Patents

Literature

312 results about "Crankcase ventilation system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The process to remove the harmful combustion gases, water vapour and fuel vapour and fuel vapour from the crank case during the operation of the engine is called Crankcase Ventilation. In an internal combustion engine, a crankcase ventilation system (CVS) is a one way, pressure-sensitive passage which allows the natural build up of gases to escape from the crankcase in a controlled manner.

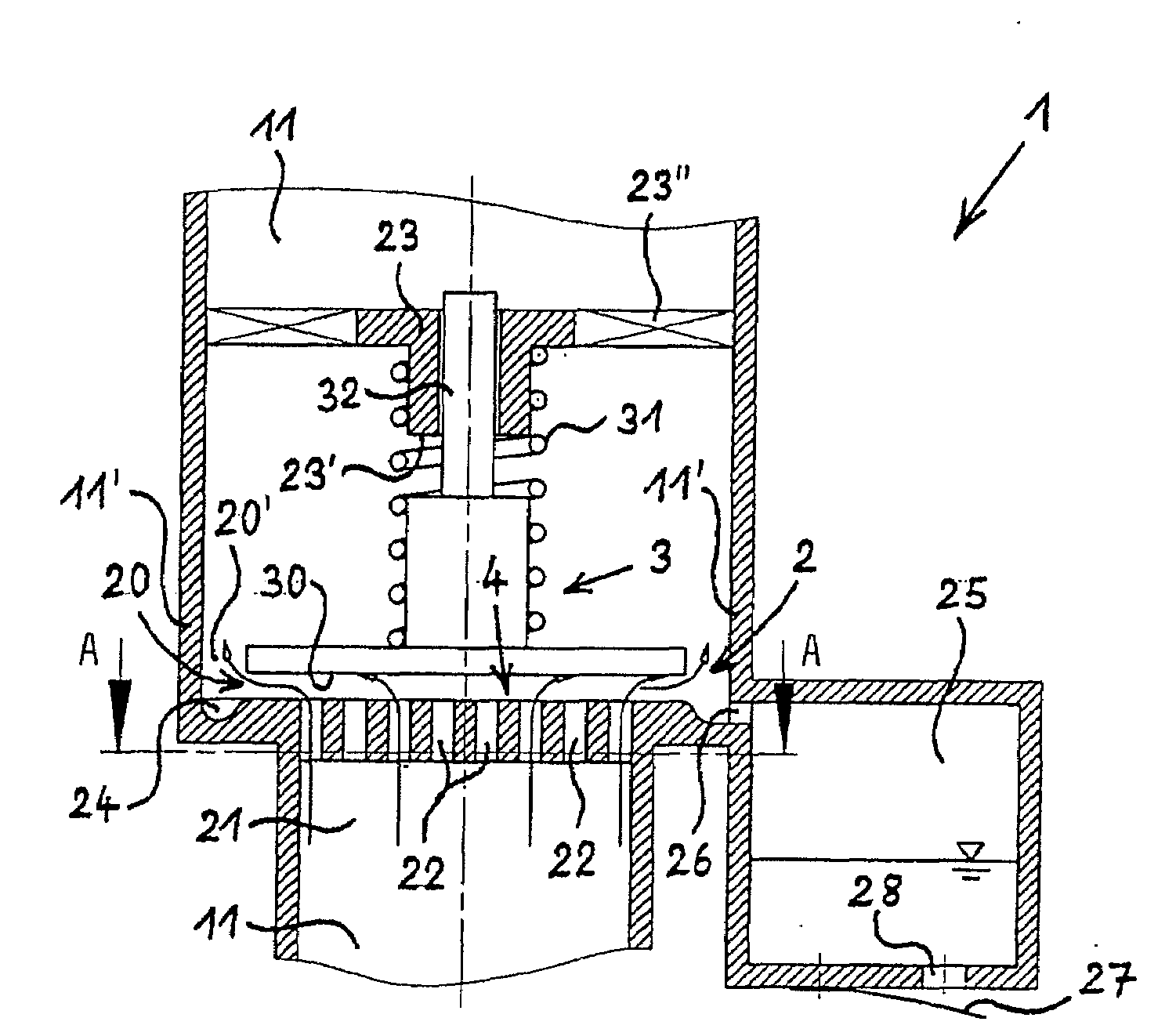

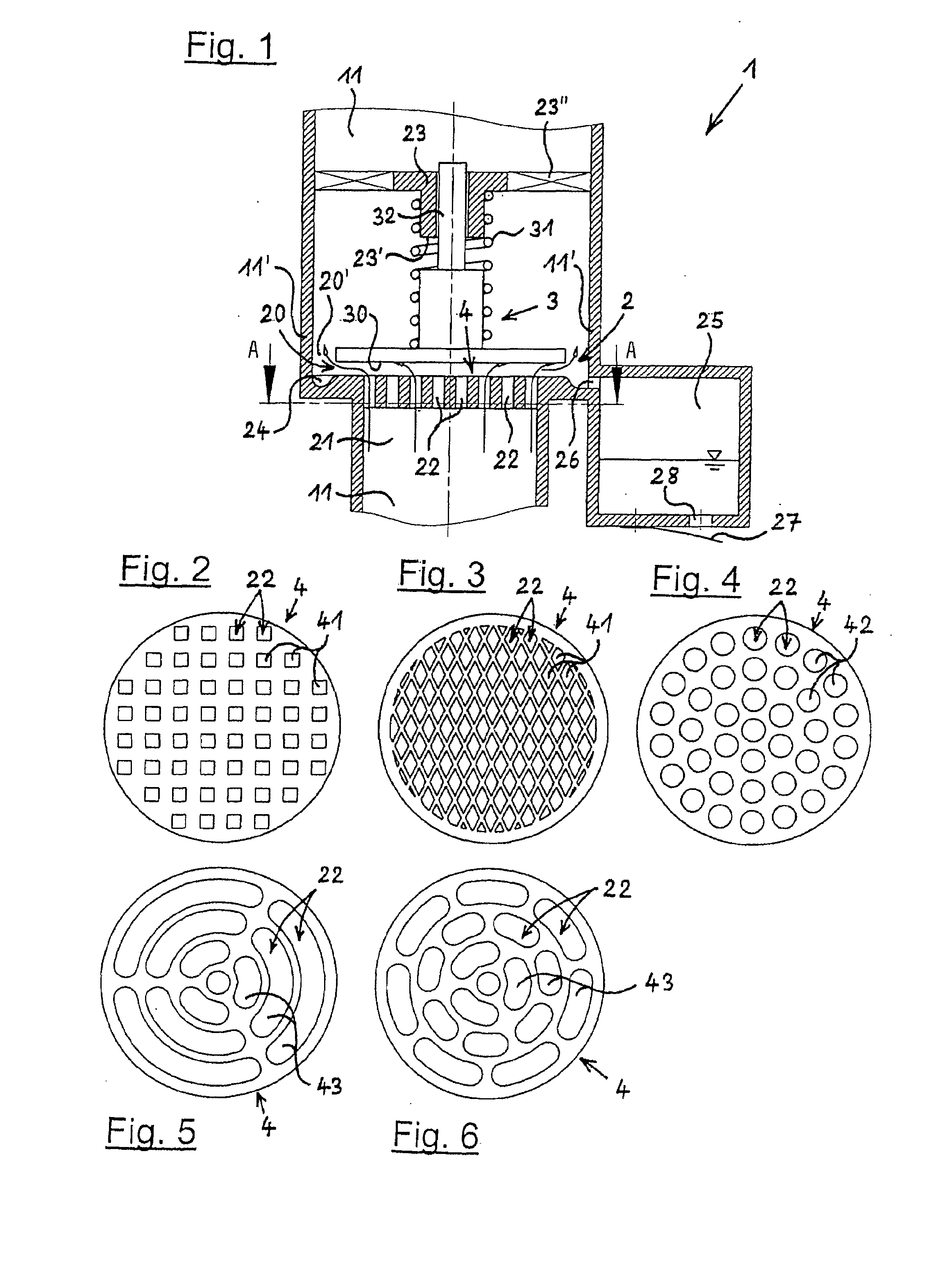

Separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, and functional module and internal combustion engine comprising a separator

ActiveUS20100180854A1Increase speedEasy to separateCombination devicesLubrication of auxillariesExternal combustion engineEngineering

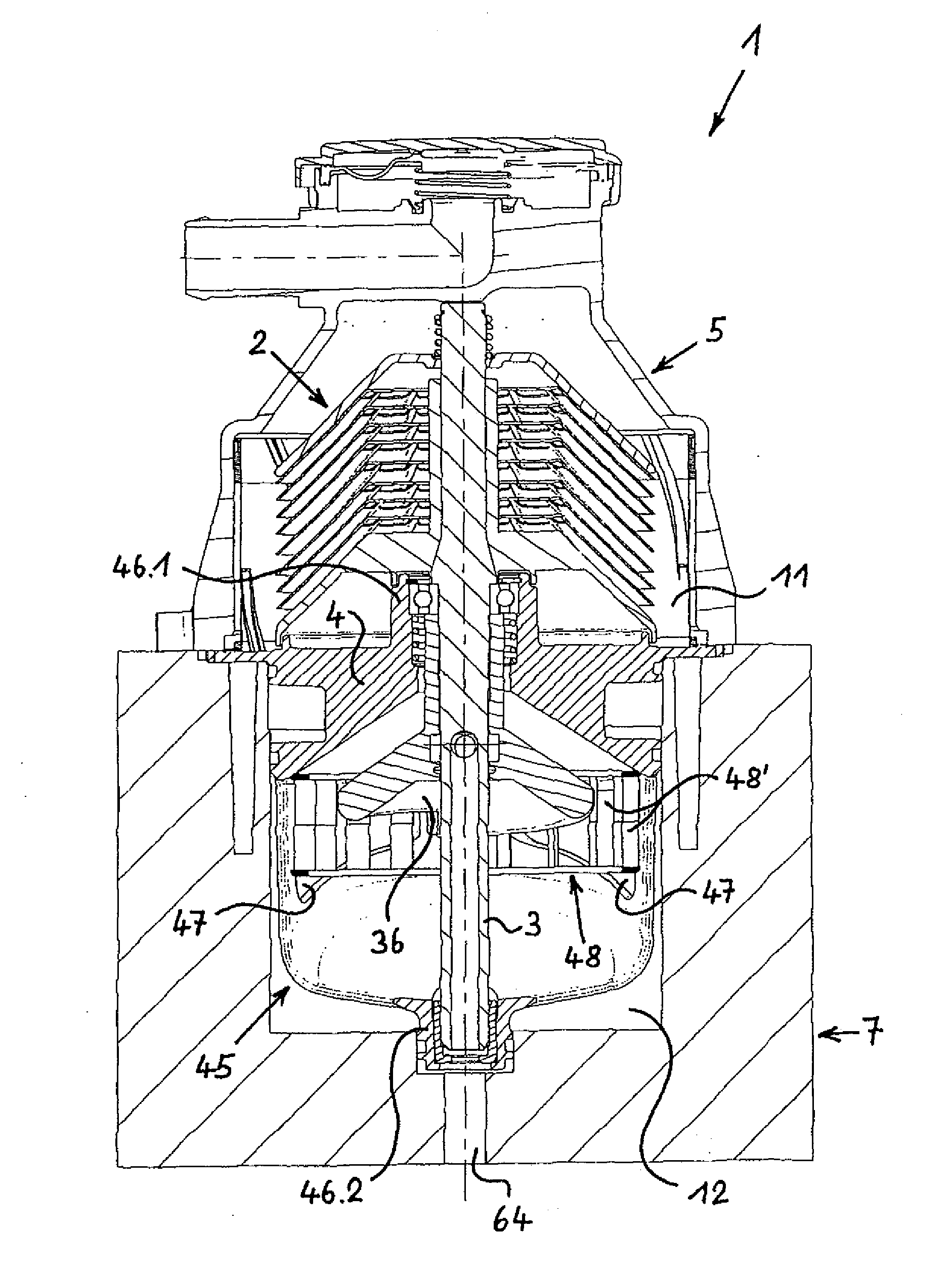

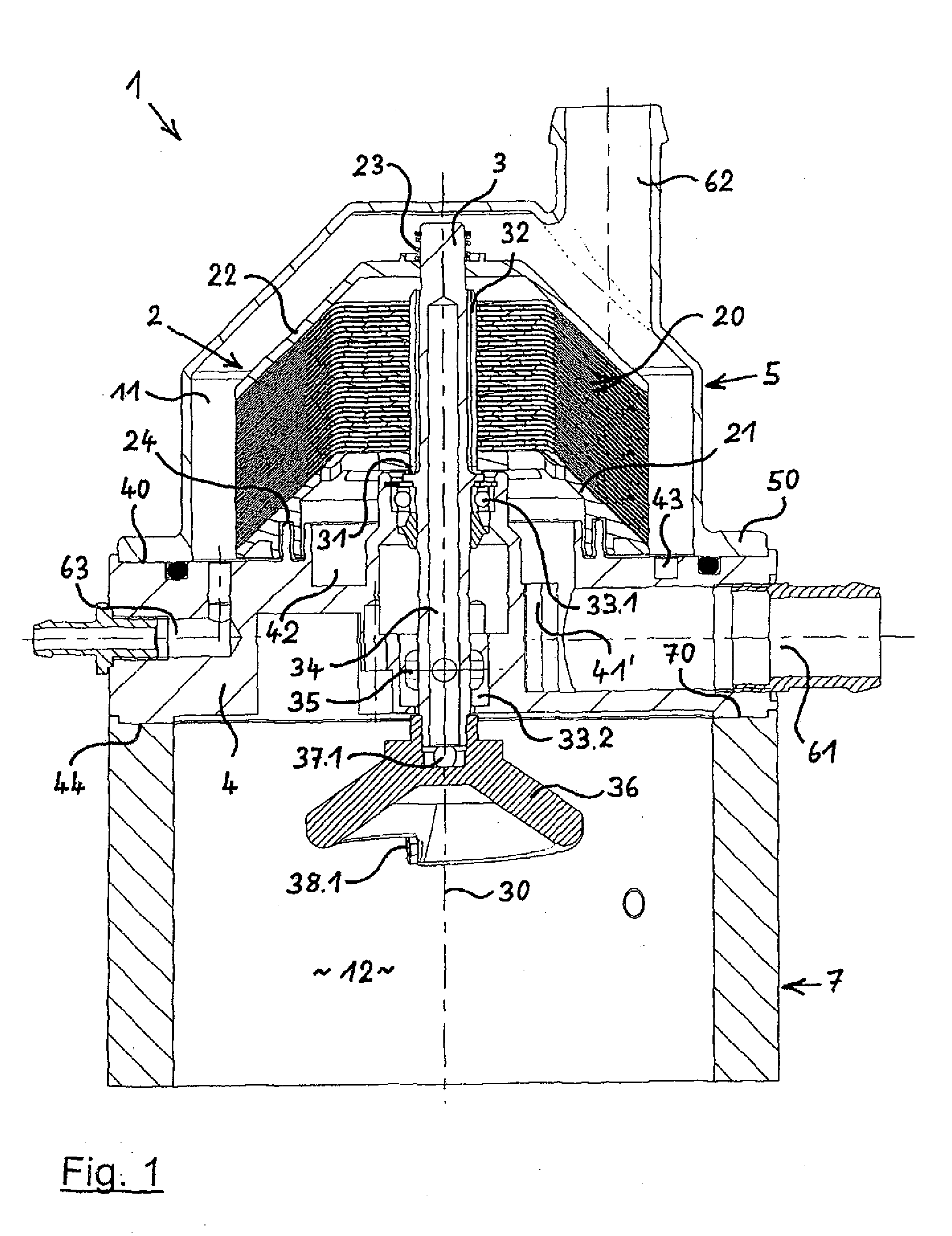

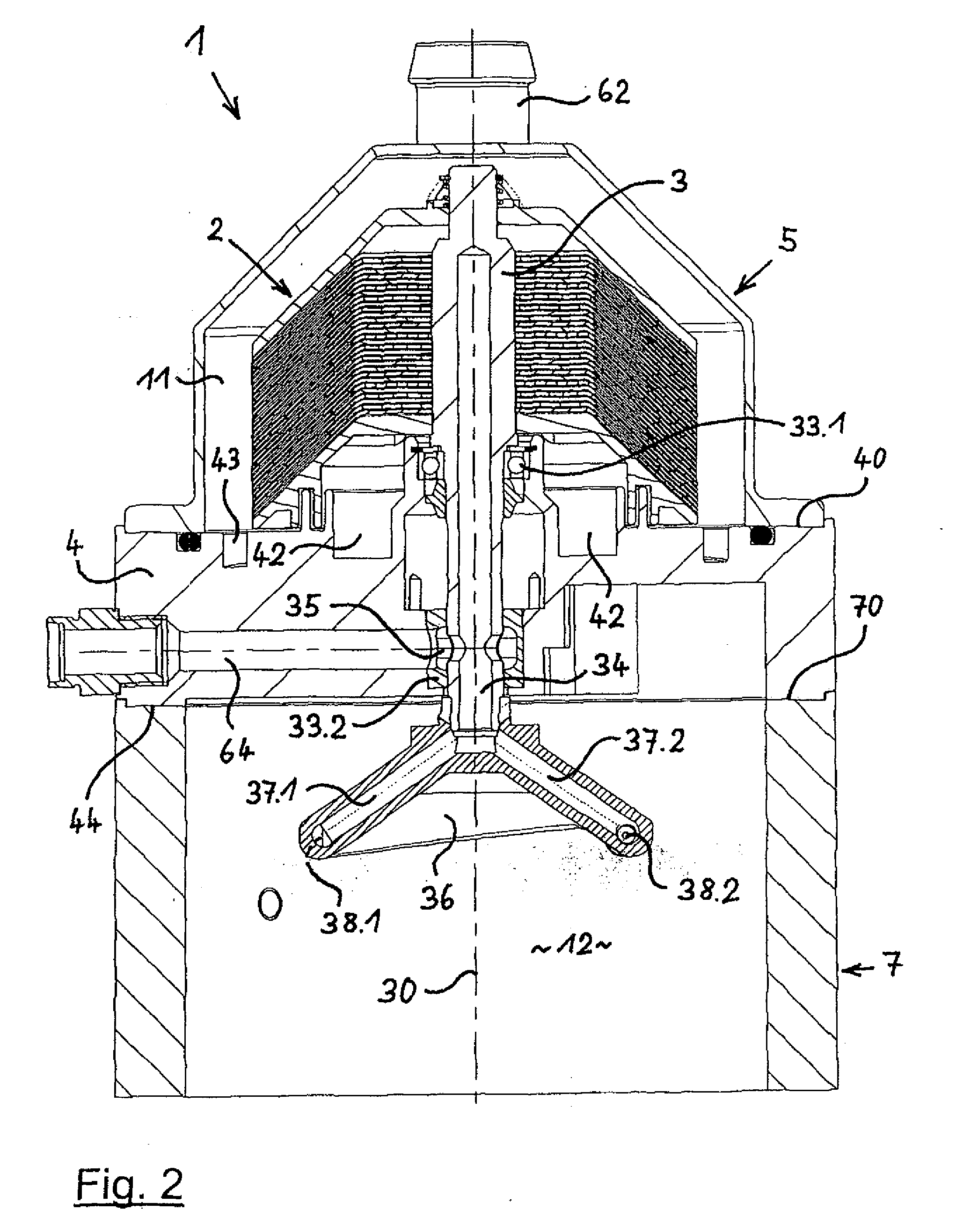

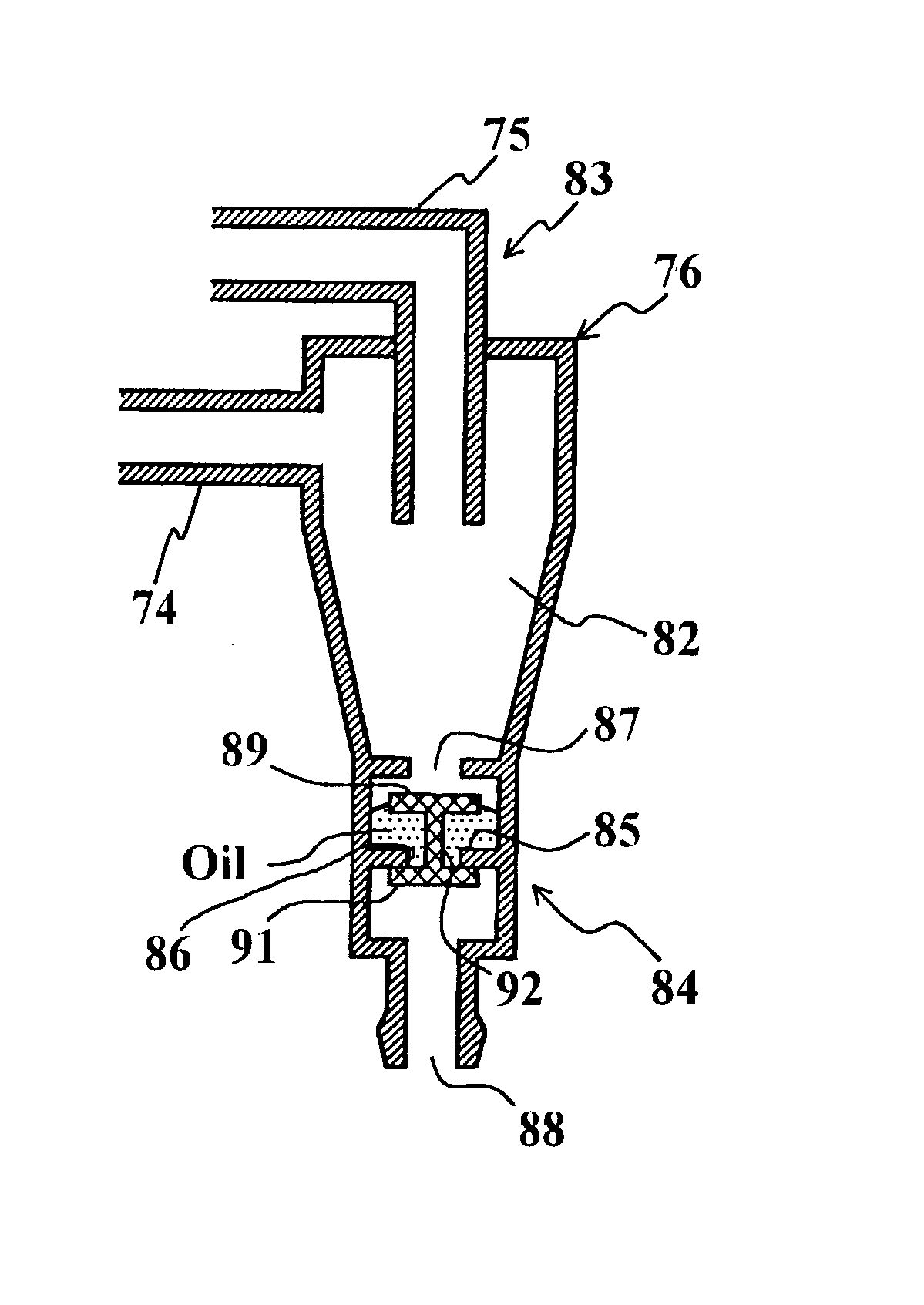

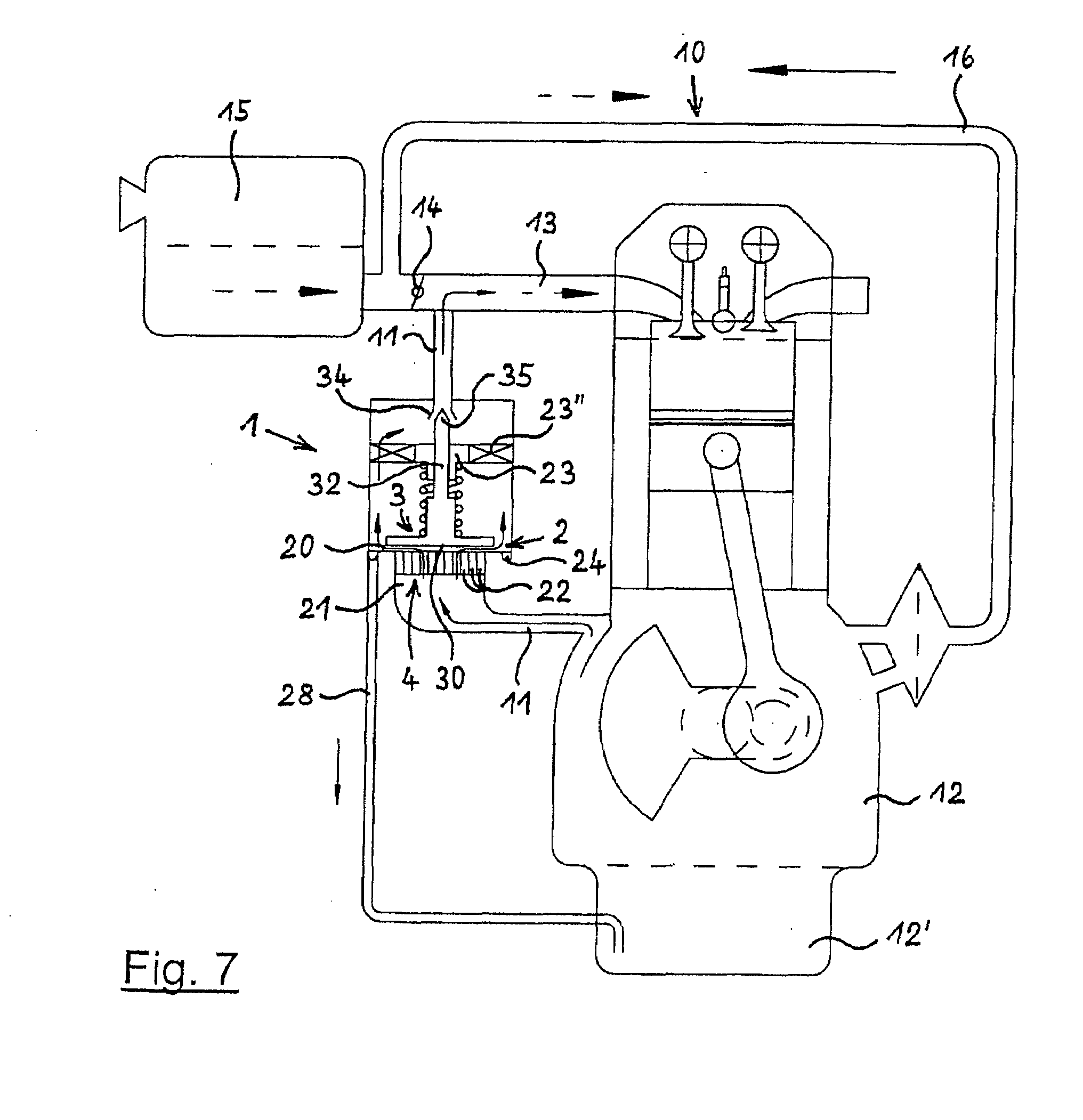

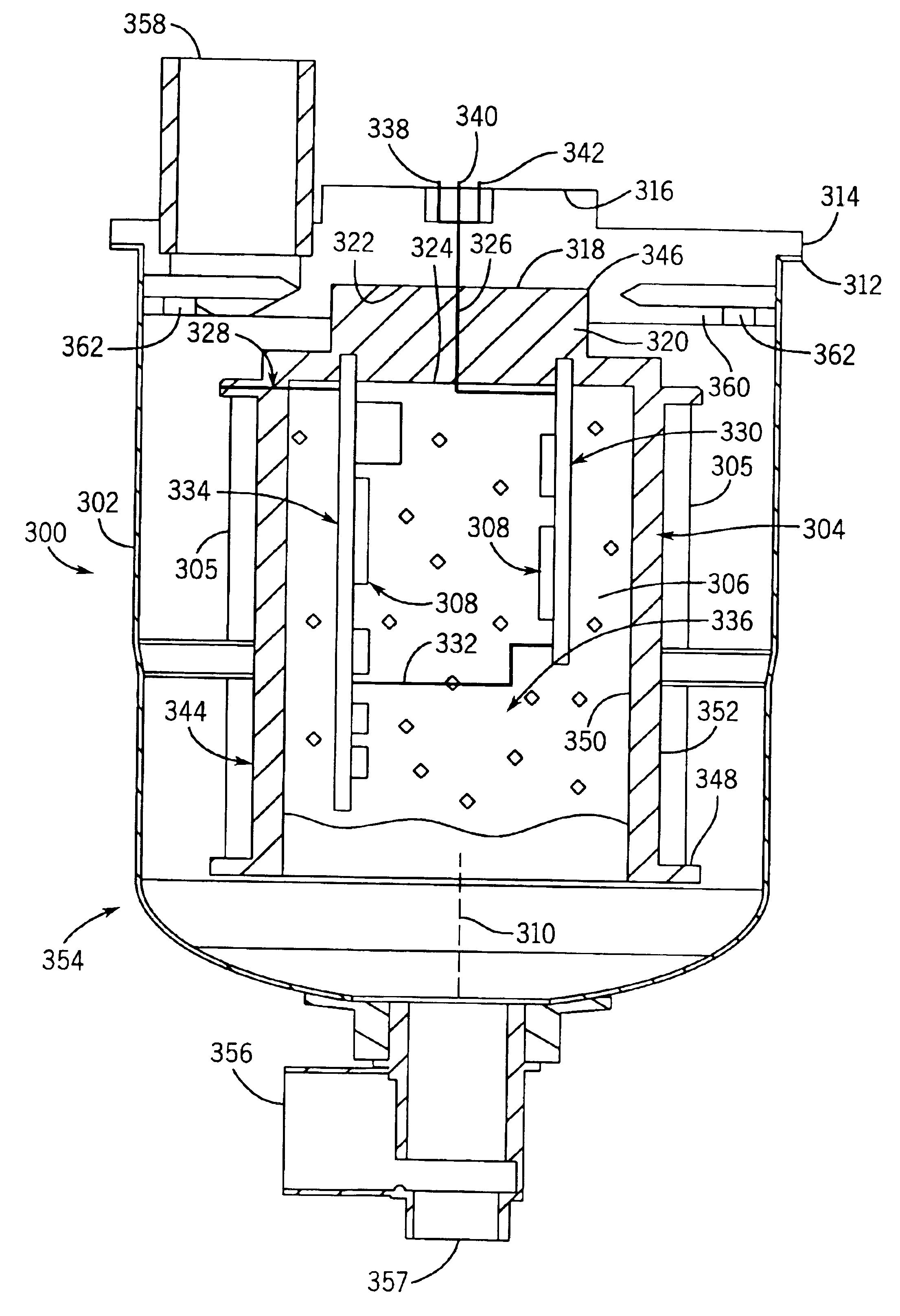

A separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, especially of a motor vehicle. The separator includes a gas purification chamber inside which a rotatably mounted centrifugal rotor is arranged. The gas purification chamber has a crude gas inlet, a pure gas outlet, and an oil outlet. The crankcase ventilation gas can be conducted into a radially internal zone of the centrifugal rotor via the crude gas inlet, while pure gas that is liberated from oil mist can be discharged from the gas purification chamber via the pure gas outlet, and oil separated from the gas can be discharged from the gas purification chamber via the oil outlet. The separator further includes a rotary drive for the centrifugal rotor. The rotary drive is disposed in a drive chamber of the separator, can be operated using pressurized lubrication oil of the internal combustion engine, and is connected to the centrifugal rotor by means of a shaft extending from the drive chamber into the gas purification chamber, from which the drive chamber is separated. The rotary drive is formed by at least one thrust nozzle which is connected to the shaft and to which the pressurized lubrication oil of the internal combustion engine can be fed. The separator includes at least one part of a base that forms the separation between the gas purification chamber and the drive chamber and extends into the drive chamber, the part of the base being fitted with a seat for a bearing of the shaft. The bearing is located at a distance from the centrifugal rotor.

