Patents

Literature

191results about How to "No oil leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

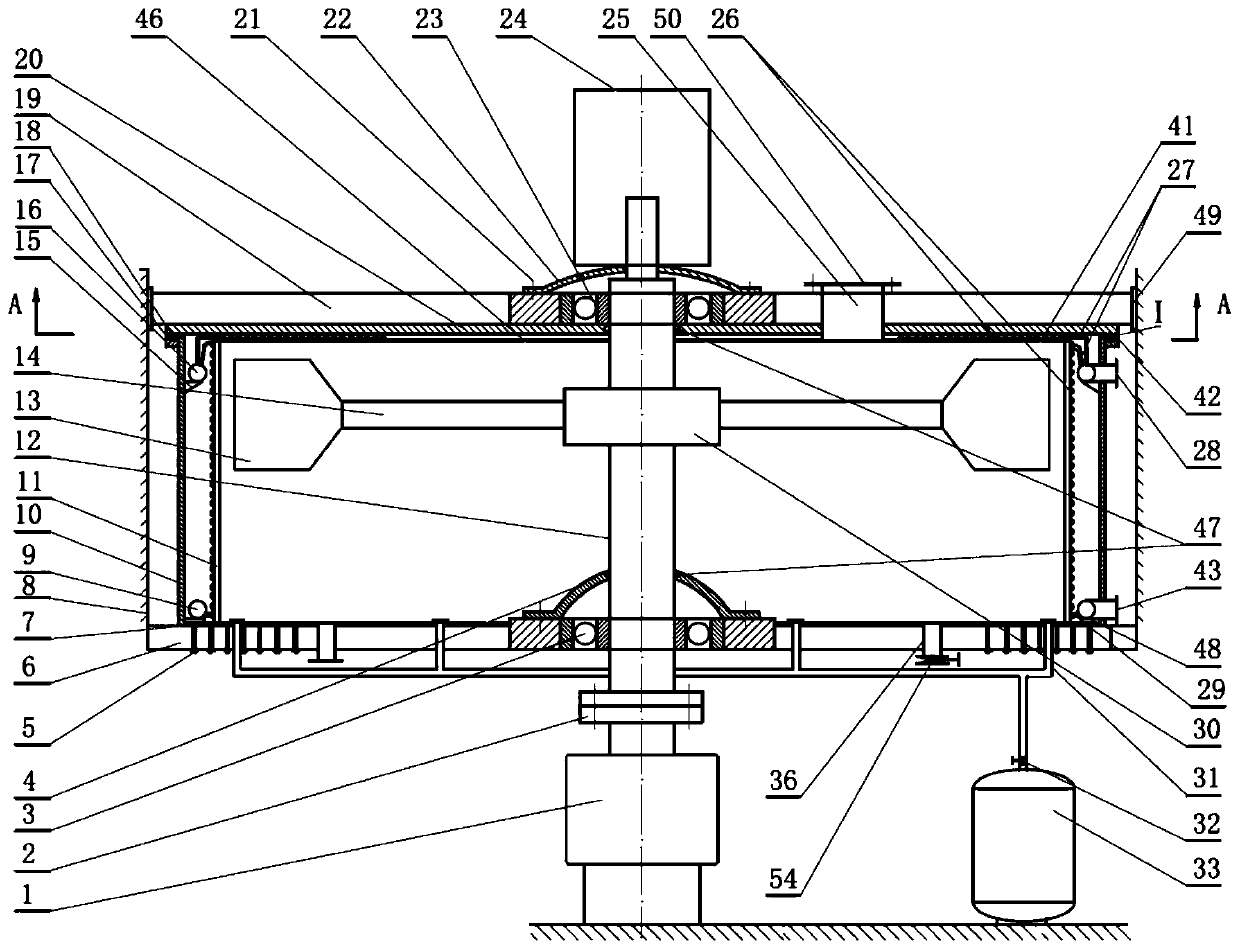

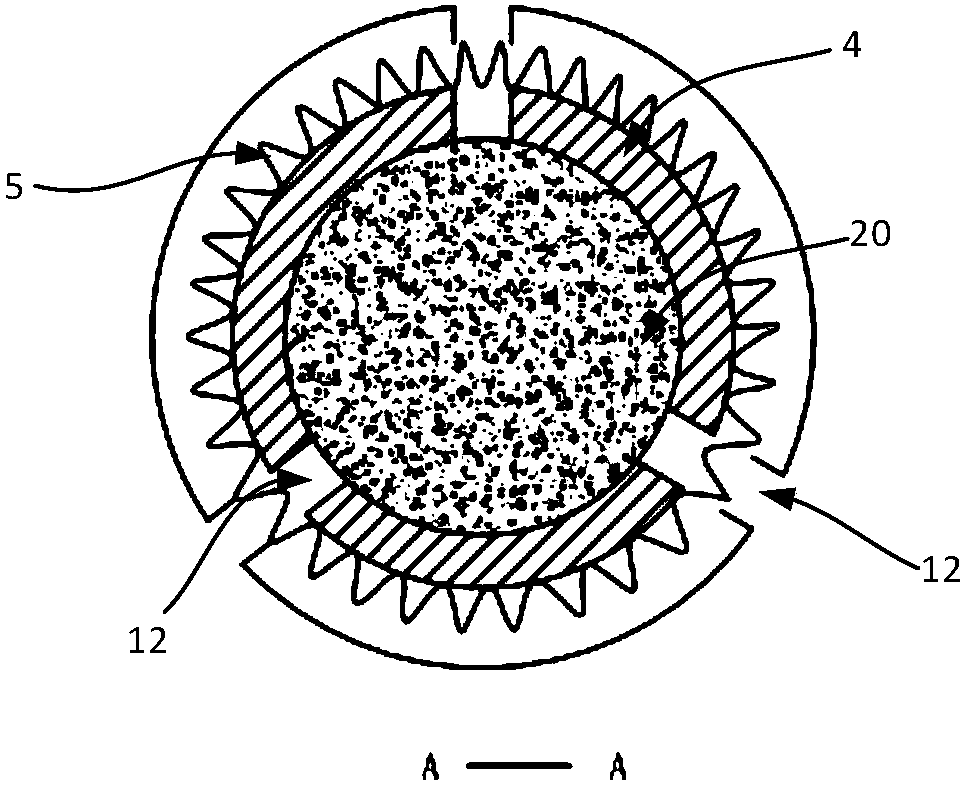

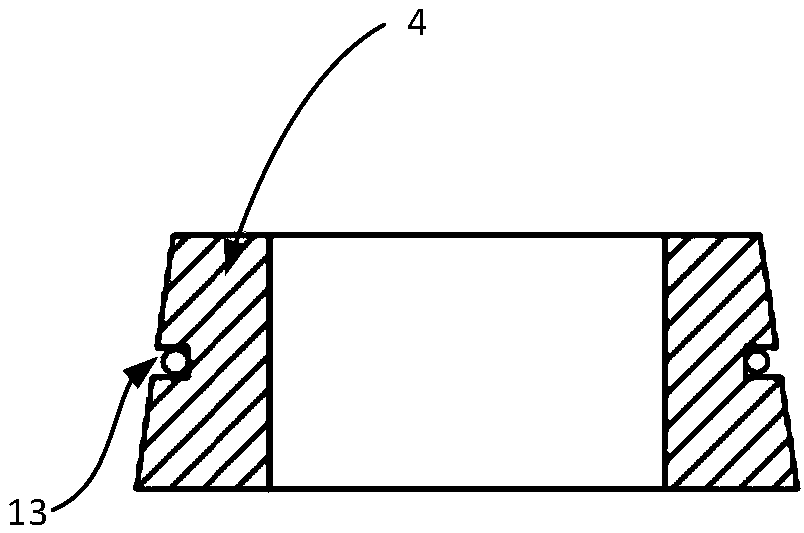

Electrical parameter test system of tri-axial compression gassy coal and rock masses

InactiveCN103105547AStable confining pressureNo oil leakageElectrical testingStructure of the EarthTest sample

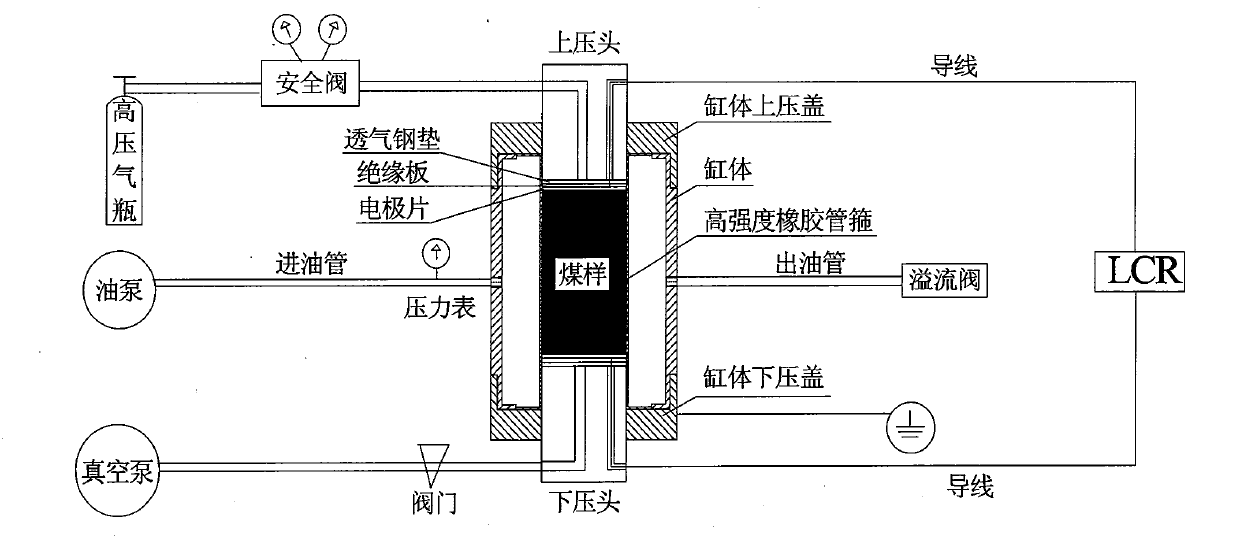

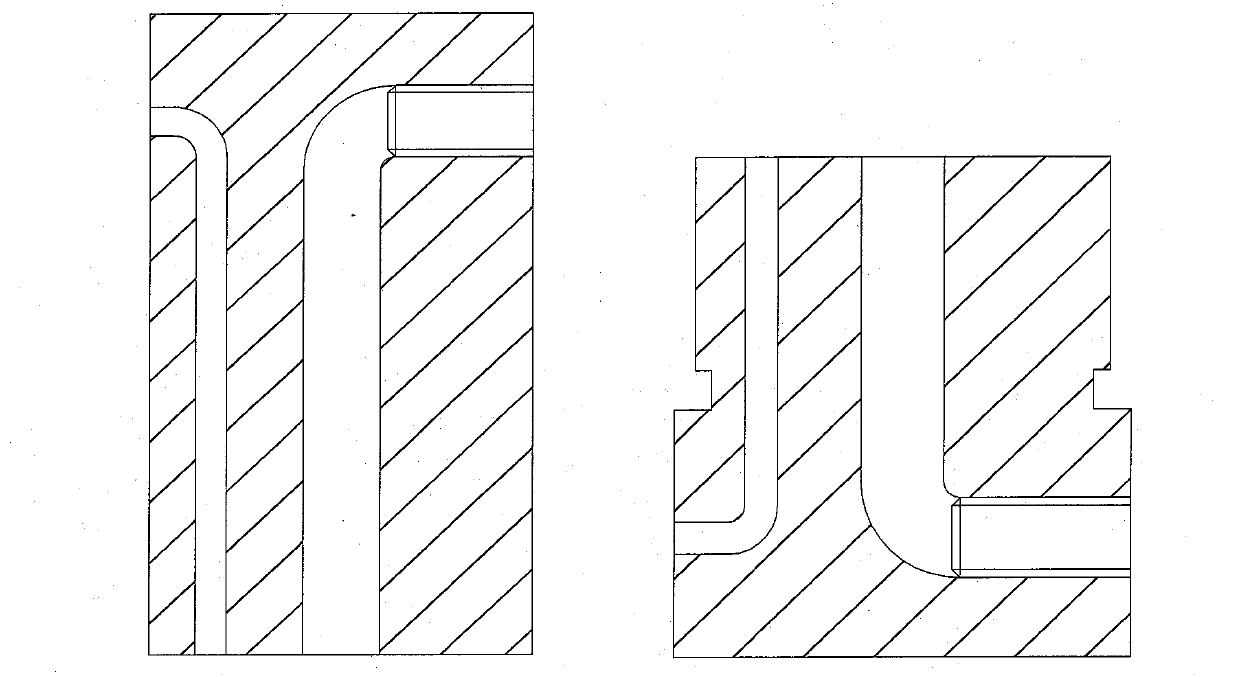

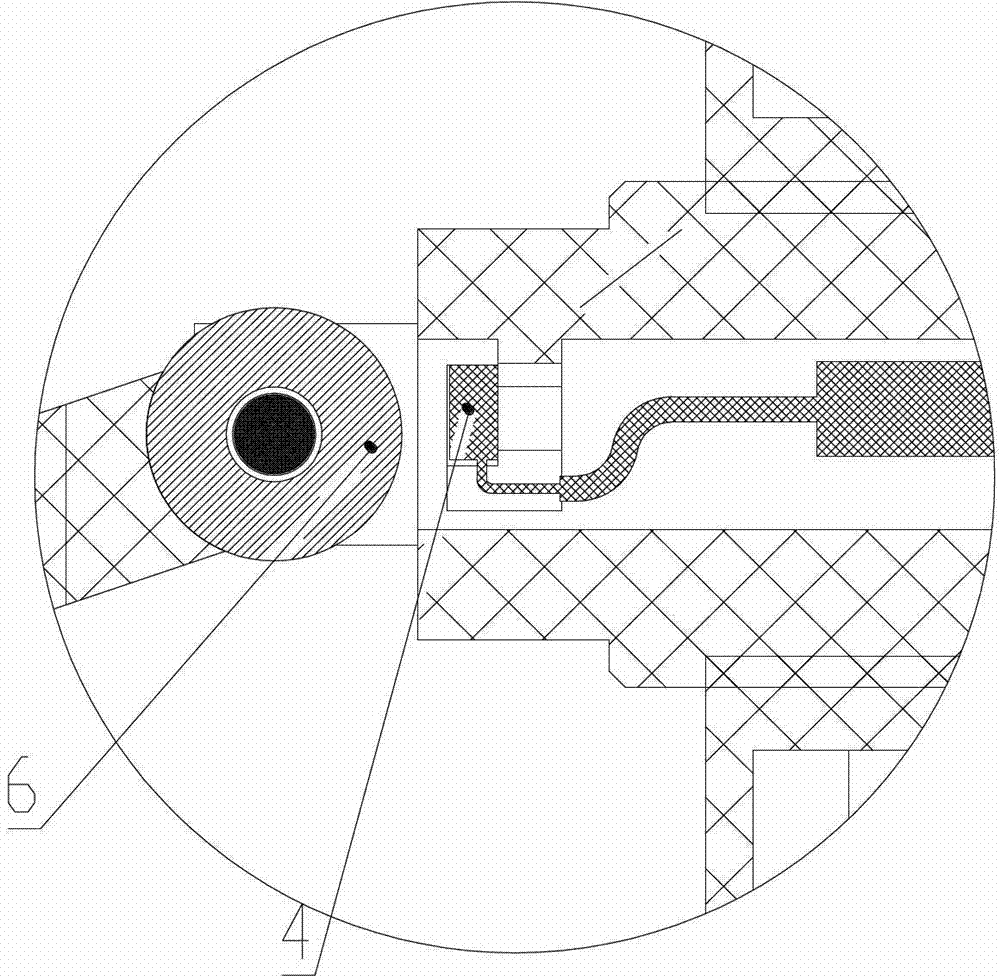

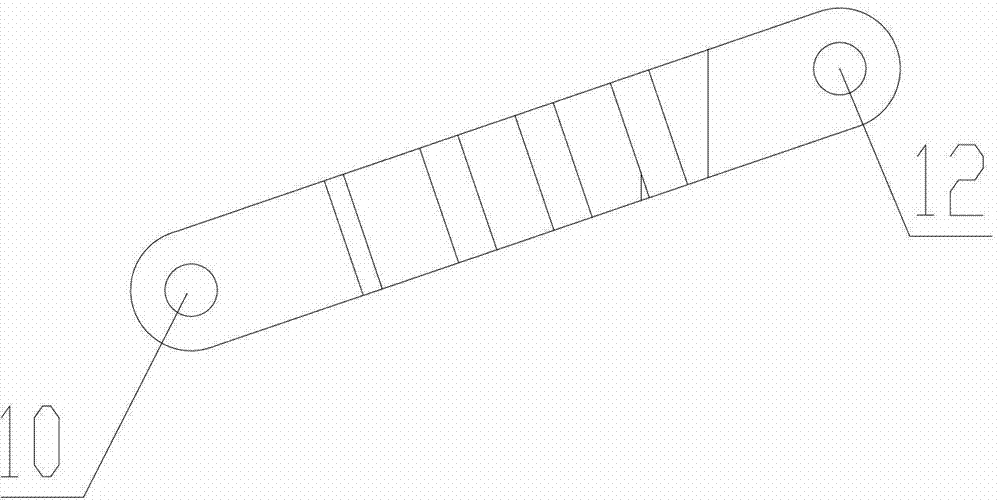

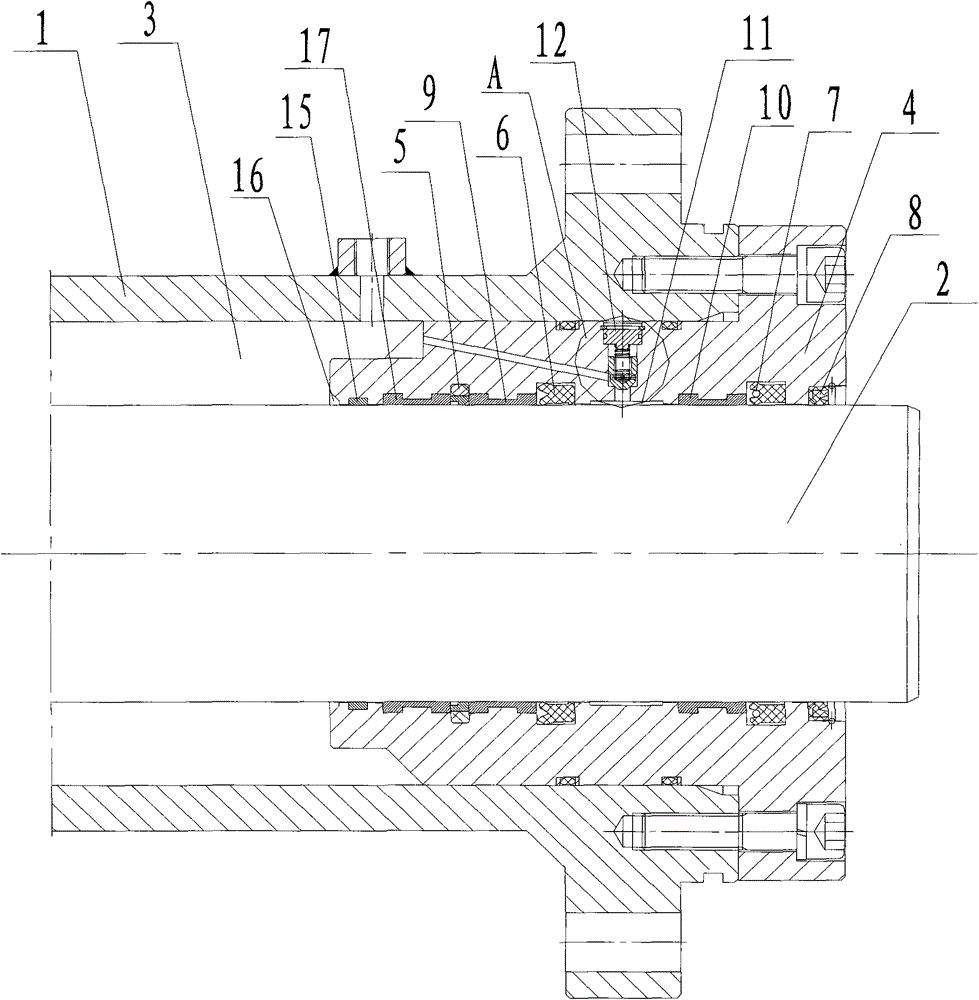

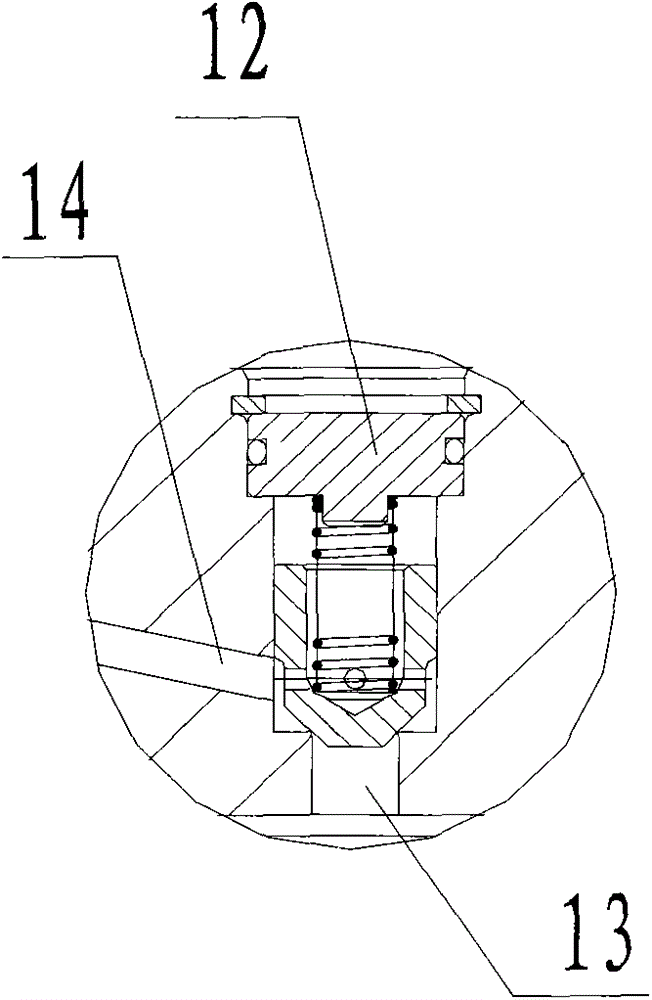

The invention relates to an electrical parameter test system of tri-axial compression gassy coal and rock masses, the problems that the electrical parameters of coal and rock masses in a gassy state can not be detected, seepage of filled gas is uneven in the coal and rock masses, and when confining pressure is loaded, oil leaks in a device, and the pressure can not be stable are effectively solved. The technical scheme is that a sealing cylinder is added, a rubber sleeve in a special shape serves as the device for separating a test sample and hydraulic oil, when the rubber sleeve bears the confining pressure, two ends of the rubber sleeve expand towards a seal pot cover to play a role in sealing, and the confining pressure is stabilized. A circular steel gasket is added between an insulating plate and a pressure head, one face of the gasket is in a concave shape, a row of small holes are formed in the gasket at intervals of each 45 degrees, the small holes are evenly distributed in the whole circular gasket, the circular gasket is used for distributing gas evenly on the end face of the test sample and enabling the gas to permeate the test sample evenly along with the filling of the gas. The electrical parameter test system of the tri-axial compression gassy coal and rock masses is simple and novel in structure and easy to manufacture, the used rubber sleeve is durable and convenient to use, and good in sealing effect and is a major innovation of various parameter and the property test of loaded gassy coals, and the effect is significant.

