Pitaya crisp sheets and preparation method thereof

A technology for dragon fruit slices and dragon fruit, which is applied in the directions of food preparation, food drying, food science, etc., can solve the problems affecting large-scale application, loss of nutrients, and high energy consumption in production, and achieves preservation of color and texture characteristics, saving Good effect of energy and nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

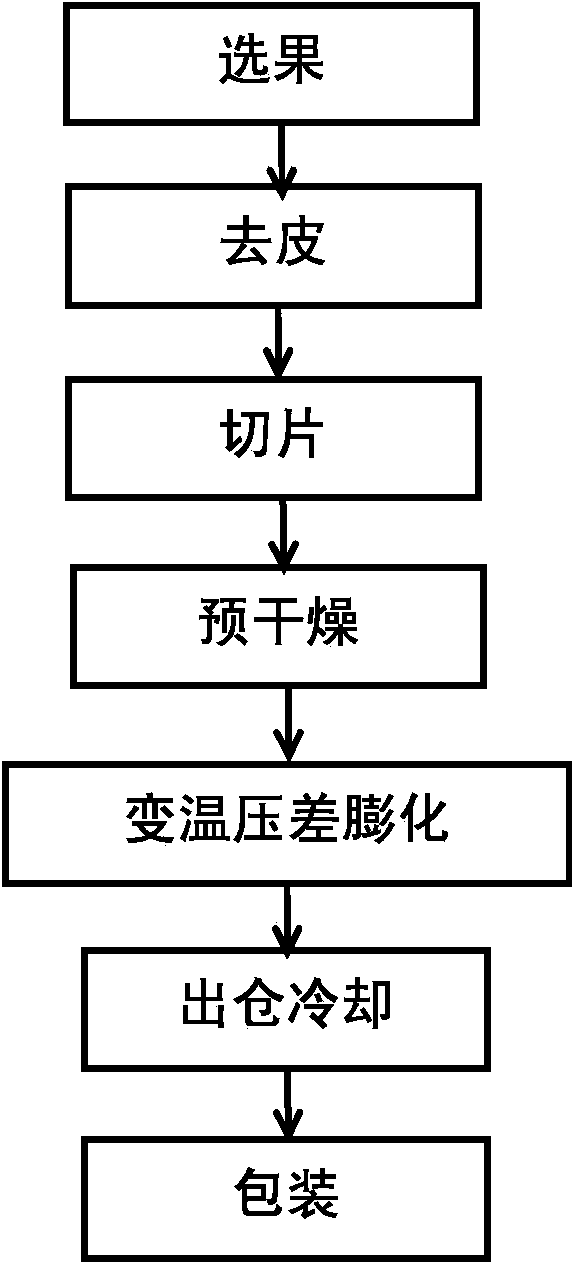

Method used

Image

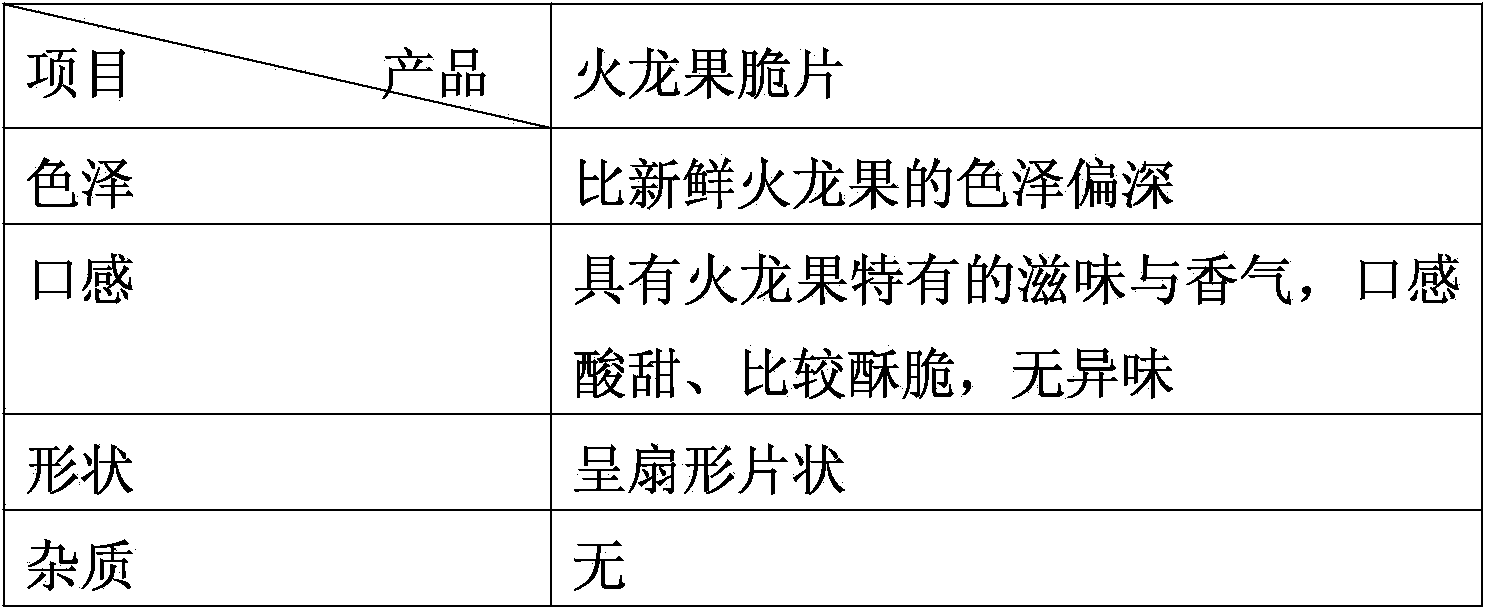

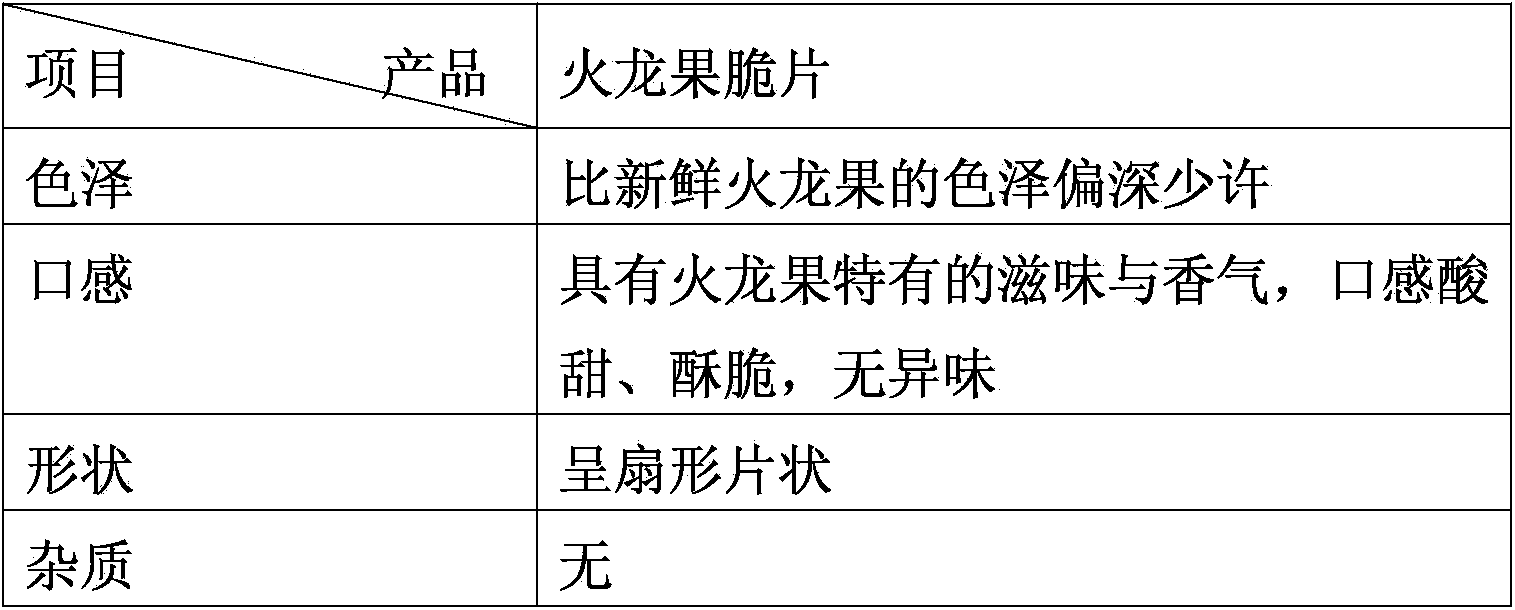

Examples

Embodiment 1

[0030] (1) Fruit selection: select complete, uninjured, seven or eight mature dragon fruits;

[0031] (2) Peeling: the selected dragon fruit is peeled off by hand or tools;

[0032] (3) Slicing: the dragon fruit pulp after peeling is cut into the dragon fruit sheet that thickness is 7mm through slicer;

[0033] (4) Pre-drying: put the dragon fruit slices obtained by cutting into a vacuum dryer, the vacuum degree is -0.01MPa, and dry to a moisture content of 20% under vacuum conditions, the drying temperature is 90 ° C, and the drying time is 3.0 h;

