Patents

Literature

265results about How to "Solve the vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

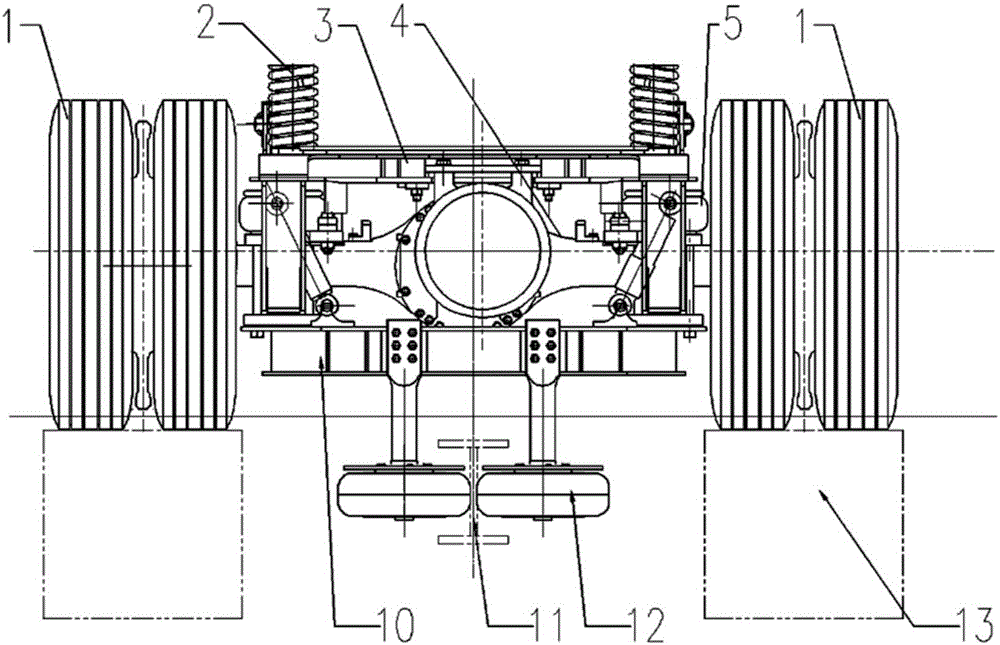

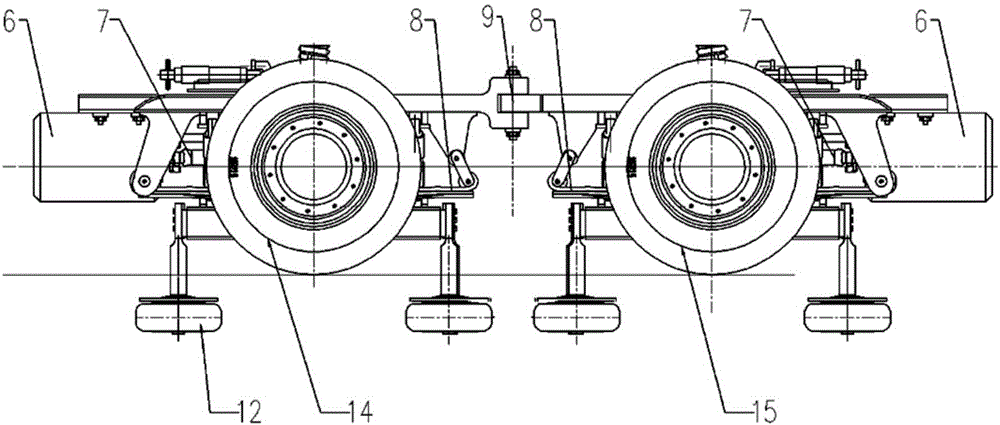

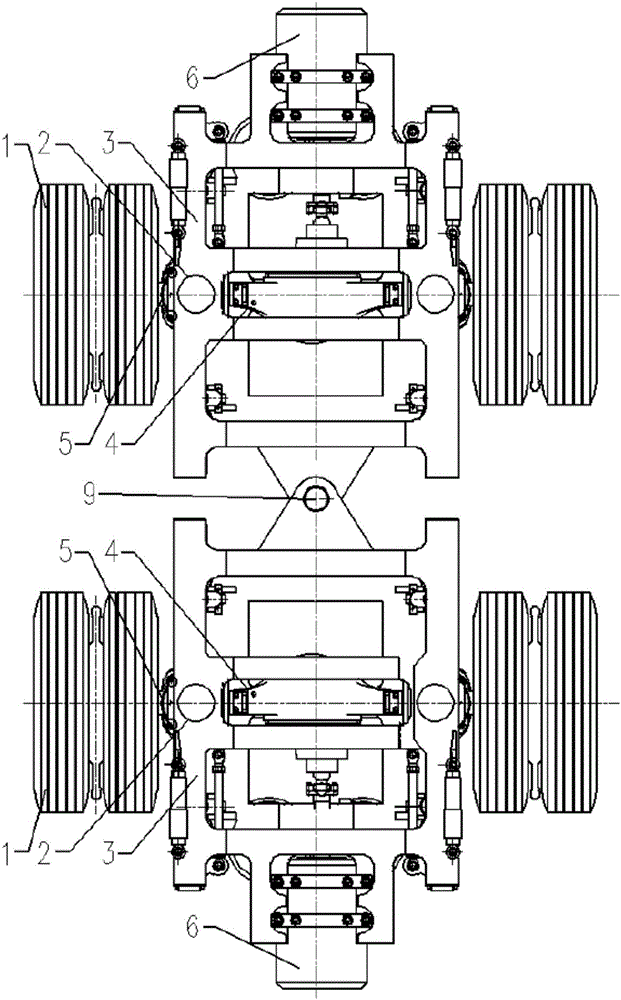

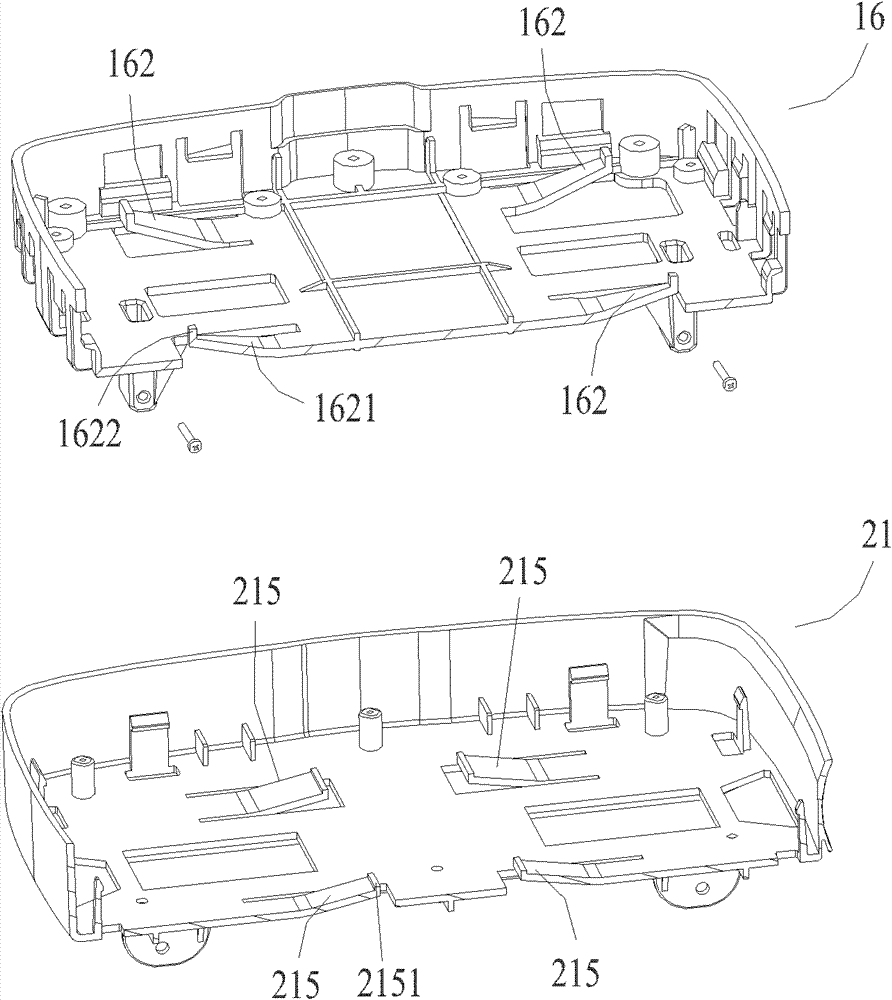

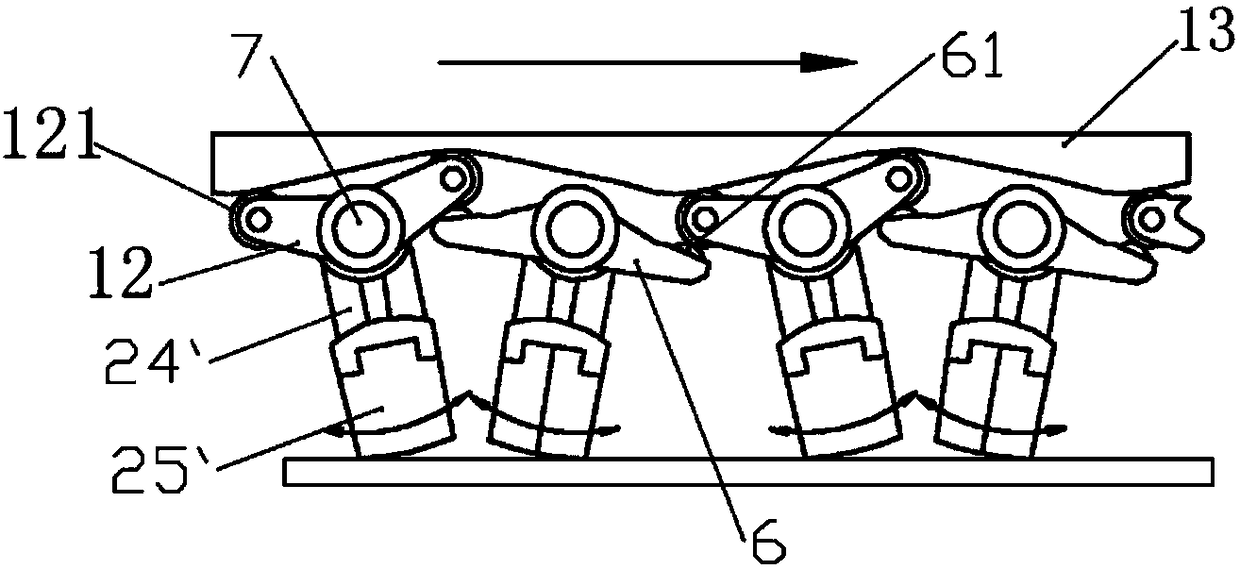

Hinged railway vehicle bogie and railway vehicle

ActiveCN106080644ASolve the distance problemSolve poor climbing abilityBogie-underframe connectionsBogieWheel and axle

The invention discloses a hinged railway vehicle bogie and a railway vehicle. The hinged railway vehicle bogie comprises a non-integral framework which is formed mainly by hinging a first portion to a second portion. A first wheel axle is installed on the first portion of the framework, a second wheel axle is installed on the second portion of the framework, and the first wheel axle and the second wheel axle form an included angle when the railway vehicle passes a curve. According to the hinged railway vehicle bogie and the railway vehicle, the accessible curve radius is small, the eccentric wear of a walking wheel is less, and the maintenance cost is low.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

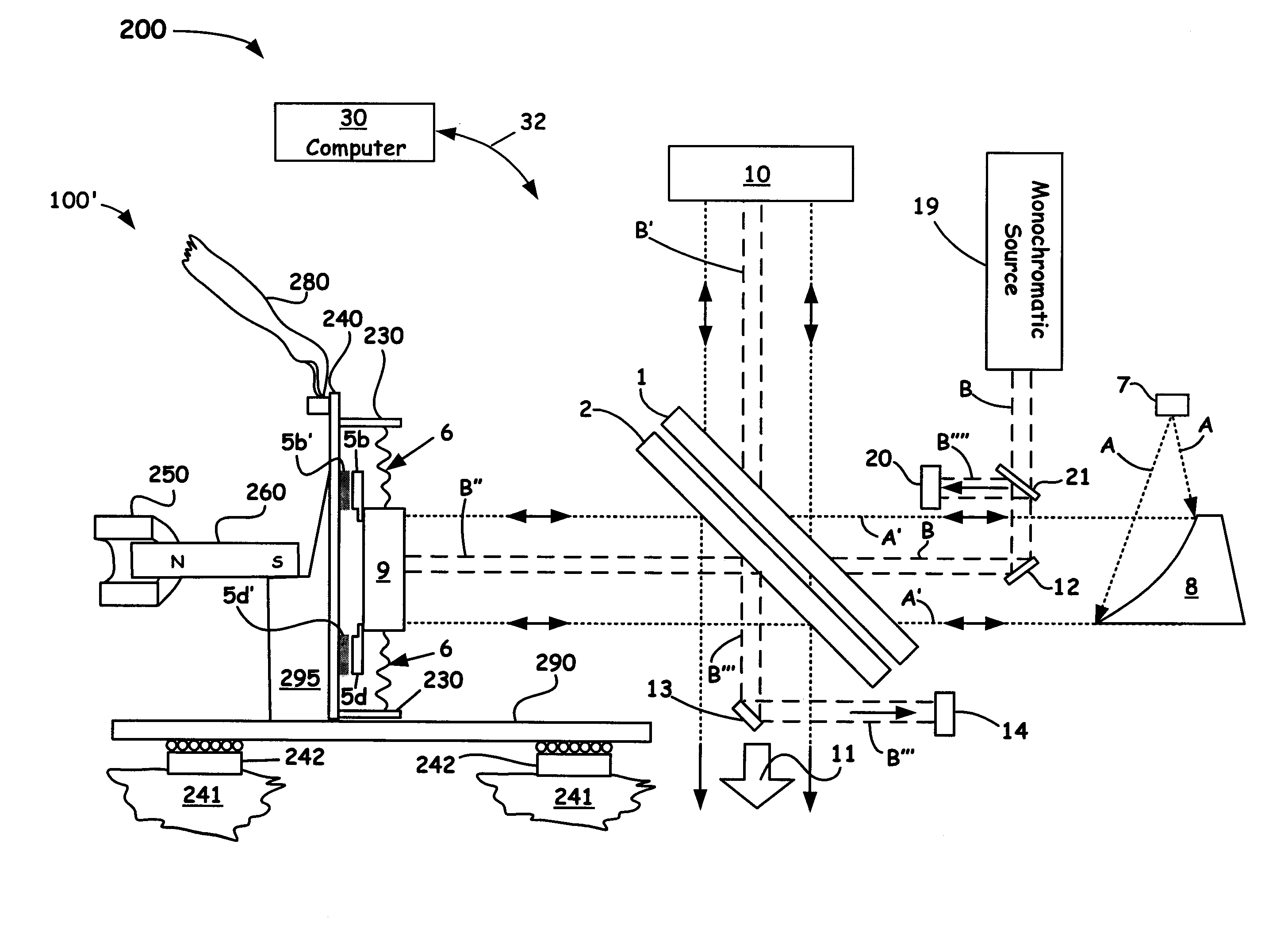

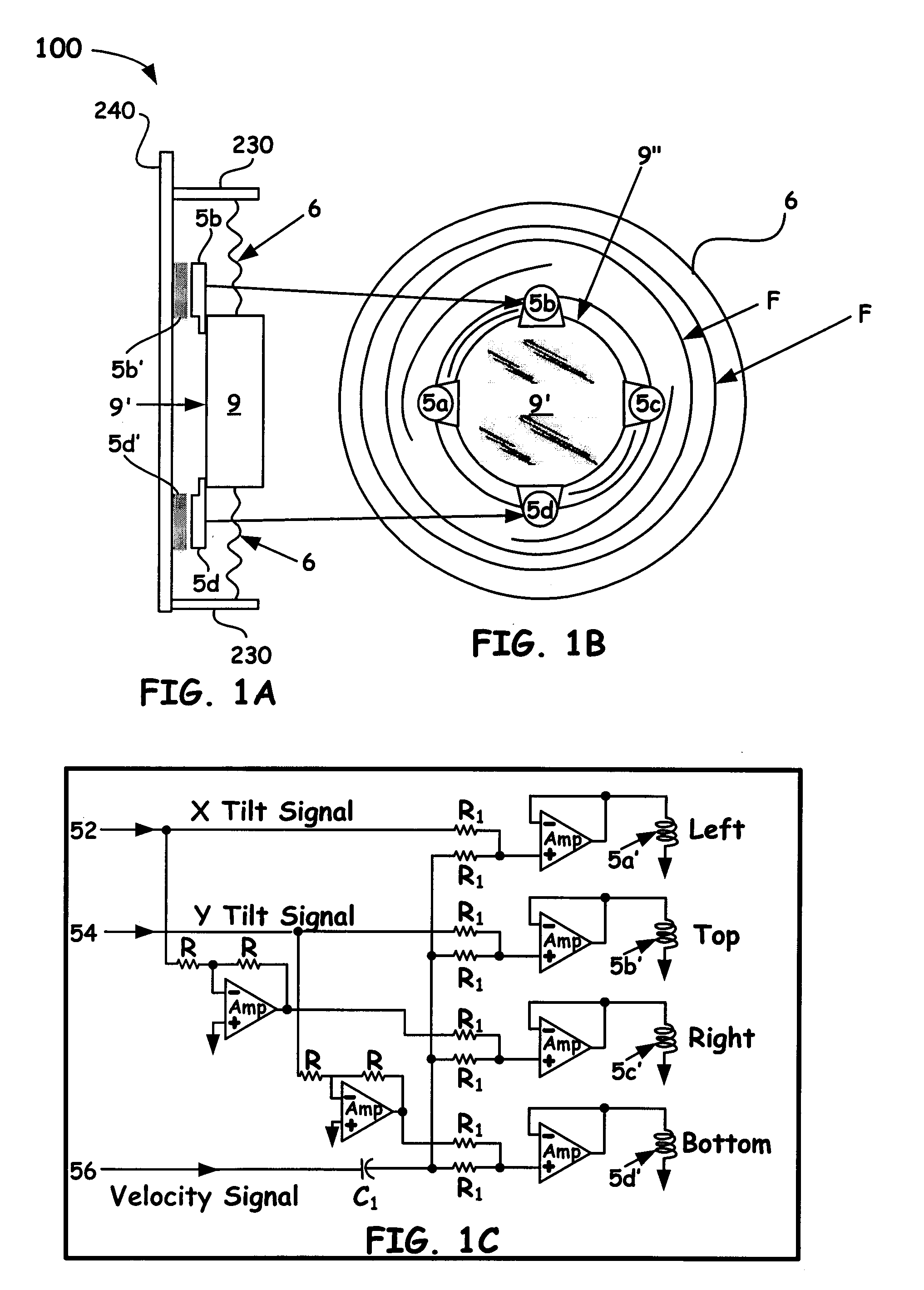

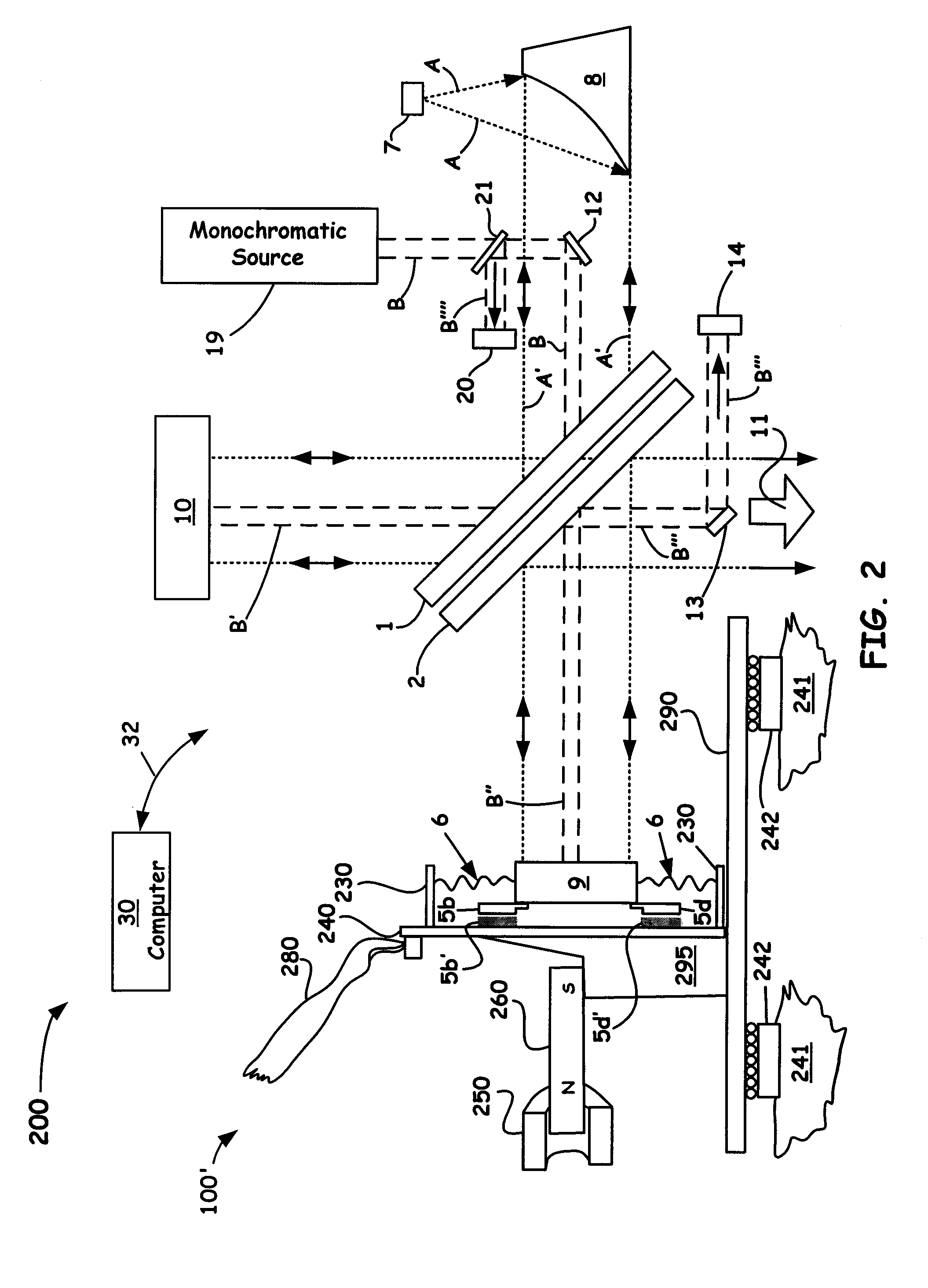

Flexure Mounted Moving Mirror to Reduce Vibration Noise

ActiveUS20120120404A1Improve speed controlStable and low spectral dataOptical measurementsRadiation pyrometryLow noiseEngineering

A novel means of provided a hybrid flexure mounted moving mirror component in an interferometer is introduced herein. In particular, a linear bearing in combination with a novel flexure mounting having novel tilt and velocity control of the moving optical component is provided. Such an arrangement enables correction of the errors at the mirror itself while also solving the problem of isolating vibration and noise caused by the imperfections in the bearing surfaces used in many conventional interferometers. Using such a coupled flexure mounting of the present invention, in addition to the above benefits, also enhances velocity control because the resultant low mass of the moving mirror assembly enables the systems disclosed herein to respond faster than conventional mirror velocity controlled interferometer instruments and with a lower velocity error so as to provide a more stable and lower noise spectra from the analytical instrument.

