A kind of bamboo-wood composite board and preparation method thereof

A composite board, bamboo and wood technology, applied in the field of composite boards, can solve the problems of low yield of young bamboo, small shrinkage, shortage of wood resources, etc., to improve mechanical properties and processing properties, moderate stiffness and elastic modulus, Simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of preparation method of bamboo-wood composite board, it comprises the following steps:

[0030] 1) Preparation of adhesive: take phenolic resin glue with a solid content of 50% as a raw material, add a sizing agent and more than one waterproofing agent, mothproofing agent or flame retardant and mix uniformly to form an adhesive, the adhesive The solid content is 40-48%, the pH value is 9-11, and the viscosity is 450mPa.s.

[0031] 2) Bamboo layer material treatment: take 5-8 years old moso bamboo, cut it off, split it, remove the knots, boil it to soften it, flatten it, set the thickness, dry it, and mill it to make bamboo slices with equal thickness at both ends, or Weave the bamboo slices into bamboo curtains with thin thread ropes, and the thickness of the bamboo slices or bamboo curtains is 0.5-1.5mm, and then dry them at 80-100°C to control their moisture content to 8-10%; The sheets or bamboo curtains are put into the adhesive and soaked for 20-35 minutes...

Embodiment 1

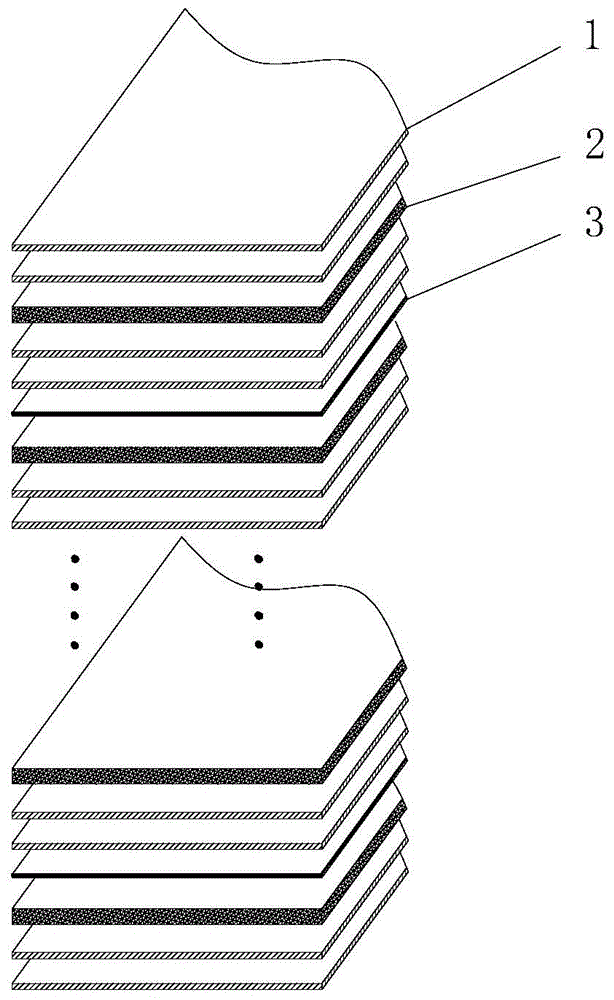

[0038] A kind of bamboo-wood composite board, it comprises bamboo layer 1, wood veneer layer 2, non-woven fabric layer 3 and adhesive, is provided with one deck wood veneer layer 2 between described every two layers of bamboo layers 1, The total number of layers of the bamboo layer 1 and the wood veneer layer 2 is 14 layers, and two layers of non-woven fabric layers 3 are arranged in the middle, and the layers are bonded and pressed into a whole by an adhesive.

[0039] Both the surface layer and the bottom layer are bamboo layer 1, and the surface is provided with a sealing wax layer with waterproof effect.

[0040] The bamboo layer 1 is a bamboo sheet or a bamboo curtain layer, and its thickness is 0.5 mm.

[0041] The thickness of the wood veneer layer 2 is 1.5mm.

[0042] The adhesive is made of phenolic resin glue with a solid content of 50% as a raw material, and is formed by adding a wetting agent and more than one waterproof agent, mothproof agent or inorganic flame ret...

Embodiment 2

[0053] A kind of bamboo-wood composite board, it comprises bamboo layer 1, wood veneer layer 2, non-woven fabric layer 3 and adhesive, is provided with one deck wood veneer layer 2 between described every two layers of bamboo layers 1, The total number of layers of the bamboo layer 1 and the wood veneer layer 2 is 20 layers, and four layers of non-woven fabric layers 3 are arranged in the middle, and the layers are bonded and pressed into a whole by an adhesive.

[0054] Both the surface layer and the bottom layer are bamboo layer 1, and the surface is provided with a sealing wax layer with waterproof effect.

[0055] The bamboo layer 1 is a bamboo sheet or a bamboo curtain layer, and its thickness is 0.8mm.

[0056] The thickness of the wood veneer layer 2 is 1.6mm.

[0057] The adhesive is made of phenolic resin glue with a solid content of 50% as a raw material, and is formed by adding a wetting agent and more than one waterproof agent, mothproof agent or inorganic flame r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com