Ventilating and heating system of crankcase

A crankcase ventilation and heating system technology, applied in crankcase ventilation, lubricant temperature control, engine components, etc., can solve problems such as icing in cold areas, to ensure reliability, solve icing problems in cold areas, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

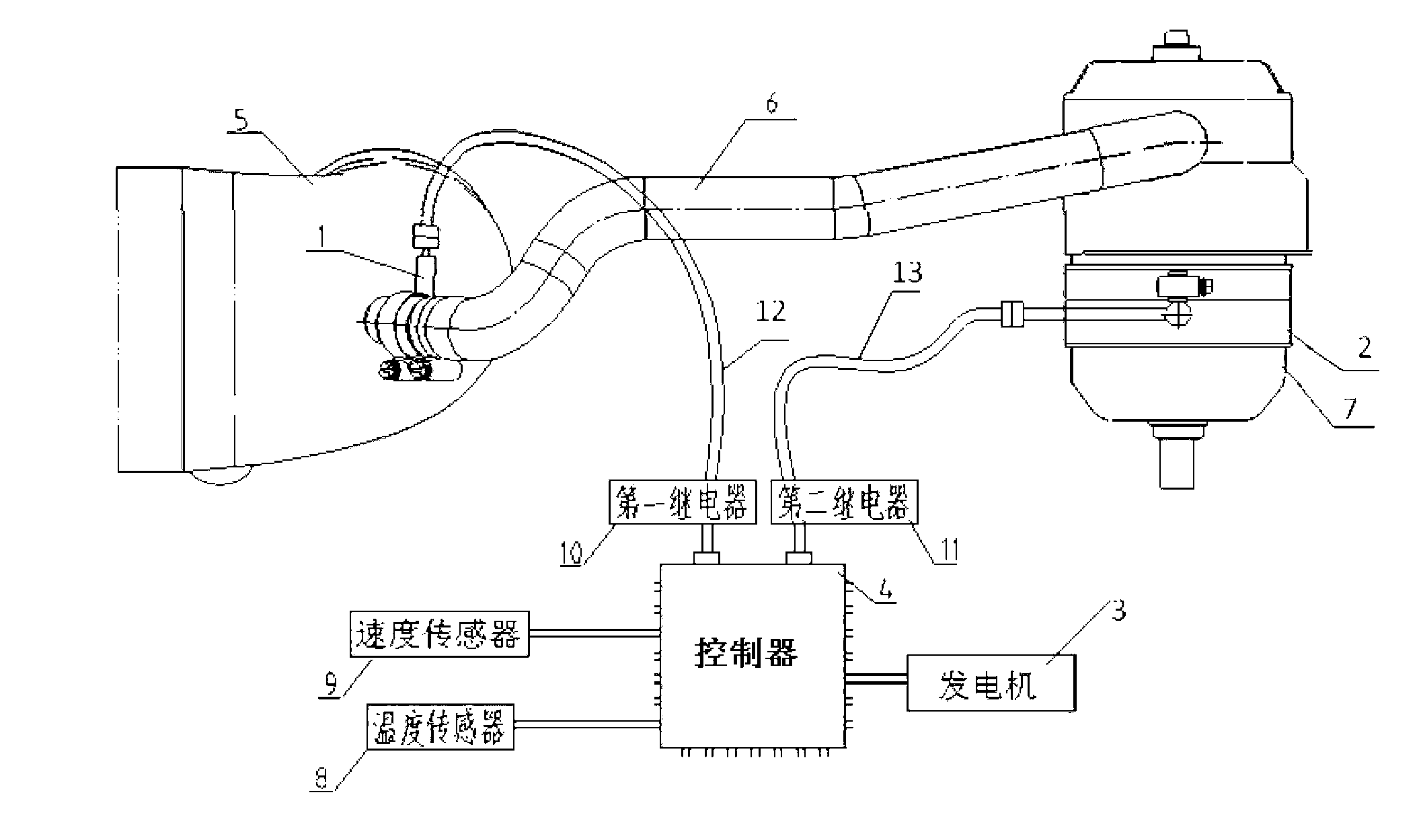

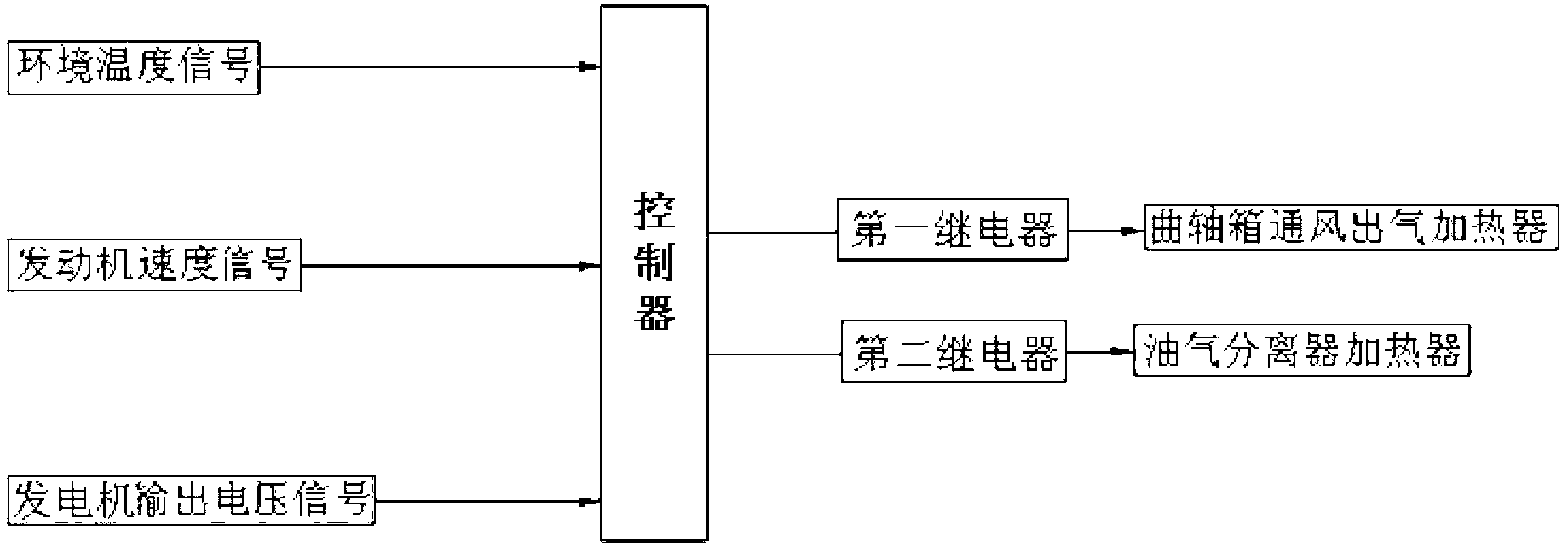

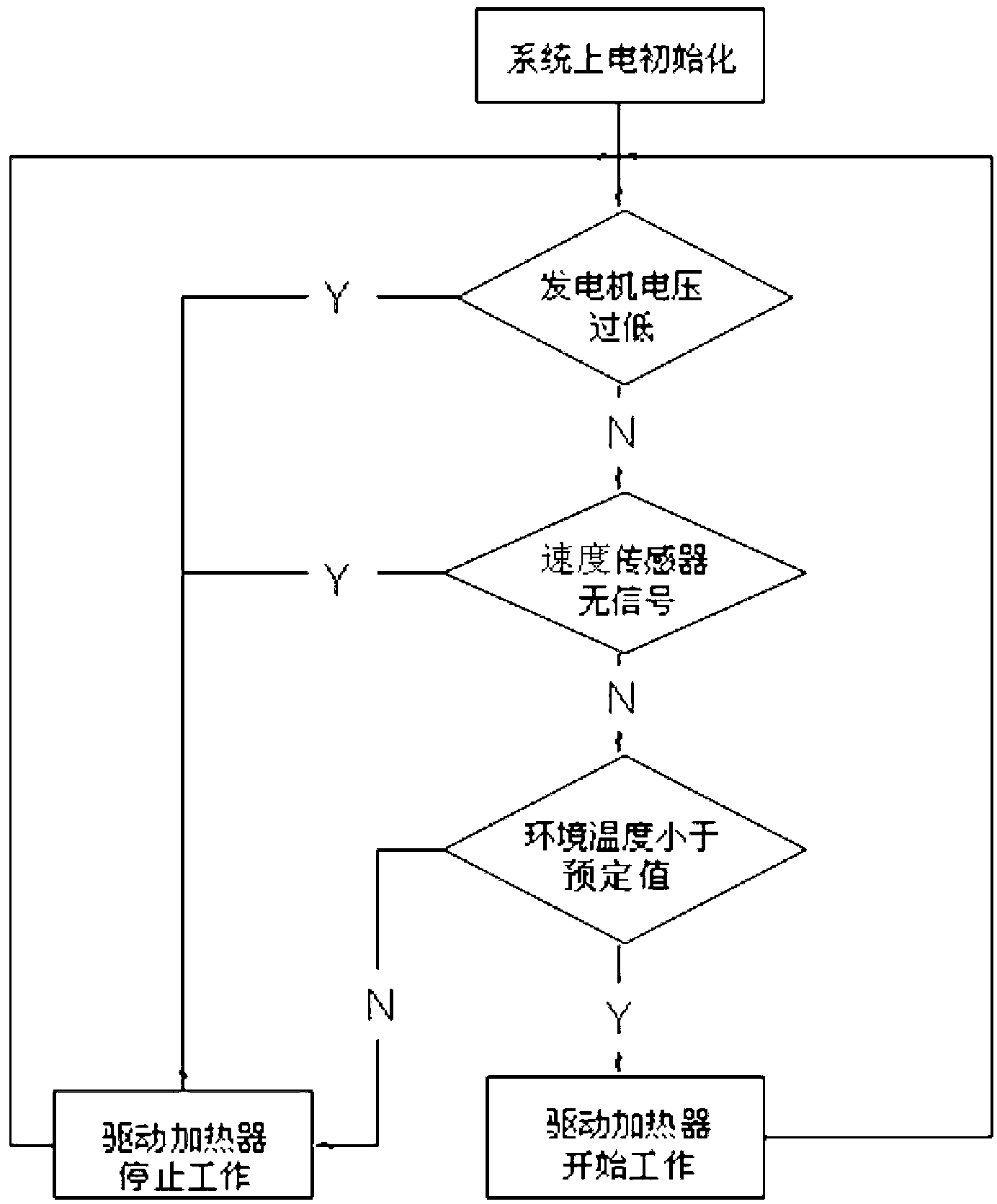

[0016] Such as figure 1 As shown, the crankcase ventilation and heating system of the present invention is composed of a ventilation outlet heater 1, an oil-gas separator heater 2, a temperature sensor 8, a speed sensor 9, a first relay 10, a second relay 11 and a controller 4. The controller can be the CPU inside the vehicle-mounted computer ECU, or other microprocessors. Ventilation air outlet heater 1 is installed and fixed between the intake hose 5 and the air outlet pipe 6 of the crankcase by a clip, and the oil-gas separator heater 2 is installed and fixed on the crankcase oil-gas separator 7 by a clip. Ventilation outlet heater 1 is connected to controller 4 through heating harness 12 and first relay 10 ; oil-gas separator heater 2 is connected to controller 4 through heating harness 13 and second relay 11 . The temperature sensor 8 is installed on the vehicle body. The speed sensor 9 is a photoelectric encoder, which is installed on the engine output shaft. Temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com