Patents

Literature

1857results about "Lubrication temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

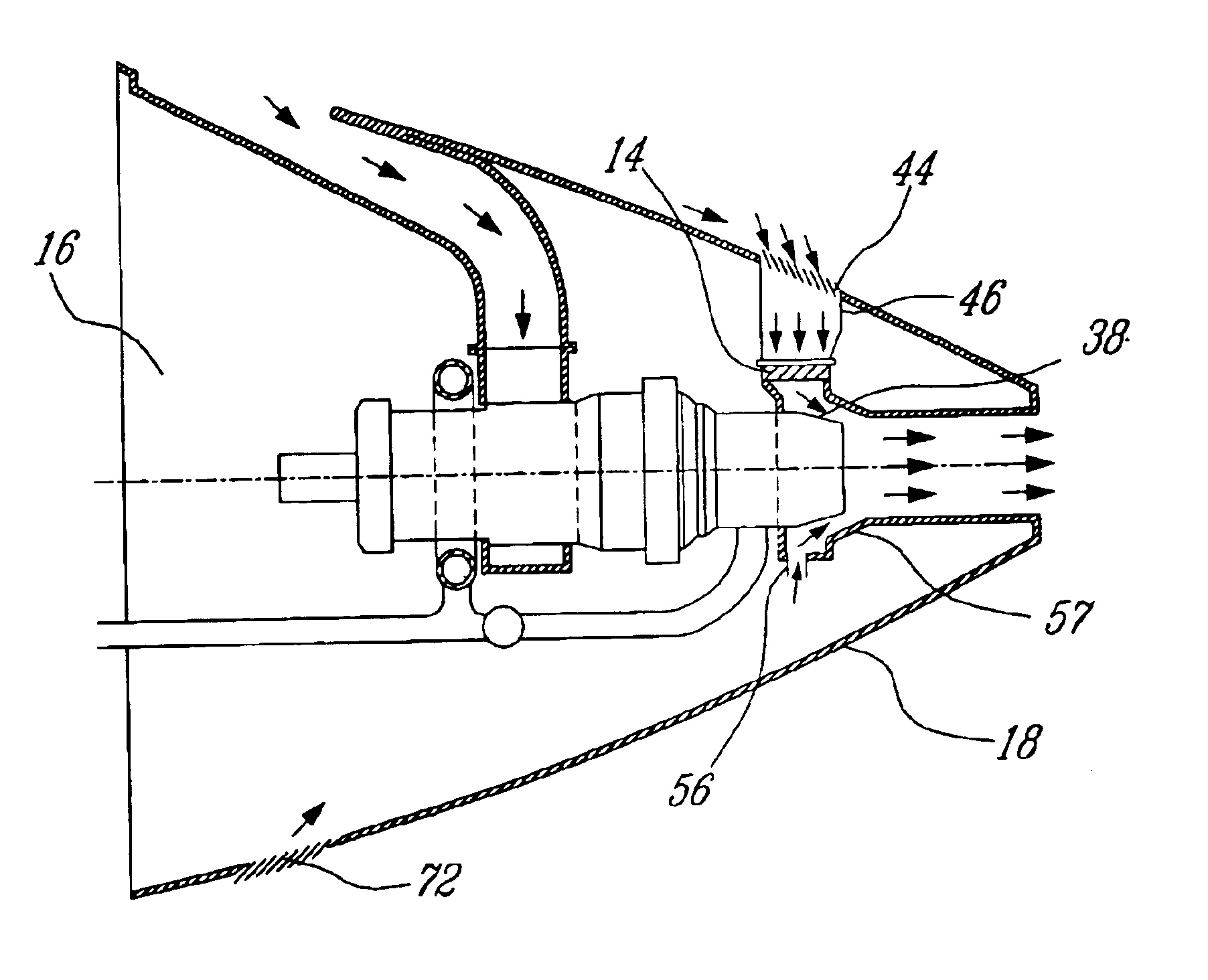

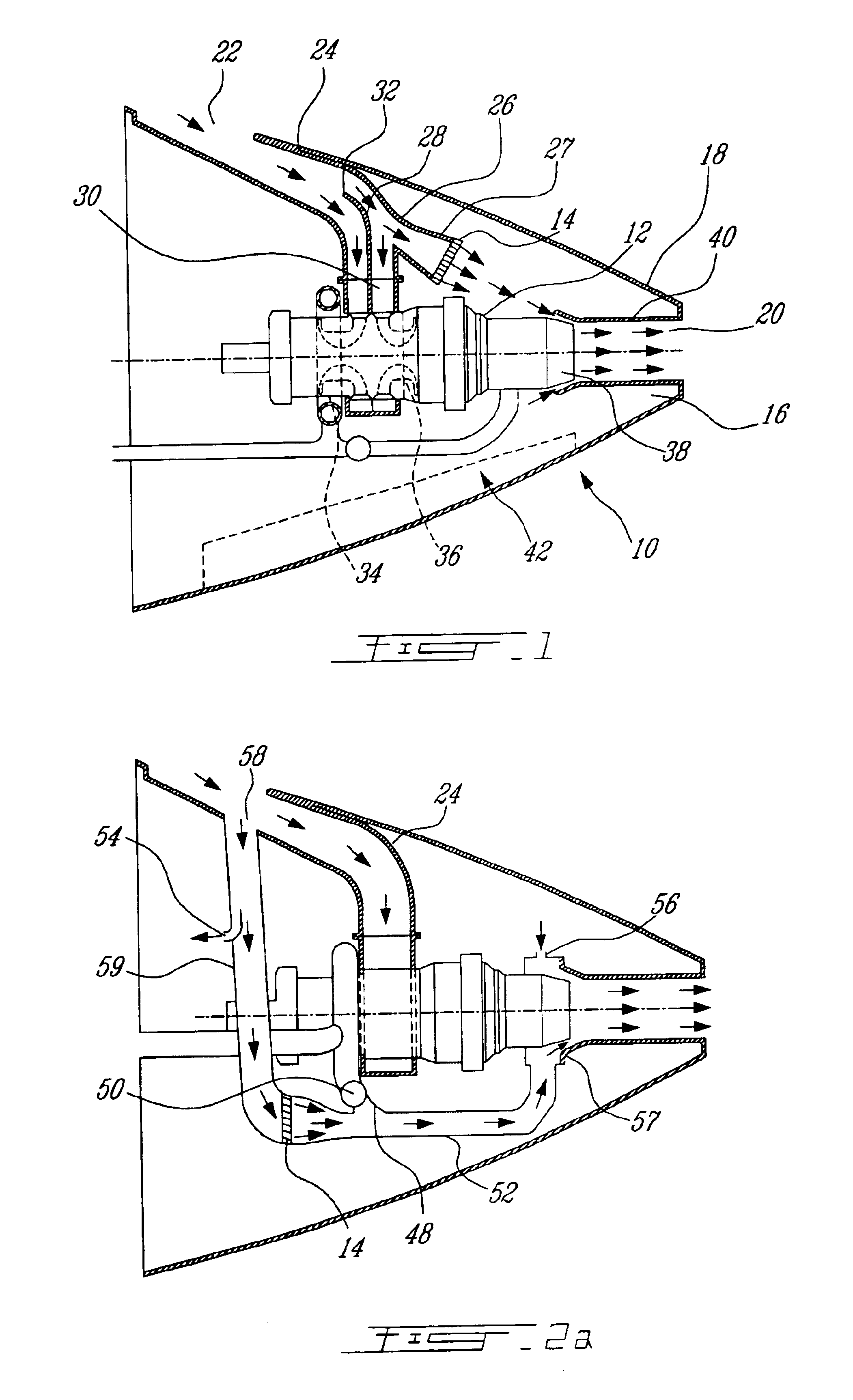

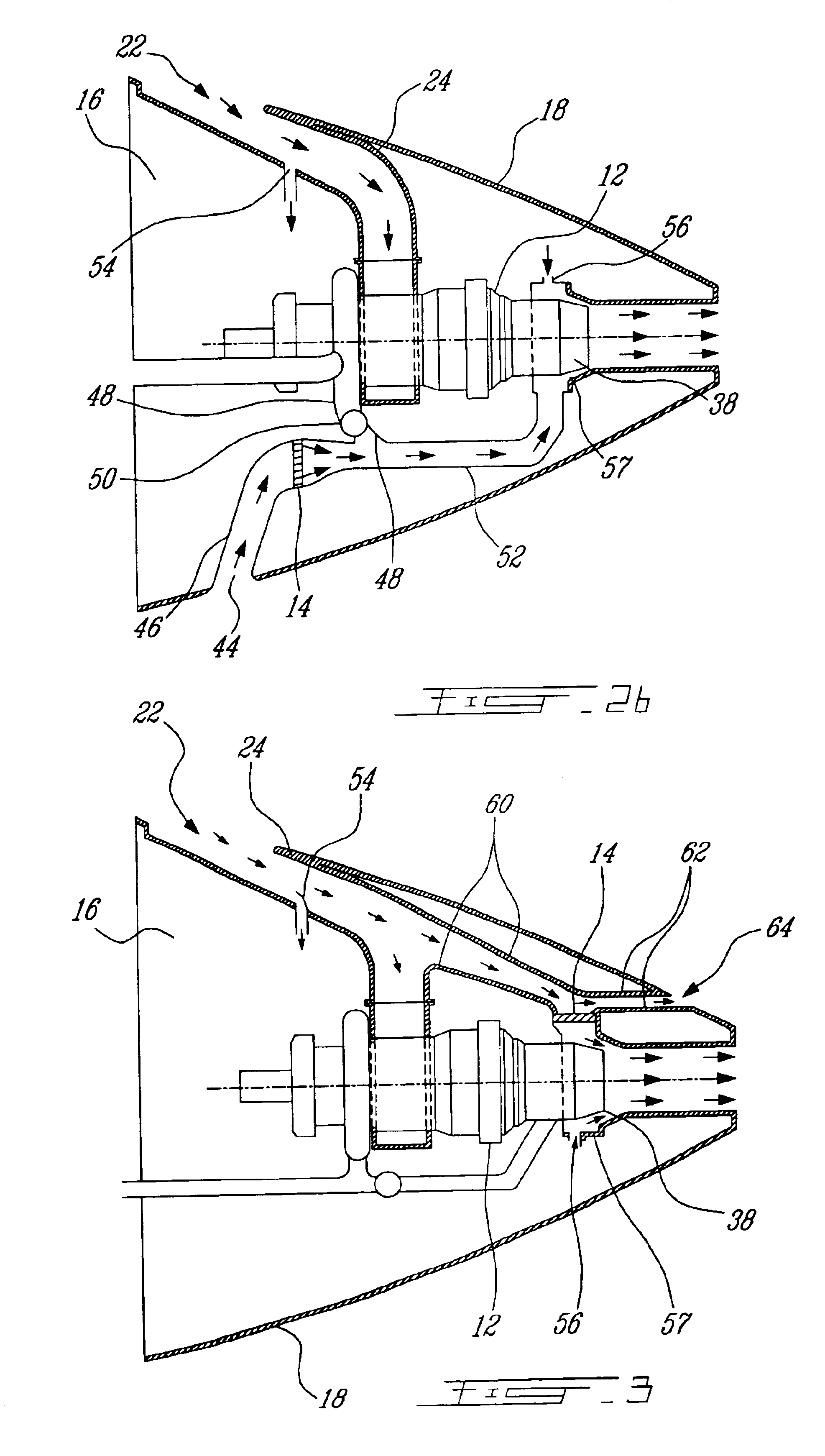

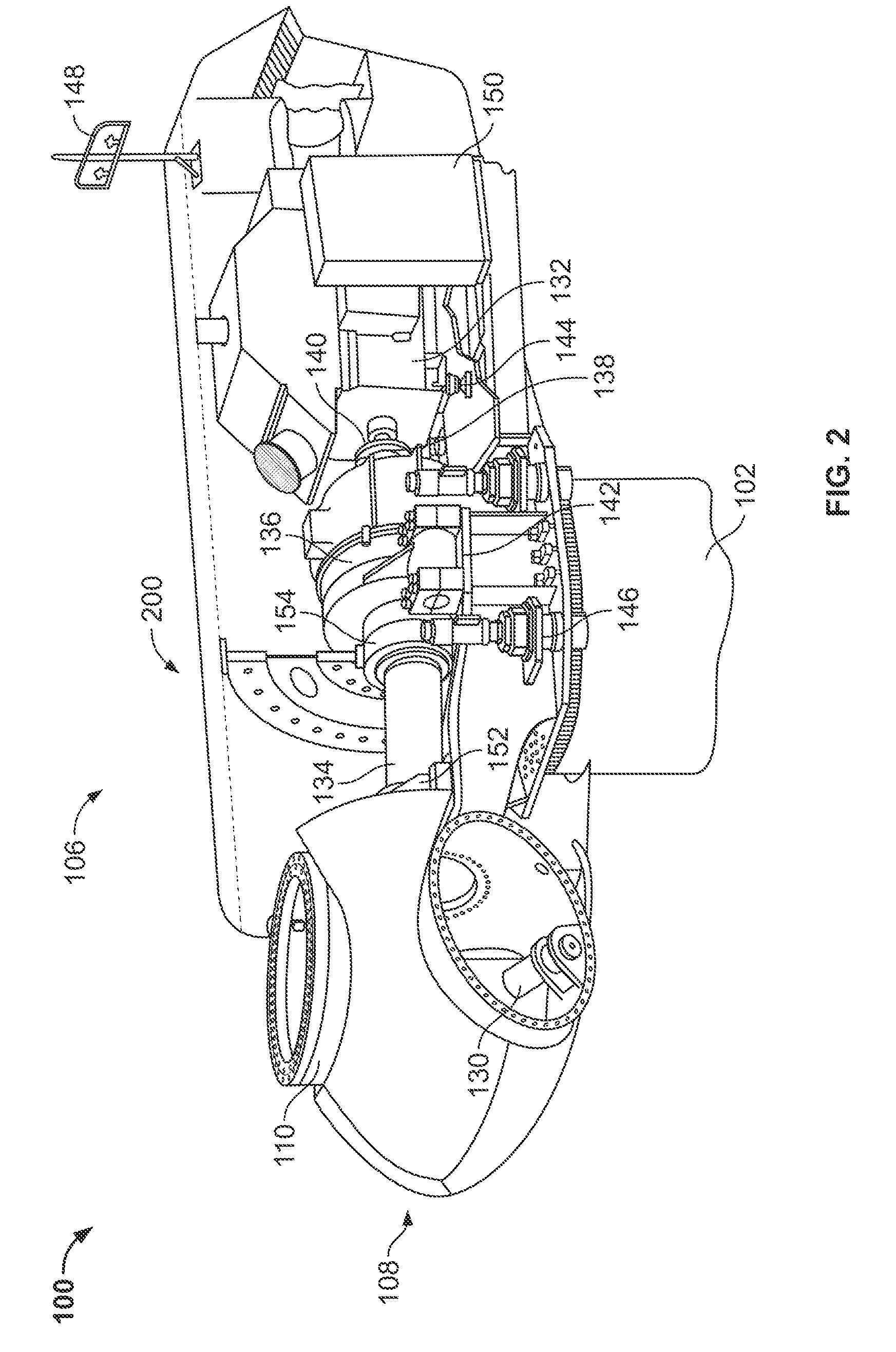

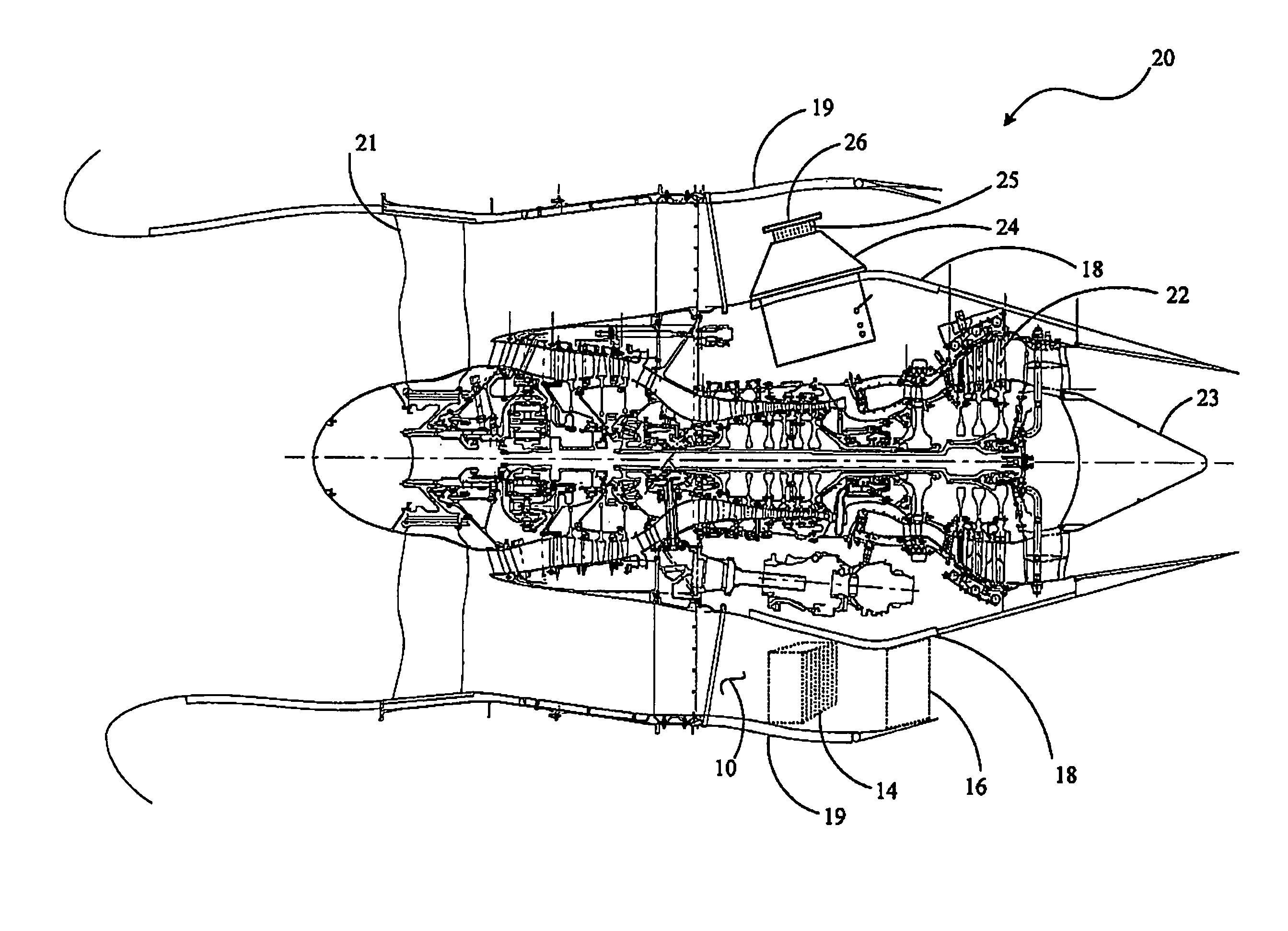

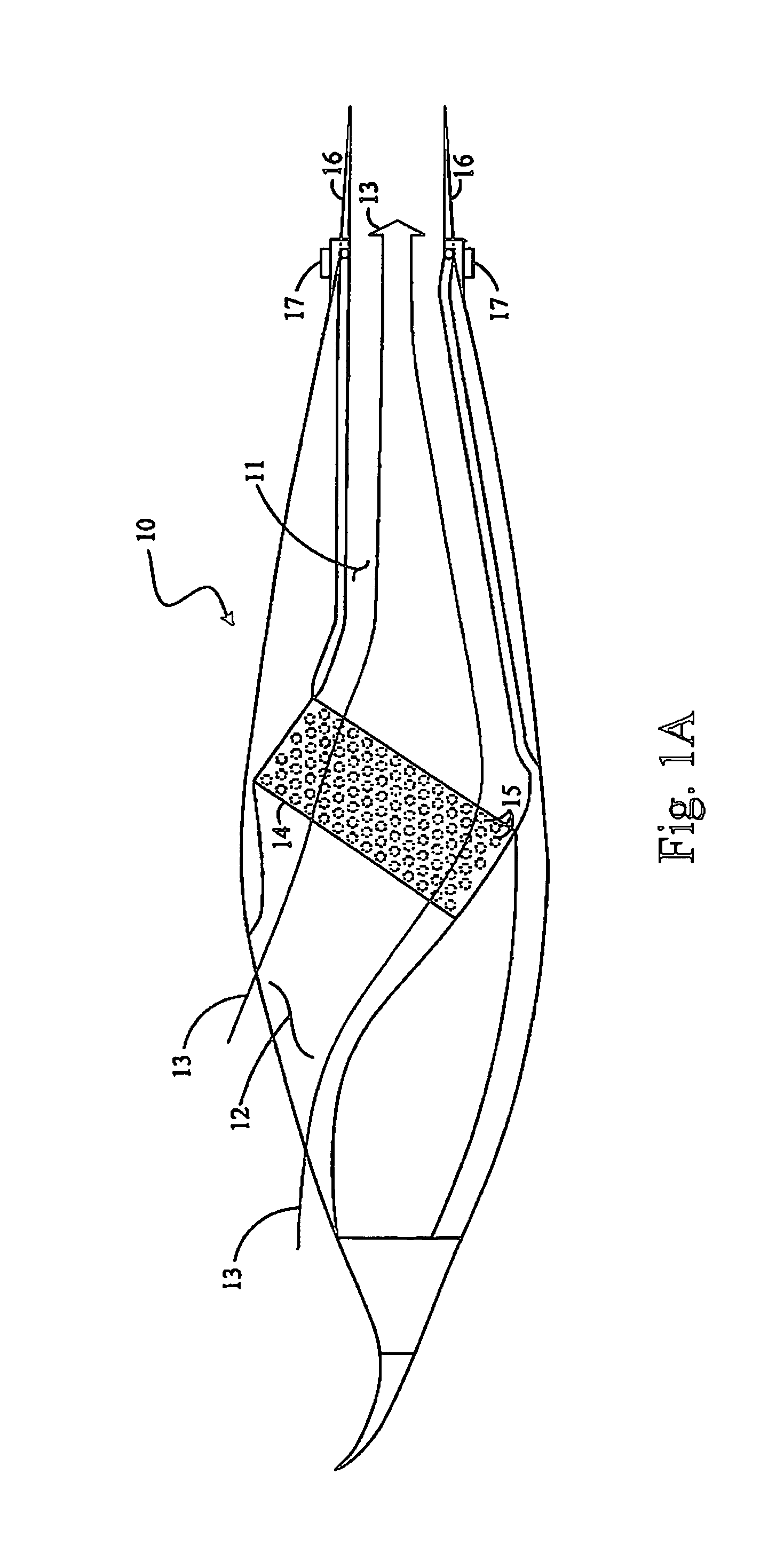

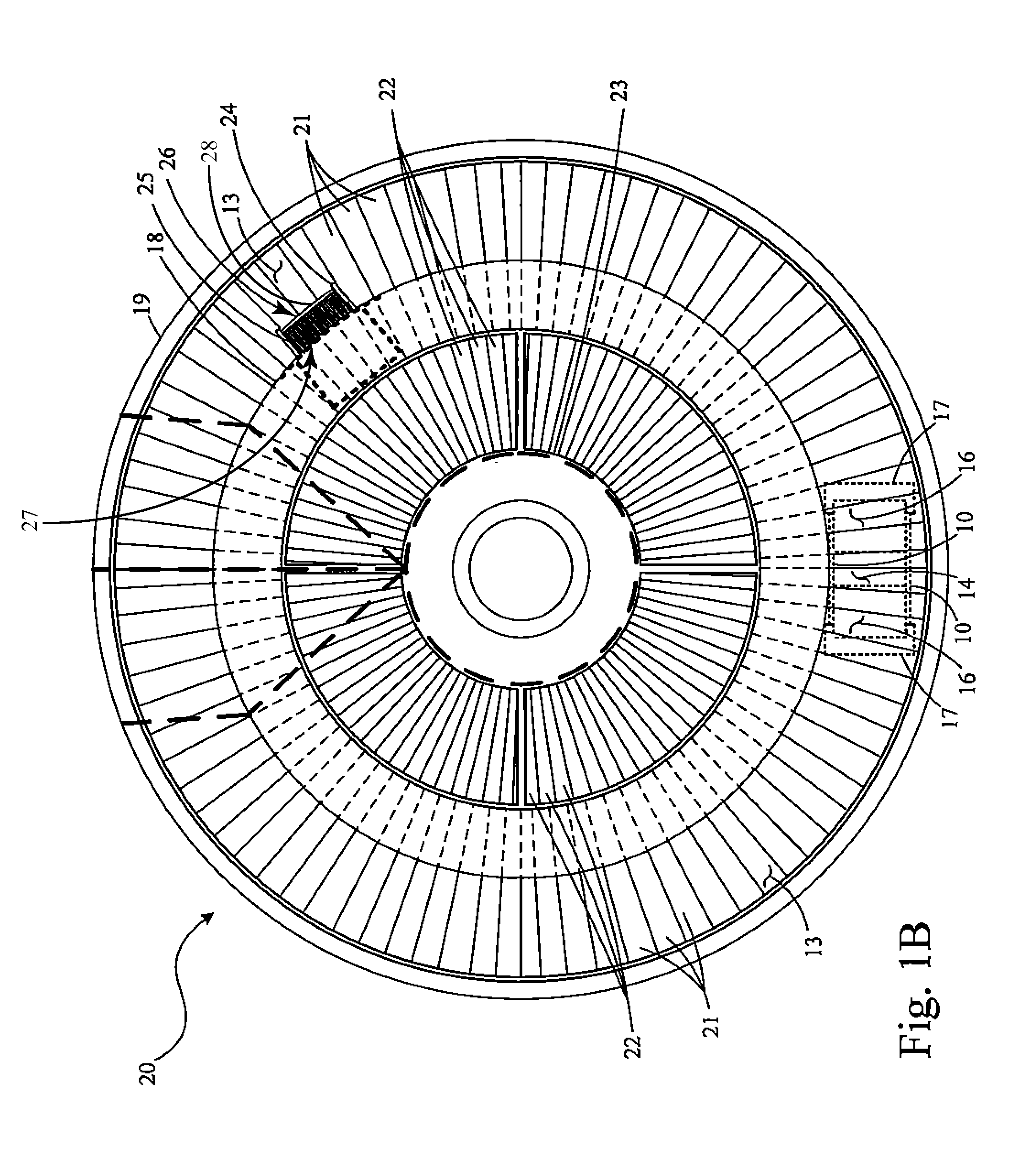

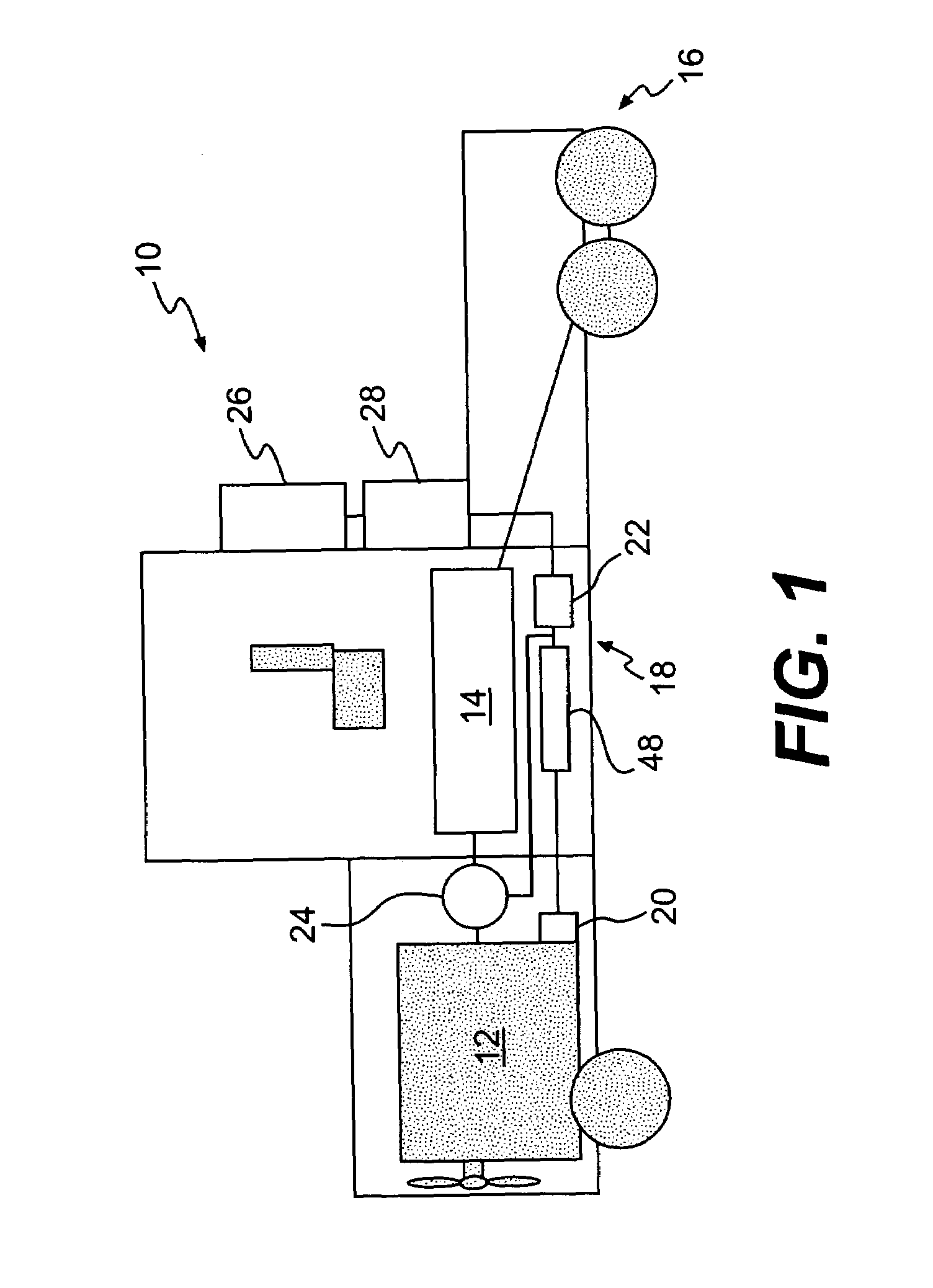

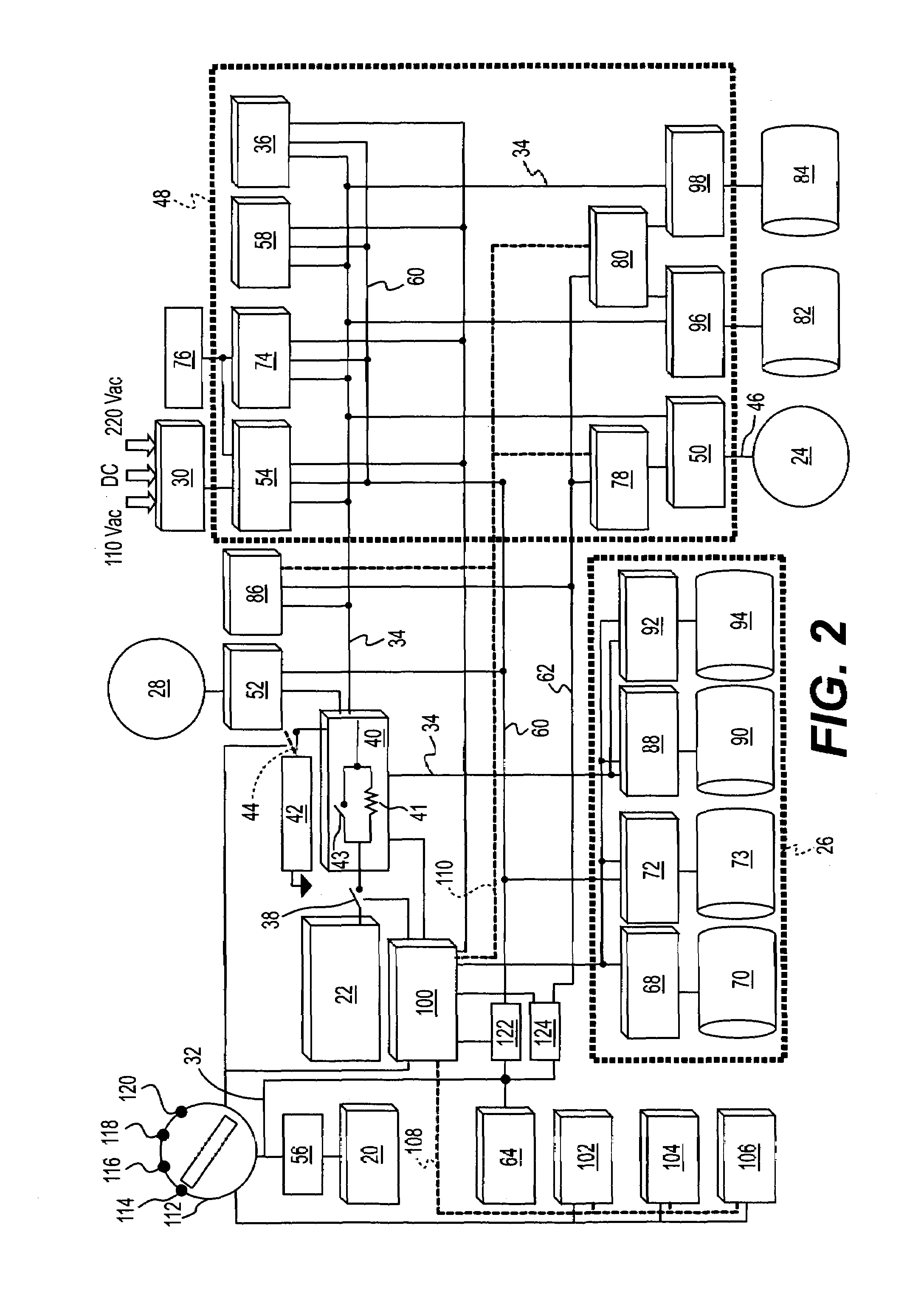

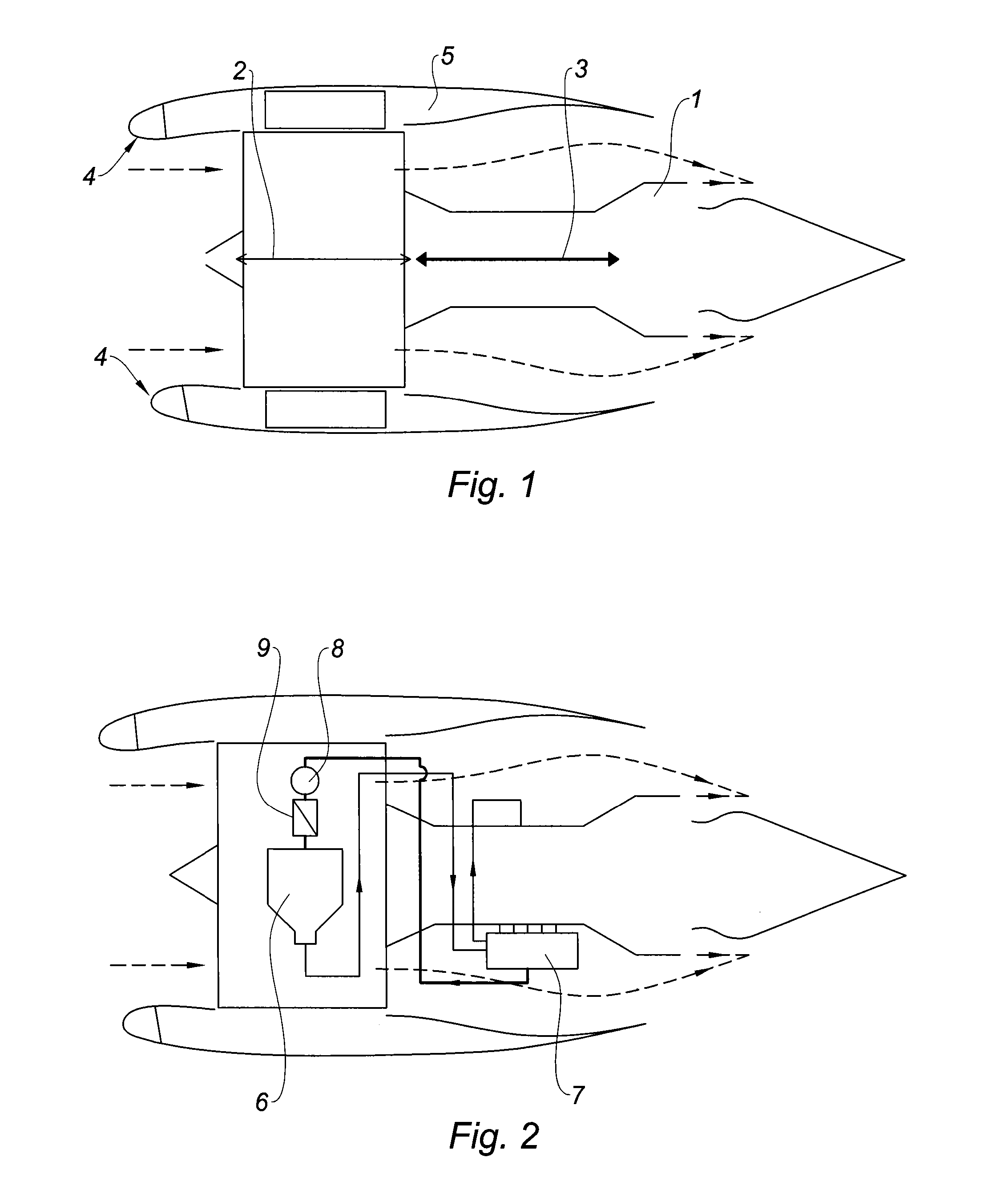

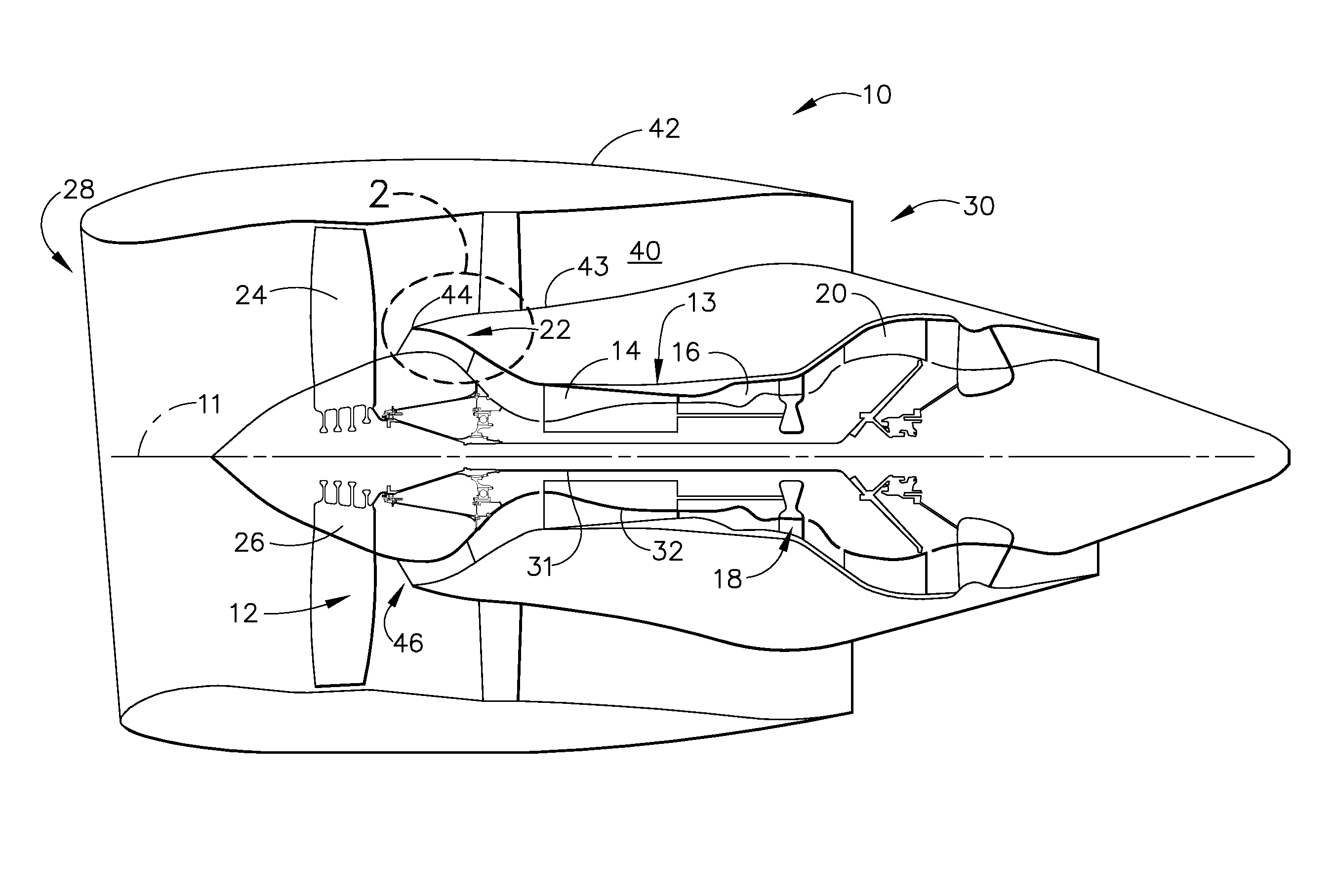

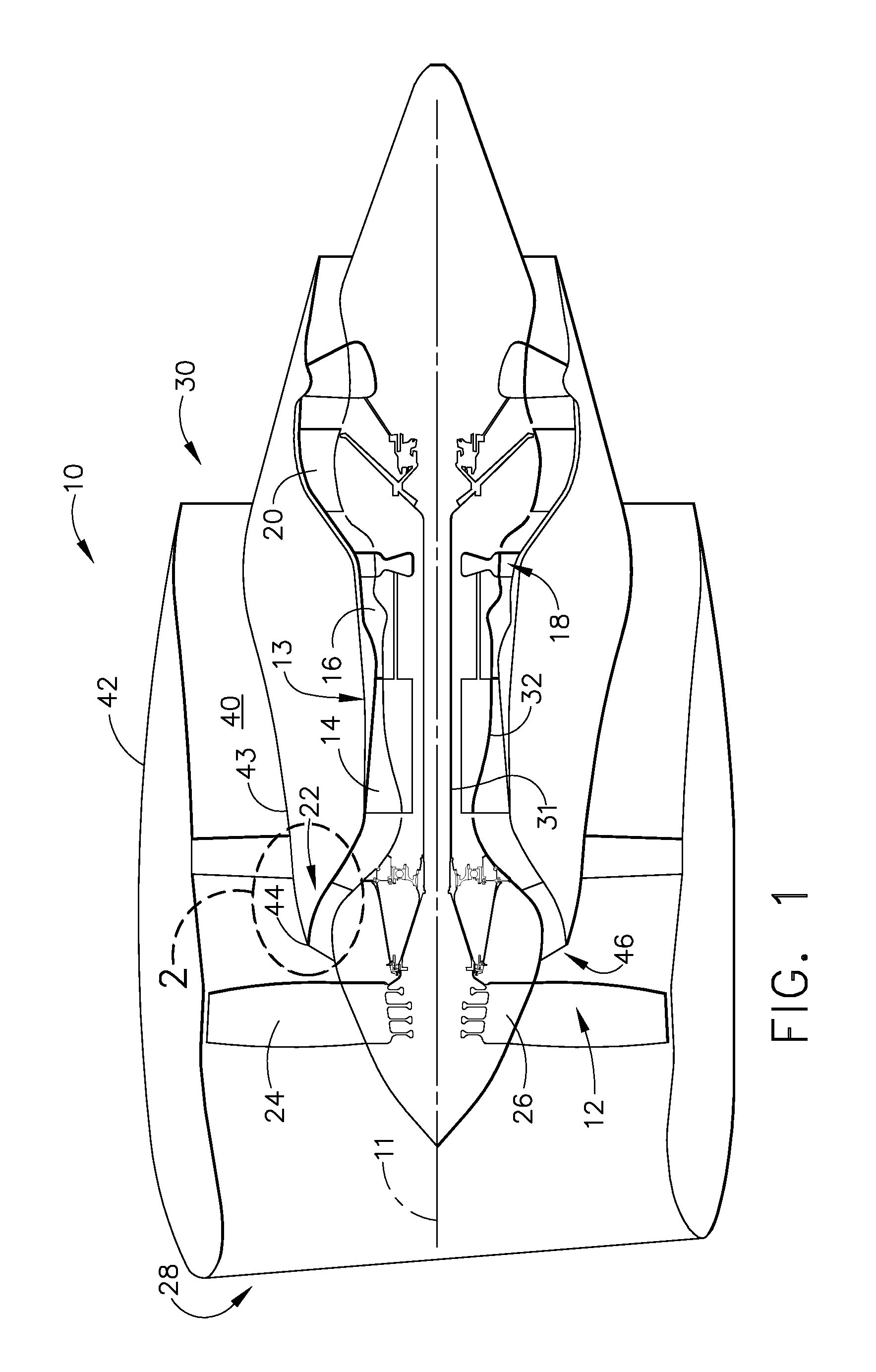

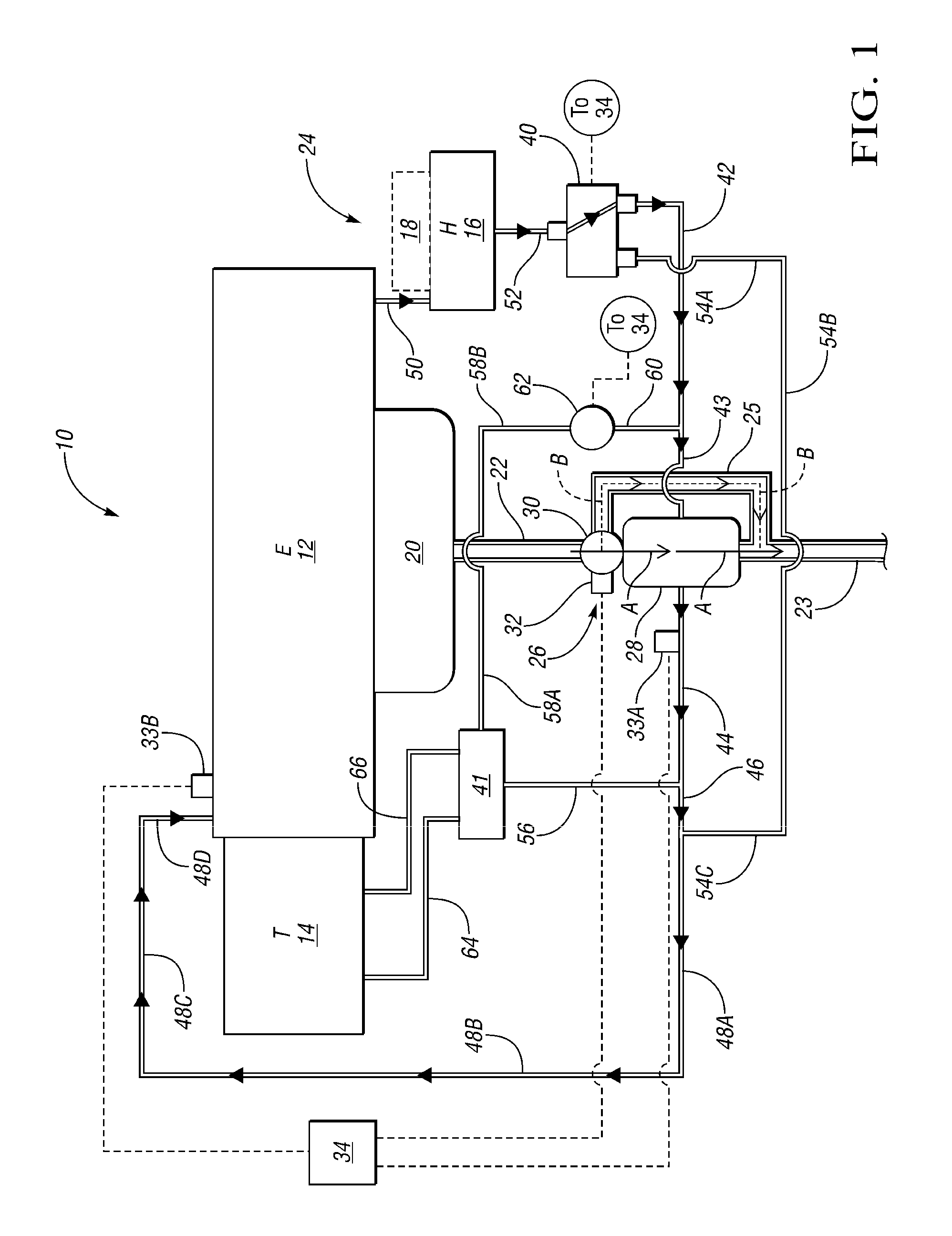

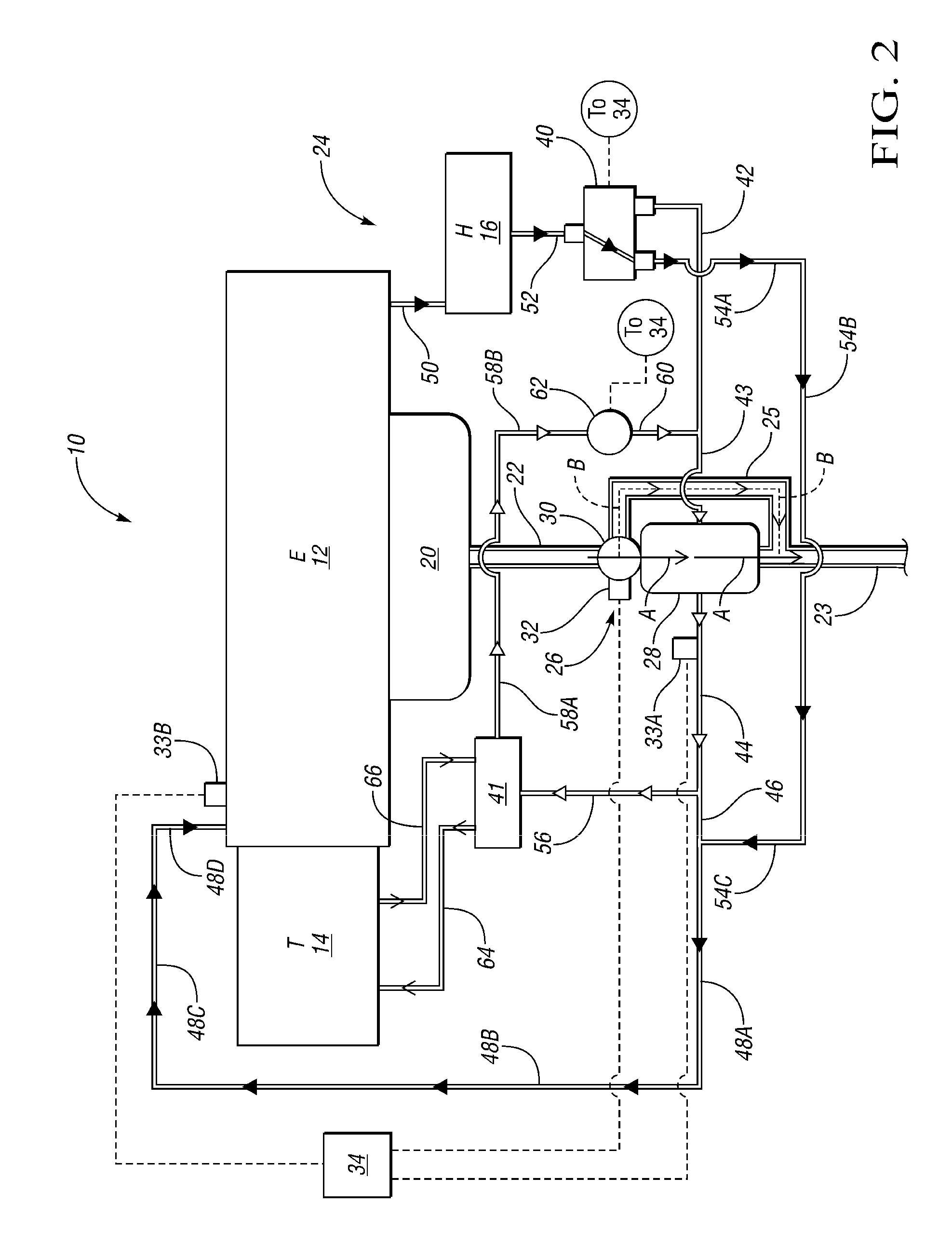

Passive cooling system for auxiliary power unit installation

InactiveUS6942181B2Improve cooling effectEnhanced cooling airflowPower plant cooling arrangmentsAir-treating devicesAuxiliary power unitOil cooling

A passive cooling system for an auxiliary power unit (APU) installation on an aircraft is provided. The system is for an auxiliary power unit having at least a compressor portion of a gas turbine engine and an oil cooler contained separately within a nacelle. The system includes the auxiliary power unit housed within the nacelle of the aircraft, an engine exhaust opening defined in the aft portion of the nacelle and communicating with the gas turbine engine, at least a first air inlet duct communicating with a second opening defined in said nacelle and with said compressor portion and the oil cooler is located within a second duct communicating with an opening other than the engine exhaust opening of said nacelle and with the engine exhaust opening. Exterior cooling air and engine exhaust ejected through said engine exhaust opening entrain cooling air through said second duct to said oil cooler, and thus provide engine oil cooling. An exhaust eductor is also provided.

Owner:PRATT & WHITNEY CANADA CORP

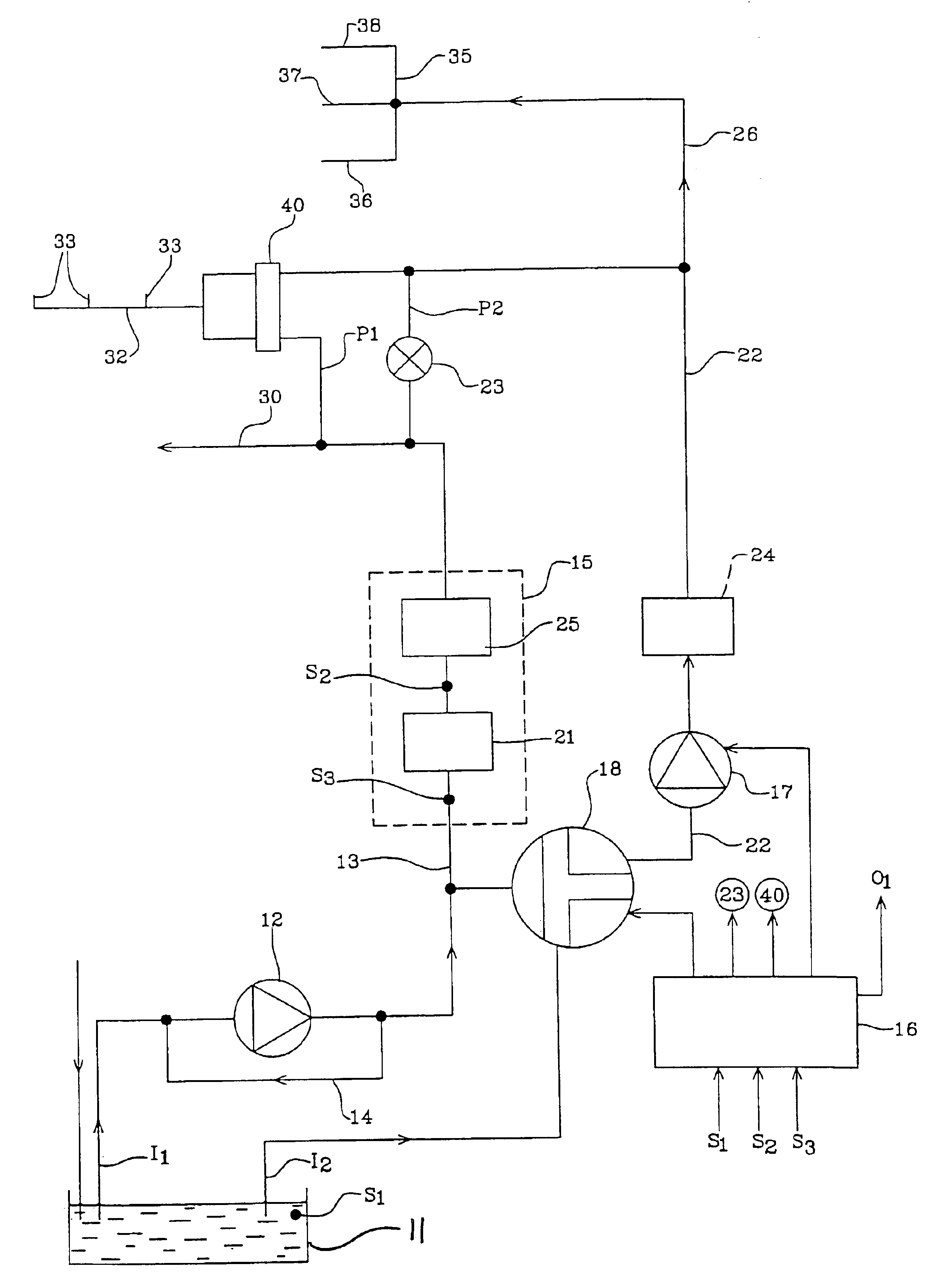

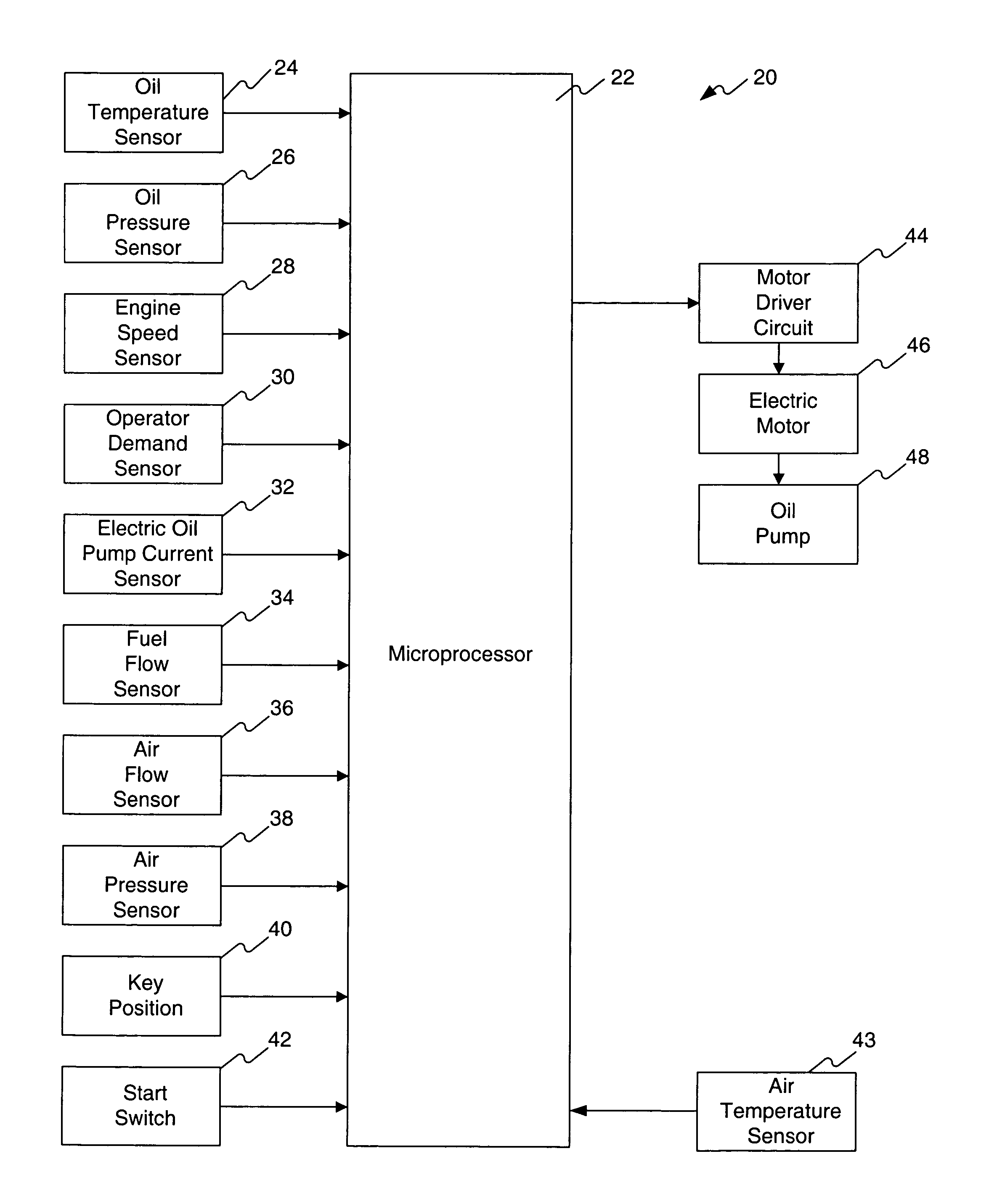

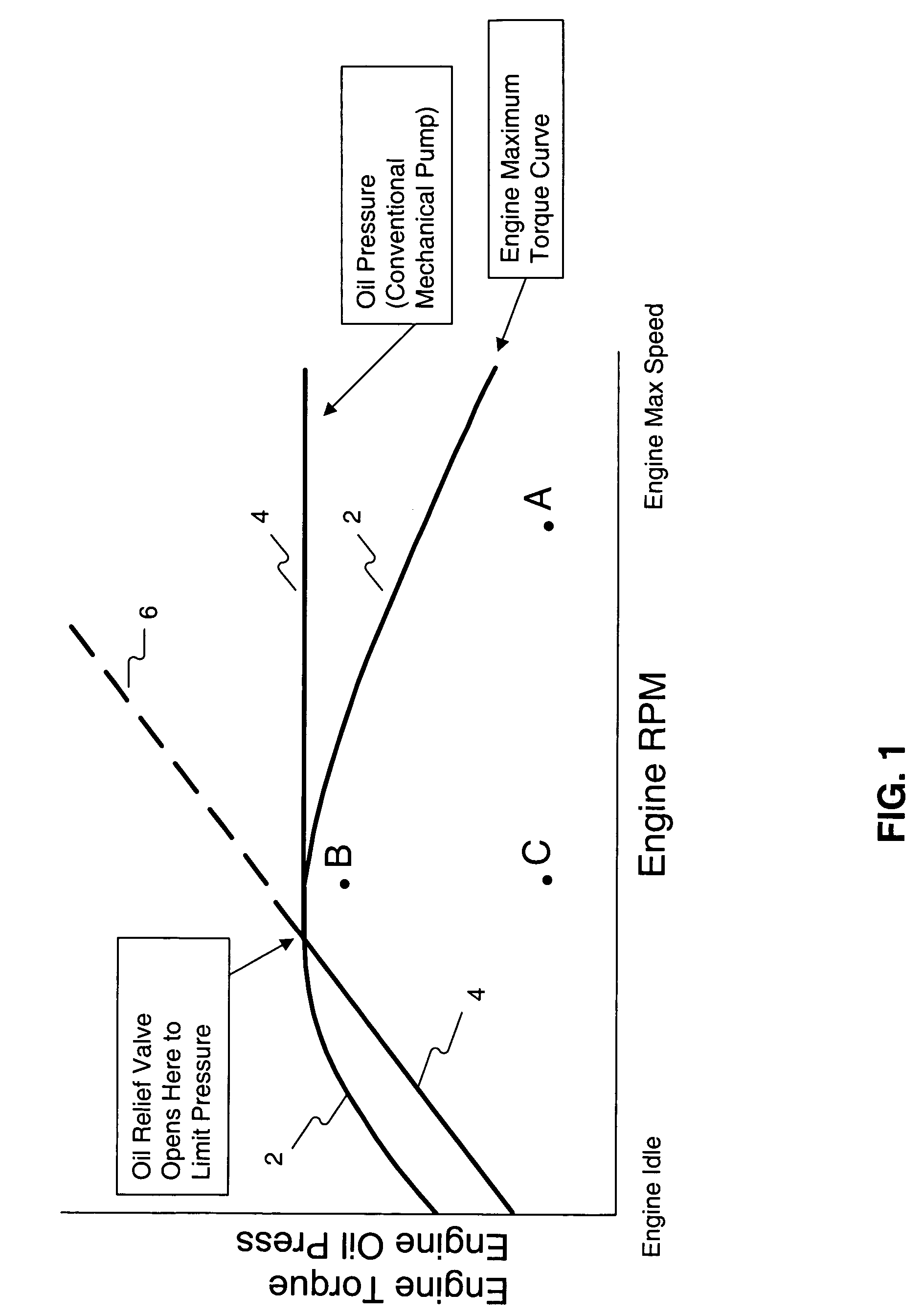