Owner:THERMO ELECTRONICS SCI INSTR LLC

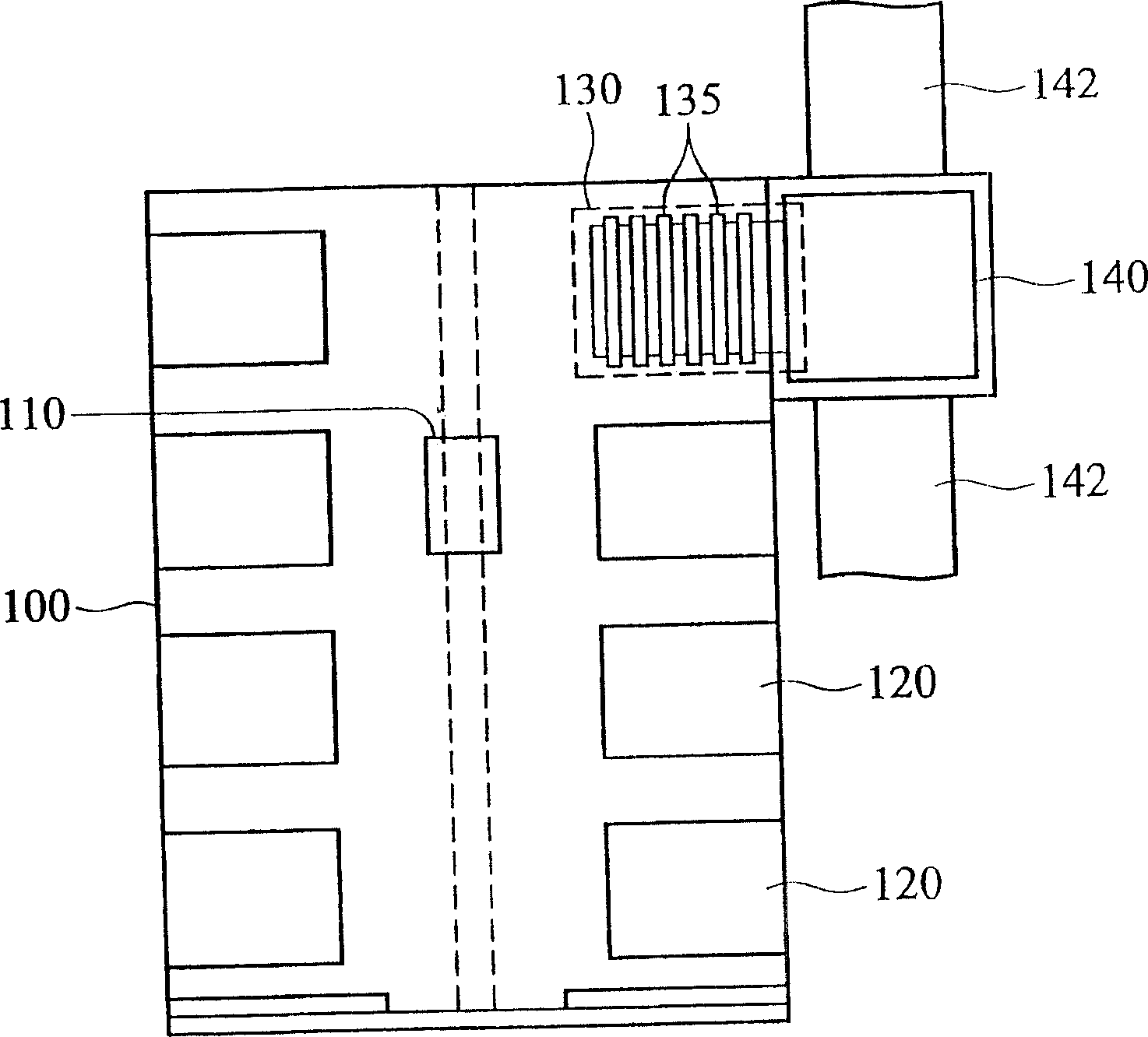

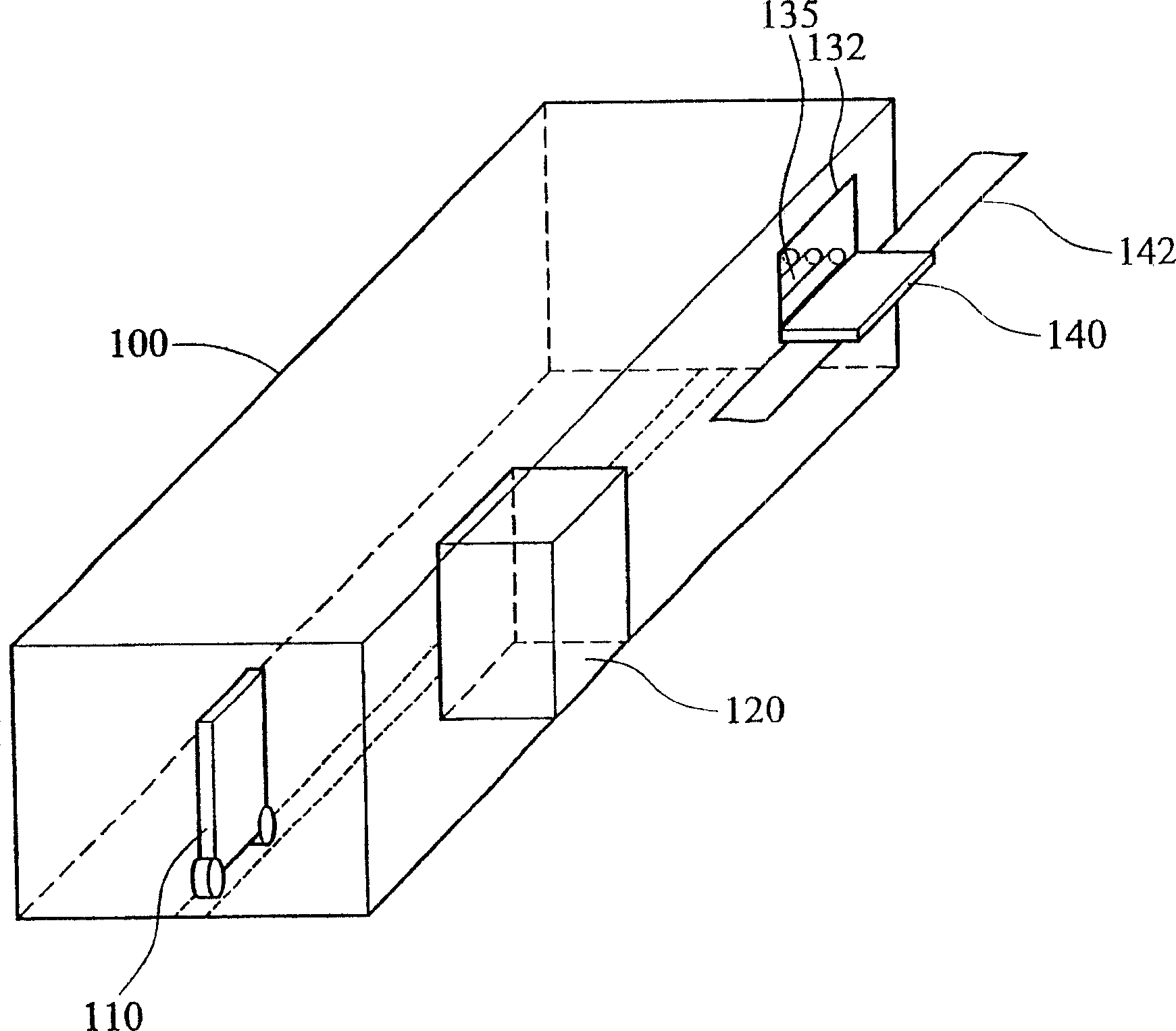

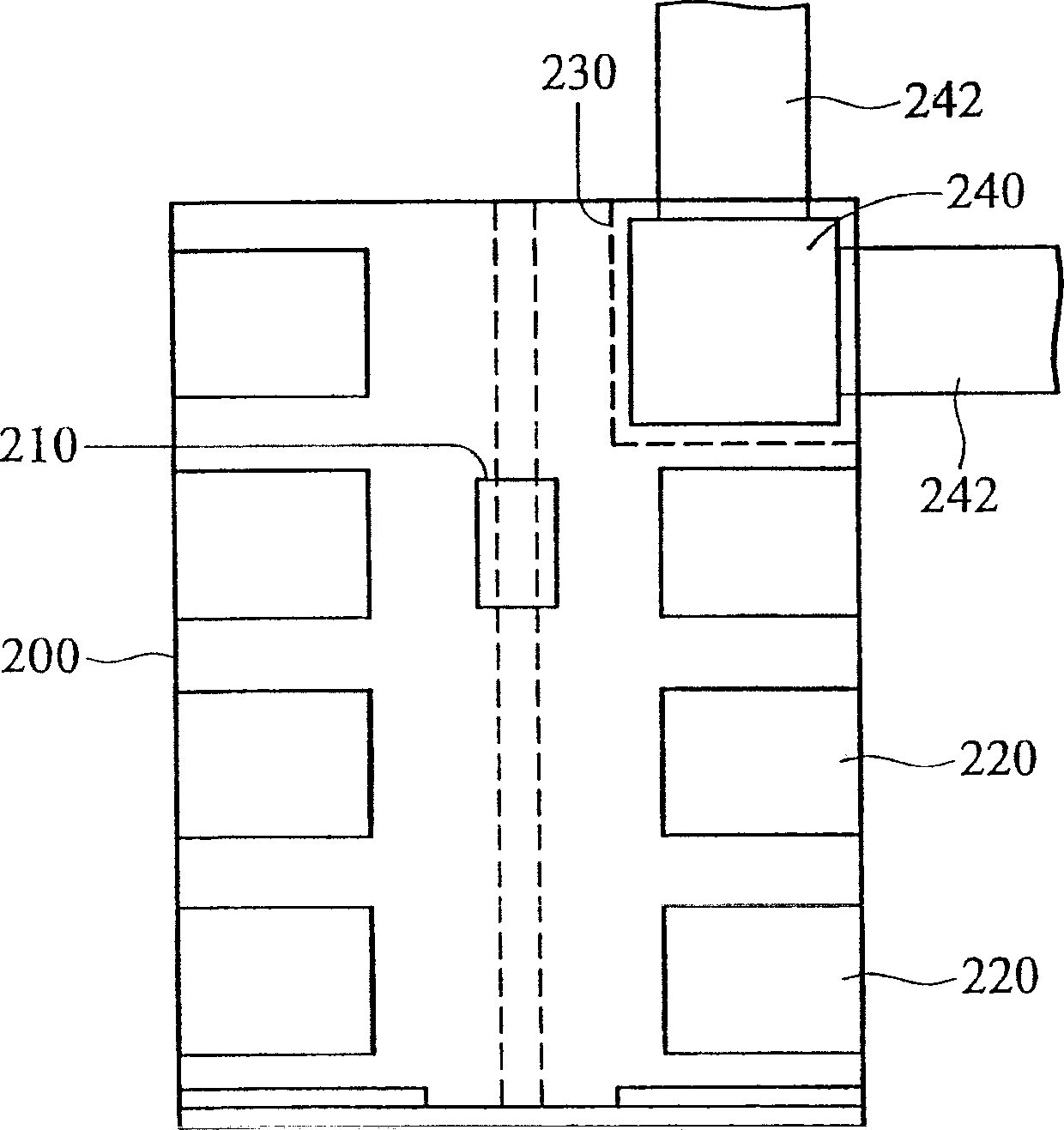

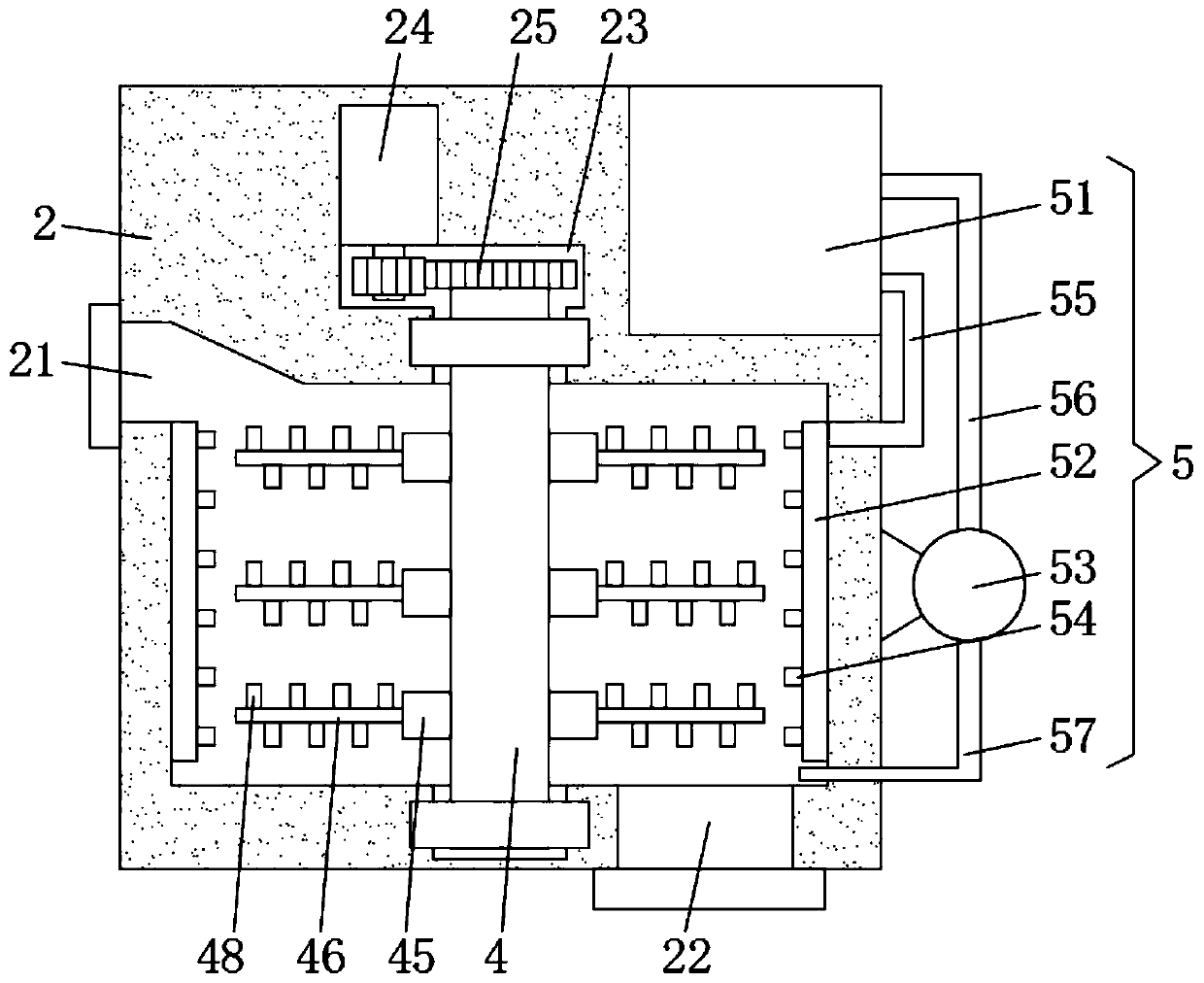

Automatized material conveying system and its storage cabinet

InactiveCN1579899ASimple designReduce waiting timeStorage devicesTrolleysEngineeringMechanical engineering

The invention discloses a automatic material lifting system, it includes a transporting trail(crown block trail), a transporting vehicle(crown block) and a storage. The transporting vehicle can move on the trail. The storage includes a taking and putting part, which is in the storage. The transporting trail enters into the storage, and overlaps with the taking and putting part, when the transporting vehicle is in the taking and putting part, the moving loading machine puttes the material into the transporting vehicle.

Owner:AU OPTRONICS CORP

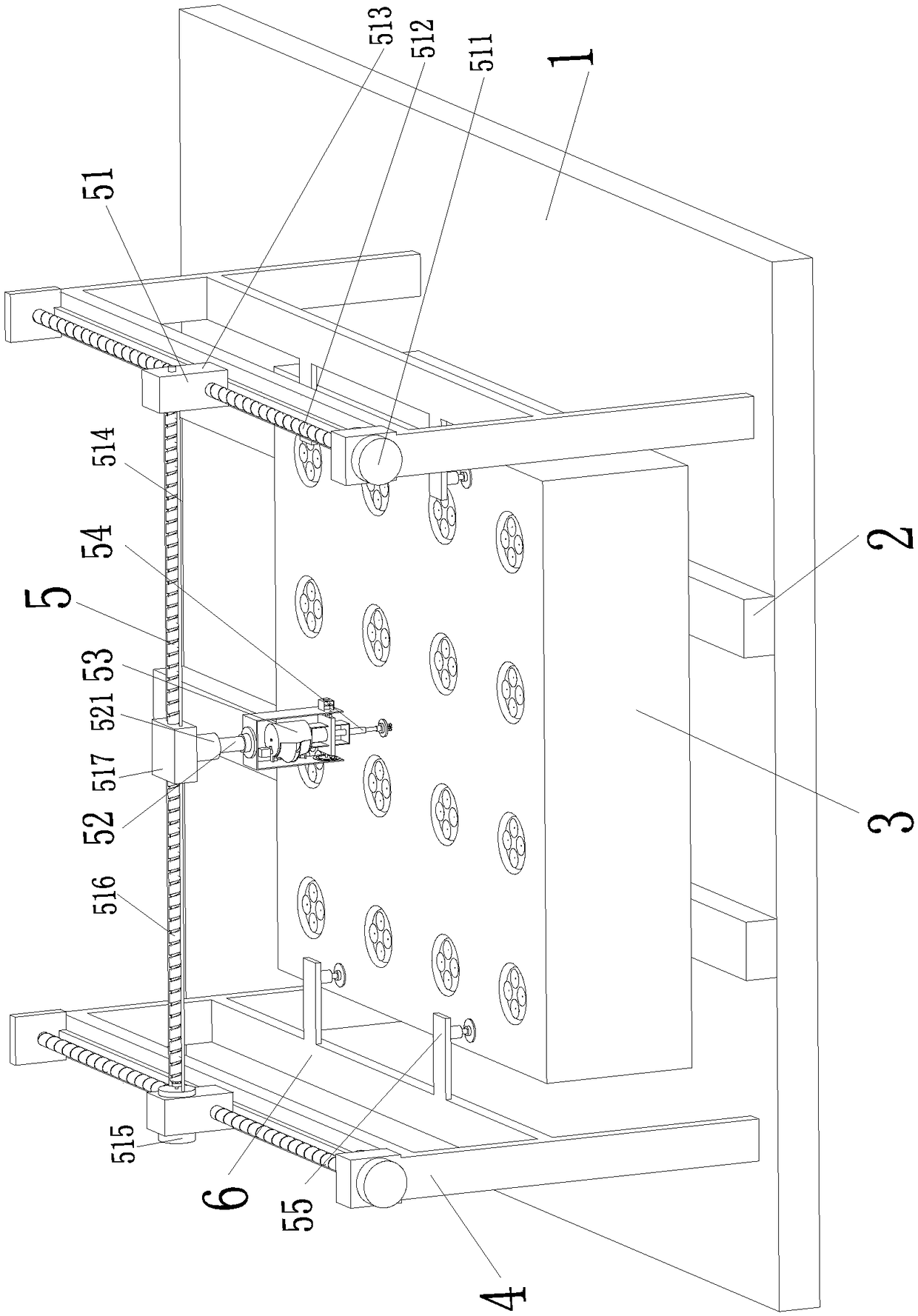

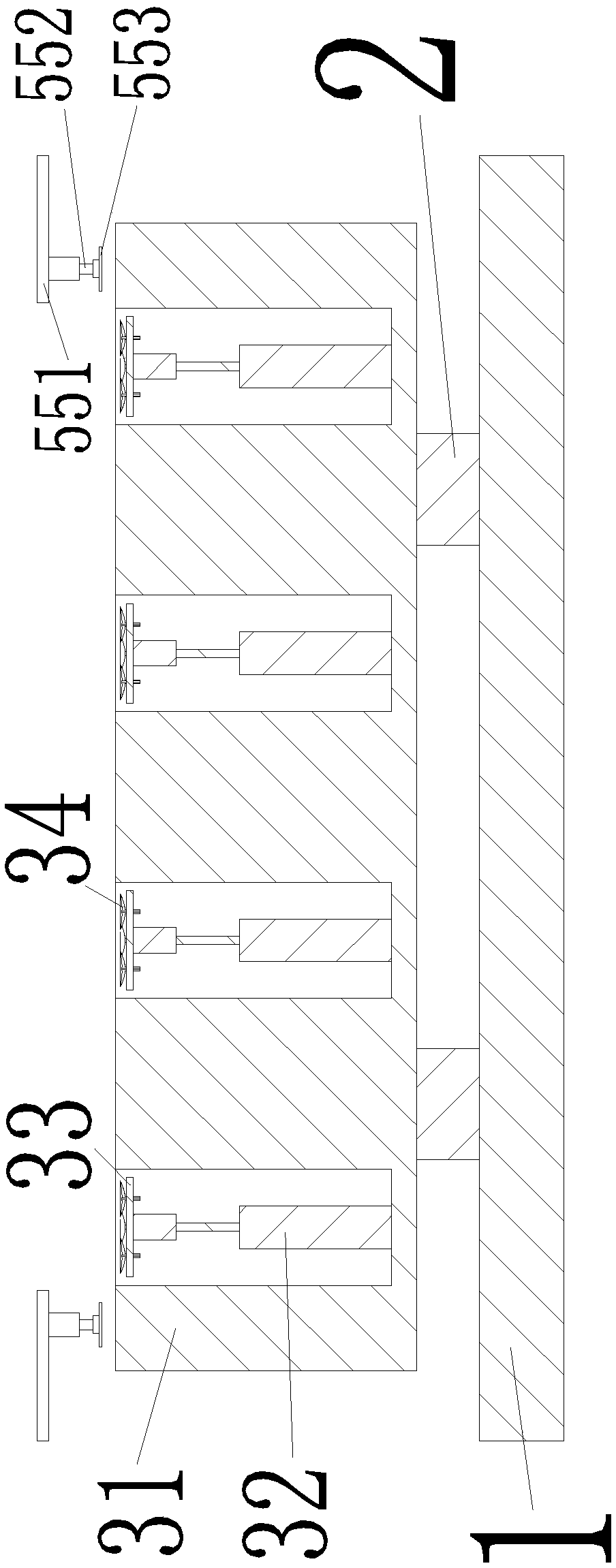

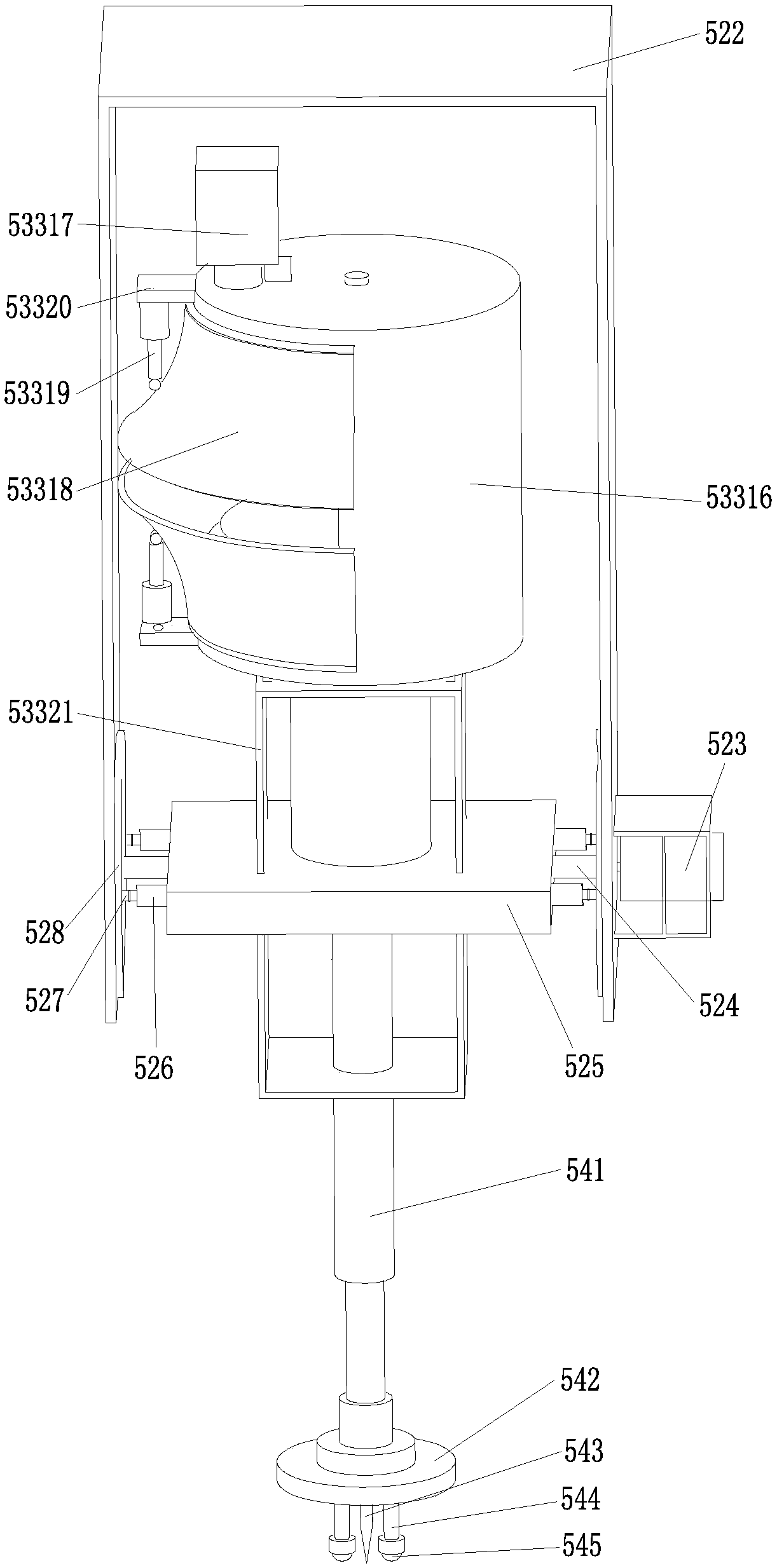

Intelligent cutting and polishing production line for deep processing of glass and deep processing method of glass

ActiveCN108840556APrevent slippingSlip off withoutEdge grinding machinesGlass severing apparatusEngineeringDeep processing

The invention relates to an intelligent cutting and polishing production line for deep processing of glass and a deep processing method of glass. The production line comprises a bottom plate, an electric support slider, a support device, feeding support frames, an execution device and a support frame transverse plate, wherein the electric support slider is mounted in the middle of the bottom plate, the support device is mounted on the electric support slider, the feeding support frames are symmetrically mounted at left and right ends of the bottom plate and adopt an inverted U-shaped structure, the support frame transverse plate is arranged between inner walls of middles of the feeding support frames, and the execution device is mounted between the two feeding support frames. During working, the glass is conveyed onto the support device, the support device fixes the glass, then, the execution device cuts and edges the glass, manual operation is not required during processing, glass breakage caused by operation errors is avoided, the labor intensity of workers is reduced, the working efficiency is improved, and a cutting and edging procedure integrated continuous processing functionduring deep processing of the glass can be realized.

Owner:ALL GLASS SUQIAN

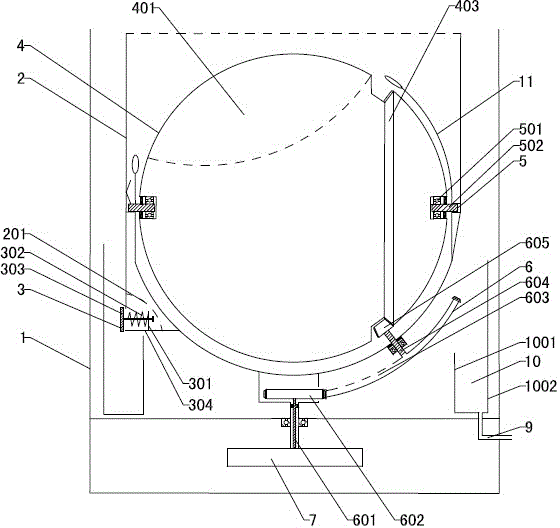

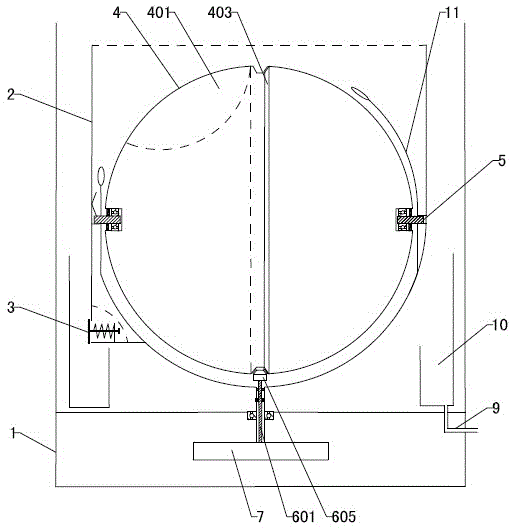

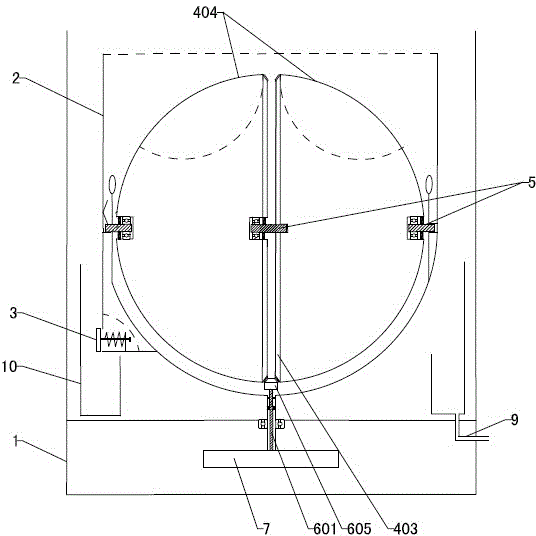

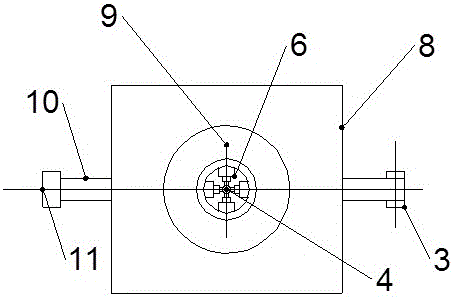

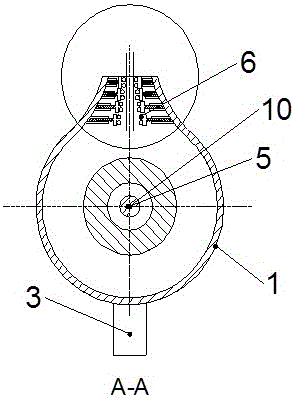

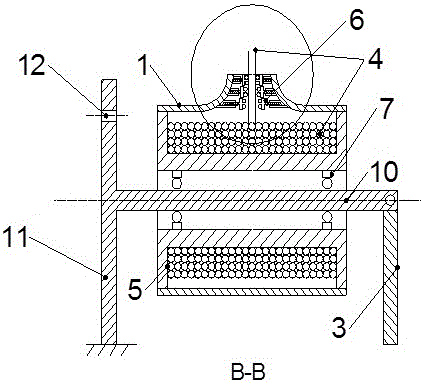

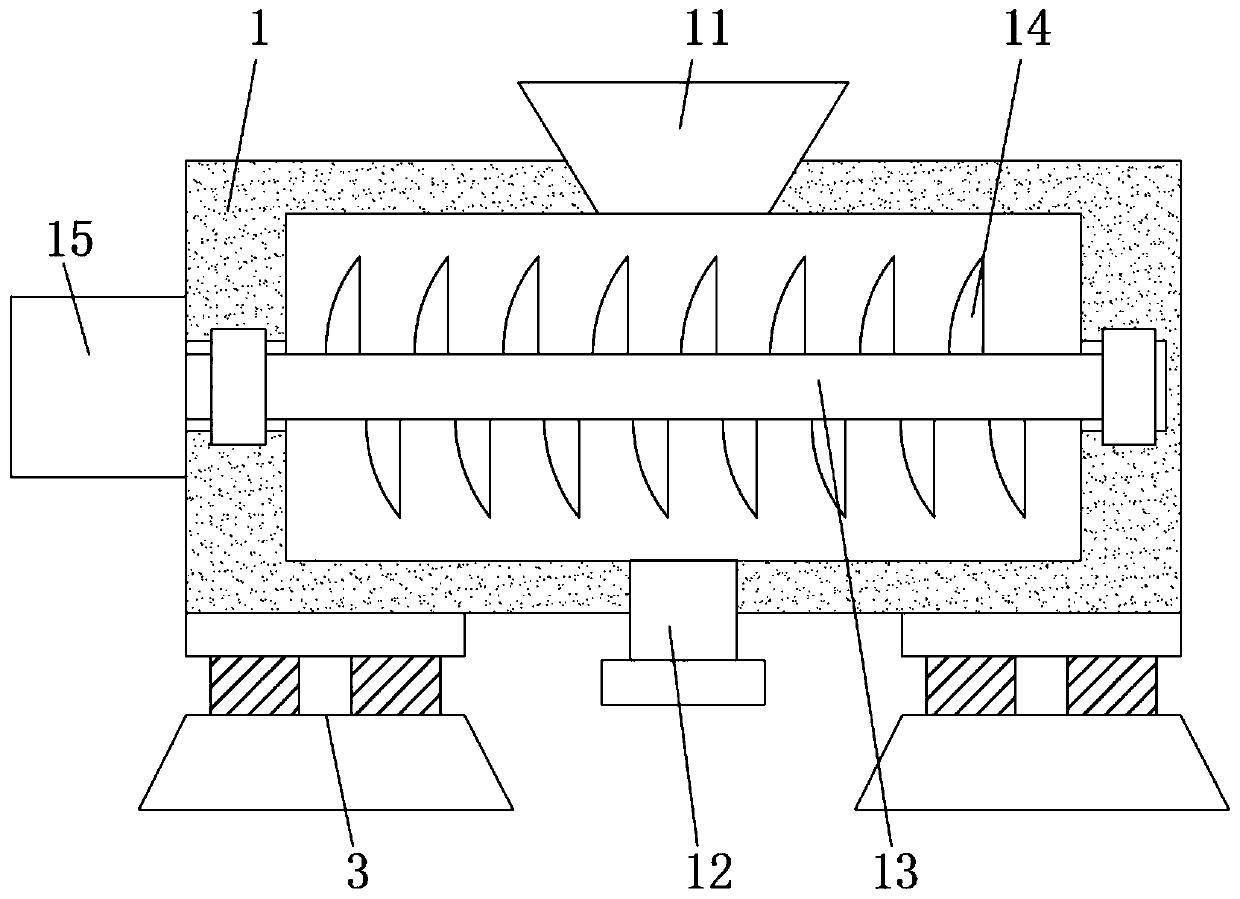

Rolling ball type washing machine

InactiveCN103603168ASolve the problem of inconvenient pick and placeCompact structureOther washing machinesWashing machine with receptaclesImpellerBall type

The invention relates to a rolling ball type washing machine belonging to the field of washing equipment, and particularly relates to a rolling ball type washing machine with a spherical washing drum. A rolling ball (4) is a spherical shell provided with a fetching hole (401) in the top and can rotate in an inner drying cylinder (2) by taking a horizontal central axis as a rotating shaft, and the rolling ball (4) and the inner drying cylinder (2) can synchronously rotate through a power device (7) by taking a central shaft in the vertical direction as a rotating shaft; one side of the lower part of the inner drying cylinder (2) is provided with a water outlet (201) where a centrifugal starting / stopping device (3) is arranged, the circumference below the inner drying cylinder (2) is provided with an annular water receiving tank (10) with an upper opening, and one side of the water receiving tank (10) is connected with a water outlet pipe (9). The rolling ball type washing machine is capable of realizing rolling type washing by using the rolling ball, good in washing effect and capable of saving water and reducing the dosage of detergents; due to the combination of a centrifugal drainage way of the water outlet of the inner drying cylinder, the problem of secondary pollution to clothes is thoroughly solved, and the rolling ball type washing machine can be conveniently changed to work in an impeller washing way.

