Single-drive multi-cylinder compressor structure

A compressor, single-drive technology, applied in the direction of machine/engine, multi-stage pump, mechanical equipment, etc., can solve the problems of low working efficiency of the compressor structure, large wear of the piston pin, affecting the service life of the compressor, etc. The effect of high pin wear, long service life and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

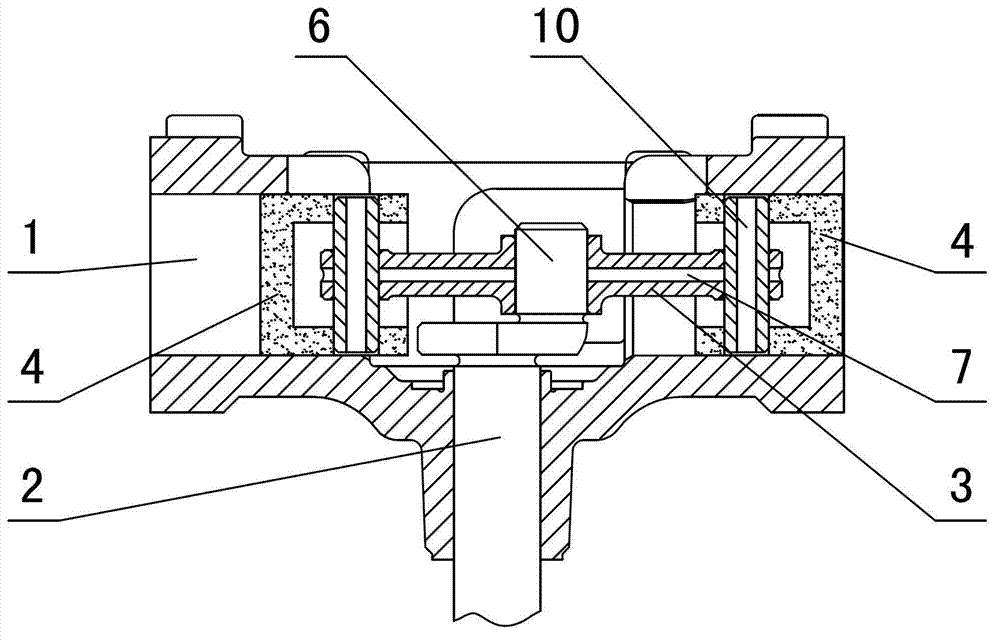

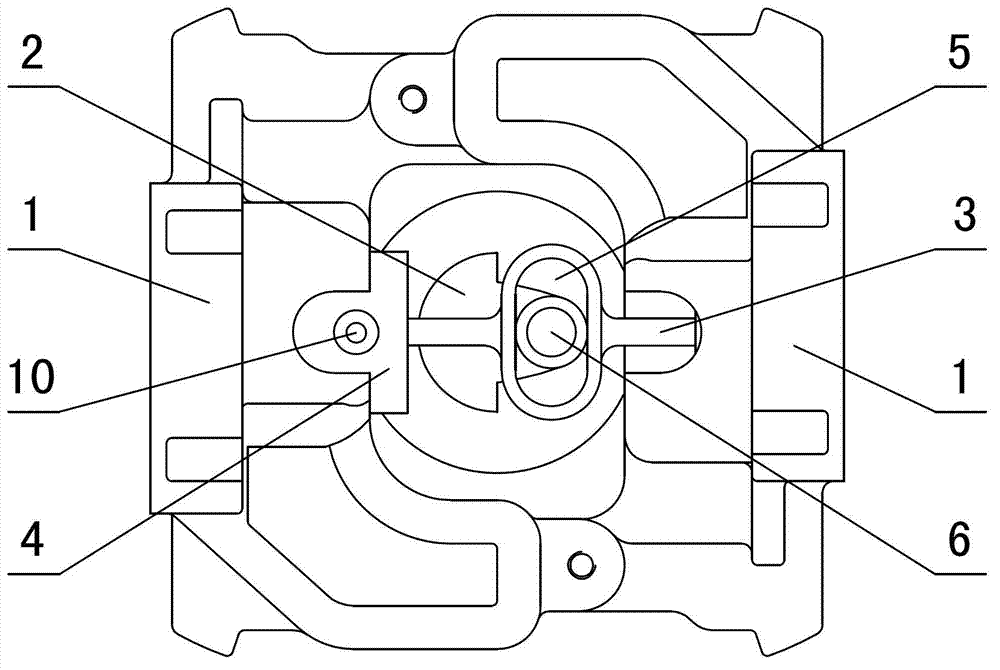

[0030] in such as figure 1 figure 2 In the shown embodiment 1, a single-drive multi-cylinder compressor structure includes a crankshaft and a cylinder arranged in the radial direction of the crankshaft and driven by the crankshaft. There are two cylinders, and the piston holes 1 of the two cylinders are symmetrical. Set on both sides of the crankshaft 2, the central axes of the two cylinders are on the same plane as the central axis of the crankshaft. The crankshaft is provided with a crank throw 6, and the crankshaft passes through an inline three-hole connecting rod 3 (see Figure 5 Figure 6 ) is connected with the pistons 4 of the two cylinders, the three-hole connecting rod is a homogeneous center-symmetrical structure, the center of the three-hole connecting rod is provided with a chute 5 perpendicular to the length direction of the three-hole connecting rod, and the three-hole connecting rod The two piston pin holes 8 are arranged symmetrically on both sides of the c...

