Double-coil pipe cold steam refrigerating low-loss liquid helium Dewar

A dual-coil, low-loss technology, applied in the field of liquid helium Dewars, can solve problems such as the inability to take into account radiation heat leakage and conduction heat leakage, and achieve improved radiation heat leakage and conduction heat leakage, low liquid helium loss, The effect of small liquid helium depletion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

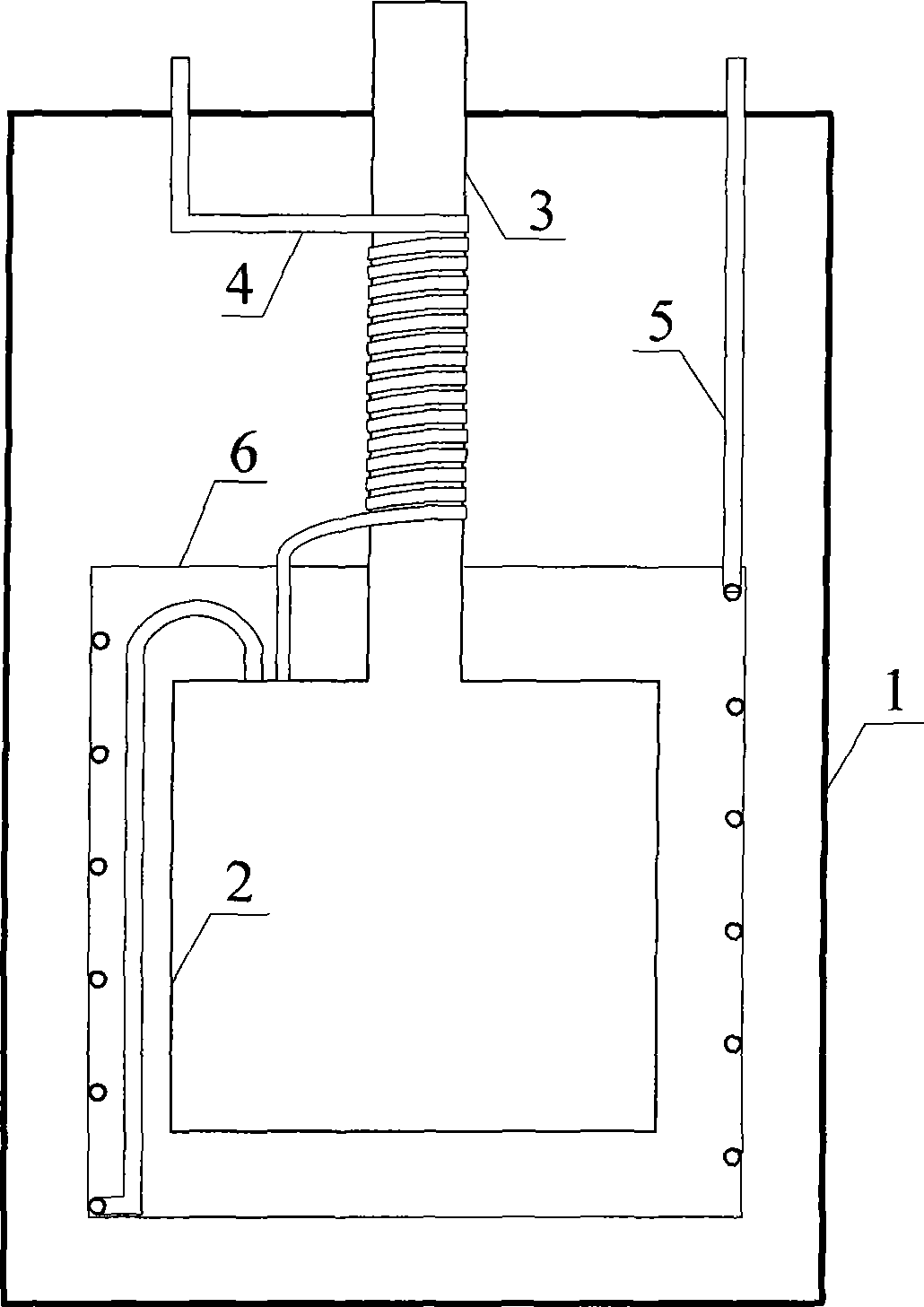

[0028] Example 1: Low-loss liquid helium Dewar for basic double-coil cold vapor refrigeration

[0029] see figure 1 , the low-loss liquid helium Dewar of the basic double-coil cold vapor refrigeration of the present invention includes an outer shell 1, an inner tank 2, a bottleneck 3 and a cold shield 6, and is characterized in that it also includes a first helium outlet pipe 4 and a second helium outlet pipe. The trachea 5 and the liner 2 are placed inside the shell 1, the two ends of the bottleneck 3 are respectively connected to the top of the liner 2 and the top of the shell 1, the inside of the liner 2 communicates with the outside of the shell 1 through the bottleneck 3, and the first helium The gas outlet coil 4 is wound on the bottleneck 3, and its two ends are connected to the inside of the liner 2 and the outside of the shell 1. The cold screen 6 is placed between the liner 2 and the shell 1, and the second helium gas outlet coil 5 is wound Above the cold shield 6, ...