Owner:张安达

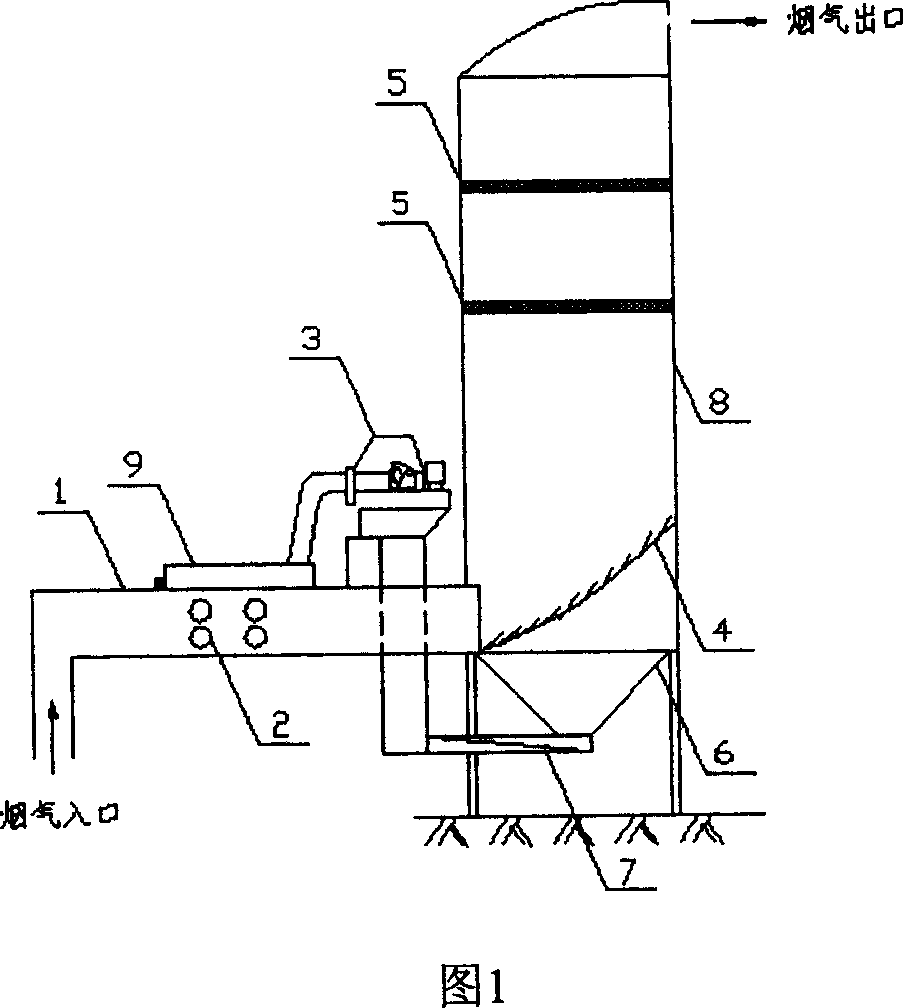

Circular dense phase fluidizing desulfurization apparatus

ActiveCN1973967AImprove utilization efficiencyAdequate responseDispersed particle separationEngineeringDistributor

The circular dense phase fluidizing desulfurization apparatus belongs to the field of environment engineering technology and is one improved fume desulfurizing apparatus. The desulfurizing apparatus includes square Venturi tube, stirrer, elevator, guide unit, web plate, collecting bin, humidifier, reaction region, and material distributor. The guide unit consists of material permeating hole, guide plate skeleton and guide plate. The apparatus of the present invention has smooth running, low power consumption, easy installation and production, light dust collector load lowered by the web plate, and capacity of recovering desulfurizer for reuse.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

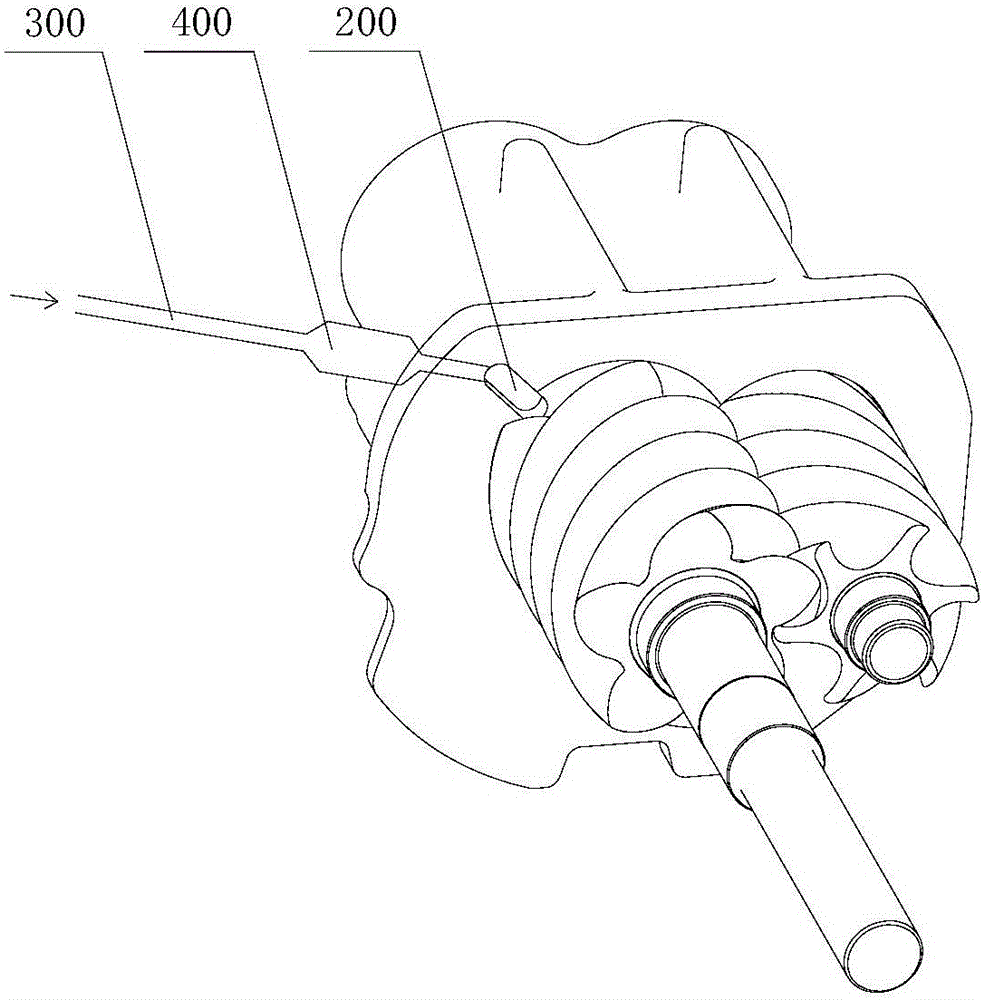

Roots vacuum pump

ActiveCN103104489AReduce volumeExtended maintenance cycleSealing arrangement for pumpsRotary piston pumpsDrive motorEngineering

The invention relates to the technical field of vacuum pumps, and in particular relates to a roots vacuum pump. The vacuum pump comprises a motor, front and back bearing cavities, a roots cavity and a gear cavity, wherein the front and back bearing cavities are located at the both sides of the roots cavity, and the gear cavity is connected with the back bearing cavity; the roots cavity is provided with an air inlet and an air outlet and is internally provided with a driving rotor shaft and a driven rotor shaft; the driving rotor shaft and the driven rotor shaft are respectively and correspondingly provided with a roots driving rotor and a roots driven rotor; one end of the driving rotor shaft is connected with the motor, and the other end of the driving rotor shaft is provided with a driving gear; one end of the driven motor shaft is provided with a driven gear which is in transmission connection with the driving gear and accommodated in a gear box; and the front bearing cavity and the back bearing cavity are internally provided with bearings and bearing support rings which are sleeved and fixed at the both ends of the driving rotor shaft and the driven rotor shaft. The roots vacuum pump has the advantages of being small in size, high in pumping speed, energy-saving, space-saving, and applicable to IC equipment.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

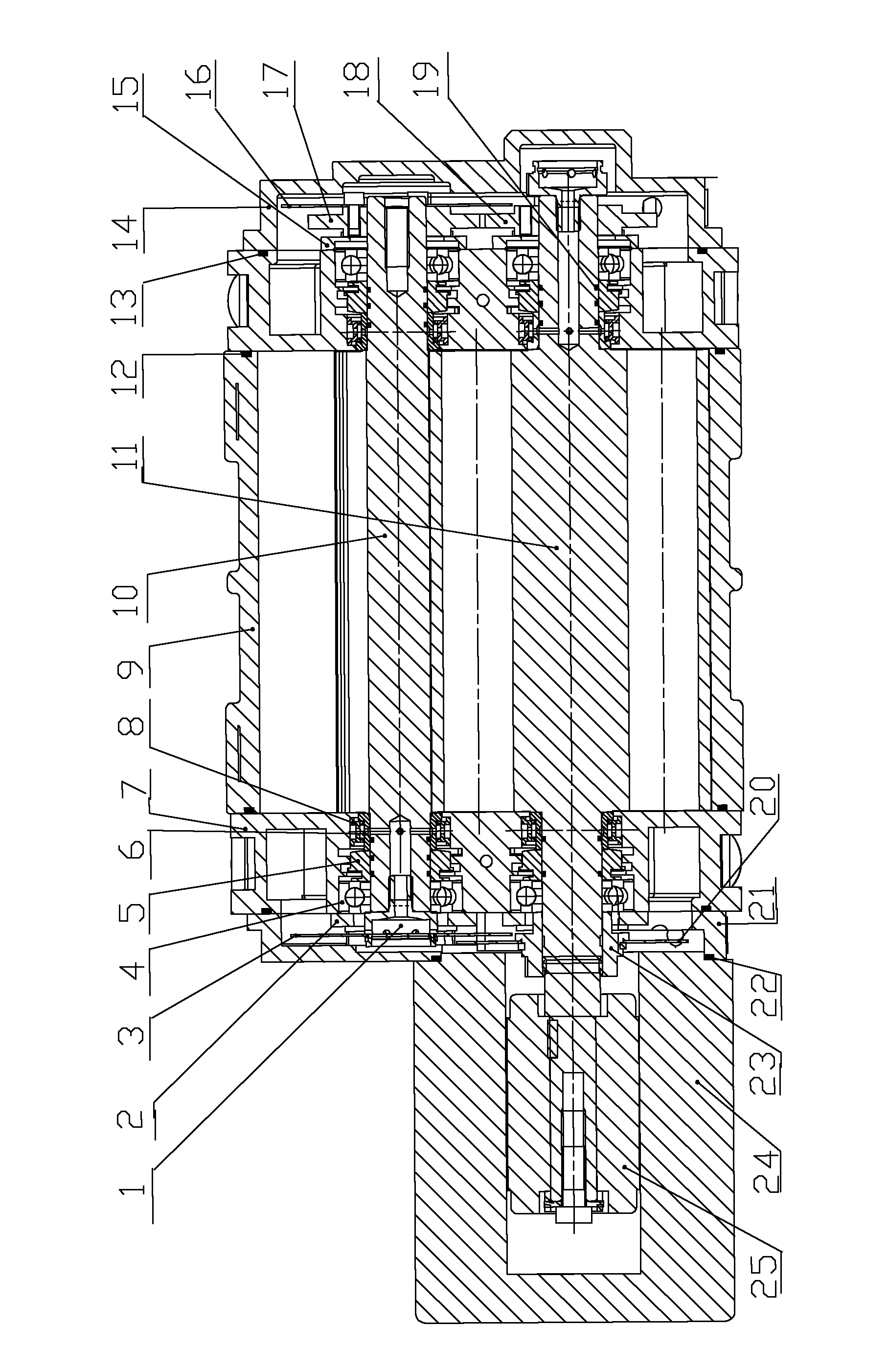

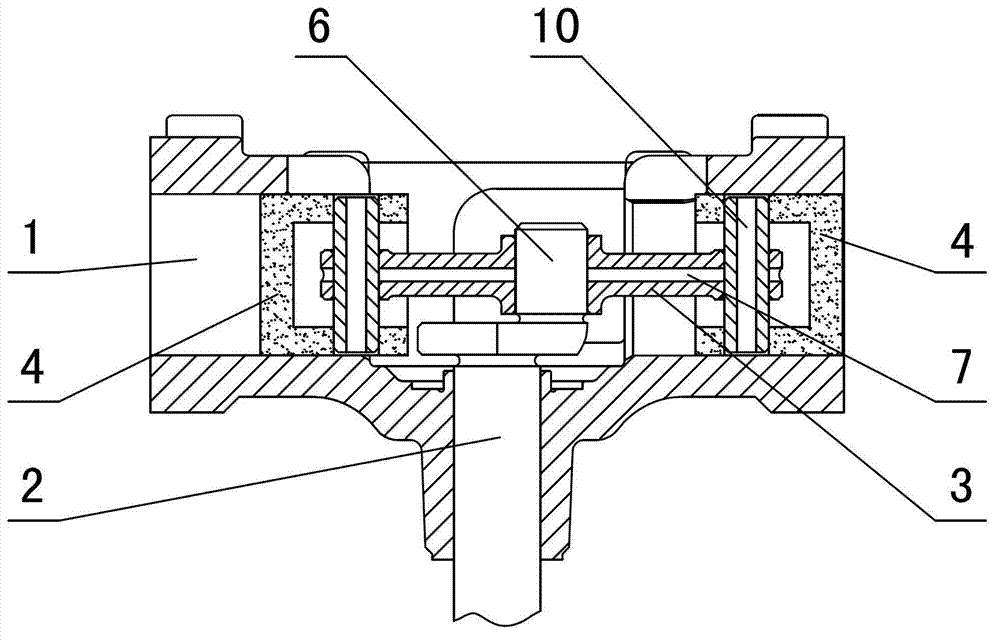

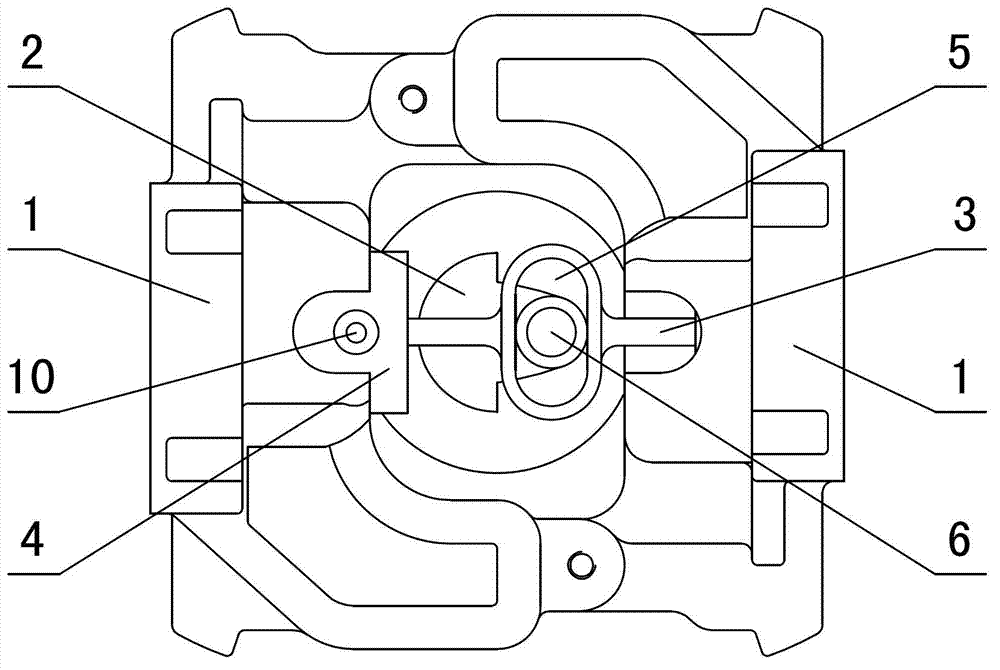

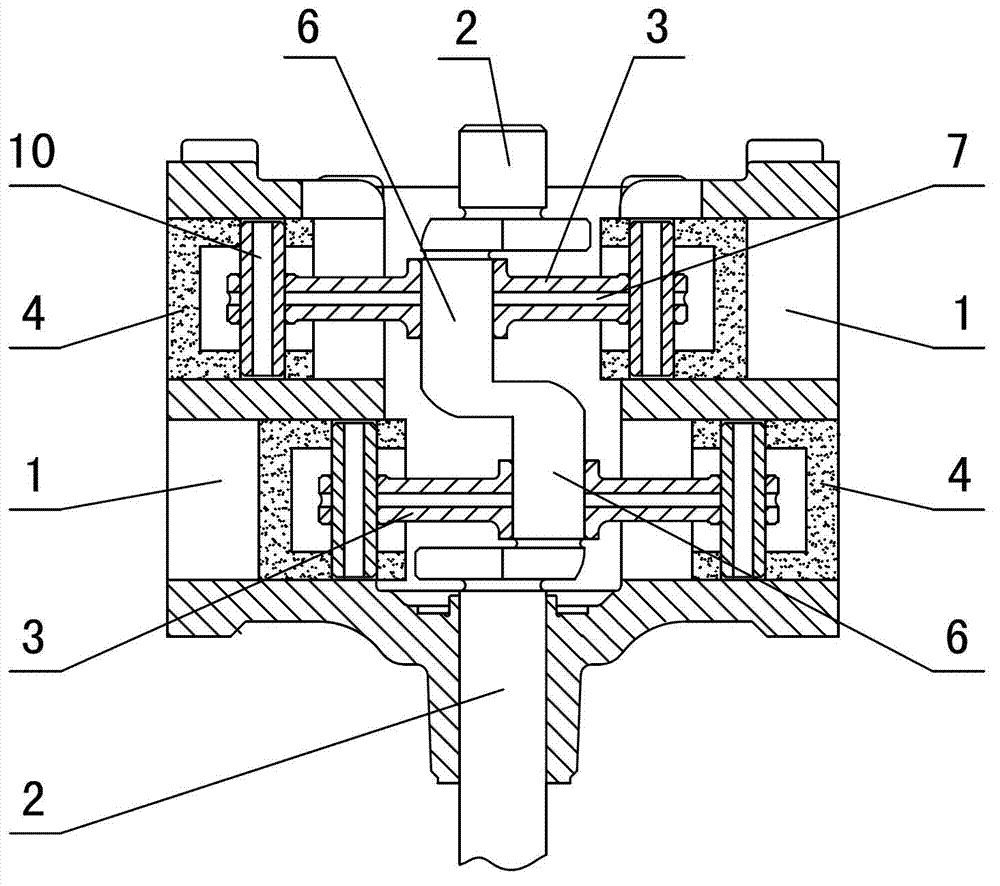

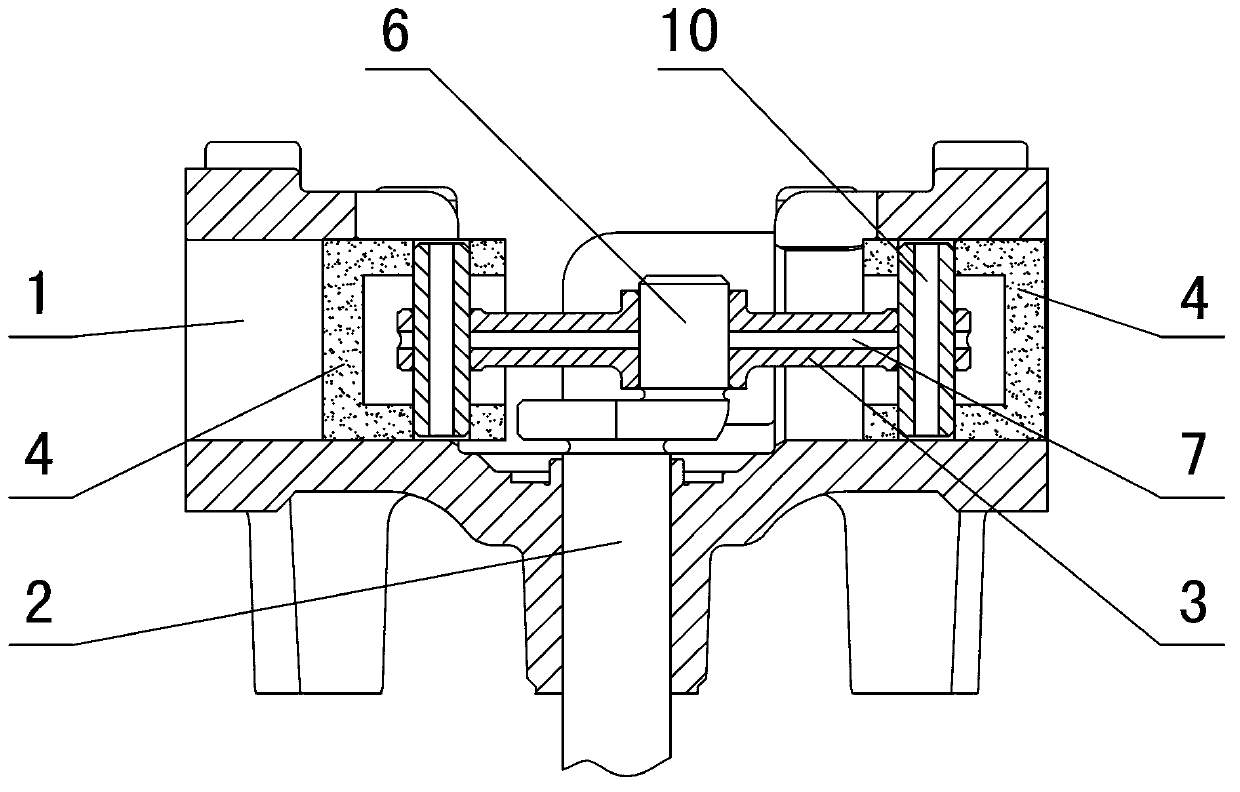

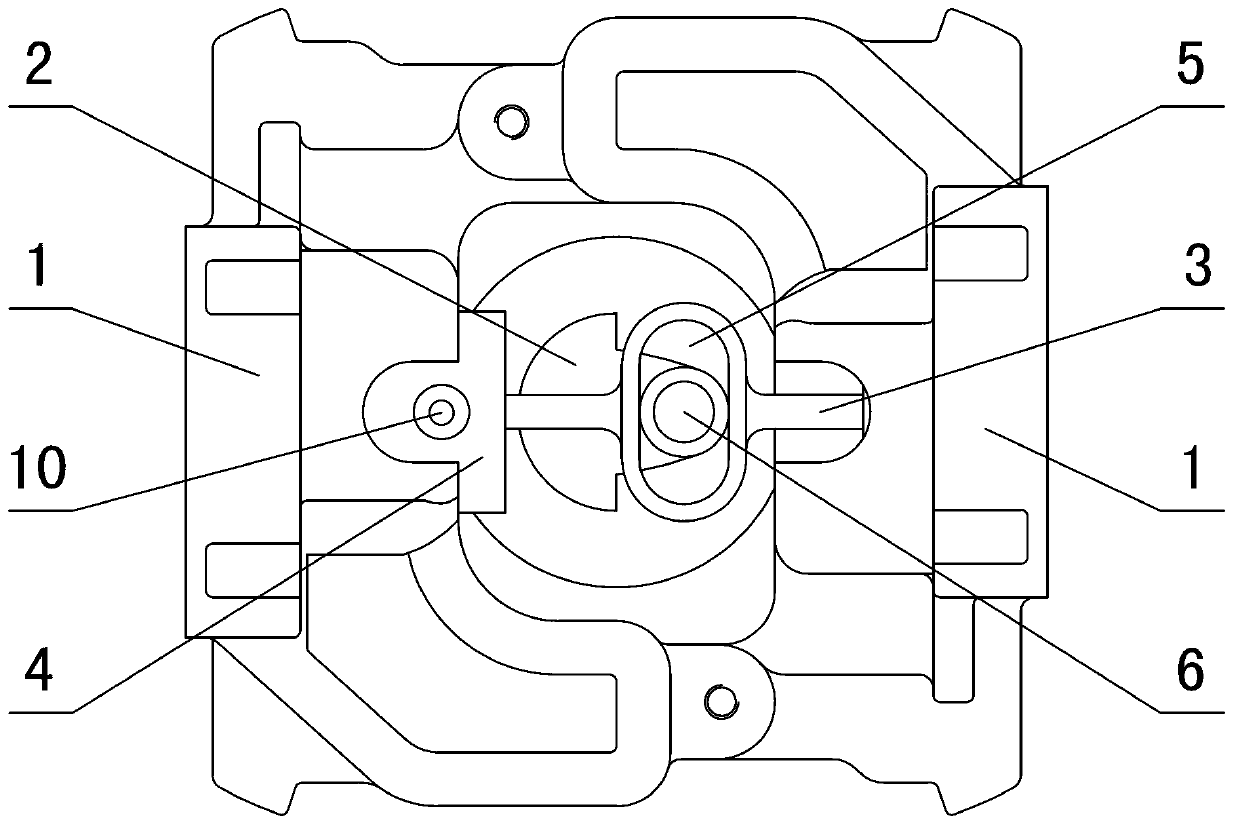

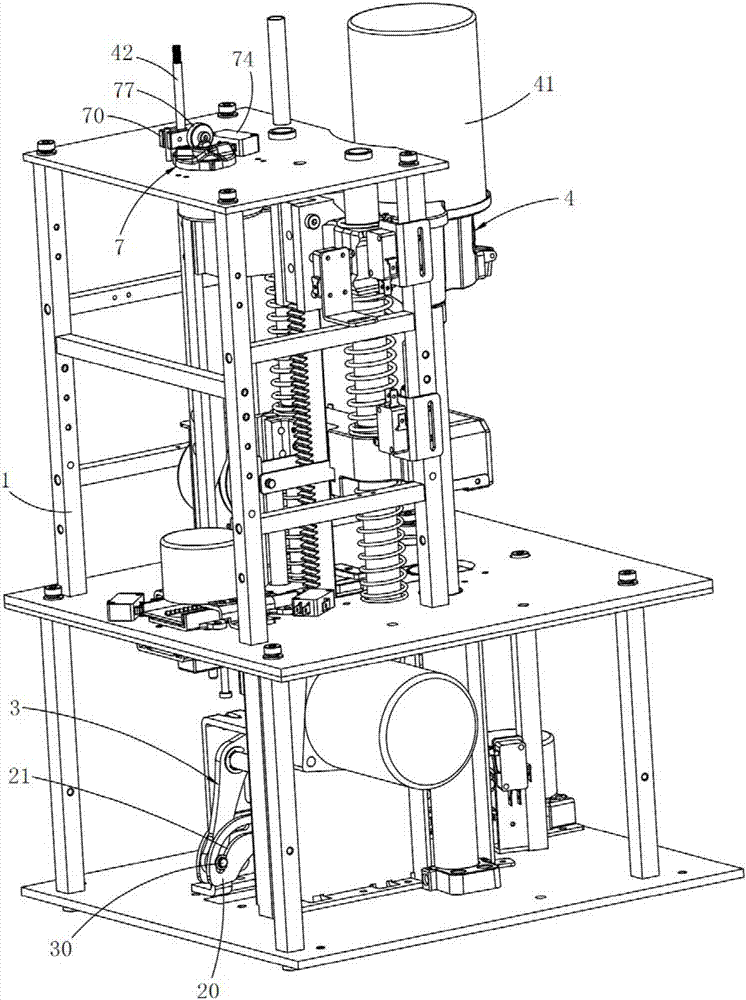

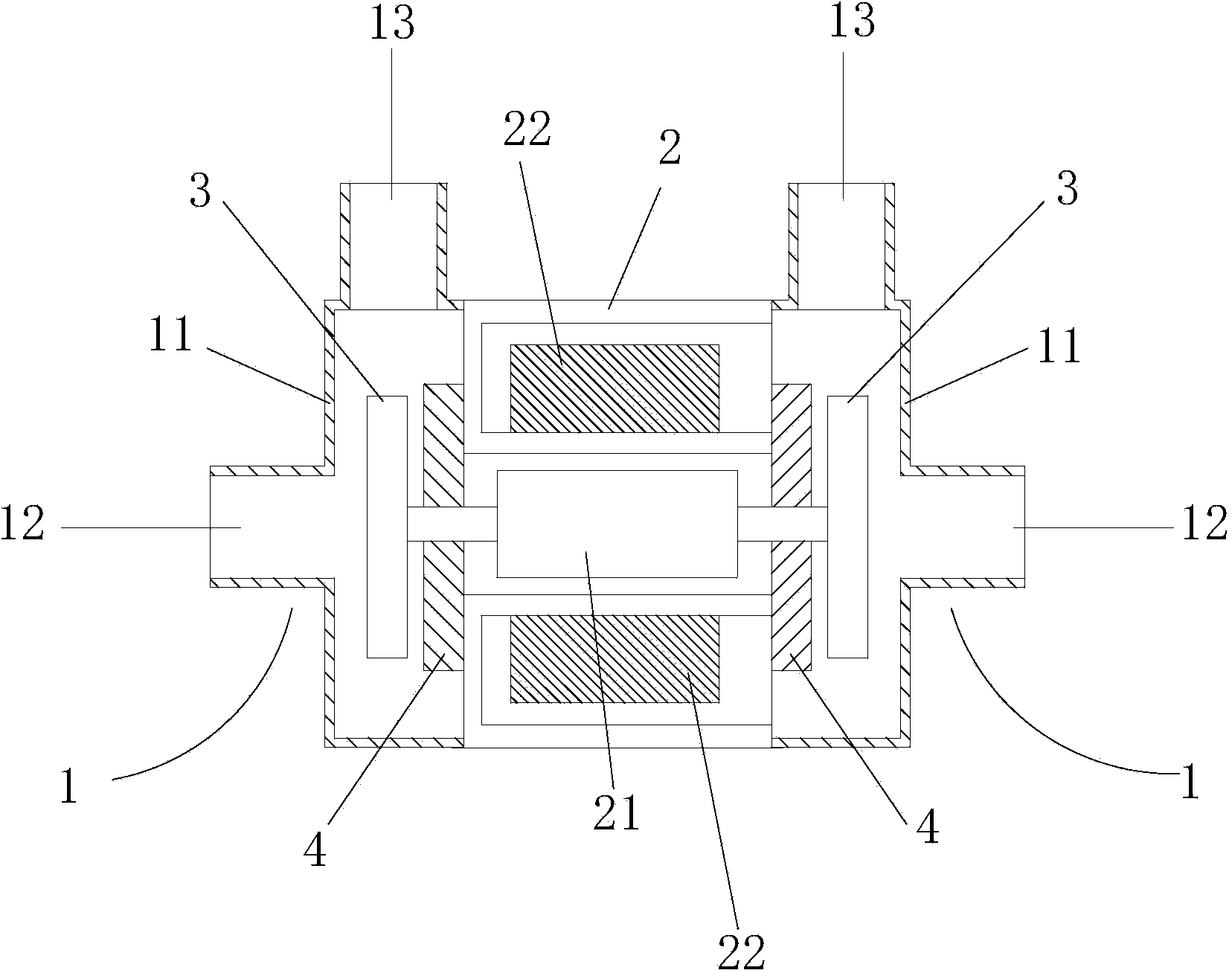

Single-drive multi-cylinder compressor structure

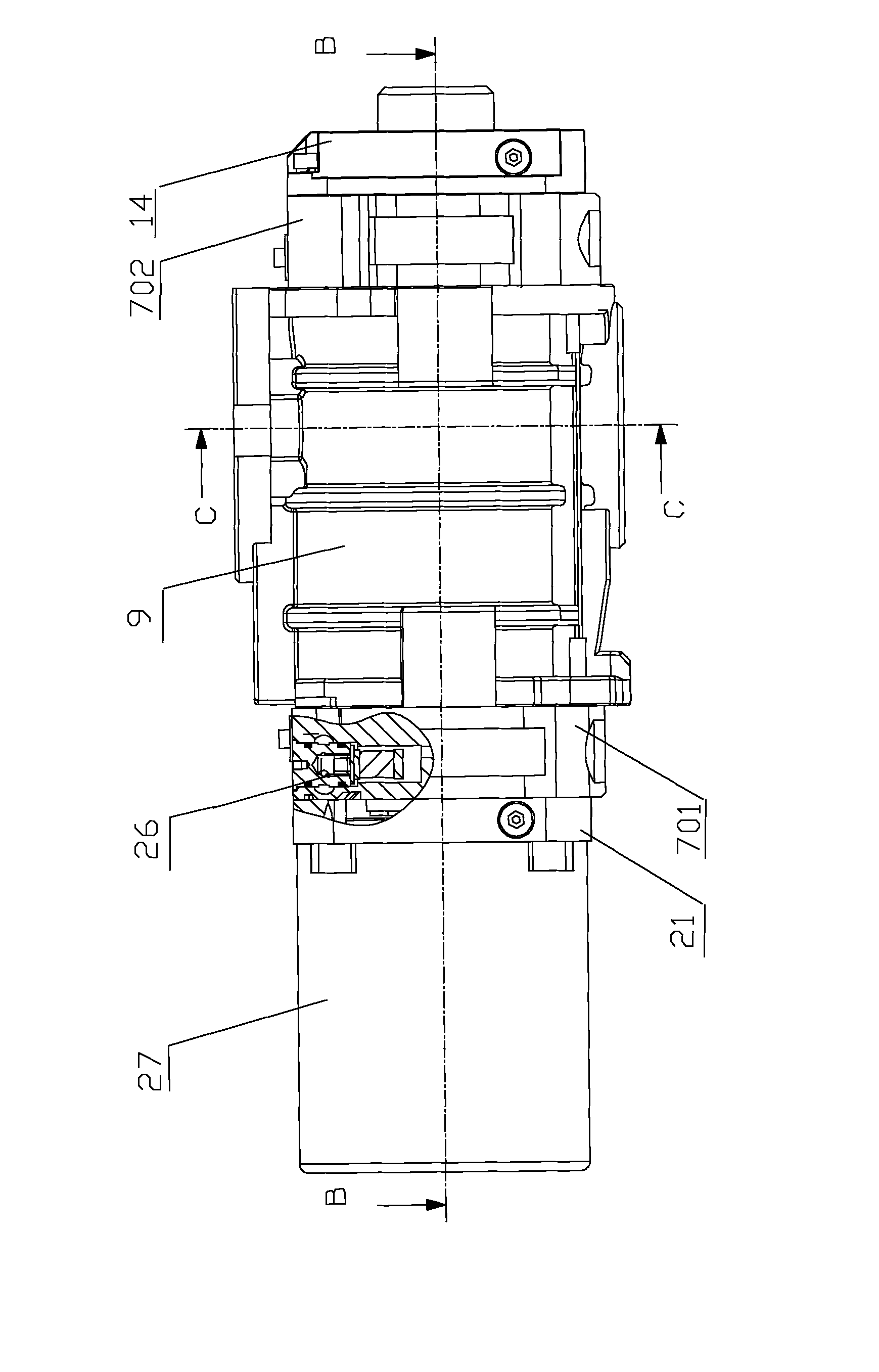

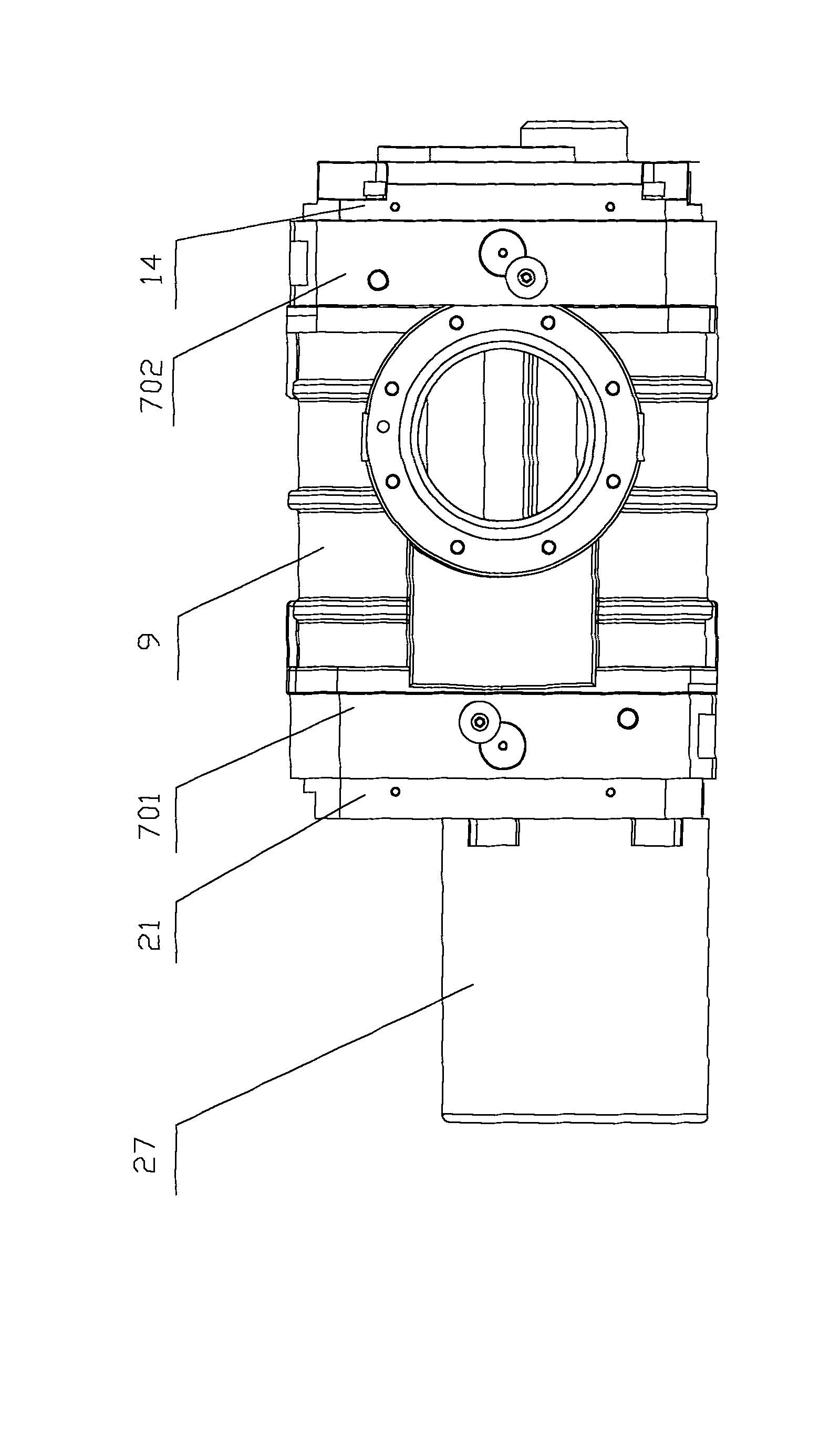

ActiveCN102777343ASolve efficiency problemsSolve the vibrationPositive displacement pump componentsMulti-stage pumpsEngineeringMechanical engineering

The invention discloses a single-drive multi-cylinder compressor structure. The structure comprises a crank shaft and cylinders, wherein the cylinders are arranged on the radial direction of the crank shaft and are driven by the crank shaft, the number of the cylinders is even, the cylinders are arranged on two opposite sides of the crank shaft in pairs, the central axis of the same pair of cylinders and the central axis of the crank shaft are arranged in the same plane, the crank shaft is connected with pistons which are arranged on the same pairs of cylinders through a linear three-hole connecting rod, a chute which is vertical to the three-hole connecting rod is arranged in the center of the three-hole connecting rod, and the crank shaft is connected with the interior of the chute in a sliding mode. By the aid of the compressor structure, problems that in existing refrigerating compressors of the prior art, working efficiency is low, the vibration is large, the noise pollution is serious, piston pins are abraded and the service life is short are solved. The compressor structure has the advantages of being stable in operation, low in noise and long in service life. The compressor structure has high usage value and is suitable to various compressors.