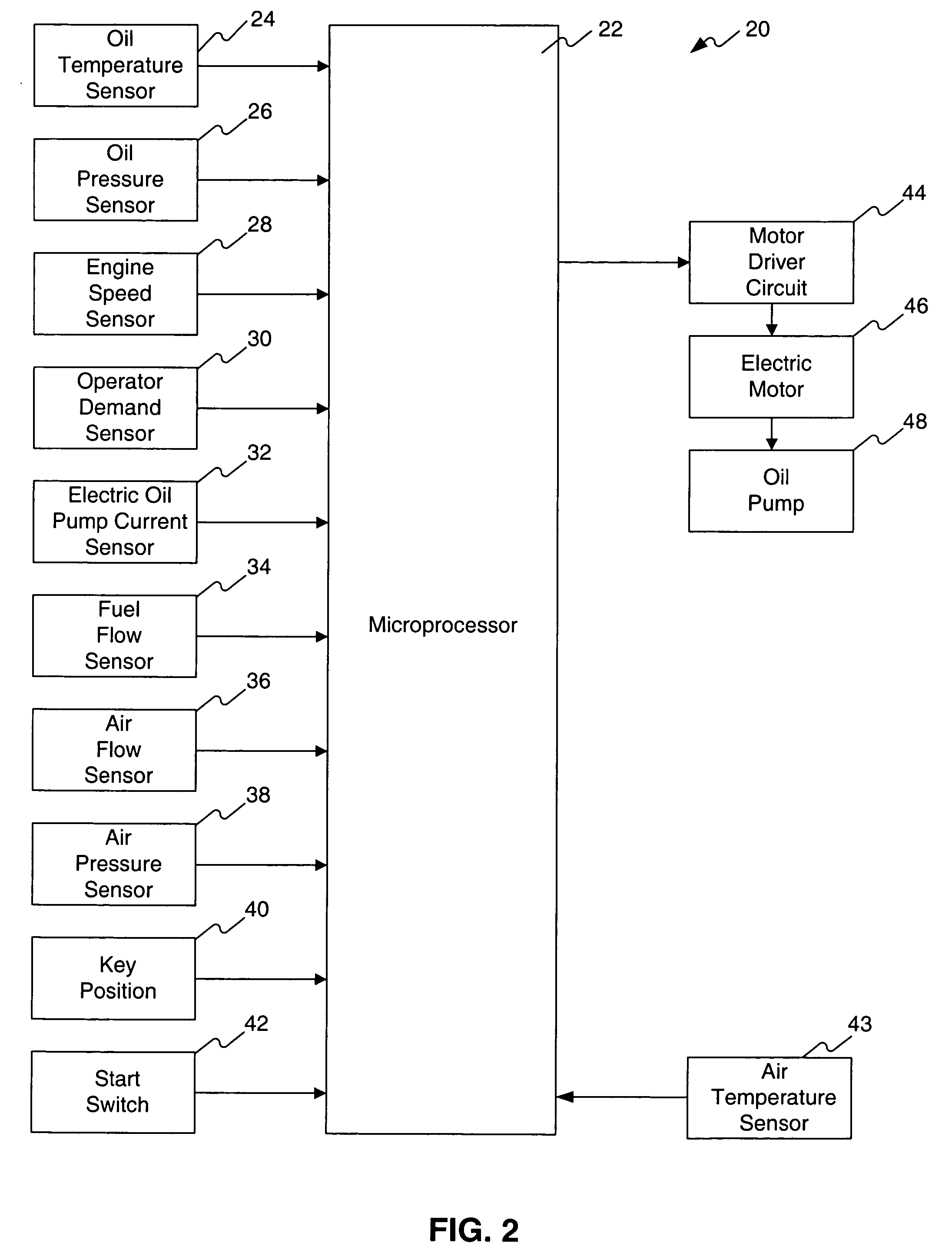

Engine lubrication system

ActiveUS6941922B2Small sizeLubrication of auxillariesLubricant conduit arrangementsLine tubingEngineering

A lubrication system for an engine including a sump for lubricant, a main pump operable to pump lubricant to first lubrication positions within the engine, and an auxiliary lubricant pump also operable to pump lubricant to second lubrication positions within the engine and wherein the auxiliary pump is an electrically driven pump which is controlled by a system controller the output of the auxiliary pump being controlled according to engine operating conditions, the main pump in use, pumping lubricant to the first lubrication positions within the engine along a main lubricant feed line, and the auxiliary pump when operated pumping lubricant to the second lubrication positions within the engine along an auxiliary feed line, and wherein the main and auxiliary feed lines, are connected via a communication passage which includes a closeable communication valve, the communication valve when closed preventing the flow of lubricant from the auxiliary feed line to the first lubrication positions, and when open permitting the flow of lubricant from the auxiliary feed line to the first lubrication positions.

Owner:PIERBURG PUMP TECH UK

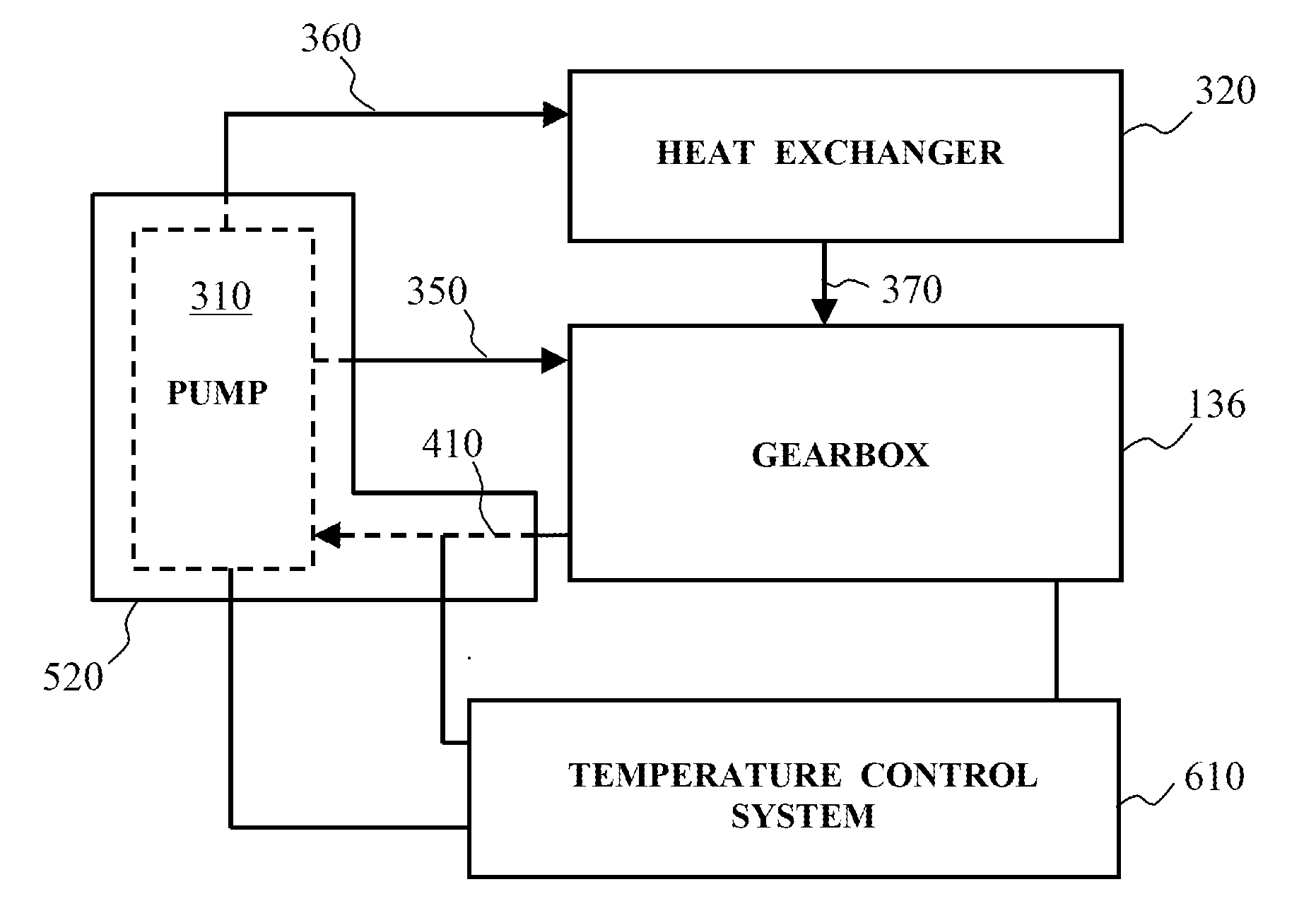

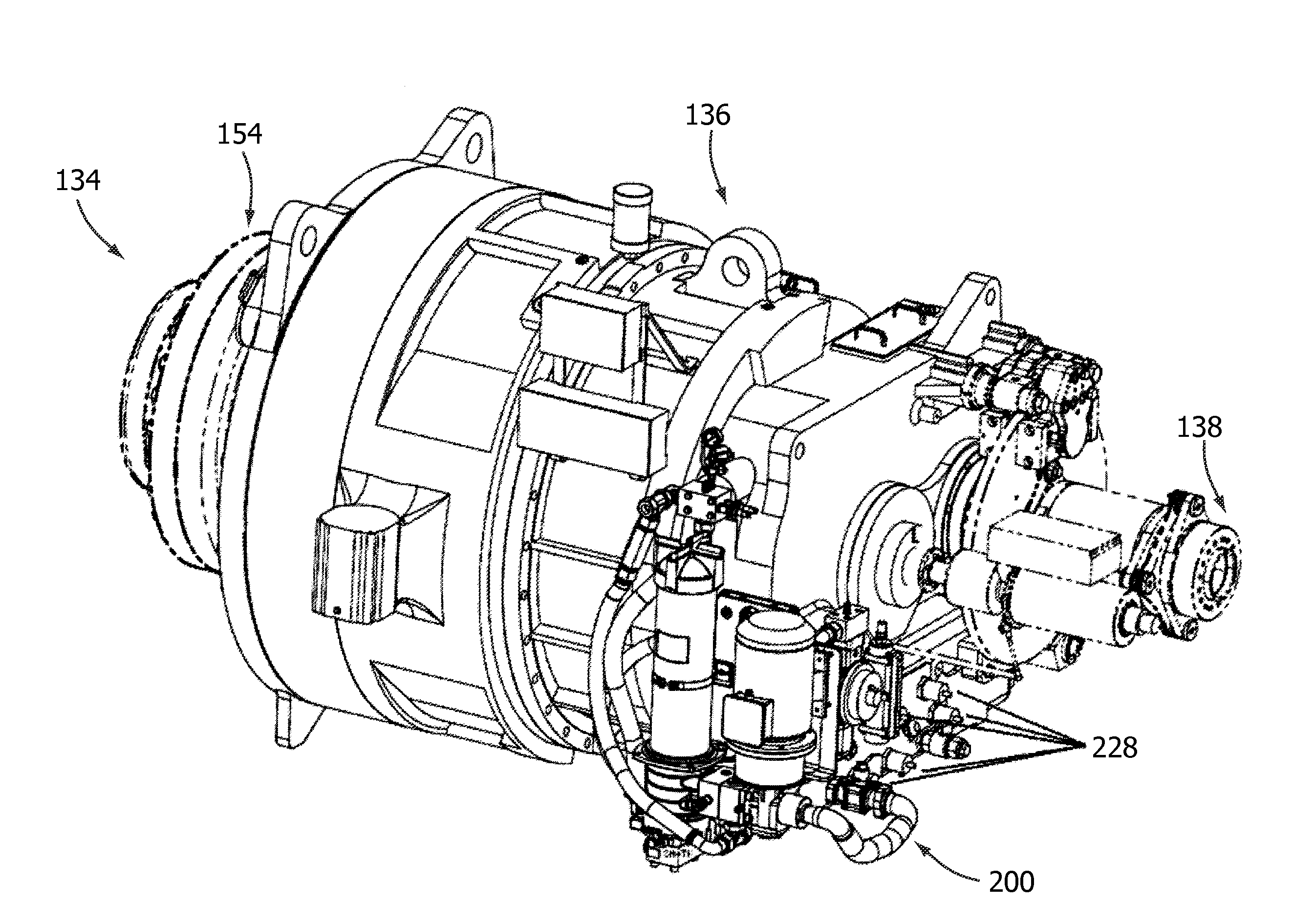

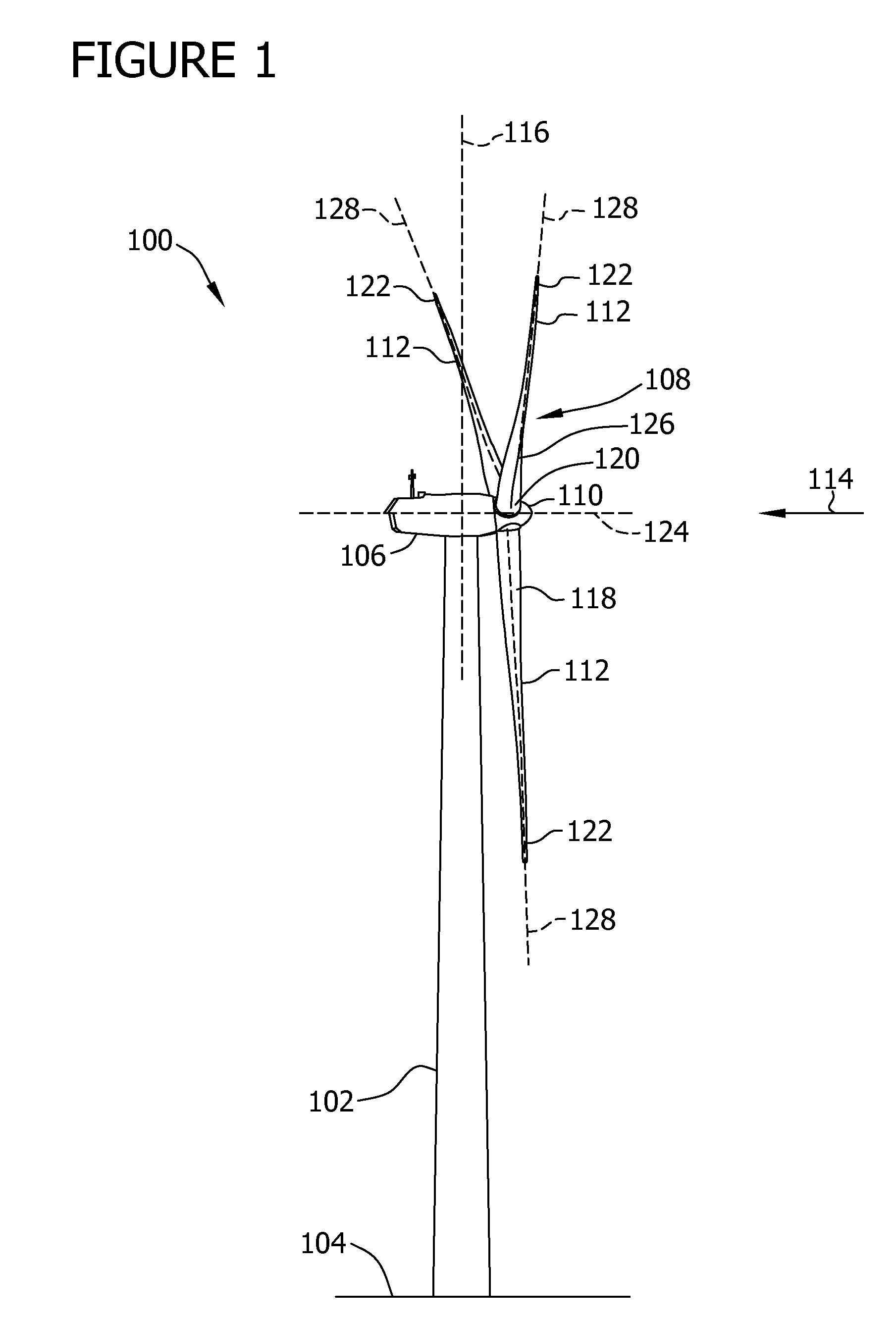

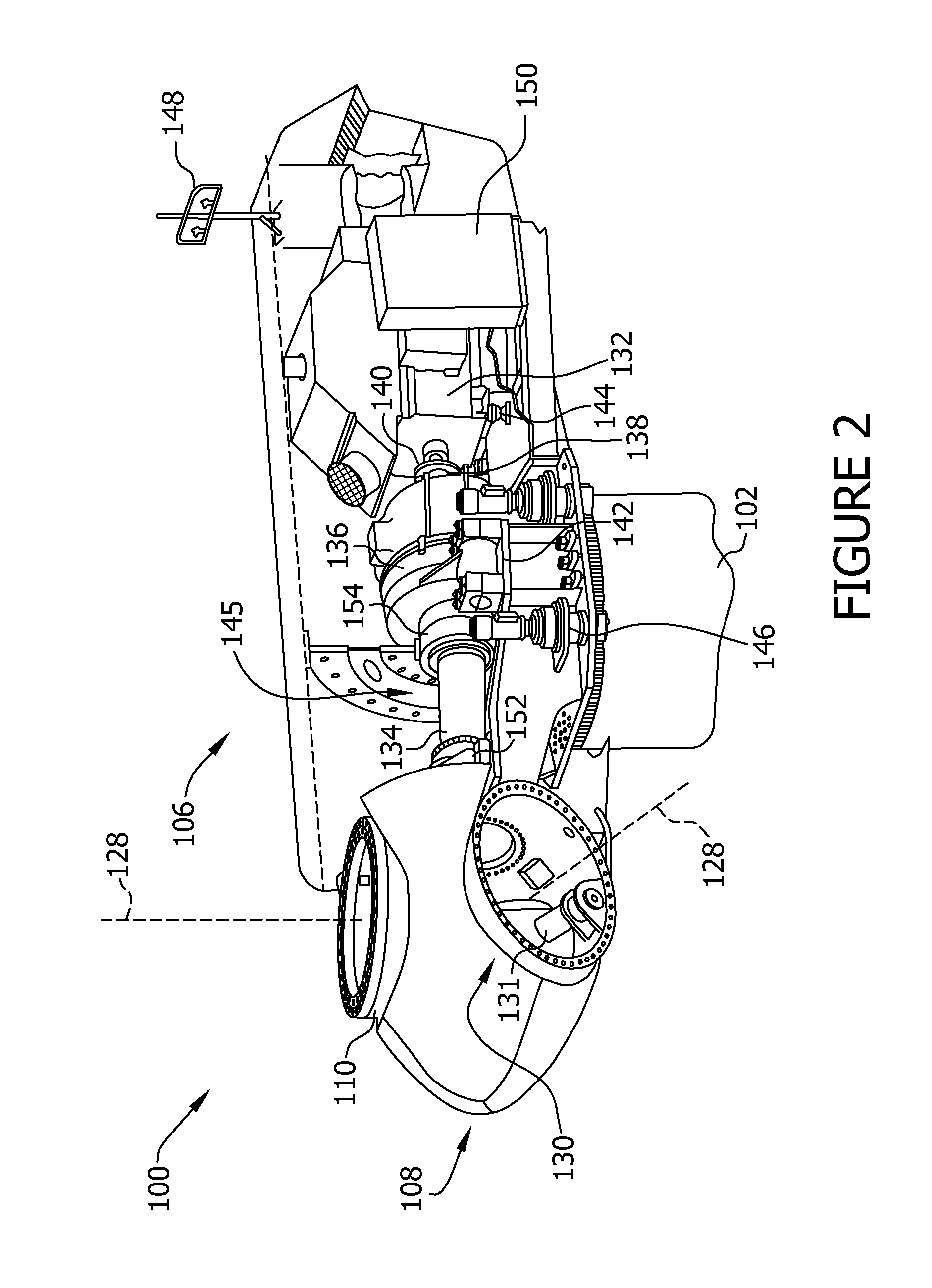

Lubrication heating system and wind turbine incorporating same

A wind turbine is provided having a gearbox containing a lubrication medium, a pump for circulating the lubrication medium. and a gearbox lubrication suction pipe for transporting the lubrication medium from the gearbox to the pump. A heater is in thermal connection to, at least a portion of, the gearbox lubrication suction pipe. This heater is used to heat the lubrication medium contained within the gearbox lubrication suction pipe to a temperature where damage to the pump is avoided.

