Patents

Literature

378results about How to "Retain properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

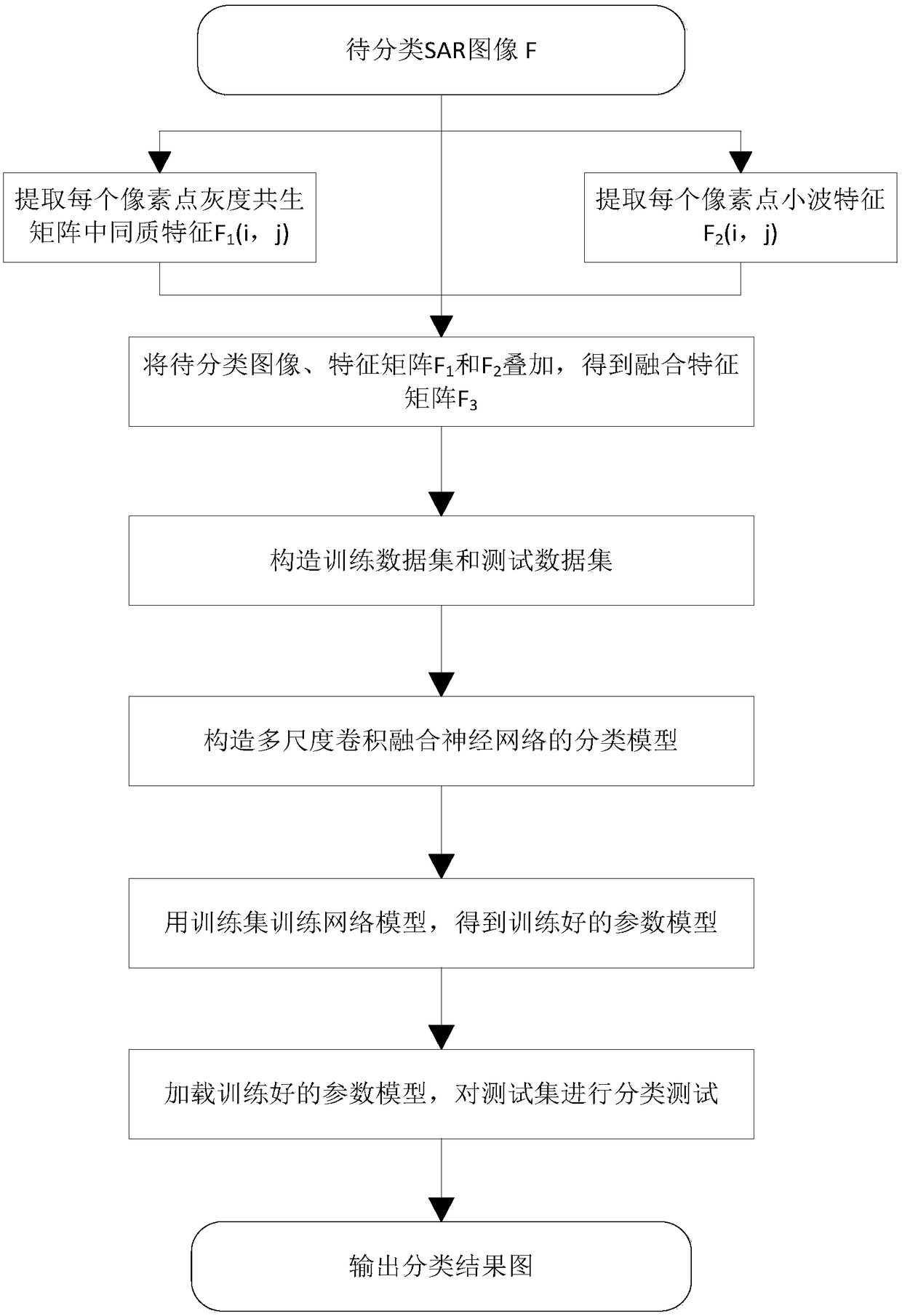

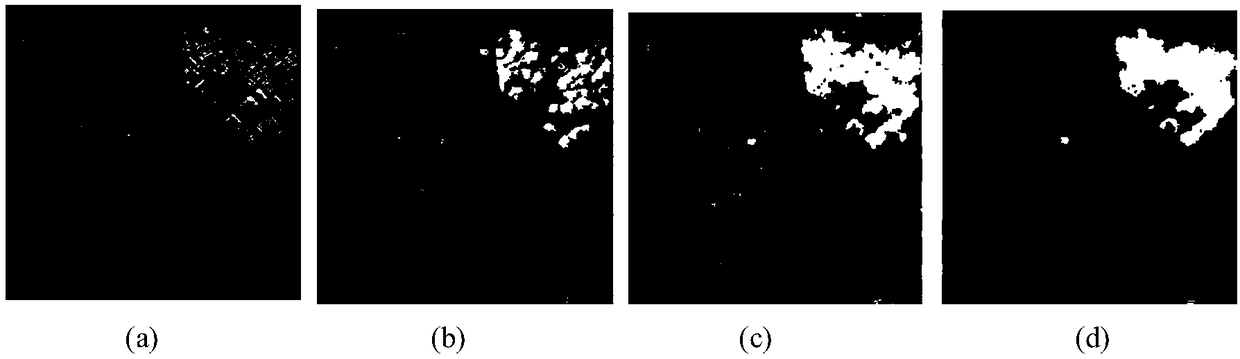

High-resolution SAR terrain classification method based on multiscale convolution and feature fusion

ActiveCN108154192ARetain propertiesPreserve scattering propertiesCharacter and pattern recognitionSmall sampleData set

The invention discloses a high-resolution SAR terrain classification method based on multiscale convolution and feature fusion, and mainly aims at solving the problem in the prior art that the classification precision is low and overfitting easily occurs. The high-resolution SAR terrain classification method comprises the steps of 1, extracting textural features and wavelet features of to-be-classified images; 2, fusing the to-be-classified images, the textural features and the wavelet features to constitute a fusion feature matrix; 3, according to the fusion feature matrix, constructing a training dataset and a testing dataset; 4, adding a multiscale convolution layer and a shuffle layer to an existing CNN network, changing a full-joint layer into a convolution layer, and constructing a multiscale convolution fusion network; 5, using the training dataset to train the multiscale convolution fusion network to obtain model parameters; 6, using the model parameters to initialize the multiscale fusion network to classify a test set. By means of the high-resolution SAR terrain classification method based on the multiscale convolution and the feature fusion, the parameters of the networkare reduced, the overfitting phenomenon of a small sample problem is solved, the classification precision is improved, and the high-resolution SAR terrain classification method can be applied to high-resolution SAR image terrain classification.

Owner:XIDIAN UNIV

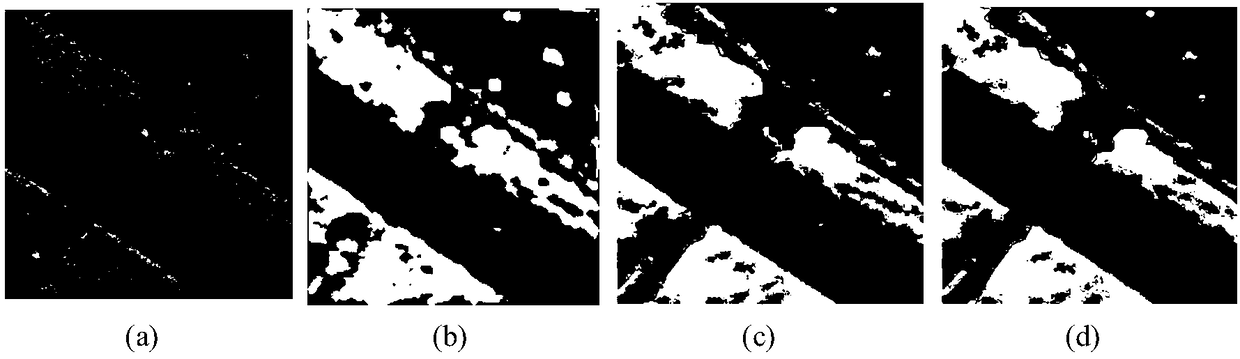

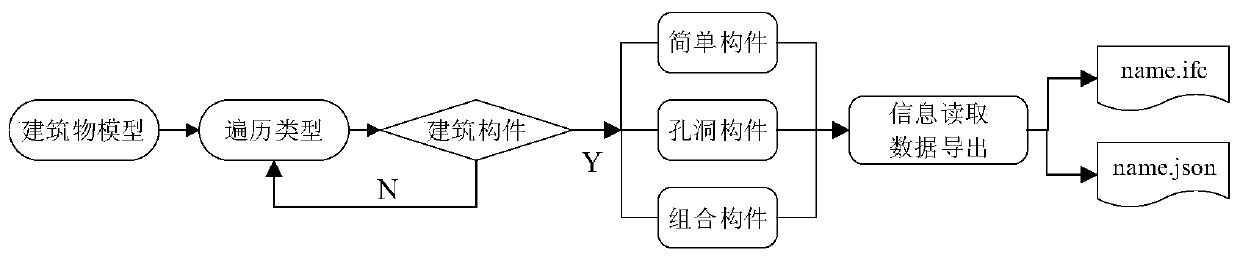

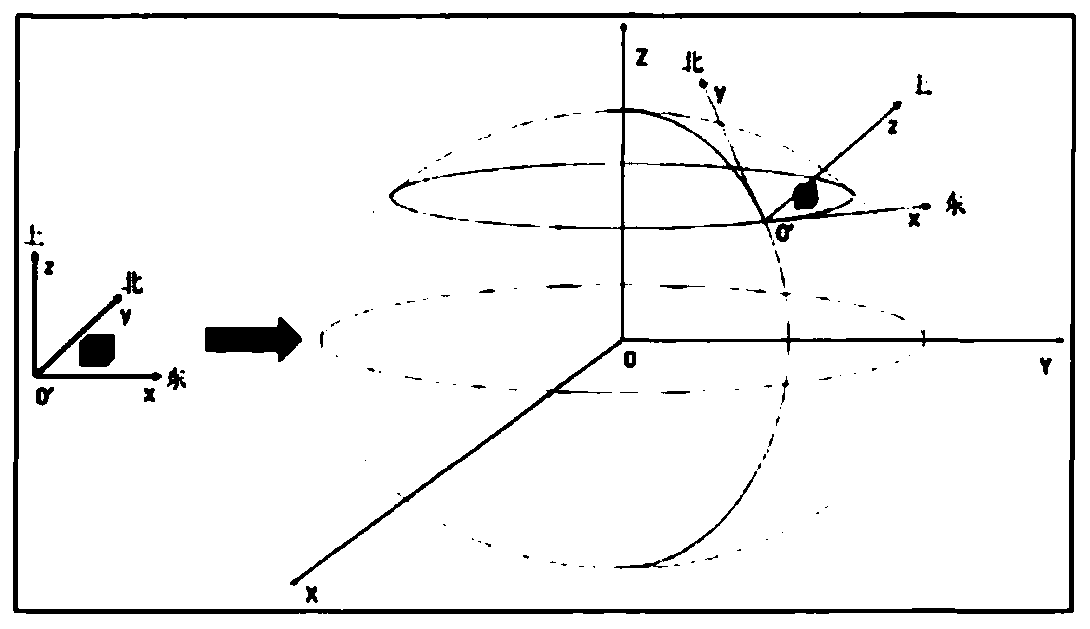

Fusion method of building BIM model and live-action three-dimensional model

ActiveCN110807835ARetain propertiesEfficient acquisitionGeometric CADImage data processingData descriptionModel reconstruction

The invention discloses a fusion method of building BIM model and live-action three-dimensional model. The fusion and conversion process mainly comprises model reconstruction, geometric information conversion, model three-dimensional registration and semantic mapping. The fusion method comprises the steps that firstly, a building BIM model is split, and json attribute files and ifc geometric filesof all components are generated; then, intermediate format exchange is carried out, and ifc is converted into obj; obj is converted into glTF, and three-dimensional geometric figure data transmissionis further achieved; then attributes and geometric data are connected, and glTF and json generate b3dm; and finally, a data description file tileset.json are added, and the data description file tileset.json and b3dm are converted into 3DTiles data. According to the method, the semantic attribute characteristics in the BIM original model are reserved while the geometric figures are completely expressed, and the spatial positions of the two models are unified in the same environment, so that an internal and external integrated display effect is achieved.

Owner:NANJING UNIV OF TECH

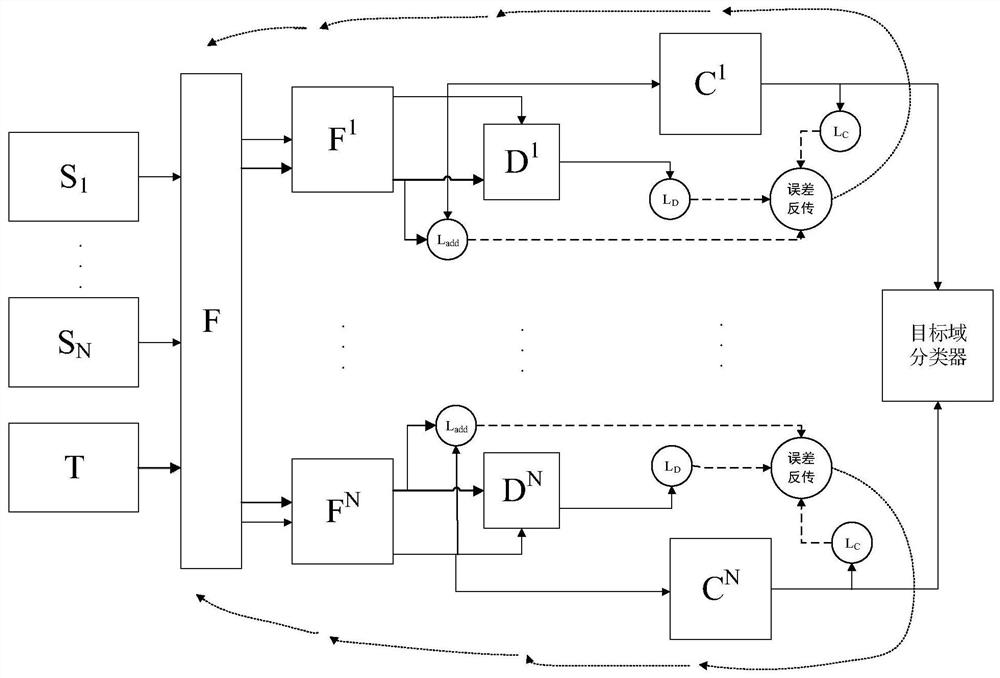

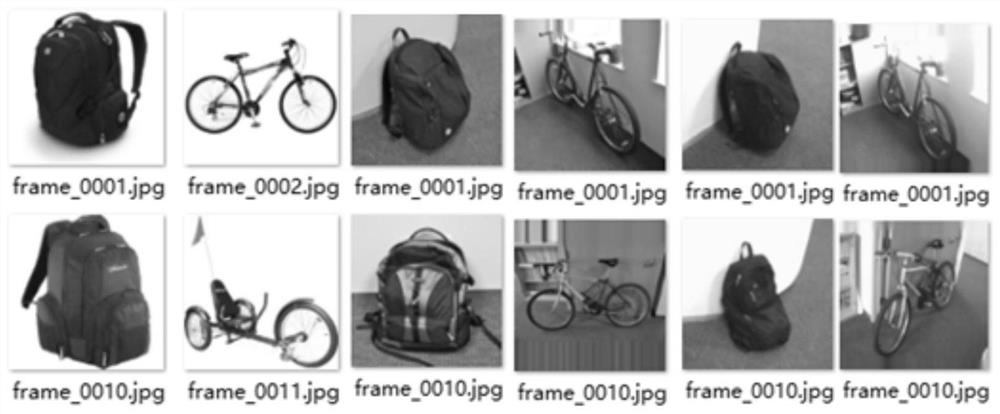

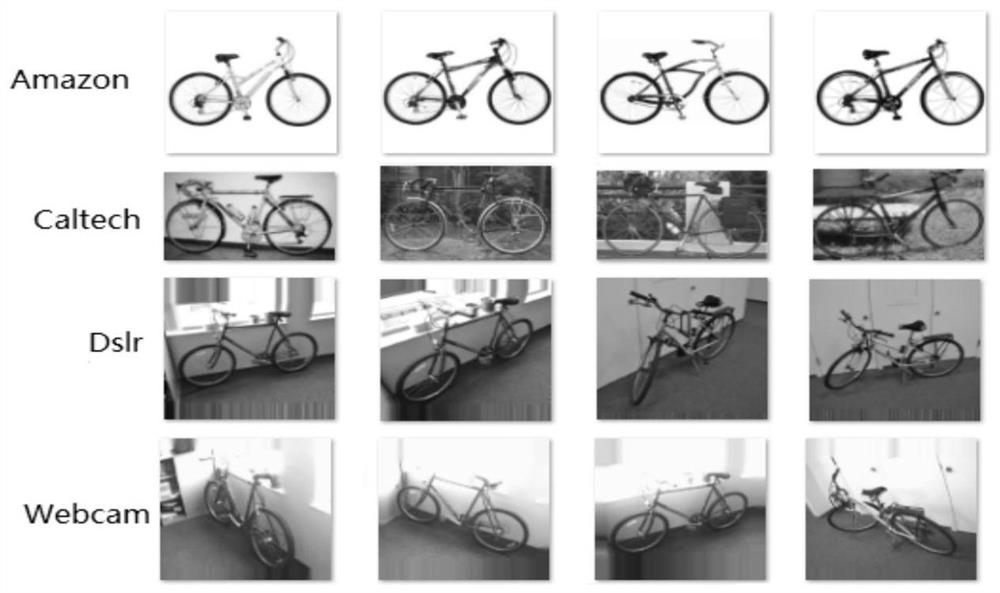

Image classification method based on adversarial fusion multi-source transfer learning

ActiveCN111738315ARetain propertiesImprove classification accuracyCharacter and pattern recognitionNeural architecturesFeature extractionClassification methods

The invention discloses an image classification method based on adversarial fusion multi-source transfer learning, and mainly solves the problem of low image classification accuracy in the prior art.According to the implementation scheme, the method comprises: 1) establishing a feature extraction network, and extracting image features from an original image file; 2) inputting the image features into a specific domain discriminator and a classifier, and calculating to obtain domain discrimination loss, a pseudo mark of target domain data and classification loss of source domain data; 3) calculating to obtain the sum of MMD distances of all classes in the source domain and the target domain by utilizing the target domain sample pseudo-mark and the source domain sample mark; 4) training thefeature extraction network, the domain discriminator and the classifier by using the sum of the domain discrimination loss, the classification loss and the MMD distance; and 5) sequentially inputtingthe sample to be detected into the trained feature extraction network, the domain discriminator and the classifier, and outputting the category marker of the sample to be detected. The method can effectively improve the classification accuracy of various images, and can be used for image classification under the condition of missing training data markers.