Owner:HENAN POLYTECHNIC UNIV

Silicone gel composition

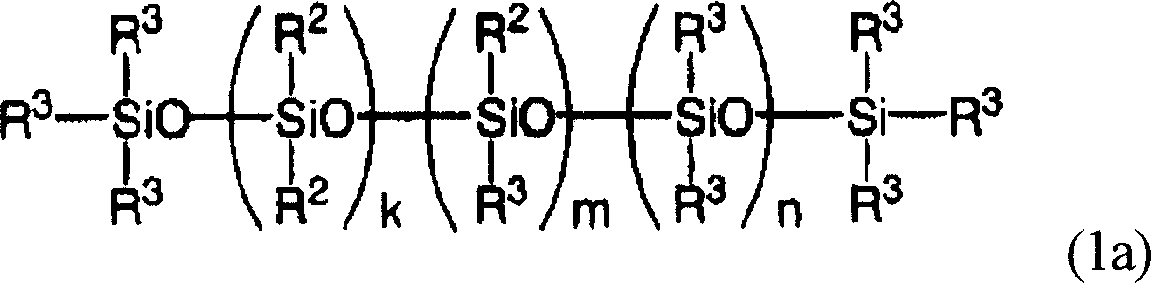

Provided is a silicone gel composition including (A) an organopolysiloxane containing at least one alkenyl group bonded to a silicon atom within each molecule, represented by an average composition formula: Ra R1b SiO(4-a-b) / 2 (wherein, each R group represents, independently, an alkenyl group, each R1 group represents, independently, an unsubstituted or substituted monovalent hydrocarbon group that contains no aliphatic unsaturated bonds, a represents a positive number from 0.0001 to 0.2, b represents a positive number from 1.7 to 2.2, and a+b represents a number within a range from 1.9 to 2.4), (B) an organohydrogenpolysiloxane containing at least two hydrogen atoms bonded to silicon atoms within each molecule, and (C) a platinum-based catalyst. Also provided is the silicone gel composition stated above, in which a penetration value of a cured product of this composition, as defined in JIS K2220, is within a range from 20 to 200. The silicone gel composition generates a silicone gel cured product which displays a low elastic modulus and low stress, and suffers no oil bleeding over time.

Owner:SHIN ETSU CHEM CO LTD

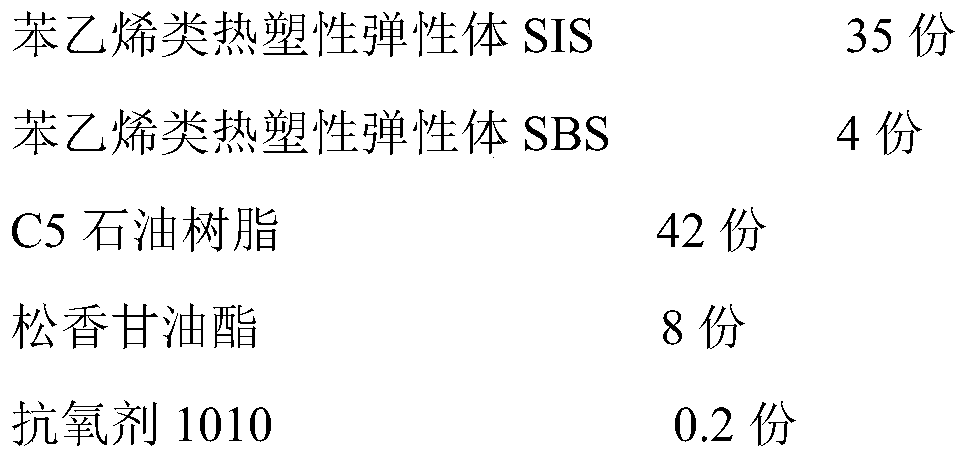

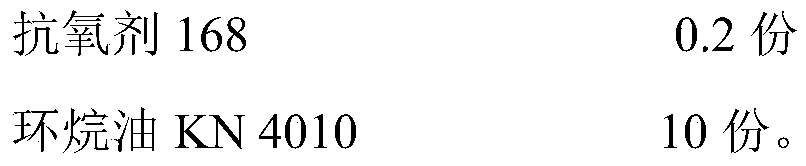

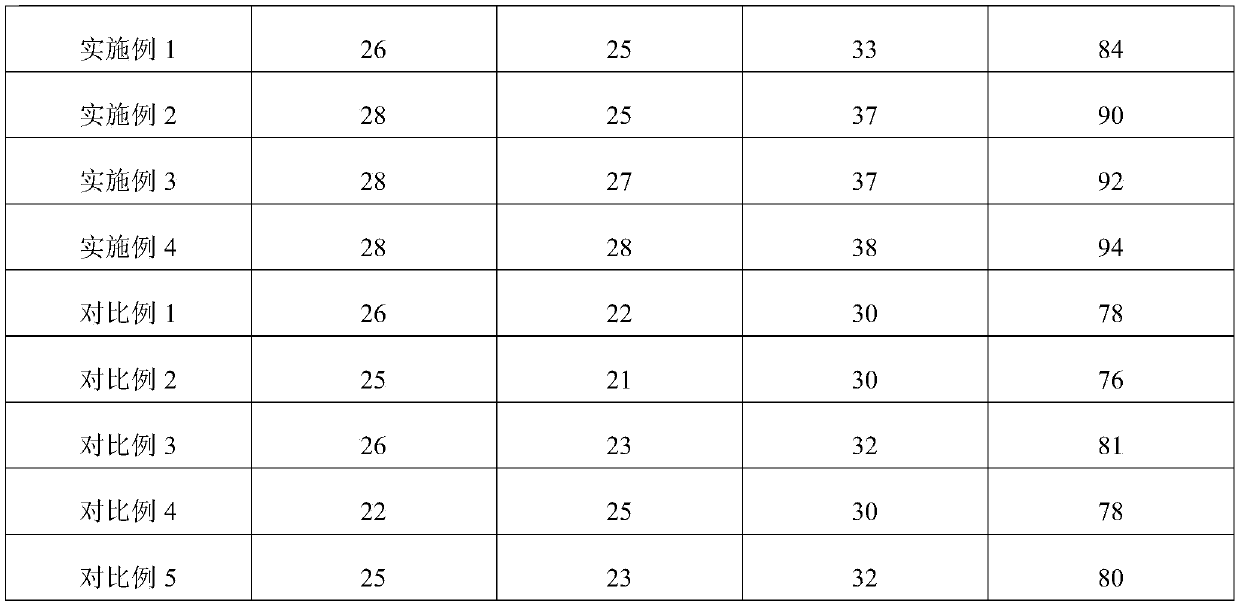

Hot-melt pressure sensitive adhesive for adhesive tapes, and preparation method thereof

InactiveCN110437778AImprove ring tackImprove peel forceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPetroleum resinAntioxidant

The invention relates to a hot-melt pressure sensitive adhesive, and concretely relates to a hot-melt pressure sensitive adhesive for adhesive tapes, and a preparation method thereof. The hot-melt pressure sensitive adhesive comprises a styrenic thermoplastic elastomer SIS, a styrenic thermoplastic elastomer SBS, petroleum resin, rosin glyceride, a primary antioxidant, an auxiliary antioxidant anda softener, wherein the styrenic thermoplastic elastomer SIS is a linear structure, the styrene content is 20-28%, and the diblock content is 20-28%; and the styrenic thermoplastic elastomer SBS is astar structure, the styrene content is 28-32%, and the diblock content is 12-18%. The purpose of the invention is to solve the problem of poor use performance of the adhesive tapes, caused by failedcombination of the initial adhesion, the permanent adhesion and the aging resistance of existing hot-melt pressure sensitive adhesives for adhesive tapes. The initial adhesion (the initial adhesion includes ring initial adhesion and 180 DEG peel strength) of the hot-melt pressure sensitive adhesive of the invention meets use requirements, and has a high adhesion and a good aging resistance. The present invention also provides the preparation method of the hot-melt pressure sensitive adhesive for adhesive tapes.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