Owner:GENERAL ELECTRIC CO

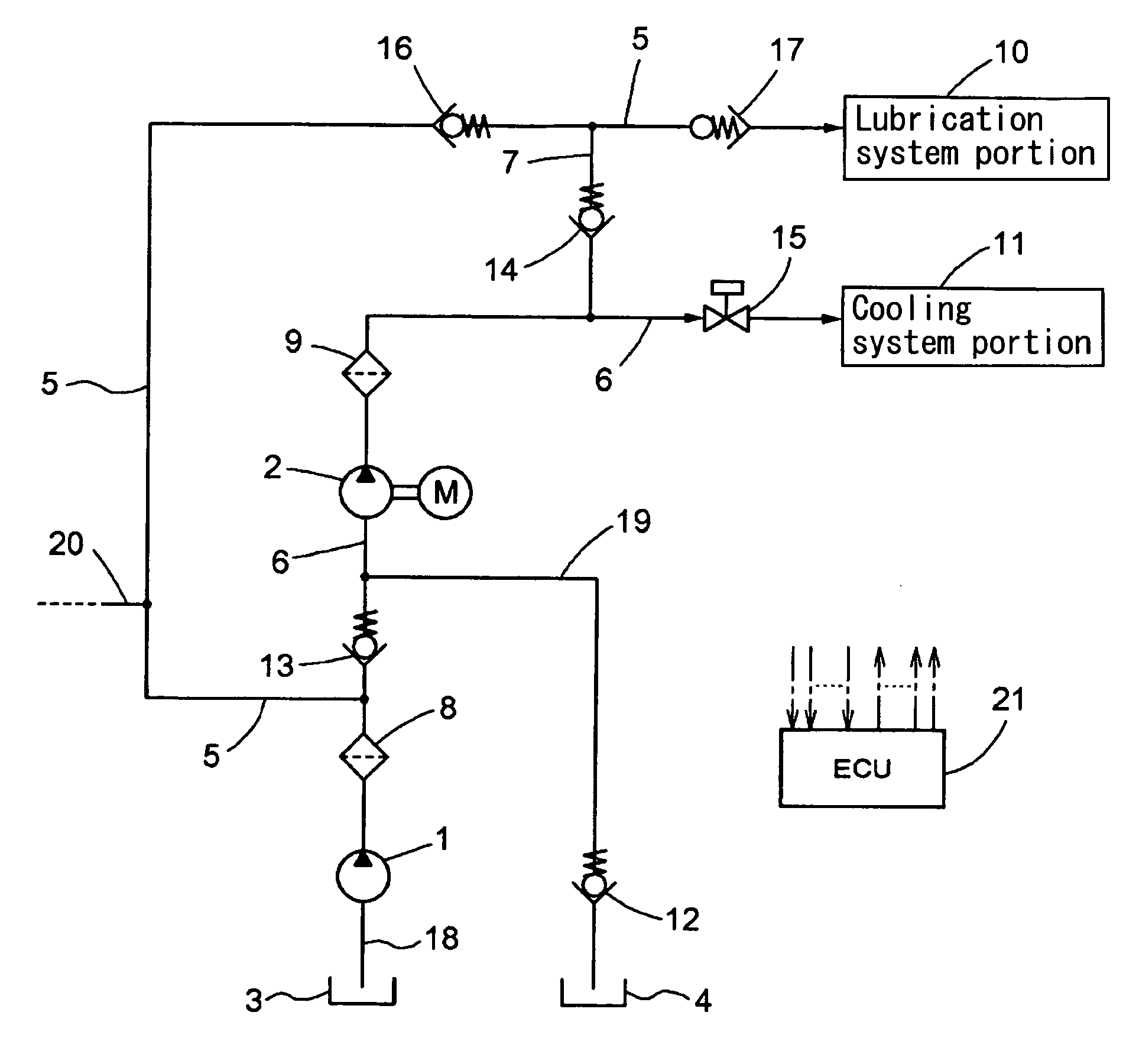

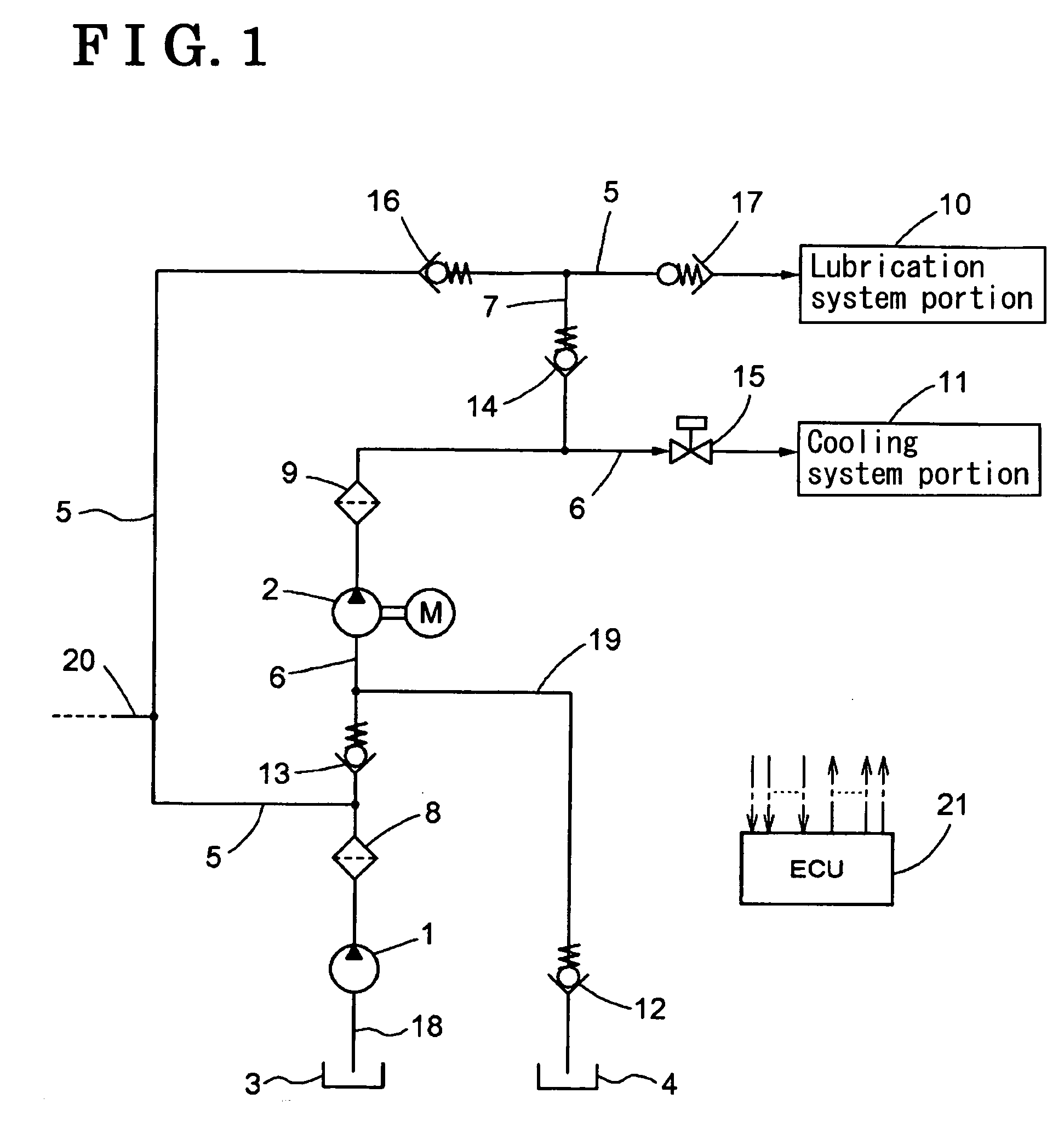

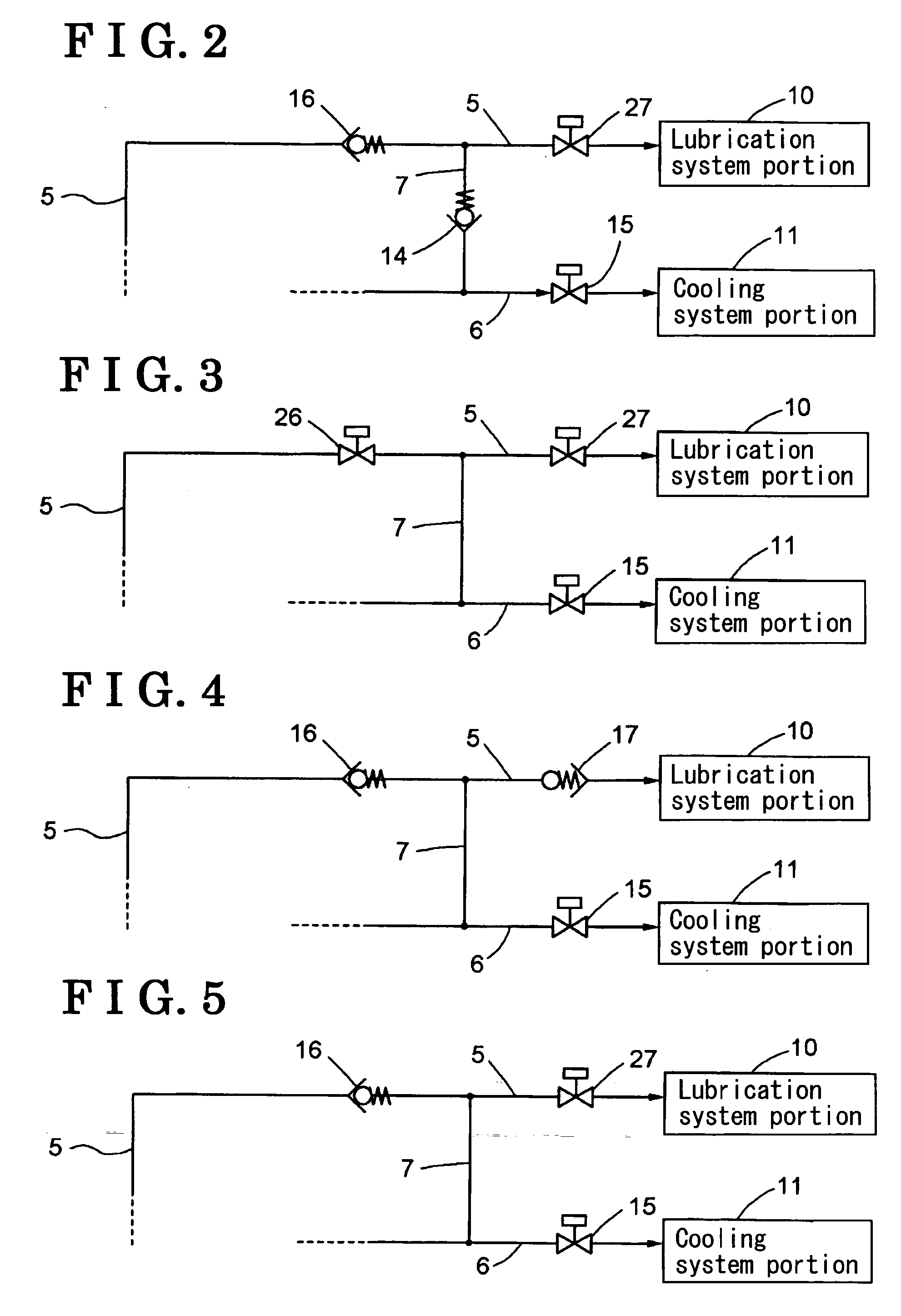

Oil supply device for engine

An oil supply device for an engine includes a first oil suction passage, a second oil suction passage, a first pump for sucking and discharging oil from the first oil suction passage, a second pump arranged in series with the first pump, the second pump for sucking and discharging oil from at least one of the first pump and the second oil suction passage, a check valve for blocking oil circulation, a first oil passage, a second oil passage, a third oil passage for establishing communication between the first oil passage and the second oil passage, and a supply volume control device for varying oil supply volume to a lubrication system portion, to a cooling system portion, or to the lubrication system portion and the cooling system portion in accordance with a change in at least one of an engine oil temperature, an engine rotation speed, and an engine load.

Owner:AISIN SEIKI KK

Thermal management system for turbofan engines

A heat exchange system for use in operating equipment in which a working fluid is utilized needing a heat exchange system to provide air and working fluid heat exchanges to cool the working fluid at selectively variable rates in airstreams. The system comprises a plurality of heat exchangers including a first heat exchanger in the plurality of heat exchangers that is mounted with respect to the equipment so as to permit corresponding portions of the airstreams to pass through the core thereof during at least some such uses of the equipment. Also, a second heat exchanger is mounted with respect to the equipment so as to selectively permit corresponding portions of the airstreams to pass through the core thereof during such uses of the equipment. A core actuator is mounted with respect to the second heat exchanger to selectively increase or reduce the passing of those corresponding portions of the airstreams through the core.

Owner:RTX CORP

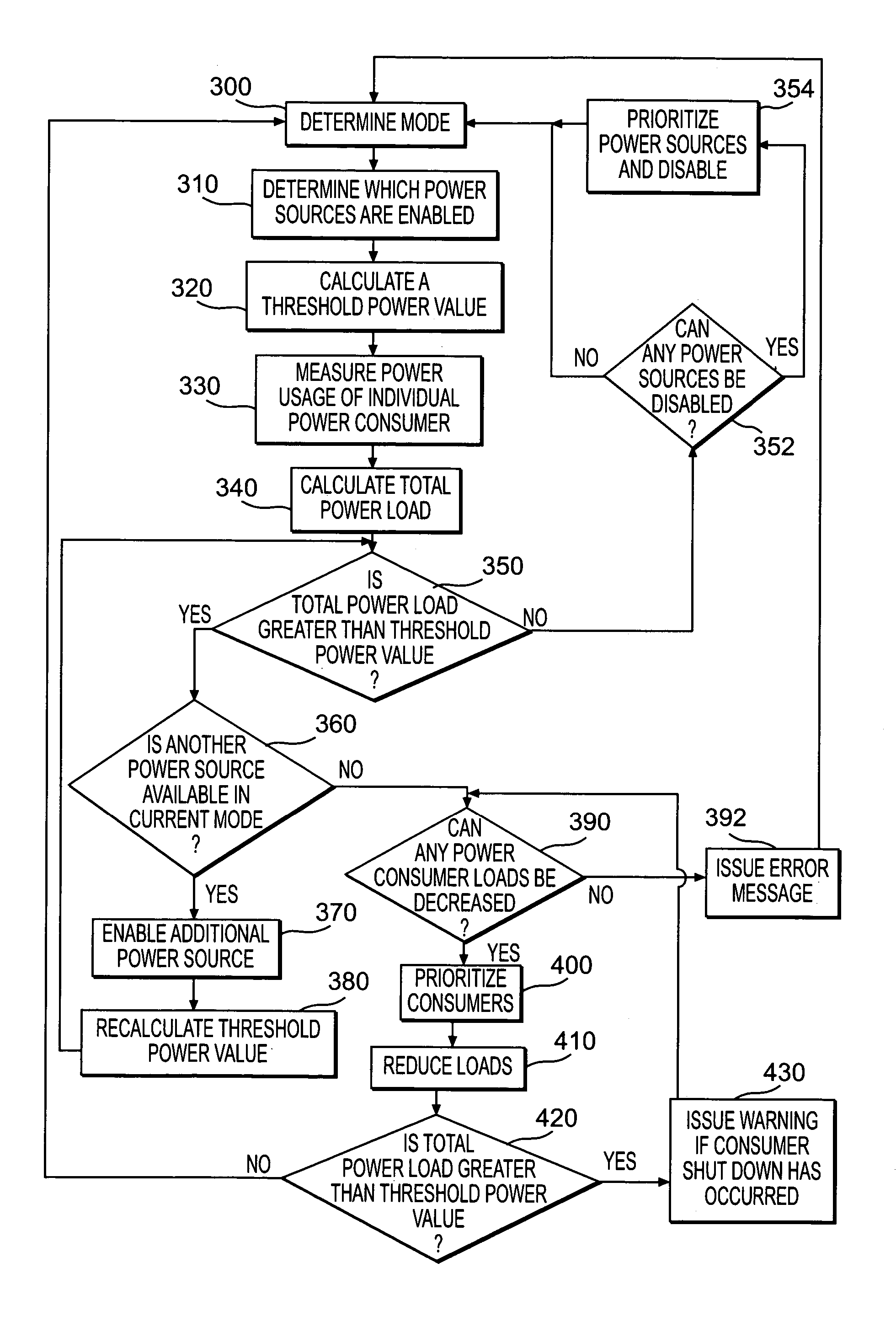

Power management system

A method of managing power resources for an electrical system of a vehicle may include identifying enabled power sources from among a plurality of power sources in electrical communication with the electrical system and calculating a threshold power value for the enabled power sources. A total power load placed on the electrical system by one or more power consumers may be measured. If the total power load exceeds the threshold power value, then a determination may be made as to whether one or more additional power sources is available from among the plurality of power sources. At least one of the one or more additional power sources may be enabled, if available.

Owner:CATERPILLAR INC

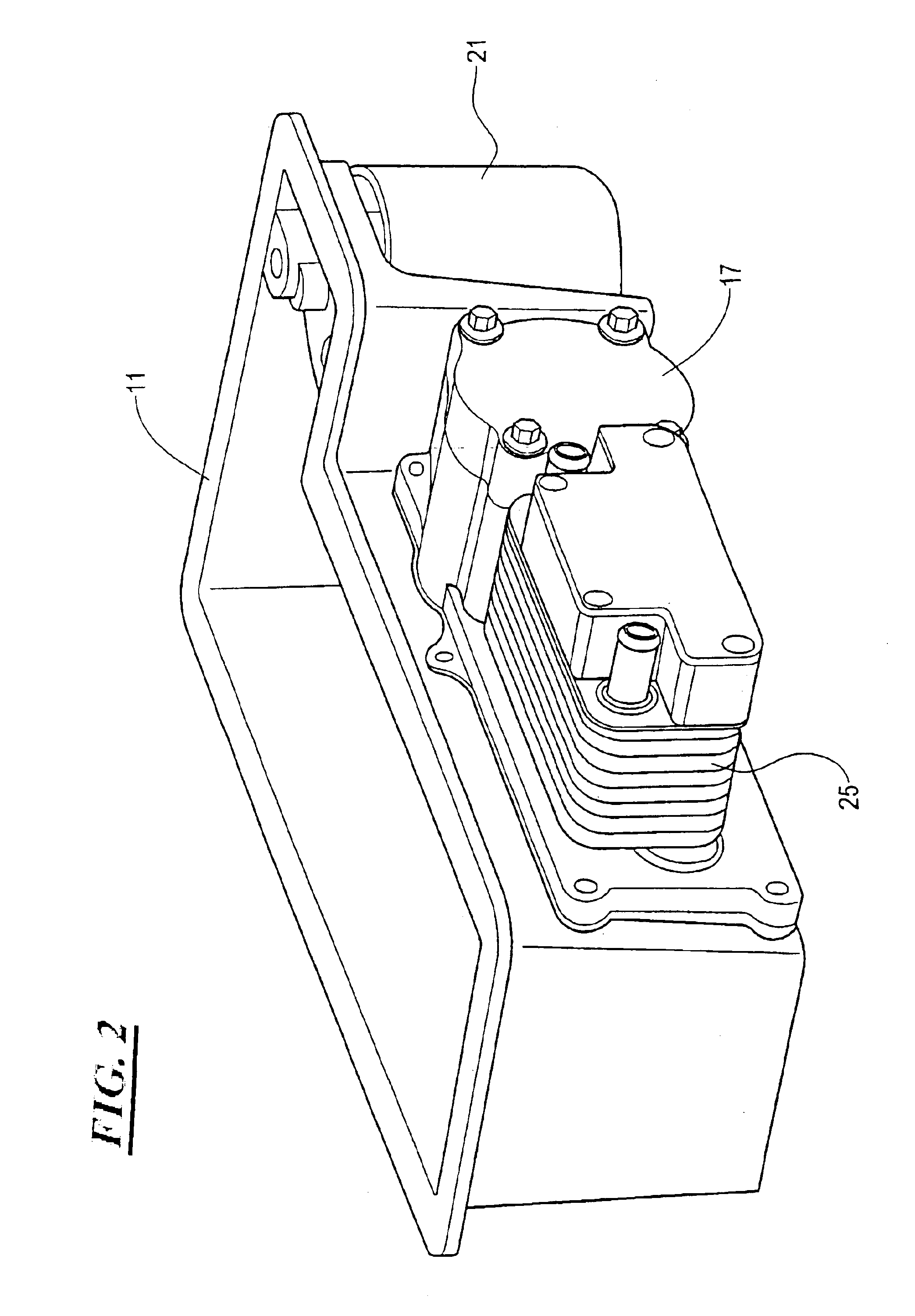

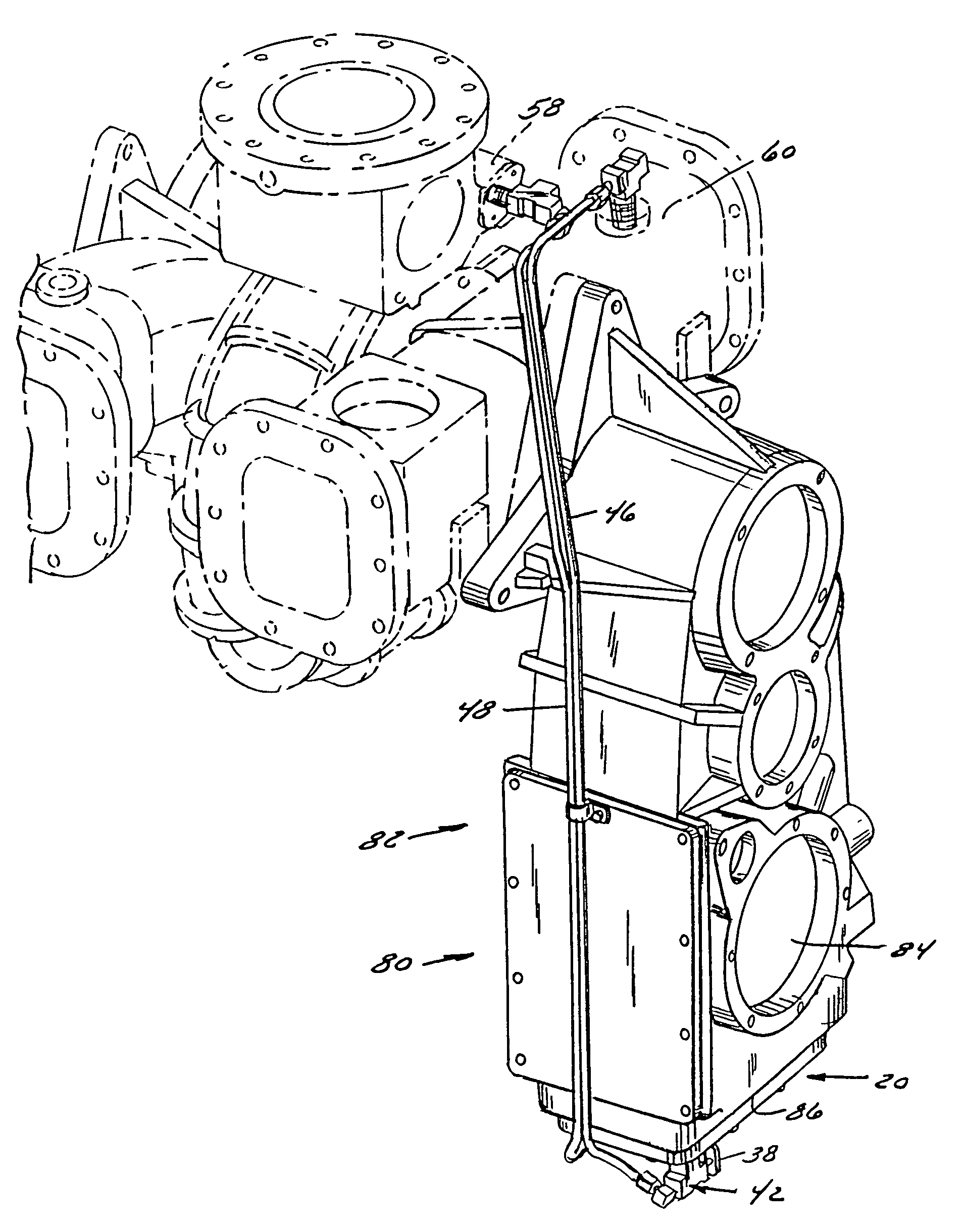

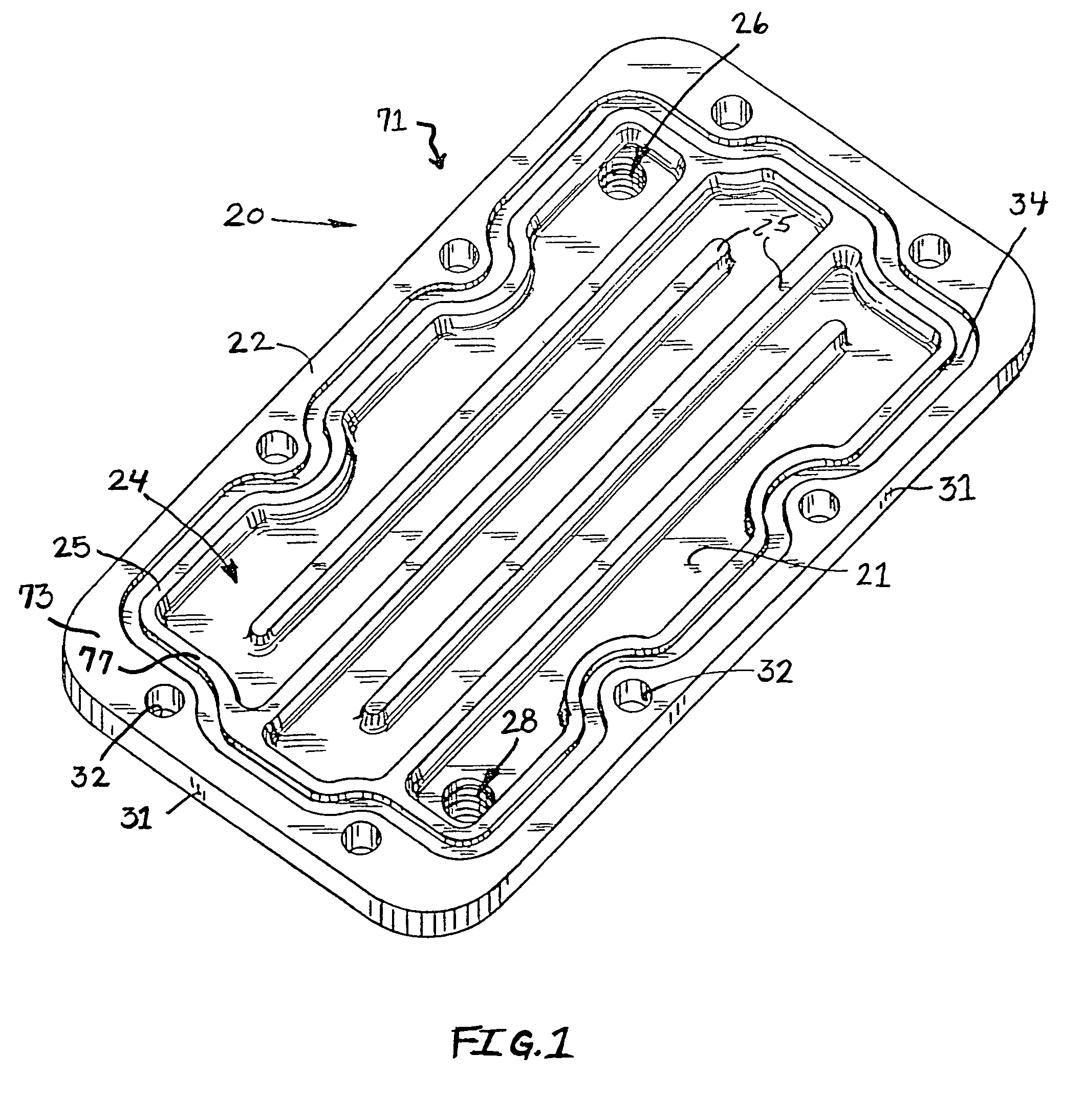

Cooler plate and gearbox assembly

A gearbox assembly comprising a casing defining a cavity for housing gears of an engine-driven apparatus, the casing having at least one substantially flat exterior surface for receiving a cooler plate, and a cooler plate mounted to the casing at the substantially flat exterior surface, the cooler plate isolated from the cavity by the flat exterior surface, the cooler plate having a channel for receiving a liquid for cooling the casing and at least one port in communication with the channel. At least one further embodiment includes a gearbox assembly where the channel is aligned with the exterior surface for supplying liquid in contact with the surface. The invention also includes a cooler plate for attachment at a closed exterior surface of a gearbox in order to supply cooling liquid in contact with the gearbox surface to cool the gearbox.

Owner:W S DARLEY & CO

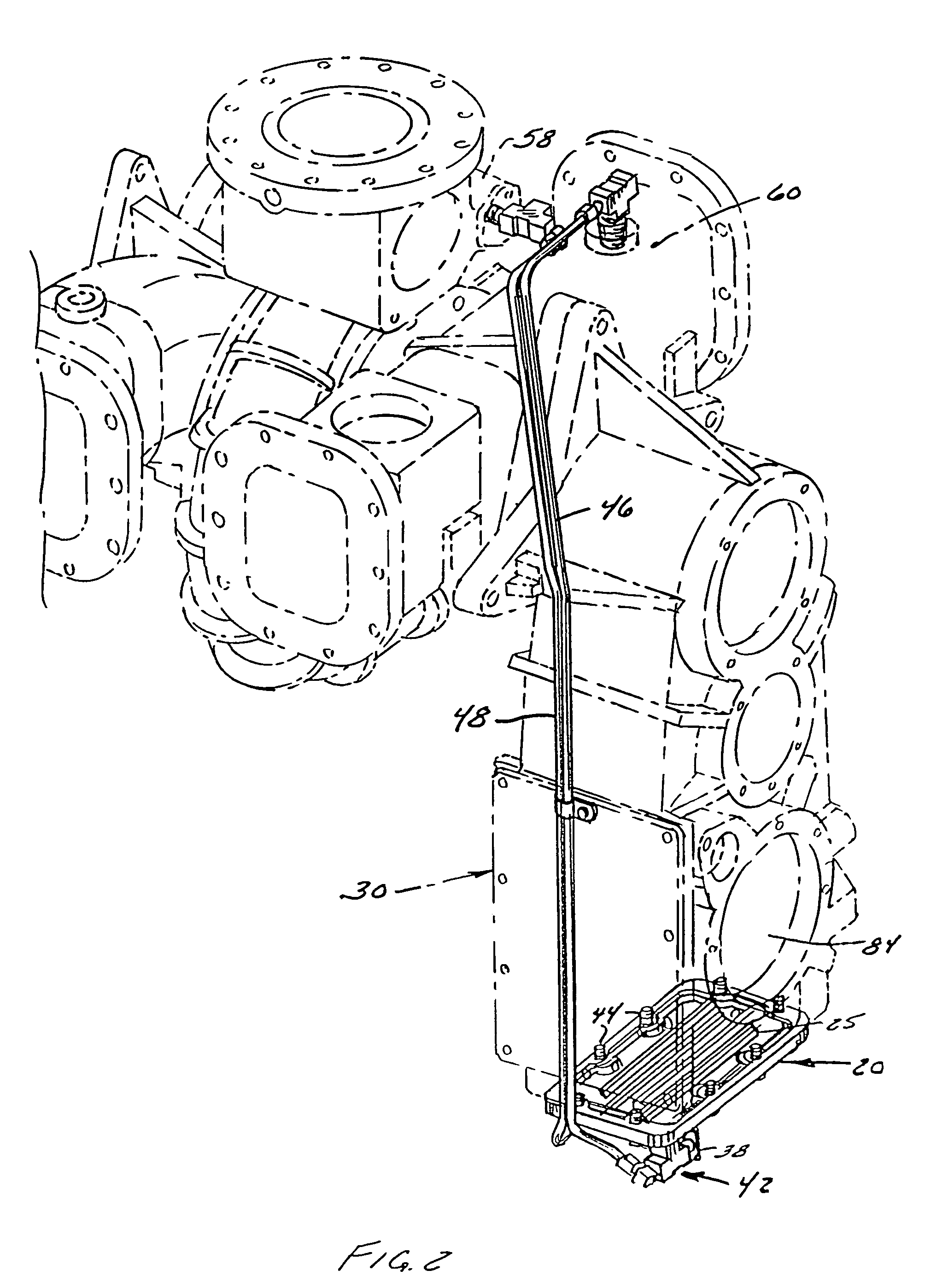

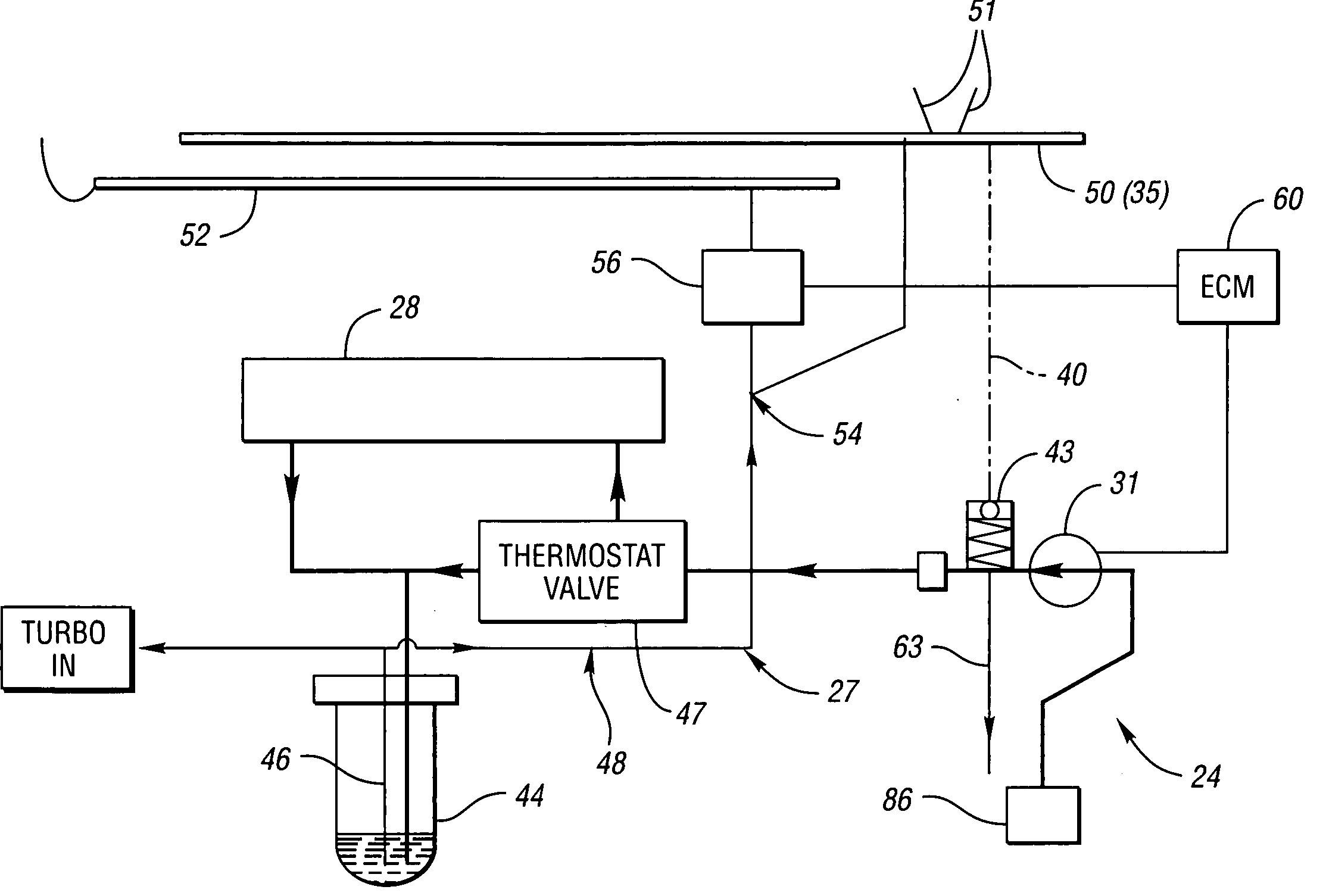

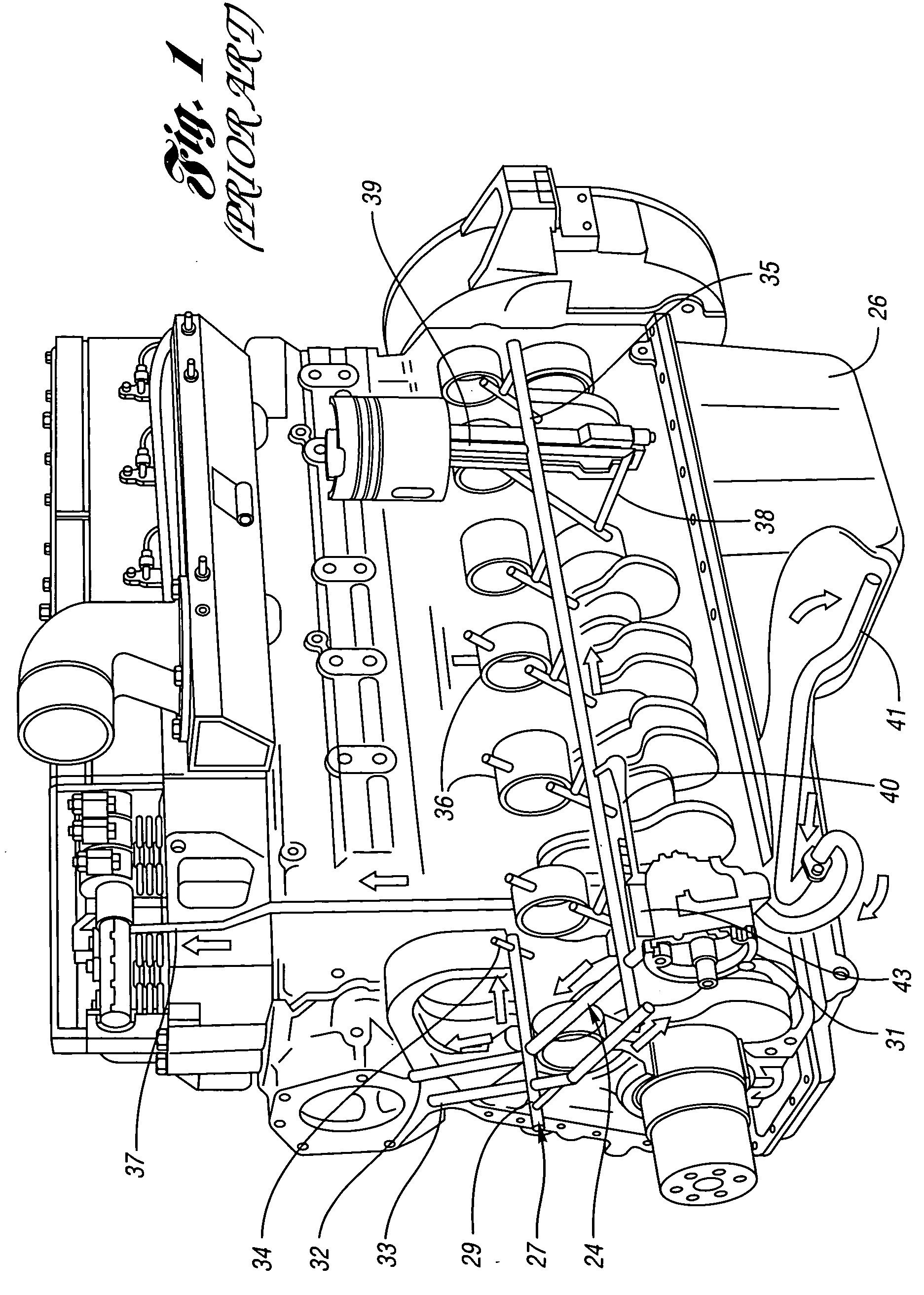

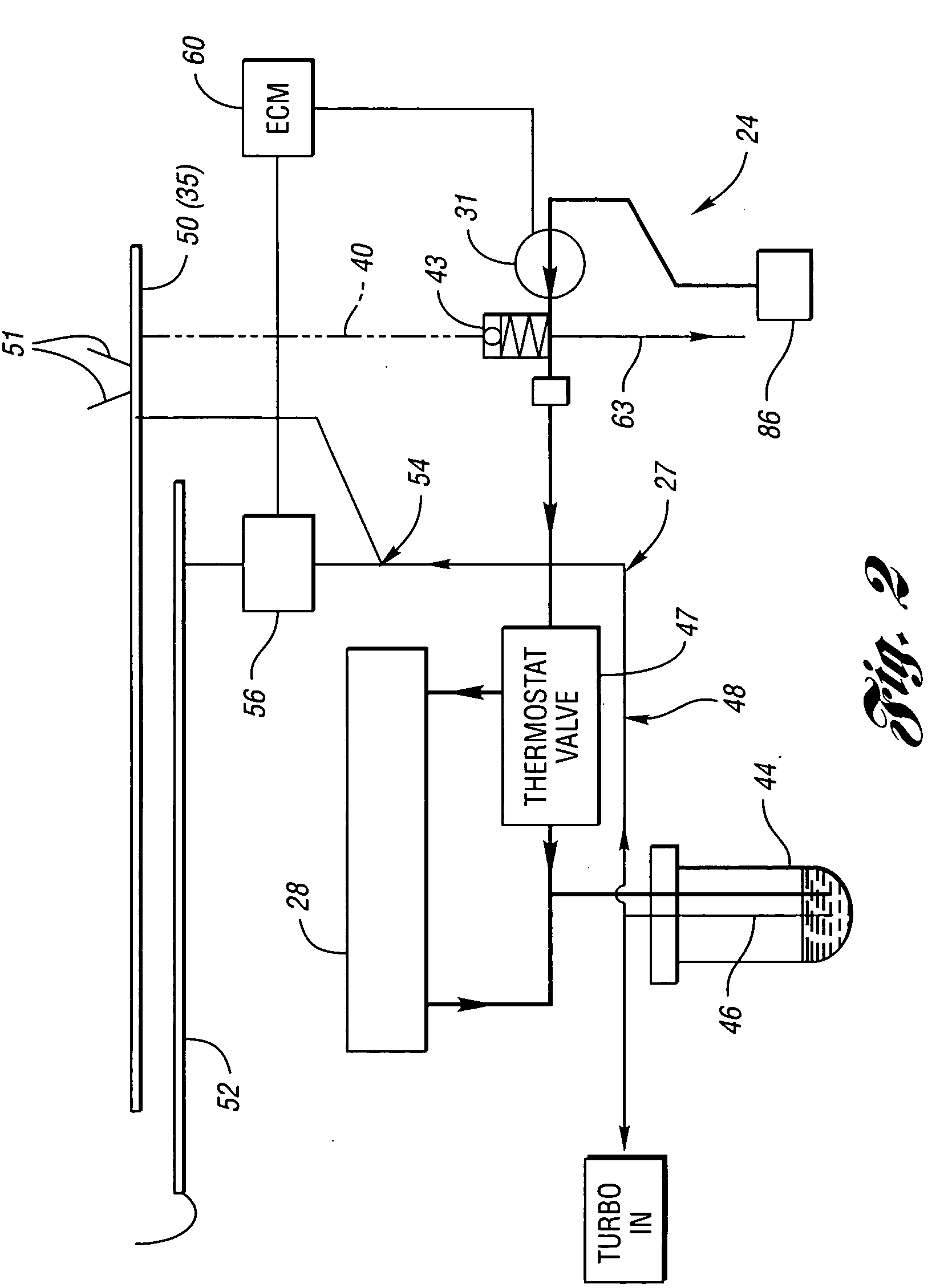

Separate oil gallery for piston cooling with electronic oil flow control

InactiveUS20050120982A1Reduce oil flowSaving in parasitic lossLiquid coolingCoolant flow controlThermal stateOil distribution

An engine oil distribution system for an internal combustion engine includes a main gallery and a separate oil gallery for piston cooling nozzles. The separate gallery may be controlled by a control valve that regulates the oil flow. The oil flow to the separate gallery may be controlled by an electronic control module in accordance with the piston cooling needs, for example, varied as a function of the load applied to the engine, or as a function of engine temperature. Preferably, engine temperature is sensed by coolant fluid temperature, or directly measured metal temperature, correlated to the thermal state of the piston.

