Patents

Literature

112 results about "Sealing wax" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sealing wax is a wax material of a seal which, after melting, hardens quickly (to paper, parchment, ribbons and wire, and other material) forming a bond that is difficult to separate without noticeable tampering. Wax is used to verify something such as a document is unopened, to verify the sender's identity, for example with a signet ring, and as decoration. Sealing wax can be used to take impressions of other seals. Wax was used to seal letters close and later, from about the 16th century, envelopes. Before sealing wax, the Romans used bitumen for this purpose.

Polymethylmethacrylate waterproof paint and preparation method thereof

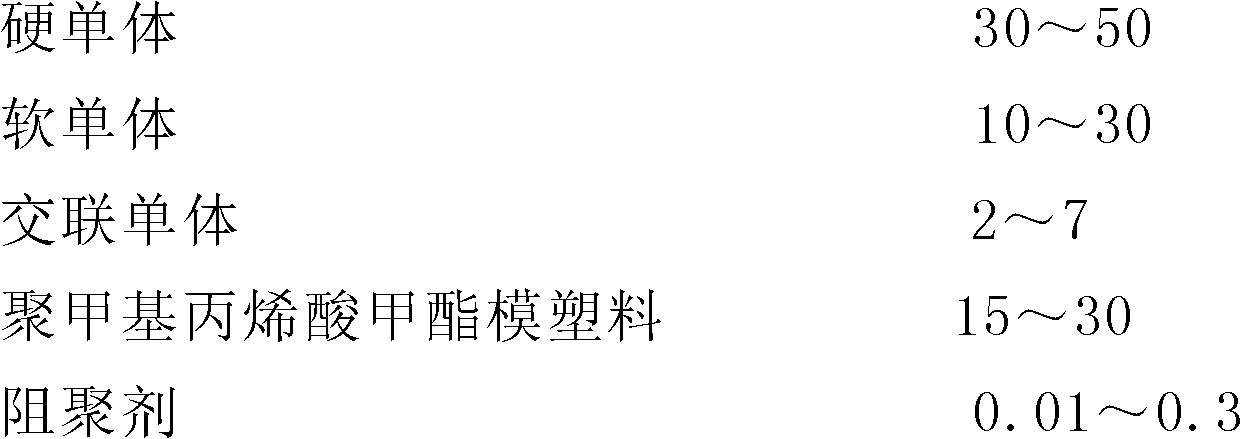

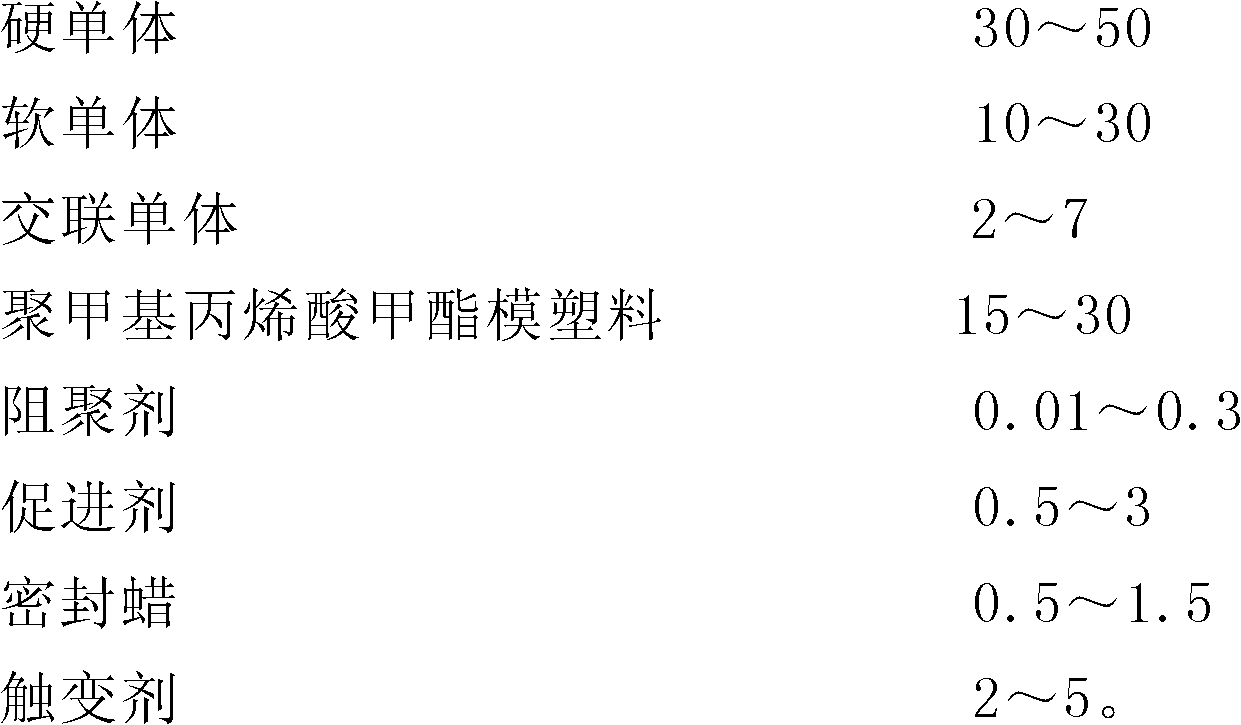

The invention relates to a polymethylmethacrylate waterproof paint and a preparation method thereof. The waterproof paint consists of components A and B, wherein the component A is a methacrylic acid resin liquid generated by reaction based on methyl methacrylate (MMA) utilized as a main composition, and the component B is an initiator. When the component A is prepared, a hard monomer, a soft monomer and a cross-linking monomer are put in a reaction kettle and evenly stirred, and then heating is carried out; polymethylmethacrylate moulding plastic is put, and then reaction is carried out for 1-6 hours at the temperature of 70-90 DEG C; cooling is carried out until the temperature is 50-65 DEG C, a polymerization inhibitor, an accelerator, sealing wax and a thixotropic agent are added and evenly stirred; and cooling is carried out until the temperature is 30-45 DEG C, and filtration and packaging are carried out so as to prepare the component A resin liquid. The components A and B are evenly stirred and mixed in a proper proportion, then coated, and finally solidified into a film. The waterproof paint has the characteristics of good strength, good elasticity, low temperature hardness, excellent weather resistance and the like, is simple and convenient for construction, can be solidified rapidly, and can be used for waterproof work of rapid transit railway bridge surfaces and super highway subgrades.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Sealing wax for electronic element coil

InactiveCN1458216AHigh drop melting pointGood high temperature performanceOther chemical processesSemiconductor/solid-state device detailsElectricitySealing wax

The present invention relates to a kind of electronic element sealing wax composite comprising petroleum wax, polymer wax, tackifier and plasticizer. The sealing wax has the features of high droppingpoint, excellent high temperature performance, good plasticity and flexibility, excellent electric performance, powerful sealing force, short solidification time, no corrosion, no impurity, etc., andhas the sealing cost lower than available sealing material with resin as main component. The sealing wax is suitable for positioning and sealing electronic tuner, inductance coil and other electronicelement coil.

Owner:CHINA PETROLEUM & CHEM CORP +1

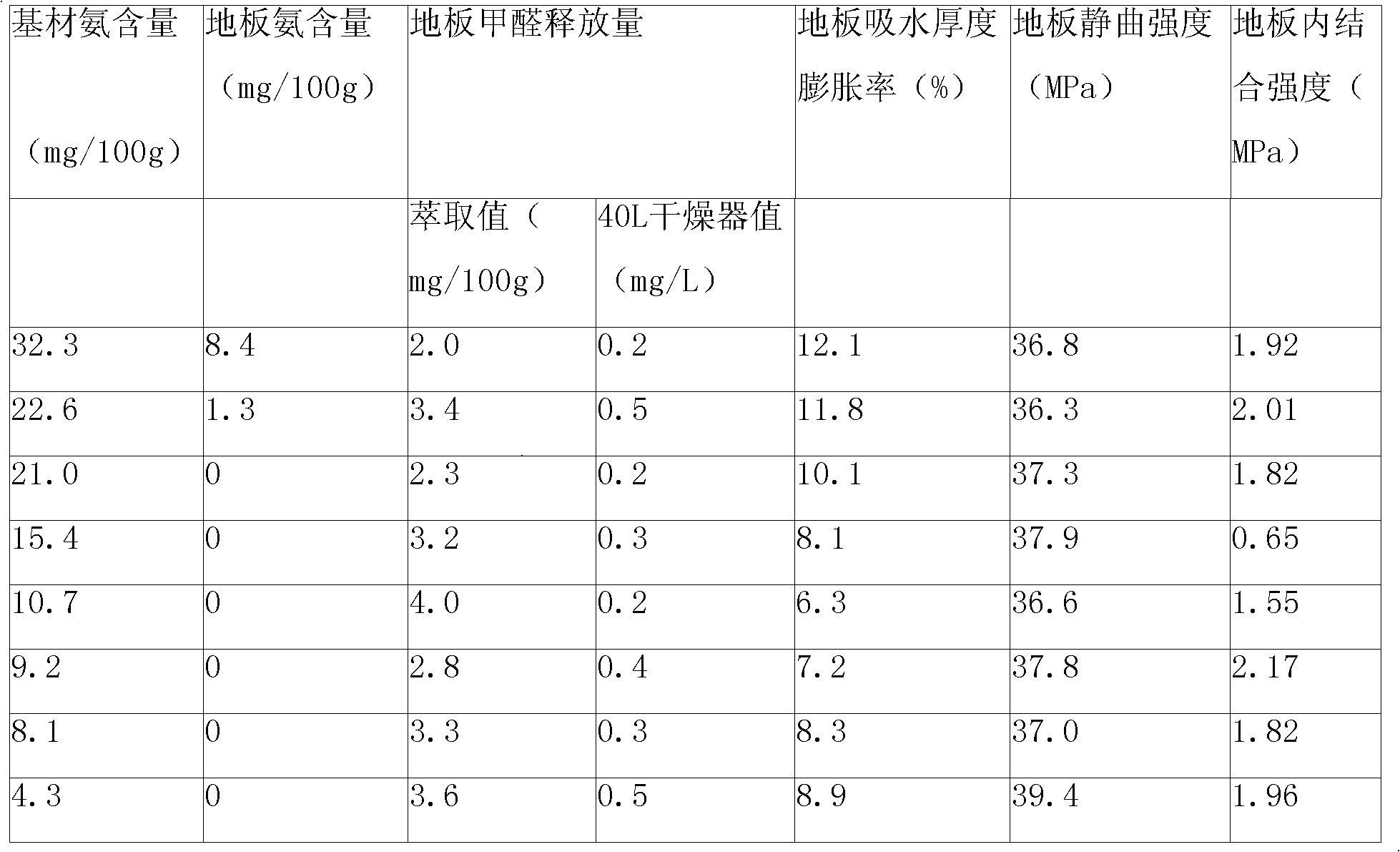

Method for processing and manufacturing environmentally friendly aggrandizement wood floor by vacuum ammonia

InactiveCN101585203AReduce formaldehyde emissionFormaldehyde emission does not reboundWood treatment detailsWood veneer joiningFiberSocial benefits

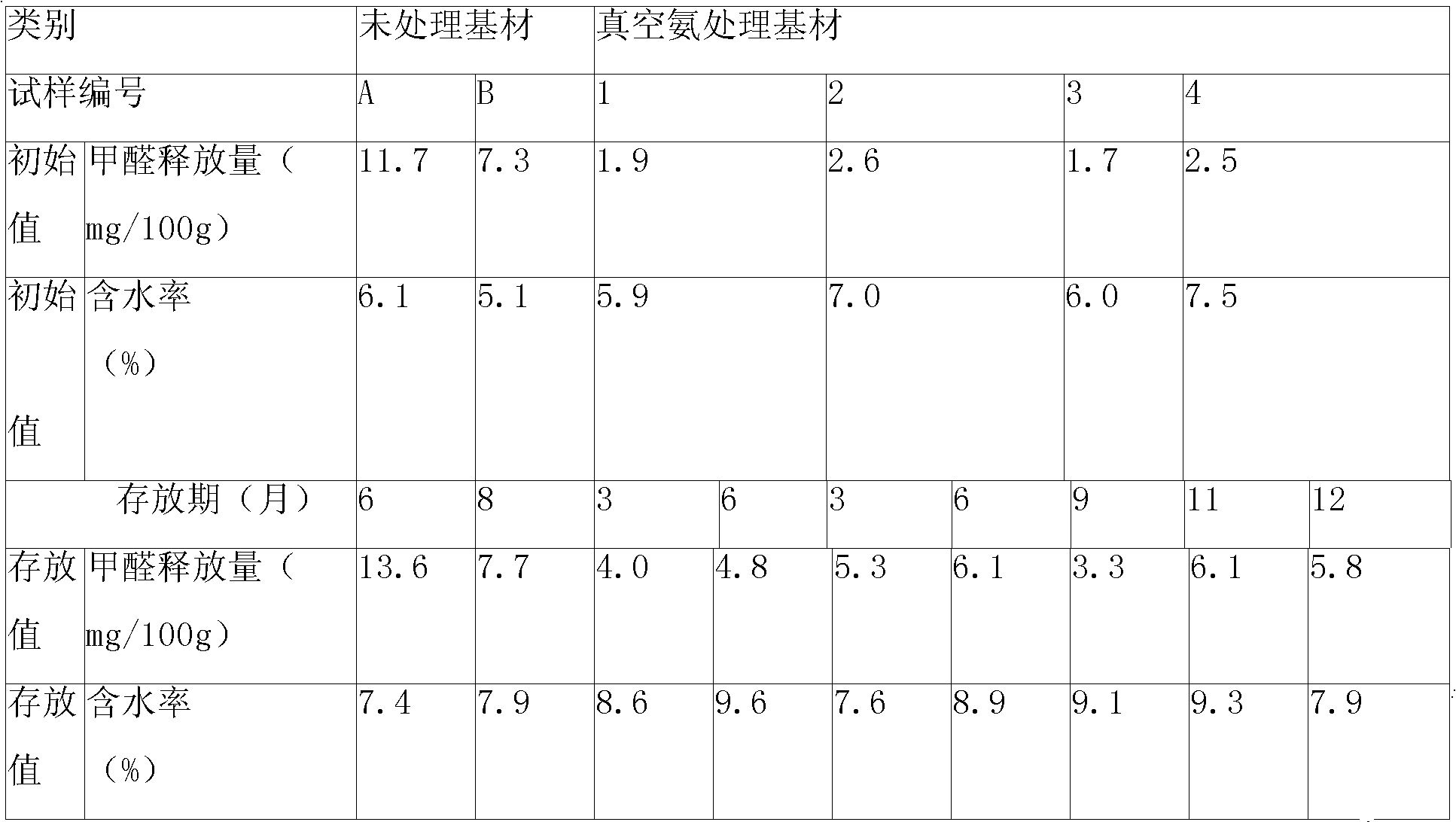

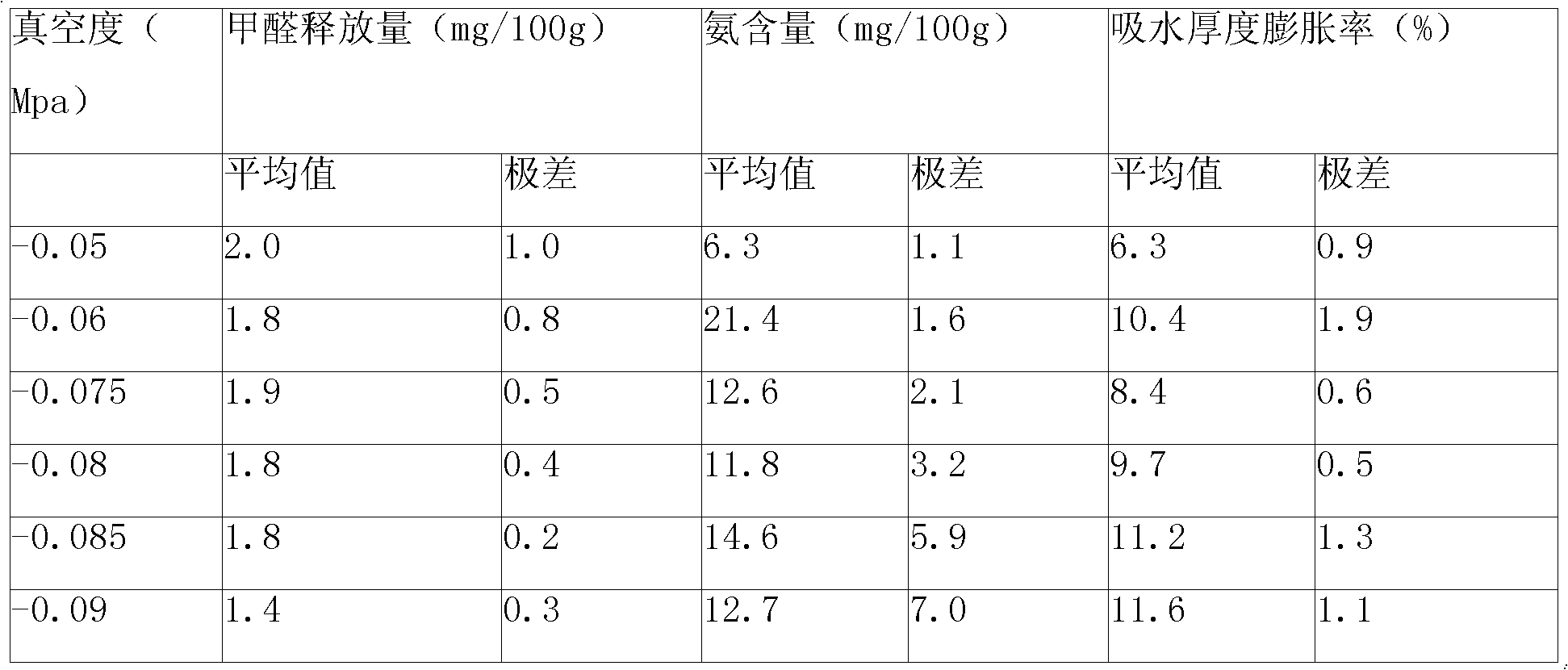

A method for processing and manufacturing environmentally friendly aggrandizement wood floor by vacuum ammonia comprises following steps: putting E2 level floor into a vacuum case, generating -0.06 to -0.08 MPa in the case; applying liquid ammonia whose unit plate consumes ammonia is 0.67-1.43 kg / m3; after the liquid ammonia is gasified and completely absorbed in a fiber plate, releasing the vacuum; fetching the plate with ammonia content is 5-15 mg / 100g; assembling the plate, a dipped abrasion-resistant paper , a dipped decorative paper and a dipped balance paper, hot-pressing in a press; performing nourishing, balance, chase-mortising, sealing wax, packaging to the formed plate and the semi-finished product of floor which is cut into a certain scale, so as to manufacture the environmentally friendly aggrandizement wood floor. This method has the advantages of good effect of aldehyde reduction, simple technique, convenient operation, high production efficiency, low cost, pollution free and so on. This invention has remarkable economic benefit, social benefit and environmental benefit when applied in the manufacturing industry of the aggrandizement wood floor and the resin impregnated paper overlaid wood-based panel.

