the base assembly, a plurality of peripheral pressing structures mounted on the base assembly, and a plurality of lateral positioning structures mounted on the base assembly. The impeller blade and impeller upper plate laser welding jig, the impeller blade and impeller upper plate clamping method with the jig and the impeller blade and impeller upper plate laser welding method through the clamping method solve the technical problems of poor versatility, clamping difficulty and low clamping efficiency, clamping positioning reliability and automation degree of existing impeller laser welding jigs.

Owner:HANS LASER TECH IND GRP CO LTD

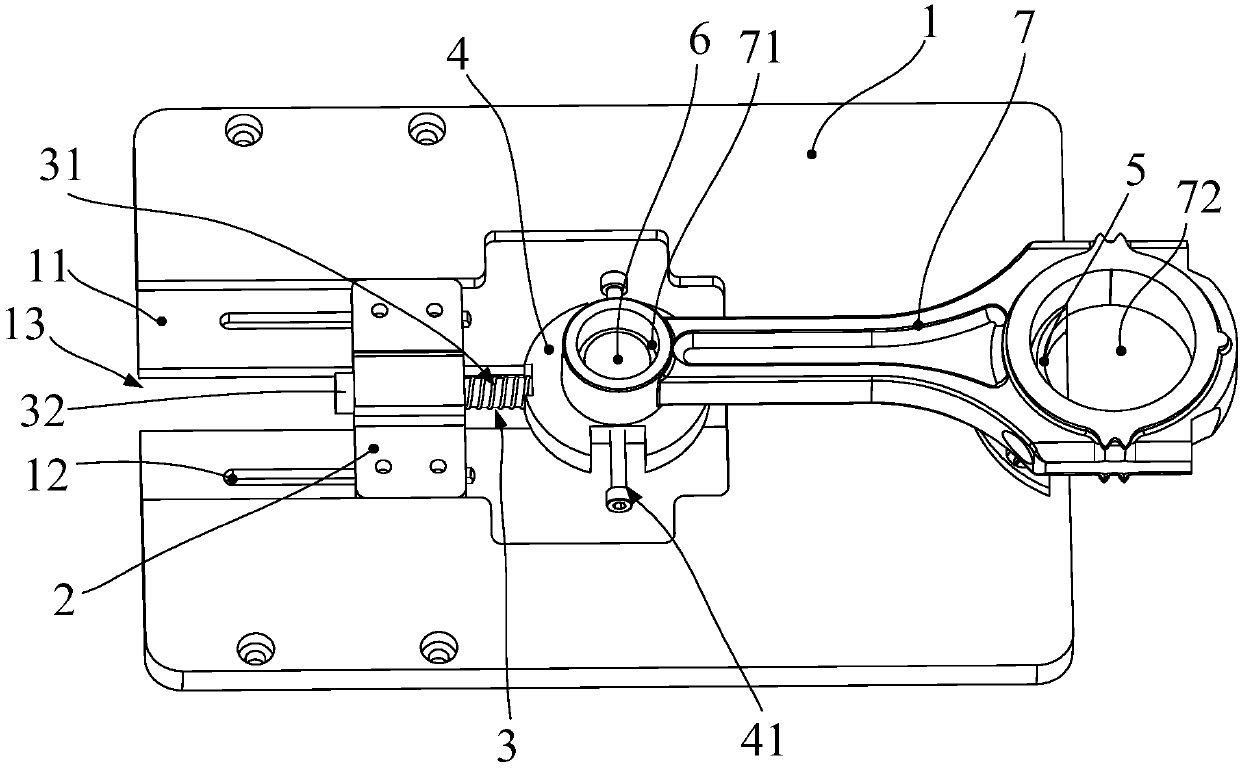

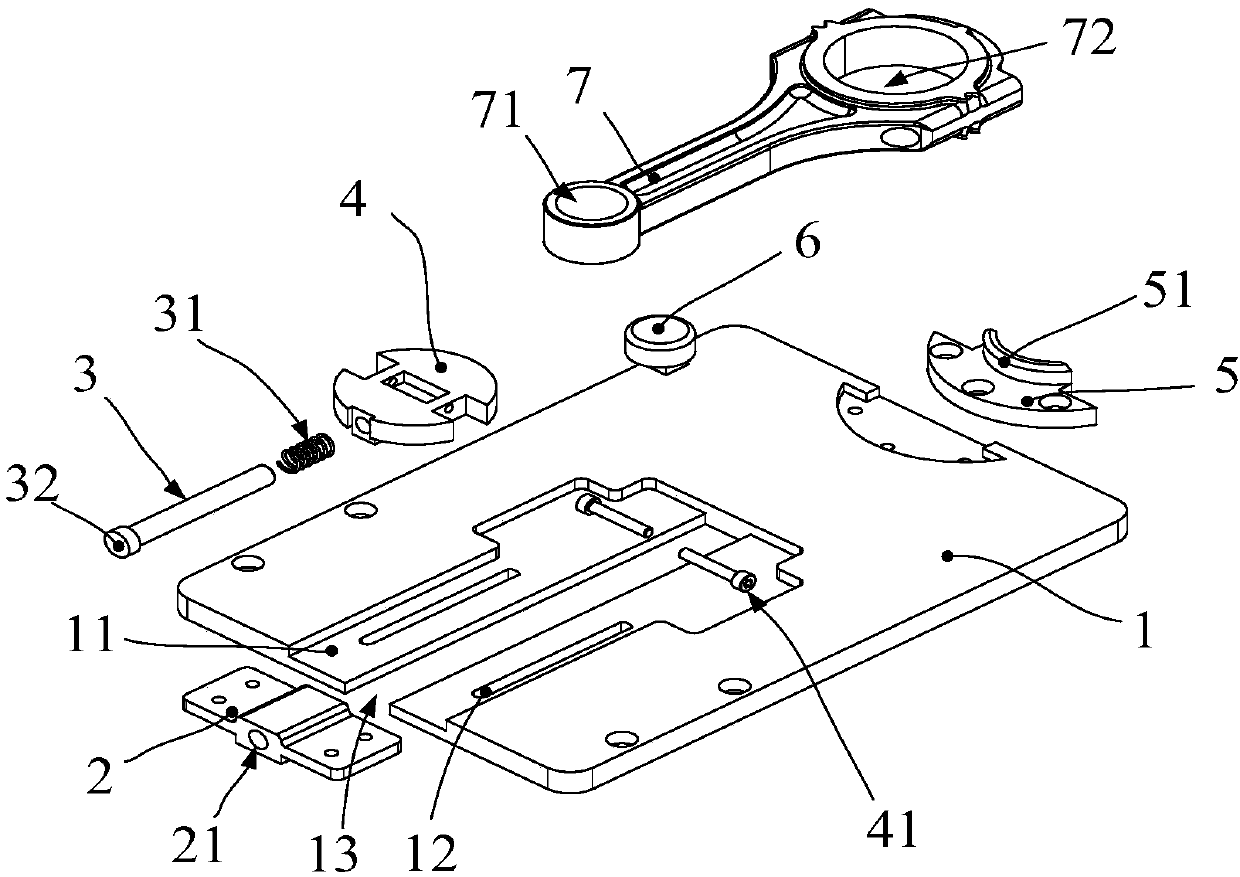

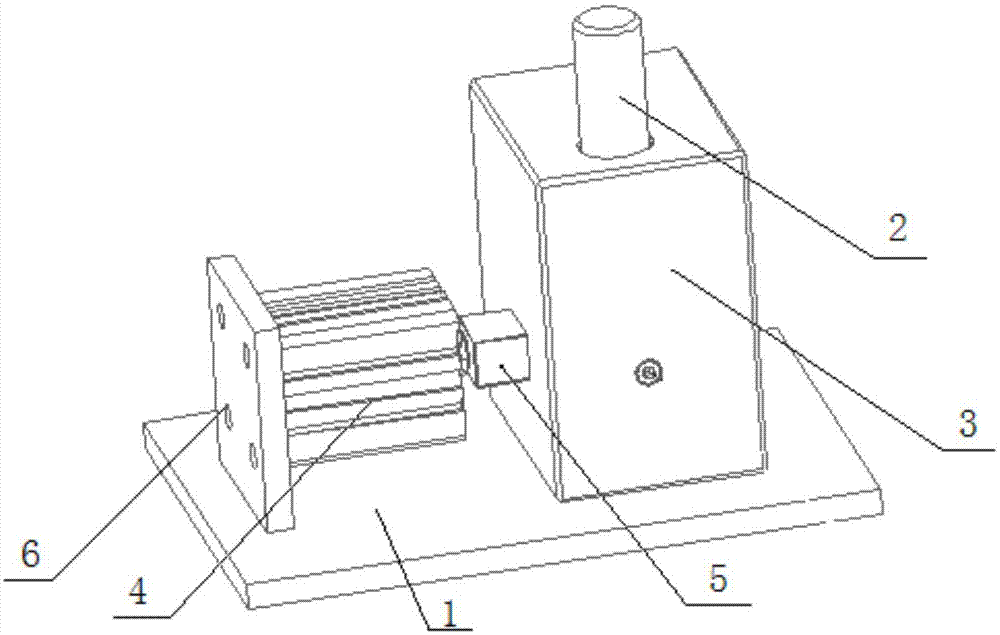

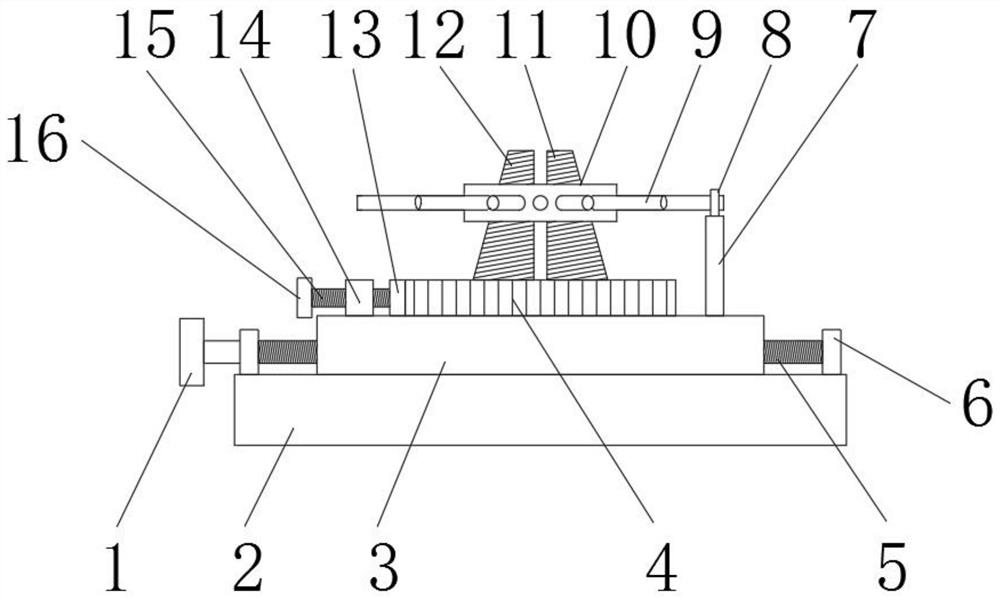

Adjustable simple clamping device and method for automobile connecting rod cracking groove machining

ActiveCN107838703AReduce the difficulty of clampingReduce wearPositioning apparatusElectrical-based auxillary apparatusEngineeringMachining

The invention discloses an adjustable simple clamping device for automobile connecting rod cracking groove machining. The adjustable simple clamping device comprises a base, the top face of the base is connected with a guide rod seat and a connecting rod big-end hole positioning seat, and a connecting rod small-end hole positioning seat is arranged between the guide rod seat and the connecting rodbig-end hole positioning seat. The guide rod seat is connected with the connecting rod small-end hole positioning seat through a guide rod arranged horizontally, the middle of the guide rod is sleeved with a spring, one end of the spring props against the other side face of the guide rod seat, and the other end of the spring props against the side face of the connecting rod small-end hole positioning seat. The top face of the connecting rod small-end hole positioning seat is further connected with a connecting rod small-end hole positioning pin, the top face of the connecting rod big-end holepositioning seat is provided with a cambered surface positioning block with a cambered surface, the connecting rod small-end hole positioning pin is inserted into a connecting rod small-end hole, andthe cambered surface positioning block is inserted into a connecting rod big-end hole, and the outer hook face props against the inner wall face of the connecting rod big-end hole and clamps and positions a connecting rod. The invention further provides a method for using the adjustable simple clamping device for automobile connecting rod cracking groove machining, and the adjustable simple clamping device and method aim to improve the automobile connecting rod clamping precision and machining efficiency.