Owner:XIDIAN UNIV

Method for preparing high-performance conductive fiber

InactiveCN101215693AReduce pollutionLow energy consumptionLiquid/solution decomposition chemical coatingWoven fabricCopper plating

The invention relates to a method for preparing a high performance conductive fiber, which comprises the following steps: V1ing, pretreatment and washing. V2ing, fiber is socked by coarsening agent to improve the surface structure of the fiber. V3ing, the fiber is socked by stannous chloride or cadmium chloride solution, and a layer of tin ions or cadmium ions are adsorbed on the surface of the fiber. V4ing, the fiber is socked by palladium chloride solution, and the tin ions or cadmium ions which are replaced by palladium colloid are adsorbed on the surface of the fiber. V5ing, electroless copper plating. V6ing, after being socked by oxalic acid solution, the fiber is dried. V7ing, the fiber which is plated with copper is socked and treated by tin dichloride solution. V8ing, the copper-plating fiber is socked by palladium chloride solution, and the tin ions or cadmium ions which are replaced by palladium colloid are adsorbed on the surface of the fiber. V9ing, chemical nickel plating. V10ing, after being socked by deionized water, the fiber is dried, and a product is obtained. The invention has small pollution to environment and less energy dissipation, and is easy to industrially produce. The conductive fiber which is prepared using the invention has excellent conductivity, the resistance of the specific surface area is 1-10 ohm, the original characteristics of the fiber is preserved, and the high performance conductive fiber is capable of being used for various non-woven fabrics.

Owner:江苏奈特纳米科技有限公司

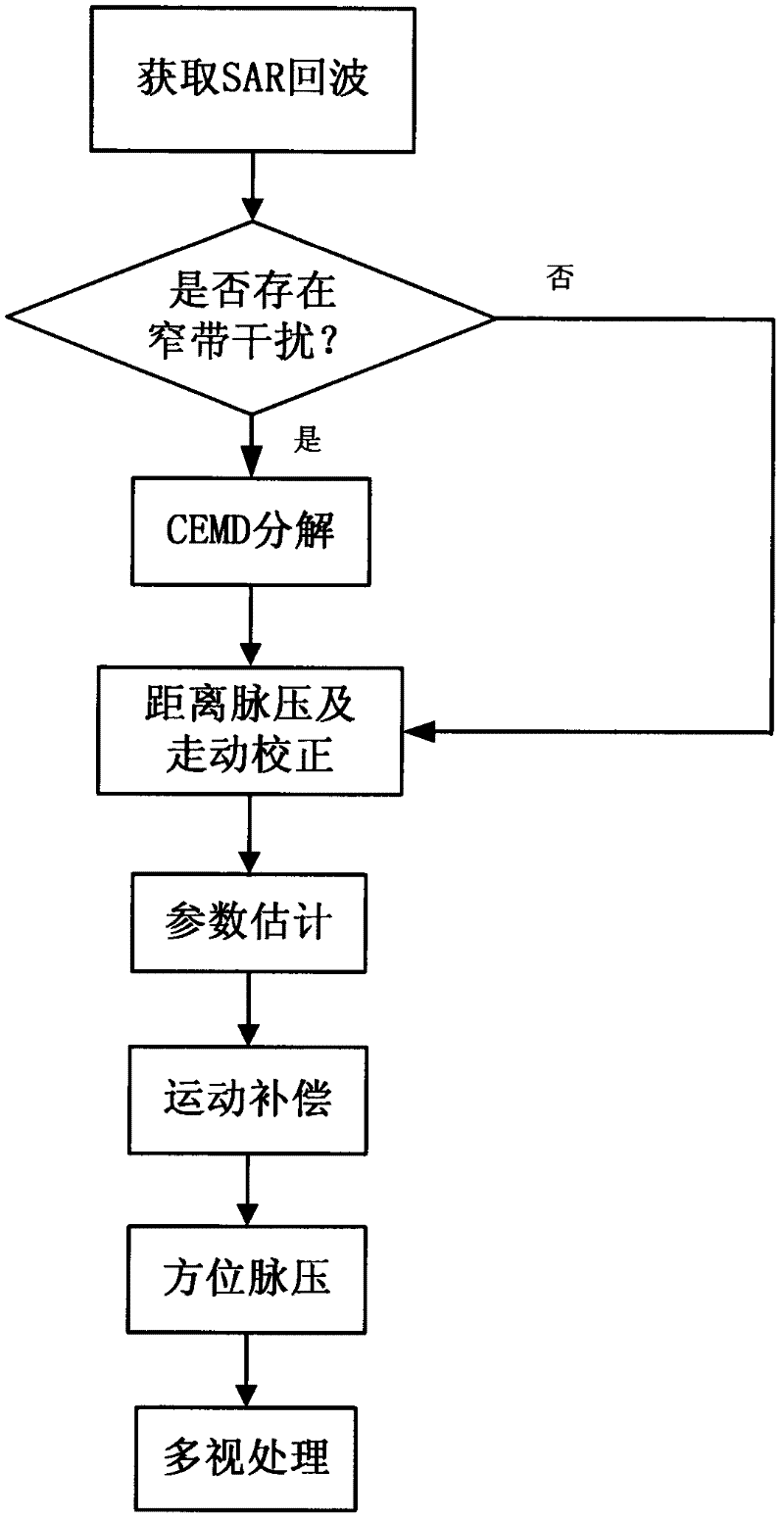

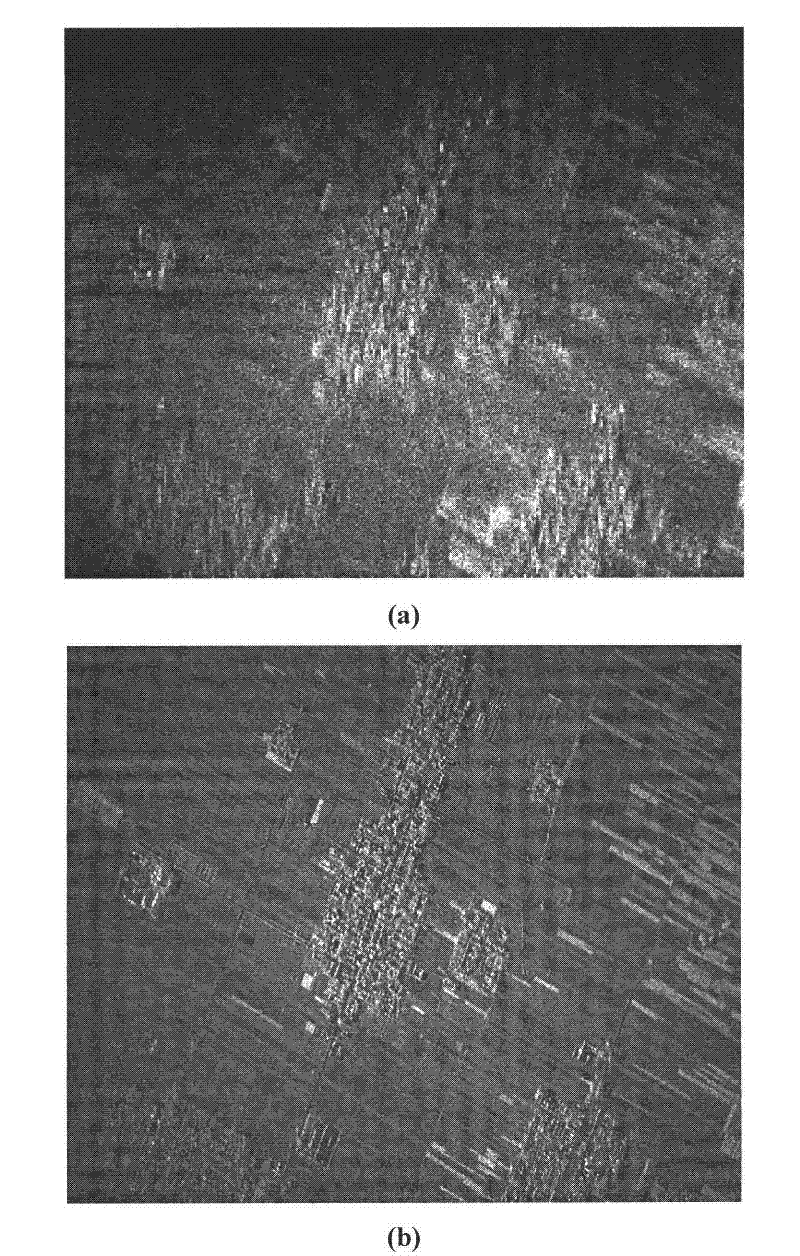

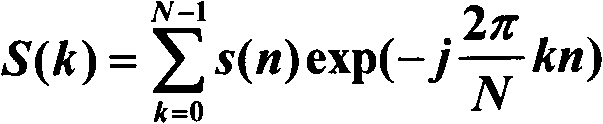

Time-varying narrow-band interference suppression method based on complex empirical mode decomposition

InactiveCN102520396AEasy to implementImprove real-time performanceRadio wave reradiation/reflectionDecompositionEngineering

The invention discloses a time-varying narrow-band interference suppression method based on complex empirical mode decomposition, which includes the following steps, (1), obtaining SAR return wave; (2), judging that whether time-varying narrow-band interference exists; (3), performing the complex empirical mode decomposition; (4), obtaining the range pulse pressure and performing the range walk correction, (5), performing parameter estimation; (6), performing motion compensation; (7), obtaining the orientation pulse pressure; and (8), performing multi-look processing. The narrow-band interference suppression method provided by the invention is suitable for range and orientation two-dimensional time-varying NBI, makes full use of the complex empirical mode decomposition method, sets the threshold suppression strong interference component, has better strong interference suppression ability, retains signals to the utmost extent, and has clearer SAR imaging.

Owner:XIDIAN UNIV

Production method for enabling pure mulberry silk fabric to have natural elasticity style in weft direction

ActiveCN101634097AWeft stress balance and stabilityGuaranteed uniformityLiquid/gas/vapor removalHeating/cooling textile fabricsFiberMoisture absorption

The invention discloses a production method for enabling a pure mulberry silk fabric to have a natural elasticity style in a weft direction. The technological processes sequentially comprise blank silk weaving, preprocessing, cooked smelting, bleaching, water washing, pickling, dewatering or squeezing, coiling, baking stentering and check mounting, wherein the cooked smelting comprises primary smelting and secondary smelting. The baking stentering comprises the following steps: firstly, carrying out baking shaping on a wool carpet finishing machine and then at least carrying out stentering processing for more than two times on a stentering machine. The technological processes of the blank cloth weaving comprise the selection of wefts, the selection of the twisting degree and the twisting direction of the wefts and the twisting direction arrangement of weft combination. Because the pure mulberry silk fabric does not depend on elastic fibre, such as urethane elastic fibre and the like, and adopts blank silk woven by super-strong twisting real silk wefts to carry out the methods of degumming, stentering, shaping and processing so as to enable a pure real silk fabric to obtain better weft direction elasticity and excellent elastic restoring force, the fabric is not easy to crack and has relatively flexible hand feel and good moisture absorption and air permeability, and a dress article made by the fabric shapes the body and has convenient movement, good form retention, small dimensional change rate and small seam slippage.

Owner:DALI SILK ZHEJIANG

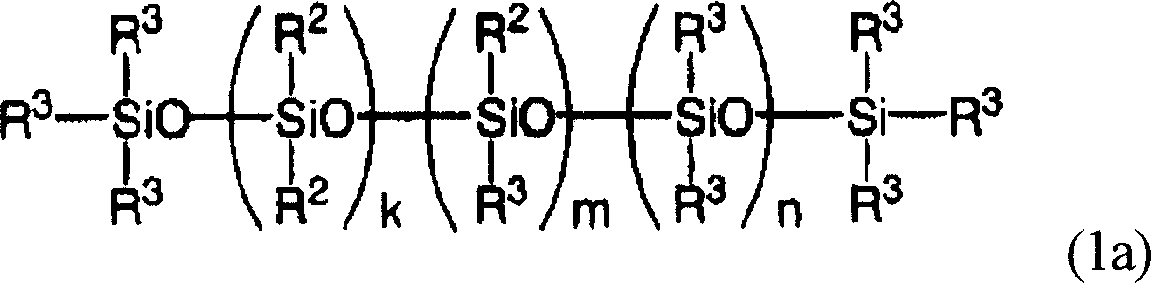

Silicone gel composition

Provided is a silicone gel composition including (A) an organopolysiloxane containing at least one alkenyl group bonded to a silicon atom within each molecule, represented by an average composition formula: Ra R1b SiO(4-a-b) / 2 (wherein, each R group represents, independently, an alkenyl group, each R1 group represents, independently, an unsubstituted or substituted monovalent hydrocarbon group that contains no aliphatic unsaturated bonds, a represents a positive number from 0.0001 to 0.2, b represents a positive number from 1.7 to 2.2, and a+b represents a number within a range from 1.9 to 2.4), (B) an organohydrogenpolysiloxane containing at least two hydrogen atoms bonded to silicon atoms within each molecule, and (C) a platinum-based catalyst. Also provided is the silicone gel composition stated above, in which a penetration value of a cured product of this composition, as defined in JIS K2220, is within a range from 20 to 200. The silicone gel composition generates a silicone gel cured product which displays a low elastic modulus and low stress, and suffers no oil bleeding over time.

