Turnover and wax-sealing device with roller wheels

A technology of turning device and roller, which is applied to the device for coating liquid on the surface, spraying device, transportation and packaging, etc. It can solve the pollution of bright surface, affect the wax sealing effect, and the two ends of the wax spray are not in contact with the wax spray tank. Good and other problems, to achieve the effect of fast speed and large injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

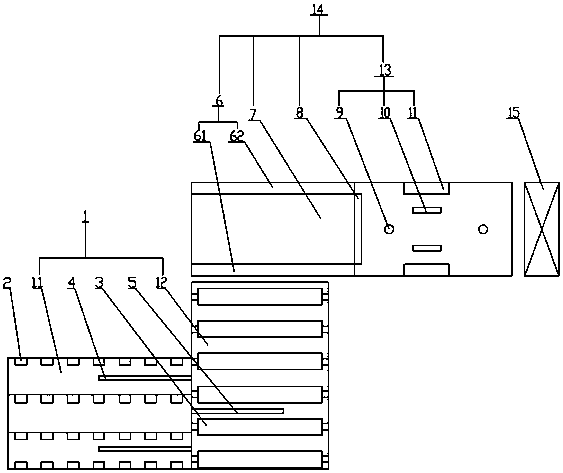

[0024] as attached figure 1 The present embodiment shown includes a cooling plate frame 1, a bracket 11, a bracket 2 12, a roller 2, a drum 3, a support rod 4, a support rod 2 5, a chute 6, a baffle 61, and a baffle 2 62, conveying device two 7, dividing plate 8, flexible roller 9, wax spray tank 10, support 11, material receiving device 12, injection device 13, sealing wax equipment 14,15-material receiving device, wooden floor is flat on cool On the plate frame 1, it is supported and rotated by the rollers 2, and enters the second bracket 12 from the first bracket 11. The two ends of the wooden floor transported by the rollers 2 are in contact with the rollers 2. The wooden floor is evenly stressed and is not easy to deform. There is a roller 3, and the upper circular surface of the roller 3 is in uniform contact with the wooden floor. The entire contact area is large, which disperses the force on the wooden floor at one point, thereby reducing the deformation of the wooden ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com