Owner:GUANGDONG UNIV OF TECH

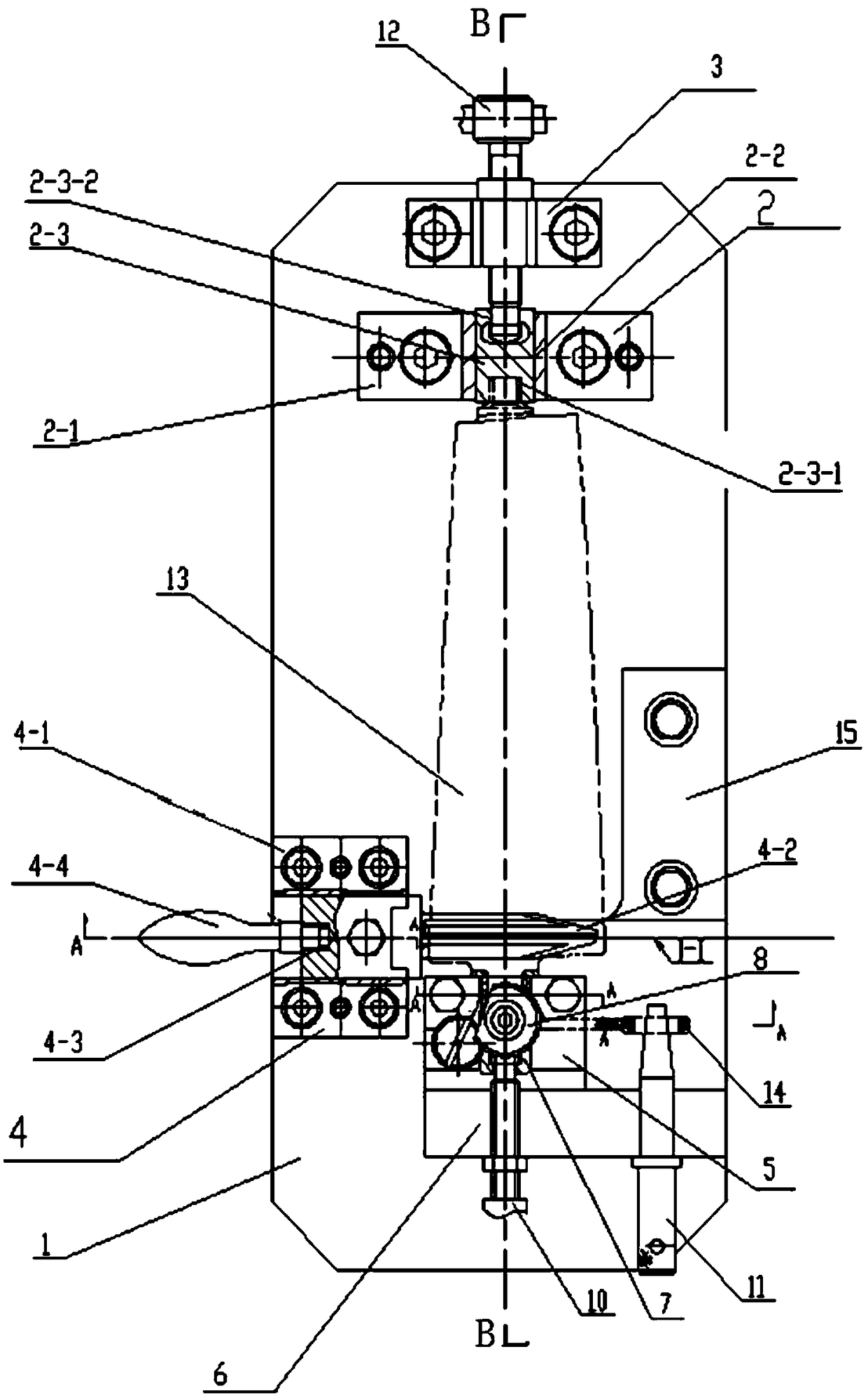

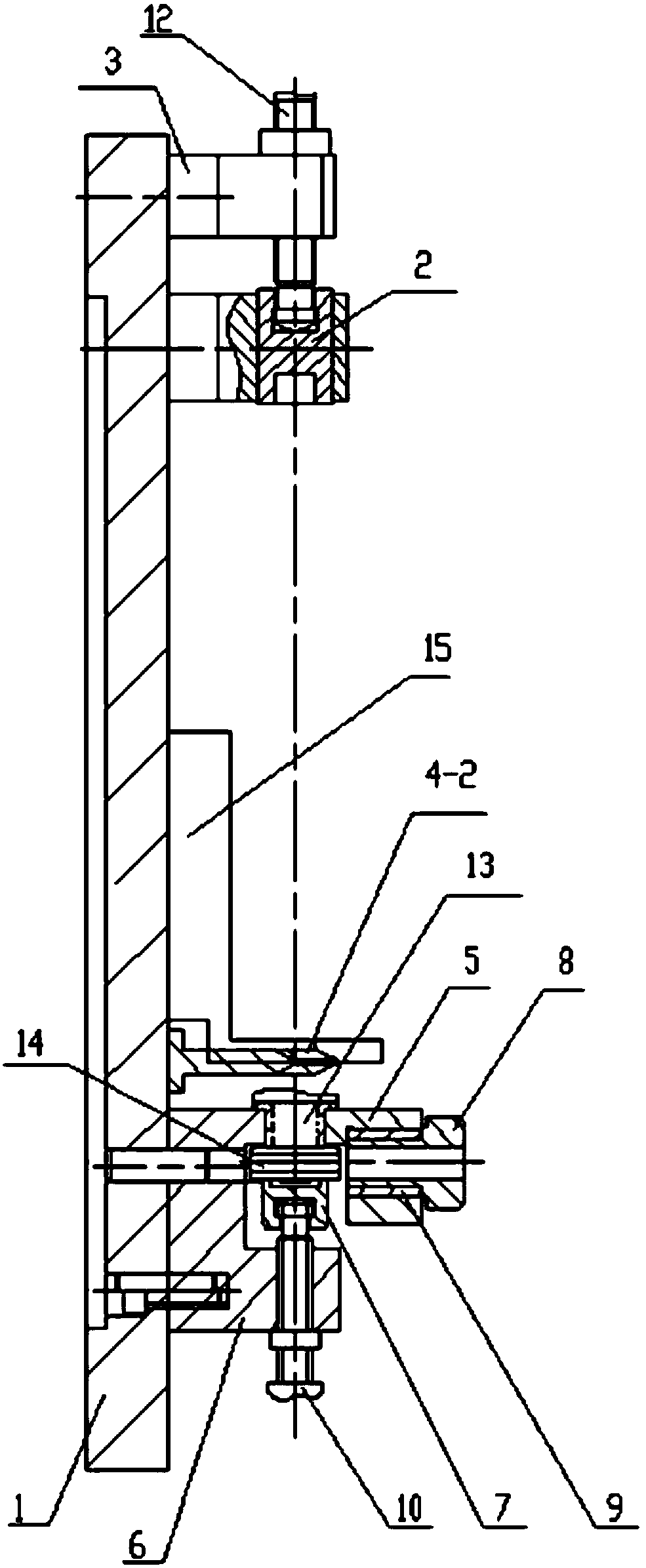

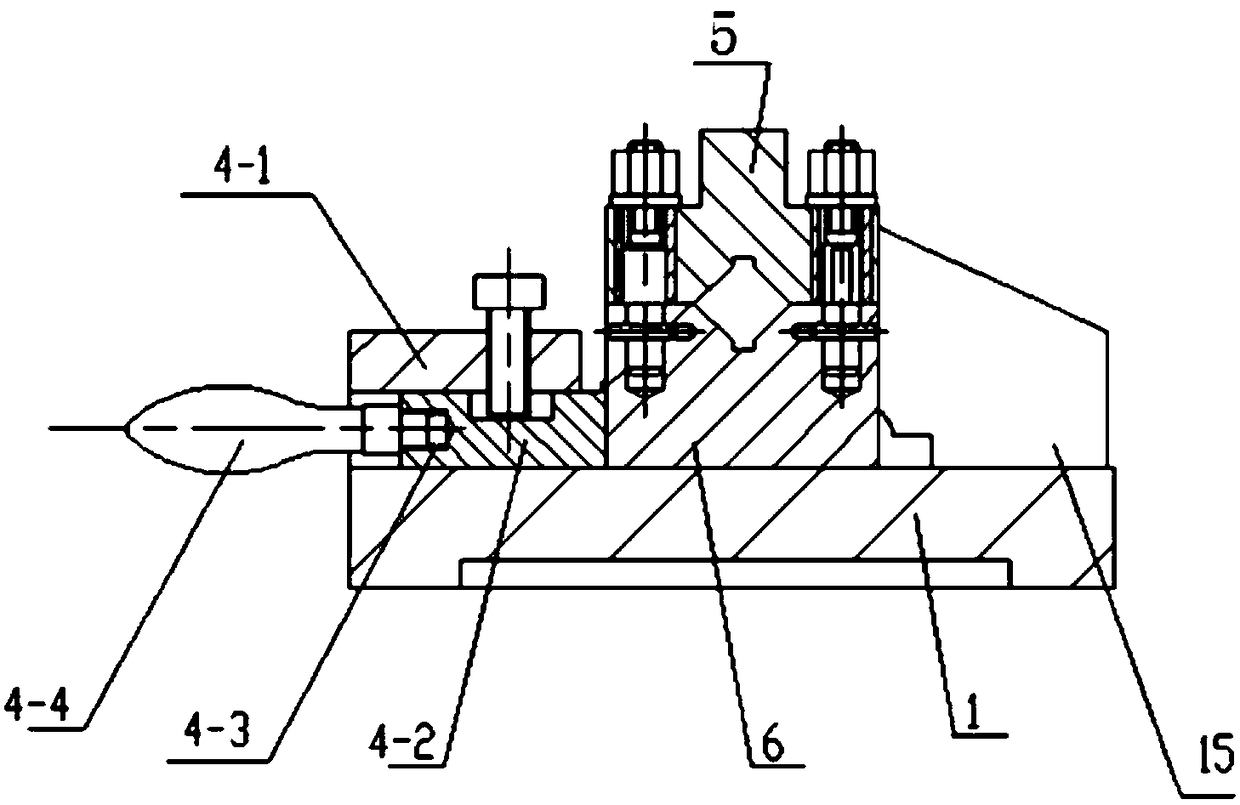

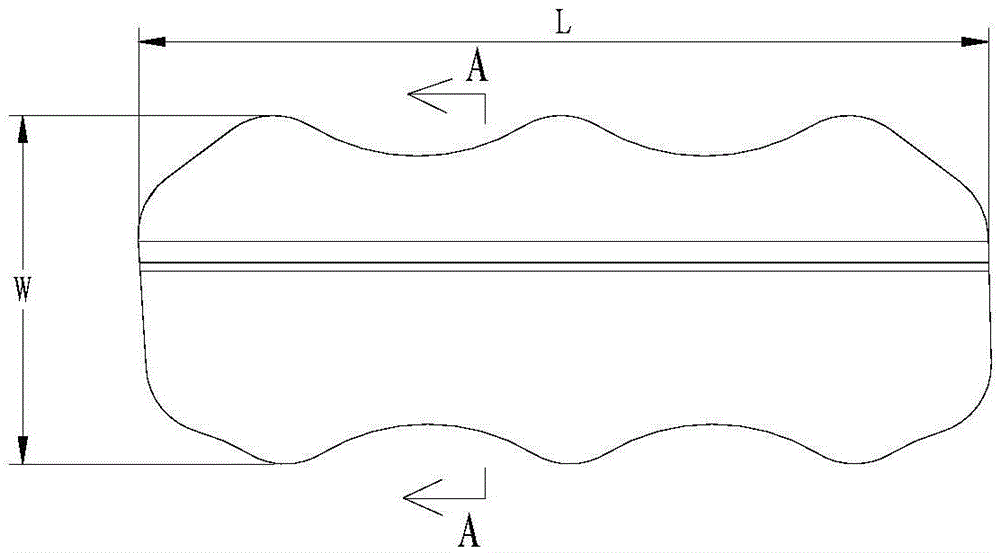

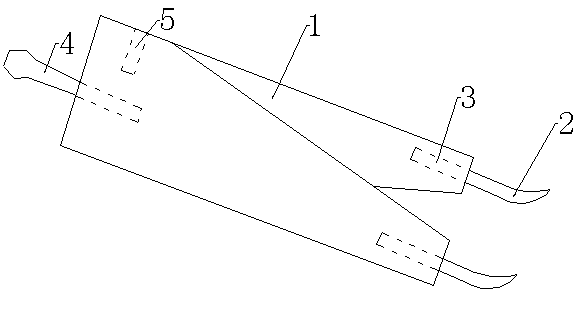

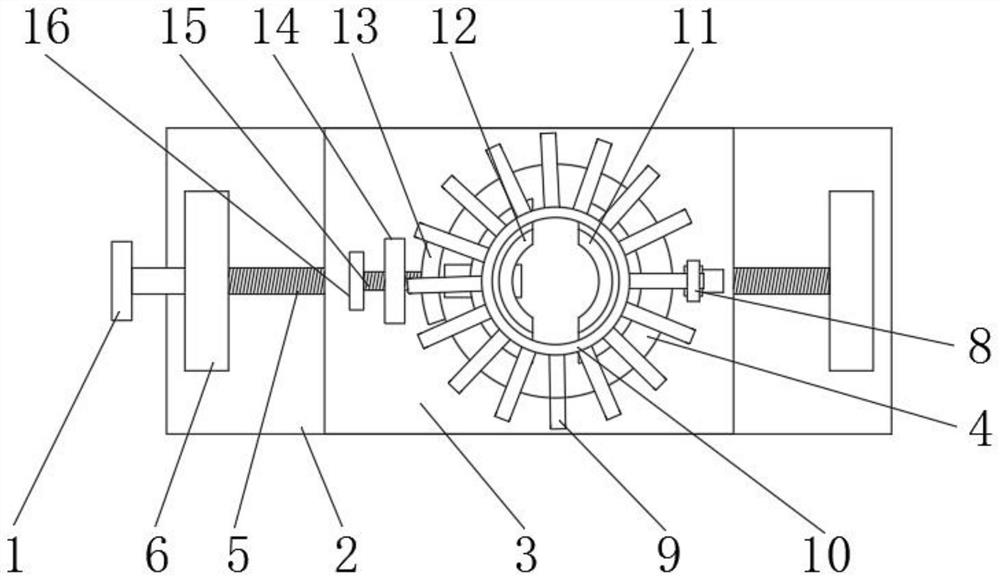

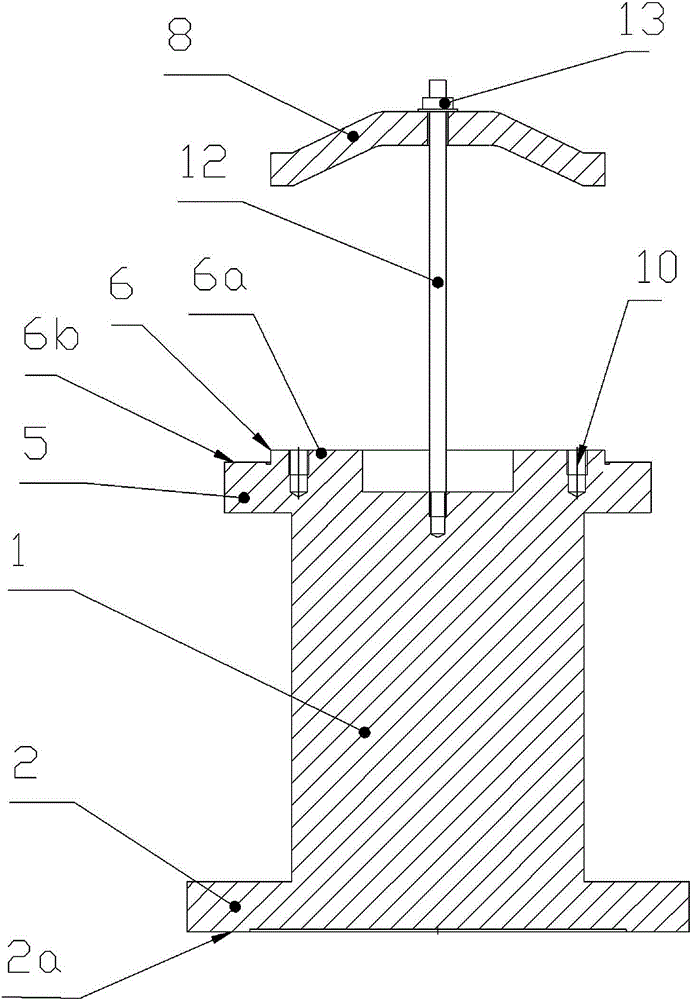

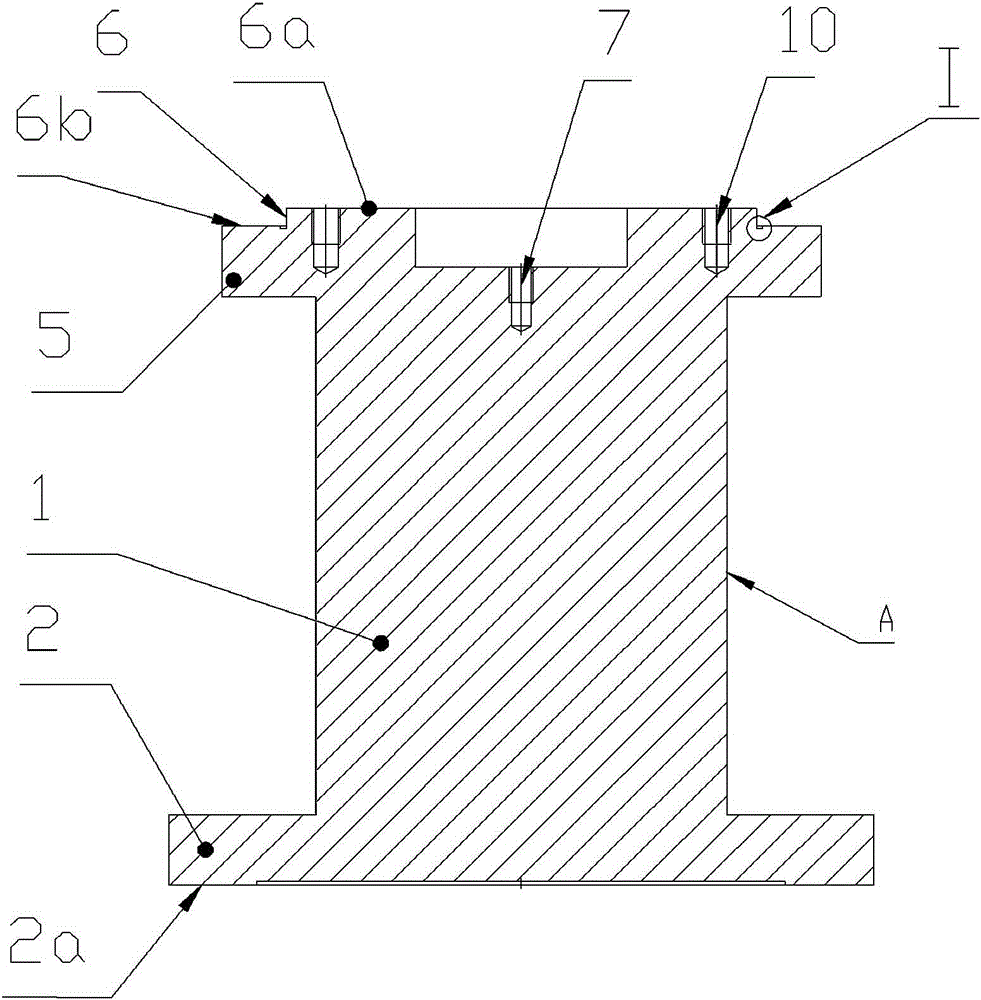

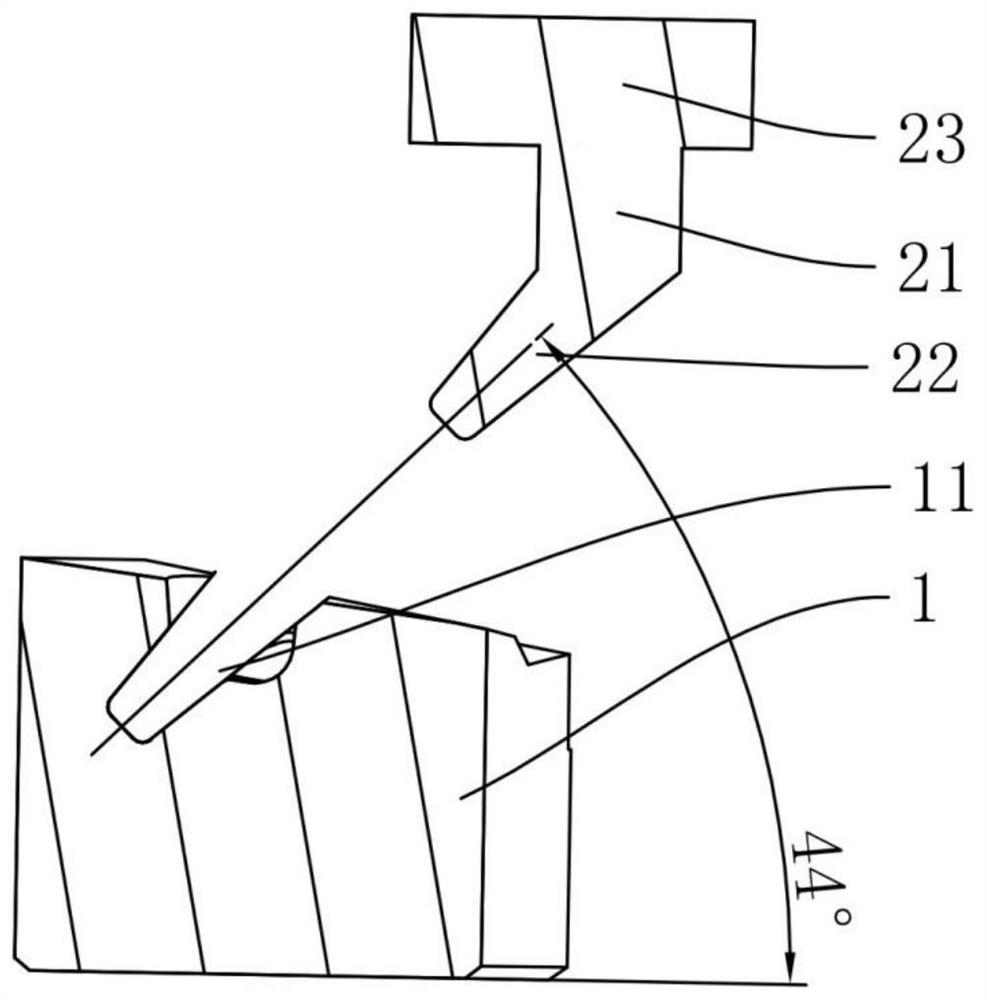

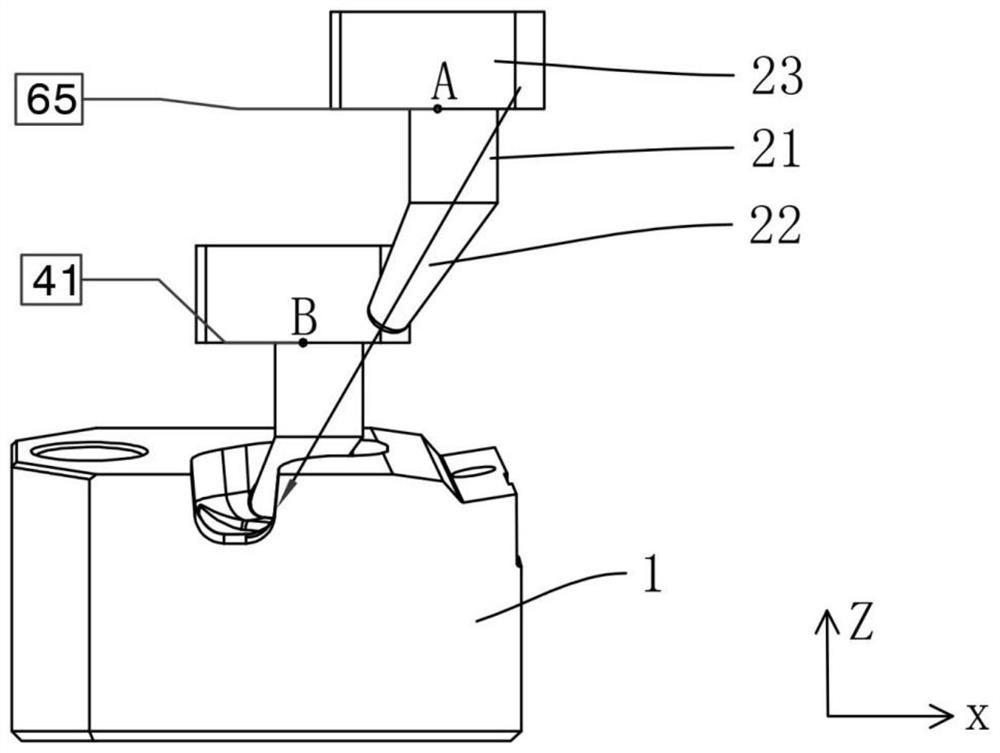

Aero-engine air inlet guide vane and rocker arm combined drilling device and using method thereof

ActiveCN108746726AImprove positioning accuracyReduce the difficulty of clampingPositioning apparatusDrill jigsAviationAxial compression

The invention discloses an aero-engine air inlet guide vane and rocker arm combined drilling device and a using method thereof. The aero-engine air inlet guide vane and rocker arm combined drilling device is positioned by two end points of an I-I cross-section chord line of a guide vane, and comprises a bottom plate, a rear journal axial positioning assembly, a front journal axial positioning piece, a rear journal positioning assembly, an axial compression screw, a pressing block, an angular positioning assembly, a compression template, a drill plate, a drill sleeve, a bushing and a rocker armpositioning pin. Since an included angle alpha between an intersecting line of the inclined surfaces of the upper portions of the two side faces of an angular positioning block of an angular positioning piece and the bottom surface is equal to an included angle between the I-I cross-section chord line of the guide vane and the axis of a rocker arm, the included angle between the I-I cross-sectionchord line of the guide vane and the axis of a rocker arm can be controlled within an allowable tolerance range by using the aero-engine air inlet guide vane and rocker arm combined drilling device to perform combined drilling operation of the guide vane and the rocker arm, and the qualification rate of parts can reach 95% or more; and meanwhile, the difficulty of clamping the guide vane during drilling operation is greatly reduced, and the efficiency is improved.

Owner:AECC AERO SCI & TECH CO LTD

Positioning machining method for thin hook-face parts

The invention discloses a positioning machining method for thin hook-face parts. The positioning machining method includes the specific machining processes that (1) the outline of a cutting part is machined; (2) the manner that one-time cutter feeding is carried out in the stock thickness direction and gradual cutter feeding is carried out in the stock width direction is used for machining the front face of the cutting part; (3) the front face of a transition part is cut to be thin; (4) a U-shaped chuck is turned over by 180 degrees around a rotation shaft of a positioning clamp, and the back face of the cutting part is machined in the cutter feeding manner adopted in the step (2); (5) the back face of the transition part is cut to be thin until only connecting lugs are left on the transition part; and (6) the connecting lugs are cut off to obtain the machined and molded thin hook-face parts. According to the positioning machining method, it is guaranteed that in the part machining process, the self rigidity keeps in the best state all the time, and vibration generated in the machining process is avoided.