Owner:HENGST WALTER

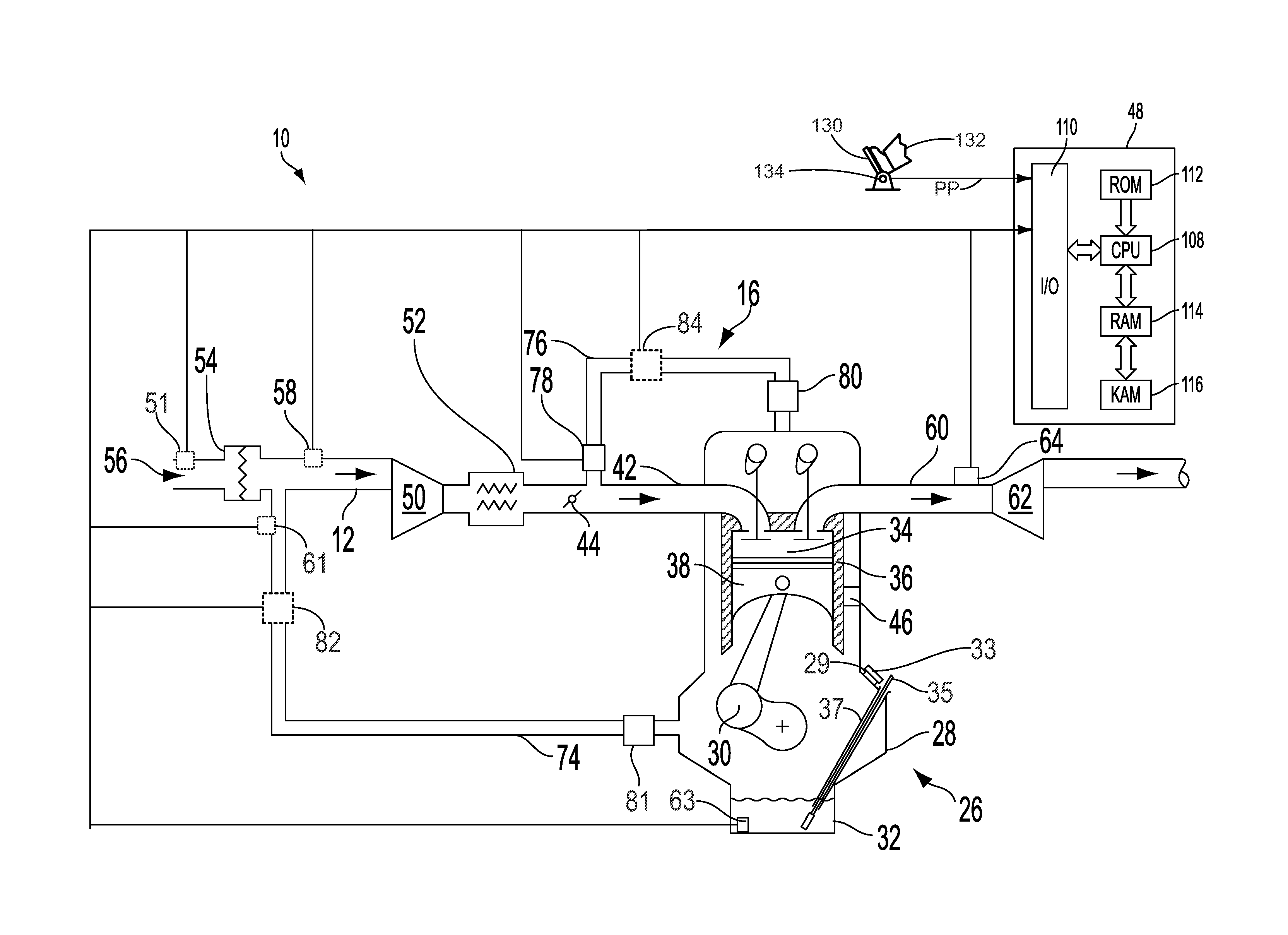

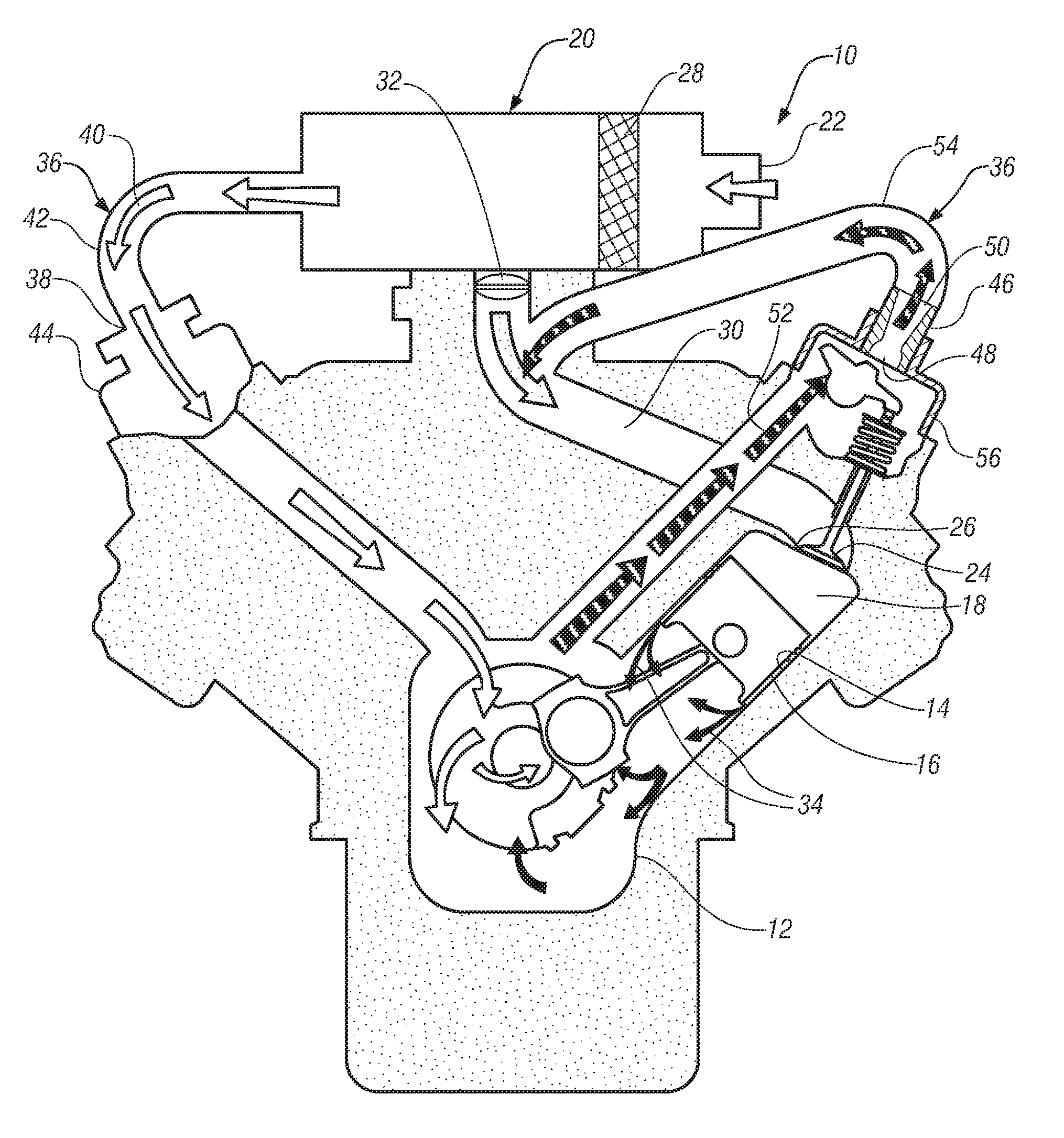

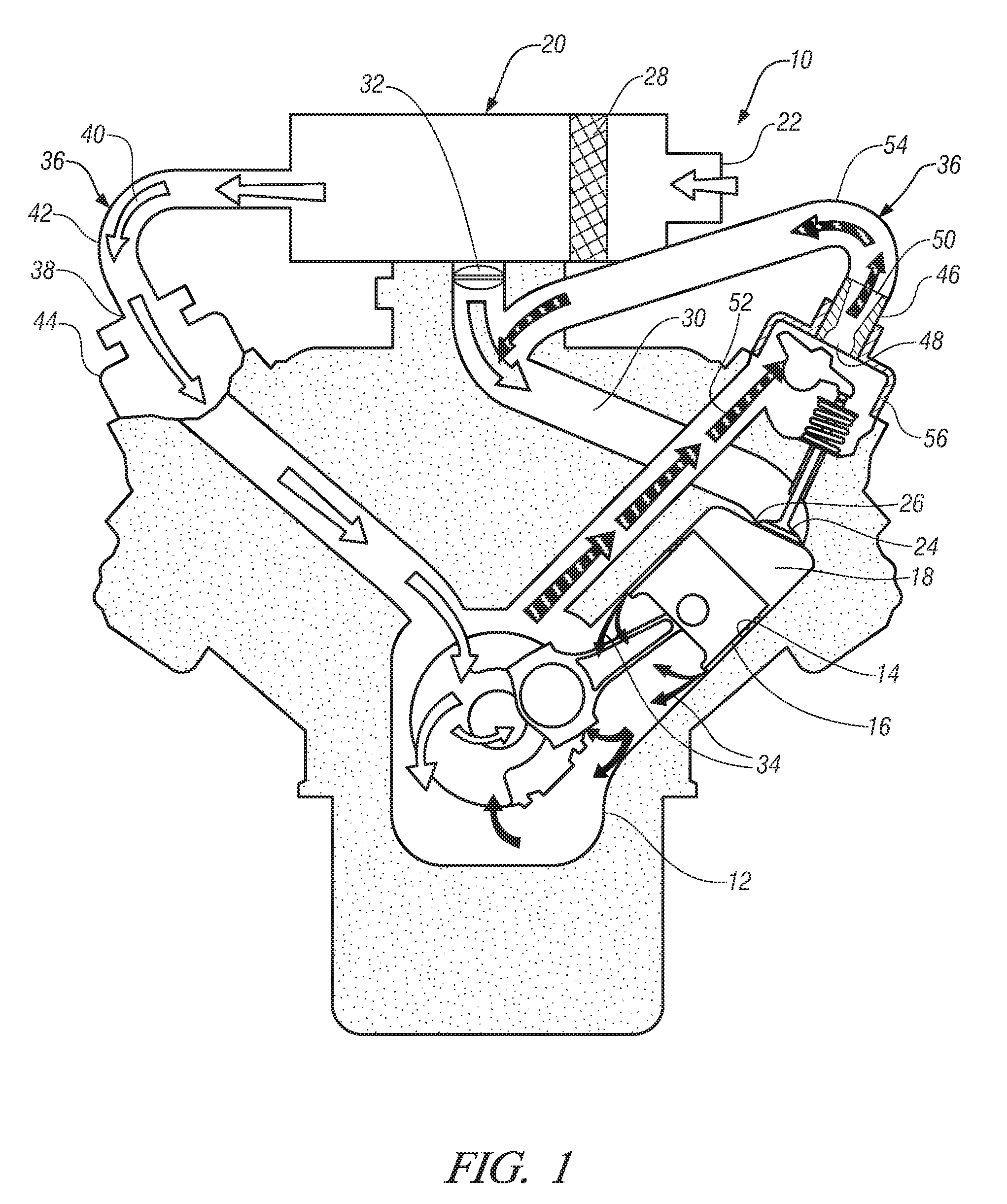

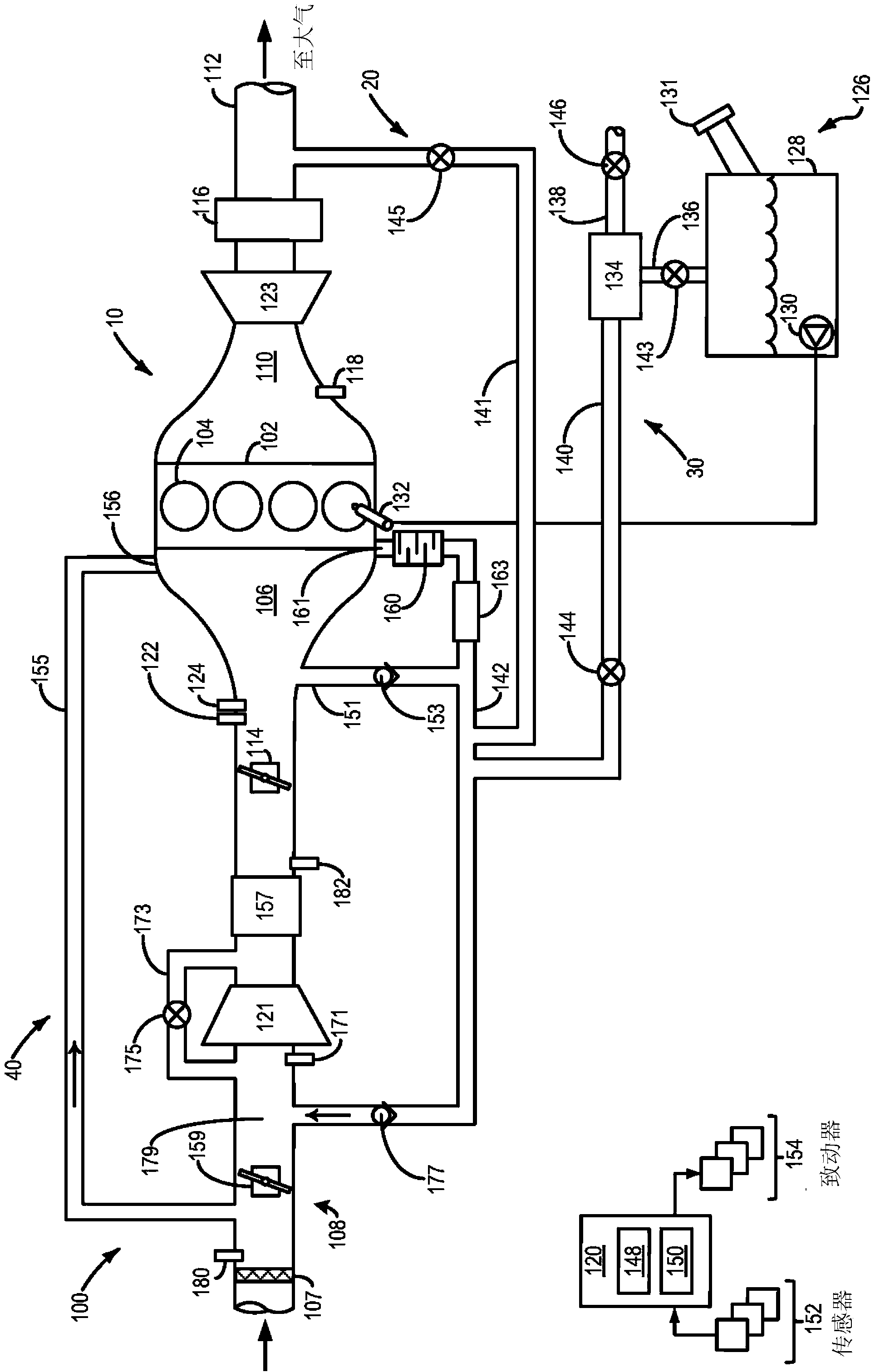

System and method for gas purge control

ActiveUS20140318514A1Reduce trafficAmount of vacuum in the intake manifold mayElectrical controlInternal combustion piston enginesControl systemEngineering

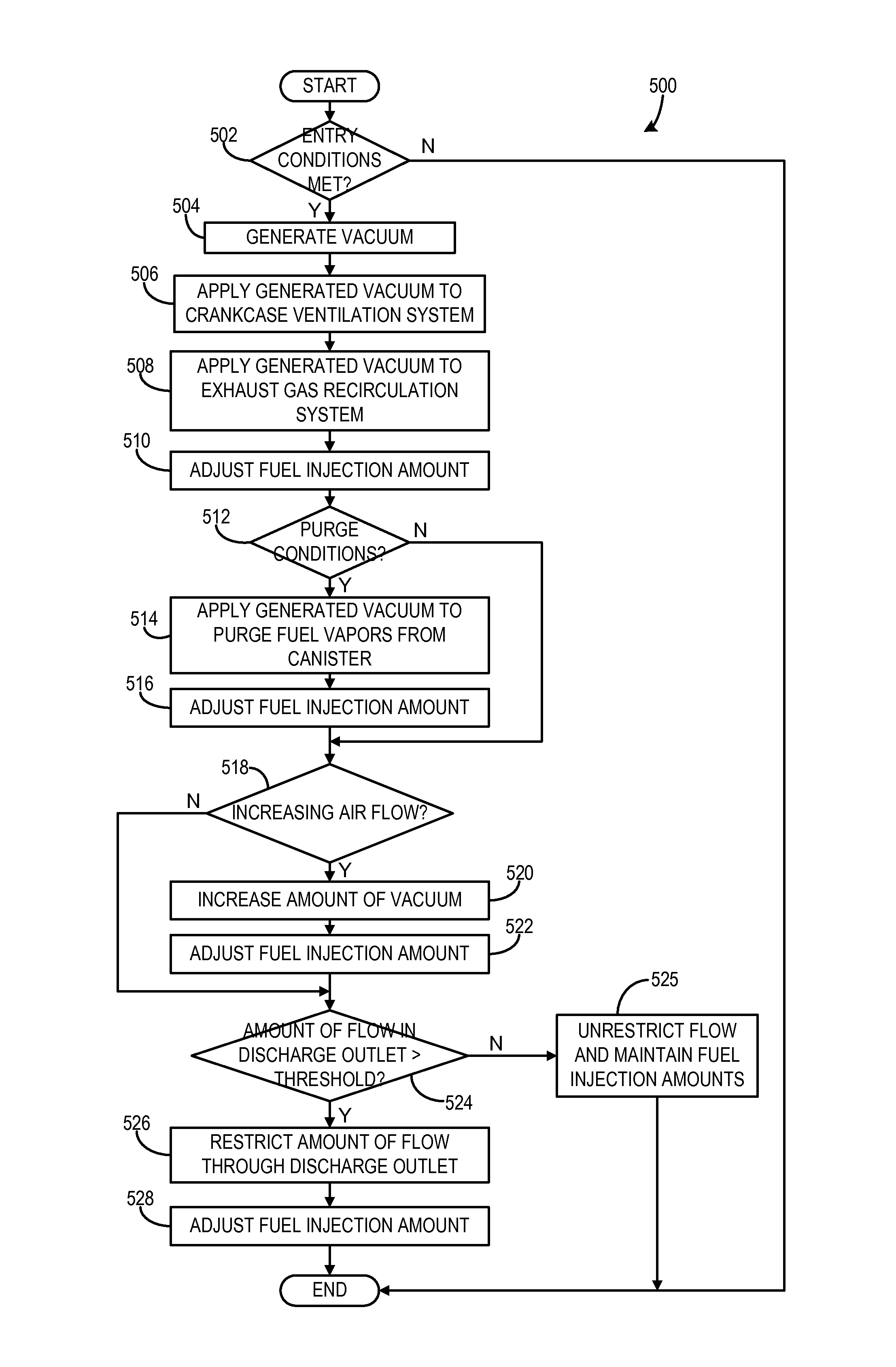

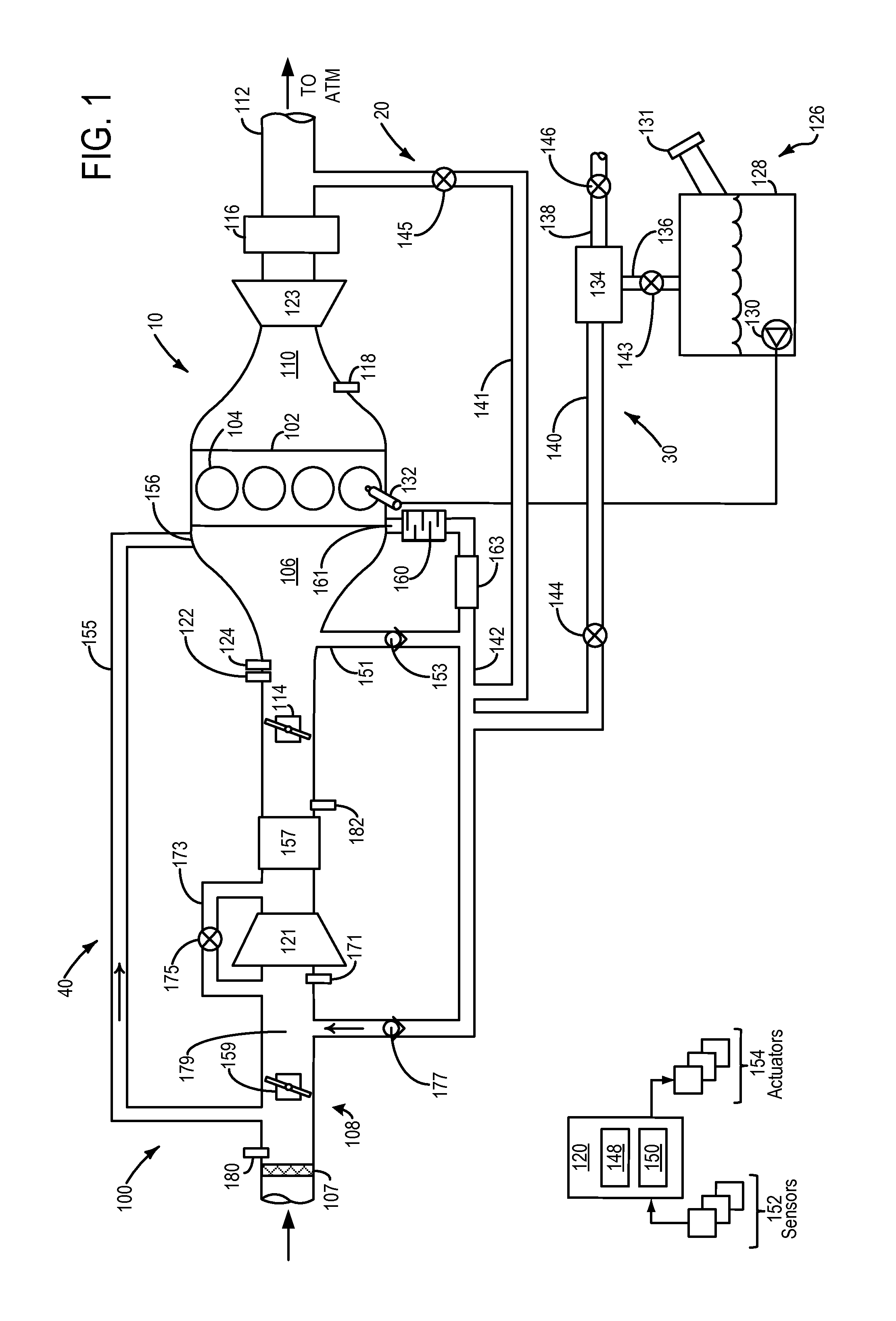

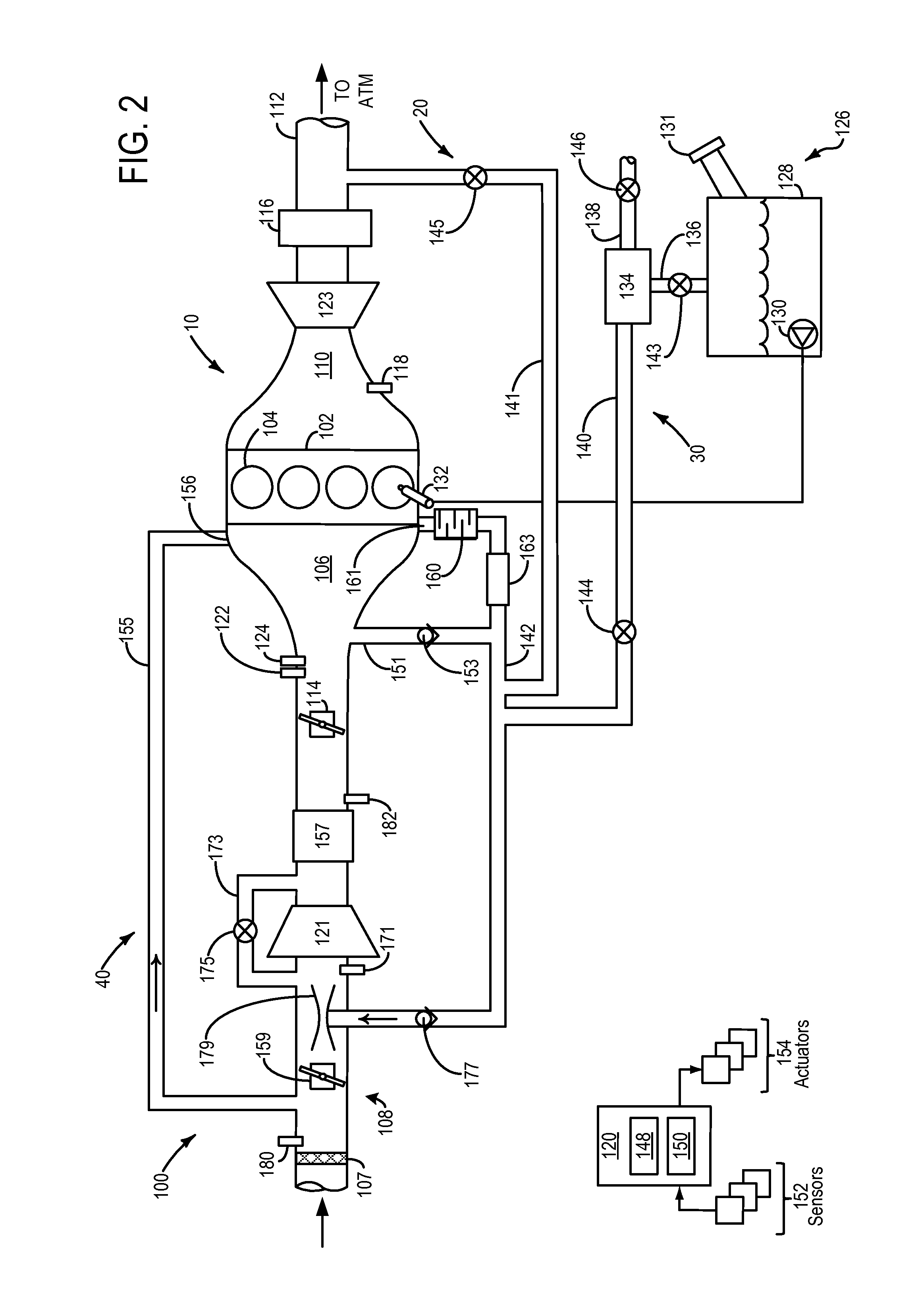

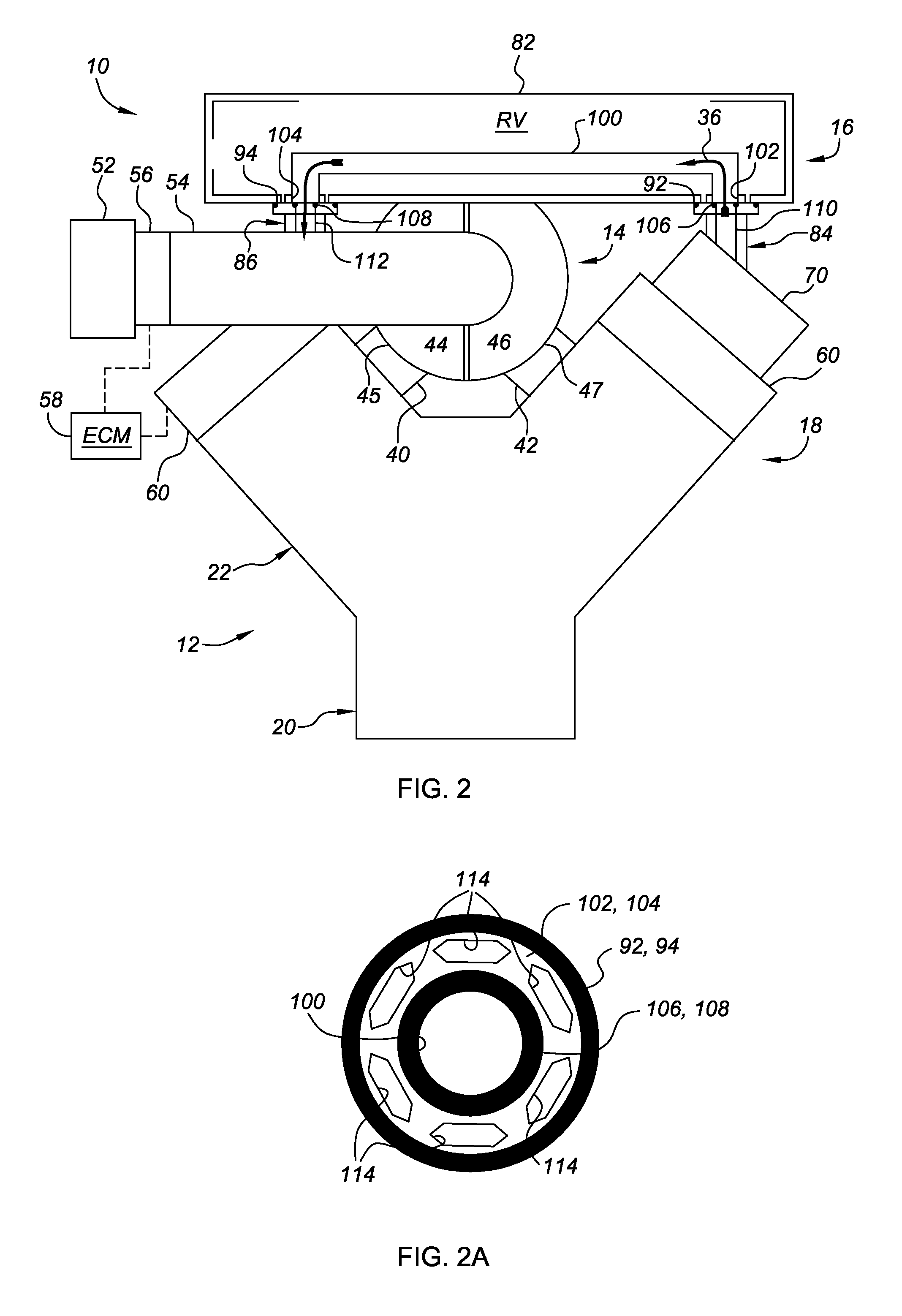

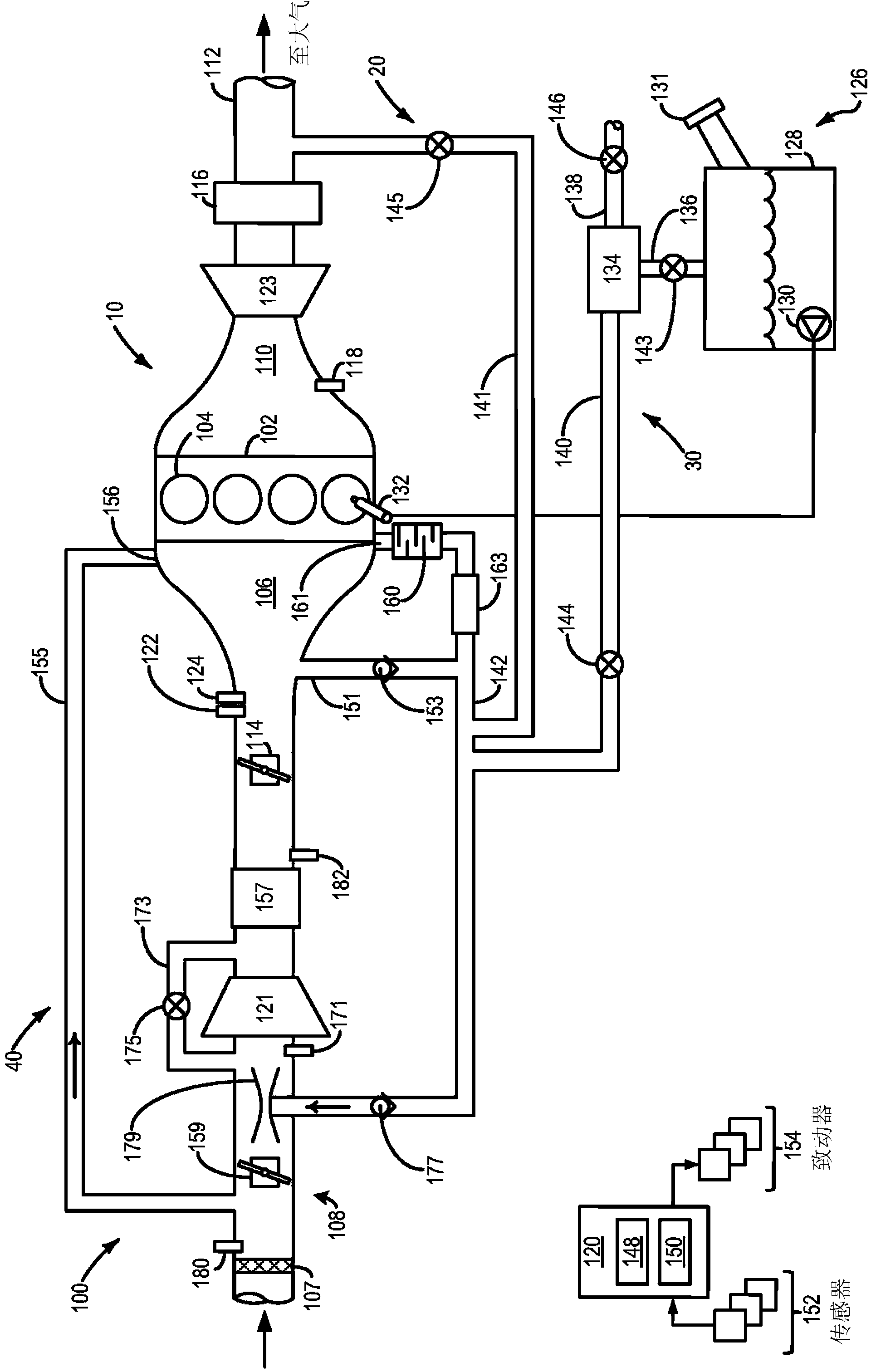

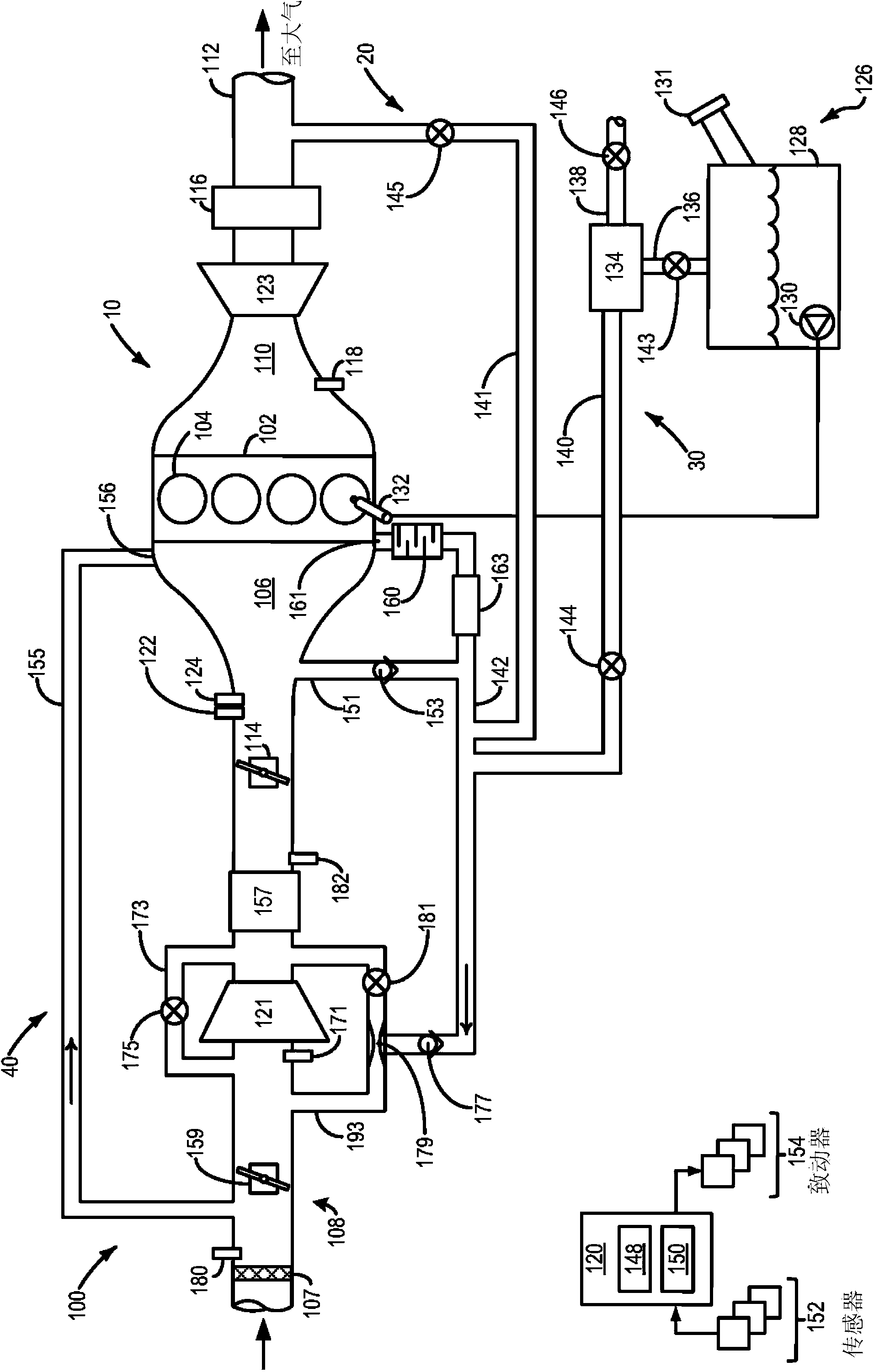

Systems and methods for providing vacuum to one or more of a crankcase ventilation system, an emission control system, and an exhaust gas recirculation (EGR) system included in a turbocharged engine system are provided. In one example, approach, a method comprises drawing vacuum from a vacuum source located in an intake of the engine downstream of a pre-compressor throttle and upstream of an intake throttle, and applying the drawn vacuum to a discharge outlet of a uni-directional crankcase ventilation system, where an inlet of the crankcase ventilation system is coupled to the intake of the engine upstream of the pre-compressor throttle.

