Preparation method of multi-layer transparent wood, prepared transparent wood and application of transparent wood

A wood and transparent technology, applied in the field of preparation of multi-layer transparent wood, can solve the problems of limited application and opacity, and achieve the effects of less chemicals, large format, and improved light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

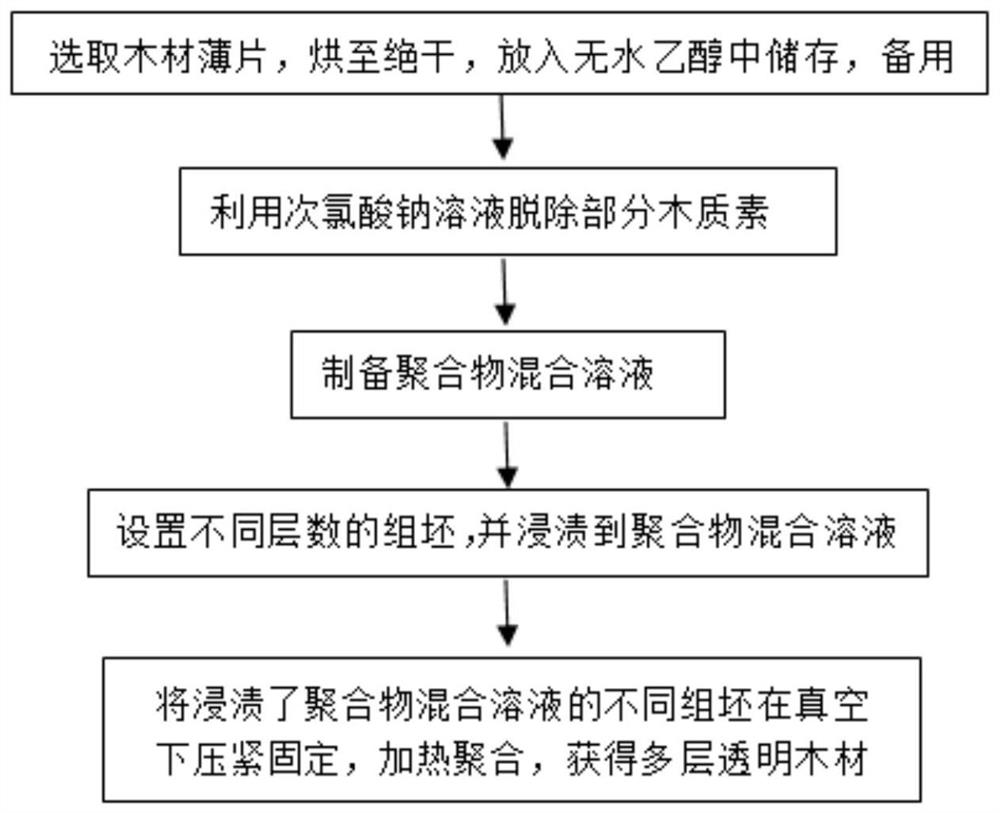

[0033] The present invention provides a kind of preparation method of multilayer transparent wood, comprises the following steps:

[0034] (1) Drying: Select New Zealand pine wood slices, dry them to absolute dryness at 102°C, soak them in absolute ethanol overnight, and set aside;

[0035] (2) Remove part of the lignin: configure 1wt% sodium hypochlorite solution, and add dropwise glacial acetic acid solution, adjust the pH to 5, get the wood flakes obtained in step (1) and soak them in the above-mentioned solution for heating in a water bath, and the wood flakes are mixed with sodium hypochlorite The bath ratio of the solution is about 1:15, the temperature of the water bath is 90°C, and the time of the water bath is 90 minutes to remove part of the lignin;

[0036] (3) Preparation of polymer mixed solution: use 4wt% NaOH solution to mix with polymer solution and separate, add 0.3wt% azobisisobutyronitrile to the above solution as an initiator, and place the above solution i...

Embodiment 2

[0040] The present invention provides a kind of preparation method of multilayer transparent wood, comprises the following steps:

[0041] (1) Drying: Select birch wood flakes, dry them to absolute dryness at 95°C, and soak them in absolute ethanol overnight for later use;

[0042] (2) Remove part of lignin: configure 0.8wt% sodium hypochlorite solution, and add dropwise glacial acetic acid solution, adjust pH to be 4.6, get the wood flakes made in step (1) and soak in the water bath heating in the above-mentioned solution, wood flakes and The sodium hypochlorite solution bath ratio is about 1:15, the water bath temperature is 90°C, and the water bath time is 110min to remove part of the lignin;

[0043] (3) Preparation of polymer mixed solution: use 6wt% NaOH solution to mix with polymer solution and separate, add 0.35wt% azobisisobutyronitrile to the above solution as an initiator, and place the above solution in a water bath at 75°C Take it out after heating the pre-polyme...

Embodiment 3

[0047] The present invention provides a kind of preparation method of multilayer transparent wood, comprises the following steps:

[0048] (1) Drying: Select oak wood thin slices, dry them to absolute dryness at 105°C, and soak them in absolute ethanol overnight, and set them aside;

[0049] (2) Remove part of the lignin: configure 1wt% sodium hypochlorite solution, and add dropwise glacial acetic acid solution, adjust the pH to 4.6, get the wood flakes obtained in step (1) and soak them in the above-mentioned solution for heating in a water bath, and the wood flakes are mixed with sodium hypochlorite The bath ratio of the solution is about 1:15, the water bath temperature is 85°C, and the water bath time is 100min to remove part of the lignin;

[0050] (3) Preparation of polymer mixed solution: use 4wt% KOH solution to mix with polymer solution and separate, add 0.38wt% azobisisobutyronitrile to the above solution as an initiator, and place the above solution in a water bath ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com