Owner:湖南康派木业有限公司

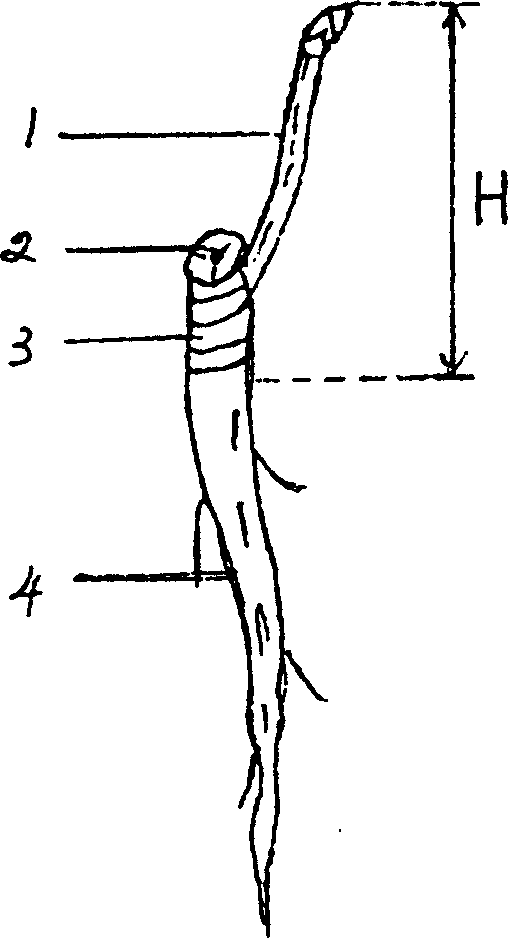

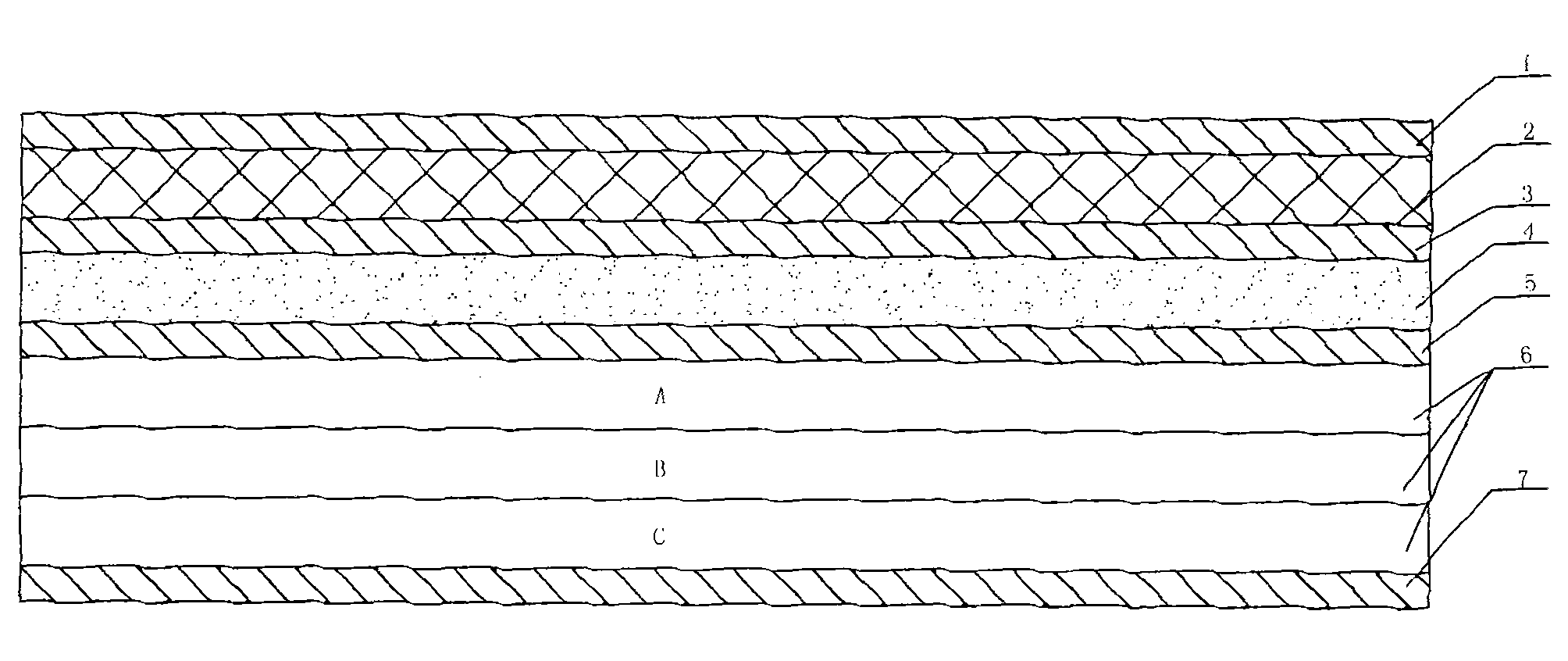

Top-grafting and superior variety-exchange cultivation method of improved variety of apricot tree

InactiveCN102783390AQuick changeSolve the problem of scion storage difficultiesCultivating equipmentsHorticultureFruit treeSealing wax

The invention relates to a management and cultivation method of fruit trees, in particular to a cultivation method of big trees of improved variety of apricot tree in cold areas along the mountain, which has high grafting survival rate, and particularly relates to a top-grafting and superior variety-exchangecultivation method of improved variety of the apricot tree. The cultivation method comprising the steps of collecting and storing, cutting ears, boiling wax liquid, sealing wax, pruning stock, grafting and cutting ears, performing management after grafting and so on. The method solves the problem that the cion is difficult to store, and comprises the steps of cutting branches of the improved variety of apricot tree into 6-7cm of ear sections; sealing wax for the whole ears; sealing and preserving the ears in the cold place at low temperature, wherein the ears can be preserved for more than 6 months; after the trees in the to-be-grafted area expand leaves, namely, the sap flows, performing grafting; strongly shaping the ansu apricot, common apricot or low-yield local big trees; performing grafting by cleft grafting, cut grafting, notch grafting and so on; after 7-10 days, germinating and branching, wherein the survival rate can reach more than 85%; even if part ears do not survive, the ears can be preserved for long period due to wax sealing of the whole ears; therefore, the un-survival ears can be grafted in time, and then 100% of survival rate of the tree in this year can be ensured.

Owner:张掖市林业科学研究院

Preserved egg mechanical wax-spraying type wax-sealing method and device

InactiveCN101692845AReduce breakage rateReduce consumptionEggs preservation by coatingParaffin waxSealing wax

The invention discloses a preserved egg mechanical wax-spraying type wax-sealing method and a device, wherein the method comprises the following steps: firstly, adding solid wax into a wax melting box and heating, secondly, pumping fused wax into a wax spraying box, thirdly, starting a main drive motor, and placing preserved eggs on a feeding device, fourthly, delivering preserved eggs to a spraying wax-sealing device to seal wax for preserved eggs, fifthly, transporting preserved eggs after sealing wax to a blanking device, and collecting by workers, sixthly, finishing wax-sealing work. The feeding device, the blanking device and the spraying wax-sealing device are respectively provided with chain transmission formed by chains and sprockets, a feed egg roller and a discharge egg roller are respectively mounted on a feeding device chain accessory and a blanking device chain accessory, and a feeding device frame, a spraying wax-sealing device frame and a blanking device frame are placed on the flat ground surface by four groups of supporting stands after connecting and fixing by screw threads. The preserved egg mechanical wax-spraying type wax-sealing device can continuously work, and has high production efficiency, compact structure, simple operation, high wax-sealing quality and low preserved egg damage rate.

Owner:HUAZHONG AGRI UNIV

Simulate five-spot network micro carve visualization model and apply method

The application discloses simulate five-spot network micro carve visualization model and apply method, wherein comprising light focus cover, base seat, base seat seal wax film, carve glass film, observe glass film, light focus cover seal wax film, screw bolt; base seat and light focus cover aligns, joins by screw bolt, the middle chamber of observe seat and visualization hold seat overlays from bottom to top in sequence placement base seat seal wax film, carve glass film, observe glass film, light focus cover seal wax film. Micro carve visualization model carve glass film and observe glass film does not burn stick together, carve glass film is reusable after washing; model accords to actual oil deposit condition, simulates out path direction current by placing longitude pipe section, reflects truthfully out oil deposit mining fluid flowing pass well hole seeping status; the application model sets stepwise hole on light focus cover, places screw bolt head in stepwise hole, results unlikely convex shapes on light focus cover surface, facilitates placement and observation.

Owner:SOUTHWEST PETROLEUM UNIV

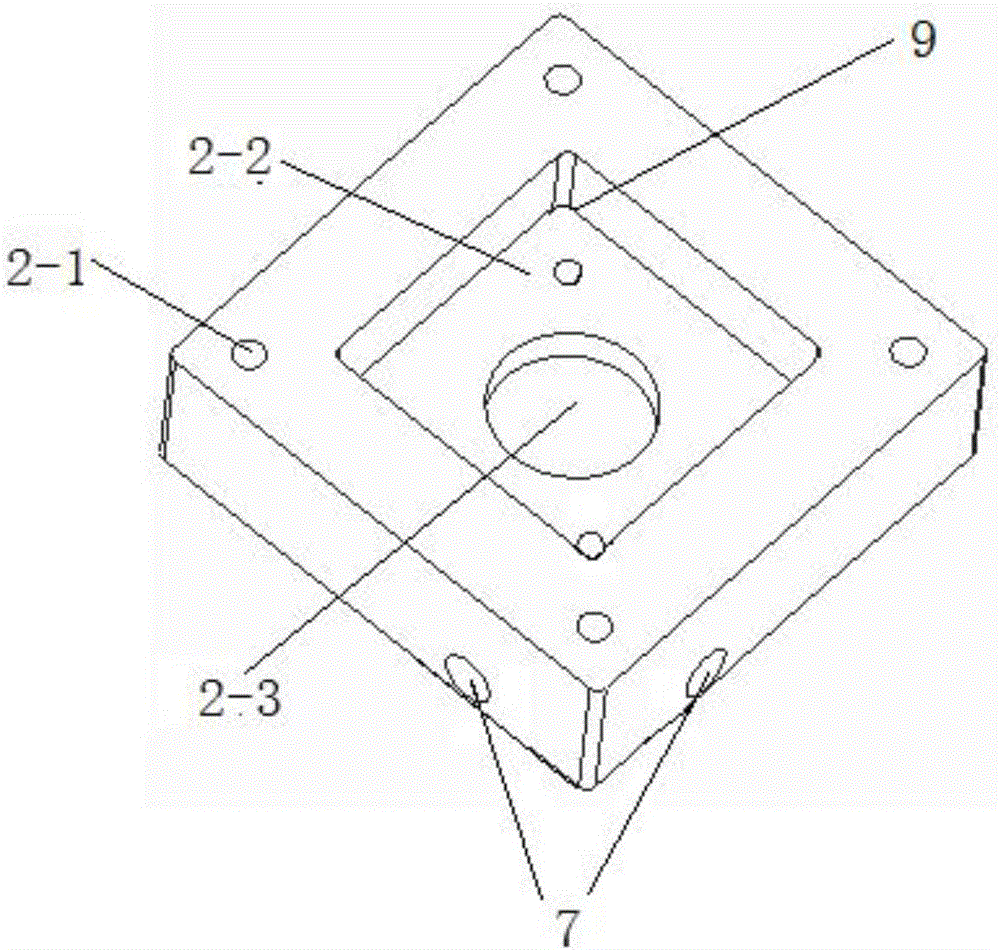

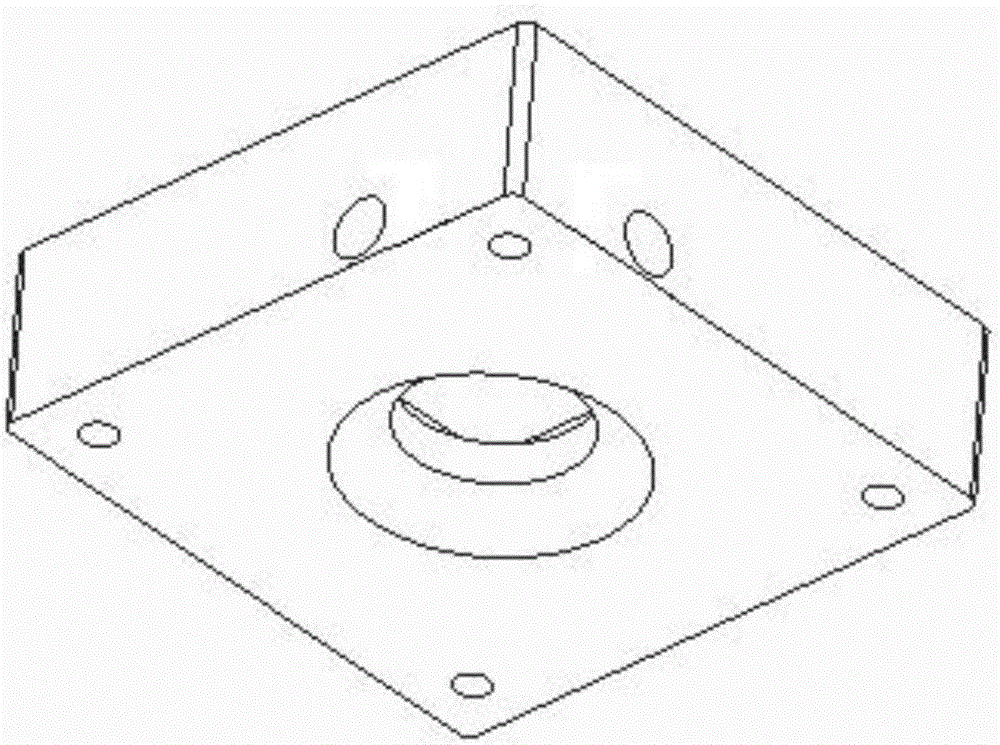

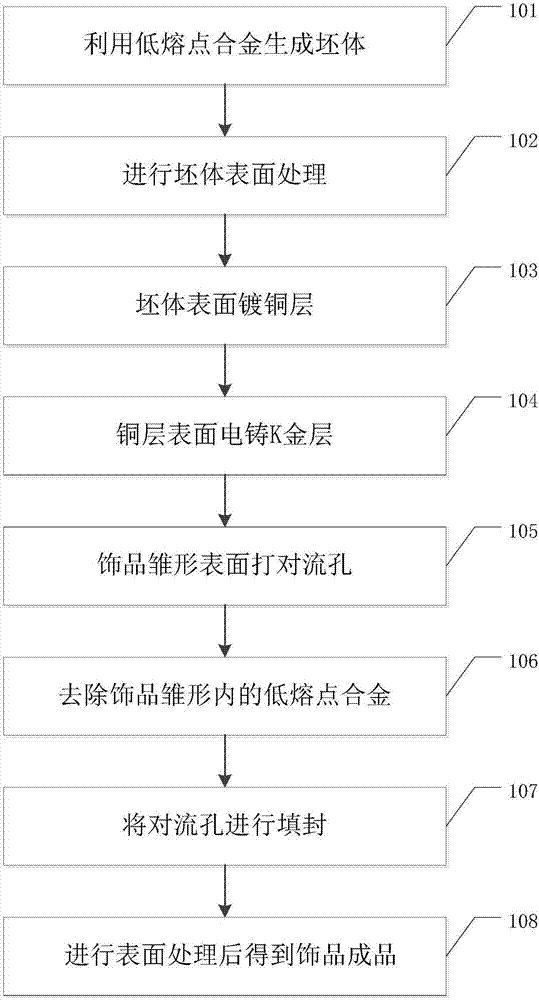

Eletroforming processing method for K gold jewellery

The invention relates to the technical field of jewellery processing, and specifically relates to an eletroforming processing method for K gold jewellery. The eletroforming processing method for the K gold jewellery comprises the following steps: pouring a melted low-melting-point alloy into a die, carrying out cooling forming on the low-melting-point alloy, and then removing the die to obtain a blank body composed of the low-melting-point alloy; eletroforming a K gold layer on the outer surface of the blank body to obtain a jewellery prototype; punching convection holes in the jewellery prototype; boiling the jewellery prototype punched with the convection holes, melting the low-melting-point alloy and enabling the low-melting-point alloy to flow out from the convection holes; then filling and sealing the convection holes in the surface of the jewellery prototype by virtue of a sealing wax; and carrying out surface treatment on the jewellery prototype with the filled-sealed convection holes to obtain finished jewellery. The eletroforming processing method for the K gold jewellery is capable of producing the hollow K gold jewellery, and the weight and the content of the K gold jewellery are effectively lowered, so that the K gold jewellery can be conveniently worn by a user, the production cost is greatly lowered, and the competitiveness of the product is effectively improved; and moreover, a fund demand on manufacturers is lowered, so that the development of the manufacturers is benefited.

