Numerically-controlled lathe allowing cutters to be installed conveniently

A technology for CNC lathes and tools, applied in the field of CNC lathes, can solve the problems of cumbersome, tool surface damage, labor and other problems, and achieve the effects of scientific and reasonable structure, safe and convenient use, and avoidance of inability to move.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

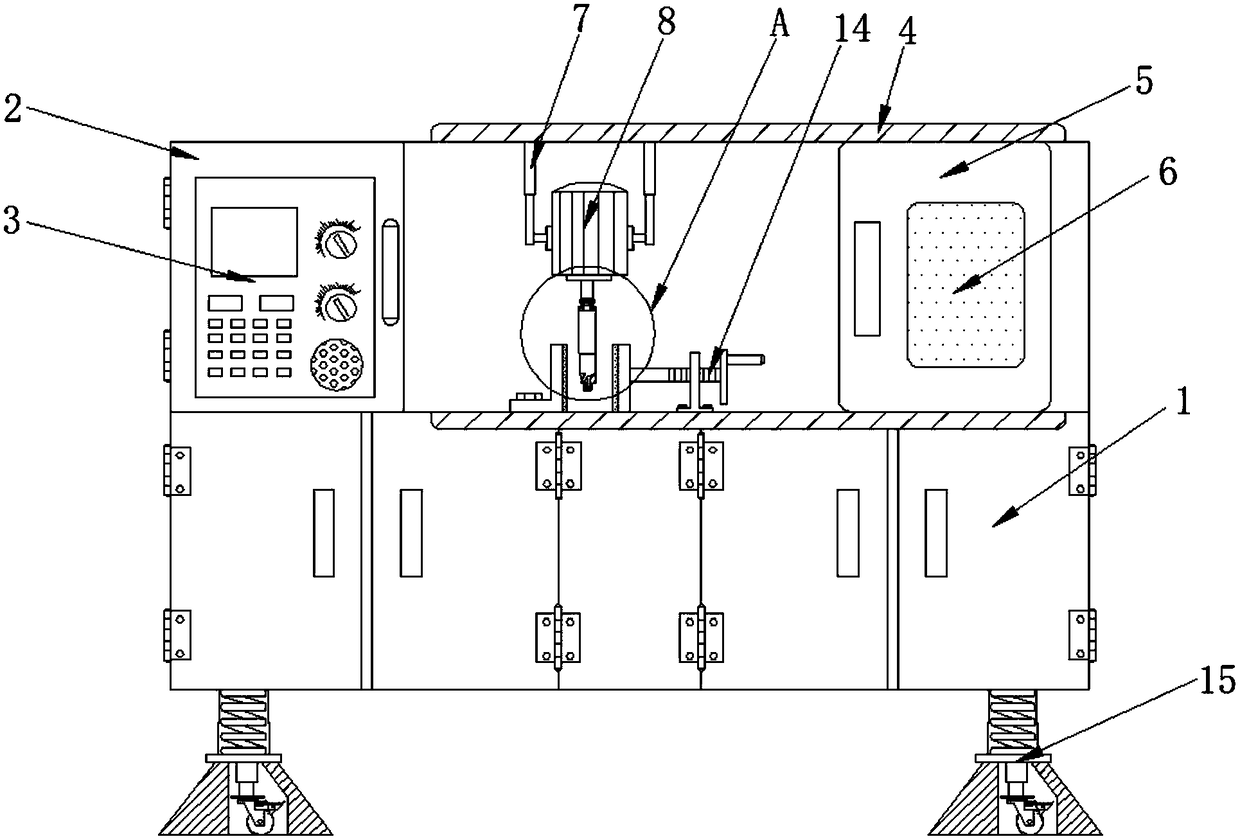

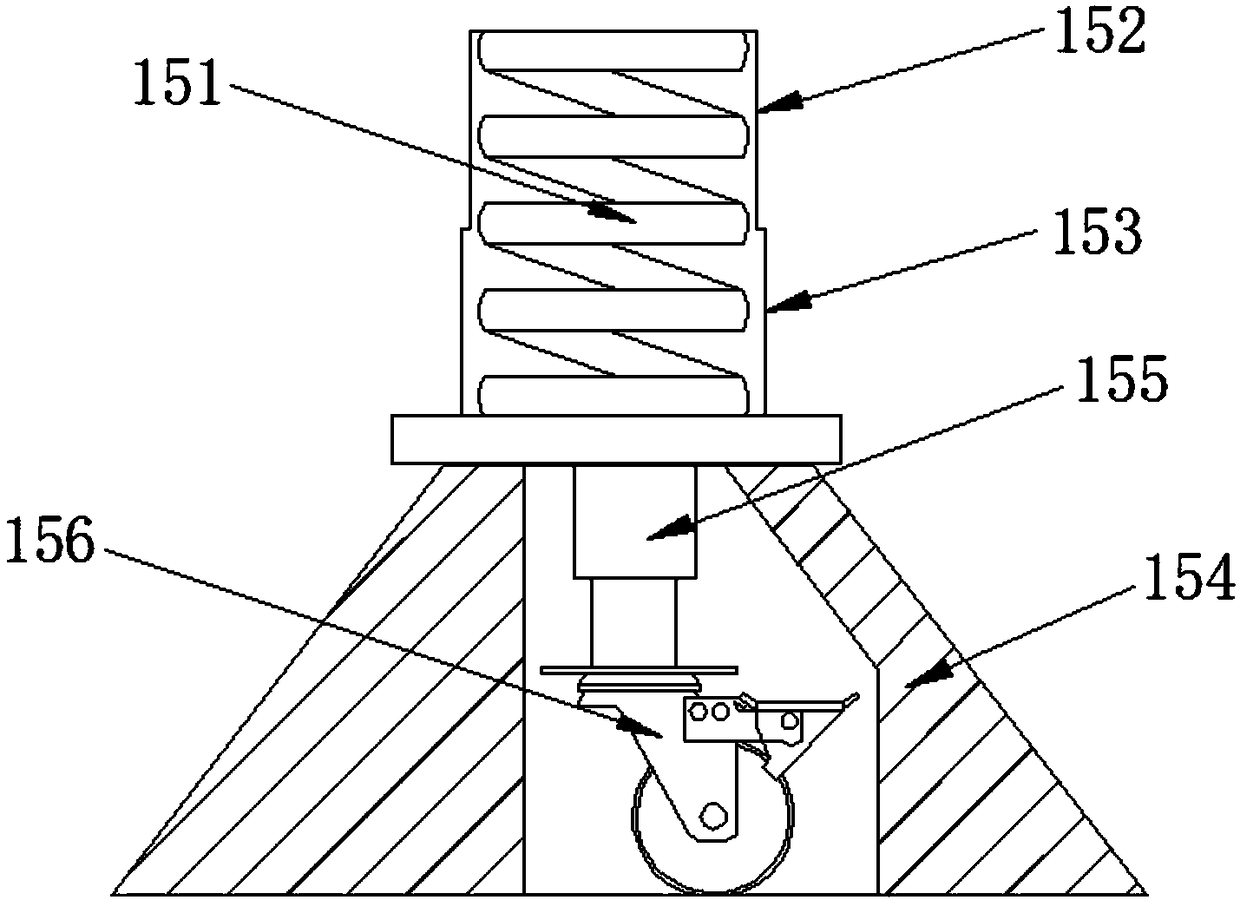