Owner:FORD GLOBAL TECH LLC

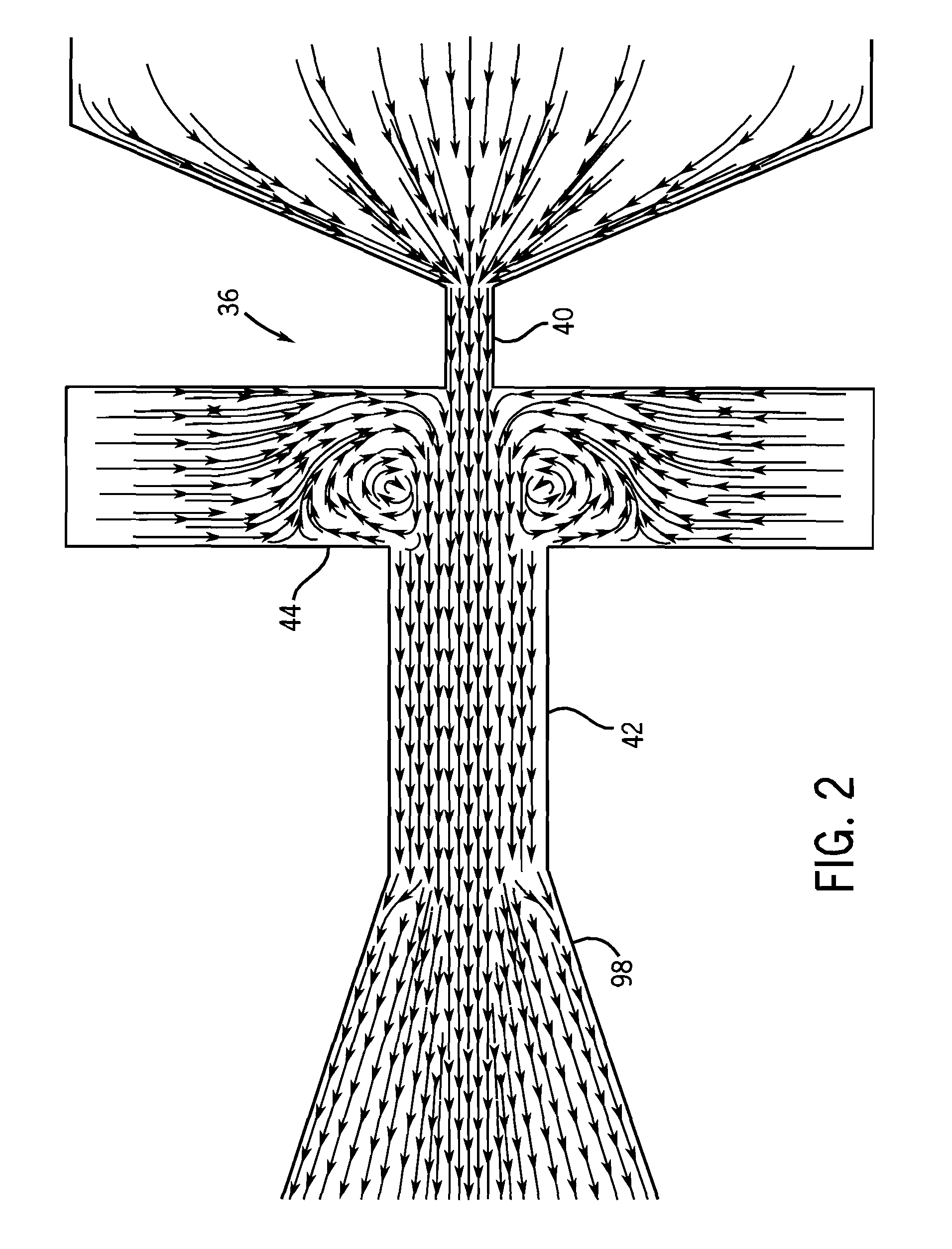

Positive crankcase ventilation system, cylinder head used for positive crankcase ventilation system, internal combustion engine including positive crankcase ventilation system, and positive crankcase ventilation method

InactiveUS20100101514A1Reduce manufacturing costSimple processCylinder headsCombustion enginesCylinder headEngineering

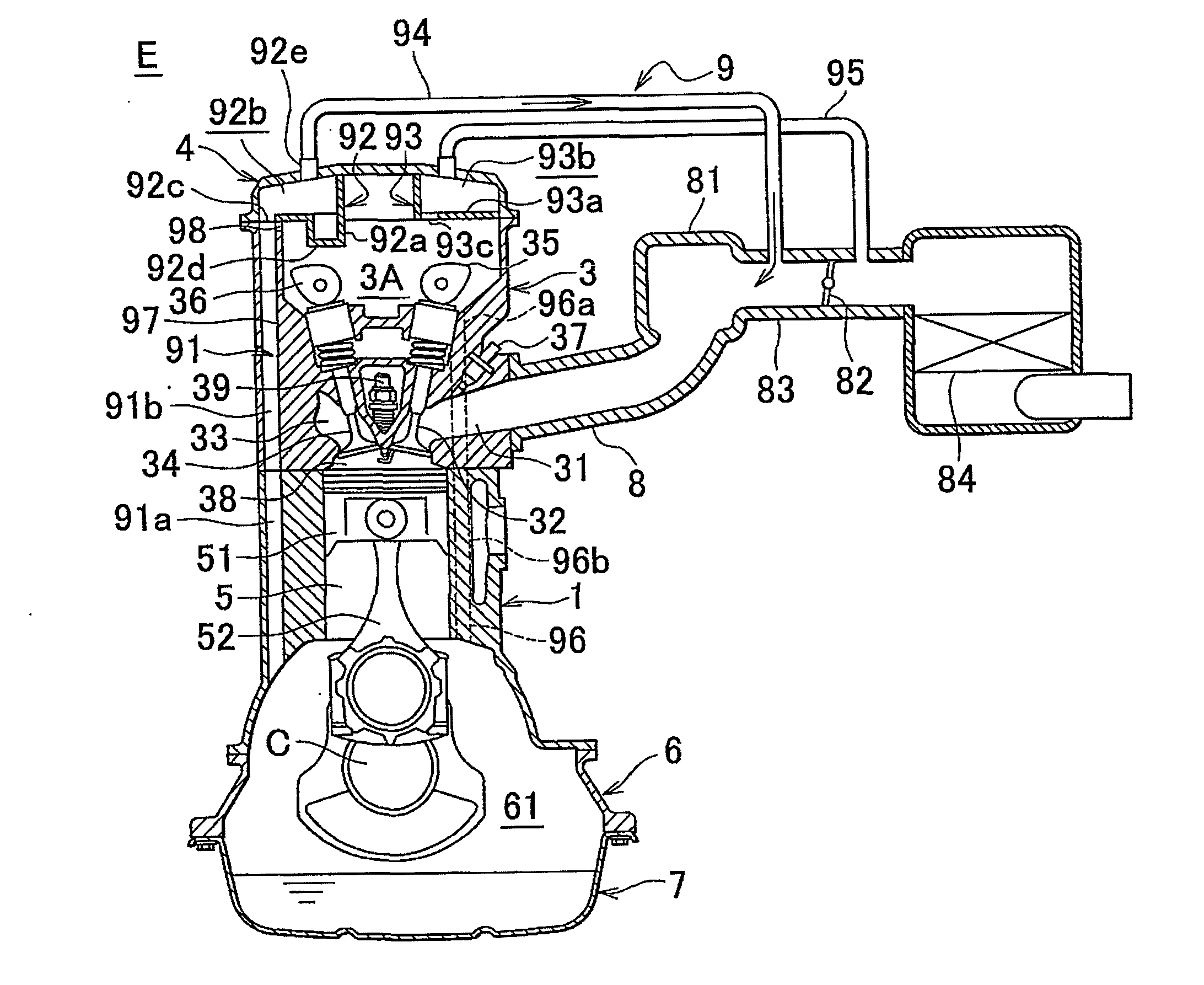

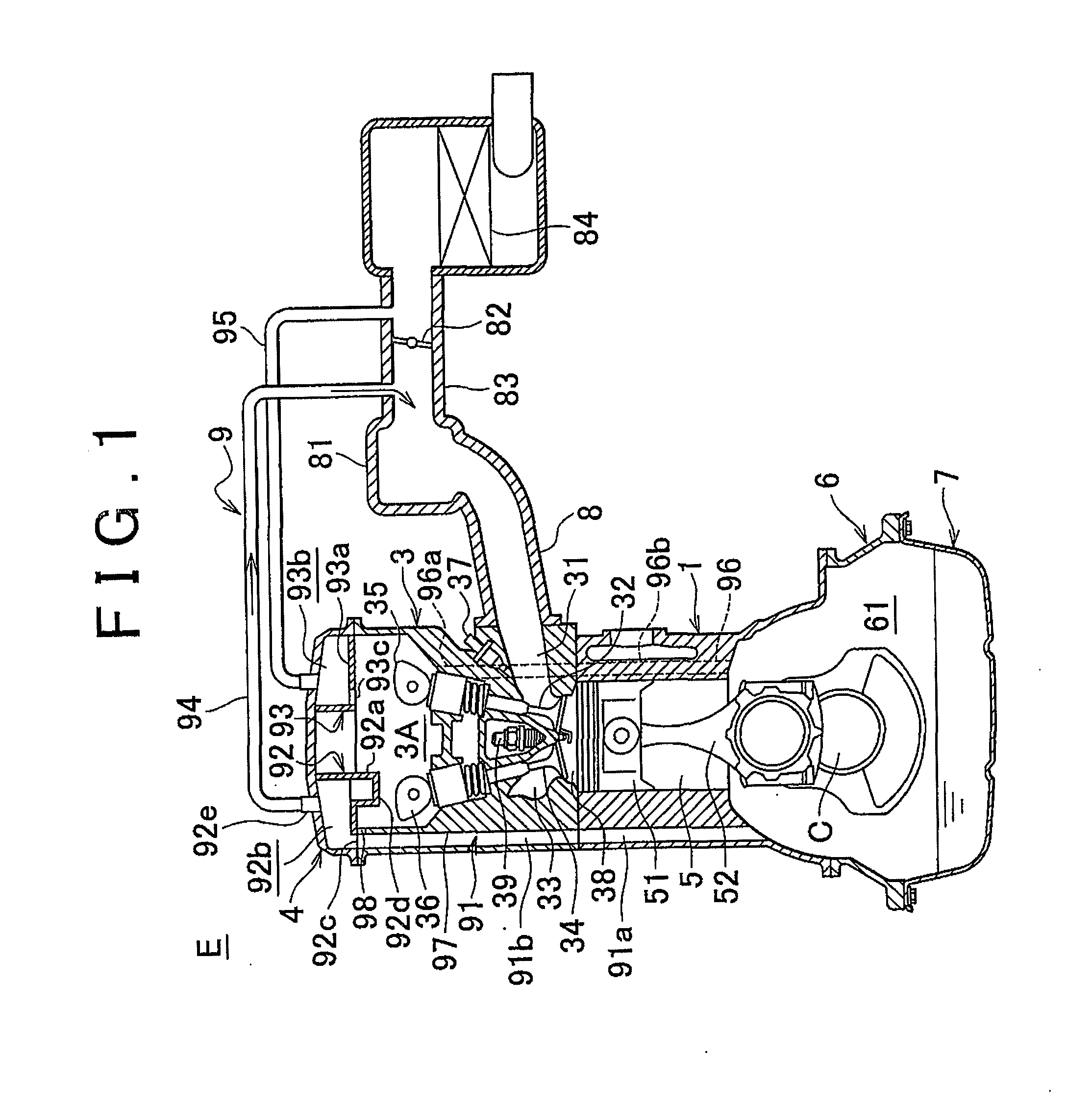

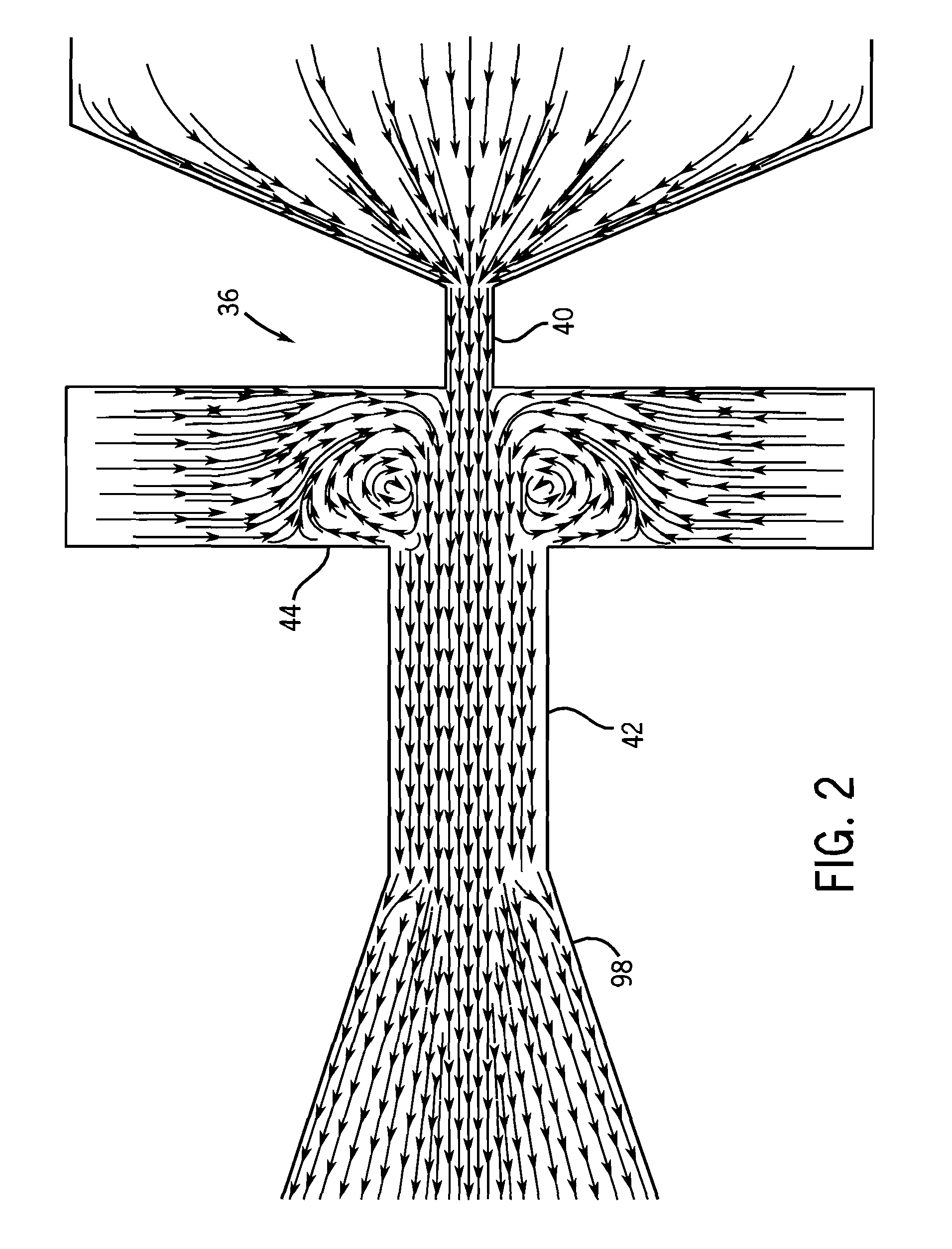

A blow-by gas collection passage (91) extends in a cylinder block (1) and a cylinder head (3). A crank chamber (61) is connected to an oil separator (92) through the blow-by gas collection passage (91). A cutout portion is formed in an upper end portion of a wall portion (97) of the blow-by gas collection passage (91), and the oil separator (92) contacts an upper surface of the cylinder head (3) to form a connection portion (98) through which the blow-by gas collection passage (91) is connected to a cam chamber (3A). Thus, new air in the cam chamber (3A) flows into the blow-by gas collection passage (91) at an inlet portion of the oil separator (92) through the connection portion (98) to dilute the blow-by gas.

Owner:TOYOTA JIDOSHA KK

Blow-by gas separator

InactiveUS7007682B2Internal combustion piston enginesNon-fuel substance addition to fuelCrankcase ventilation systemInduction system

An improved crankcase ventilation system including an improved blow-by gas separator wherein it will be insured that oil cannot accumulate in the separator chamber under any running conditions so that the oil is totally precluded from being able to pass into the induction system.

Owner:YAMAHA MOTOR CO LTD

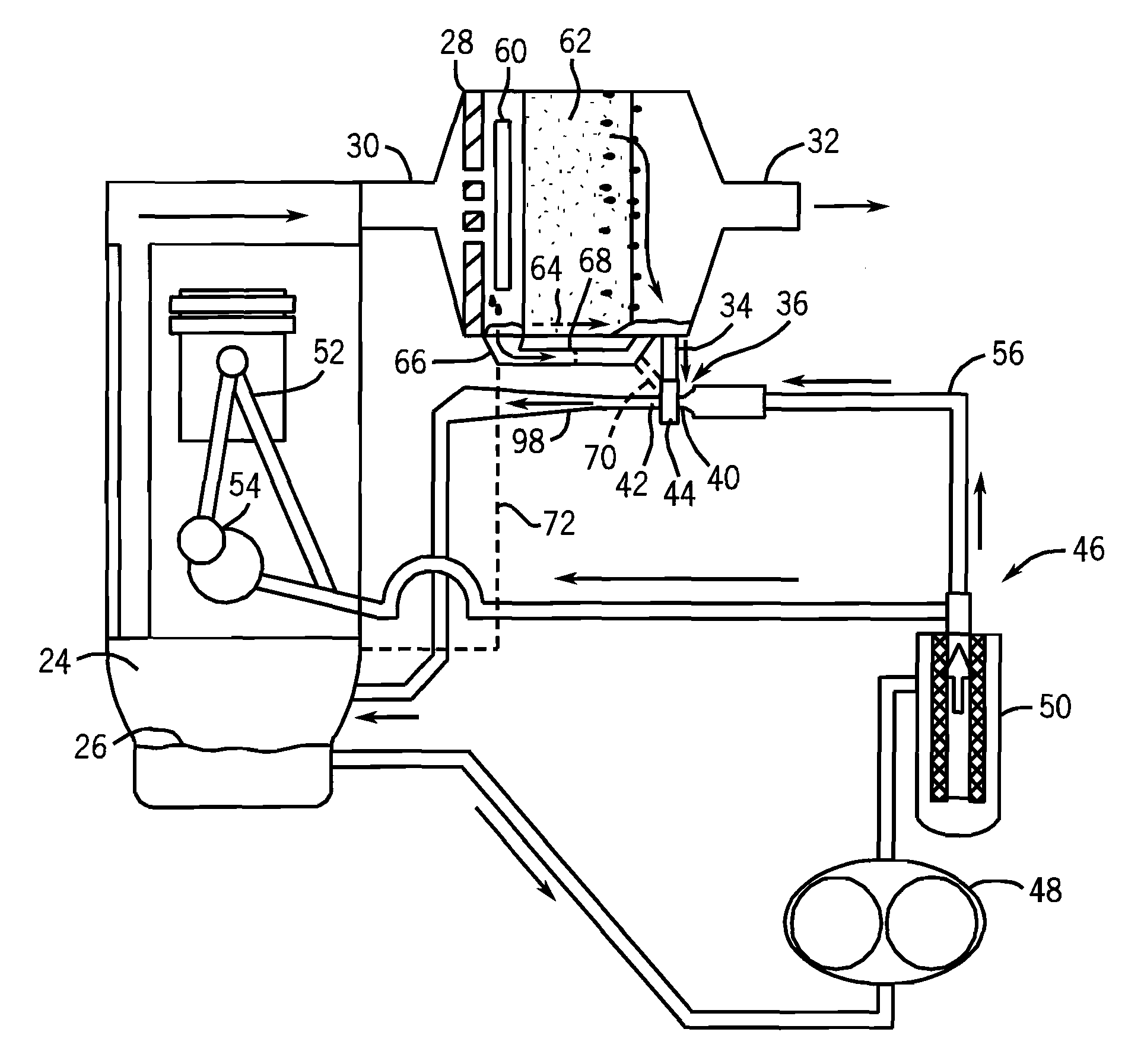

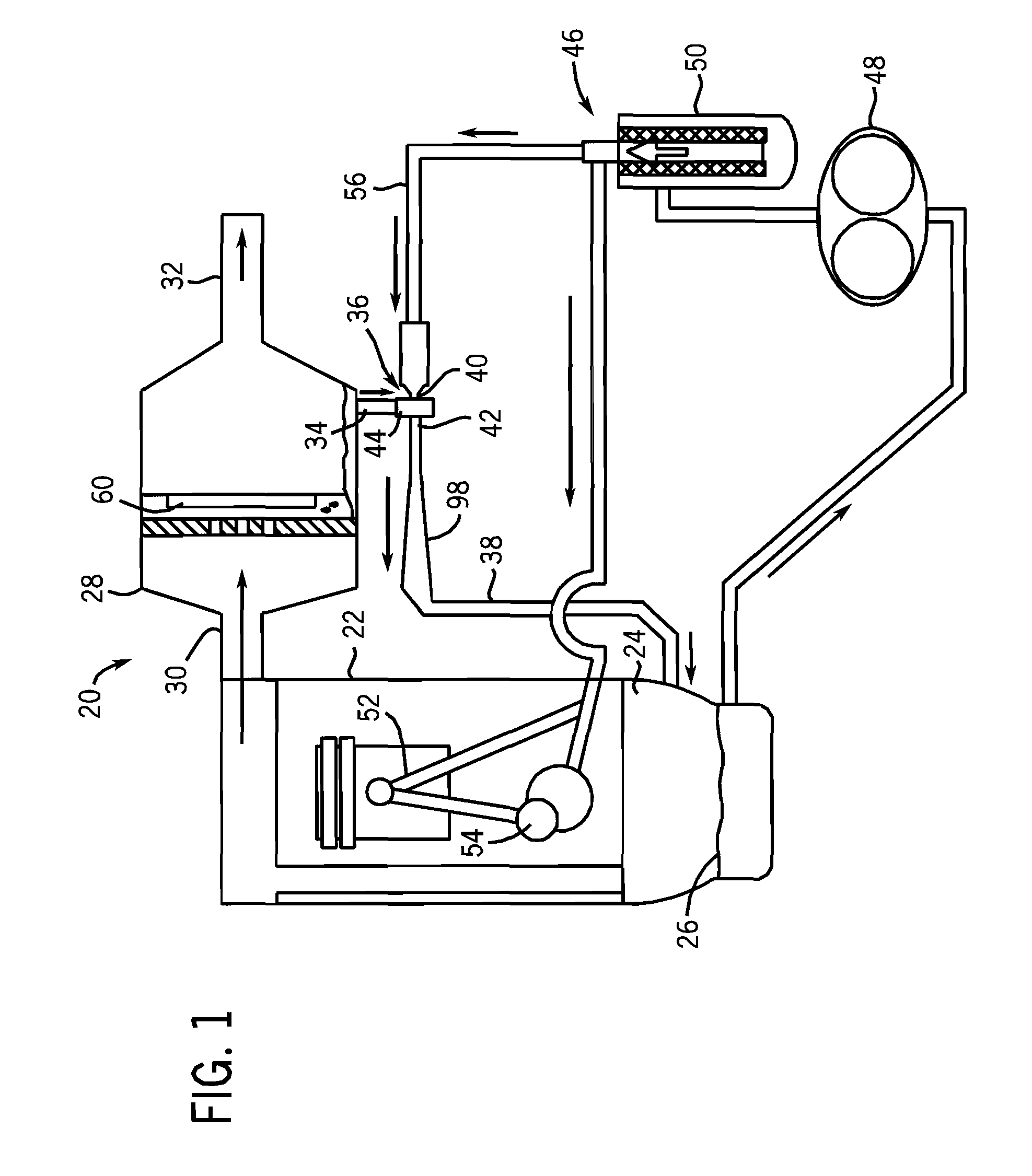

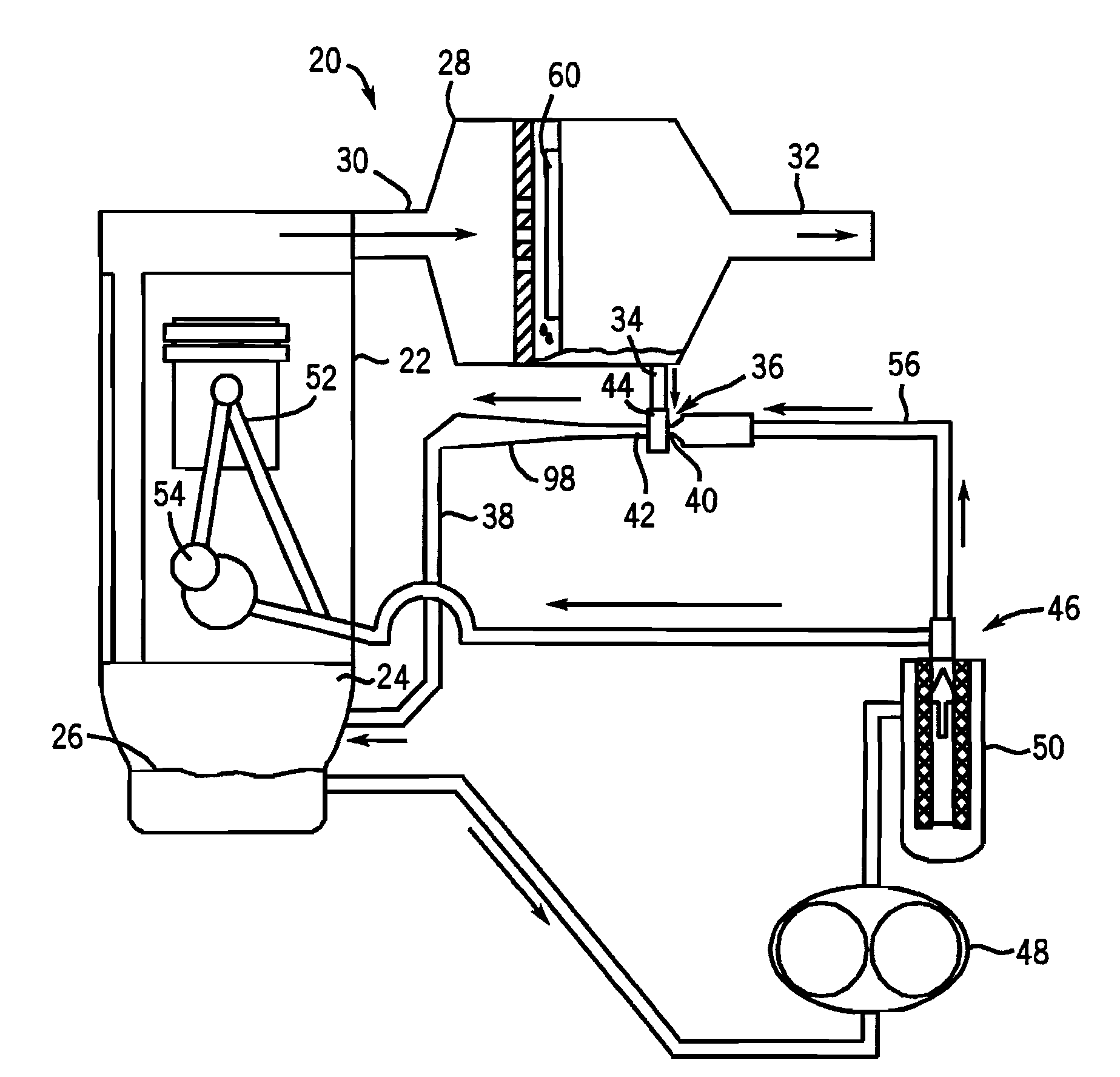

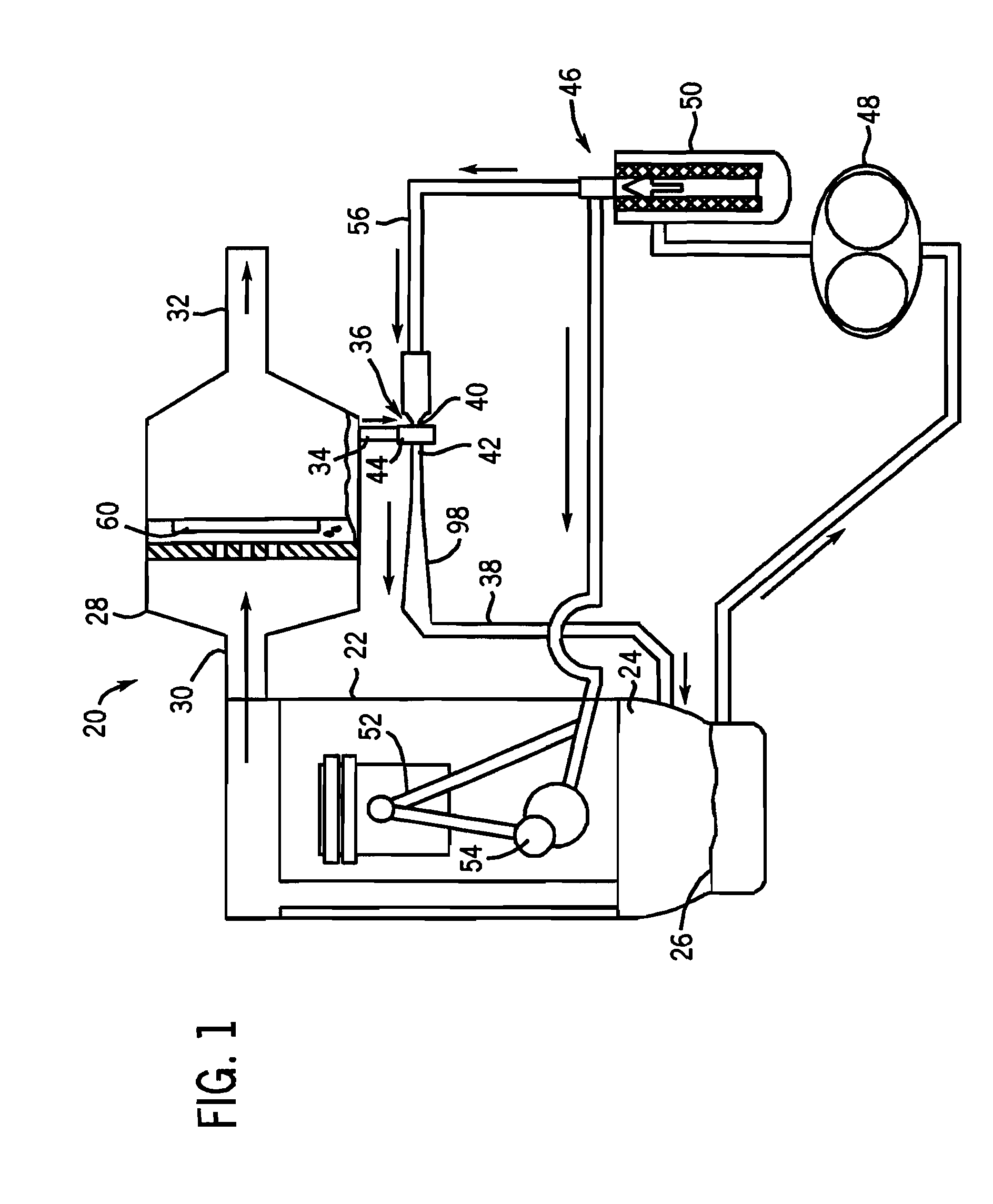

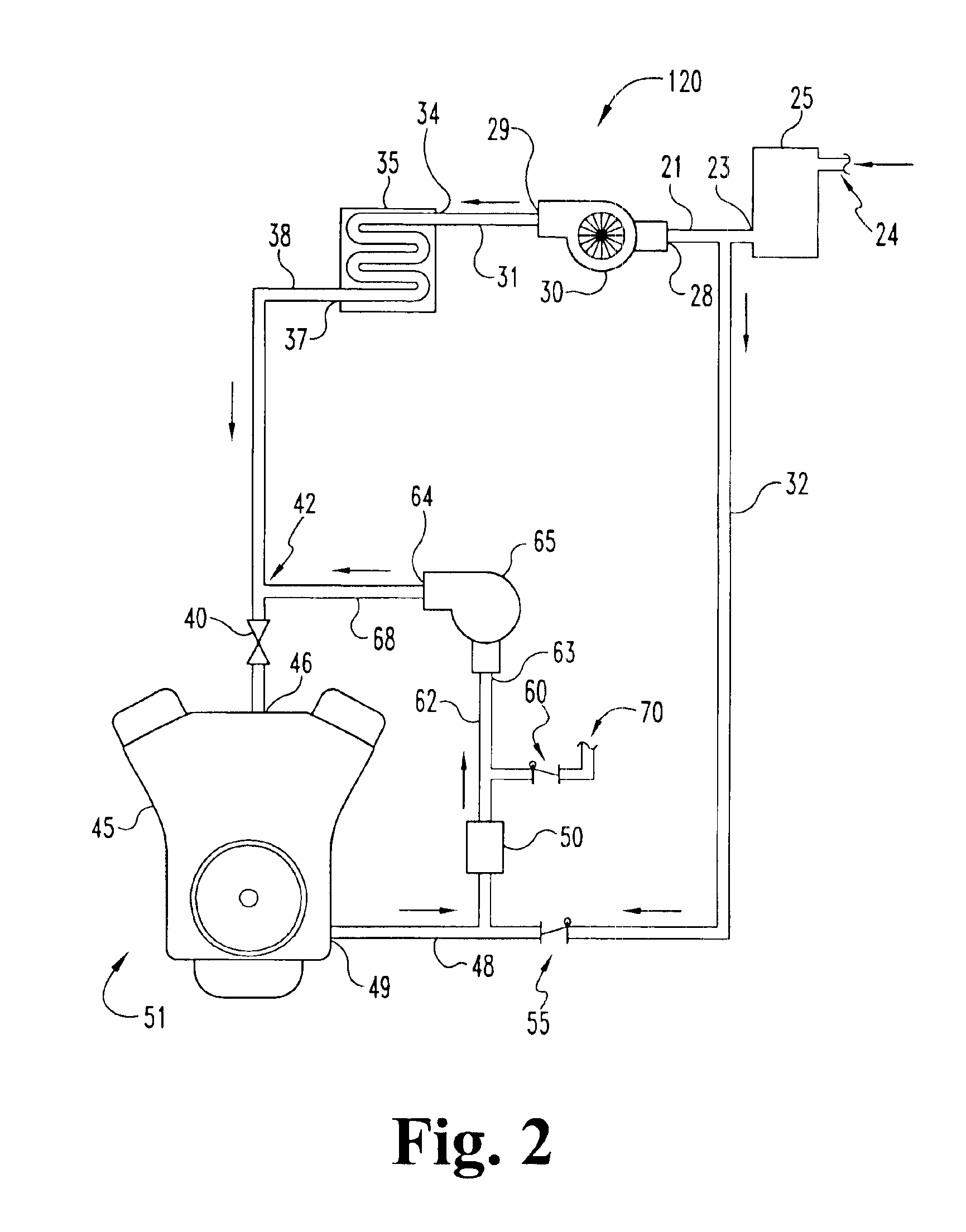

Crankcase Ventilation System with Pumped Scavenged Oil

ActiveUS20090025662A1Simple wayThe process is simple and effectiveDispersed particle filtrationCombustion enginesExternal combustion engineInjection pump

A crankcase ventilation system for an internal combustion engine has a jet pump suctioning scavenged separated oil from the oil outlet of an air / oil separator and pumping same to the crankcase.

Owner:CUMMINS FILTRATION IP INC

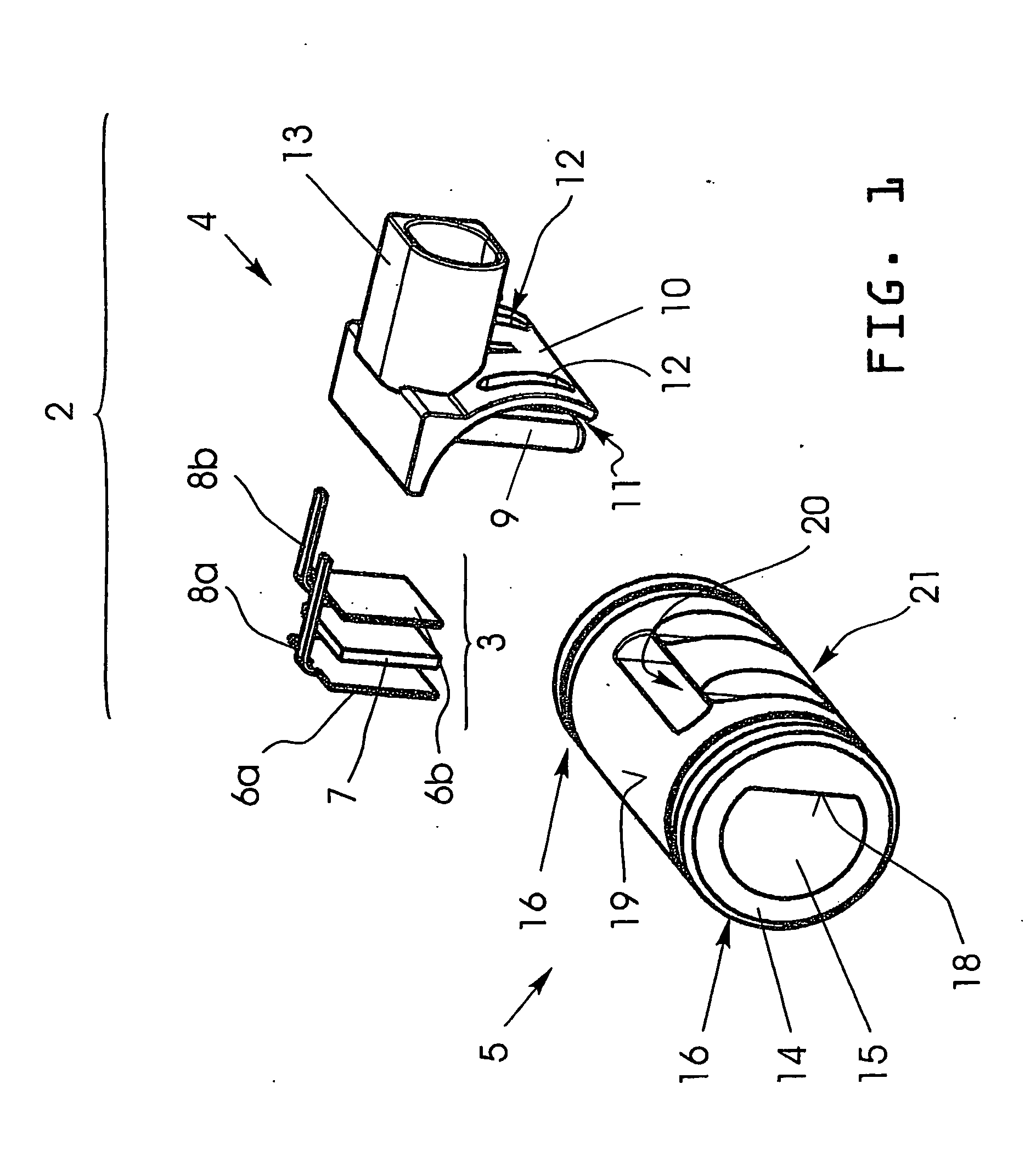

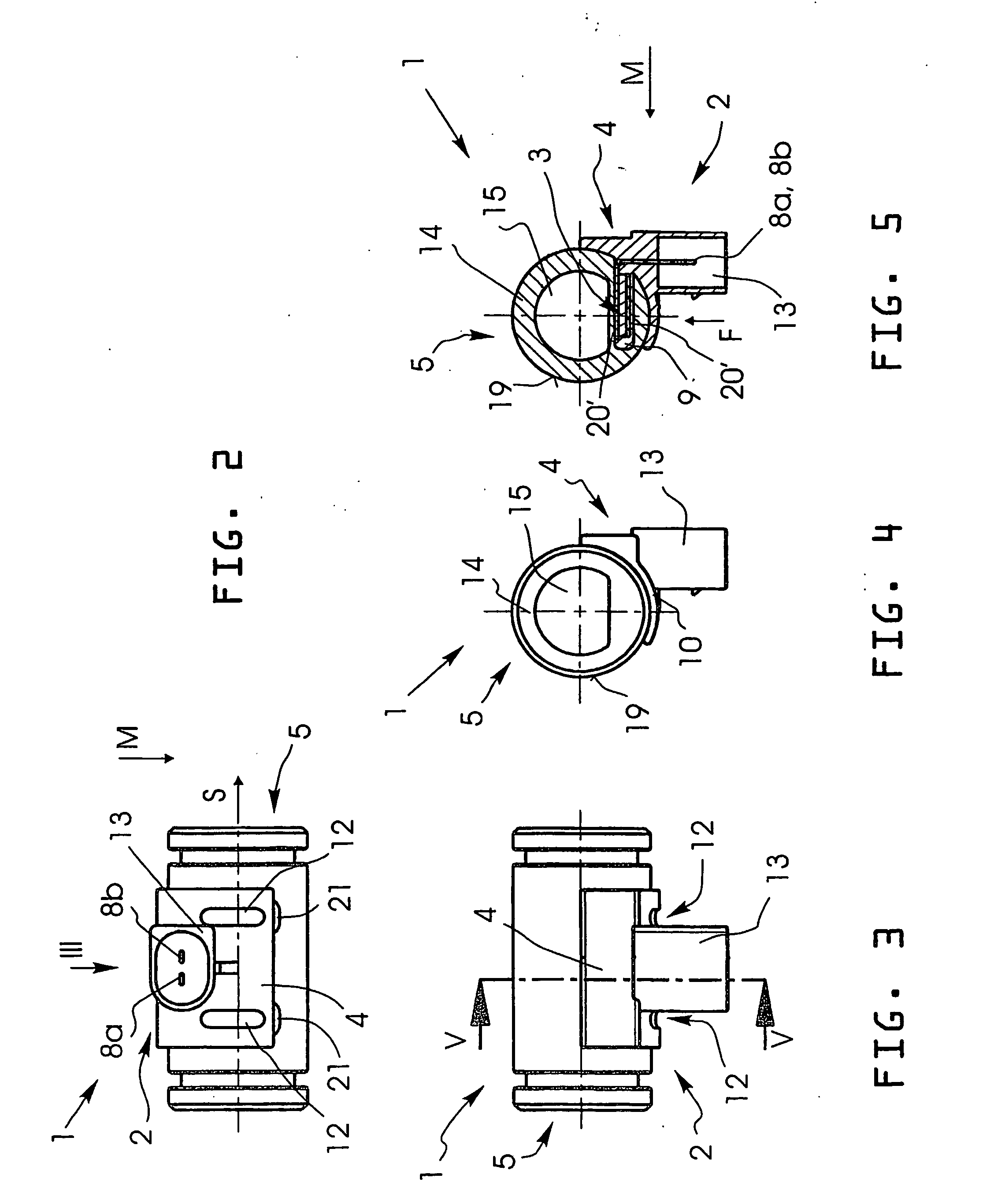

Heating device for a fluid line and method for the production thereof

InactiveUS20060144376A1Achieve trafficSmall sizeNon-fuel substance addition to fuelHeater elementsLine tubingEngineering

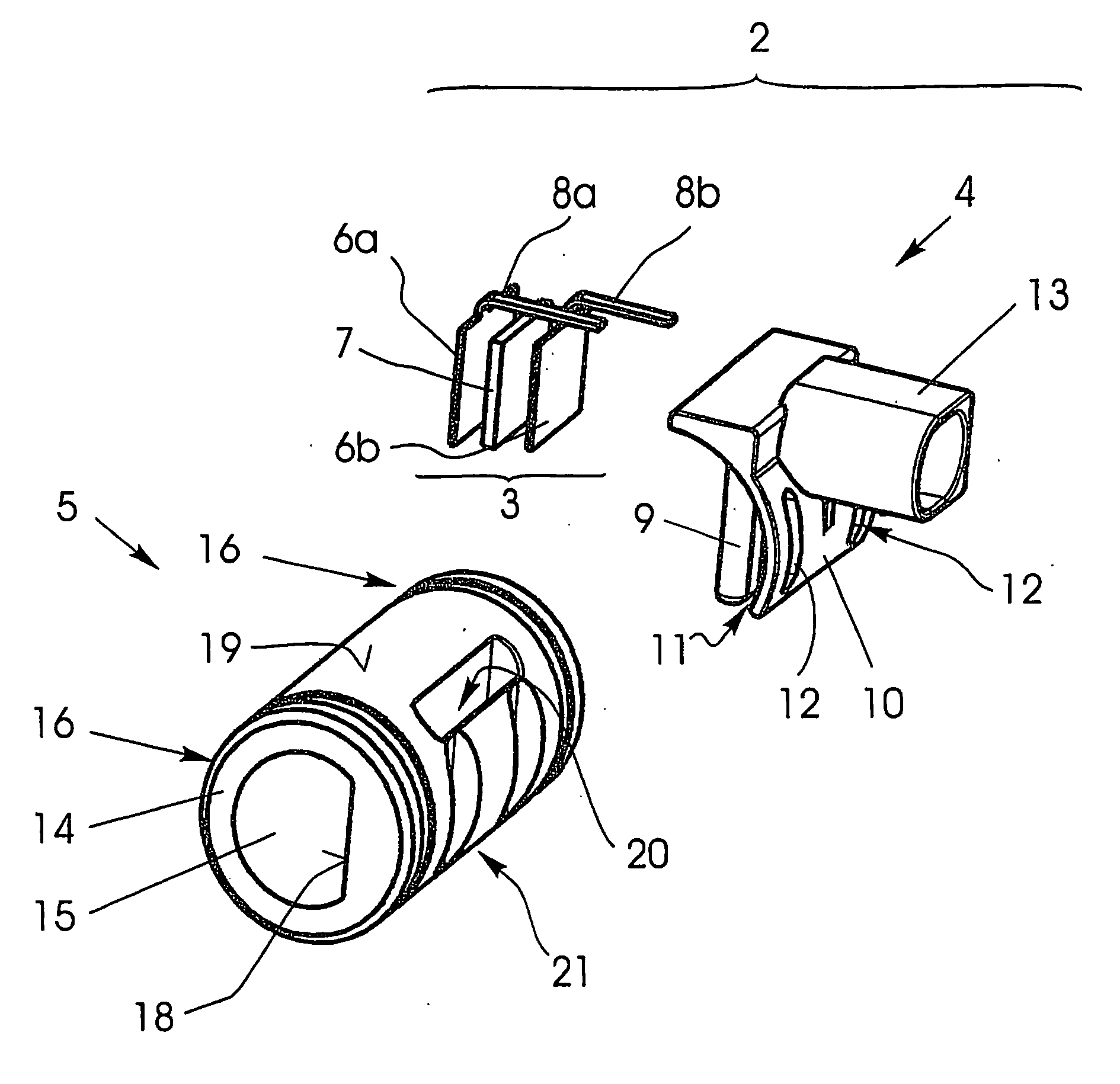

Embodiments of the present invention relate to a heating device for a fluid line, in particular for a crankcase venting system in an internal combustion engine, with a heating element and with a holding device, through which the heating element can be mounted on the fluid line. Embodiments of the invention also relate to a fluid line for the accommodation of the said heating device and to a heating module with a fluid line and a heating device fitted to it. Embodiments of the invention also relate to a method for the manufacture of the heating device mentioned above.