Owner:深圳市金玉福珠宝首饰有限公司

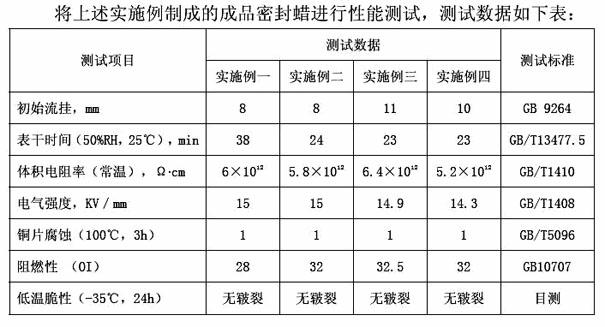

Seal wax composition for train end connector of motor train unit and preparation method thereof

The invention discloses a seal wax composition for a train end connector of a motor train unit. The seal wax composition comprises the following components in percentage by weight: 62-70% of wax material, 1-10% of tackifier, 15-25% of fire retardant, 5-15% of hydroxyl-terminated polydiorgaonsiloxane polymer, 1-5% of siloxane cross-linking agent and 0.1-3% of catalyst. The invention also discloses a preparation method of the seal wax composition. The seal wax composition prepared by the method contains no solvent and has good initial adhesion and favorable sealing, waterproofing, insulating and antiflaming properties; and the seal wax composition does not flow at the high temperature of 100 DEG C and does not crack at the low temperature of -35 DEG C, is in a paste state at room temperature and can be filled in a hose with a sharp mouth to be extruded, thereby facilitating construction. More importantly, the surface of the wax coating is not tacky and can become properly tackier along with elapse of time; the surface of the wax coating is in a plastic or rubber state, but the inside of the wax is still in a semi-solid state; and the original signal line can be replaced with a new one by simply removing the wax around the signal line and then refilling the seal wax.

Owner:江苏泰尔新材料股份有限公司

Method for grafting and breeding improved varieties of jujube at root collar of wild jujube

The invention discloses a method for grafting and breeding improved improved varieties of jujube at root collar of wild jujube, comprising the steps of a, collecting cutting woods: after jujube tree falls leaves and before the jujube tree germinates, collecting 1-year-old cutting woods of the improved varieties of jujube; b, cutting scion: cutting the cutting woods of improved varieties of jujube according to one bud, straightly cutting at place with distance of 1.5cm above the bud, and straightly cutting at place with distance of 5-6cm below the bud; c, preserving short cutting woods after cutting: sealing wax for the cut cutting woods, putting the treated cutting woods in bags according to variety, sealing and preserving in dark and shade place; d, cutting stock: cutting 2-3cm of all overgroundparts before the wild jujube seedling germinates and expands leaves, and digging up roots of the wild jujube as stock; e, grafting: using the cleft graft method with the stock with thickness of less than 1cm and the cut grafting method with thickness of more than 1cm. The method adopts the method for grafting and breeding improved varieties of jujube by grafting the 1-year-old cutting woods of improved varieties of jujube at the root collar of the wild jujube. Because the root of the wild jujube stock is extensive, the resistance is strong; the transplanting survival rate is high; the survival rate reaches 85-90%; and the overwintering cold resistance is improved. Due to extensive root of the nursery stock, the absorbing capacity is strong, thereby being beneficial to improving the fruit quality and cold resistance.

Owner:张掖市林业科学研究院

Sealing wax method for graft

A wax sealing method for graft features that after the scion is grafted on the stock and the grafted position is fixed, said grafted position is instantaneously immersed in the fused paraffin wax at 85-90 deg.C and then cooled. Its advantages are high survival rate and high growing speed.

Owner:新昌县苦丁茶研究所 +1

Method of processing supersonic vibration machine grinding of sapphire steel bar

InactiveCN101041227AQuality improvementEfficiently manufacture low costEdge grinding machinesOil/fat/wax adhesivesMachined surfaceSealing wax

The invention relates to an ultrasonic vibration grinding machining method for sapphire bar. After the sapphire blank workpeice is located upper and lower surfaces are grinded flat and it is bonded on bakelite by sealing wax glue; then the bakelite is fixed on the working table of machine. The ultrasonic wave is started and the frequency of ultrasonic wave is adjusted in 17kHz-23kHz to make it in resonance state. The cooling liquid is started and the workpeice is cooled by inner and outer cooling ways. The ultrasonic vibration grinding machining is carried out. After machining is accomplished the sapphire workpeice and the bakelite are set on electrical furnace together to be heated to 115deg.C-125deg.C. The sapphire workpeice is fetched from the bakelite to obtain sapphire bar with diameter of 20-140mm and length of 50-150mm. the invention is provided with good machining surface quality and low producing cost so on. It has a wide applicable prospect and can create obvious social and economical benefits.