Owner:SHIN ETSU CHEM CO LTD

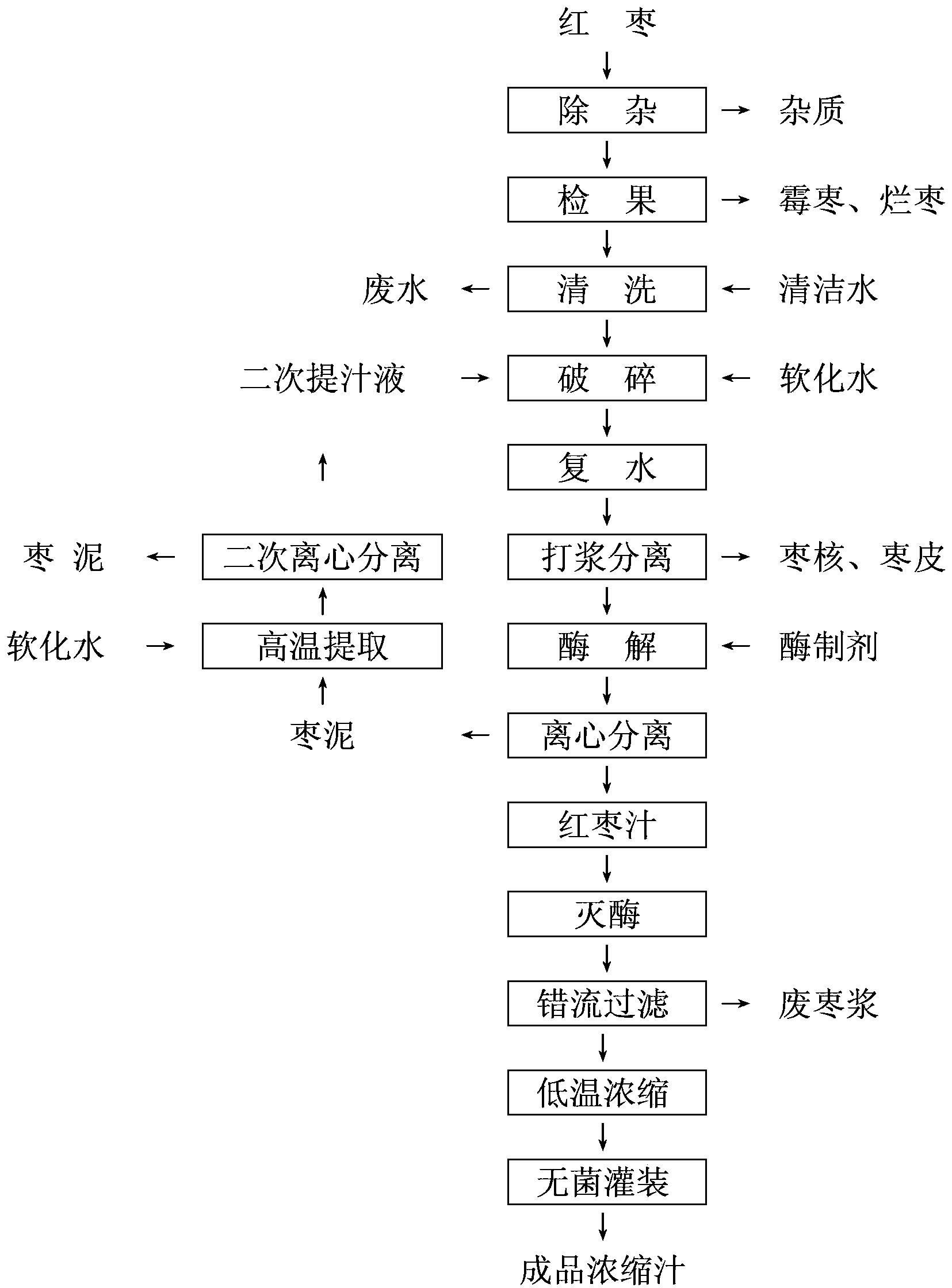

Production technology of red date concentrated clear juice

ActiveCN103519260AAdd flavorKeep the aromaFood thermal treatmentFood preparationAdditive ingredientCross-flow filtration

The invention relates to a production technology of red date concentrated clear juice, which comprises the following steps: impurity removal, fruit check and cleaning; breaking and rehydration; pulping and separation; enzymolysis; centrifugal separation; enzyme deactivation; high-temperature extraction; secondary centrifugal separation; cross flow filtration; vacuum low-temperature concentration; and sterile filling. The production technology provided by the invention has the advantages that with the red dates as the raw materials and by adopting a two-step breaking process, the breaking effect is improved, and the extraction rate of the raw materials is improved; by adopting the low-temperature rehydration process, the bright color, pure flavor and high content of nutritional ingredients of the date juice are guaranteed; by adopting the high-temperature extraction process, the physiologically-active substances in the red dates can be extracted to the greatest degree; since the high-temperature extracted juice returns to the rehydration section, the utilization rate of the raw materials is improved; and by adopting the cross flow filtration, the product has bright color and rich date aroma and is the best raw material for the deep processing of red dates. The production technology provided by the invention is reliable in the production technique of the domestic advanced level, fills up the blank of the key processing technology in domestic red date juice production, is a national initiative and meets the industrial production need.

Owner:CHINA LIGHT IND INT ENG CO LTD

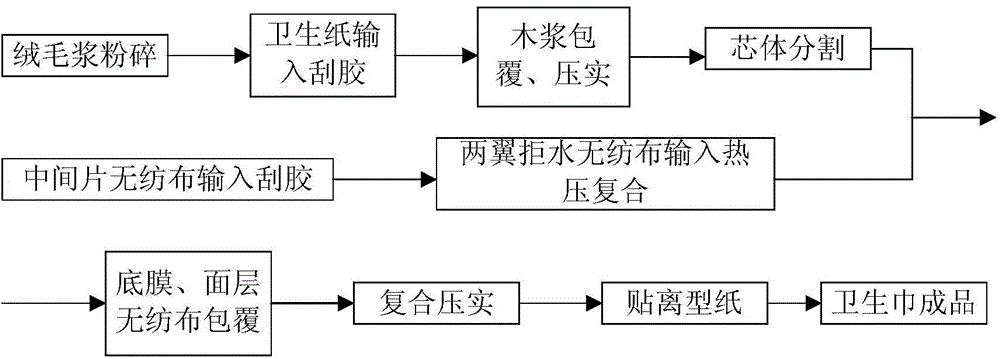

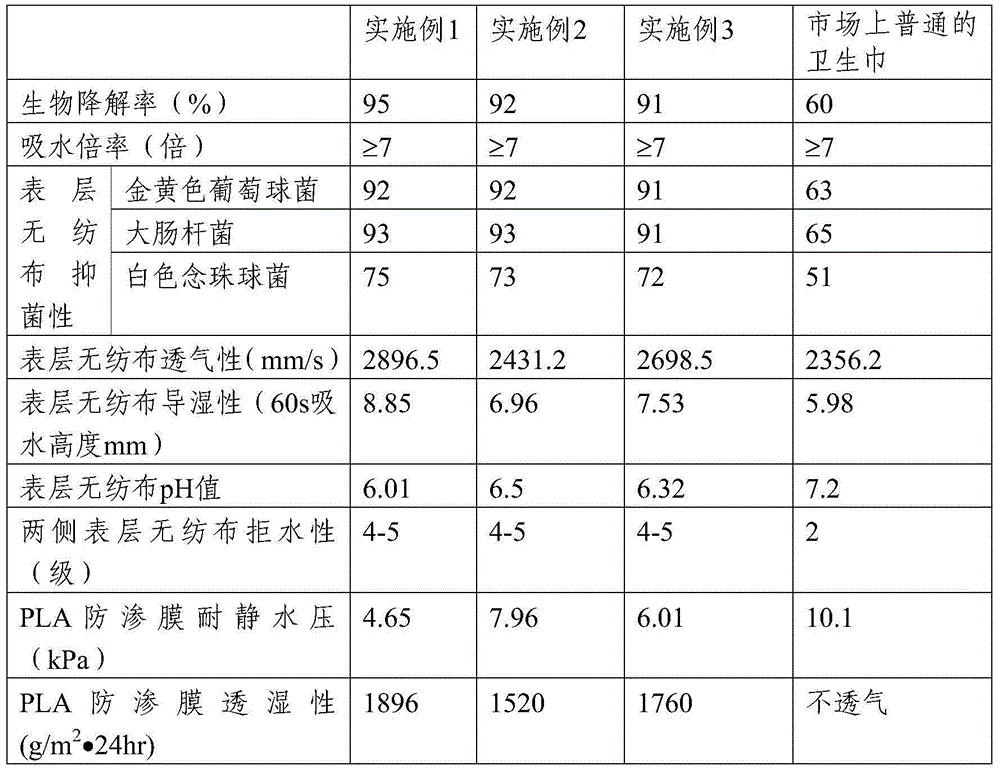

Anti-side leakage degradable polylactic acid sanitary napkin and preparation method thereof

The invention provides an anti-side leakage sanitary napkin, which includes a surface non-woven fabric and a bottom impermeable membrane disposed from the inside out. The surface non-woven fabric has a three-piece structure, the intermediate piece of surface non-woven fabric and the two-wing surface non-woven fabrics are sticked together, and the space between the intermediate piece of surface non-woven fabric and the bottom impermeable membrane is filled with a toilet paper coated wood pulp cellulose absorption core. The surface of the sanitary napkin provided by the invention is composed of 100% polylactic acid fiber or PLA / PBHV fiber hot blast nonwoven fabric. The polylactic acid fiber retains the original characteristics and does not cause any damage. As polylactic acid is formed by polymerization of lactic acid molecules as monomers and spinning, polylactic acid molecules with short molecular chains possibly exist on the fiber surface, so that the pH value of a polylactic acid non-woven fabric surface shows weak acidity and is consistent with that of human body skin. Also an odor removal function is provided. The lateral two pieces of non-woven fabrics have greater gram weight and thickness than the intermediate piece, and side leakage cannot be caused.

Owner:马鞍山同杰良生物材料有限公司

Purple skin onion wine and preparation process thereof

The invention discloses purple skin onion wine and a preparation process thereof, and belongs to the technical field of wine making. The invention discloses a purple skin onion wine technology. The purple skin onion wine comprises the following main raw materials in percentage by weight: 70 to 90 percent of fresh grapes, 5 to 20 percent of purple skin onion, and 5 to 15 percent of skin of purple skin onion. The purple skin onion wine is prepared by the following brewing working procedures of: 1, pulping and mixing; 2, performing alcoholic fermentation; 3, performing malic acid-lactic acid fermentation; 4, storing in an oak barrel; and 5, performing stability treatment, and finally, filtering, filling and bottling. The purple skin onion health-care wine is advanced in process, and has the advantages that the content of flavonoid substances is higher, the fragrance of onions is coordinated with the fragrance of wine, and the stability of the wine is higher; the purple skin onion health-care wine has the health-care effect of preventing arteriosclerosis and cardiovascular and cerebrovascular diseases; and the purple skin onion health-care wine has good economic and environmental protection benefits.

Owner:QILU UNIV OF TECH

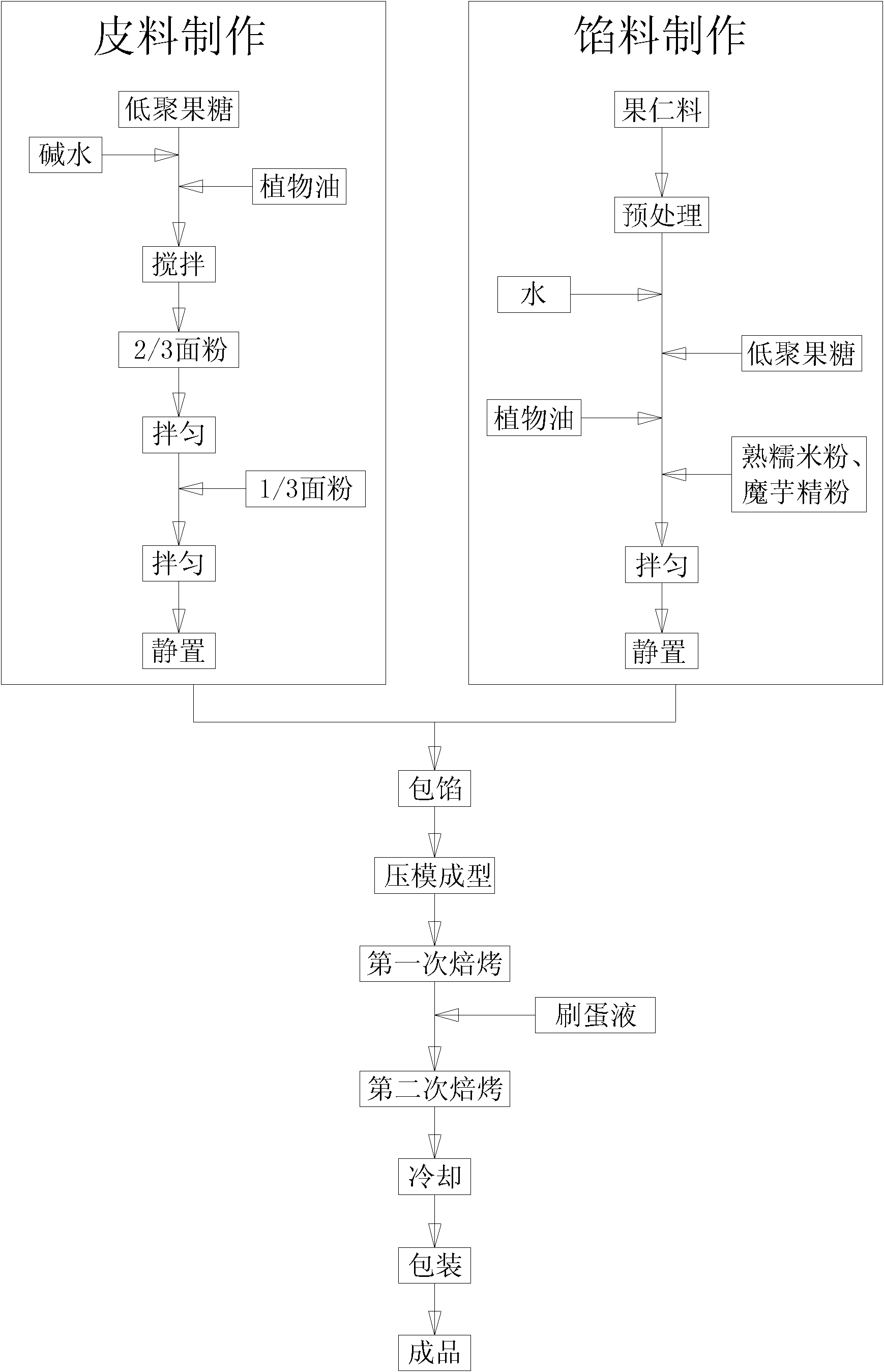

Nut maigre moon cake and preparation method thereof

The invention discloses a nut maigre moon cake and a preparation method thereof, wherein the nut maigre moon cake comprises a cake skin and fillings, and the cake skin is coated outside the cake fillings, wherein the cake skin comprises the following components in percentage by weight: 47%-55% of flour, 32%-38% of fructo-oligose, 10%-16% of plant oil and 1.0%-1.5% of alkaline water. The fillings comprise the following components in percentage by weight: 15%-19% of fructo-oligose, 8.5%-11% of ripe glutinous rice powder, 8.5%-11% of water, 10%-14% of sesame seeds, 8.5%-11% of apricot kernel, 8.5%-11% of cashew kernel, 8.5%-11% of melon seeds, 8%-10% of olive kernel, and 6.5%-8.5% of plant oil. In the cake skin provided by the invention, the fructo-oligose is used for replacing the traditional granulated sugar so as to reduce the heat of the moon cake; and in the fillings, the pure plant oil is used for replacing the traditional animal oil so as to improve the unsaturated fatty acid content in the moon cake, so that not only can the technology and mouth feel of the Guangdong-type nut crisp moon cake be kept, but also more nutrition value and health protection function are given.