Owner:ZHEJIANG XIZI AVIATION IND

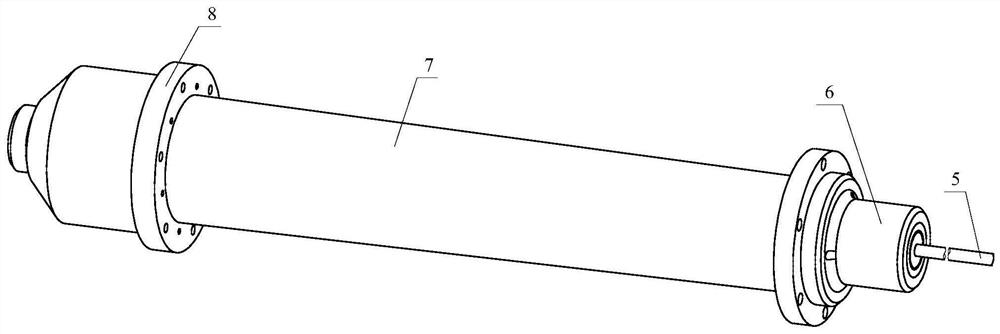

Rolling bearing no-load starting torque measuring device

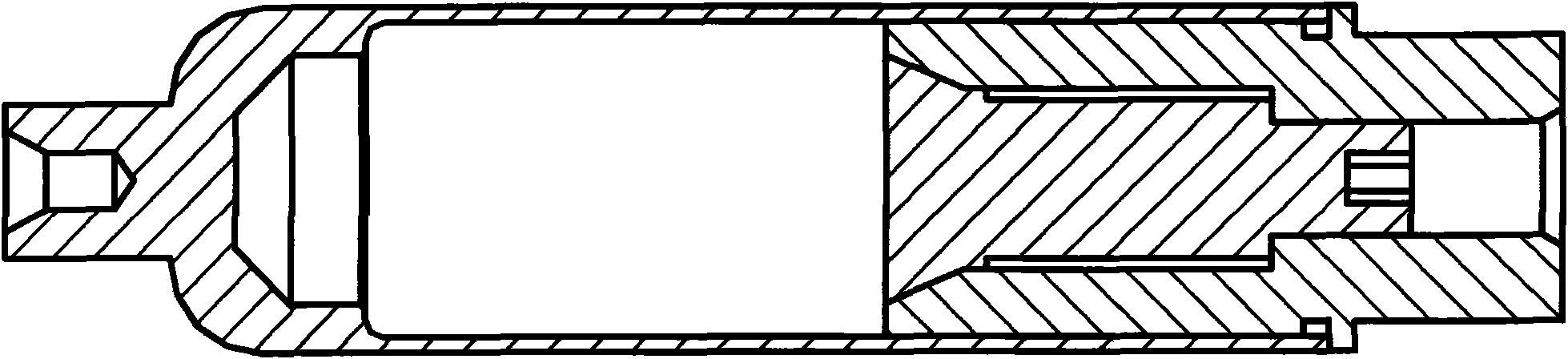

PendingCN109323790AAchieve fixationRealize measurementMachine bearings testingForce sensorsRolling-element bearingCoupling

The invention provides a rolling bearing no-load starting torque measuring device. The device comprises a rotating motor, a bearing seat, a measured bearing, a measuring mandrel, a coupling and a sensor, wherein the rotating motor is fixed on a rack; the cylindrical outer surface of the lower end of the bearing seat is connected with an output shaft of the rotating motor; an inner hole of the bearing seat is fixed to an outer ring of the measured bearing; the bottom of the measuring mandrel is connected with the measured bearing; the measuring mandrel is matched with the inner surface of an inner ring of the mandrel bearing and is fixed through a friction force between the measuring mandrel and the measured bearing; the upper part of the measuring mandrel is connected with the spring coupling through a connecting mechanism; and the spring coupling is connected with the torque sensor. The conical measuring mandrel is simple in structure, low in machining precision requirement and low inmachining difficulty, so that the detection cost can be effectively reduced.

Owner:CHINA AERO POLYTECH ESTAB

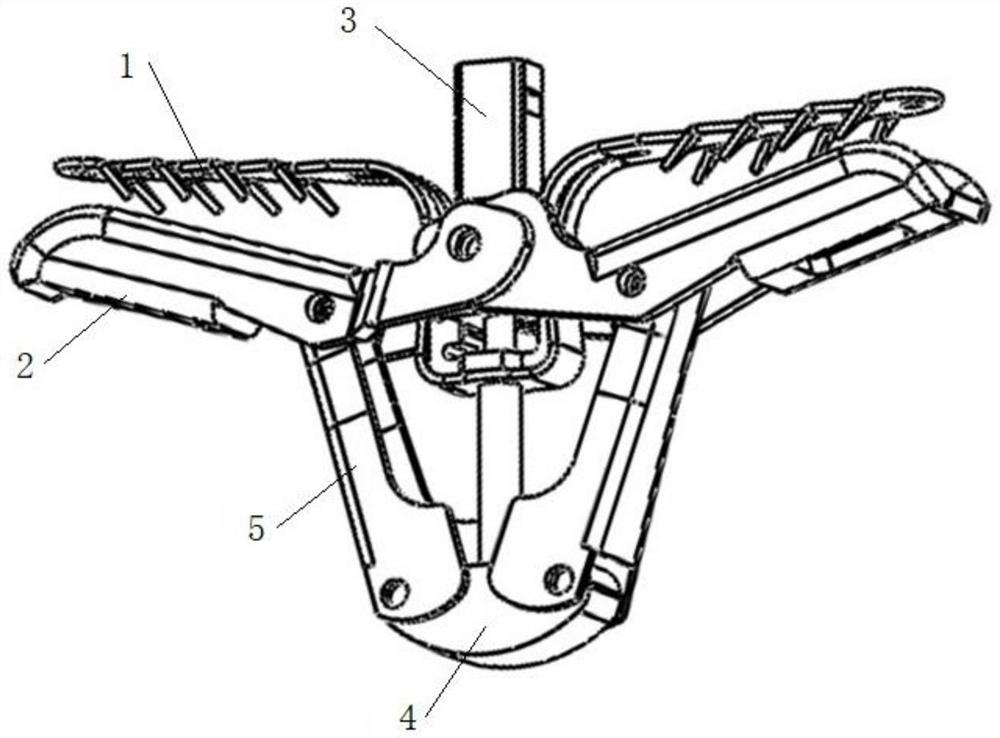

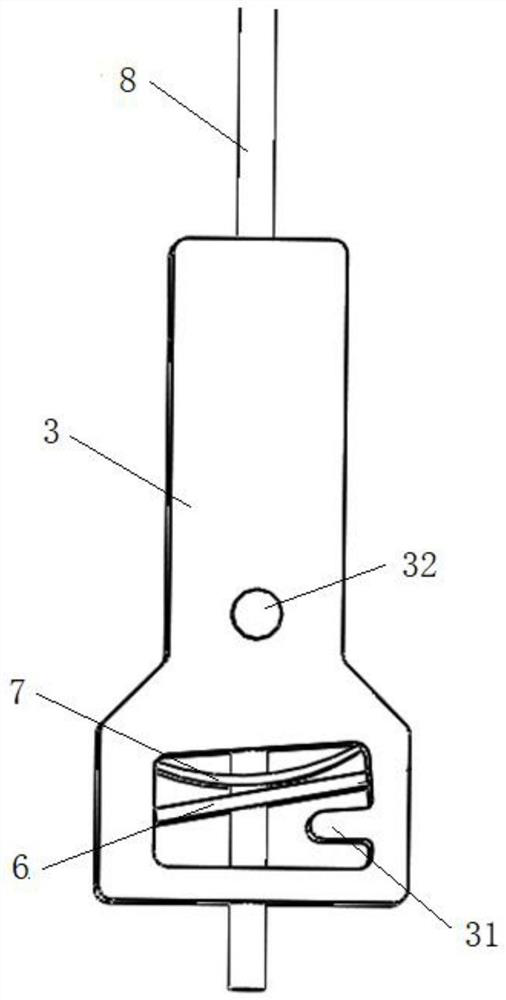

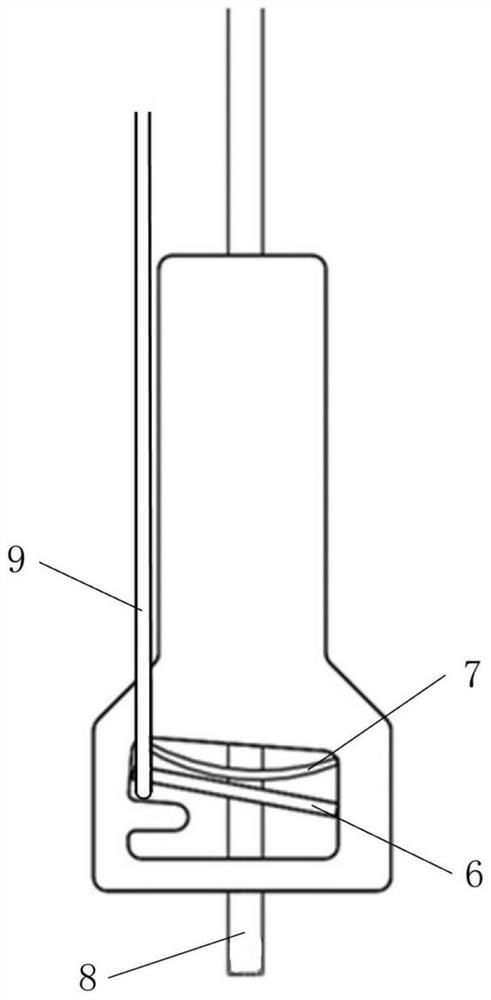

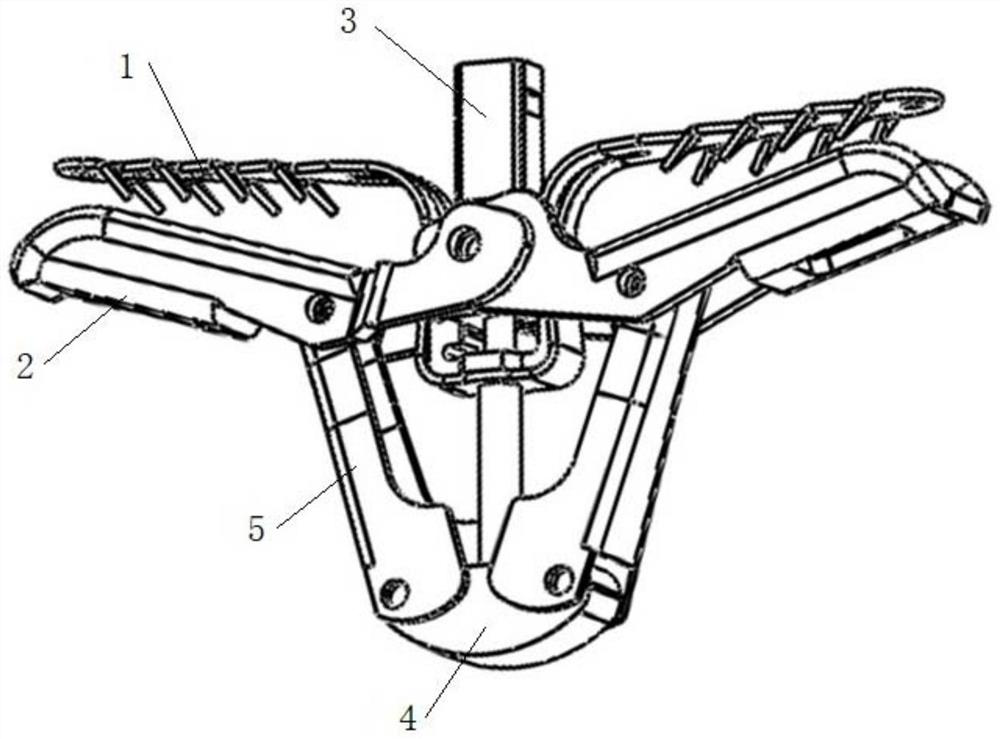

Multi-purpose tweezers

InactiveCN103831749AFlexible use and replacementReduce the difficulty of clampingMetal-working hand toolsForcepsMechanical engineering

The invention discloses a pair of multi-purpose tweezers. The pair of multi-purpose tweezers comprises two tweezers arms, a screwdriver and two tweezers heads, wherein the tails of the two tweezers arms are integrally formed. The front portions of the tweezers arms serve as free ends, the front ends of the free ends are both provided with installation holes of the tweezers heads, the screwdriver is arranged at the tail ends of the tweezers arms backwards, and the tweezers heads are in threaded connection with the installation holes of the tweezers heads. The pair of multi-purpose tweezers achieves multi-functionalization and improves the production operation efficiency. According to the multi-purpose tweezers, by the arrangement of the installation holes of the tweezers heads, the replaceable standardized tweezers heads and the screwdriver, the pair of tweezers can be more convenient and more flexible to use, achieve multi-functionalization in use, and improve the production efficiency.

Owner:叶小平

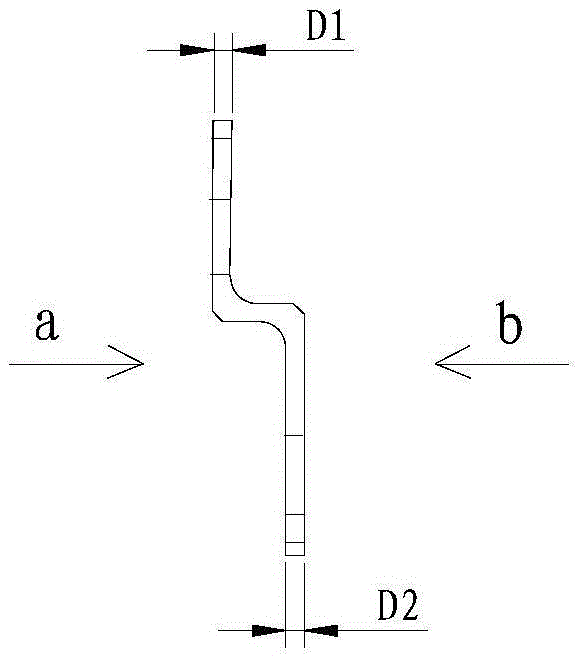

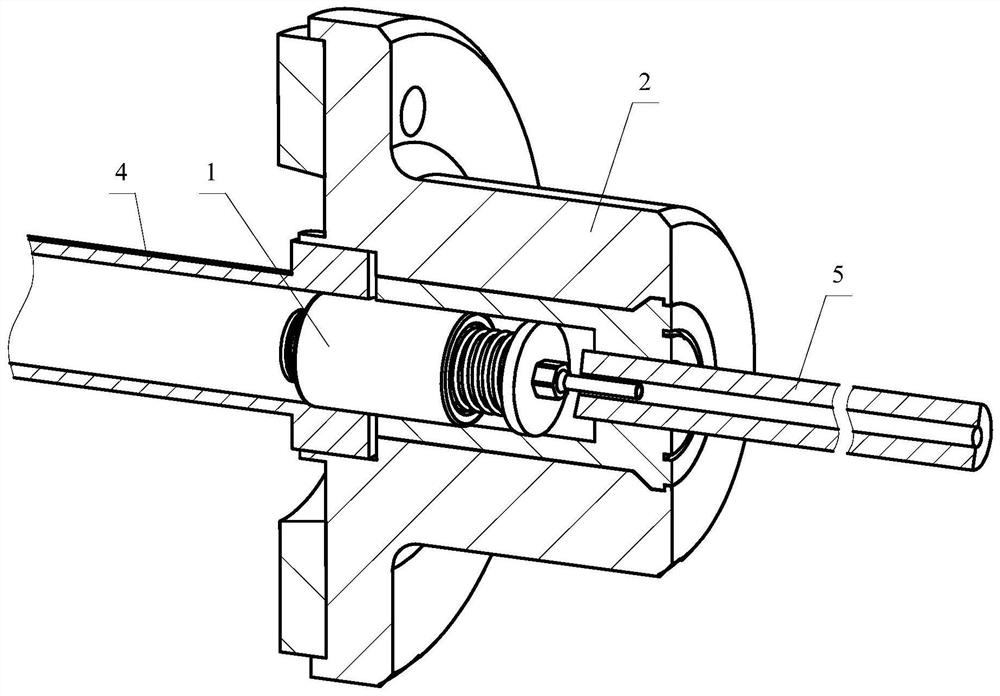

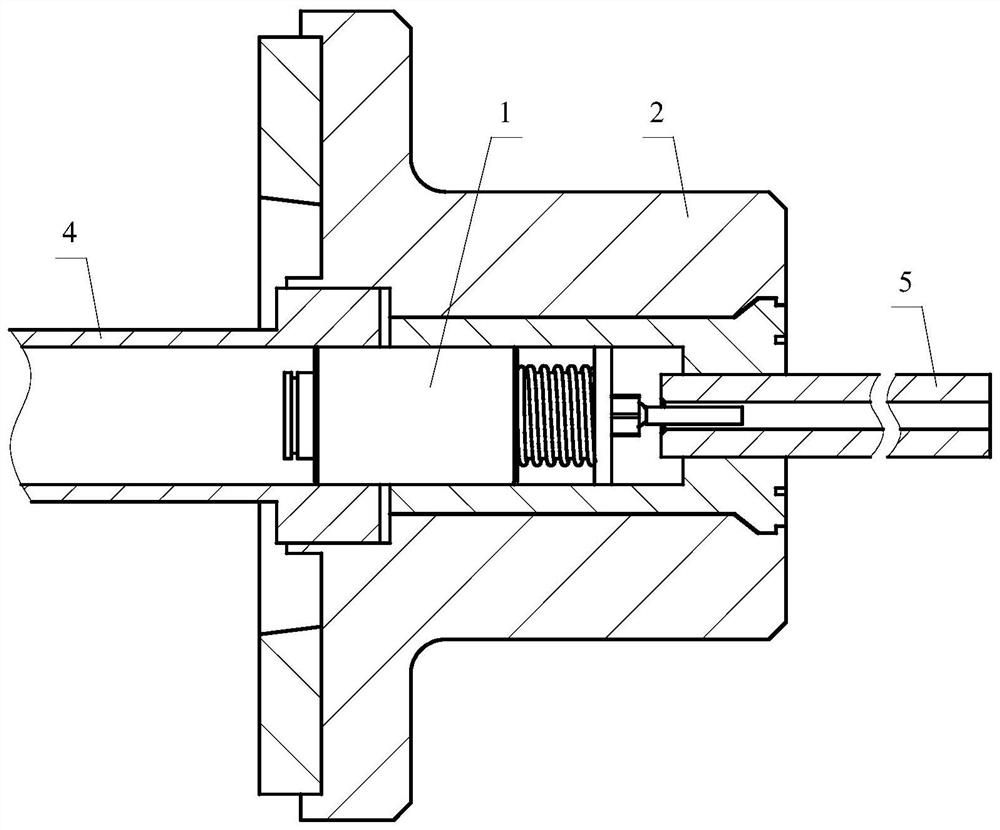

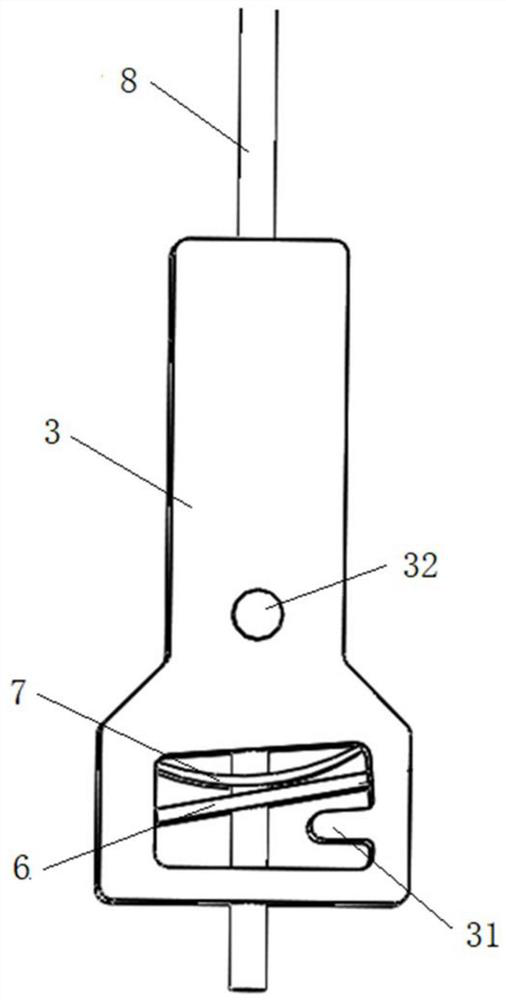

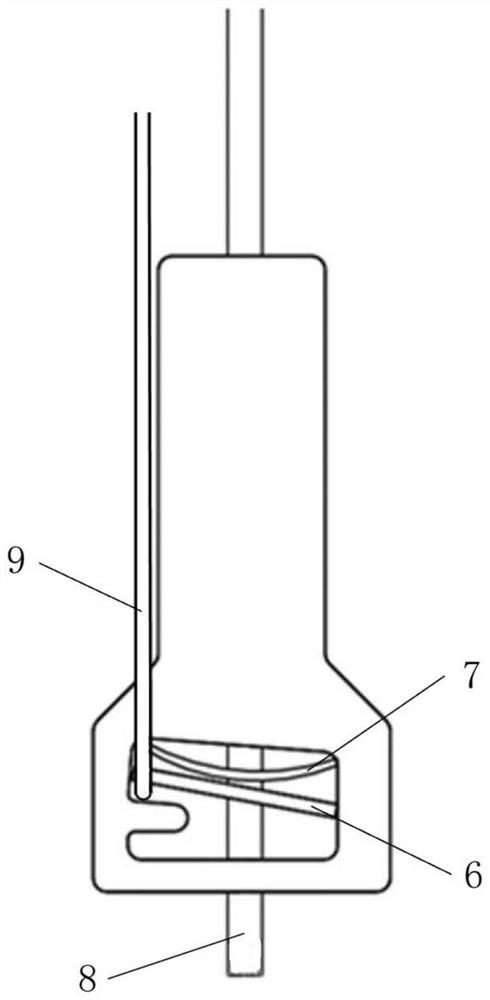

Flexible sealing main shaft center cooling device

ActiveCN112792615AContact stabilityAvoid destructionPositioning apparatusMaintainance and safety accessoriesEngineeringAxial vibration

The invention relates to the technical field of machining, in particular to a flexible sealing main shaft center cooling device. The flexible sealing main shaft center cooling device comprises a flexible sealing part and a clamping part with which the outer wall of the flexible sealing part is sleeved, wherein the flexible sealing part comprises an outer sleeve and an inner sliding sleeve which are sleeved with each other and can slide relatively; the outer sleeve is fixedly connected with the clamping part; an elastic element is arranged between the outer sleeve and the inner sliding sleeve so as to realize the axial reset movement of the inner sliding sleeve; a sealing head used for abutting against a workpiece is arranged at the end portion of the inner sliding sleeve; the sealing head is provided with an arc-shaped top face so as to be matched with and seal an end face round hole of the workpiece; a water nozzle used for being inserted into the workpiece is arranged on the arc-shaped top face; and cooling liquid channels are formed in the inner sliding sleeve and the sealing head and used for injecting cooling liquid into the workpiece in a circulating mode. According to the flexible sealing main shaft center cooling device, the length tolerance of a pipe can be compensated, the axial vibration impact can be buffered, the machining efficiency of the pipe is improved, the service life of a cutter is prolonged, precision manufacturing, especially the manufacturing process requirement of a multi-taper special-shaped hole, can be well adapted, and the labor intensity is effectively reduced.