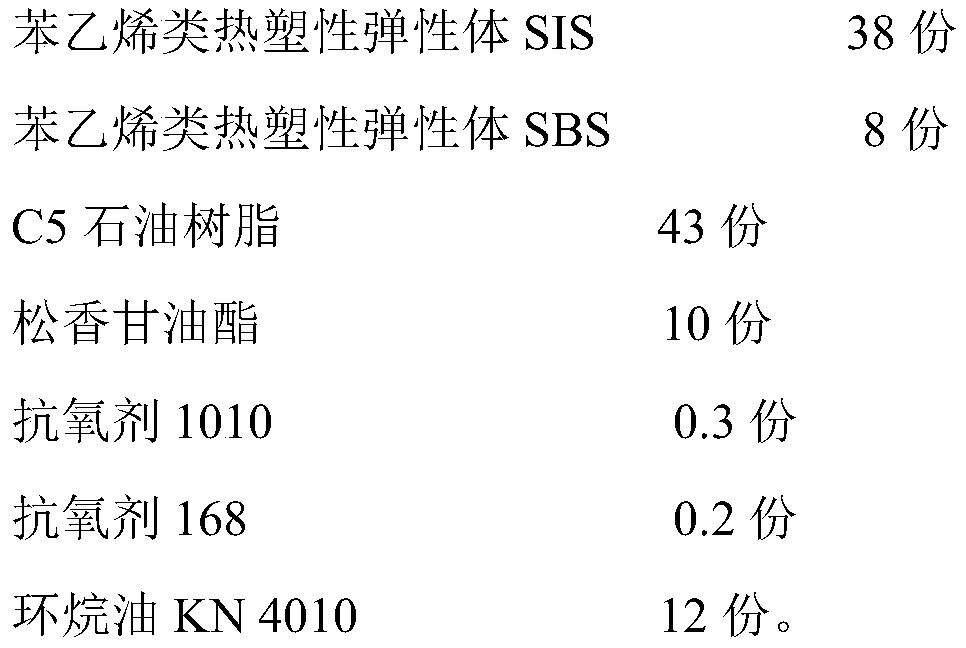

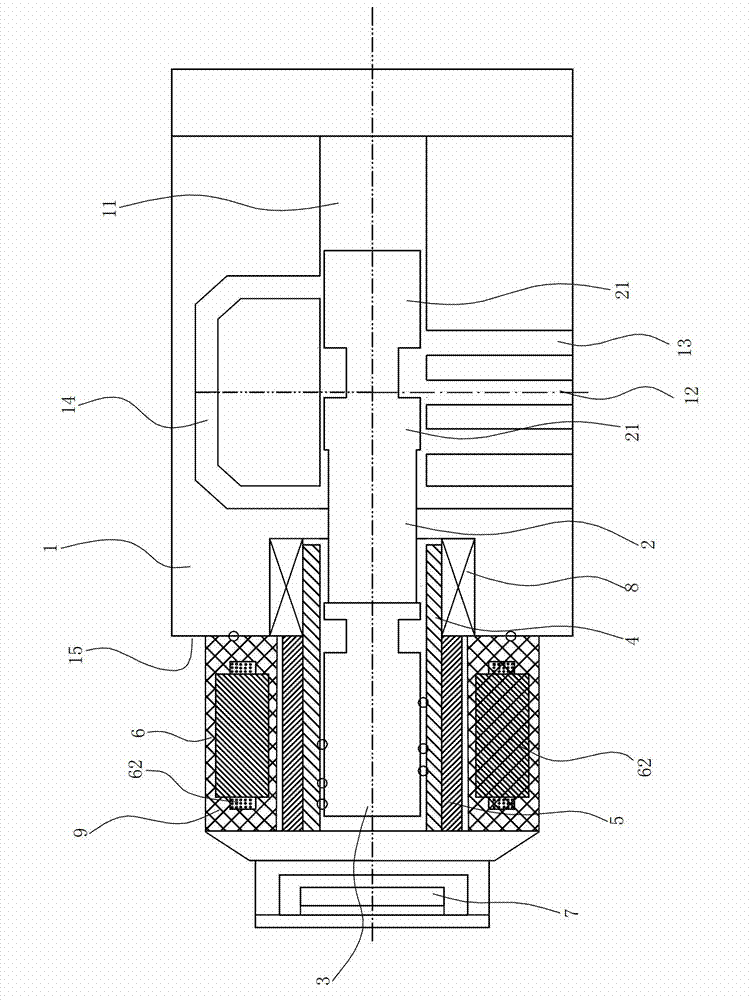

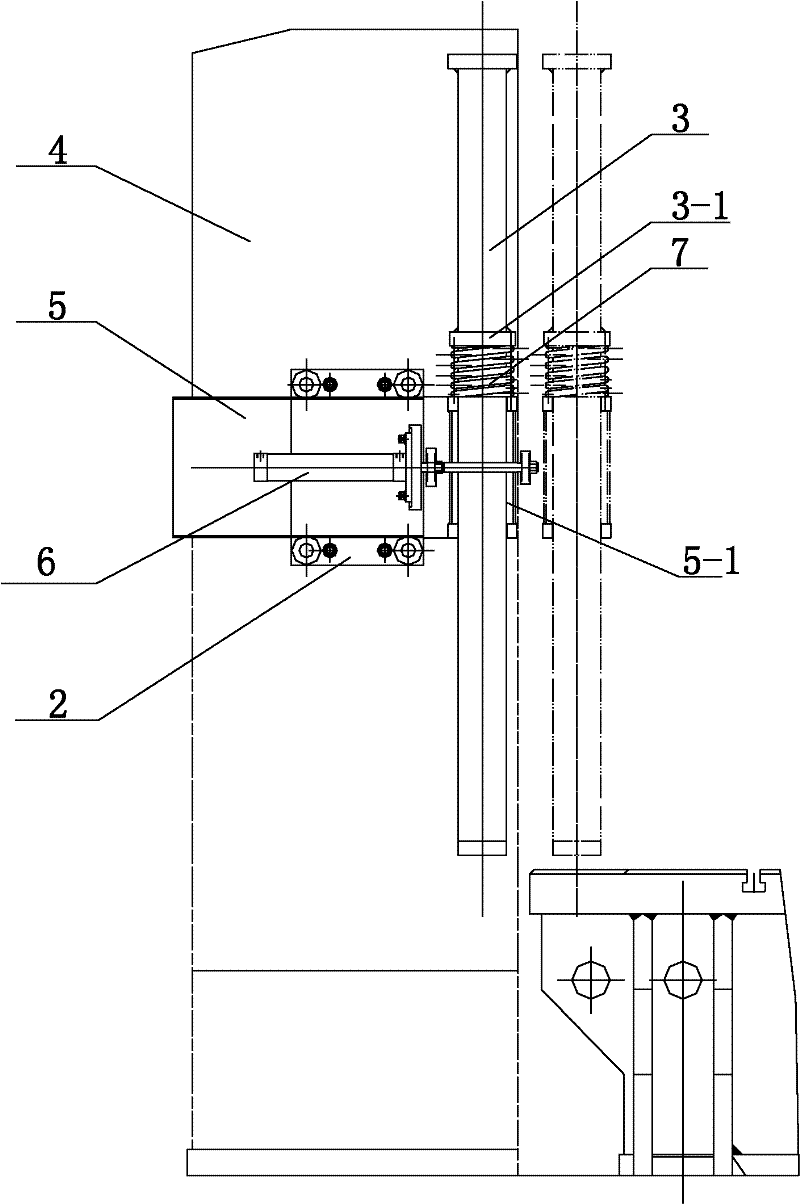

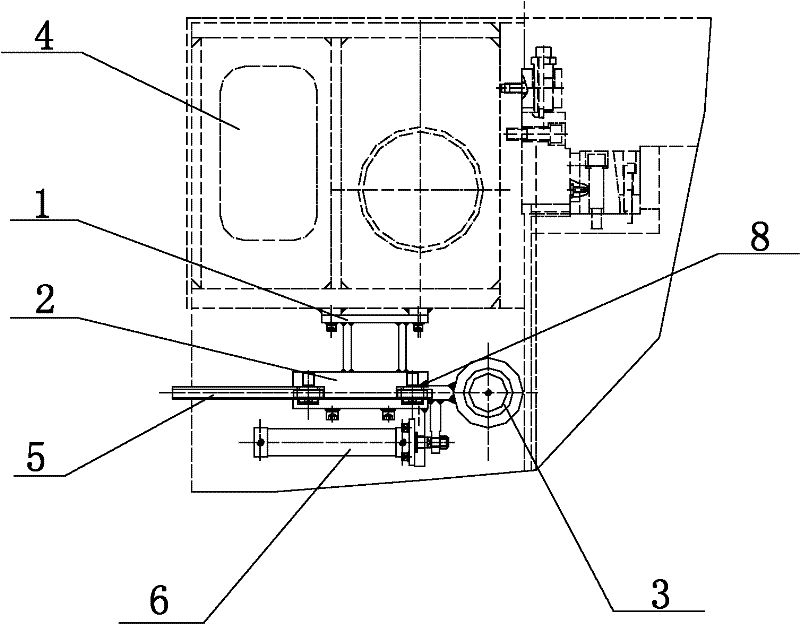

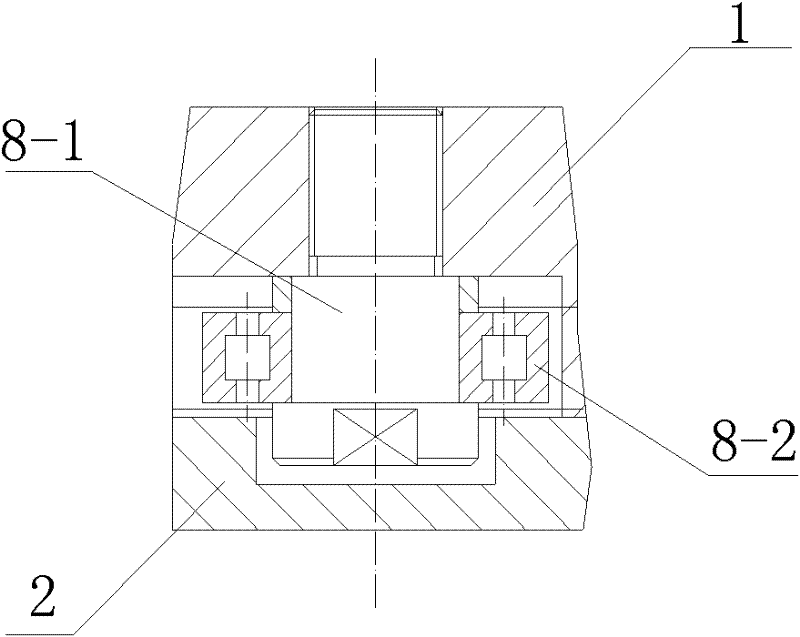

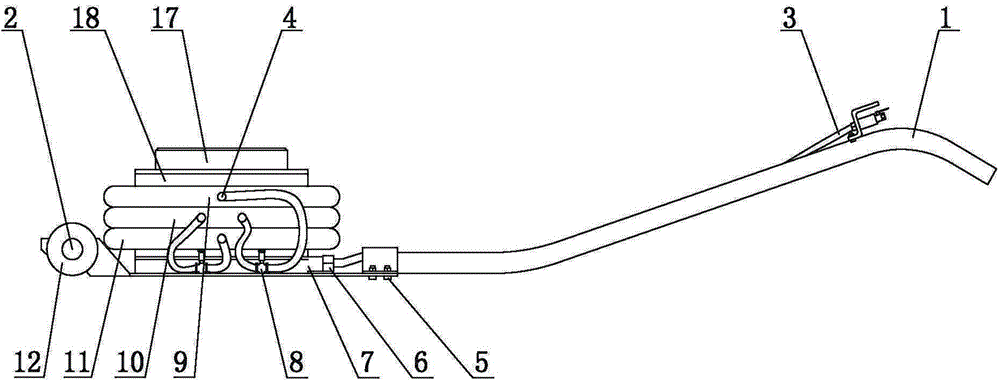

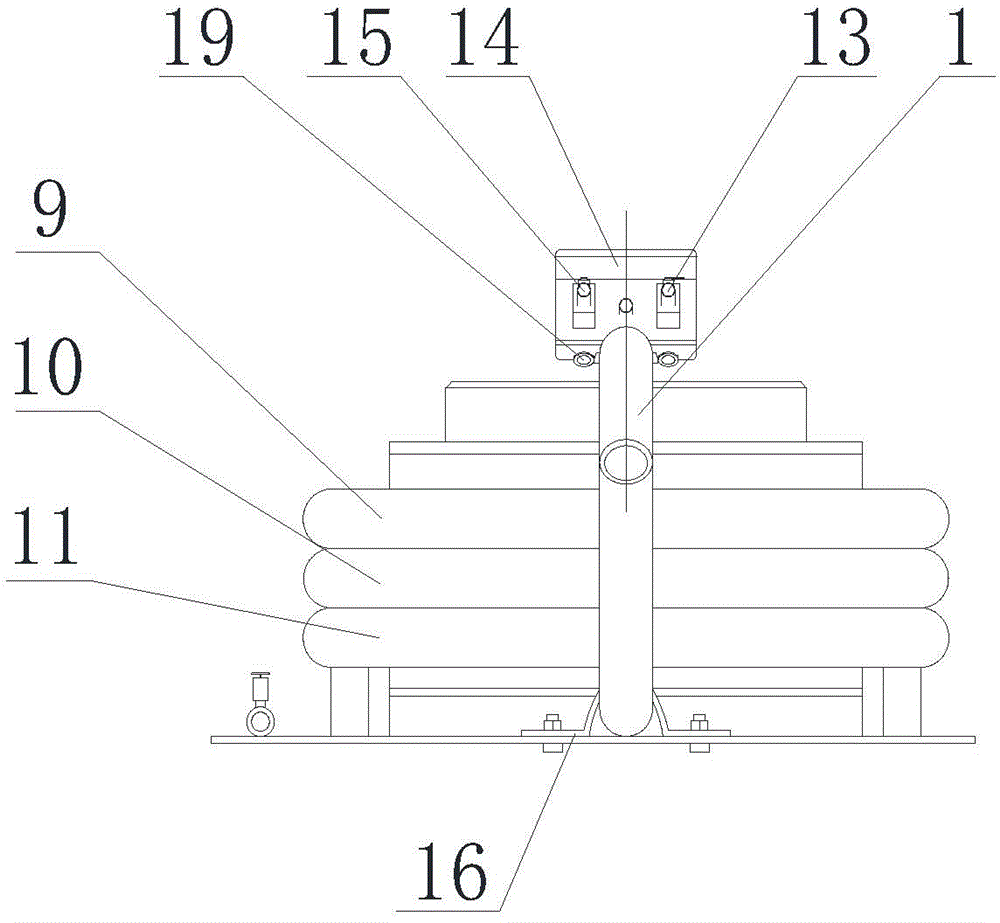

Multi-functional built-in dynamic-static-pressure motorized spindle for efficient high-speed precision machine

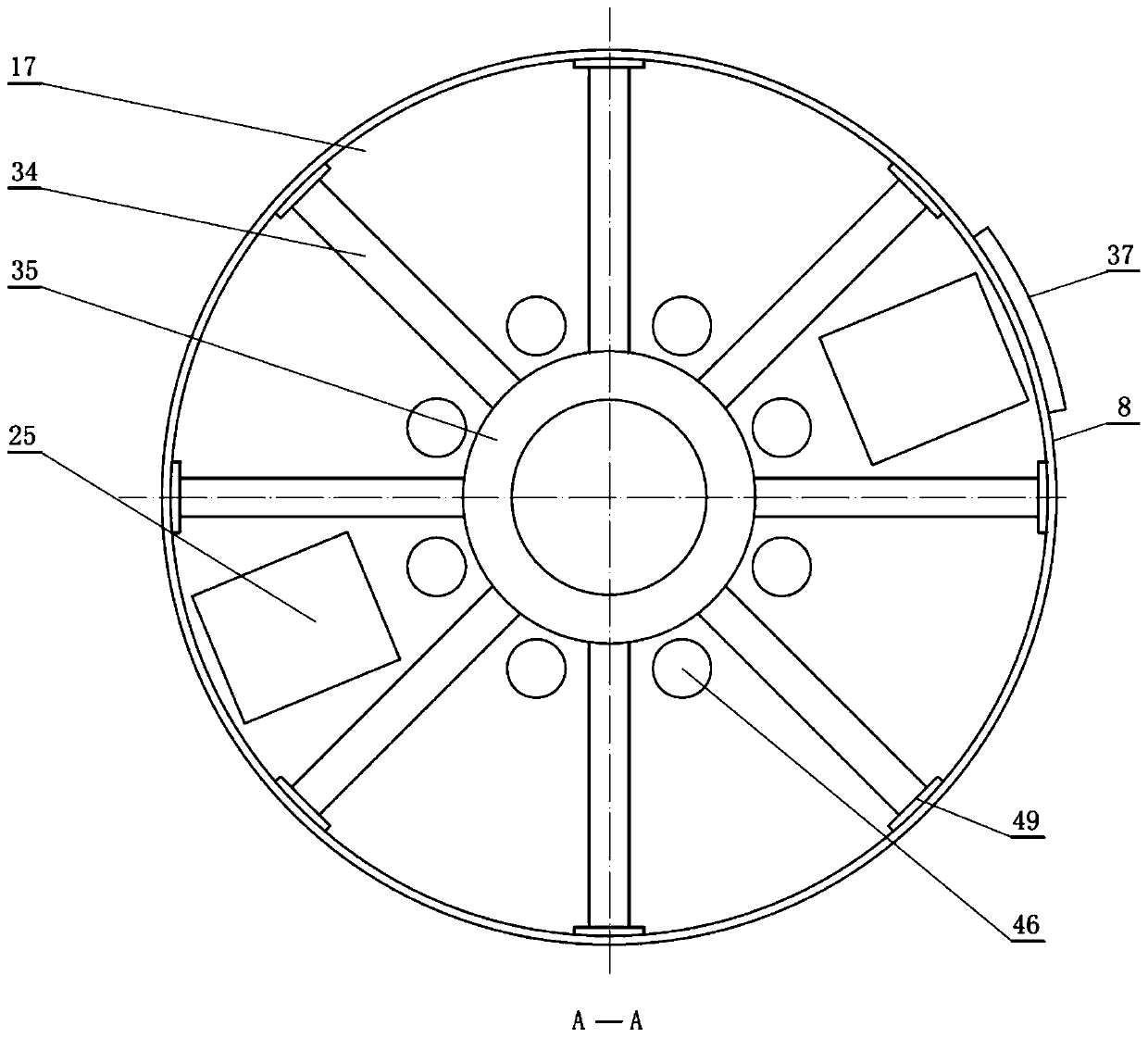

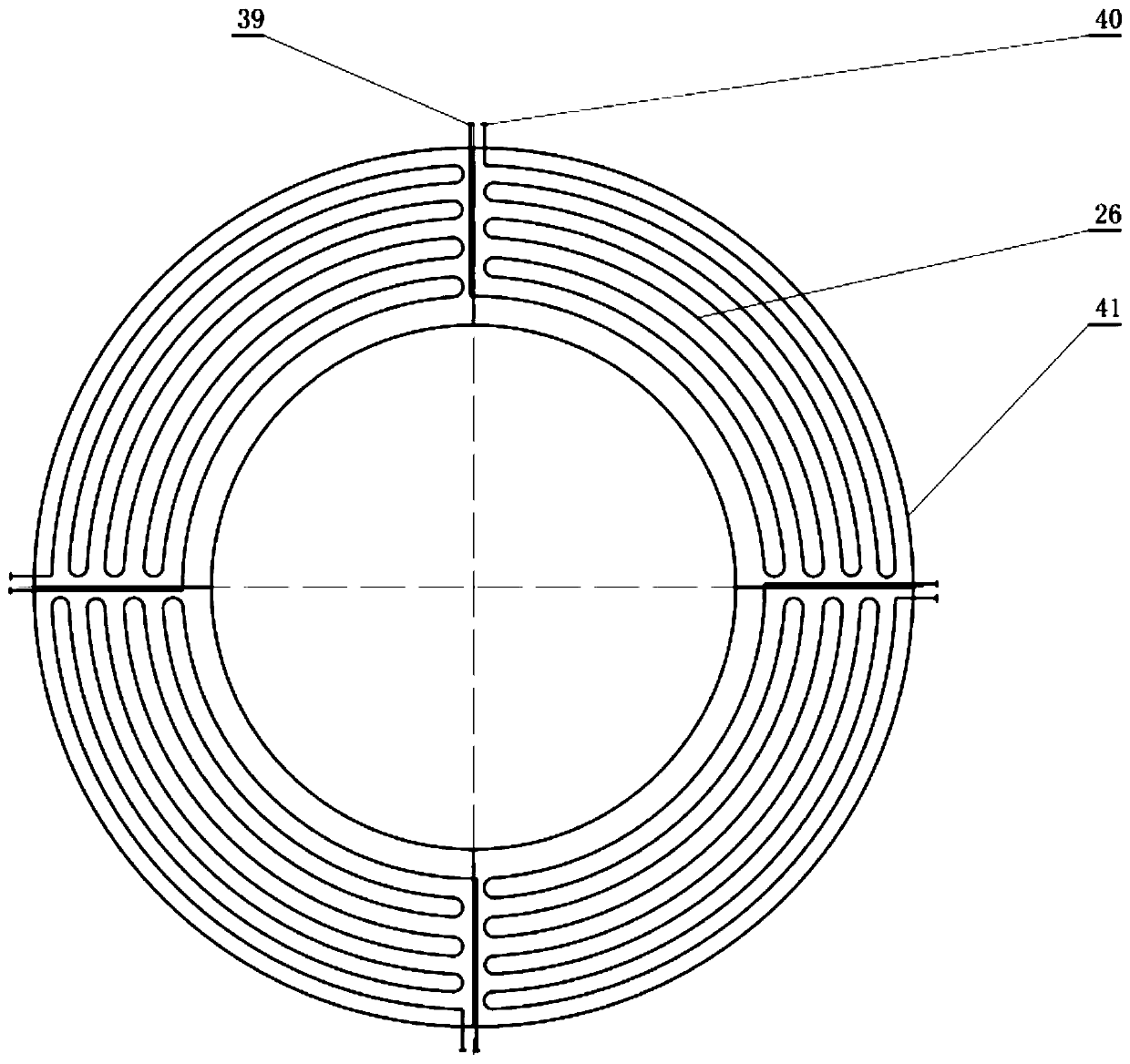

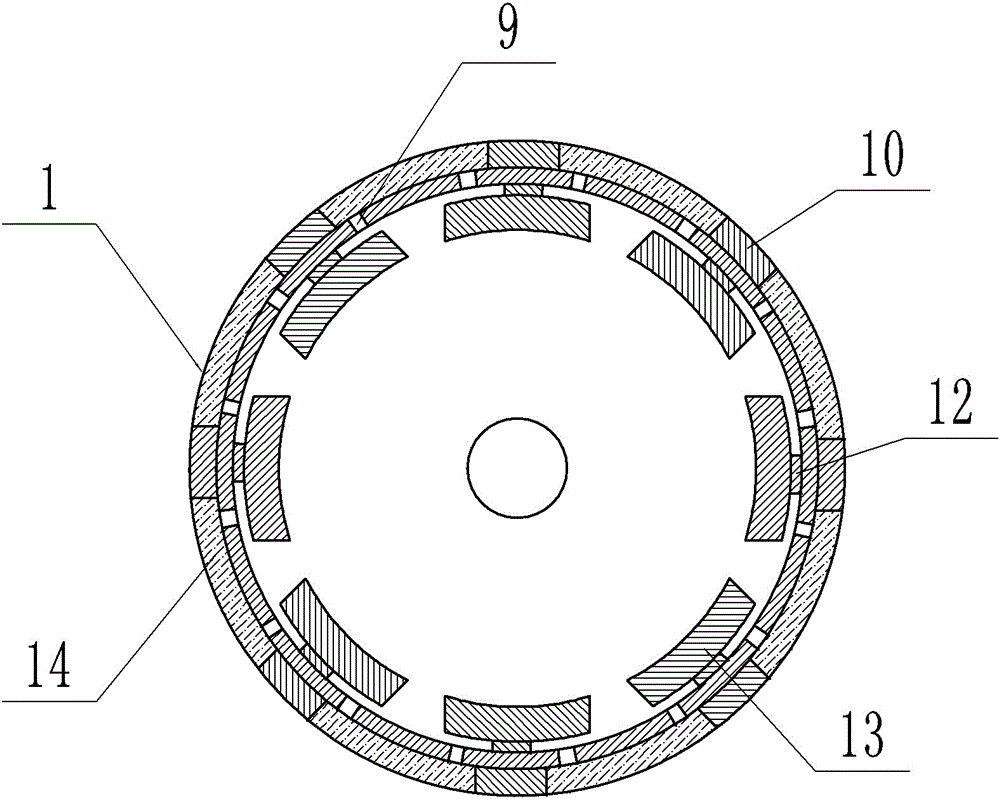

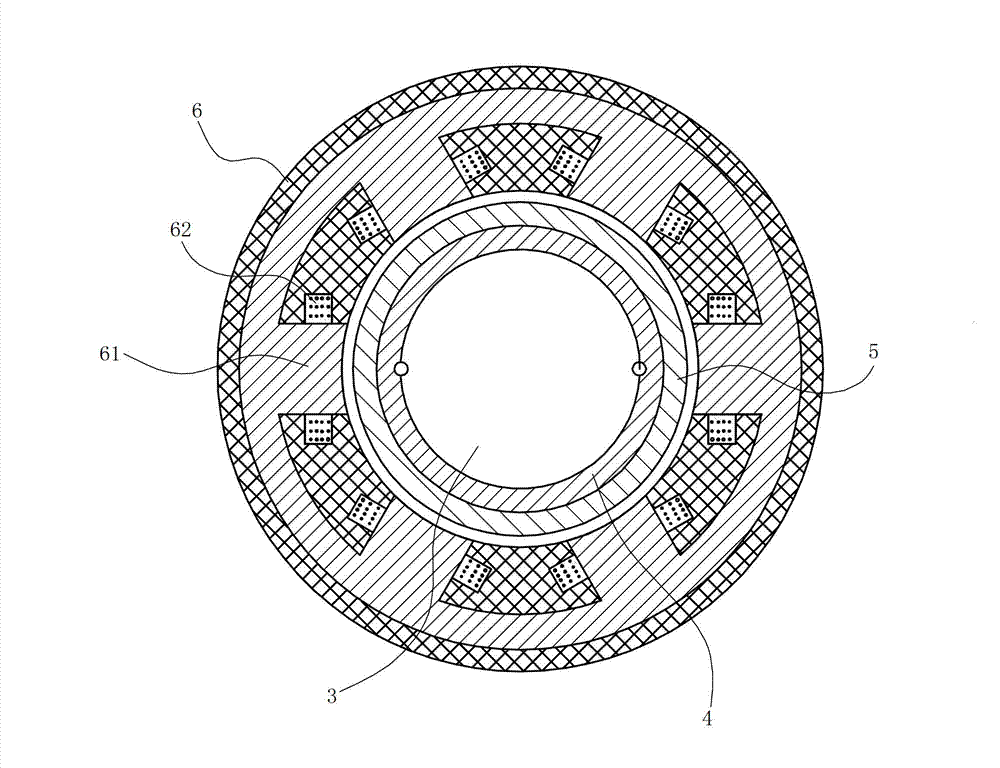

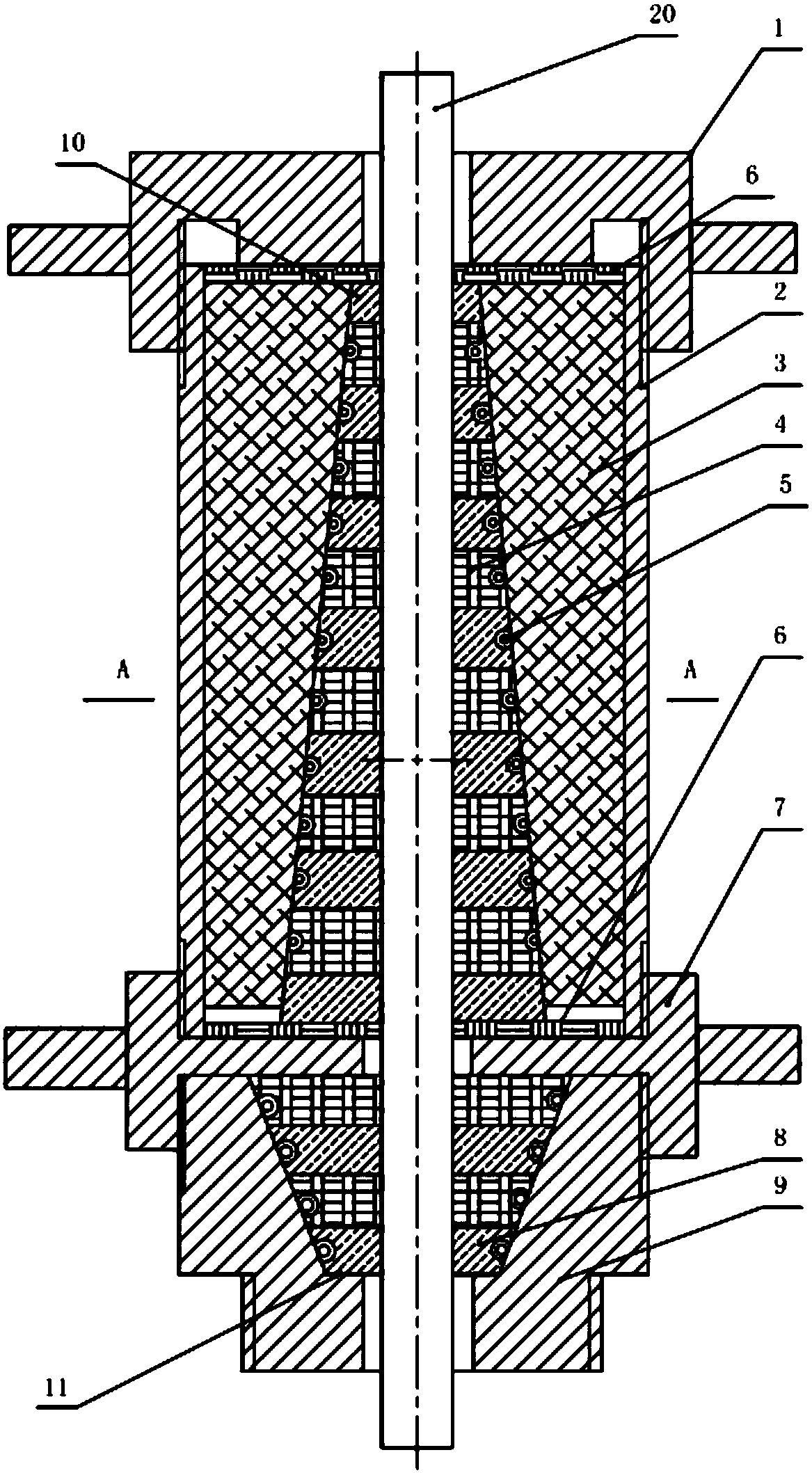

InactiveCN103286678AReduce radiationAvoid Limiting AppsGrinding machine componentsThrust bearingGrinding wheel

The invention relates to a multi-functional built-in dynamic-static-pressure motorized spindle for an efficient high-speed precision machine. The multi-functional built-in moving piezo spindle comprises a shell, a spindle body, a bearing, an oil sealing cover, a motor rotor and a stator. A front bearing is arranged at the right end of the shell and forms a static-pressure push bearing with the spindle. The inner surface of the front bearing is provided with a static-pressure oil cavity, and part of the large diameter of the inner surface matches with a pre-tightening piston. A rear bearing is mounted in a rear-bearing seat. The motor rotor is arranged between the front bearing and the rear bearing. The outer cylindrical face of the motor stator matches with a water sleeve tightly. The water sleeve matches with a hole in the middle of the shell and is connected to the shell. The rear bearing is sealed through a gas sealing ring, and the front bearing is sealed through the oil sealing cover and a gas sealing hole at the rear end. Heat shielding devices are arranged at two ends of the motor stator. The spindle can be mounted at different positions according to different using conditions. The multi-functional built-in dynamic-static-pressure motorized spindle can serve as a spindle of a grinding wheel of a precision machine, a milling center or a grinding machine or a spindle of a workpiece, and has the advantages of high precision, high rigidity, long service life, fine producing process, good sealing effect and the like.