Owner:DAVID & BAADER DBK

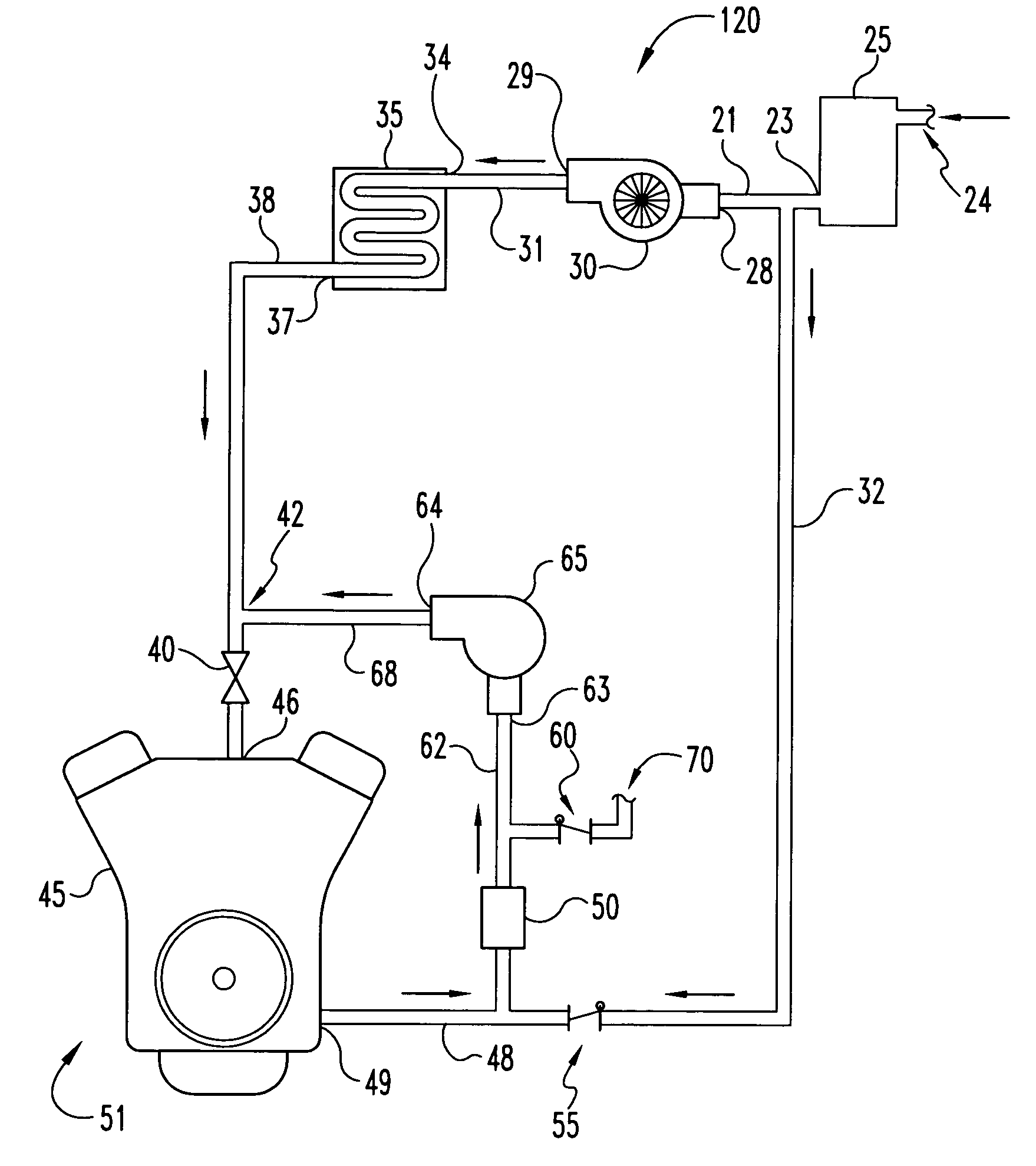

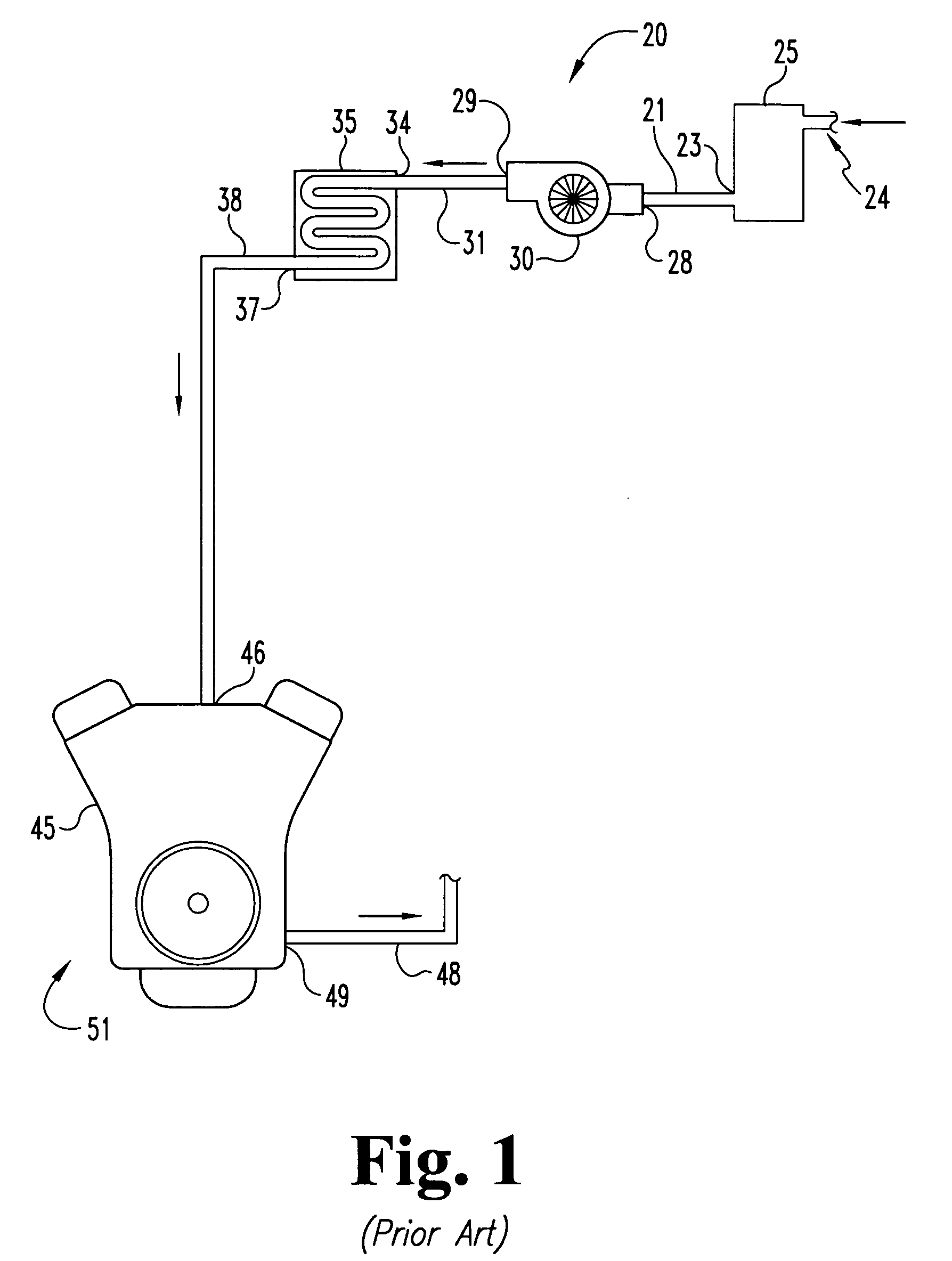

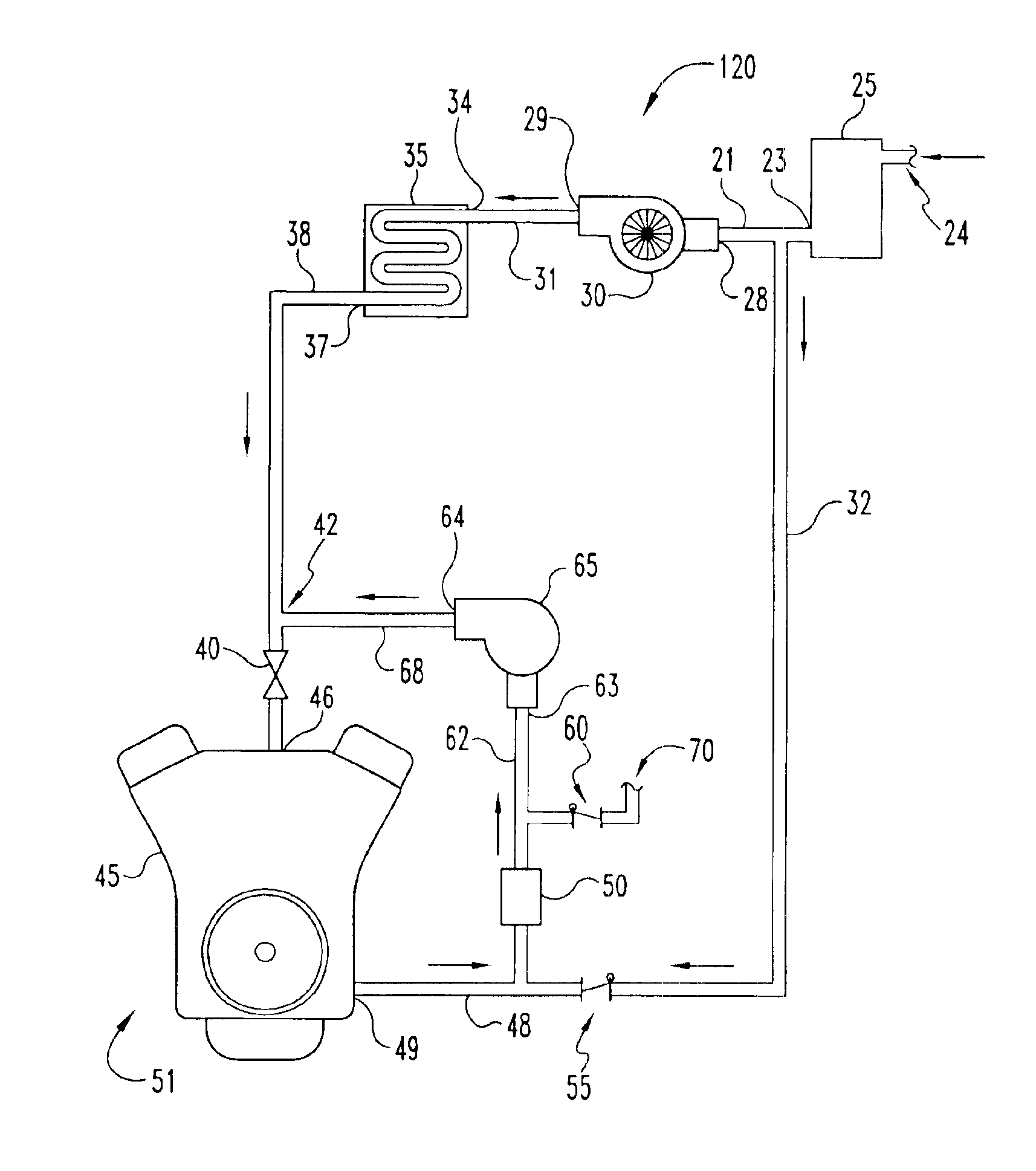

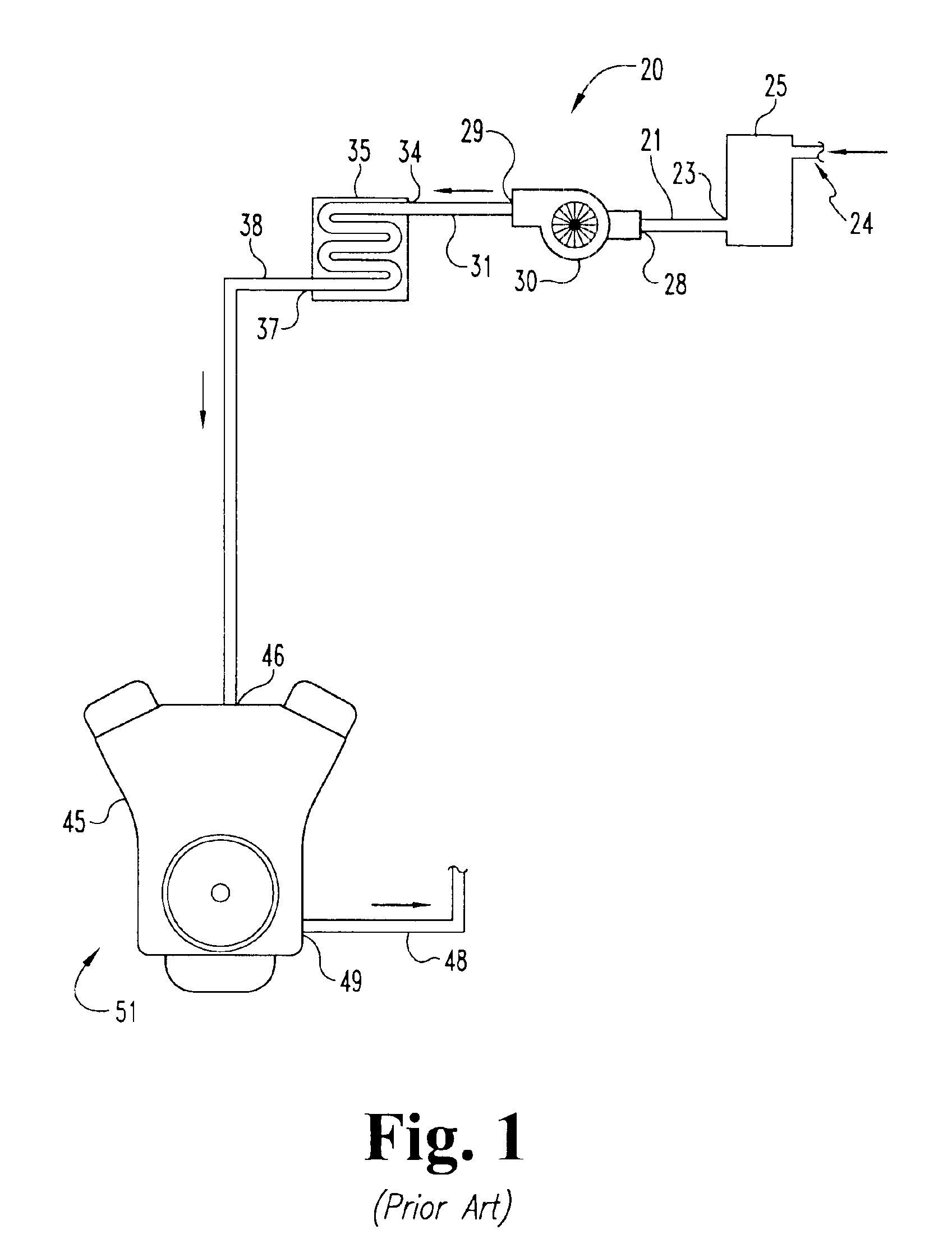

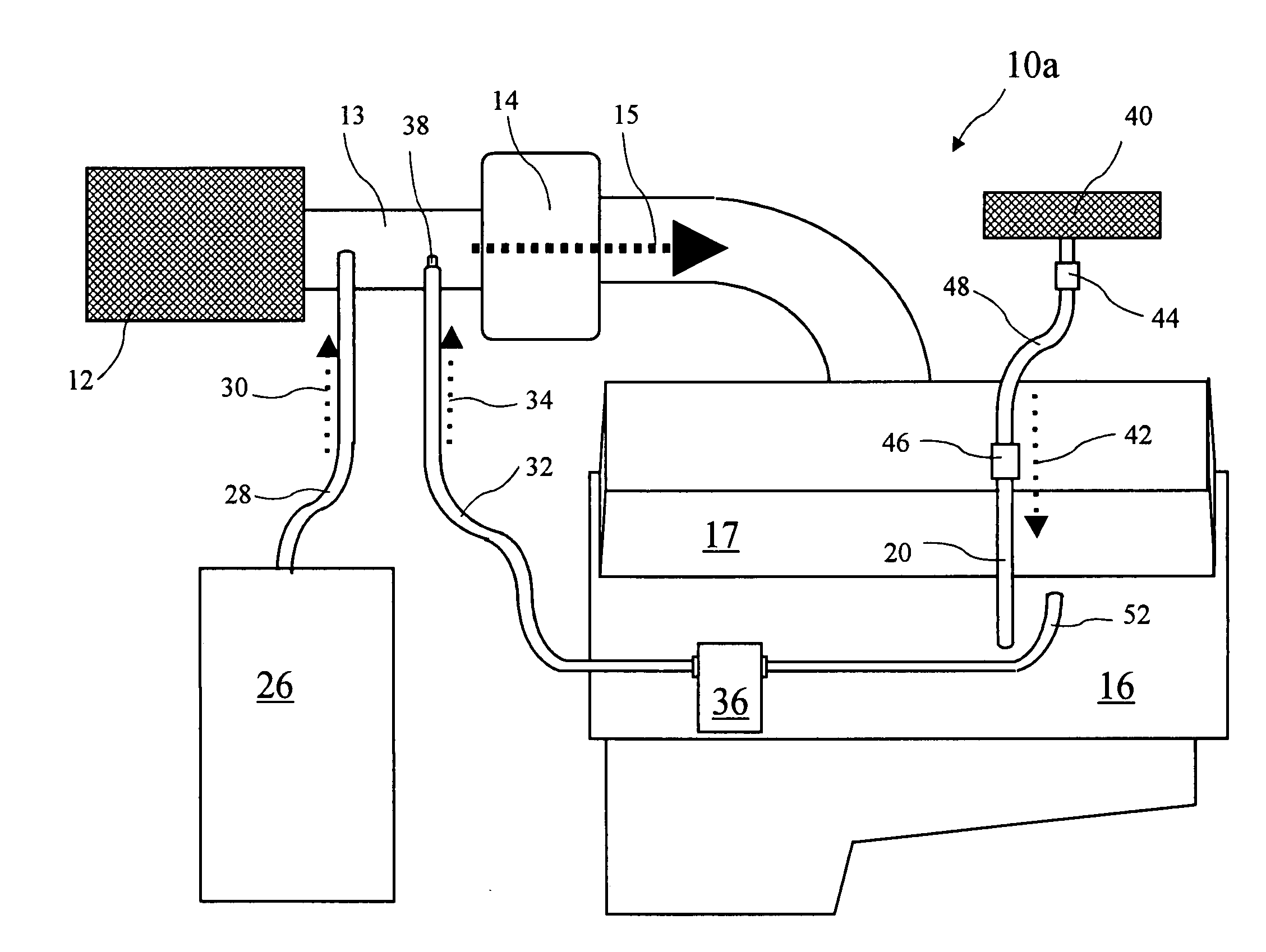

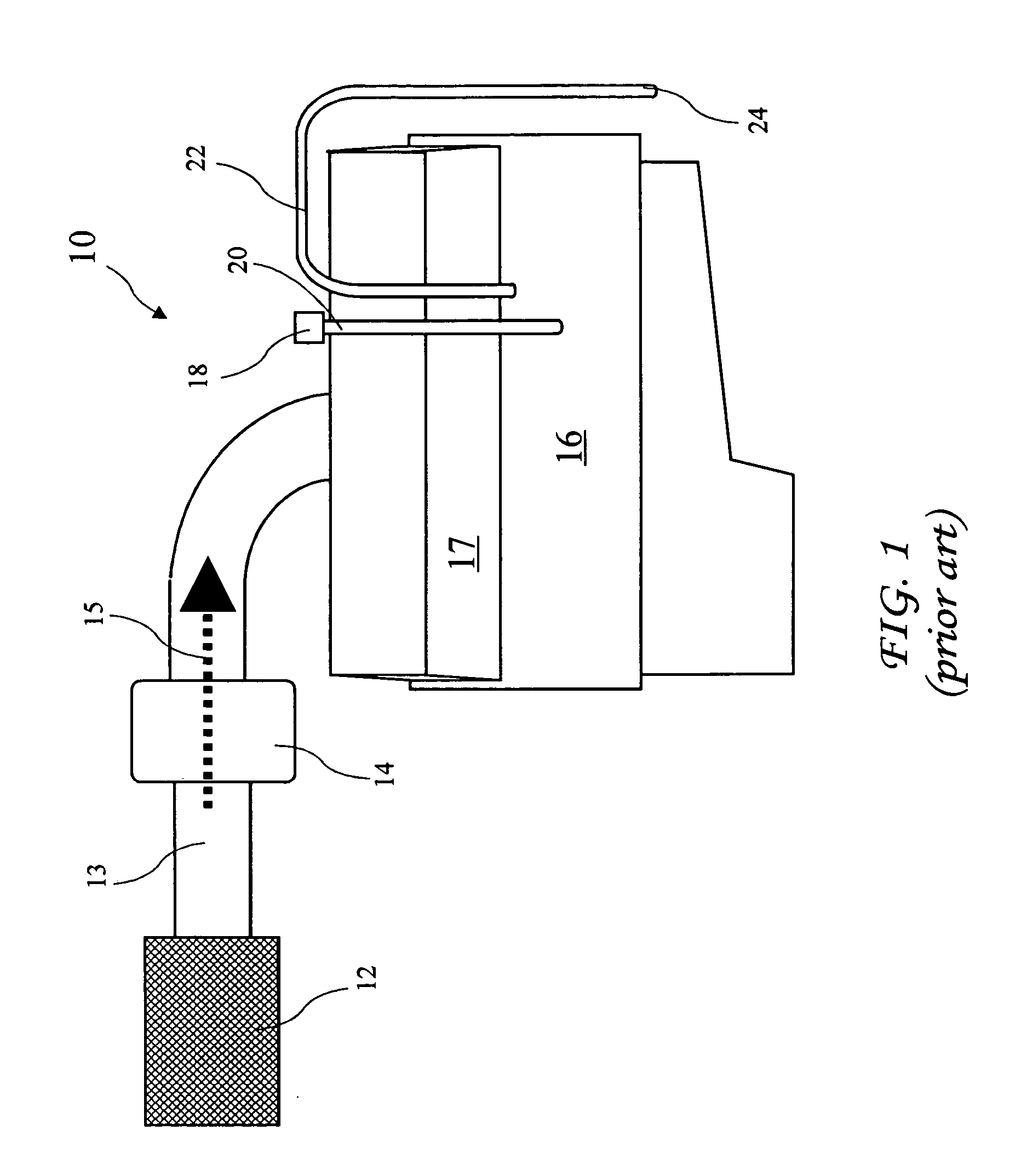

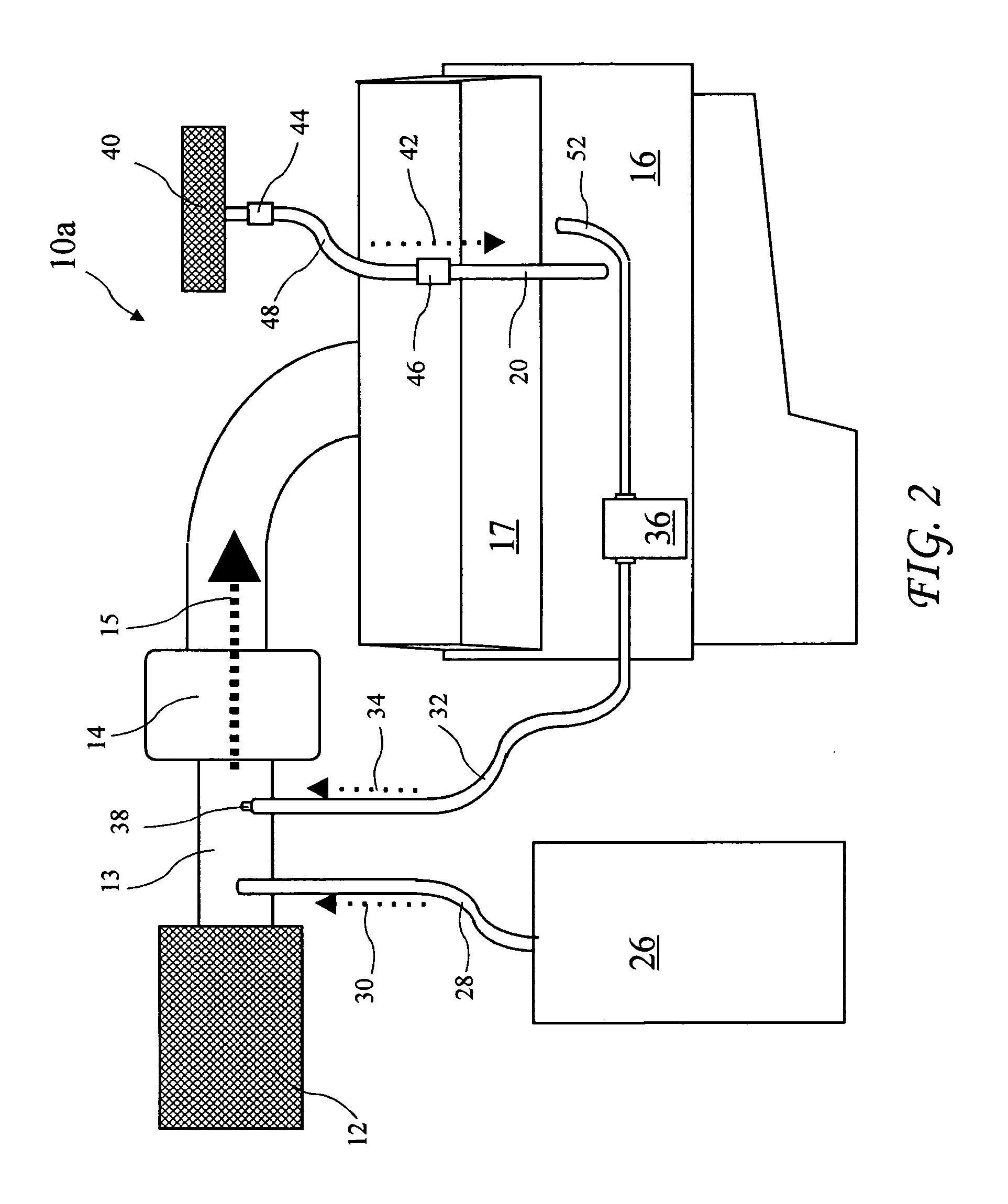

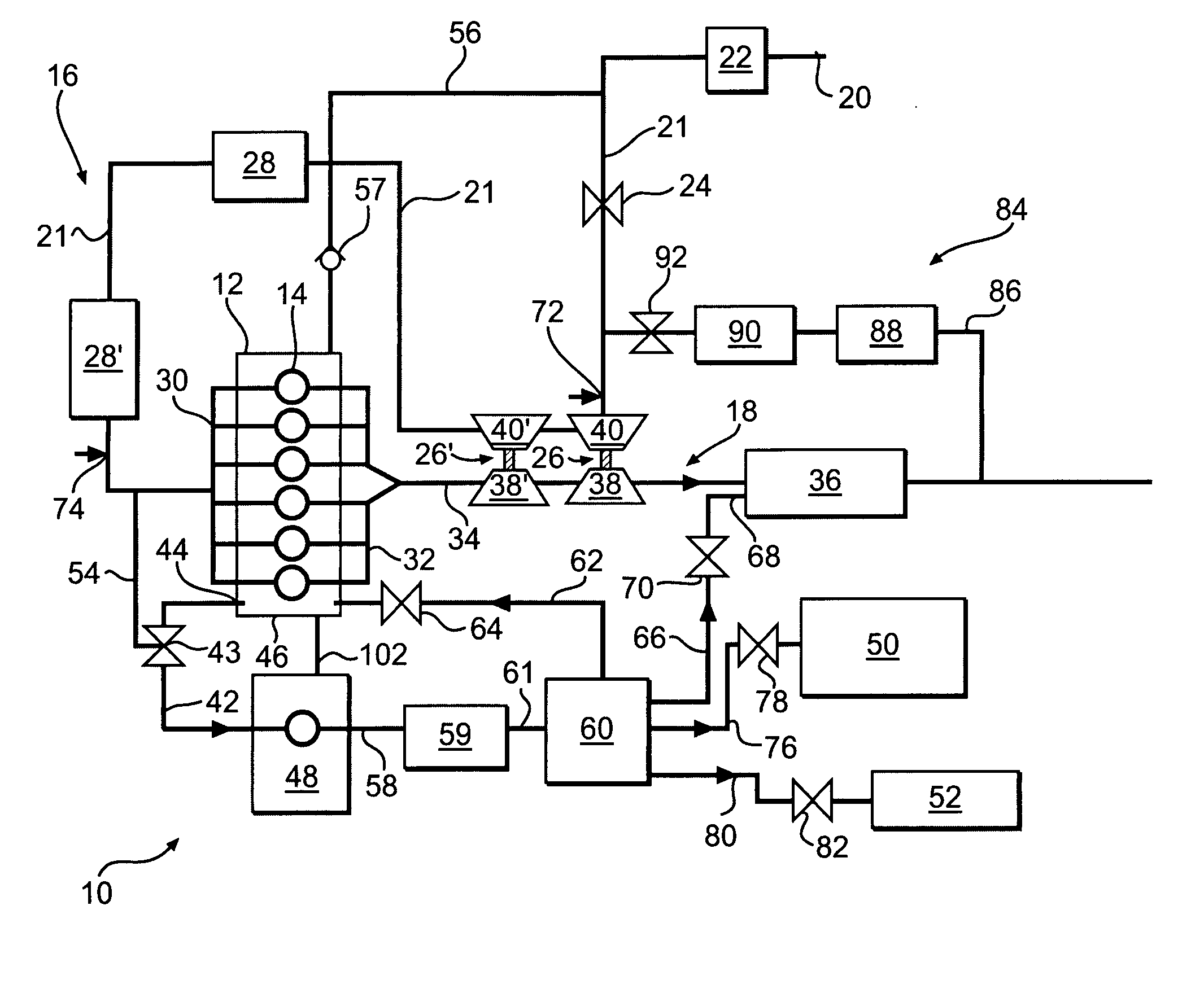

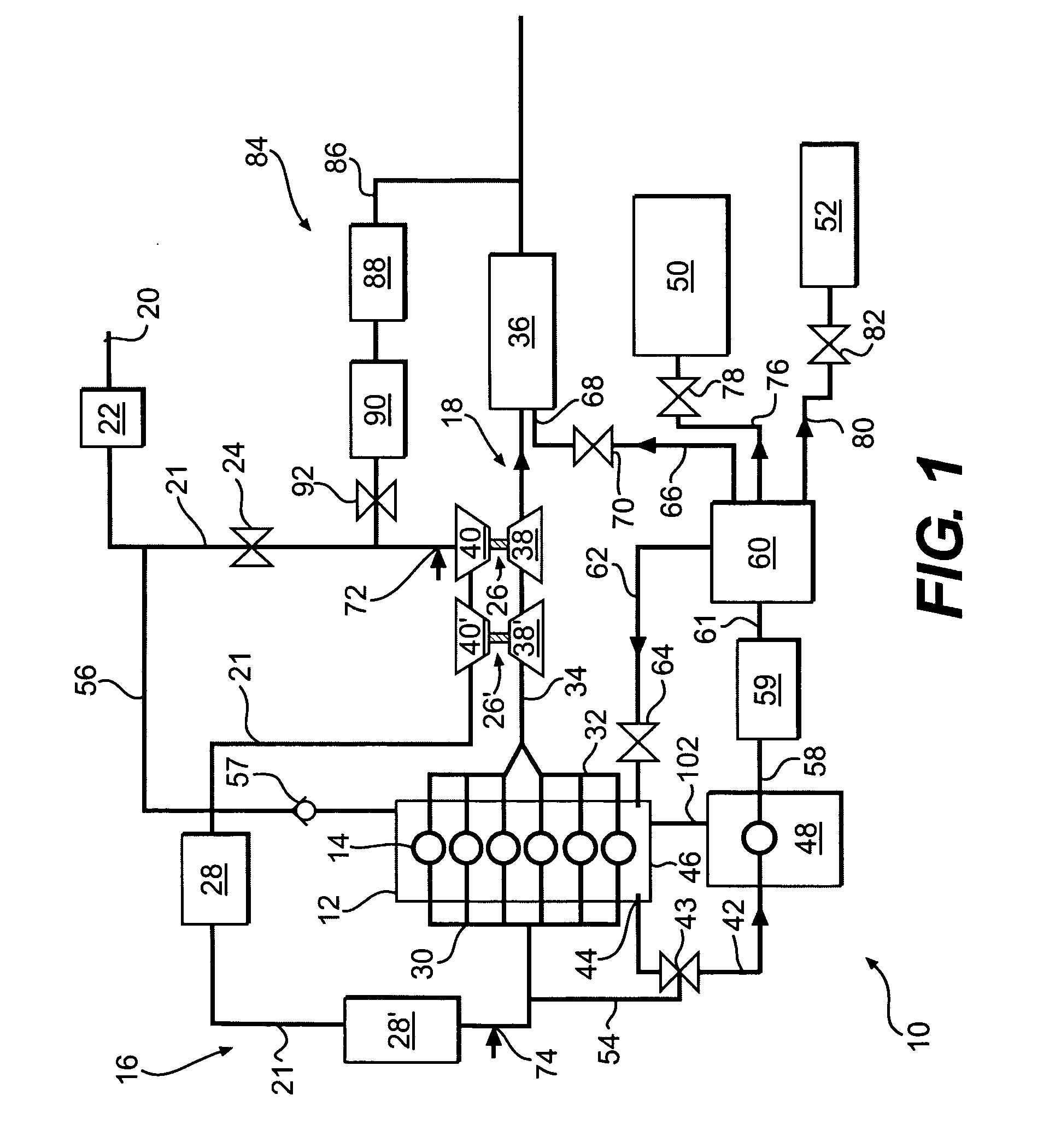

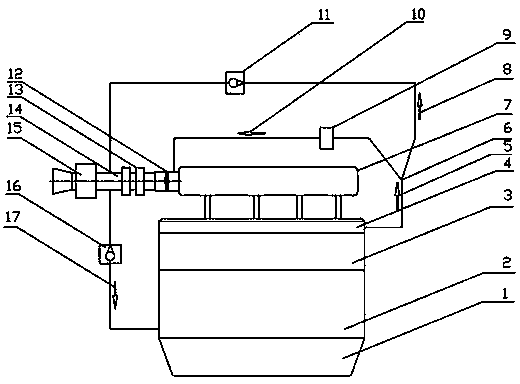

Crankcase ventilation system

InactiveUS20050000496A1Easy to optimizeImprove ventilationNon-fuel substance addition to fuelInternal combustion piston enginesInternal pressureCombustion