Owner:CHENGDU TECHCAL UNIV +1

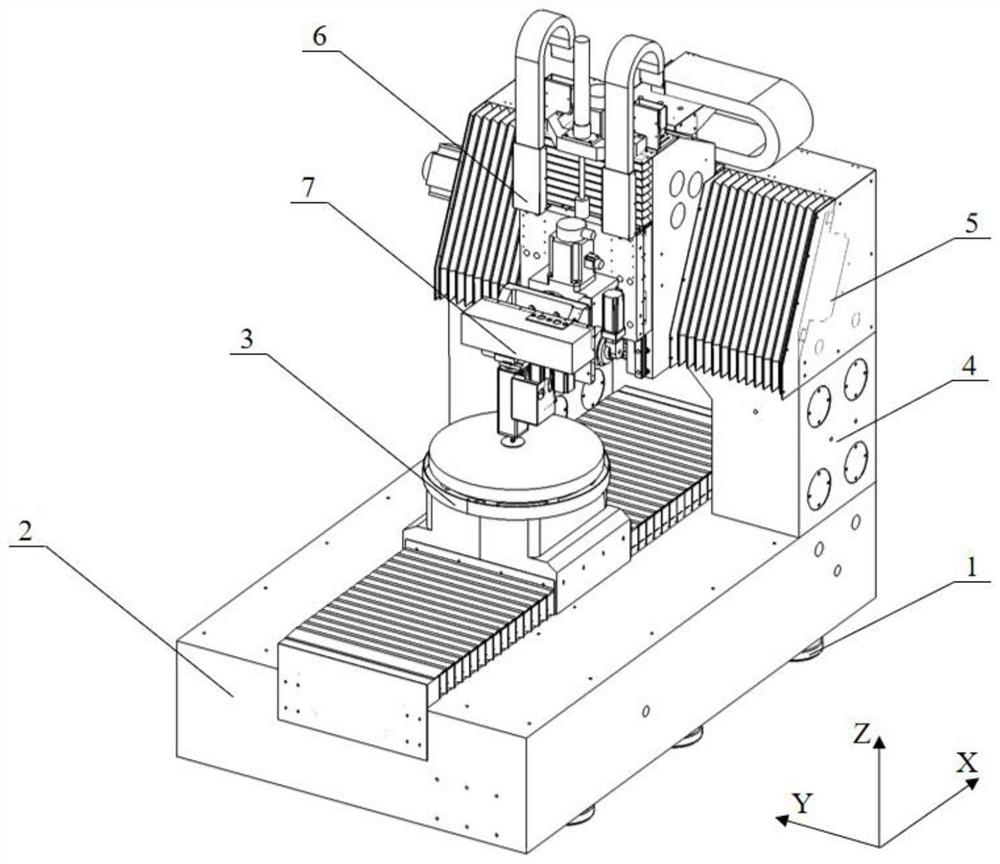

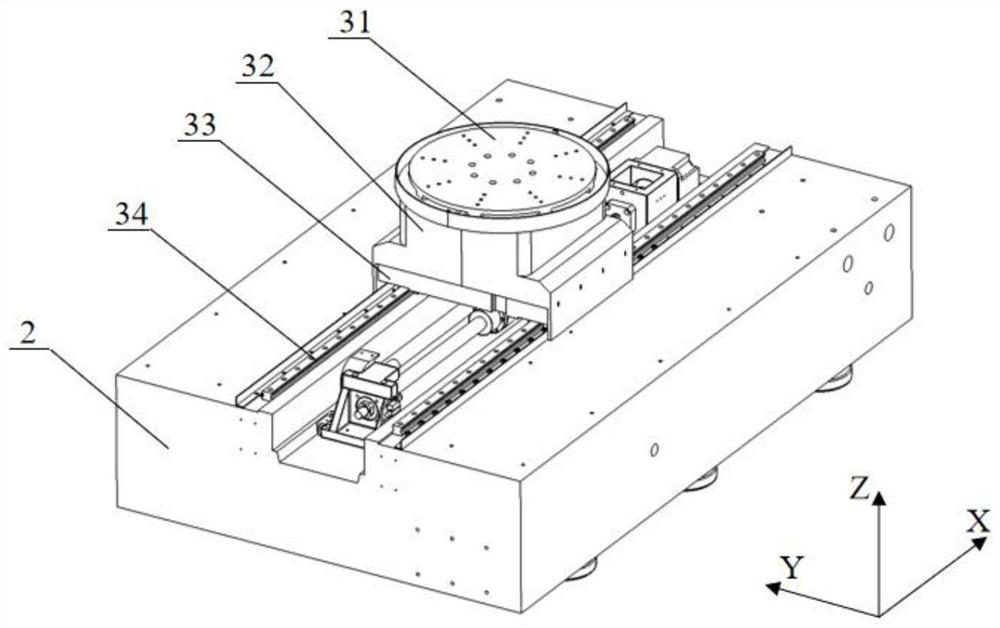

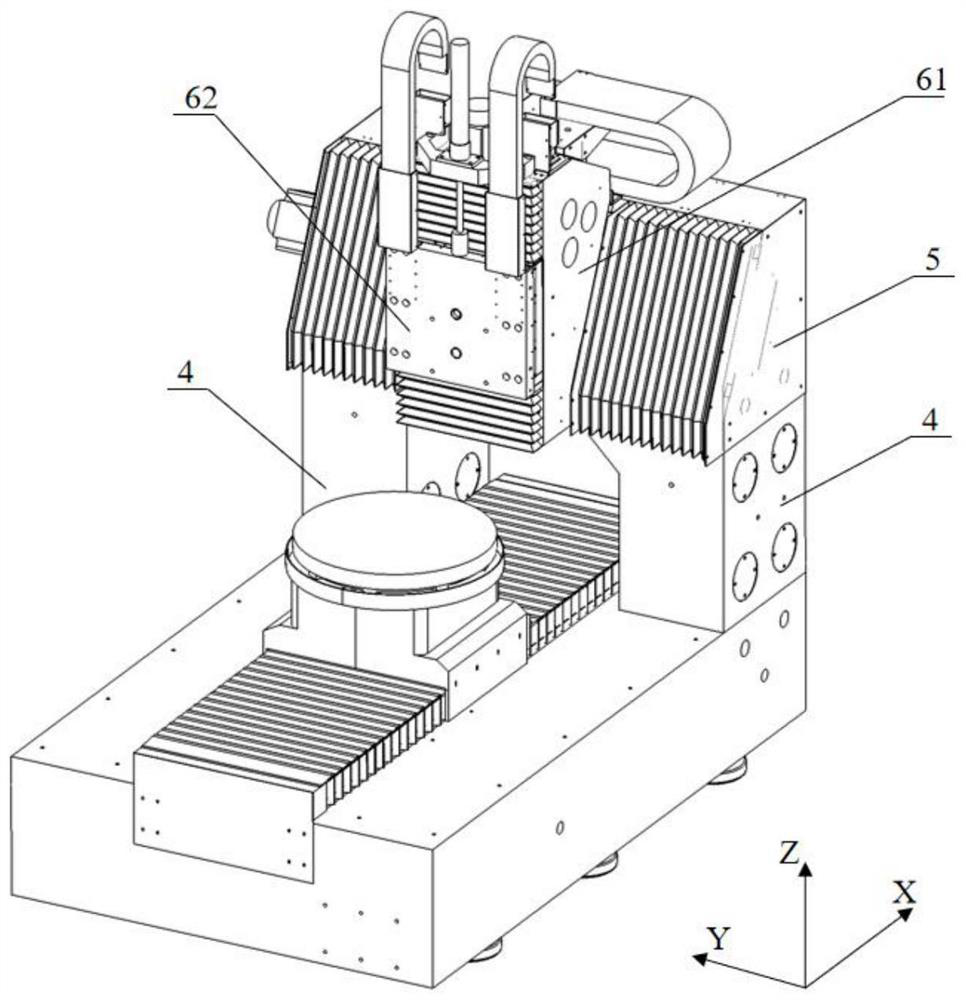

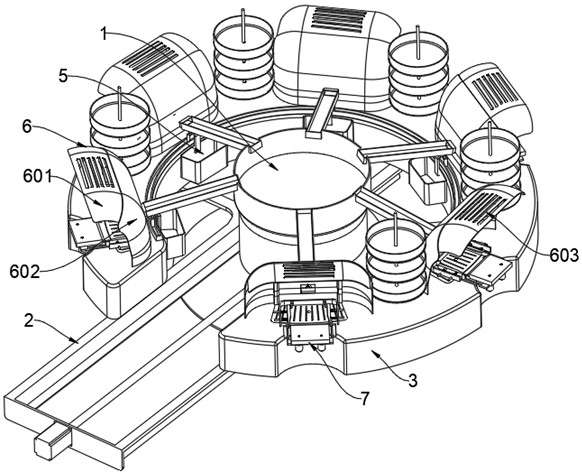

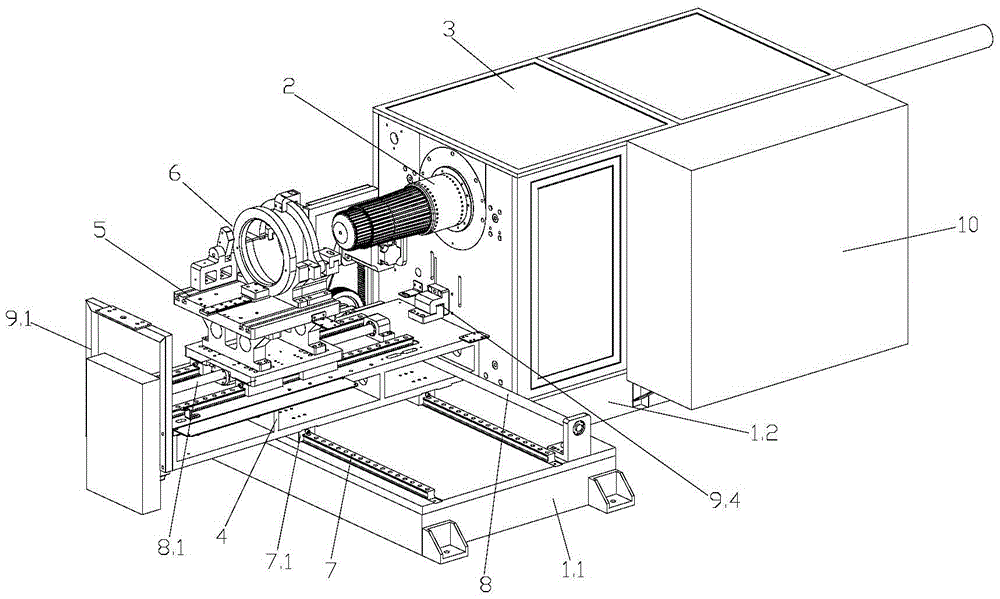

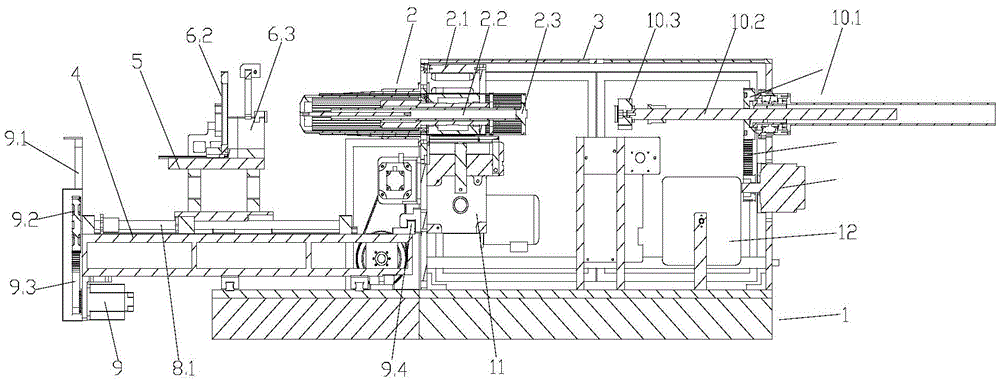

Polishing equipment for multi-axis free-form surface optical element and working method

PendingCN112847017APrecise positioningEasy clampingGrinding carriagesOptical surface grinding machinesPolishingUltra precision

The invention discloses polishing equipment for a multi-axis free-form surface optical element and a working method. A lathe bed is horizontally placed, and a workpiece to be machined is horizontally placed on a high-precision rotary table through a clamp, so that positioning and clamping are facilitated, the machining efficiency is improved, the clamping difficulty and deformation caused by clamping are reduced, and the large-diameter free-form surface optical element can be machined. The high-precision rotary table can move along the X axis relative to the lathe bed and rotate around the C axis, a multi-axis free-form surface polishing device can move on a cross beam in the Y-axis direction and the Z-axis direction, and can conduct servo rotation around an A axis parallel to the X axis and a B axis parallel to the Y axis. Therefore, the optical element subjected to ultra-precision turning and grinding can be further shaped, and the precision better than that of traditional machining can be achieved.

Owner:湖南大敏尚东精密机械有限公司

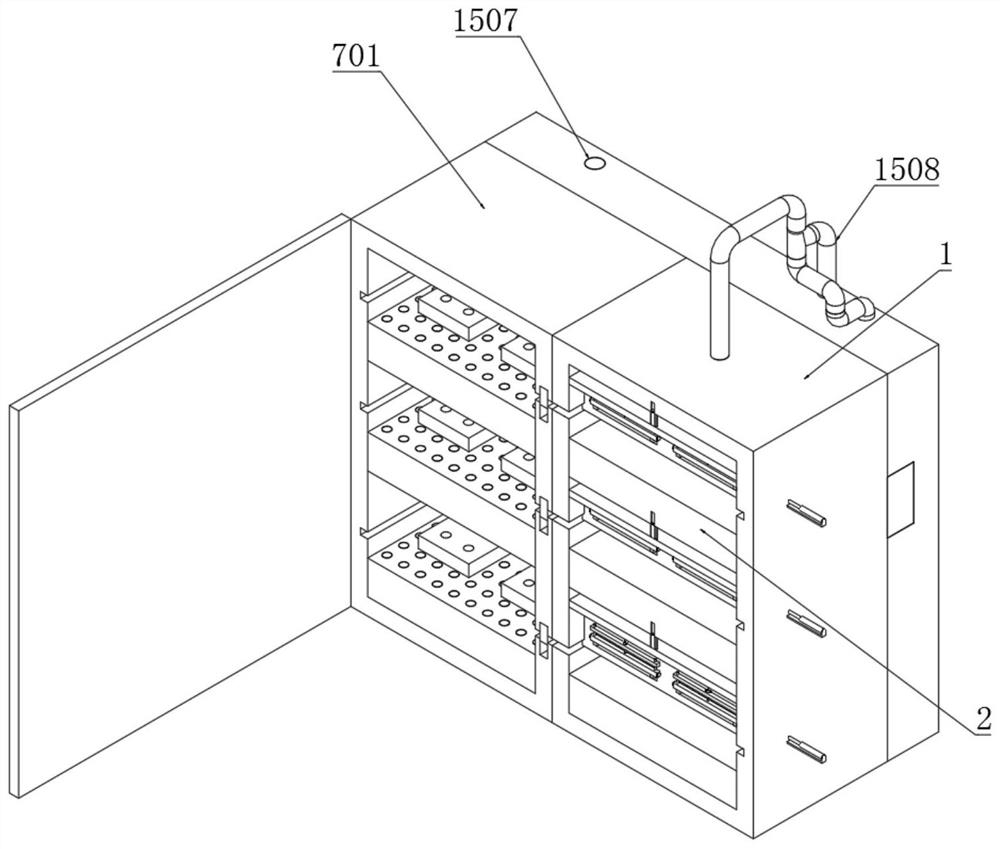

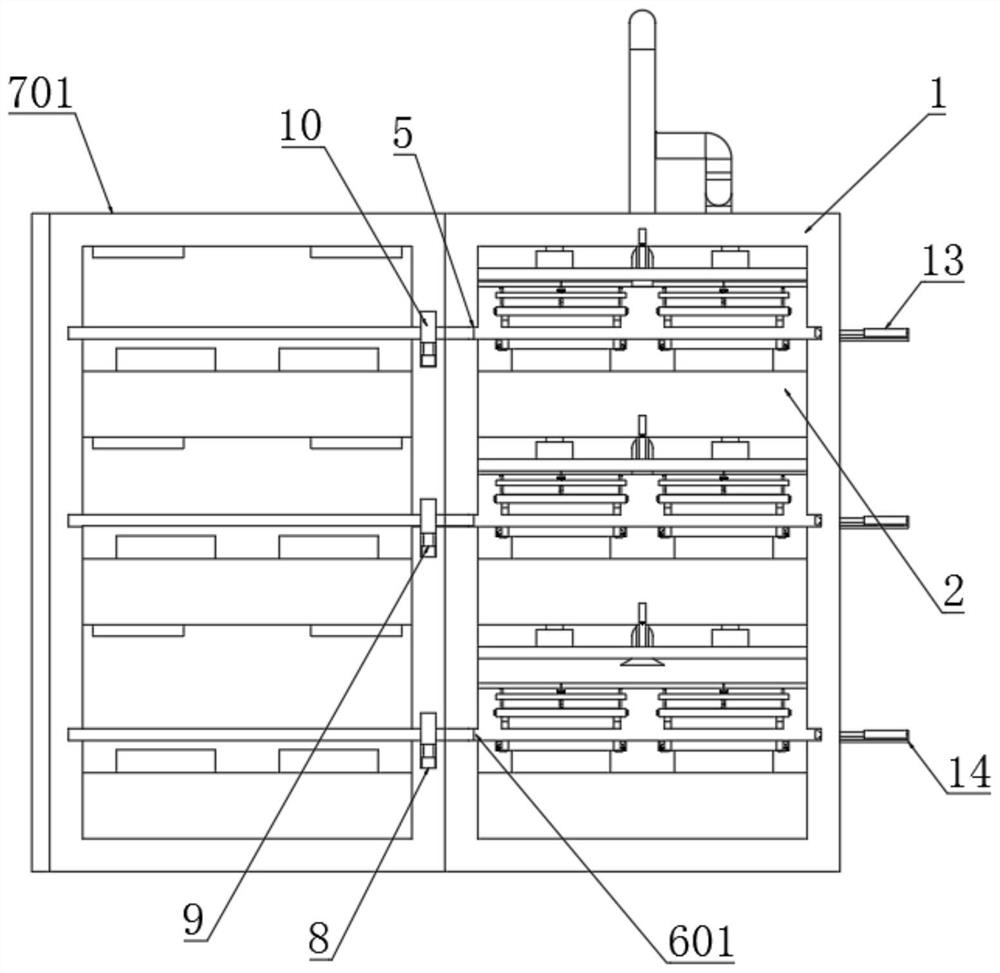

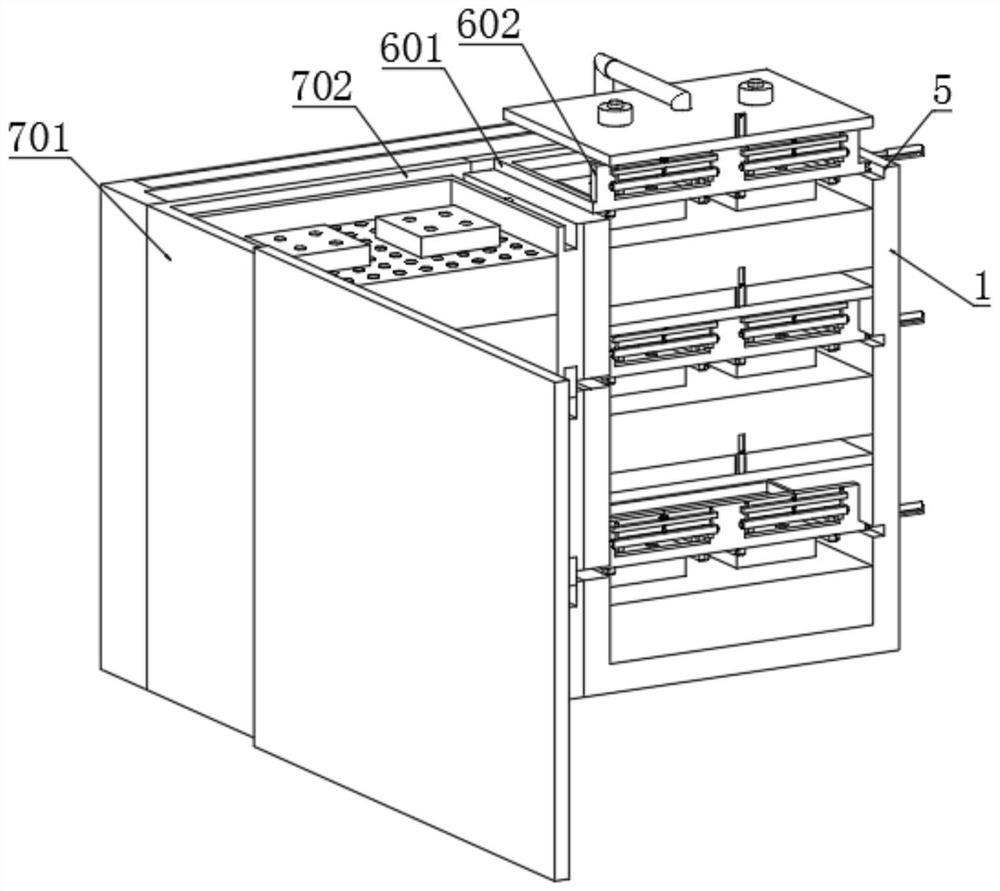

Baking and shaping device based on vacuum switch tube

PendingCN111863487ASmooth rotationAvoid shakingLighting and heating apparatusDispersed particle separationElectric machineVacuum switch

The invention discloses a baking and shaping device based on a vacuum switch tube. The device comprises a baking box, wherein partition plates are welded to an inner wall of the baking box at equal intervals, a slave moving groove is formed in a front surface of an inner wall of the baking box corresponding to a top end edge of the partition plate, heaters are fixedly mounted in positions, corresponding to edges of top ends of the moving grooves, of the front surface of the inner wall of the baking box, and clamping rotating mechanisms are fixedly mounted on two sides of the inner walls of thepartition plates. The device is advantaged in that the structure is scientific and reasonable, safe and convenient use, a positioning gear, a rotating gear, a rotating plate, a groove, a wedging holeand a mold plate are arranged, a mold plate can be conveniently mounted, mounting difficulty of the mold plate is reduced, meanwhile, the position of the mold plate can be limited, a phenomenon thatthe position shakes when the mold plate rotates is prevented, the rotating plate can rotate conveniently through the motor, and therefore a surface of the mold plate can rotate conveniently, and a vacuum switch tube on a surface of the mold plate can be rotated and baked.