Owner:JUXIANGYUAN HEALTH FOOD ZHONGSHAN

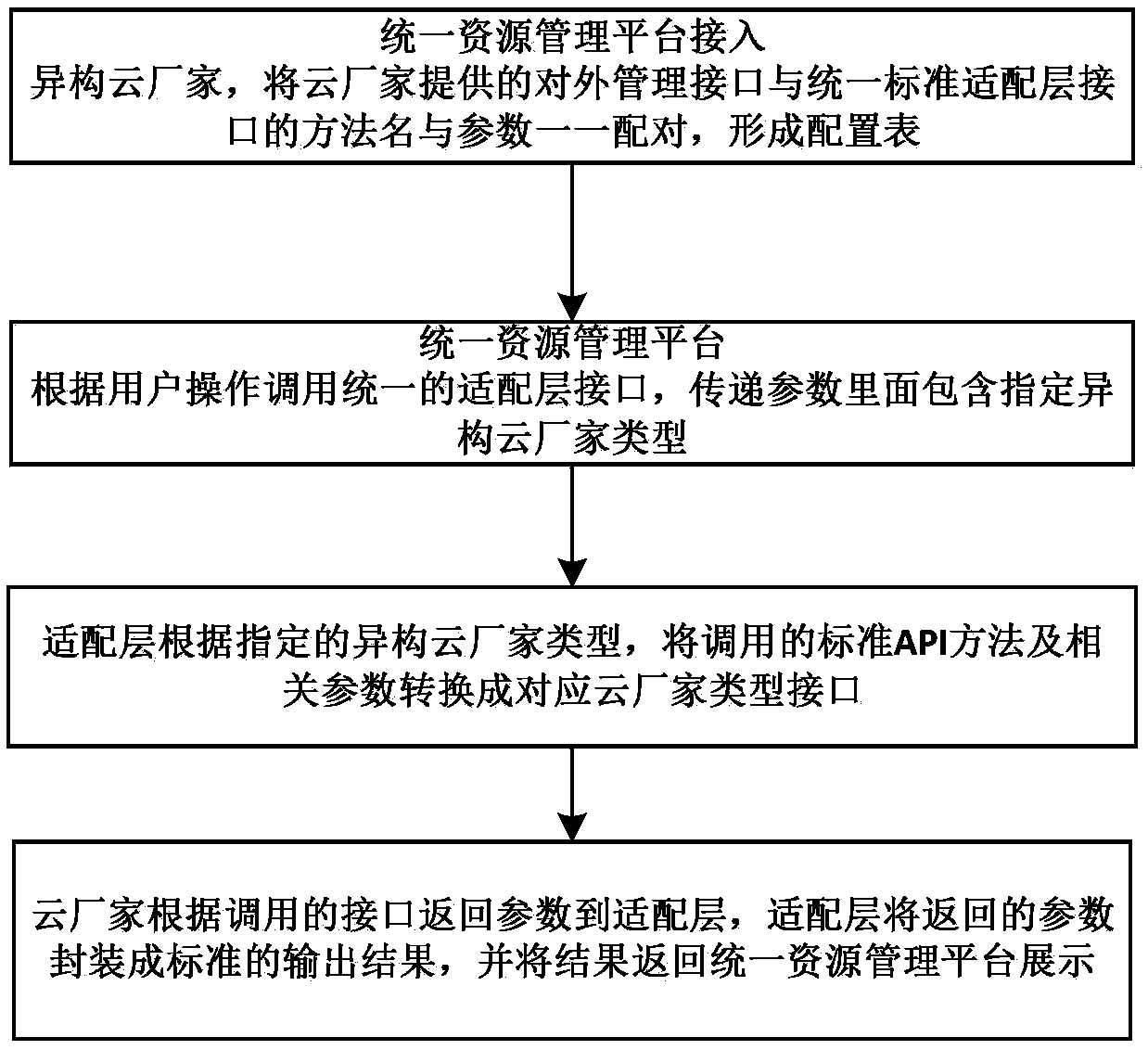

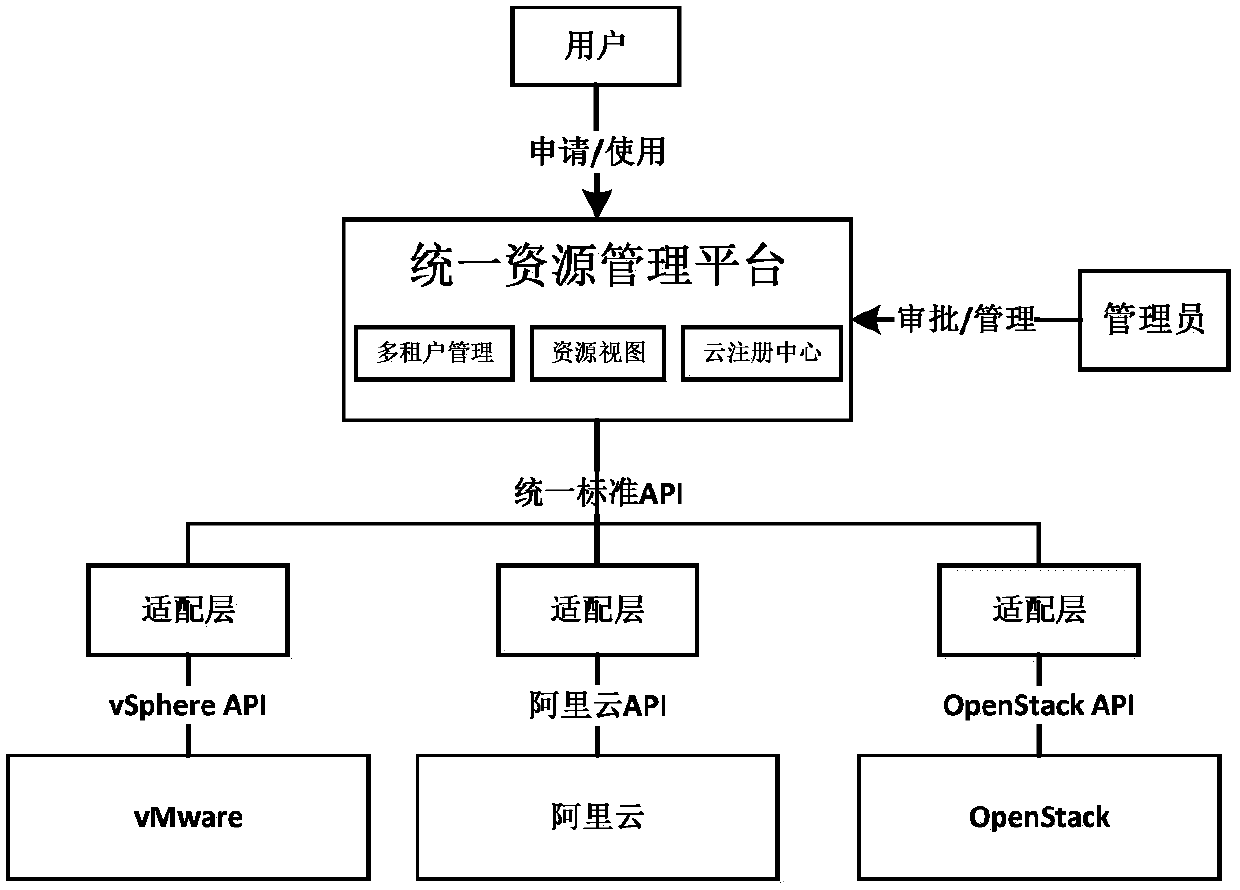

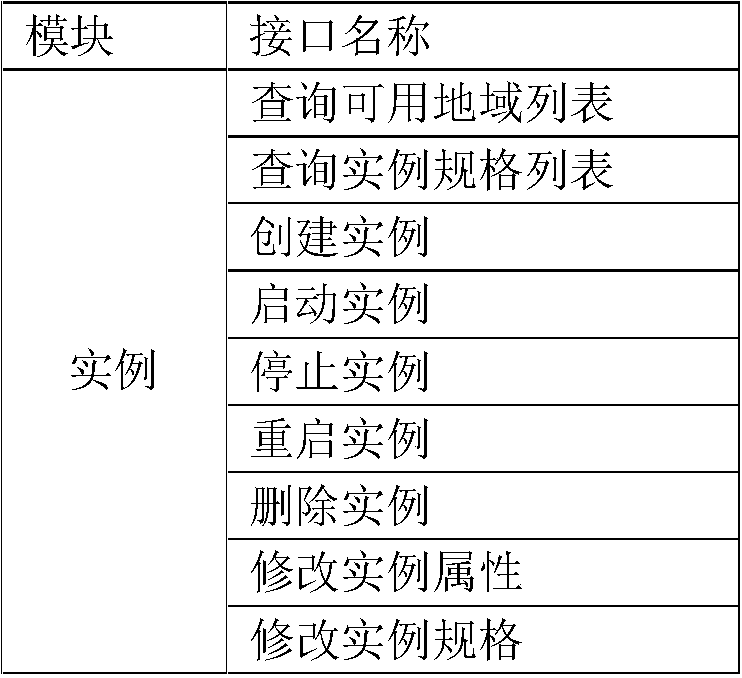

Heterogeneous cloud management system and method suitable for cloud computing

InactiveCN107659624AReduce development complexityRetain propertiesTransmissionLayer interfaceCloud management

The invention relates to the technical field of cloud computing, and particularly relates to a heterogeneous cloud management system and method suitable for cloud computing. The method comprises the steps of first, accessing a heterogeneous cloud manufacture, and matching method names and parameters of external management interfaces provided by the cloud manufacture and uniform standard adapter layer interfaces correspondingly, so as to form a configuration table; then, invoking a uniform adapter layer interface by a platform according to a user operation, wherein a transmission parameter comprises a designated heterogeneous cloud manufacture type; then, converting the invoked standard API method and related parameter into an interface of a corresponding cloud manufacture by an adapter layer according to the designated heterogeneous cloud manufacture type; and finally, returning the parameter to the adapter layer by the cloud manufacture according to the invoked interface, packaging the returned parameter into a standard output result by the adapter layer, and returning the result to the platform to display. The method solves the management problem of the heterogeneous cloud platform, and can be applied to unified management of the heterogeneous cloud platform.

Owner:G CLOUD TECH

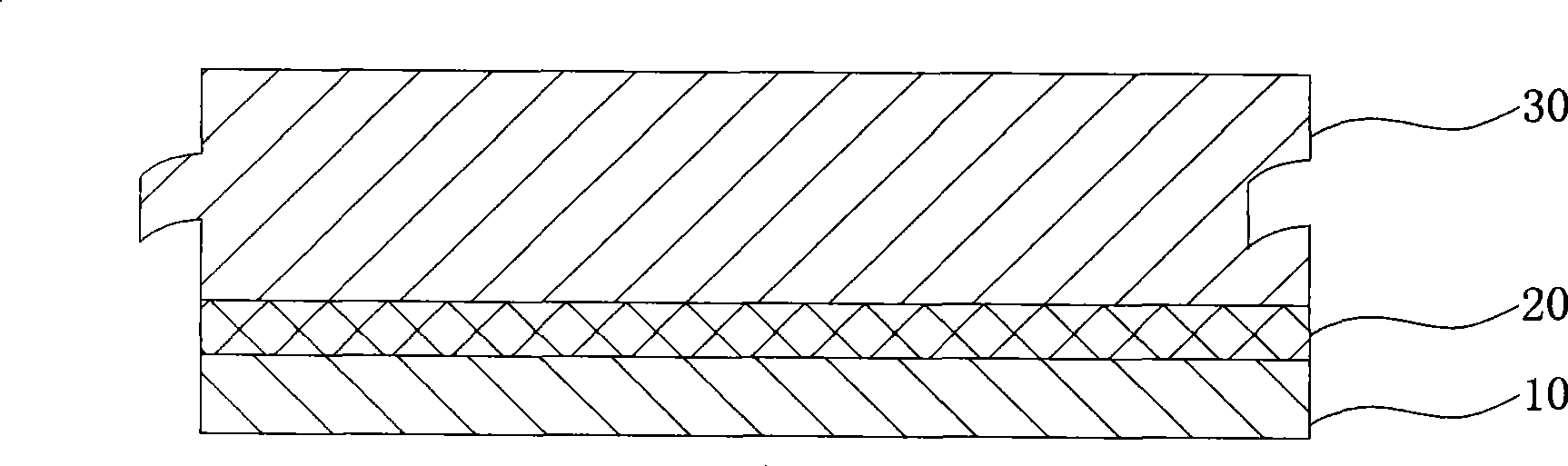

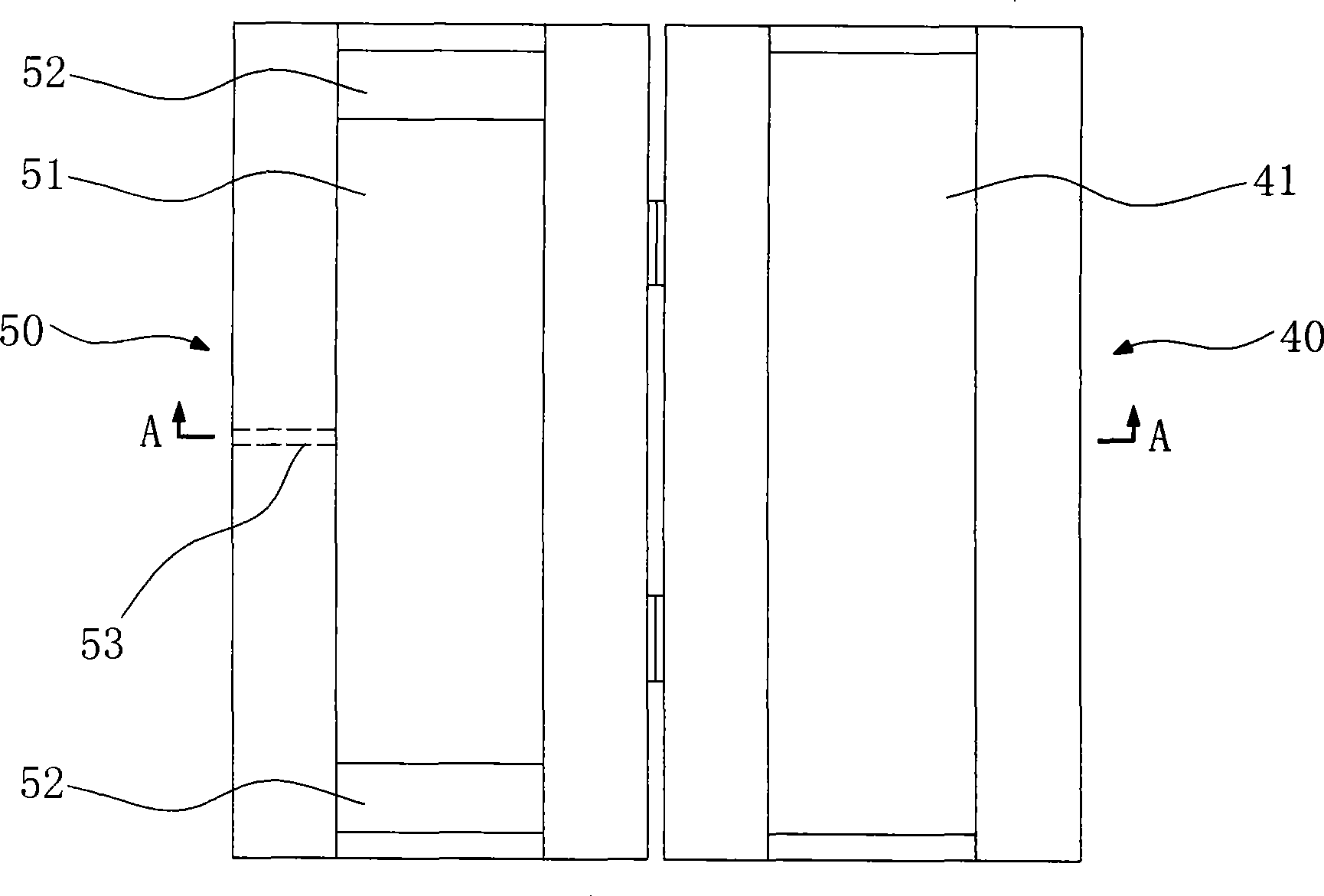

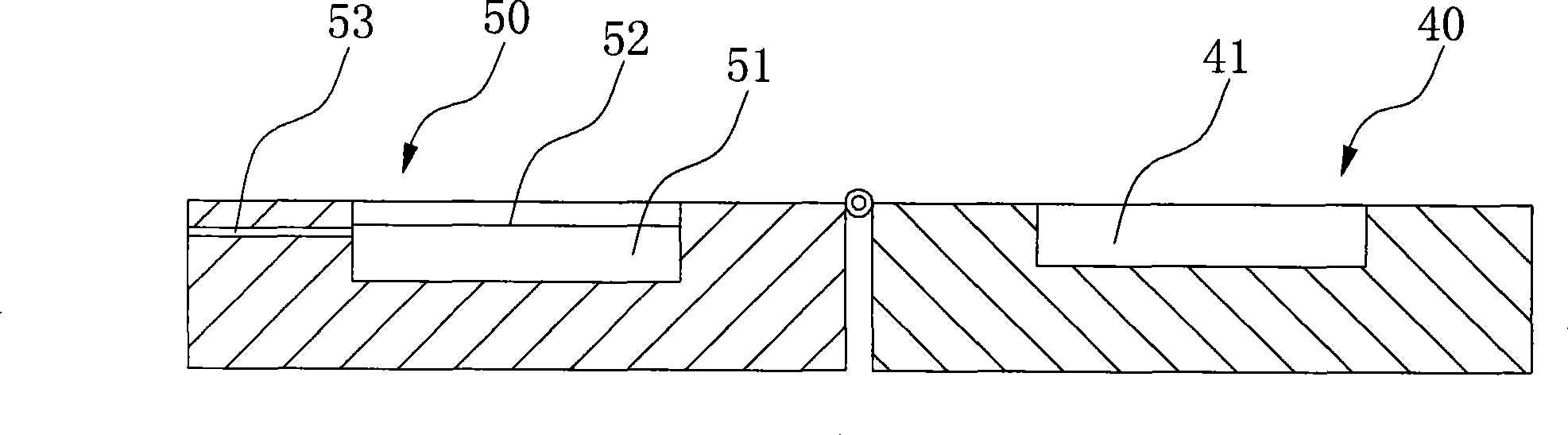

Novel composite flooring, mold thereof and processing method

The invention belongs to the technical field of floor, in particular to a novel composite floor, a die and a processing method thereof. The substrate of the composite floor is a plastic-wooden plate, the surface layer of the composite floor is a solid wood plate, and an elastic layer is arranged between the substrate and the surface layer. When the composite floor is processed, raw materials such as PVC resin and so on are mixed and extruded to obtain a PVC plastic-wooden plate; the PVC plastic-wooden plate taken as the substrate and the solid wood plate taken as the surface layer are placed into the die respectively, and polyurethane foam materials are injected to a space enclosed by the solid wood plate, the PVC plastic-wooden plate and the die through a passage on a base of the die, and is foamed; and the composite floor is pressed by a press machine after the polyurethane foam materials are foamed fully. The invention has simple processing and manufacturing, high production efficiency and low production cost; and the obtained composite floor is safe, environment-friendly, moistureproof, waterproof and mothproof, has soft and comfortable foot feeling, good temperature insulating effect and high service performance, and has good effect of vibration reduction and sound insulation because the polyurethane foam materials play a role of vibration reduction in the middle layer.