Embodiment 2

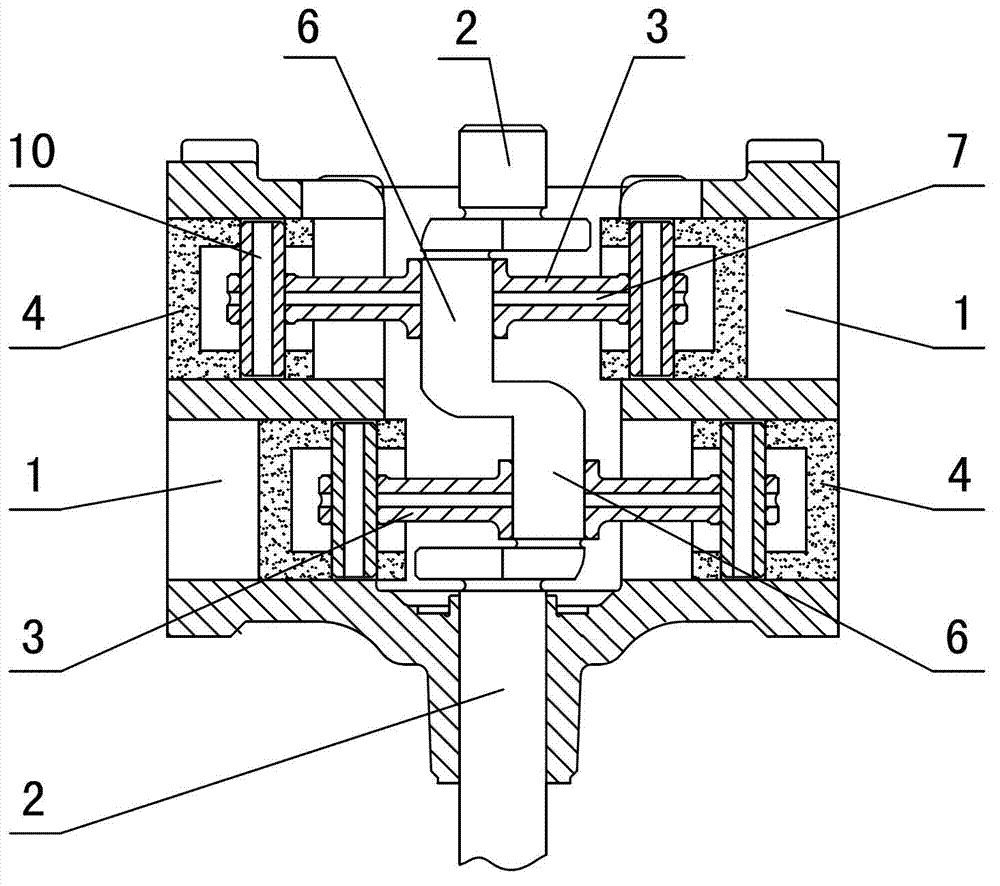

[0032] in such as image 3 In the shown embodiment 2, there are four cylinders, and the central axes of the four cylinders are on the same plane as the central axis of the crankshaft. The piston holes of the cylinders are divided into two pairs and arranged symmetrically on both sides of the crankshaft. There are two crank throws arranged in dislocation on both sides, and the two crank throws are connected to the pistons on both sides of the crankshaft through two three-hole connecting rods. The three-hole connecting rods are segmented structures, that is, the three-hole connecting rods are composed of The two-section connecting rod body is screwed together (see Figure 7 ), the chute in the middle of the three-hole connecting rod is formed by closing two opposite openings, so that the three-hole connecting rod can be conveniently set on the crank throw. The phase difference between the piston movements of the two cylinders on the same side of the crankshaft is 180 degrees. T...

Embodiment 3

[0034] There are four cylinders in embodiment 3, the central axes of the four cylinders and the central axis of the crankshaft are on the same plane, and the piston holes of the cylinders are divided into two pairs and symmetrically arranged on both sides of the crankshaft. Two bellcranks arranged in dislocation, the two bellcranks are connected to the pistons on both sides of the crankshaft through two three-hole connecting rods. The three-hole connecting rods are segmented structures, that is: the three-hole connecting rods body screw connection (see Figure 7 ), the chute in the middle of the three-hole connecting rod is formed by closing two opposite openings, so that the three-hole connecting rod can be conveniently set on the crank throw. The phase difference between the piston movements of the two cylinders on the same side of the crankshaft is 180 degrees, and each of the four cylinders is provided with an air outlet branch pipe, and the rest are the same as in Embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com