Owner:HANGZHOU QIANJIANG REFRIGERATION COMPRESSOR GRP CO LTD

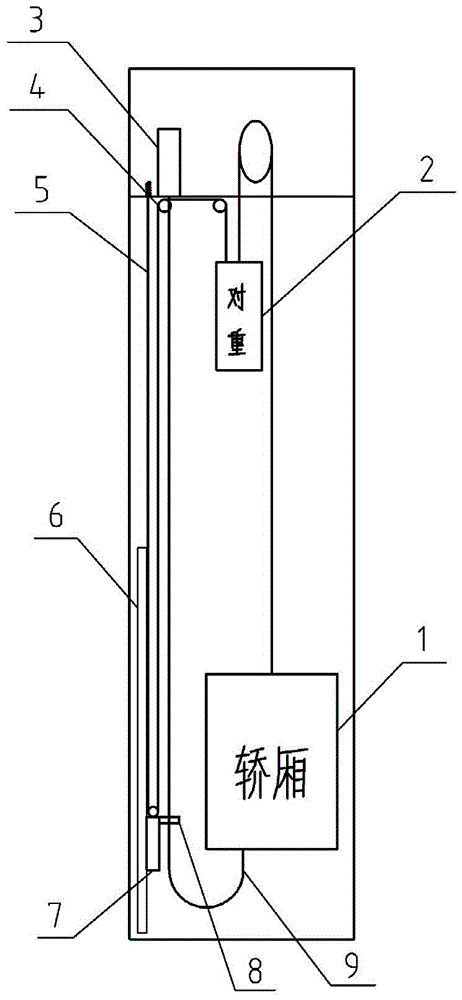

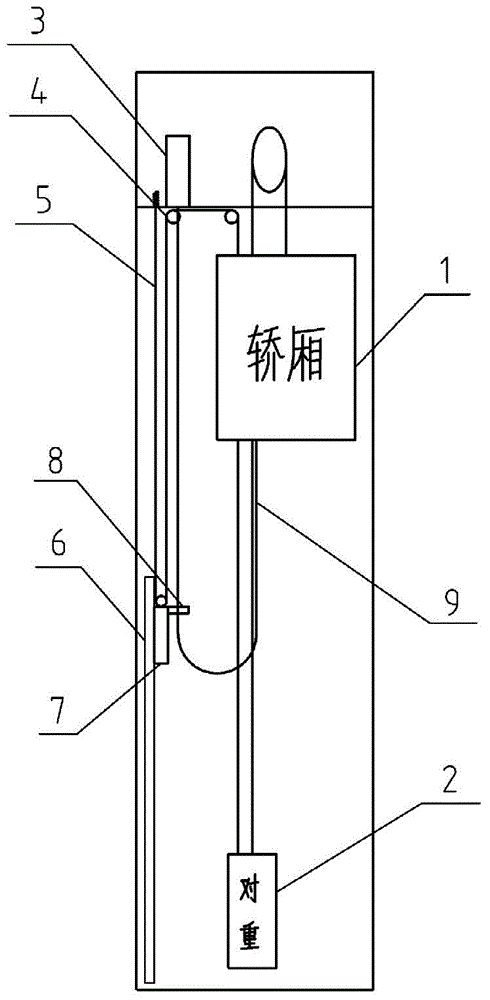

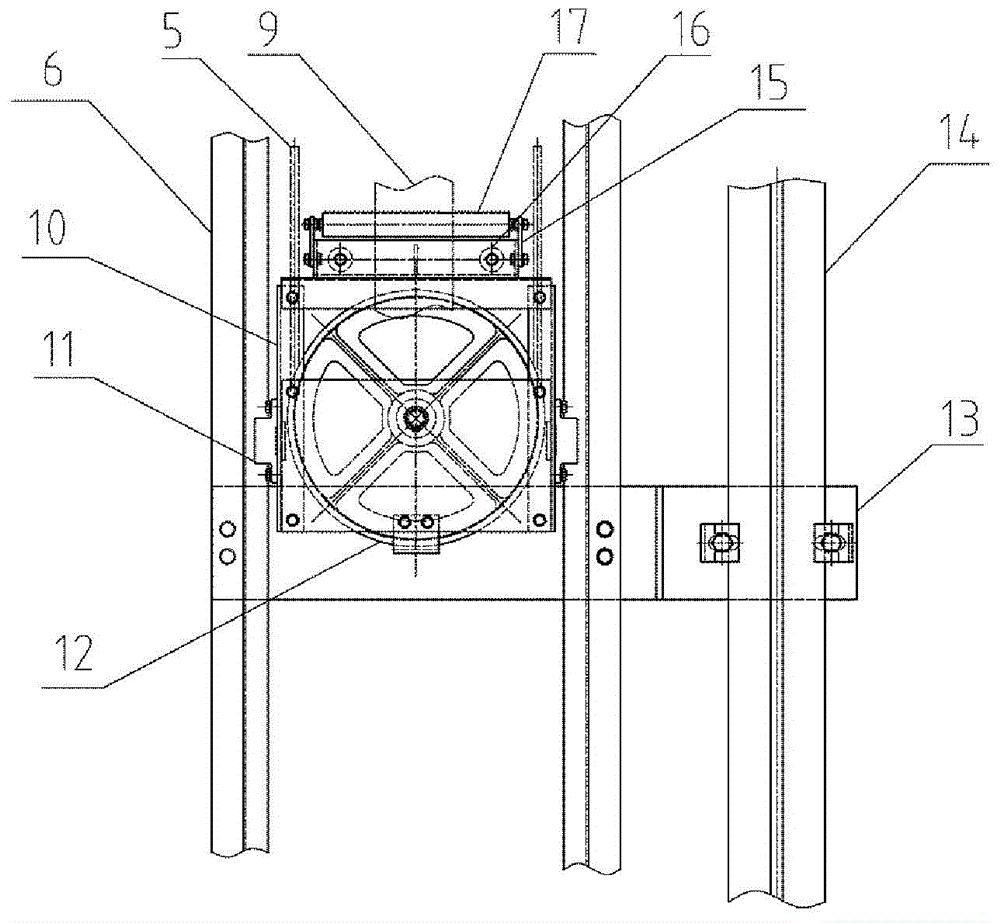

Elevator traveling cable protection device

The invention discloses an elevator traveling cable protection device which comprises a diversion sheave assembly. The diversion sheave assembly can move up and down along a vertical guide piece. Through vertical movement of an elevator counterweight, the diversion sheave assembly and the lower portion of an elevator traveling cable move synchronously. An idler wheel guide mechanism for traveling cable protection is fixedly connected with the diversion sheave assembly. The elevator traveling cable penetrates the idler wheel guide mechanism for traveling cable protection to prevent the elevator traveling cable from swinging in the movement process of an elevator. According to the elevator traveling cable protection device, a fixing device is additionally arranged on the lower portion of the traveling cable, tension is provided for the traveling cable, the problems of vibration and swing of the traveling cable in the operation process of the elevator can be solved effectively and fundamentally, and collision with a shaft component of the traveling cable in the movement process is avoided, so that the risk that a traveling cable is snapped in the operation process of the elevator is avoided, the service life of the traveling cable is improved, and stable operation of the elevator is guaranteed.

Owner:MITSUBISHI ELECTRIC SHANGHAI ELECTRIC ELEVATOR

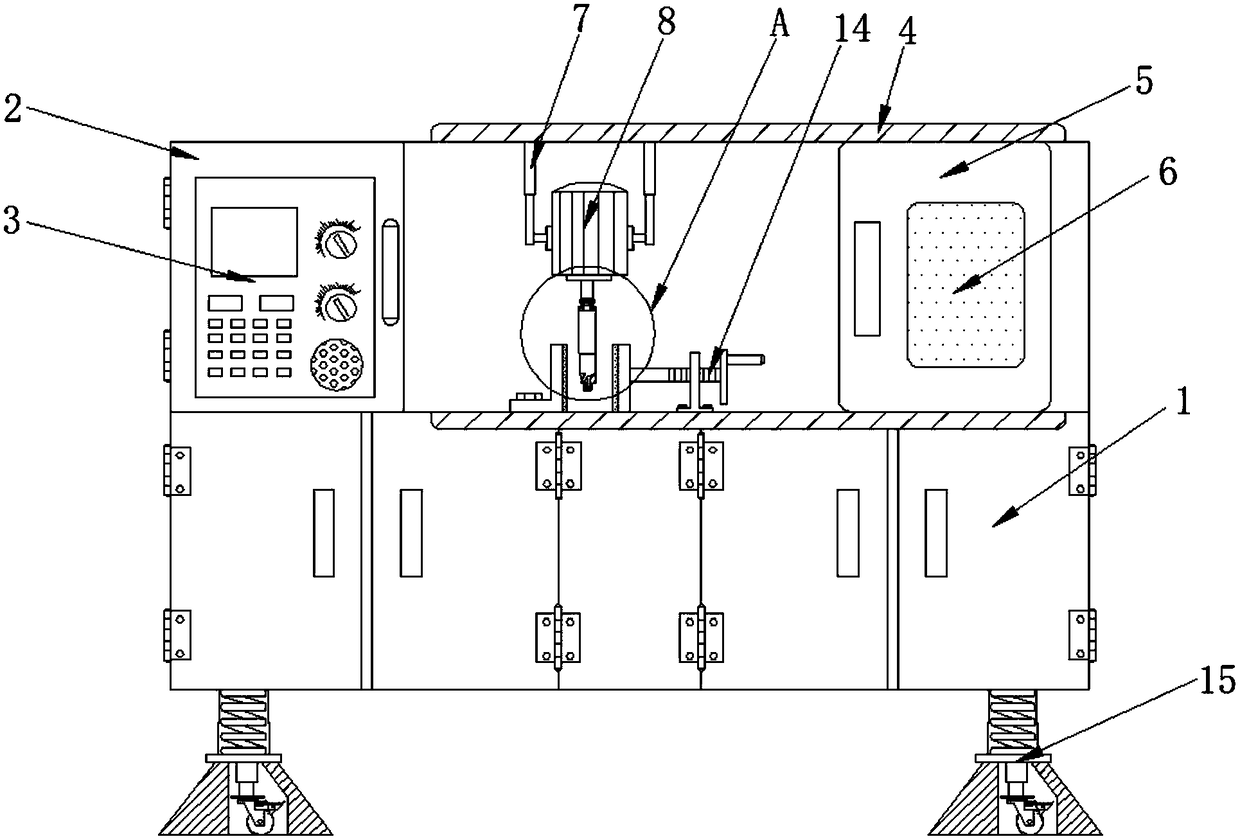

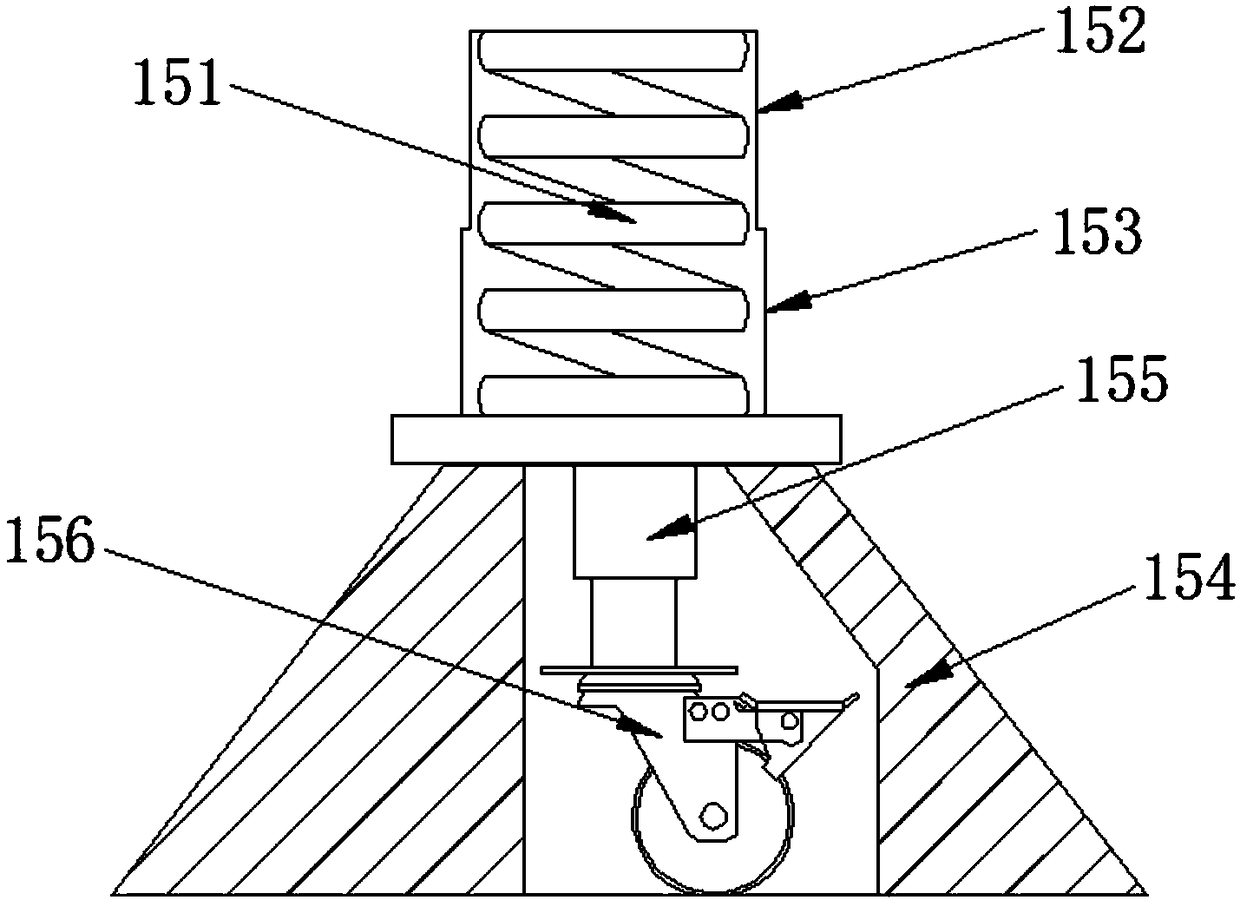

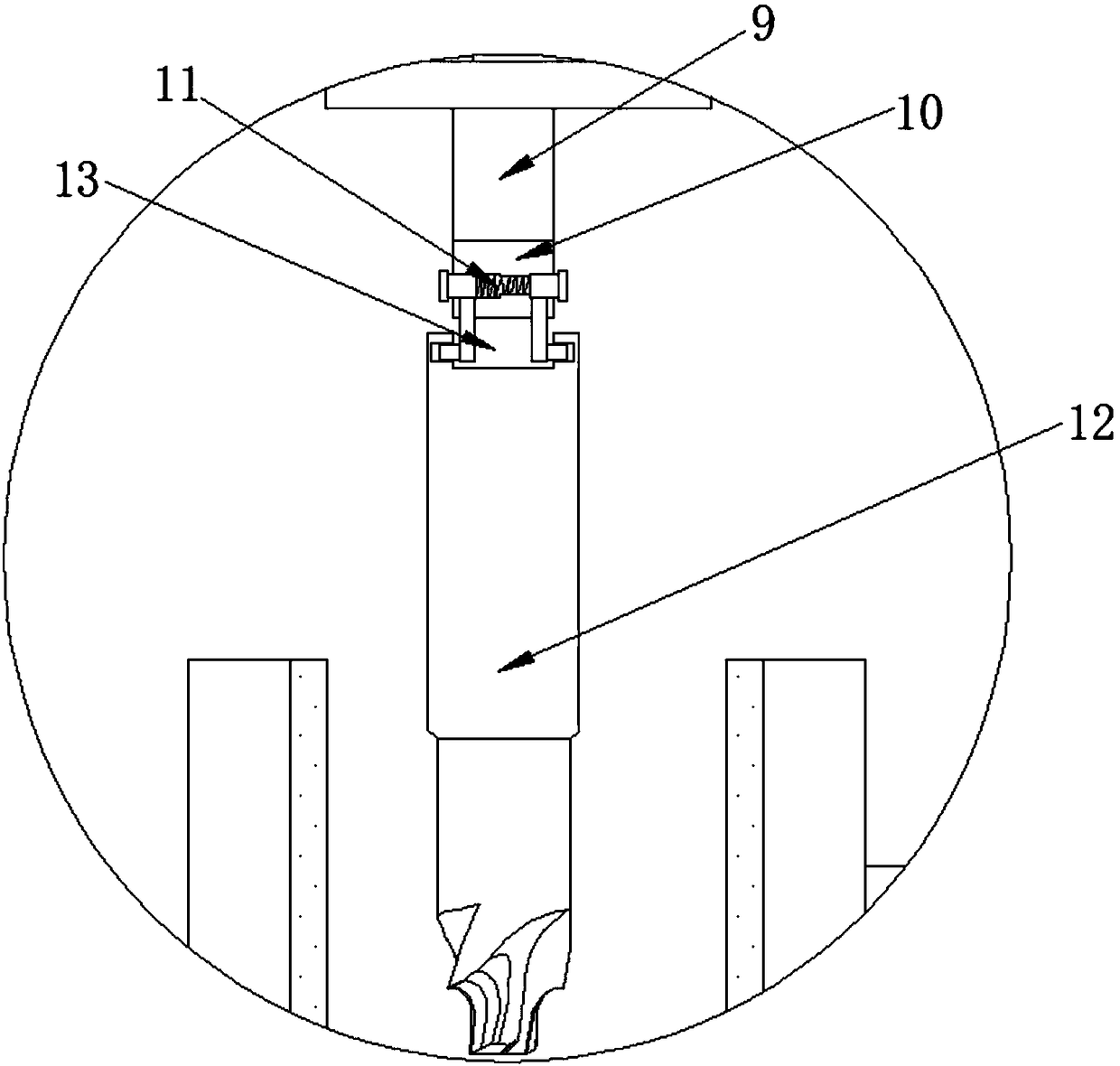

Numerically-controlled lathe allowing cutters to be installed conveniently

ActiveCN108098375AQuick changeQuick installationAutomatic control devicesFeeding apparatusEngineering

The invention discloses a numerically-controlled lathe allowing cutters to be installed conveniently. The numerically-controlled lathe comprises an operation platform, a first electric telescoping rod, a servo motor, an installing assembly, the cutters, a fixed assembly and a damping moving assembly. The first electric telescoping rod is installed on the inner side of the middle portion of the upper end of the operation platform. The servo motor is installed on one side of the lower end of the first electric telescoping rod. The installing assembly is installed in the groove. The cutters are connected below a transmission rod. The fixed assembly is installed on the outer side of the middle portion of the operation platform. The damping moving assembly is installed on the outer side of thelower end of the operation platform. The numerically-controlled lathe is scientific and reasonable in structure and safe and convenient to use, the installing assembly is arranged, the cutters can bereplaced or installed fast, and the problems that when the numerically-controlled lathe machines different components, the different cutters need to be replaced, however, an existing cutter replacingmethod is tedious and wastes time and labor, the installed cutters break away from a cutter rest easily, and an operator is threatened are avoided.

Owner:NANTONG XINRUIT MACHINERY CO LTD

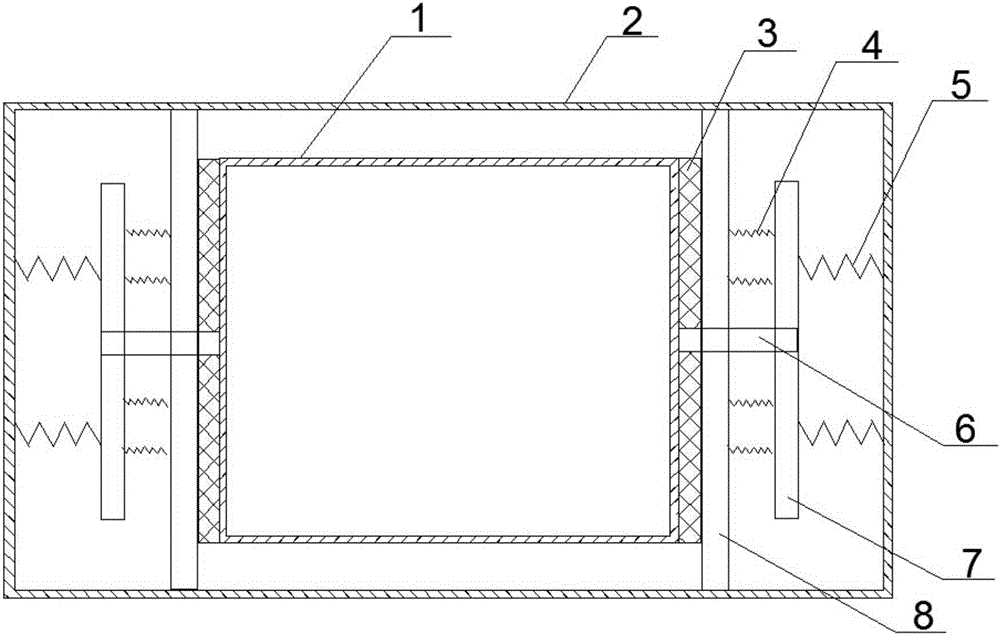

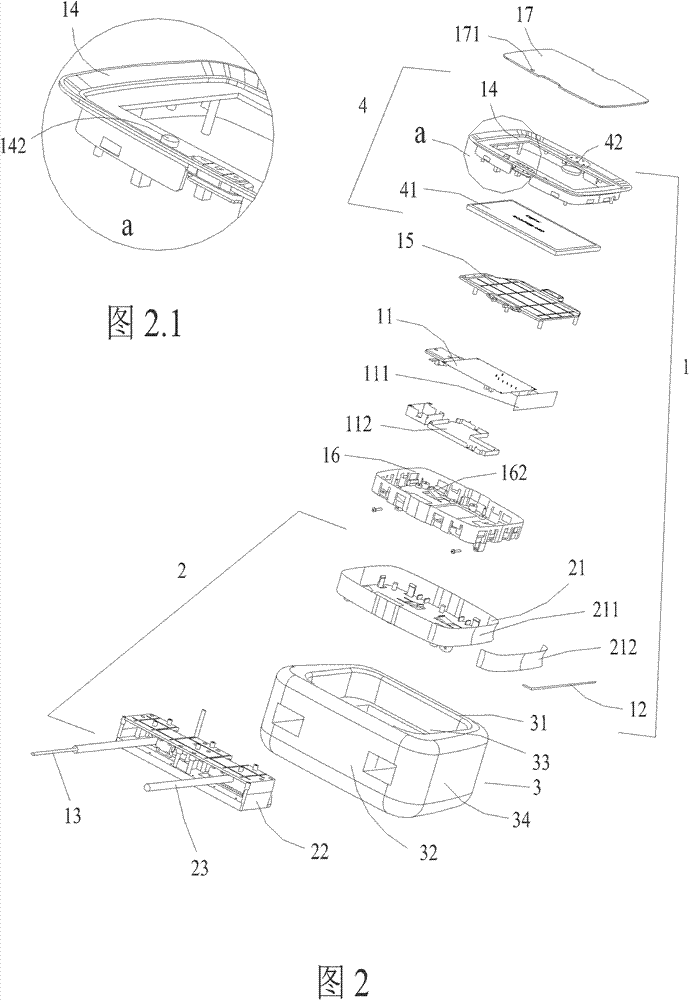

Anti-shock vehicular navigator

ActiveCN106274726ASolve the vibrationEffective protectionVehicle componentsABSORPTION BASEElastic component

An anti-shock vehicular navigator comprises a navigator body and a shock absorption base. The navigator body is arranged in the shock absorption base, shock absorption mechanisms are symmetrically arranged on the inner left side and the inner right side of the shock absorption base, each shock absorption mechanism comprises an elastic component, a clamping plate, a connecting rod and a connecting plate, each elastic component comprises a first spring and a second spring, one end of the first spring is connected with the inner wall of one side of the shock absorption base, the other end of the first spring is connected with one side of the connecting plate, the other side of the connecting plate is connected with the clamping plate through a second spring, two ends of the clamping plate are fixed to the upper side and the lower side of the navigator body respectively, the navigator body is fixedly connected with the connecting plate through the connecting rod, a shock absorption layer is arranged between the navigator body and the clamping plate and slidably connected with the connecting rod, and the clamping plate is slidably connected with the connecting rod. The shock absorption mechanisms can realize third-level shock absorption and can effectively solve the problem of shock of the navigator body along with a vehicle body in the running process of a vehicle, the navigator body is effectively protected, and the service life of the navigator body is prolonged.