Owner:郎玉山

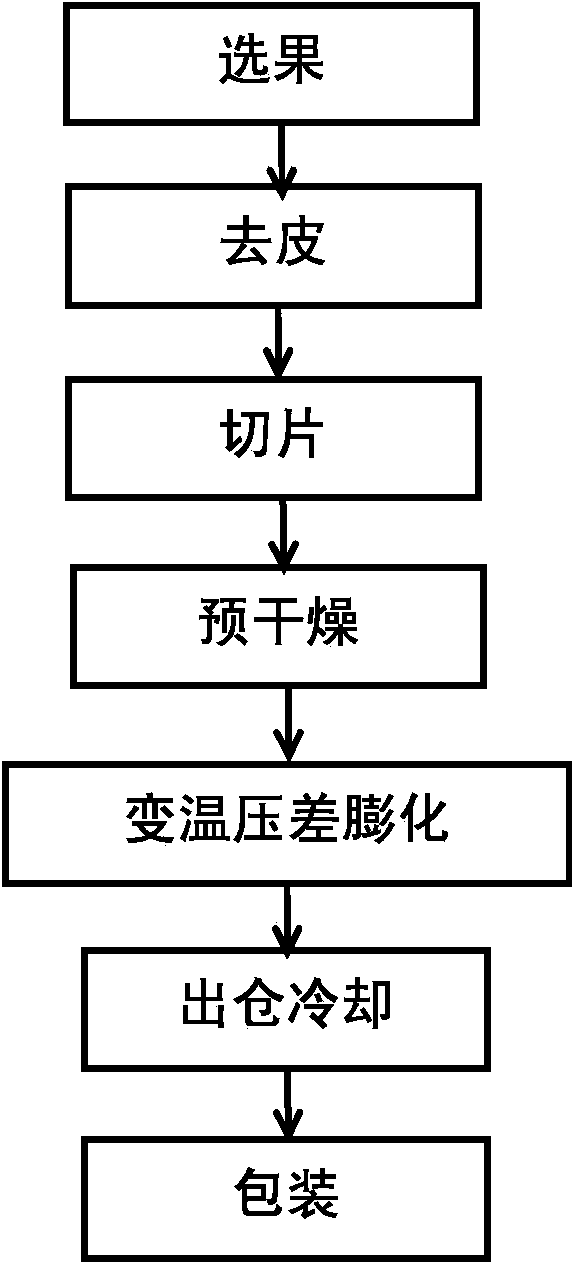

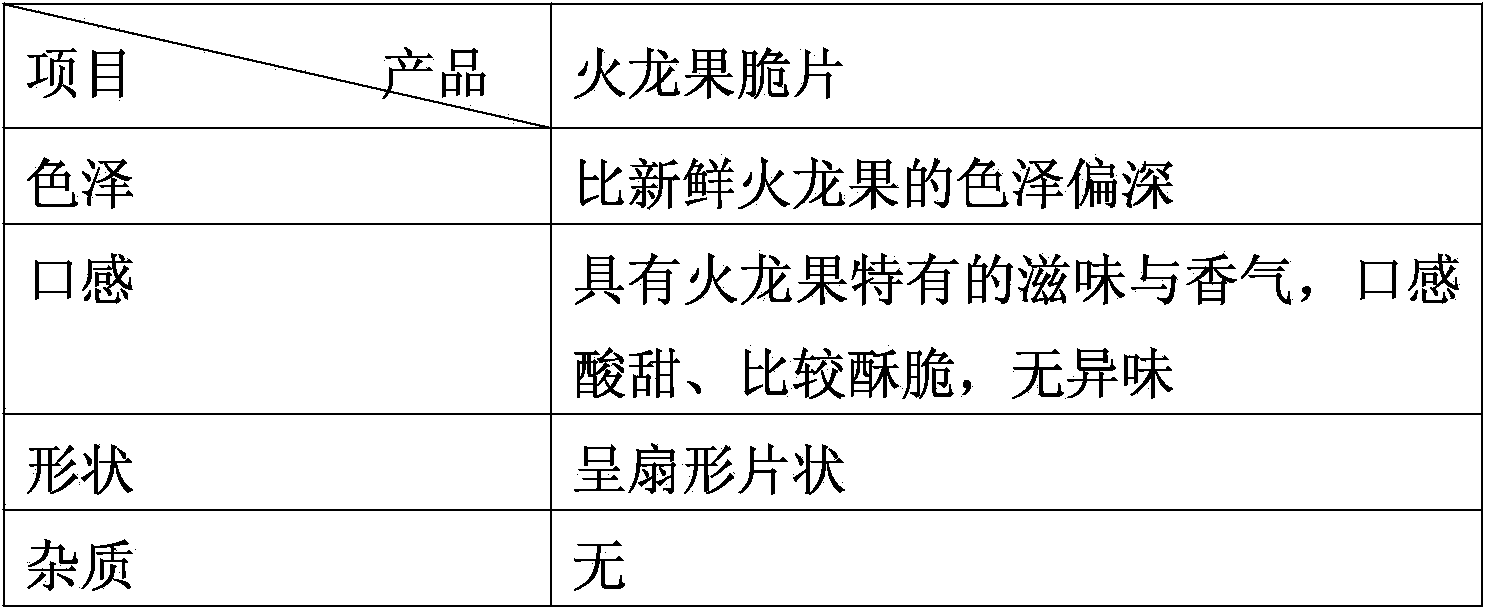

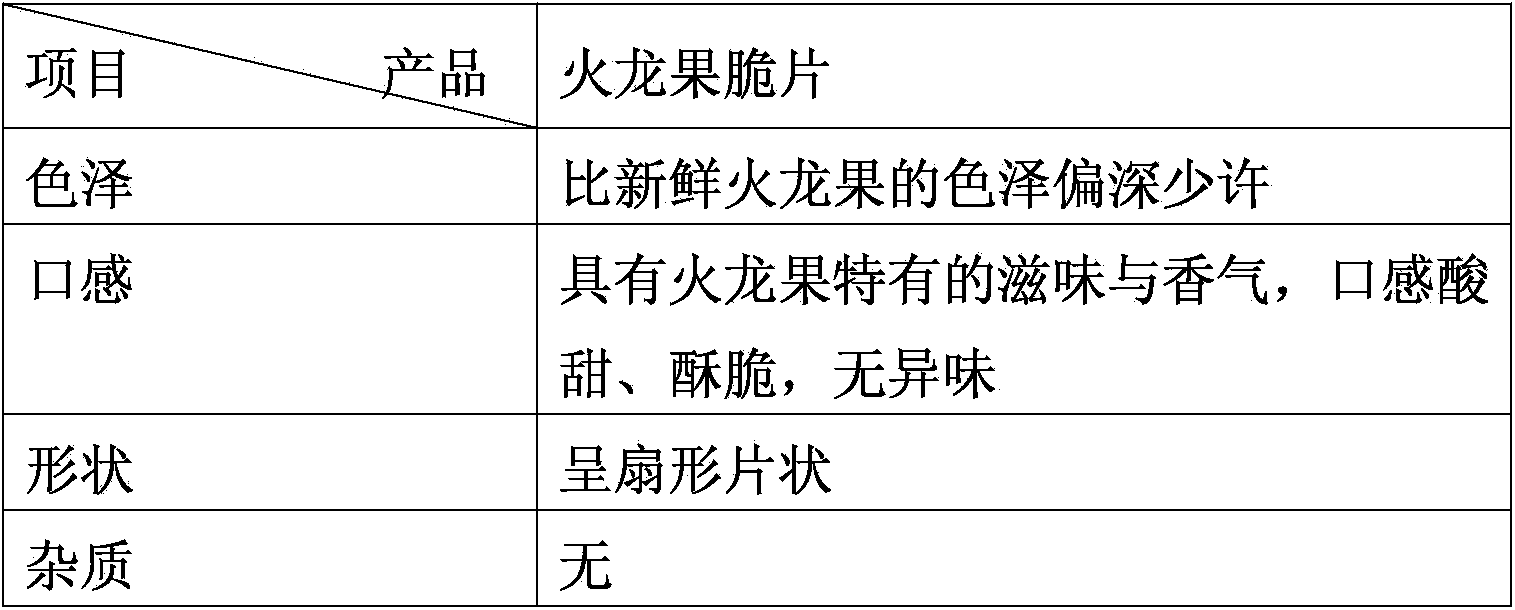

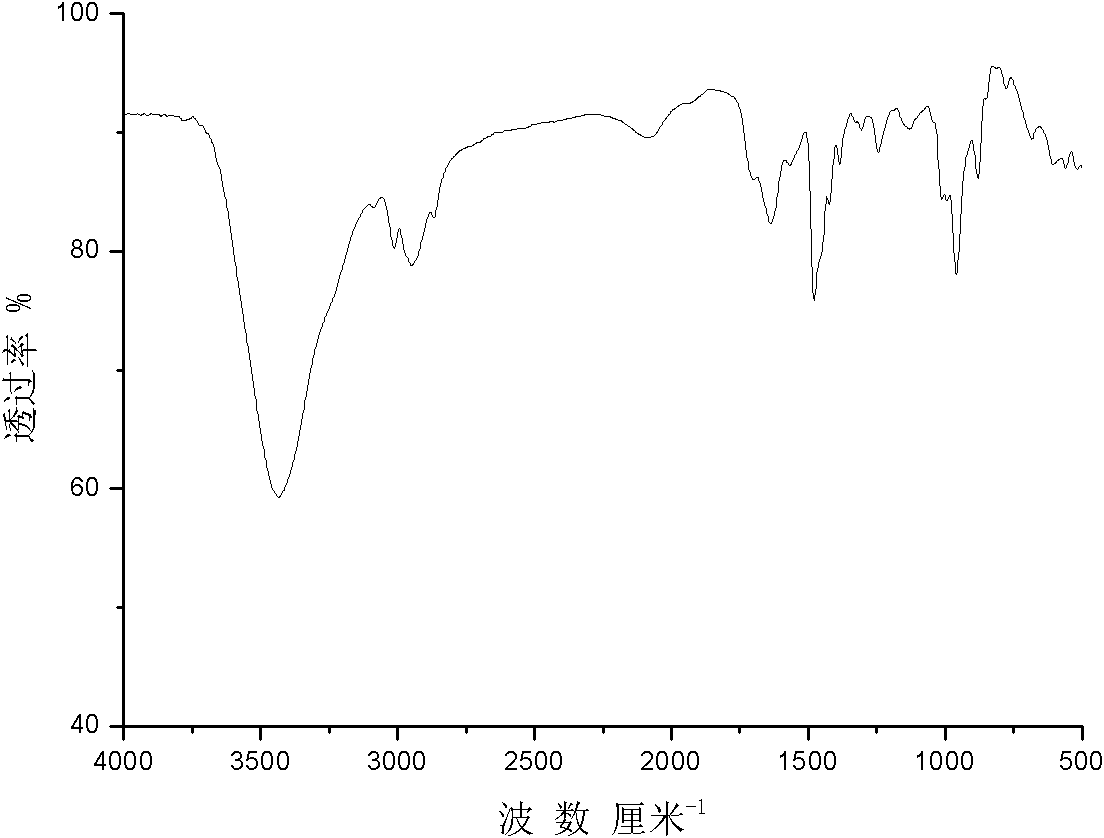

Pitaya crisp sheets and preparation method thereof

The invention relates to pitaya crisp sheets and a preparation method thereof, and belongs to the technical field of foodstuff processing. The preparation method comprises: performing pre-drying on pitaya sheets to have a water content of 10-20% by employing a vacuum drying method, then putting pitaya sheets in a puffing tank to perform variable-temperature different-pressure puffing, specifically, stagnating at 70-90 DEG C for 5-10 min, then instantaneously reducing the pressure to a vacuum state to perform puffing, keeping the vacuum state at 60-80 DEG C for 1.5-3.5 h, and finally cooling to 40-50 DEG C and keeping for 15-45 min. According to the preparation method provided by the invention, no pigments and no additives are added during operation, so that the original color, the original flavor and the original nutrition of the fruit are relatively kept; the product is crisp in mouthfeel and good in quality; and the preparation method is simple in technological process, easy to operate and relatively low in energy consumption.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

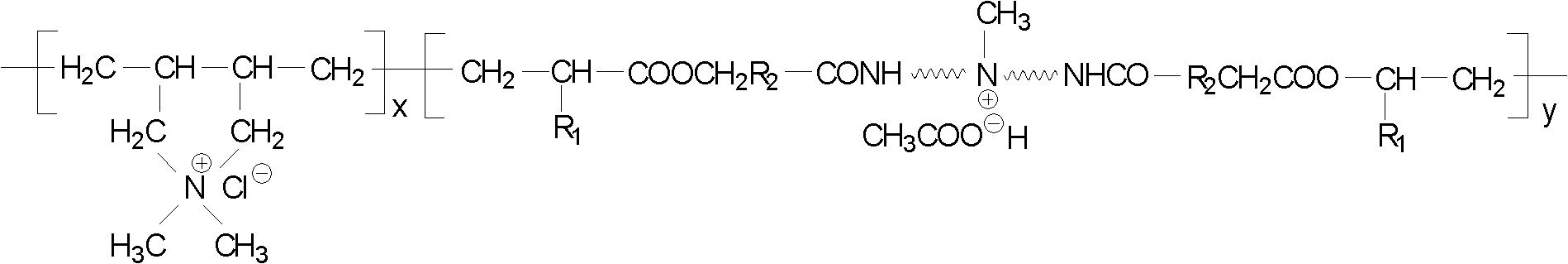

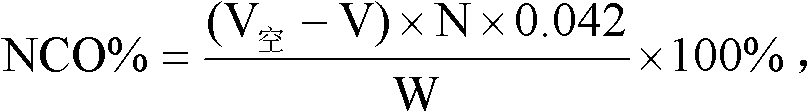

Method for preparing cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent

The invention discloses a method for preparing a cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent, which comprises: synthesizing vinyl terminated cationic polyurethane prepolymer by using isocyanate, polyol, N-methyldiethanolamine and acrylate functional monomers as polymerization monomers; hydrating and dispersing the vinyl terminated cationic polyurethane prepolymer, and performing reversed emulsion polymerization of the vinyl terminated cationic polyurethane prepolymer and dimethyl diallyl ammonium chloride in a water soluble initiator to obtain the formaldehyde-free poly(urethane-dimethyldiallylammonium chloride) color fixing agent. The cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent contains no formaldehyde, retains the property of a polyurethane material, realizes the organic combination of the high performance of the two kinds of resins due to the high positive charge density of a poly(dimethyl diallyl ammonium chloride) chain segment and can effectively improve the color fastness of the dyed fabrics. When the color fixing agent is used, the color fastness of the fabrics dyed with direct dye and active dye is as follows: the dry friction fastness is grade 5, the wet friction fastness is grade 3 to 4, and the brushing fastness is 4 to 5.

Owner:ANHUI UNIVERSITY

Artificial culture method of cordyceps longissima sporocarp

InactiveCN102742454AAddressing resource scarcityGrow fastHorticultureBiological activationCulture fungus

The invention relates to an artificial culture method of cordyceps longissima sporocarp. A strain is cordyceps longissima agamotype-hirsutella longissima. The artificial culture method of the cordyceps longissima sporocarp includes A, cant tube strain activation culture; B, liquid shake flask seed culture; C, hypha stage culture; and D, sporocarp culture. The cordyceps longissima sporocarp cultured artificially has rodlike stroma and is solitary or branching and cinnamon, length is 1-7cm, the diameter is 1-3mm, a large amount of white coremium is grown at the top end or the side face of the stroma at later stage of sporocarp culture and is compact. The artificial culture method of the cordyceps longissima sporocarp is initiated, can perform large-scale culture of the cordyceps longissima sporocarp, solves the problem that wild cordyceps longissima sources are deficient, establishes a foundation for comprehensive development of cordyceps longissima edible value and industrialized production, provides technical support, and is simple in process, low in cost, wide in raw material source, non-toxic, free of pollution and capable of performing large-scale production.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Preparation method of enzyme hydrolysis pearl powder

InactiveCN101695505AIncrease hydrolysis rateRetain propertiesCosmetic preparationsSenses disorderNeutral proteaseWet grinding

The invention discloses a preparation method of enzyme hydrolysis pearl powder, comprising the following steps of: superfine pulverizing and wet grinding the pearl until more than 90 percent of the particles have a diameter less than 0.5 micron, mixing the pearl powder with water into turbid liquid, heating the turbid liquid to 40 to 60 DEG C, adding neutral protease for enzyme hydrolysis and enzyme destruction, and drying by spraying to obtain the enzyme hydrolysis pearl powder. The technical method is simple, the proteolysis ratio of the pearl is high, and the special flavour and effective constituent of the pearl powder are maintained to the maximum. The pearl powder can be easily digested and absorbed by a human body, can be easily absorbed by the skin and is applicable to medicine, nutrition and skin-care product as an additive.

