Patents

Literature

56results about How to "Meet the installation space requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

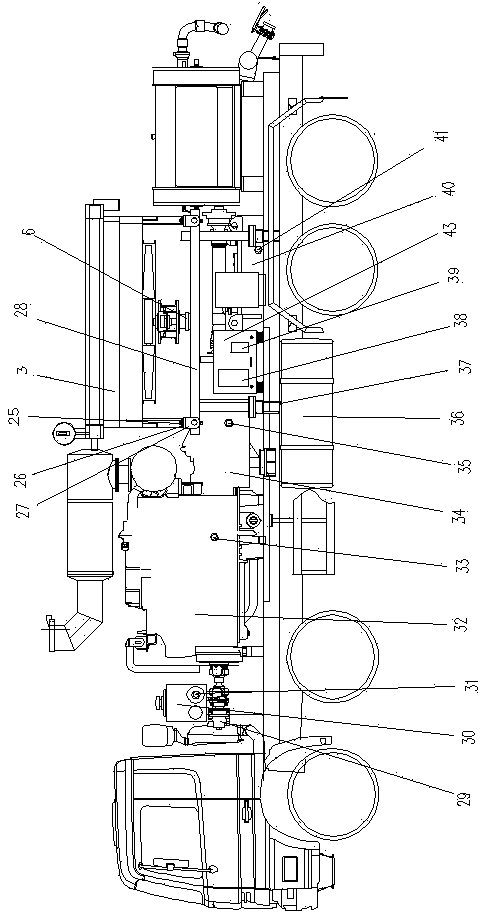

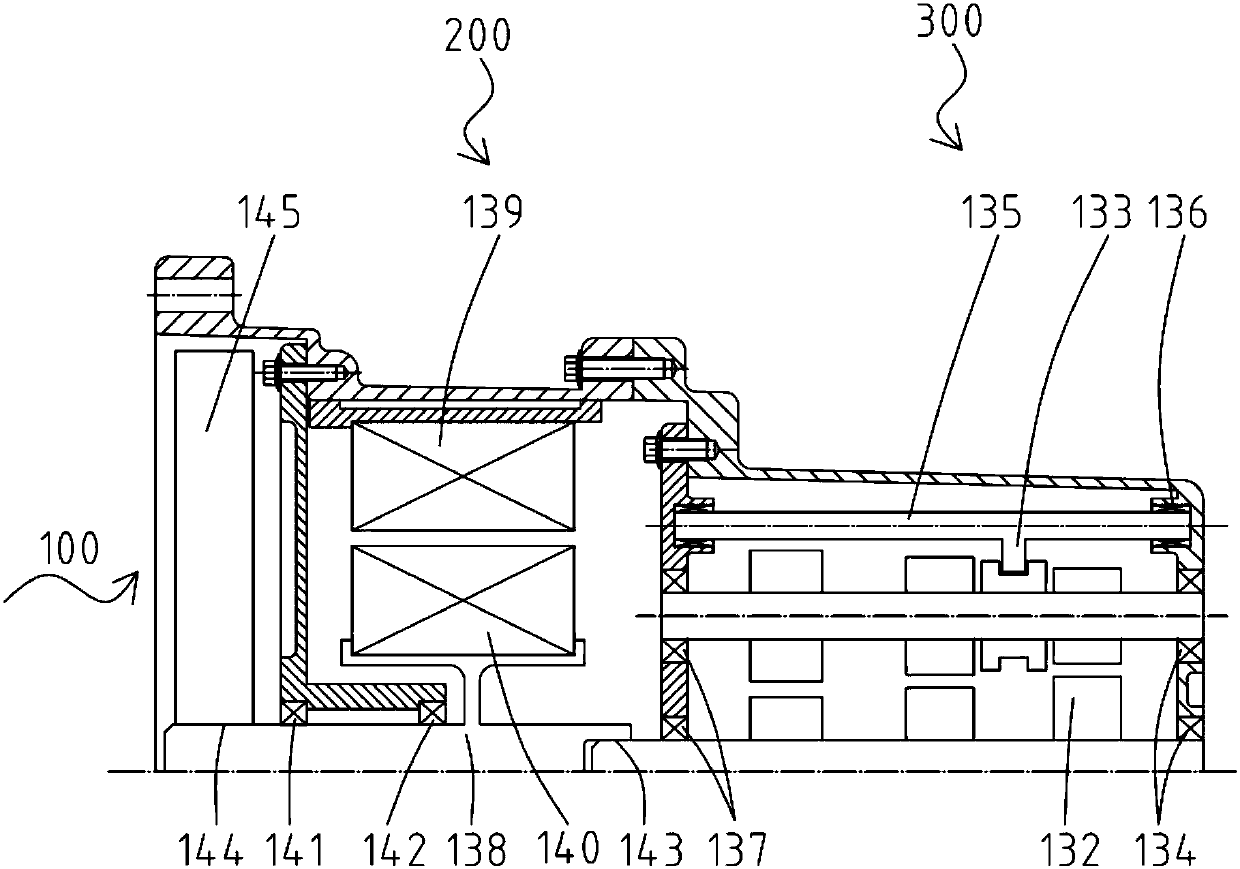

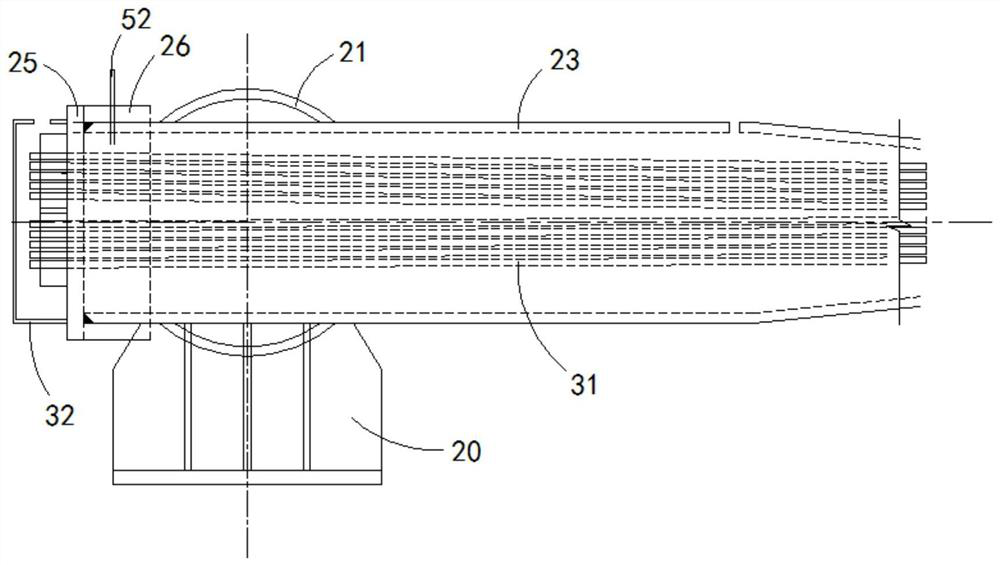

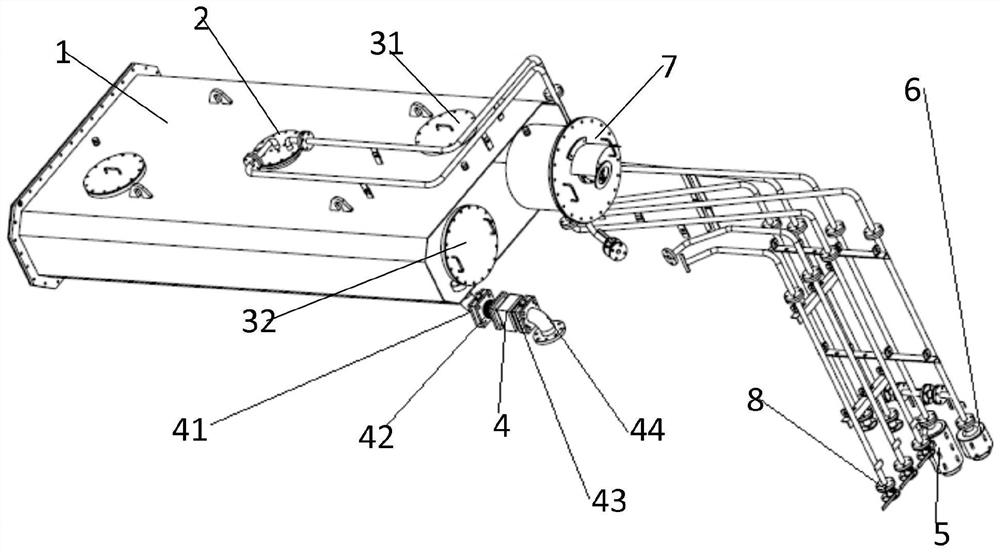

Cooling device of fracturing truck

InactiveCN104196613AMeet quality requirementsMeet the installation space requirementsCoolant flow controlGear lubrication/coolingFuel tankHydraulic pump

The invention provides a cooling device of a fracturing truck. A support of the integrated cooling device of the fracturing truck is connected with a connection base and a chassis crossbeam connection frame through a shock pad by means of a bolt, a control device and a lubrication oil tank provided with a lubrication oil temperature sensor are arranged below the chassis crossbeam connection frame, a fuel tank provided with a fuel temperature sensor is arranged at the lower portion a truck crossbeam, the upper front portion of the truck crossbeam is provided with a hydraulic oil tank provided with a hydraulic oil temperature sensor, an electrically-controlled volume adjustable hydraulic pump is arranged at the lower portion of the hydraulic oil tank, the electrically-controlled volume adjustable hydraulic pump is connected with an engine provided with a water temperature sensor, and the other side of the engine is provided with a transmission tank provided with a transmission tank oil temperature sensor. A horizontal heat sink is respectively provided with an engine water-cooling device, a power end cooling device, a hydraulic cooling device, a fuel cooling device and a transmission tank cooling device. According to the cooling device of the fracturing truck, a horizontal structure and a concentrated heat dissipation mode are adopted, a pipeline of a cooling system is arranged reasonably, and the requirements for the weight and installation space of vehicle-mounted fracturing equipment are met.