Owner:凯扬光电(苏州)有限公司

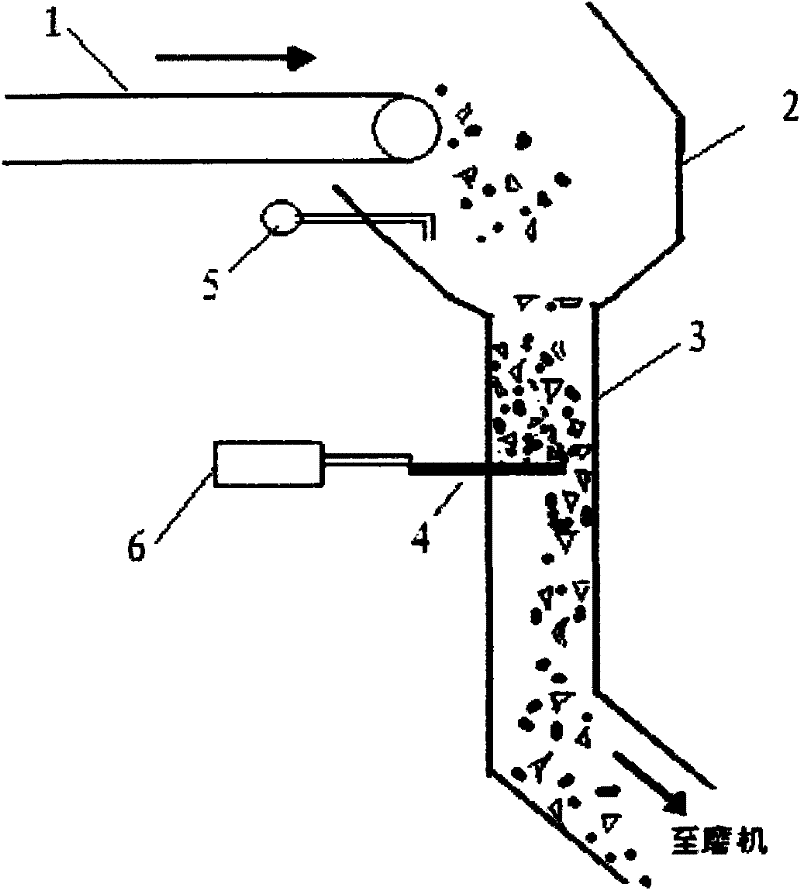

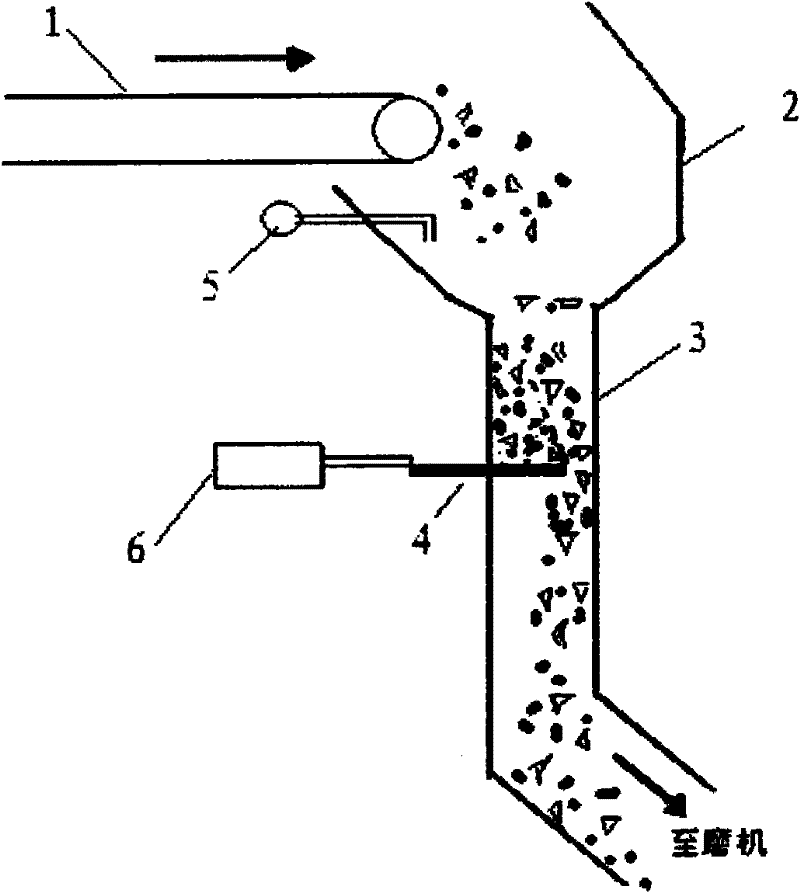

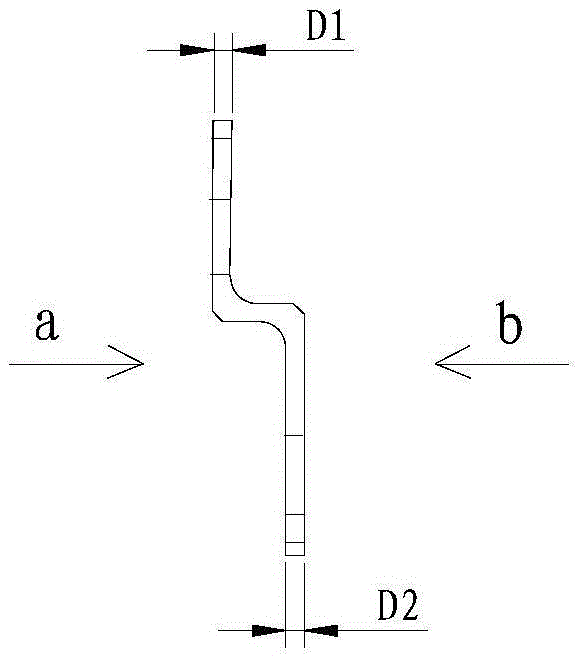

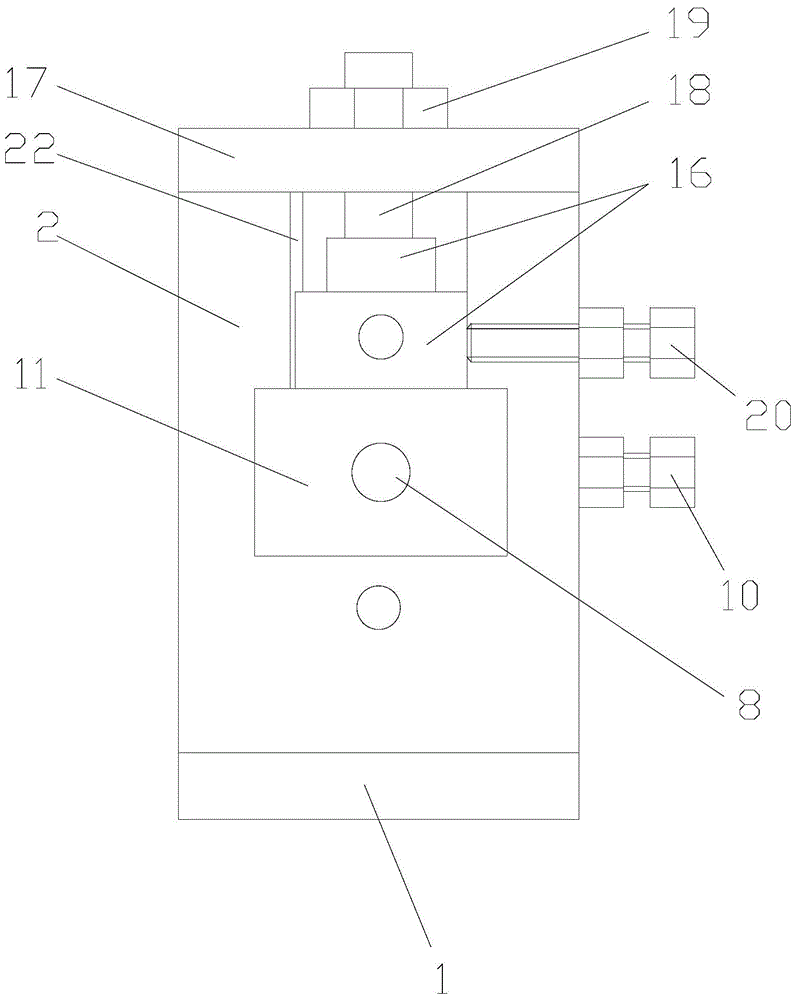

Vertical Mill Sealed Feeder

ActiveCN102259758ASolve the problem of air leakageSolve the vibrationLarge containersConveyor partsLower limitPressure rise

The invention provides a hermetic feeder for a vertical mill. The feeder comprises a mill feed belt, a blanking pipe, a blanking straight pipe, a horizontal insertion plate and a negative pressure meter, wherein the blanking pipe is arranged below the mill feed belt; the blanking straight pipe is connected below the blanking pipe; the horizontal insertion plate is arranged in the middle section of the blanking straight pipe; the length of the horizontal insertion plate stretching into the blanking straight pipe can be adjusted by an actuating mechanism, so that a blanking space is formed by agap between the horizontal insertion plate and the blanking straight pipe and is used for materials to pass through; and the negative pressure meter is arranged above the blanking pipe, is connected with an automatic control system and a central controller, and is provided with an upper limit value and a lower limit value, so that negative pressure starts dropping from a normal value when the blanking straight pipe is blocked, the automatic control system makes the actuating mechanism start acting to open the horizontal insertion plate when the negative pressure reaches the lower limit value,the negative pressure rises due to automatic dredging of material scouring, the automatic control system makes the actuating mechanism close the horizontal insertion plate when the negative pressure reaches the upper limit value, and the negative pressure is restored to the normal value.

Owner:SICHUAN ESHENG CEMENT GROUP

Static-pressure gas bearing

The invention relates to a static-pressure gas bearing comprising a cylindrical bearing body, a rotor rotatably arranged in the bearing body, a front cap fixed on a right side of the bearing body, and a back cap fixed on a left side of the bearing body. Threaded holes arranged coaxially with a back cap gas-ejection hole are provided on the back cap on the left of a back cap gas chamber. Gas outlets are arranged in the back cap along an axial direction of the back cap. Each threaded hole is provided with a screw. A rotor gas chamber is provided in the rotor. Radial gas outlets are arranged in the rotor along a radial direction of the rotor. An annular groove is provided on a peripheral wall of the rotor. An axial gas outlet is arranged on a left end of the rotor along an axial direction ofthe rotor. A round recess is provided on the left end-face of the rotor. During an operation process of a traditional gas bearing, only a radial air film is provided, direct contact of boundary solids can easily happen, and locking is caused, such that the bearing and a main shaft might be damaged. With the static-pressure gas bearing provided by the invention, the problem can be solved, and the bearing can work under both a radial load and an axial load.

Owner:保山鑫隆电子科技有限公司

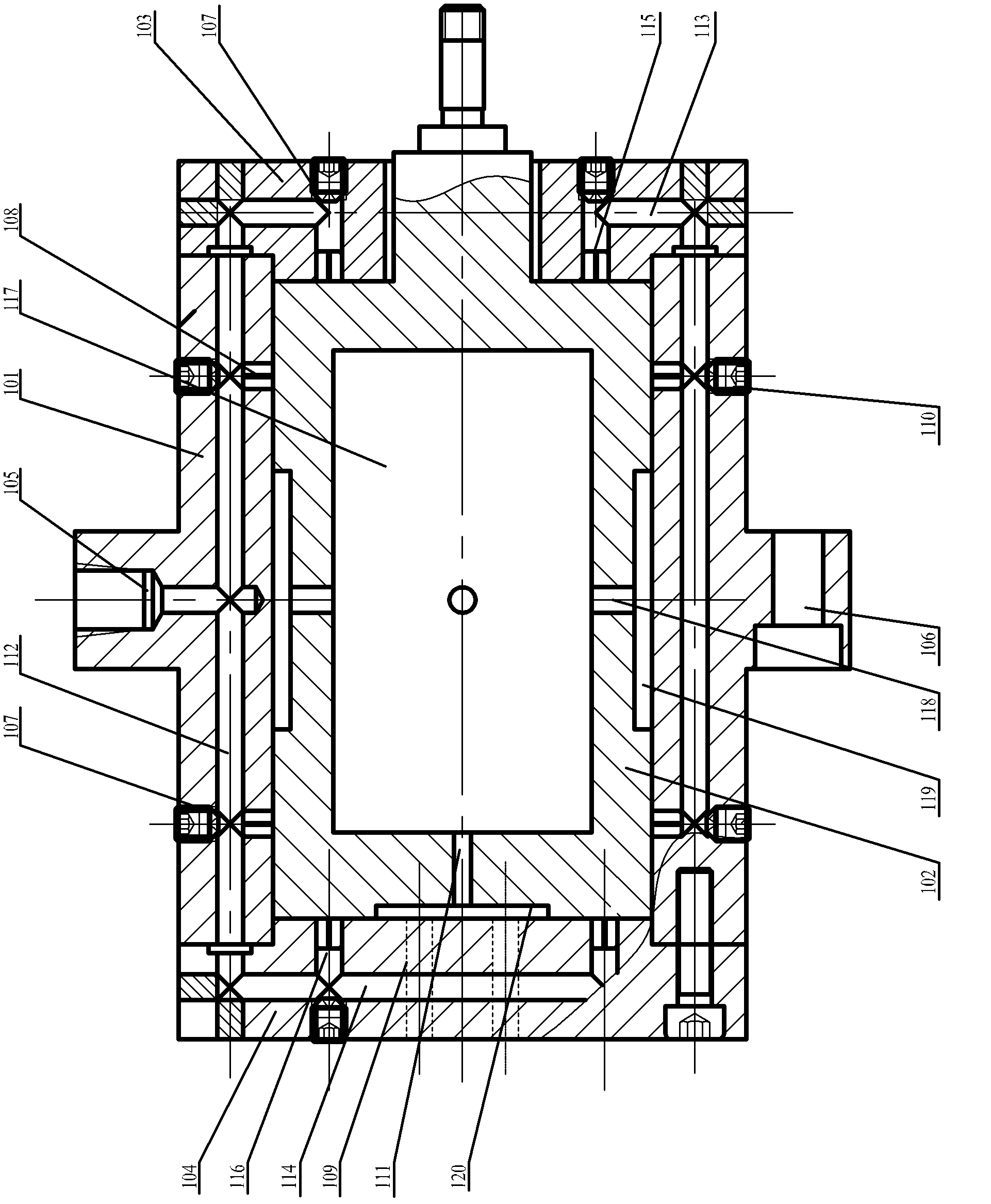

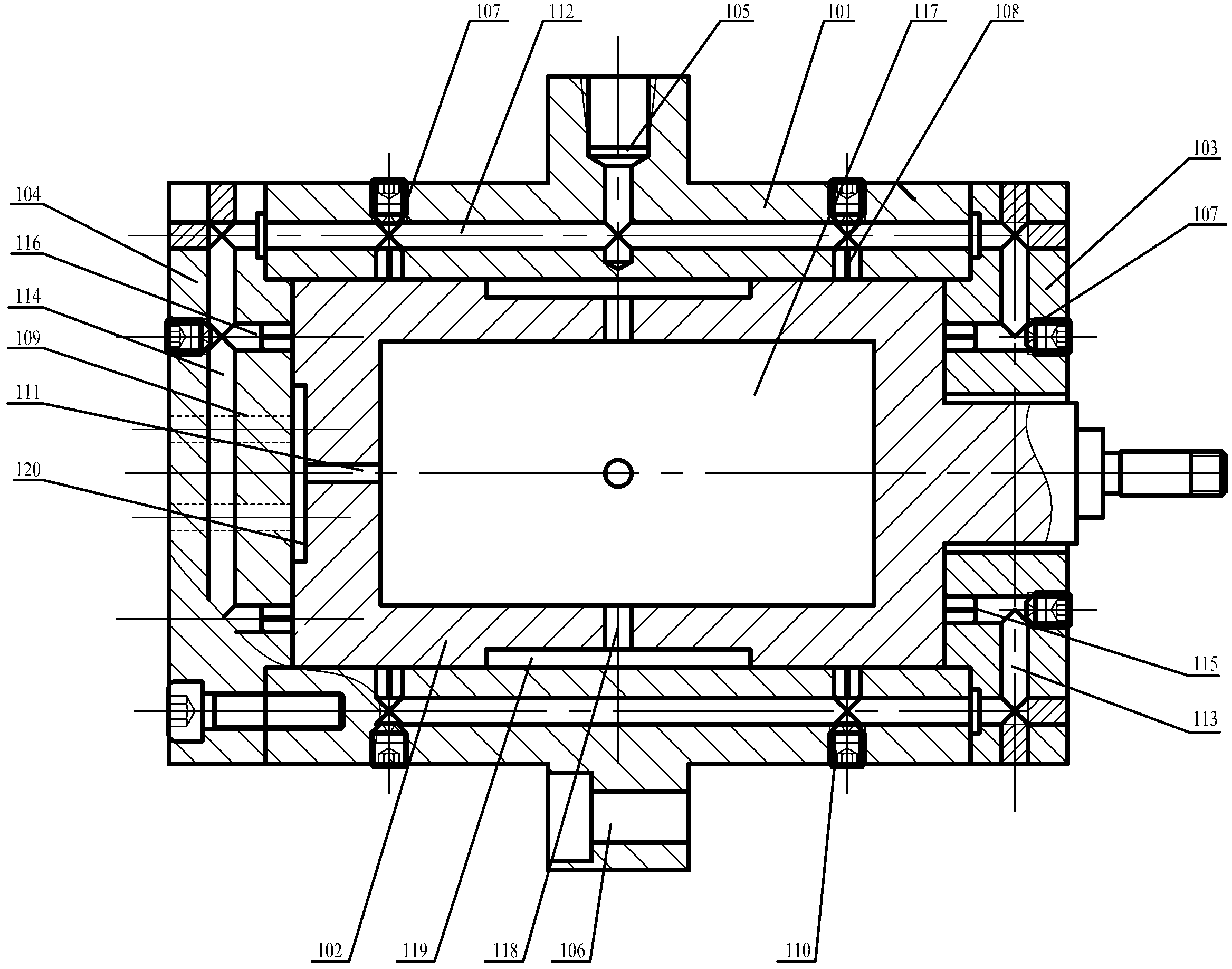

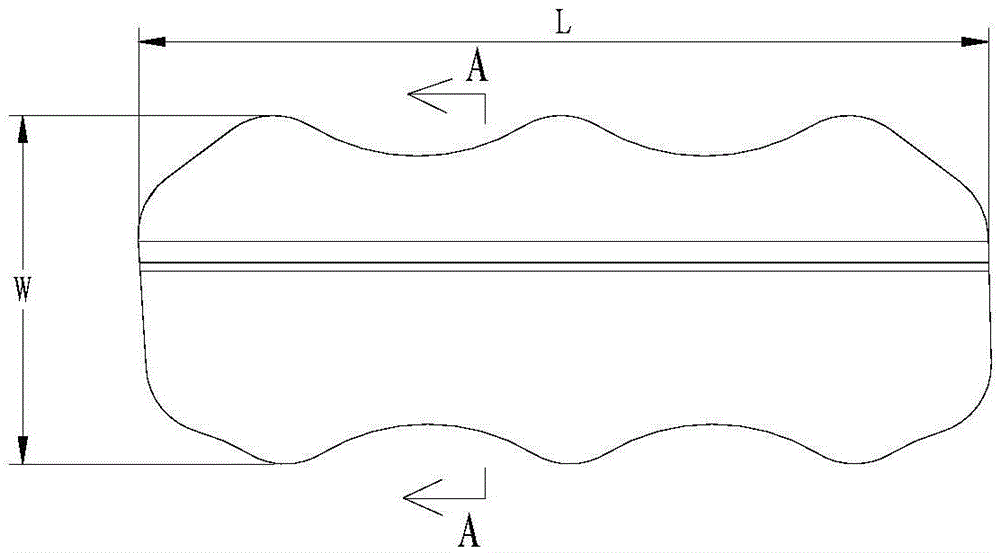

Positioning machining method for thin hook-face parts

The invention discloses a positioning machining method for thin hook-face parts. The positioning machining method includes the specific machining processes that (1) the outline of a cutting part is machined; (2) the manner that one-time cutter feeding is carried out in the stock thickness direction and gradual cutter feeding is carried out in the stock width direction is used for machining the front face of the cutting part; (3) the front face of a transition part is cut to be thin; (4) a U-shaped chuck is turned over by 180 degrees around a rotation shaft of a positioning clamp, and the back face of the cutting part is machined in the cutter feeding manner adopted in the step (2); (5) the back face of the transition part is cut to be thin until only connecting lugs are left on the transition part; and (6) the connecting lugs are cut off to obtain the machined and molded thin hook-face parts. According to the positioning machining method, it is guaranteed that in the part machining process, the self rigidity keeps in the best state all the time, and vibration generated in the machining process is avoided.

Owner:ZHEJIANG XIZI AVIATION IND

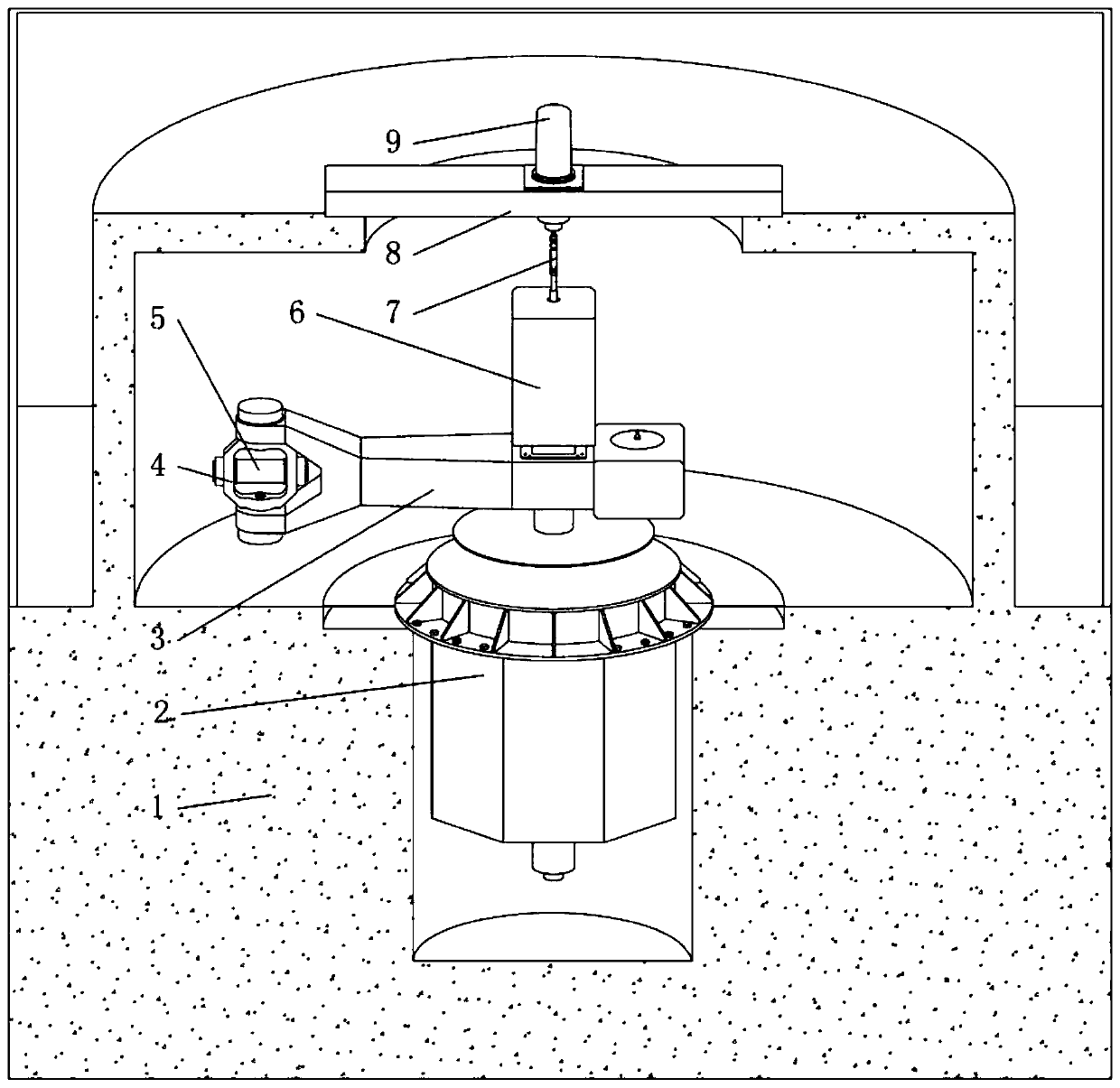

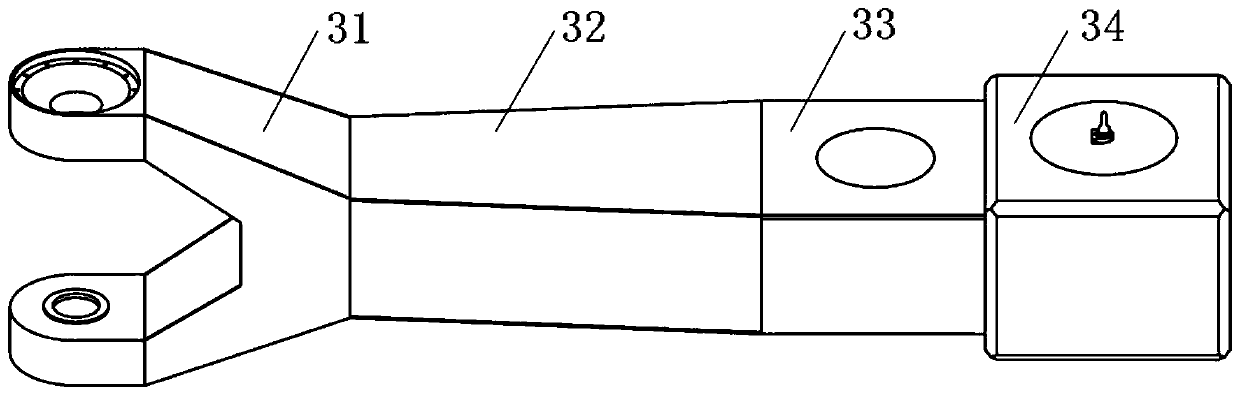

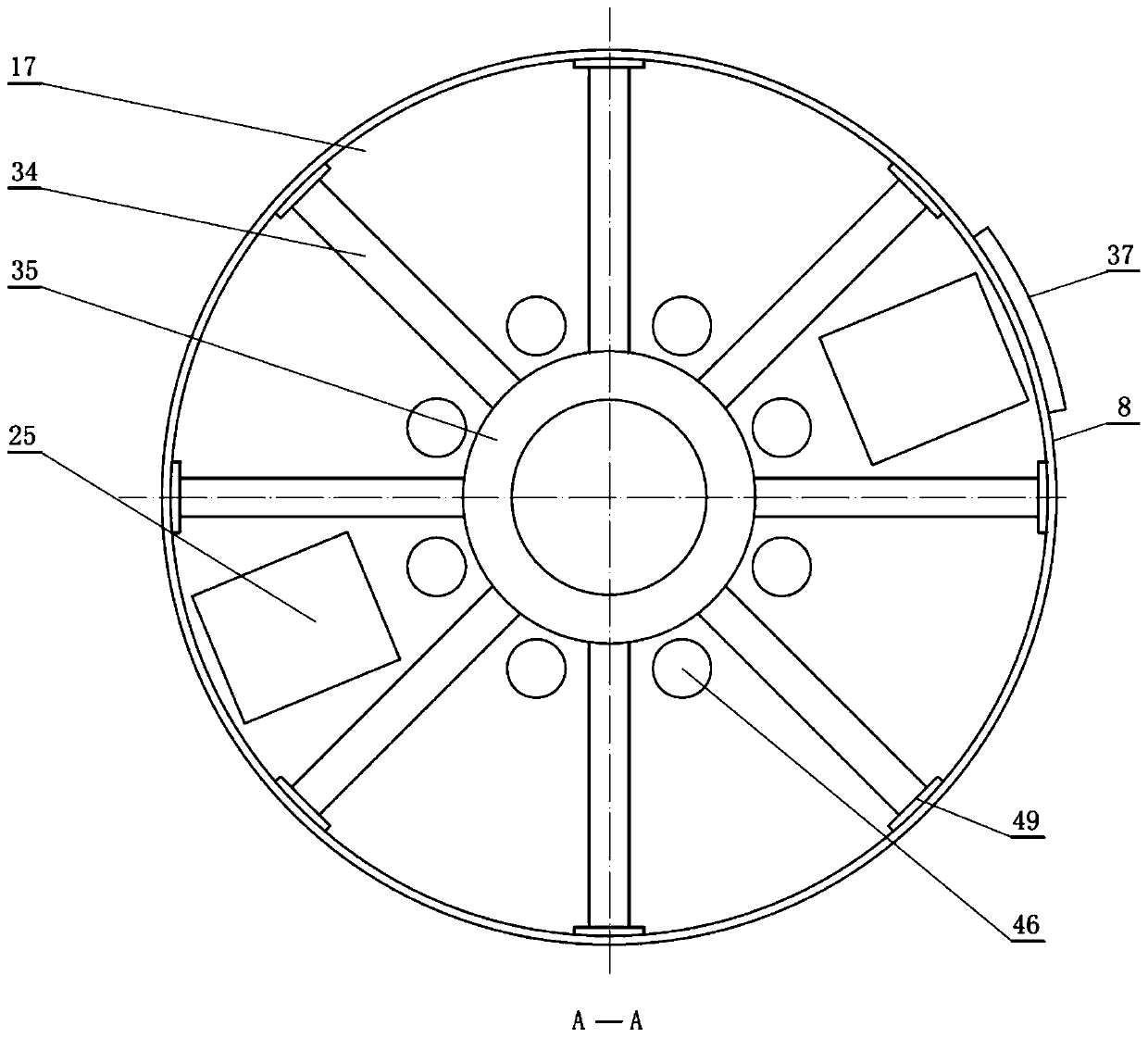

High-dynamic centrifuge overload simulation test device

PendingCN110683074ASolve the problem of attitude and overload couplingLarge space for exerciseAircraft components testingFlight vehicleDynamic simulation

The invention discloses a high-dynamic centrifuge overload simulation test device. The high-dynamic centrifuge overload simulation test device comprises a first freedom degree device for providing static overloads for a test piece, a second freedom degree device for providing the yaw rotating movement for the test piece, and a third freedom degree device for providing the rolling rotating movementfor the test piece. The test piece is arranged on the third freedom degree device, and the second freedom degree device is used for freedom degree control of the third freedom degree device. The first freedom degree device is used for freedom degree control of the second freedom degree device. According to the three-axis acceleration of a centrifugal machine resultant acceleration simulation aircraft, specifically, through rapid changing of the main arm system rotation speed, rapid changing of the centrifugal machine resultant acceleration value is achieved. Through rapid changing of the rotation direction of the second freedom degree device, and rapid changing of centrifugal machine resultant acceleration in the aircraft three-axis projection direction is achieved; and accordingly dynamic simulation of aircraft test piece three-axis acceleration changes is achieved, and continuous rapid dynamic changing overloads are accurately provided.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

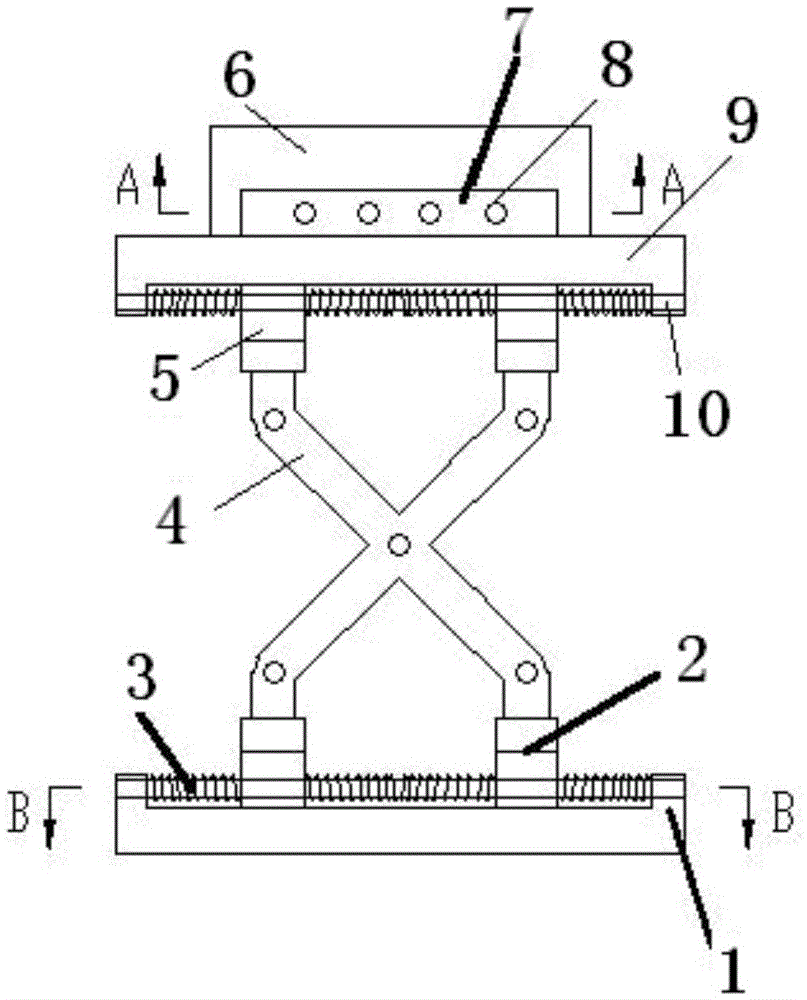

Linkage roll adjustment-type rolling mill for rectangular steel tubes

InactiveCN104384189AGood symmetryEasy to adjustMetal rolling stand detailsMetal rolling arrangementsStrip millEngineering

The invention discloses a linkage roll adjustment-type rolling mill for rectangular steel tubes. The linkage roll adjustment-type rolling mill comprises a base, a left rack, a right rack, a top roll, a bottom roll, a left roll and a right roll; two rectangular guide holes are respectively formed in the left rack and the right rack, and the left rack and the right rack are respectively provided with a left support plate and a right support plate; a left sliding seat and a right sliding seat are respectively arranged in the rectangular guide holes; the left support plate and the right support plate are respectively provided with a cylinder of which the piston rod is connected with the corresponding sliding seat; the linkage roll adjustment-type rolling mill also comprises a reversing valve for controlling the left cylinder and the right cylinder; the linkage roll adjustment-type rolling mill also comprises an arch adjusting bracket, a cross beam, a lifting rod and a locknut. According to the linkage roll adjustment-type rolling mill disclosed by the invention, the sliding seats are respectively pushed by the cylinders to adjust the left roll and the right roll in position, and moreover, the left cylinder and the right cylinder are controlled by the identical reversing valve, so that the left roll and the right roll are equal in amount of movement; moreover, the arch adjusting bracket is connected with the left end and the right end of the top roll, and the top roll is adjusted by the lifting screw rod to rise and fall; roll adjustment is convenient, the adjustment time is short, and the work efficiency is high.