Owner:HAINAN JINGRUN PEARL BIOTECH

Method for processing black benne oil

InactiveCN101317610ARetain nutrientsRetain propertiesEdible oils/fatsFood preparationEngineeringBottle

The invention discloses a processing method for preparing purely natural health-caring black sesame oil by using black sesame as the raw material. The method of the invention comprises the steps as follows: colour selecting of the black sesame, washing by clean water, centrifugal dewatering, drying, smoking and dedusting, grinding, stirring with water, separating, depositing, sterilizing and bottle filling; as the stone grinding process is adopted, no high temperature is generated during the grinding process of the invention, thus completely preserving the nutrition composition of the black sesame, generating no glutin or little glutin and generating more oil correspondingly; during the deposition process, diatomite is not added, the black sesame is statically put hermetically under normal temperature; the temperature preservation disposal is not required and the energy resource is not wasted; in the whole processing, no matters are added, thus preserving the unique fragrance and the nutrition composition of the black sesame oil. Compared with the prior art, the processing method of the invention has high yield, the produced black sesame oil can preserve the nutrition composition and the unique fragrance of the black sesame to the utmost extent and has no poor impurities and wastes no energy resource.

Owner:任艳丽

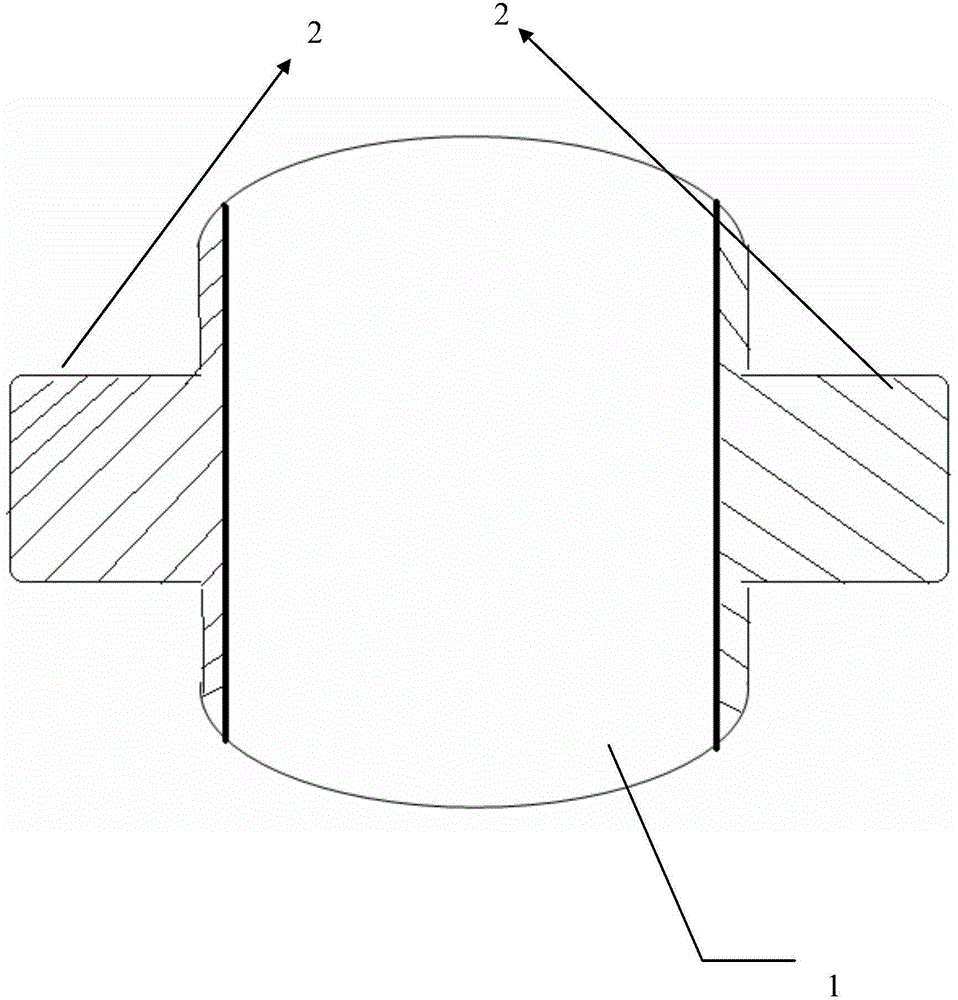

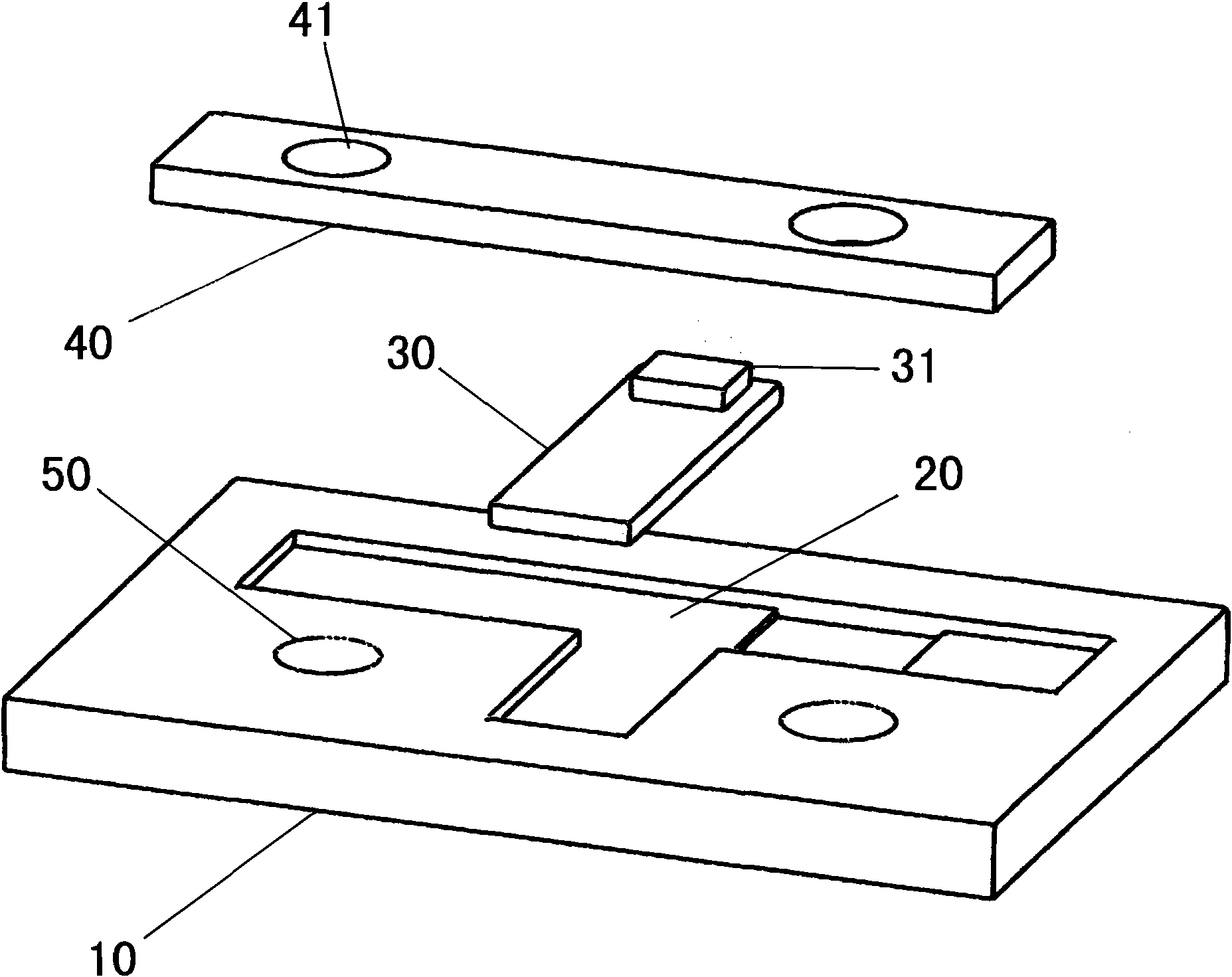

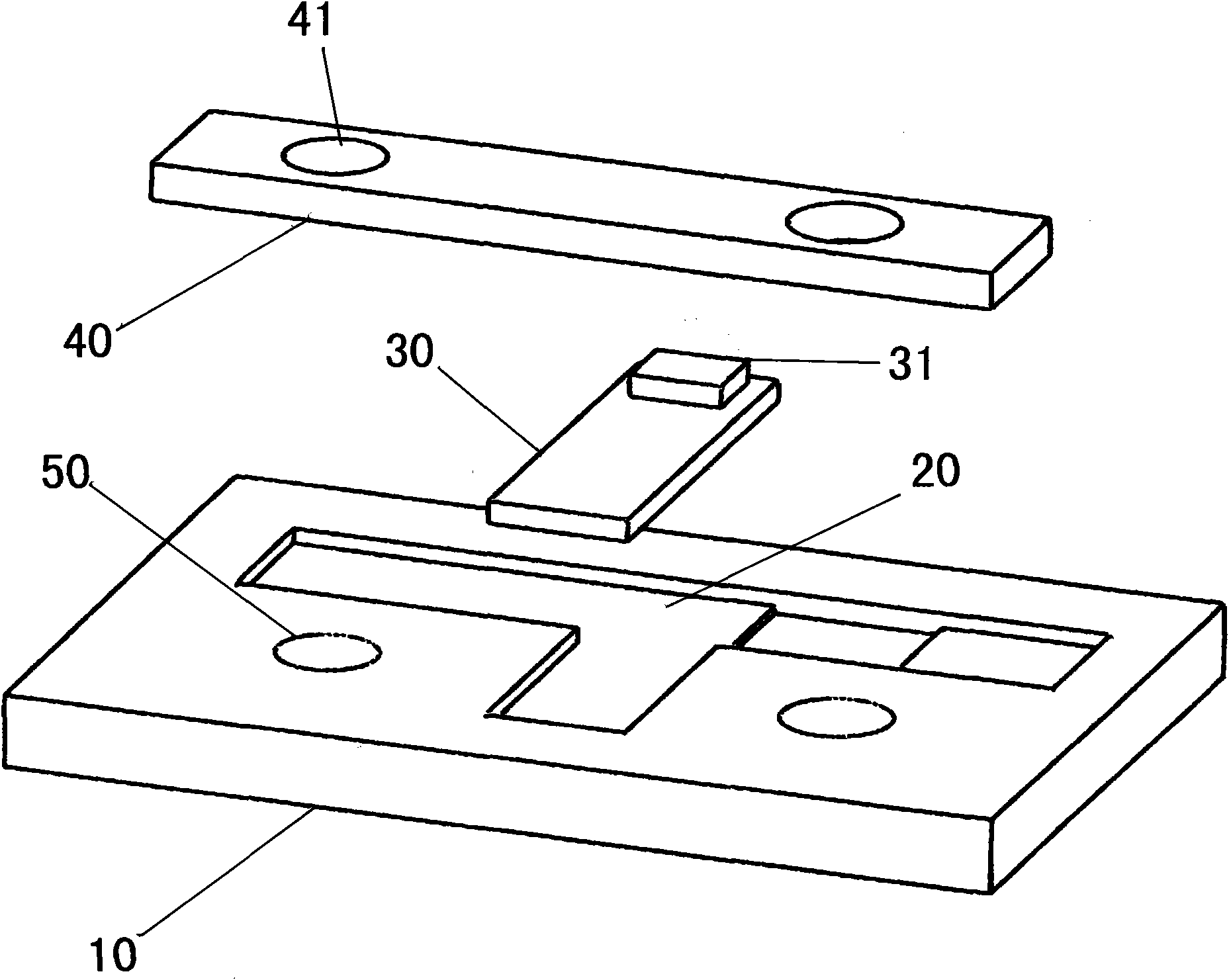

Semiconductor laser aging clamp

InactiveCN101872936ASimple designReduced Alignment DifficultyLaser detailsSemiconductor lasersSemiconductor packageEngineering

The invention provides a semiconductor laser aging clamp which comprises a main body, a heat sink and a cover plate, wherein the main body is a printed circuit board, a square, bar-shaped or T-shaped groove is arranged in the middle of the main body, and screw holes are arranged at two sides of the groove on the main body and correspond to circular holes on the cover plate; the heat sink with a laser is positioned in the groove; and the cover plate is used for covering the heat sink, and the circular holes are arranged at two sides on the upper surface of the cover plate and used for fixing the cover plate on the main body through screws.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

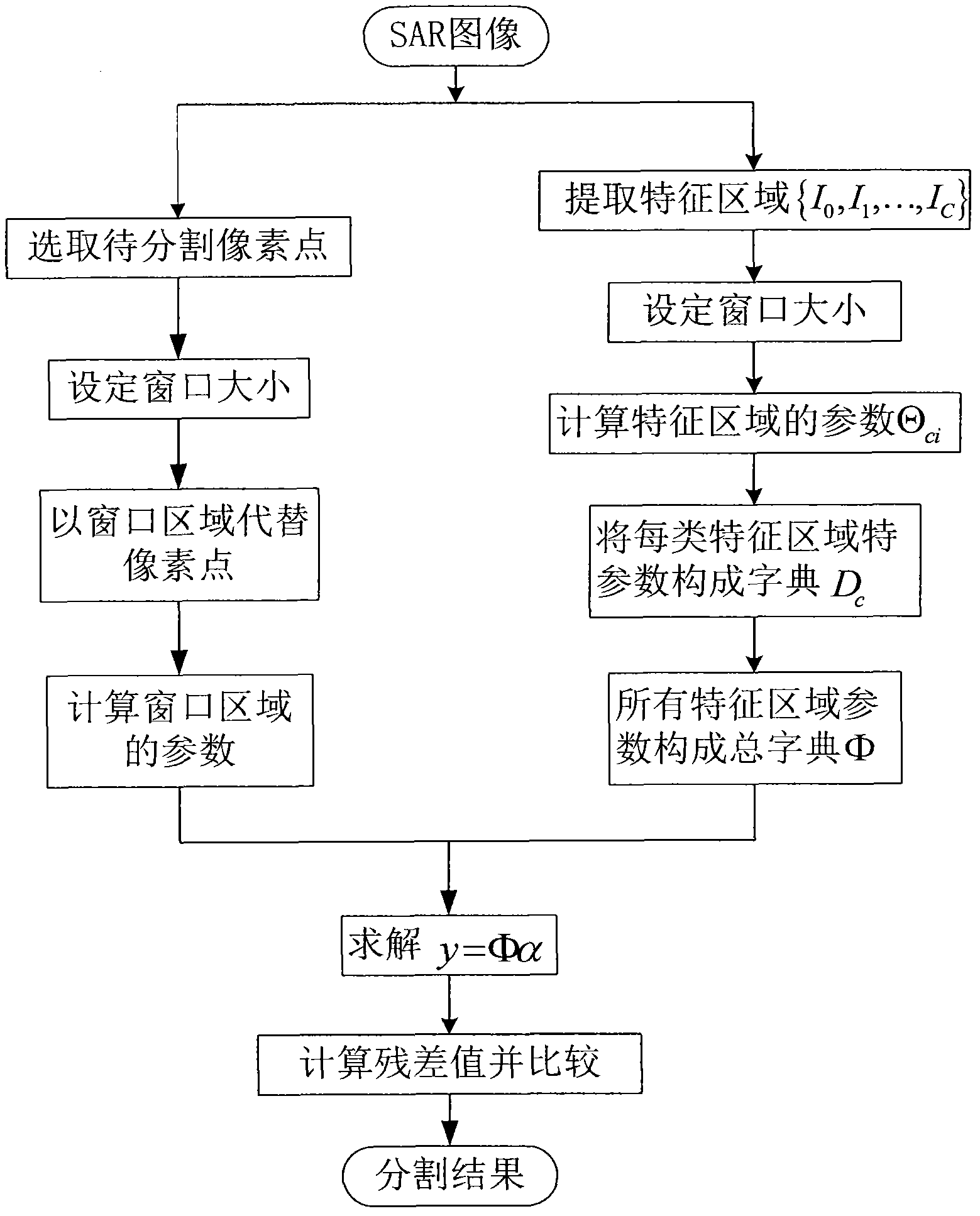

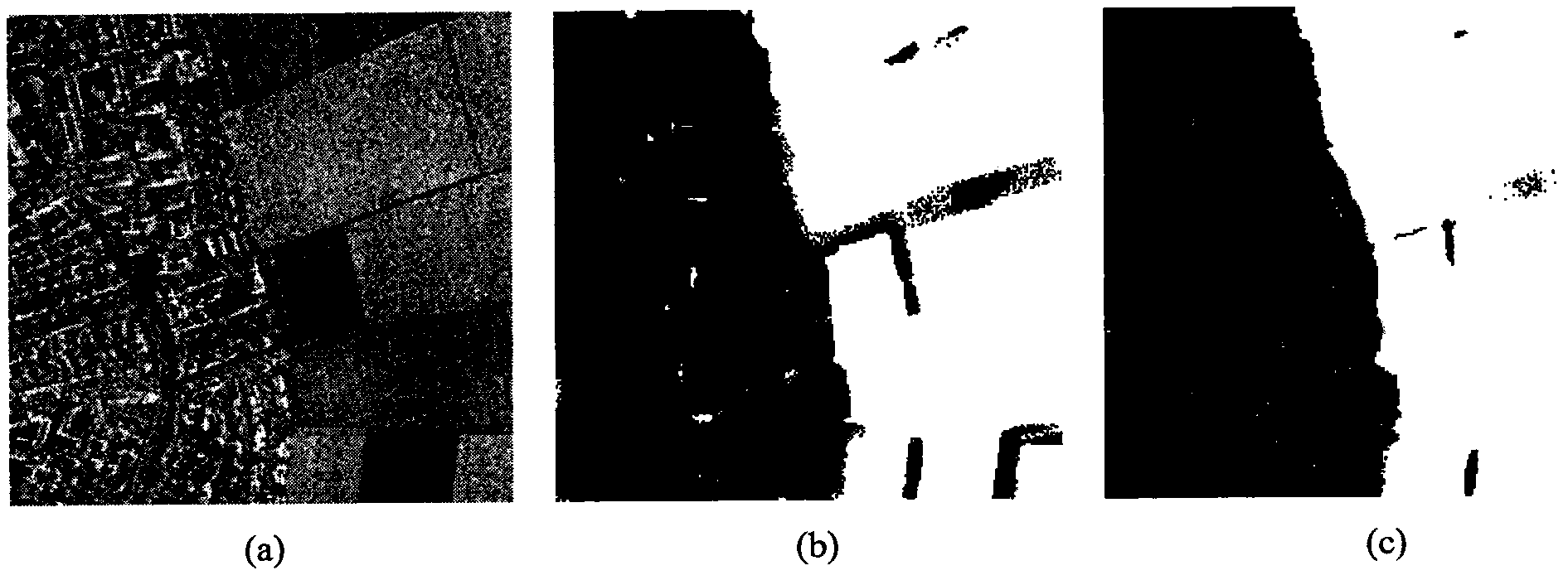

K distribution and texture feature-based SAR (Synthetic Aperture Radar) image segmentation method

