Lifting type belt plate fetching machine

A plate taking machine and lifting technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of glass surface abrasion, breaking, and high labor intensity, so as to reduce abrasion, eliminate abrasion, The effect of improving quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The lift-type belt plate removal machine of the present invention will be further described below in conjunction with specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

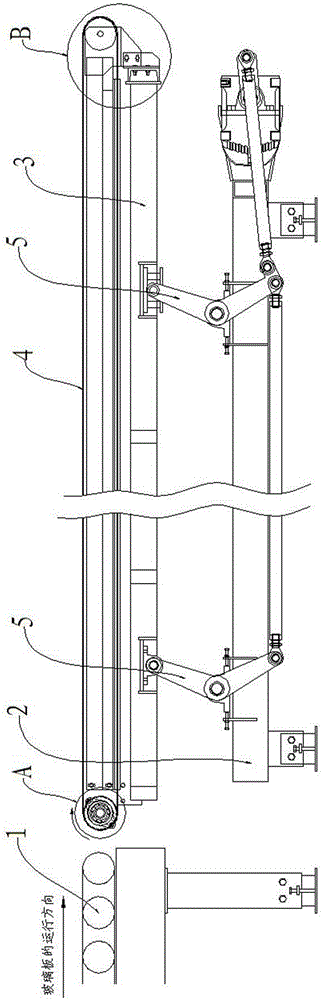

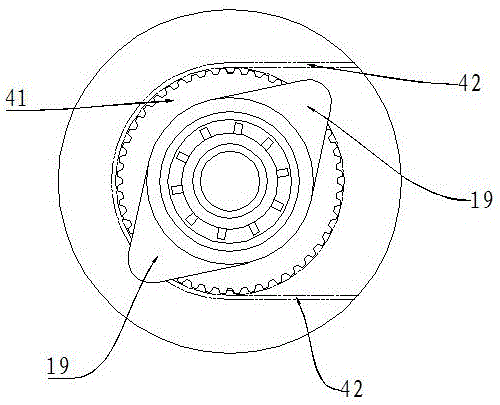

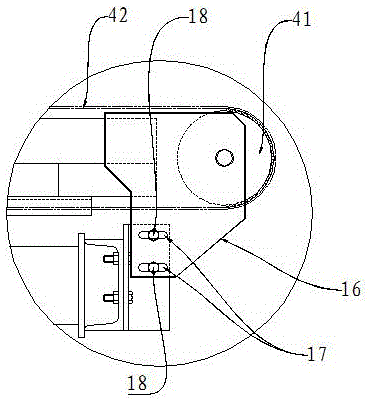

[0028] The lift-type belt take-off machine of the present invention is a device for collecting glass at the cold end of float glass, and mainly includes: a base 2, a belt transmission frame 3, a belt transmission mechanism 4, a lifting mechanism 5, a belt transmission motor 6 and a lifting mechanism In the transmission station, on the one hand, the belt transmission frame 3 can carry out regular ups and downs under the drive of the lifting mechanism 5; The transmission speed of roller table 1 is adjusted synchronously and steplessly to ensure that when the glass enters the lifting belt plate picker, it is consistent with the speed of roller table 1 and seamlessly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com