Owner:CHONGQING LONGSHAN METAL MATERIAL

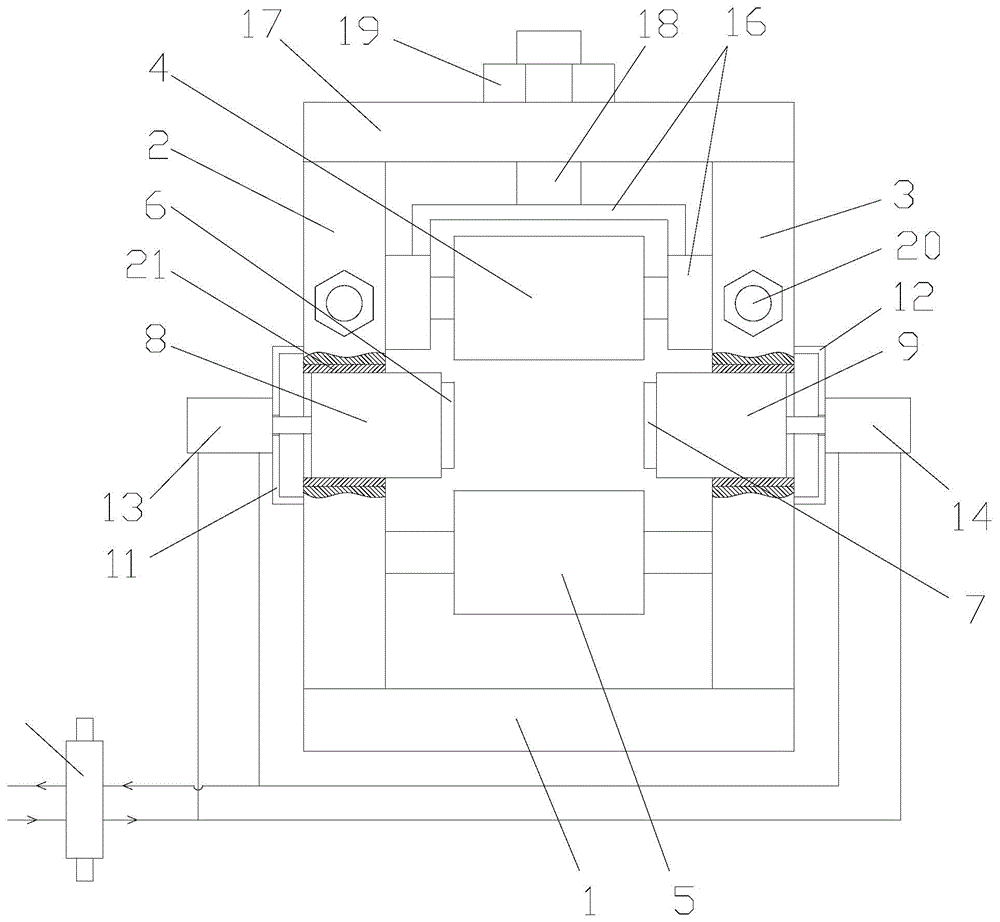

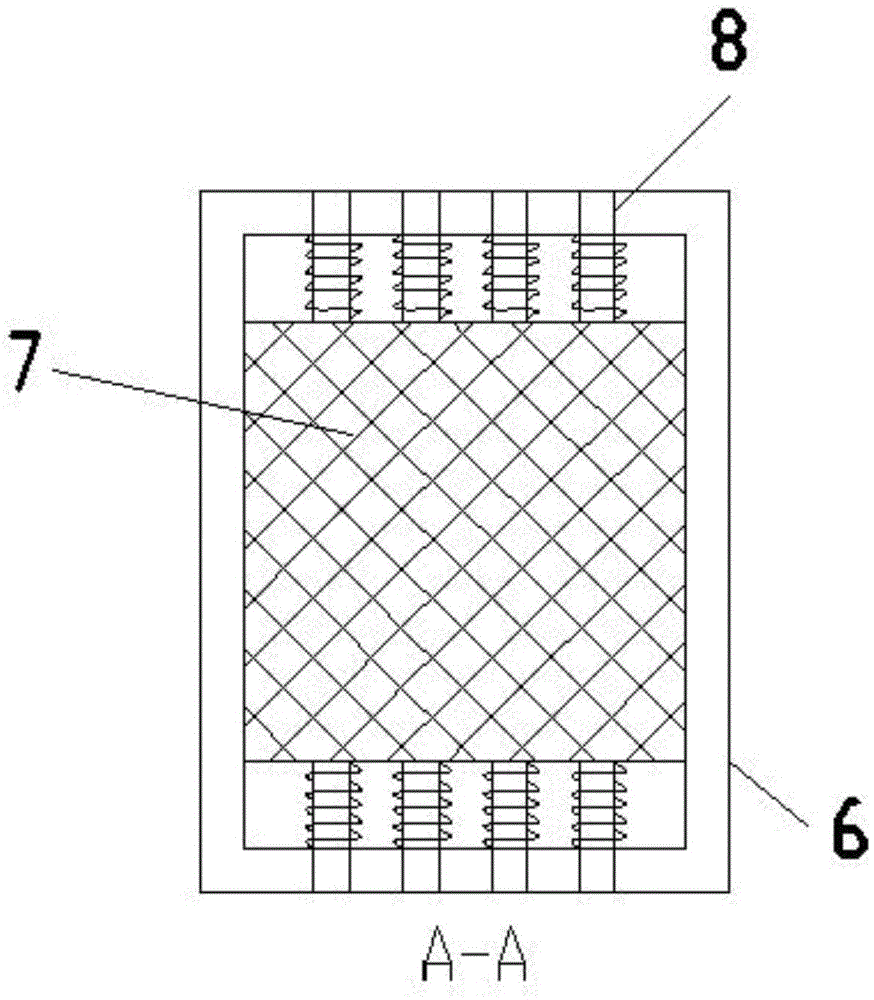

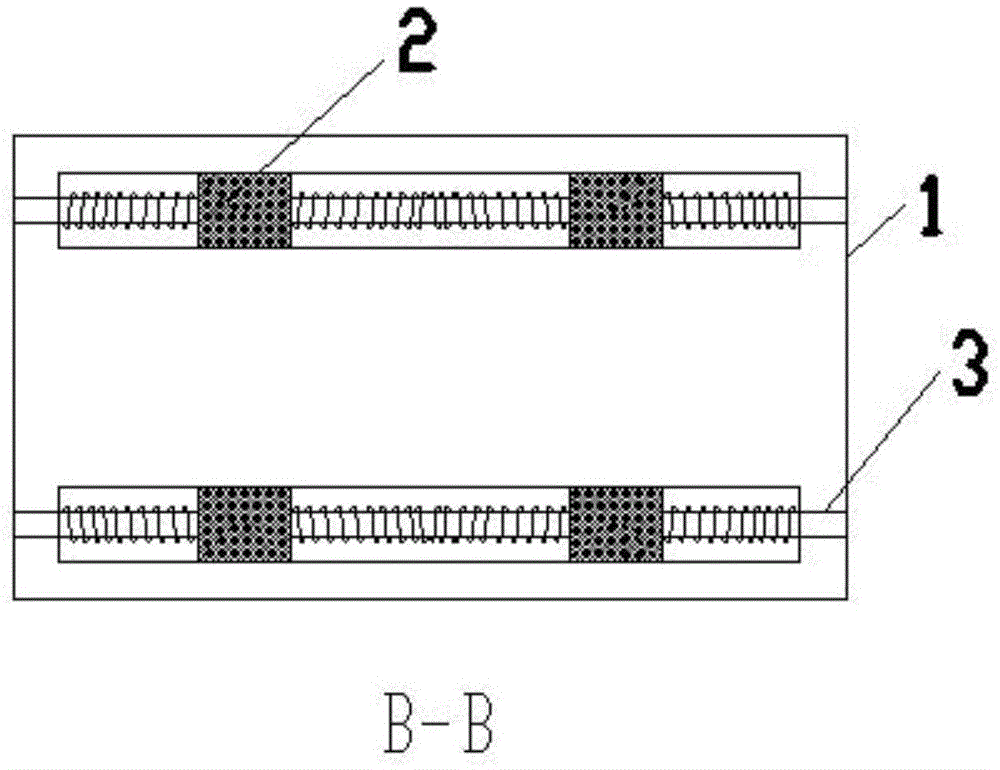

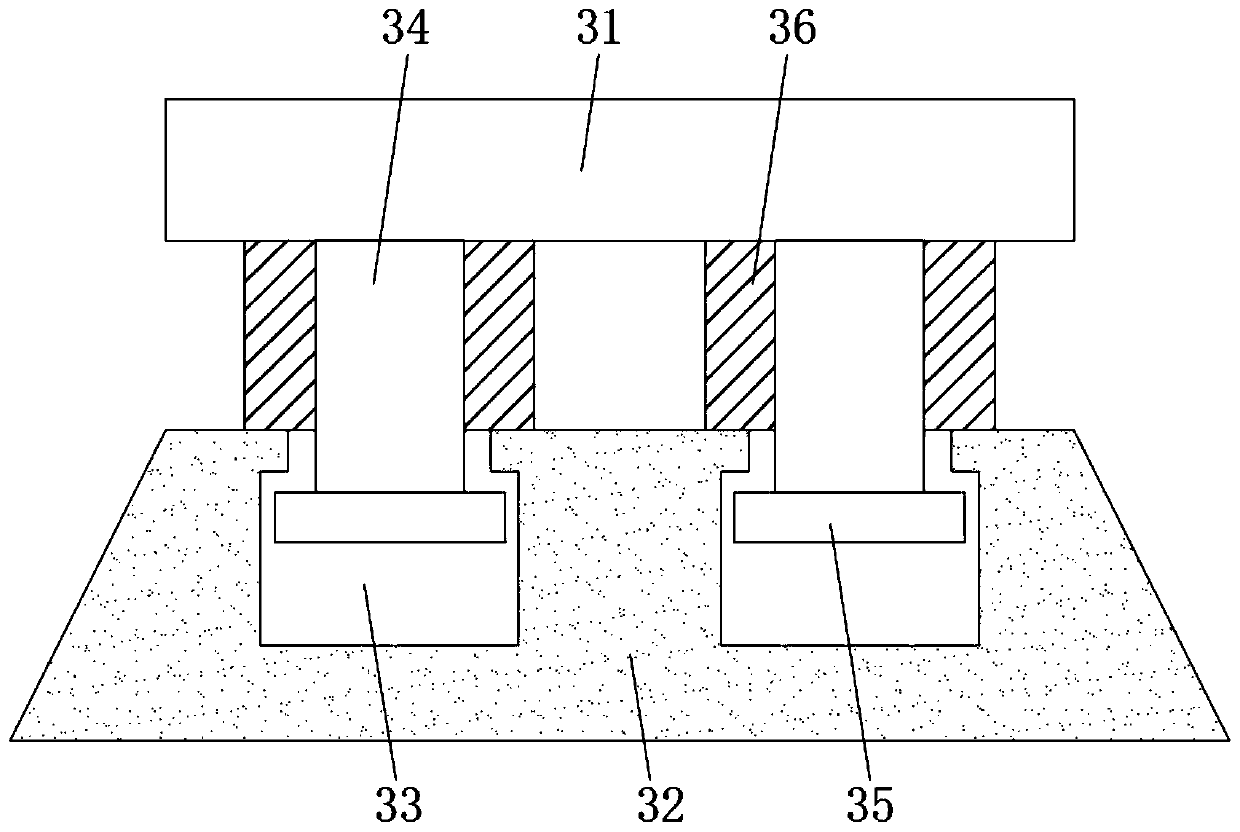

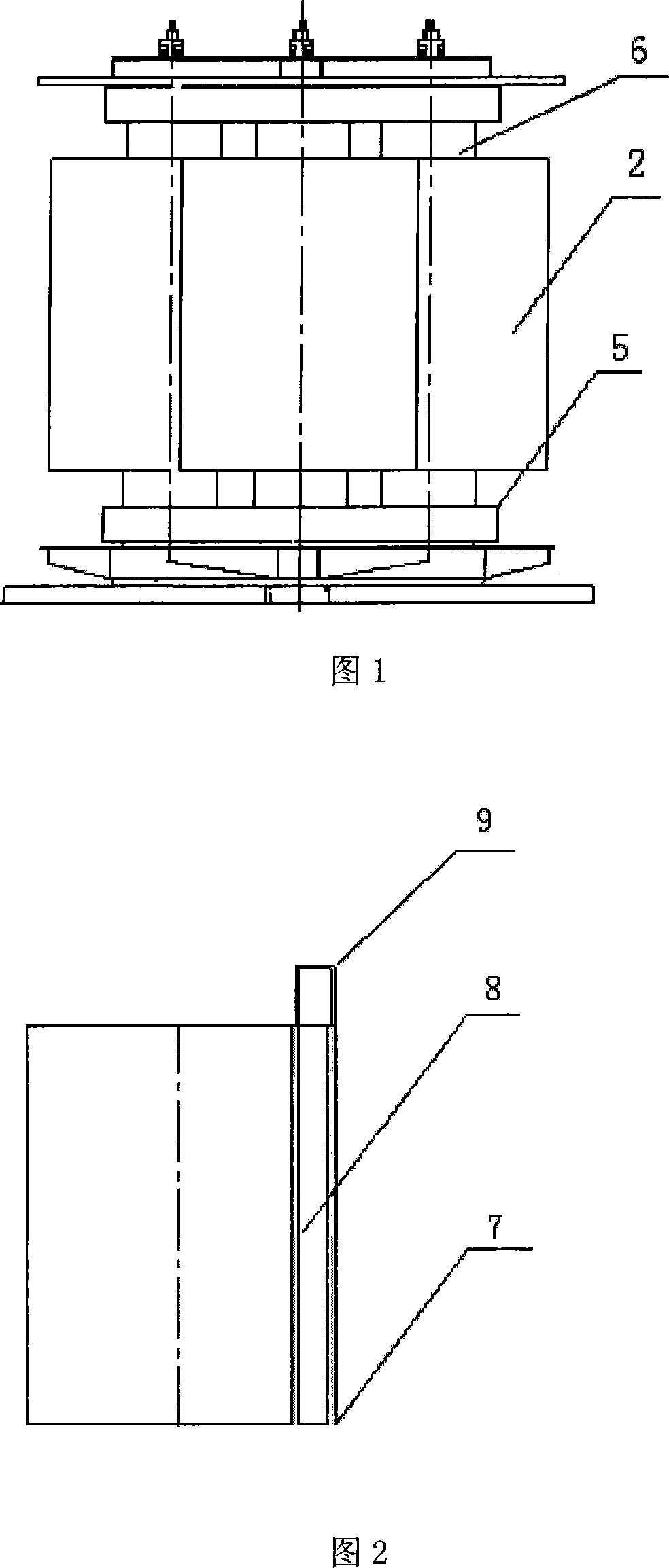

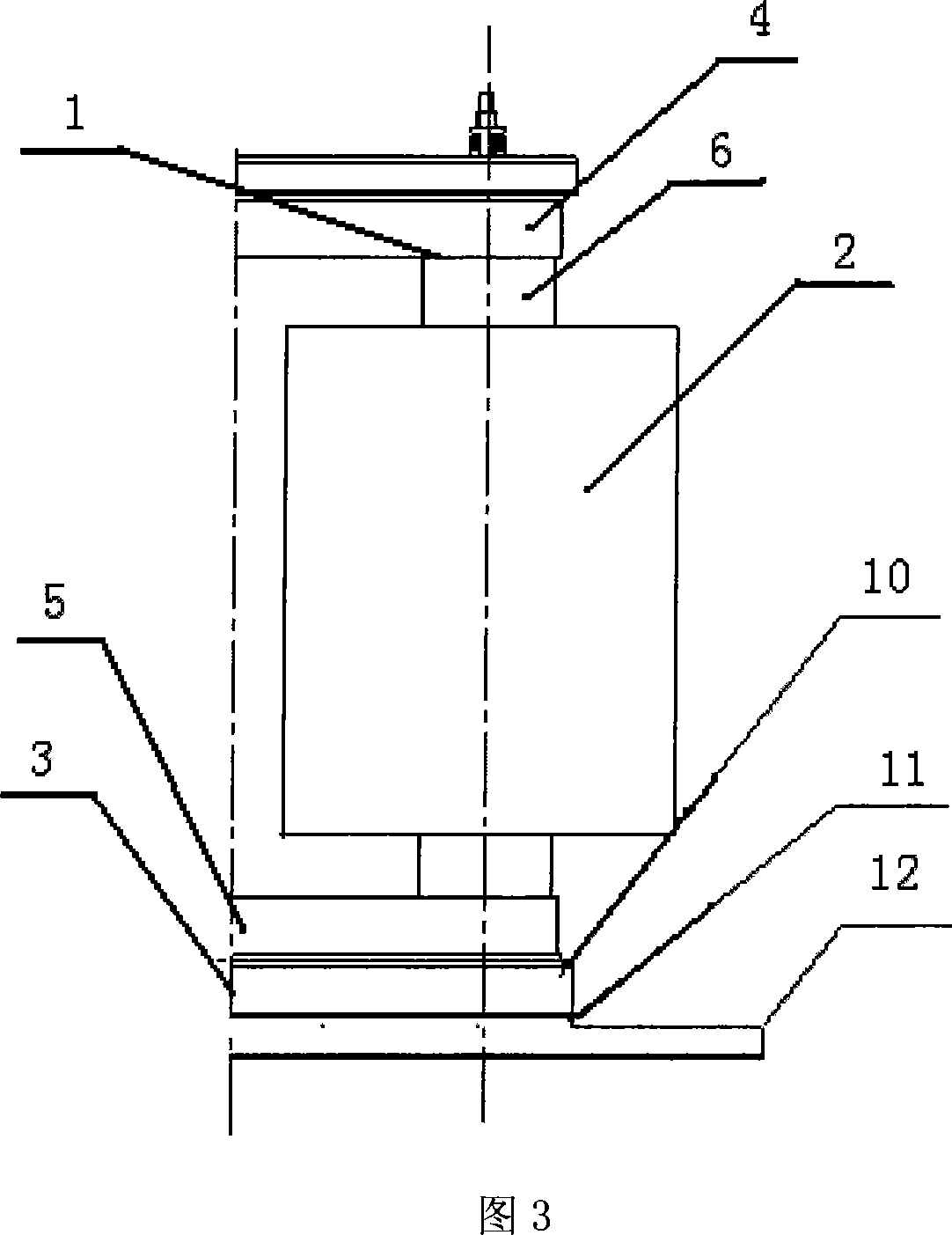

Damping mounting rack for smoothing reactor

InactiveCN105627043AImprove shock absorptionSolve the vibrationNon-rotating vibration suppressionStands/trestlesStructural engineeringControl theory

The invention discloses a damping mounting rack for a smoothing reactor. The damping mounting rack comprises a first mounting base, a second mounting base and a third mounting base, wherein the top surface of the first mounting base is provided with two first mounting grooves formed in parallel; each first mounting groove is internally provided with a first sliding rod, and each first sliding rod is fixedly connected with the first mounting base; each first sliding rod is sleeved by two first sliding blocks; and the first sliding rod between the two sliding blocks and the first sliding rods between the first sliding blocks and the inner walls of the first mounting grooves are sleeved by first damping springs. The damping mounting rack is of a combination structure of the sliding blocks, connecting rods and the damping springs, six spatial all-dimensional dampers are adopted, so that upper, lower, left, right, front and rear acting forces generated by vibration during operation of the smoothing reactor are completely counteracted, the smoothing reactor achieves a favorable damping effect during operation, and the work and life of people are prevented from negative influence during operation of the smoothing reactor.

Owner:徐光武

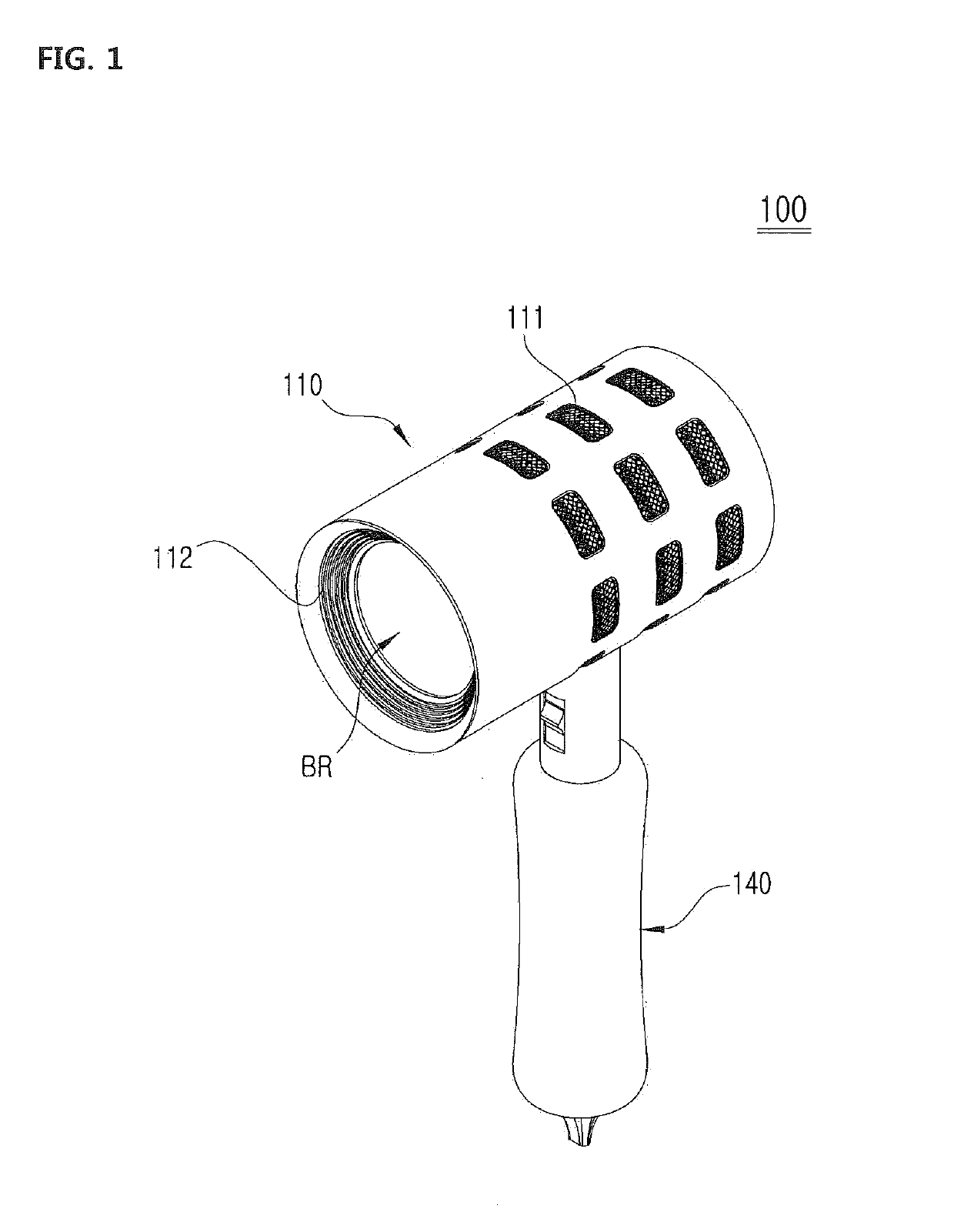

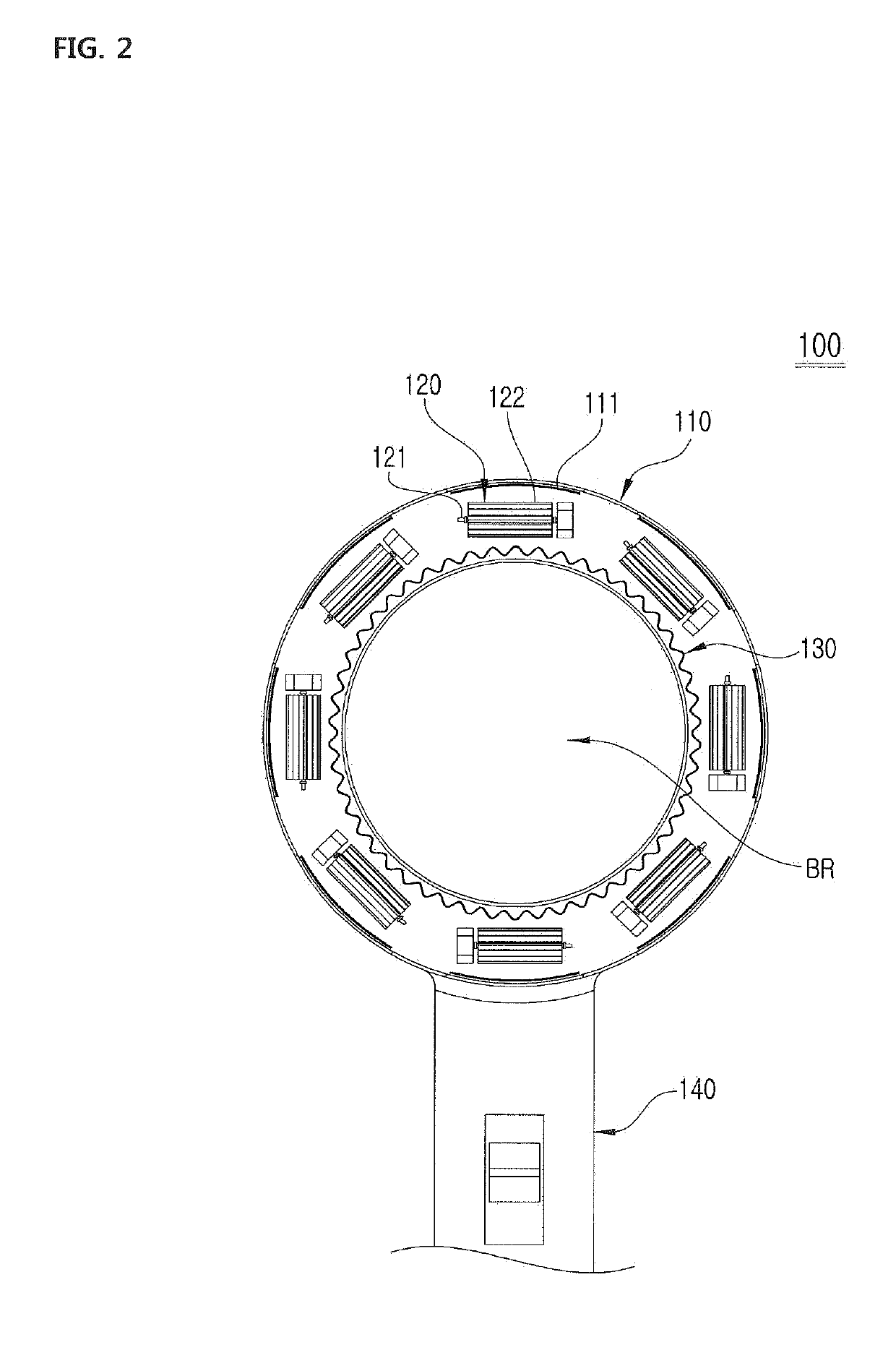

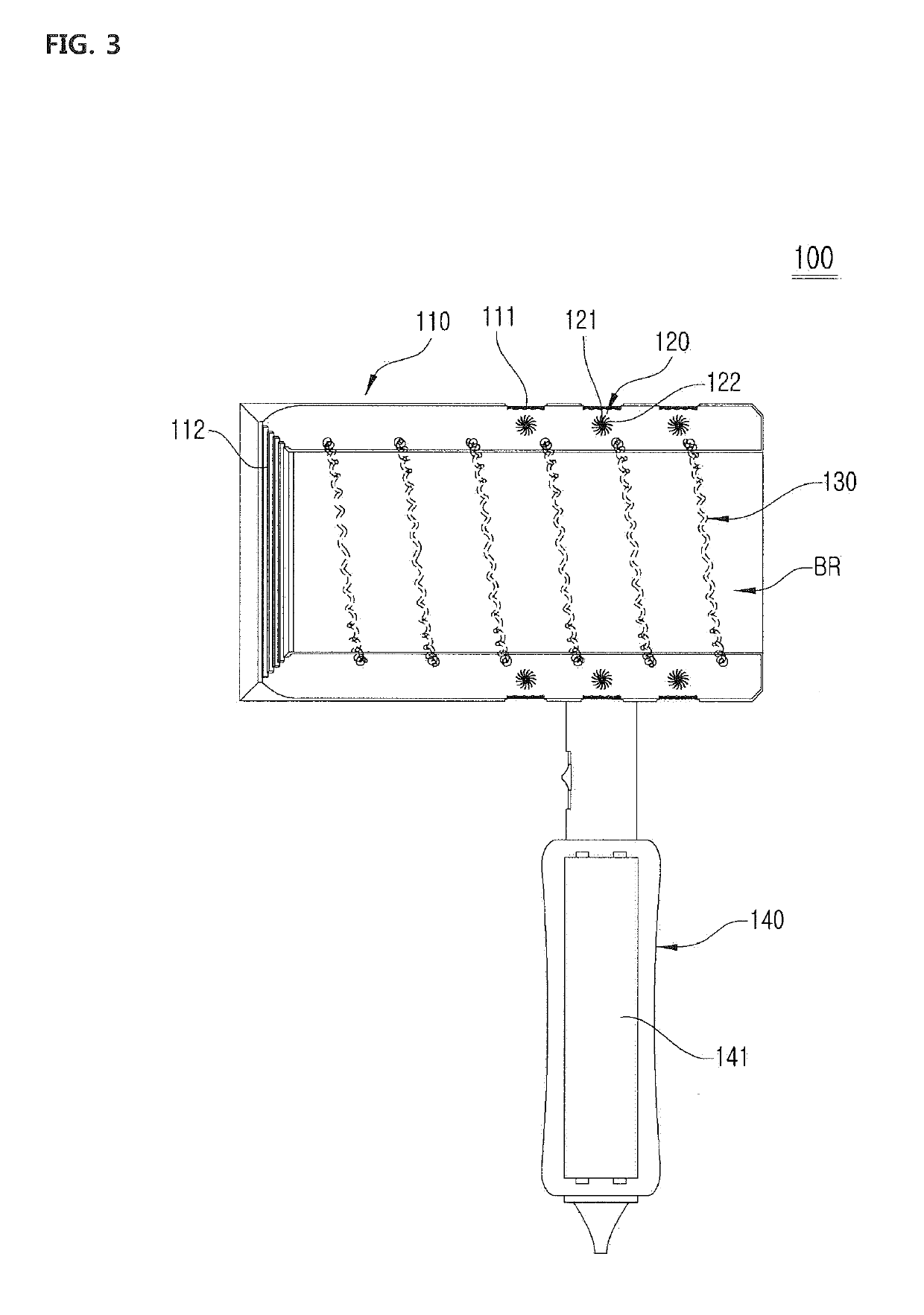

Hair dryer

InactiveUS20190110571A1Overcome problemsSolve the noiseDrying solid materials with heatHair dryingEngineeringAtmospheric pressure