ActiveCN103366371AEasy to captureRetain propertiesImage analysisImaging processingSynthetic aperture radar

The invention discloses a K distribution and texture feature-based SAR (Synthetic Aperture Radar) image segmentation method, which belongs to the technical field of image processing. The segmentation method comprises the following steps: intercepting category C training samples on an SAR image to be segmented; intercepting 100 training samples of 9*9 at a feature region; extracting feature parameters of the training samples by using a K distribution statistical model and a gray scale co-occurrence matrix; arranging each category of feature coefficients into a matrix, i.e., a dictionary of cth category targets; calculating the dictionary of each category of targets and arranging the dictionaries to form a global big dictionary in sequence according to the method; inputting the SAR image to be segmented, substituting each pixel point by 9*9 pixel points of a neighbor of the pixel point, and solving a feature coefficient inverse solution matrix operation of the pixel point to obtain weight a; making delta i (a), i=1, ellipsis, wherein C is a vector which only remains the coefficient corresponding to the cth category in a and enable zero setting of the rest coefficients; and calculating a residual error function and repeating the steps to obtain a segmentation result of each pixel point of the SAR image to be processed according to the fact that the minimum error function is a category label of the feature coefficients.

Owner:XIDIAN UNIV

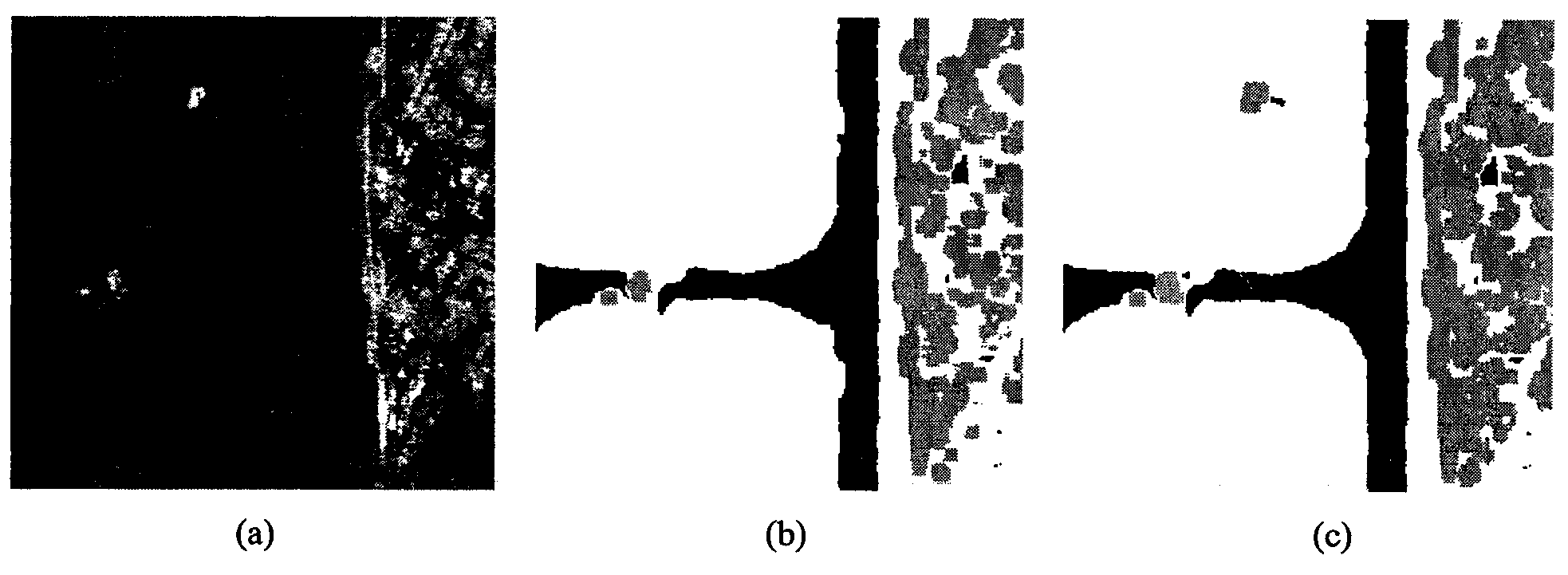

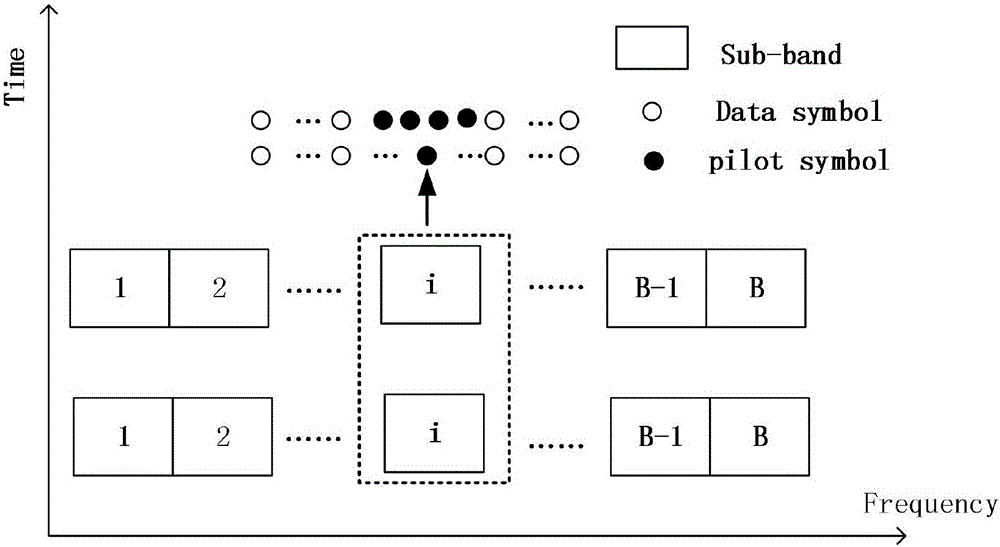

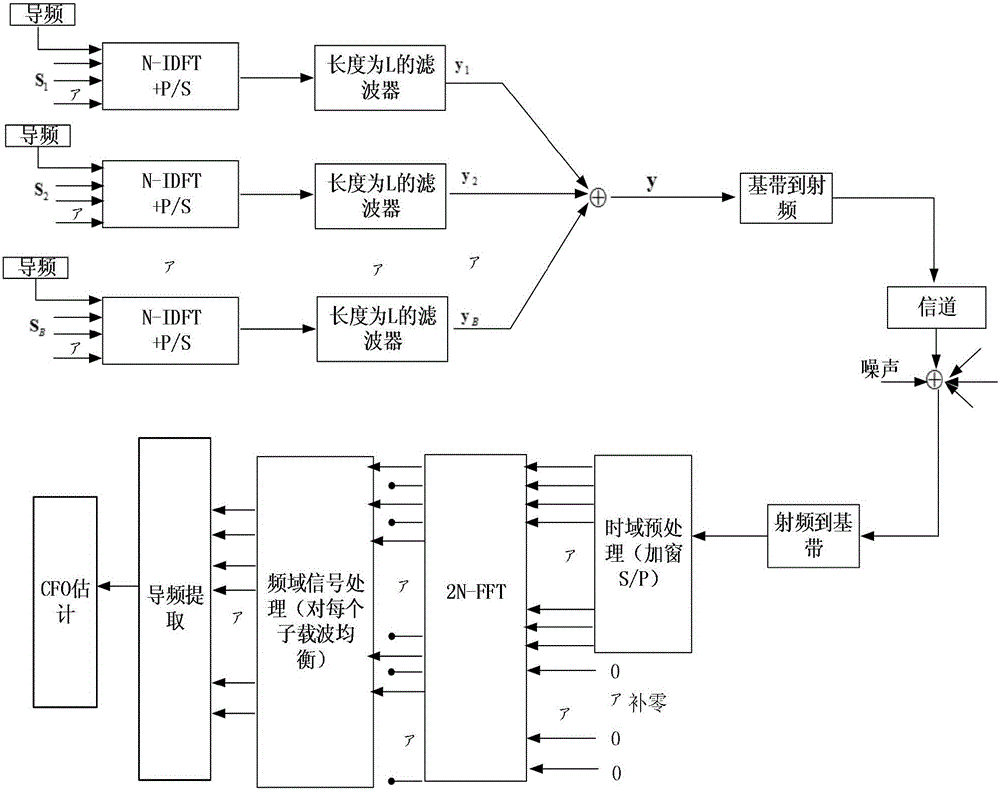

Carrier synchronization method in UFMC system

ActiveCN106059979ARetain propertiesImprove featuresMulti-frequency code systemsTime domainOriginal data

The invention relates to a carrier synchronization method in a UFMC system, comprising the following steps: first, generating two sets of orthogonal codes at a sender, inserting the orthogonal codes as pilot sequences into original data, and modulating, filtering and sending the original data through UFMC; then, performing time-domain zero filling and 2N-FFT transform at a receiver, extracting data on even bands, sending the data to a filter matching the sender, getting the estimated value of data information using a zero forcing equalizer, extracting pilot signals and calculating the correlation between the two sets of pilot signals, and minimizing the correlation to achieve UFMC system carrier frequency synchronization; and finally, using an iterative algorithm to improve the accuracy of frequency offset estimation. According to the invention, the carrier frequency offset of the system is estimated by inserting a pilot frequency into each sub band of UFMC, so good properties of the UFMC system are maintained, and the accuracy and stability of frequency offset estimation are improved through iteration. Therefore, the bit error performance of the system is enhanced, the quality of communication is improved, and the design complexity of the filter in the UFMC system is reduced to a certain extent.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

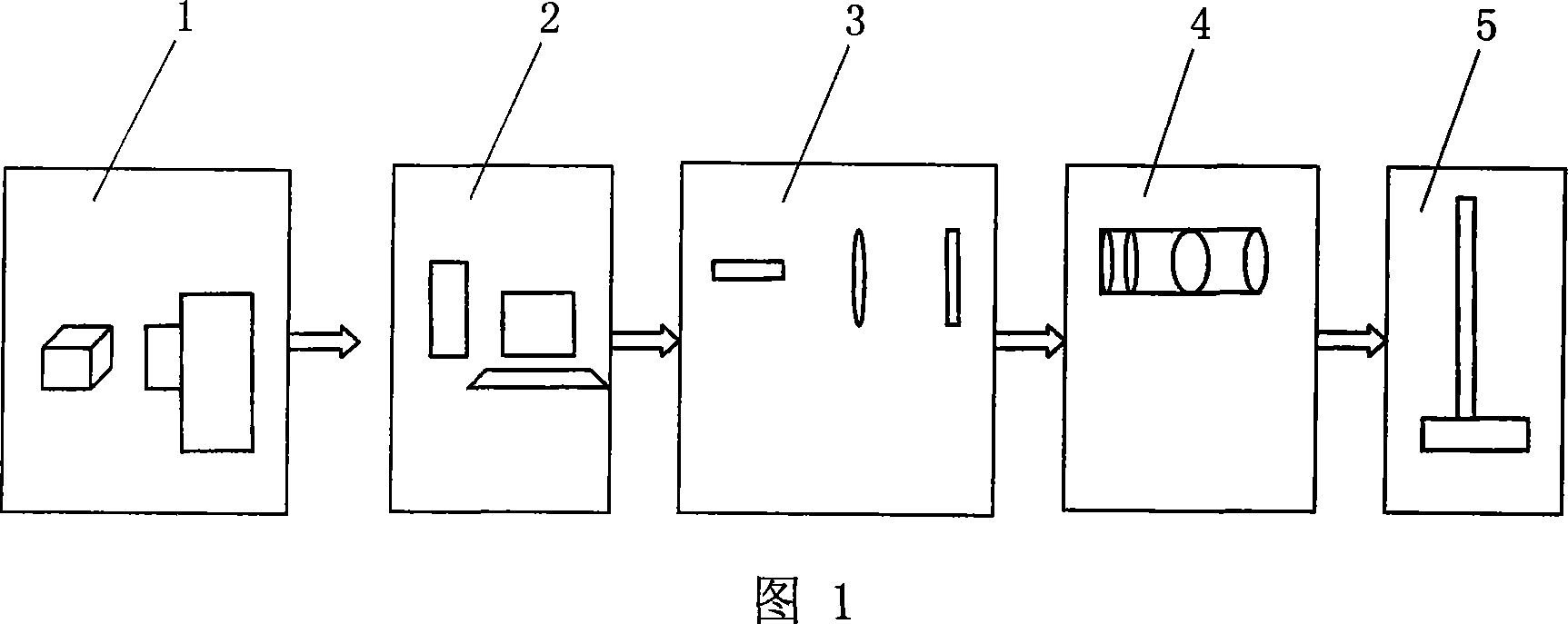

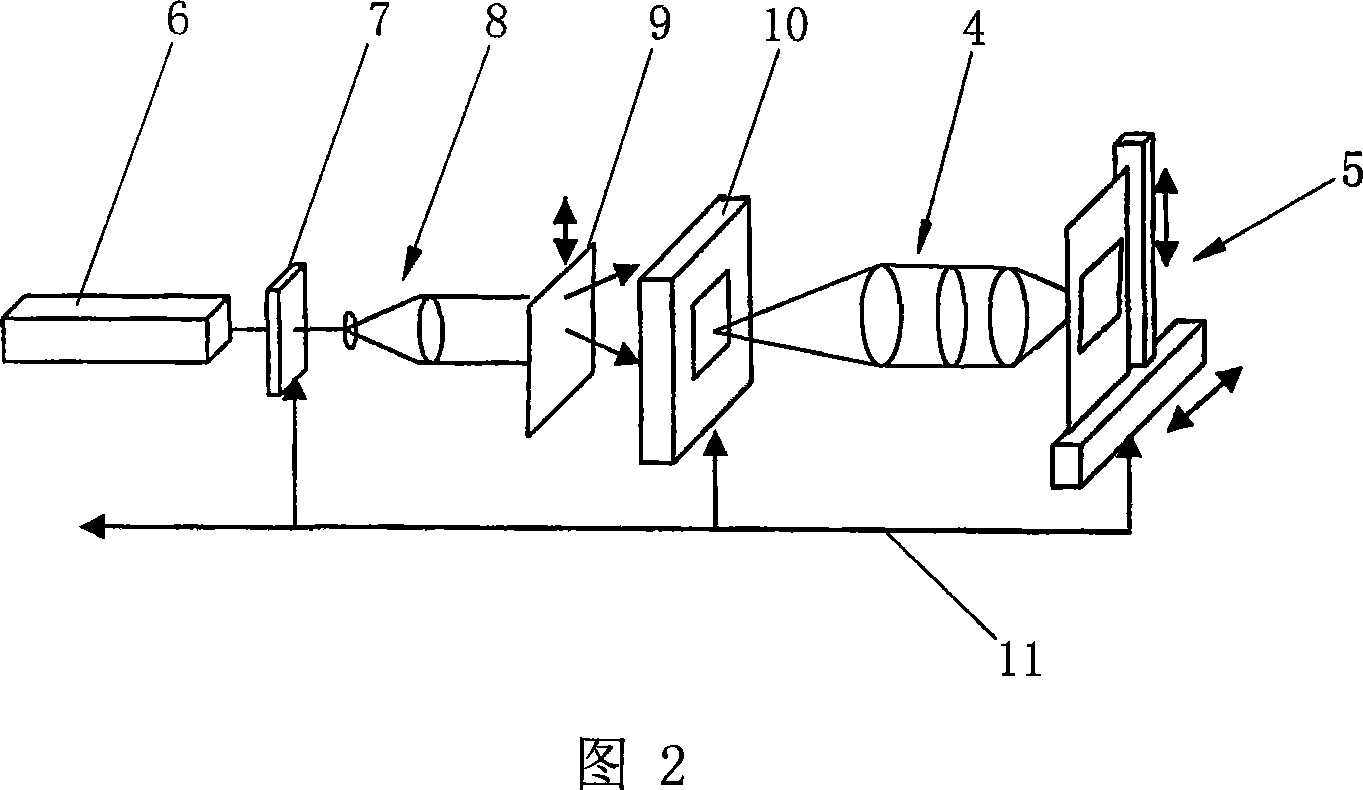

Calculation holographic production and output system

InactiveCN101051097AAvoid vibrationRealize three-dimensional holographic displayOptical computing devicesOptical elementsMicro imaging

A calculation and preparation as well as output system of hologram comprises 3-D scanner for obtaining stereo and color distribution information of 3-D object to be displayed, computer for carrying out control on hologram calculation and hologram preparation as well as hologram output, LCD for outputting hologram in framing mode, micro-imaging unit for carrying out micro-imaging on hologram and recording unit for recording hologram in step by step mode.