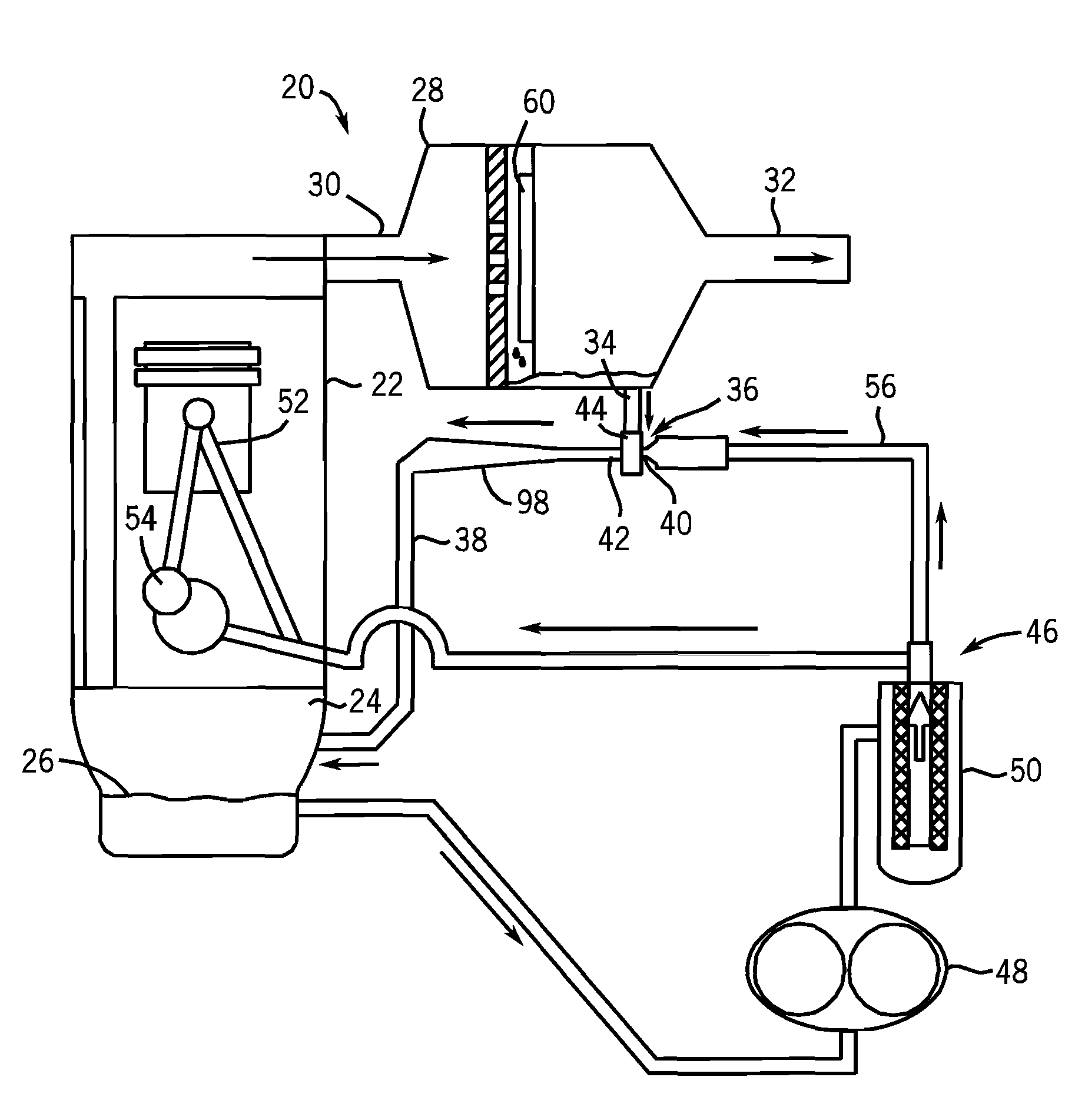

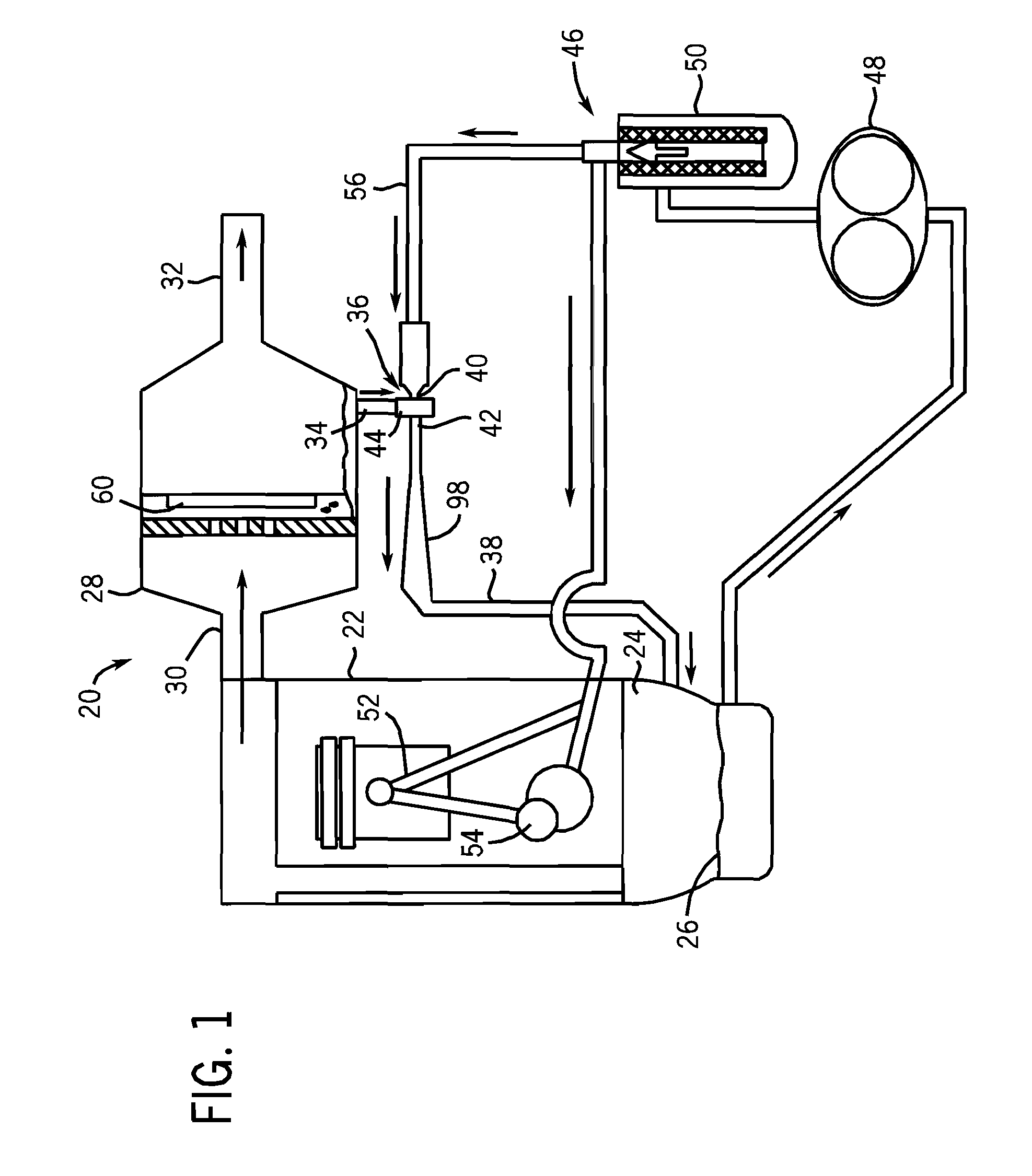

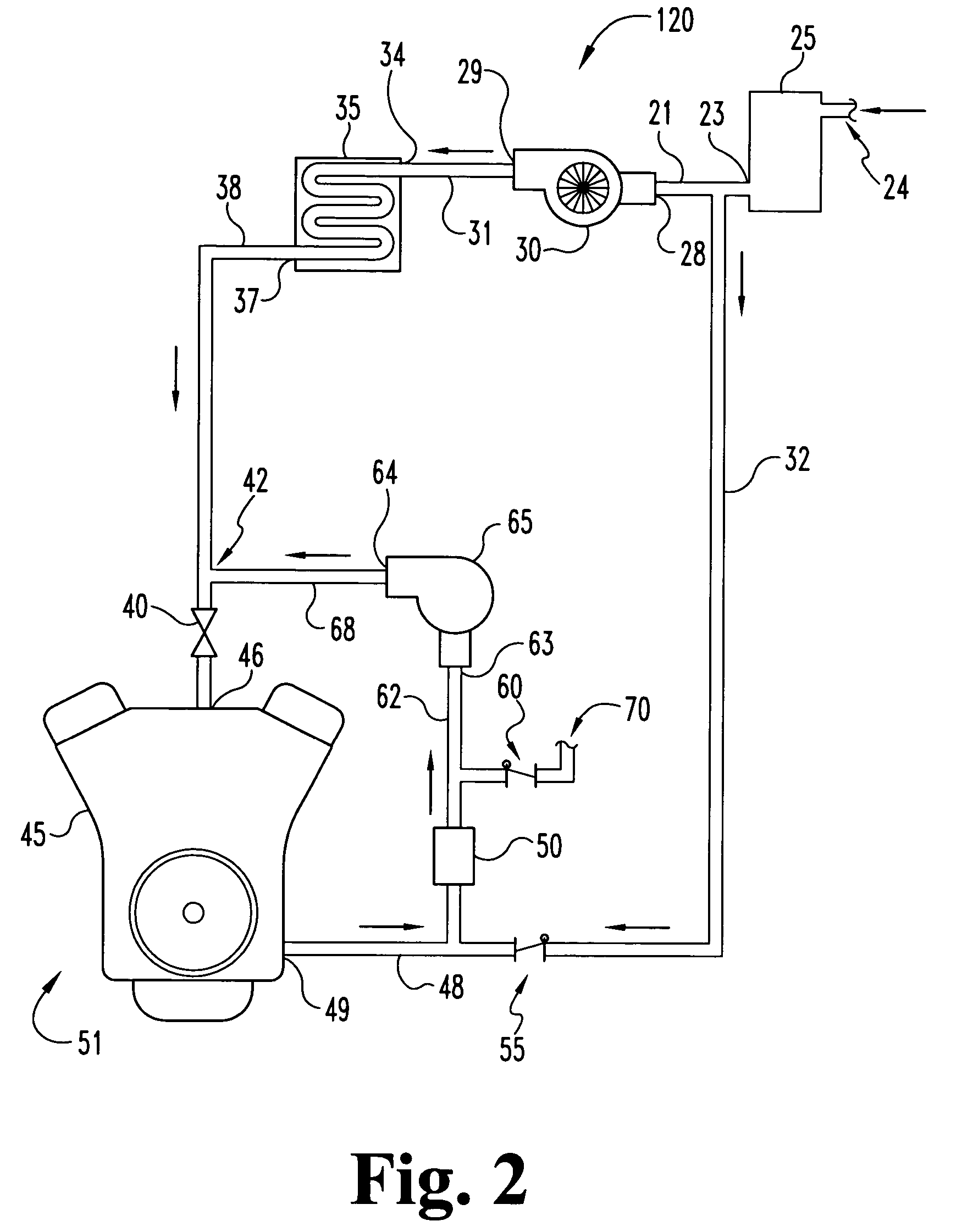

An improved crankcase ventilation system for a vehicle which includes an air compressor to route crankcase gases to the intake manifold for combustion. The primary vehicle components include and aircleaner, a turbocharger compressor positioned downstream from the aircleaner, an optional aftercooler positioned downstream from the turbocharger compressor, and an engine having an intake manifold and a crankcase equipped with a breather port for venting crankcase gases. Crankcase gases are vented through the breather port to the air compressor. Clean air from downstream of the aircleaner but upstream of the turbocharger compressor is drawn into the air compressor as needed to prevent the air compressor from drawing too much crankcase gas and reducing the internal pressure of the crankcase to undesirable levels. The pressurized crankcase gases are introduced into the intake air stream downstream of the aftercooler and upstream of the intake manifold so as to prevent fouling of the turbocharger compressor and aftercooler by contaminants in the crankcase gases. The crankcase gases are then combusted in the engine and not vented directly to the environment.

Owner:CUMMINS INC

Modular intake manifold and integrated air intake system

ActiveUS20060060163A1Short response timeImprove performanceNon-fuel substance addition to fuelInternal combustion piston enginesEngineeringInlet manifold

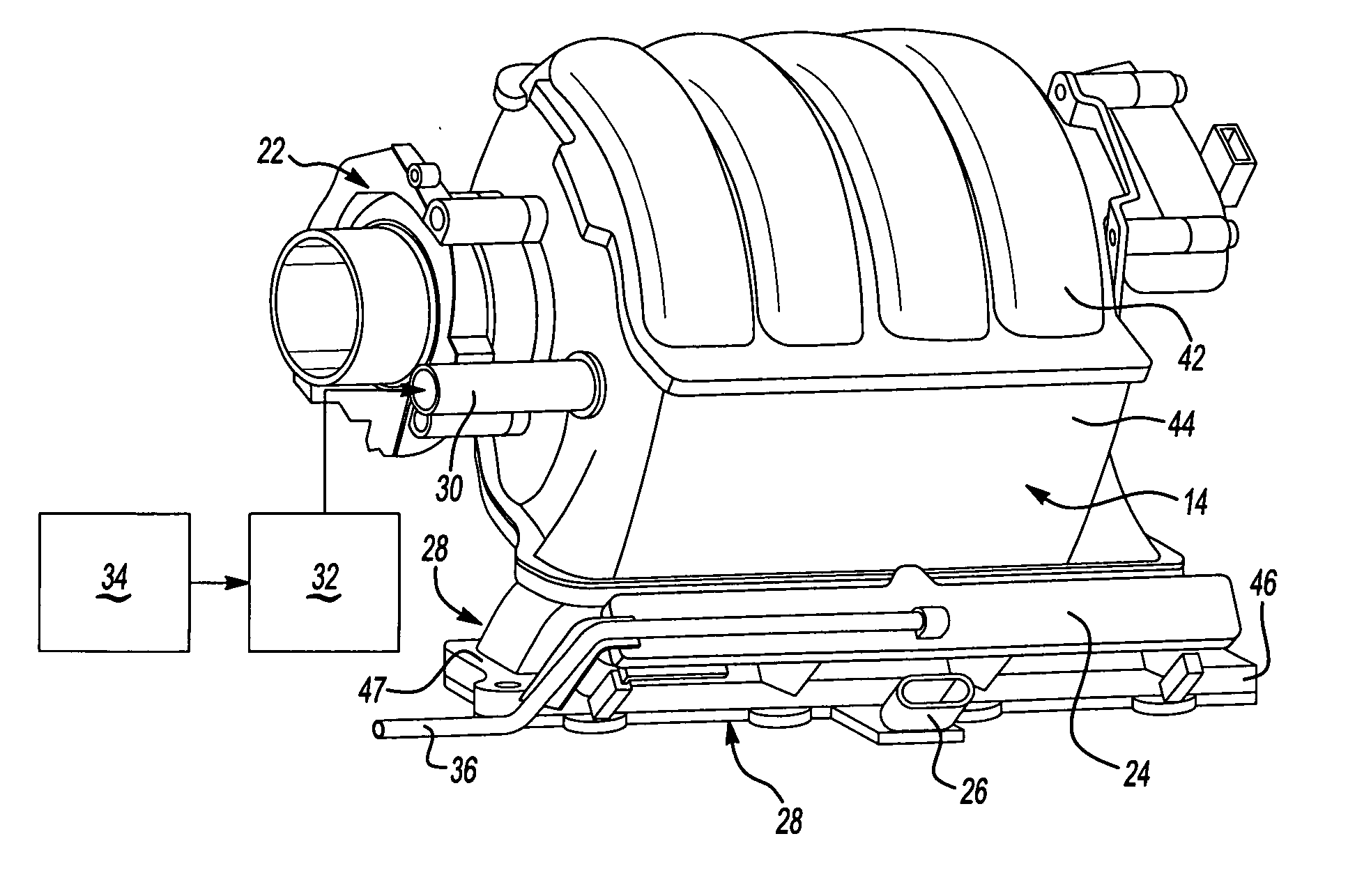

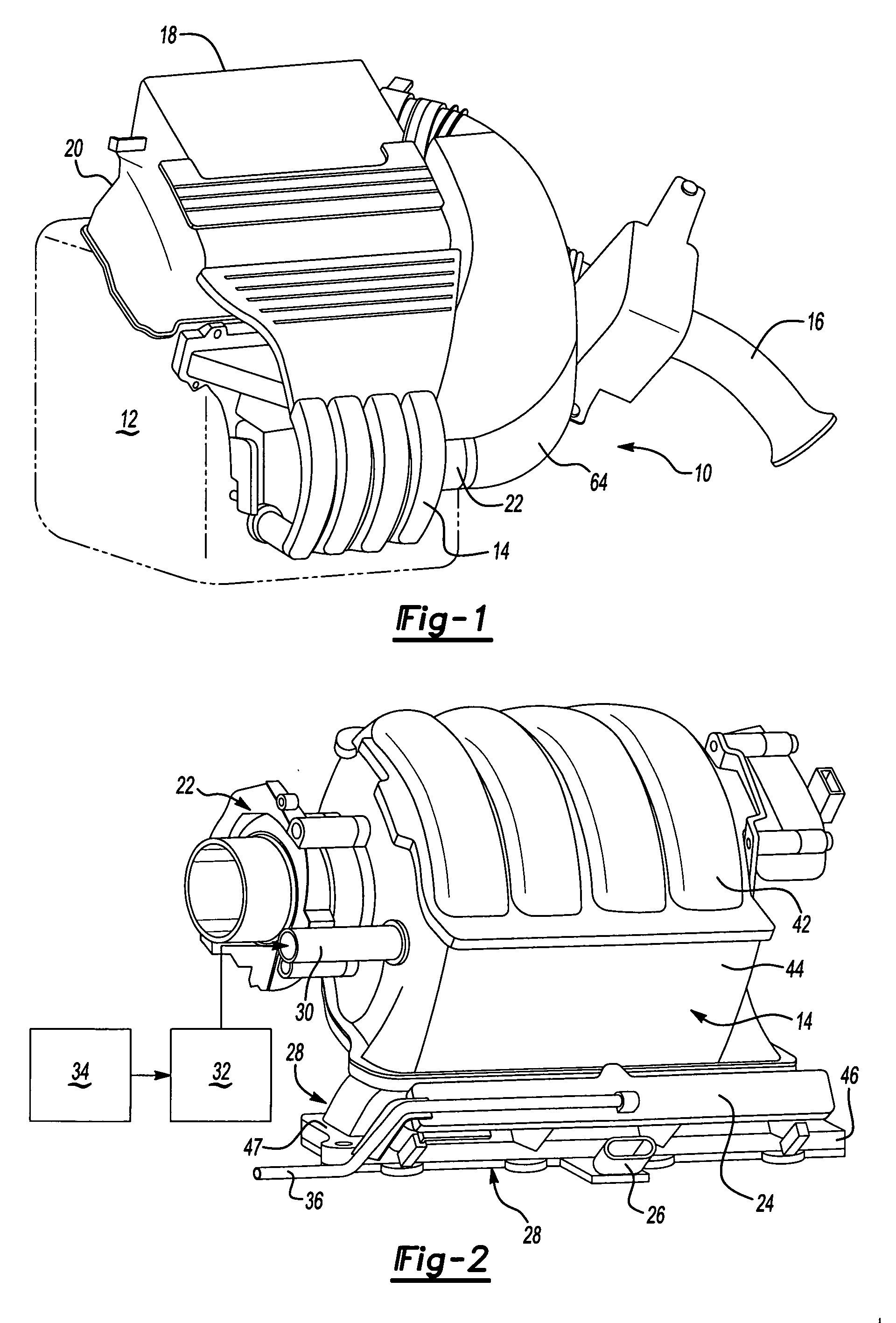

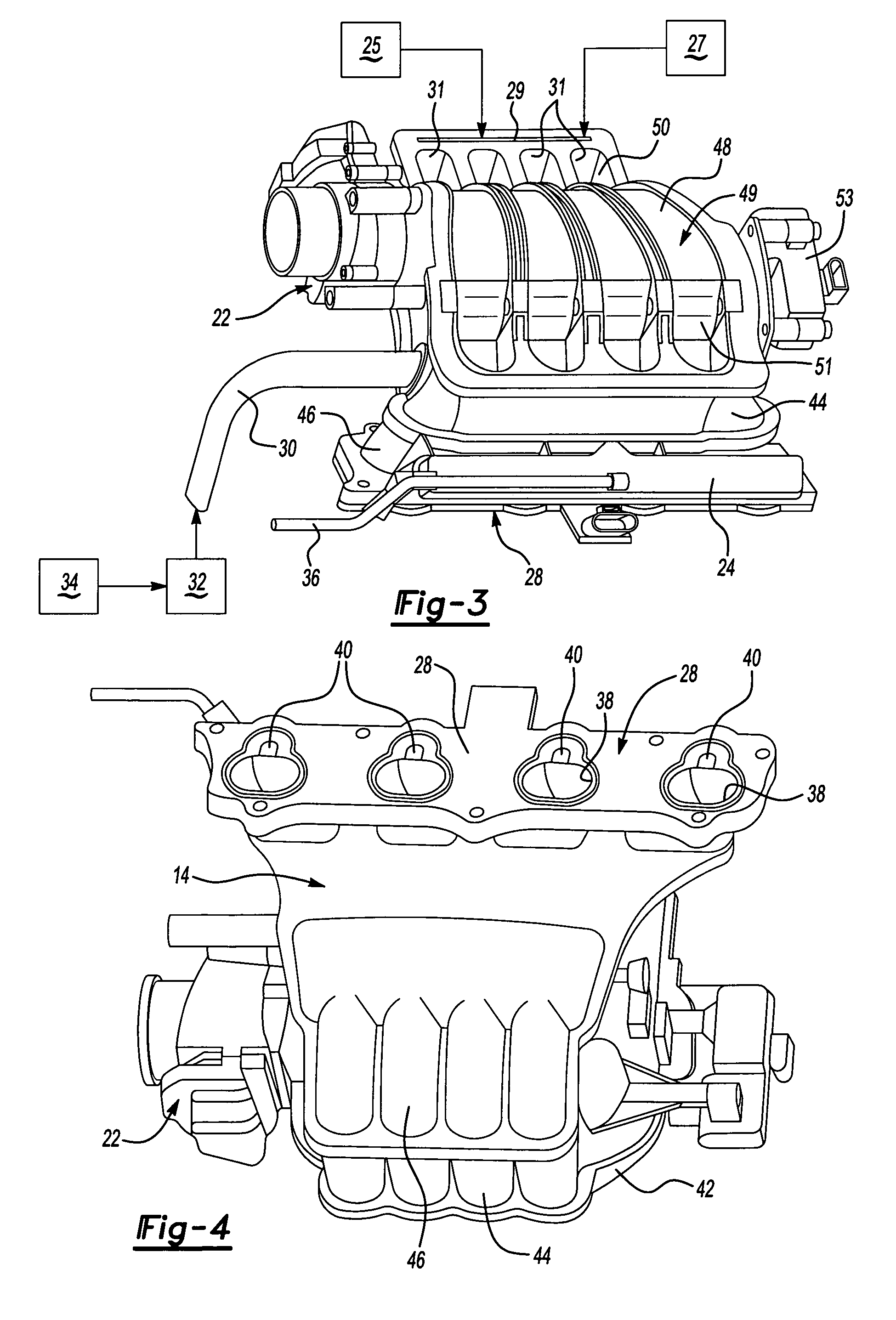

An intake assembly includes an intake manifold comprising several interfitting sections attached to each other to define a plurality of air passages, and an EGR conduit within the intake manifold including openings in communication with each of the plurality of air passages. The EGR conduit is in communication with a source of exhaust gases and provides for the proximate and decentralized injection of exhaust gases into the intake manifold assembly. The intake manifold assembly also includes a passage that is in communication with a positive crankcase ventilation system (PCV) and a purge gas system. Gases from the PCV system and the gas purge system mix in the passage and then are communicated to the each of the air passages through individual opening passages.

Owner:SIEMENS CANADA LTD

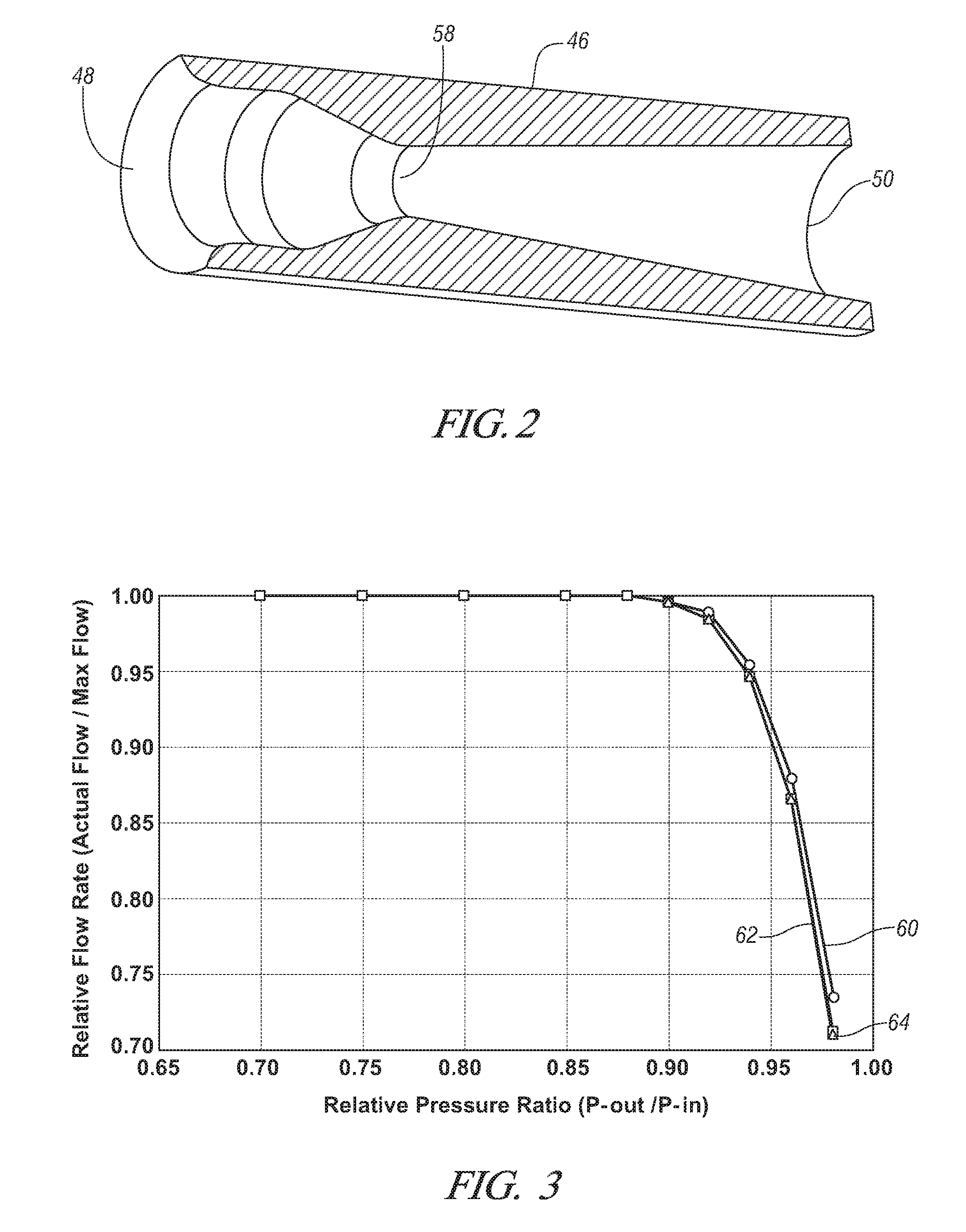

Crankcase ventilation system with pumped scavenged oil

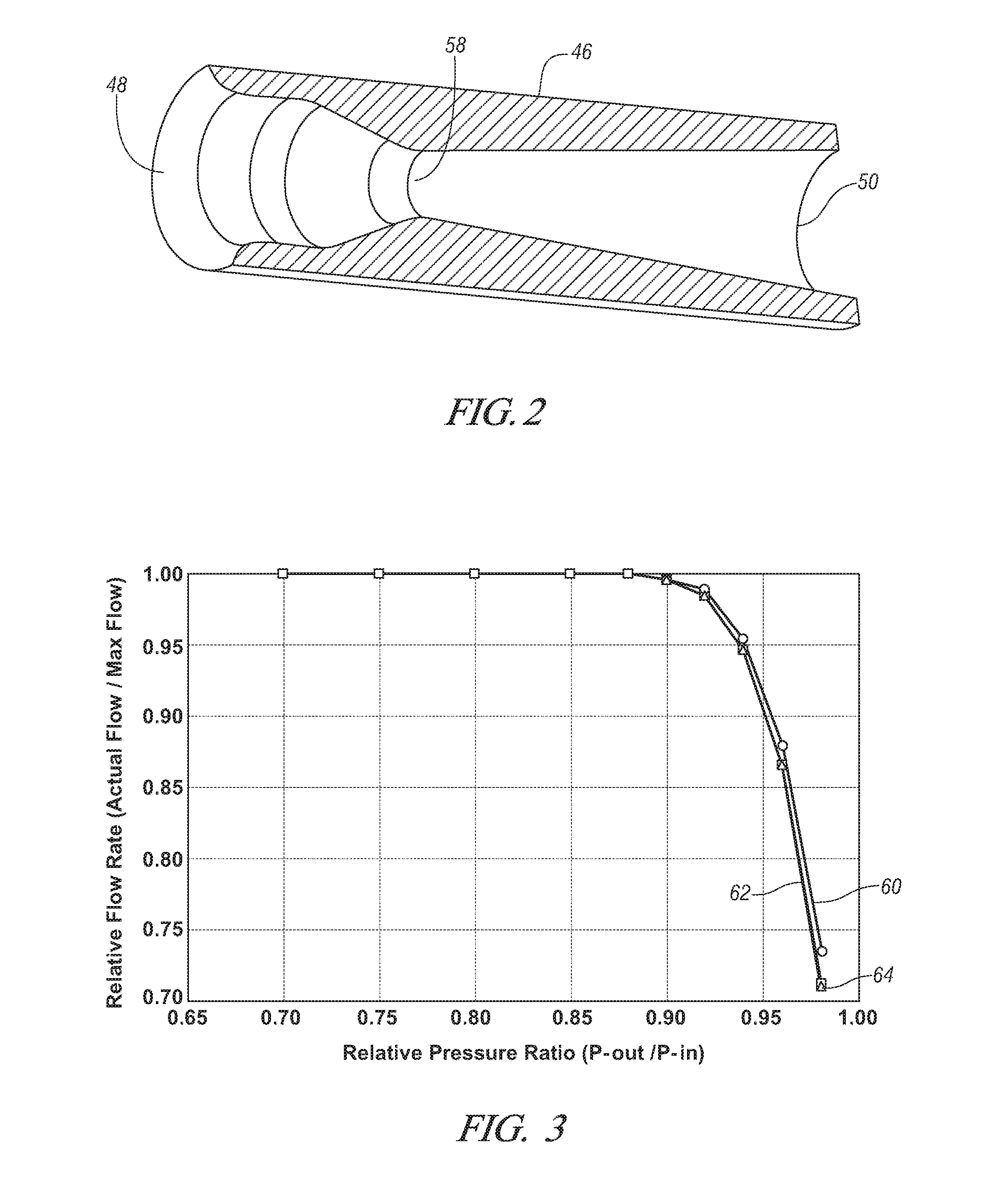

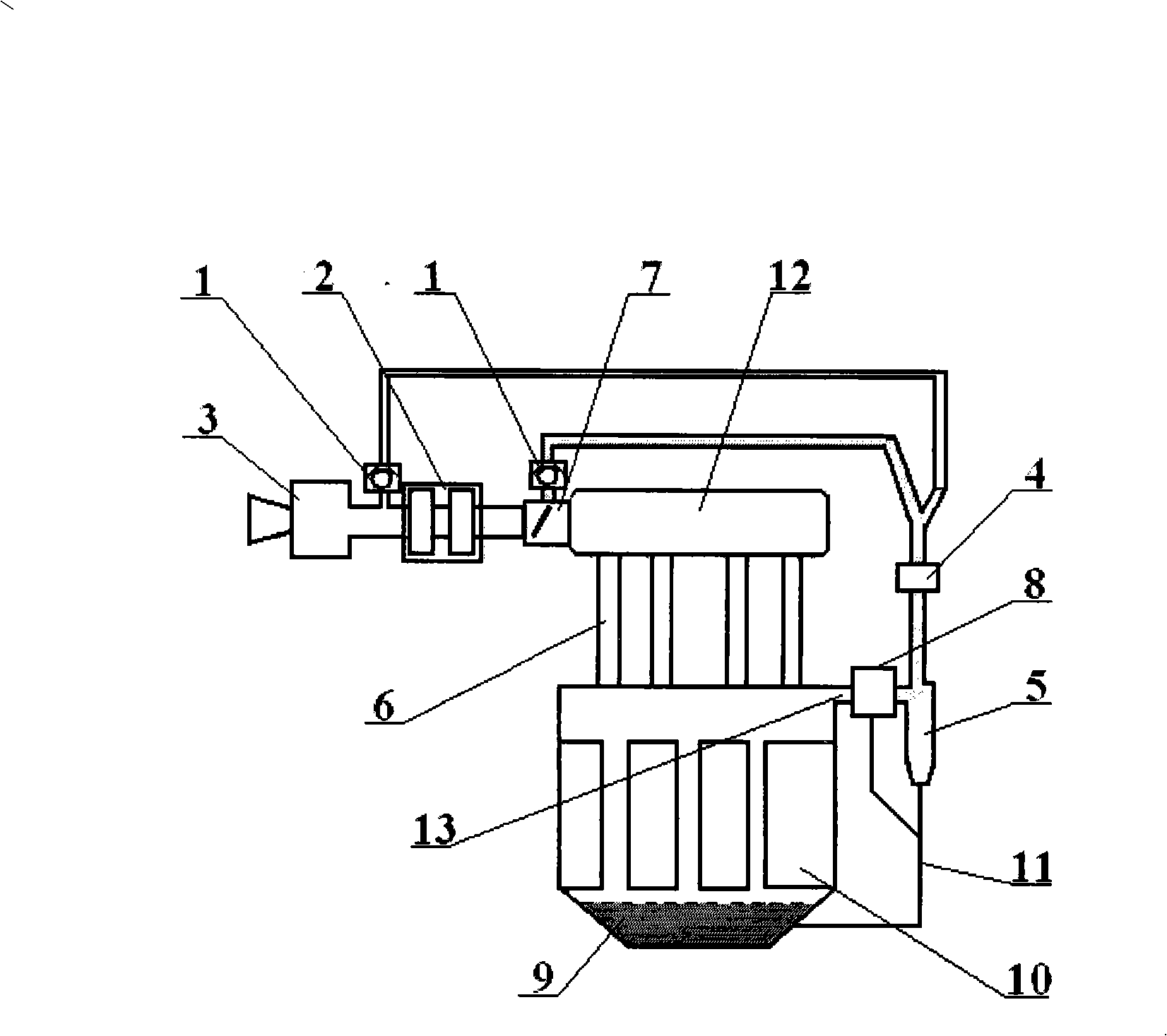

ActiveUS7699029B2The process is simple and effectiveDispersed particle filtrationCombustion enginesHigh pressurePressure difference

A crankcase ventilation system for an internal combustion engine has a jet pump suctioning scavenged separated oil from the oil outlet of an air / oil separator and pumping same to the crankcase. The jet pump supplies pumping pressure greater than the pressure differential between the higher pressure crankcase and the lower pressure oil outlet, to overcome such pressure differential and the back flow tendency otherwise caused thereby, and instead cause suctioning of scavenged separated oil from the oil outlet and pumping same to the crankcase.