Owner:刘丽娟

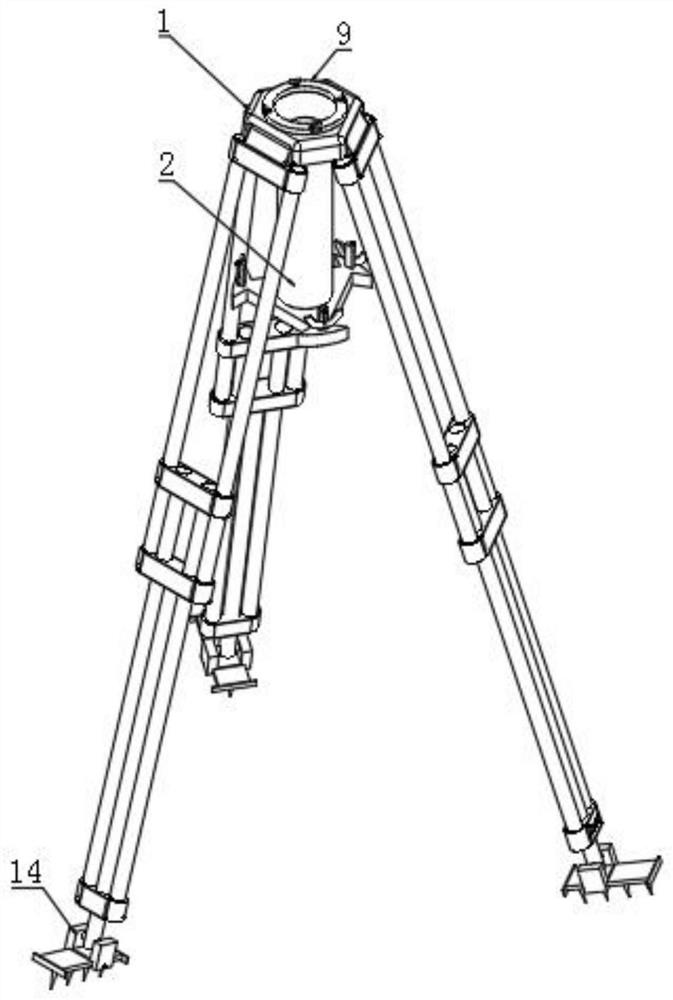

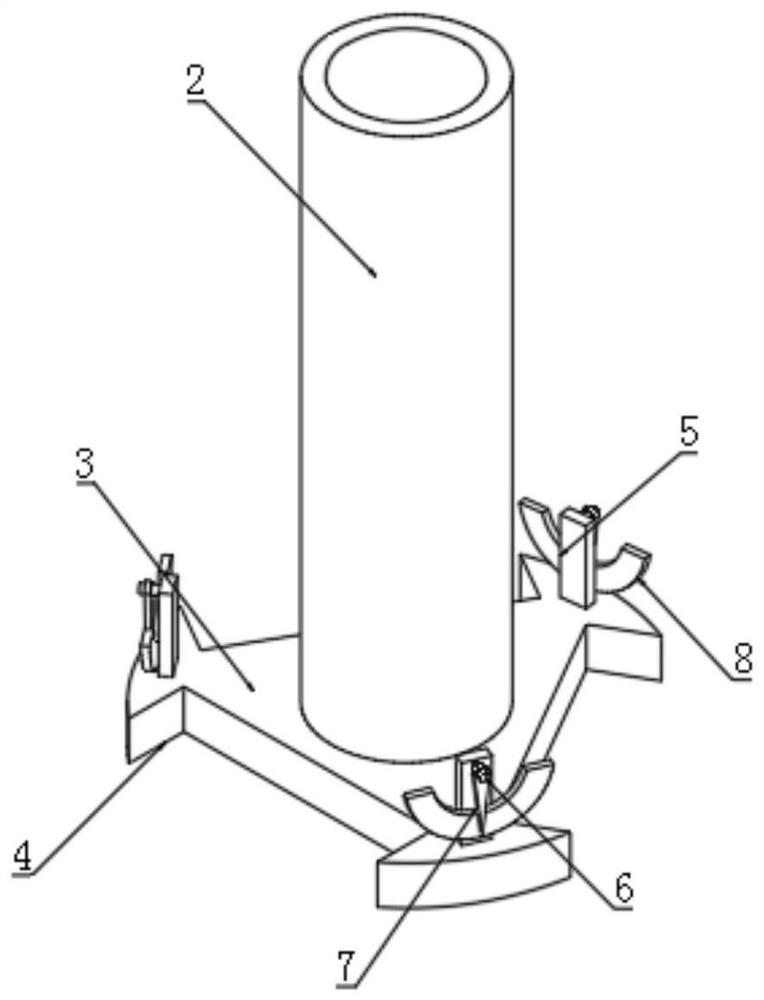

Surveying and mapping device for land consolidation

InactiveCN113028211AEasy accessReduce difficultySurveying instrumentsStands/trestlesLand consolidationPipe

The invention discloses a surveying and mapping device for land consolidation. The surveying and mapping device comprises a triangular supporting frame, a hollow pipe is welded to the middle of the bottom end of the triangular supporting frame, a connecting plate is fixedly installed on the edge of the bottom end of the hollow pipe, notches are formed in the middles of the three edges of the outer surface of the connecting plate, and fixing blocks are welded to the three corners at the top ends of the connecting plate. A rotating column is welded to the middle of one end of each fixing block, and a hanging rod is rotationally connected to one end of the outer surface of each rotating column. Through the triangular supporting frame, the hollow pipe, the connecting plate, the notches, the fixing blocks, the rotating columns, the hanging rods and arc-shaped strips, supporting legs of the triangular supporting frame can be conveniently clamped, and the phenomenon that the supporting legs of the triangular supporting frame shake after being gathered is prevented. Meanwhile, the levelness of the triangular supporting frame can be observed, the observation difficulty of the levelness of the triangular supporting frame is lowered, then the triangular supporting frame can be leveled conveniently, and the leveling difficulty of the triangular supporting frame is lowered.

Owner:盐城兴城置业有限公司

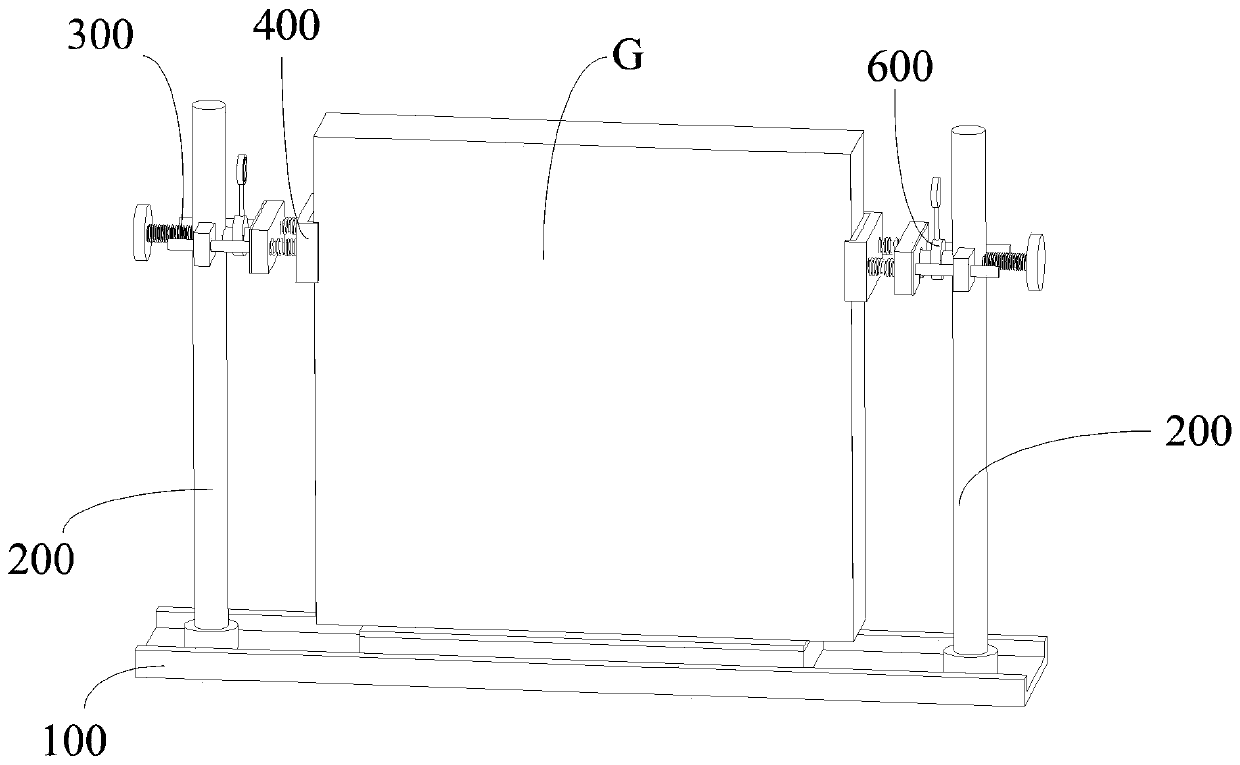

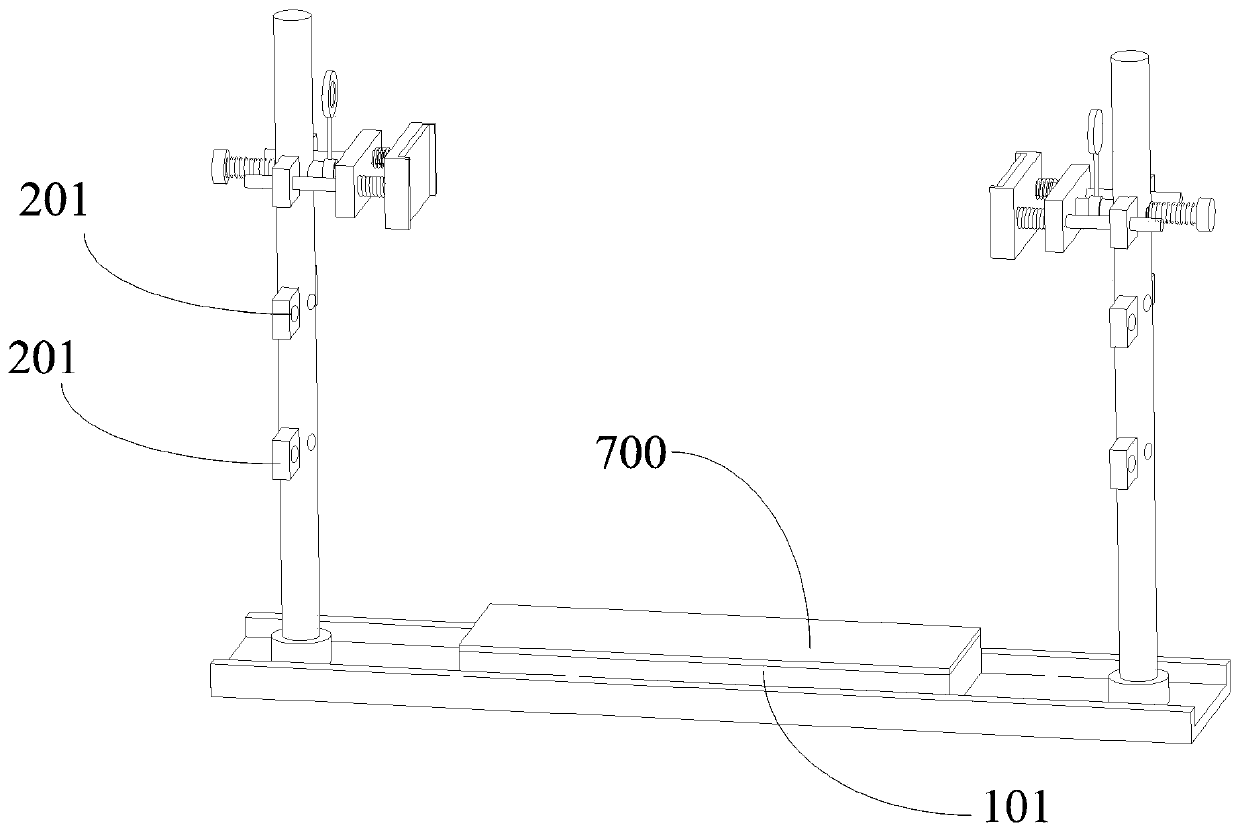

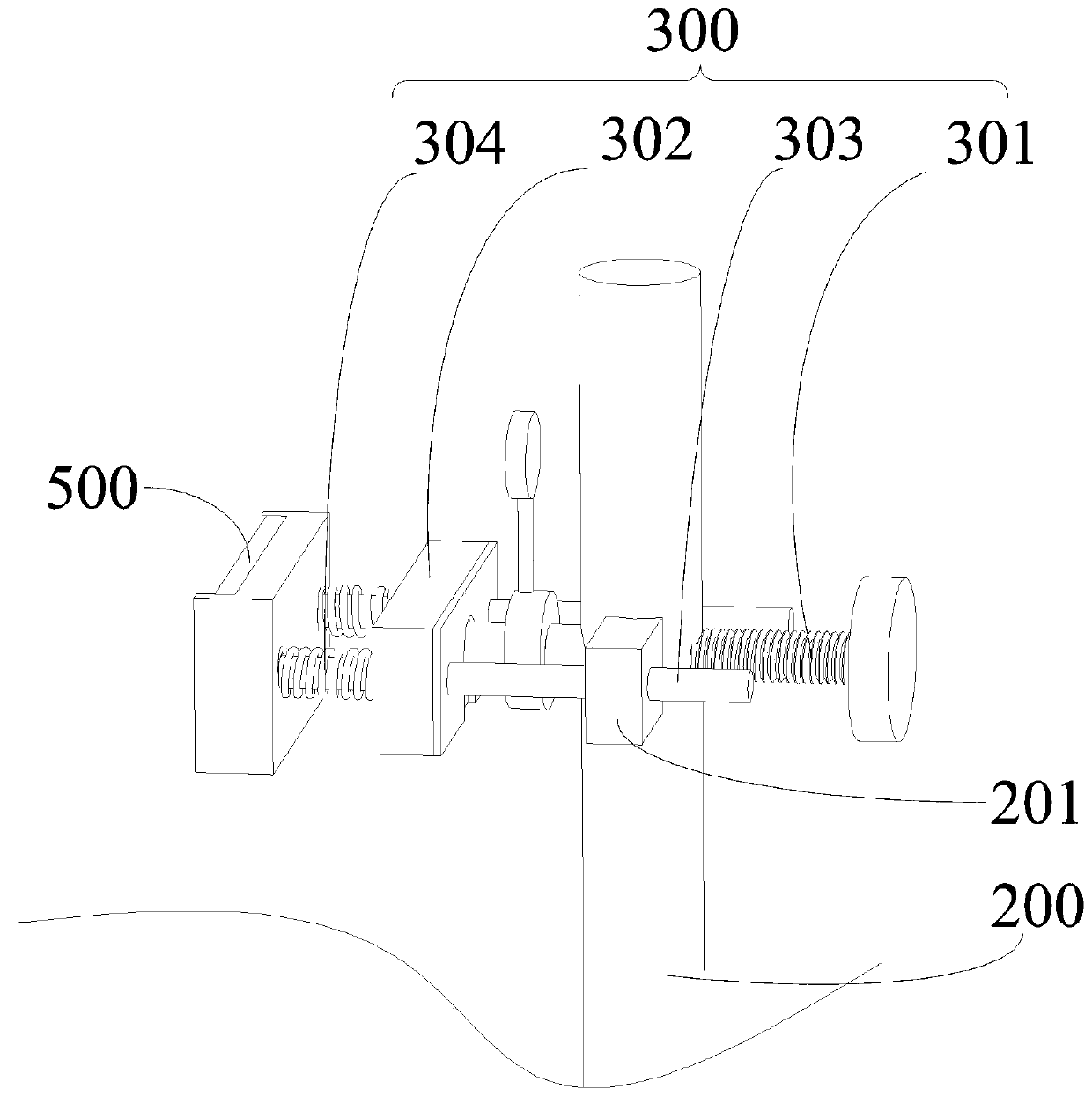

Clamping device in high-precision optical element interference detection

PendingCN110954016APrecise positioningImprove uniformityUsing optical meansTesting optical propertiesEngineeringMechanical engineering

The invention relates to a clamping device in high-precision optical element interference detection. The clamping device comprises a base, and the two sides of the base are each provided with a groupof supporting columns. One side of each group of connecting pushing parts is connected with the supporting columns, and the other side of each group of connecting pushing parts is correspondingly connected with one group of clamping parts. The two groups of clamping parts do clamping or loosening motion along the opposite directions, each group of clamping parts is provided with an elastic piece abutting against the side face of an optical element, and a force sensor is fixed on the connection pushing parts and is used for measuring the counter-acting force of the clamping parts on the clamping force of the optical element. The optical element is clamped through the base and the clamping parts at the two sides, so that the clamping stability of the optical element is guaranteed. The elastic piece is beneficial to improving the uniformity of the clamping force of the clamping parts on the optical element, and therefore the deformation of the optical element and the influence of the deformation on the detection precision are reduced. The force sensor is used for measuring the counter-acting force of the clamping part on the clamping force of the optical element, and a reference for adjusting the clamping force in the clamping process is provided.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

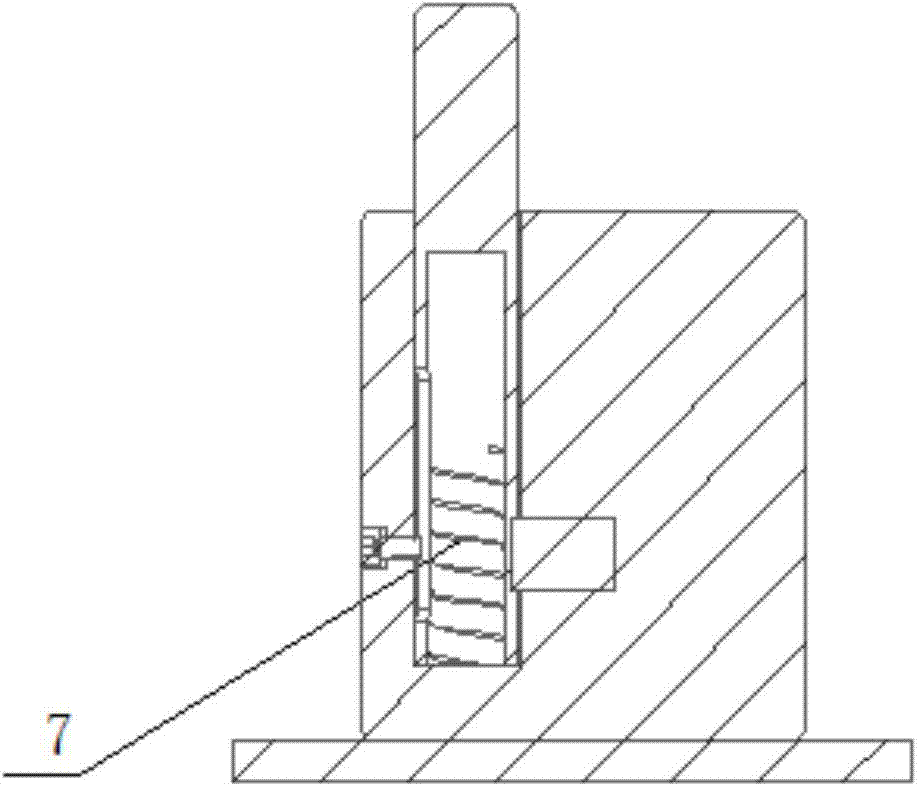

Floating supporting mechanism

ActiveCN103586708AReduce vibrationReduce the difficulty of clampingLarge fixed membersPositioning apparatusElastic componentEngineering

The invention discloses a floating supporting mechanism. The floating supporting mechanism comprises a base, a driving device, a supporting rod, a box body, a locking device and an elastic component, wherein the driving device and the box body are installed on the base, a mounting groove is vertically formed in the box body, the upper portion of the mounting groove is communicated with the outside, the supporting rod and the elastic component are installed in the mounting groove, the elastic component is located below the supporting rod, the upper portion of the supporting rod stretches out of the box body, and the supporting face at the top end of the supporting rod is a horizontal plane; a channel groove is formed in the horizontal position, corresponding to the locking device, of the box body, the horizontal position of the channel groove is lower than the side face of the supporting rod, and the driving device is in driving connection with the locking device and drives the locking device to act, so that the locking device enters the box body through the channel groove to lock the supporting rod.