Owner:上海原创精密机床主轴有限公司

Peony seed oil microcapsule and preparation method of peony seed oil microcapsule

InactiveCN105028706AGood water solubility and stabilityUniform particle sizeEdible oils/fatsEmulsionChemistry

The invention discloses a peony seed oil microcapsule and a preparation method of the peony seed oil microcapsule, and belongs to the technical field of food engineering. The peony seed oil microcapsule comprises a core material phase and a wall material phase. Through being metered by weight parts, the core material phase consists of 10 to 60 parts of peony seed oil and 0.5 to 5 parts of oil soluble emulsifiers; the wall material phase consists of 20 to 75 parts of wall materials, 5 to 50 parts of wall material connecting auxiliary agents, 20 to 150 parts of water, 1 to 8 parts of water-soluble emulsifiers and 0.5 to 5 parts of stabilizers. The pressure emulsification homogenizing is used, so that the particle diameter of an emulsion reaches the nanometer level, so that the particle size of an obtained product is uniform; the reconstitution capacity is good; the solubleness is good; the peony seed oil microcapsule can be dissolved in cold water; no precipitate and no floating object exist in a solution; no floating oil exists after the still standing for 48 hours; the solution can be compounded with other emulsions such as milk; the application range of the peony seed oil is expanded. The peony seed oil microcapsule and the preparation method have the advantages that the process is simple; the production cost is low; the product stability is greatly improved; and the nutrition activity of the peony seed oil is maintained.

Owner:刘进

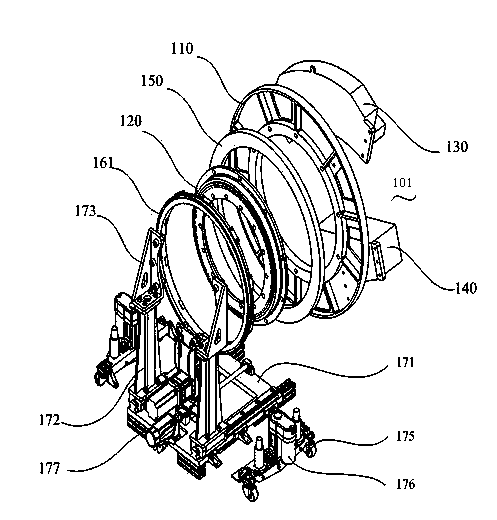

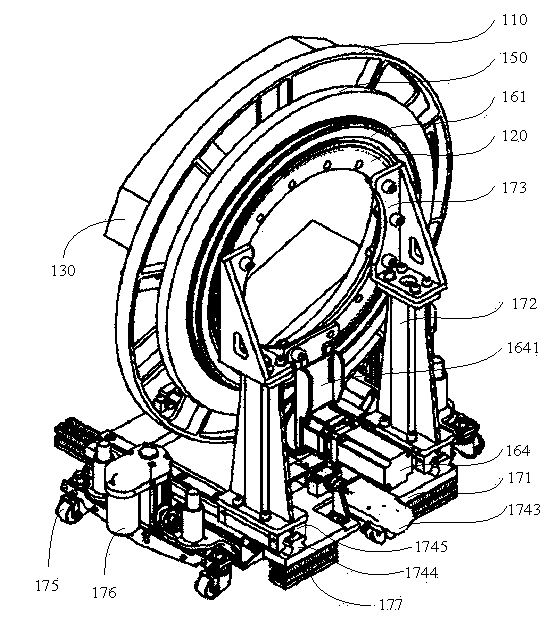

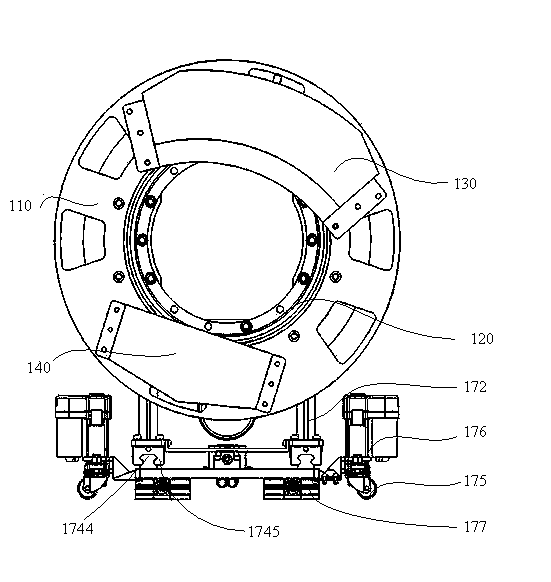

Movable CT machine

InactiveCN103720485AImprove running stabilityImprove image qualityComputerised tomographsTomographyEngineeringMechanical engineering

The invention discloses a movable CT machine which comprises a detector system, a radiation source, a fixing mechanism, a bearing, a rotary plate and a sliding ring. The inner ring of the bearing is fixedly connected with the fixing mechanism, the rotary plate is fixedly connected with the outer ring of the bearing, the detector system and the radiation source are fixed to the rotary plate, the sliding ring is fixed to the rotary plate, and the sliding ring is in signal connection with the detector system. The rotary plate is connected with the outer ring of the bearing, the diameter of the rotary plate is larger than that of the bearing, and therefore the small bearing can be selected, the whole CT machine is more compact in structure, the overall size of the CT machine can be reduced, and the movable CT machine is lighter and more convenient to use.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH +2

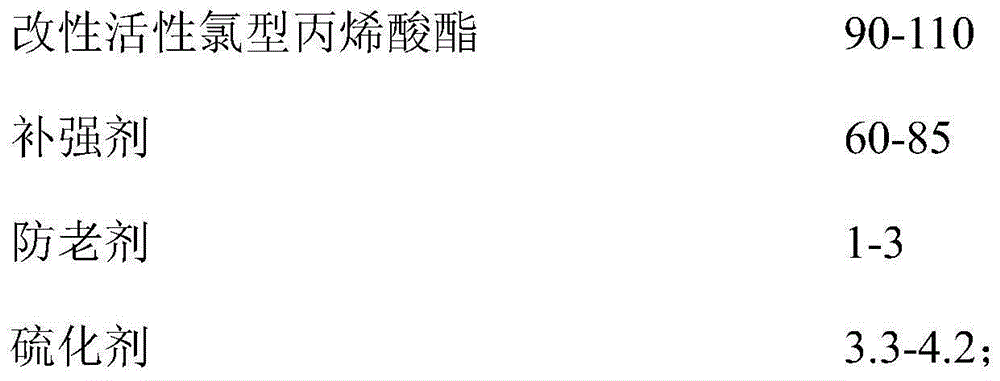

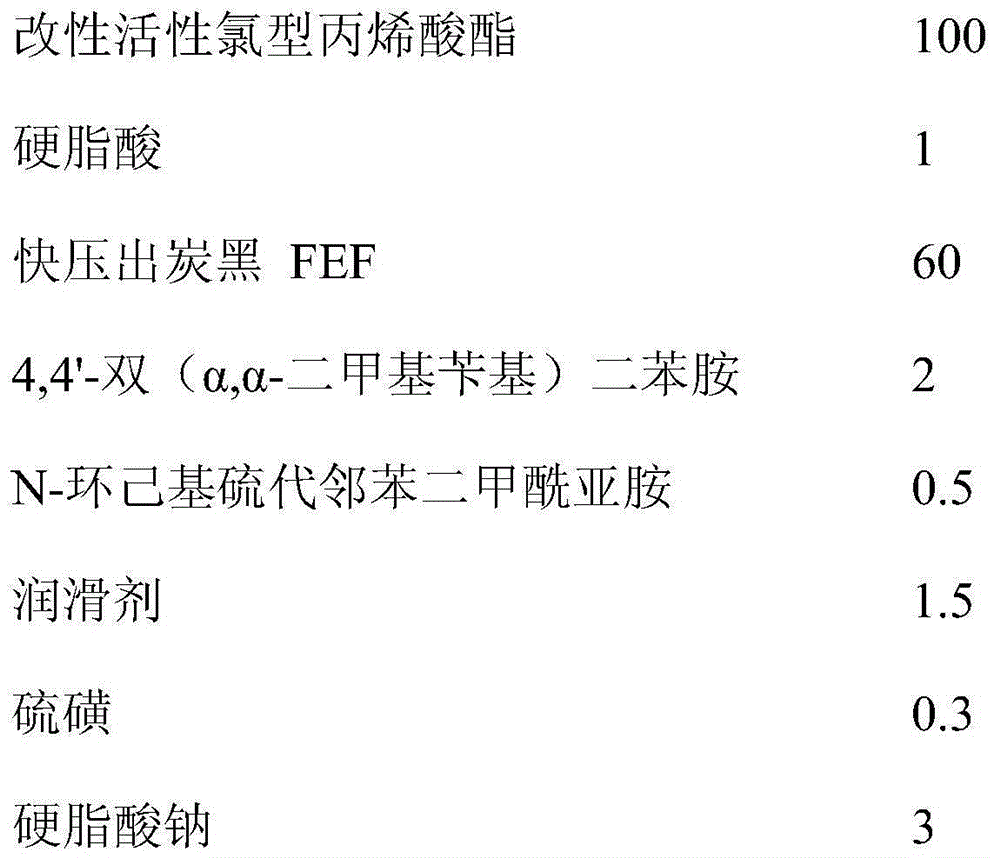

Acrylate rubber material, and preparation method and application thereof

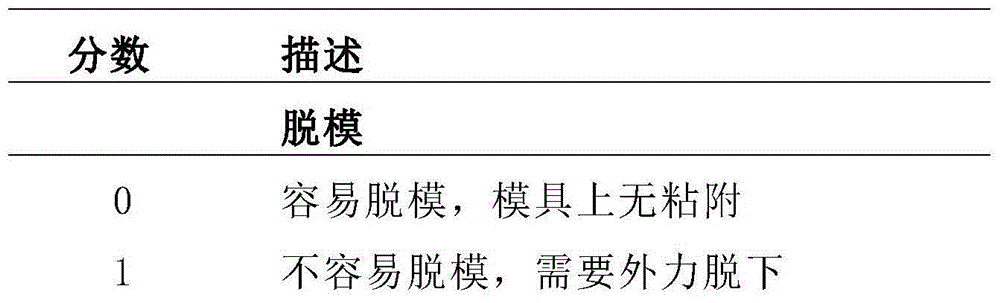

The invention relates to an acrylate rubber material, and a preparation method and application thereof. The acrylate rubber material is prepared from the following raw materials by weight: 90 to 110 parts of modified active chlorine acrylate, 60 to 85 parts of a reinforcing agent, 1 to 3 parts of an anti-aging agent and 3.3 to 4.2 parts of a vulcanizing agent, wherein the acrylate rubber material undergoes secondary vulcanization, and the time of the secondary vulcanization is 6 to 8 h. The acrylate rubber material provided by the invention has excellent processing performance, is easy to demold, has wide temperature application range, can be used at minus 35 to 150 DEG C, has good lubricating oil resistance, small loss of tensile property, small volume change and small compression deformation, meets compression deformation of Volkswagen PV3307, has low cost, and facilitates to popularization and application.

Owner:ANHUI ZHONGDING SEALING PARTS

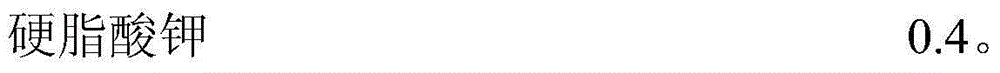

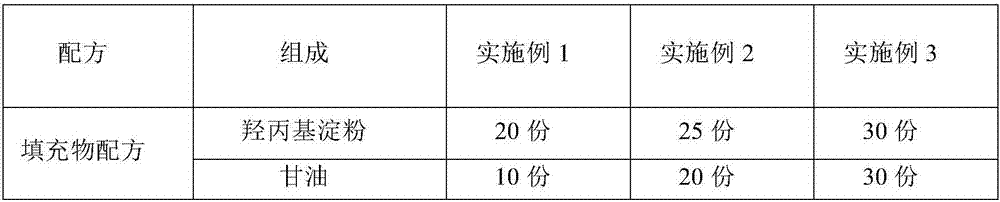

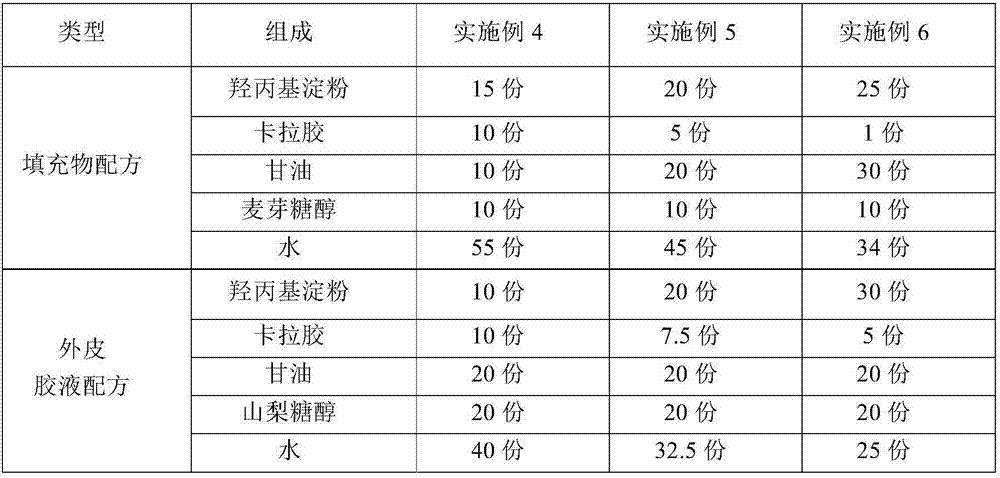

Chewable plant soft capsule and preparation method thereof

InactiveCN107375229AImprove heat stabilityAvoid the problem of too much resiliencePharmaceutical non-active ingredientsCapsule deliveryGellan gumCarrageenan

The invention discloses a chewable plant soft capsule. The plant soft capsule comprises a filler (i) and a shuck (ii); the filler comprises a first gelatinizer, a first elasticizer and water, wherein the first gelatinizer is chosen from one or several of carrageenan, gellan gum and modified starch; and the filler is encapsulated in the shuck, and the shuck comprises a second gelatinizer, a second elasticizer and water. The sources of the chewable plant soft capsule are plant sources, and the chewable plant soft capsule has good heat stability and is suitable for being chewed and good in mouthfeel. The invention further discloses a preparation method of the chewable plant soft capsule.

Owner:SIRIO PHARMA CO LTD

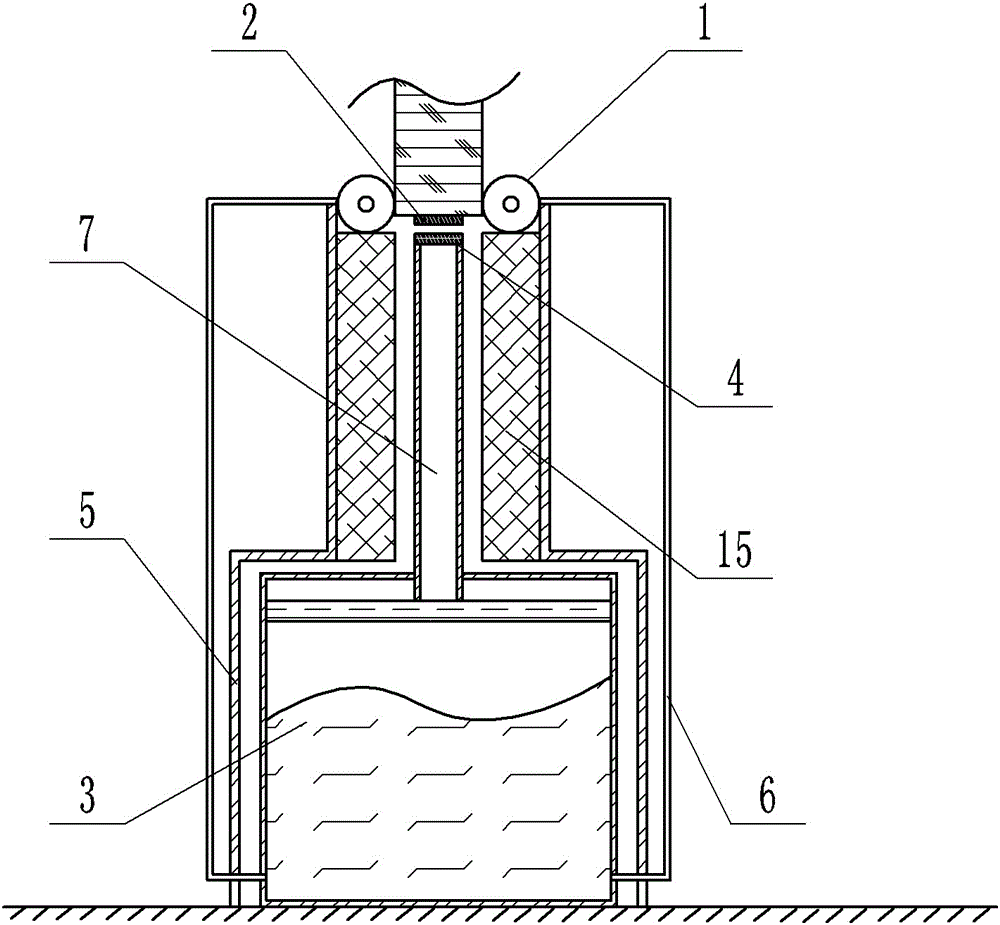

Wooden door painting device

ActiveCN106733484AReduce falling speedAchieve transferLiquid surface applicatorsCoatingsLacquerEngineering

The invention belongs to the field of automatic spraying equipment, and particularly discloses a wooden door painting device. The wooden door painting device comprises a rack, and further comprises a roller couple, a first magnet arranged at the bottom of a wooden door, and a paint cylinder, wherein the roller couple is arranged at the upper end of the rack, the paint cylinder is arranged in the middle of the bottom of the rack, a paint pipe communicating with the roller couple is arranged on the paint cylinder, a cavity for a wooden door to pass through is formed between the rollers in the roller couple, a plurality of press type paint outlet mechanisms are evenly distributed on the surface of each roller in the roller couple circumferentially, and paint outlets are formed in the outer wall of each roller in the roller couple. Each press type paint outlet mechanism comprises a spring seat, a connecting rod, a spring, a through hole for the connecting rod to penetrate through, and a sealing plate which can block off the corresponding paint outlet from the inner side of one roller in the roller couple, wherein the spring seat is movably connected with one end of the corresponding connecting rod, the other end of each connecting rod penetrates through the corresponding through hole to be connected to the corresponding sealing plate, and the spring is connected between the corresponding spring seat and the outer wall of the corresponding roller in the roller couple. With the wooden door painting device, the two surfaces of one wooden door can be painted synchronously, painting is more uniform, and the painting efficiency is high.