Owner:SJ PETROLEUM MACHINERY CO LTD SINOPEC

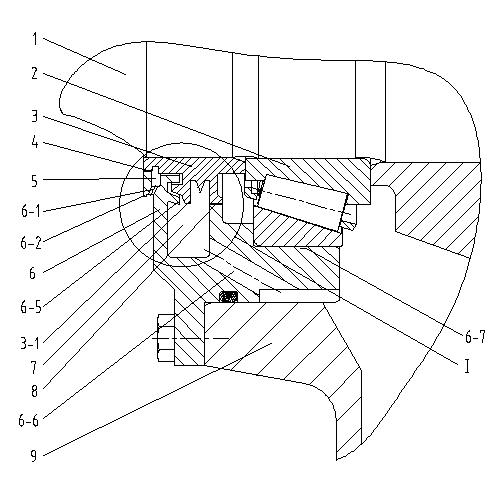

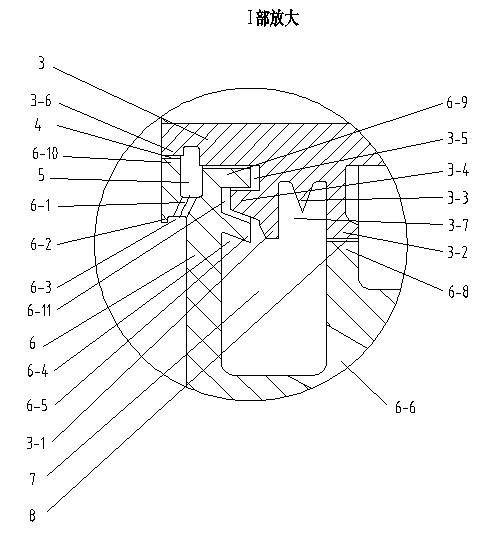

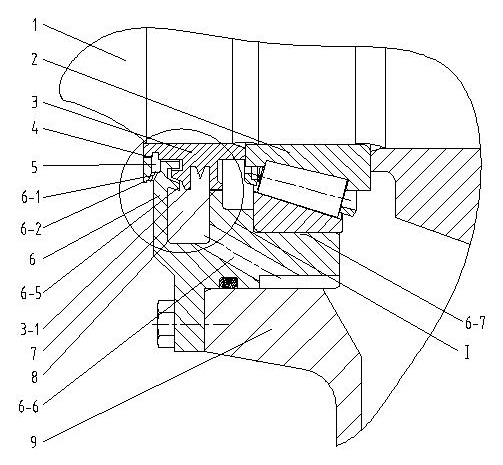

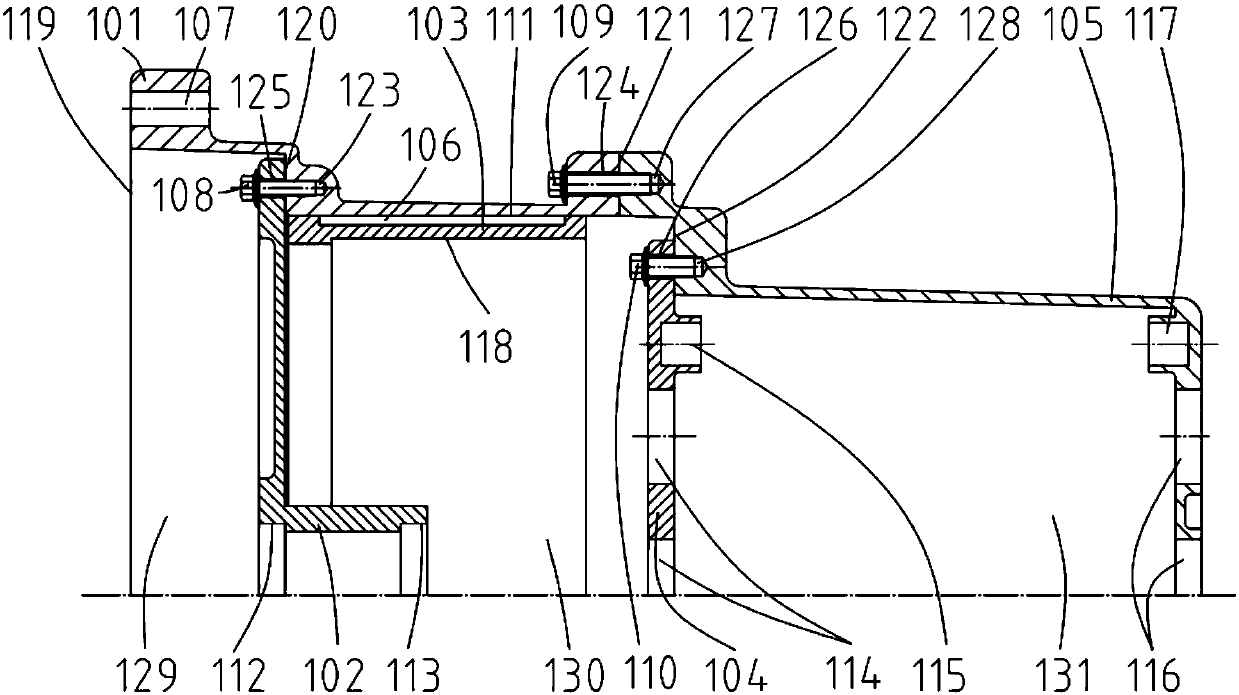

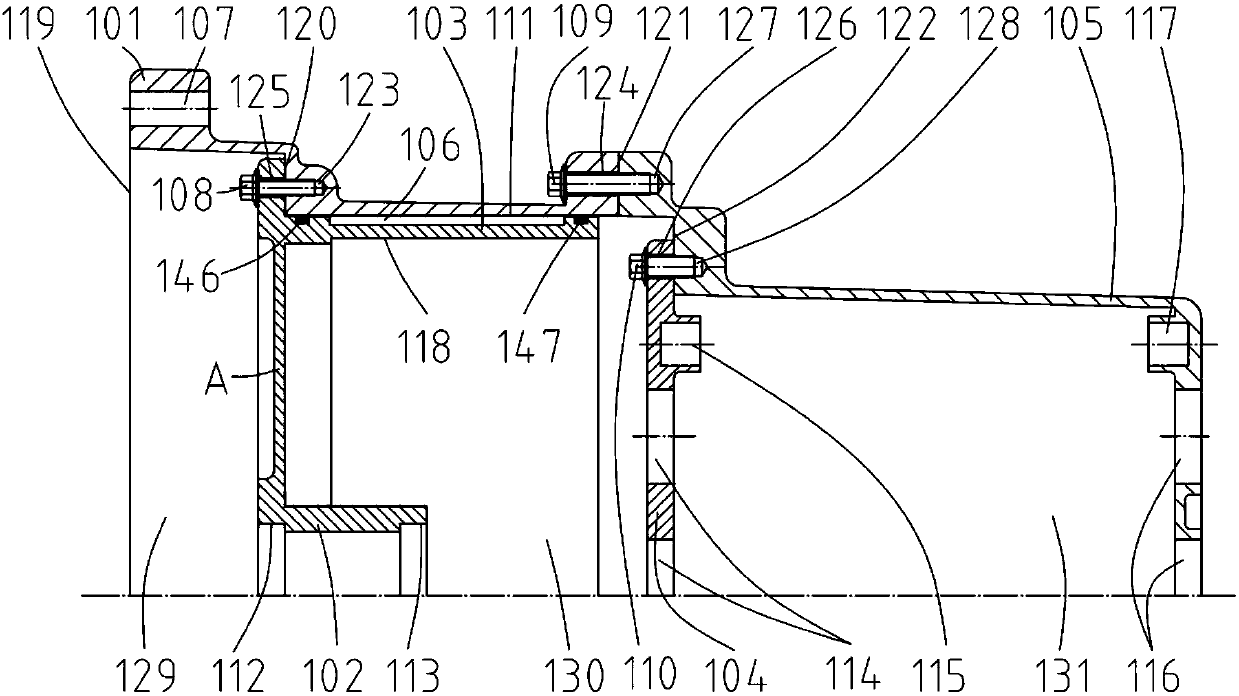

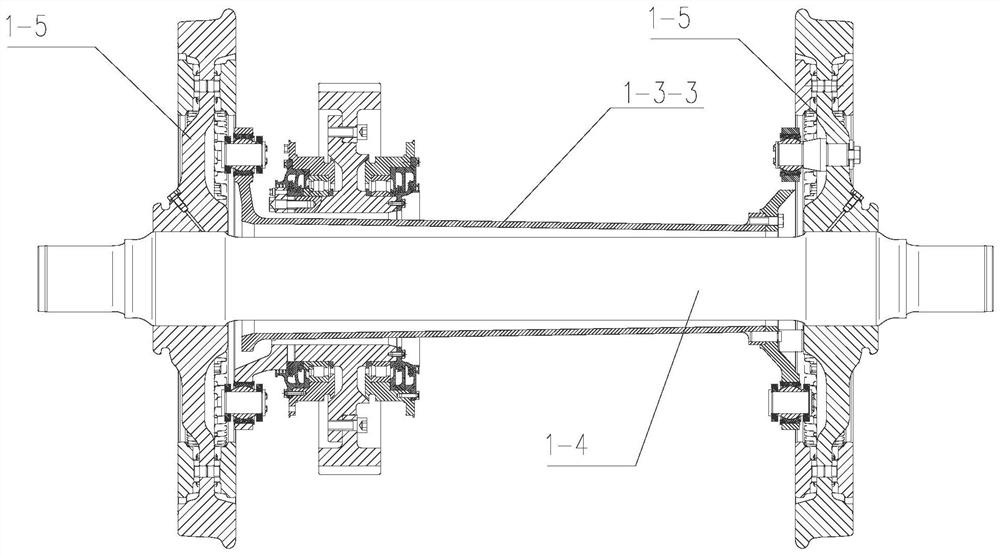

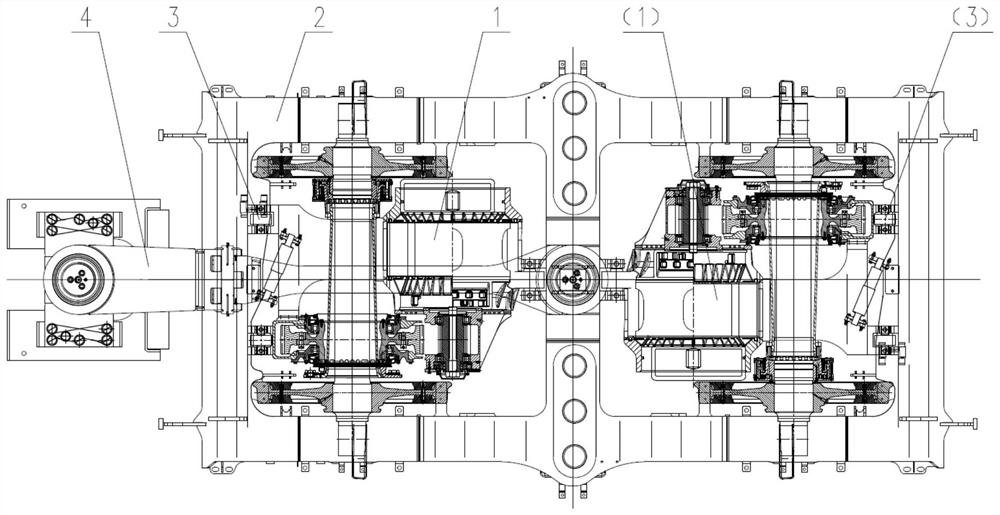

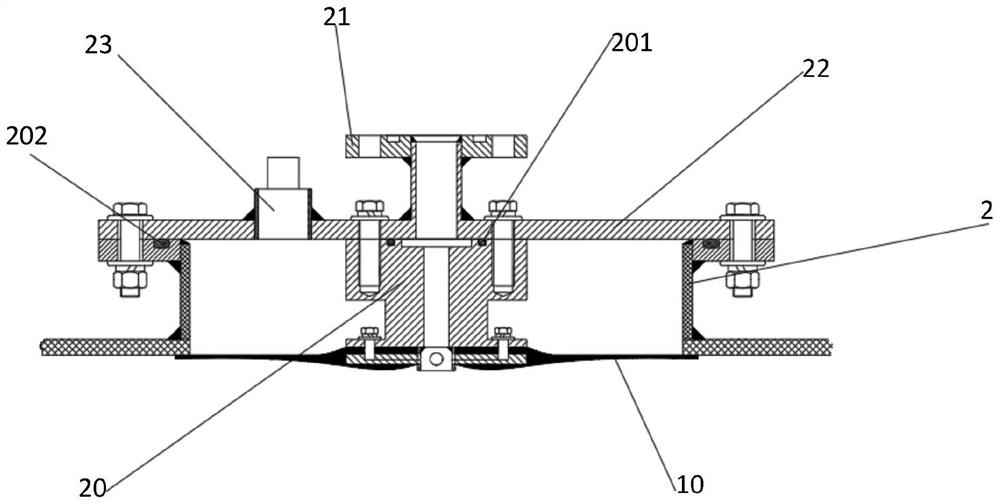

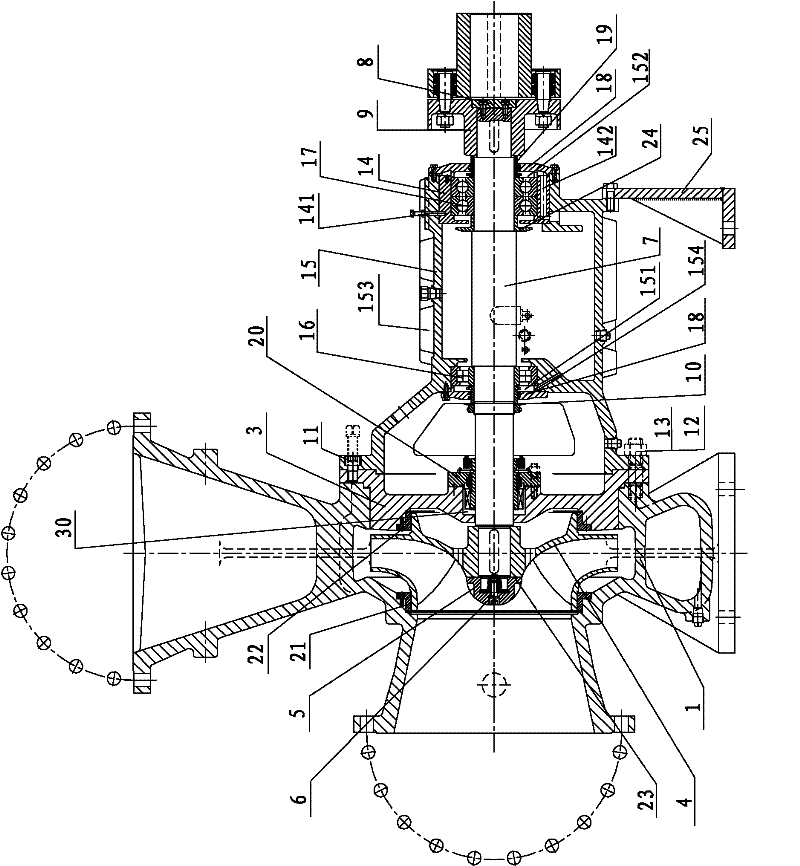

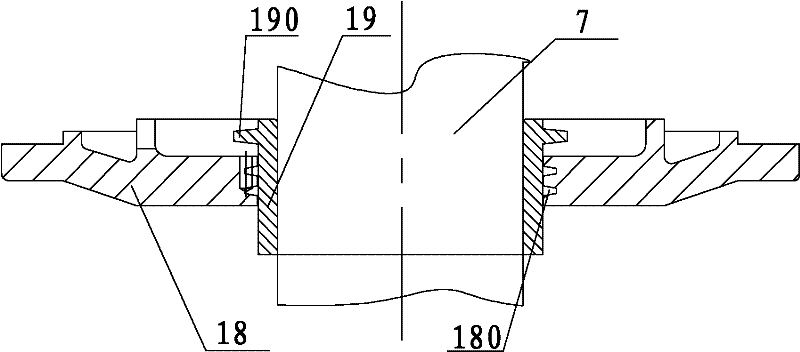

Gear case sealing structure of urban rail vehicle

ActiveCN102009663AReduce in quantityMeet the installation space requirementsEngine sealsAxle-boxesEngineeringFlange

The invention discloses a gear case sealing structure of an urban rail vehicle, comprising a bearing pedestal fixed to a case body and a sealing ring fixed on a rotation shaft, the bearing pedestal includes a matching hole for installing an outer ring of the bearing, and further includes a first sealing flange of the bearing pedestal, a second sealing flange of the bearing pedestal, a third sealing flange of the bearing pedestal and a fourth sealing flange of the bearing pedestal, the sealing ring includes a first flange of the sealing ring and a second flange of the sealing ring, a third flange of the sealing ring, a lubricating flange and a second sealing groove; the bearing pedestal and the sealing ring form a first radial clearance seal, a second radial clearance seal and a labyrinth seal; a first ring-shaped sealing chamber and a second ring-shaped sealing chamber are further formed between the bearing pedestal and the sealing ring, the bottom of the first ring-shaped sealing chamber is provided with an oil return hole, and the bottom of the second ring-shaped sealing chamber is provided with a through hole. The invention is simple in structure, reliable in sealing, and convenient in detaching and maintaining.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

