Engine crankshaft ventilation system

A technology for crankcase ventilation and engines, which is applied in crankcase ventilation, engine components, machines/engines, etc., to achieve the effects of improving safety, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

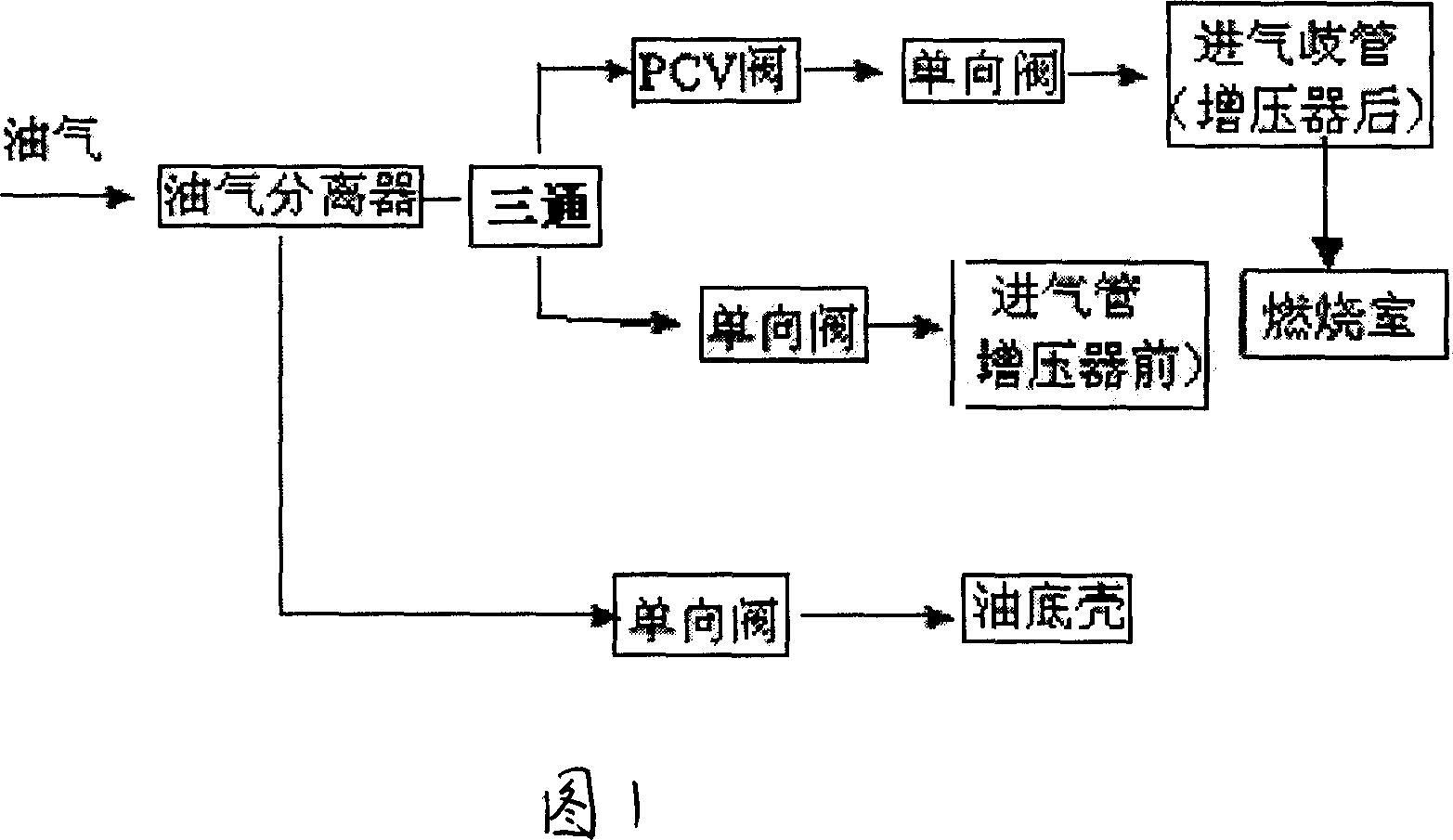

[0010] In the embodiment shown in Fig. 1, a kind of engine crankcase ventilation system comprises PCV valve, oil-gas separator and pipeline; It enters into the oil pan; its characteristic is that the separated gas is divided into two sets of pipelines through the three-way pipe. When the engine is at low speed, the vacuum inside the intake manifold is greater than the vacuum inside the front tube of the supercharger, and the gas enters the intake air. Inside the manifold, at the same time, in order to prevent the air in the front pipe of the supercharger from entering the ventilation pipeline, a check valve needs to be installed between the air pipe in front of the supercharger and the oil-air separator; The vacuum degree is greater than the intake manifold, and the gas enters the air pipe in front of the supercharger. At the same time, in order to prevent the compressed gas in the intake manifold from entering the ventilation system, a check valve needs to be installed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com