[0034] (5) Variable temperature and pressure difference puffing: put the dried dragon fruit slices in step (4) into the puffing tank, raise the temperature until the puffing temperature is 90°C, the pressure is normal pressure, and the stagnation time is 10 minutes. When the stagnation is over, the pressure of the puffing tank will drop instantly Puffing in a vacuum state, the vacuum degree is -0.01MPa, after the puffing ends in ...

Embodiment 2

[0042] (1) Fruit selection: select complete, uninjured, seven or eight mature dragon fruits;

[0043] (2) Peeling: the pitaya that step (1) is selected adopts manual or instrument to peel off the outer skin;

[0044] (3) Slicing: the pitaya pulp after the peeling of step (2) is cut into thickness of 9mm through a slicer;

[0045] (4) Pre-drying: the pitaya slices obtained by cutting are put into a vacuum dryer, the vacuum degree is 0.04MPa, the drying temperature is 80°C, the drying time is 4.0h, and dried to a moisture content of 10%;

[0046] (5) Variable temperature and pressure difference puffing: Put the dried dragon fruit slices in step (4) into the puffing tank, raise the temperature until the puffing temperature is 70°C, the pressure is normal pressure, and the stagnation time is 5 minutes. After the stagnation is over, the pressure of the puffing tank will drop instantly Puffing in a vacuum state, the vacuum degree is 0.04MPa, after the puffing ends in the vacuum sta...

Embodiment 3

[0054] (1) Fruit selection: select complete, uninjured, seven or eight mature dragon fruits;

[0055] (2) Peeling: the pitaya that step (1) is selected adopts manual or instrument to peel off the outer skin;

[0056] (3) Slicing: the pitaya pulp after step (2) peeling is cut into a thickness of 8mm through a slicer;

[0057] (4) Pre-drying: the pitaya slices obtained by cutting are put into a vacuum dryer, the vacuum degree is 0.01MPa, the drying temperature is 85°C, the drying time is 3.5h, and dried to a moisture content of 15%;

[0058] (5) Variable temperature and pressure difference puffing: Put the dried dragon fruit slices in step (4) into the puffing tank, raise the temperature until the puffing temperature is 75°C, the pressure is normal pressure, and the stagnation time is 7 minutes. When the stagnation is over, the pressure of the puffing tank will drop instantly Expand in a vacuum state with a vacuum degree of 0.02MPa. After the expansion is completed in the vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com