Owner:LIM SEUNG PHILL

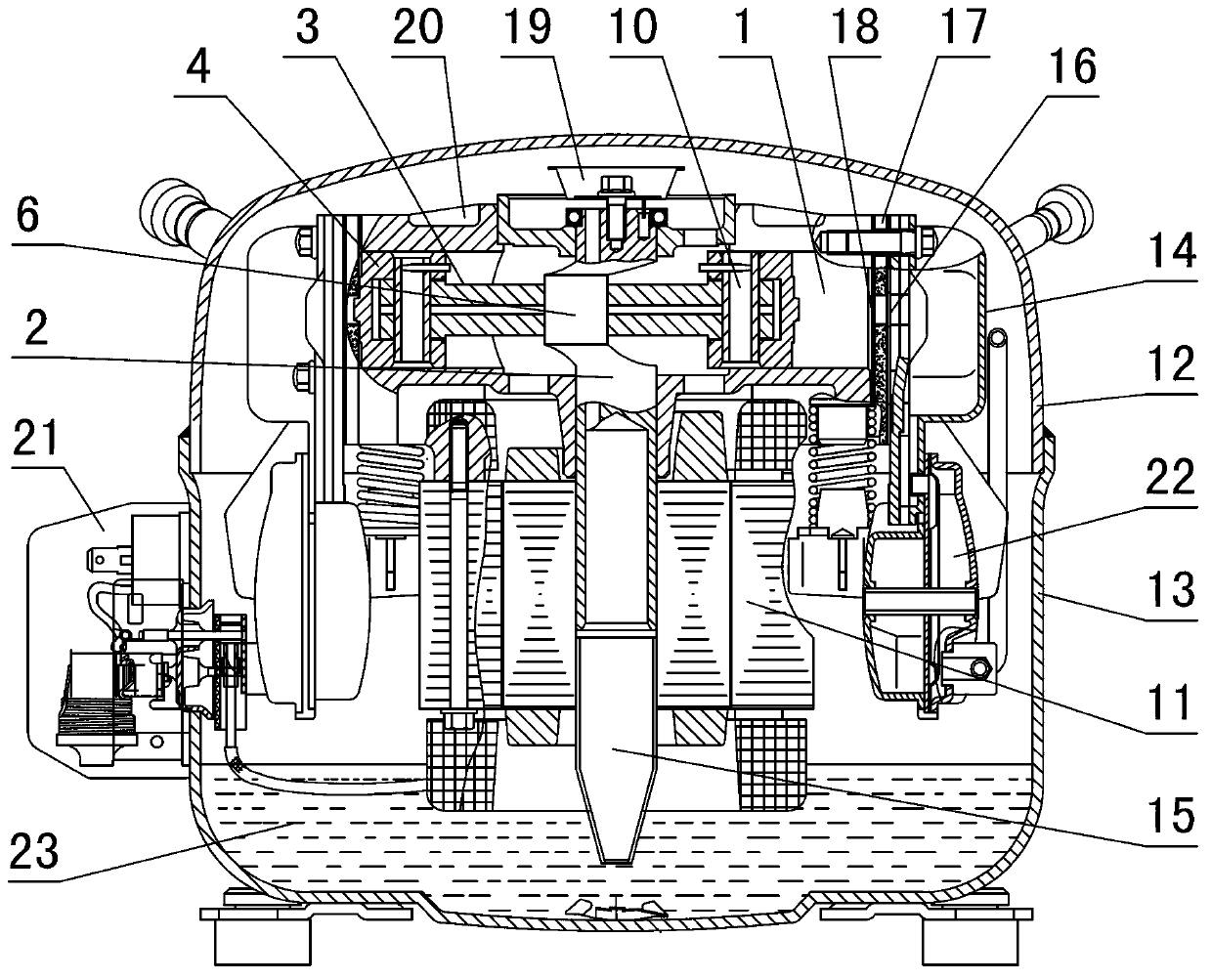

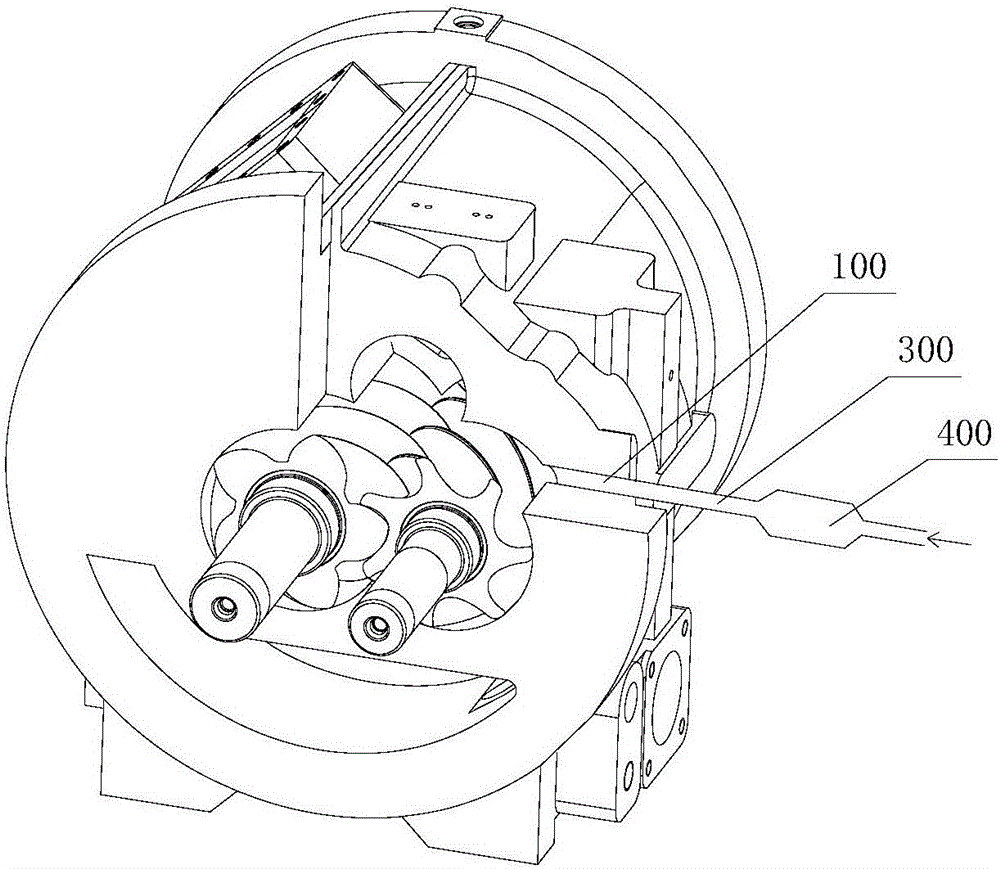

Sealing type single-drive multi-cylinder refrigerating compressor

ActiveCN102777349ASolve efficiency problemsSolve the vibrationPositive displacement pump componentsPositive-displacement liquid enginesRefrigeration compressorEngineering

The invention discloses a sealing type single-drive multi-cylinder refrigerating compressor. The compressor comprises a sealing type housing, a motor and a control device, wherein the motor is arranged in the housing and is connected with a crank shaft, the crank shaft is arranged vertically, even numbers of cylinders which are driven by the crank shaft through a connecting rod are arranged on the radial direction of the crank shaft, cylinders are arranged on two opposite sides of the crank shaft in pairs, the crank shaft is connected with pistons which are arranged on the same pairs of cylinders through a three-hole connecting rod, a horizontal chute which is vertical to the length direction of the three-hole connecting rod is arranged in the center of the three-hole connecting rod, and the crank shaft can be connected with the interior of the chute in a sliding mode. By the aid of the compressor, problems that in existing refrigerating compressors of the prior art, working efficiency is low, the vibration is large, the noise pollution is serious, piston pins are abraded and the service life is short are solved. The compressor has the advantages of being stable in operation, low in noise and long in service life. The compressor has high usage value and is worthy of application and popularization.

Owner:HANGZHOU QIANJIANG REFRIGERATION COMPRESSOR GRP CO LTD

Wire releasing device with replaceable outer sleeve

The invention provides a wire releasing device with a replaceable outer sleeve. The replaceable outer sleeve is sheathed on a winding drum and the outer sleeve is provided with an outer bulge; a shock absorber is arranged inside of the outer bulge connected with a pulling rope to carry out combined shock absorption. The wire laying device takes full account of vibration state of the optical fiber and can be well applied to the occasions where the wiring requirements are high. The wire laying device has the advantages of artful structure and low cost.

Owner:陈小娜

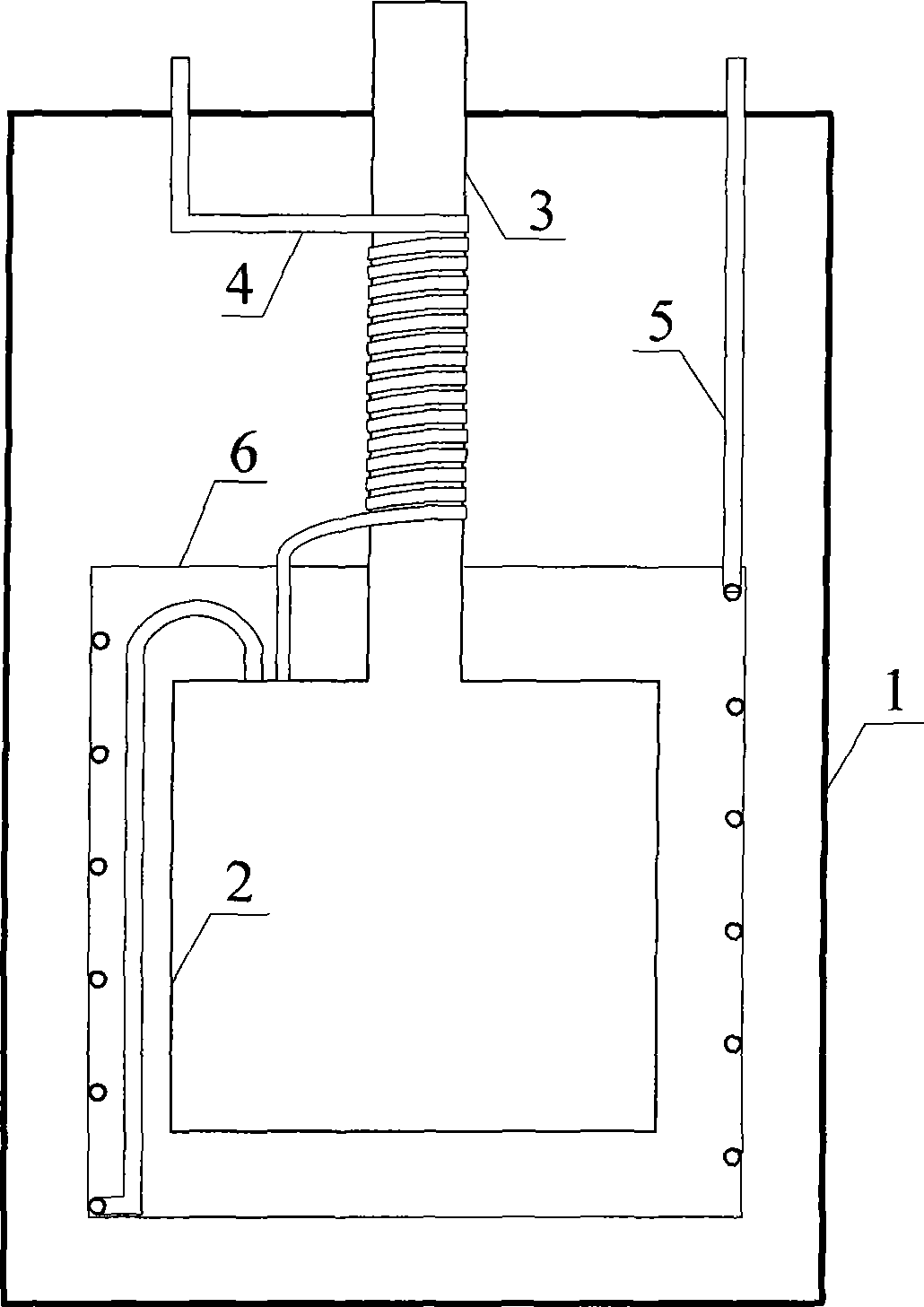

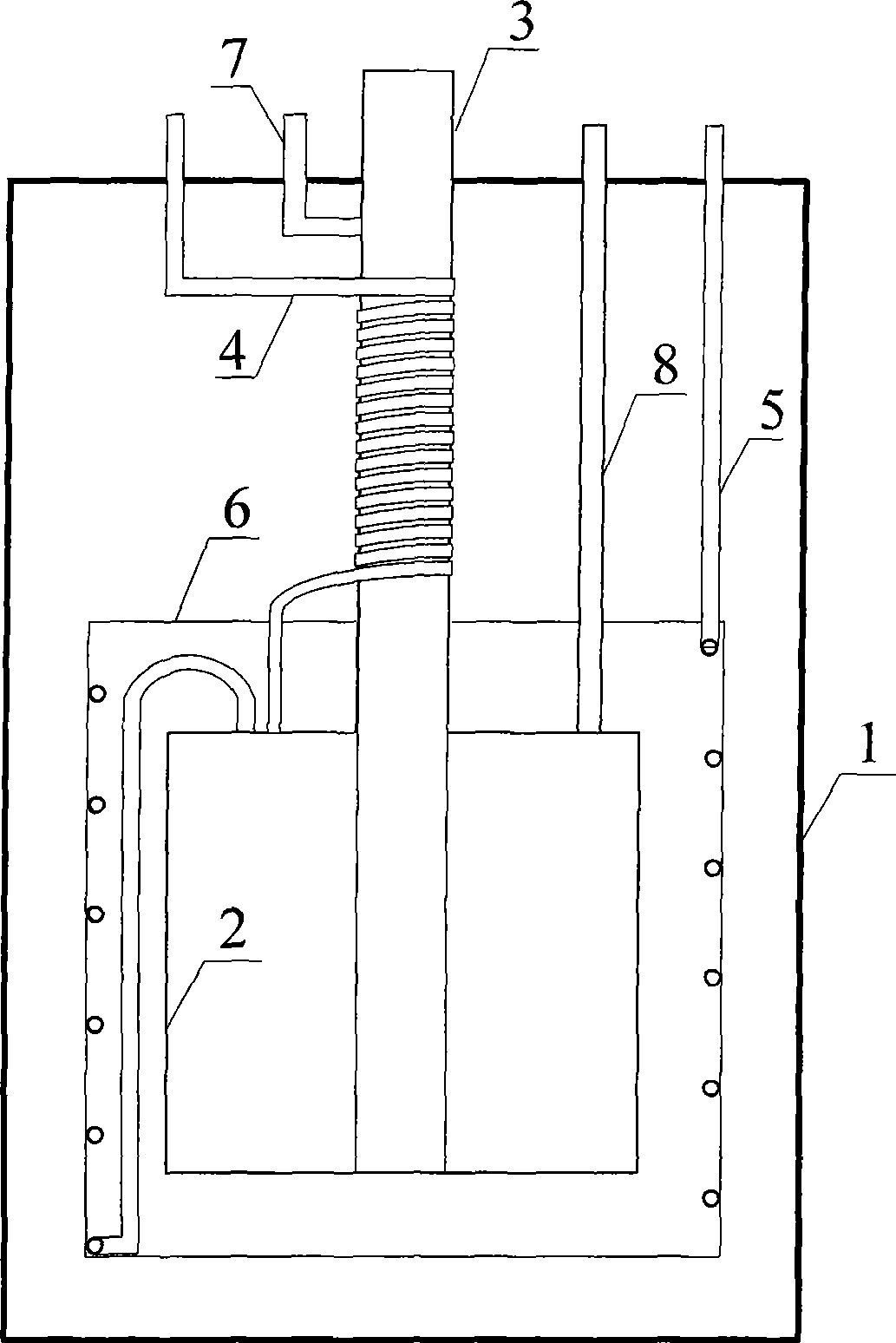

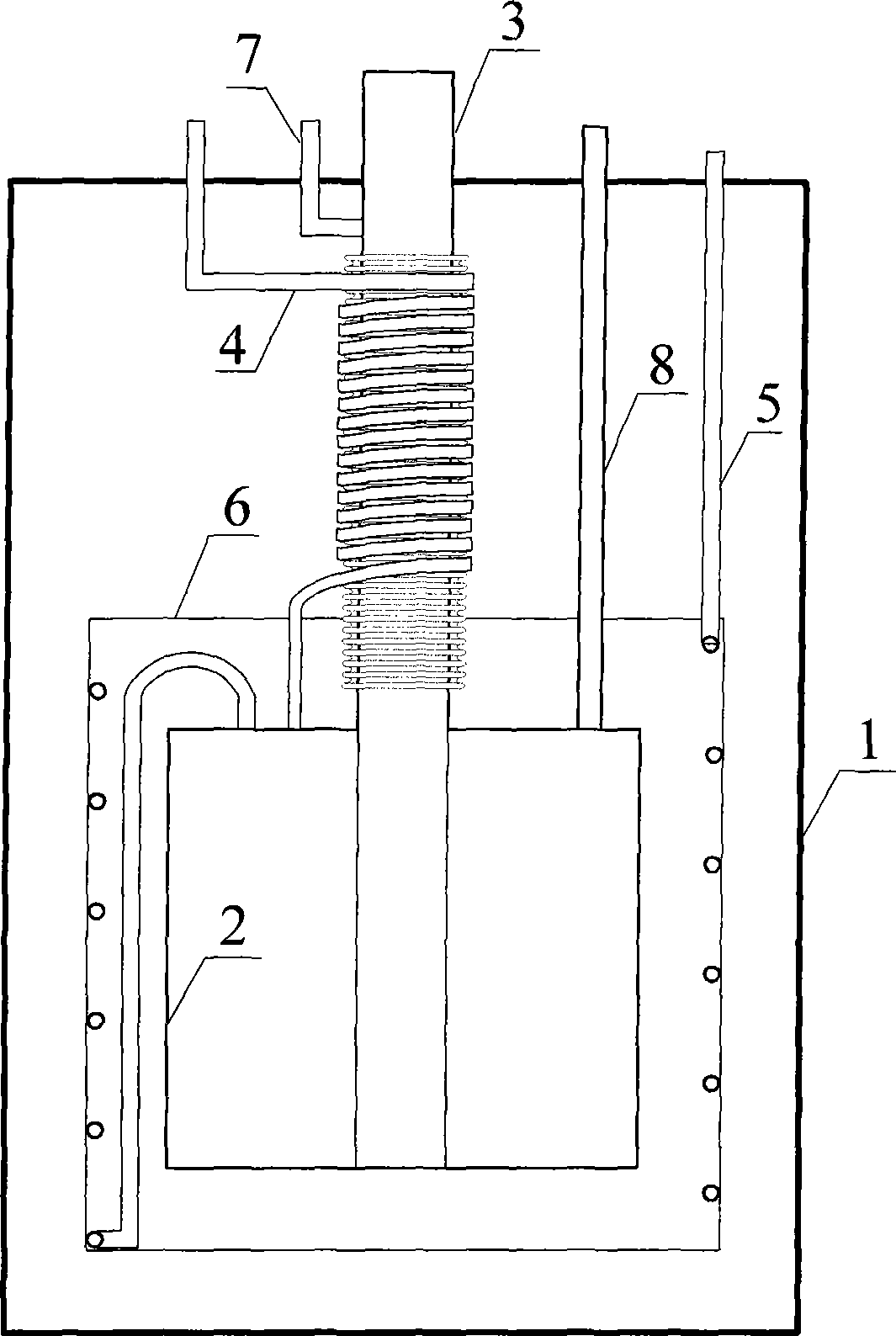

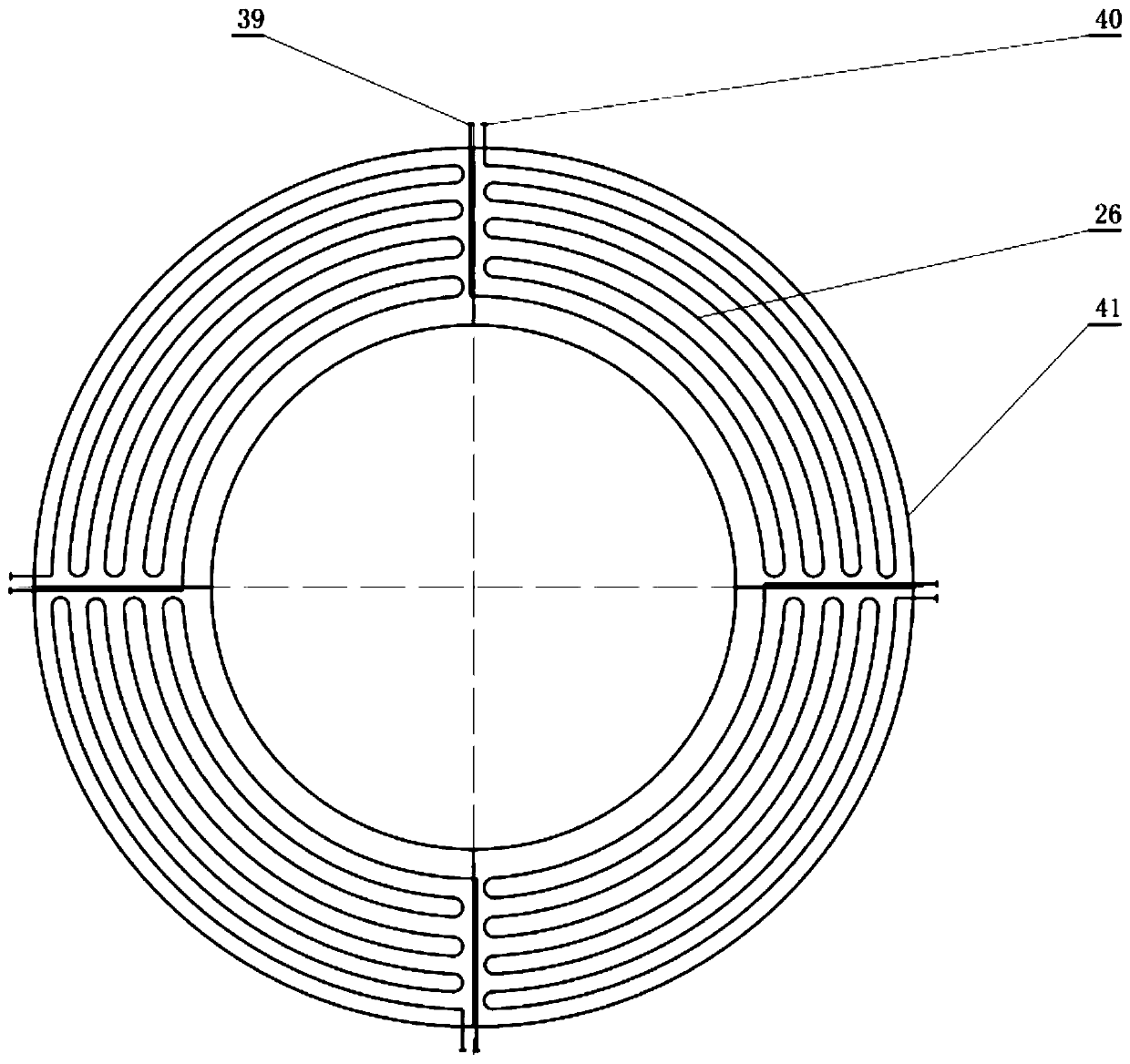

Double-coil pipe cold steam refrigerating low-loss liquid helium Dewar

InactiveCN101498538AReduce vibrationReduce conduction heat leakageDomestic cooling apparatusLighting and heating apparatusCooling effectEngineering

The invention relates to a low-loss liquid helium Dewar for the refrigeration of the cold vapor of double pipe coils, belonging to the liquid helium Dewar. The low-loss liquid helium Dewar comprises a shell, a liner, a bottleneck, a cold screen, a first helium outlet tube and a second helium outlet tube, wherein the liner is arranged in the shell, both ends of the bottleneck are respectively connected to the top of the liner and the top of the shell, the inner part of the liner is communicated with the outer part of the shell through the bottleneck, the first helium outlet tube is coiled on the bottleneck, both ends of the first helium outlet tube are communicated with the inner part of the liner and the outer part of the shell, the liner is covered by the cold screen, the second helium outlet tube is coiled on the cold screen, both ends of the second helium outlet tube are communicated with the inner part of the liner and the outer part of the shell, and vacuum exists between the outer part of the liner and the inner surface of the shell. The bottleneck can extend from the top of the liner to the bottom of the liner and be hermetically connected with the bottom of the liner, and the bottleneck can be made by a ripple tube. The invention uses two helium outlet tubes to nicely improve the cooling of the cold screen and the bottleneck and reduce the evaporation rate of helium. The flow quantity of both helium outlet tubes can be independently controlled, the best velocity ratio can be adjusted according to actual situation to obtain the best cooling effect without complex and unreliable self-consistent calculation.