Owner:日照福临门业有限公司

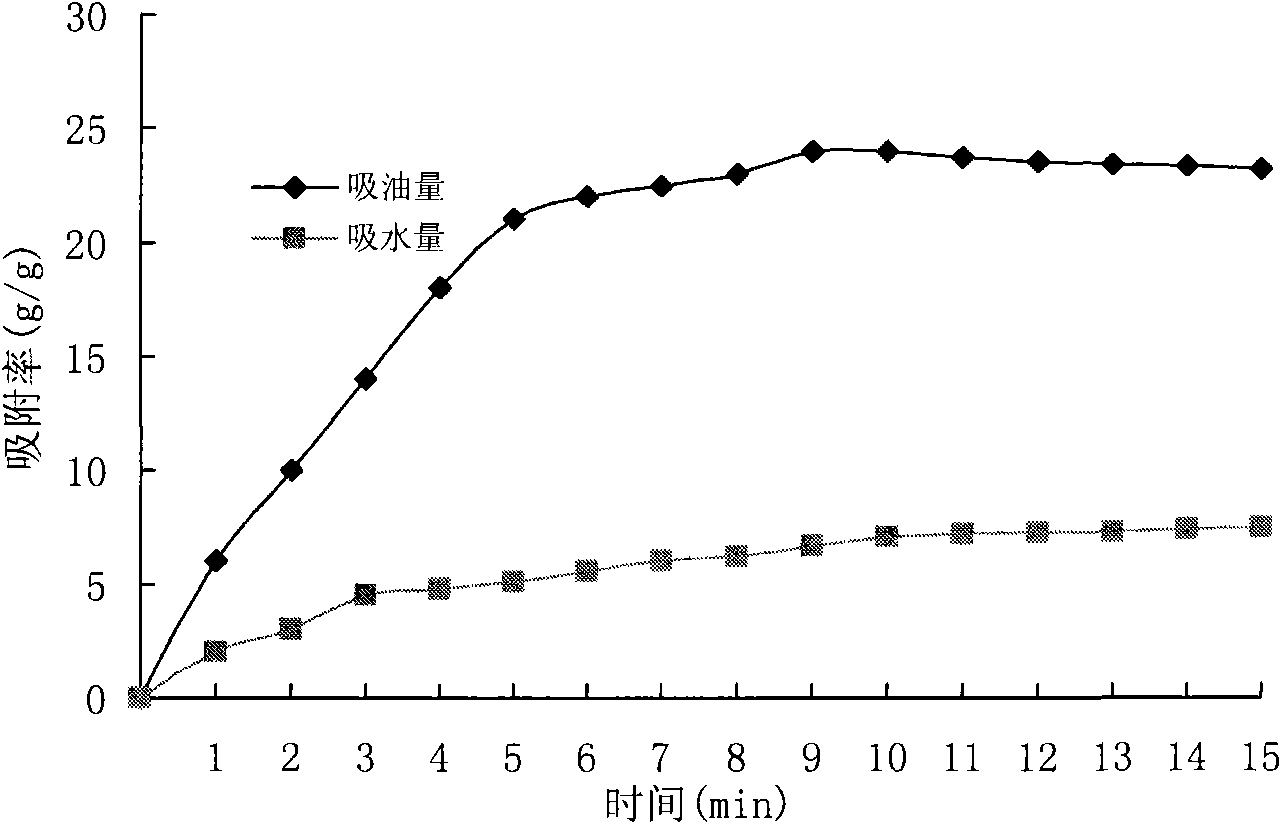

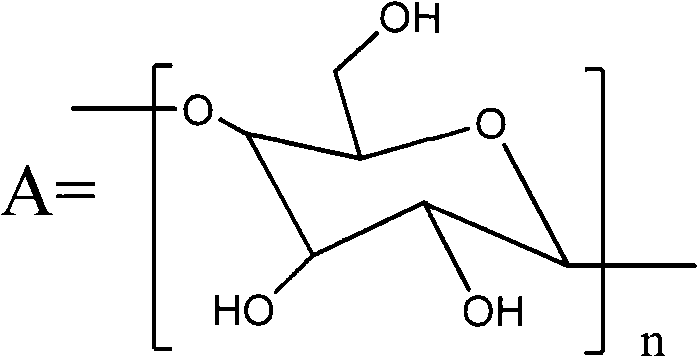

Method for preparing biodegradable oil absorption material

The invention discloses a method for preparing a biodegradable oil absorption material, which comprises the following processing steps of: 1) mixing a mixture of fiber base material and starch and 10 to 80 mass percent sodium hydroxide solution in a mass ratio of 1:0.2-1; 2) adding acrylate monomer accounting for 10 to 30 percent of the total mass of the fiber base material and the starch and an initiator accounting for 0.1 to 2 percent of the total mass of the fiber base material and the starch, and uniformly blending; 3) placing the solution in a microwave reactor with the working frequency of 80 to 140 KHz and the power of 300 to 20,000W, raising the temperature to between 50 and 60 DEG C, and reacting for 20 to 60 minutes. The oil absorption material prepared by the method has excellent biodegradation performance and high-efficiency oil absorption performance, has small volume before oil absorption, and is convenient to store and transport. After oil absorption, oil cannot be leaked under the action of permitted external force. Under the condition that even if water is present, the oil absorption material can effectively absorb oil in an oil-water mixed system.

Owner:GUANGXI UNIV

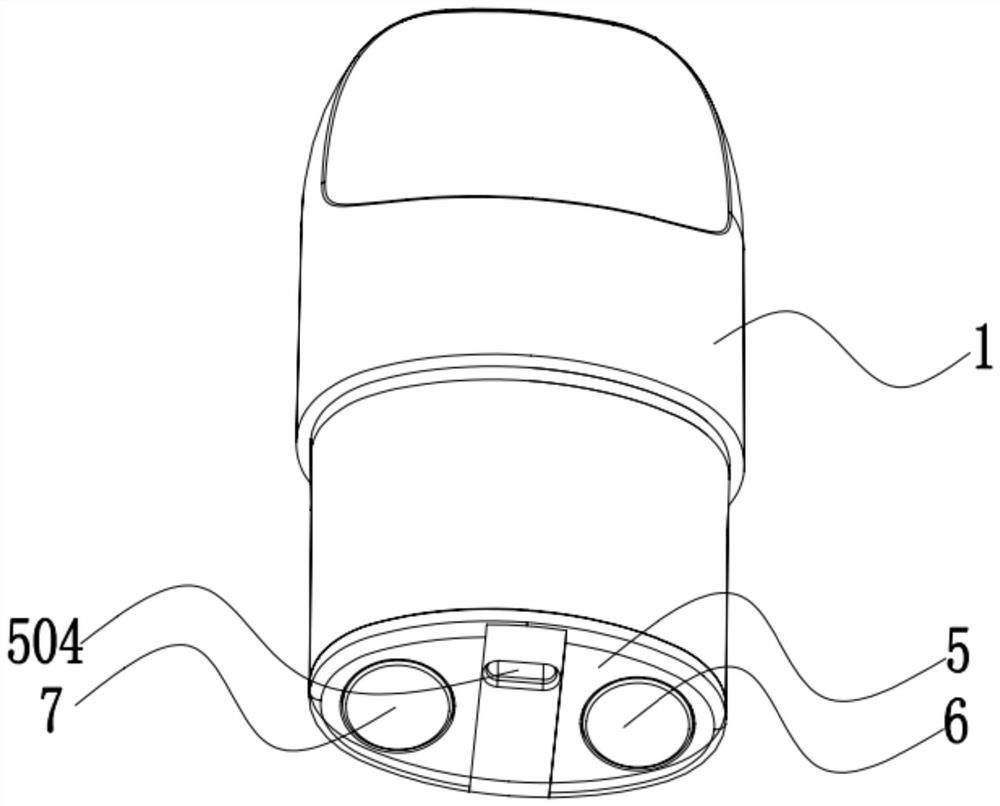

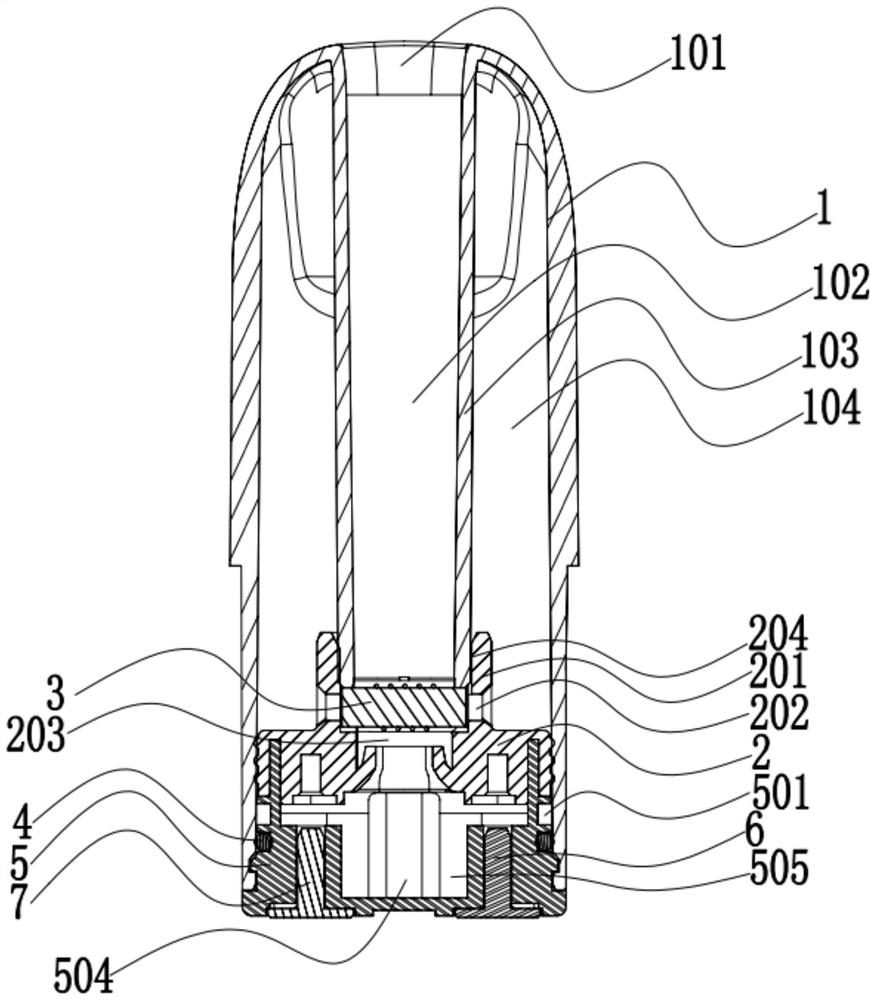

Air pressure balance atomizer and electronic cigarette

PendingCN113068871AEasy to processOil enters and cools down quicklyTobaccoEngineeringElectronic cigarette

The invention discloses an air pressure balance atomizer and an electronic cigarette. The air pressure balance atomizer comprises a tar storage device; a tar storage cavity is formed in the tar storage device; a tar oil sealing piece used for sealing the tar storage cavity is arranged at one end of the tar storage device in a sealed mode; an air channel is formed in the atomizer; an air pressure balance groove is formed in the tar sealing piece; the two ends of the air pressure balance groove are communicated with the tar storage cavity and the air channel respectively. According to the air pressure balance atomizer, the air pressure balance groove is formed in the tar sealing piece, production and machining are facilitated, meanwhile, the air groove is slightly shrunk through extrusion in the sealing process of the tar storage cavity, air can be fed into the tar storage cavity, and therefore tar can enter the tar storage cavity more rapidly without tar leakage; and meanwhile, the problems that tar suction pieces are burnt out and leaks tar due to slow tar feeding and insufficient tar supply are solved.

Owner:SHENZHEN EIGATE TECH CO LTD

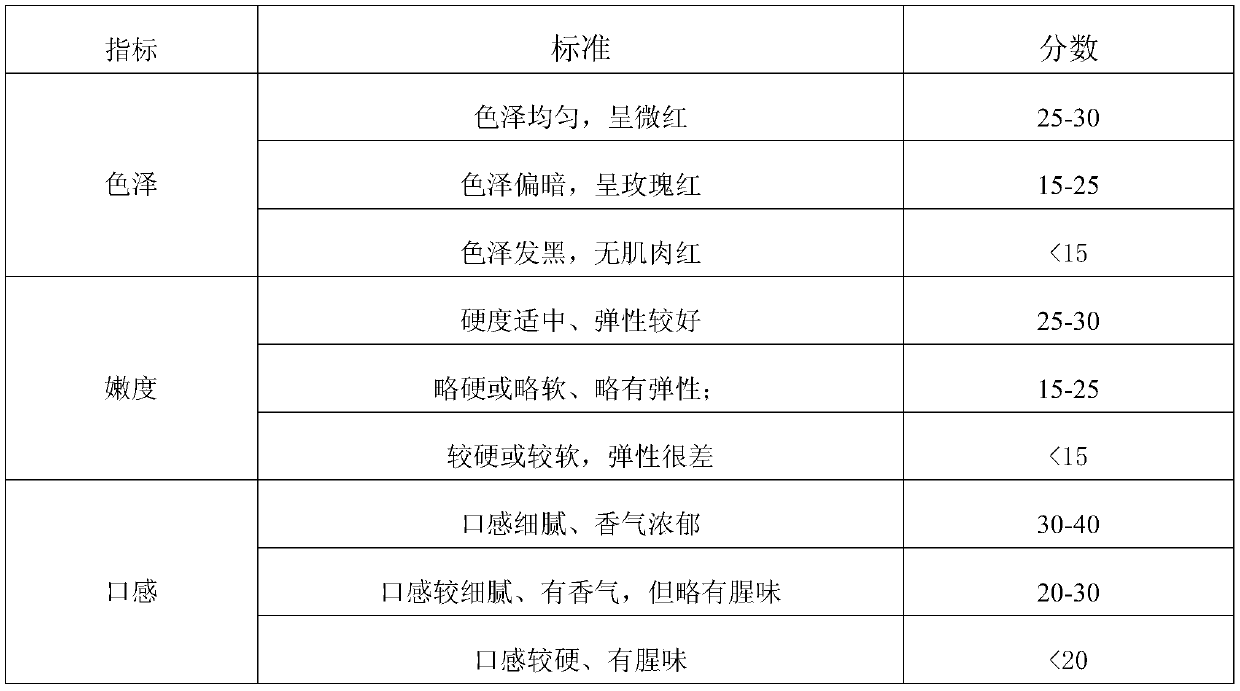

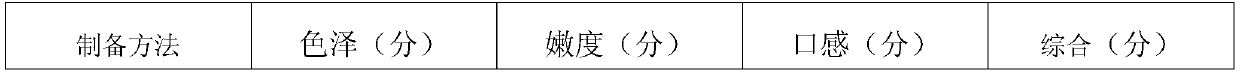

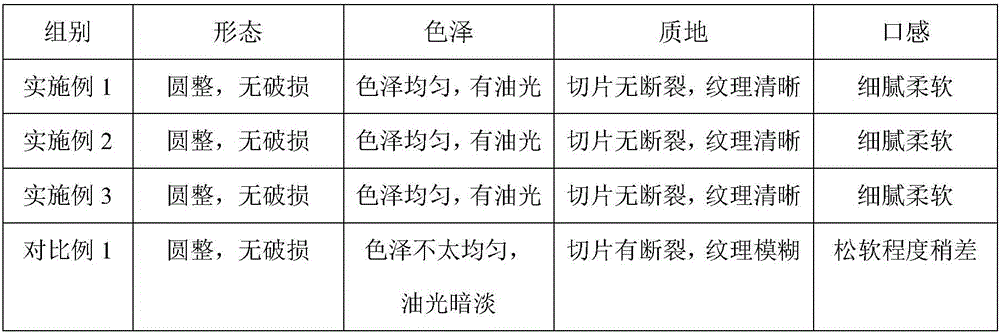

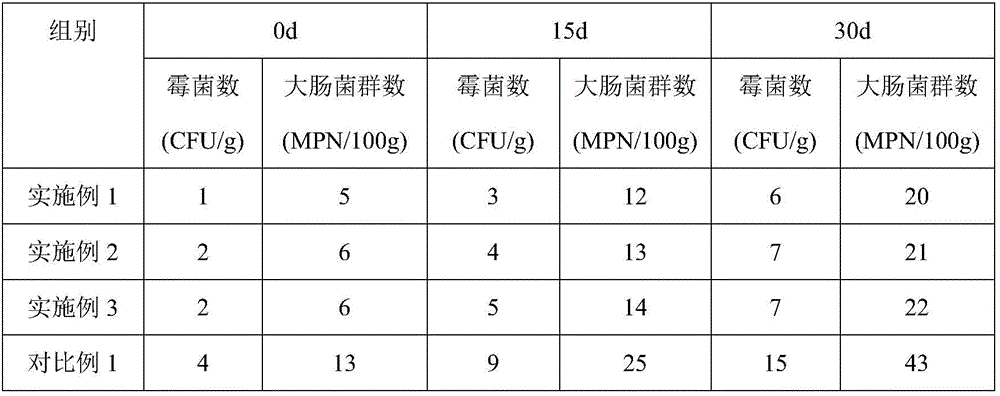

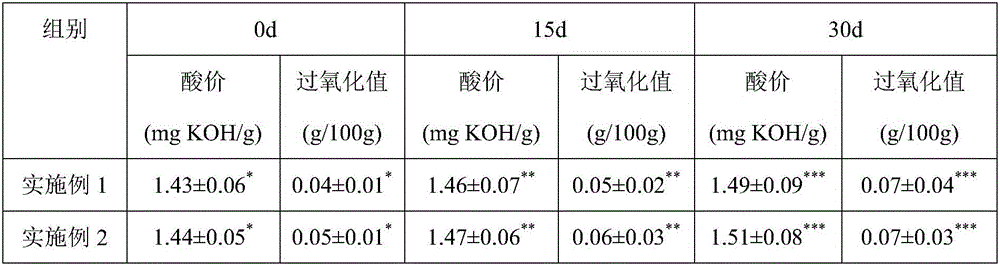

Preparation method of instant pickled beef

ActiveCN109730238AIncrease elasticityImprove tendernessClimate change adaptationFood scienceCarrageenanPhosphate

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

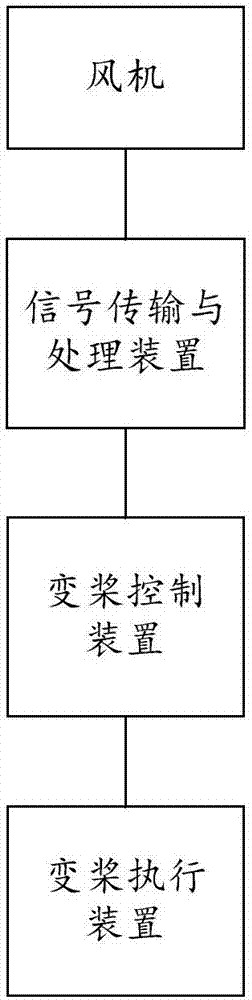

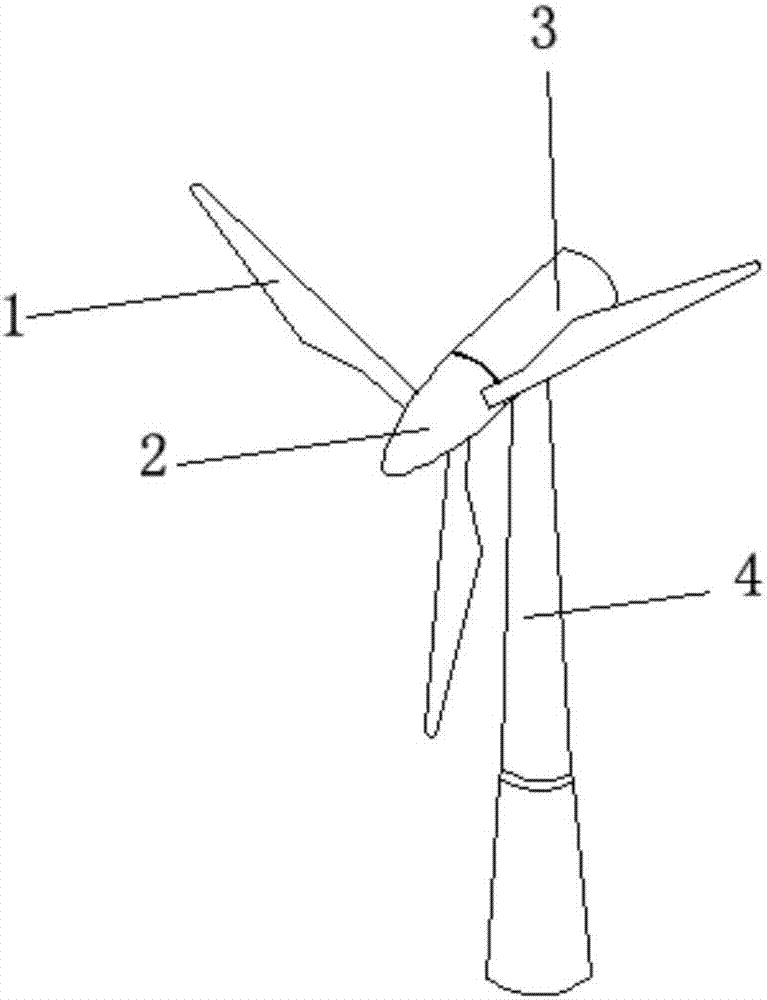

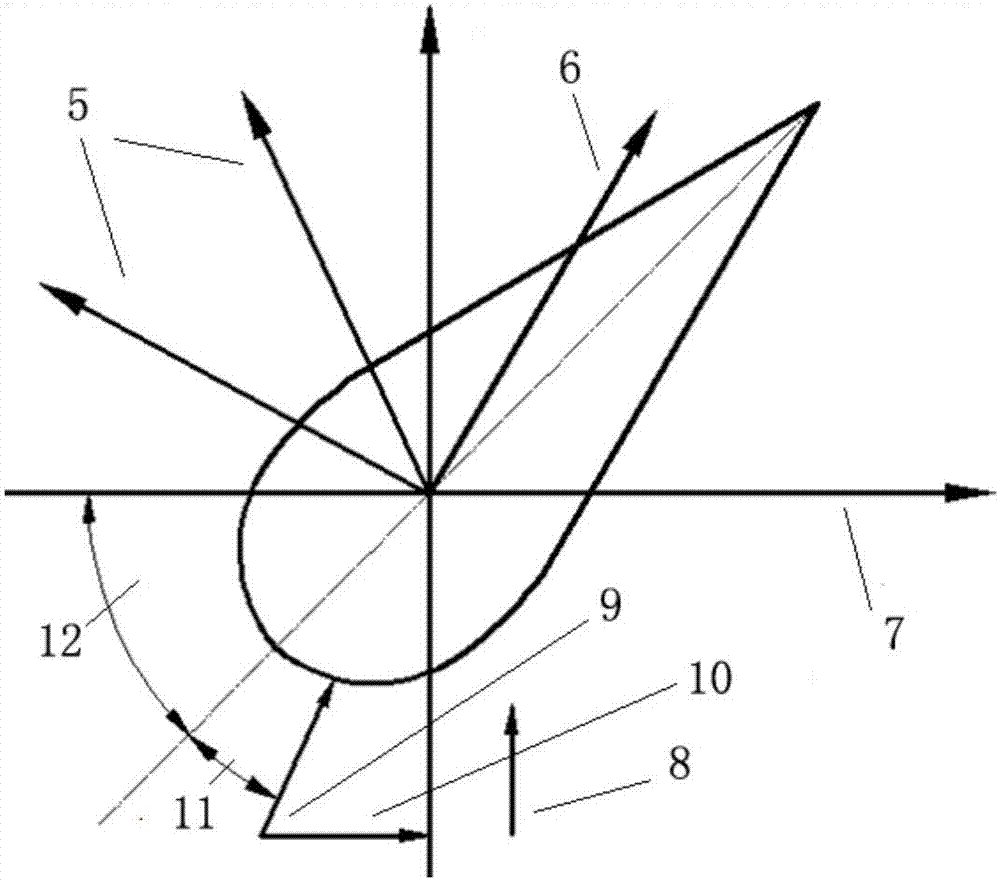

Intelligent variable pitch system for inhibiting waving resonance of wind turbine based on SMA differential pressure feedback