Embodiment 2

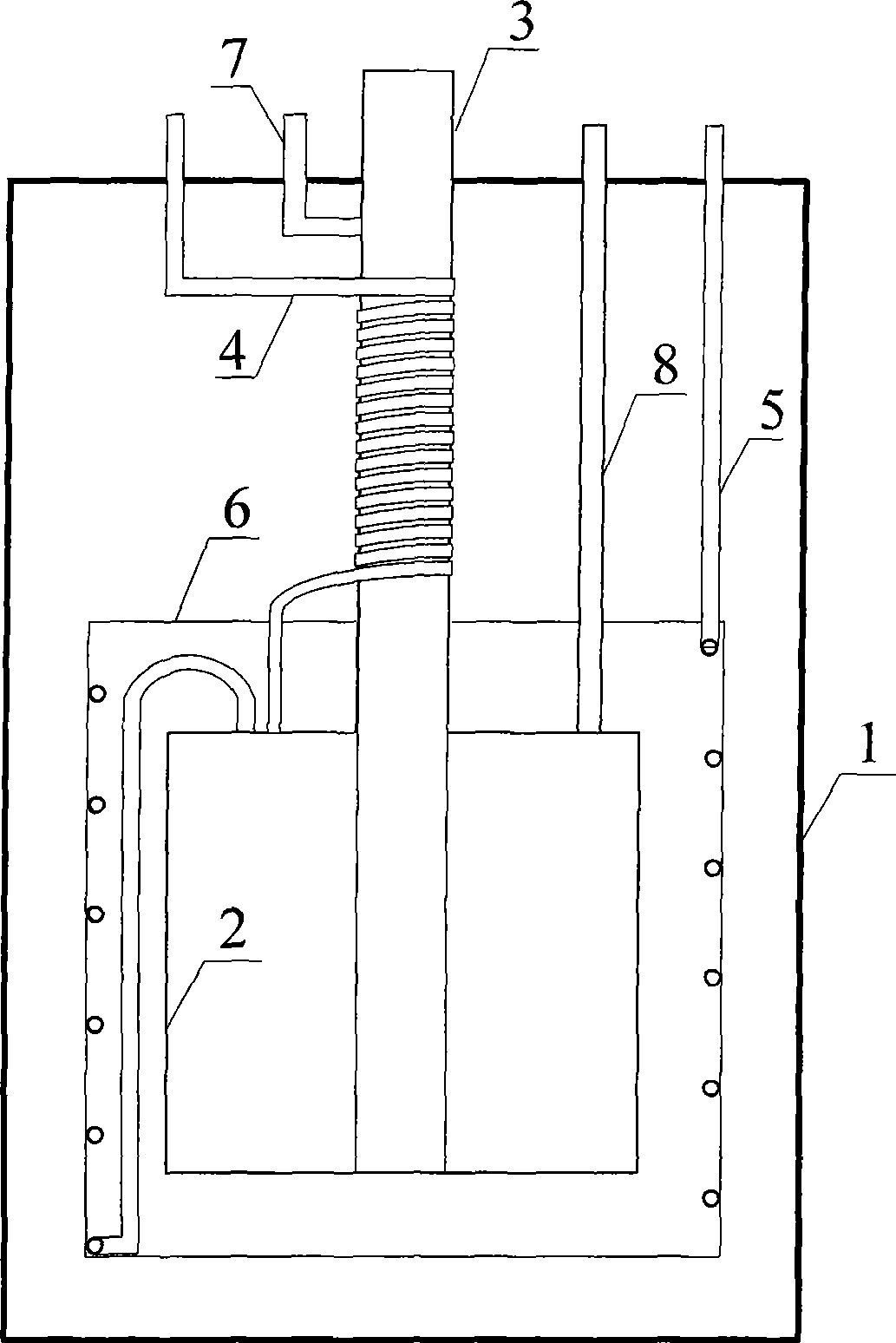

[0033] Example 2: Low-loss liquid helium Dewar with double-coil cold vapor refrigeration with the bottle neck and the bottom of the liner sealed

[0034] In the above-mentioned embodiment 1, in order to isolate a low-temperature liquid-free helium cavity inside the inner tank 2 to reduce the vibration caused by the boiling of the liquid helium to the measuring instrument, the bottleneck 3 is extended into the bottom of the inner tank 2 and connected with the inner tank 2. Bottom seal of liner 2, see figure 2 . It is also possible to add a helium liquid injection pipe 8 connecting the top of the inner tank 2 and the top of the outer shell 1 to facilitate replenishing liquid helium in the inner tank 2, and at the same time also add a pumping and charging tube 7 connecting the inside of the bottleneck 3 and the outside of the outer shell 1, It is used to fill a certain amount of helium into the bottleneck 3 for heat exchange, and to cool down the experimental device in the isol...