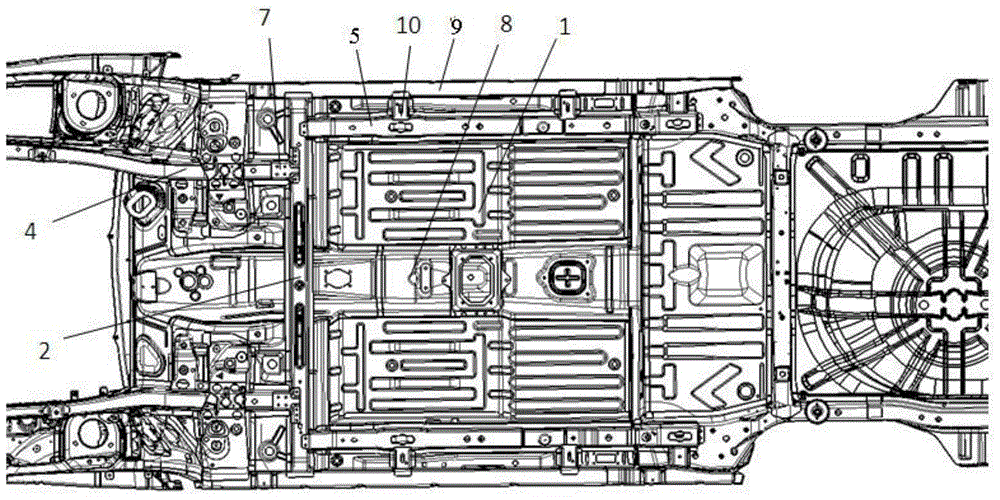

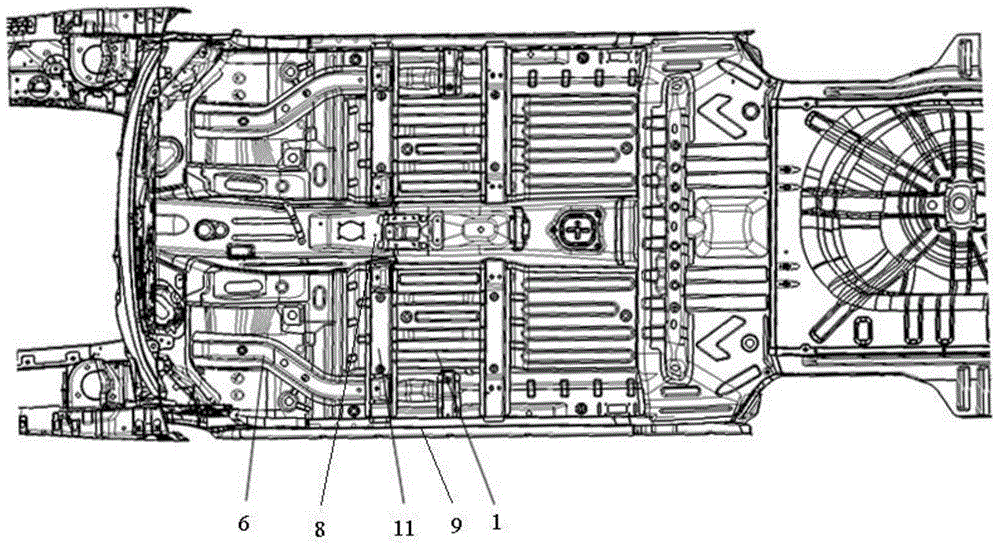

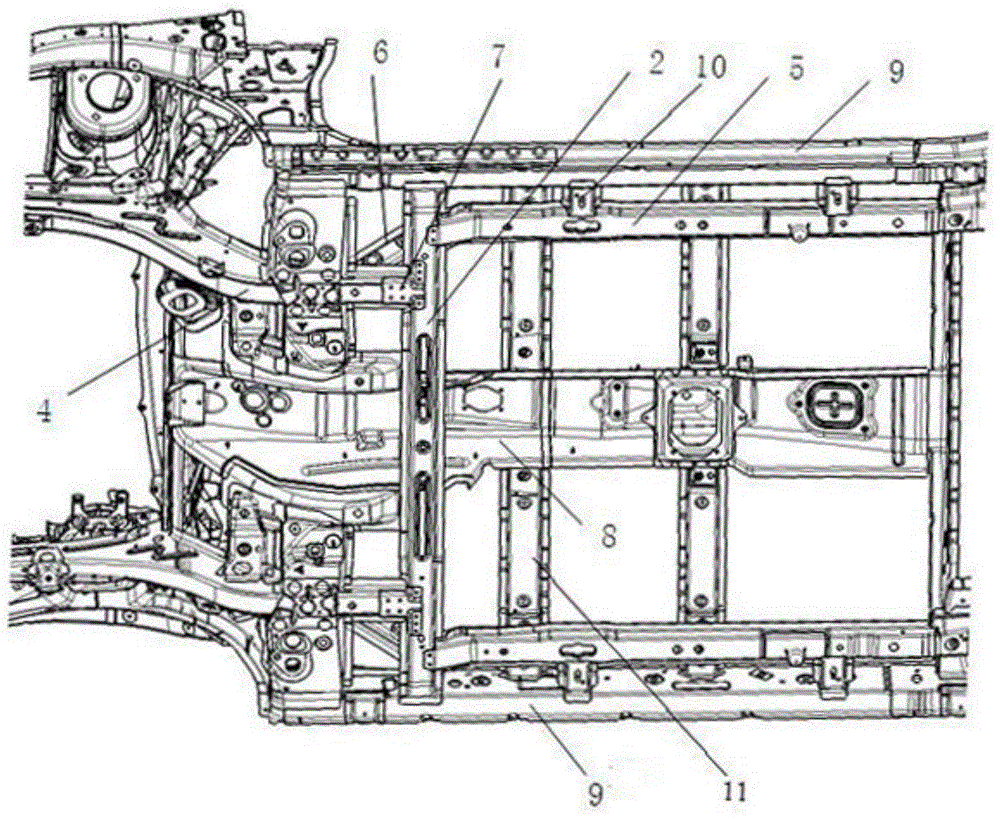

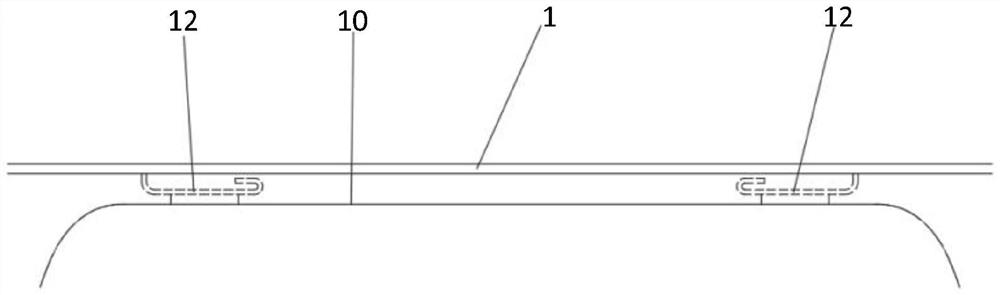

Front floor lower beam connecting structure of battery-changing type electric vehicle body

ActiveCN104787123AIncreased longitudinal stiffnessIncrease lateral stiffnessSuperstructure subunitsAutomotive batteryElectric vehicle

The invention discloses a front floor lower beam connecting structure of a battery-changing type electric vehicle body. The front floor lower beam connecting structure comprises a vehicle body front floor, a front floor lower beam is arranged in front below the vehicle body front floor, the two ends of the front floor lower beam are fixedly connected with front floor side longitudinal beams, the middle of the front floor lower beam is fixedly connected with a middle channel, the rear ends of vehicle body front longitudinal beams are fixedly connected with the front floor lower beam, and the front ends of front floor inner longitudinal beams are fixedly connected with the front floor lower beam. The front floor lower beam connecting structure is simple, convenient to assemble and reliable to use, and installs and fixes a vehicle battery pack without substantially changing a traditional vehicle body structure, meanwhile, longitudinal and transverse rigidity of the lower portion of an electric vehicle body floor is guaranteed, the performance of resisting front face and side face collision of the vehicle body is effectively improved, the safety and the stability of an electric vehicle are improved, the manufacturing cost of the electric vehicle is lowered, and the consumed tooling time for the electric vehicle is shortened.