Owner:ZHEJIANG NORMAL UNIVERSITY

Preparation method of composite material for removing chorine ion in water

InactiveCN107661742AUnique layered structureUnique microporous structureOther chemical processesWater/sewage treatment by sorptionHigh concentrationAmbient technology

The invention relates to a preparation method of a composite adsorption material for removing chlorine ions in water, and belongs to the technical field of materials and environment. In the invention, solid magnesium salt raw material and aluminum salt are prepared into metal salt solution and mixed with molecular sieve, and a precipitating agent is added to load hydrotalcite formed by magnesium and aluminum on the surface of molecular sieve. The invention can effectively remove high-concentration chloride ions in waste water, and the composite material can be regenerated and reused. The preparation method of the composite material in the invention is simple, the source of raw materials is wide, the price is low, the process flow is simple, the equipment investment is small, there is no environmental pollution, and the chlorine removal efficiency is high.

Owner:湖北永绍科技股份有限公司

Spleen-invigorating beverage and preparation method thereof

InactiveCN103750441AKeep strong fragranceRetain propertiesNatural extract food ingredientsFood ingredient functionsLimoniumLentinula

The invention discloses a spleen-invigorating beverage. The spleen-invigorating beverage is characterized by being prepared from the following raw materials by weight: 20 to 23 parts of lucid ganoderma, 18 to 20 parts of mushroom, 3 to 5 parts of milkvetch root, 2 to 4 parts of solomonseal rhizome, 4 to 5 parts of coix seed, 10 to 11 parts of Chinese chive seed, 11 to 12 parts of hyacinth bean, 11 to 12 parts of broad bean, 10 to 12 parts of fig twig, 9 to 12 parts of black rice, 11 to 12 parts of lemon, 10 to 15 parts of carrot, 15 to 18 parts of Chinese cabbage, 13 to 15 parts of pumpkin, 17 to 19 parts of beef, 7 to 8 parts of an auxiliary agent and a proper amount of water. According to the invention, the beverage prepared by mixing a plurality of coarse cereals and then adding traditional Chinese medicines retains not only health care effects of traditional Chinese medicines like lucid ganoderma, milkvetch root and solomonseal rhizome but also rich fragrance and the characteristics of digestion promotion and easy absorbability of the plurality of coarse cereals, and the beverage can protect the stomach, invigorate the spleen and improve human immunity after long-term drinking and has wide application prospects.

Owner:MAANSHAN ANKANG FUNGUS IND

A kind of synbiotics liquid goat milk beverage and preparation method thereof

The invention discloses a synbiotic liquid goat's milk drink and a preparation method thereof, comprising 35-50 parts of synbiotic sour goat's milk, 5-10 parts of sucrose, and 0.15-0.5 parts of a stabilizer in parts by mass; 38-60 parts of water; the synbiotic yogurt goat milk is to add 2-5.5% probiotics and 0.1-2.5% prebiotics by mass to goat milk or goat milk reconstituted milk, and carry out anaerobic treatment for 5-18 hours. fermentation. Synbiotic sour goat milk is fermented with a probiotic after adding oligosaccharides and prebiotics; probiotics have a great effect on improving the microenvironment of probiotics in the human intestinal tract and promoting human health; adding oligosaccharides promotes probiotics The growth of goat milk not only retains the nutritional value and unique flavor of goat milk, but also strengthens the functional properties of oligosaccharides.

Owner:SHAANXI UNIV OF SCI & TECH

Surface-modified microcrystalline cellulose and preparation method thereof

The invention discloses surface-modified microcrystalline cellulose and a preparation method thereof, and belongs to the field of adjuvant preparation. The preparation method includes the steps that an inorganic acid solution is prepared for use; plant fiber is cut into proper dices for use; the inorganic acid solution is added into a reaction device, stirring is started, the plant fiber is put in and continuously stirred, a heating system is started to heat the solution till the solution nearly boils, and a heat preservation reaction is performed for certain time; a product formed after the reaction is filtered, and a filter cake is washed till the washing water is nearly neutral; pure water is added into a mixing device, stirring is started, polyethylene glycol is put in and stirred for 30 min, the materials are added into the mixing device, stirring continues to be performed for 60 min, and white uniform slurry is obtained; spray drying equipment is started for spray drying, and then the surface-modified microcrystalline cellulose product is obtained. The technology is simple, large-scale production is easy, and the obtained product is good in redispersibility and can be evenly dispersed in water more easily; the product is not likely to produce static and is better in formability.

Owner:ANHUI SUNHERE PHARMA EXCIPIENTS

Method for activating electroless copper-plated textile with nickel salt

InactiveCN103805971AStrong chelating abilityLow raw material costLiquid/solution decomposition chemical coatingCopper platingNickel salt

The invention relates to a method for activating electroless copper-plated textile with a nickel salt. The method comprises the steps of soaking the textile into a 10-30g / L coarsening liquid, heating to 60 DEG C and preserving heat for 30min, next, heating to 90 DEG C and preserving heat for 60min, and then washing and drying; soaking the textile into a chitosan solution, soaking twice and rolling twice, and air-drying; soaking the textile in a nickel sulfate solution at the normal temperature, and then soaking into a sodium borohydride solution, cleaning and air-drying to obtain the activated textile, and finally, soaking in an electroless copper plating liquid for plating, and finally washing with water and drying. A macromolecule adsorption nickel salt activating fluid developed in the method is friendly to the environment and capable of either improving the binding force of a coating and the substrate textile or activating a palladium salt with a nickel salt, and therefore, the activation cost is low and the pollution caused by noble metals is reduced, and the method is high in operability.

Owner:JINAN YUMO SCI & TRADE CO LTD

Preparation method of modified montmorillonite-containing reticulated polyurethane microbial carrier

ActiveCN105440304AImprove water resistancePromote degradationTreatment with aerobic and anaerobic processesTreatment with microorganism supports/carriersPolyesterPolymer science

The invention belongs to the technical field of microbial carrier preparation methods and relates to a preparation method of a modified montmorillonite-containing reticulated polyurethane microbial carrier with an interpenetrated network structure. The preparation method comprises adding vinyl polyether polyol, polyether polyol, polyester polyol, H2O, silicone oil, a tin catalyst, an amine catalyst and an olefin monomer into a reactor, carrying out stirring to obtain a uniform mixture, adding modified montmorillonite into the mixture, carrying out stirring to obtain a uniform mixture, carrying out thermal insulation, wherein the mixture is used as a component 1, adding isocyanate and a free radical polymerization initiator into a reactor, carrying out stirring to obtain a uniform mixture as a component 2, mixing the component 1 and the component 2 to obtain a uniform mixture, carrying out foaming to obtain polyurethane flexible foam and carrying out meshing treatment on the polyurethane flexible foam through an alkali liquor immersion or explosion method to obtain the reticulated polyurethane microbial carrier with an interpenetrated network structure. The olefin polymer is introduced into the reticulated polyurethane microbial carrier through the interpenetrated network structure so that hydrolysis resistance and biodegradation resistance of the carrier are improved and compatibility of the polyurethane ingredient and the olefin polymer ingredient is improved.

Owner:青岛水务集团有限公司

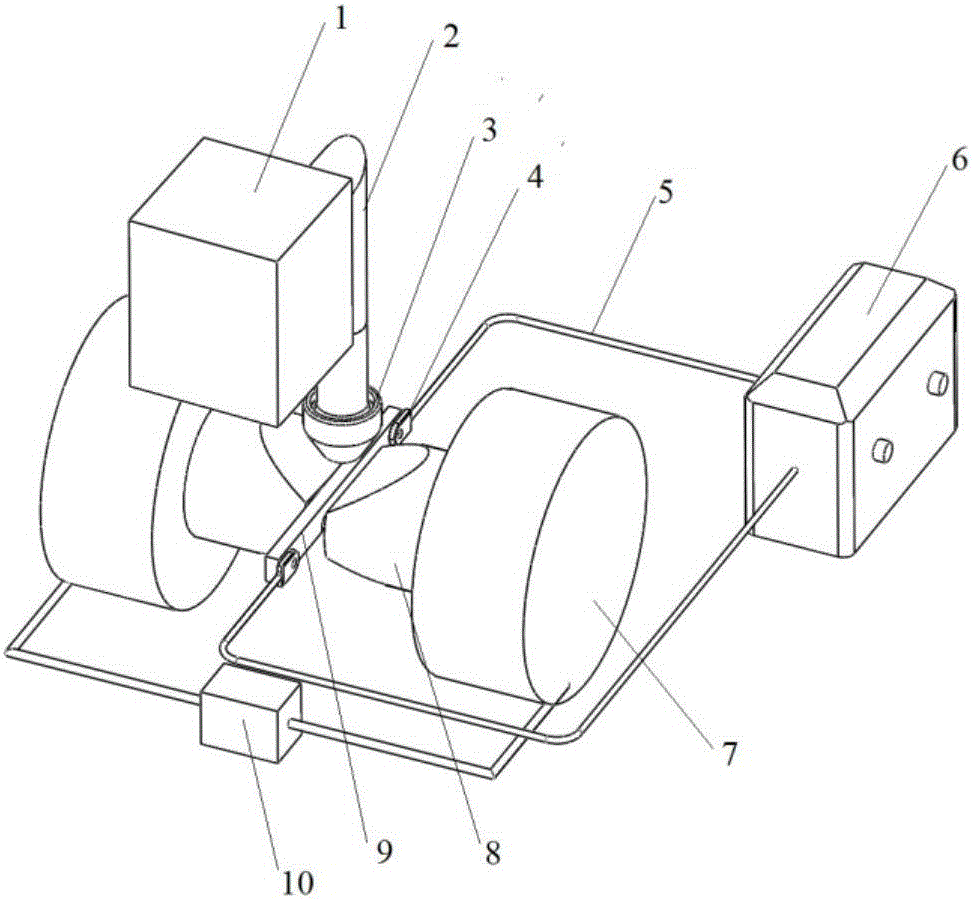

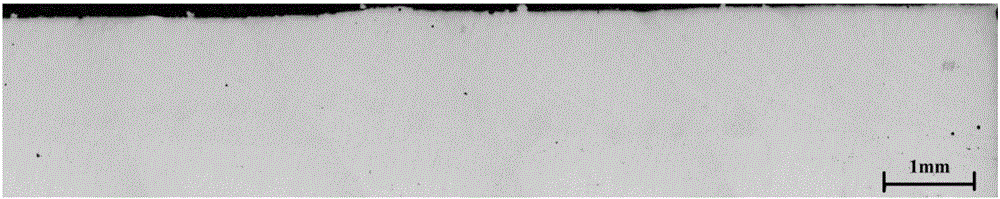

Preparation method of porosity controllable nickel base coating layer

ActiveCN106191854ARetain mechanical propertiesRetain propertiesMetallic material coating processesPorosityPower flow

The invention relates to a preparation method of a porosity controllable nickel base coating layer. The preparation method comprises the steps of: (A) polishing, cleaning and dirt removal; (B) laser cladding: a coaxial powder feeder is used for feeding nickel base powder to the surface of a basal body to form a laser cladding molten pool; and laser scanning is used for laser cladding layer by layer to enable the cladding molten pool to form bubbles; and (C) Lorentz force and volume force coupling: on the basis of bubble formation in the cladding molten pool in the step (B), gradient-adjustable Lorentz force is introduced to adjust distribution of the bubbles formed in the process in the step (B), so that formed air holes are gradually or uniformly distributed in the cladding layer in the depth direction from surface to inside. The method influences the reducing gradient of the Lorentz force through adjusting the magnitude of direct current applied to the surface of a substrate and the strength gradient of the magnetic field on the surface of the molten pool. The method is suitable for laser cladding of the nickel base coating layer, can be synchronously suitable for such processing modes as welding and laser cladding for molten pool production, and is wide in application range.

Owner:ZHEJIANG UNIV OF TECH

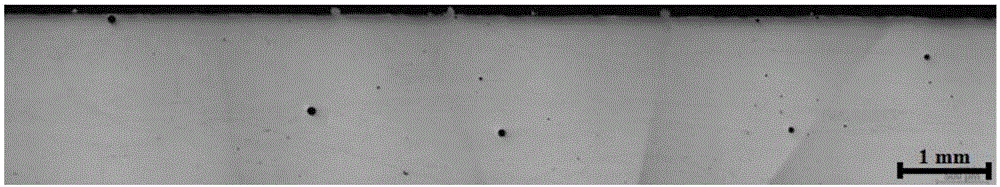

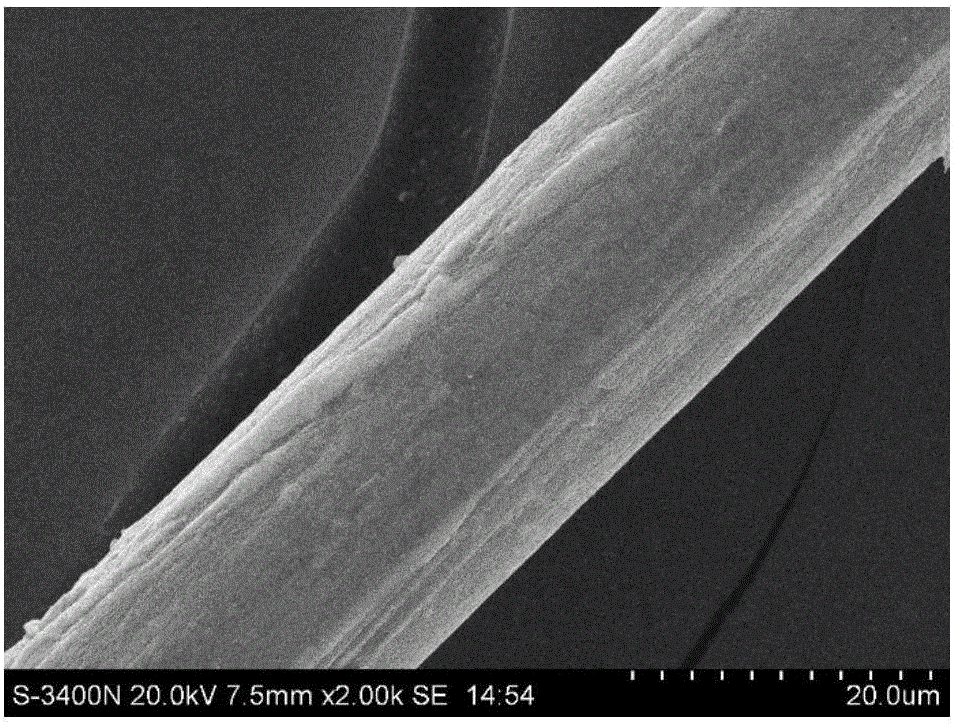

Preparing method for silver-plated fibers

InactiveCN105734959ARetain propertiesImprove bindingBiochemical fibre treatmentFibre typesFiberPolyester

The invention relates to a preparation method of silver-plated fiber, which comprises the following steps: the first step: chemical modification treatment on the surface of the substrate to increase the active groups and roughness on the surface of the substrate fiber; the second step: activation treatment, Active points are directly introduced into the surface of the substrate fiber; the third step: electroless silver plating treatment, a layer of silver is plated on the surface of the substrate fiber. The silver-plated polyester fiber prepared by the invention has good electrical conductivity and excellent antibacterial property, retains the characteristics of the original fiber, has soft hand feeling, and the plating layer is not easy to peel off.

Owner:SHANGHAI AOMI NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com