Positioning machining method for thin hook-face parts

A curved surface part and processing method technology, applied in the field of part processing, can solve the problems of high processing cost, unsuitable for batch processing, low processing efficiency, etc., achieve high accuracy of repeated clamping and positioning, easy to master processing strategies, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

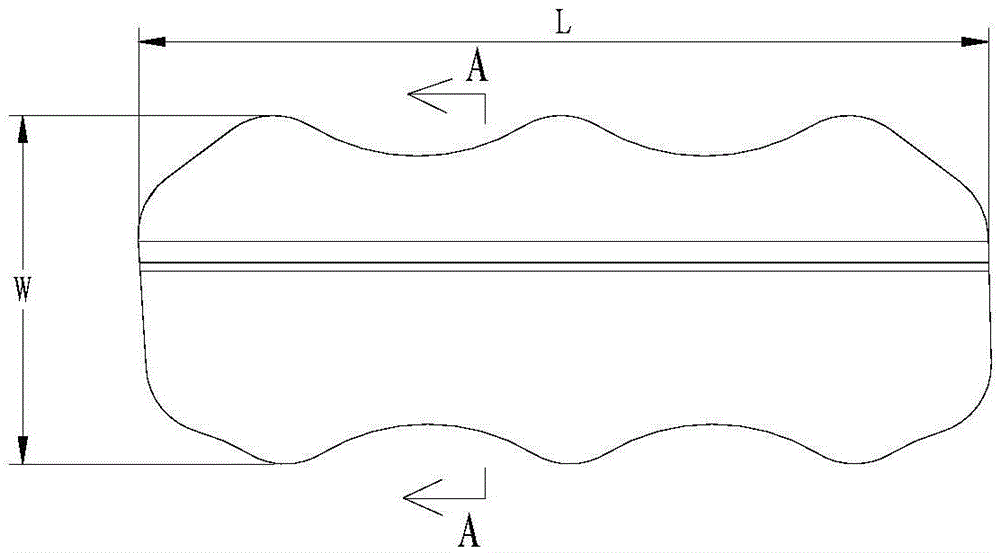

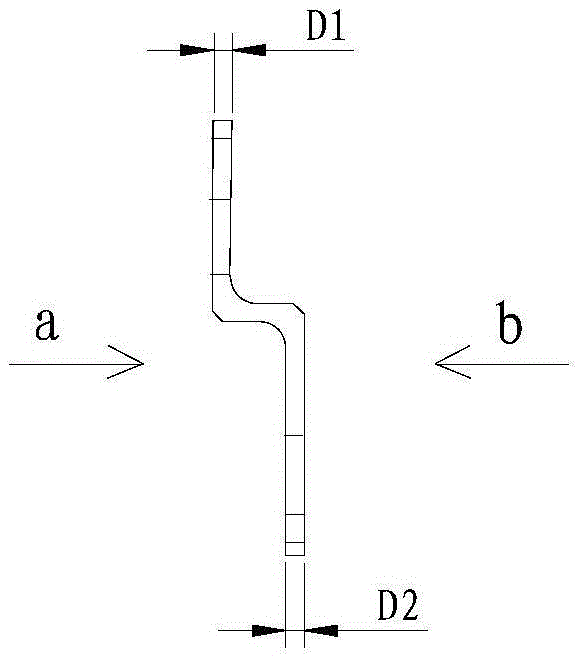

[0046] as Figure 1a , Figure 1b The thin curved surface part shown is taken as an example, and the positioning processing method of the thin curved surface part according to the present invention is described in detail.

[0047] like Figure 1a As shown, the length L of the thin curved surface part is 160mm, and the width W is 80mm, such as Figure 1b As shown, the thickness D1 and D2 of the thin curved surface part are both 2mm, and the front and back sides of the thin curved surface part ( Figure 1b The planes indicated by arrows a and b in the middle) are both curved surfaces.

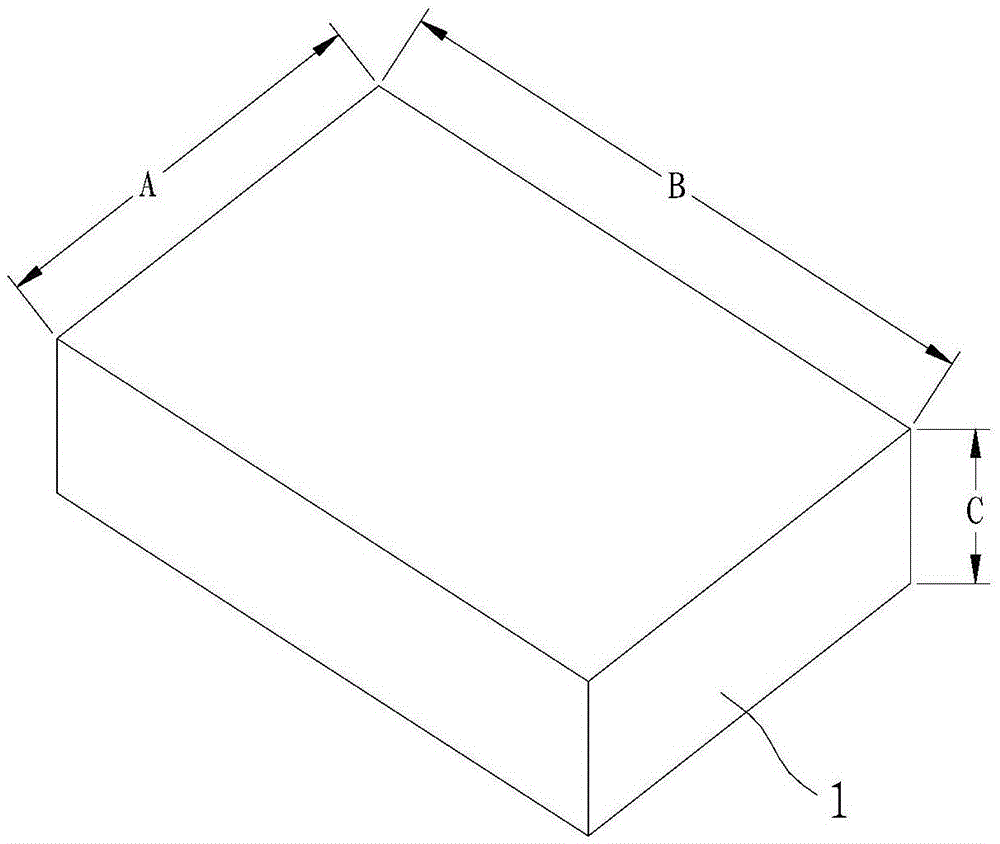

[0048]The positioning fixture of the three-axis CNC machine tool used in this embodiment is as follows image 3 As shown, the pneumatic clamping method is adopted, the main body is a pneumatic rectangular positioning seat, and the origin of the machining coordinate system XYZ of the part coincides with the rotation center of the positioning fixture 2 (that is, the origin of the machining coordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com