Owner:DETROIT DIESEL CORP

Regulated oil cooling system for a turbine engine with deicing of the nacelle

InactiveUS20140205446A1Many timesDischarging heatPump componentsGas turbine plantsNacelleCooling capacity

The invention relates to an oil cooling system of a turbine engine installed in an aircraft comprising a circuit suitable for circulating the oil between the engine and at least one external heat exchanger placing the oil in thermal communication with a part of the lip of the nacelle, wherein it also comprises at least one air / oil heat exchanger placing the oil in thermal communication with the air circulating in the cold zone of the turbine engine, equipped with a device suitable for varying its oil cooling capacity, and with a control means for said cooling capacity variation device.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

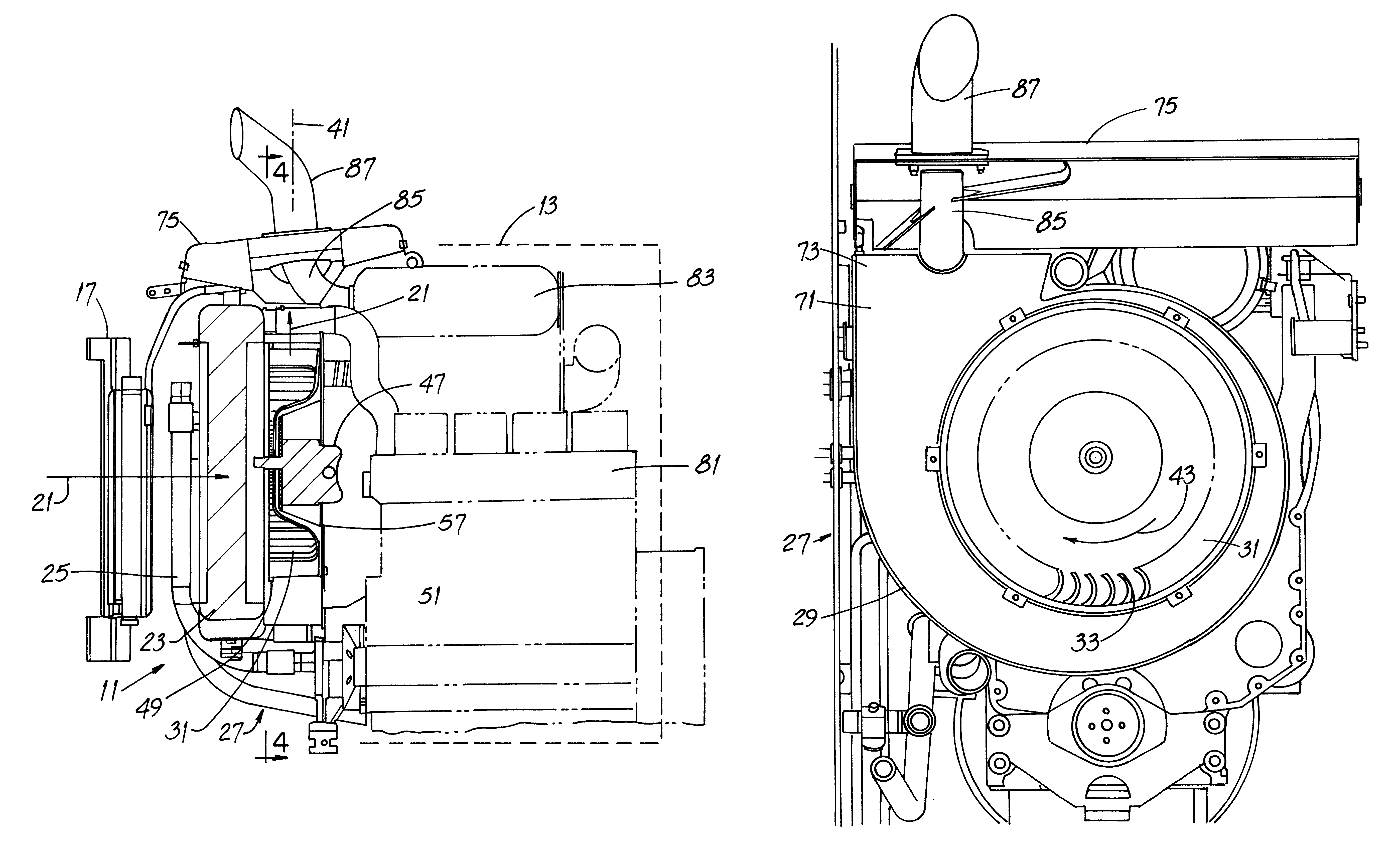

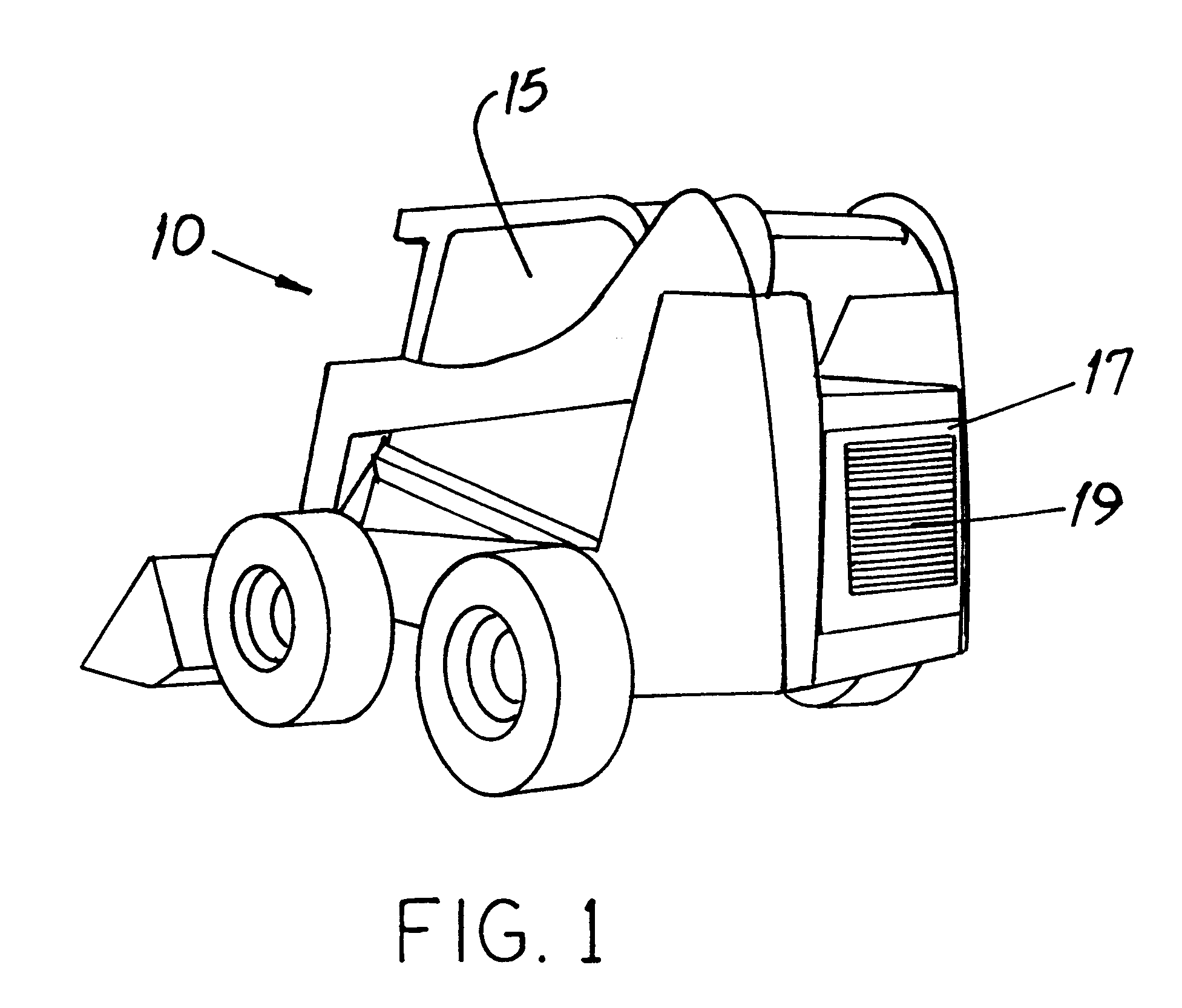

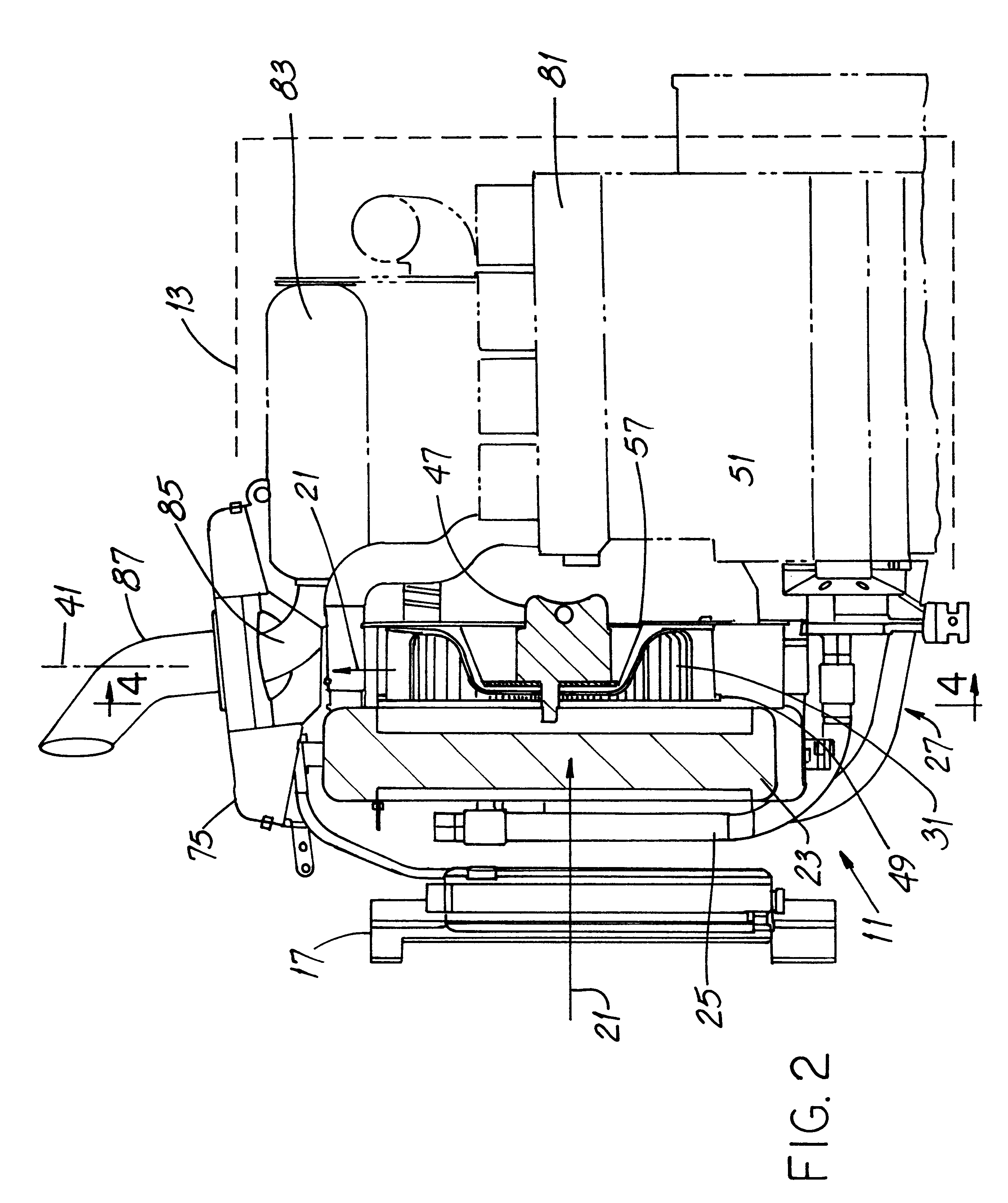

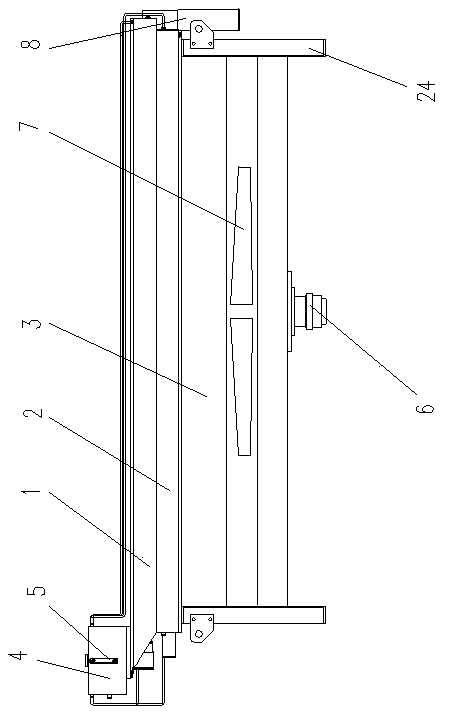

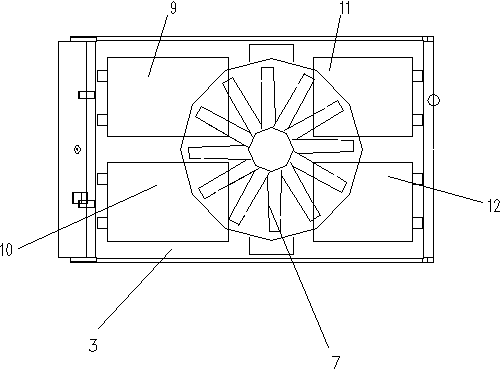

Cooling system for an off-highway vehicle

InactiveUS6216778B1Reduce system noiseReduce back pressurePump componentsExhaust apparatusDiameter ratioControl theory

A cooling system for an off-highway vehicle includes a heat exchanger (e.g., an engine coolant or hydraulic oil heat exchanger) and a fan mechanism for flowing air along a flow path through the heat exchanger. In the improvement, the fan mechanism is a centrifugal fan mechanism and is substantially the sole means for flowing air along the flow path. That is, there is substantially no ram-urged air. The mechanism includes a housing and a fan in the housing. The fan has forward curved blades, thereby to reduce system noise. A preferred fan has a depth-to-diameter ratio not in excess of about 0.4 and, most preferably, not in excess of about 0.25. An alternate embodiment includes what might be termed a split-discharge arrangement wherein air blown by the fan is discharged along two paths.

Owner:BLUE LEAF I P INC +1

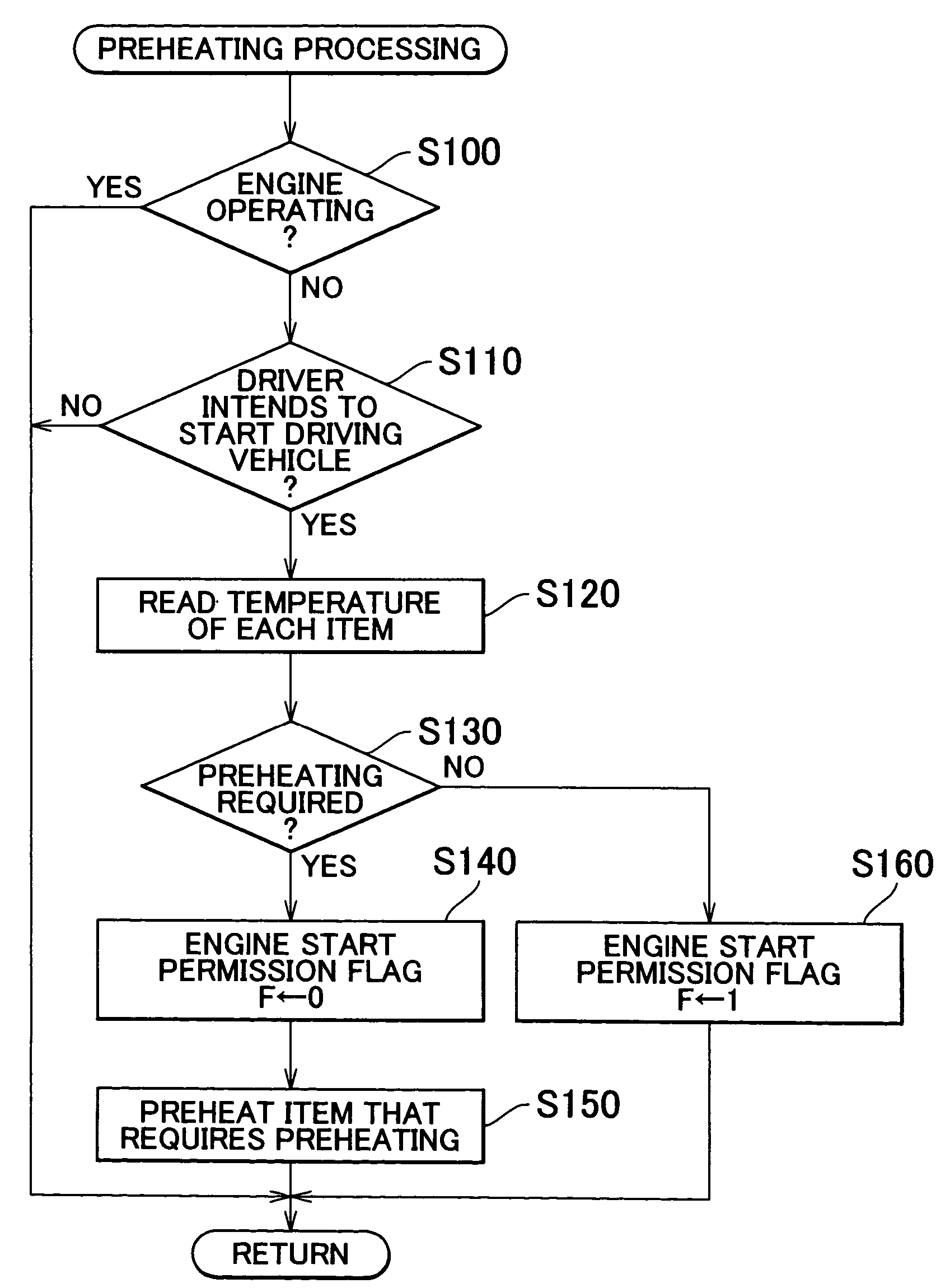

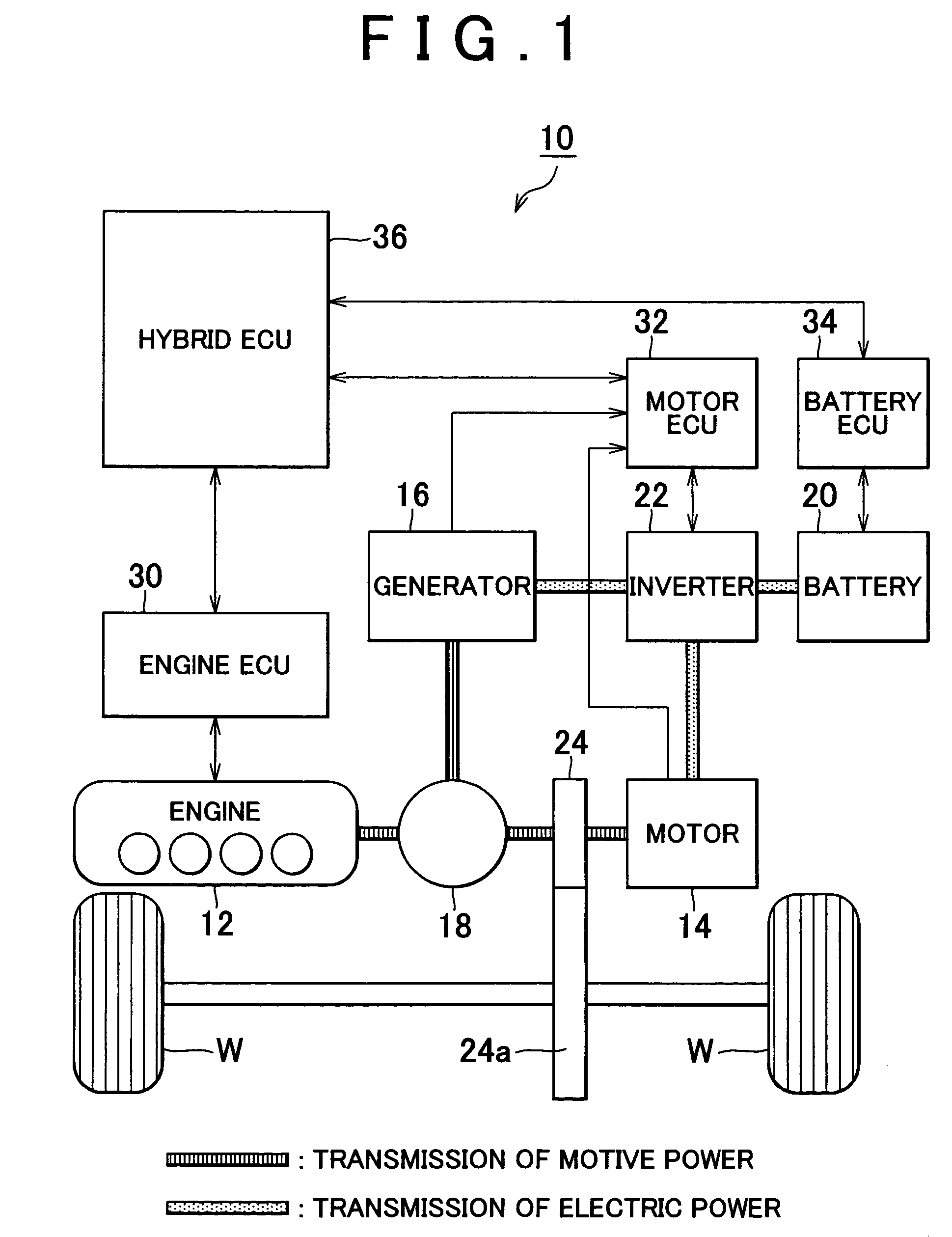

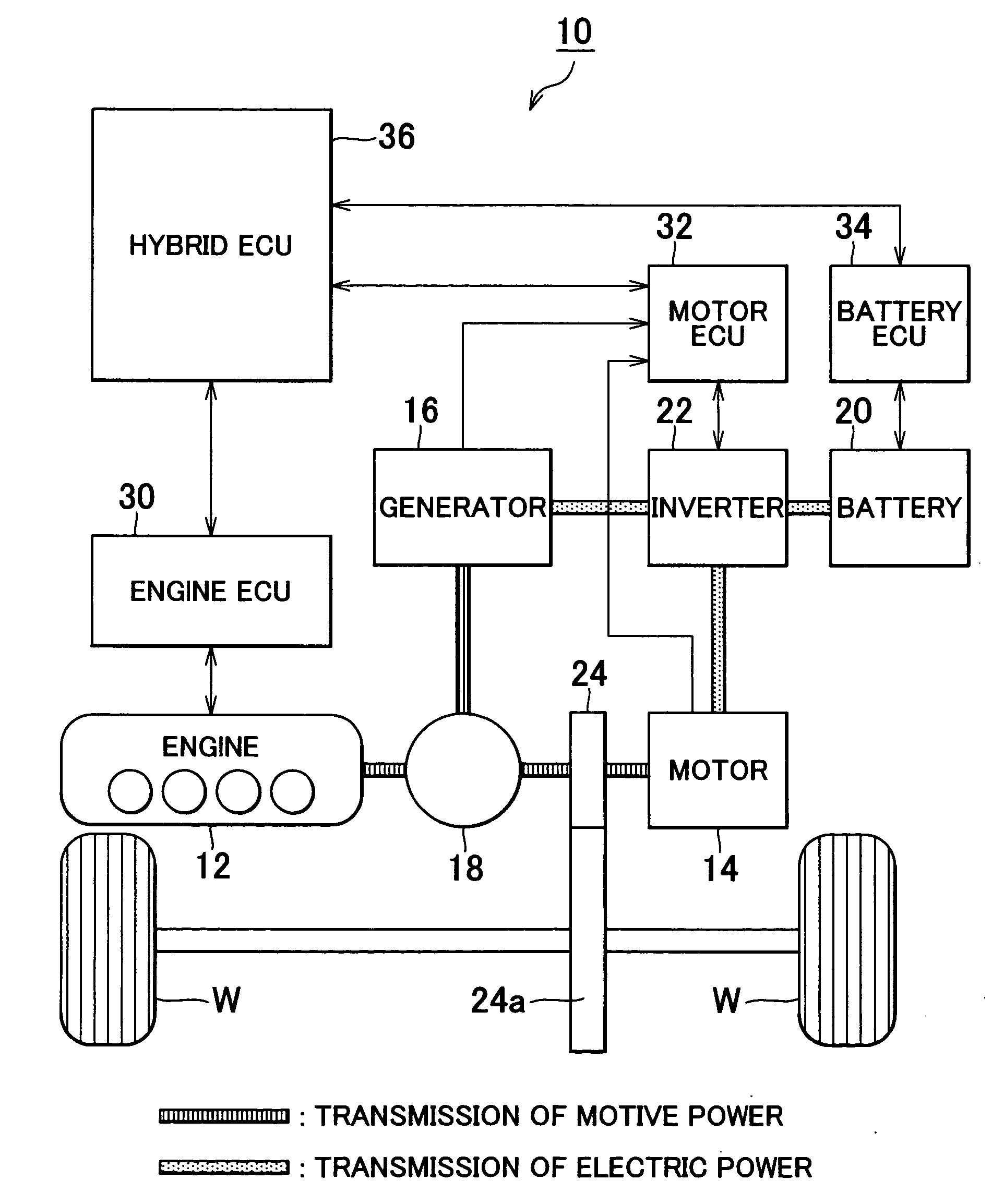

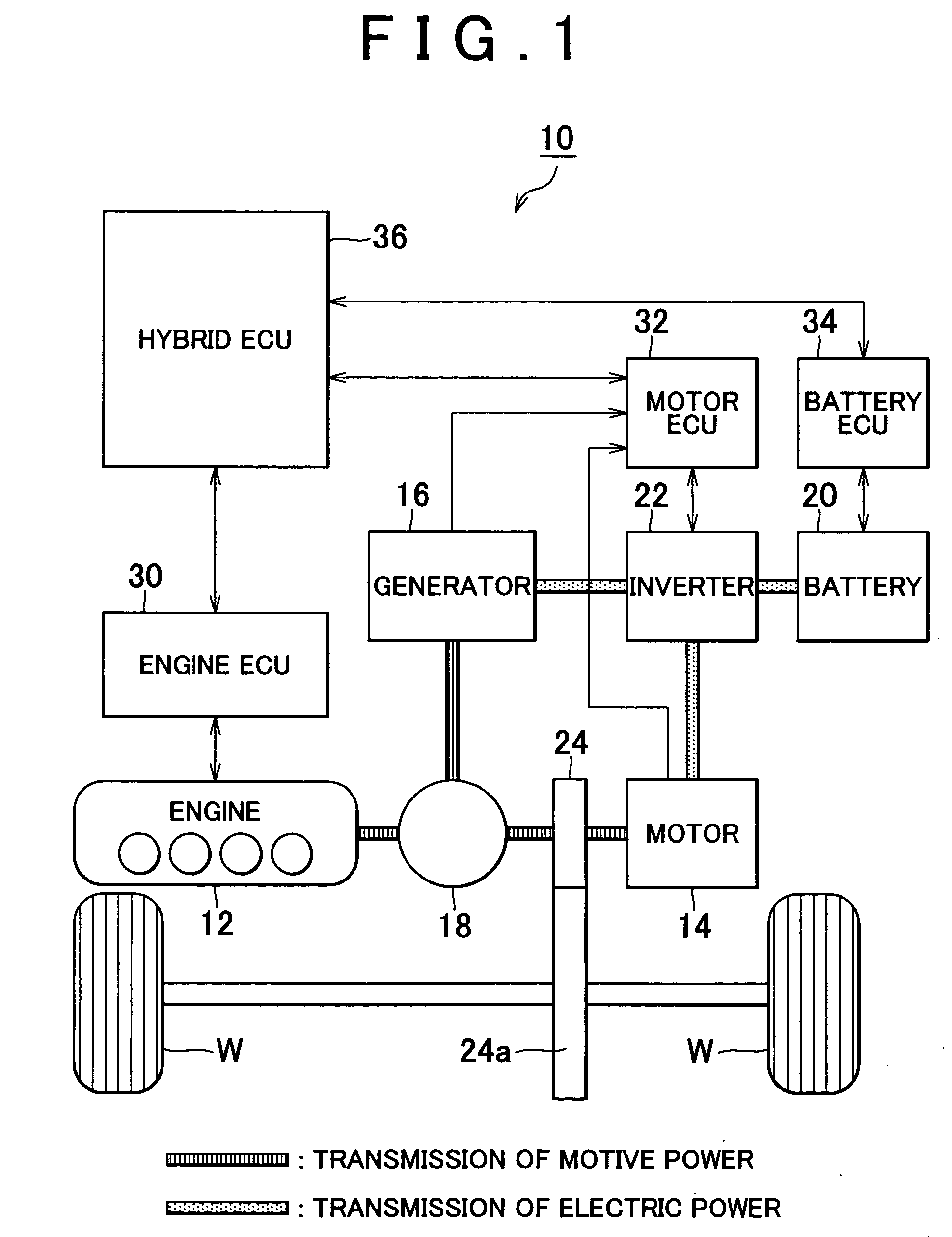

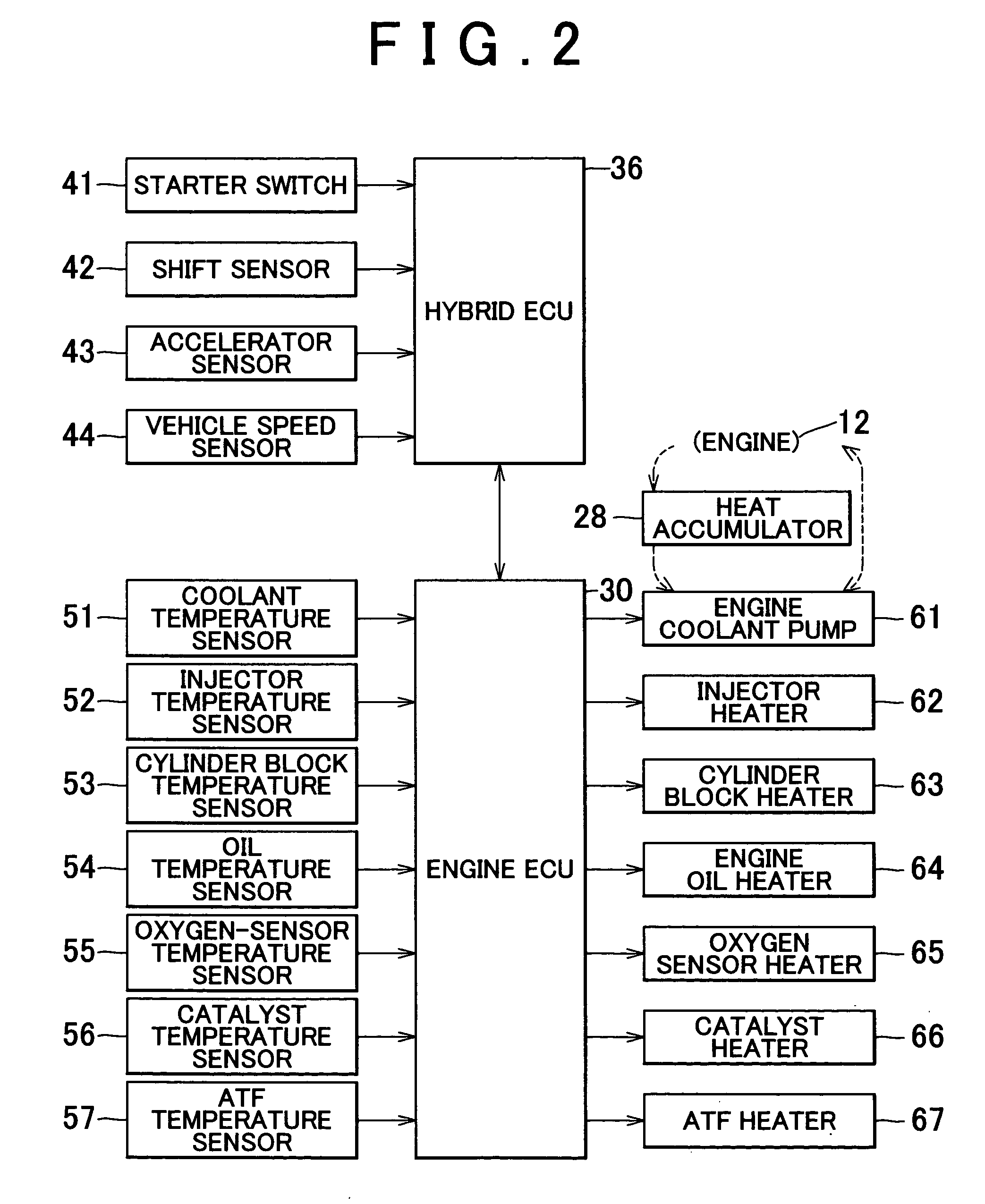

Hybrid vehicle and method of controlling the same

InactiveUS7077224B2Avoid wastingIncrease consumptionHybrid vehiclesInternal combustion piston enginesHybrid vehicleCoolant

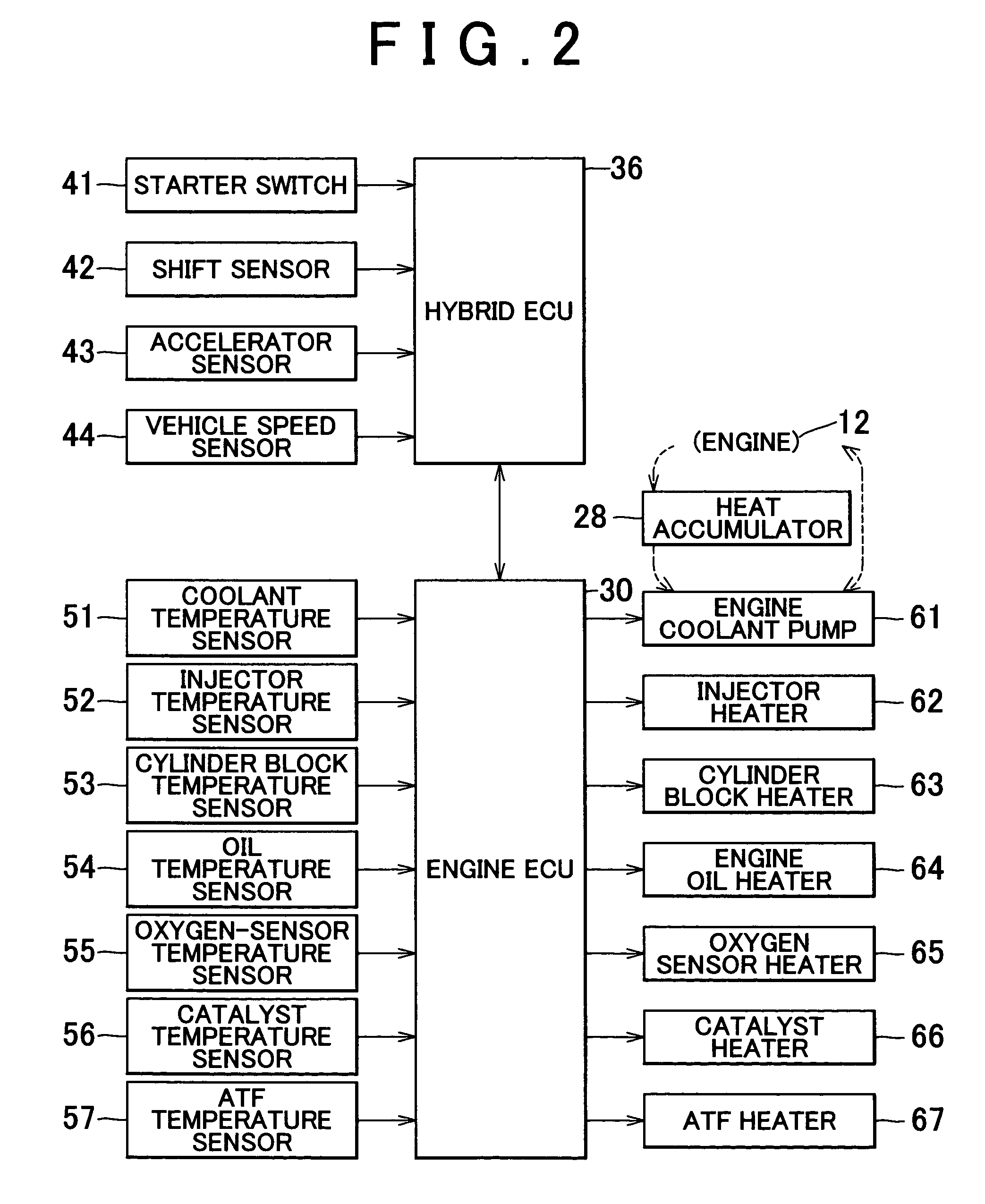

When a starter switch is switched from OFF to ON, a hybrid ECU determines that a driver intends to start driving a vehicle, reads a temperature of each of items (engine coolant, injectors, lubricating oil, and the like), and makes a determination on the necessity of preheating depending on whether each of the items has reached a corresponding one of suitable temperatures. If preheating is required, the hybrid ECU sets an engine start permission flag so as to prohibit the engine from being started, and instructs an engine ECU to preheat the item requiring preheating. On the other hand, if every one of the items has reached the suitable temperature range of its own, the hybrid ECU determines that preheating is not required, and sets the engine start permission flag so as to permit the starting of the engine.