InactiveCN108005848AReduce loss costExcellent fatigue propertiesWind motor controlWind motor supports/mountsHysteresisDifferential pressure

The invention discloses an intelligent variable pitch system for inhibiting the waving resonance of a wind turbine based on SMA differential pressure feedback. The wind turbine, a signal transmittingand processing device, a variable pitch control device and a variable pitch executing device are included; shape memory alloy SMA materials are laid on the upper layer and the lower layer of wind turbine blades, and the SMA materials located between the upper layer and the lower layer on the same blade are connected through a guide wire; when the wind turbine blades generate the waving displacement of the tip portions of the blades, the SMA material arranged between the upper layer and the lower layer generates differential pressure, and a voltage signal is output; the signal transmitting andprocessing device processes the voltage signal, the processed voltage signal is transmitted to the variable pitch control device; the variable pitch control device judges the processed voltage signaland sends a control instruction to the variable pitch control device according to the judging result; and control over the variable pitch angle of the wind turbine blades is achieved. By means of thesystem, hysteresis of resonance inhibiting of the wind turbine blades can be reduced, the conducting process of waving resonance detection is simplified, and the sensitivity and the accuracy of wavingresonance detection are improved.

Owner:SHANDONG UNIV OF SCI & TECH

An automobile engine cleaning agent and a using method thereof

InactiveCN103695092AEfficient removalExtended service lifeMachines/enginesEngine componentsKeroseneCleansing Agents

The invention relates to the technical field of cleaning agents and the technical field of using methods of the cleaning agents, and particularly relates to an automobile engine cleaning agent and a using method thereof. According to the automobile engine cleaning agent and the using method thereof, cleaning is thorough, thus reducing the oil consumption and prolonging the service lifetime of vehicles. No protective agent is needed after cleaning processes, and a crankshaft oil seal and a valve-chamber cover periphery are free from oil leakage phenomena. The automobile engine cleaning agent comprises following components by weight: 11%-17% of kerosene, 0.5%-2% of alcohol, 0.5%-1.0% of a thickening agent methacrylic acid, 0.1%-1.0% of a corrosion inhibitor cetylamine, 0.4%-1.0% of an emulsifier calcium stearoyl lactate, 0.5%-1.5% of an antiwear additive calcium borate, 0.5%-1.0% of N,N'-bis(salicylidene) diaminopropane, 0.5%-1.5% of a surfactant sodium dodecylsulfate and 80% of engine oil.

Owner:SHENYANG TIANYISHUN SCI & TECH CO LTD

Pericarpium citri reticulatae mooncake and preparation method thereof

InactiveCN106106690ASmall particle sizeImprove thermal stabilityDough treatmentBakery productsSodium bicarbonateRed bean

The invention belongs to the field of food and particularly relates to a pericarpium citri reticulatae mooncake and a preparation method thereof. The pericarpium citri reticulatae mooncake comprises a mooncake wrapper and stuffing. The mooncake wrapper is prepared from wheat flour, arrowroot starch, waxy highland barley starch, syrup, vegetable fat, sodium bicarbonate and egg white. The stuffing is prepared from pericarpium citri reticulatae powder, red bean paste or red bean particles, syrup and vegetable fat. In the preparation process, the pericarpium citri reticulatae mooncake is easy to form, good in figurability, easy to demould after being baked, low in sugar and calorie, mellow in mouthfeel, delicious, capable of tonifying spleen and helping and promoting digestion and beneficial to health, and mooncake oil leaking and cracking phenomena cannot occur in the storing process.

Owner:广东橘香斋大健康产业股份有限公司

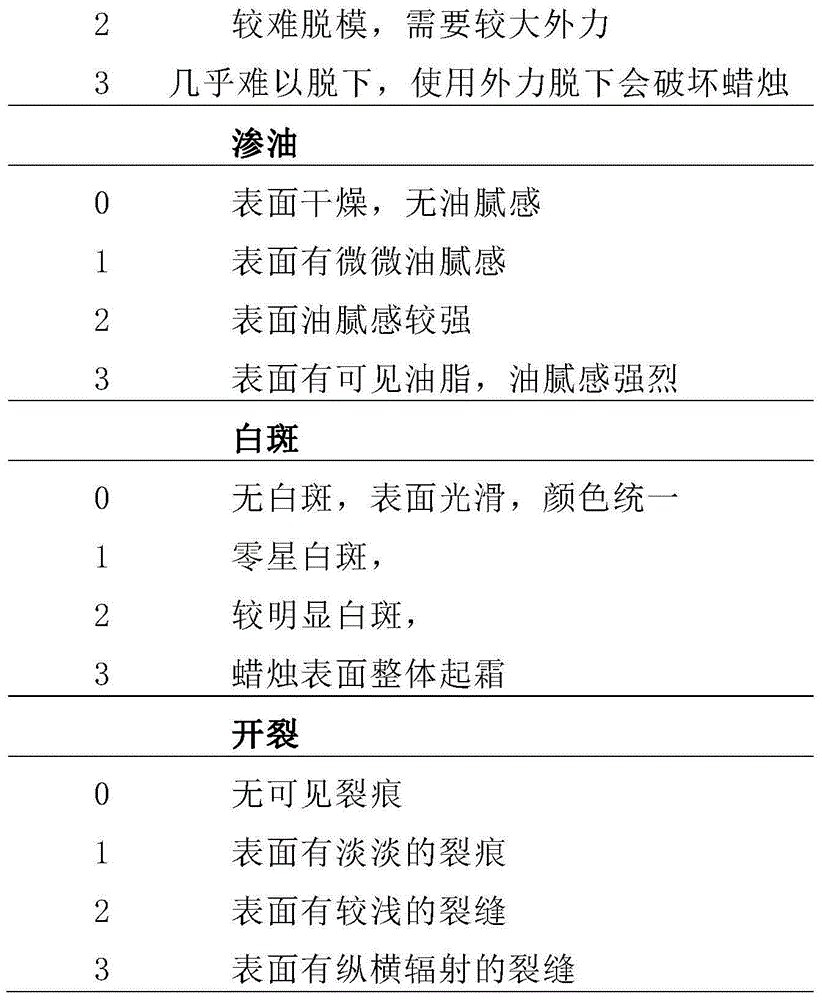

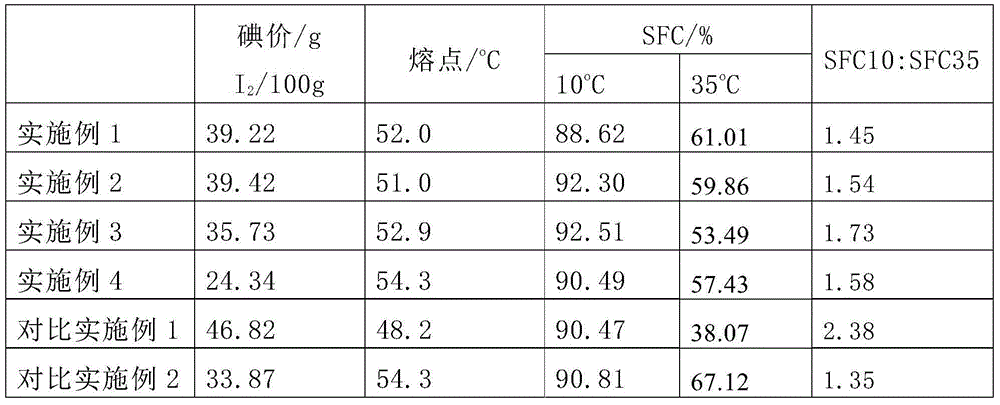

Grease for plant-based candle and preparation method thereof

ActiveCN105586155ARich sourcesLow priceCandlesFatty acid hydrogenationOil and greaseTransesterification

The invention provides grease for plant-based candles. The grease is prepared from a grease raw material, which includes rice bran grease, through transesterification. The full-triglyceride plant-based candle is free of cracking and oil leakage and is anti-frosting, and has excellent demoulding performance.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

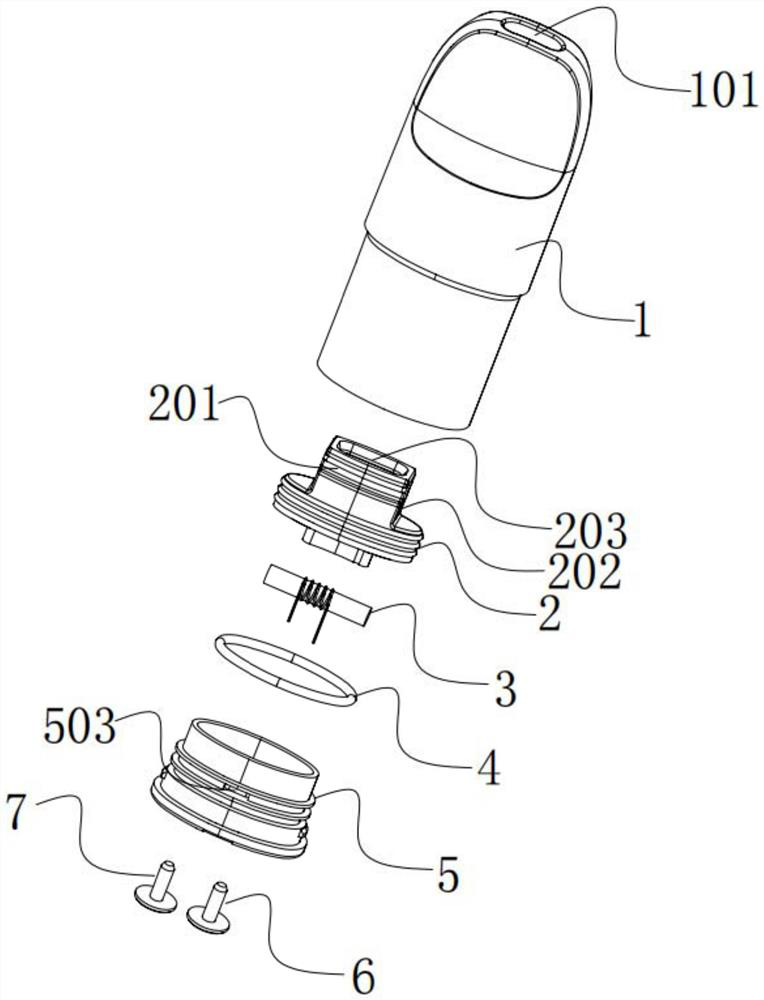

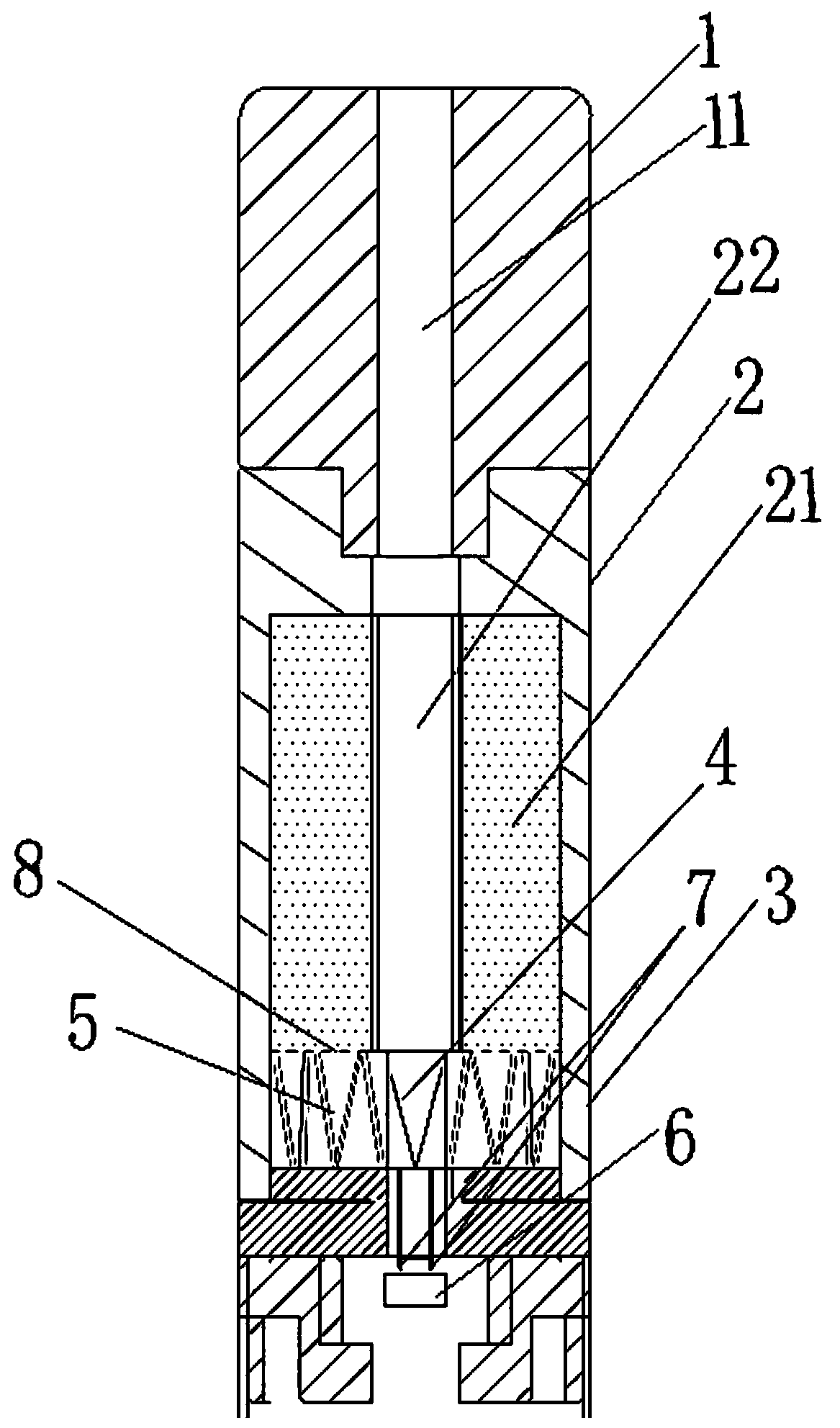

Porous glass atomizing device and electronic cigarette comprising same

PendingCN110477463AImprove adsorption capacitySolve the problem of powder fallingTobacco devicesElectronic cigarettePorous ceramics

The invention discloses a porous glass atomizing device. The porous glass atomizing device comprises an atomizing core (5) and a heater (4), wherein the atomizing core (5) is porous glass. The invention further discloses an electronic cigarette comprising the atomizing device. The electronic cigarette comprises a suction nozzle part (1), an oil storage part (2), an electrode (7), a power supply (6) and a shell (3); the suction nozzle part (1) is provided with a first airflow channel (11); the oil storage part (2) is provided with an oil storage cavity (21) and a second airflow channel (22); smoke liquid stored in the oil storage cavity (21) passes through a hole (8) and permeates into the atomizing core (5); and the heater (4) atomizes the smoke liquid in the atomizing core (4) to generatesmoke that can be sucked. The porous glass atomizing core not only solves the problem that powder is liable to fall off in the using process of a porous ceramic, but also avoids the situation that atomizing cotton is burnt to generate the smell of burnt food in the using process; and the porous glass atomizing core is sufficient in atomization, mellow and full in smoke, long in service life and high in safety.

Owner:深圳市天士力神通本草技术开发有限公司

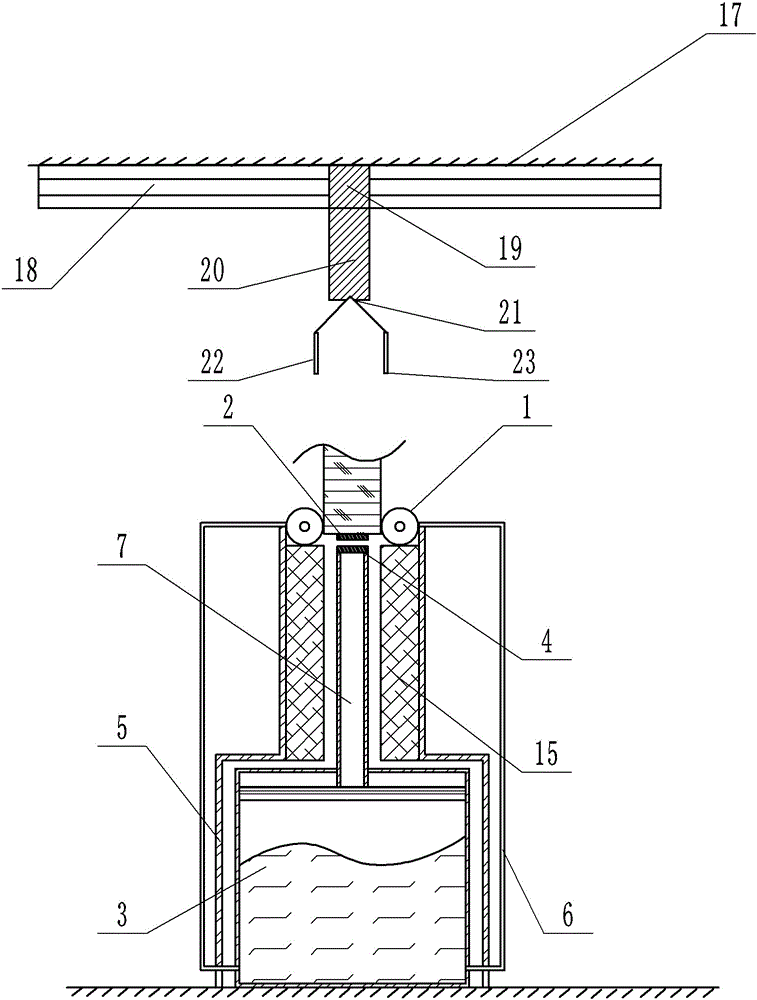

Device and method for lowering wind resistance power for large geotechnical centrifuge

ActiveCN110302906AReduced drag powerWind power reductionRotary centrifugesStructural/machines measurementResonanceHanging basket

The invention discloses a device and method for lowering wind resistance power for a large geotechnical centrifuge. A semicircle pipe cylindrical cooling device is arranged between the inner side of acylindrical barrel and a high-speed rotor system. A snakelike top semicircle pipe cooling plate is arranged over a hanging basket. The tope center is provided with an air return opening. Helium in ahelium storage tank enters a centrifugal bin from a lower seal plate through helium outlets in a plurality of helium inlet pipes. The helium is adopted for replacing air in the centrifugal bin, so that wind resistance power and corresponding energy consumption are lowered. A vacuum is not needed, so that the sealing requirements are lower. Radiating equipment is arranged in a centrifugal bin cavity, a helium inner circulation wind channel is added, the heat exchange coefficient is increased, and the radiating effect is improved. A special vibration isolation seal pad is adopted, vibration transmitted by a spindle to an upper bearing system support device is isolated from the centrifugal bin cavity, thus resonance of the cavity and the spindle is avoided, and safety of the centrifugal bin cavity is ensured. During operation under gravitational acceleration below 1500 g, economy is good, and temperature can be controlled below 45 DEG C.

