Device and method for lowering wind resistance power for large geotechnical centrifuge

A geotechnical centrifuge and air resistance technology, applied in the direction of centrifuges, centrifuges with rotating drums, measuring devices, etc., can solve the problems of reducing air density, decreasing heat transfer capacity, increasing heat production in centrifuge chambers, and achieving increased Rigidity and running stability, heat transfer coefficient improvement, effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

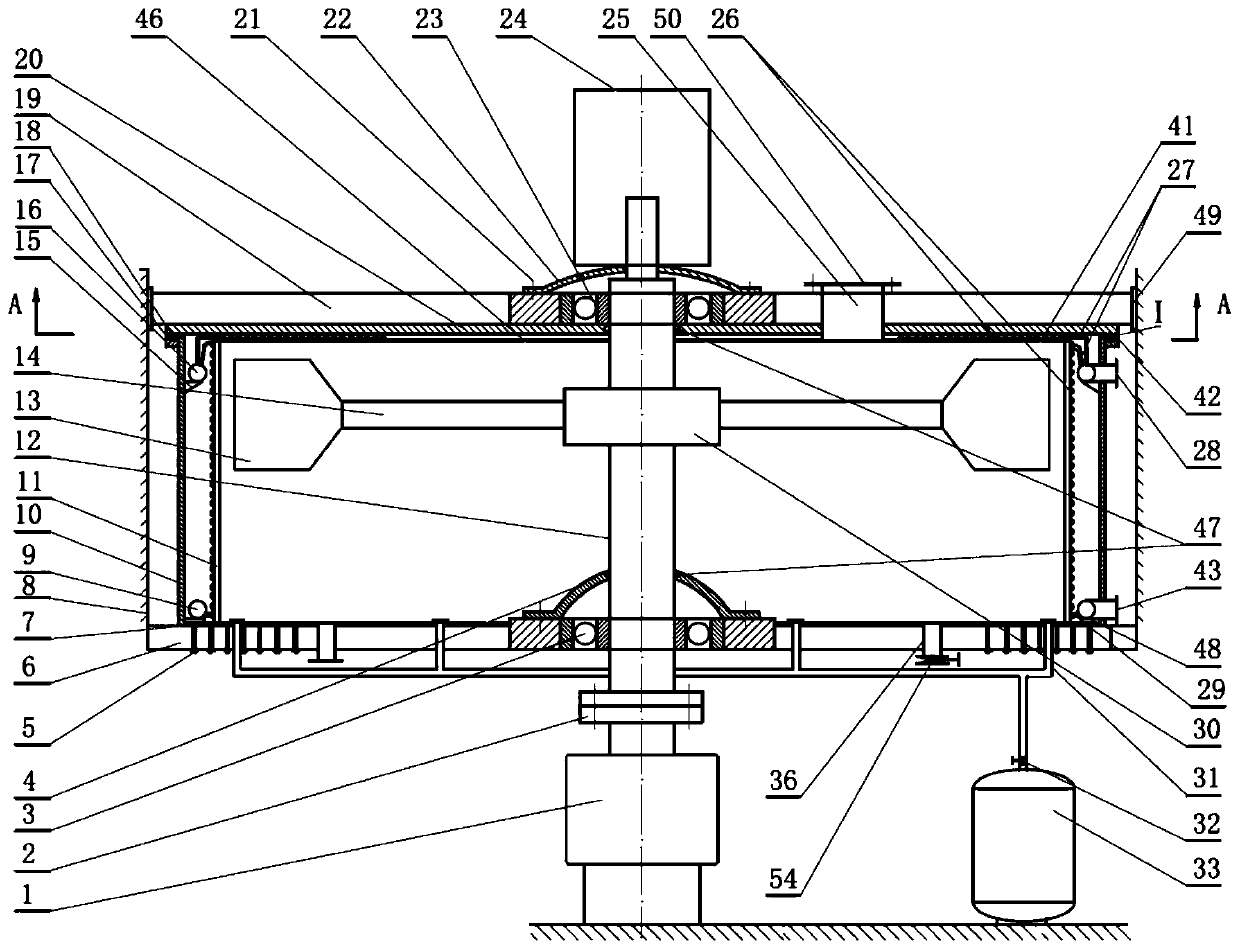

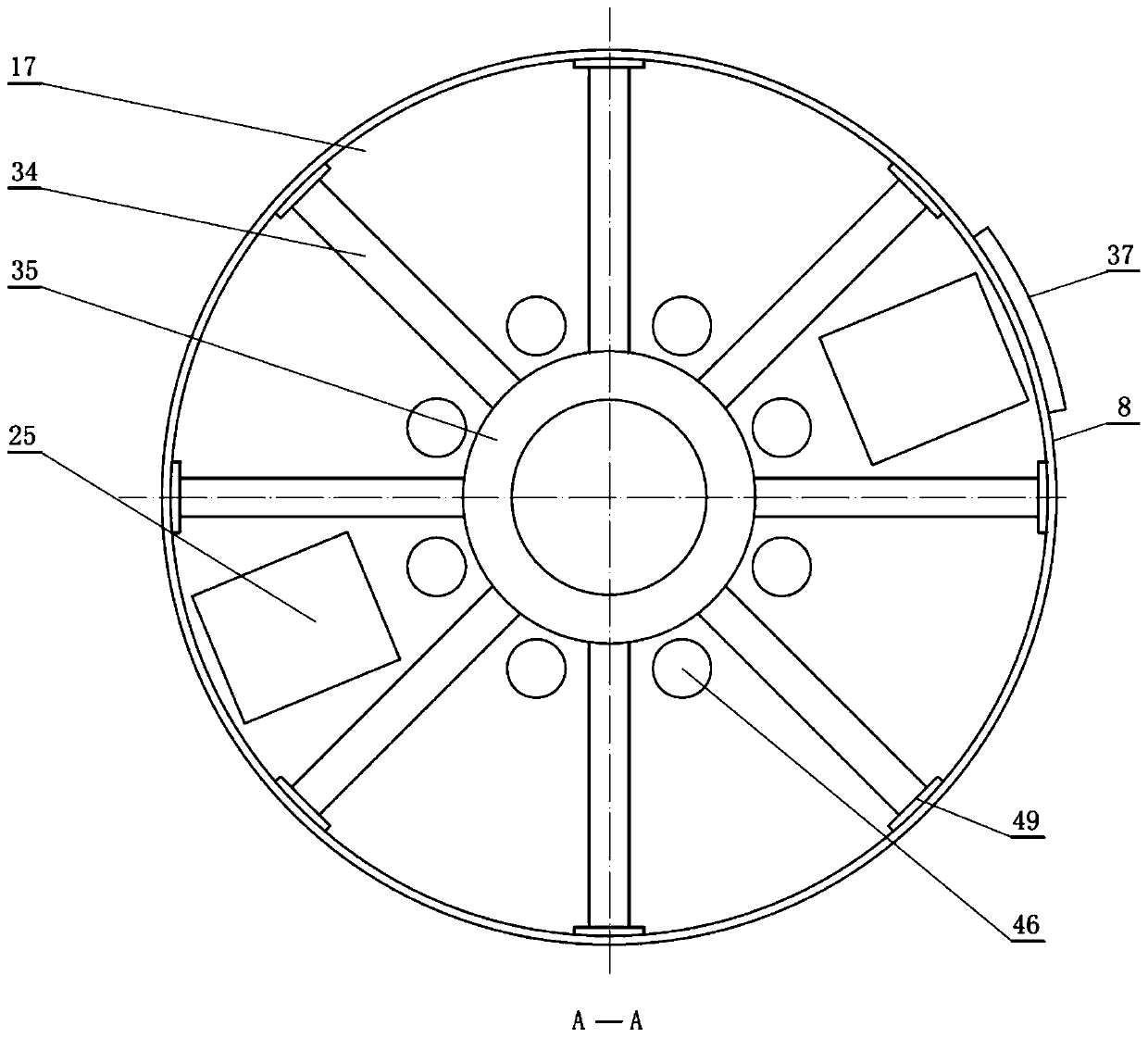

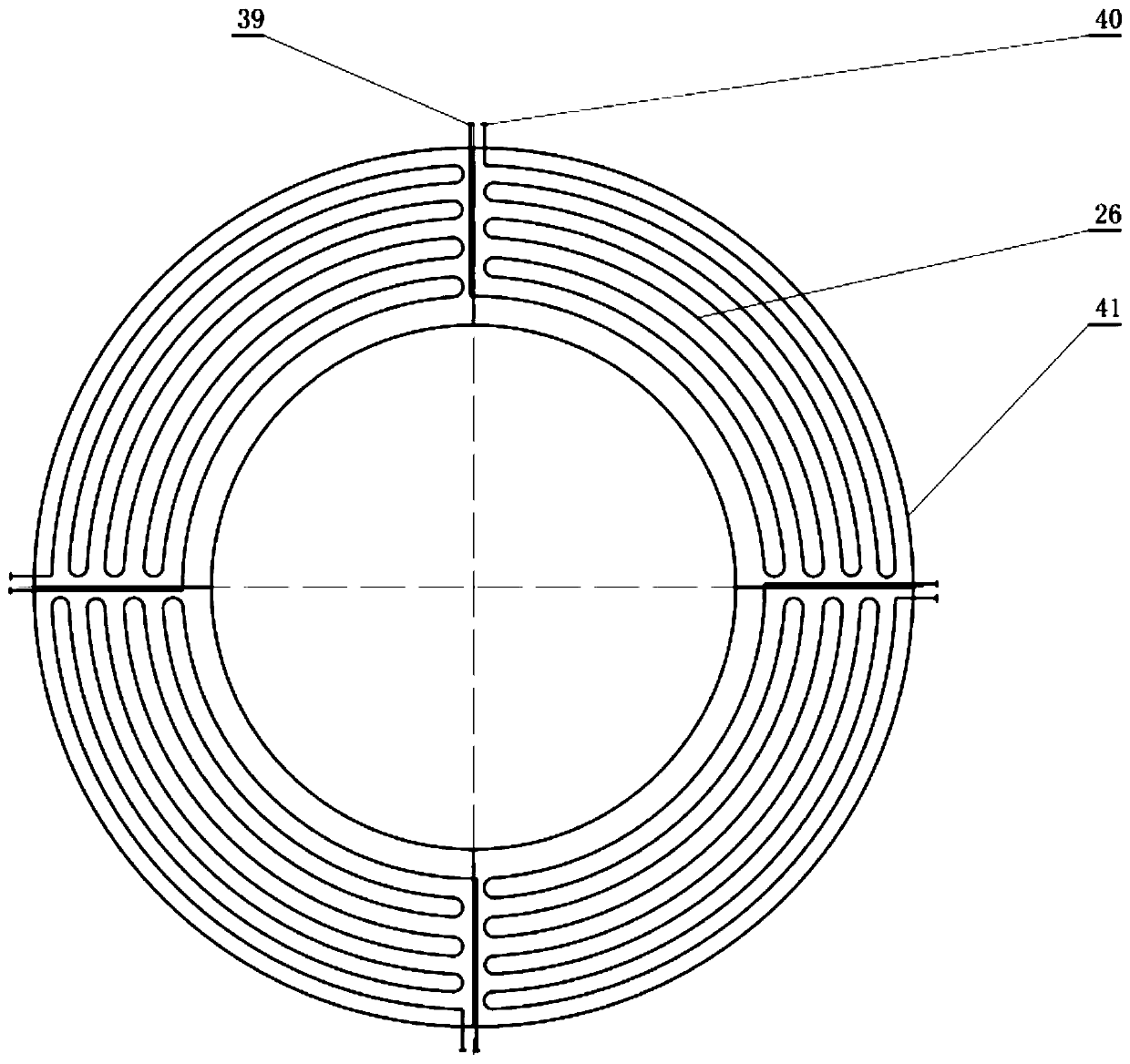

[0046] Such as figure 1 , figure 2 As shown, the present invention includes a cylindrical shell 10, an upper sealing plate 20 with a top semicircular tube cooling plate 41 below, a lower sealing plate 7 and a vibration isolation gasket 18 to form a centrifuge chamber cavity.

[0047] The high-speed rotor system 30 is enclosed in the cavity of the centrifuge chamber. A semi-circular cylindrical cooling device 11 is provided between the inner side of the cylindrical cylinder 10 and the high-speed rotor system 30. The lower end of the main shaft 12 of the high-speed rotor system 30 passes through the lower bearing seal cover. 4 and the lower bearing system 3, extend the lower sealing plate 7, and then connect with the coupling 2 and the motor 1 in turn, the main shaft 12 and the lower bearing sealing cover 4 are sealed by a main shaft dynamic seal; the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com