Owner:HARBIN INST OF TECH

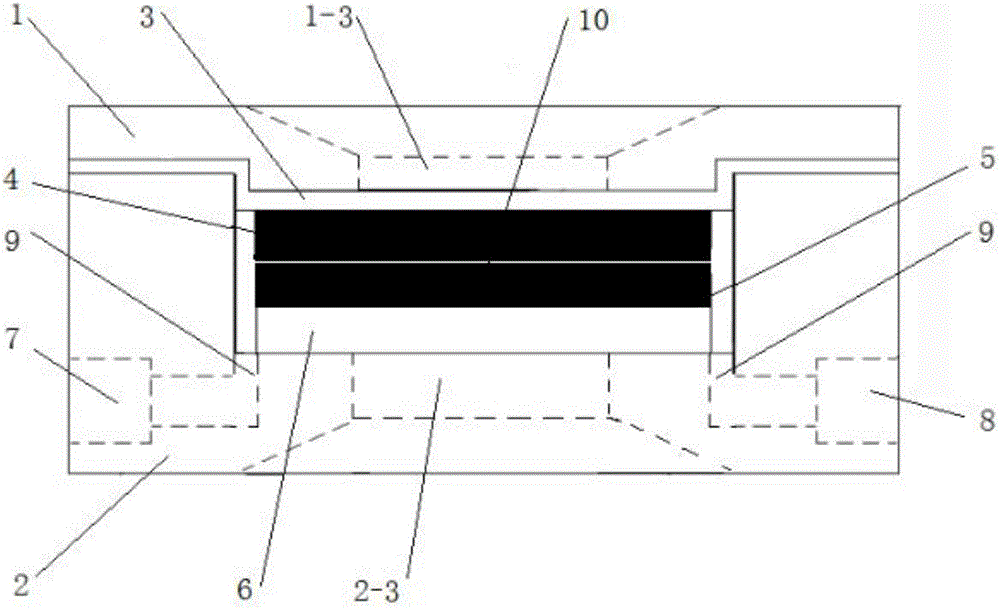

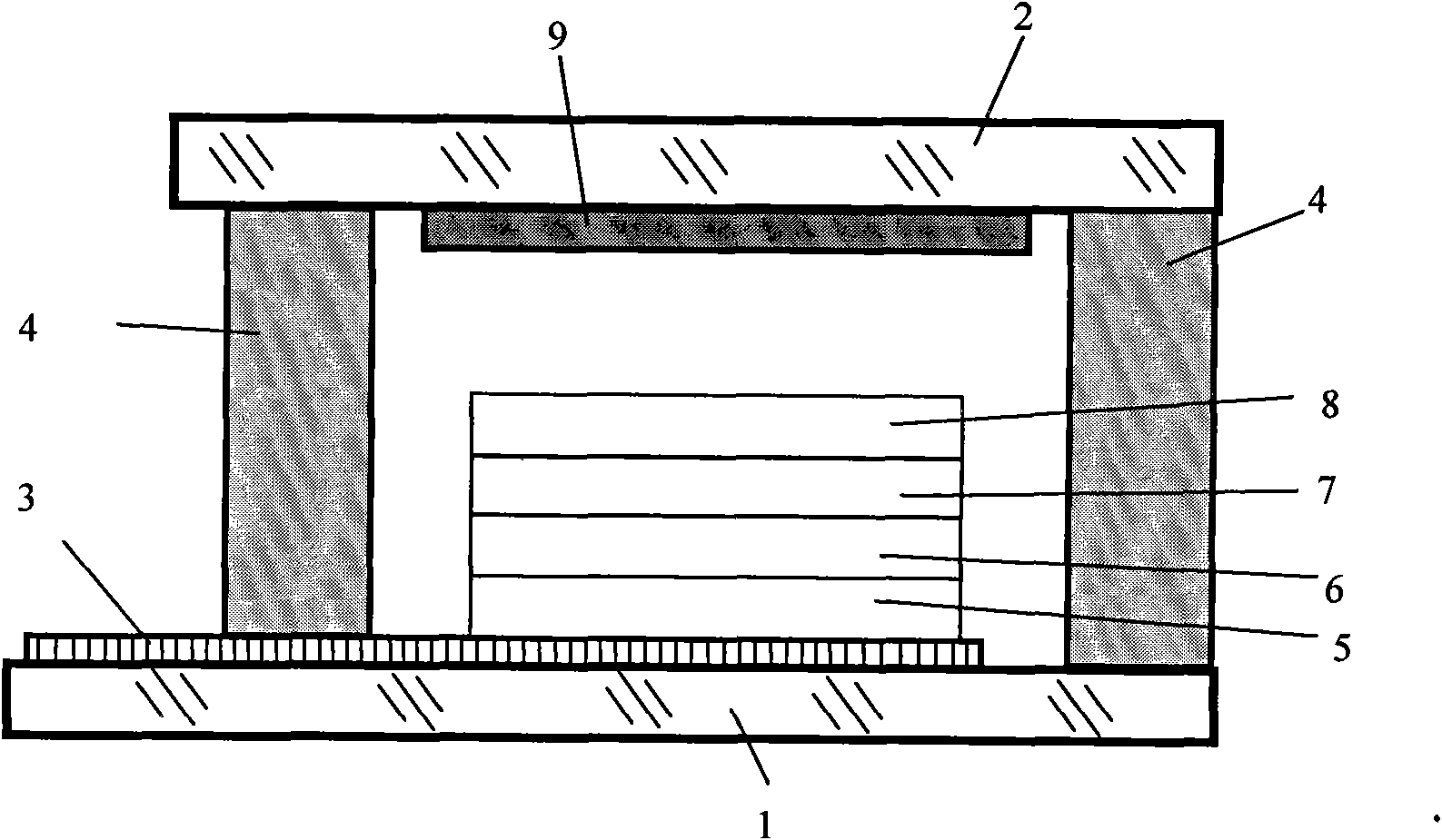

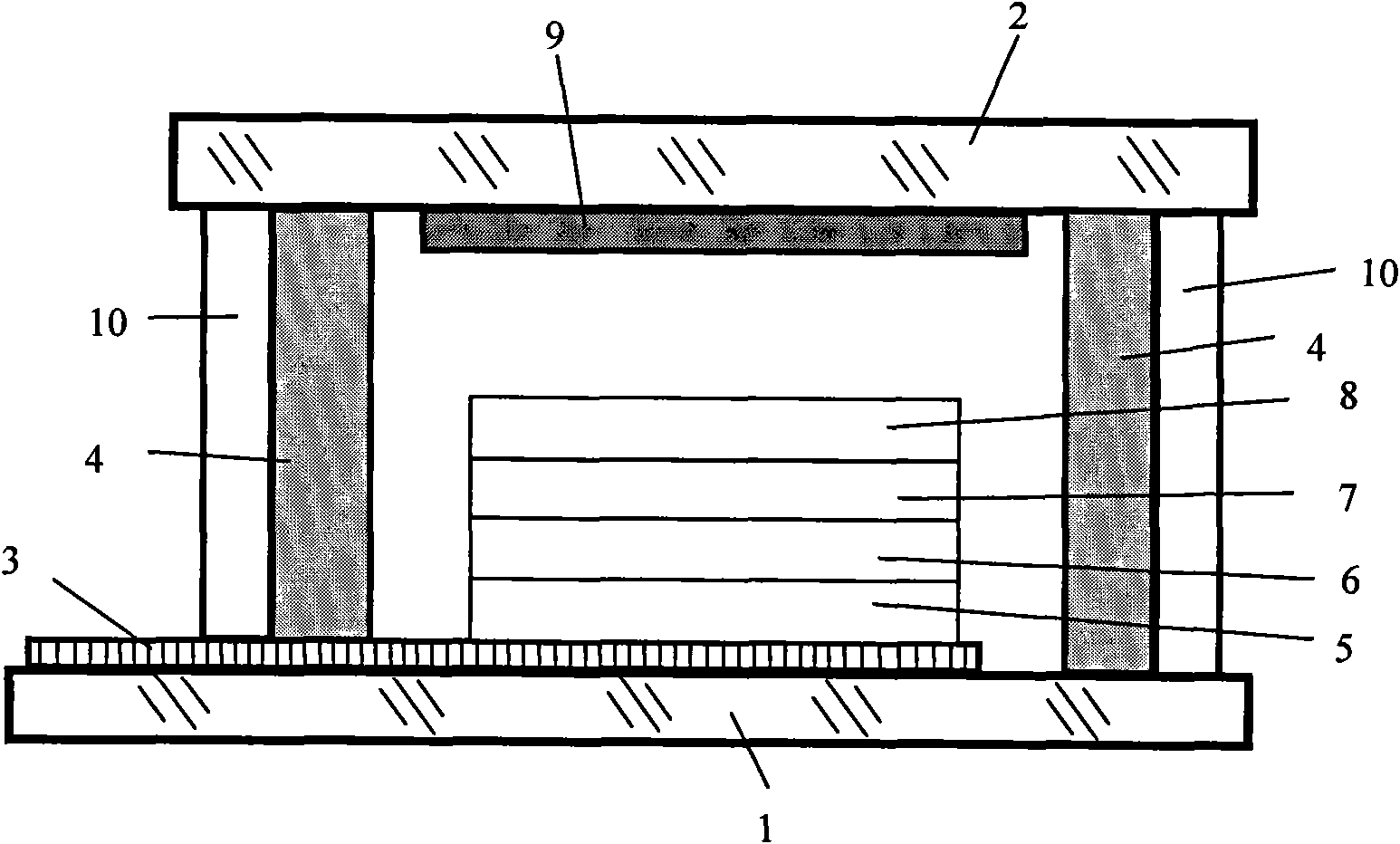

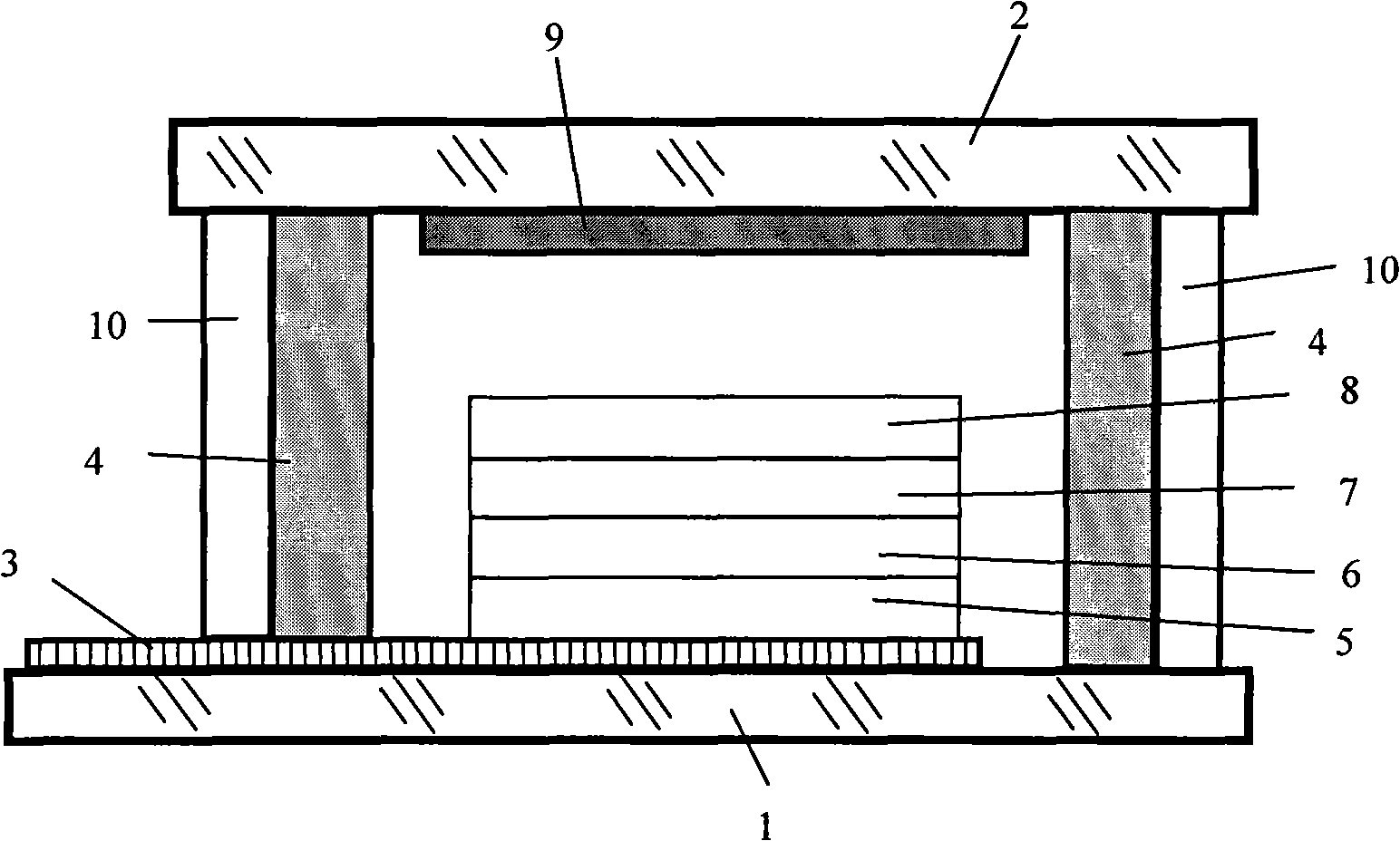

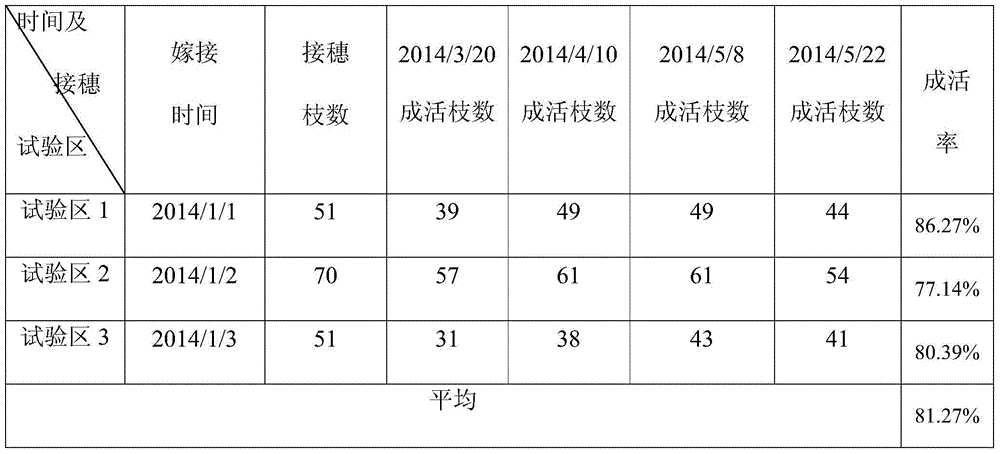

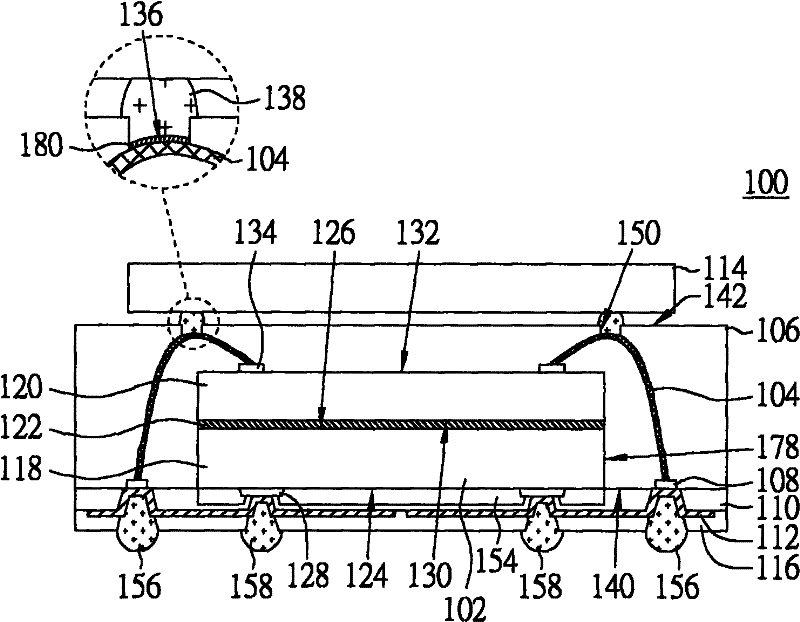

Packaging structure and packaging method of organic electroluminescent device

InactiveCN101931058AImprove barrier propertiesReduce penetrationSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionTransport layer

The invention discloses a packaging structure of an organic electroluminescent device. The packaging structure comprises a bottom plate 1 and a cover plate 2, wherein the bottom plate 1 is provided with a transparent conductive electrode layer 3; and an organic light-emitting functional layer which at least comprises a hole transport layer 5, a luminous layer 6, an electron transport layer 7 and a cathode layer 8 is arranged on the transparent conductive electrode layer 3 in turn. The packaging structure is characterized in that: a sealing layer 4 at a corresponding sealing position between the bottom plate 1 and the cover plate 2 is made of vacuum sealing wax; and ultraviolet curing resin or thermosetting rein is arranged in a gap formed by the bottom plate 1 and the cover plate 2 on theouter side of the sealing layer 4 to serve as a sealing enhancement layer 5. The packaging structure and a packaging method can overcome the defects in the prior art and reduce the permeation of water vapor and oxygen to water vapor and oxygen on the sealing layer of the device.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