Owner:TOYOTA JIDOSHA KK

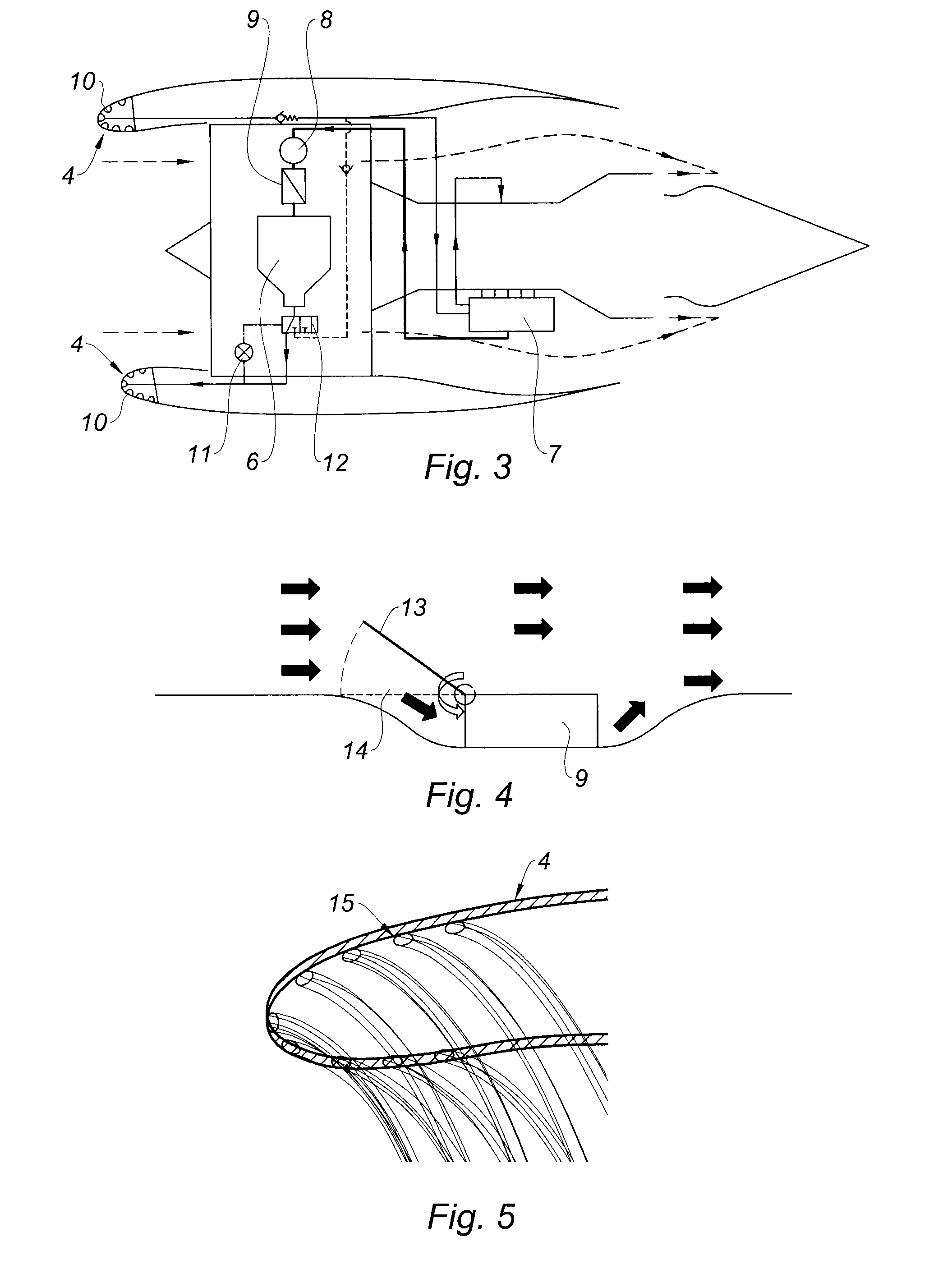

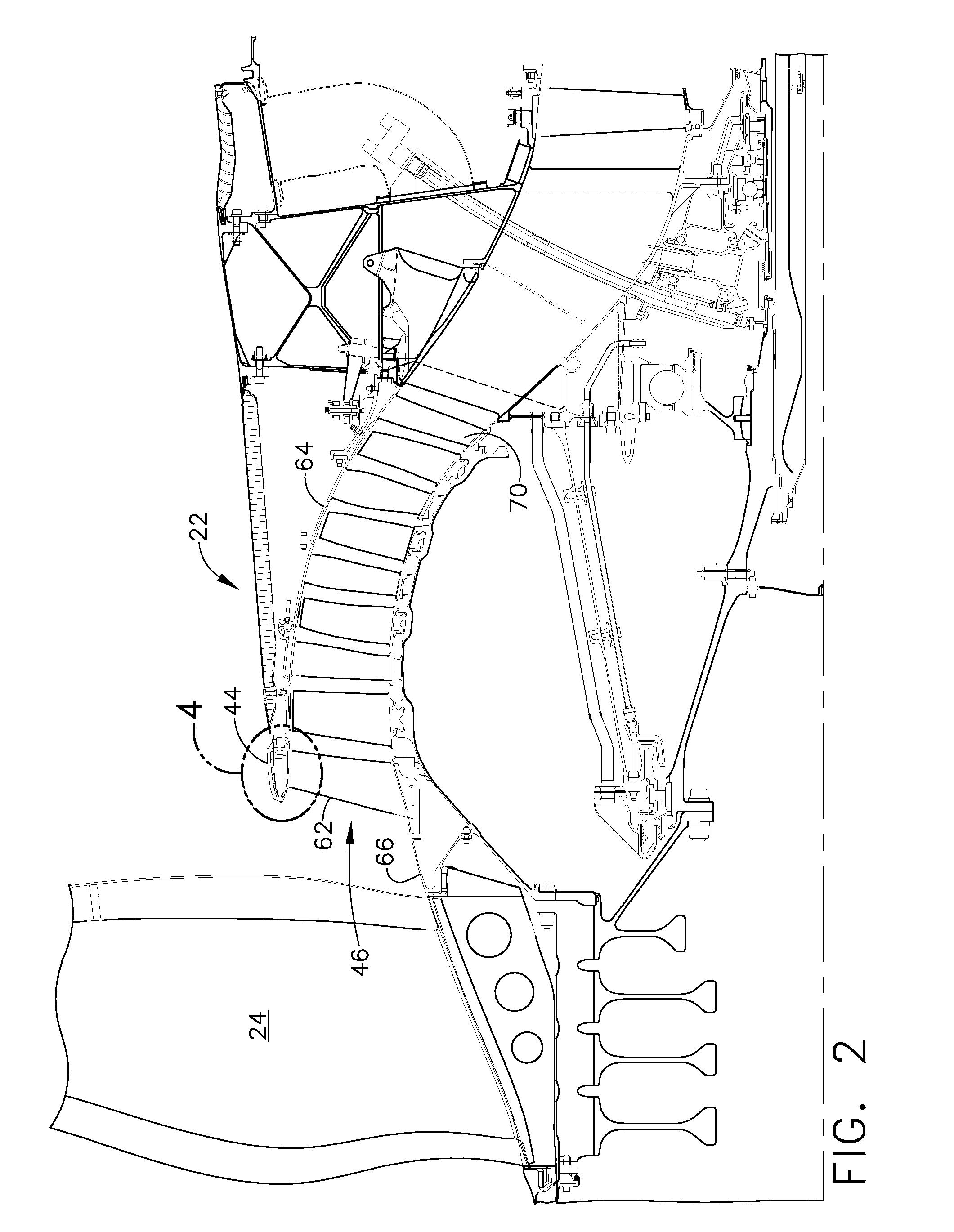

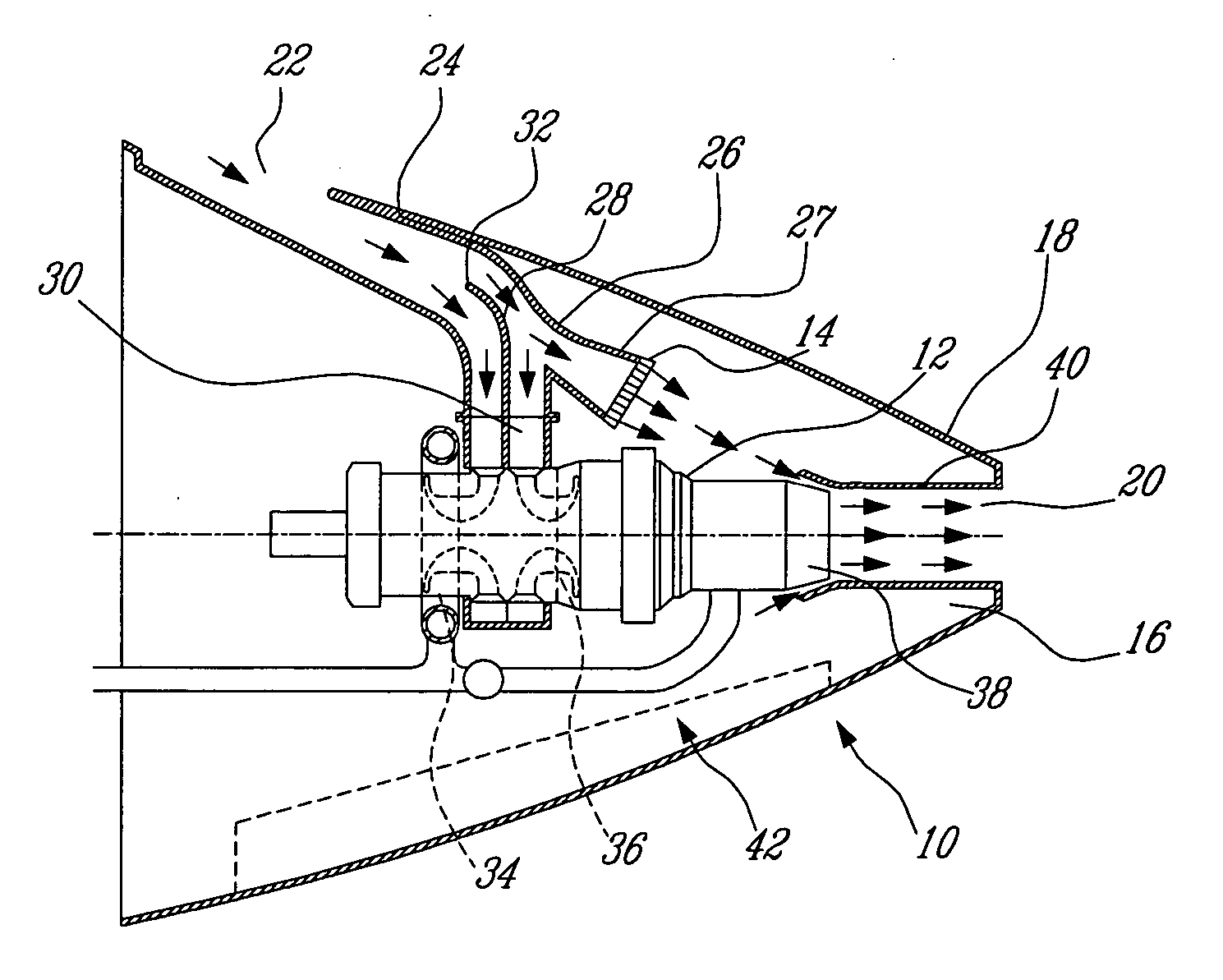

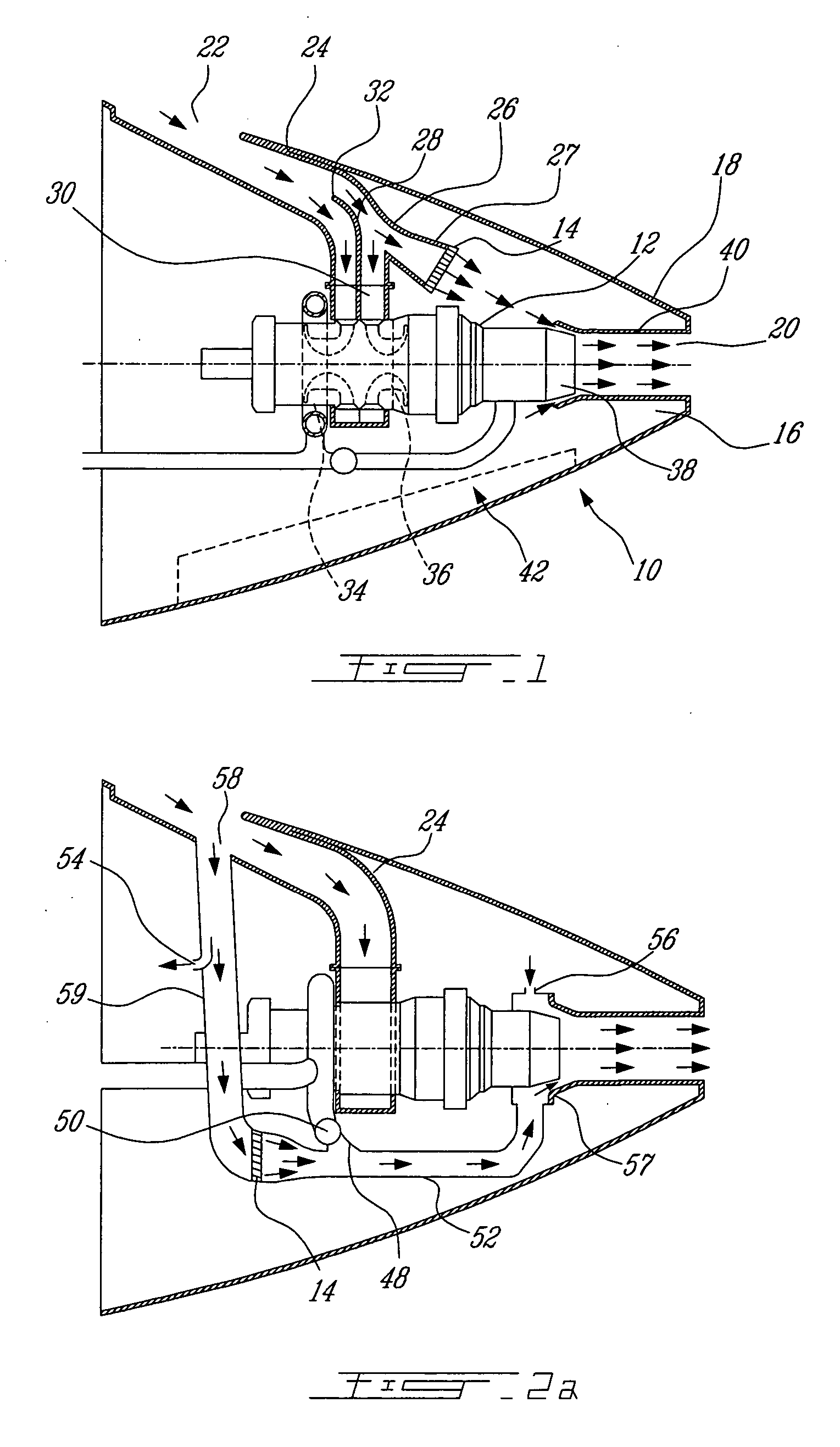

Method and apparatus for operating gas turbine engines

ActiveUS20100236213A1Outer walls isReduce the temperatureTurbine/propulsion engine coolingEfficient propulsion technologiesLeading edgeEngineering

A method for assembling a turbine engine to facilitate reducing an operating temperature of a lubrication fluid during engine operation, the gas turbine engine including a fan assembly, a booster downstream from the fan assembly, and a splitter circumscribing the booster. The method includes coupling a radially inner wall and a radially outer wall at a leading edge to form a splitter body, and coupling an inner support structure within the splitter body such that a cooling circuit is defined between at least a portion of the inner support structure and the inner and outer walls, said cooling circuit configured to circulate lubrication fluid therethrough such that as a temperature of the lubrication fluid is reduced and a temperature of at least a portion of the inner and outer walls is increased.

Owner:GENERAL ELECTRIC CO

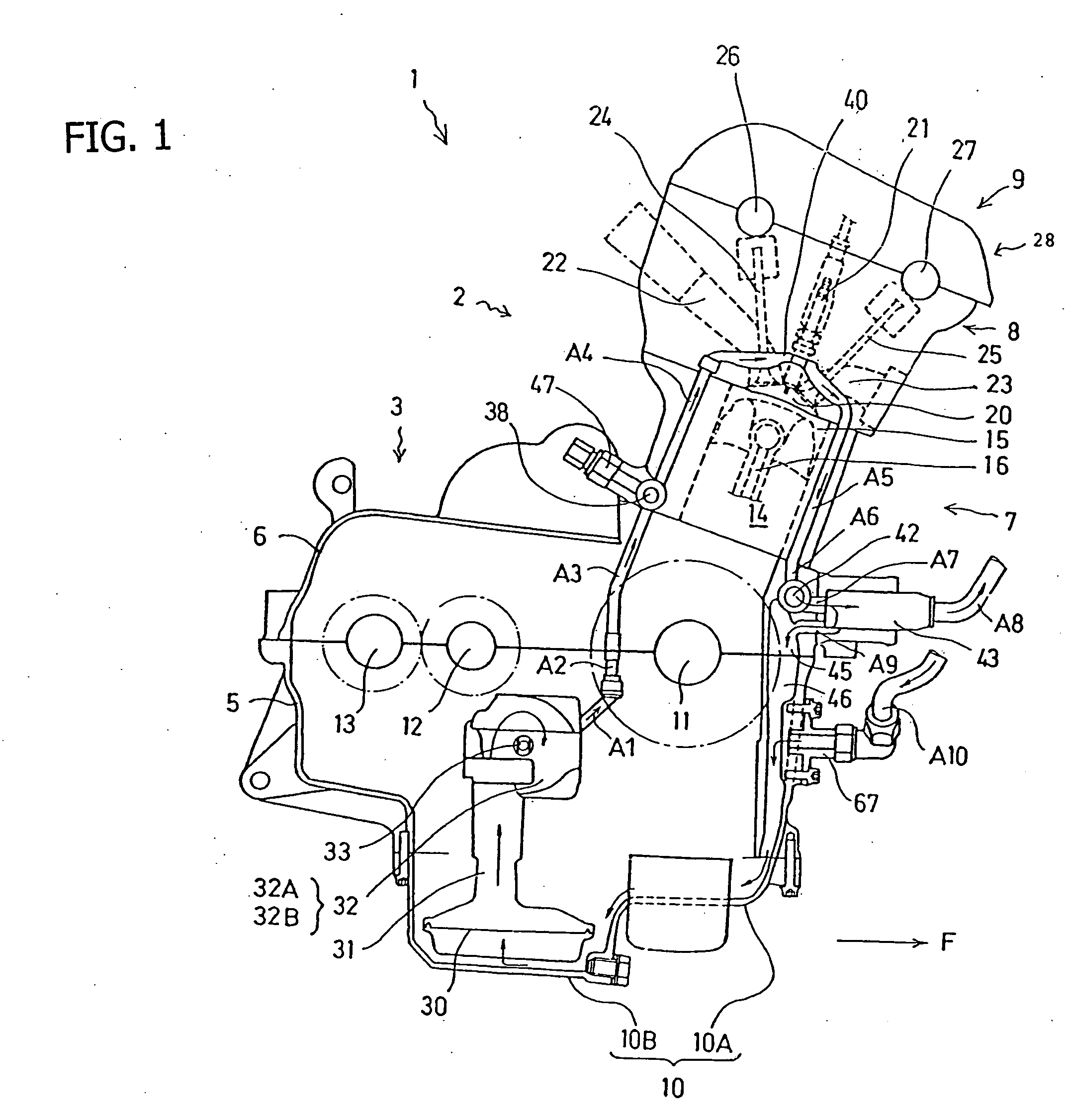

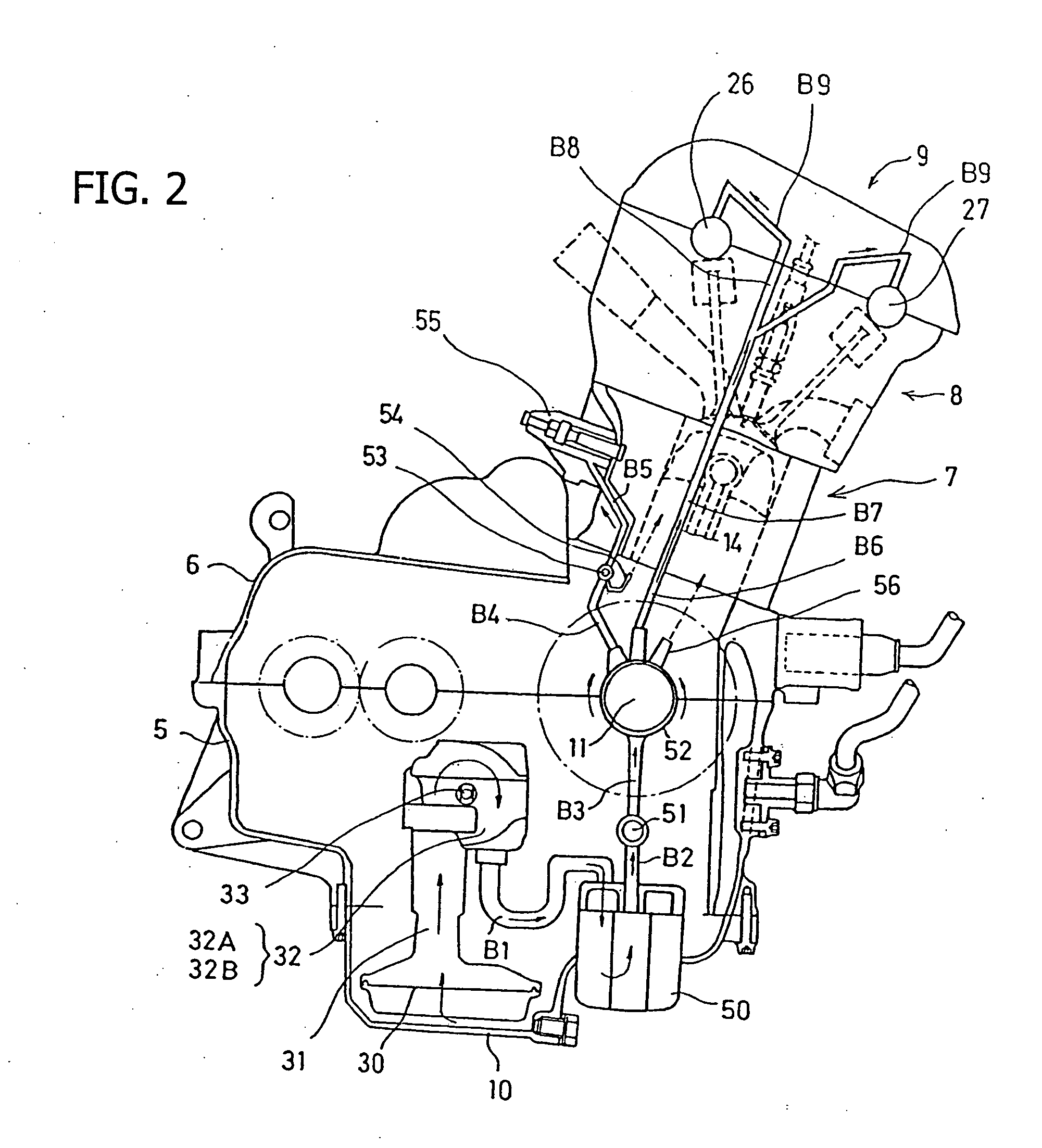

Cylinder head cooling structure for an internal combustion engine, including an oil temperature sensor and an oil temperature control system

ActiveUS20060065218A1Efficient use ofAvoid contactLiquid coolingCoolant flow controlTemperature controlCylinder head

A cylinder head cooling structure and an oil temperature control system are provided for an internal combustion engine having a plurality of cylinders, each having a plurality of intake ports and a plurality of exhaust ports. The engine includes cooling oil jackets surrounding the spark plugs in the cylinder head, a thermostat attached to the front surface of the crankcase independently of an oil filter, and an oil temperature sensor disposed on a rear face of the cylinder block above the crankcase in an oil supply path formed on the cylinder rear face for supplying oil to the oil jackets. Oil passages conducting oil into the oil jacket are provided between two separate parts of a bifucated intake port and between two separate parts of a bifurcated exhaust port, and only cooling system oil reaching high temperatures is allowed to flow through the thermostat, thereby improving temperature control response.

Owner:HONDA MOTOR CO LTD

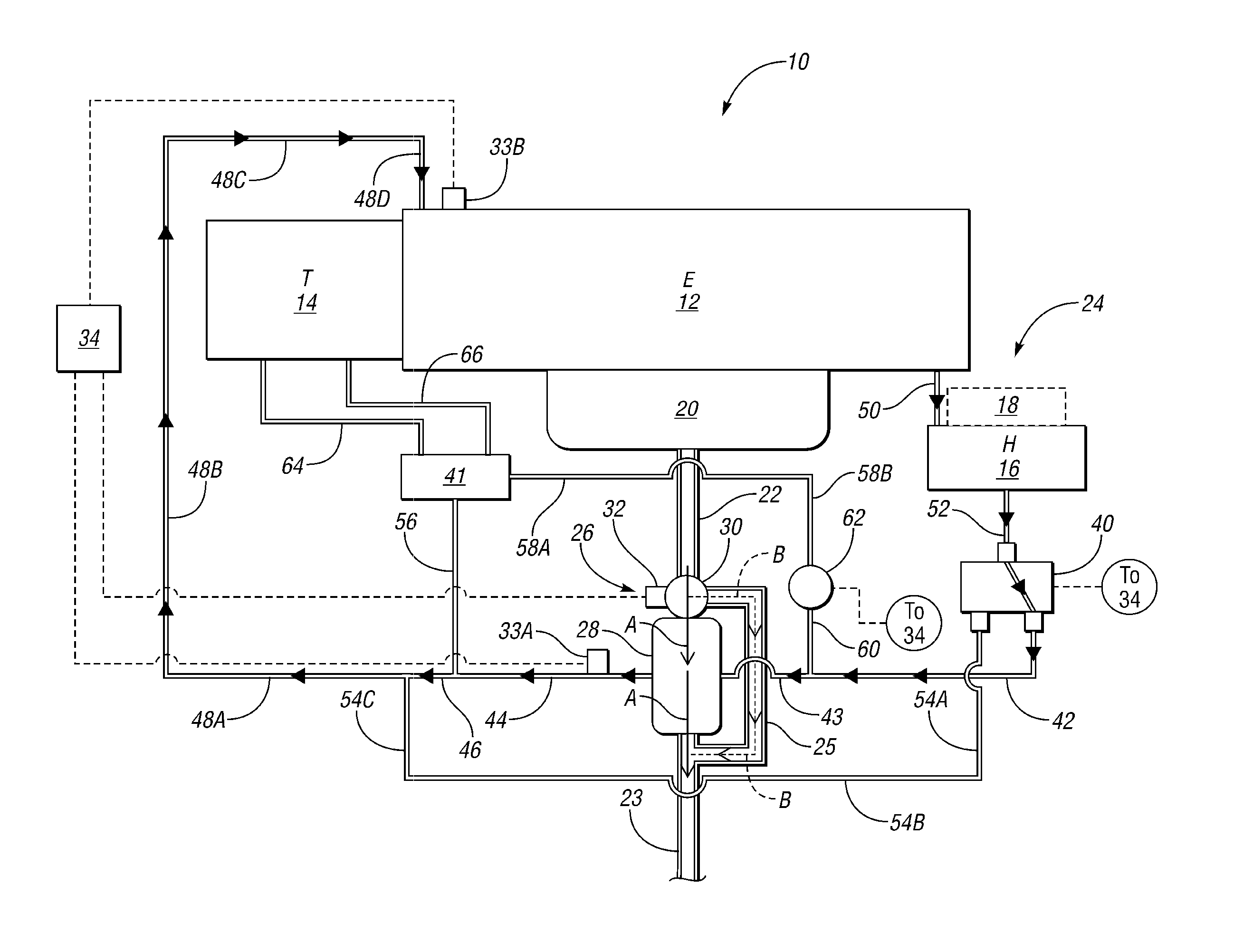

Exhaust heat recovery for transmission warm-up

ActiveUS20110088378A1Waste heat recoveryAvoid insufficient heatingCoolant flow controlInternal combustion piston enginesOperant conditioningOperating temperature

An exhaust heat recovery system (EHRS) for a vehicle is provided that is operable to direct coolant heated by exhaust heat to a vehicle transmission under certain operating conditions after the engine is adequately heated by the exhaust heat and without further heating the engine with the exhaust heat. Thus, recovery of exhaust heat is increased as the transmission is heated to a higher operating temperature than the engine using the heated coolant. The EHRS may also operate in a bypass mode during which exhaust heat is not directed to the engine or the transmission. A method of managing exhaust heat is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

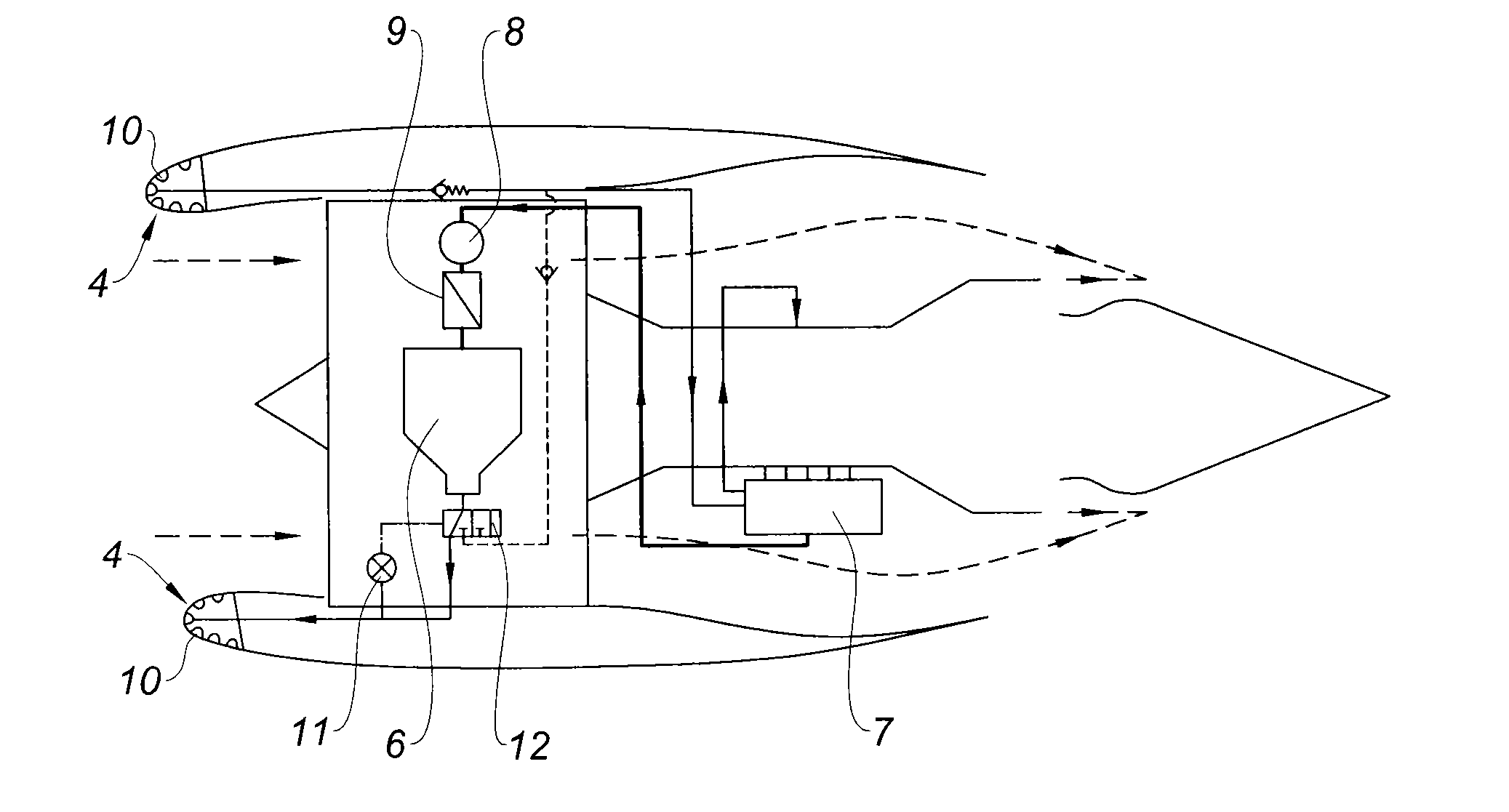

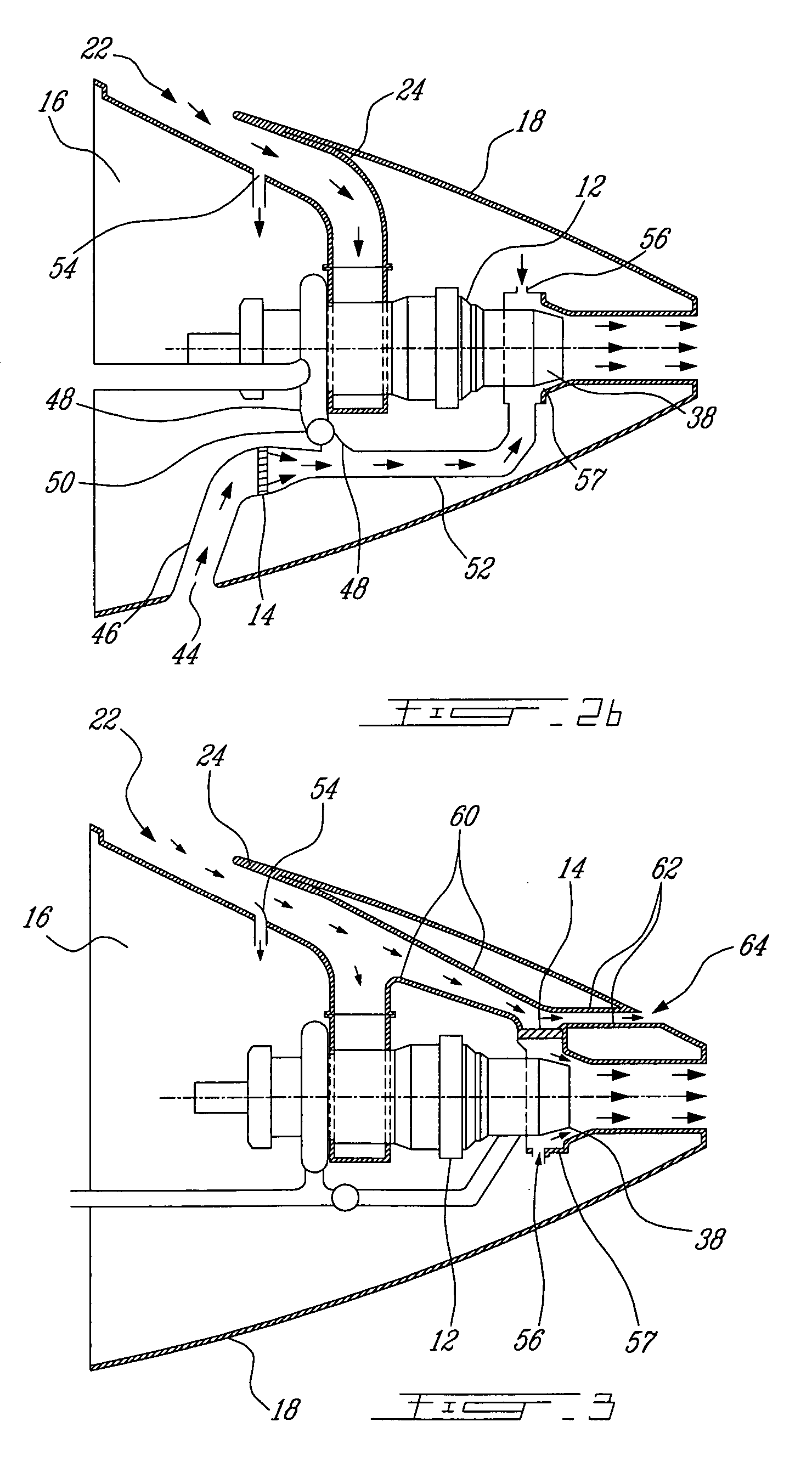

Passive cooling system for auxiliary power unit installation

InactiveUS20070063098A1Improve cooling effectEnhanced cooling airflowPower plant cooling arrangmentsPower installationsNacelleAir entrainment

A passive cooling system for an auxiliary power unit (APU) installation on an aircraft is provided. The system is for an auxiliary power unit having at least a compressor portion of a gas turbine engine and an oil cooler contained separately within a nacelle. The system includes the auxiliary power unit housed within the nacelle of the aircraft, an engine exhaust opening defined in the aft portion of the nacelle and communicating with the gas turbine engine, at least a first air inlet duct communicating with a second opening defined in said nacelle and with said compressor portion and the oil cooler is located within a second duct communicating with an opening other than the engine exhaust opening of said nacelle and with the engine exhaust opening. Exterior cooling air and engine exhaust ejected through said engine exhaust opening entrain cooling air through said second duct to said oil cooler, and thus provide engine oil cooling. An exhaust eductor is also provided.

Owner:PRATT & WHITNEY CANADA CORP

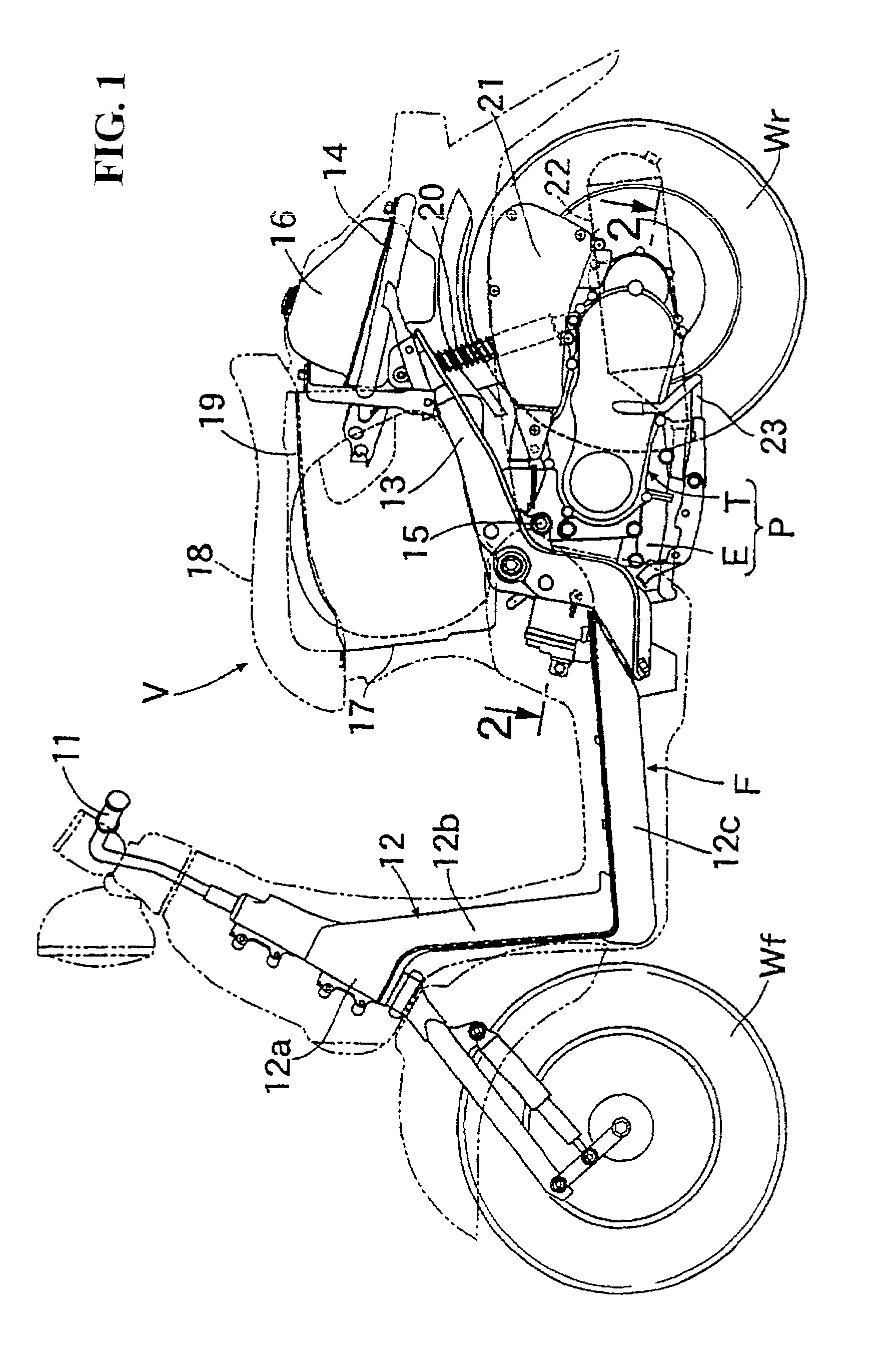

Vehicle radiator device

InactiveUS6971438B2Enhancing vibration isolation function of structureReduce weightExhaust apparatusMotorised scootersSynthetic resinPower unit

A vehicle radiator device having a radiator with a first tank and a second tank coupled through a heat radiation core. The radiator is mounted onto an engine in a power unit supported by a vehicle body frame. The first and second tanks of the radiator are made of synthetic resin. The radiator is mounted onto the engine through a shroud for conducting cooling wind passing through the radiator. The shroud is made of elastic material for conducting cooling so that vibrations of the engine are absorbed by the elasticity of the shroud, thus preventing vibration of the radiator.