Owner:DONGFENG MOTOR CORP HUBEI

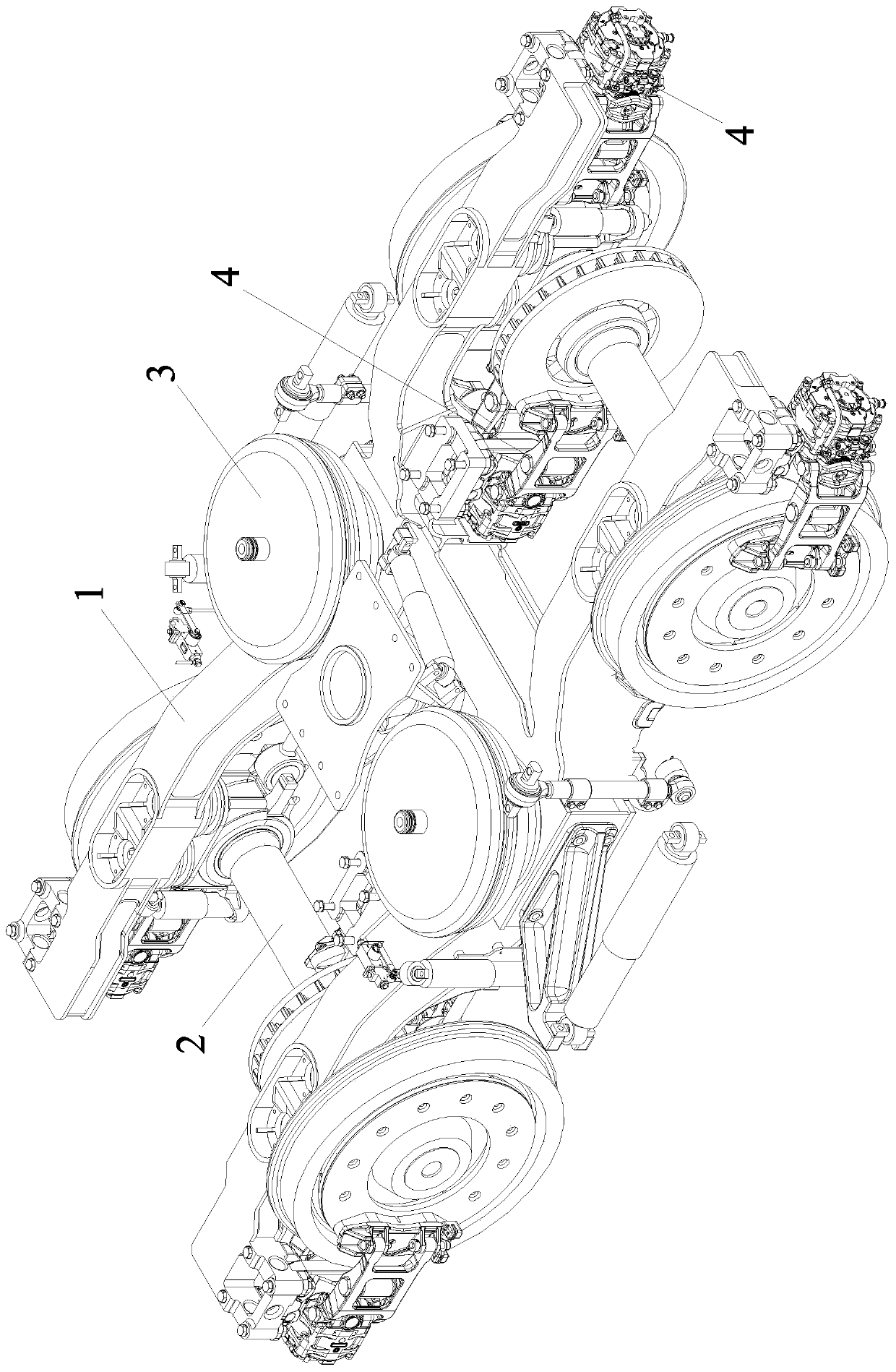

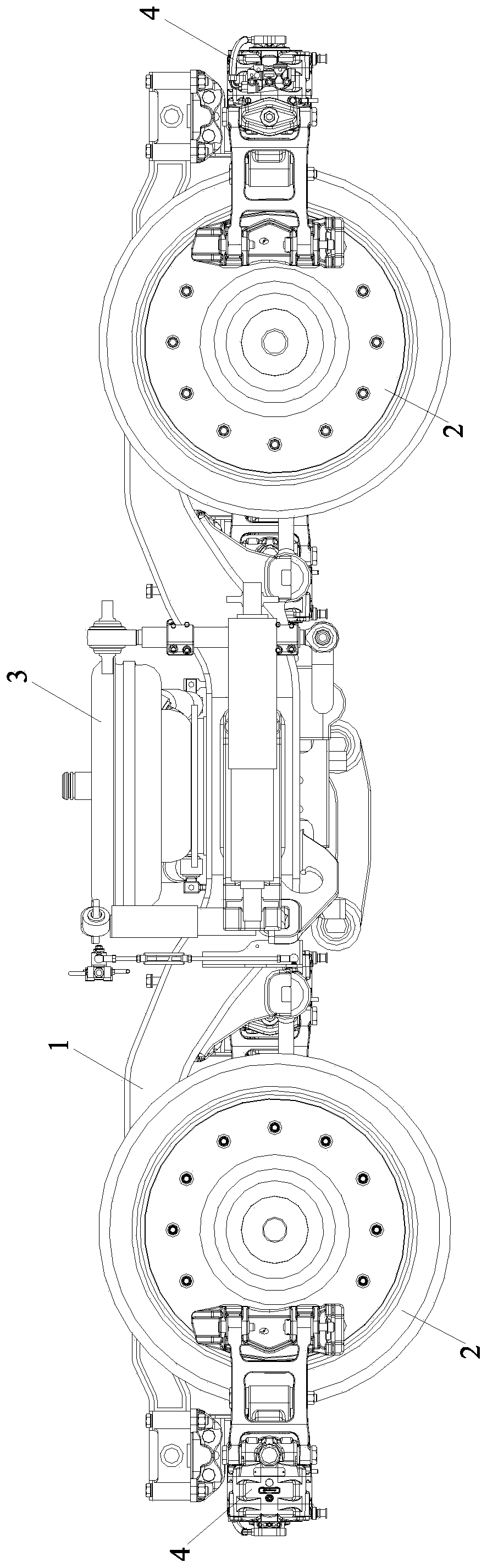

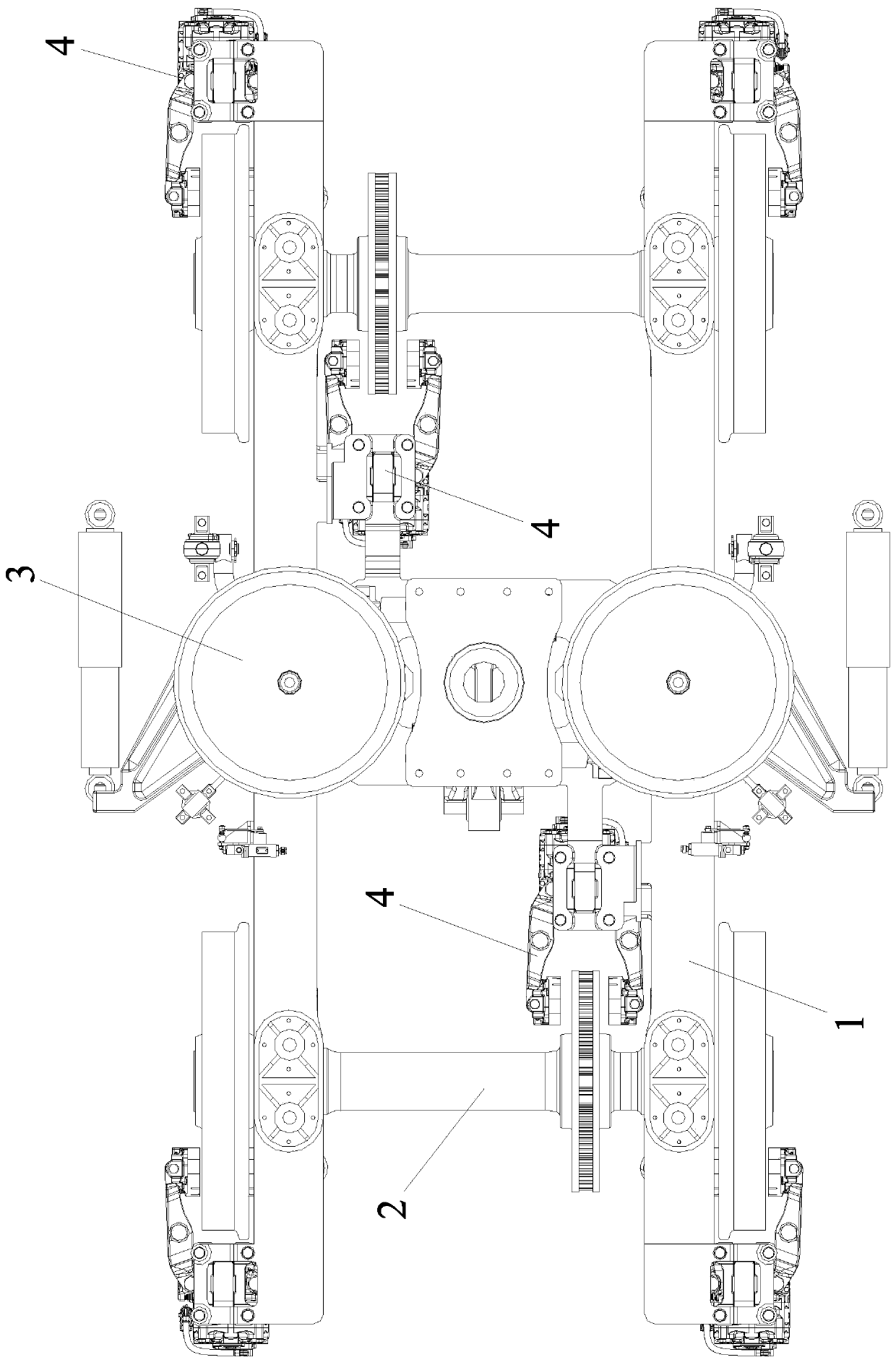

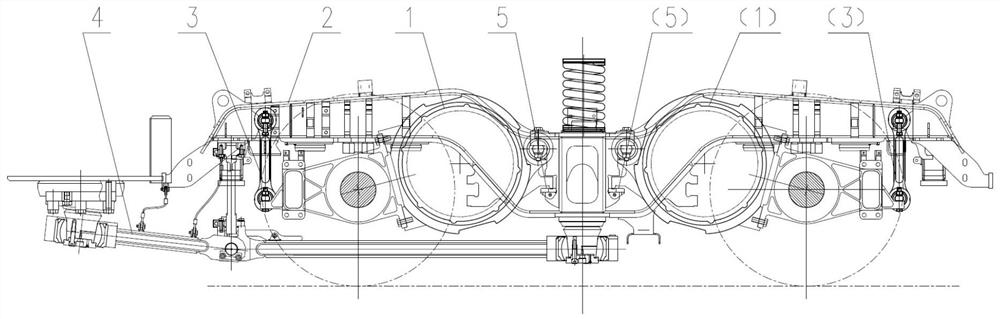

Trailer bogie with built-in axle boxe of high-speed motor train unit

PendingCN110877624AReduce horizontal footprintMeet the installation space requirementsRailway braking systemsBogiesBogieBrake