Owner:ANHUI PROVINCE JIEYONGDA INTELLIGENT MACHINE

Floating support device

InactiveCN104308565AReduce vibrationReduce the difficulty of clampingPositioning apparatusMetal-working holdersLocking mechanismEngineering

The invention discloses a floating support device. The floating support device comprises a base, a support mechanism, a box body and a locking mechanism, wherein the support mechanism comprises a support rod and a first spring; the locking mechanism comprises a locking block and a second spring; a mounting groove and a mounting cavity are formed in the box body; the upper part of the mounting groove is communicated with the outsides, and the lower part of the mounting groove is communicated with the mounting cavity; the inner wall of the mounting groove is provided with a groove; the middle of the support rod is provided with a circle of flange; the first spring is connected to the support rod in a sleeving manner and is fixed in the mounting groove through the matching of the first flange with the groove; the locking mechanism is positioned in the mounting cavity; the locking block is positioned below the support rod; one end of the second spring is connected with the inner wall of the mounting cavity, and the other end of the second spring is connected with the side face of the locking block; the upper part of the support rod extends out of the box body; the top bearing surface of the support rod is a horizontal plane; the bottom surface of the support rod and the top surface of the locking lock are respectively a first bevel and a second bevel which are matched with each other; the support rod and the locking block are mutually attached through the matching of the first bevel with the second bevel.

Owner:ANHUI PROVINCE JIEYONGDA INTELLIGENT MACHINE

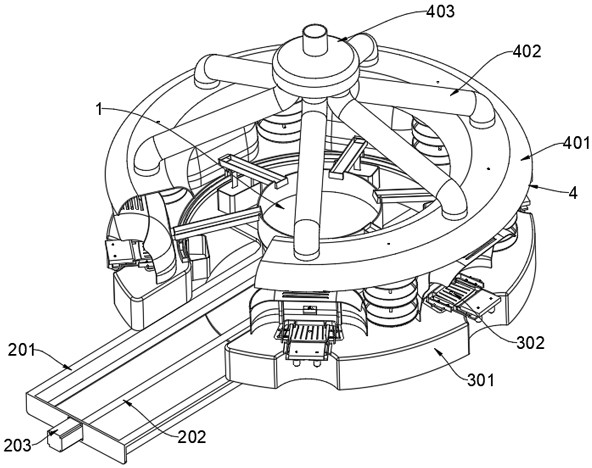

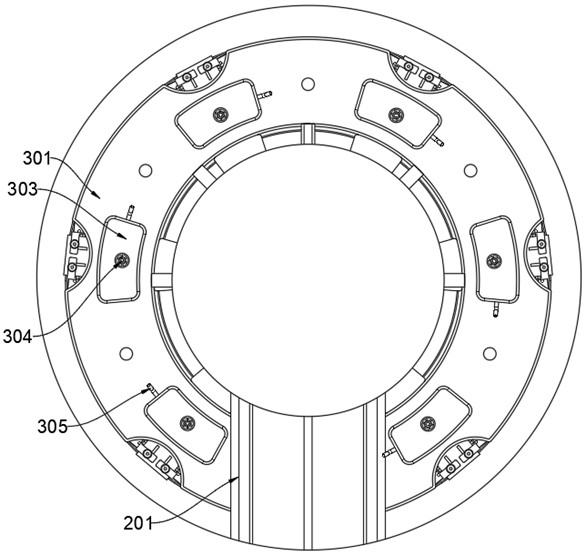

Multi-station welding workbench of laser welding machine

ActiveCN113634932AEasy to assemble and disassembleEasy to cleanWelding/cutting auxillary devicesAuxillary welding devicesSlag (welding)Engineering

The invention discloses a multi-station welding workbench of a laser welding machine. The multi-station welding workbench of the laser welding machine comprises a material changing adjusting mechanism, wherein a welding platform mechanism is fixedly installed on the upper end face of the material changing adjusting mechanism, and comprises a workbench body, slag removing plates, slag collecting boxes, a locking rod, liquid injection pipes and a connecting sleeve; the six slag removing plates are evenly installed on the upper end face of the workbench body; the six slag collecting boxes are installed on the lower end face of the workbench body; and a liquid injection pipe is arranged at one end of each slag collecting box. According to the multi-station welding workbench of the laser welding machine provided by the invention, multiple welding stations are arranged on the laser welding workbench, so that material conveying, welding and slag discharging operation can be conducted at the same time, the welding environment is effectively guaranteed, and the welding efficiency is improved.

Owner:江苏光大杆塔有限公司

Special equipment for milling machine for processing small-size parts, and application method thereof

ActiveCN109605086AConvenient and rapid processingReduce the difficulty of clampingPositioning apparatusMetal-working holdersInstabilityMachine tool

The invention discloses special equipment for a milling machine for processing small-size parts, and an application method thereof. The equipment provides to installation manners suitable for most working scenes; the equipment adopts a peripheral mechanical clamping manner assisted by an external negative pressure adsorption function, so that on one hand, the parts are ensured to be clamped stablyand reliably, meanwhile, a limited space above a small-size part to be processed is gained, the operable space of a machine tool is greatly improved, the processing difficulty is reduced, and the potential safety hazard caused by instability in clamping and accidental collision is avoided; and on the other hand, the local stress degree of the part is dispersed to a large extent, and the occurrence of the phenomena of scrap and the like since the surface of the part is easily damaged by clamping is further avoided.

Owner:KUNMING UNIV OF SCI & TECH +1

Grinding clamp for diamond cutter machining

InactiveCN112847132AEasy to processAdjust the horizontal positionGrinding drivesOther manufacturing equipments/toolsEngineeringSlide plate

The invention discloses a grinding clamp for diamond cutter machining, and relates to the technical field of precision measurement. The grinding clamp specifically comprises a base, wherein a sliding plate is slidably mounted on the base; a rotating disc is rotationally mounted on the sliding plate; a fixed clamping block is welded to one end of the upper surface of the rotating disc; a sliding clamping block is slidably mounted at the other end of the upper surface of the rotating disc; and a rotary knob is in threaded connection with the exteriors of the fixed clamping block and the sliding clamping block. In the using process of the grinding clamp, the horizontal position of a cutter is convenient to adjust through a first lead screw, and the orientation of the cutter is convenient to adjust through the rotating disc, so that the cutter is convenient to machine, operation is easy and use is convenient during clamping and fixing of the cutter, and the cutter clamping difficulty is reduced; and meanwhile, a handle is fixed through a lantern ring, so that the rotary knob is fixed, the situation that the cutter is clamped loosely due to rotation of the rotary knob is effectively avoided, and the fixing effect of the cutter is improved.

Owner:HUBEI SANXIANG SUPERHARD MATERIAL

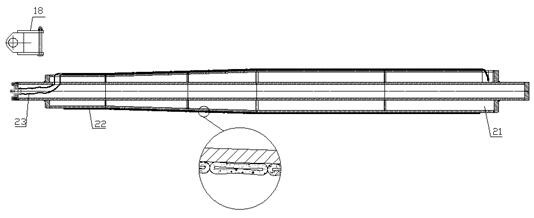

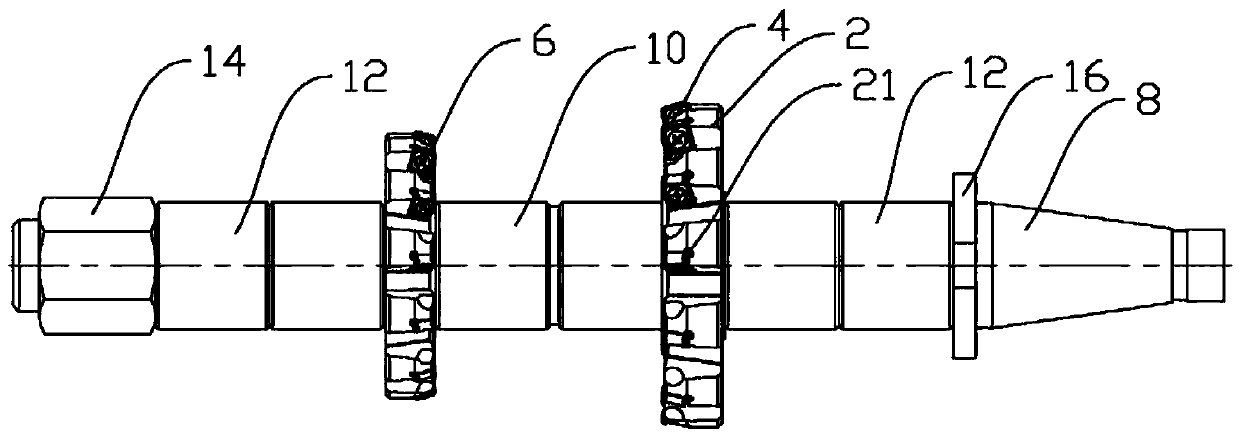

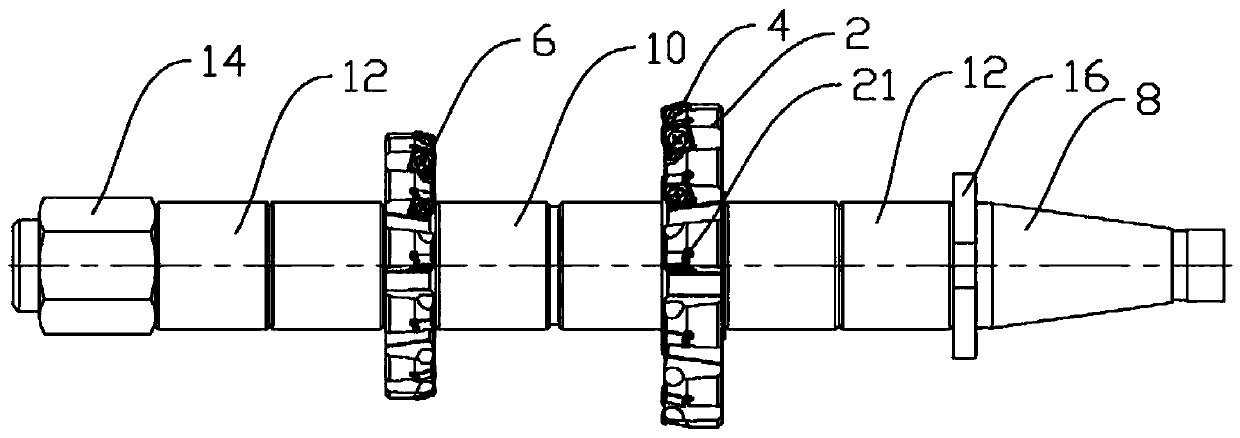

Expansion mandrel for horizontal machining of electrical ceramic blank

PendingCN112092164ASolve horizontal placementSolve processabilityAuxillary shaping apparatusGrinding machinesMachining processComposite material

The invention discloses an expansion mandrel for horizontal machining of an electrical ceramic blank. The expansion mandrel is inserted and connected into a hole in the axis direction of the electricceramic blank and comprises a metal mandrel body and an air bag, wherein the outer wall of the metal mandrel body is coated with the air bag, the air bag is filled with an expansion medium, and the air bag abuts against the metal mandrel body and the inside of the hole of the electric ceramic blank. By the adoption of the expansion mandrel for horizontal machining of the electrical ceramic blank,the blank can be transversely machined, the product surface is improved, the problems that the electrical ceramic blank is prone to breakage during machining when being transversely placed is solved,the equipment height can be effectively reduced, the clamping difficulty and risk are lowered, the dust raising problem is relieved, and the dust collection effect is improved; and moreover, the safety risk of injuring the machining personnel due to product breakage, chipping and the like in the high-speed rotary machining process is lowered.

Owner:NANJING ZHIDA ELECTRICAL EQUIP CO LTD

Gear grinding clamping device of planetary gear of wind power generation device

ActiveCN105252086ASimple structureReduce labor intensityGear-cutting machinesGear teethGear grindingScrew thread

Provided is a gear grinding clamping device of a planetary gear of a wind power generation device. The gear grinding clamping device comprises a clamp holder used for supporting a workpiece and a shaft locating pressing block, the clamp holder is shaped like a ladder-shaped cylinder, the bottom of the ladder-shaped cylinder is provided with an installing locating bottom platform with the diameter larger than that of the middle section cylinder, and multiple radial open slots used for installing and fixing are formed in the circumference of the installing locating bottom platform; a workpiece locating platform with the diameter larger than that of the middle section cylinder is arranged on the upper portion of the ladder-shaped cylinder, the upper end of the workpiece locating platform is provided with a circular centering locating step, a convex table portion of the circular centering locating step and the installing locating bottom platform are concentric circles, the diameter of the convex table portion is 0.05-0.1 mm smaller than that of a shaft hole of a machined gear, and the horizontal plane of the circular centering locating step is parallel to the bottom face of the installing locating bottom platform; a threaded hole is formed in the circle center of the circular centering locating step, the lower end of a screw is fixedly connected with the threaded hole, the shaft locating pressing block is arranged on the screw in a sleeving mode through a formed via hole, and the shaft locating pressing block is pressed through a nut.

Owner:CHONGQING WANGJIANG IND

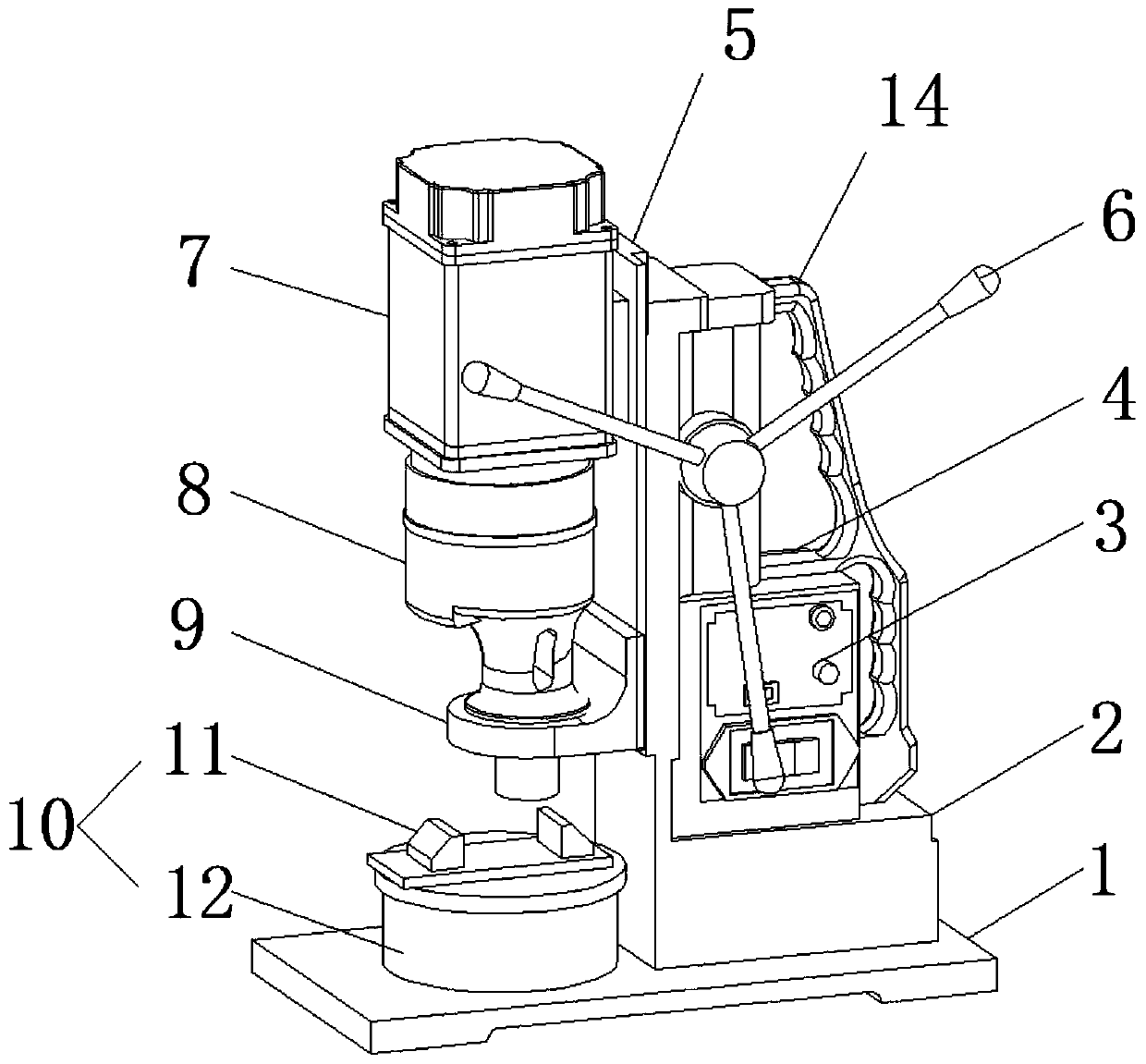

Novel permanent magnet brushless bench drill

ActiveCN109954901AImprove efficiencyImprove operational efficiencyLarge fixed membersDriving apparatusBrushless motorsEngineering