Owner:HONDA MOTOR CO LTD

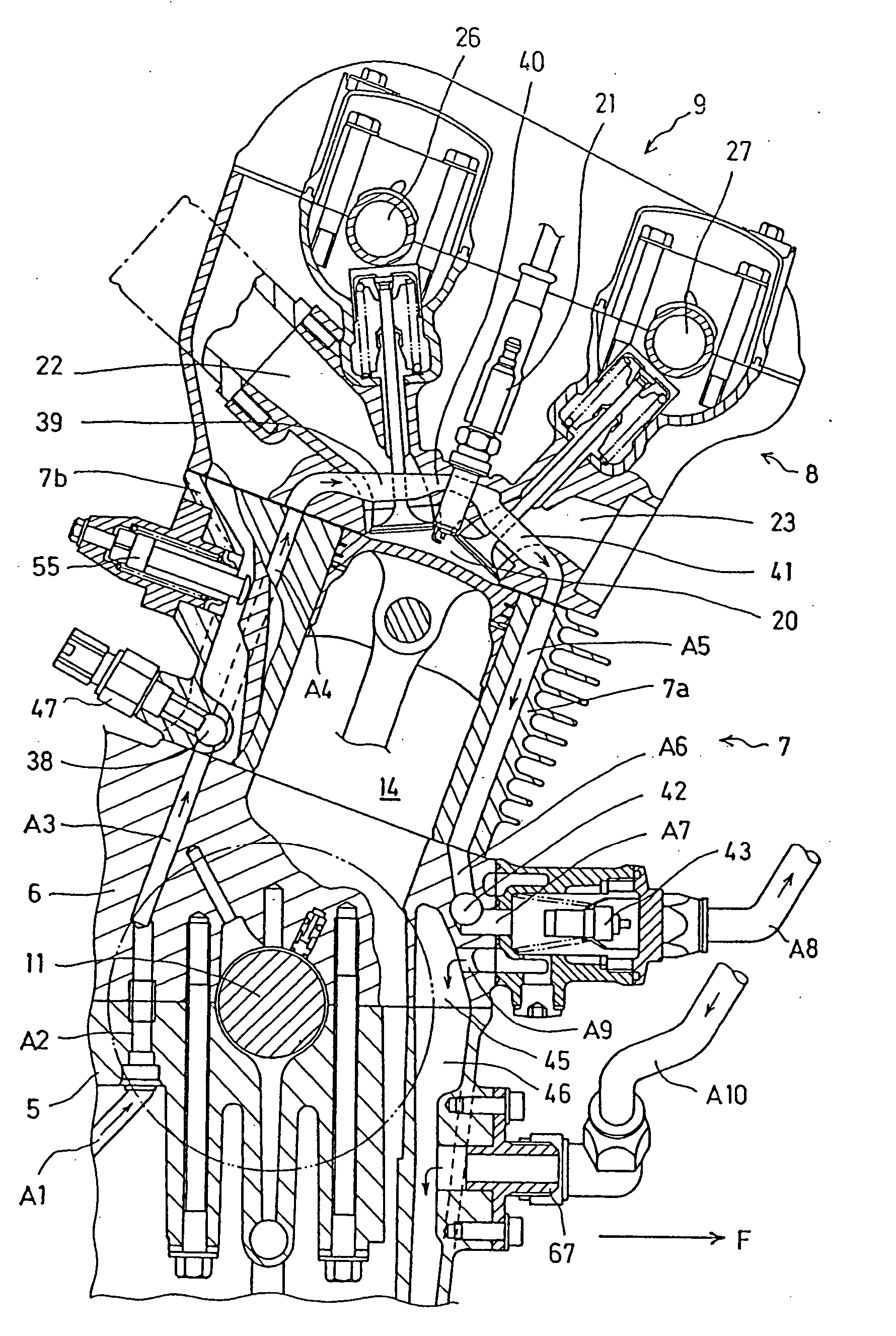

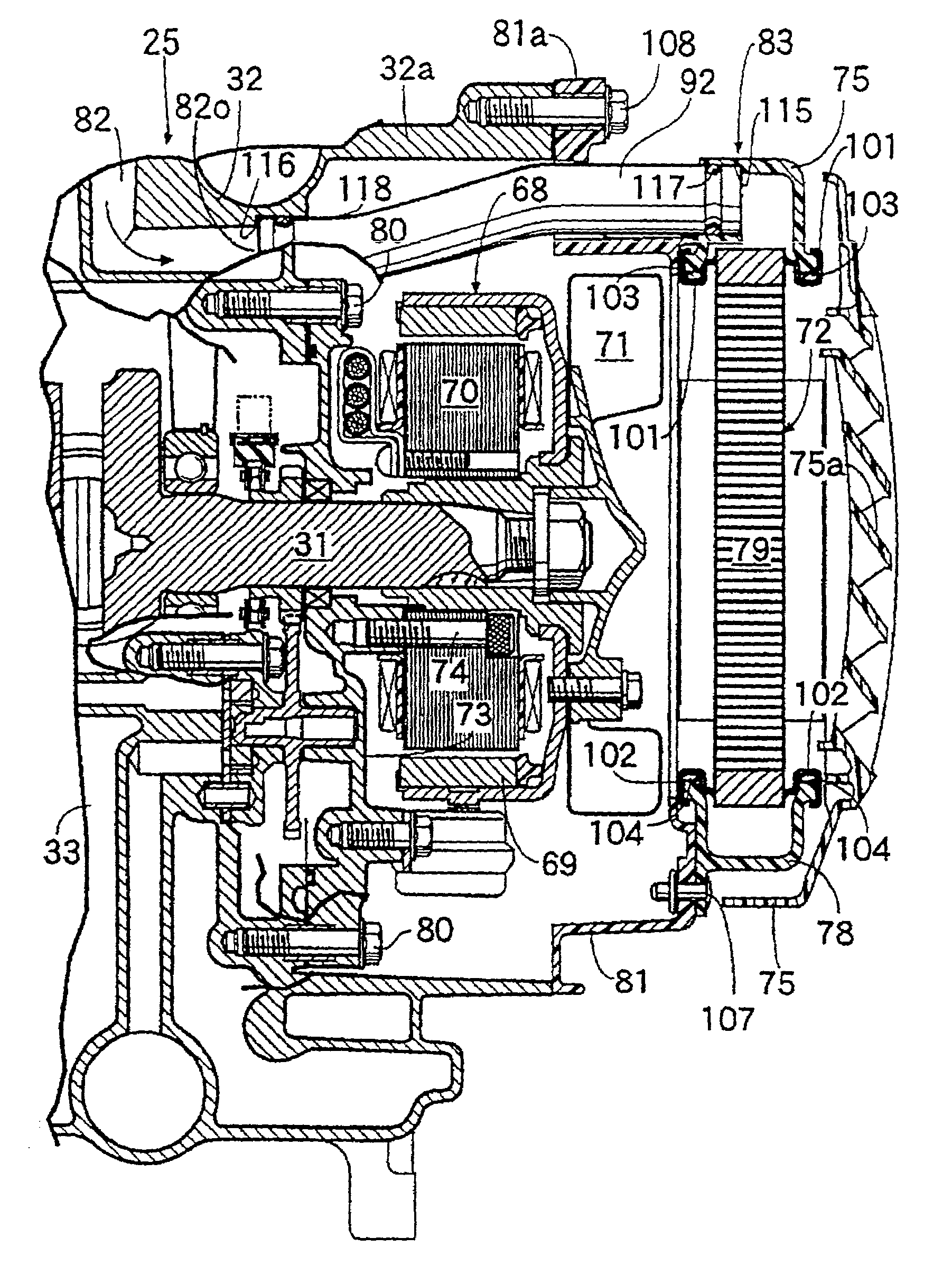

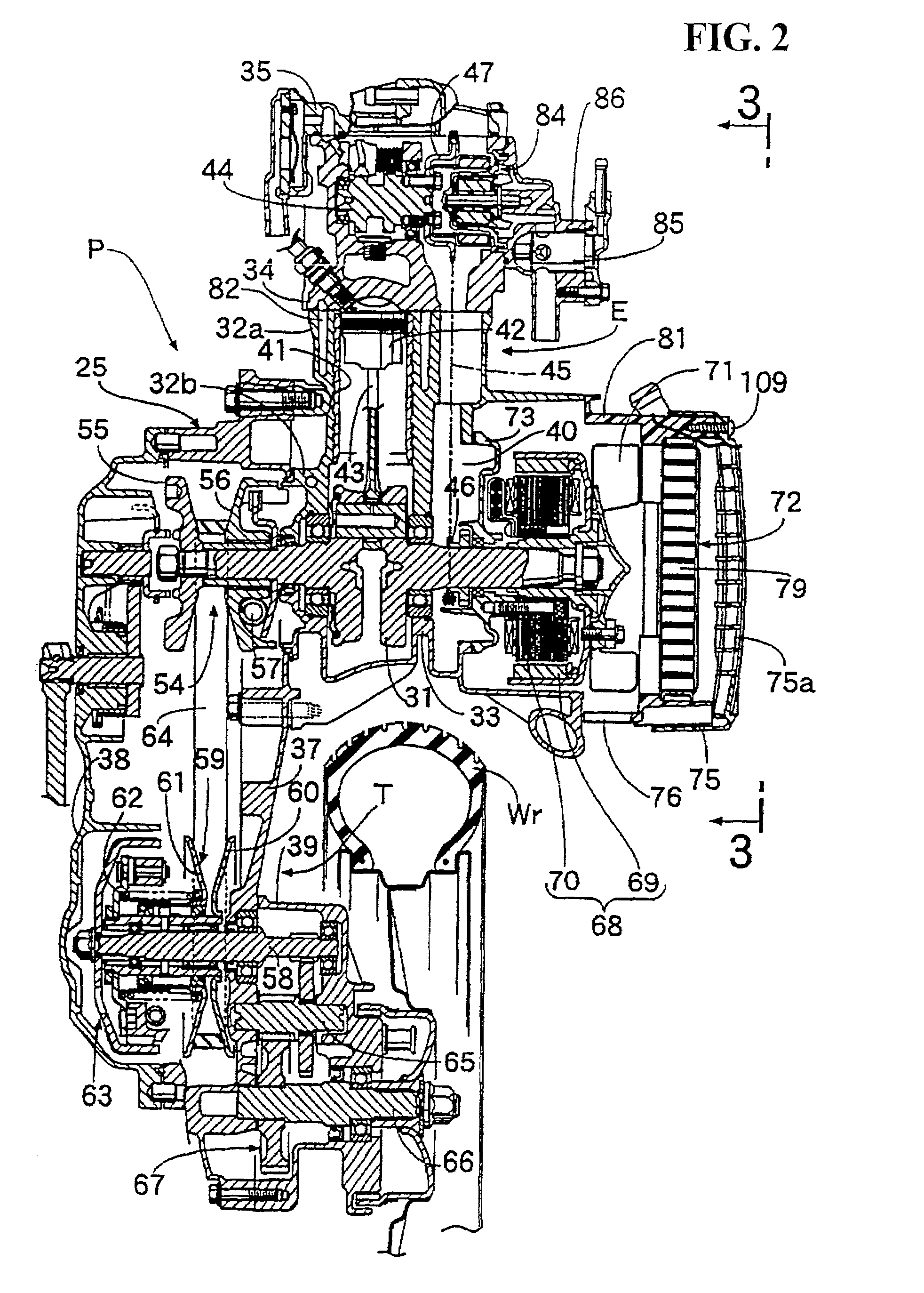

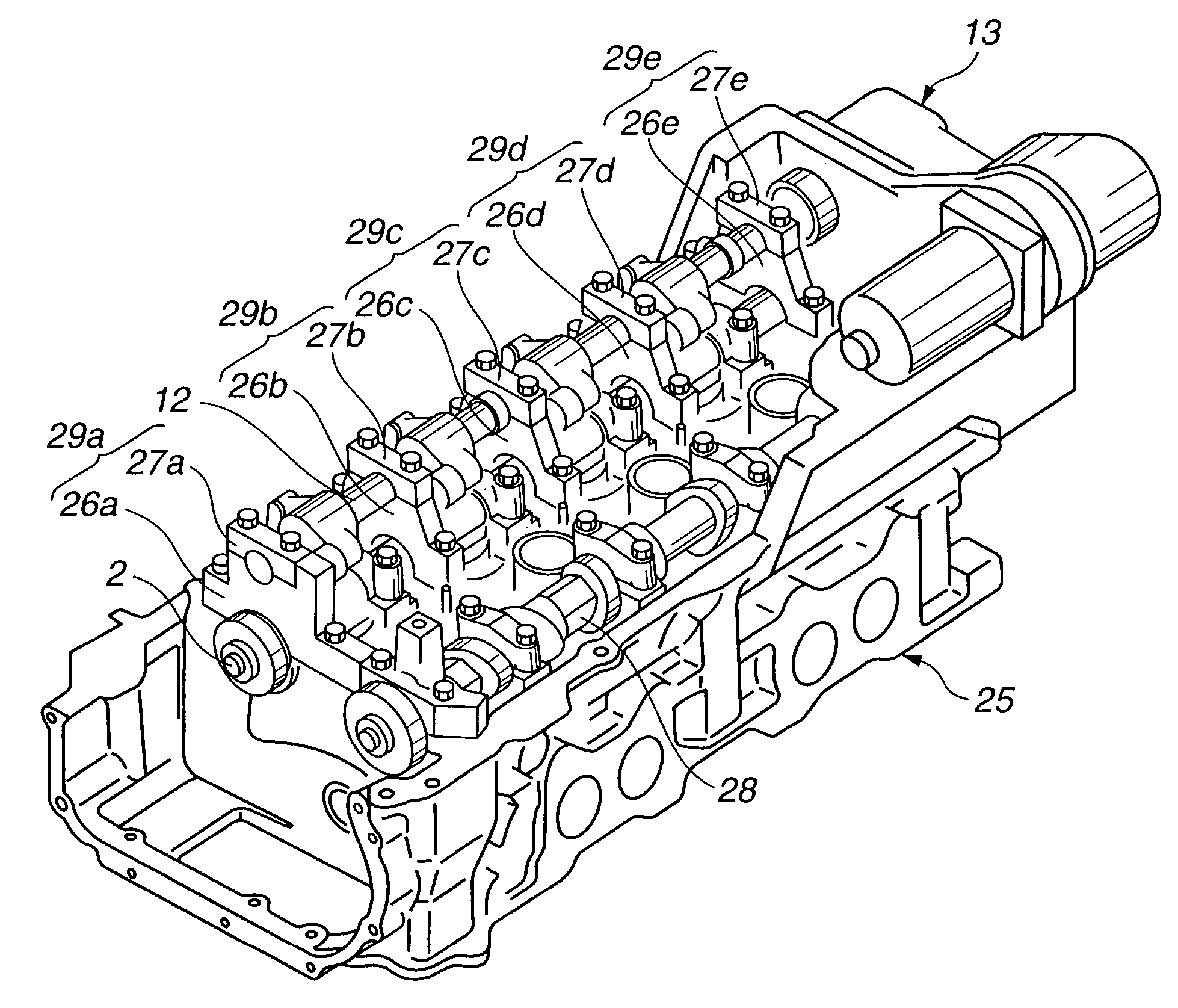

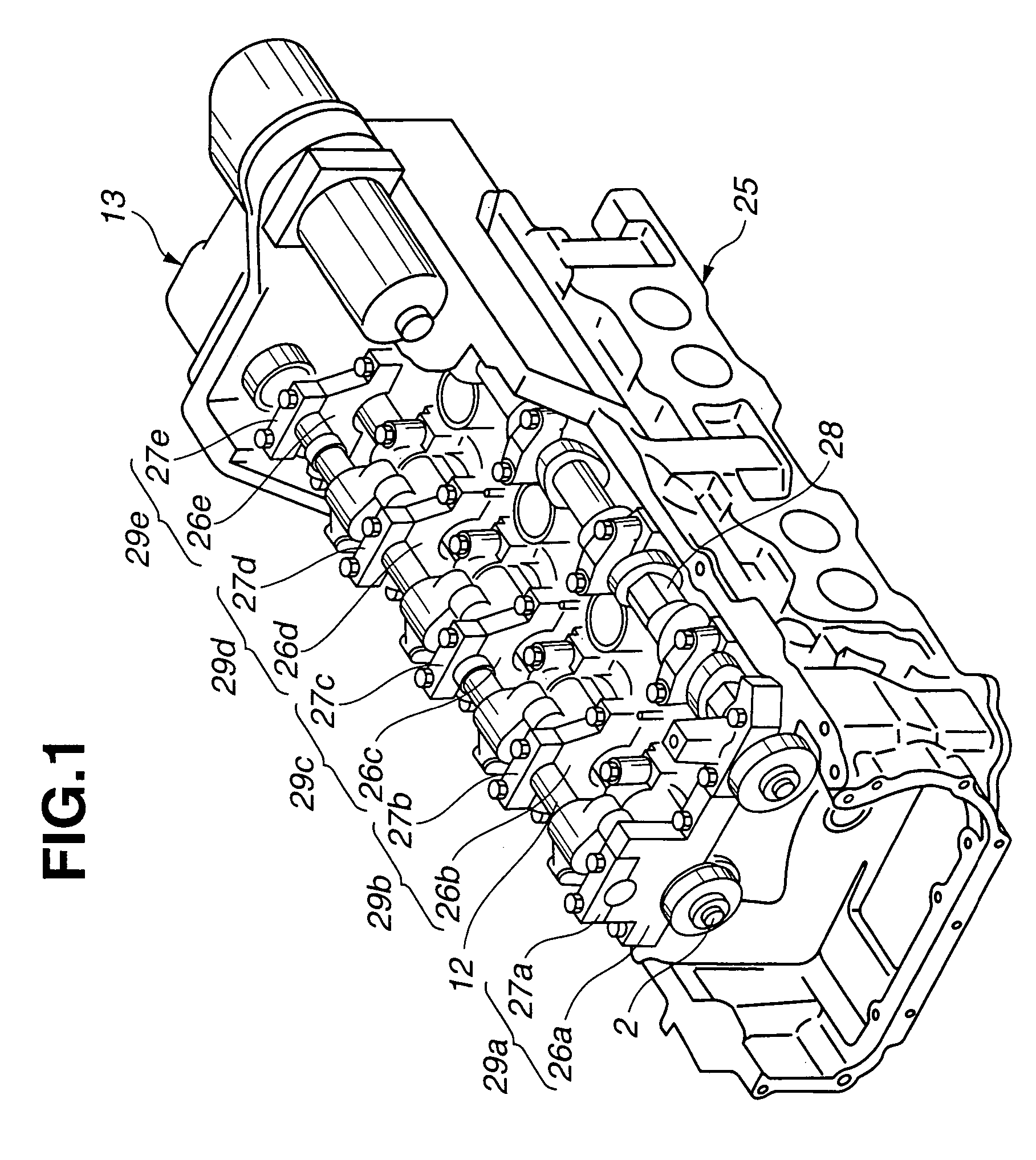

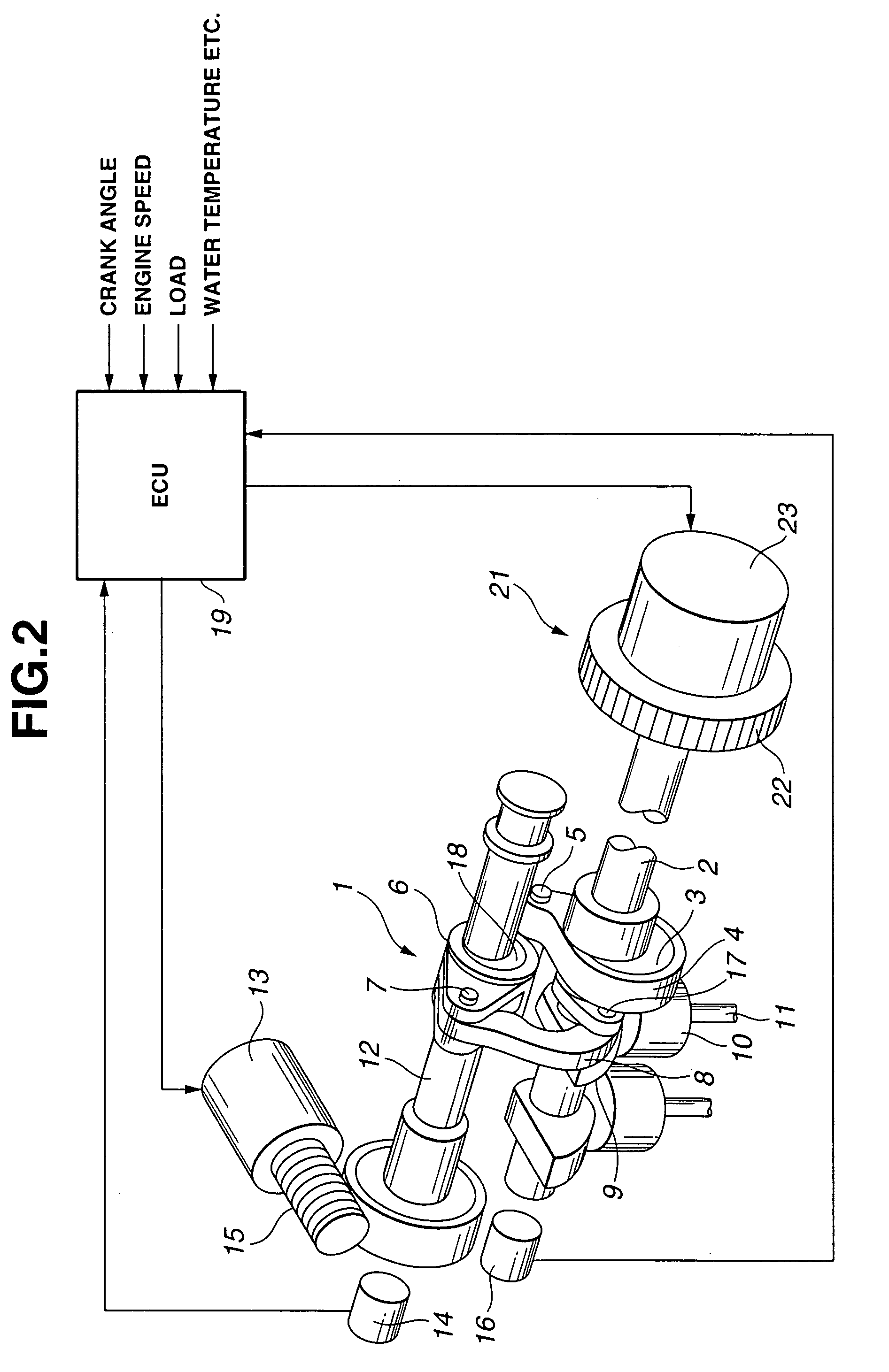

Variable valve actuating mechanism for internal combustion engine

ActiveUS7107950B2Reduce temperature non-uniformityReduce unevennessClutchesCrankshaftsExternal combustion engineInlet valve

A lift and operating angle varying mechanism is arranged to vary an intake valve operation angle and an intake valve lift of the engine continuously by rotating a control shaft with an actuator disposed at an end of the control shaft which is rotatably supported by a plurality of bearings. A lubricating oil is supplied to the bearings so as to reduce nonuniformity in temperature distribution of the control shaft in the longitudinal direction.

Owner:NISSAN MOTOR CO LTD

Hybrid vehicle and method of controlling the same

InactiveUS20040007403A1Deterioration in consumptionDeterioration in propertiesHybrid vehiclesInternal combustion piston enginesHybrid vehicleCoolant

When a starter switch is switched from OFF to ON, a hybrid ECU determines that a driver intends to start driving a vehicle, reads a temperature of each of items (engine coolant, injectors, lubricating oil, and the like), and makes a determination on the necessity of preheating depending on whether each of the items has reached a corresponding one of suitable temperatures. If preheating is required, the hybrid ECU sets an engine start permission flag so as to prohibit the engine from being started, and instructs an engine ECU to preheat the item requiring preheating. On the other hand, if every one of the items has reached the suitable temperature range of its own, the hybrid ECU determines that preheating is not required, and sets the engine start permission flag so as to permit the starting of the engine.

Owner:TOYOTA JIDOSHA KK

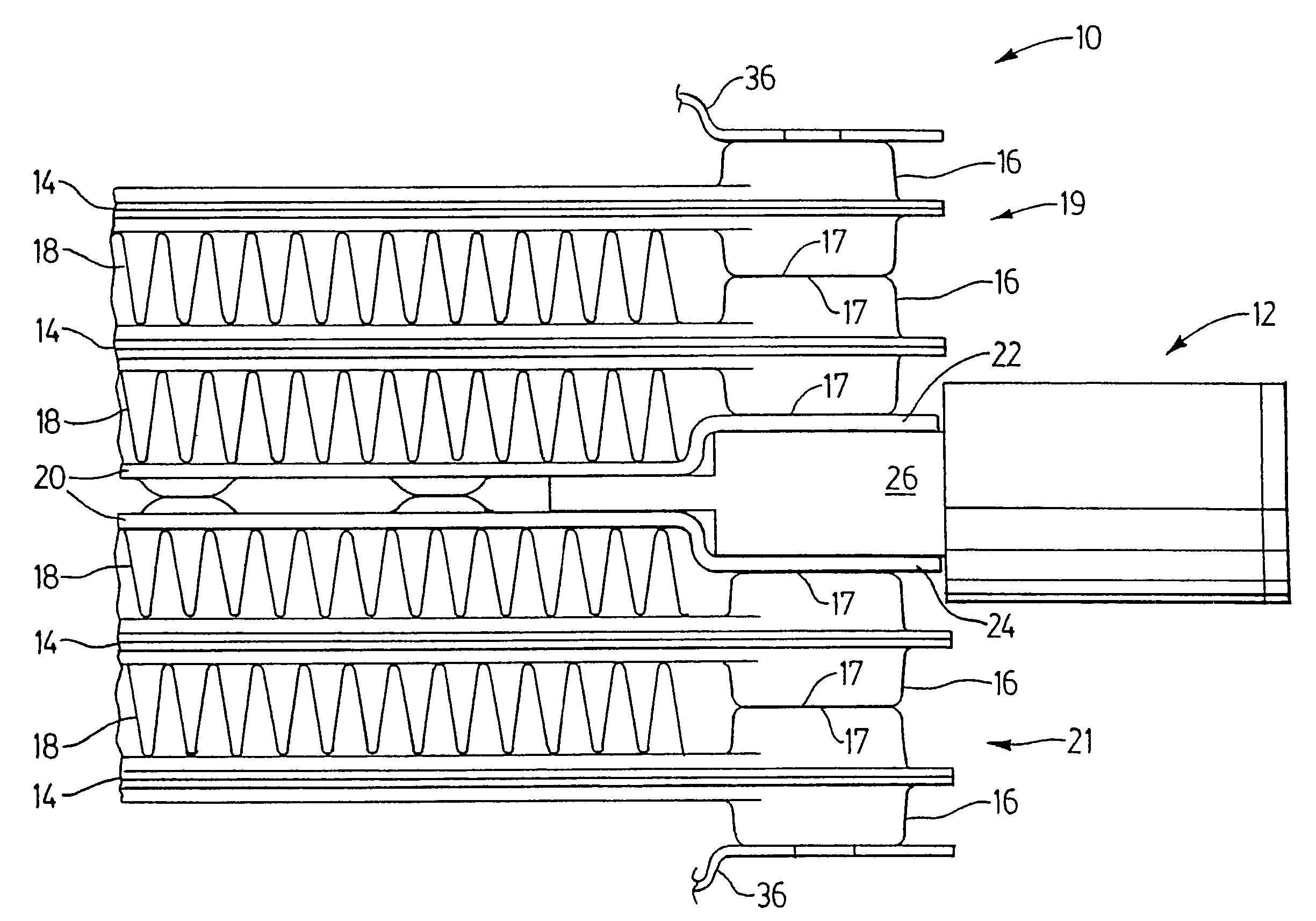

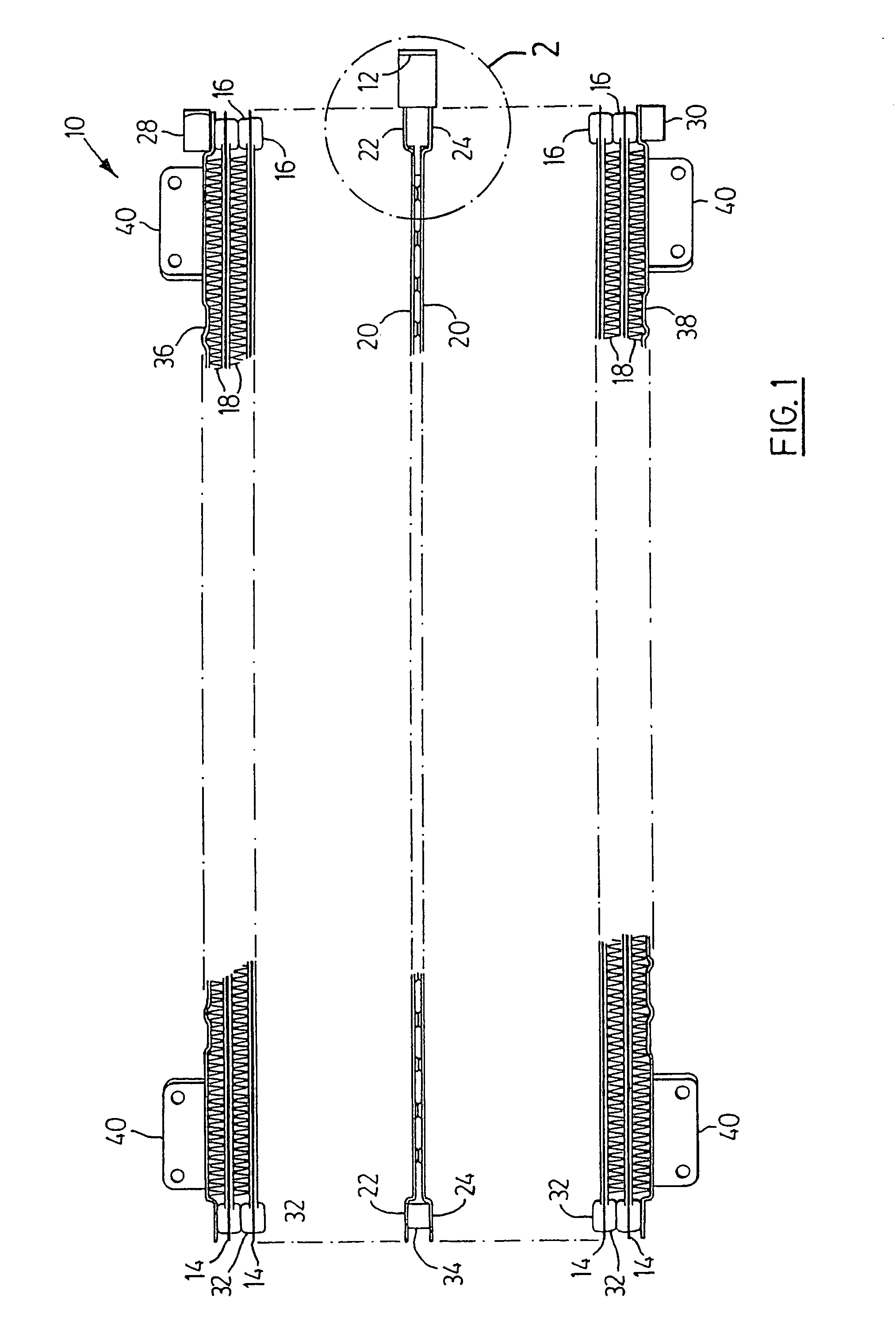

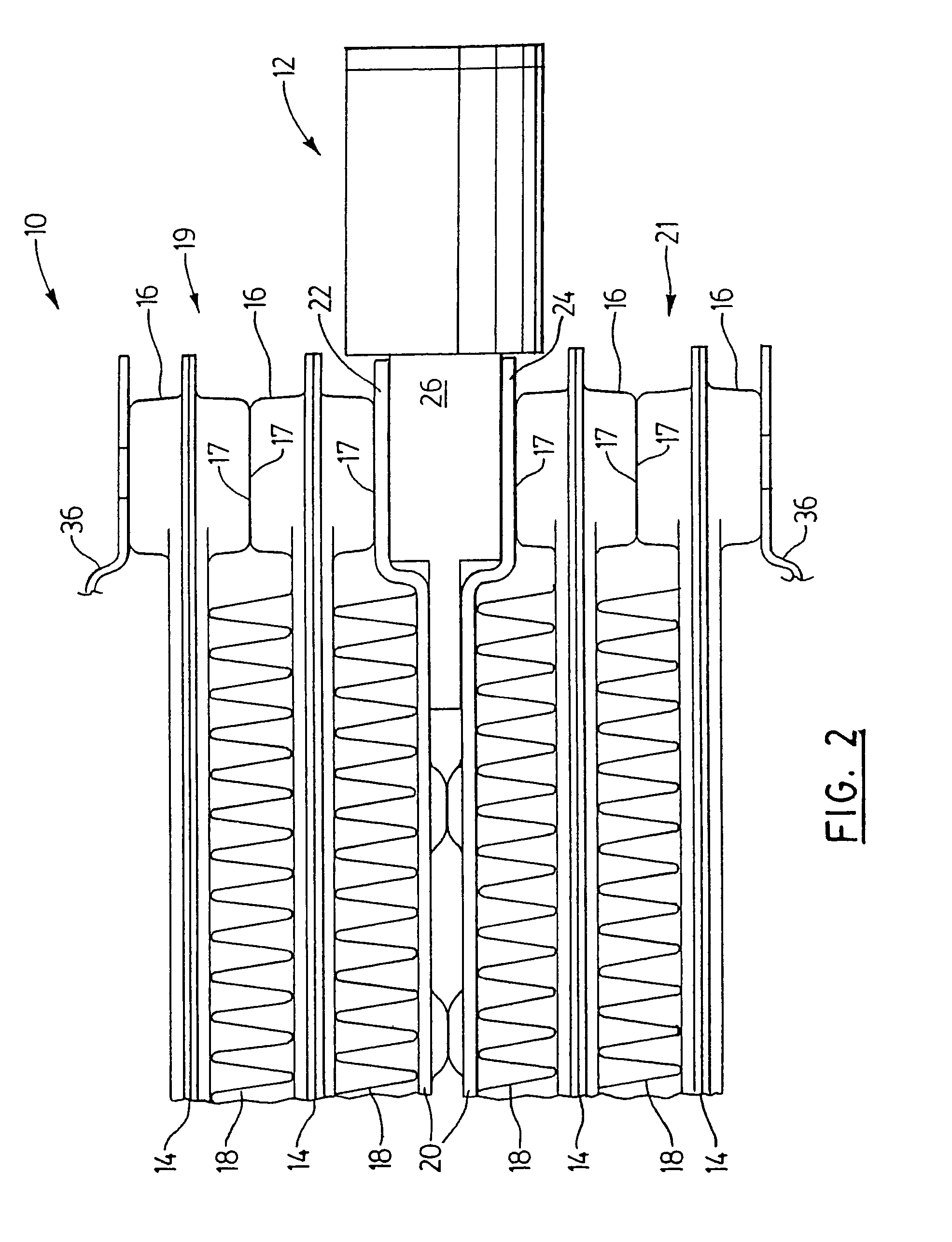

Plug bypass valves and heat exchangers

InactiveUS7487826B2Temperature control without auxillary powerCoolant flow controlActuatorVALVE PORT

Bypass valves and heat exchangers employing same are provided where the bypass valves cause the flow through the heat exchangers to be short-circuited under certain temperature conditions. The heat exchangers are formed of stacked plate pairs or tubes having enlarged communicating distal end portions forming inlet and outlet manifolds. The bypass valves can be plugged in where desired between the enlarged distal end portions to produce bypass flow between the inlet and outlet manifolds. The bypass valves include a housing which can be brazed in place during brazing of the heat exchanger. The housing has inlet and outlet openings in communication with the respective inlet and outlet manifolds for bypass flow therebetween. A removable temperature responsive actuator is located in the housing for blocking and unblocking the bypass flow through the valve.