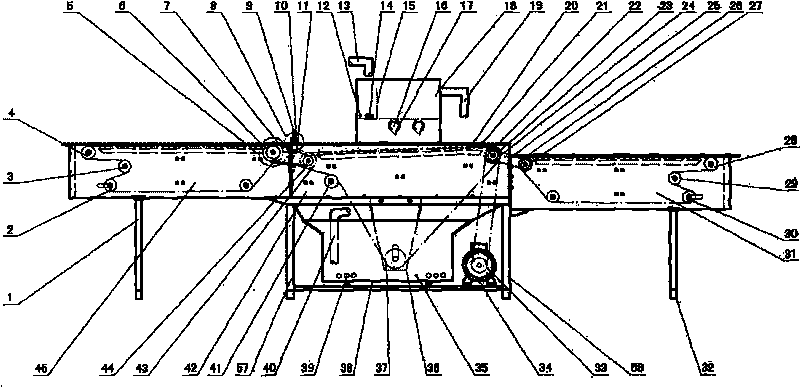

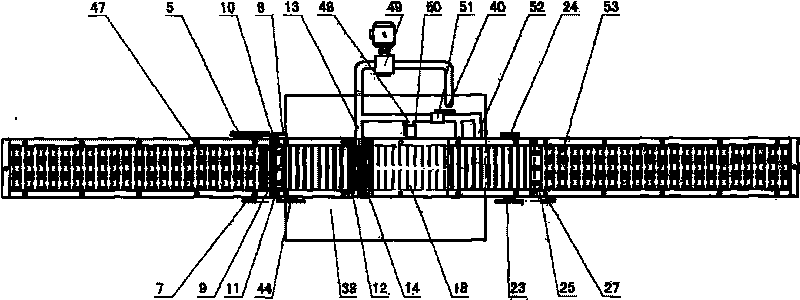

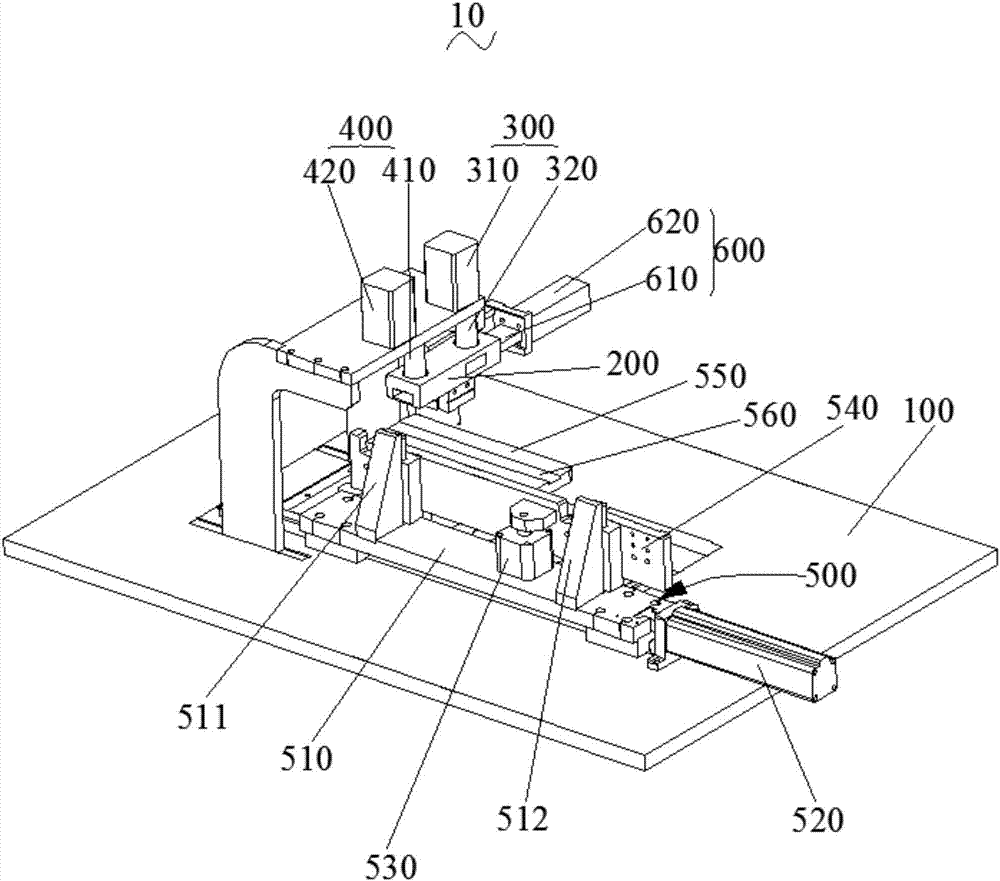

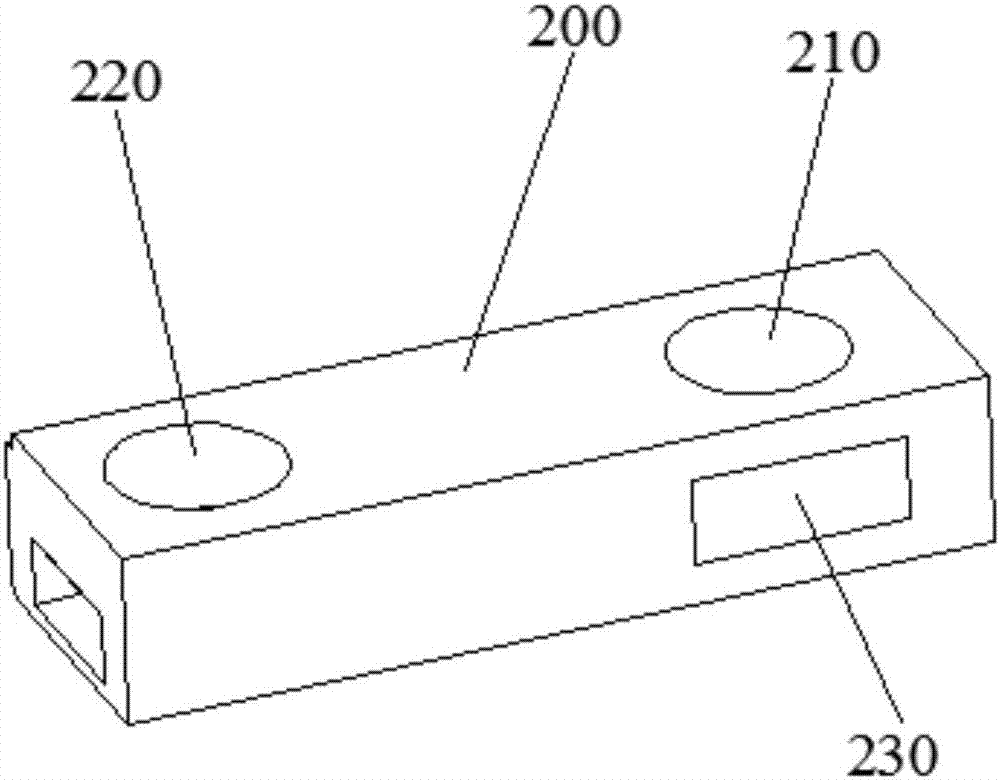

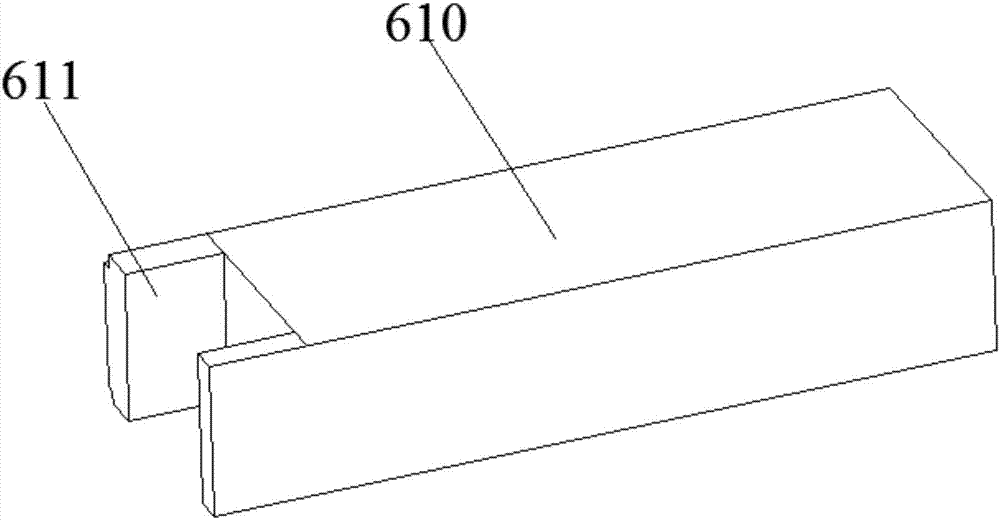

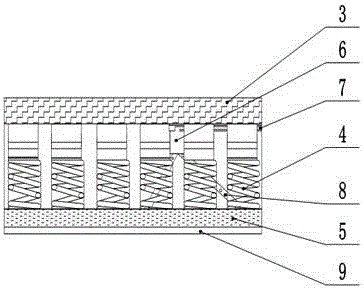

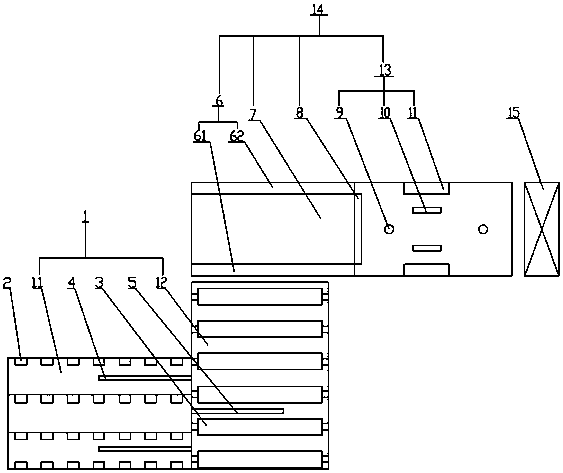

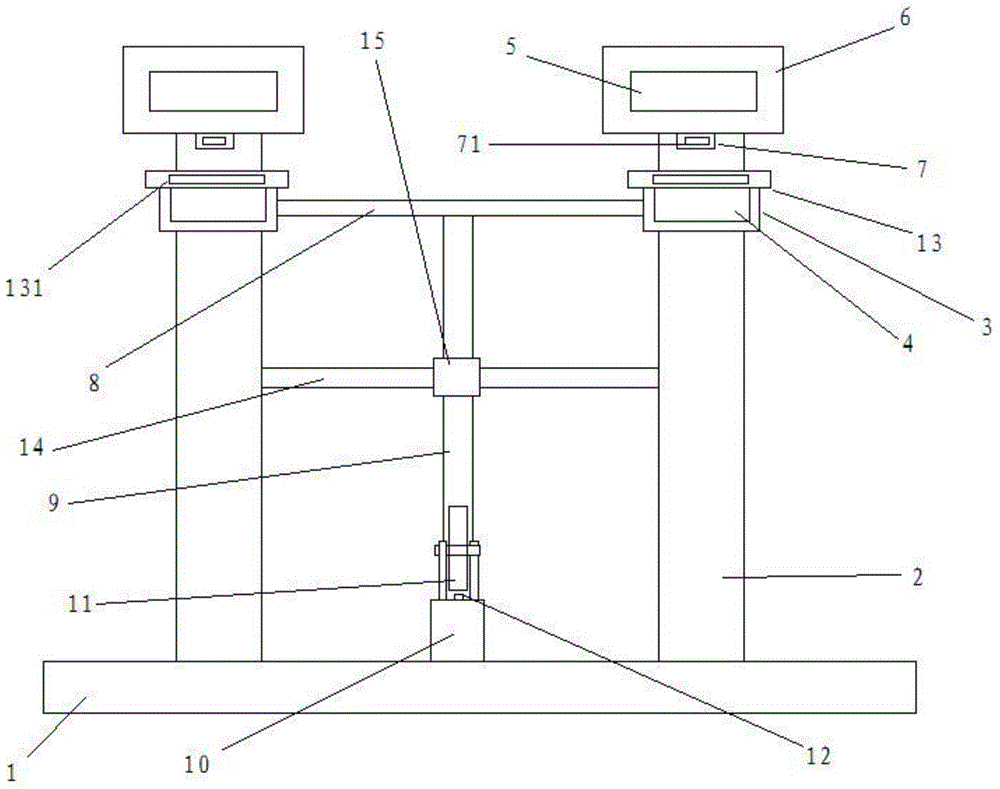

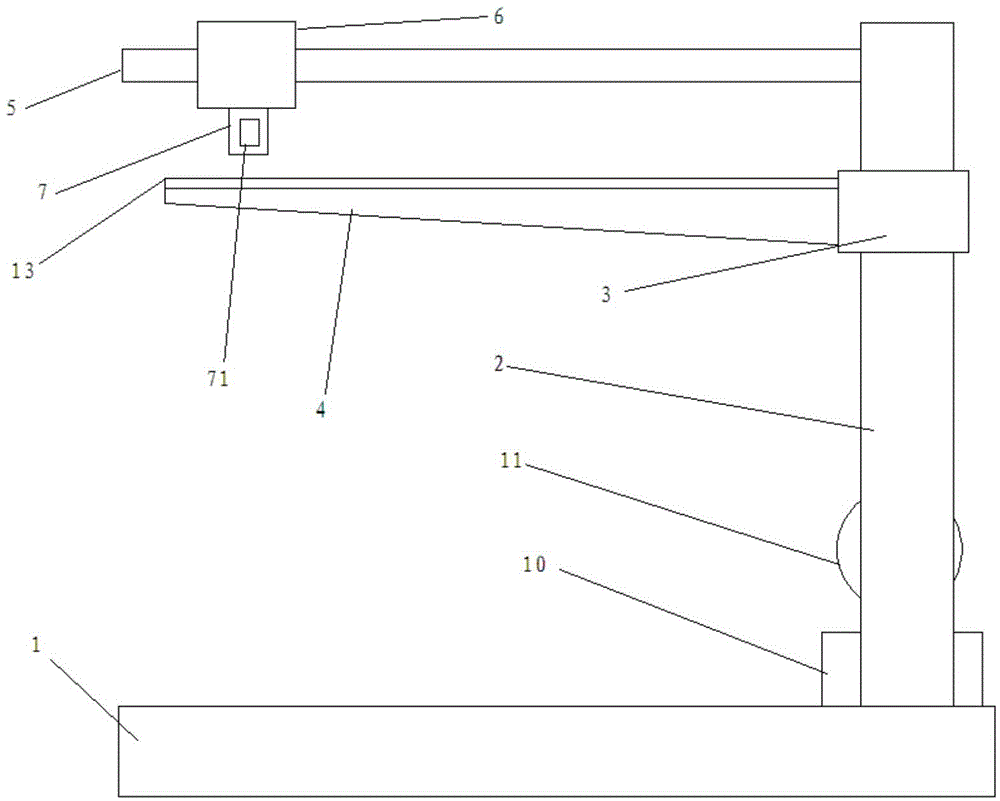

Battery pack wax-sealing processing mechanism

InactiveCN107253546AQuality assuranceIncrease productivityLiquid surface applicatorsPrimary cell manufactureSealing waxEngineering

The invention discloses a battery pack wax-sealing processing mechanism. The battery pack wax-sealing processing mechanism comprises a wax-sealing support, a wax-sealing cavity block mounted on the wax-sealing support, a wax injecting device used for injecting and feeding wax into the wax-sealing cavity block, a wax-sealing shaping device used for shaping battery packs in the wax-sealing cavity block, and a wax-sealing discharging device used for conducting discharging after wax-sealing processing. The wax-sealing discharging device is arranged below the wax-sealing cavity block, and a sealing wax pushing device is arranged at one end of the wax-sealing cavity block. According to the battery pack wax-sealing processing mechanism, stacked battery packs are subjected to wax-sealing processing by arranging the wax-sealing support, the wax-sealing cavity block, the wax injecting device, the wax-sealing shaping device, the wax-sealing discharging device and the sealing wax pushing device, and thus production efficiency is greatly improved, a good stacking shaping effect is achieved, and the wax-sealing processing quality of the battery packs can be guaranteed.

Owner:惠州市佳呈得科技有限公司

Laminate flooring colorized solid sealing wax and preparation method thereof

InactiveCN102627862AImprove aestheticsWith moisture resistanceOther chemical processesColor effectMetallurgy

A laminate flooring colorized solid sealing wax comprises, by weight, 50-85% of paraffin, 10-45% of a polymer material, 1-8% of an organic pigment, and 1-8% of a surface modifier. A preparation method of the laminate flooring colorized solid sealing wax comprises the following steps: weighing required raw materials according to above proportions, fuse-mixing the raw materials, and cooling. Lock catches of wood floors processed with the laminate flooring colorized solid sealing wax have moisture-proof lubrication effects of the lock catches of the floors processed with traditional paraffin, and the colorized solid sealing wax is configured according to the color of the floor surface to unify the floor in color to effectively cover base materials at the lock catches of the floors, so a uniform color effect is obtained, and the overall aesthetic degree of the floor is greatly improved.

Owner:JIAXING UNIV +1

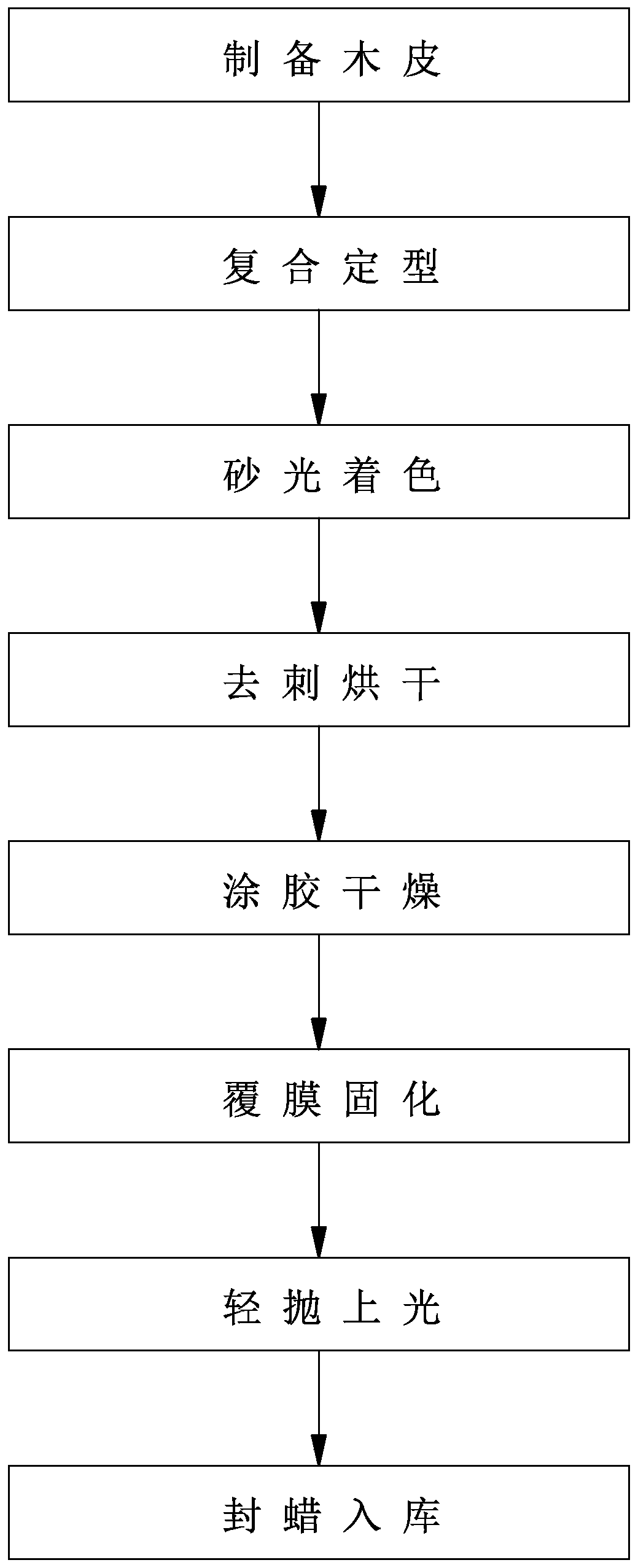

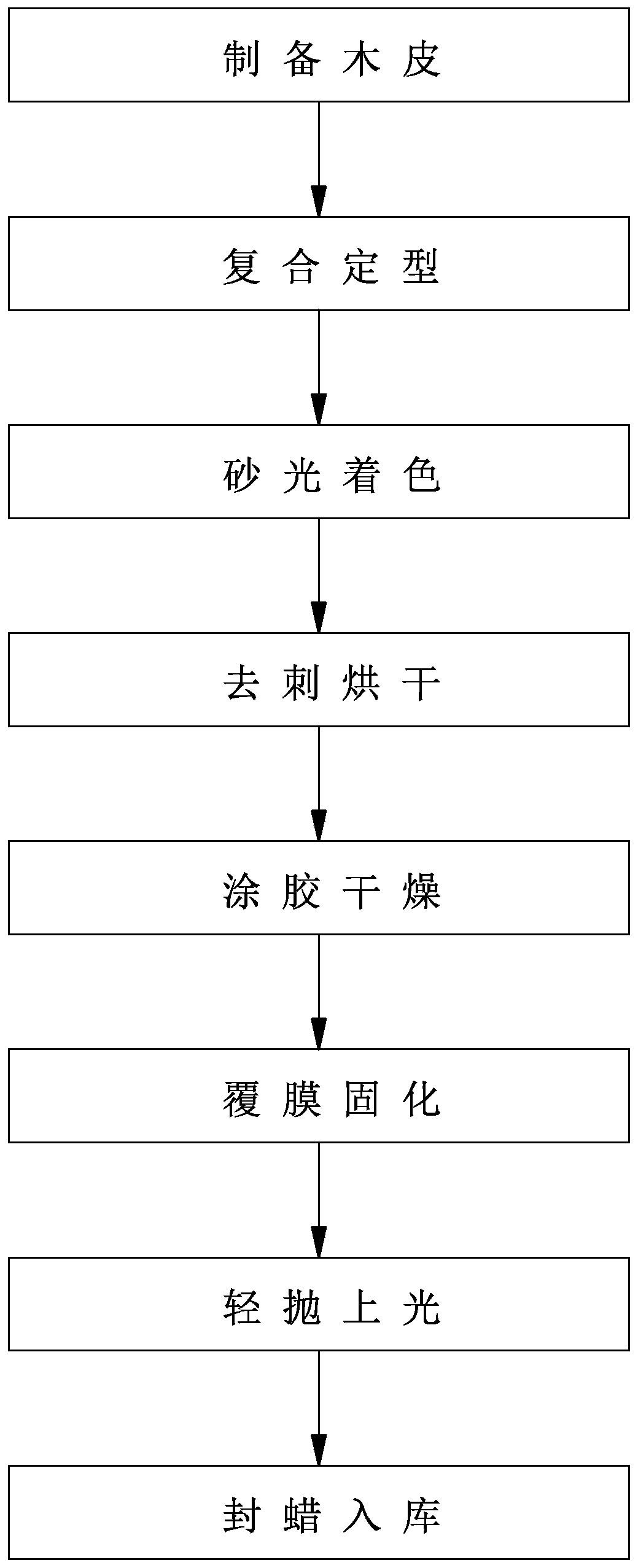

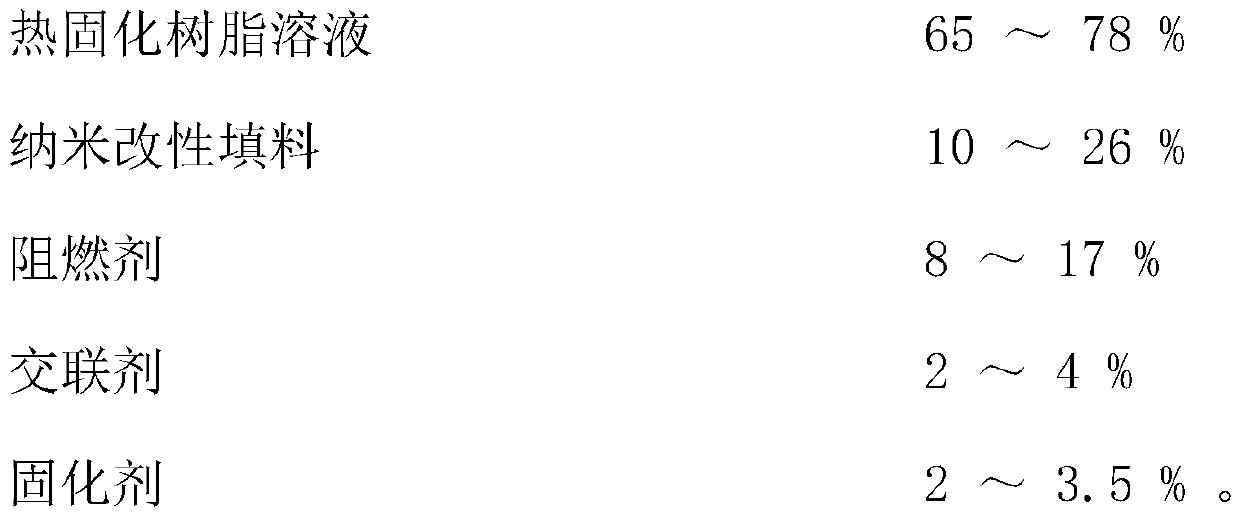

Manufacturing process of composite paint-free thin-coating wood veneer

InactiveCN109702825AImprove surface strengthGood chemical resistanceNon-macromolecular adhesive additivesWood treatment detailsWood veneerSurface layer

The invention discloses a manufacturing process of a composite paint-free thin-coating wood veneer. The process is realized through the following steps sequentially that step 1, a wood veneer is prepared, step 2, compounding and shaping are conducted, step 3, sanding and coloring are conducted, step 4, deburring and drying are conducted, step 5, gluing and drying are conducted, step 6, coating andcuring are conducted; step 7, light-polishing is conducted, and step 8, sealing wax and storing are conducted. According to the manufacturing process of the composite paint-free thin-coating wood veneer, the wood veneer manufactured has the outstanding characteristics of environmental protection, high flame retardancy, high wear resistance, strong water resistance and the like, in addition, due to the fact that a thin glue layer and an is adhesive film layer are arranged on the surface layer of the wood veneer, original wood grains of a log skin can be touched on the surface of the wood veneer, the vertical physique feeling of the log skin and the original and natural characteristics of the log skin can be further embodied, in addition, the manufacturing process of the composite paint-free thin-coating wood veneer has the advantages that the production process is greatly simplified, resources can be further saved, the production cost of production enterprises can be reduced, and themarket competitiveness of the production enterprises can be improved.