The invention provides a trailer bogie with built-in axle boxes for a high-speed motor train unit, and relates to the technical field of motor train unit bogies. The bogie comprises a framework, a wheel set axle box device, a central suspension device and a basic brake device. An axle box assembly of the bogie and a side beam of a framework are both located on the inner side of a wheel set. The axle box assembly adopts a split type structural design. The axle box positioning is primary positioning pull rod positioning which is horizontally arranged. The primary rubber springs are two rubber conical springs with high bearing capacity. The basic braking device adopts a mode of combining wheel disc braking and shaft disc braking. The central traction device adopts a longitudinally-arranged single rubber pile. The two anti-side-rolling torsion bars are located on the lower portion of a framework cross beam. The whole bogie is compact in structure, and the transverse size of the bogie meetsthe operation requirement of a small limit. The running speed of the bogie can reach 250 km / h, the maximum axle load is 19 tons, and the running requirements for high speed and high bearing capacitycan be met.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

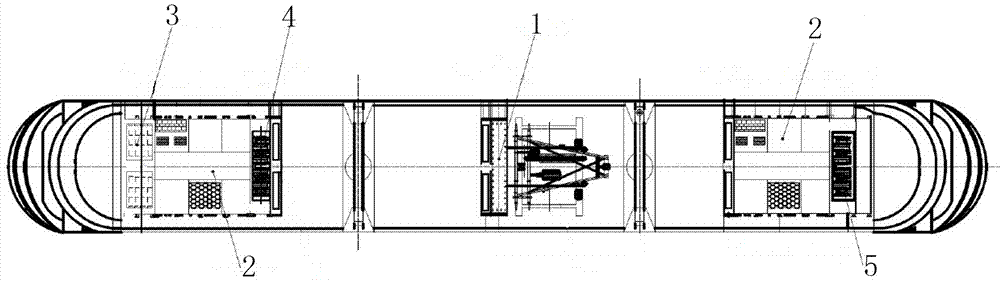

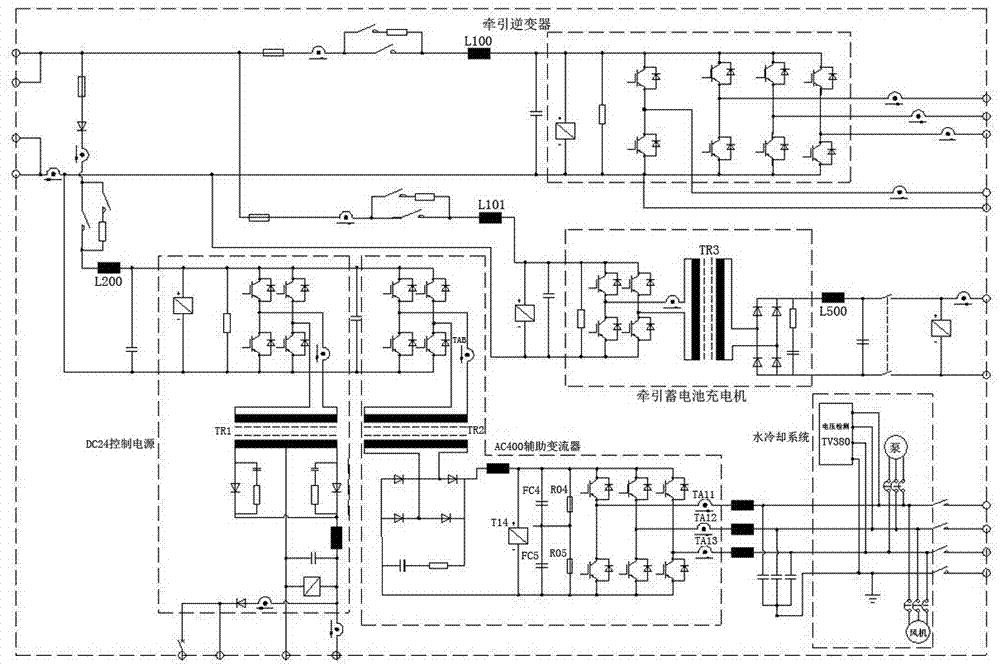

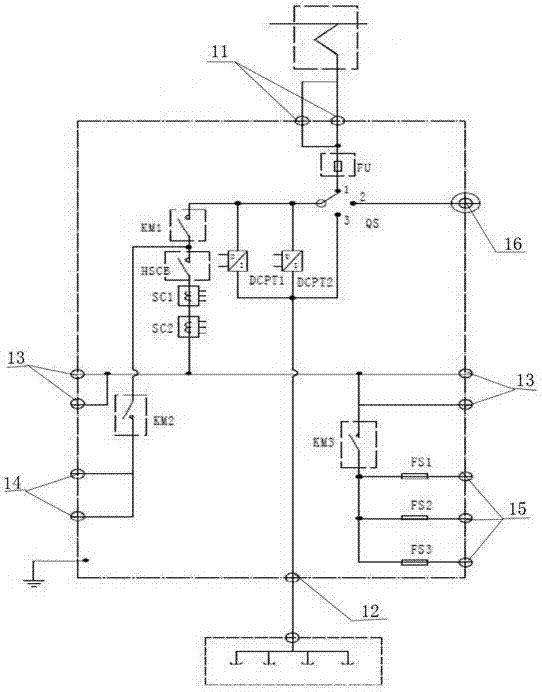

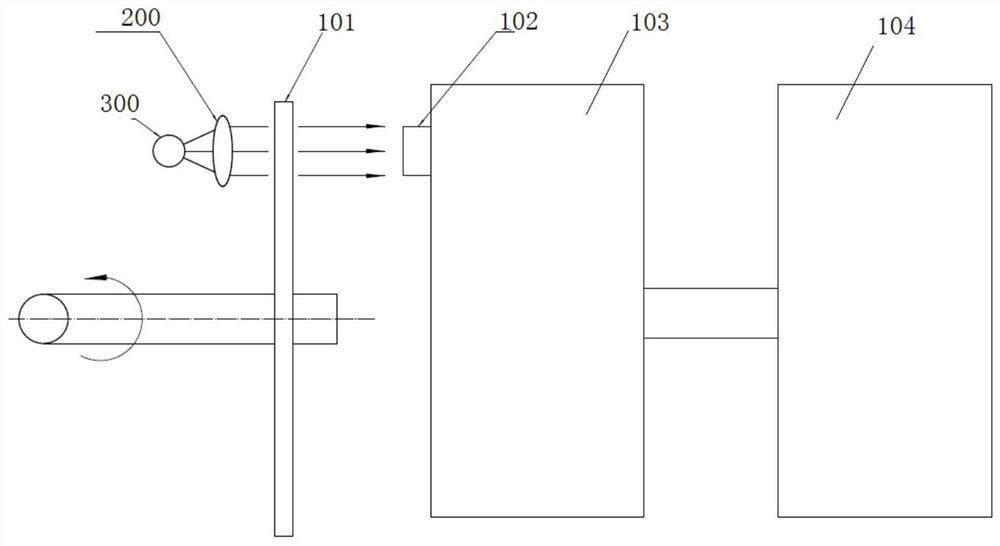

Electric transmission system of low-floor light rail vehicle

PendingCN107487220AFulfilling installation space requirementsMeet lightweight design requirementsElectric locomotivesPropulsion by batteries/cellsElectric power transmissionTransformer

The invention relates to electric transmission systems of vehicles, in particular to an electric transmission system of a low-floor light rail vehicle. The problem that a traditional electric transmission system cannot adapt to a low-floor light rail vehicle is solved. The electric transmission system of the low-floor light rail vehicle electric comprises a high-voltage box, two traction auxiliary converters, a brake resistor box, a 24V storage battery and a traction storage battery. The high-voltage box comprises a main fuse, an isolating switch and a high-speed circuit breaker. Each traction auxiliary converter comprises a traction inverter, a smoothing reactor, a DC24V control power supply, an AC400V auxiliary inverter and a traction storage battery charger, wherein transformers included in the DC24V control power supply, the AC400V auxiliary inverter and the traction storage battery charger are high-frequency transformers. The high-voltage box, the traction auxiliary converters and the brake resistor box are all of box-type design with the height being no more than 530 mm. The electric transmission system has the characteristics of being high in integration degree, small in size, high in reliability, good in seismic resistance, high in protection grade, powerful in function and the like.