Owner:ZHEJIANG UNIV

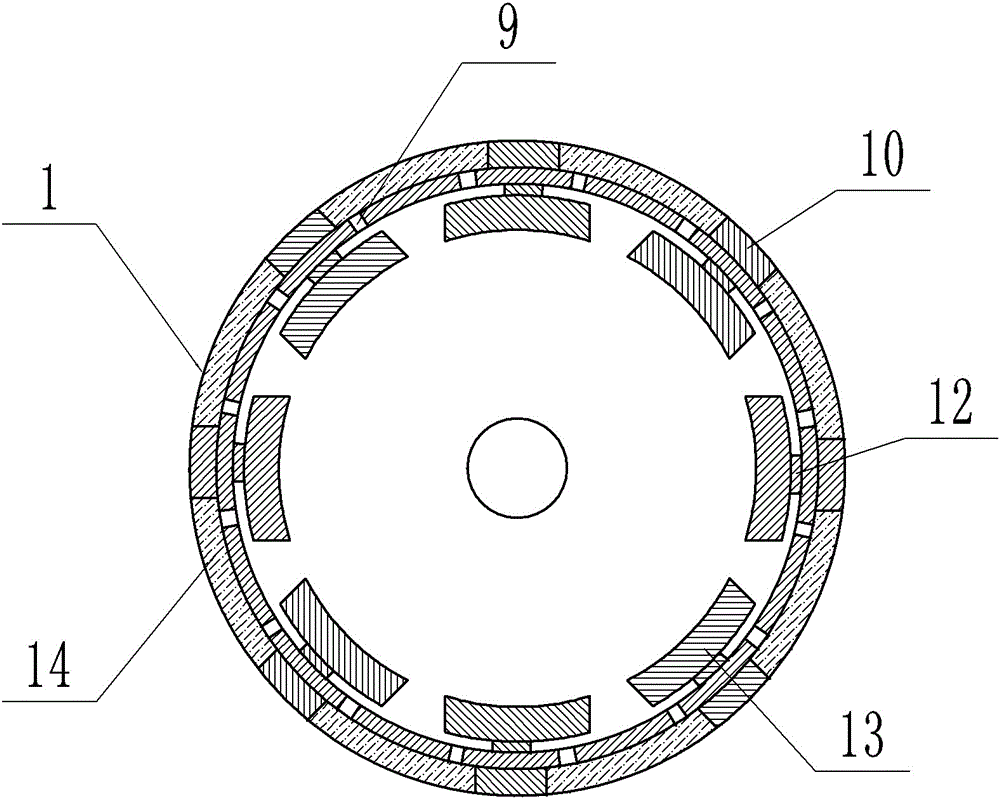

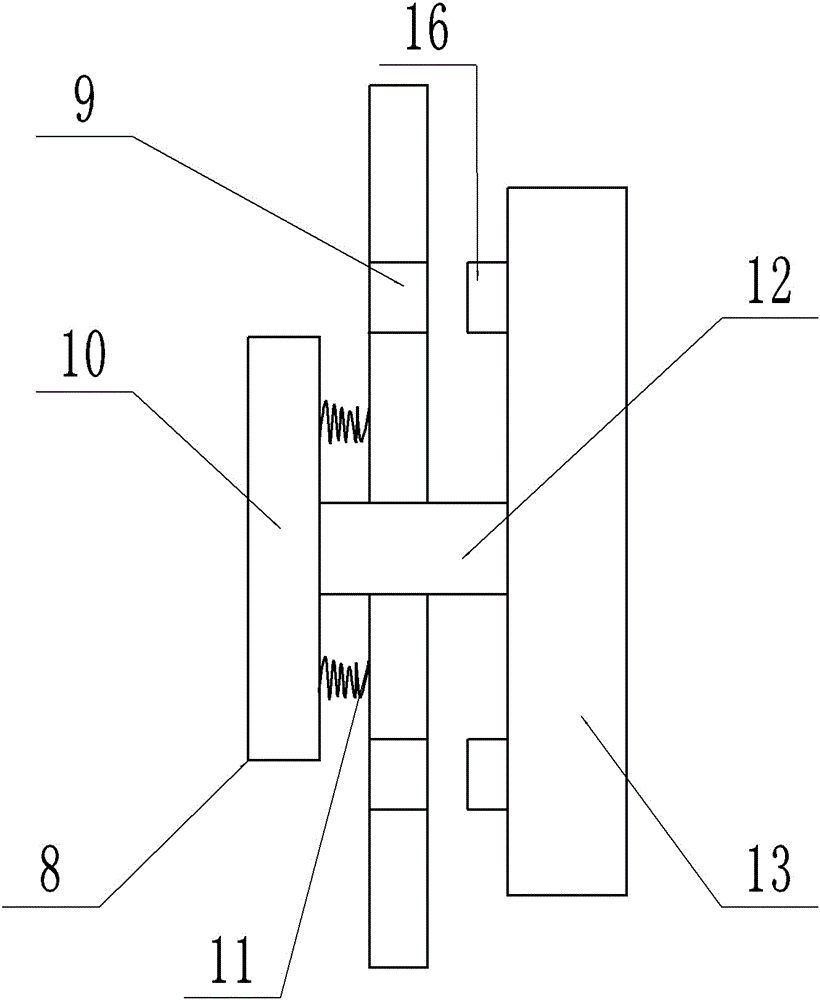

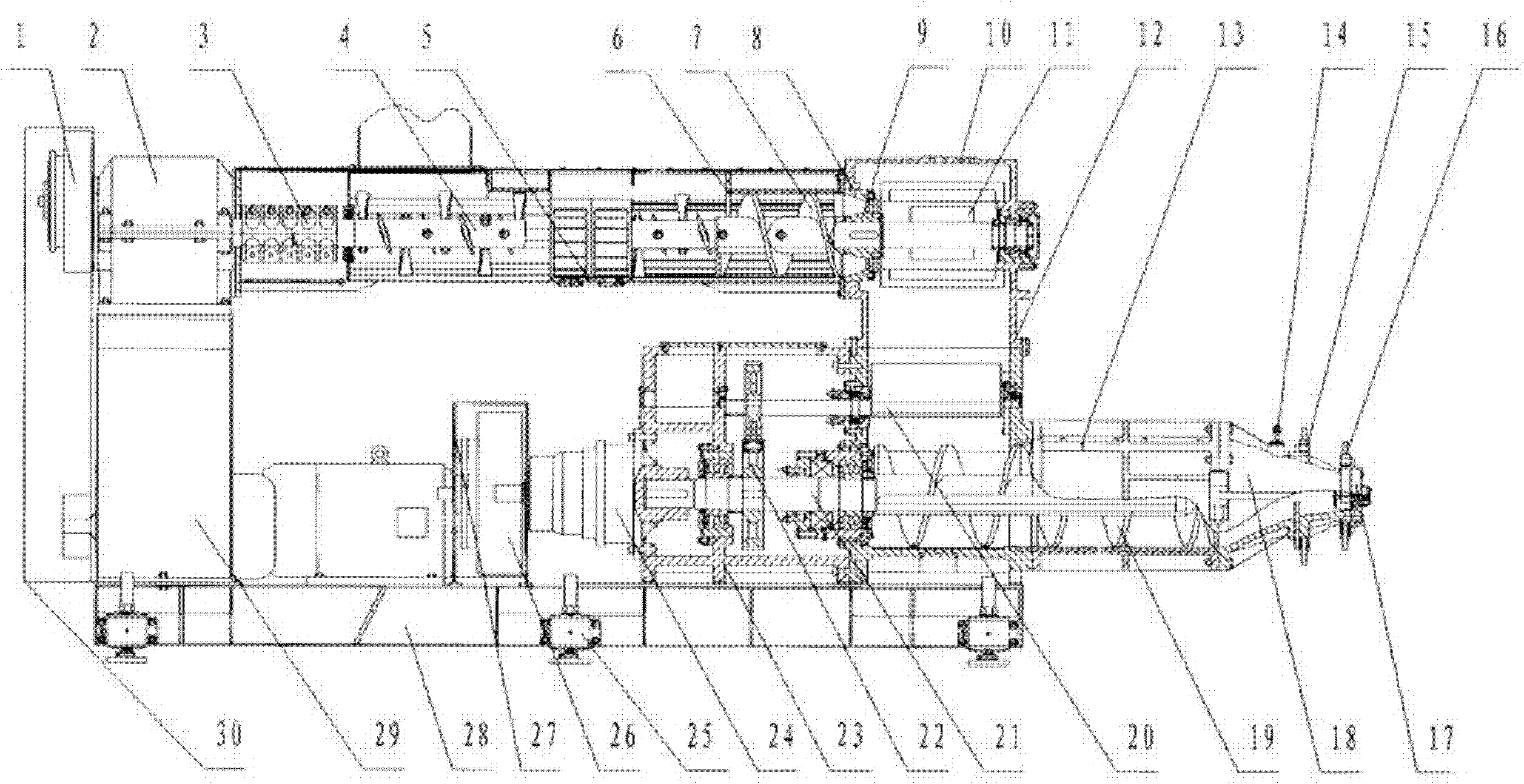

Equipment for automatically painting wood door

ActiveCN106694311ASave manpower and material resourcesSimultaneous paintingLiquid surface applicatorsCoatingsLacquerEngineering

The invention belongs to the field of automatic spraying equipment and particularly discloses equipment for automatically painting a wood door. The equipment comprises a rack and a grabbing mechanism and further comprises two pairs of roller couples, a first magnet and an oil paint cylinder. The first magnet is arranged at the bottom of the wood door. A cavity where the wood door passes is formed between the roller couples. A push piston is arranged on the side, close to the cavity, of the oil paint cylinder; one end of the push piston is located in the oil paint cylinder, and the other end of the push piston is located in the cavity; a second magnet is connected to the top of the end, in the cavity, of the push piston; turbines are arranged in the connection positions of oil paint pipes and the roller couples; a plurality of oil paint outlet devices are uniformly and circumferentially distributed on the surfaces of the roller couples; and paint outlets are formed in the outer walls of the roller couples. By means of the equipment for automatically painting the wood door, the multiple surfaces of the wood door can be synchronously and simultaneously painted, painting is more uniform, and the painting efficiency is high.

Owner:吉事达建材科技启东有限公司

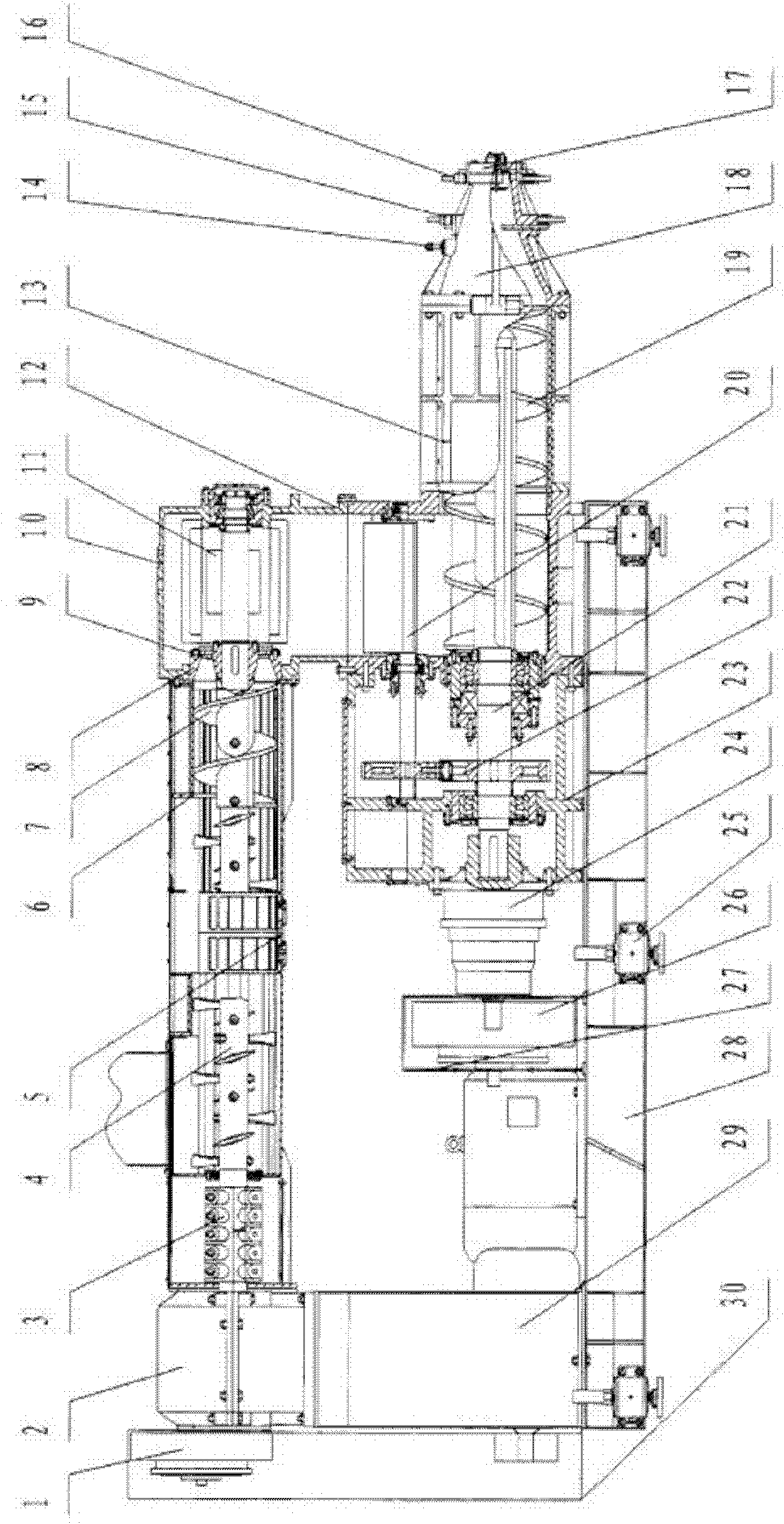

Hollow Hanging Board and Split Brick Multifunctional Vacuum Extruder

The invention aims to provide a vacuum extruder for hollow hanging plates and split bricks. The multifunctional vacuum extruder is provided with two parts, namely an upper mechanism which is positioned on the upper part and is used for transporting, extruding and mixing materials, and a lower mechanism which is positioned on the lower part and is used for extruding the materials, wherein the lower mechanism is positioned on a base; one end of the upper mechanism is fixedly supported on the base through an upper bracket and the other end of the upper mechanism is communicated with a mud feeding hopper in the lower mechanism through a vacuum chamber; a variable frequency motor in the upper mechanism is connected with a clutch to drive the clutch to rotate and is connected with a shell coupler through two output shafts of a double output shaft arc bearing speed reducer for coaction so as to rotate two stirring shafts relatively; an output shaft of a variable frequency motor of the lower mechanism is connected with a planet speed reducer; the planet speed reducer is directly connected with a spindle; the spindle is connected with a spiral extrusion reamer; the tail end of the spiral extrusion reamer is positioned in a cylinder II; and an outer end of the cylinder II is connected with a core, a middle section, an outlet end adjusting plate and a machine head in turn. The vacuum extruder can adapt to various raw materials to produce the hollow hanging plates and the split bricks, and also can produce sintered insulating bricks and sintered insulating block bricks in various specifications and sizes.

Owner:程永科

Digit proportional control valve

InactiveCN102927349ARealize digital controlHigh control precisionOperating means/releasing devices for valvesProportional controlPhase difference

The invention relates to a digit proportional control valve which comprises a valve body and a valve rod. The valve rod is arranged in a valve cavity of the valve body and connected with a driving mechanism. The digit proportional control valve is characterized in that the driving mechanism comprises a tubular jacket which is arranged outside the valve body, a plurality of pairs of inwards protruded electromagnetic windings are arranged on the inner circumferential wall of the jack at intervals, two electromagnetic windings in the diameter direction form a pair of electromagnetic windings, each pair of electromagnetic windings is connected with corresponding pulse current transmitting devices, and pulse current transmitted by the pulse current transmitting devices sequentially have phase differences along the peripheral direction; a permanent magnet and a nut are arranged in a tubular cavity of the jack, the permanent magnet with a tubular structure is capable of rotating relative to the jack under the action of electromagnetic fields generated by the electromagnetic windings, the nut rotates with the permanent magnet, an inner cavity of the nut is communicated with the valve cavity in a sealing mode, a screw is arranged in the nut, and the screw is connected with the valve rod in a driving mode; and the permanent magnet is located outside the valve cavity. Compared with digit proportional control valves in prior art, the digit proportional control valve is good in sealing performance, stable in running and high in control accuracy.

Owner:陈国永

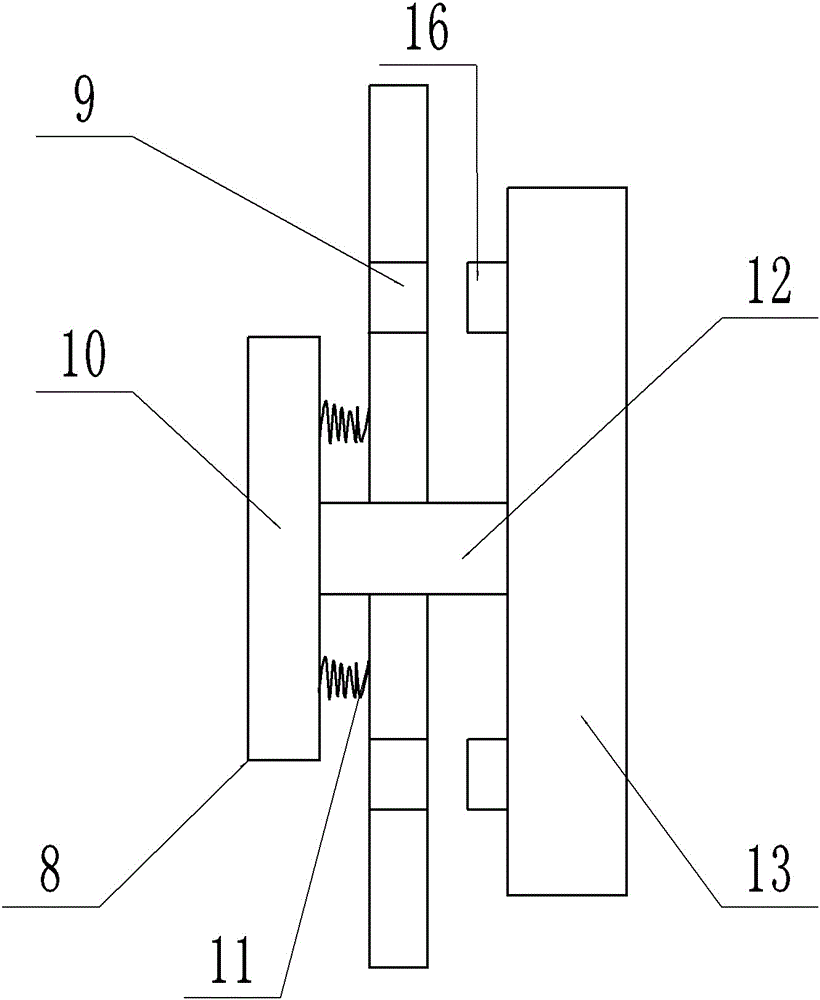

Wellhead sealing device

The invention discloses a wellhead sealing device. The wellhead sealing device comprises a shell which can be arranged outside a sucker rod in a sleeving mode, a plurality of sealing rings located ina first sealing space and a second sealing space and elastic pieces arranged on the sealing rings; the shell is provided with the first sealing space and the second sealing space; the first sealing space is located above the second sealing space; the cross-sectional area of one of the first sealing space and the second sealing space is gradually increased from top to bottom, and the cross-sectional area of the other one of the first sealing space and the second sealing space is gradually reduced from top to bottom; the multiple sealing rings are up-down sequentially laminated and arrayed so asto be arranged outside the sucker rod in a sleeving mode, the sealing rings are provided with at least two parts separated from each other in the circumferential direction, a separation gap is formedbetween the at least two parts in the circumferential direction, and the separation gaps of the at least two sealing rings are staggered in the circumferential direction; and the elastic pieces exerts acting force for shrinking the separation gaps in the circumferential direction to the sealing rings. The wellhead sealing device can play a very good sealing role on an oil well wellhead.

Owner:PETROCHINA CO LTD

Plug pin type safety device for hydraulic machine

The invention relates to a plug pin type safety device for a hydraulic machine, which is characterized by mainly comprising a support frame, a cover plate, a safety bolt and an air cylinder, wherein the support frame is fixedly arranged on the side wall of an upright post of the hydraulic machine, the cover plate is fixedly arranged at the outer side of the support frame, a rectangular groove is formed by the cover plate and the support frame, a plug pin plate is arranged in the rectangular groove and is connected with a piston rod of the air cylinder, the air cylinder is fixedly arranged on the cover plate, the end part of the plug pin plate is provided with an installing hole, the safety bolt is arranged in the installing hole in a penetrating way, a support spring is sheathed on the safety bolt, the lower end of the support spring is seated and arranged on the plug pin plate, a position limiting ring is arranged on the safety bolt, and a guide device is arranged between the plug pin plate arranged in the rectangular groove and the inner wall of the rectangular groove. Compared with the prior art, the plug pin type safety device has the advantages that the structure is simple, the installation and the use are convenient, in addition, the occupied space is small, the maintenance is easy, the safety performance is high, and the like.