Owner:DANA CANADA CORP

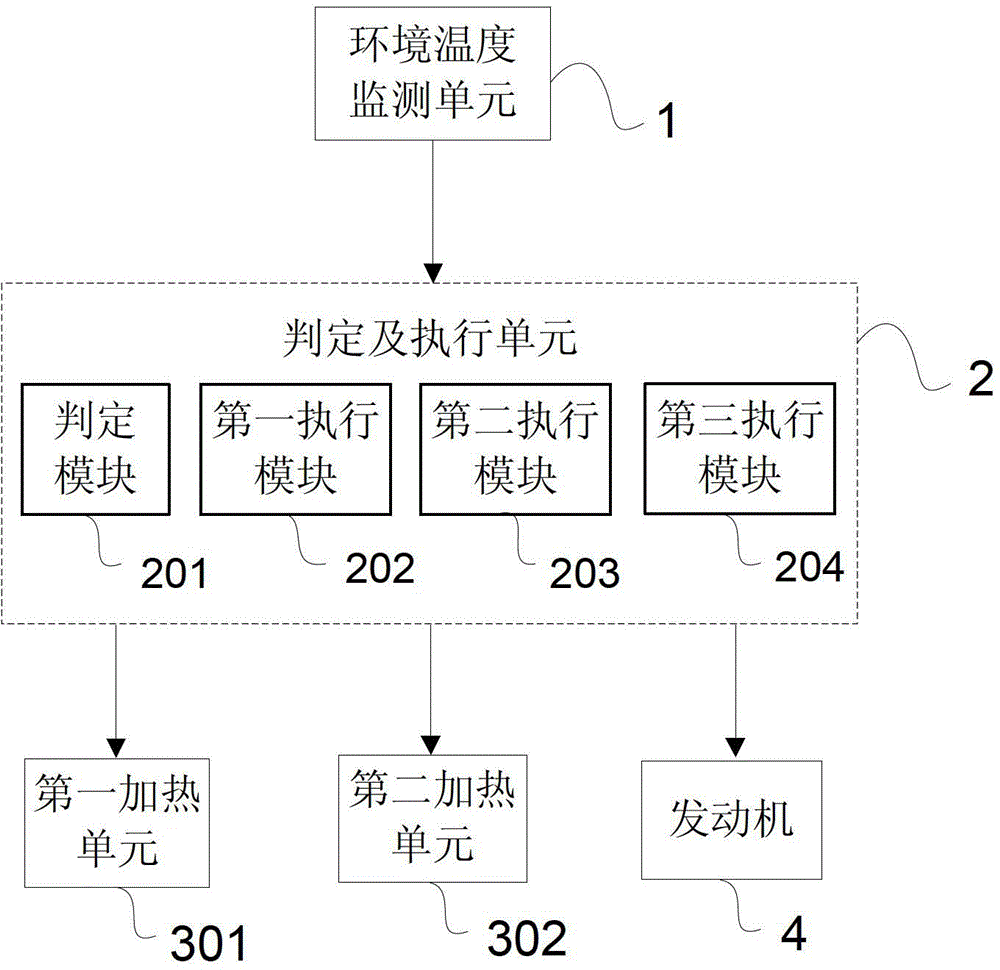

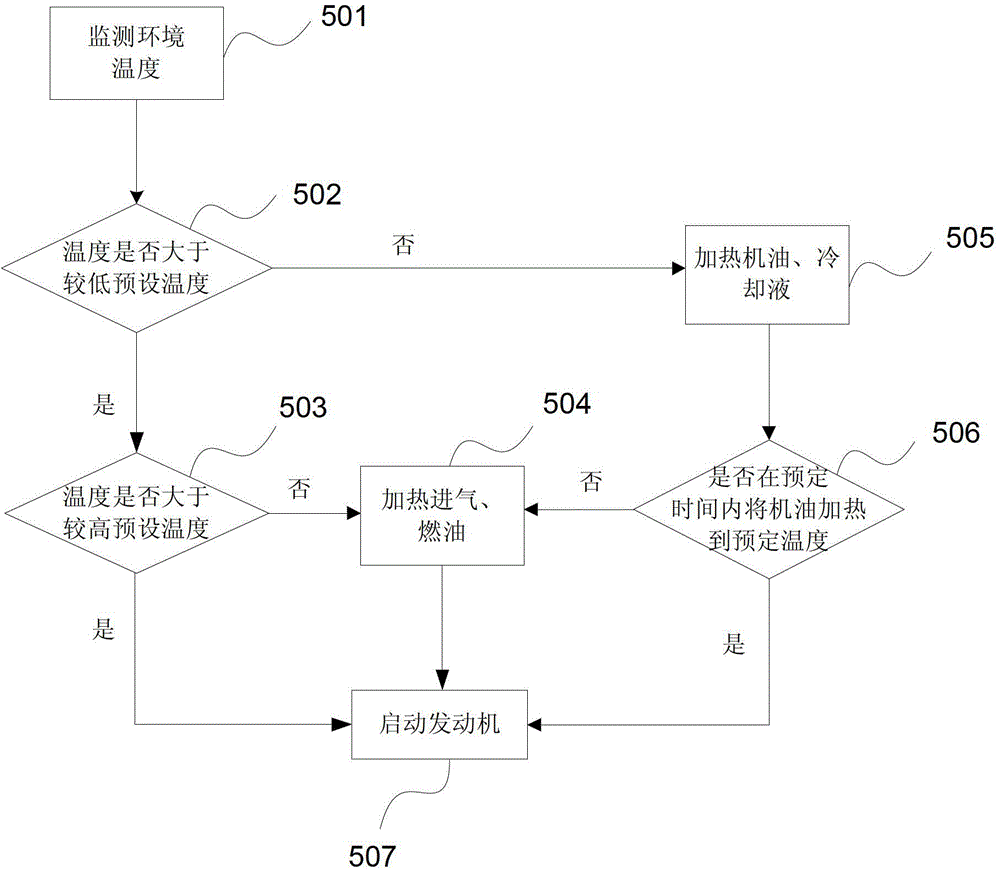

Preheating method and preheating system for cold start of engine

ActiveCN103147897AFast heatingHigh heating efficiency and safetyMachines/enginesEngine startersWorking environmentAutomotive engine

The invention discloses a preheating method and a preheating system for the cold start of an engine. The preheating method includes the steps of monitoring the external work environment temperature of an automobile engine in real time, and comparing the external work environment temperature with a lower preset temperature value and a higher preset temperature value; if the external work environment temperature is larger than the higher preset temperature value, starting the engine directly; if the external work environment temperature is smaller than or equal to the higher preset temperature value and larger than the lower preset temperature value, heating intake air and fuel oil of the engine for second scheduled time and then starting the engine; and if the external work environment temperature is smaller than or equal to the lower preset temperature value, heating engine oil and a coolant liquid of the engine for first scheduled time, and determining whether the engine oil temperature is larger than or equal to an engine oil expected value, if yes, starting the engine, or otherwise, heating the intake air and the fuel oil of the engine for the second scheduled time and then starting the engine. The preheating system is simple in structure and high in heating efficiency.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

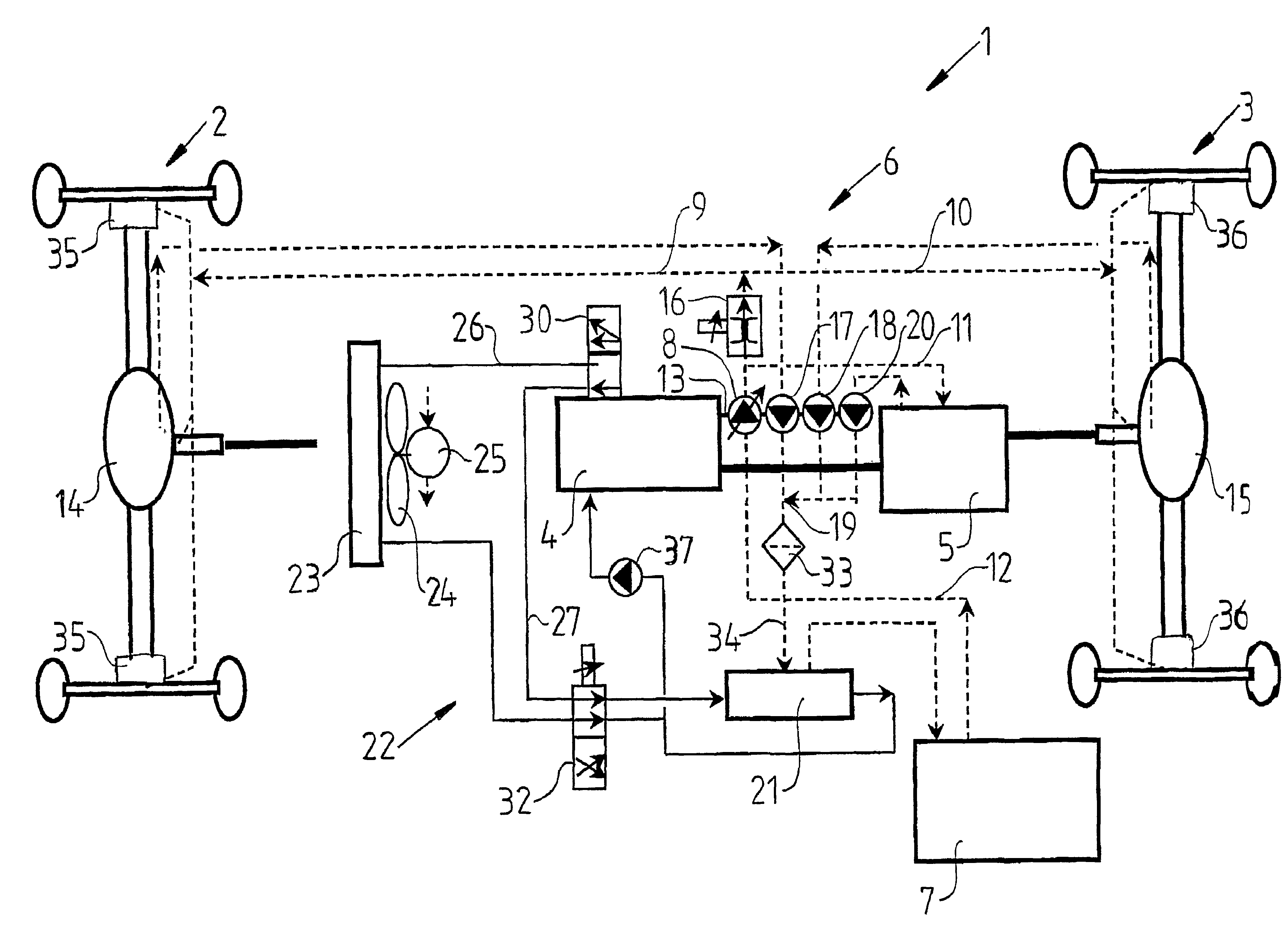

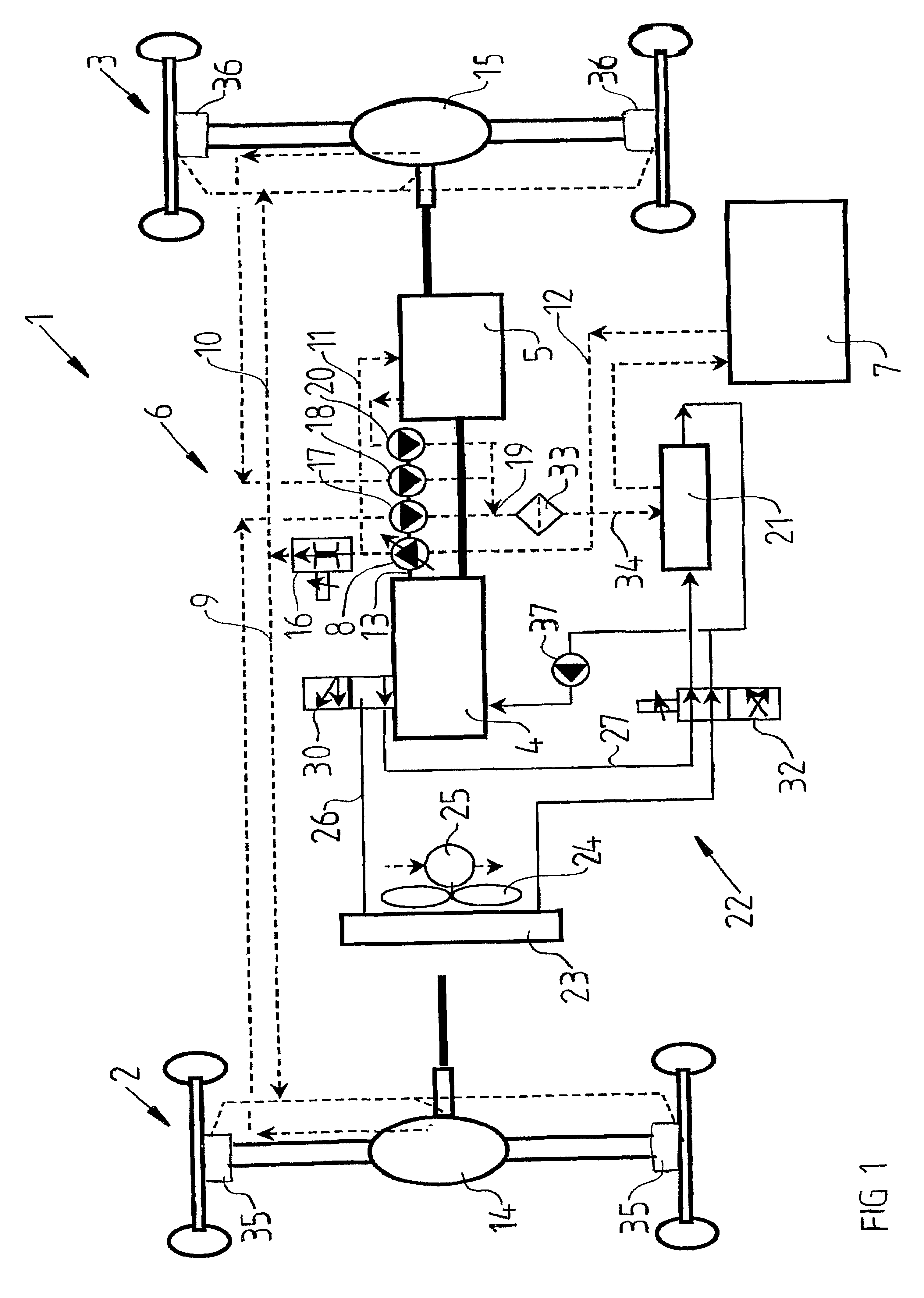

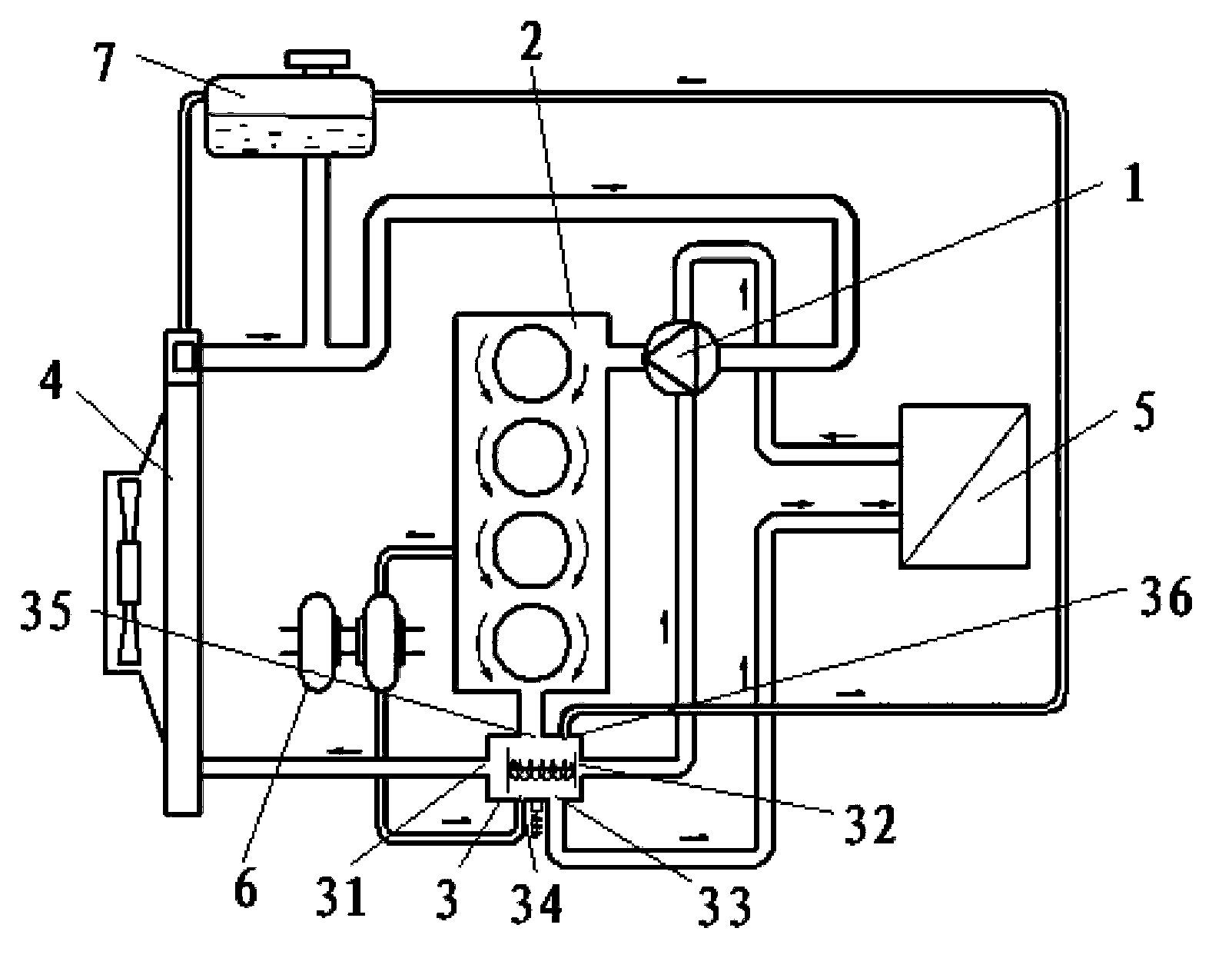

Temperature regulating system

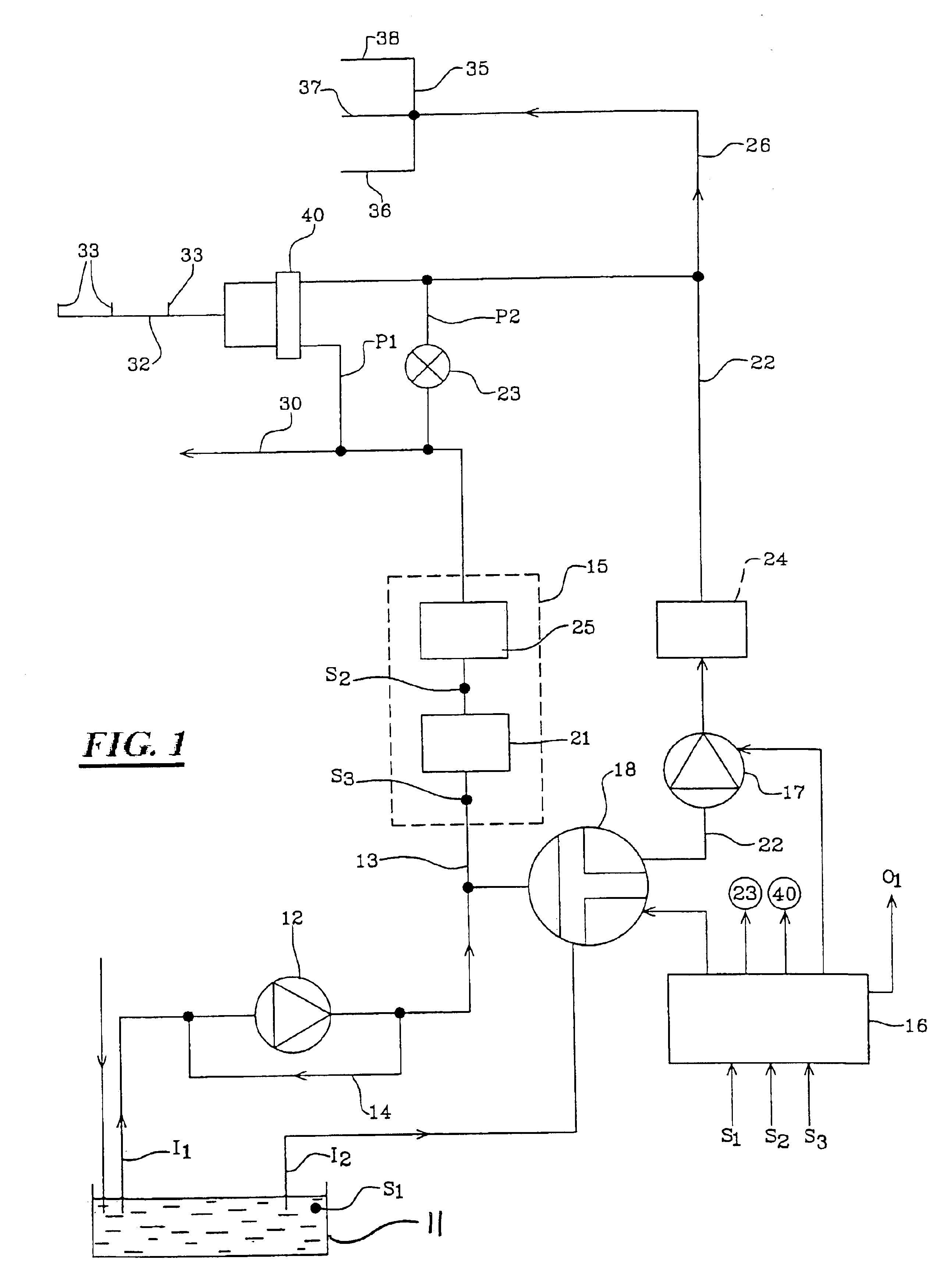

InactiveUS6899074B1Guaranteed uptimeReduce wearAir coolingGear lubrication/coolingHeat exchangerAutomotive engineering

Method and arrangement for providing a temperature regulating system (1) in a vehicle. The system includes an hydraulic arrangement (6) that is adapted to provide components intended for rotation belonging to a gearbox (5) of the vehicle and at least one of the axles (2, 3) of the vehicle with hydraulic oil from the same container (7). The system also has an arrangement (22) for regulating the temperature of the oil in the hydraulic arrangement (6) via a heat exchanger unit (21). The temperature regulating arrangement (22) is also adapted to cool the engine (4) of the vehicle.

Owner:VOLVO CONSTR EQUIP COMPONENTS AB

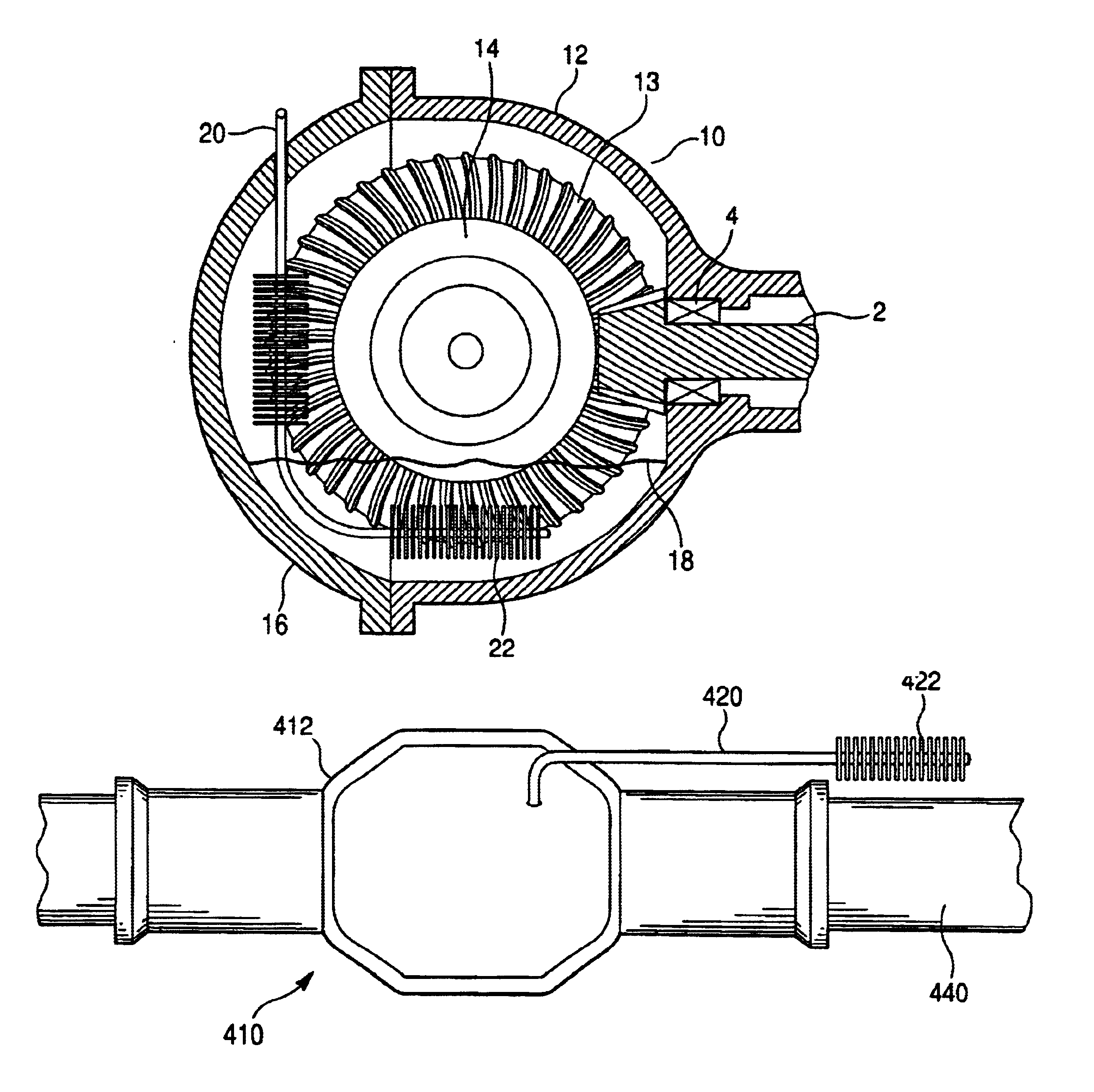

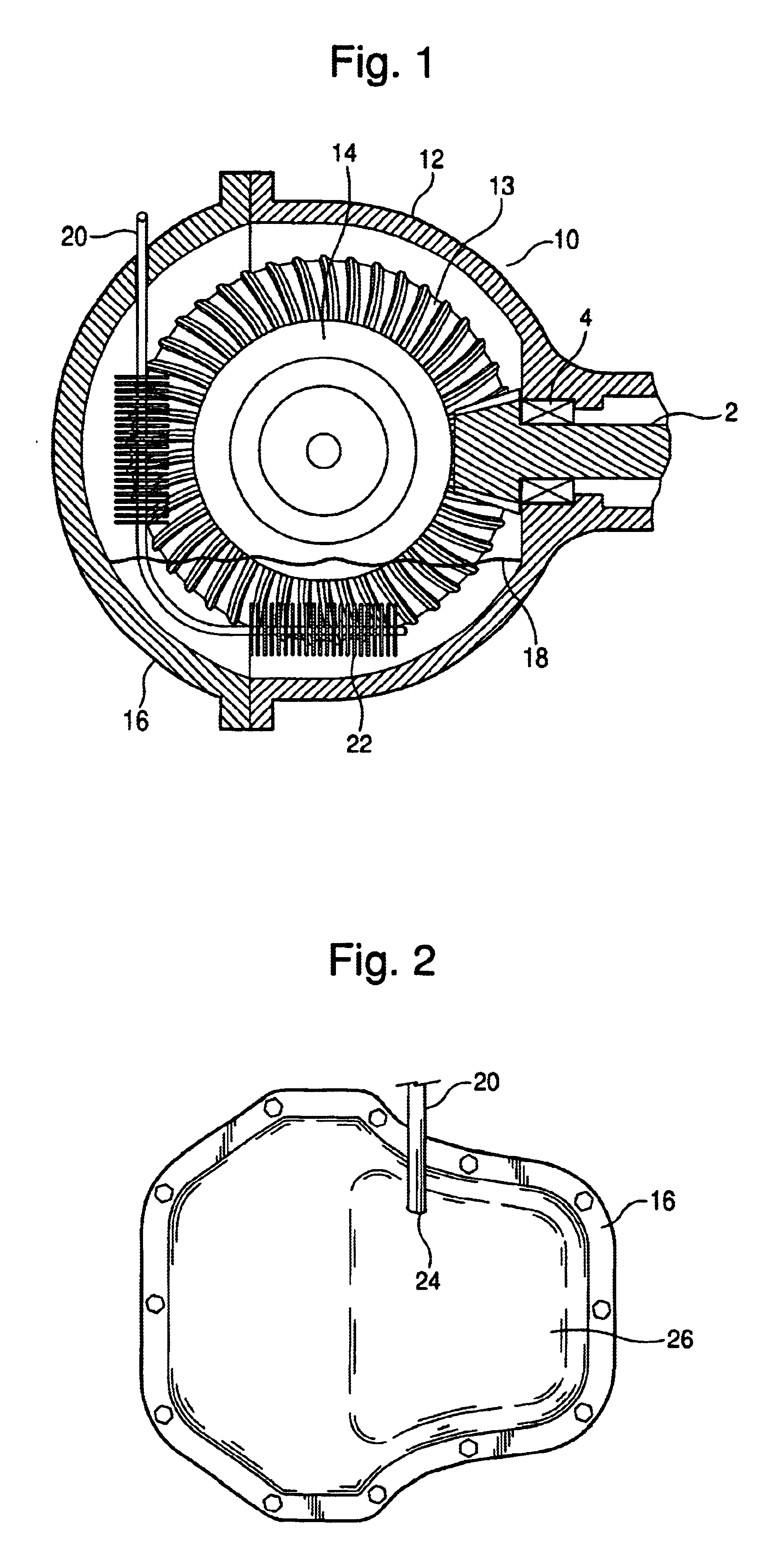

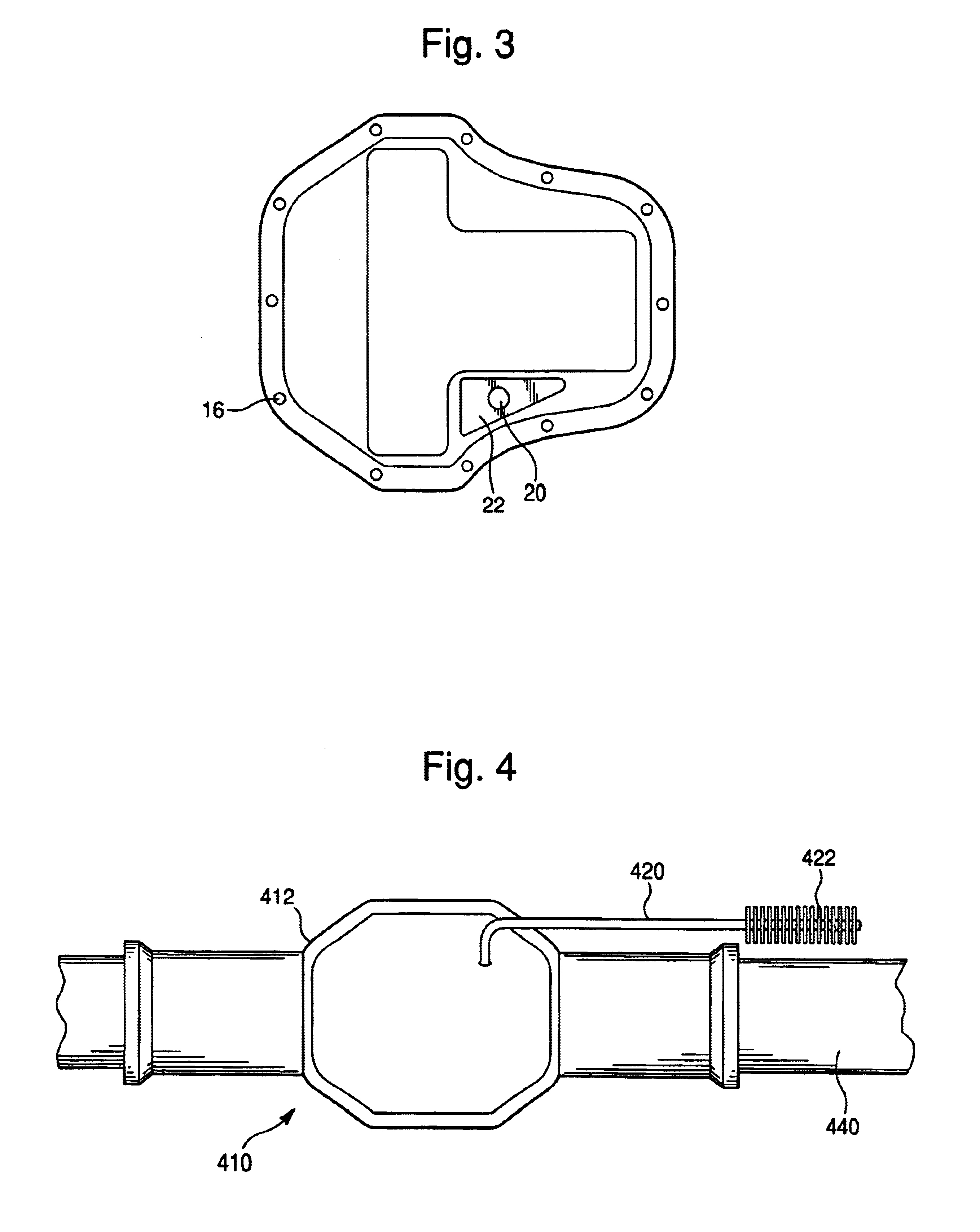

Heat pipe for differential assembly

An apparatus to regulate and control the temperature of an axle assembly for a vehicle. A heat pipe is inserted though the axle housing cover, the heat pipe travels the length of the cover. Near the lower region of the carrier and beneath the lubricating fluid level, the heat pipe bends to continue in the horizontal direction. Disposed about the terminal end of the heat pipe below the lubricating fluid line are a series of cooling fins. Heat generated within the lubricating fluid that is heated during operation conduit is dissipated via the cooling fins.

Owner:TORQUE TRACTION TECH INC

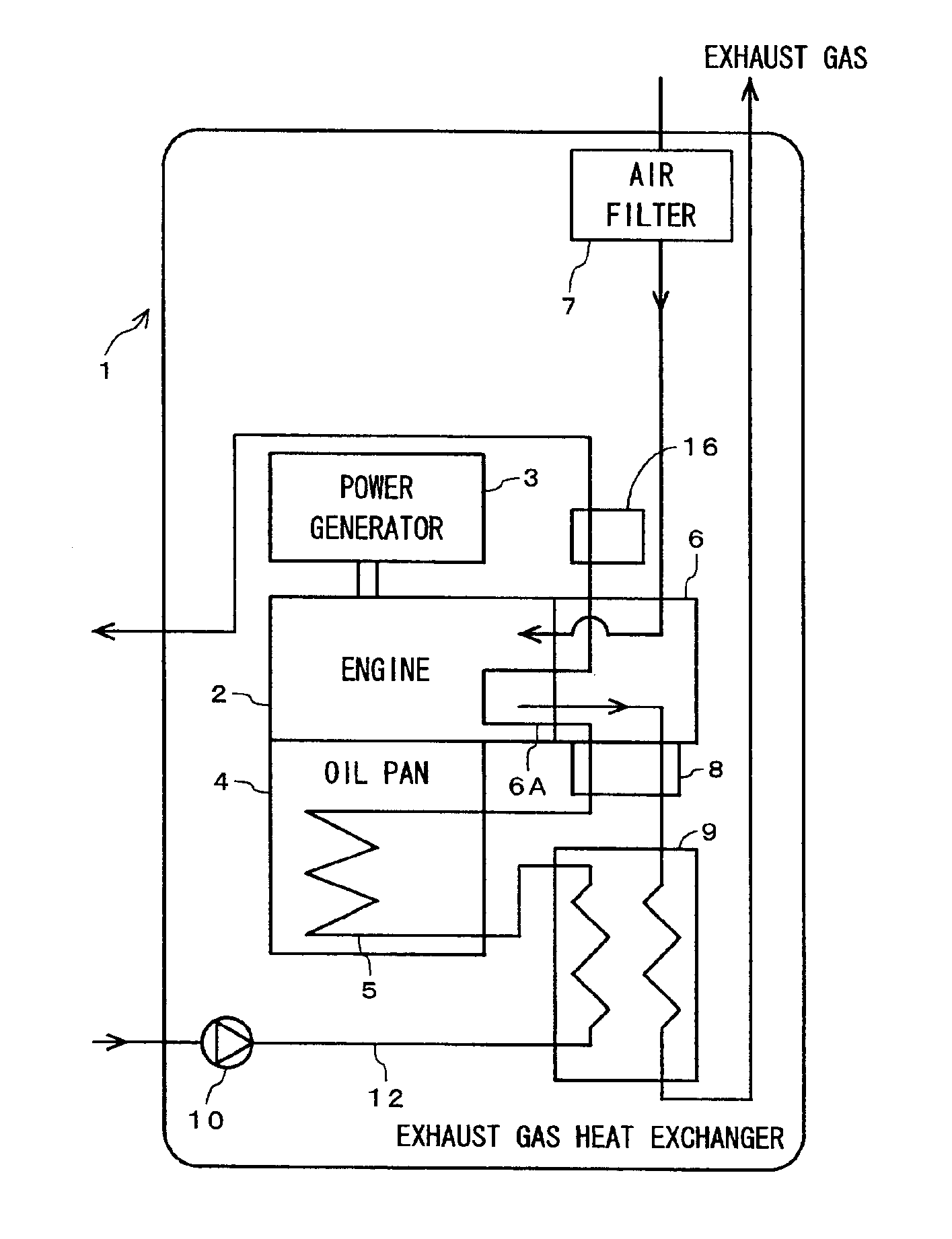

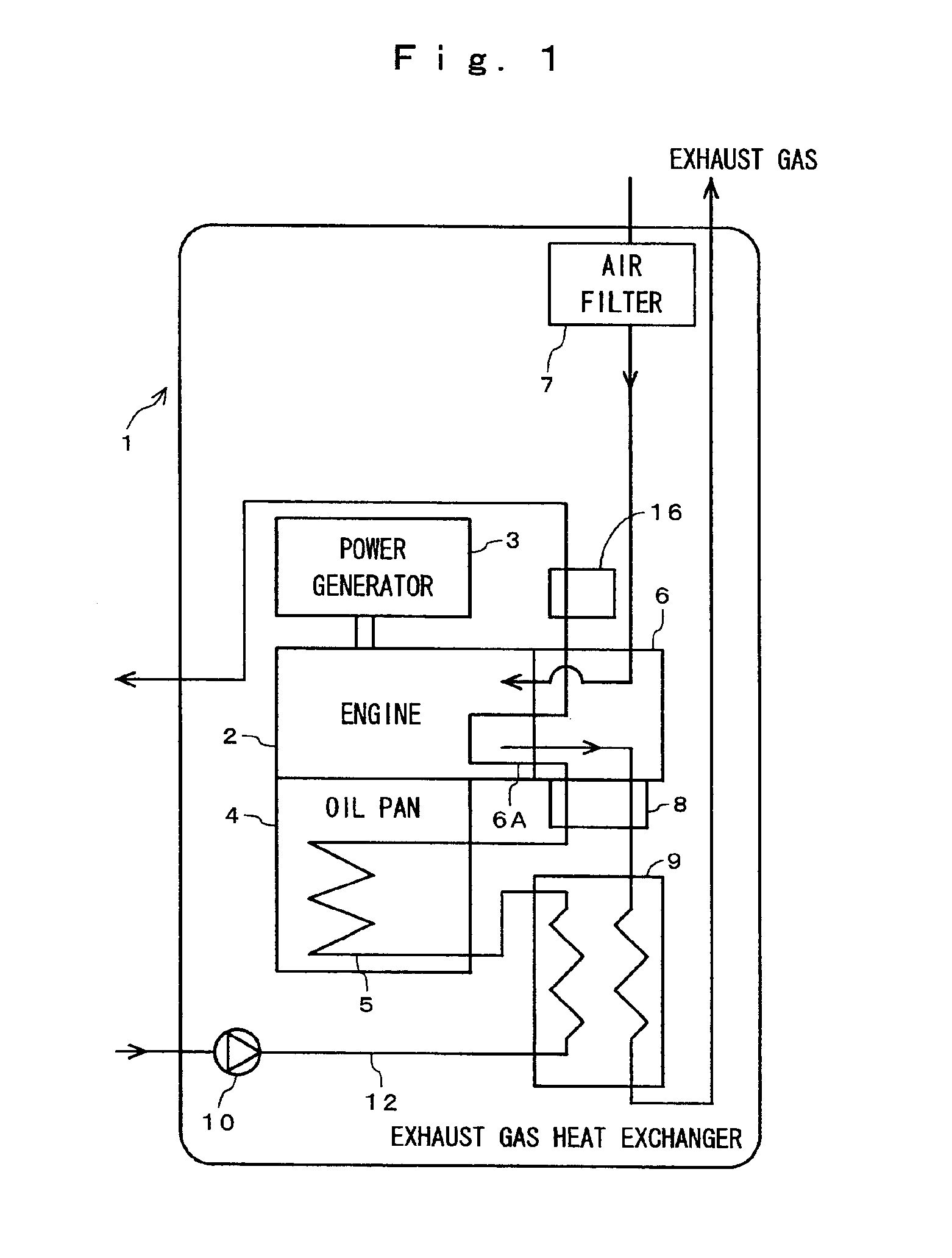

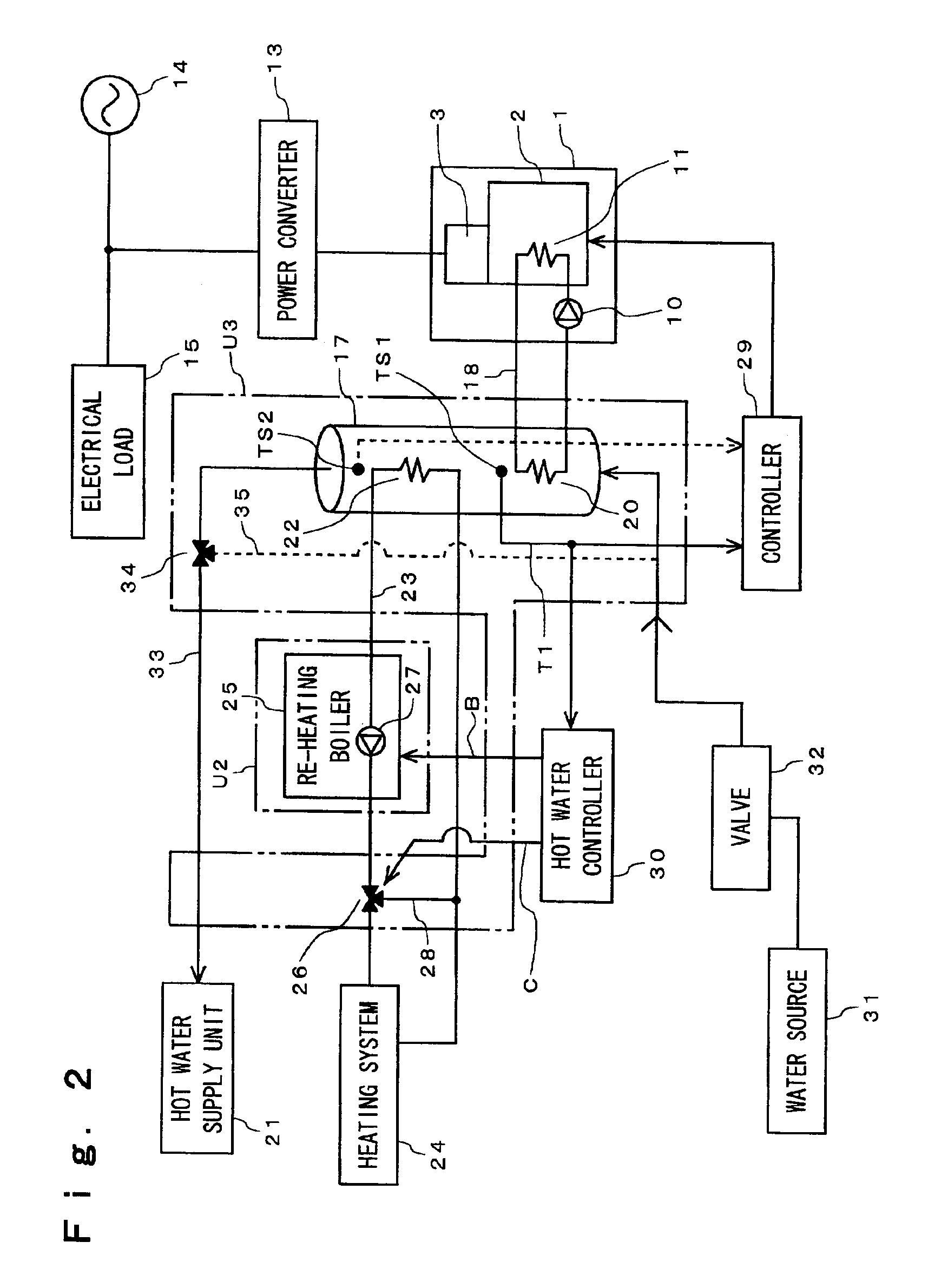

Engine exhaust heat recovering apparatus

InactiveUS6913068B2Minimize degradationReduce the temperatureInternal combustion piston enginesExhaust apparatusWater vaporExhaust fumes

A circulating path 12 is provided for circulating a heat transfer medium across the cooling section 6A and an exhaust heat exchanger 9. The circulating path 12 is communicated to an output heat exchanger which is mounted on a hot water storage. The heat transfer medium is circulated by a pump 10 from the exhaust heat exchanger 9 to the oil heat exchanger 5 and the cooling section 6A. The heat transfer medium to be introduced into the exhaust heat exchanger 9 is so controlled in the flow rate that a temperature of the water vapor in the exhaust gas is declined to a temperature lower than the dew point. The heat transfer medium when having received heat directly from the exhaust gas and heat generated by condensation of the exhaust heat is conveyed to the cooling section 6A where its temperature soars up further.