Owner:CUMMINS FILTRATION IP INC

Crankcase Ventilation System with Engine Driven Pumped Scavenged Oil

InactiveUS20100043734A1The process is simple and effectiveSimple wayCombustion enginesCrankcase ventillationRelative pressureCrankcase ventilation system

A crankcase ventilation system for an internal combustion engine has an engine driven pump pumping scavenged separated oil from the oil outlet of an air-oil separator to the crankcase, preferably using engine generated pulsating oscillatory positive and negative relative pressure pulses.

Owner:CUMMINS FILTRATION IP INC

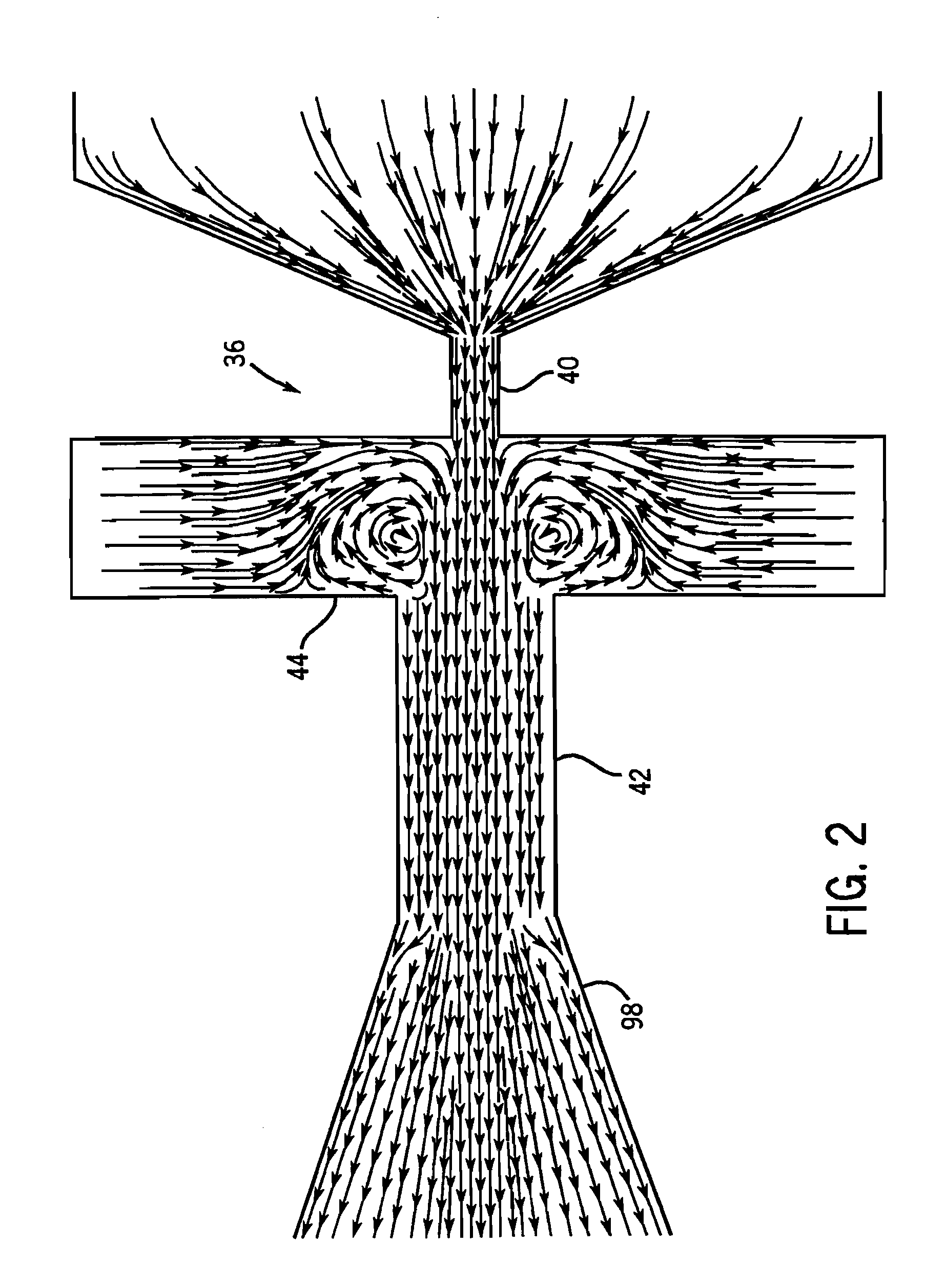

Device for eliminating oil particles from the crankcase ventilation gas in an internal combustion engine

ActiveUS20090199826A1Exhibit optimumPrevents degree of separationCombination devicesAuxillary pretreatmentDifferential pressureExternal combustion engine

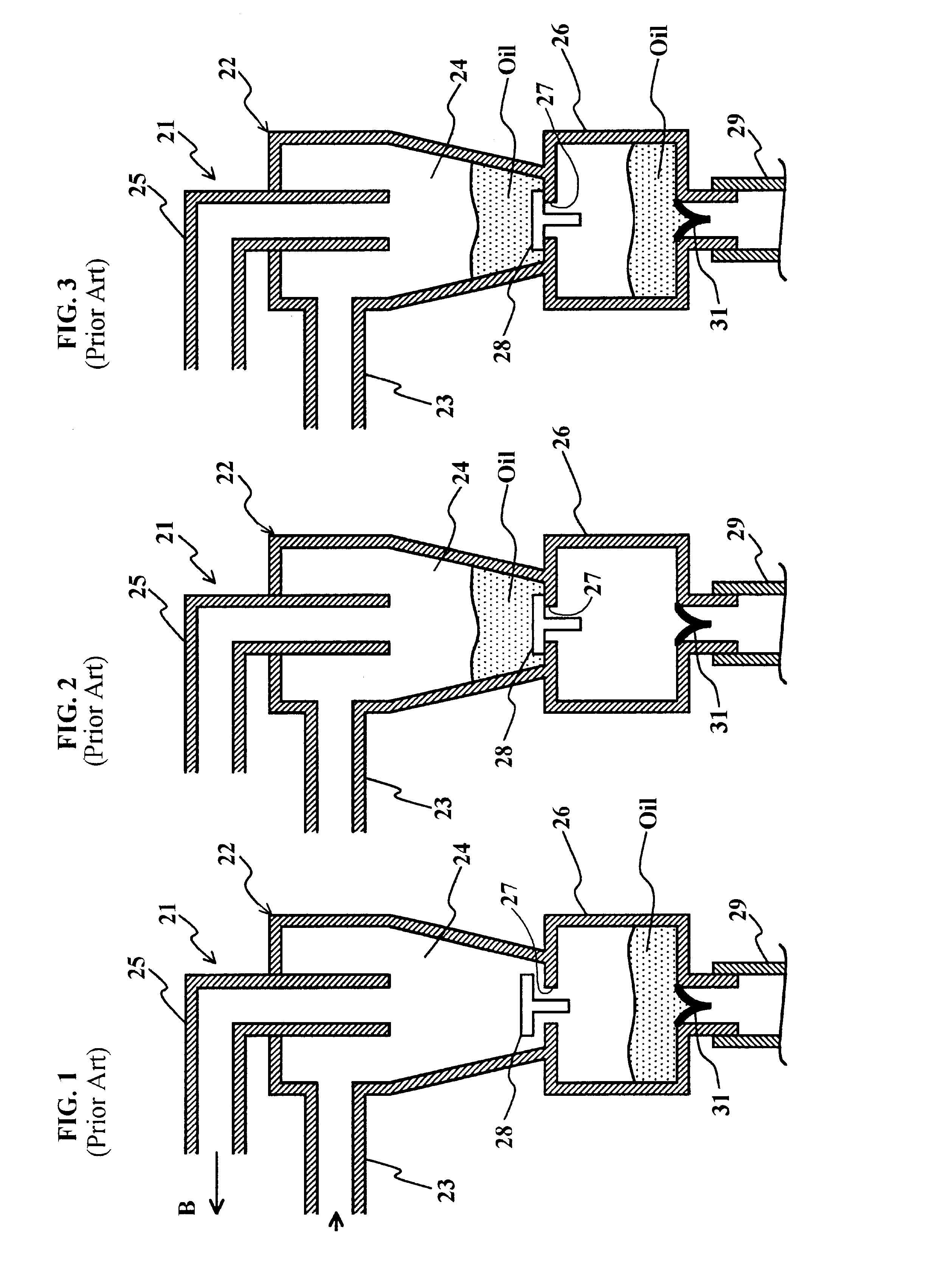

A device for eliminating oil particles from the crankcase ventilation gas of an internal combustion engine. The device is located in the flow duct of the gas that runs from the crankcase to an induction tract of the engine. The device includes an oil separator in the form of an outlet for the gas with a deflection of the flow, causing the oil particles to be deposited on a baffle surface and thus to be eliminated from the crankcase ventilation gas flow. The device has an infeed cross-section, which lies upstream of the baffle surface when viewed from the flow direction of the crankcase ventilation gas, and which is sub-divided into several infeed sub-sections. The baffle surface is a solid surface that is devoid of perforations. The baffle surface is configured on a valve body, which lies downstream of the infeed sub-sections when viewed in the flow direction of the gas, and which is pre-tensioned by a force. The valve body can be displaced in the opening direction in opposition to the pre-tension, as a result of the differential pressure in the gas between the crankcase and the induction tract.

Owner:HENGST WALTER

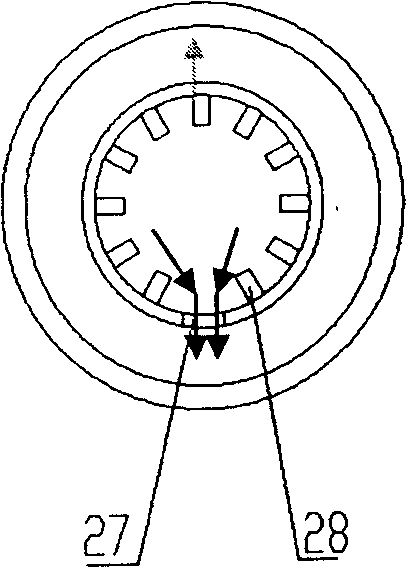

Corona discharge electrode assembly for electrostatic precipitator

InactiveUS20050028676A1High mechanical strengthSolution to short lifeParticle charging/ionising stationsElectrode constructionsElectricityCorona discharge

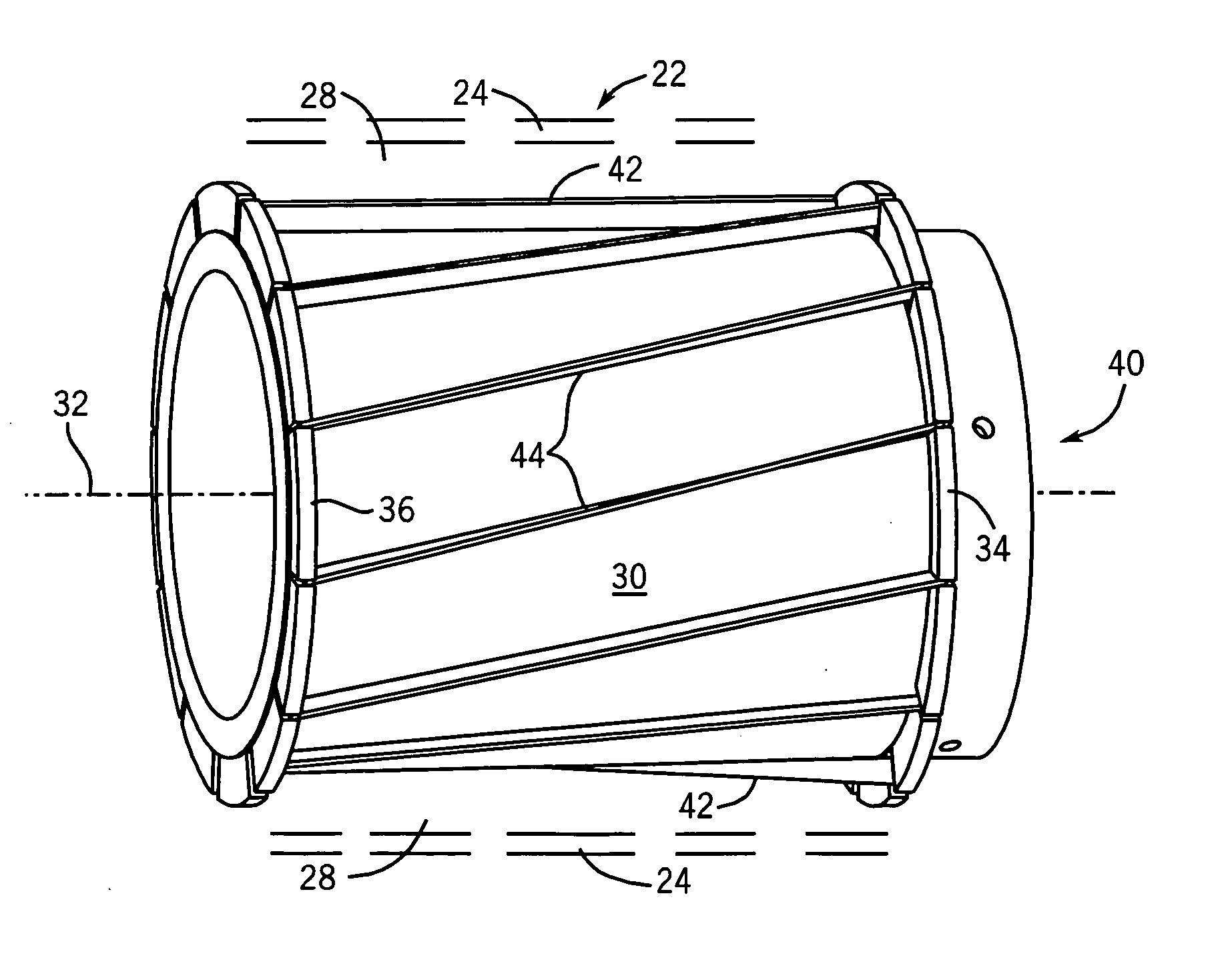

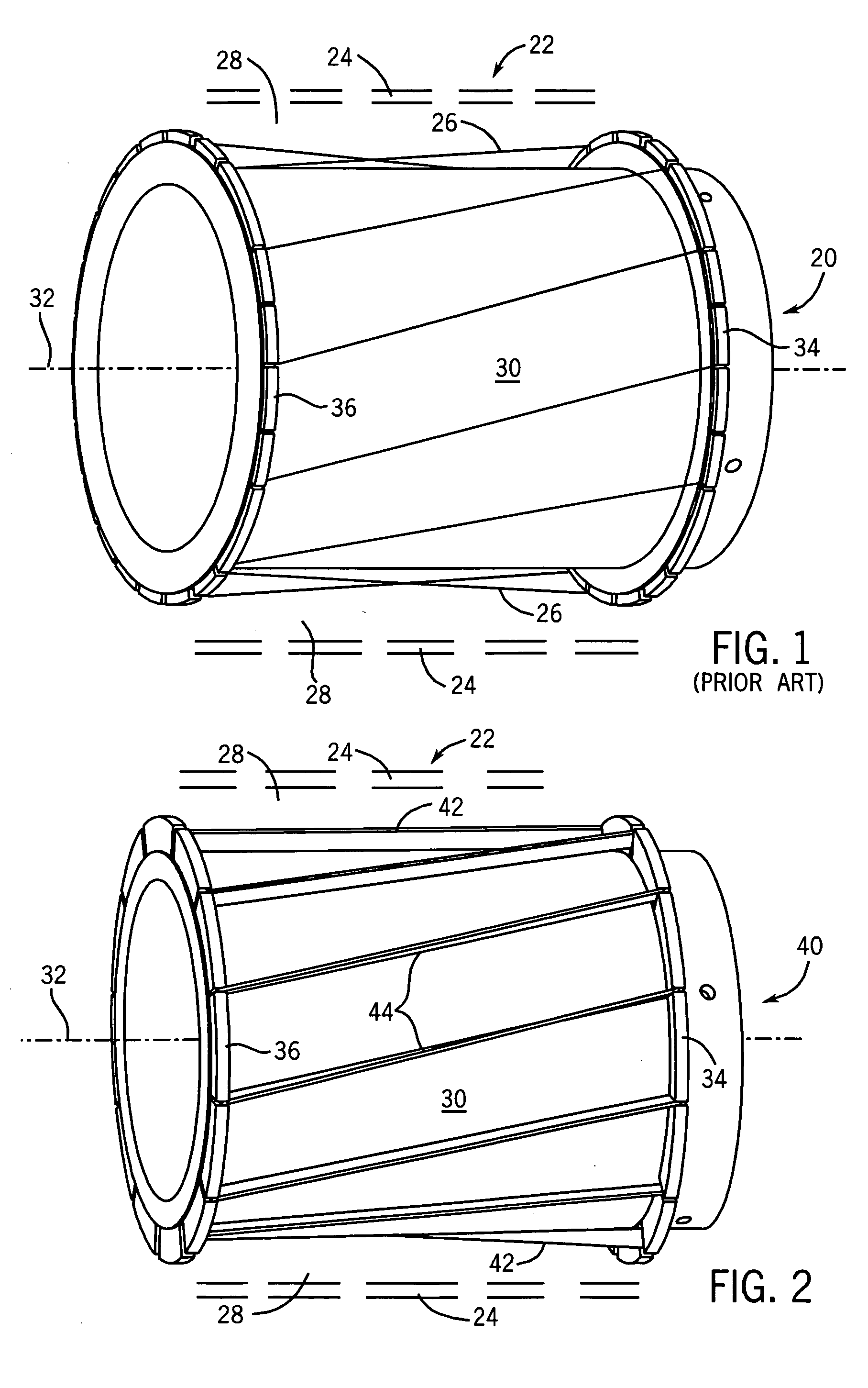

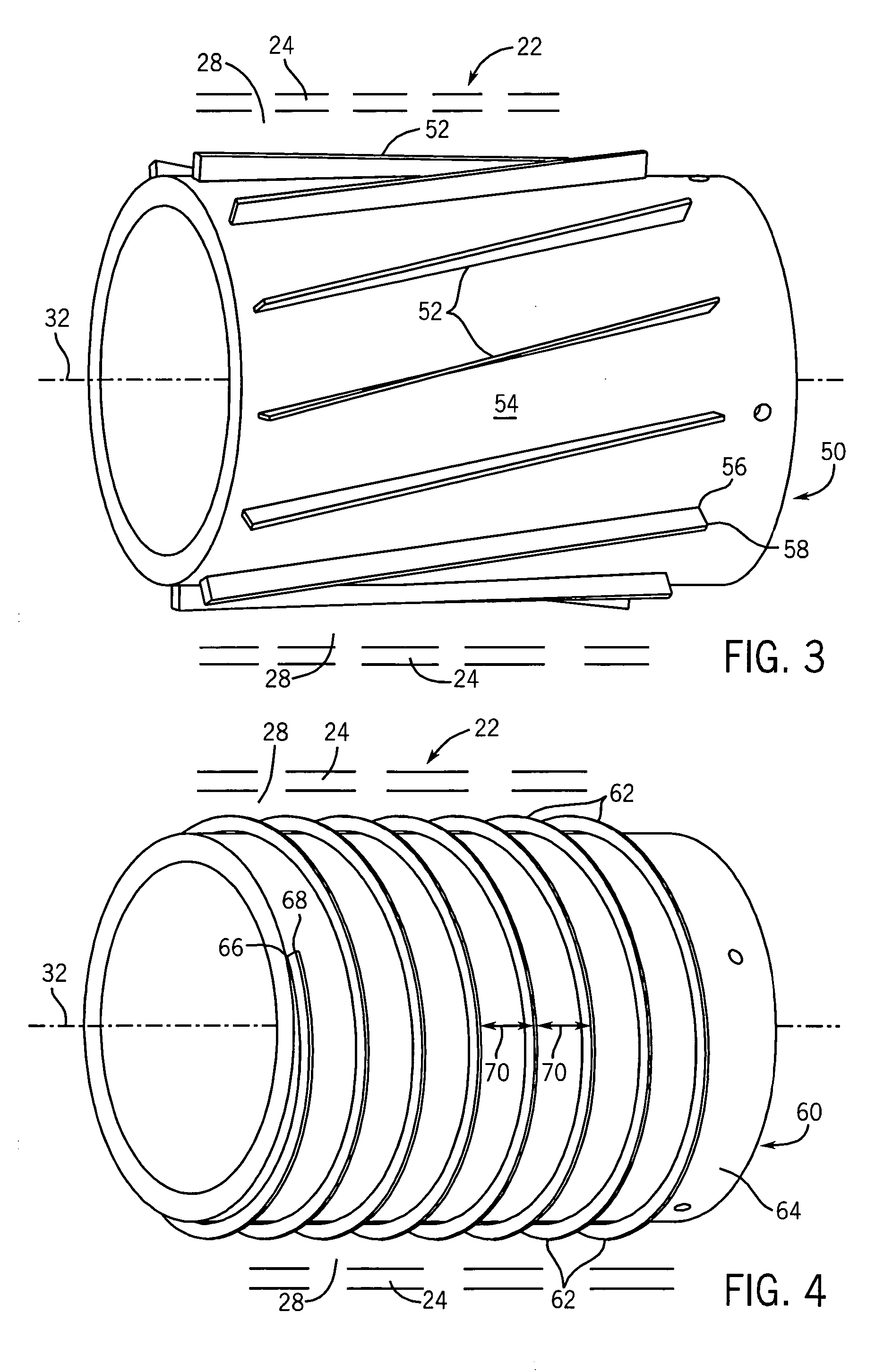

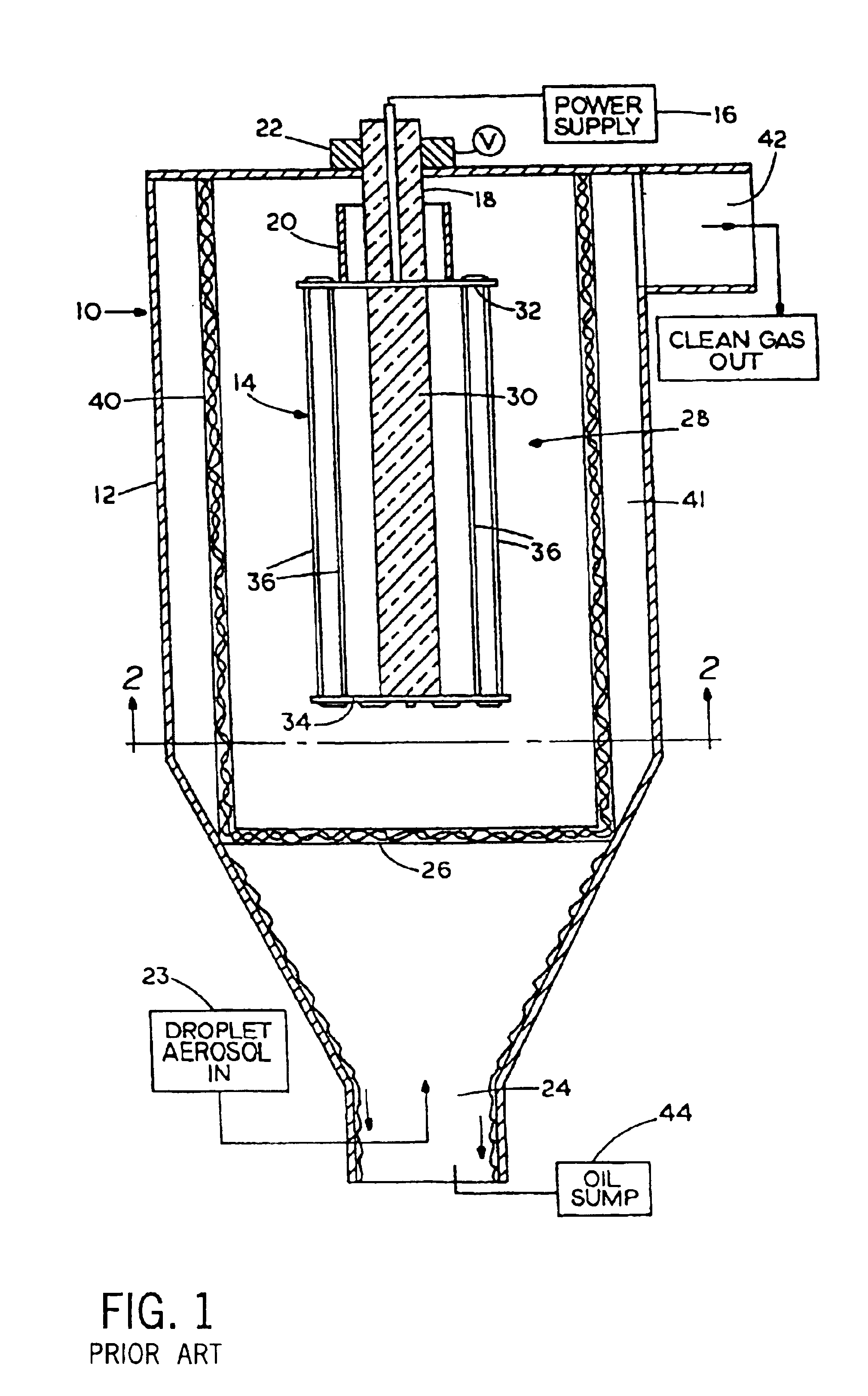

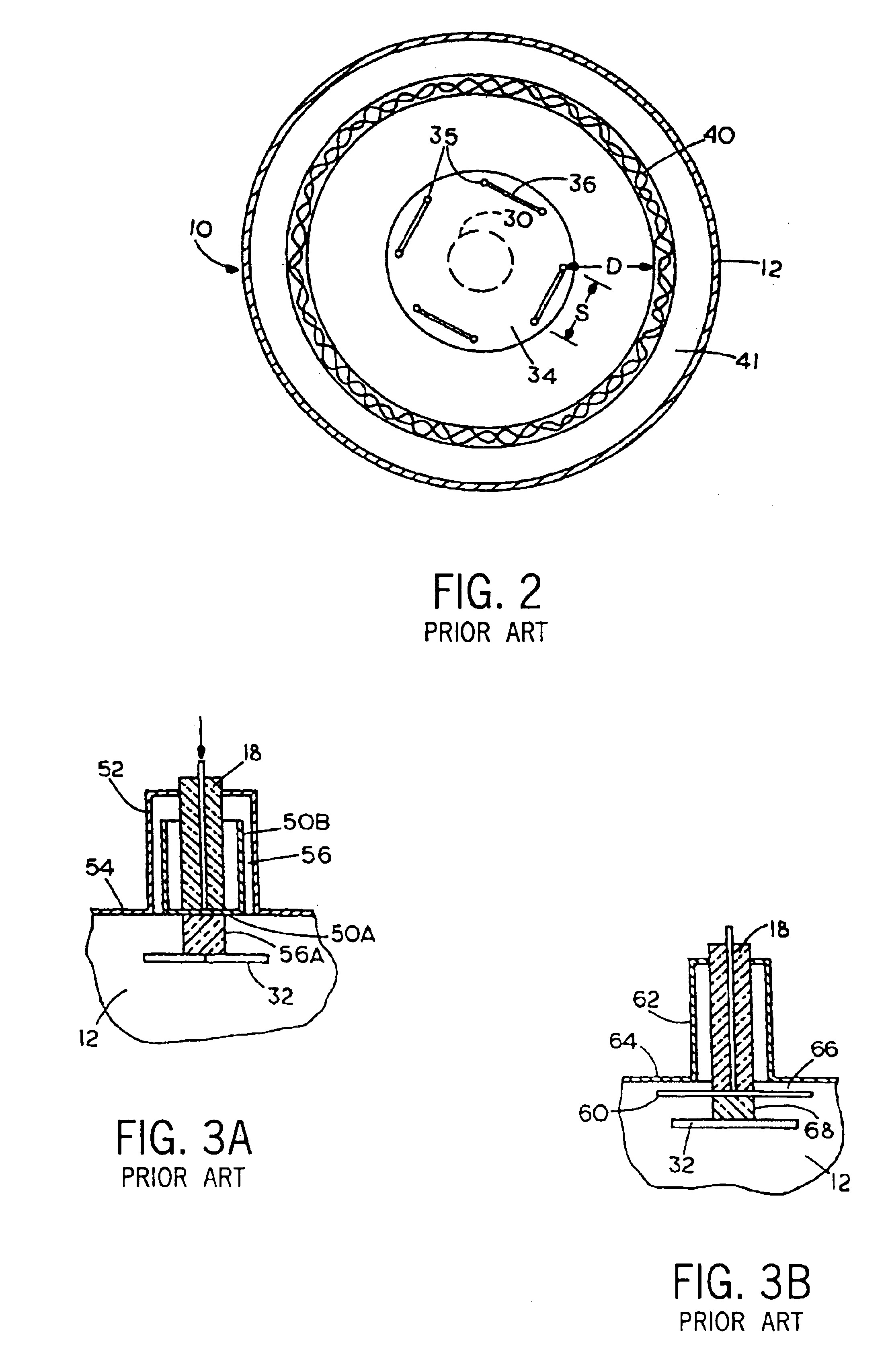

A corona discharge electrode assembly is provided for an electrostatic precipitator, including for a diesel engine electrostatic crankcase ventilation system for blowby gas, having a collector electrode spaced from a discharge electrode by a gap to facilitate corona discharge therebetween. The corona discharge electrode assembly includes a drum having strips, louvers or spikes providing corona discharge tips.

Owner:FLEETGUARD INC

Crankcase ventilation system

InactiveUS6892715B2Improve ventilationNon-fuel substance addition to fuelInternal combustion piston enginesInternal pressureCombustion

An improved crankcase ventilation system for a vehicle which includes an air compressor to route crankcase gases to the intake manifold for combustion. The primary vehicle components include and aircleaner, a turbocharger compressor positioned downstream from the aircleaner, an optional aftercooler positioned downstream from the turbocharger compressor, and an engine having an intake manifold and a crankcase equipped with a breather port for venting crankcase gases. Crankcase gases are vented through the breather port to the air compressor. Clean air from downstream of the aircleaner but upstream of the turbocharger compressor is drawn into the air compressor as needed to prevent the air compressor from drawing too much crankcase gas and reducing the internal pressure of the crankcase to undesirable levels. The pressurized crankcase gases are introduced into the intake air stream downstream of the aftercooler and upstream of the intake manifold so as to prevent fouling of the turbocharger compressor and aftercooler by contaminants in the crankcase gases. The crankcase gases are then combusted in the engine and not vented directly to the environment.

Owner:CUMMINS INC

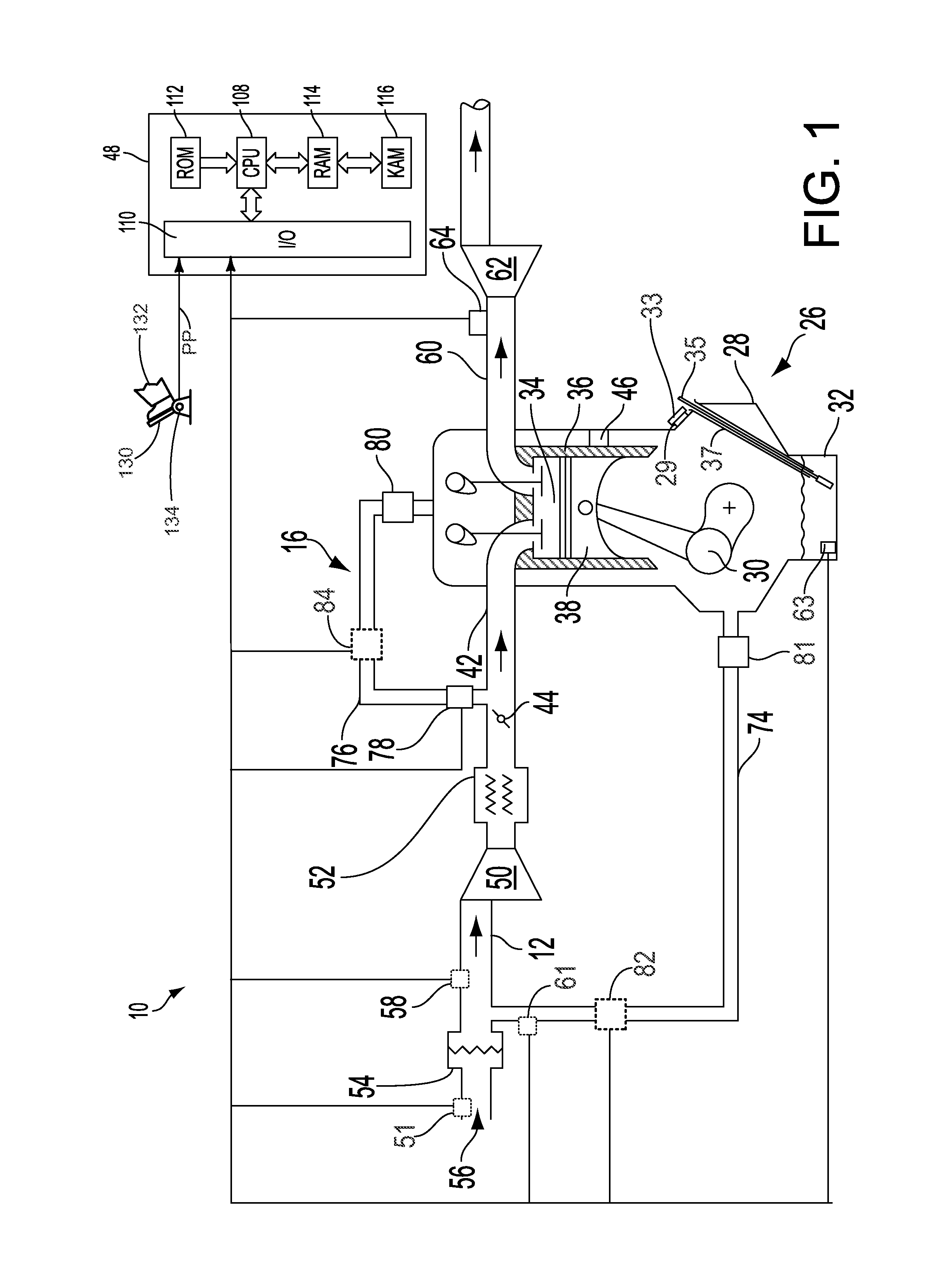

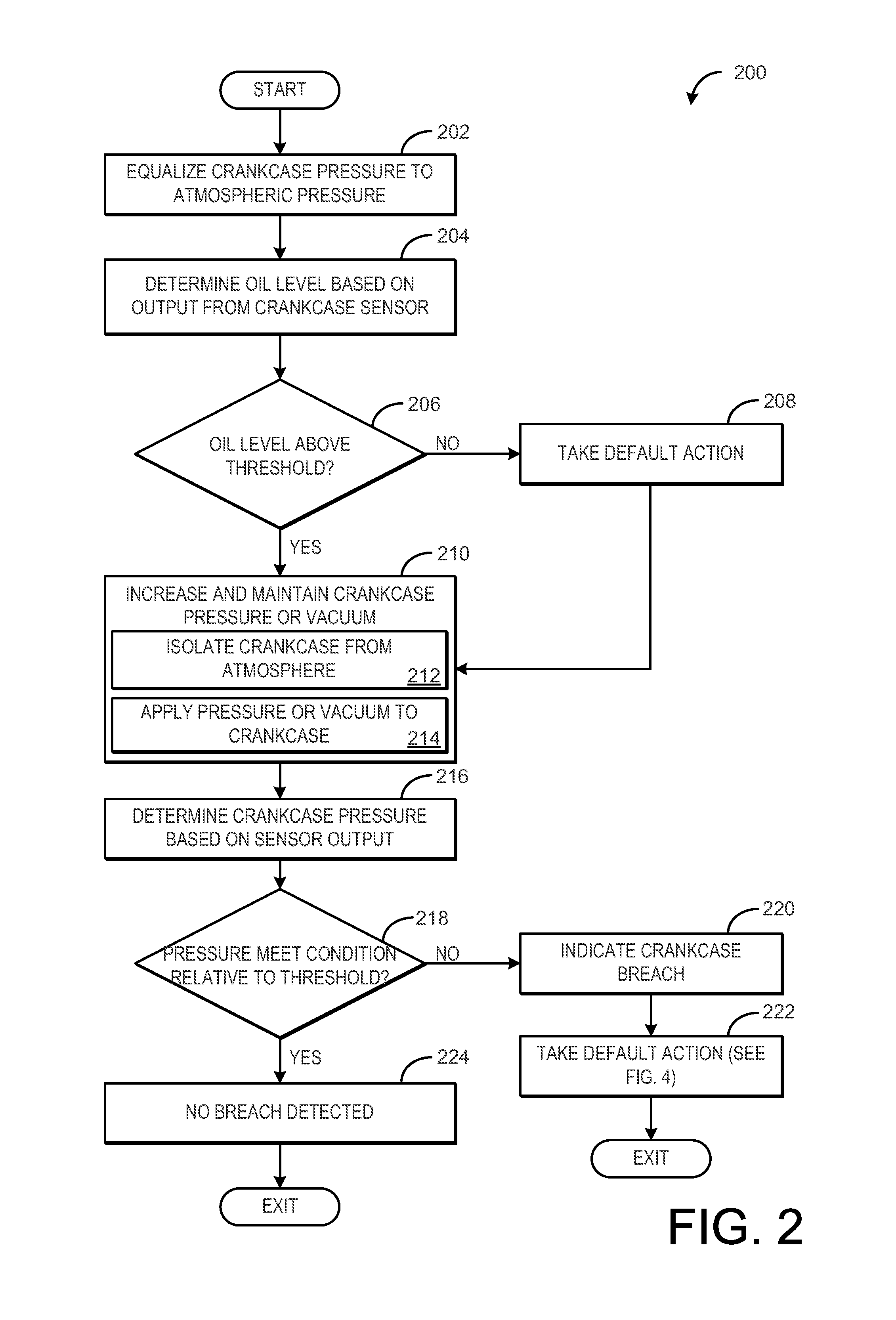

Method for determining crankcase breach and oil level

ActiveUS20130282255A1Reduce degradationIncreased complexityAnalogue computers for vehiclesInternal-combustion engine testingEngineeringCrankcase ventilation system

Embodiments for detecting crankcase breach are provided. In one example, a method includes indicating both crankcase ventilation system degradation and a crankcase oil sump level based on a common crankcase sensor. In this way, the same sensor can provide both crankcase breach detection and oil level determination.