Owner:福建微龙电子科技有限公司

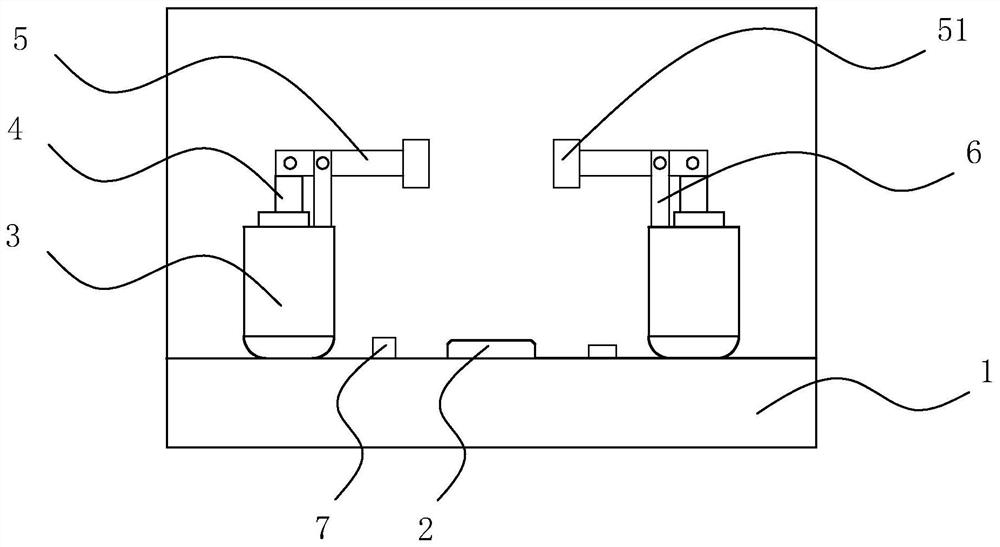

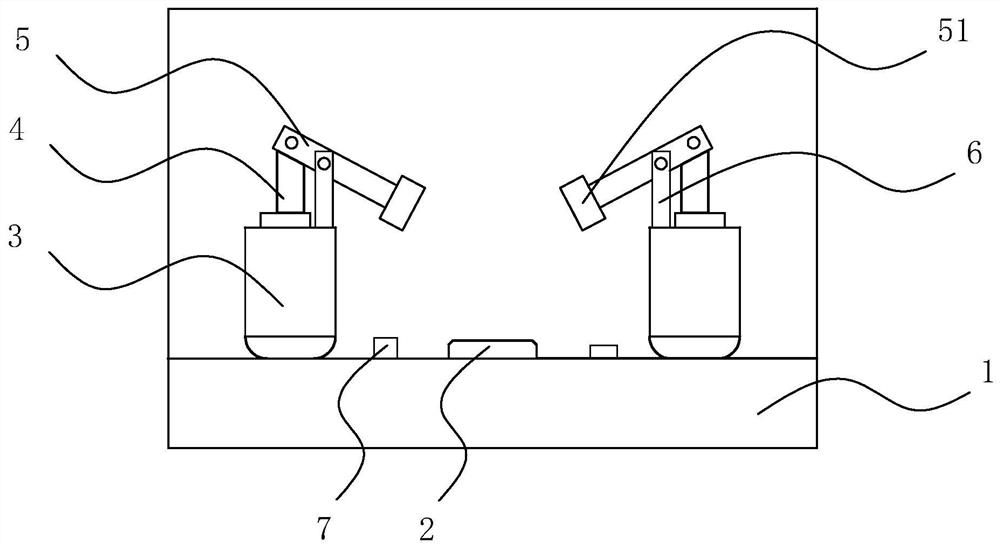

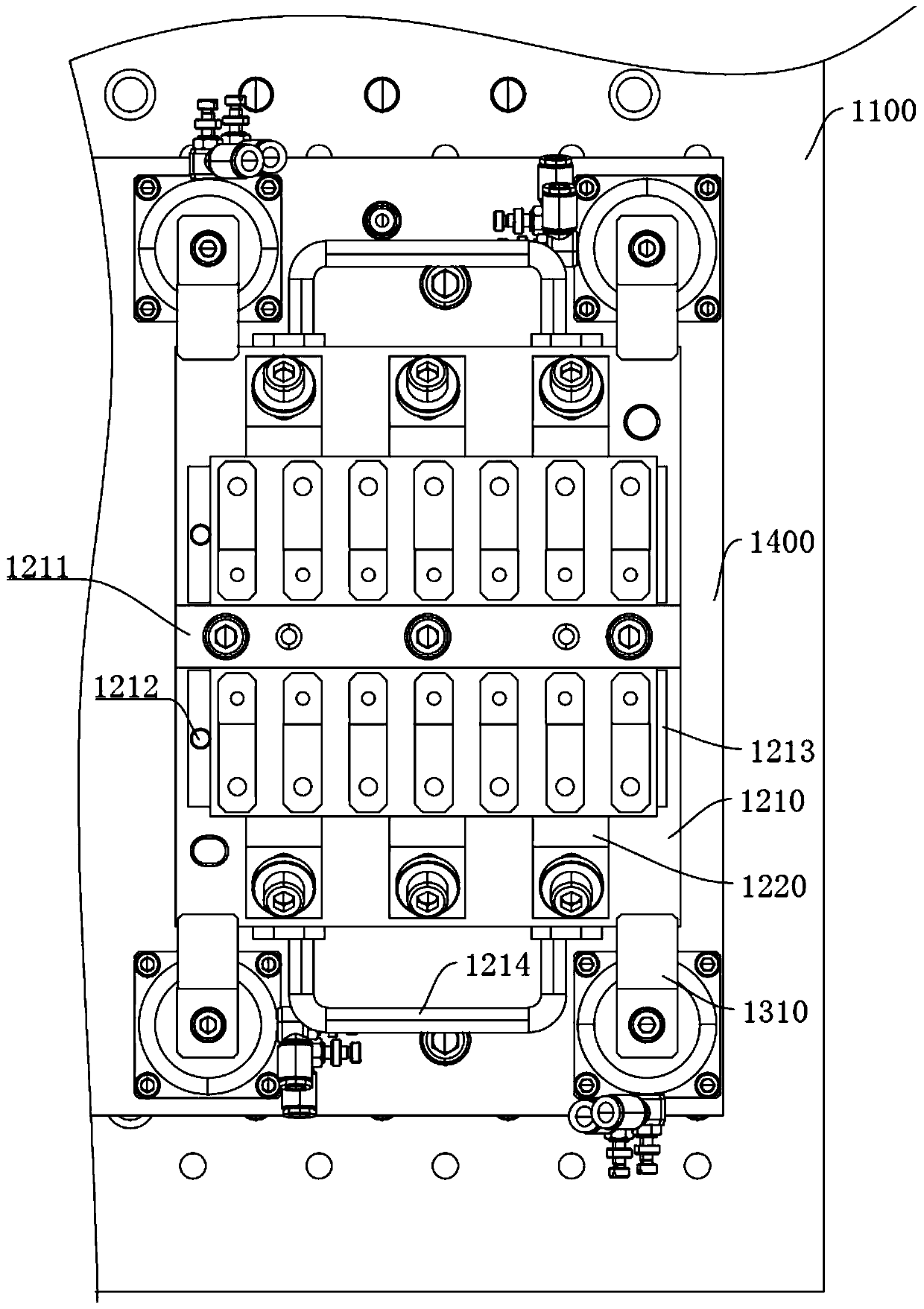

Clamp for clamping engine cylinder block

InactiveCN112296904AReduce the difficulty of clampingReduced clamping damageWork holdersEngineeringCylinder block

The invention discloses a clamp for clamping an engine cylinder block. The clamp comprises a base, wherein a positioning buffer block is arranged on the base; piston cylinders are arranged at the twosides of the positioning buffer block respectively; piston rods are arranged on the piston cylinders; pressing rods are hinged to the piston rods; supporting rods are fixedly arranged on the piston cylinders; and the ends of the supporting rods are hinged to the middles of the pressing rods. According to the clamp, the positioning buffer block on the base is adopted for positioning the engine cylinder block, then the piston cylinders at the two sides of the positioning buffer block are started, and the piston rods drive the pressing rods to clamp the engine cylinder block through the lever principle; and through the design, the clamping difficulty of the engine cylinder block can be lowered, the clamping stability is improved, and the clamping damage of the clamp to the engine cylinder block is reduced.

Owner:JIANGMEN CHAOYANG PRECISION MFG

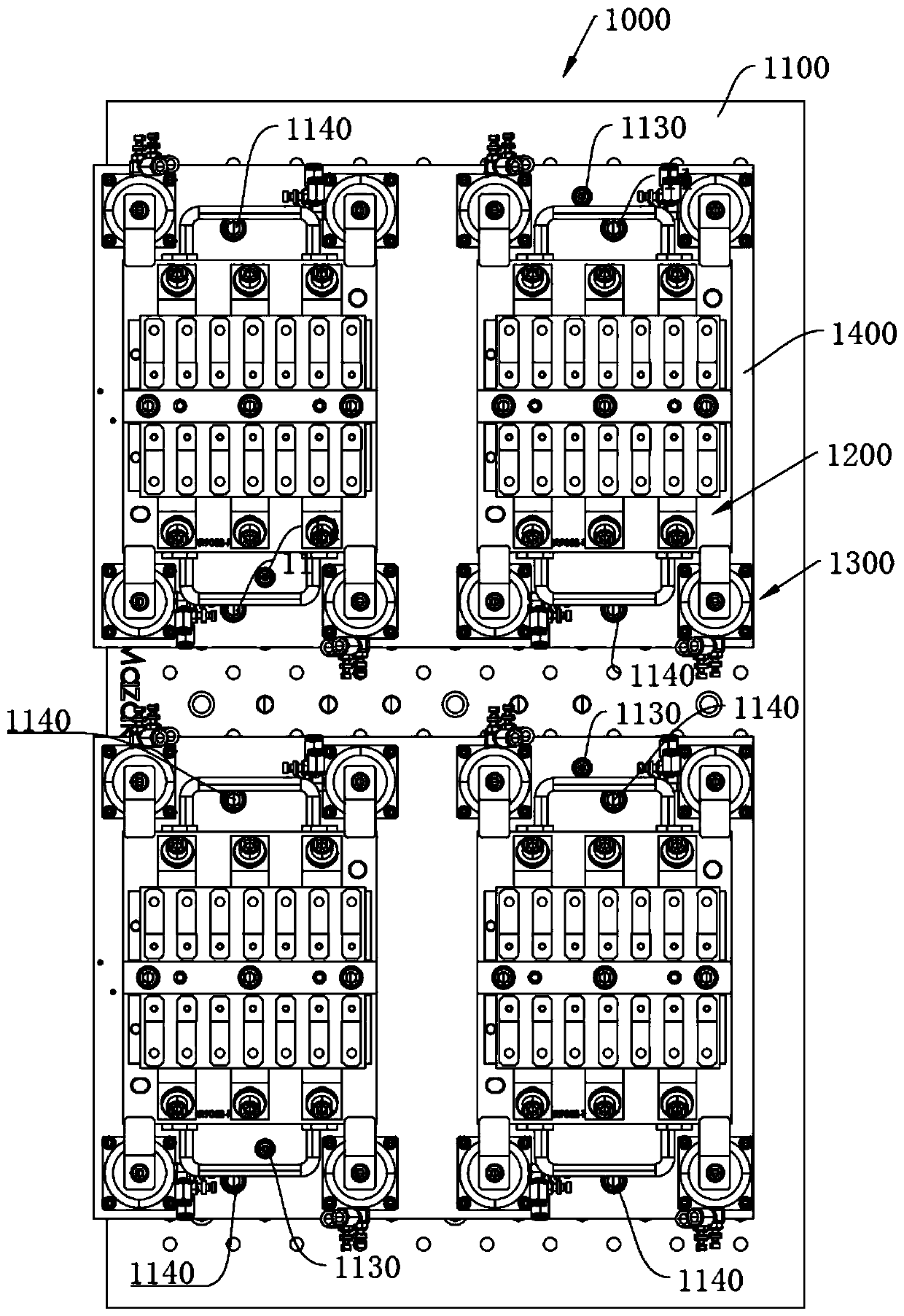

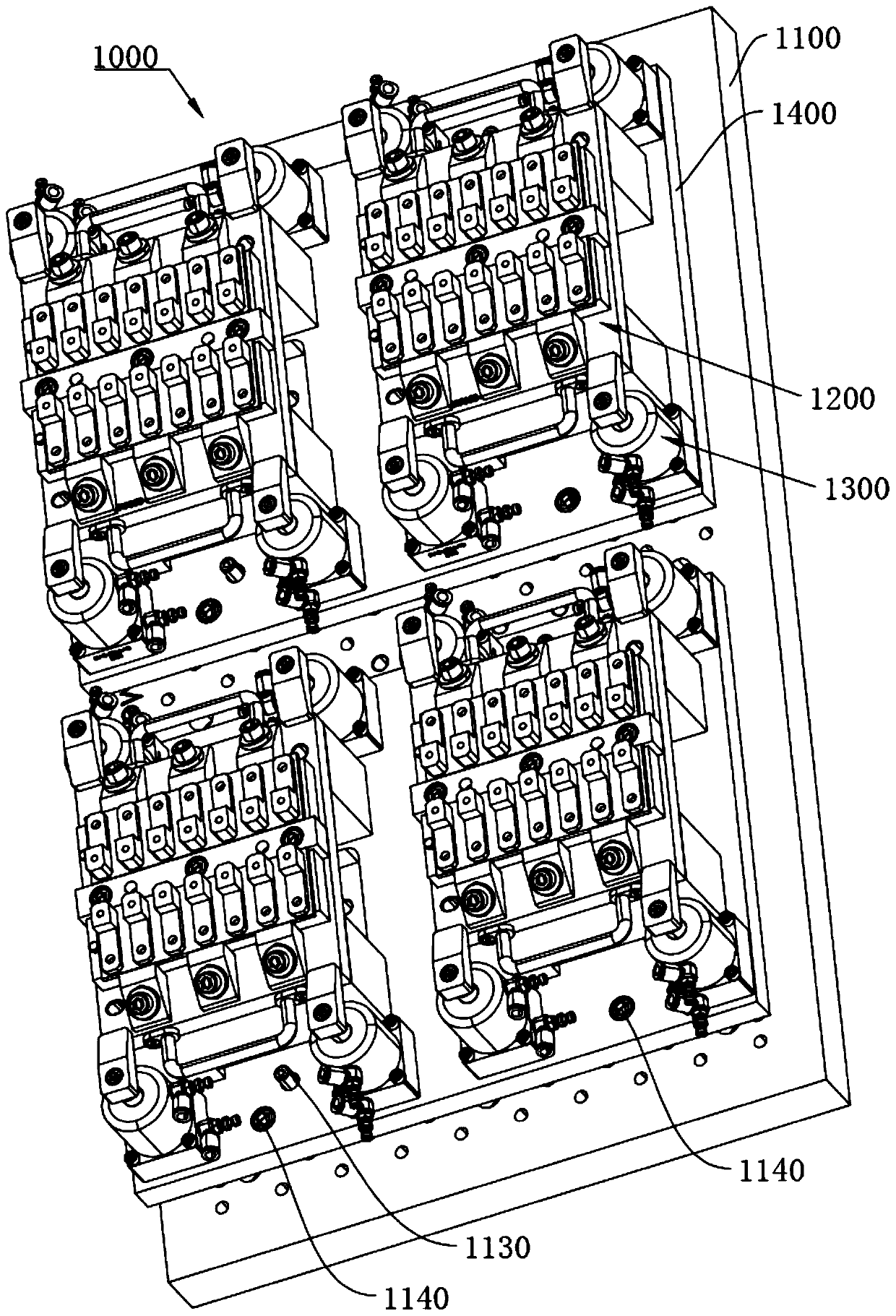

Multi-station clamp

PendingCN110091193APrecise positioningReduce program processing timePositioning apparatusMetal-working holdersMachining timeMachine tool

The invention provides a multi-station clamp. The multi-station clamp comprises a bottom plate and workpiece clamping mechanisms. The bottom plate is provided with a plurality of positioning parts. Each workpiece clamping mechanism comprises an interchanging plate and at least one workpiece clamping assembly arranged on the interchanging plate. Each workpiece clamping mechanism is used for clamping a workpiece, wherein the workpiece clamping mechanism and the workpiece are positioned on the bottom plate together. The bottom plate is provided with the multiple positioning parts and positioned on a machine tool through at least one positioning part, and different positioning installing positions can be provided for the interchanging plates. Since the bottom plate and the interchanging platesare detachable, the workpiece clamping mechanisms and the workpieces can be dismounted and mounted relative to the bottom plate, machine exterior clamping can be achieved, and the workpiece clampingmechanisms corresponding to different products can be replaced. The bottom plate can be provided with the multiple workpiece clamping mechanisms so that the machine tool can have multiple stations during machining, the product clamping frequency during machining is reduced, the clamping difficulty is lowered, program tool linkage is adopted, batched treatment is conducted, and the program machining time for single products is shortened.