Owner:HONDA MOTOR CO LTD

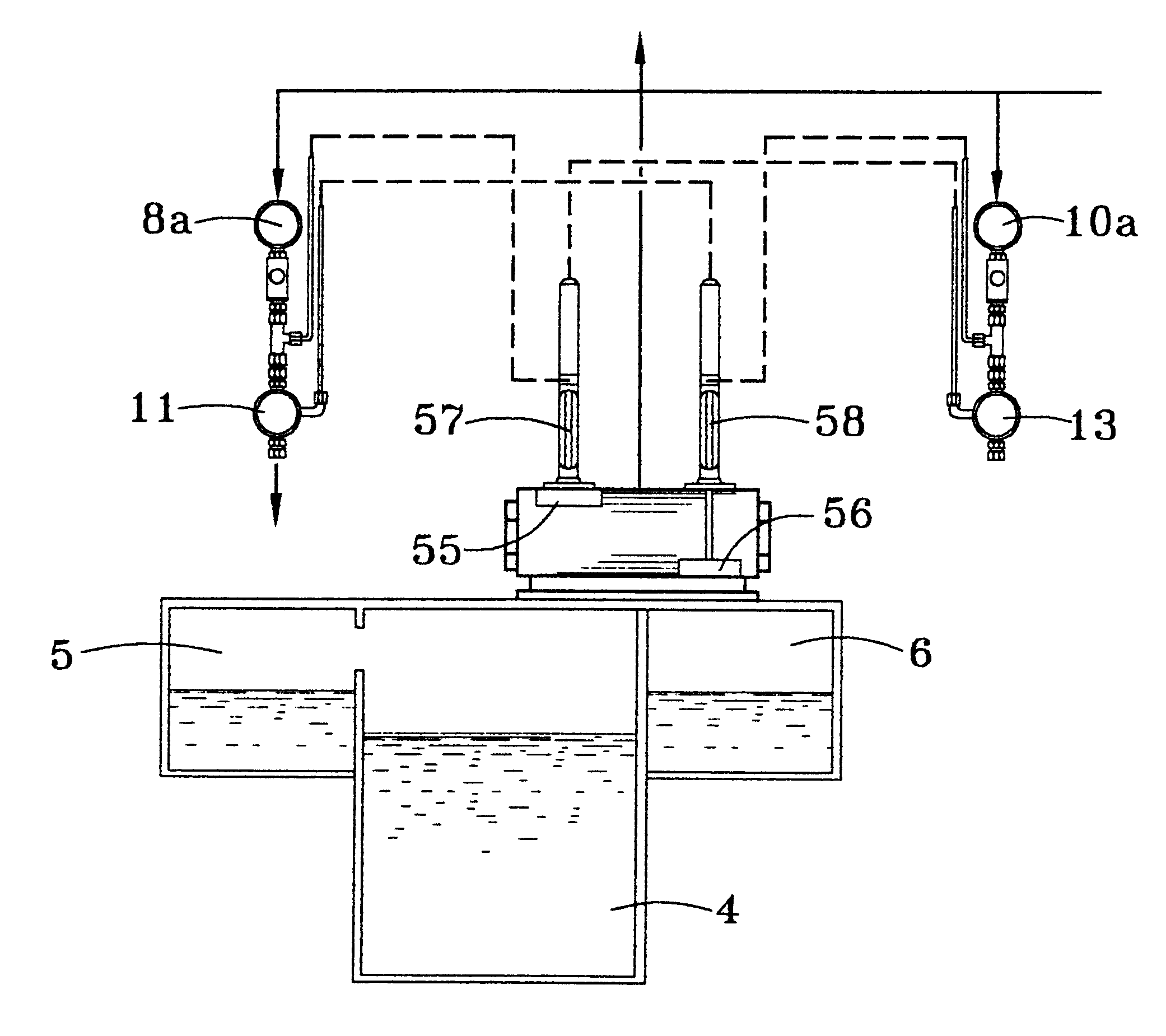

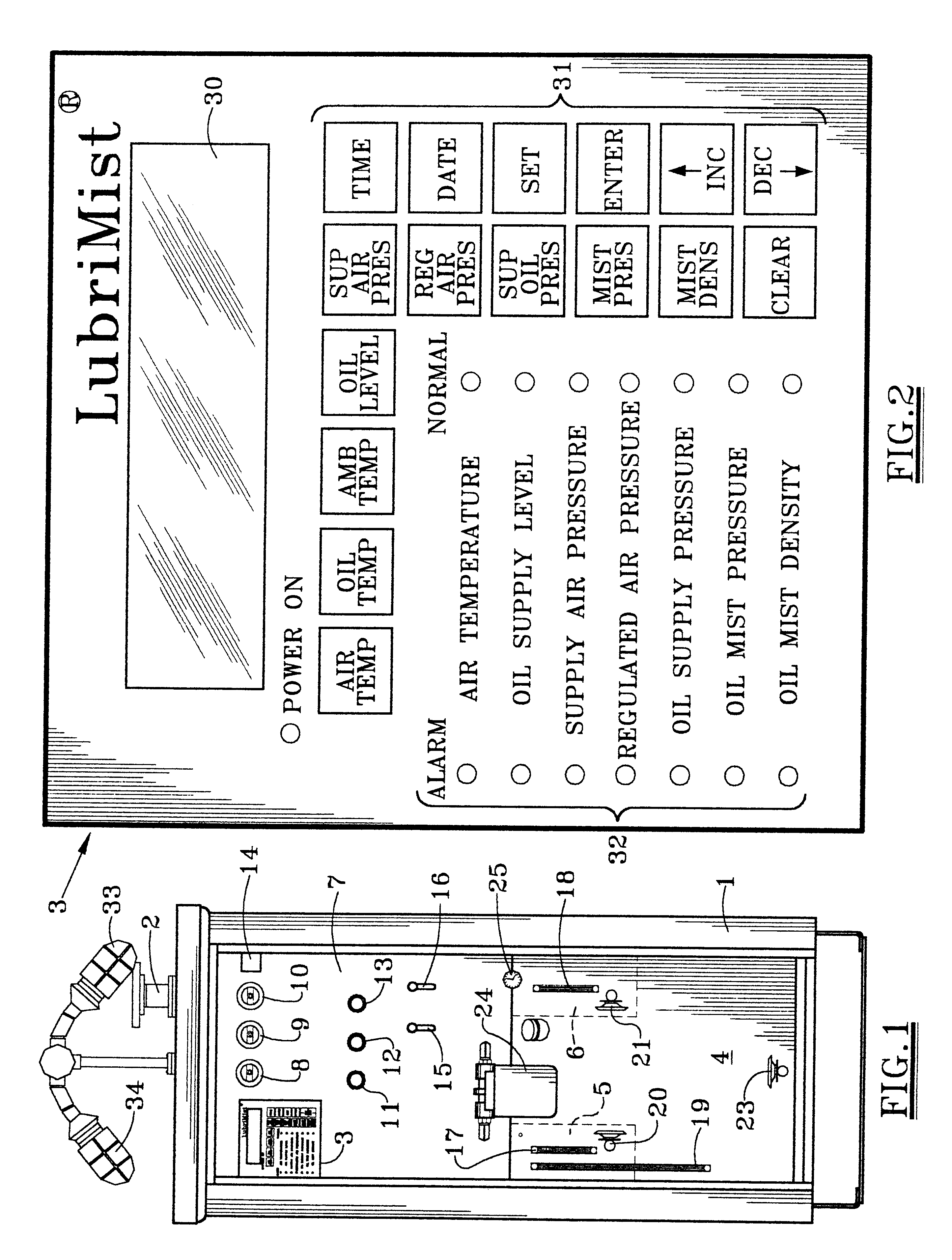

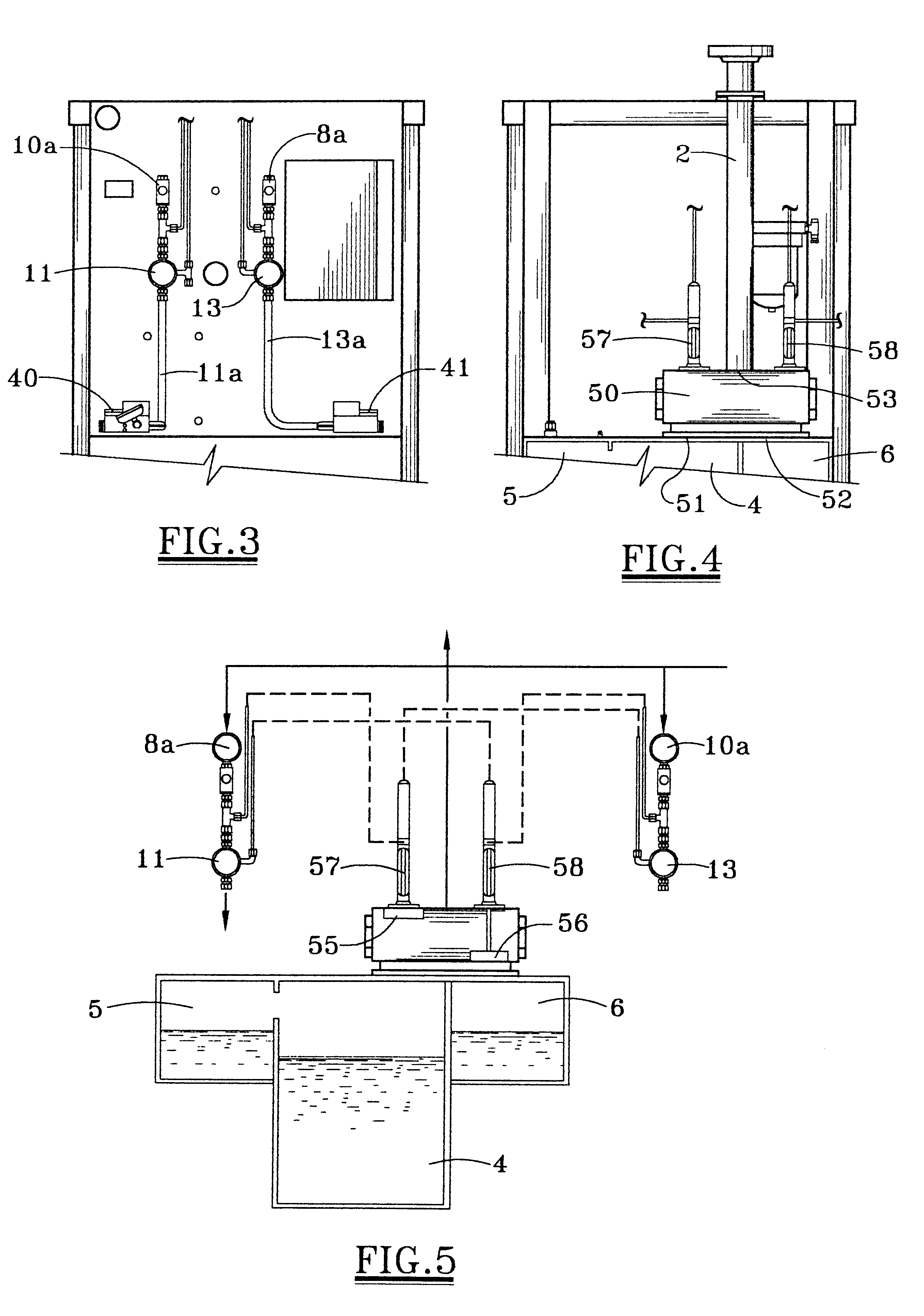

Oil mist generating system

An improved oil mist generating system in which air and oil are supplied to a mist generator in which the air and oil are combined to form oil mist. The system is characterized in that the oil is alternately provided by a main oil reservoir and an auxiliary oil reservoir each of which is provided with a mist generator. Each mist generator is operatively associated with a control device for alternatively activating one of the mist generators while deactivating the other. Also disclosed is an oil mist generator which includes a heater manifold extending into an oil reservoir heating both air and oil prior to entry into a mist head in which the air and oil are combined to form an oil mist. Air and oil are introduced into the mist head through plates which are removable for replacement by plates of different sizes, allowing oil mist capacity to be changed.

Owner:CIRCOR RELIABILITY SERVICES CO

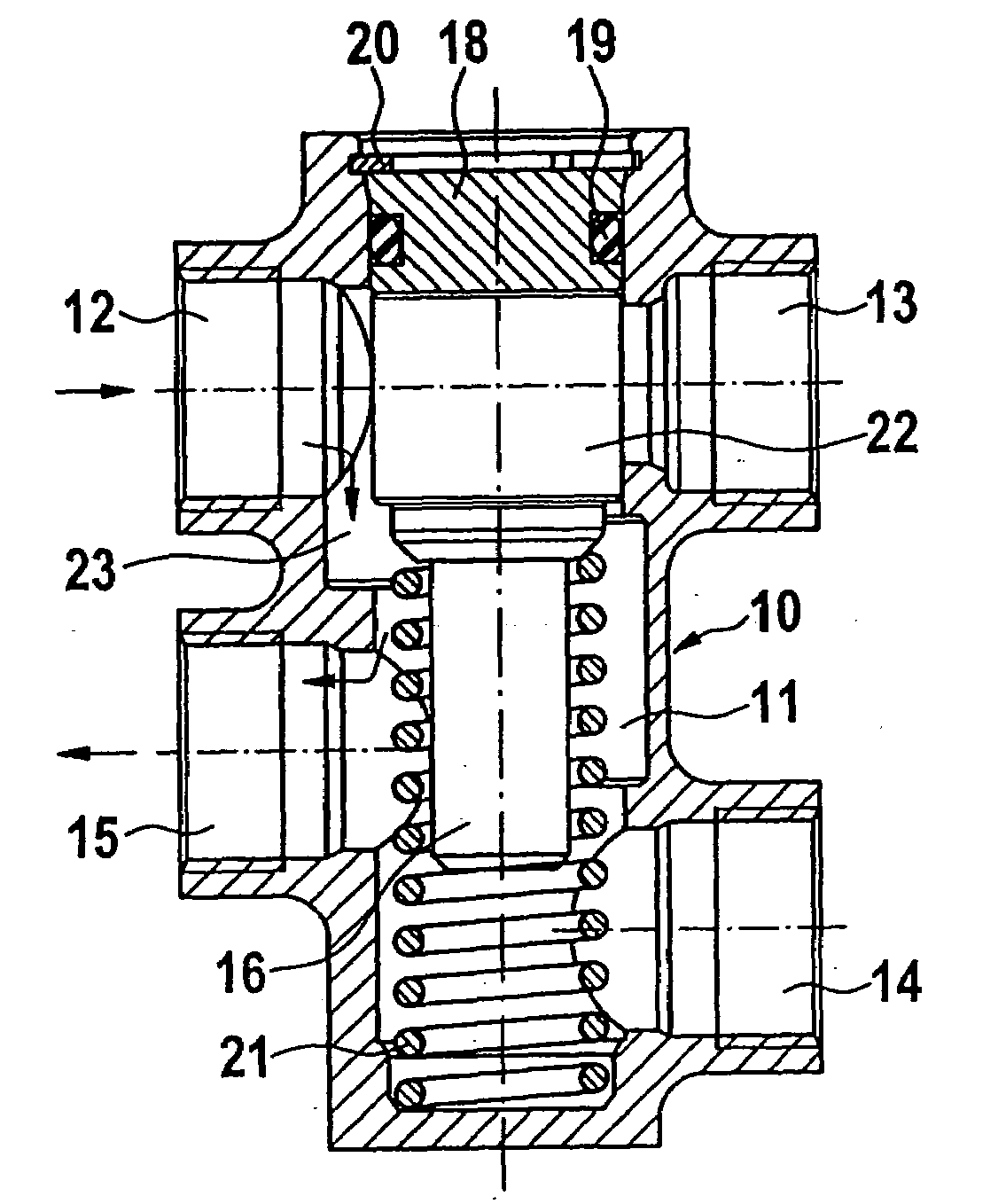

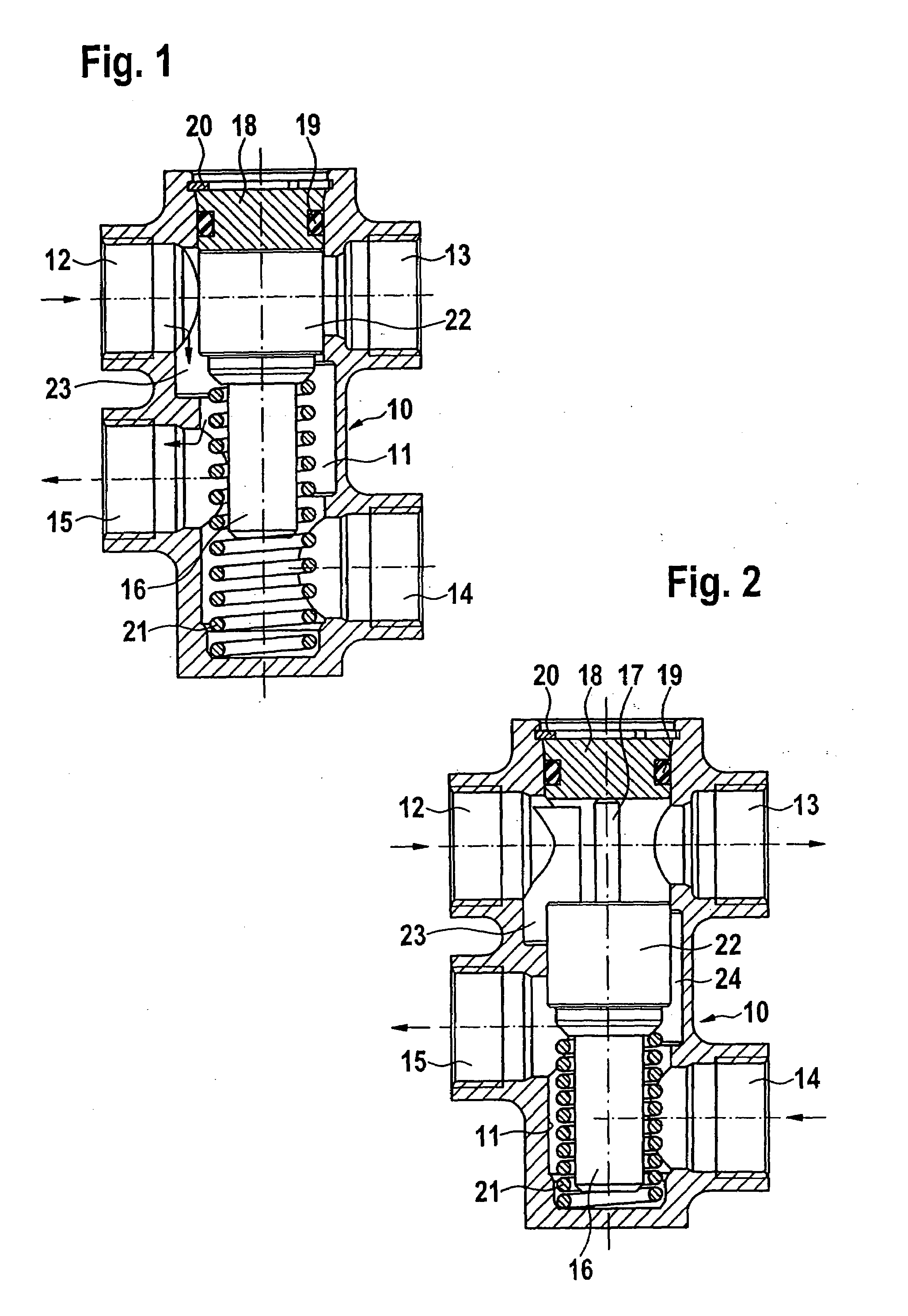

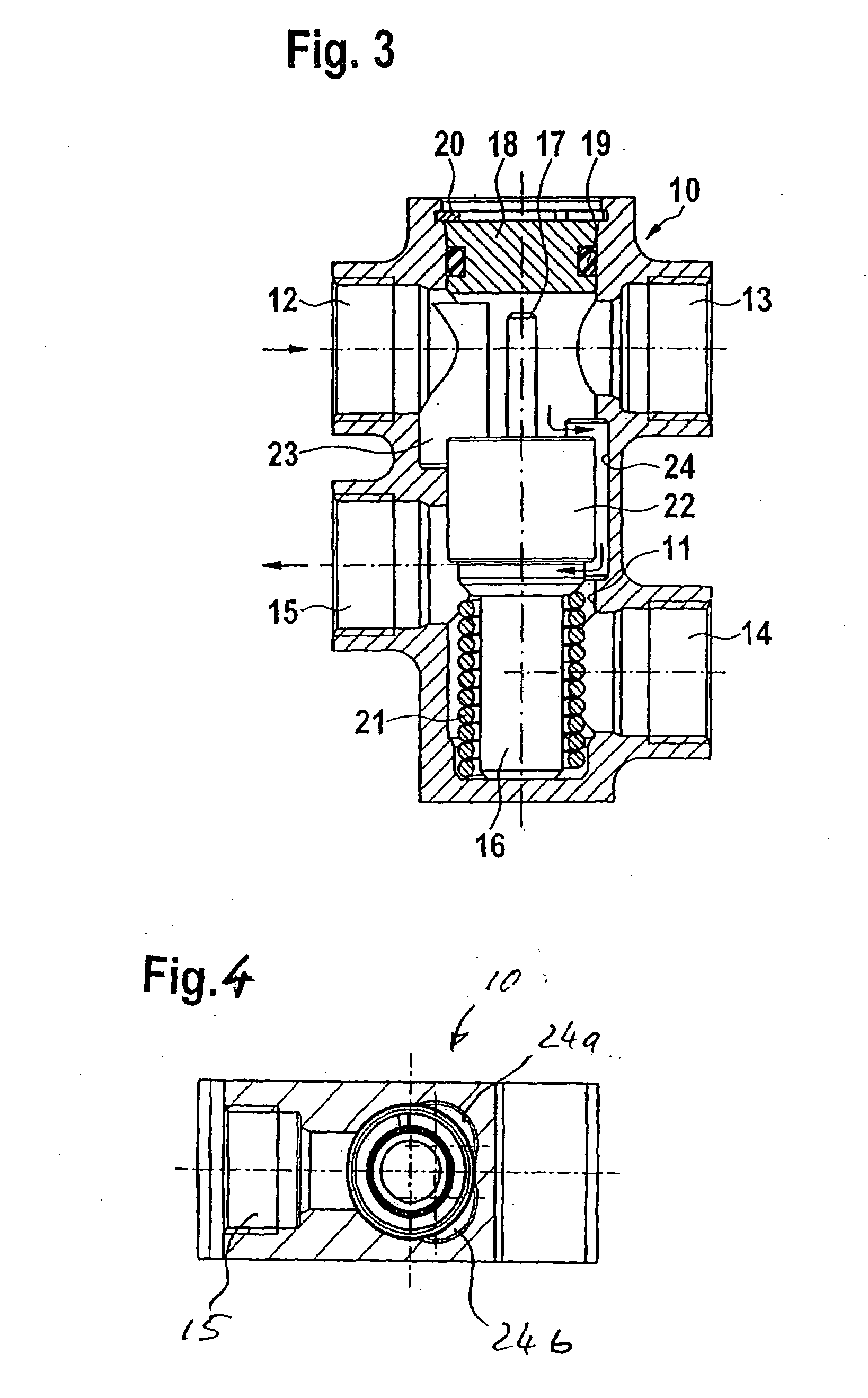

Thermostatic valve for connecting an automatic transmission with an oil cooler

ActiveUS20070164123A1Temperature control without auxillary powerCoolant flow controlAutomatic transmissionControl valves

In a thermostatic valve for connecting an automatic transmission with an oil cooler, wherein the connection between an inlet conduit 12 for oil coming from the transmission and an outlet conduit 13 to the oil cooler is released or blocked by means of a valve slider element 22, which is actuated by a thermostatic actuating element 16, 17 and is spring-loaded by a restoring spring 21, the valve slider element 22 with the restoring spring 21 is designed as a pressure-control valve which, with the open connection between the inlet conduit 12 for oil coming from the transmission and the outlet conduit 13 to the oil cooler, opens a bypass conduit 24 when a predetermined pressure of the oil is exceeded.

Owner:BEHR THERMOT TRONIK

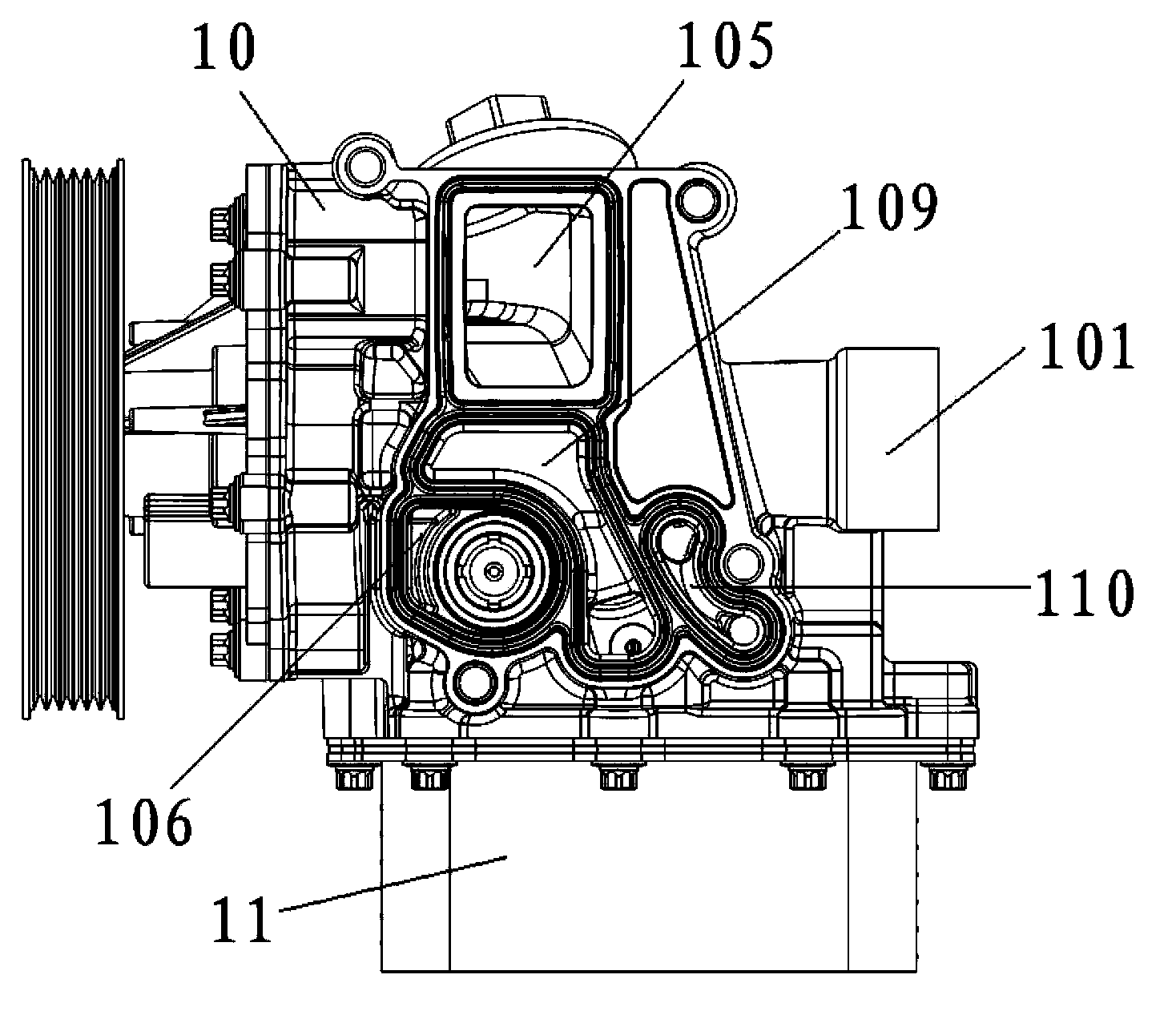

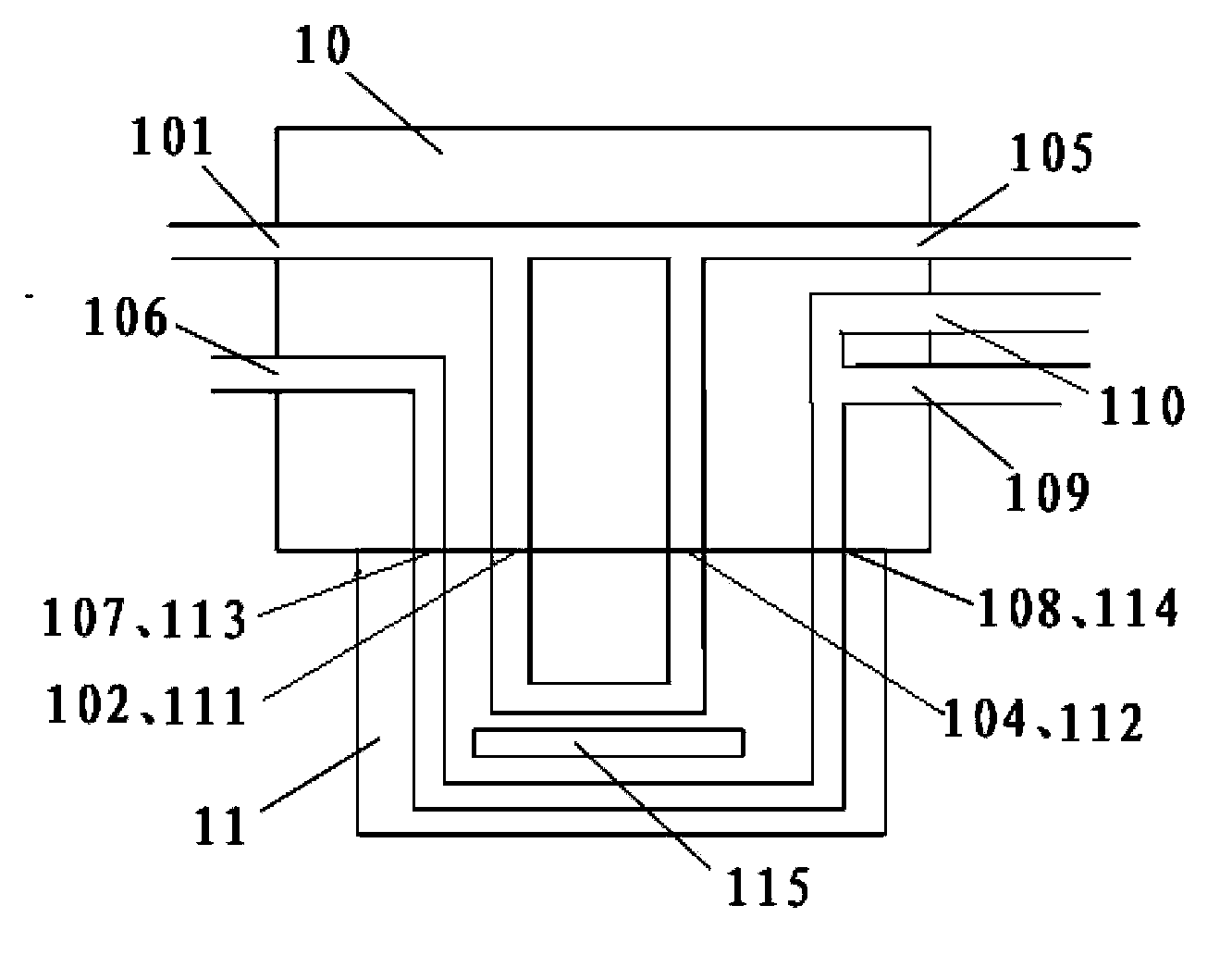

Engine cooling system, engine and vehicle

ActiveCN103670657AImprove fuel economyImprove comfortCoolant flow controlInternal combustion piston enginesThermostatAir conditioning

Owner:北京汽车动力总成有限公司

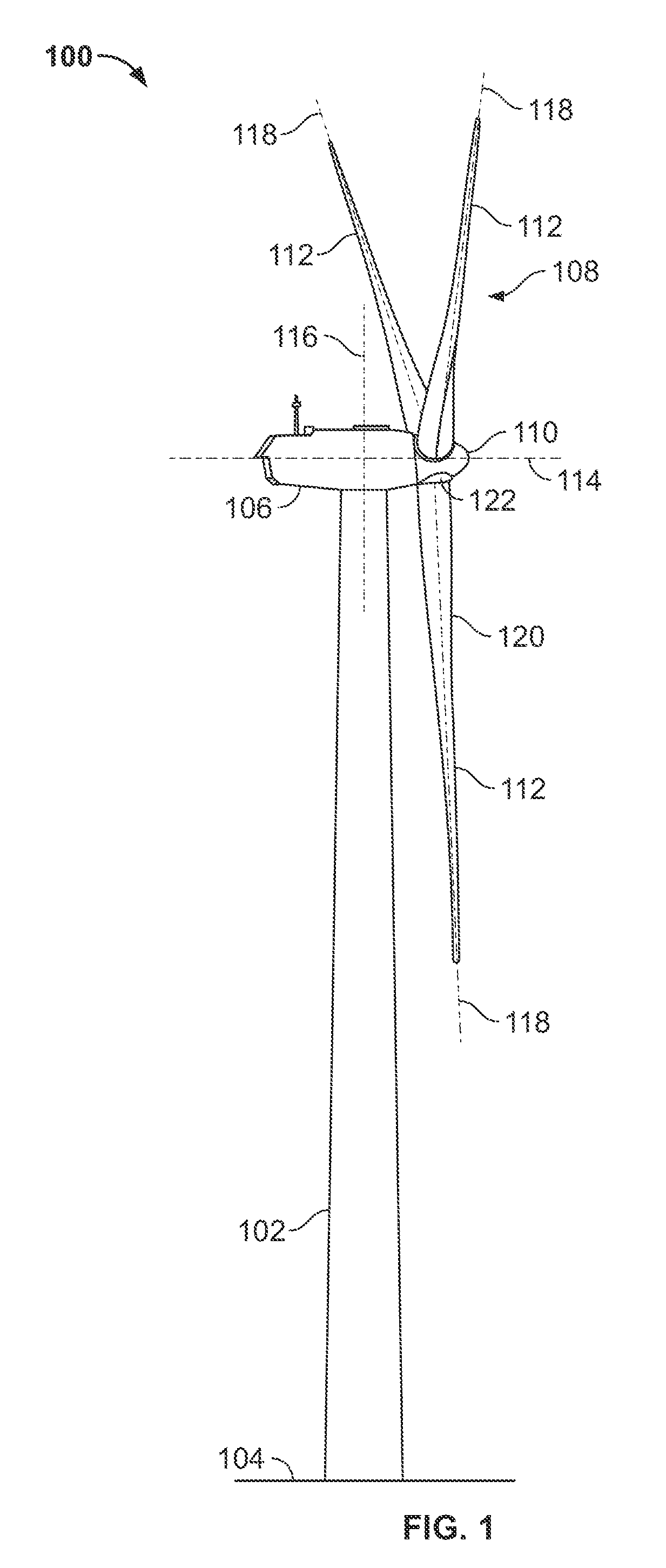

Method and system for operating a wind turbine

A lubrication system for a wind turbine having a control system, the lubrication system including a sump configured to collect a lubrication fluid, and at least one heating unit configured to heat the lubrication fluid based on at least one forecasted condition.

Owner:GENERAL ELECTRIC CO

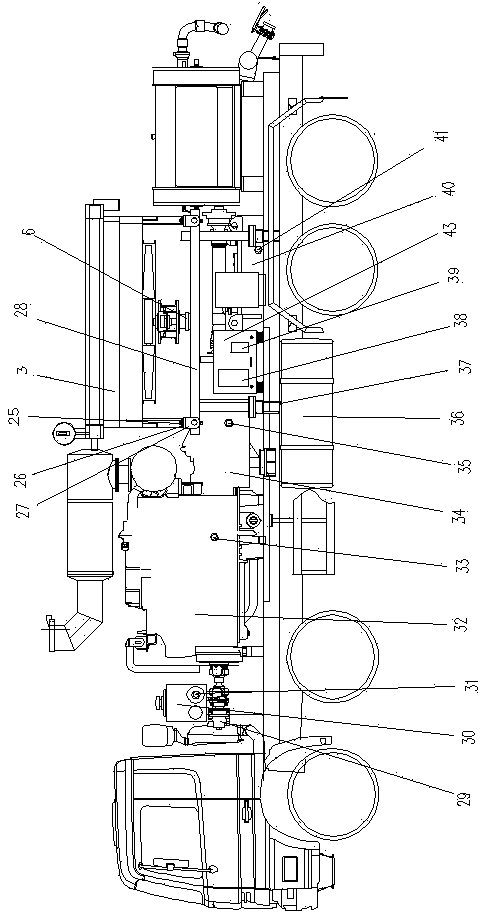

Cooling device of fracturing truck

InactiveCN104196613AMeet quality requirementsMeet the installation space requirementsCoolant flow controlGear lubrication/coolingFuel tankHydraulic pump

The invention provides a cooling device of a fracturing truck. A support of the integrated cooling device of the fracturing truck is connected with a connection base and a chassis crossbeam connection frame through a shock pad by means of a bolt, a control device and a lubrication oil tank provided with a lubrication oil temperature sensor are arranged below the chassis crossbeam connection frame, a fuel tank provided with a fuel temperature sensor is arranged at the lower portion a truck crossbeam, the upper front portion of the truck crossbeam is provided with a hydraulic oil tank provided with a hydraulic oil temperature sensor, an electrically-controlled volume adjustable hydraulic pump is arranged at the lower portion of the hydraulic oil tank, the electrically-controlled volume adjustable hydraulic pump is connected with an engine provided with a water temperature sensor, and the other side of the engine is provided with a transmission tank provided with a transmission tank oil temperature sensor. A horizontal heat sink is respectively provided with an engine water-cooling device, a power end cooling device, a hydraulic cooling device, a fuel cooling device and a transmission tank cooling device. According to the cooling device of the fracturing truck, a horizontal structure and a concentrated heat dissipation mode are adopted, a pipeline of a cooling system is arranged reasonably, and the requirements for the weight and installation space of vehicle-mounted fracturing equipment are met.

Owner:SJ PETROLEUM MACHINERY CO LTD SINOPEC

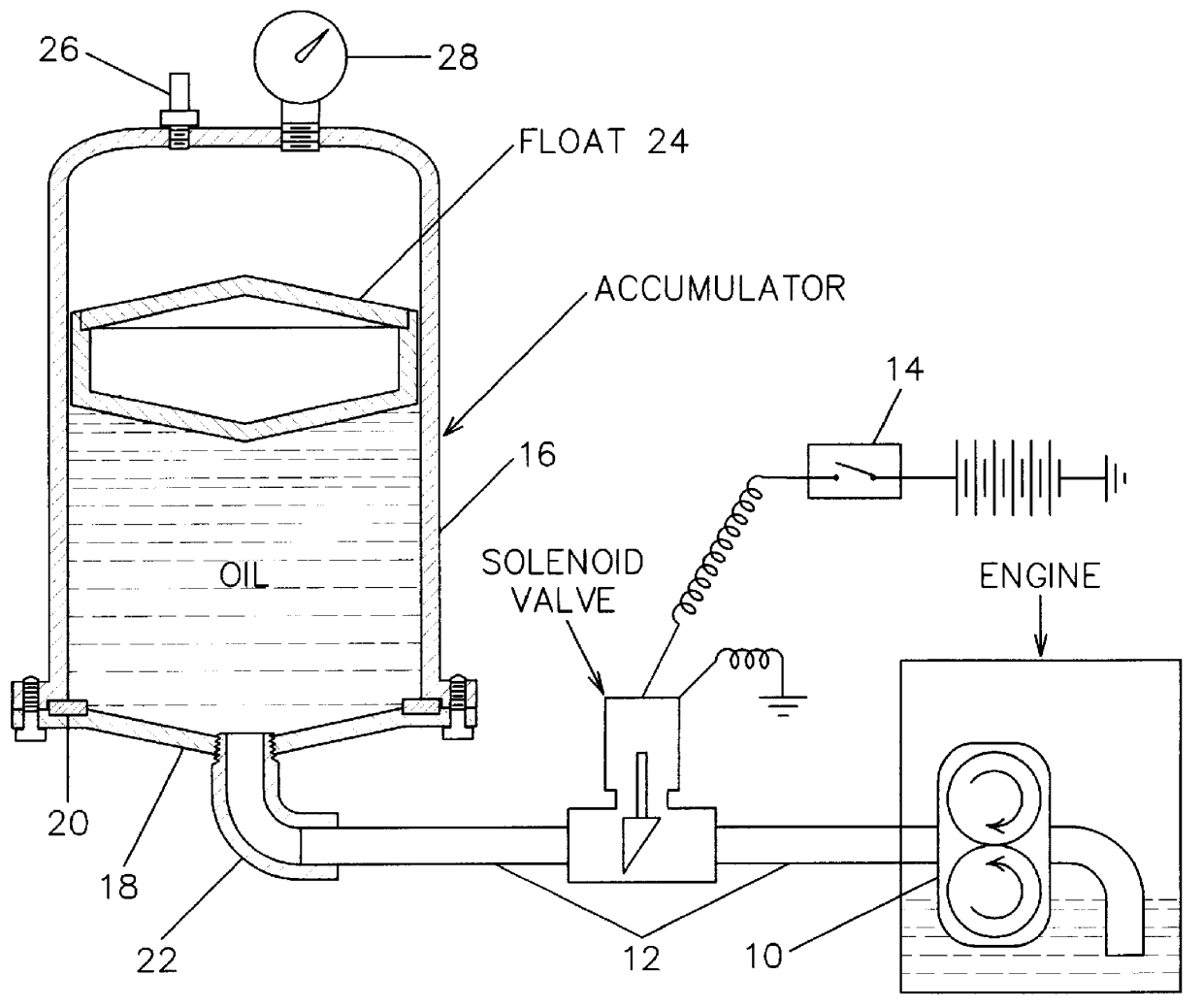

Engine-pressurized prestart oiler

InactiveUS6148789AEasy to modifyMinimal modificationLubrication of auxillariesLubricant conduit arrangementsAutomatic controlSolenoid valve

An engine-pressurized prestart oiler for an engine having pressure lubrication is provided, which rapidly lubricates critical engine bearing surfaces prior to the starting sequence. An accumulator for storing oil and pressurized air contains an air-oil separation float, which essentially fills the internal cross-sectional area and prevents absorption of the air. Discharge and recharge of the accumulator is preferably implemented by a normally closed solenoid valve. Discharge is controlled either manually by a switch or automatically by circuitry containing ignition-off time and accumulator pressure comparators, a starter interrupter, and a prestart oiling timer. Recharge is automatic, as the solenoid valve allows oil flow whenever the engine oil pressure sufficiently exceeds the accumulator pressure. A conduit connects the accumulator, solenoid valve, and engine, connecting to the engine either at the oil pressure sensor port or through an adaptor installed between the oil filter and the oil filter mount.

Owner:JOHNS RALPH HOWARD

Popular searches

Railway heating/cooling Engine fuctions Lubrication temperature control Turbine/propulsion lubrication Jet propulsion plants Hot gas positive displacement engine plants Lubricating pumps Closed-circuit pressure lubricating systems Pressure lubrication with lubrication pump Lubrication pressure control

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com