Owner:TIANJIN TIANDUAN PRESS CO LTD

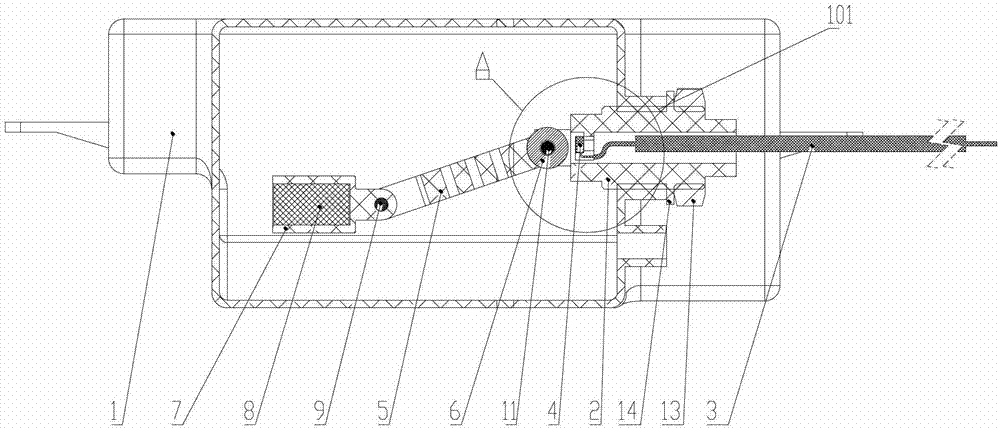

Oil quantity detection and alarm mechanism of industrial sewing machine

An oil quantity detection and alarm mechanism of an industrial sewing machine comprises a rotating shuttle oil supply box (1) and is characterized in that a mounting hole (101) is formed on the box wall of one side of the rotating shuttle oil supply box (1); an oil quantity detection rack (2) is fixedly mounted in the mounting hole (101); a lead (3) is mounted in an inner cavity channel of the oil quantity detection rack (2); one end of the lead (3) stretches out of the rotating shuttle oil supply box (1) and the other end of the lead (3) is connected with a Hall (4); the Hall (4) is fixed at one end of the oil quantity detection rack (2), which is near an inner cavity of the rotating shuttle oil supply box (1); one end of the oil quantity detection rack (2), which is near an inner cavity of the rotating shuttle oil supply box (1), is moveably connected with a connecting rod (5); a magnet (6) is mounted at the connection position; the magnet (6) corresponds to the Hall (4); and the other end of the connecting rod (5) is moveably connected with a buoy (7). The oil quantity detection and alarm mechanism displays the oil quality indication of the industrial sewing machine in a mechanical and electrical combined mode; and the whole mechanism does not need a pipeline connected with the outside, has high sealing property, accurately displays the oil quantity, has a simple structure, is convenient to manufacture and guarantees no oil leakage in the transportation process of industrial sewing machine.

Owner:上海富山精密机械科技有限公司

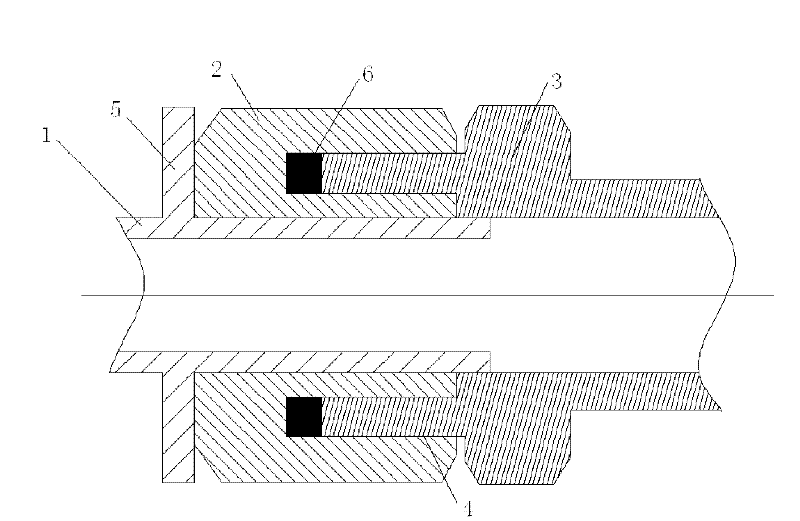

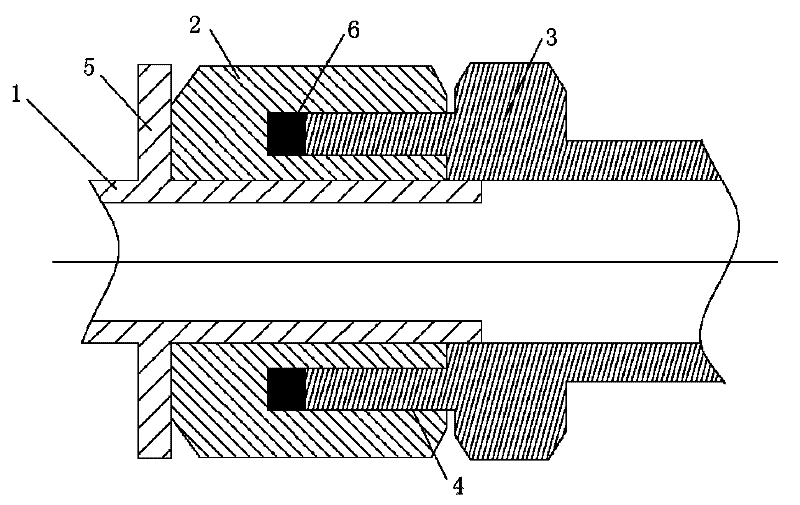

A sealing connection device for fuel metal pipe of diesel engine

InactiveCN102261530AMeet sealing requirementsFirmly connectedScrew threaded jointsPipe fittingCoupling

The invention relates to a sealing connection device for a diesel engine fuel metal pipe, which comprises a pipe nut installed on the low-pressure fuel metal oil pipe of a diesel engine and a pipe joint matched with the pipe nut. A connecting thread is arranged in the groove, and the connecting end of the pipe joint is located in the connecting groove and is provided with a thread matched with the connecting thread. The invention belongs to the sealing structure of the end surface of the rubber sleeve, and adopts a straight-through pipeline connection structure, that is, a pipe nut and a sealing rubber are assembled on the metal oil pipe to connect with the pipe joint, and the space between the pipe nut and the pipe joint is sealed by compressing the sealing rubber. Meet the requirements of sealing performance, the connection is firm and there will be no oil leakage due to the breakage of the joint of the metal pipe and oil pipe.

Owner:CHANGZHOU CHANGRUI TIANLI POWER MACHINERY

Water-resisting colloidal emulsion explosive and preparation method thereof

The invention discloses water-resisting colloidal emulsion explosive. The water-resisting colloidal emulsion explosive is prepared from the following components in parts by mass: 88-96 parts of ammonium nitrate, 6-10 parts of sodium nitrate, 4-8 parts of potassium nitrate, 3-5 parts of urea, 1-3 parts of an emulsifying agent, 9-11 parts of water, 5-7 parts of an oil phase, 4-6 parts of expanded perlite and 0.5-1.5 parts of mixed rare earth. The invention further discloses a preparation method of the water-resisting colloidal emulsion explosive. When the product is used, the product has low sensitivity on mechanical and thermal effects; the medicine filling density can be adjusted; the product has good water resistance and can be stored in flowing water, even deep water; the detonation sensitivity can be adjusted so that a relay detonator is used for detonating when necessary from the detonation of a standard detonator; no dust is generated and no electrolysis and oil seepage phenomena occur; and meanwhile, the system is close to zero oxygen balance, the toxicity of gas released in a detonation process is small, raw materials are easily available and the construction cost is relatively cheap.

Owner:宜兴市阳生化工有限公司

Sealing structure for pumping oil cylinder rod

InactiveCN104912870AEasy dischargeAct as a primary sealEngine sealsFluid-pressure actuatorsEngineeringMechanical engineering

The invention discloses a sealing structure for a pumping oil cylinder rod. The sealing structure comprises an oil cylinder body, a piston rod and a rod end chamber. One end of the oil cylinder body is connected with a guide sleeve, and the piston rod is sleeved with the guide sleeve. In the direction from one end, close to the rod end chamber, of the guide sleeve to the other end of the guide sleeve, a Sitefeng seal, a U-shaped sealing ring, a BA sealing ring and a dustproof ring are arranged between the guide sleeve and the piston rod in sequence, a first guide ring is arranged between the Sitefeng seal and the U-shaped sealing ring, a second guide ring is arranged between the U-shaped sealing ring and the BA sealing ring, a ring tank is arranged between the U-shaped sealing ring and the second guide ring, the ring tank is connected with a one-way valve, the ring tank is communicated with an inlet of the one-way valve, and an outlet of the one-way valve is communicated with the rod end chamber. According to the sealing structure for the pumping oil cylinder rod, trapped oil between sealing elements can be conveniently discharged in time, and the situation that trapped oil pressure is excessively high and consequently the sealing effect is affected is avoided.

Owner:HUNAN XIELI HYDRAULIC

New-style pneumatic jack

ActiveCN104671143ALifting and descending extremely fastImprove securityLifting devicesPneumatic valveEngineering

A new-style pneumatic jack consists of five parts, namely, an air bag, a draw bar, a base plate, a pulley and an air duct. The air bag part of the new-style pneumatic jack is divided into an upper bag, a middle bag and a lower bag in sequence from top to bottom, and the inner spaces of three air bag bulges are mutually independent. The side of each air bag is equipped with an air valve, and adjacent two air bag bulges are connected in series by a pneumatic stop valve used for the air duct. An upper air bag bulge is equipped with an anti-skidding rubber plate, so as to come into contact with the chassis of a car, and a lower air bag bulge is connected with the base plate. The air bag is equipped with a pneumatic valve device, and the device inflates quickly when the air bag enters the working state, and can be unloaded slowly during deflation. The new-style pneumatic jack is additionally equipped with a safety protection device on the basis of enhancing air bag strength, and overcomes the defect that the safety factor of a pneumatic jack in the prior art is low.

Owner:宣城优度科技服务有限公司

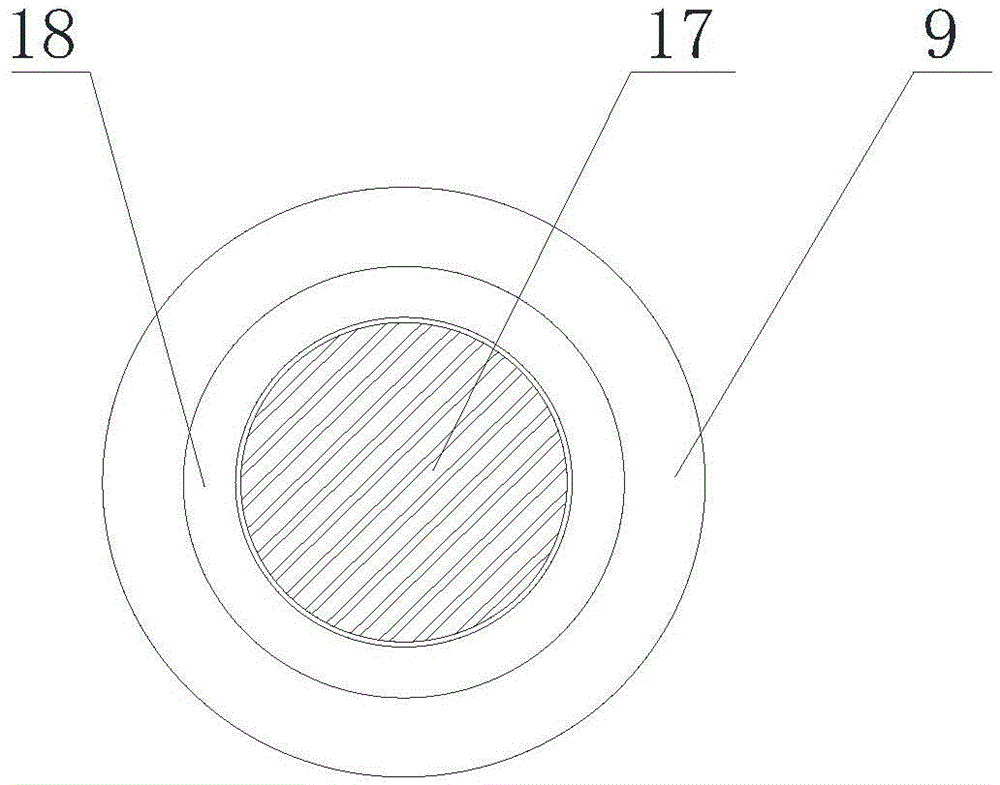

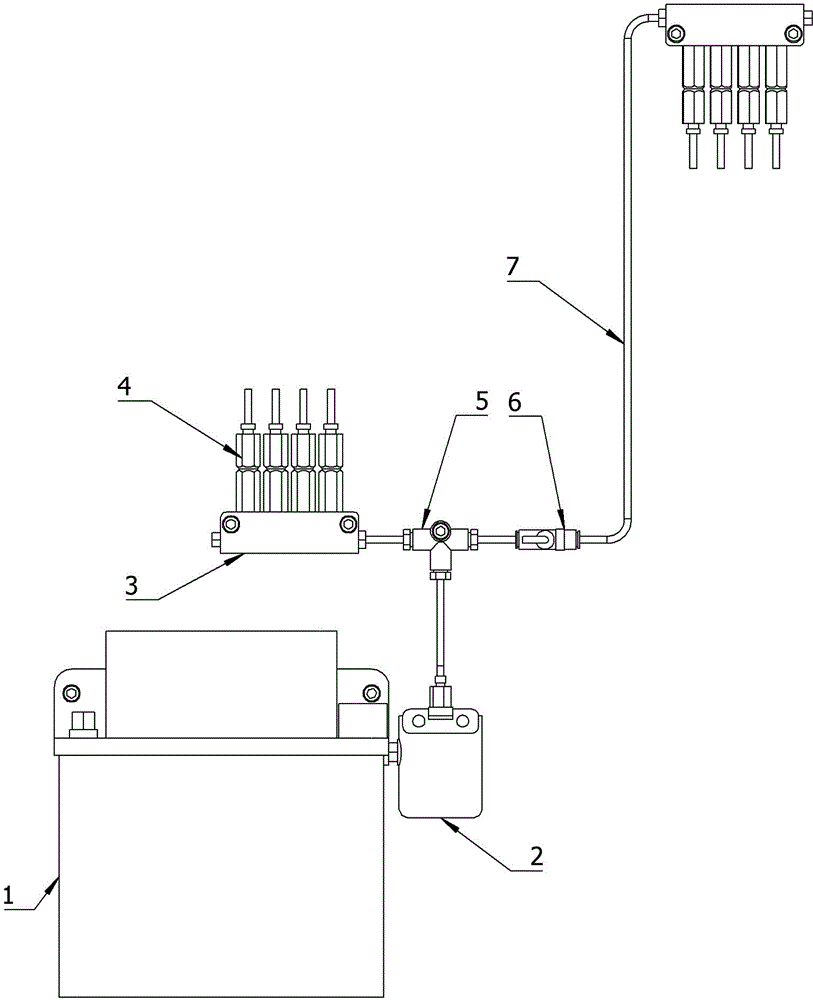

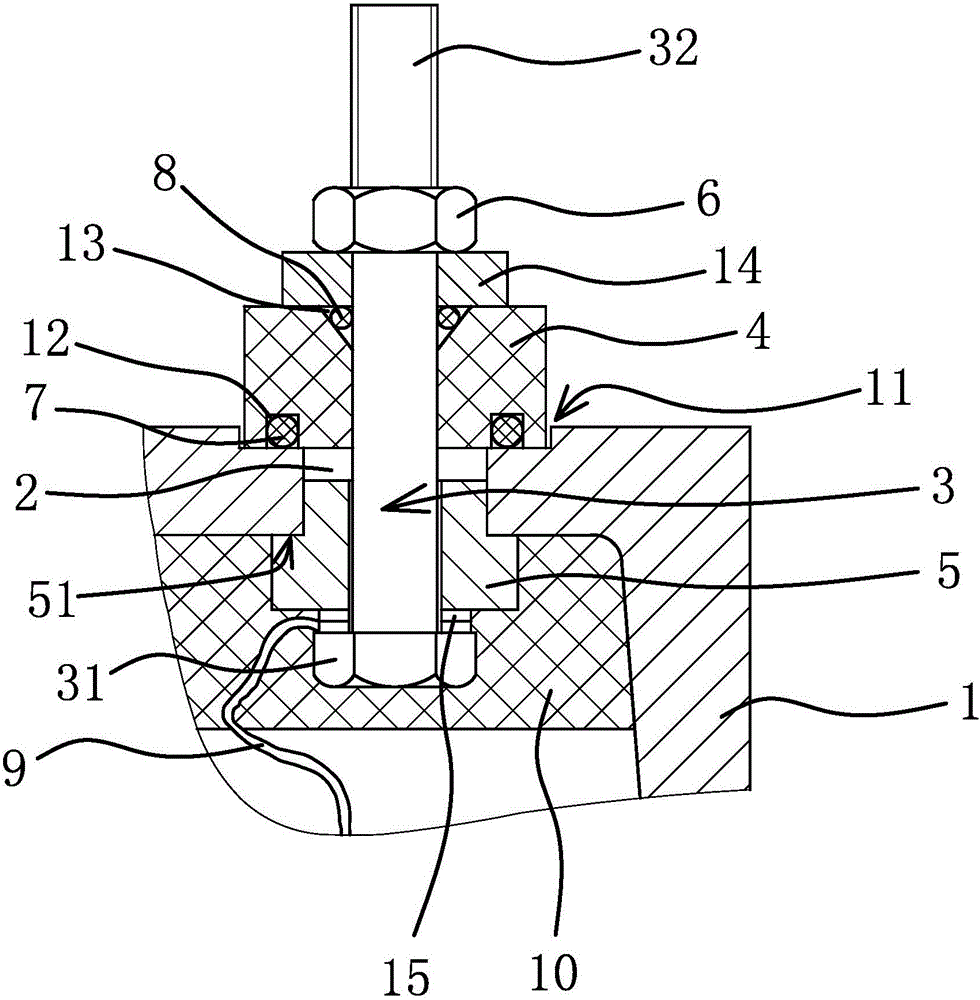

Thin oil lubricating device

InactiveCN104676228AFix bugsFully lubricatedShaping pressEngine lubricationMotor driveOil distribution

The invention discloses a thin oil lubricating device used on a tablet press in pharmaceutical machinery to achieve quantitative lubricating oil adding for an upper track, a lower track, an upper drift nail and a lower drift nail. The thin oil lubricating device comprises a motor-driven lubricating pump, an oil filter, a multi-way oil distribution block, quantitative oil injectors, a three-way connector, a one-way throttling valve and an oil pipe. The oil filter is installed on the motor-driven lubricating pump and connected with the three-way connector through the oil pipe, the three-way connector is connected with the multi-way oil distribution block in two ways, wherein the one-way throttling valve is installed in one oil way, the quantitative oil injectors are installed on the multi-way oil distribution block and connected to lubricating oil points through oil pipes, and lubricating period, lubricating time and lubricating oil quantity are set by means of control of the motor-driven lubricating pump by the electric control system. The thin oil lubricating device can serve as an upgraded product of a mechanical oil cup oil filling device arranged on the existing rotating tablet press.

Owner:上海天和制药机械有限公司

Outgoing line sealing structure of transformer oil pump

ActiveCN105743270AImprove the sealing effectImprove securitySupports/enclosures/casingsFastenerSealant

The invention provides an outgoing line sealing structure of a transformer oil pump, belongs to the technical field of transformer oil pump sealing and solves the problem of an existing transformer oil pump that the sealing effect is poor. The outgoing line sealing structure of the transformer oil pump is characterized in that the transformer oil pump comprises pump body, a wiring hole is formed in the pump body, an external positioning block is arranged at the outer side of the pump body, and an internal positioning block is arranged at the inner side of the pump body; the internal positioning block, the external positioning block, a conductive rod and the pump body are fixedly connected with a fastener, a first sealing ring is arranged between the external positioning block and the pump body, and a second sealing ring is arranged between the external positioning block and the conductive rod; an inner end, arranged in the pump body, of the conductive rod is connected with a lead-out line; and the part, close to the inner end of the conductive rod, in the pump body is filled with a pouring sealant, the pouring sealant enables the lead-out line connected with the inner end of the conductive rod to be fixed in the pump body, and the pouring sealant blocks the gaps among the pump body, the internal positioning block, the conductive rod and the lead-out line. The outgoing line sealing structure improves the sealing effect and the safety performance of the transformer oil pump.

Owner:ZHEJIANG ERG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com