Owner:UNIV OF SCI & TECH OF CHINA

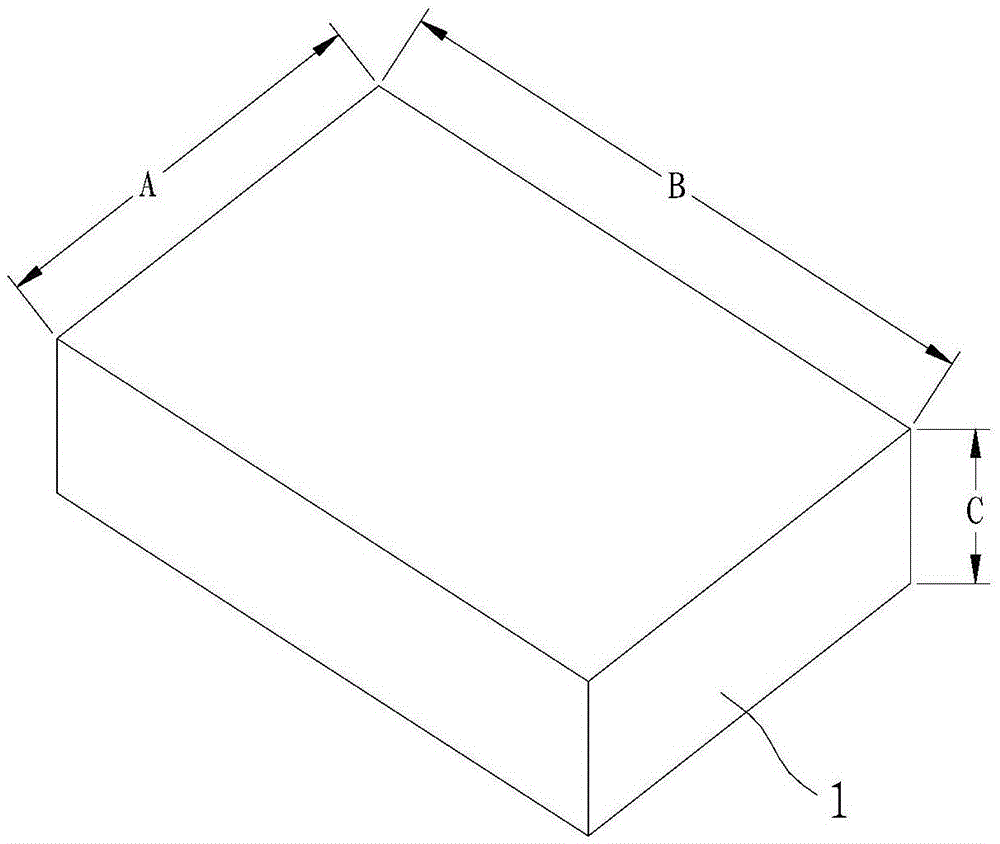

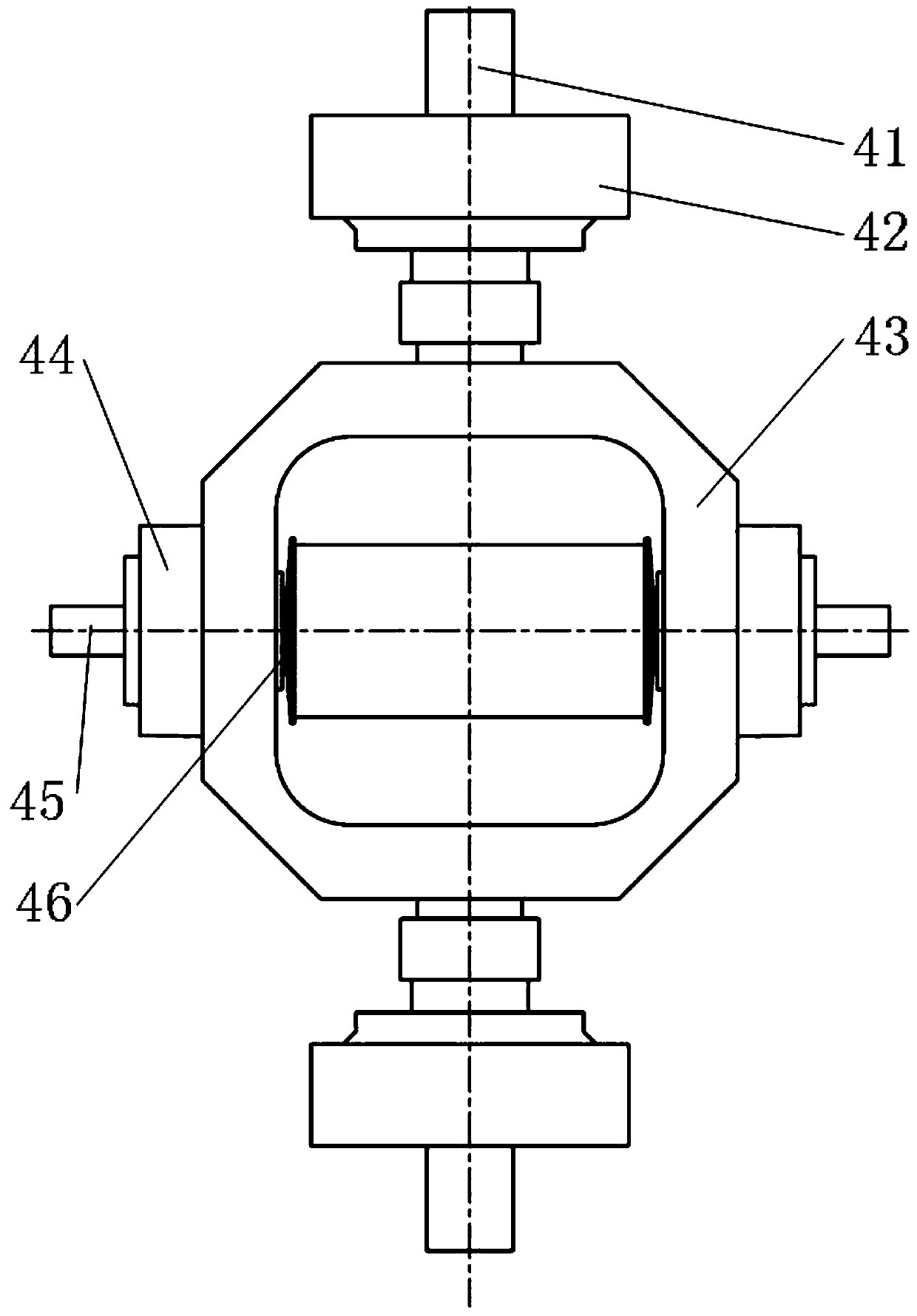

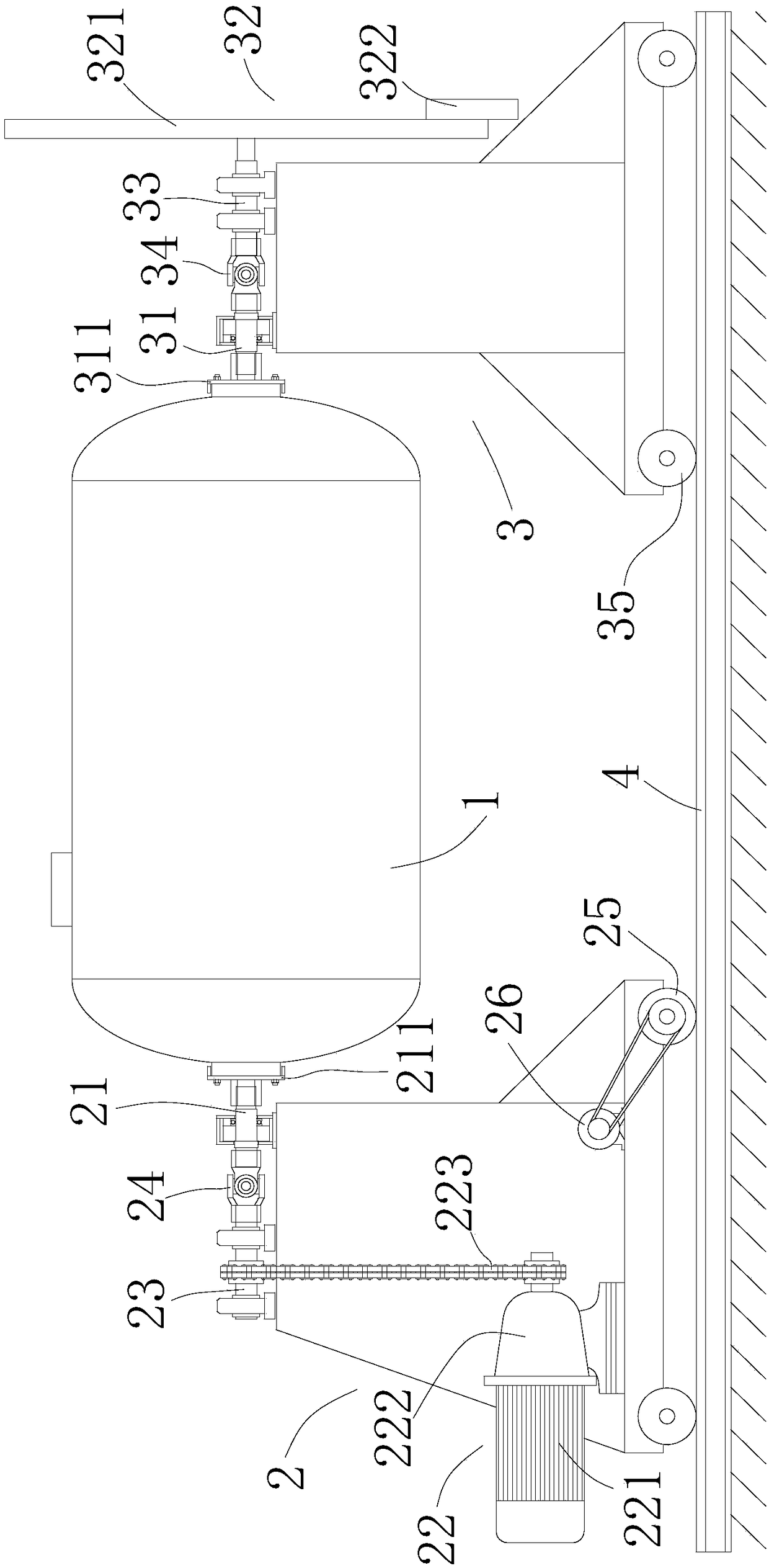

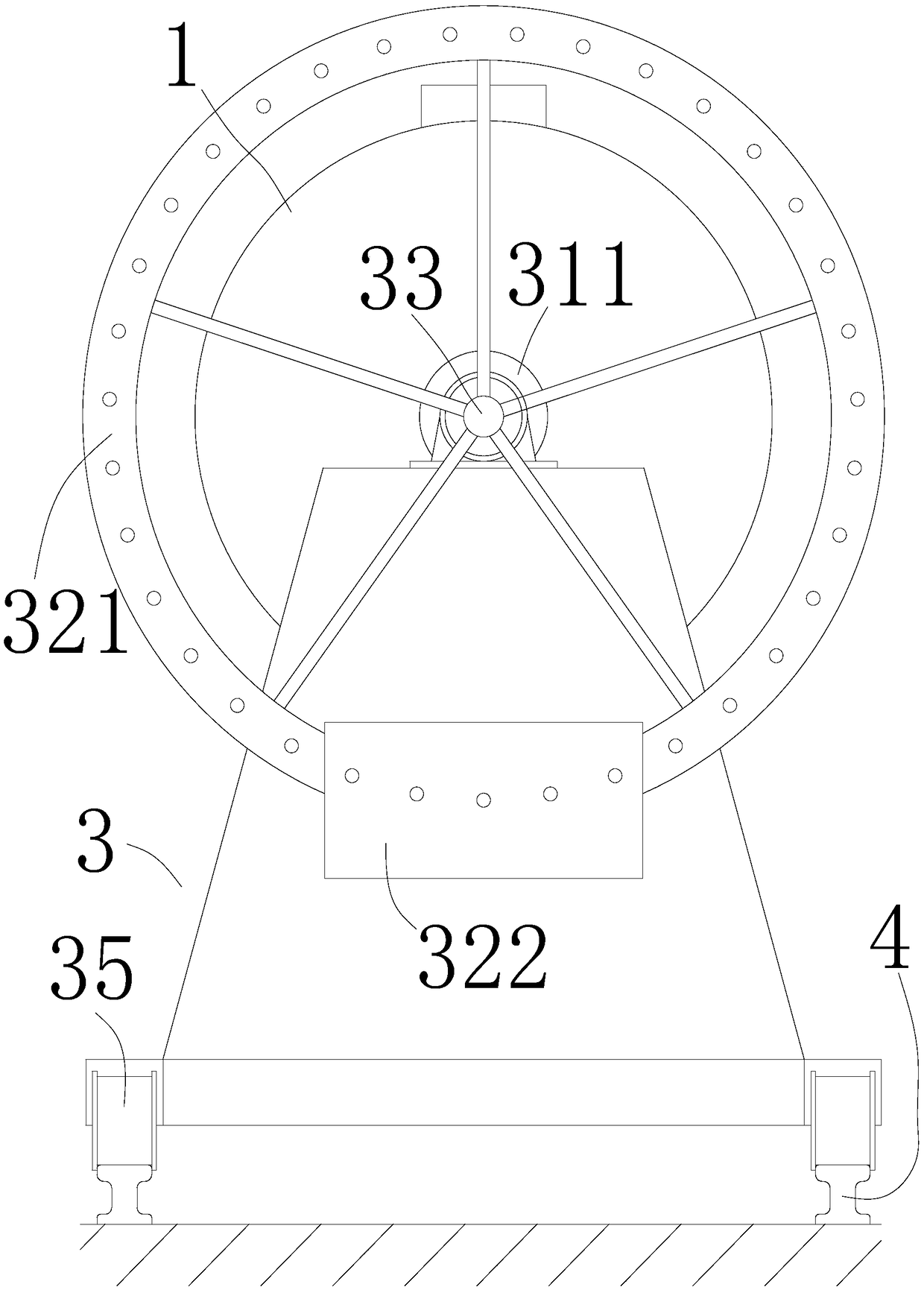

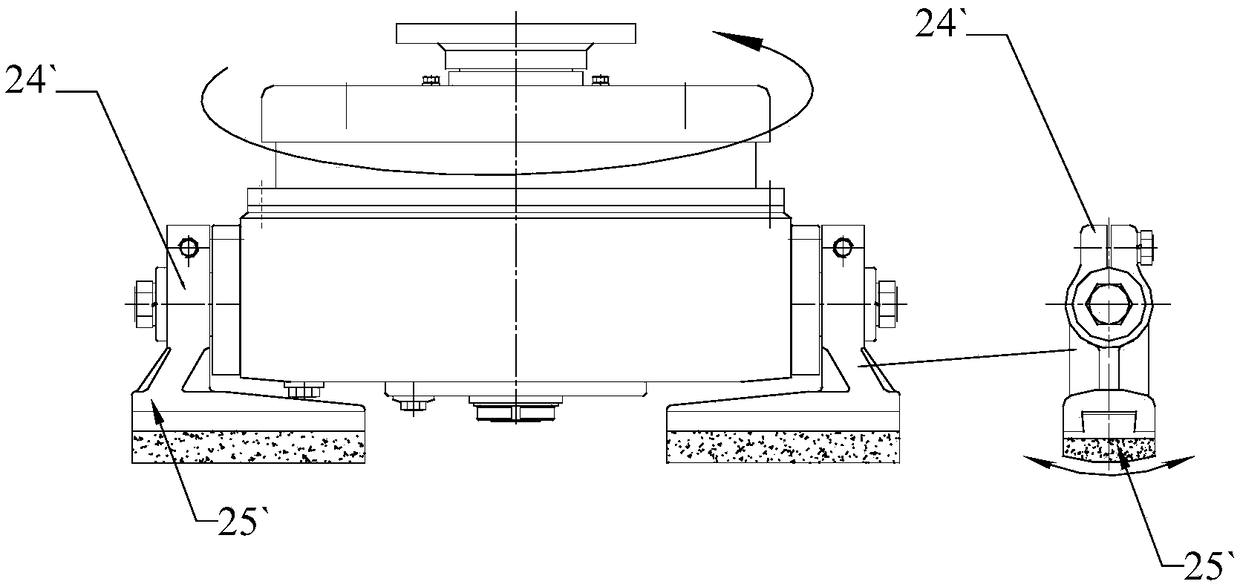

Oil tank rotation clamp

InactiveCN108942063AEven weight distributionSolve the vibrationLiquid surface applicatorsSpraying apparatusMass distributionInstability

The invention relates to the field of clamps, in particular to an oil tank rotation clamp. The oil tank rotation clamp comprises a drive frame clamped at the first end of an oil tank, and a driven frame clamped at the second end of the oil tank. The drive frame is provided with a drive shaft and a drive device driving the drive shaft to rotate. The second end of the drive shaft and the first end of the oil tank are connected together. The driven frame is provided with a driven shaft, the first end of the driven shaft is connected with the second end of the oil tank, and the driven shaft is connected to a balance weight device. The oil tank rotation clamp has the beneficial effects that through cooperation of the drive frame and the driven frame, the oil tank is clamped; then the drive device is utilized for conveniently adjusting the position of the oil tank, the oil tank is rotated, and accordingly welding, paint spraying and other operation are conducted; and through the balance weight device, the weight of the oil tank can be distributed more evenly, and accordingly the problem that during oil tank rotation, centrifugal force is generated due to uneven mass distribution of the oil tank, and vibration and instability of the oil tank are caused is solved.

Owner:淮北市向阳锅炉厂

Polyester waste silk recycling and purifying device and recycling process thereof

InactiveCN110524745ASolve the vibrationReduce damage speedNon-rotating vibration suppressionPlastic recyclingPolyesterVibration Problem

The invention discloses a polyester waste silk recycling and purifying device and relates to the related technical field of polyester waste silk recovery. The device comprises a cutting-off bin and awashing bin, a feeding hopper is fixedly connected to the top end of the cutting-off bin, a discharging pipe is fixedly connected to the bottom end of the cutting-off bin, a cutting-off shaft is arranged in the middle of the cutting-off bin, one end of the cutting-off shaft is movably connected with the cutting-off bin, the other end of the cutting-off shaft penetrates through the cutting-off binand is fixedly connected with a first servo motor, and the cutting-off shaft is circumferentially and fixedly connected with a cutting-off knife. The invention further discloses a polyester waste silkrecycling and purifying process. The process comprises the following steps of A, cutting, B, washing, C, water circulation, D, stirring, E, dehydration, F, aggregation and G, inspection. The dampingmechanism is arranged at the bottom of the cutting-off bin, the buffering effect is achieved, the vibration problem of the cutting-off bin is solved, the efficient washing effect is achieved through the arrangement of the fixing shaft, the machining efficiency is improved, the equipment requirement is low, and the machining cost is low.

Owner:安徽正力纺织科技有限公司

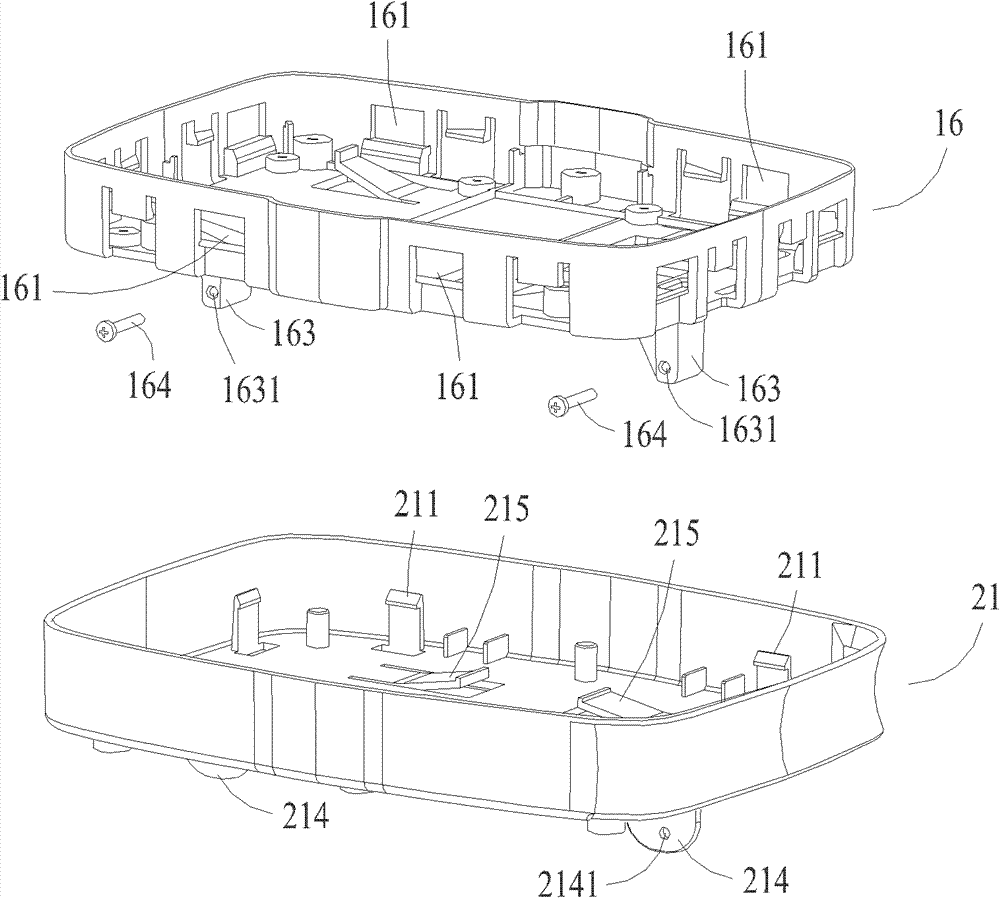

Shock absorption mechanism and mobile multimedia broadcast device

ActiveCN102958306AEasy to manufactureSolve the vibrationCasings/cabinets/drawers detailsTransmissionEngineering plasticEngineering

The invention provides a shock absorption mechanism which comprises an enclosure and a fixed plate fixed below the enclosure, wherein the enclosure comprises at least one curled-up first protruded part which is positioned at the bottom and is provided with three surfaces hollowed out; the fixed plate comprises a curled-up second protruded part which is positioned at the bottom of the fixed plate and provided with three surfaces hollowed out and corresponds to the first protruded part of the enclosure; and the head of the second protruded part abuts against the root of the first protruded part of the enclosure. The invention also provides a mobile multimedia broadcast device using the shock absorption mechanism. The problem of shock during use can be well solved. By the shock absorption mechanism, the problem of shock of equipment during working can be well solved by a dual-shock-absorption mode; the shock absorption mechanism is particularly applicable to an electronic device; the mechanism is convenient to manufacture and is applied to the enclosure made of an engineering plastic material; and the shock absorption mechanism is particularly applicable to vehicle-mounted devices. By the mobile multimedia broadcast device with the shock absorption mechanism, the problem of shock of the device during working can be solved and a good seeing and hearing effect is guaranteed.

Owner:KUANG CHI INST OF ADVANCED TECH

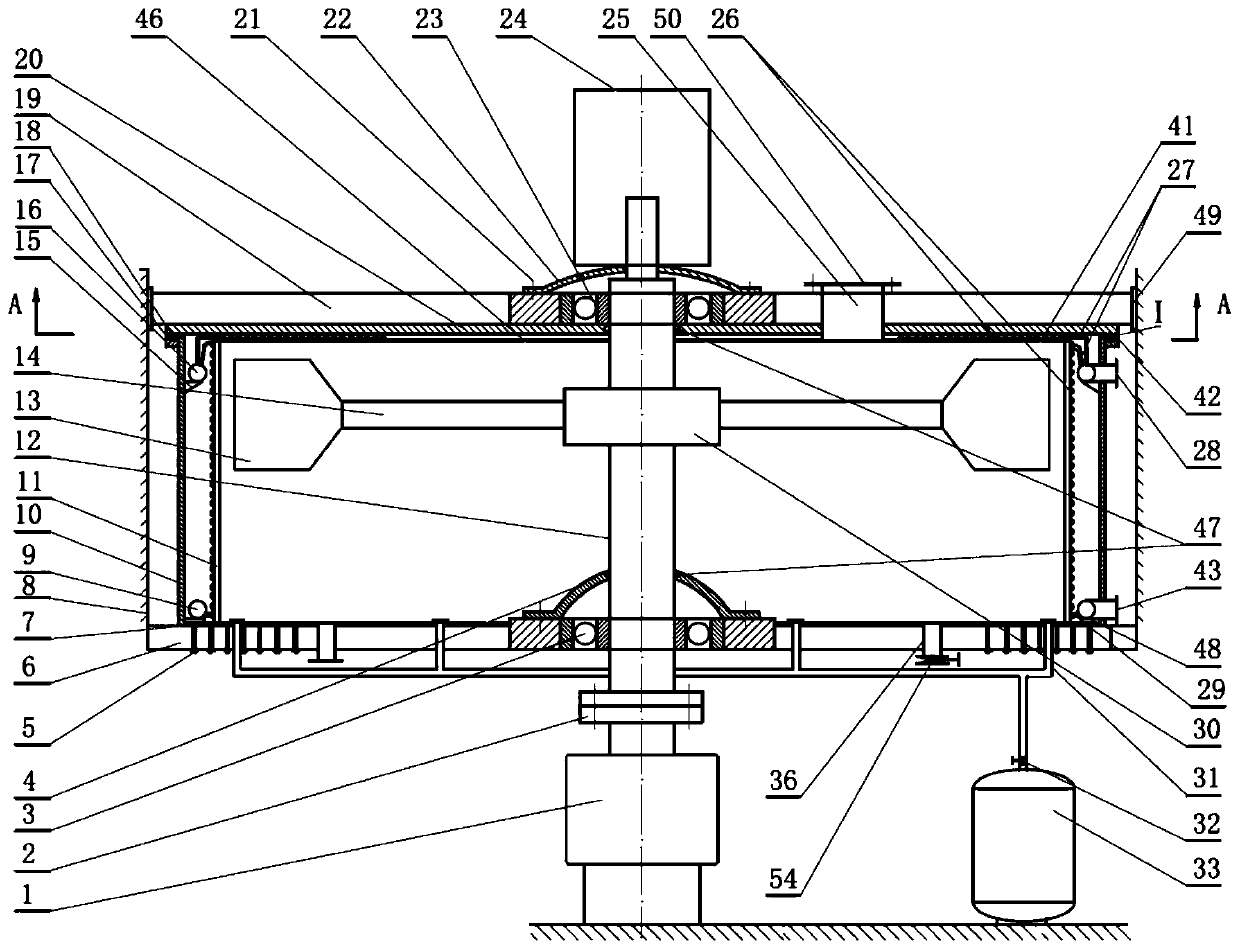

Device and method for lowering wind resistance power for large geotechnical centrifuge

ActiveCN110302906AReduced drag powerWind power reductionRotary centrifugesStructural/machines measurementResonanceHanging basket

The invention discloses a device and method for lowering wind resistance power for a large geotechnical centrifuge. A semicircle pipe cylindrical cooling device is arranged between the inner side of acylindrical barrel and a high-speed rotor system. A snakelike top semicircle pipe cooling plate is arranged over a hanging basket. The tope center is provided with an air return opening. Helium in ahelium storage tank enters a centrifugal bin from a lower seal plate through helium outlets in a plurality of helium inlet pipes. The helium is adopted for replacing air in the centrifugal bin, so that wind resistance power and corresponding energy consumption are lowered. A vacuum is not needed, so that the sealing requirements are lower. Radiating equipment is arranged in a centrifugal bin cavity, a helium inner circulation wind channel is added, the heat exchange coefficient is increased, and the radiating effect is improved. A special vibration isolation seal pad is adopted, vibration transmitted by a spindle to an upper bearing system support device is isolated from the centrifugal bin cavity, thus resonance of the cavity and the spindle is avoided, and safety of the centrifugal bin cavity is ensured. During operation under gravitational acceleration below 1500 g, economy is good, and temperature can be controlled below 45 DEG C.

Owner:ZHEJIANG UNIV

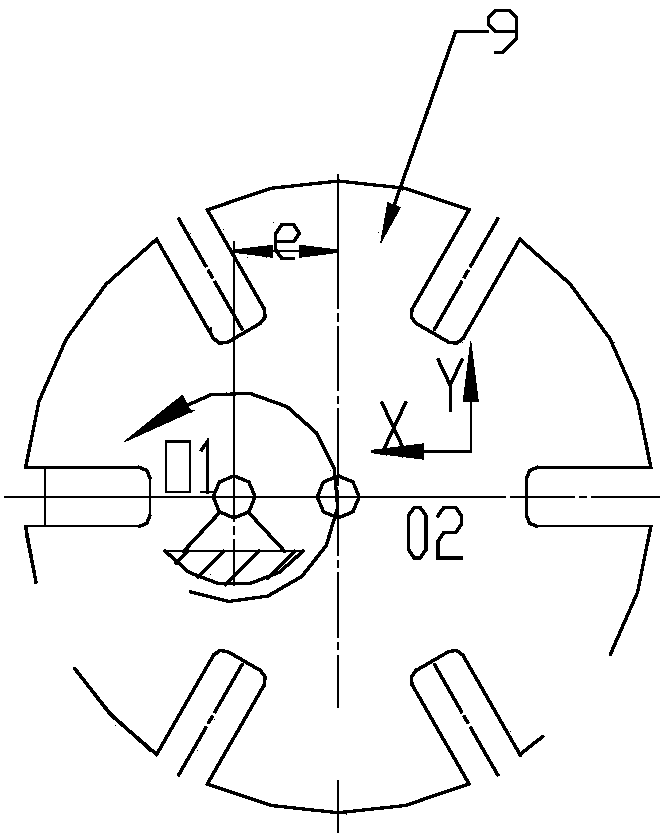

Eccentric translation type polishing grinding head and polisher containing grinding head

ActiveCN108247518ABeneficial technical effectIncrease the number ofPolishing machinesGrinding headsGyrationCeramic tiles

The invention discloses an eccentric translation type polishing grinding head. The eccentric translation type polishing grinding head comprises an eccentric wheel, a drive plate and oscillating bar mechanisms, wherein the eccentric wheel is connected with the drive plate, the geometric center of the eccentric wheel coincides with the geometric center of the drive plate, the gyration center of eccentric wheel is located at one side of the geometric center of the eccentric wheel, eccentric distance exists between the gyration center of the eccentric wheel and the geometric center of the eccentric wheel, a plurality of radial slots are arranged around the circumference of the drive plate, oscillating bar ball heads of the oscillating bar mechanisms are inserted into the radial slots, when theeccentric wheel rotates, the drive plate does not rotate but horizontally and circularly moves in a plane along an X axis and a Y axis, when the drive plate moves, each oscillating bar mechanism continuously circularly swings along the radial direction of the corresponding radial slot under the action of the side face of the corresponding radial slot and the corresponding oscillating bar ball head, and it is achieved that a grinding block connected to one end of each oscillating bar mechanism circularly swings. The eccentric translation type polishing grinding head and the polisher containingthe grinding head have the advantages that the structure is simple, it is achieved that when the grinding blocks revolve around the grinding heads, the grinding blocks can circularly swing at the same time, the grinding efficiency on ceramic tile is high, the operation is smooth and steady, and the reliability is high.

Owner:KEDA INDUSTRIAL GROUP CO LTD

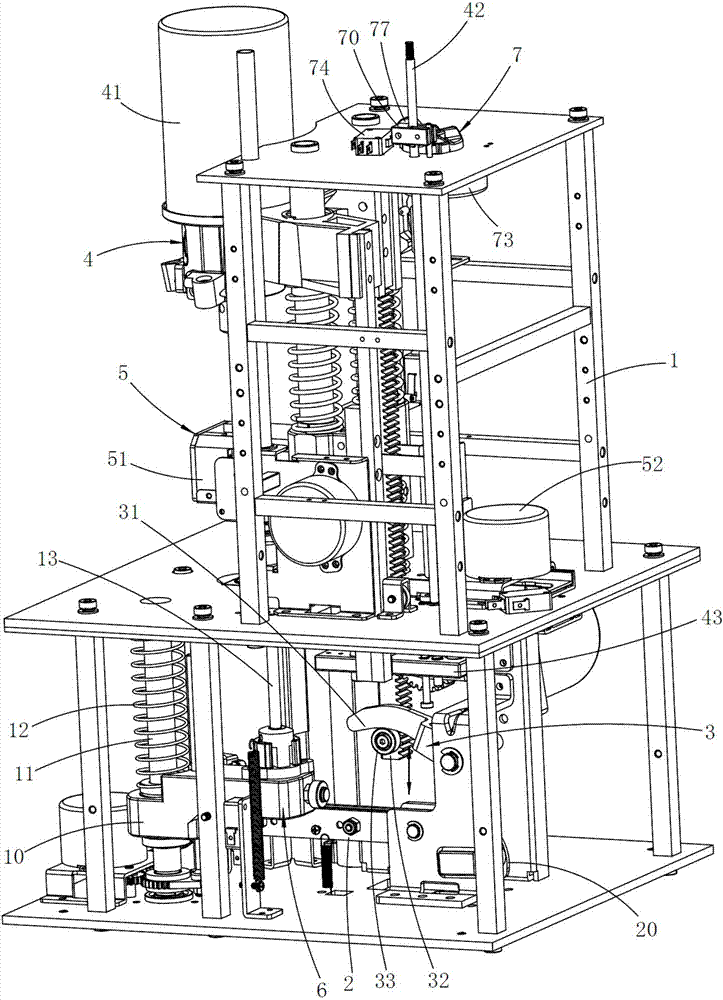

Epoxy mould dry type vibration reduction denoise iron core shunt reactor

ActiveCN101226816ASolve the vibrationSolve the noiseTransformers/inductances coils/windings/connectionsTransformers/inductances noise dampingEpoxyChinese characters

An epoxy resin cast dry-type vibration-damping and noise-reducing iron core paralleling reactor comprises a iron core, a wire circle and a vibration-damping and a noise-reducing device, wherein the iron core is composed of upper and lower yokes and three phase core limbs. The upper and lower yokes are respectively clamped by clips, the centre of the center circles of the upper and lower yokes is utilized as benchmark, the iron core is arranged on the lower yoke along the direction of the 120 DEG included angle of the three phase core limbs with Chinese character 'pin' type, the wire circle is coated on the three phase core limbs and the iron is connected with the vibration-damping and noise-reducing device. The invention changes the traditional '-' structure into the Chinese character 'pin' type, if casting dry-type product for the epoxy resin, simultaneously the structure of one wire circle of each phase is divided into a plurality of wire circles with upper independent, which increases the safety and reliability of operation, the invention adds pressing frames between the iron core and the elastic rubber cushion, the structure of which can better reduce vibration, decrease noise and has relatively good reliability.

Owner:SIEYUAN ELECTRIC CO LTD

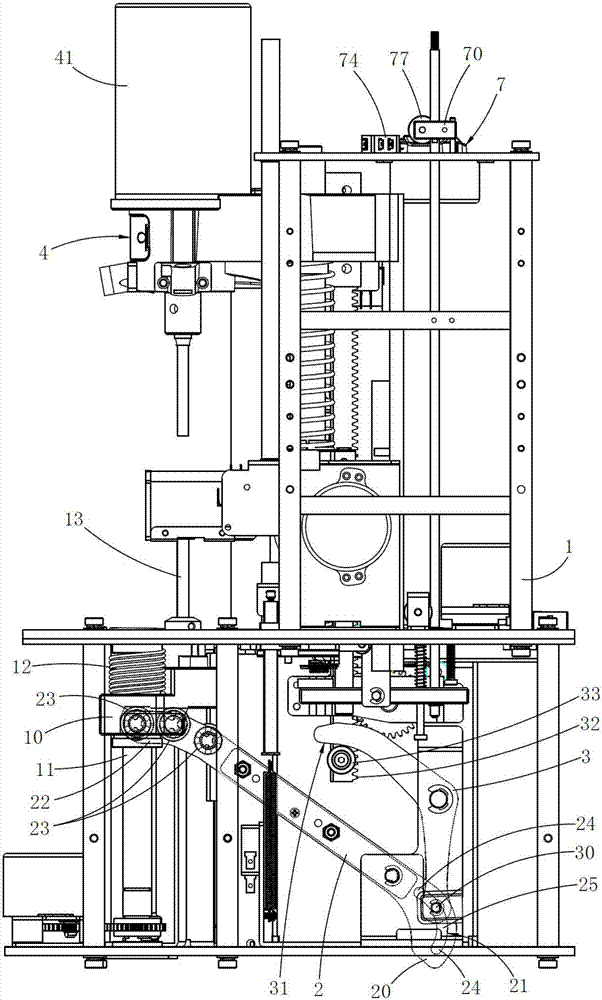

Improved full-automatic financial binding machine

The invention discloses an improved full-automatic financial binding machine which comprises a rack, an ejecting pin mechanism mounted under a binding table, a lever and a transmission rack of a transmission mechanism connected to the upper portion of the binding machine in a transmission mode. The first end of the lever is in transmission fitting with the ejecting pin mechanism. A lifting control arm is mounted under the binding table. The middle of the lifting control arm is pivoted to the rack. The first end of the lifting control arm is in transmission fitting with the transmission rack. The second end of the lifting control arm is in transmission fitting with the second end of the lever. The improved full-automatic financial binding machine is simple in structure and low in cost; and the problem that impacting, vibration and collision exist during operation of a lever mechanism is solved, the problem of jumping and jamming during rising and falling of a rotating arm is also solved, the lever mechanism and the rotating arm operate stably, and nearly no noise is generated during operation of the lever and the relevant transmission mechanism.

Owner:张华

Exhaust bearing block and screw compressor

ActiveCN106401965AReduce vibrationReduce noiseRotary piston pumpsRotary piston liquid enginesUltrasound attenuationGas compressor

The invention relates to the related field of compressors, and discloses an exhaust bearing block and a screw compressor. The exhaust bearing block comprises a bearing block body. An air supply port is formed in the end face of the bearing block body, an air supply ripple attenuation chamber communicating with the air supply port is further formed in the bearing block body, and the volume of the air supply ripple attenuation chamber is larger than that of the air supply port. The exhaust bearing block is included in the screw compressor. According to the bearing block and the screw compressor, because the bearing block body is provided with the air supply ripple attenuation chamber communicating with the air supply port, low-frequency vibration generated by the air supply port in the air supply process can superpose mutually in the air supply ripple attenuation chamber, airflow ripples generated by the air supply port in the air supply process can attenuate in the air supply ripple attenuation chamber, the purpose of reducing the airflow ripples of air supply is achieved, then, the vibration of an air supply pipe of the screw compressor is reduced, the noise of the air supply pipe of the screw compressor is lowered, and the reliability of the screw compressor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

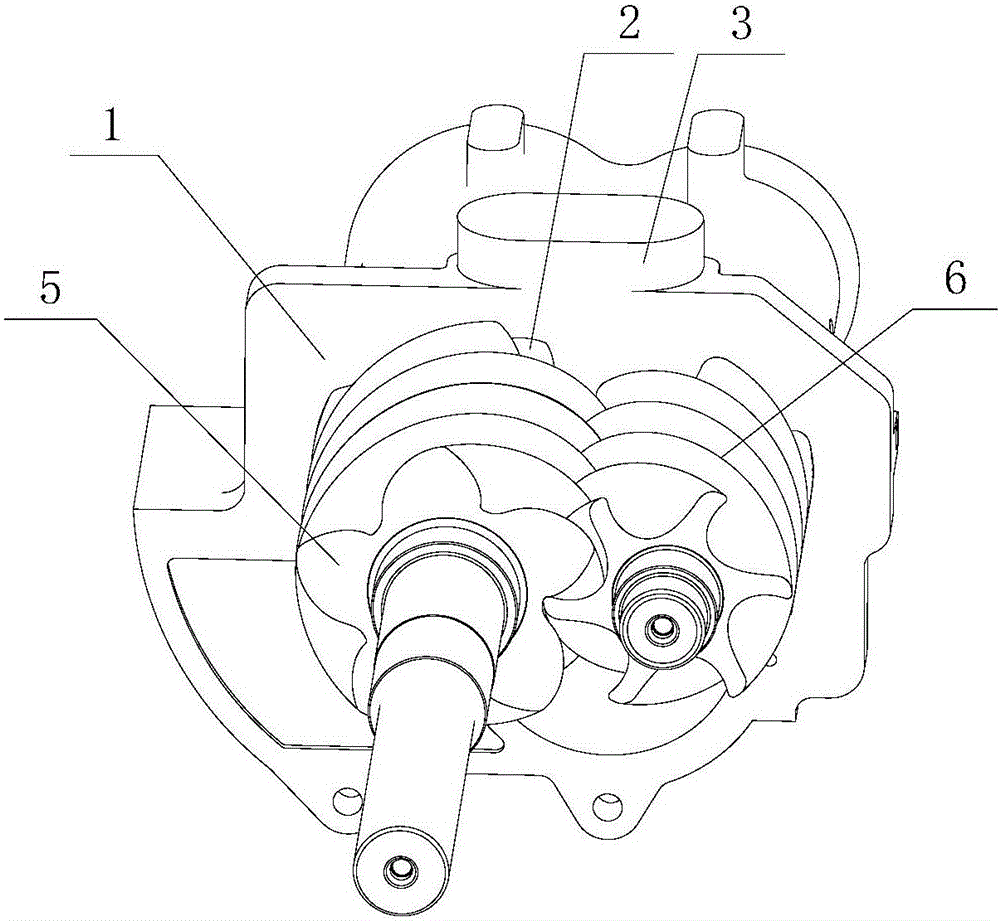

Dual-head pump

InactiveCN103541906ASimple structureImprove practicalityRadial flow pumpsNon-positive displacement fluid enginesImpellerEngineering

The invention discloses a dual-head pump. The dual-head pump comprises two pump heads and a pump body, wherein the two pump heads are symmetrically arranged at both ends of the pump body, each pump head comprises a pump chamber cover, a horizontal water inlet and a vertical water outlet, and the pump body comprises a rotor and a stator; each end of the rotor extends into the corresponding pump body; impellers are symmetrically arranged at both ends of the rotor. By means of the symmetrical design of the pump heads, reaction forces generated at both ends of the dual-head pump can counteract mutually, so that vibration, noise and friction can be reduced, energy efficiency can be improved and the like.

Owner:ZHUHAI VBV DIGITAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com