Owner:广东尚联新材料科技有限公司

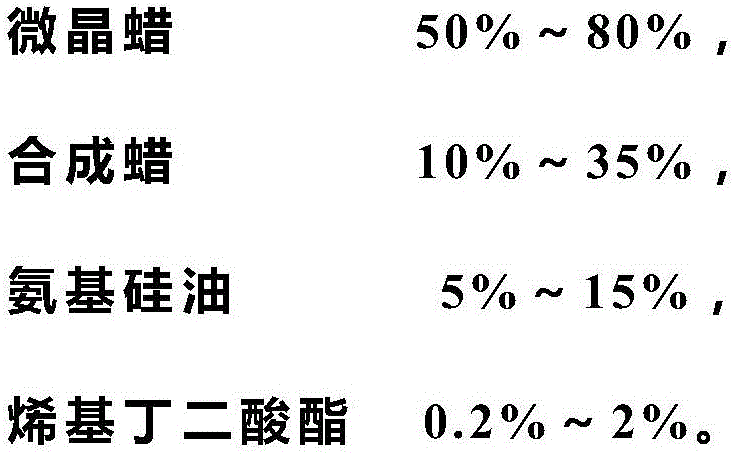

Film capacitor sealing wax and preparation method thereof

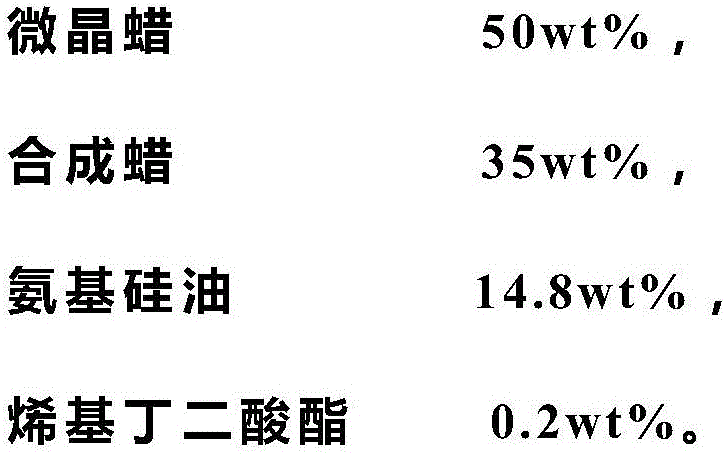

ActiveCN106783165ADoes not affect healthIncrease productivityThin/thick film capacitorStacked capacitorsMicrocrystalline waxSealing wax

The invention relates to film capacitor sealing wax and a preparation method thereof. The film capacitor sealing wax comprises, by weight percentage, 50-80% of microcrystalline wax, 10-35% of synthetic wax, 5-15% of amino silicone oil, and 0.2-2% of alkenyl succinic acid ester. The sealing wax of the invention is resistant to both high temperature and moisture permeation, and does not affect the electrical performance.

Owner:江苏聚冠新材料科技有限公司

Weak light-cured wood coating

ActiveCN107227056AImprove performancePromote sustainable developmentCoatingsSealing waxResource saving

The invention belongs to the field of wood coatings and particularly relates to a wood surface coating which can be cured to form a film under any weak light source. The weak light-cured wood coating is composed of two components of A and B. The component A is main paint and is composed of a main resin, sealing wax, an accelerator, a polymerization inhibitor, a thixotropic agent, auxiliaries, an active diluent and a dye. The component B comprises an initiator. The weak light-cured wood coating has solid content near to 100%, is not limited by a wood shape and is a low-VOC emission, excellent performance, widely used, environment-friendly and resource-saving wood coating.

Owner:HUNAN JINHAI SCI & TECH

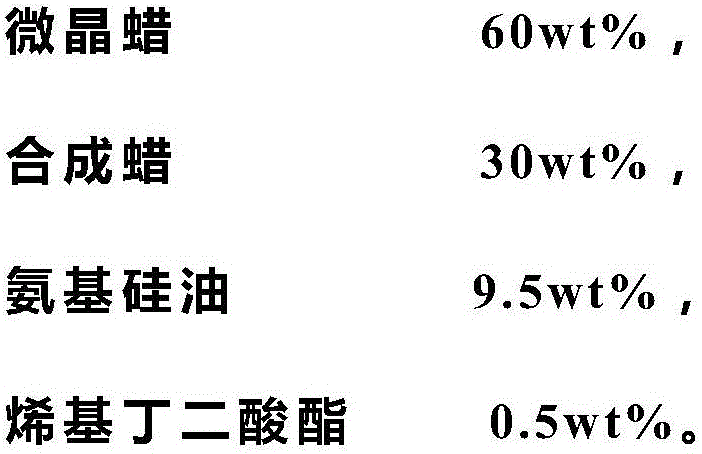

Aluminized high water resistant solar battery back membrane and manufacturing method thereof

InactiveCN101789454AIncreased durabilityMeet performance requirementsFinal product manufacturePhotovoltaic energy generationSealing waxEngineering

The invention relates to an aluminized high water resistant solar battery back membrane and a manufacturing method thereof, belonging to the technical field of solar-cell panel back membranes. The back membrane comprises seven layers of structures arranged in sequence from top to bottom, wherein a high-fluorine mixcrystal coating is coated between the lower surface of a first basic level and the upper surface of a second basic level, a PET (polyethylene terephthalate) layer is coated between the lower surface of a third basic level and the upper surface of a fourth basic level and an aluminum sheet layer is arranged between the lower surface of the second basic level and the upper surface of the third basic level which are arranged between the high-fluorine mixcrystal coating and the PET layer. The aluminized high water resistant solar battery back membrane with seven layers of structures is prepared by adopting a advanced high-fluorine mixcrystal interconnection permeating fusion technology, a plasma titanium silicide nanometer treatment technology, a high-precision unrippled coating technology and aluminum surface silylation, and the compositely arranged silylation aluminum sheet enhances the water-resistance of the product. The membrane is subjected to vacuum thermal forming integrally with ethylene vinyl acetate (EVA) sealing wax, solar battery plates and high-transmittance nonferrous glass for 15min, and the forming temperature is 135 DEG C. The assembly after forming satisfies the performance requirement of photovoltaic devices and has over 25 years of service life.

Owner:杭州联合新材科技股份有限公司

Method for conducting freshness retaining on tea tree grafting scion

ActiveCN104126425AStrong drought resistanceImprove cold resistanceHorticultureParaffin waxAxillary bud

The invention provides a method for conducting freshness retaining on a tea tree grafting scion. Timely wax sealing and thin film capping are conducted on the tea tree scion which has the ear length ranging from 8 cm to 15 cm, has one to two axillary bud growing points, is one year old or two years old, has been lignified and does not have leaves. The method includes the steps of placing beewax and paraffin wax in a pot according to the proportion of 1:1-3, heating the mixture, conducting low-fire heating after the mixture is completely melted so that the mixture can be kept not condensed, arranging the scion on a gourd-ladle-shaped leakage sieve, immersing the gourd-ladle-shaped leakage sieve into the melted wax solution, rapidly and perpendicularly lifting the gourd-ladle-shaped leakage sieve, spreading the scion covered with liquid wax to be cooled, and winding plastic thin film at the upper end of the scion where sealing wax cooling is conducted, and conducting capping for standby application. The method has the advantages that the short scion which is one year old or two years old and has been lignified is adopted, the scorching resistance, the drought resistance and the cold resistance are high compared with a semi-lignified scion which is mainly used in current grafting, the wax sealing technology is easy and practicable and low in cost; the grafting time of the scion where sealing wax freshness retaining and moisture preservation are conducted can be as long as one month, the method can adapt to the long-distance transportation and large-area grafting and the seed changing improvement, the stress resistance is improved, and the grafting survival rate is 80% or higher.

Owner:TEA INST YUNNAN ACADEMY OF AGRI SCI

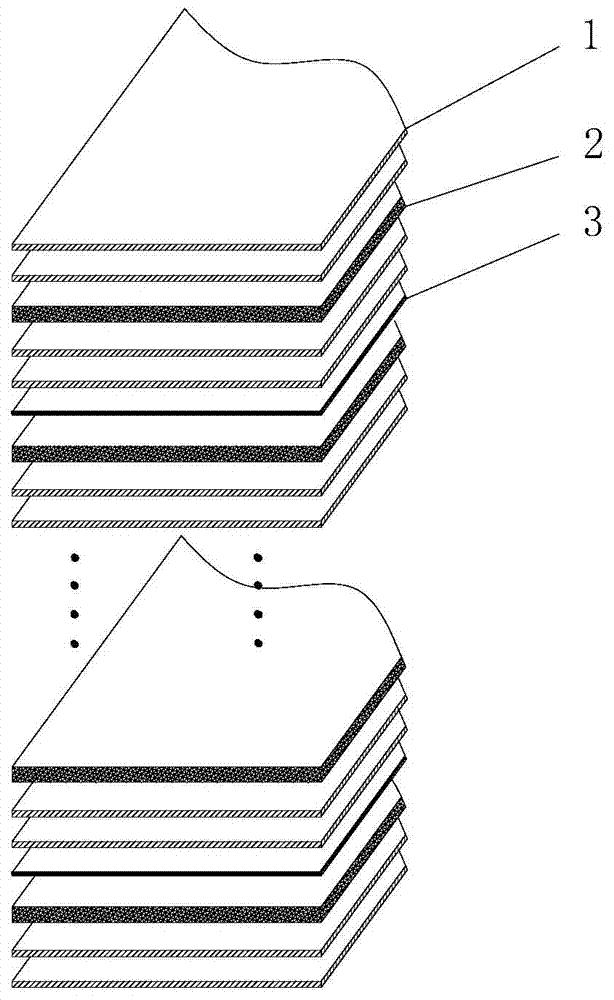

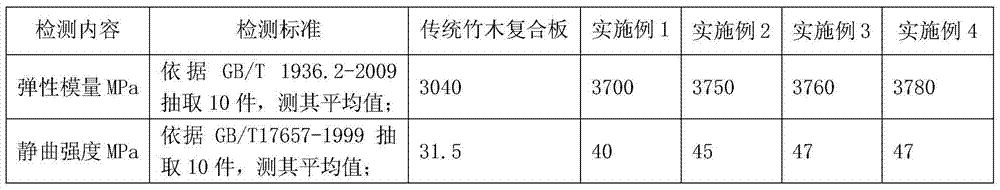

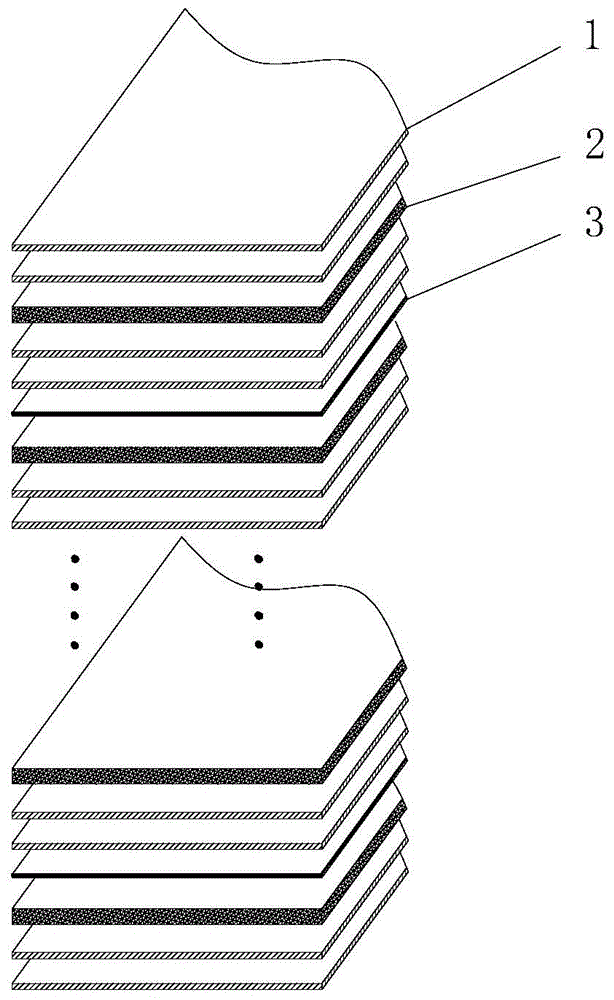

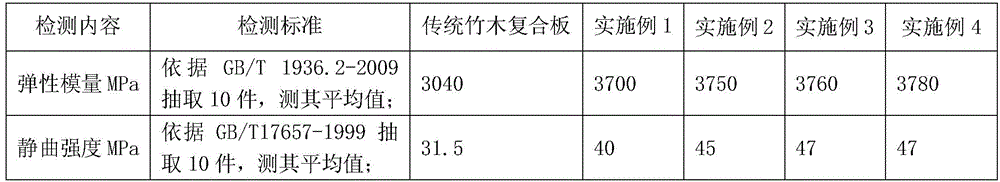

Bamboo and wood composite board and method for manufacturing same

ActiveCN104493916AImprove mechanical propertiesEasy to processWood veneer joiningWood veneerSurface layer

The invention relates to the technical field of composite boards, and discloses a bamboo and wood composite board and a method for manufacturing the same. The bamboo and wood composite board comprises bamboo layers, wood veneer layers, more than two non-woven fabric layers and adhesive. The corresponding wood veneer layer is arranged between each two bamboo layers, the total quantity of the bamboo layers and the wood veneer layers ranges from 14 to 35, the non-woven fabric layers are arranged between the bamboo layers and the wood veneer layers, the various layers are adhered with one another by the adhesive and are integrally laminated, a surface layer and a bottom layer of the bamboo and wood composite board are bamboo layers respectively, sealing wax layers with waterproof effects are arranged on the surfaces of the bamboo and wood composite board, the bamboo layers are bamboo chip layers or bamboo curtain layers, the thickness of each bamboo layer ranges from 0.5mm to 1.5mm, the thickness of each wood veneer layer ranges from 1.5mm to 2.0mm, the adhesive is made of phenolic resin adhesive with the solid content of 50%, impregnating compounds and more than one type of waterproof agents, mothproofing agents or inorganic flame retardants are added into the phenolic resin adhesive, and the adhesive is applied to double surfaces of each of the bamboo layers, the wood veneer layers and the non-woven fabric layers. The method for manufacturing the bamboo and wood composite board includes steps of manufacturing the adhesive; treating materials of the bamboo layers; treating wood veneers; arraying and assembling blanks; laminating and forming the blanks; treating the surfaces of the blanks and warehousing the finished product.

Owner:DEYI CULTURAL & CREATIVE GRP CO LTD

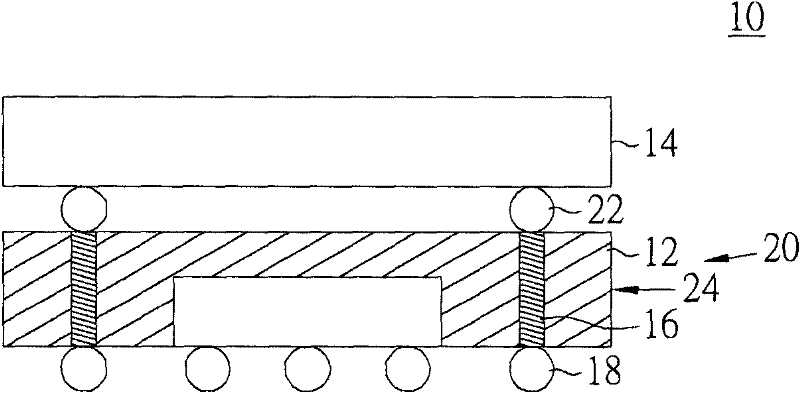

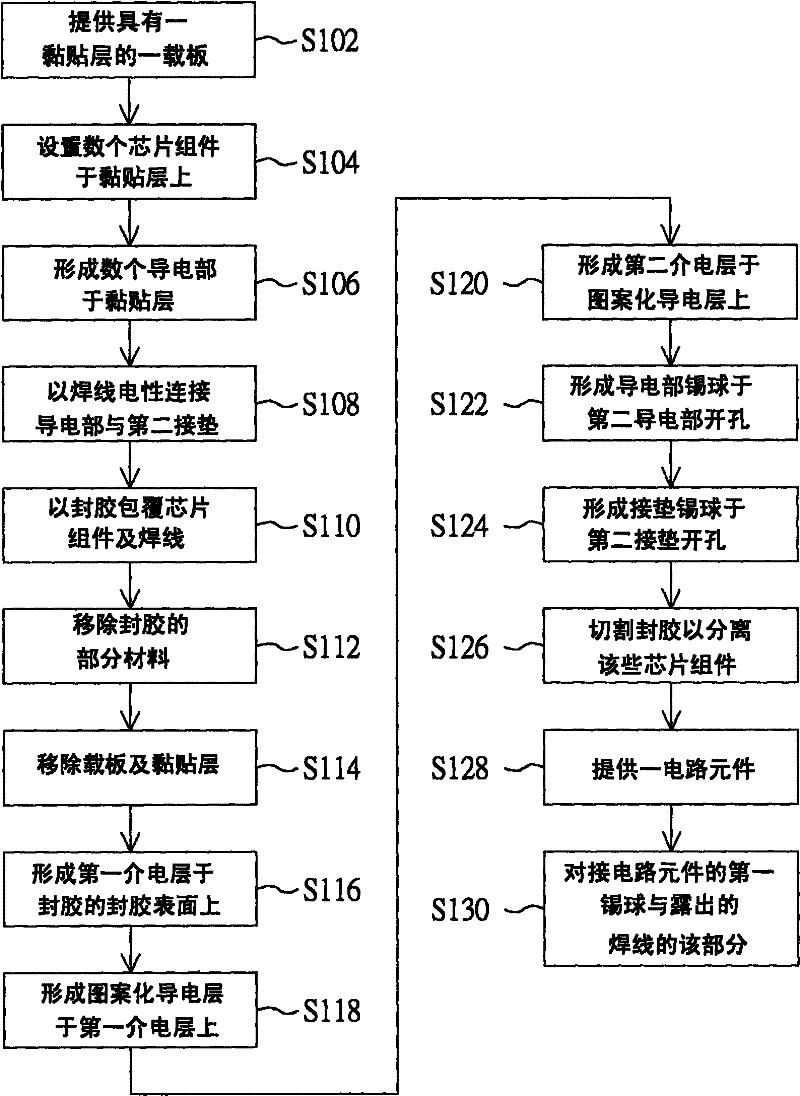

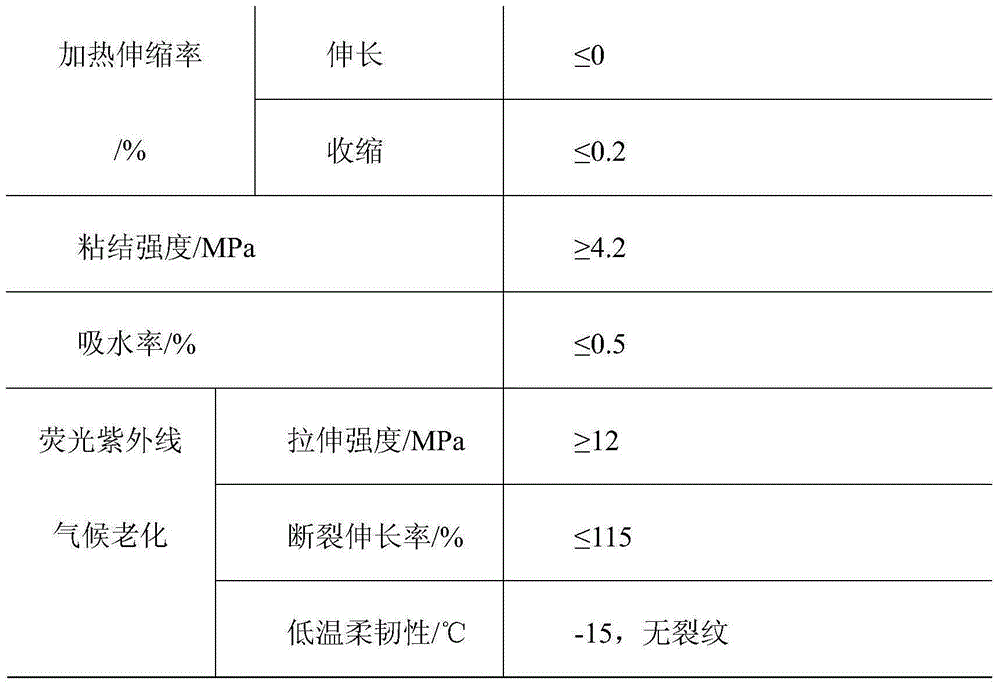

Semiconductor package part and manufacturing method thereof

InactiveCN102208396ASemiconductor/solid-state device detailsSolid-state devicesSealing waxSemiconductor package