Owner:CRRC YONGJI ELECTRIC CO LTD

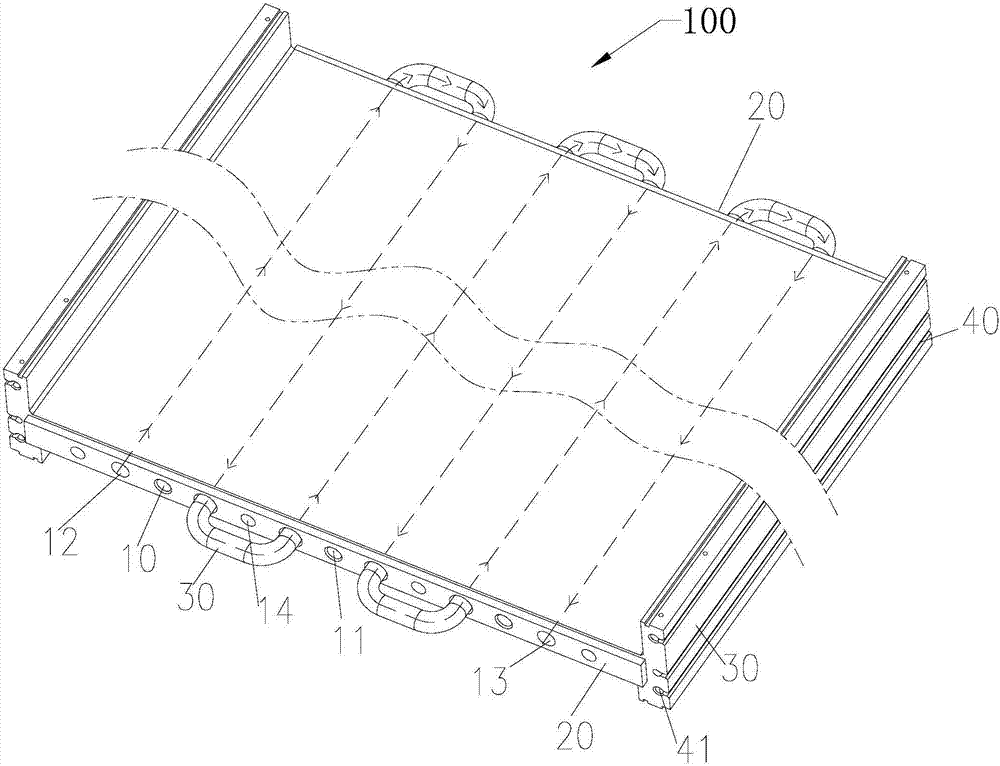

Optical fiber laser and liquid cooling plate thereof

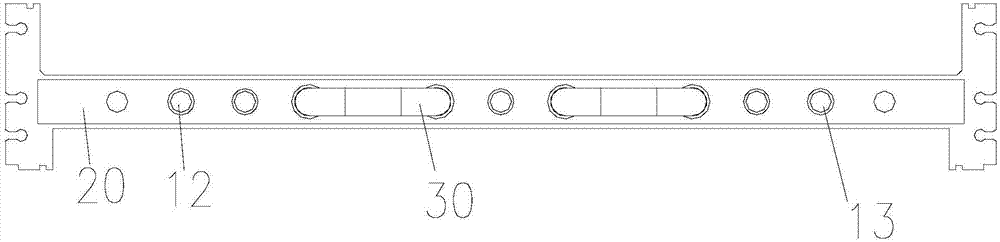

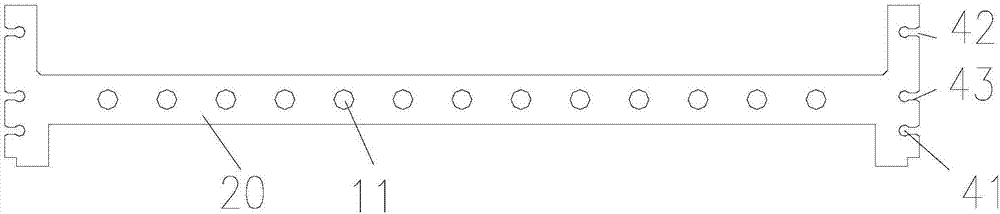

ActiveCN107093834AIncrease usageImprove versatilityLaser cooling arrangementsComputer moduleEngineering

The embodiment of the invention discloses a liquid cooling plate for an optical fiber laser. The liquid cooling plate is used for the heat radiation of an optical fiber laser optical path module and a circuit module, and the liquid cooling plate is a scalable integrated liquid cooling plate. One side of the liquid cooling plate is used for installing the optical path module, and the other side is used for installing the circuit module. When liquid cooling plates of different sizes are needed, for example when the manufacturing of optical fiber lasers of different output powers is needed, multiple scalable integrated liquid cooling plates can be connected to use together, namely the overall length of the liquid cooling plates can be adjusted, the requirements of different heating units and device installation spaces can be satisfied, the requirement of installation position change of optical path modules and circuit modules of different sizes of optical fiber lasers can be satisfied, the use rate of the liquid cooling plate is improved, the versatility of the liquid cooling plate is improved, the cost of manufacturing multiple sizes of liquid cooling plates can be saved, and the production efficiency is improved.

Owner:SU ZHOU MAXPHOTONICS CO LTD

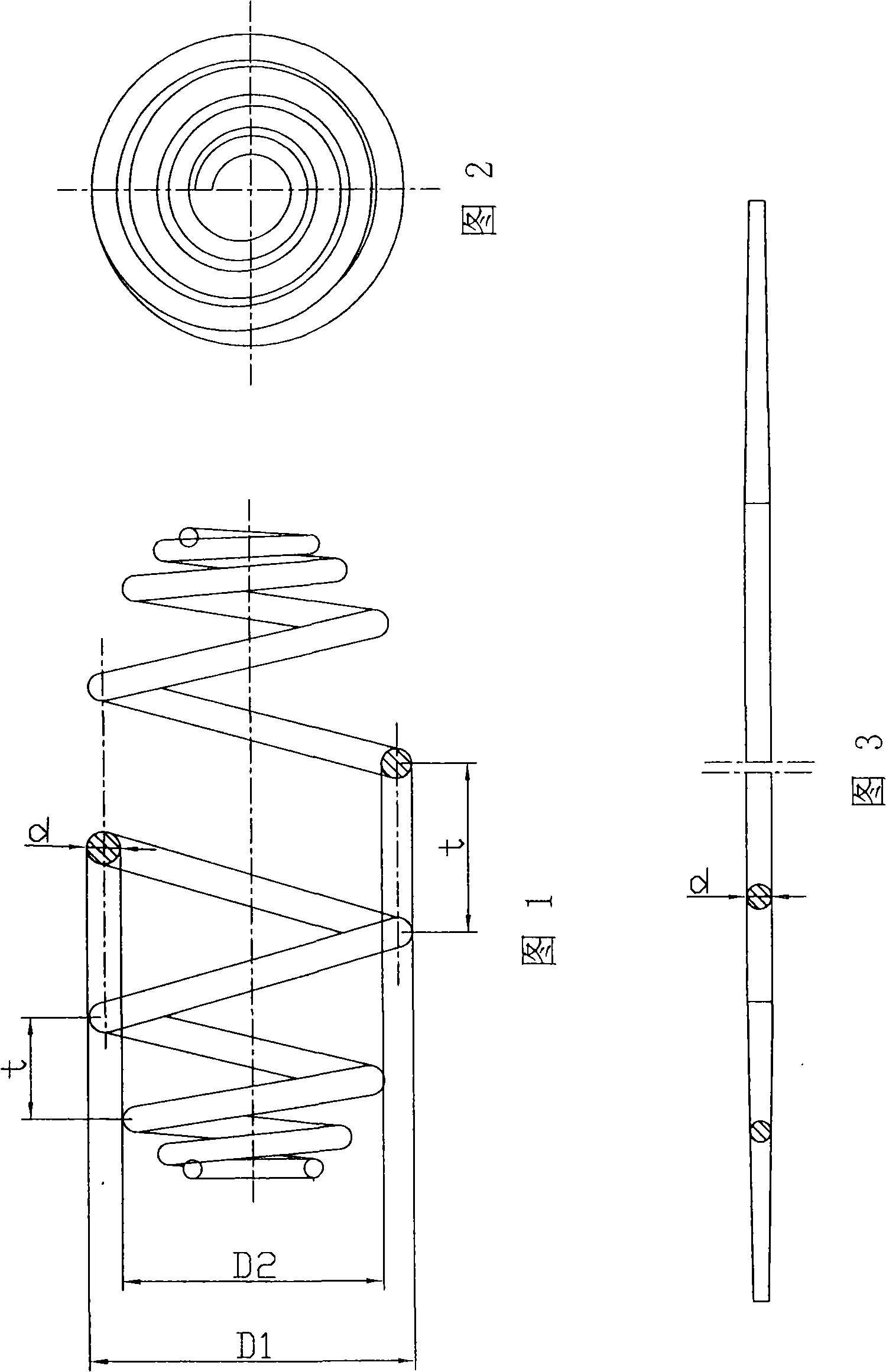

Multiple rigidity-variable automotive suspension spring

InactiveCN101307805ACompensates for uneven weight distributionReduce tiltWound springsEngineeringSuspension spring

The invention relates to a multi-rigidity automotive suspension spring, belonging to an elastic element. The prior art has the drawbacks in ride and comfort. The spring is formed by spiraling a spring wire, and is characterized in that the spring wire has a diameter reducing form middle to the two ends. The spring has comfort, steadiness, superstrength, small volume, light weigh, no noise and high fatigue resistance.

Owner:ZHEJIANG MEILI HIGH TECH

Mounting structure of derailing detection sensor applicable to unmanned vehicle

InactiveCN109501819AMeet height adjustment requirementsMeet the installation space requirementsLocomotivesBogieEngineering

The invention relates to a mounting structure of a derailing detection sensor applicable to an unmanned vehicle. The mounting structure comprises a bogie connector mounting seat, a derailing sensor connector mounting seat and a transition bracket which extends in an up-down direction, wherein the upper end of the transition bracket is fixed to the outer side of the bogie connector mounting seat; the derailing sensor connector mounting seat is fixed to the bottom end of the transition bracket; an auxiliary bracket is further arranged at the outer side of the bogie connector mounting seat; a transverse reinforcing rib and a longitudinal reinforcing rib are fixed between the auxiliary bracket and the transition bracket; the transverse reinforcing rib is fixed on an external facade of the bogie connector mounting seat; the longitudinal reinforcing rib is vertically arranged below the transverse reinforcing rib. According to the mounting structure provided by the invention, the requirementsof a derailing sensor on a bogie framework end mounting space, the requirements on strength and the requirements on sensor height adjustment are met; the mounting structure is convenient to operate and maintain, and an equipment connector can also be actually mounted according to a specific project; the form and size of connectors for forming the structure are adjusted to be adaptive to the mounting requirements of sensors of different types.

