Silicone gel composition

一种硅氧烷凝胶、组合物的技术,应用在硅氧烷凝胶固化产品领域,能够解决丧失硅氧烷凝胶固化产品低应力特性等问题,达到低应力、低弹性模量、没有污染的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

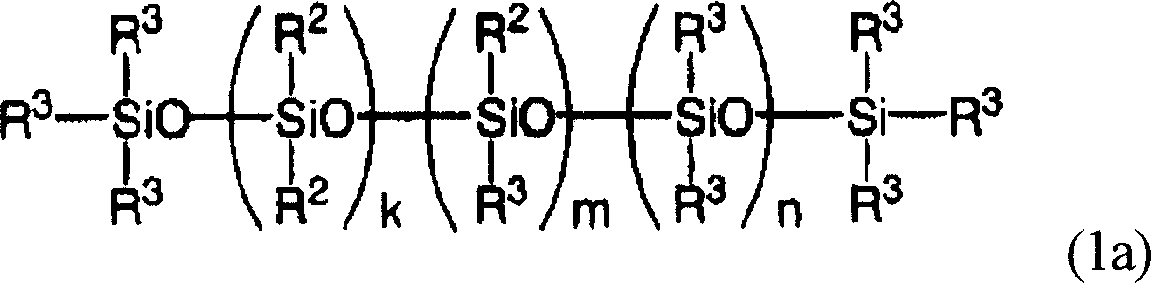

[0059] 100 parts of dimethylpolysiloxane with a viscosity of 1000mPa·s terminated by dimethylvinylsiloxy at both ends; 63 parts of dimethylpolysiloxane with a viscosity of 1000mPa·s terminated by trimethylsiloxy at both ends The copolymer of siloxane and methyl hydrogen siloxane, as shown in following formula (3):

[0060]

[0061] (corresponding to each silicon-bonded alkenyl group in component (A), the number of silicon-bonded hydrogen atoms in component (B) (expressed here as H / Vi) is 1.05); and 0.05 Parts of dimethylpolysiloxane solutions of chloroplatinic acid-vinylsiloxane complexes containing 1% platinum atoms are evenly mixed together, and the prepared composition is heated to 150°C for 30 minutes to cure, so as to obtain needle penetration A cured product with a degree of 70. According to the regulation of JIS K2220 (this regulation is also applied in each of the following examples), the penetration is 1 / 4 cone penetration.

Embodiment 2

[0063] 100 parts of dimethylpolysiloxane with a viscosity of 5000mPa·s terminated by dimethylvinylsiloxy at both ends; 25 parts of dimethyl polysiloxane with a viscosity of 600mPa·s terminated by dimethylhydrogensiloxy The copolymer of base siloxane and methyl hydrogen siloxane, as shown in following formula (4):

[0064]

[0065] (H / Vi is 1.3); and 0.05 part of dimethylpolysiloxane solution of chloroplatinic acid-vinylsiloxane complex containing 1% platinum atoms are uniformly mixed together, and the prepared composition is heated Curing at 150°C for 30 minutes to obtain a cured product with a penetration of 40.

Embodiment 3

[0067] 100 parts of a copolymer of dimethylsiloxane and methylvinylsiloxane with a viscosity of 1000mPa·s terminated by trimethylsiloxy at both ends, as shown in the following formula (5):

[0068]

[0069] 40 parts of dimethyl polysiloxane with a viscosity of 600 mPa·s terminated by dimethyl hydrogen siloxy at both ends, as shown in the following formula (6):

[0070]

[0071] (H / Vi is 0.95); and 0.05 part of dimethylpolysiloxane solution of chloroplatinic acid-vinylsiloxane complex containing 1% platinum atoms are uniformly mixed together, and the prepared composition is heated Curing at 150°C for 30 minutes to obtain a cured product with a penetration of 120.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com