Embodiment 3

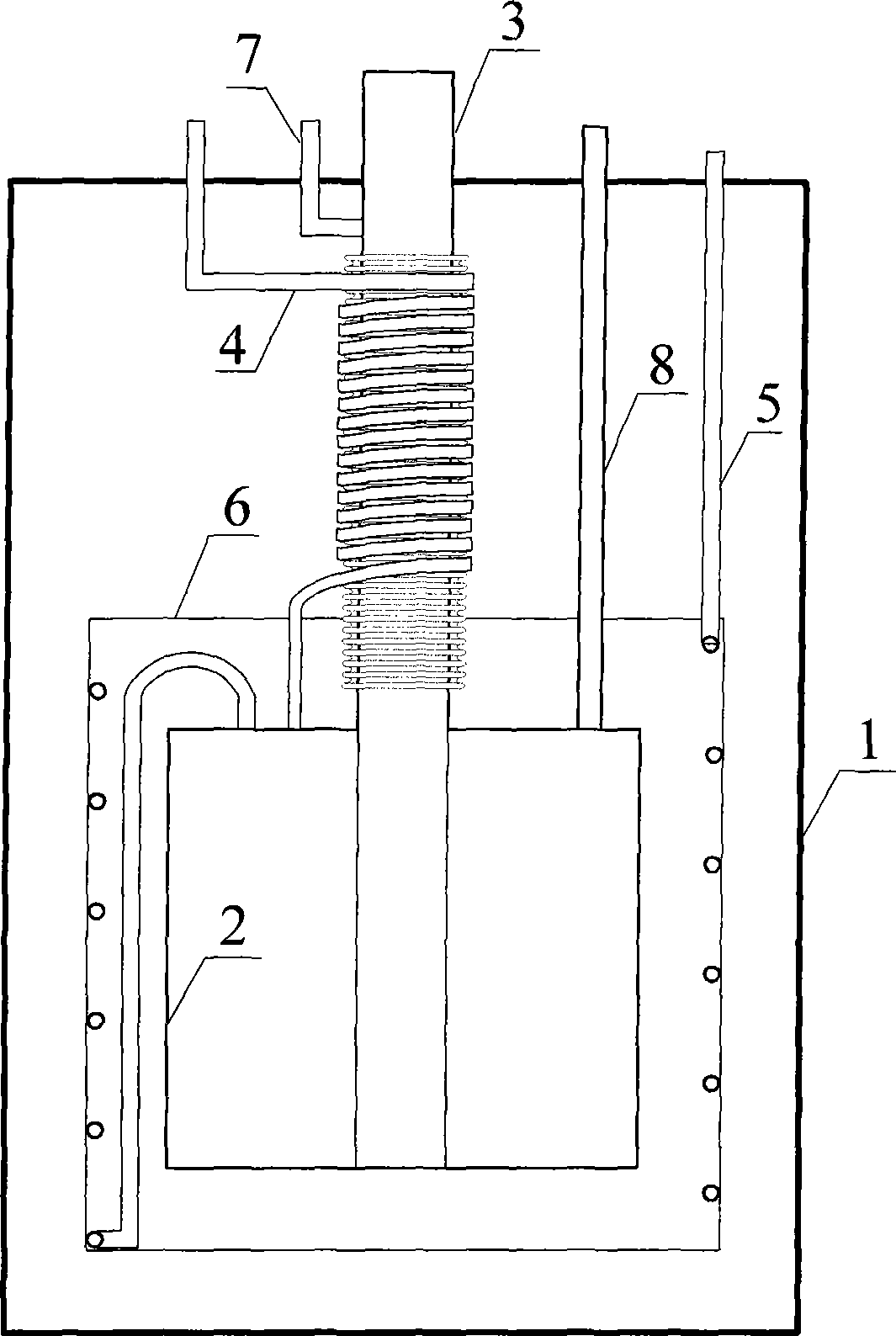

[0035] Embodiment 3: Low-loss liquid helium Dewar with double-coil cold vapor refrigeration with bellows as the bottleneck

[0036] In the above-mentioned embodiments 1 and 2, in order to further reduce the solid conduction heat leakage from the outer shell 1 to the inner tank 2 through the bottleneck 3, the bottleneck 3 between the inner tank 2 and the outer shell 1 uses a thinner wall. , instead of bellows with longer effective heat conduction length, see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com