The invention discloses a semiconductor package part and a manufacturing method thereof. The semiconductor package part comprises a chip assembly, a sealing wax, a metal weld line, a conducting part, a dielectric layer and a patterned conducting layer; the chip assembly comprises a first connecting pad and a second connecting pad which are oppositely configured; the sealing wax covers the chip assembly and the metal weld line and has a sealing wax surface; a part of the metal weld line and the first connecting pad are exposed out of the sealing wax surface; the conducting part is formed on the sealing wax and at least one part of the conducting part is exposed out from a first sealing wax surface; the dielectric layer is formed on the first sealing wax surface and has a conducting part hole exposed out of the conducting part; the patterned conducting layer is formed on the conducting layer and a part of the patterned conducting layer is formed in the conducting part hole so as to be electrically connected the conducting part; and the metal weld line is electrically connected with the conducting part and the second connecting pad.

Owner:ADVANCED SEMICON ENG INC

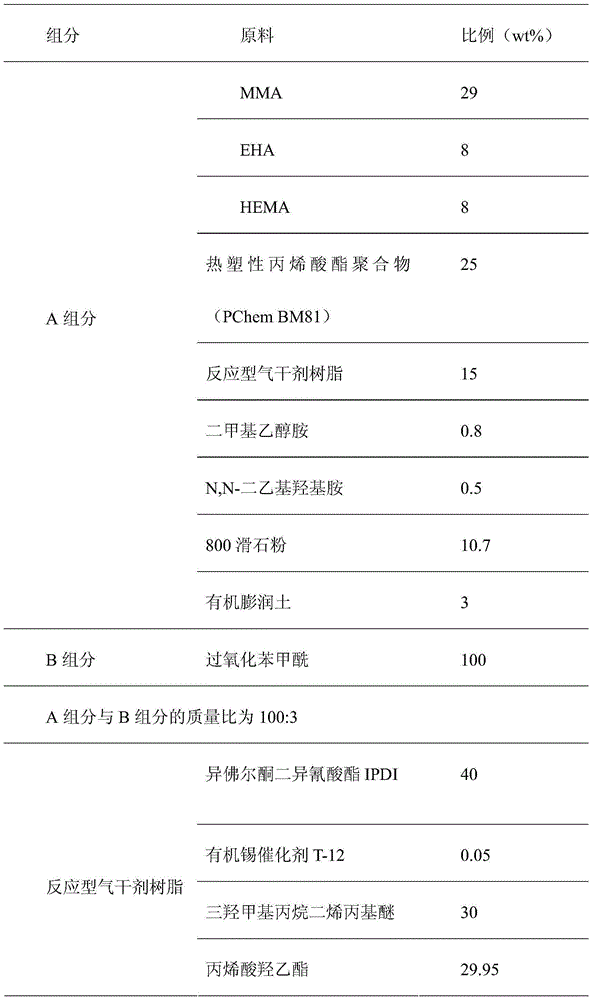

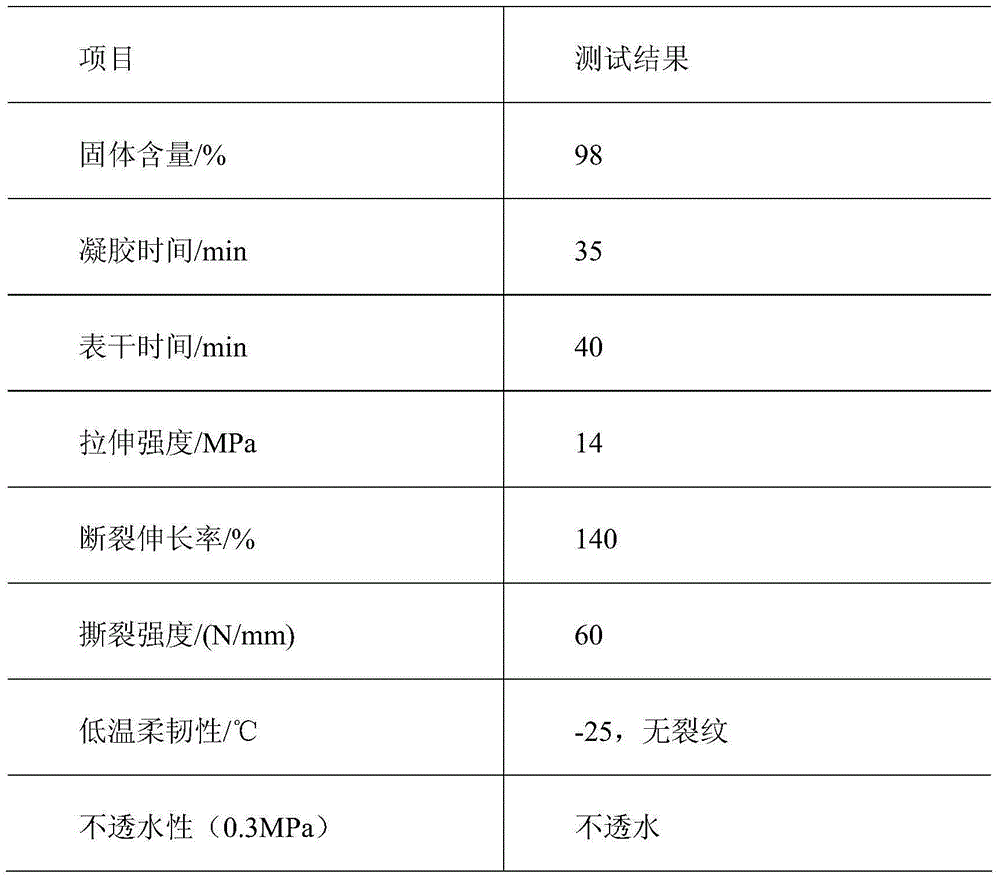

Air-dried type acrylic ester waterproof paint and preparation method thereof

ActiveCN105238200AImprove air drynessLittle impact on mechanical propertiesCoatingsSealing waxDouble bond

The invention provides air-dried type acrylic ester waterproof paint and a preparation method thereof. For solving the problem that in actual construction of the acrylic ester waterproof paint, the sealing wax cannot effectively solve the oxygen inhibition problem and the problems such as incomplete curing exist, reaction type air drying agent resin is introduced to replace sealing wax. Allyl ether in the reaction type air drying agent resin contains an allyl double bond and an ether bond, and hydrogen on a positive carbon atom in the double bond is very prone to being lost and then becomes free radicals to be combined with oxygen in air to generate hyperoxide; meanwhile, the hyperoxide generates free radicals with the high activity to promote continuing of the next-step reaction, therefore, a series of double-bond crosslinking reactions take place, and the inhibition action of oxygen on PMMA paint reacting is effectively isolated, so that the paint is cured in the air but is not tacky.

Owner:FOSHAN KESHUN BUILDING MATERIAL CO LTD

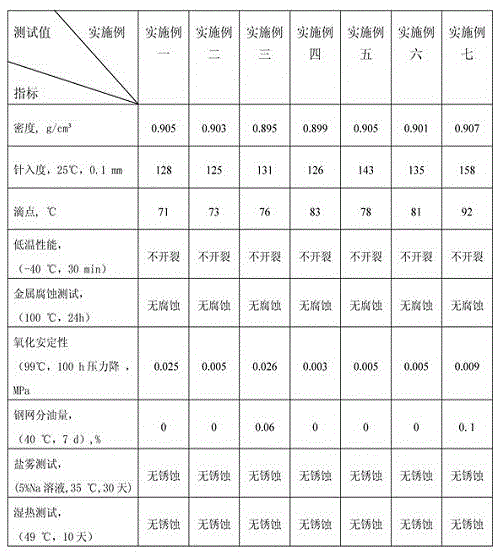

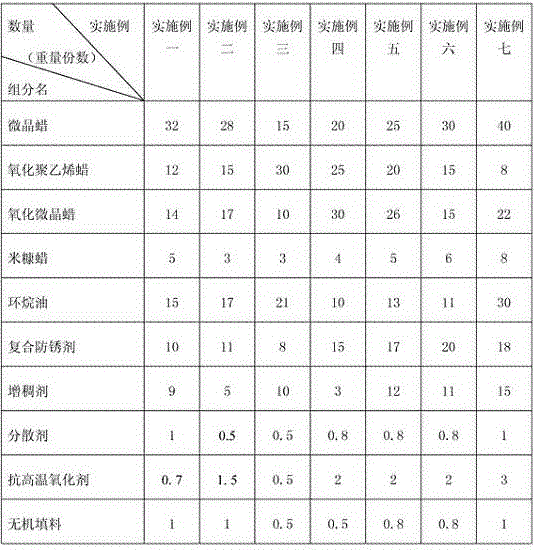

Anticorrosion sealing wax for bridge cables and anchor heads and preparation method thereof

The invention discloses anticorrosion sealing wax for bridge cables and anchor heads. The anticorrosion sealing wax is a mixture composed of, by weight, 15-40 parts of microcrystalline wax, 8-30 parts of oxidized polyethylene wax, 10-30 parts of oxidized microcrystalline wax, 3-8 parts of rice bran wax, 10-30 parts of naphthenic oil, 8-20 parts of composite antirust agent, 3-15 parts of thickening agent, 0.5-1 part of dispersing agent, 0.5-3 parts of high temperature resistance oxidizing agent and 0.5-1 part of inorganic filler. According to a preparation method of the anticorrosion sealing wax, all the components are sequentially put in a heating container, a certain temperature is maintained, stirring is performed, and then the anticorrosion sealing wax is prepared. The anticorrosion sealing wax for the bridge cables and anchor heads has the advantages of being high in compactness and sealing performance, low in shrinking rate, high in adhesive force, free of losses, high in dampness and heat resistance, salt mist resistance and oxidation resistance and long in anticorrosion period, and has long-term protective properties on the bridge cables and anchor heads and other steel components.

Owner:LIUZHOU OVM MASCH CO LTD

Safe mattress for patient with lumbar spondylosis

InactiveCN106213886AAvoid creating a situation of no escapeStuffed mattressesSpring mattressesPush and pullLumbar spondylosis

The invention discloses a safe mattress for a patient with lumbar spondylosis. The safe mattress comprises a mattress frame, mattress cores arranged in the mattress frame and a cover coating the mattress frame, wherein two sides of the central part of the mattress frame are provided with empty grooves which are filled with the reversible filling mattress cores; the interior of each filling mattress core is provided with a sponge layer, a spring layer and a loose cotton layer which are laminated from bottom to top, a hard board is arranged above the loose cotton layer, and the outer side of the filling mattress core is provided with a push-and-pull handle; a water tank is arranged in the spring layer and connected with a plurality of shower pipes; each shower pipe is provided with a plurality of water seepage holes and a sealing wax layer coats the external surface of each shower pipe; and the mattress frame is provided with a water conveying pipe tank in which a water inlet pipeline is fixedly arranged, and the water inlet pipeline is communicated with the interior of the water tank. The safe mattress provided by the invention can efficiently improve the sleep quality of the patient with lumbar spondylosis.

Owner:武侯区华聚家私经营部

Natural ripe raw honey production method of apis sinensis honey

InactiveCN106136166APromote growth and developmentIncrease productionHoney collectionFood scienceSealing waxAdditive ingredient

The invention discloses a natural ripe raw honey production method of apis sinensis honey. A beehive is opened, an uppermost first layer of the beehive is enabled to cock up by a blade, ripe sealed honey on the uppermost first layer is cut by a stainless steel wire, a sealing wax cover is cut off by a honey cutter to destroy honeycomb ticks, the honey is filtered with gauze, filtered honey is contained in a container, the container is sealed, after-ripening storing is conducted, floating pollen is separated and removed through a stainless steel ladle, a finished product is bottled, and products are sold. Bees are kept by adopting the square vertical overlapped beehive, therefore, child ticks and unripe and non-sealed beehive ticks can be prevented from being destroyed, development and growth of a bee swarm are promoted, and the honey yield is increased; by adopting the mode of taking the honey through cutting, the honey quality can be improved, and it is guaranteed that all beneficial ingredients in the honey are not artificially destroyed.