Owner:CRRC NANJING PUZHEN CO LTD

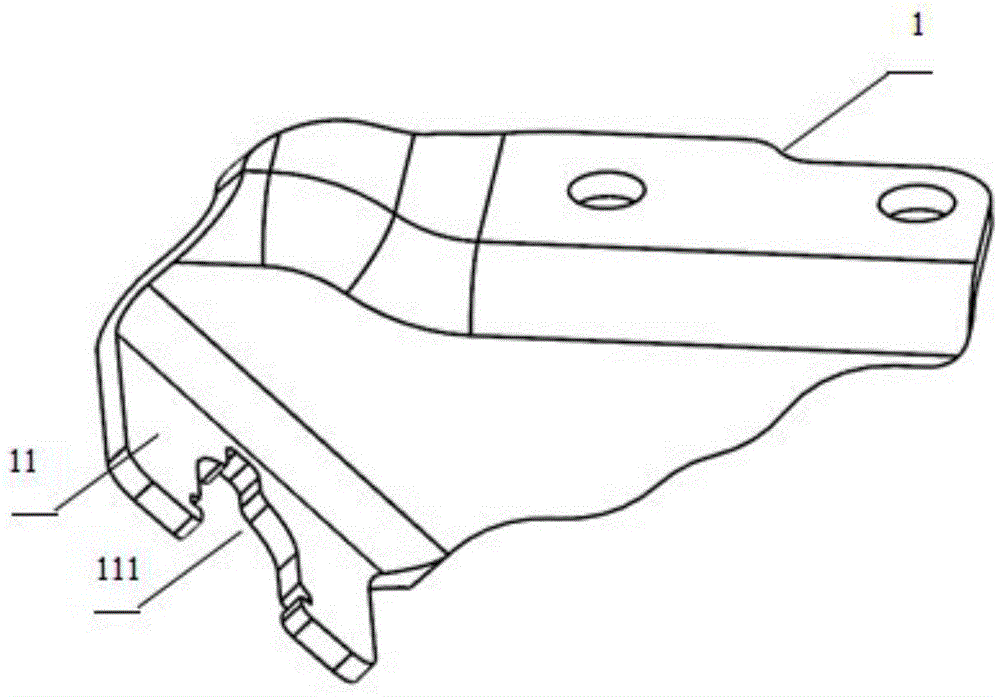

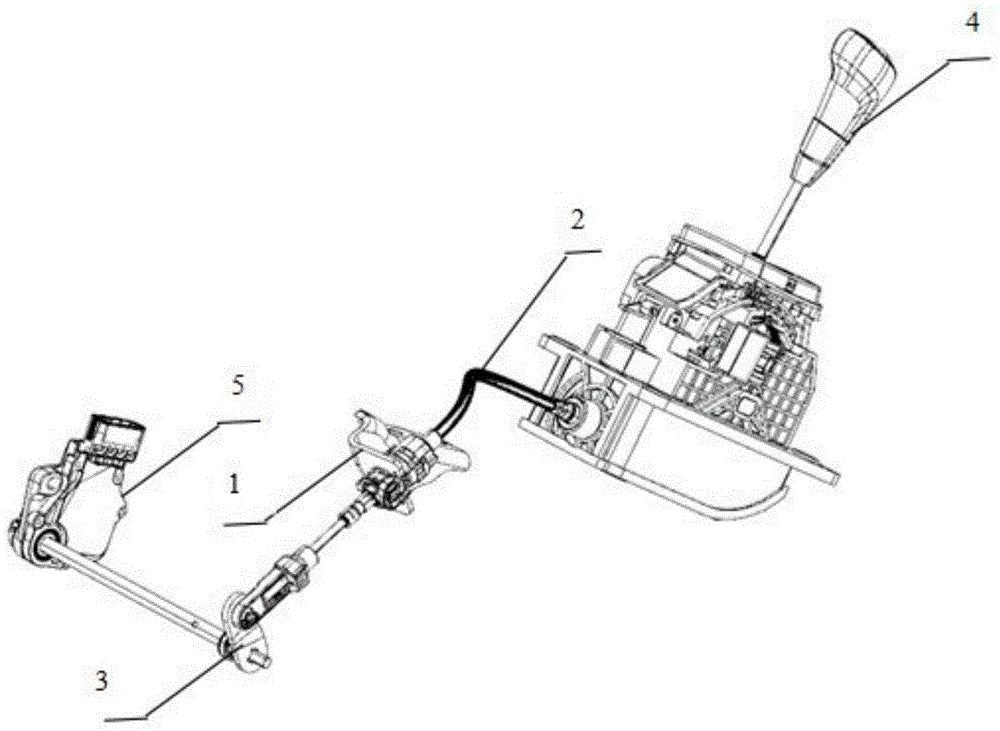

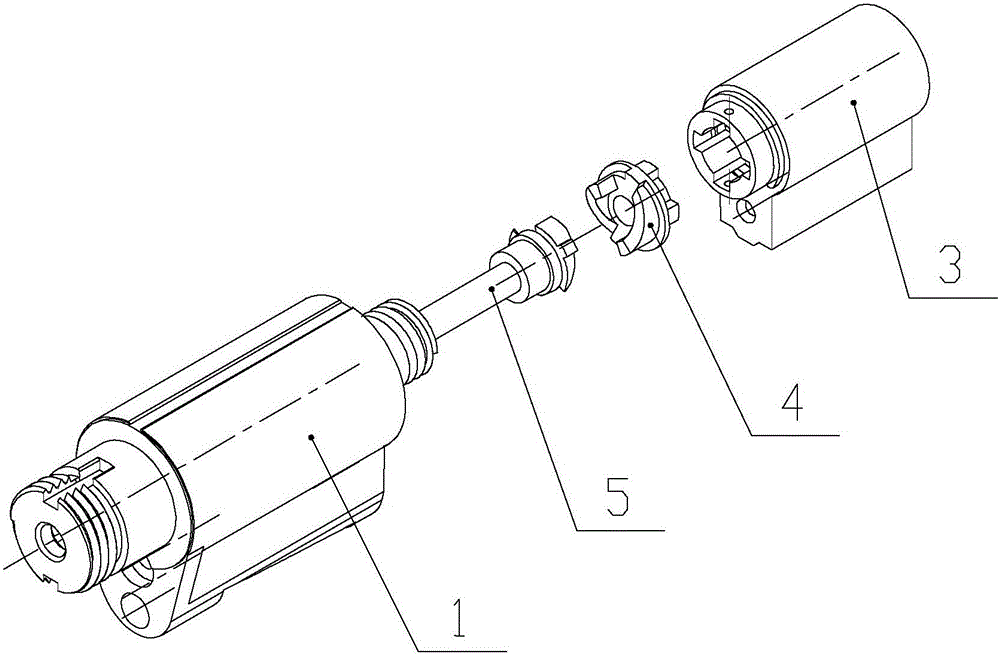

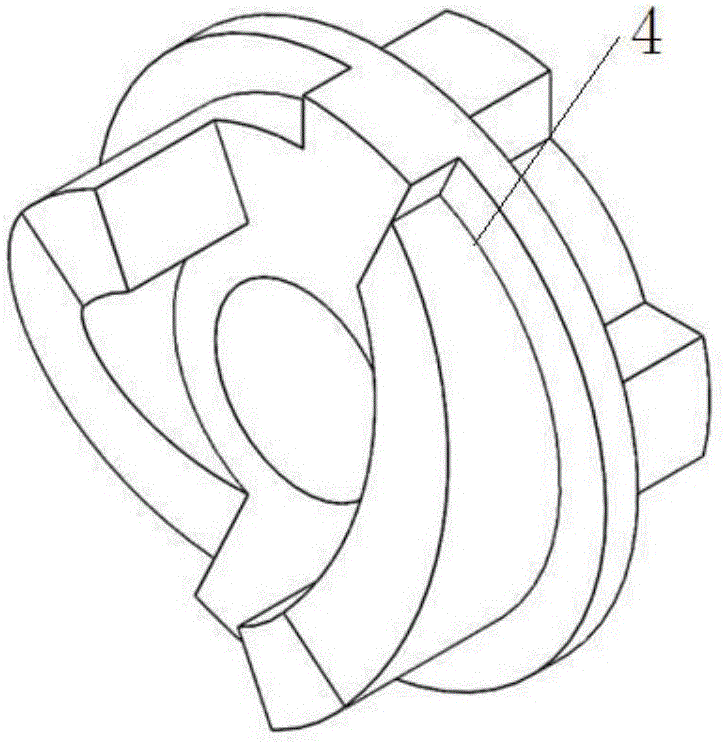

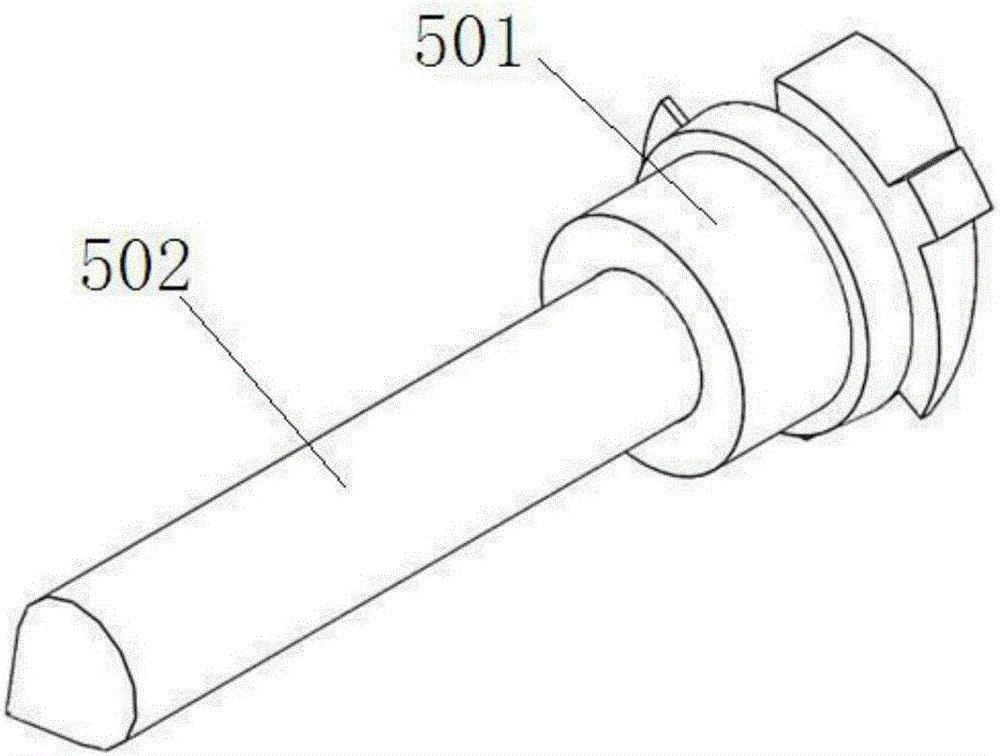

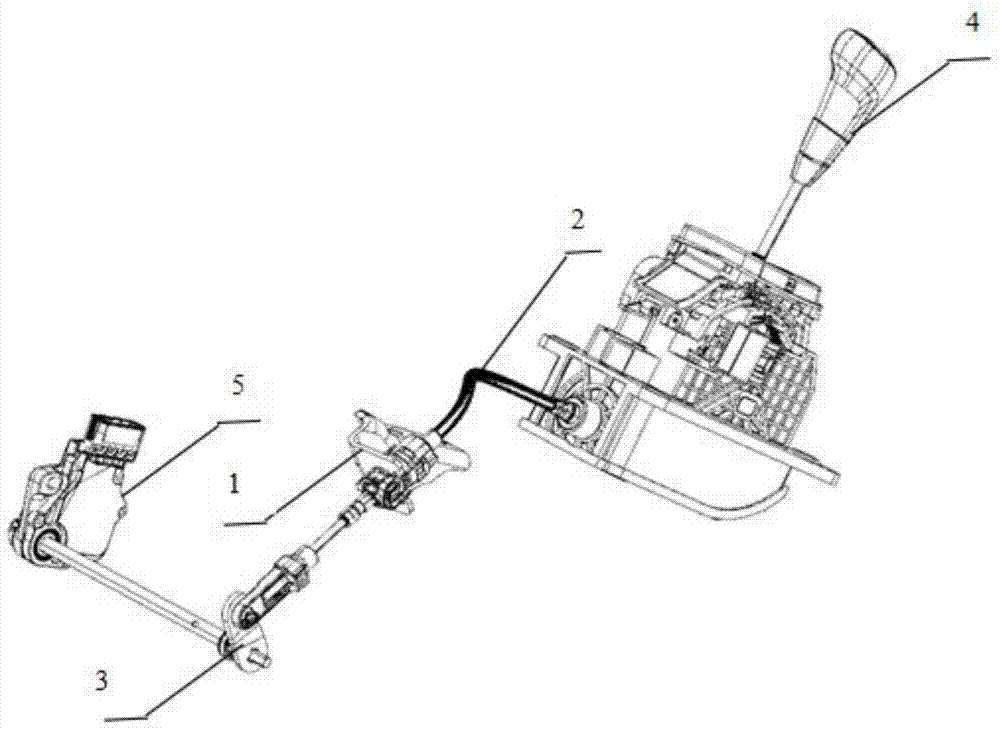

Gear shifting inhaul cable device and automatic gearbox gear shifting system

ActiveCN104613168AReduce installationEasy to fixGearing controlControl devicesEngineeringElectrical and Electronics engineering

The invention provides a gear shifting inhaul cable device, and belongs to the field of parts of a car gear shifting system. The gear shifting inhaul cable device comprises an inhaul cable and an inhaul cable support, a notch is formed in the contact face of the inhaul cable support and the inhaul cable, the inhaul cable is connected to the notch of the inhaul cable support in a sleeving mode, an elastic piece is arranged at the connecting position of the inhaul cable and the inhaul cable support, and a gear-shaped clamping structure is arranged on the inhaul cable to be matched with the notch in the inhaul cable support. By means of the gear shifting inhaul cable device, in limited space, the requirements for simpleness and firmness are met, the assembling space is reduced, the number of the parts is decreased, the assembling efficiency is improved, and the cost is better optimized.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

