Electric conduction type crankcase ventilation pipe

A crankcase ventilation and conductive technology, applied in the direction of crankcase ventilation, pipe elements, couplings, etc., can solve the problems of oil circuit blockage, accelerated wear, damage to crankcase seals, etc., and achieve the effect of avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

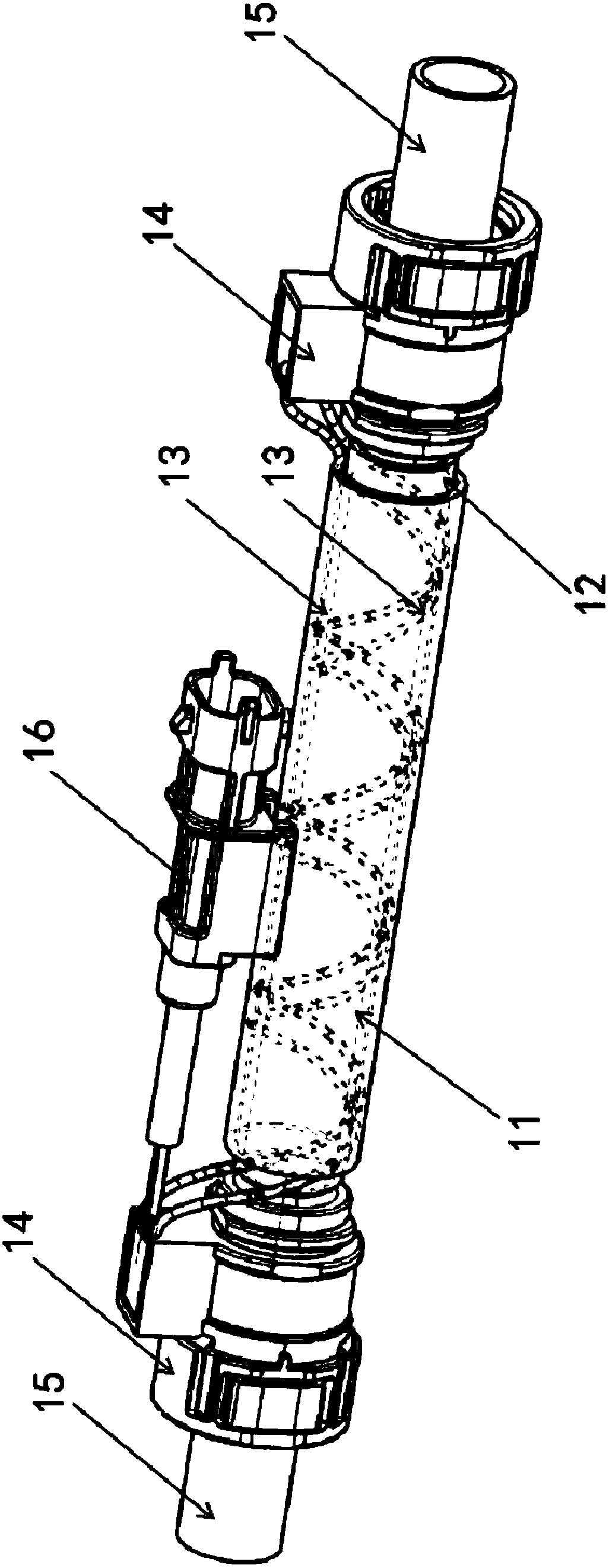

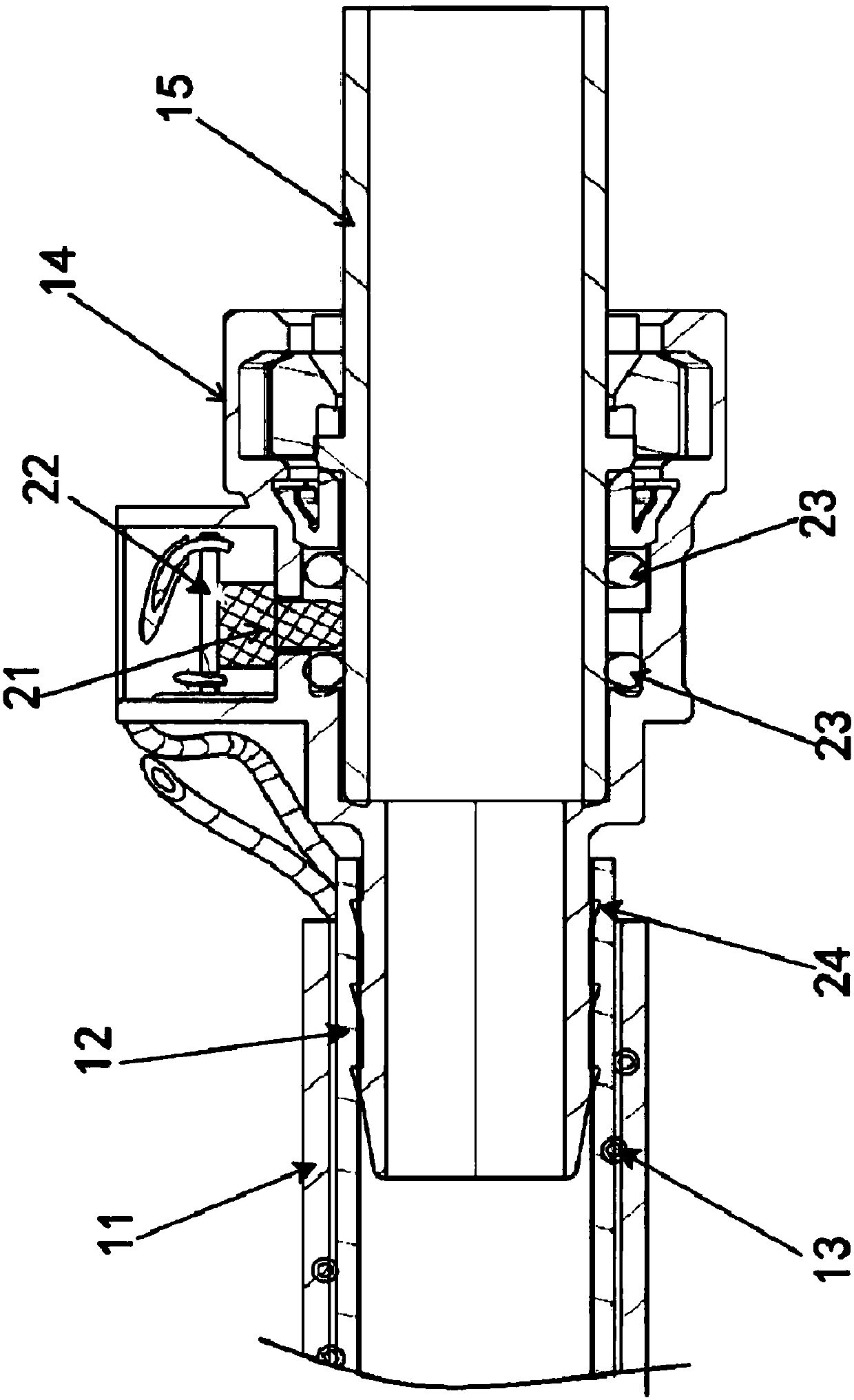

[0025] refer to figure 1 and 2 The conductive crankcase ventilation pipe provided by the present invention includes: a nylon sealing pipe 12 meeting the SAE J2044 leak test standard and quick-fit joints 14 arranged at both ends of the sealing pipe 12. The working temperature range of the sealing pipe 12 is -40°C to 150°C; two helically wound helical wires 13 are provided on the outer side of the sealing tube 12, and an insulating tube 11 is set on the outer side of the sealing tube 12 and the helical wire 13; The micro switch 21, and the circuit board 22 connected to the micro switch 21, the two ends of the two spiral wires 13 are connected to the circuit board 22 at the corresponding end to form a conduction loop; the circuit board 22 at one end is also connected with an ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com