Owner:麻栗坡县杨万乡瑶山蜂蜜专业合作社

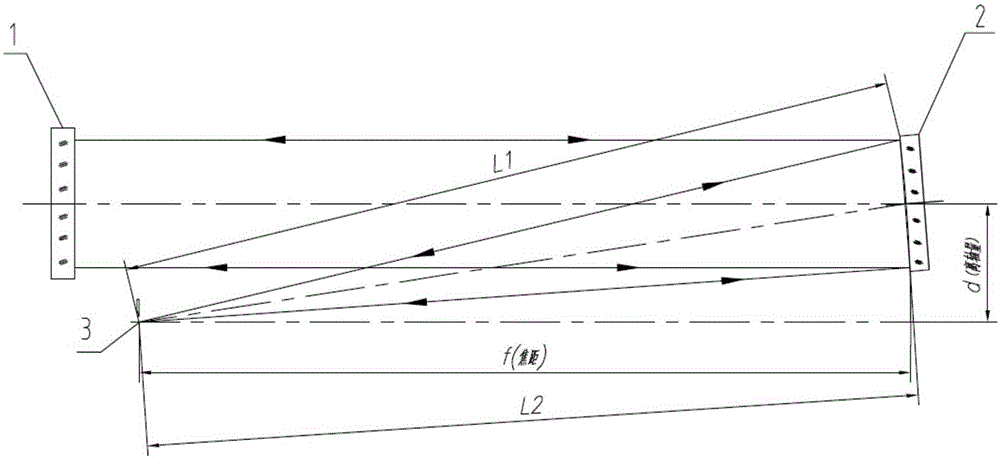

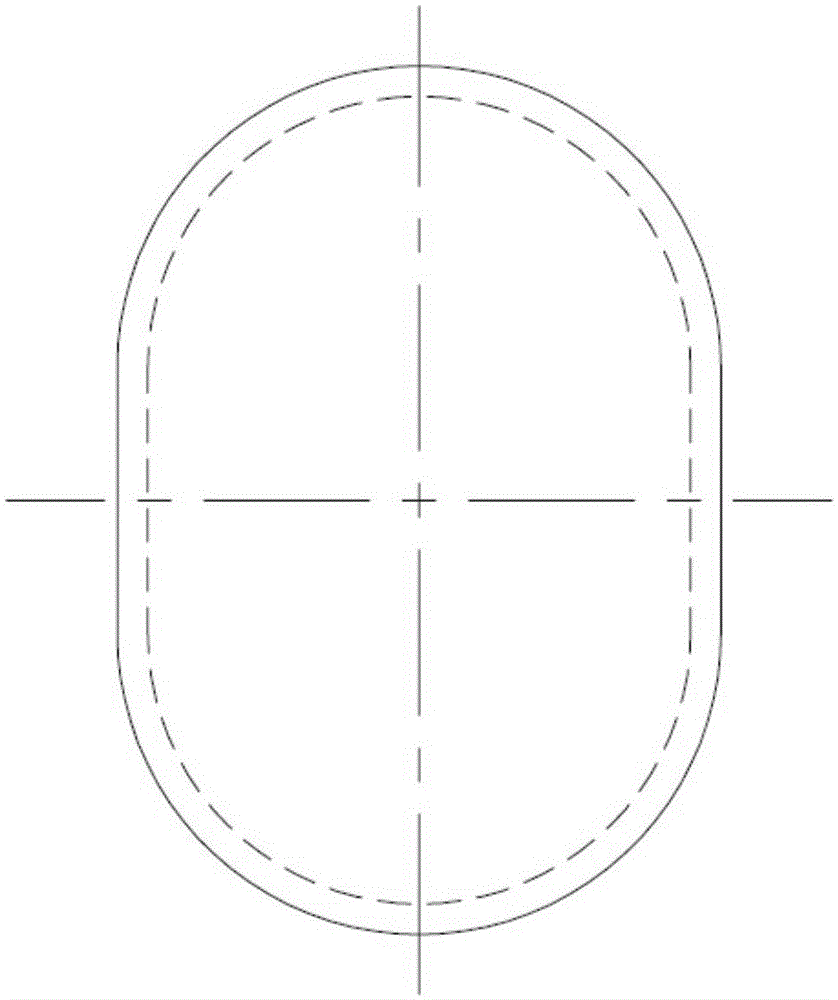

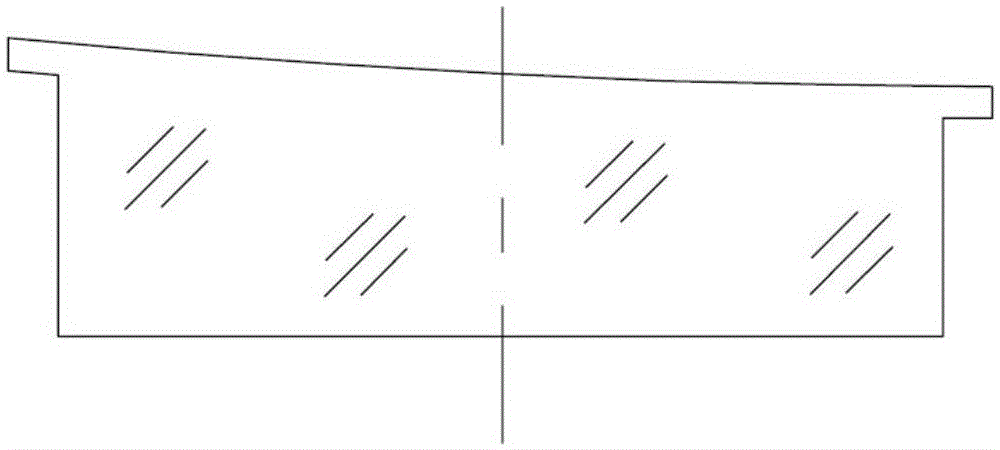

Nesting process machining method for off-axis reflection type optical part

ActiveCN105150049AEffective control of off-axisEffective control of eccentricityOptical surface grinding machinesSealing waxEngineering

The invention discloses a nesting process machining method for an off-axis reflection type optical part. The nesting process machining method includes the steps that the outline of an off-axis aspheric surface optical part is measured, and the machining allowance for the subsequence procedure is reserved according to the machining process; a nesting mother lens is designed and ground; an abrasive disk of an assembly is designed and machined; the machined abrasive disk is fed in an inverted covering mode, and the off-axis aspheric surface optical part is put in the nesting mother lens; an opposite abutting mechanism is embedded to control the splicing gap between the nesting mother lens and the off-axis aspheric surface optical part; heated sealing wax is poured in, and a back plate is arranged in a cushioning mode; and finally a bottom plate of the assembly is bonded, is overturned and stands so that glue can be solidified. A common machine tool is used, the off-axis amount can be controlled to be within the range of + / - 0.1 mm, requirements for equipment are lowered, and the machining efficiency and the smoothness degree of a lens surface are improved. As a tool can be reused, the nesting process machining method can be reused as well.

Owner:NANJING ZHONGKE ASTROMOMICAL INSTR

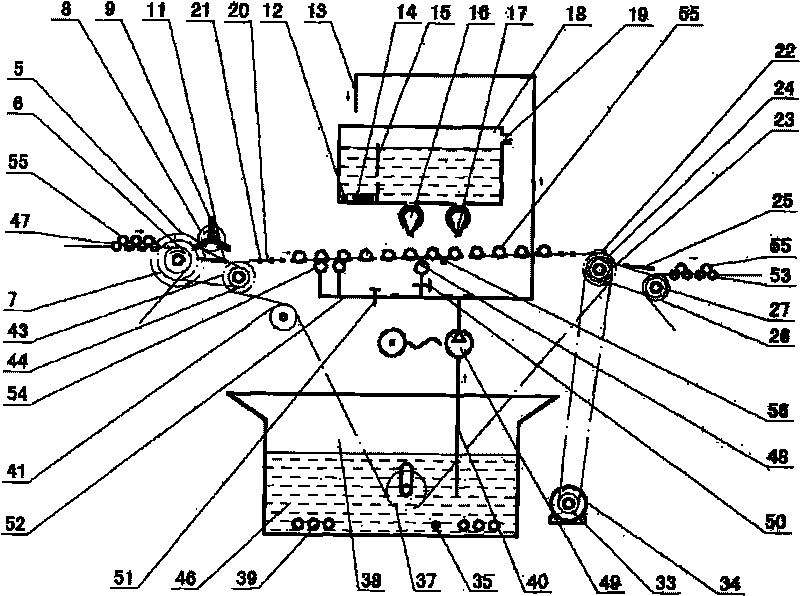

Turnover and wax-sealing device with roller wheels

InactiveCN107777315ASmooth entryStable deliveryLiquid surface applicatorsConveyorsSealing waxPulp and paper industry

The invention relates to the field of decoration materials processing, in particular to a wax sealing device with rollers, which includes a cooling plate frame, the cooling plate frame includes a bracket one and a bracket two, the bracket one is provided with rollers, and the middle part of the cooling plate frame The card is equipped with an overturning device, and the outlet of the cooling plate frame is connected with the inlet of the wax spraying system. After the action of the overturning device, the pockmarked surface of the wooden floor is turned downward, and the wooden floor is transported by the roller to the wax sealing equipment. The wax spray tank of the wax spray system is in contact with the two ends of the wooden floor to be sprayed with wax, so as to achieve a good sealing effect of wax spray.

Owner:中江德宝木业有限公司

Double-nail-head wax sealing and nailing machine

InactiveCN104802453AConvenient double-row continuous bindingReduce the number of adjustmentsPaper-makingBox making operationsSealing waxCarton

Owner:JURONG DINGSHENG CARTON PACKING

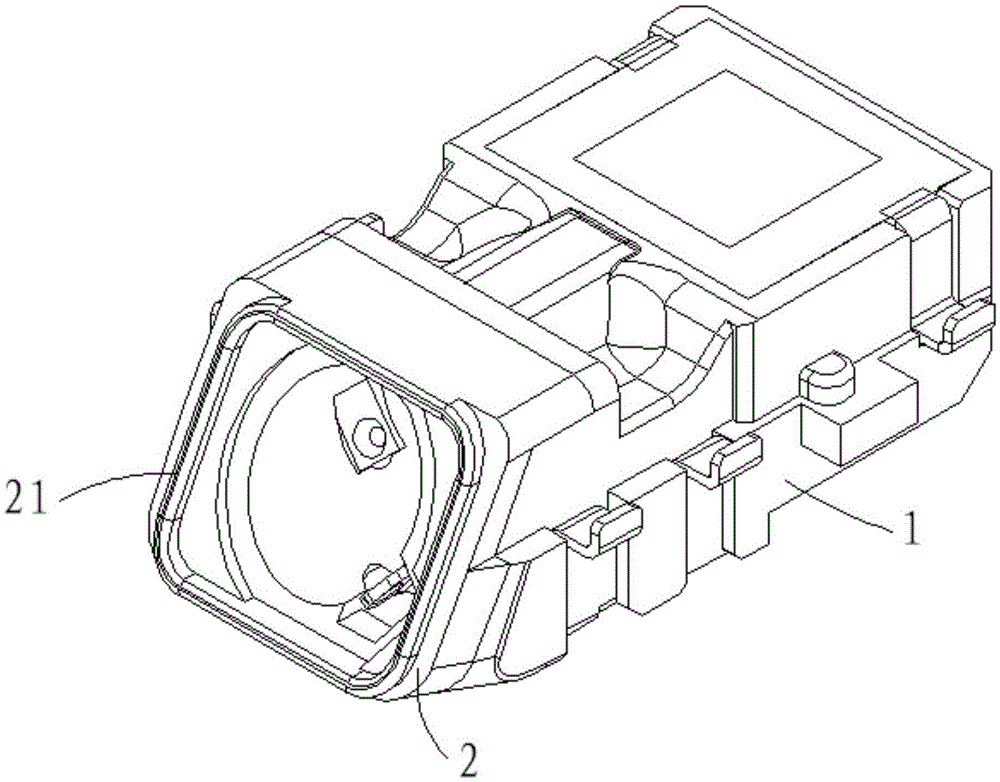

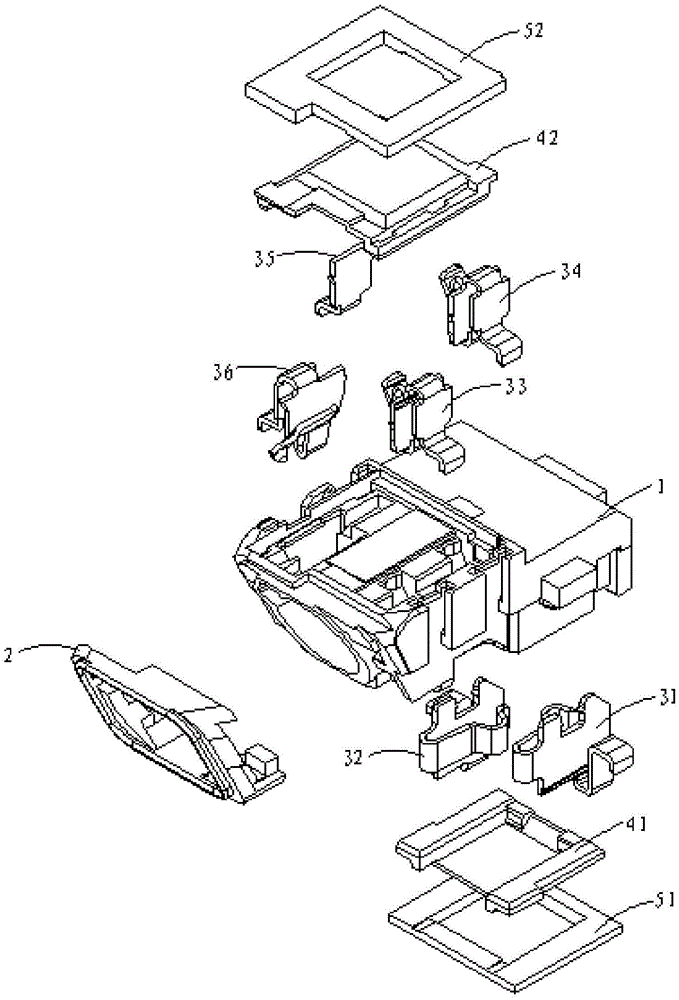

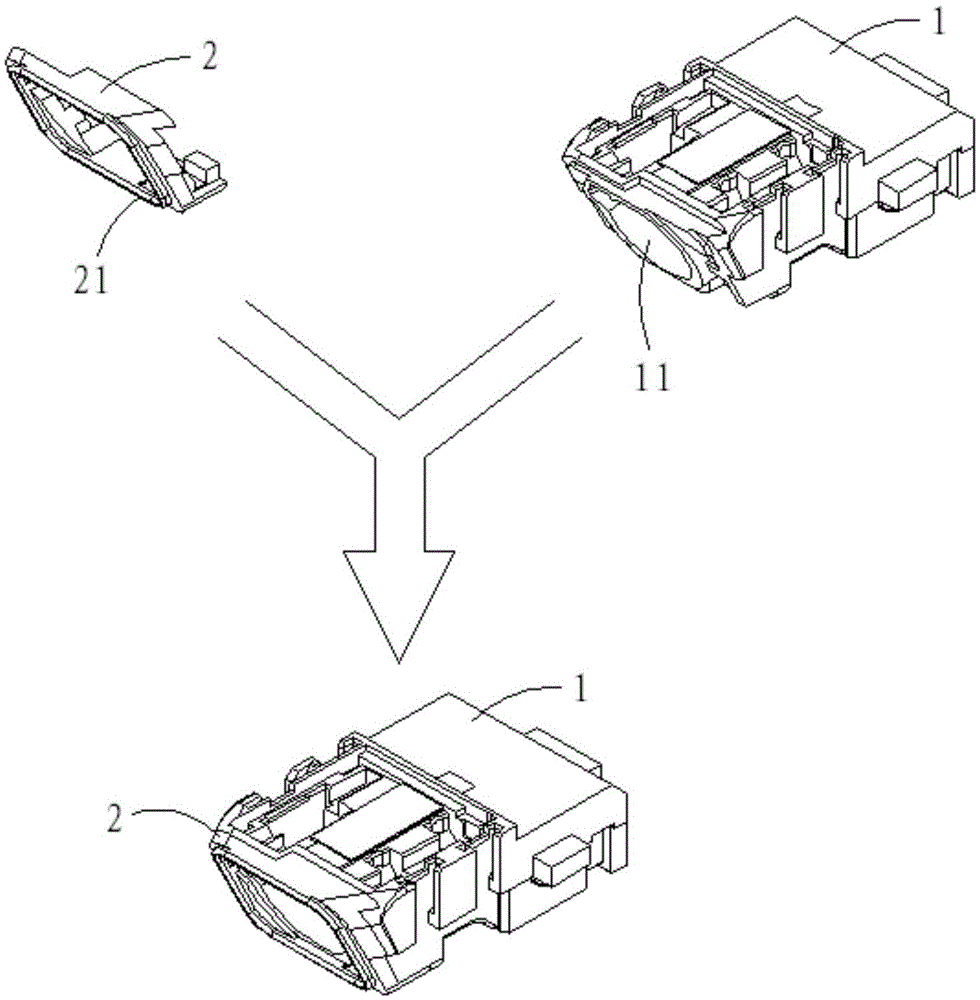

Earphone connector and manufacturing method thereof, mobile terminal having earphone connector

InactiveCN106803625AHigh waterproof requirementsAvoid enteringCouplings bases/casesTelephone set constructionsSealing waxComputer terminal

The invention is applicable to the technical field of earphone connectors and discloses an earphone connector and a manufacturing method thereof, a mobile terminal having the earphone connector. The earphone connector includes an earphone holder main body has one end provided with a jack for insertion of an earphone plug, a sealing wax piece which is embedded in the jack, a terminal assembly which is inserted to the earphone holder main body, a rear cover assembly which covers the two sides of the earphone holder main body, and a sealing assembly which is filled between the rear cover assembly and the earphone holder main body. According to the invention, the sealing wax piece characterized by high-temperature resistance and insusceptibility to shrinkage or deformation is installed to the jack of the earphone holder main body, and a product can be directly subject to an IR furnace and welded to a PCB, such that the earphone connector addresses the problem of manual welding of conventional water-proof earphone holders, increases the efficiency of welding PCBs, lowers manufacturing cost of products, and meets requirements for water resistance in a manner that even if the earphone connector is in water under a certain pressure, water does not easily get into the mobile terminal via through the earphone holder.

Owner:SHENZHEN LINKCONN ELECTRONICS

A kind of bamboo-wood composite board and preparation method thereof

ActiveCN104493916BImprove mechanical propertiesEasy to processWood veneer joiningWood veneerSurface layer

The invention relates to the technical field of composite boards, and discloses a bamboo and wood composite board and a method for manufacturing the same. The bamboo and wood composite board comprises bamboo layers, wood veneer layers, more than two non-woven fabric layers and adhesive. The corresponding wood veneer layer is arranged between each two bamboo layers, the total quantity of the bamboo layers and the wood veneer layers ranges from 14 to 35, the non-woven fabric layers are arranged between the bamboo layers and the wood veneer layers, the various layers are adhered with one another by the adhesive and are integrally laminated, a surface layer and a bottom layer of the bamboo and wood composite board are bamboo layers respectively, sealing wax layers with waterproof effects are arranged on the surfaces of the bamboo and wood composite board, the bamboo layers are bamboo chip layers or bamboo curtain layers, the thickness of each bamboo layer ranges from 0.5mm to 1.5mm, the thickness of each wood veneer layer ranges from 1.5mm to 2.0mm, the adhesive is made of phenolic resin adhesive with the solid content of 50%, impregnating compounds and more than one type of waterproof agents, mothproofing agents or inorganic flame retardants are added into the phenolic resin adhesive, and the adhesive is applied to double surfaces of each of the bamboo layers, the wood veneer layers and the non-woven fabric layers. The method for manufacturing the bamboo and wood composite board includes steps of manufacturing the adhesive; treating materials of the bamboo layers; treating wood veneers; arraying and assembling blanks; laminating and forming the blanks; treating the surfaces of the blanks and warehousing the finished product.

Owner:DEYI CULTURAL & CREATIVE GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com