Owner:FORD GLOBAL TECH LLC

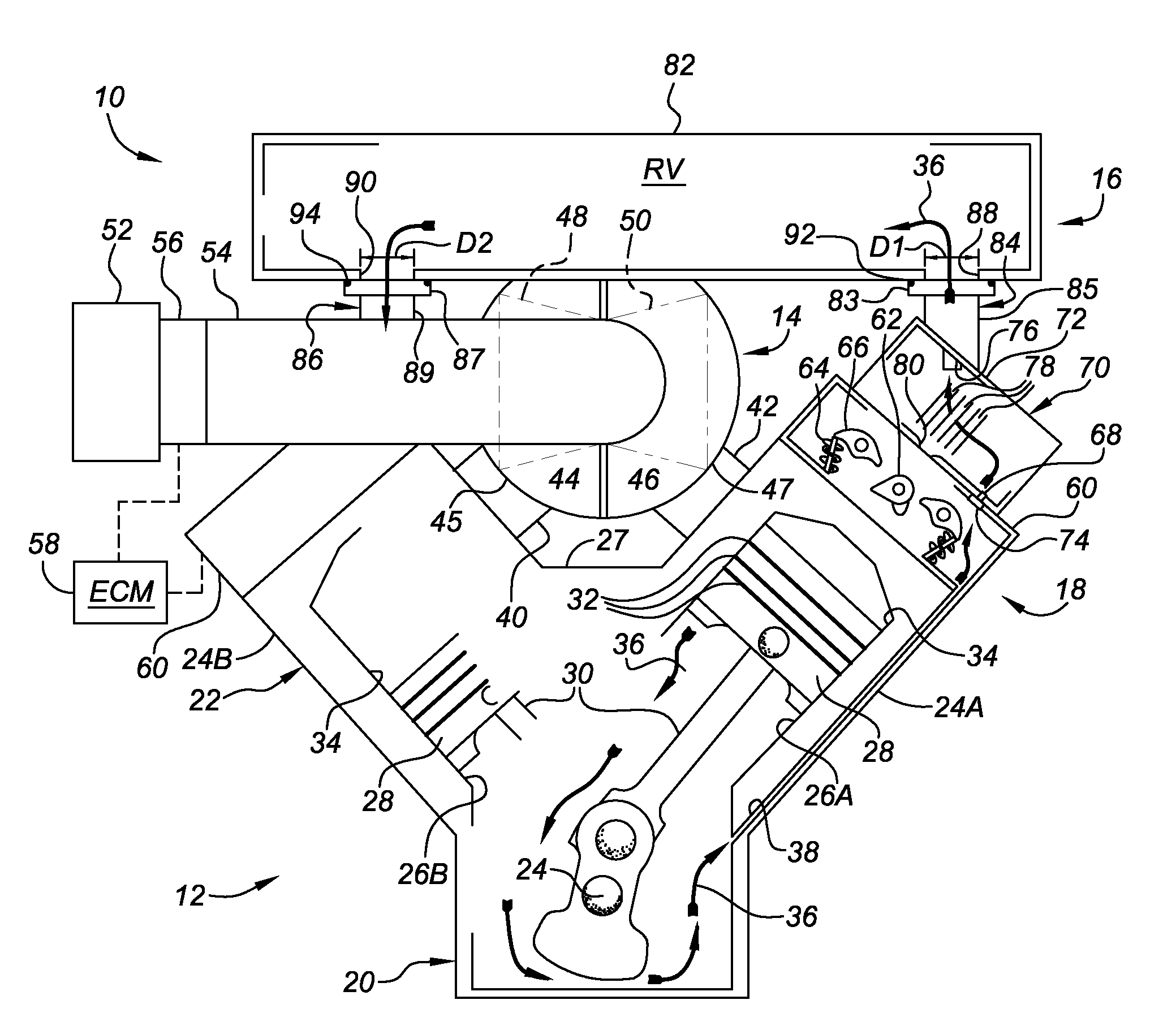

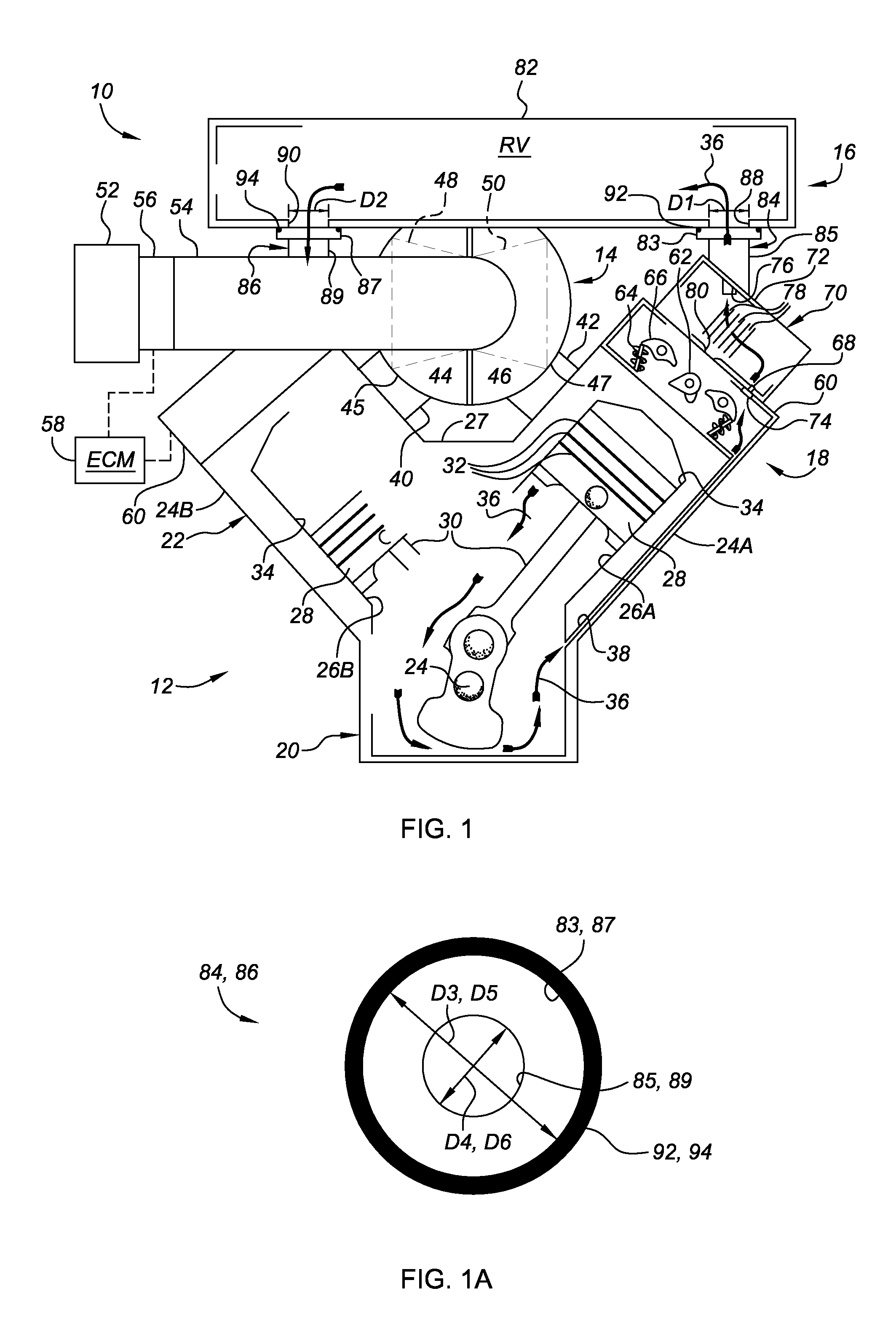

Resonator and crankcase ventilation system for internal combustion engine

ActiveUS20100071676A1Limit potential numberReduce the numberInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerMonobloc engine

The present invention provides a crankcase ventilation system and resonator for a turbocharged internal combustion engine assembly. The resonator, designed for intake noise reduction, is mounted to the engine. An oil separation unit, designed for passage of blowby gases, is mounted to a cam cover, sandwiched between the resonator and cam cover. The resonator has a resonator body defining a resonator volume therein. The resonator fluidly communicates the oil separation unit with the turbocharger air inlet pipe, whereby blowby gases are evacuated from the cam cover and delivered through the resonator volume for reintroduction to the engine's air intake system. Integration of the blowby passages into the resonator reduces the number of potential leak paths in the air induction system, and reduces overall engine mass, cost, and packaging size. The present design also offers improved On-board Diagnostics (OBD) by allowing only large flow areas to be disconnected.

Owner:GM GLOBAL TECH OPERATIONS LLC

Electrostatic precipitator with internal power supply

InactiveUS6902604B2Prevent moisturePrevent contaminant accumulationCombination devicesIsotope separationElectricityLow voltage

An electrostatic precipitator, including for a diesel engine electrostatic crankcase ventilation system for blowby gas, includes a corona discharge electrode assembly in a housing, an insulator extending along an internal surface of a wall of the housing, a power supply in the housing on the opposite side of the insulator from the housing wall such that the insulator is between the housing wall and the power supply, and a low voltage lead extending through the housing wall and through the insulator to the power supply, eliminating pass-through of a high voltage lead through the housing wall and through the insulator. The power supply is preferably provided in the hollow interior of the corona discharge electrode assembly.

Owner:CUMMINS FILTRATION INC +1

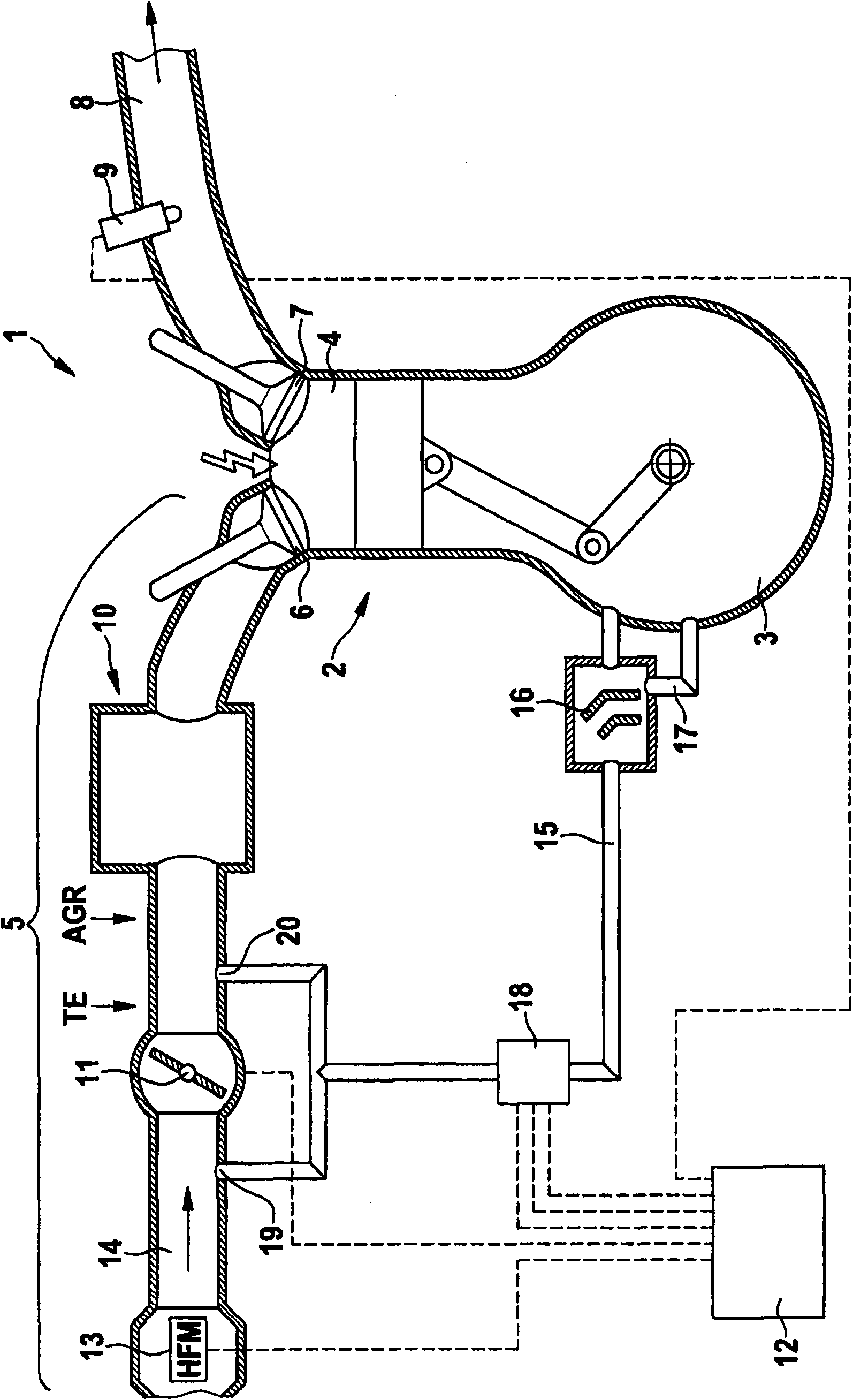

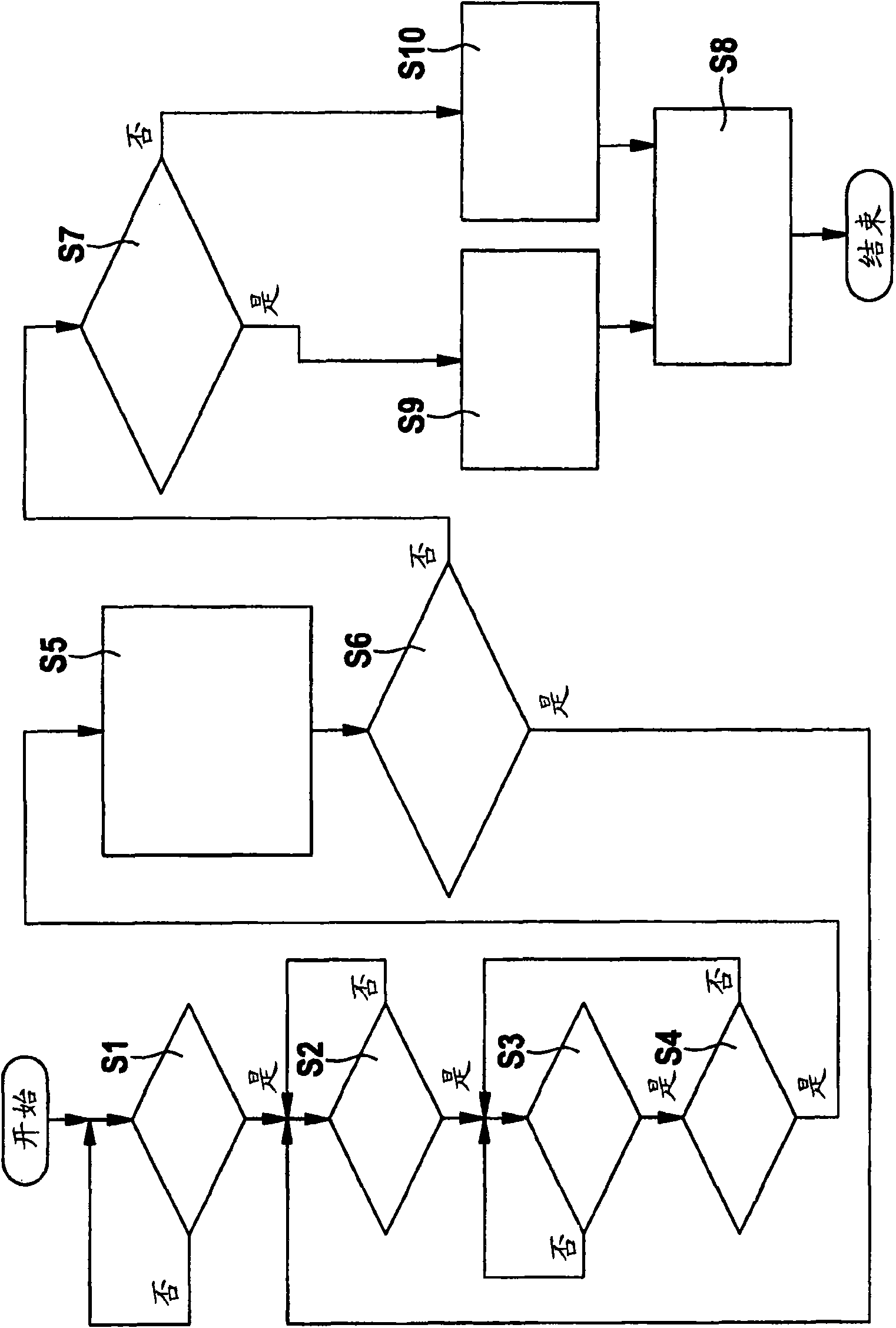

Method and device for diagnosing the ventilation in crankcase of internal combustion engine

InactiveCN101614144ADetermine the faultAvoid no changeElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

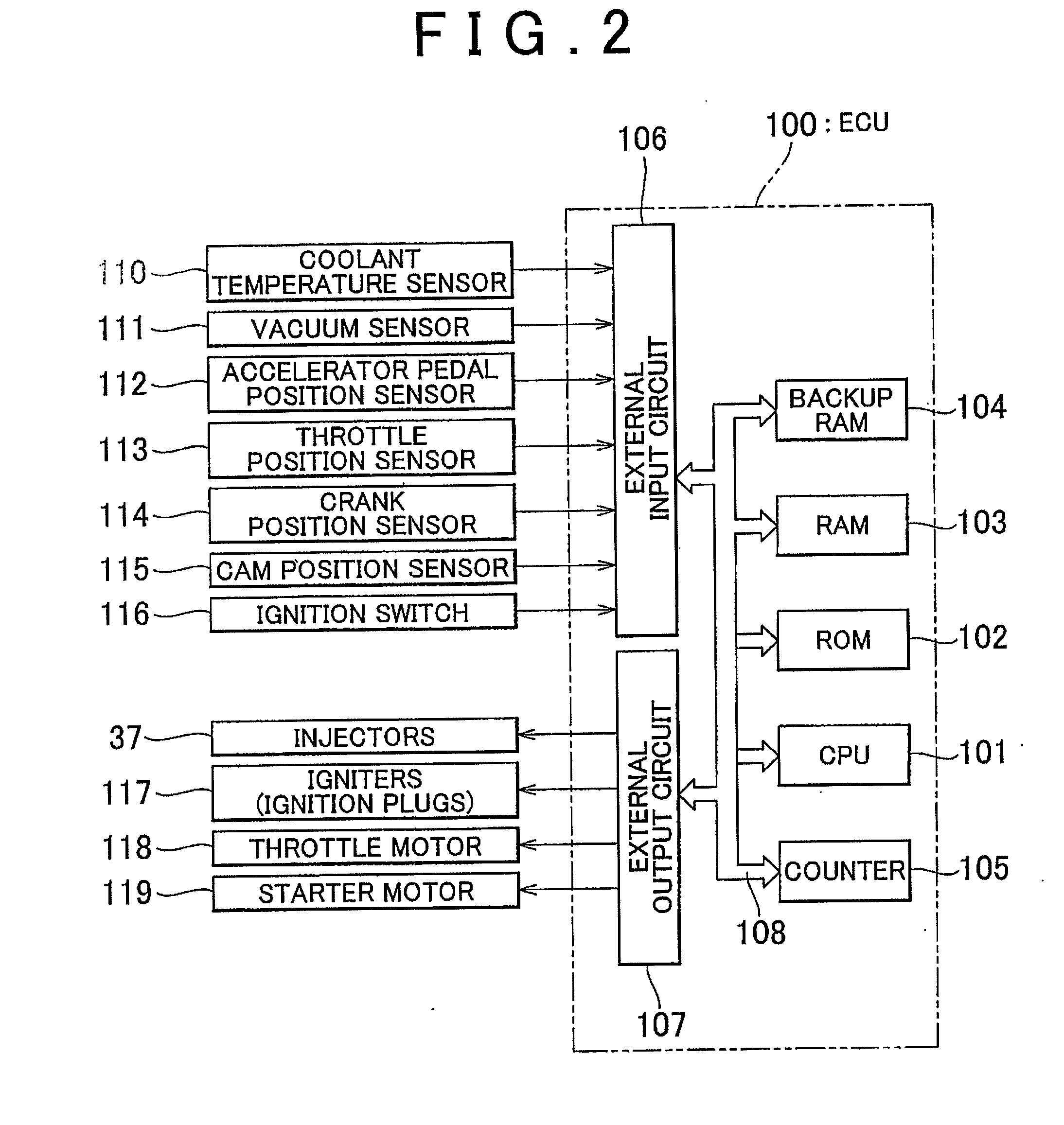

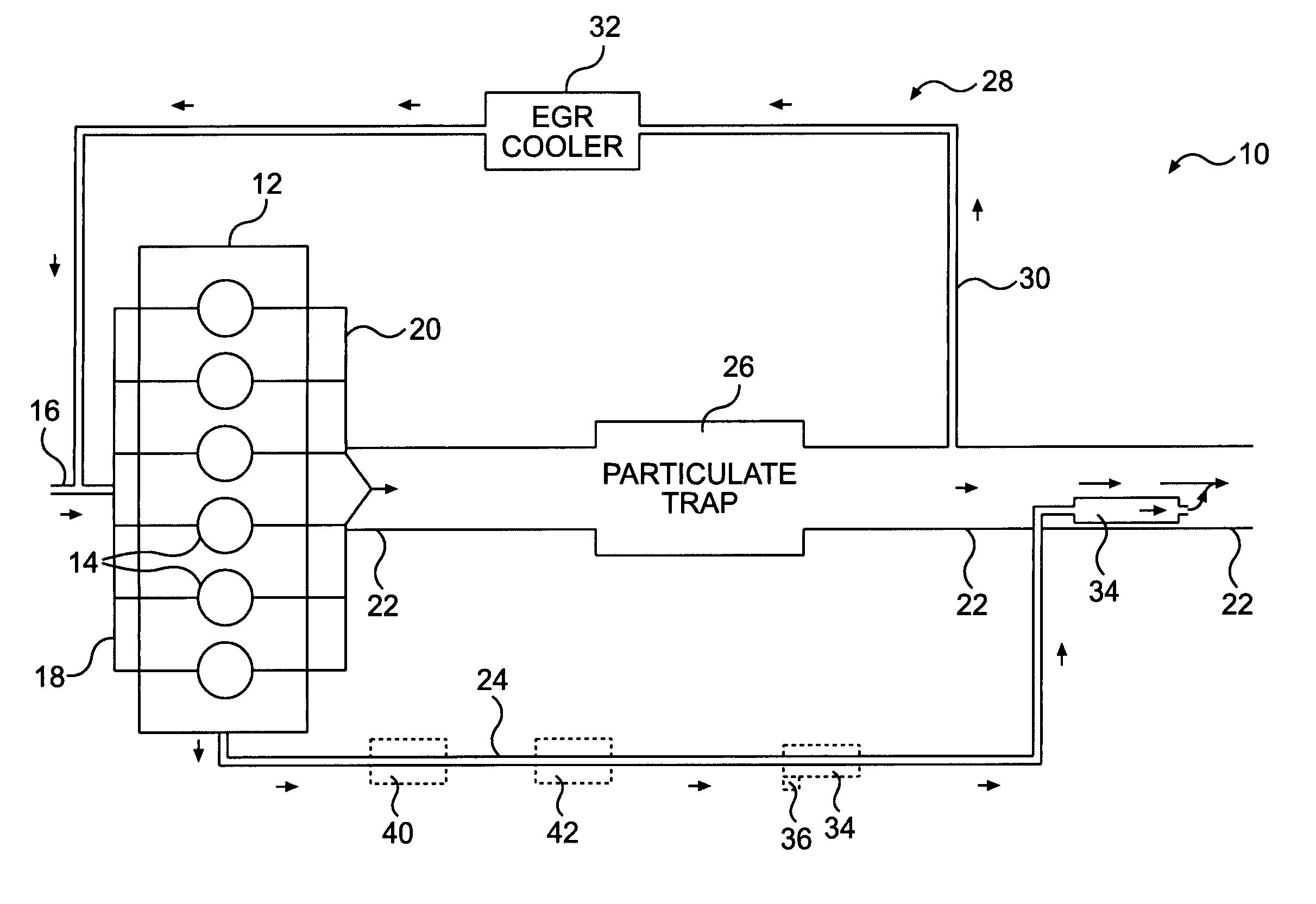

The invention relates to a method and a device for diagnosing the ventilation in a crankcase of an internal combustion engine. The invention relates to a method for detecting the function of a crankcase ventilation system of an engine system with the internal combustion engine, wherein, the method comprises the following steps of: blocking off a ventilation pipeline between the crankcase of the internal combustion engine and an air system during the duration of detection; determining the variation of operating parameters of the internal combustion engine during the duration of detection; and determining the failure of the crankcase ventilation system in virtue of the determined variation of the operating parameters.

Owner:ROBERT BOSCH GMBH

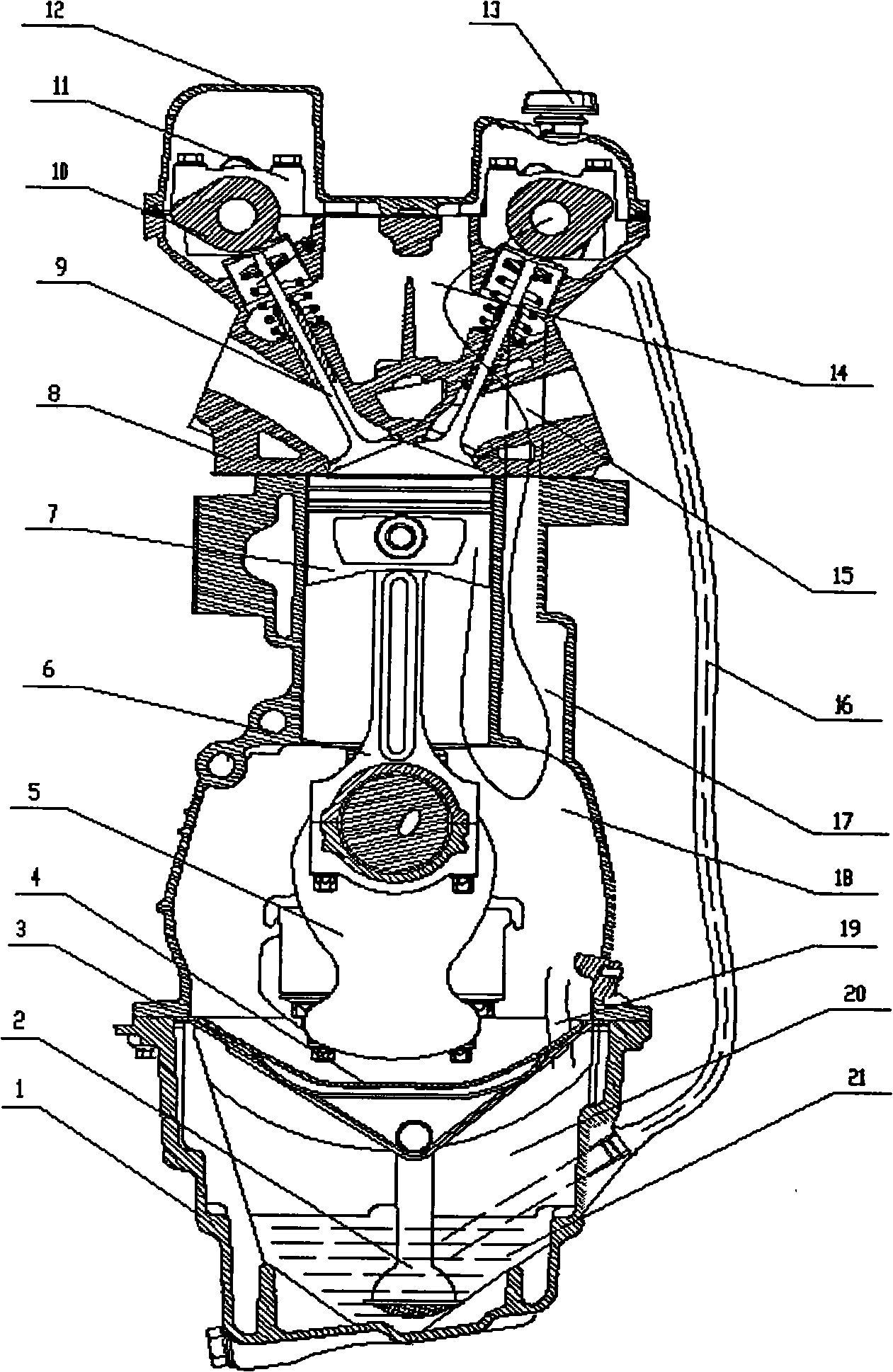

Engine PCV system with venturi nozzle for flow regulation

ActiveUS7431023B2Low costSimple designNon-fuel substance addition to fuelCombustion enginesVacuum pressureStreamflow

A positive crankcase ventilation system for an internal combustion engine is disclosed. The system includes an engine having a cylinder air intake system connected to associated cylinders and a filtered air inlet to a crankcase for admitting air to mix with crankcase vapors. A throttle is disposed in the cylinder air intake system for controlling airflow to the associated cylinders. The system further includes a venturi nozzle having an inlet and an outlet. The venturi nozzle inlet is connected to the crankcase for receiving the mixture of filtered air and crankcase vapors. The venturi nozzle outlet is connected to the cylinder air intake system at a location subject to variable intake vacuum pressure between the throttle and the cylinders to allow the mixture of filtered air and crankcase vapors to be drawn into the inlet air passing to the cylinders downstream of the throttle.

Owner:GM GLOBAL TECH OPERATIONS LLC

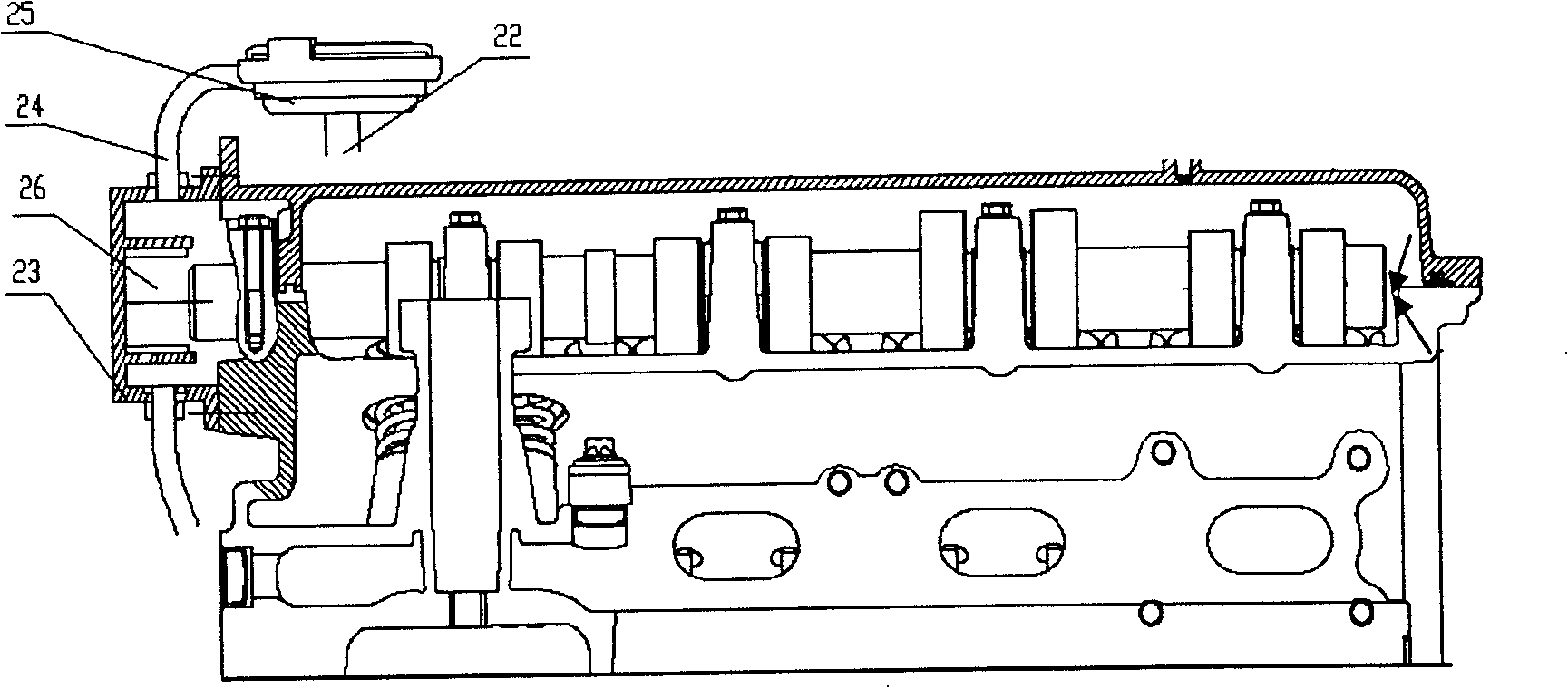

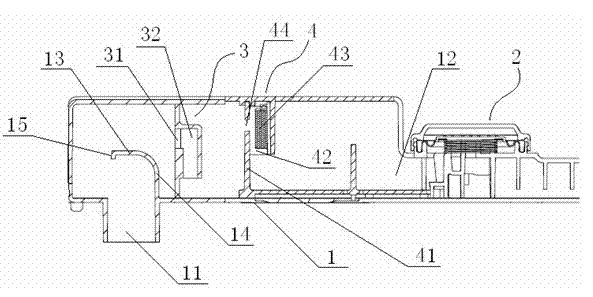

Gas oil separation structure of internal combustion engine crankcase ventilation system

InactiveCN101270683ASeparation is sufficient and effectiveFully effective separabilityMachines/enginesCrankcase ventillationCombustionCylinder head

The invention relates to gas-oil dissociation structure of a ventilating system of an internal-combustion engine crankcase, comprising a cylinder head, a camshaft cover and a camshaft. One end of the camshaft extends and outstretches the cylinder head that is covered by an end cap. The end cap and the cylinder head are fixed to form an impact dissociation chamber with the cylinder head and the camshaft. The bottom of the end cap is provided with an impact slot. The upper and the lower sides of the end cap are provided with a gas vent and an oil-returning opening. The gas vent upwards goes through an air channel and enters a PCV valve. The oil-returning opening downwards goes through an oil-returning pipe and is connected with the engine oil chamber of the crankcase. The structure of the camshaft is hollow with a rotary dissociation chamber formed in middle. The end of the rotary dissociation chamber facing one end of the end cap is an air outlet and the other end of the rotary dissociation chamber is an air inlet. A plurality of pores are distributed among the middle part of the camshaft that are communicated with the rotary dissociation chamber and a valve chamber. The gas-oil dissociation structure leads the inter-combustion engine to higher efficiency of gas-oil dissociation. On the premise that the pressure of the crankcase is ensured to be in line with state rules, the consumption of lubricant is lower.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Engine crankshaft ventilation system

InactiveCN1924308AAvoid damageImprove reliabilityMachines/enginesCrankcase ventillationCrankshaftPetroleum engineering

This invention discloses one motor curve shaft ventilating system, which comprises PCV valve, oil and gas isolator and pipe path, wherein, it leads out oil gas into oil and gas isolator from curve shaft case gas cover then through PCV valve into gas-in branch tube into oil bottom shell; the isolator and oil bottom tube path are set with single valve; at high speed of motor, gas enters pressure increasing device with one single valve fixed between gas tube and oil and gas isolator.

Owner:CHERY AUTOMOBILE CO LTD

Hydrogen augmented diesel crankcase ventilation

InactiveUS20070157911A1Prevent backflowInternal combustion piston enginesNon-fuel substance addition to fuelHydrogenEngineering

A hydrogen augmented diesel crankcase ventilation system uses hydrogen to allow crankcase fumes, for example blow-by, to be burned by the engine. The system preferably includes a hydrogen generation system as a hydrogen source connected to an engine air intake by a first hose, a second hose connecting the crankcase to the air intake, and a third hose connecting a fresh air source to the crankcase. An orifice or a vacuum regulator in cooperation with the second hose may be included to regulate crankcase vacuum. A filter may reside inline with the second hose to capture solids or liquids which enter the second hose from the crankcase. A back flow preventor may be included in cooperation with the third hose to prevent a back flow of crankcase fumes through the third hose.

