Preparation method of porosity controllable nickel base coating layer

A coating, nickel-based technology, applied in the field of nickel-based coating preparation, can solve the problem of inability to regulate the pore distribution, and achieve the effect of improving the control effect, wide application range, and increasing control ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

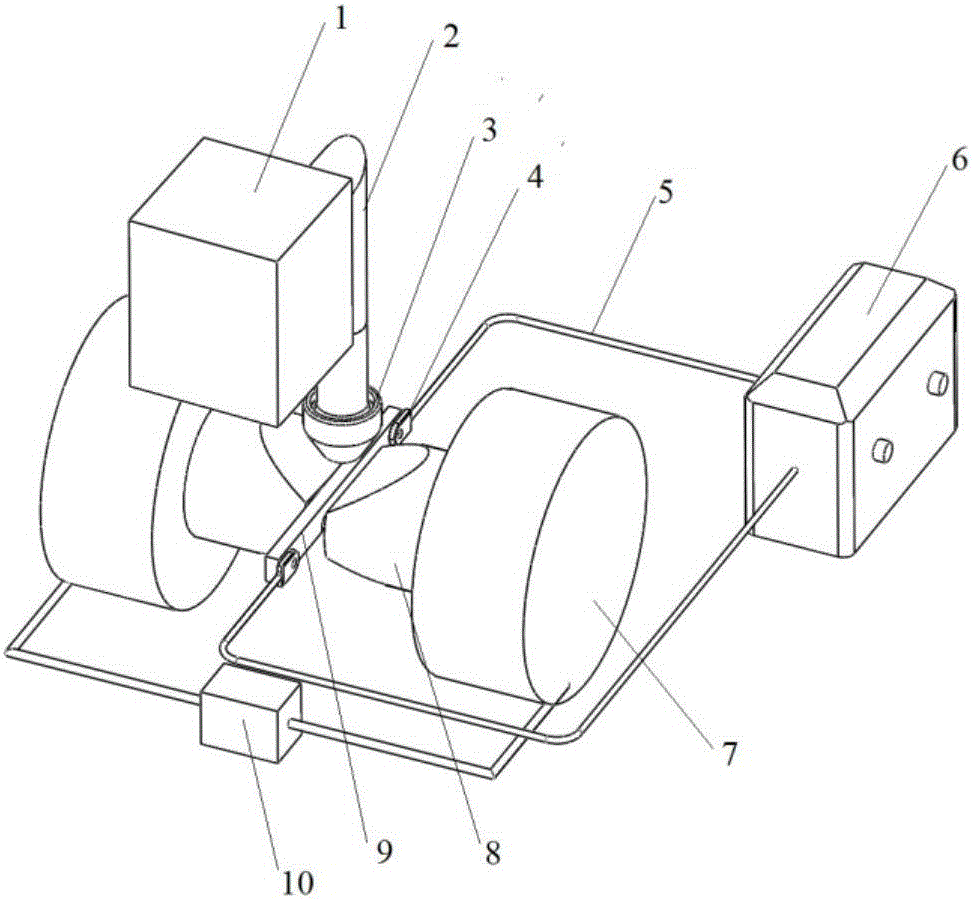

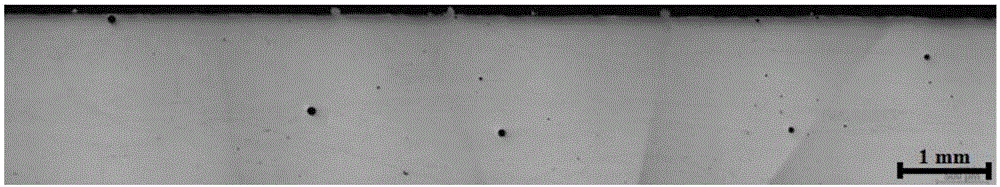

Embodiment 1

[0044] The base material of laser cladding is 316 austenitic stainless steel, which is machined into a metal sample of 100×10×10mm. Grease removal. The cladding powder is nickel-based alloy powder, and the powder is placed in a drying oven with a set temperature of 100° C. and a drying time of 60 minutes. After the powder is cooled, put it into the powder feeder, place the sample to be clad horizontally on the workbench, turn on the laser generator (the power is 1600W), the gas protection device (the protection gas is argon, the flow rate is 20HF / min, moisture content 0.05%) and powder feeder (powder feeding amount 10g / min), 10mm / s scan speed to carry out cladding according to the preset cladding trajectory. The particle size of the powder is 50-75 μm, and the sphericity is 0.8-0.9, wherein the mass fraction of the nickel-based powder is: Ni 52.5%, Cr 15%, C 0.1%, Si 0.3%, Mn0.3%, S 0.01%, P 0.01%, Al 0.4%, Ti 1.5%, Mo 3%, Nb 5%, Fe 21.88%. figure 2 It is the distribution ...

Embodiment 2

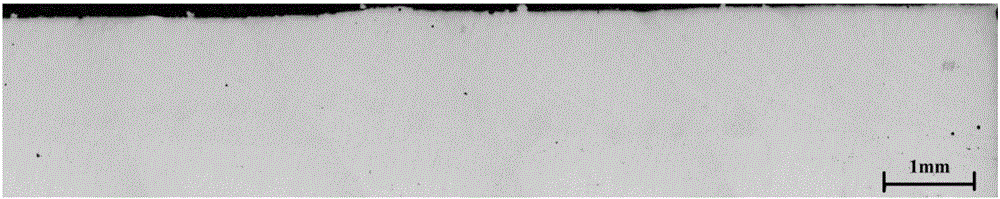

[0047] This example is a comparative example, and the water content in the shielding gas in Example 1 is reduced to 0.04%, and the powder chemical composition (mass fraction, %) is consistent with Example 1: Ni 52.5%, Cr 15%, C 0.1%, Si 0.3%, Mn 0.3%, S 0.01%, P 0.01%, Al 0.4%, Ti 1.5%, Mo 3%, Nb 5%, Fe 21.88%. Guarantee that other technological parameters are consistent with embodiment 1, obtain cladding layer longitudinal section pore distribution figure ( image 3 shown), wherein the shape of the pores of the cladding layer is spherical, and the diameter ranges from 5 to 10 μm, and the total volume of the pores of the cladding layer is about 0.05% of the total volume of the cladding layer; contrast figure 2 It can be found that the number of pores and the diameter of the pores in the cladding layer are significantly reduced, indicating that the moisture content in the shielding gas is reduced, which makes the oxygen content in the cladding layer decrease and the pore conte...

Embodiment 3

[0049] This example is a comparative example. Only according to the conditions in Example 1, when the particle size of the nickel-based powder is increased to 150 μm to 180 μm, the sphericity is 0.8 to 0.9, and the laser process and powder chemical composition are kept consistent with Example 1, and the cladding layer is obtained. Pore distribution in longitudinal section ( Figure 4 shown). It can be seen from the figure that when the particle size increases to more than 150 μm, there are micropores on the surface of the cladding layer, and the total volume of the pores in the cladding layer is about 0.05% of the total volume of the cladding layer, indicating that the increase in particle size makes the particle surface The gas-carrying capacity is reduced, resulting in a lower porosity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com