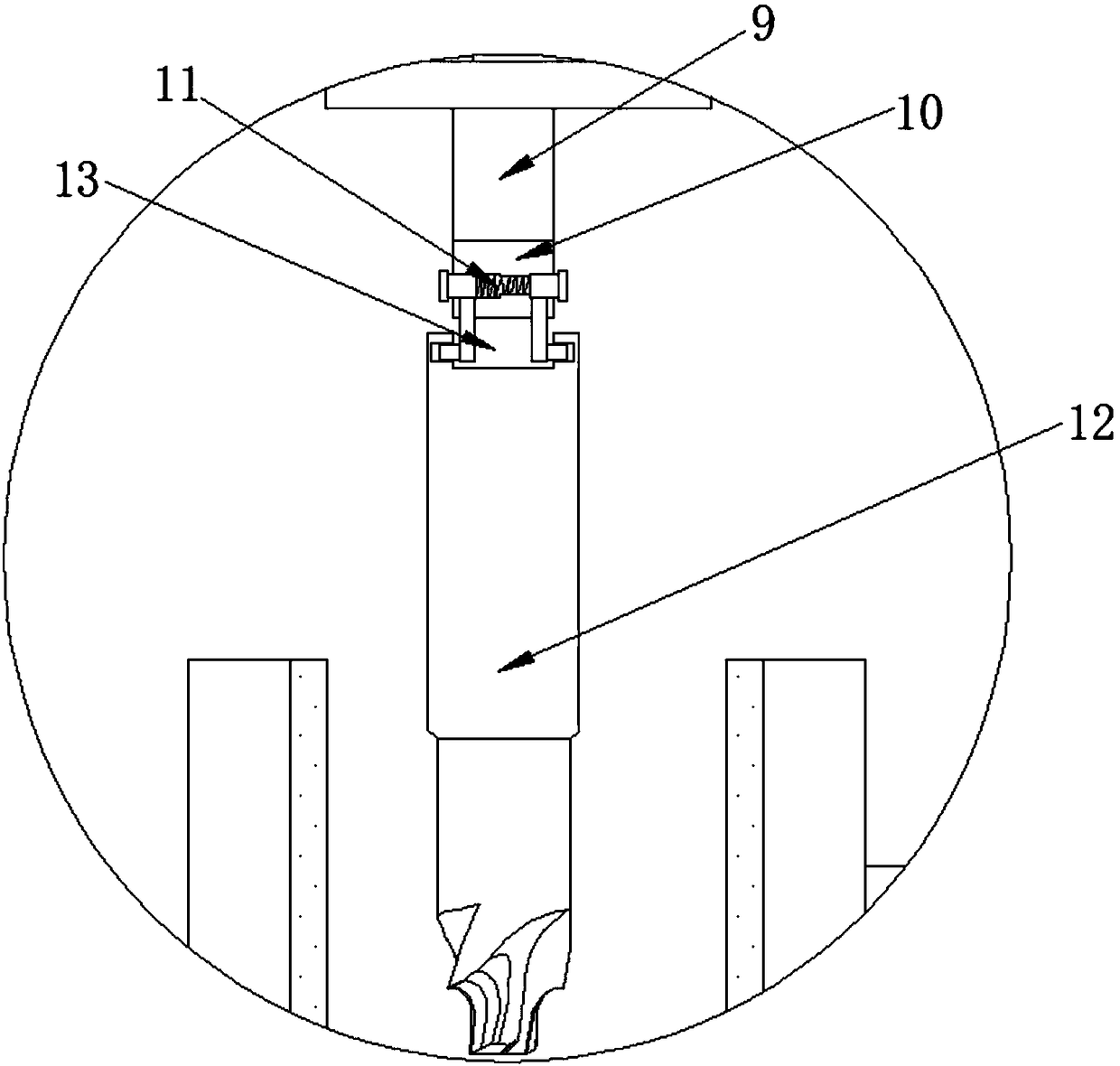

[0022] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a CNC lathe that is convenient for tool installation, including an operating platform 1, a control box 2, a control panel 3, a slide rail 4, a protective door 5, a window 6, and a first electric telescopic rod 7 , servo motor 8, transmission rod 9, groove 10, mounting assembly 11, cutter 12, card slot 13, fixed assembly 14 and shock-absorbing moving assembly 15, control box 2 is installed on the upper end of one side of operation platform 1, control box 2 A control panel 3 is installed on the outer surface of the rear end, a first electric telescopic rod 7 is installed on the inner side of the upper middle part of the operation platform 1, a servo motor 8 is installed on one side of the lower end of the first electric telescopic rod 7, and a transmission rod 9 is connected to the outer side of the lower end of the servo motor 8 , a groove 10 is provided on the inner side of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com