Owner:RICHARDSON JAMES M

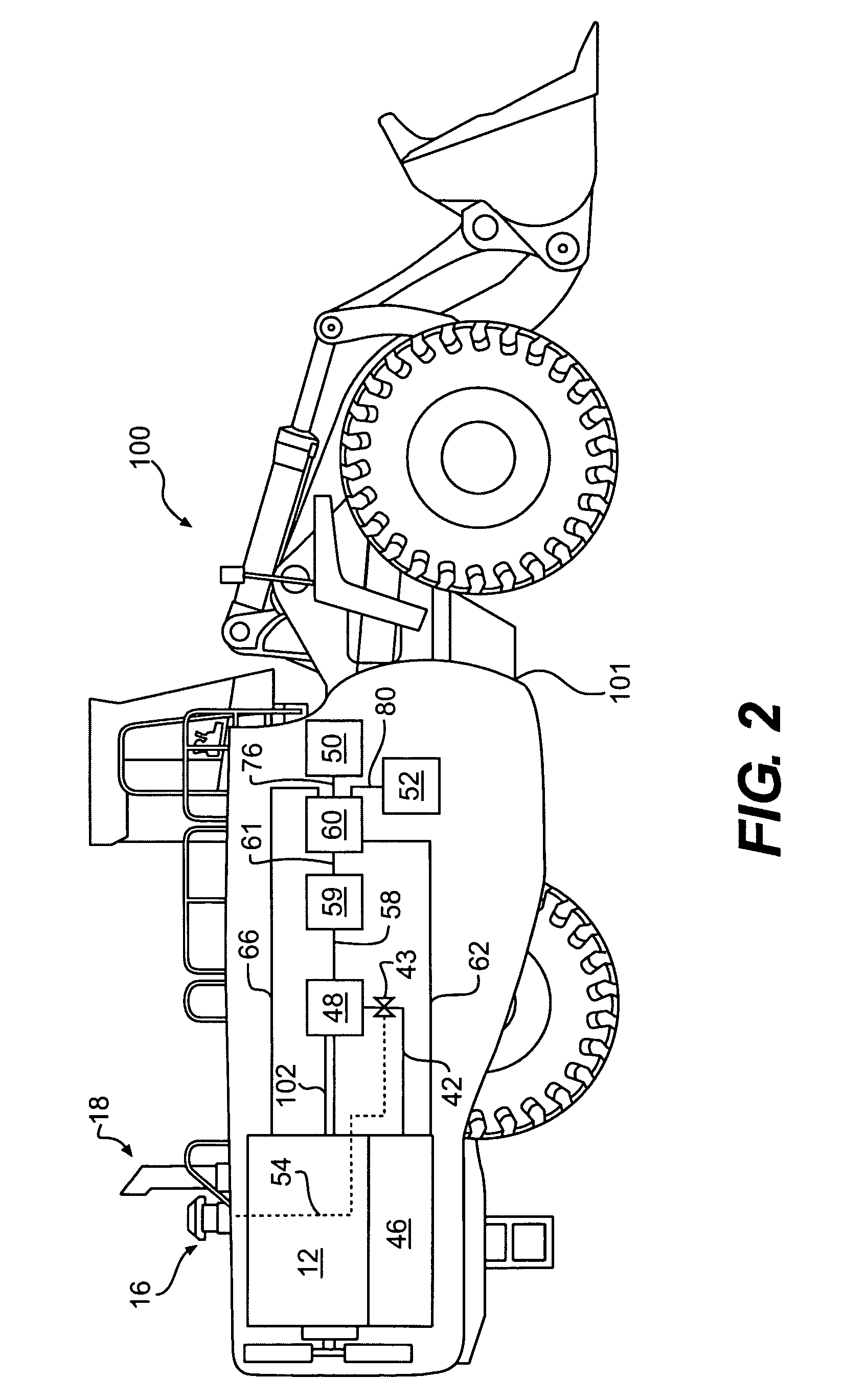

Closed crankcase ventilation system

InactiveUS20070107709A1Improve ventilationHigh trafficInternal combustion piston enginesNon-fuel substance addition to fuelGuide tubeCrankcase ventilation system

A closed crankcase ventilation system for an internal combustion engine is disclosed. A compressor is configured to compress air and enhance the venting of crankcase emissions from a crankcase of the engine. A flow path is provided between the crankcase and an intake of the compressor. A prioritizing device is situated in the flow path and configured to regulate the flow of crankcase emissions and control pressure within the crankcase. A treatment element is provided downstream of the compressor and configured to treat the compressed air and crankcase emissions to remove entrained oil. A first conduit downstream of the treatment element is configured to introduce a first portion of the compressed air and crankcase emissions into one of an exhaust system for the engine and an air intake system for the engine. A second conduit downstream of the treatment element is configured to introduce a second portion of the air and crankcase emissions into a system having at least one component utilizing compressed air for its operation.

Owner:CATERPILLAR INC +1

System and method for gas purge control

ActiveCN104121087AForced ventilationElectrical controlInternal combustion piston enginesControl systemExhaust gas recirculation

Systems and methods for providing vacuum to one or more of a crankcase ventilation system, an emission control system, and an exhaust gas recirculation (EGR) system included in a turbocharged engine system are provided. In one example, approach, a method comprises drawing vacuum from a vacuum source located in an intake of the engine downstream of a pre-compressor throttle and upstream of an intake throttle, and applying the drawn vacuum to a discharge outlet of a uni-directional crankcase ventilation system, where an inlet of the crankcase ventilation system is coupled to the intake of the engine upstream of the pre-compressor throttle.

Owner:FORD GLOBAL TECH LLC

Engine pcv system with venturi nozzle for flow regulation

ActiveUS20080173284A1Low costSimple designCombustion enginesCrankcase ventillationVacuum pressureStreamflow

A positive crankcase ventilation system for an internal combustion engine is disclosed. The system includes an engine having a cylinder air intake system connected to associated cylinders and a filtered air inlet to a crankcase for admitting air to mix with crankcase vapors. A throttle is disposed in the cylinder air intake system for controlling airflow to the associated cylinders. The system further includes a venturi nozzle having an inlet and an outlet. The venturi nozzle inlet is connected to the crankcase for receiving the mixture of filtered air and crankcase vapors. The venturi nozzle outlet is connected to the cylinder air intake system at a location subject to variable intake vacuum pressure between the throttle and the cylinders to allow the mixture of filtered air and crankcase vapors to be drawn into the inlet air passing to the cylinders downstream of the throttle.

Owner:GM GLOBAL TECH OPERATIONS LLC

Engine crankcase oil gas separation system and its oil gas separation method

InactiveCN101260819AIncrease liquid contentImprove separator effectMachines/enginesCrankcase ventillationLiquid stateIntercooler

The invention discloses an oil-gas separating system of an engine crankcase, which is arranged in a ventilation system of the engine crankcase and comprises an oil-gas separator (5) connected with an oil-gas outlet (13) of a crankcase; a gas outlet of the oil-gas separator (5) is communicated with a pipeline in a gas inlet end of a gas inlet main pipe (12); an intercooler (8) is arranged on a pipeline connected with the oil-gas outlet (13) of the crankcase and the oil-gas separator (5). The technical proposal is adopted on the basis of the ventilation system of the crankcase, the middle cooling part is arranged for cooling high-temperature mixed oil gas from the crankcase. With the temperature dropping, oil in the high-temperature mixed oil gas is changed from a gaseous state to a liquid state, thereby improving liquid content of the mixed oil gas. Part of the oil gas can be directly condensed and separated in the intercooler; liquid oil mist can be separated in the later oil-gas separation to improve the effect of the oil-gas separator.

Owner:CHERY AUTOMOBILE CO LTD

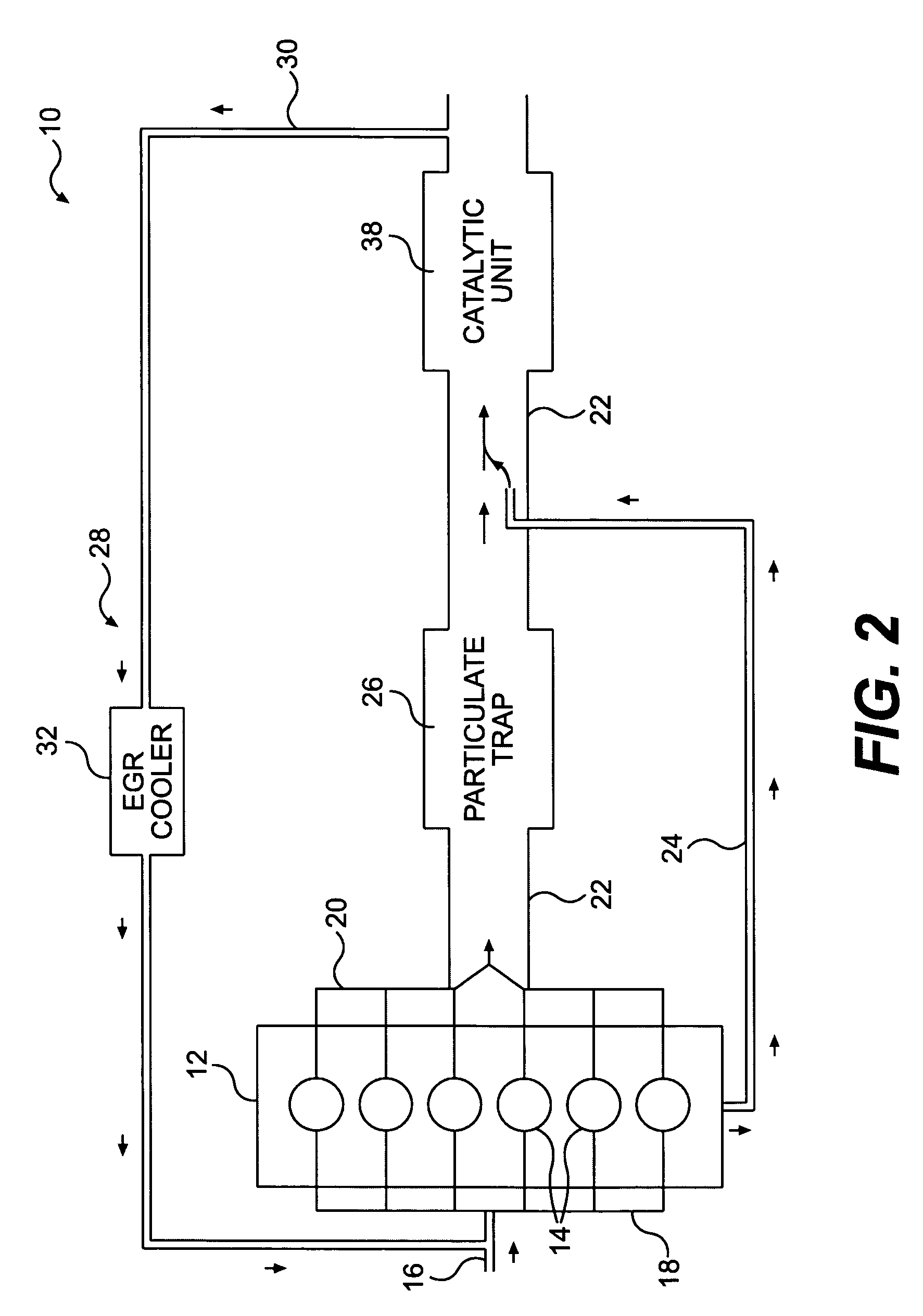

Crankcase ventilation system

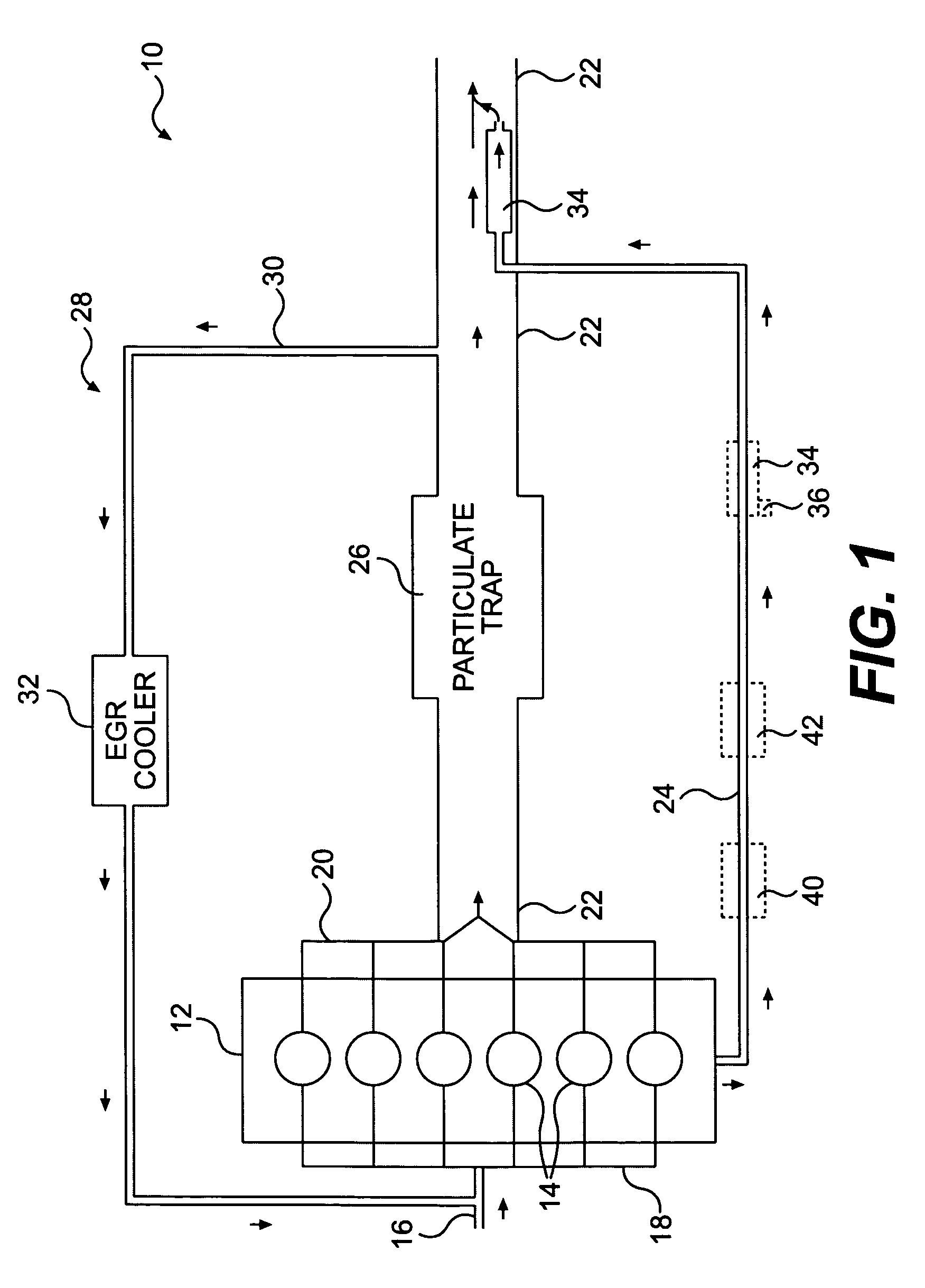

ActiveUS20060064966A1Non-fuel substance addition to fuelExhaust apparatusParticulatesExternal combustion engine

A crankcase ventilation system may include a first exhaust flow path configured to permit flow of main exhaust gases from a combustion chamber of an internal combustion engine and a particulate trap disposed in the first exhaust flow path. The system may also include a second exhaust flow path configured to enable flow of crankcase gases from a crankcase of the internal combustion engine and to merge the crankcase gases with the main exhaust gases at a point in the first exhaust flow path located downstream of the particulate trap.

Owner:CATERPILLAR INC

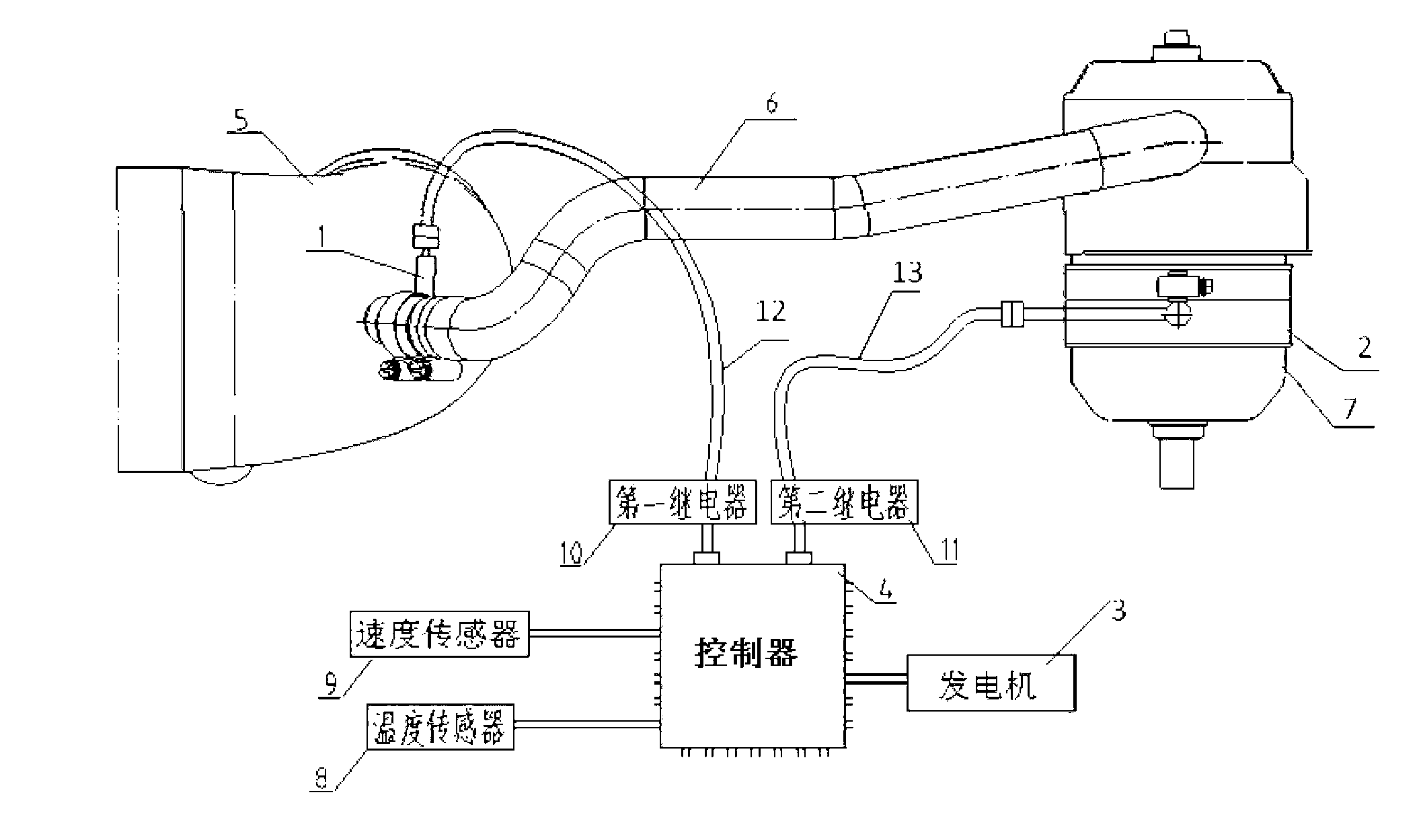

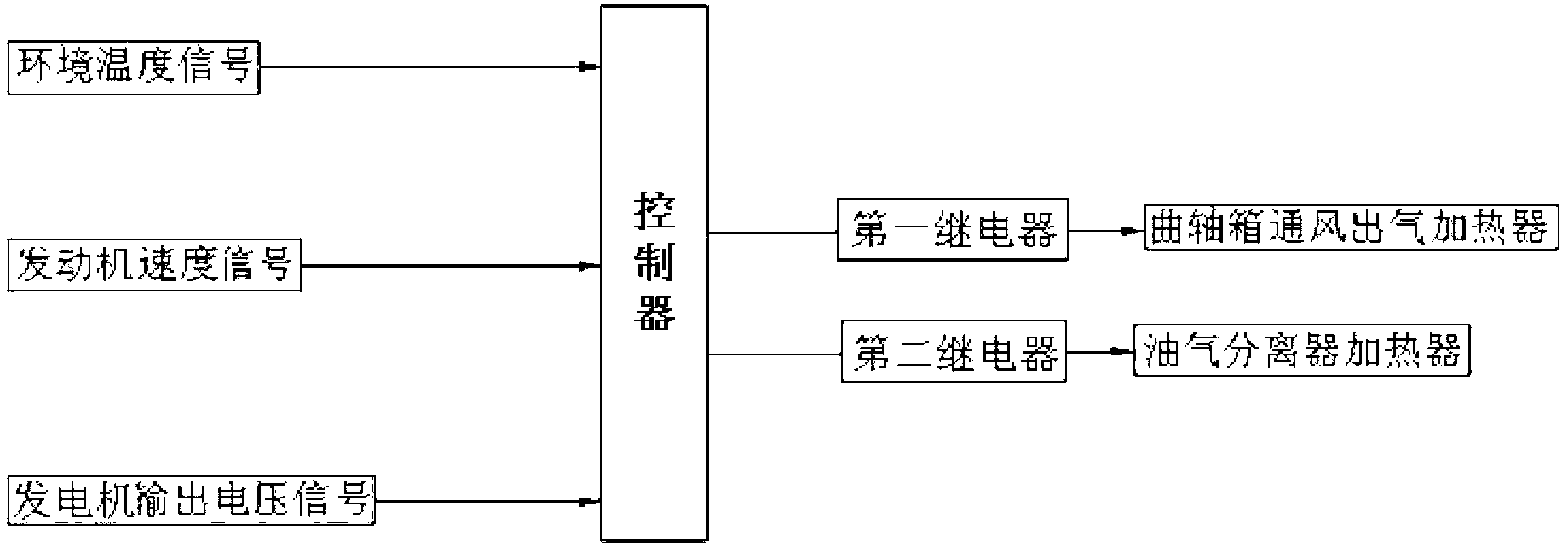

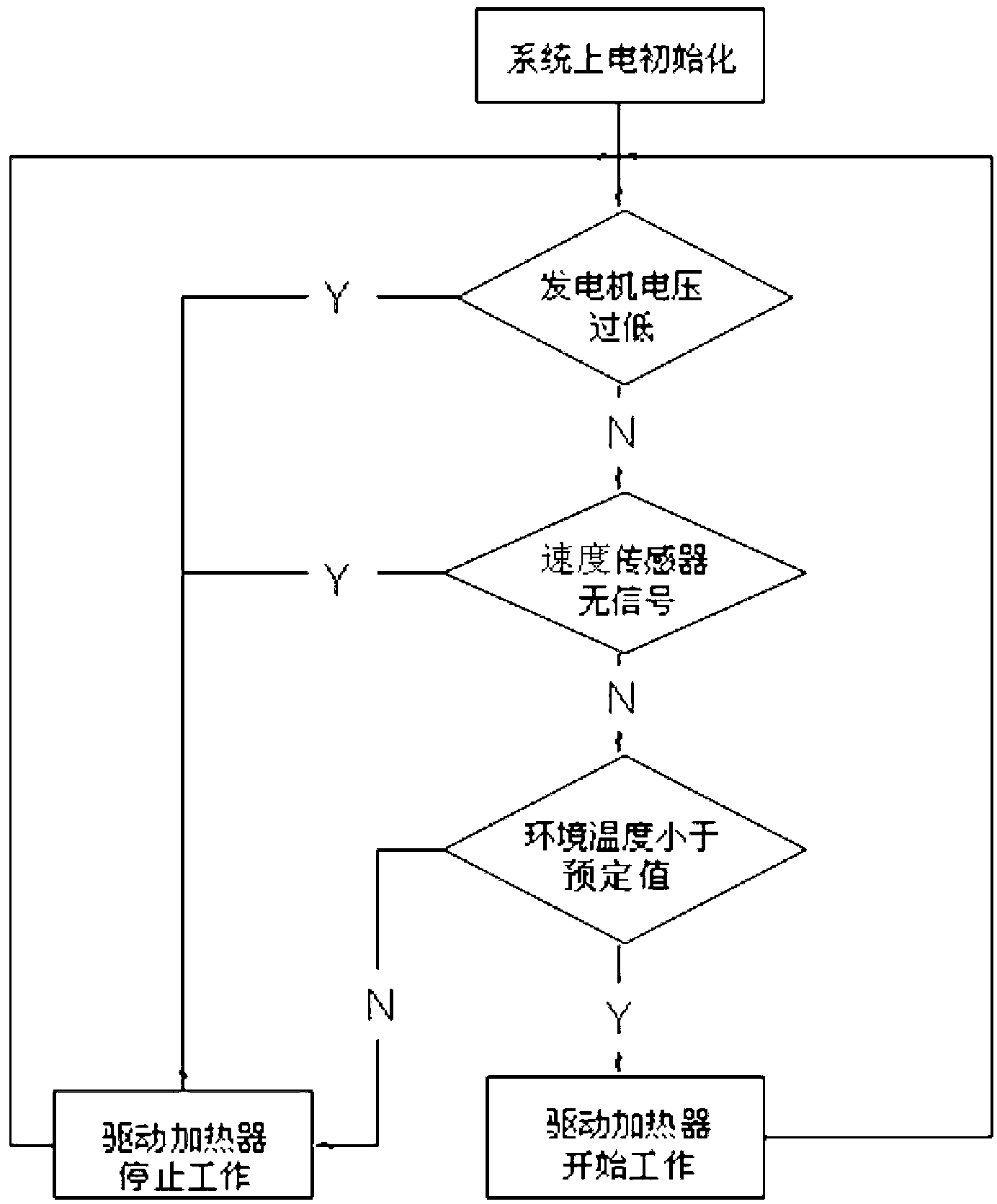

Ventilating and heating system of crankcase

ActiveCN103016099ASolve the problem of icing in cold areasGuaranteed reliabilityMachines/enginesLubrication temperature controlLower limitControl signal

The invention relates to a ventilating and heating system of a crankcase, which comprises a ventilation gas outlet heater, a controller, a temperature sensor and a first relay, wherein the ventilation gas outlet heater is fixedly arranged between a gas inlet hose and a gas outlet pipe of a crankcase, and the temperature sensor is fixedly arranged on a vehicle body; the temperature sensor is used for converting the measured environment temperature into an electrical signal and transmitting the electrical signal to the controller, and the controller is used for judging whether the environment temperature is lower than the normal working temperature lower limit of the crankcase according to the electrical signal, and outputs a control signal to be connected with the first relay if the environmental temperature is lower than the normal working temperature lower limit of the crankcase to ensure that the ventilation gas outlet heater starts working. The ventilating and heating system of the crankcase solves the problem of cold region freezing of the engine crankcase ventilating system, and ensures the reliability when a vehicle is used in an extremely cold area. The ventilating and heating system of the crankcase has a simple structure, and brings convenience for arrangement.

Owner:CHINA FIRST AUTOMOBILE

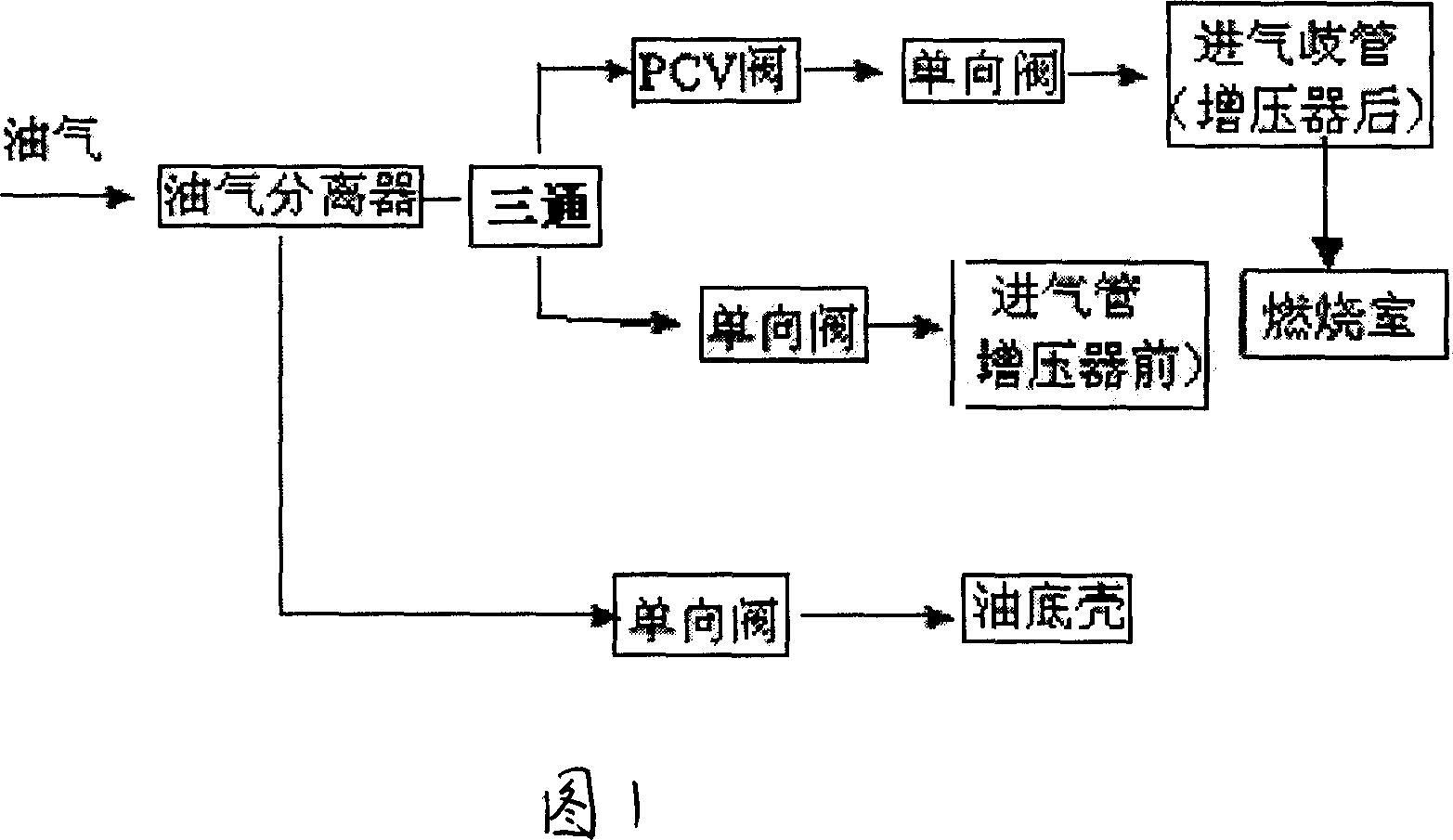

Crankcase ventilation system of supercharged gasoline engine and work method of crankcase ventilation system

ActiveCN103362597APlay a role in regulating the bending pressureOptimize the ventilation systemMachines/enginesCrankcase ventillationCombustion chamberLow load

The invention relates to a crankcase ventilation system of a supercharged gasoline engine and a work method of the crankcase ventilation system. Crankcase waste gas in a low-load state passes through a valve cover (4), a three-way pipe (6), a PCV (positive crankcase ventilation) valve (9), an air inlet manifold (7) and a combustion chamber in sequence; an air supply channel (17) is formed between an air inlet hose (14) and a crankcase; an air supply channel one-way valve (16) is arranged on the air supply channel (17); supplied fresh air passes through the air inlet hose (14), the air supply channel (16), the air supply channel one-way valve (16), the crankcase, an air cylinder body (2) and the valve cover (4) in sequence; generated waste gas passes through the same path as the crankcase waste gas. According to the crankcase ventilation system, the one-way valve is opened to supply the fresh air to the crankcase by the characteristic that the negative crankcase pressure value in the low-load supercharged gasoline engine is excessively high, so that on one hand, an effect of adjusting the crankcase pressure is achieved, and on the other hand, the supplied fresh air has the effects of scavenging and purifying the crankcase waste gas.

Owner:CHERY AUTOMOBILE CO LTD

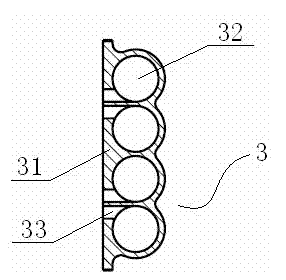

Oil-gas separator assembly of crankcase ventilation system

InactiveCN102852593ASimple structureImprove oil and gas separation effectMachines/enginesCrankcase ventillationFiberEngineering

The invention aims at providing an oil-gas separator assembly of a crankcase ventilation system with small occupied space and high oil-gas separation efficiency. The oil-gas separator assembly of the crankcase ventilation system disclosed by the invention comprises a case provided with an air inlet and an air outlet, wherein the air outlet is connected with a PCV (pollution-control valve), and the oil-gas separator assembly is characterized in that the case is internally provided with a centrifugal oil-gas separation device and a fiber oil absorption device along an airflow advancing direction. The centrifugal oil-gas separation device and the fiber oil absorption device are arranged, two-stage oil-gas separation is adopted, the oil-gas separation effect can be improved, and the centrifugal oil-gas separation device occupies small space, so that the centrifugal oil-gas separation device can be conveniently arranged.

Owner:CHERY AUTOMOBILE CO LTD

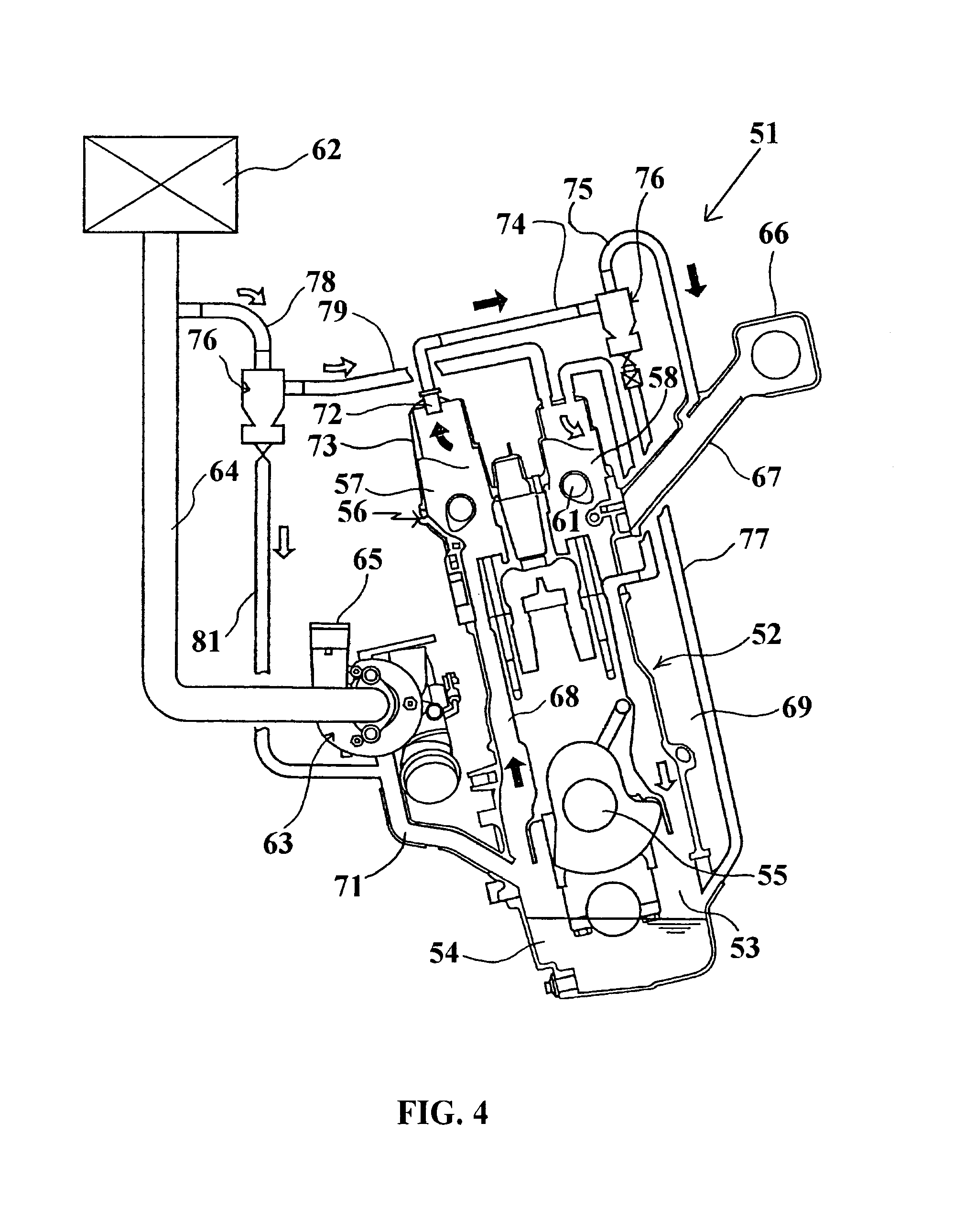

Engine component layout for outboard motor

An engine of an outboard motor includes an improved engine component layout to minimize the size of the engine and to improve the performance of the components. A separator of a crankcase ventilation system is located on a cam cover outside the cam chamber in order to reduce the size of the cam cover while providing the necessary spacing between the separator and the valve mechanism within the cam chamber. A fuel pump is positioned at about the center of the cam cover, beneath the separator, to generally balance the length of fuel travel to each of the carburetors. A fuel filter also is located on the cam cover, beneath the fuel filter, to generally isolate the fuel filter from the effects of the heated cylinder head and block. The arrangement of these components does not interfere with the hinge-like travel of a top cowling, which surrounds the engine, relative to a lower tray.

Owner:SANSHIN KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com