Owner:SHENZHEN SILVER BASIS TECH

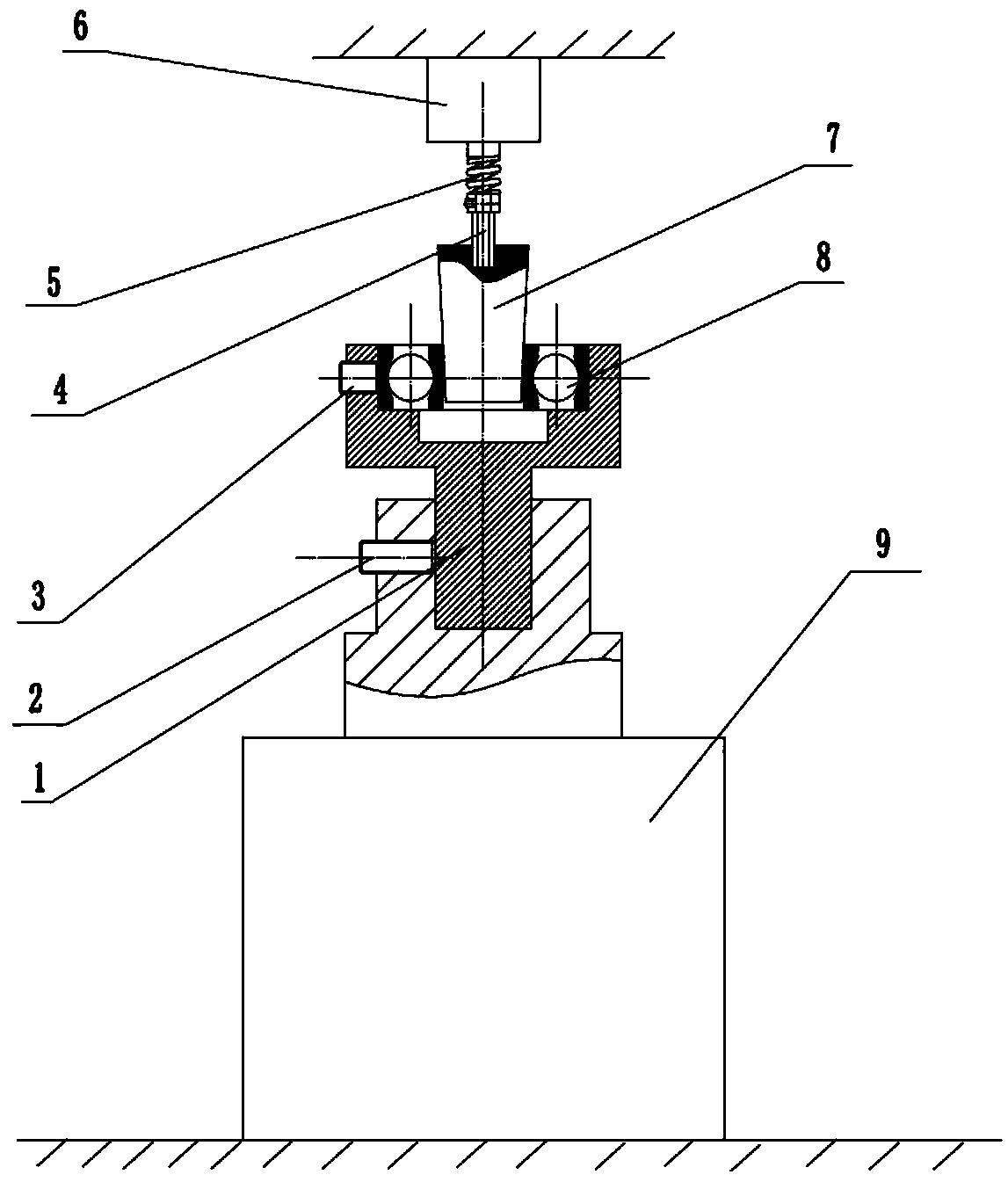

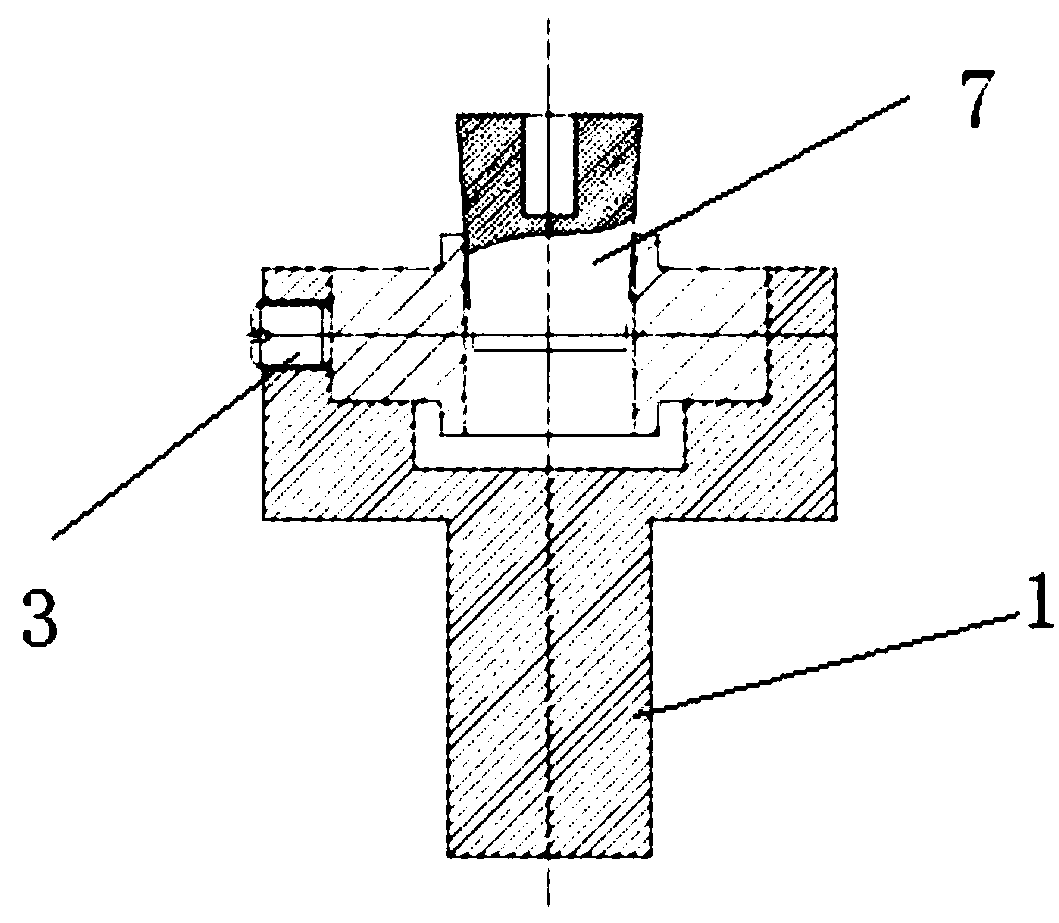

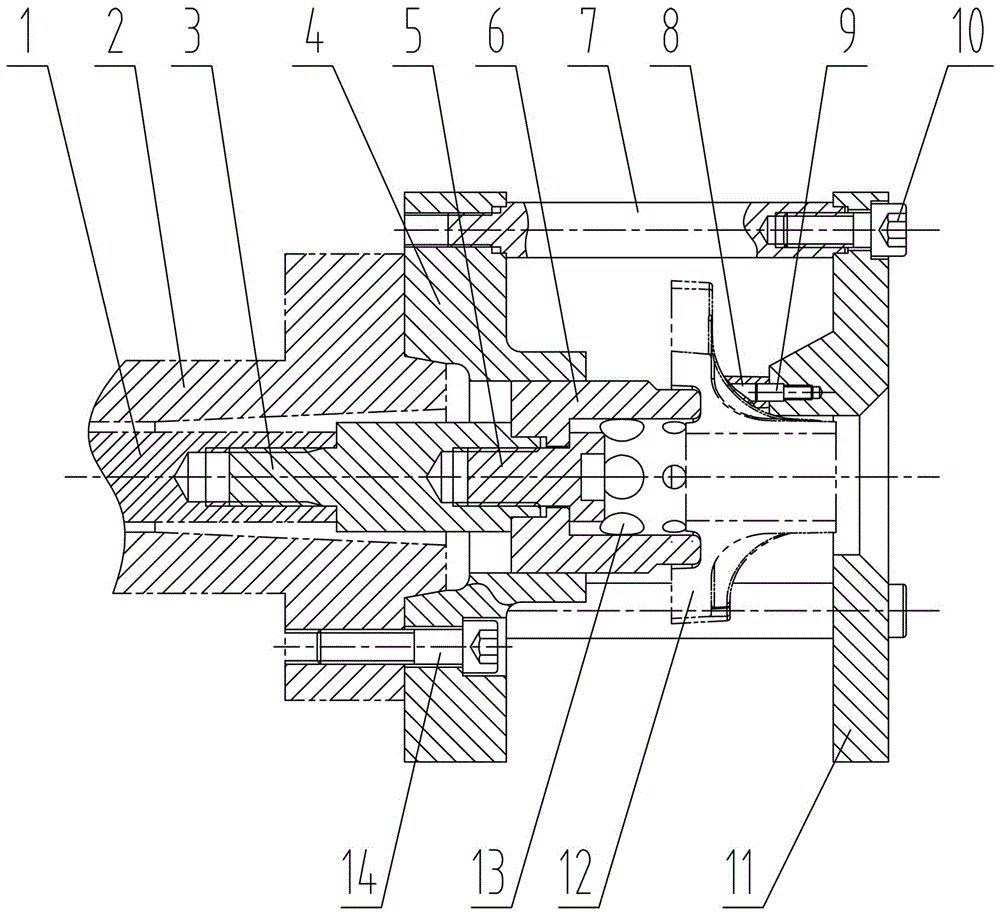

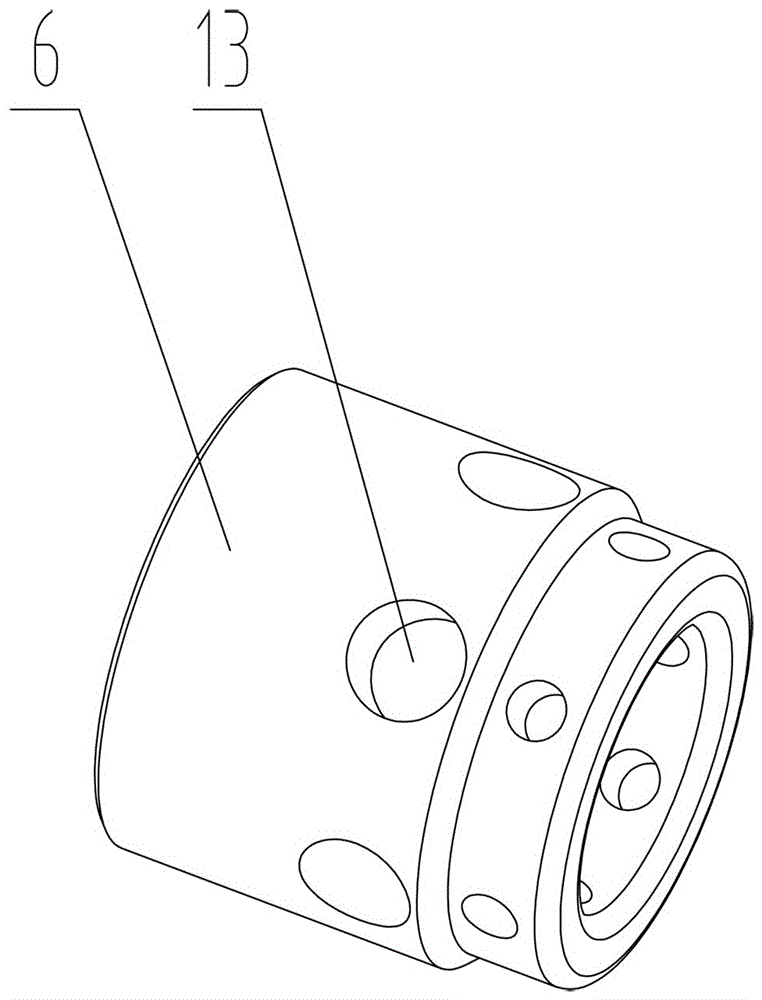

Vehicle water pump shell inner hole machining device

InactiveCN106002420ASolve the problem of mass production without fixturesImprove business efficiencyWork clamping meansPositioning apparatusEngineeringScrew thread

The invention discloses a vehicle water pump shell inner hole machining device. The device comprises a pull rod transfer sleeve, a fixture body, an ejecting sleeve, a large screw, a support column, a dowel pin and a positioning base. One end of the pull rod transfer sleeve is locked on a pull rod of a lathe through a thread; the fixture body is fixed on a main shaft of the lathe through a long screw; the ejecting sleeve is mounted on the pull rod transfer sleeve through the large screw, and an outer circle is sleeved in the fixture body in a shaft hole clearance fit manner; a shaft at one end of the support column is matched and locked with a hole in the fixture body, and a shaft at the other end is matched with a hole in the positioning base and locked through a short screw; and the dowel pin is pressed on the positioning base. The vehicle water pump shell inner hole machining device can effectively solve the problem of incapability of clamping a pump shell in machining of an inner hole by the lathe, greatly improves the product quality and the production benefit, and increases the enterprise benefit.

Owner:阙智坚

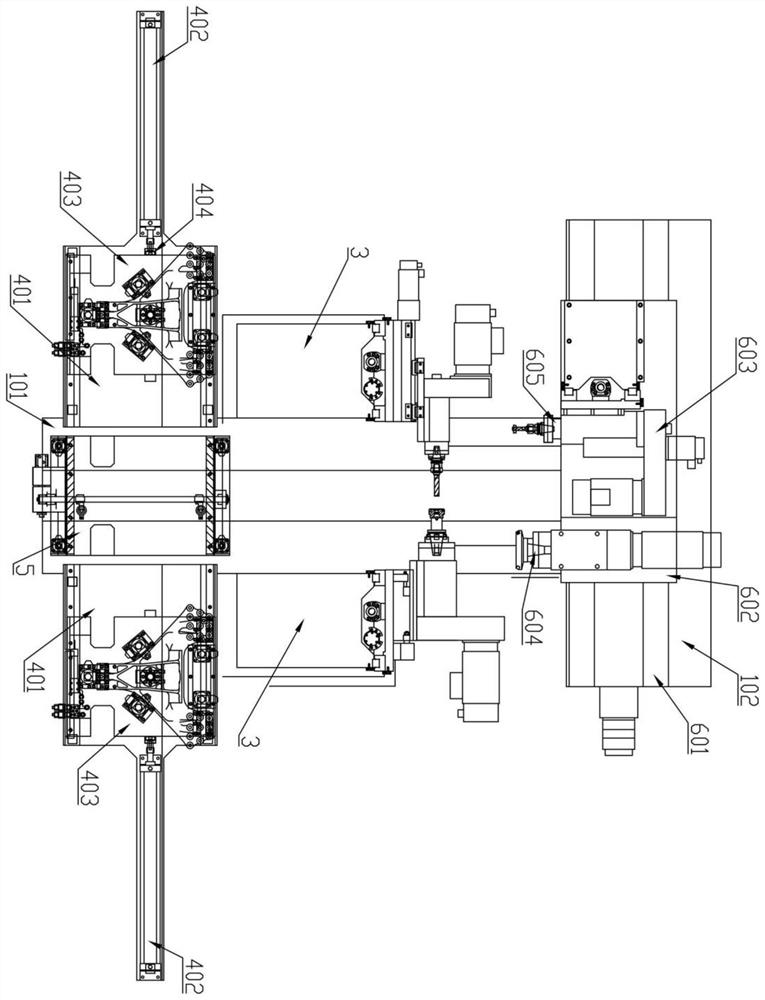

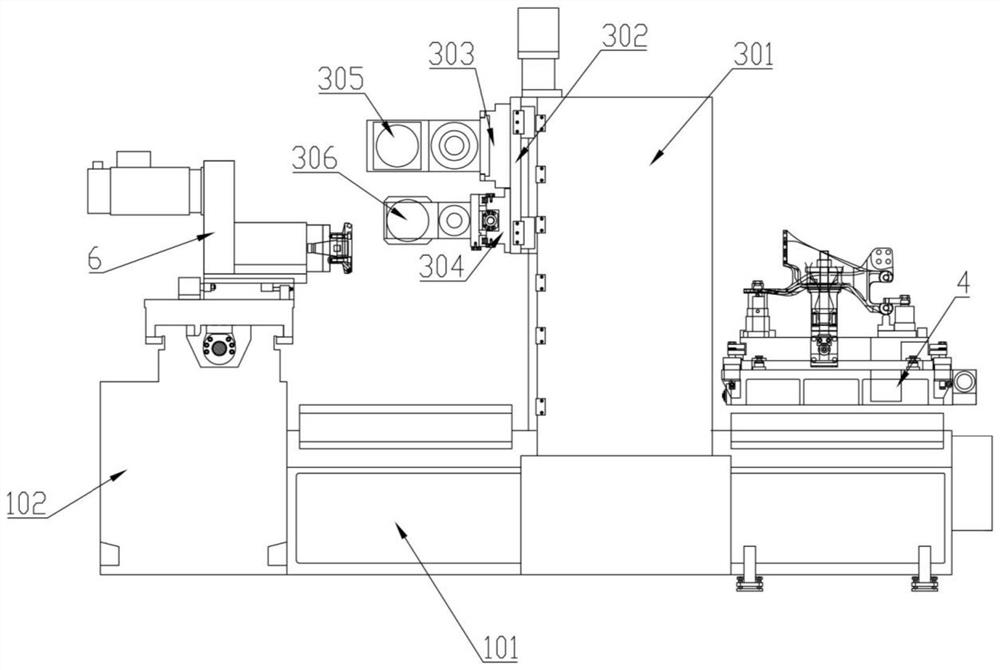

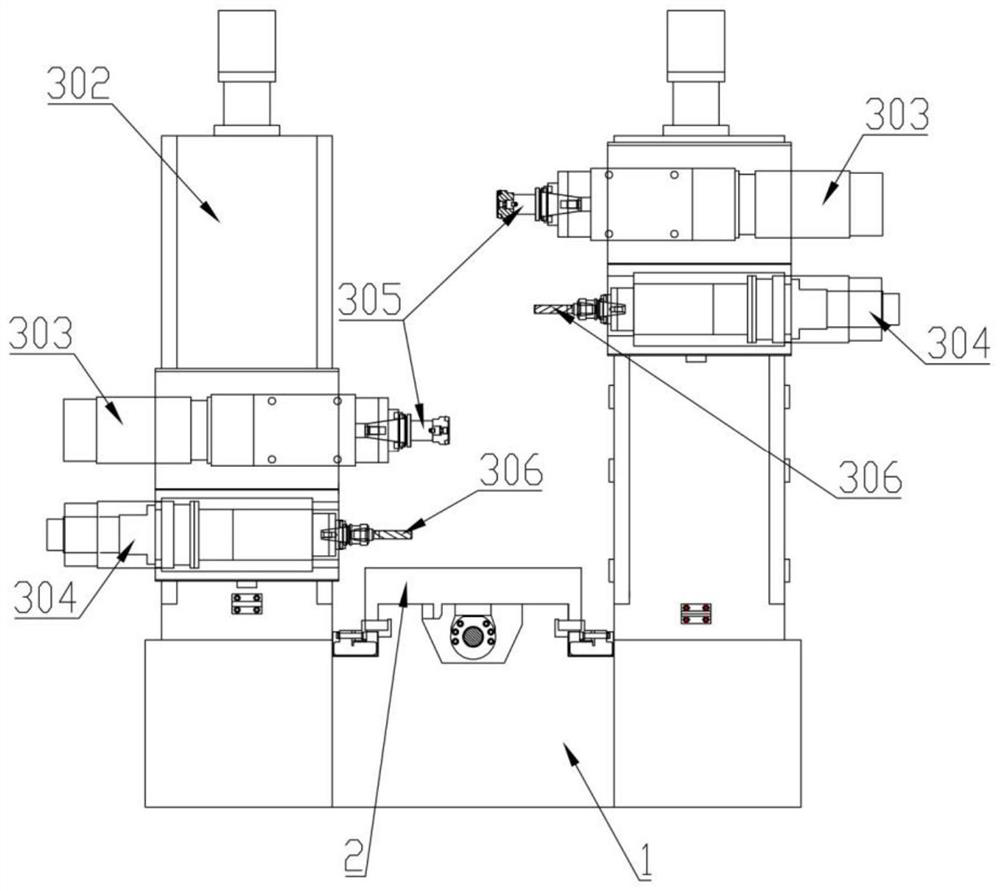

Suspension support three-face numerical control milling machine

PendingCN114178596AReduce the number of clampingReduce processing timeOther manufacturing equipments/toolsLarge fixed membersNumerical controlControl engineering

The invention relates to a suspension support three-face numerical control milling machine which comprises a composite base, the composite base is provided with a first base and a second base, the first base is provided with a middle servo sliding table, and vertical machining devices and feeding bins are symmetrically arranged on the two sides of the middle servo sliding table. The vertical machining device is located between the feeding bin and the second base, the middle servo sliding table is connected with a conveying bottom plate, the second base is provided with a horizontal machining device, the horizontal machining device is provided with a transverse servo sliding table, and a Y-direction hydraulic sliding table and a cross-shaped servo sliding table are arranged on the transverse servo sliding table in parallel. The Y-direction hydraulic sliding table is connected with an end face milling power head, the cross-shaped servo sliding table is connected with a drilling power head, and the end face milling power head and the drilling power head face the vertical machining device. Multi-station simultaneous machining is adopted, the product clamping frequency is reduced, and the machining precision is improved.

Owner:YANCHENG BAOLILAI PRECISION MACHINERY MFG

A horizontal thread embedding machine

ActiveCN104218747BImprove applicabilityQuality improvementManufacturing dynamo-electric machinesChassisStator

Owner:CHANGZHOU JINKANG PRECISION MECHANISM

Valve clamping system

InactiveCN113367844AEasy to operateReduce the difficulty of clampingAnnuloplasty ringsSurgical riskMedicine

The invention relates to the field of medical instruments, and discloses a valve clamping system. The valve clamping system comprises an adjusting mechanism and a locking mechanism. The adjusting mechanism comprises near-end clamping pieces, far-end clamping pieces, a central seat body and a base body, the near-end clamping pieces are clamped to the central seat body, the near-end clamping pieces have elasticity, the far-end clamping pieces are rotatably connected to the central seat body and the base body so as to be close to or far away from the near-end clamping pieces. The locking mechanism comprises a fixing piece A, a fixing piece B, a pushing rod and a control piece, the central seat body is provided with a containing cavity, the fixing piece A and the fixing piece B abut against each other and are clamped in the containing cavity, the pushing rod penetrates through the fixing piece A and the fixing piece B to be connected to the base body, opposite penetrating holes are further formed in the side wall of the center base body, and the control piece can pass through the penetrating holes and bypass the fixing piece A and the fixing piece B from any side of the pushing rod. The control piece and the fixing piece B are used for adjusting the position of the fixing piece A in the containing cavity, so that stable clamping of valve leaflets is achieved. The valve clamping system is simple to operate, and surgical risks can be reduced.

Owner:SHANGHAI SHENQI MEDICAL TECH CO LTD

Valve clamping system

PendingCN113616385AEasy to operateReduce the difficulty of clampingAnnuloplasty ringsSurgical riskMedicine

The invention relates to the field of medical instruments, and discloses a valve clamping system, which comprises an adjusting mechanism and a locking mechanism; the adjusting mechanism comprises a near-end clamping piece, a far-end clamping piece, a central seat body and a base body; the near-end clamping piece is clamped to the central seat body; the far-end clamping piece is rotationally connected to the central seat body and the base body so as to be close to or away from the near-end clamping piece; the central seat body is provided with a containing cavity; opposite penetrating holes are formed in the side wall of the central seat body; the locking mechanism comprises a fixing piece A, a fixing piece B, a pushing rod and a control piece; the fixing piece A and the fixing piece B are arranged in the containing cavity in a mutual abutting mode; the pushing rod is located in the containing cavity and penetrates through the fixing piece A and the fixing piece B to be connected to the base body; and the control piece and the fixing piece B are jointly configured to adjust the position of the fixing piece A in the containing cavity. Therefore, a valve can be stably clamped; the valve clamping system is simple to operate; and surgical risks can be reduced.

Owner:SHANGHAI SHENQI MEDICAL TECH CO LTD

Connecting rod milling tool and connecting rod milling tool assembly

PendingCN111136311AReduce the difficulty of clampingImprove the clamping methodMilling cuttersEngineeringKnife blades

Owner:HANGZHOU JIULONG MACHINERY MFG

Suspension type headstock chair bracket welding fixture

ActiveCN108817794AConvenient welding operationPrevent slidingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHeadstock

The invention discloses a suspension type headstock chair bracket welding fixture. The suspension type headstock chair bracket welding fixture comprises a locating rack, a lifting stand, and a plurality of driving oil cylinders for driving the lifting stand to lift; a plurality of first fixing devices for fixing a headstock chair bracket are arranged on the locating rack and a plurality of secondfixing devices for fixing footboard front upright columns; the first fixing devices comprise first base rods, part supporting plates and a plurality of binding bands; the second fixing devices comprise second base rods, part supporting plates and a plurality of binding bands; and the lifting stand is located above and connected with the locating rack. The suspension type headstock chair bracket welding fixture has the beneficial effects that clamping location can be carried out effectively, and during clamping, an operating position is low, the clamping difficulty is low, the height is reasonable during welding and welding operation by a worker is facilitated.

Owner:浙江恒源机器有限公司

Subsurface gate processing technology

InactiveCN111673208AHigh precisionGood discharge qualityElectrical-based auxillary apparatusElectric dischargeEngineering physics

The invention discloses a subsurface gate processing technology. The subsurface gate processing technology comprises the following steps that a, an integrated electrode is manufactured according to the gate shape, wherein an electrode head matched with the gate shape is arranged on the integrated electrode; b, the integrated electrode is installed on a machine head of an electric discharge machine, and a gate axis line of a to-be-processed workpiece coincides with an axis line of the electrode head of the integrated electrode; c, according to the initial installation position of the electrodehead of the integrated electrode, processing starting coordinates are determined by the position of a point on the integrated electrode, when processing of the electrode head of the integrated electrode is finished, the electrode head of the integrated electrode is located in a gate, and processing ending coordinates are determined by the position of the point on the integrated electrode; and d, the starting processing coordinates and the ending processing coordinates are input on the electric discharge machine. According to the subsurface gate processing technology, the electrode precision ishigh, the discharge quality is good, processing is convenient, manual clamping and disassembly are omitted, and the degree of automatic production is improved.

Owner:NINGBO JOYSONQUIN AUTOMOTIVE SYST HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com