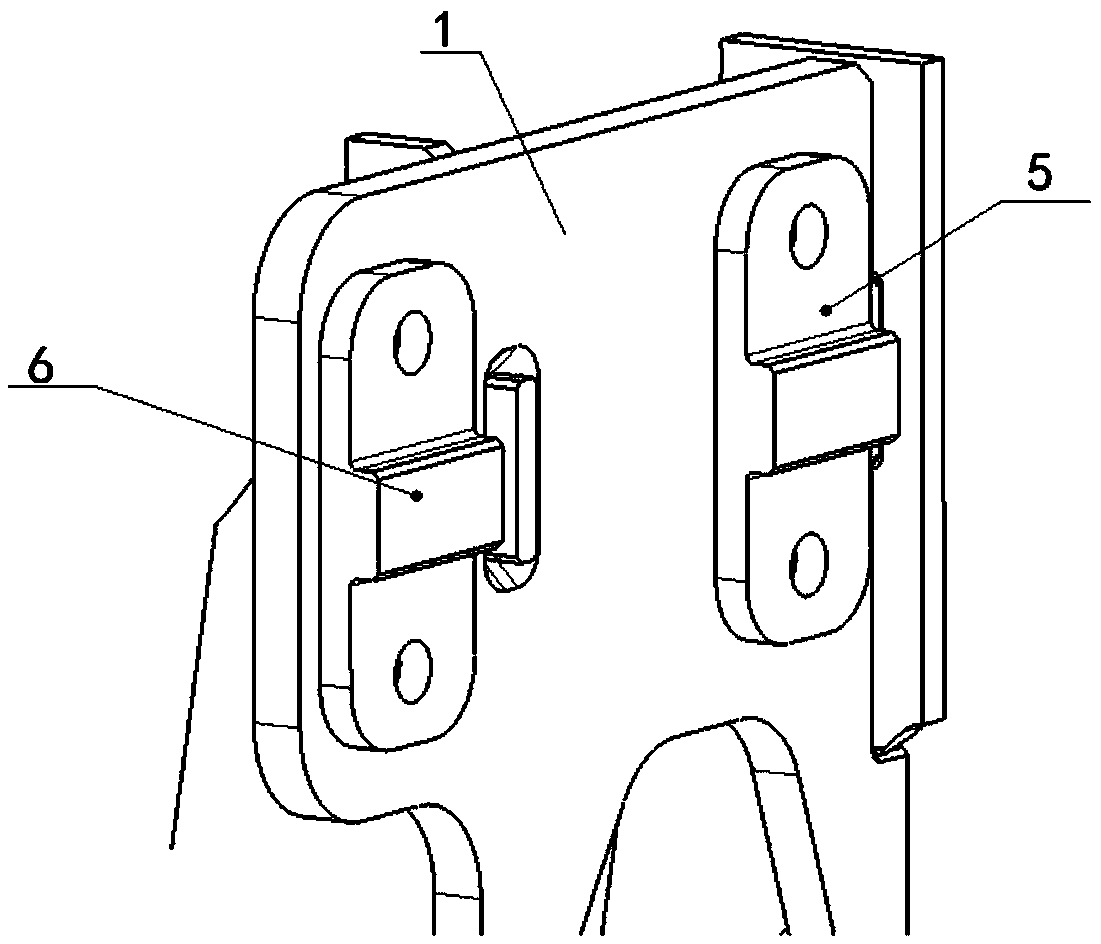

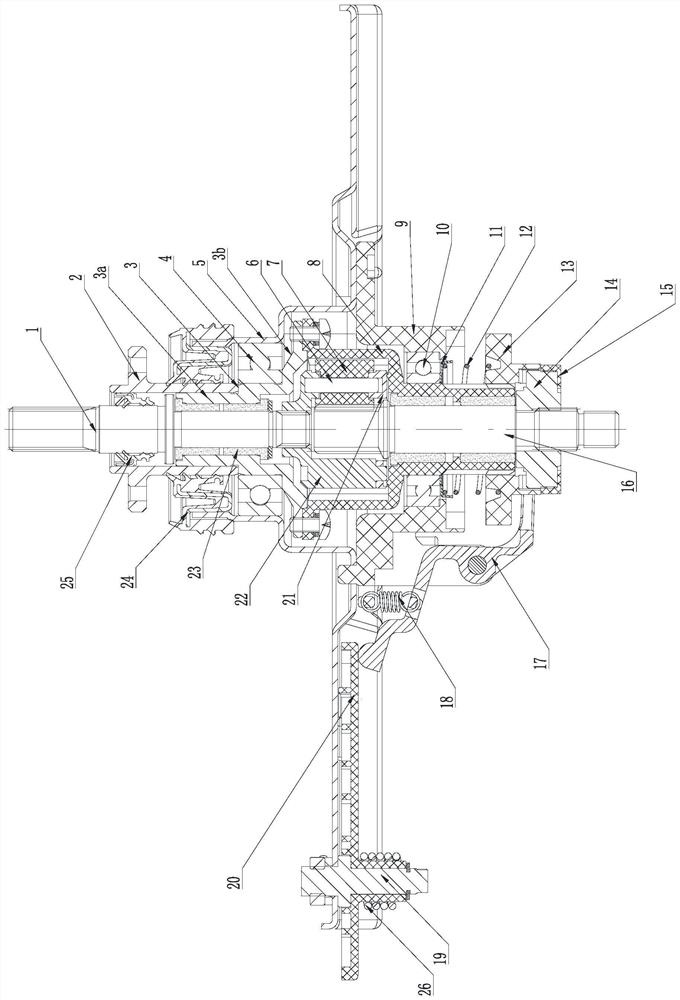

Lock core mechanism

ActiveCN105971408ASimple, reasonable and compact structureSimple mechanical transmission connectionNon-mechanical controlsLock casingsLinear motionEngineering

The invention discloses a lock core mechanism. The lock core mechanism comprises a lock chamber shell and a clutch part, wherein a lock chamber, a cam positioned inside the lock chamber, and a clutch ejector part which are sequentially connected are arranged inside the lock chamber shell; the clutch ejector part comprises a clamping end which is combined with the cam in a clamping manner and an ejector shaft; a reset spring is arranged on the ejector shaft in a sleeving manner, and stretches into the clutch part; a dowel is arranged in the clutch part; and when a key is inserted into the lock chamber and drives the cam to rotate, the cam pushes the clutch ejector part to perform axial linear motion in a clutch manner to eject the dowel to achieve unlocking. According to the lock core mechanism, the rotating motion of the key is converted into the linear motion of the ejector shaft through the combined structure of the cam and the clutch ejector part, and the ejector shaft ejects the dowel to achieve unlocking; and the rotating motion of the key is converted into the linear motion of the ejector shaft, so that the mechanical transmission connection of the lock core mechanism is more simple, efficient and reliable, and the safety of the lock core mechanism is improved.

Owner:NANJING EASTHOUSE ELECTRIC CO LTD

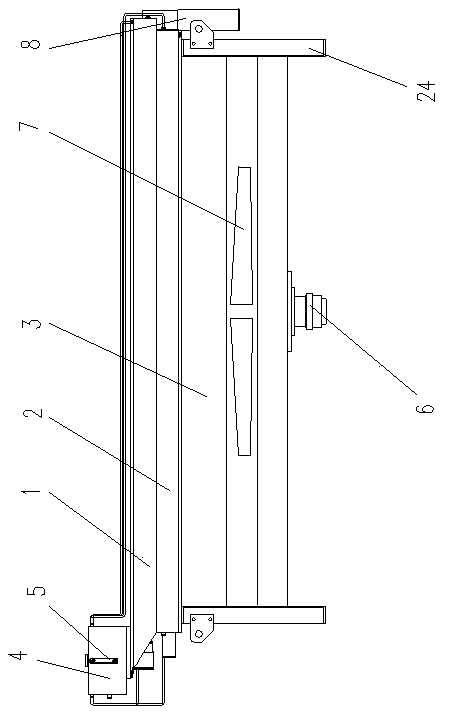

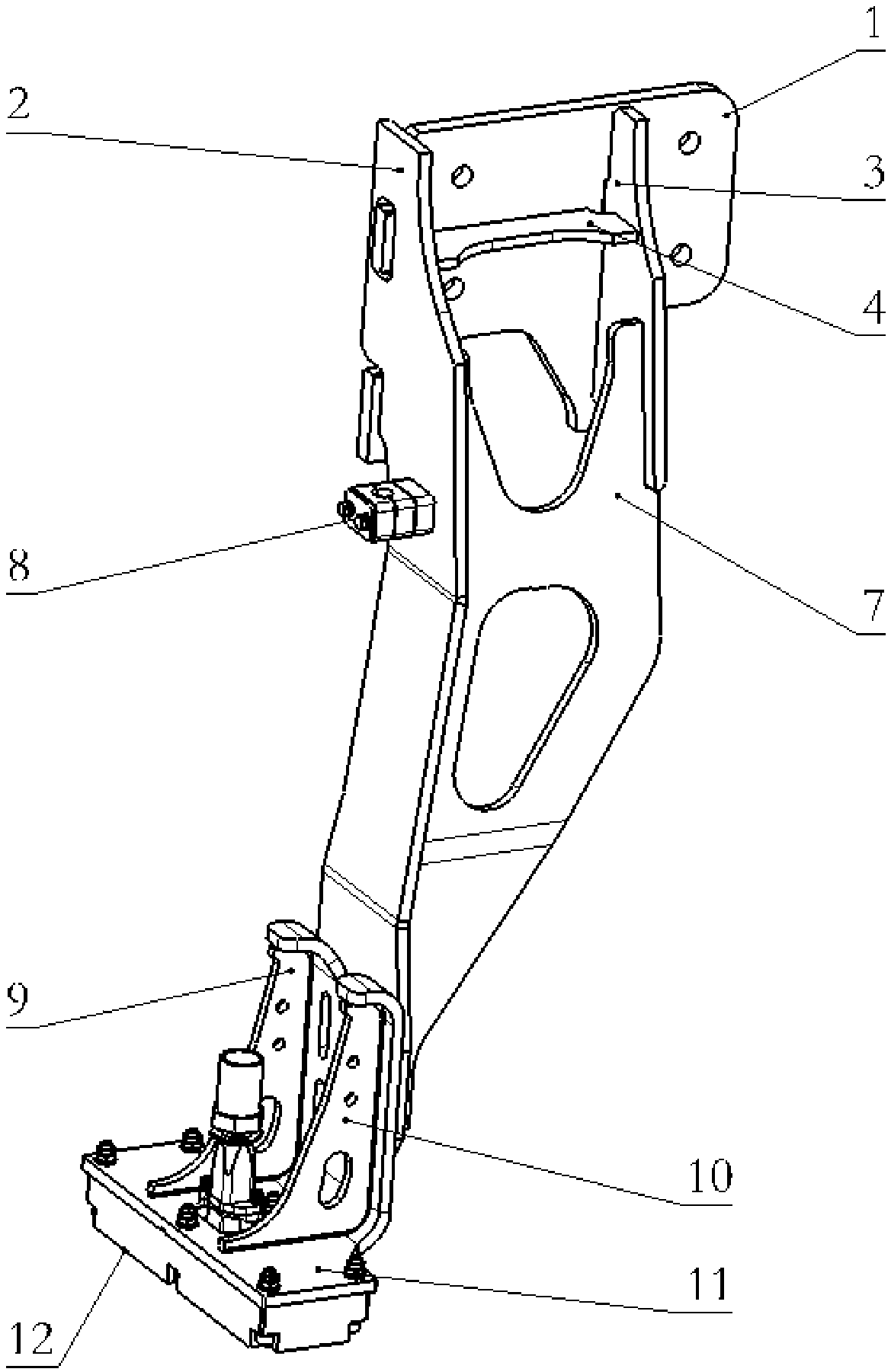

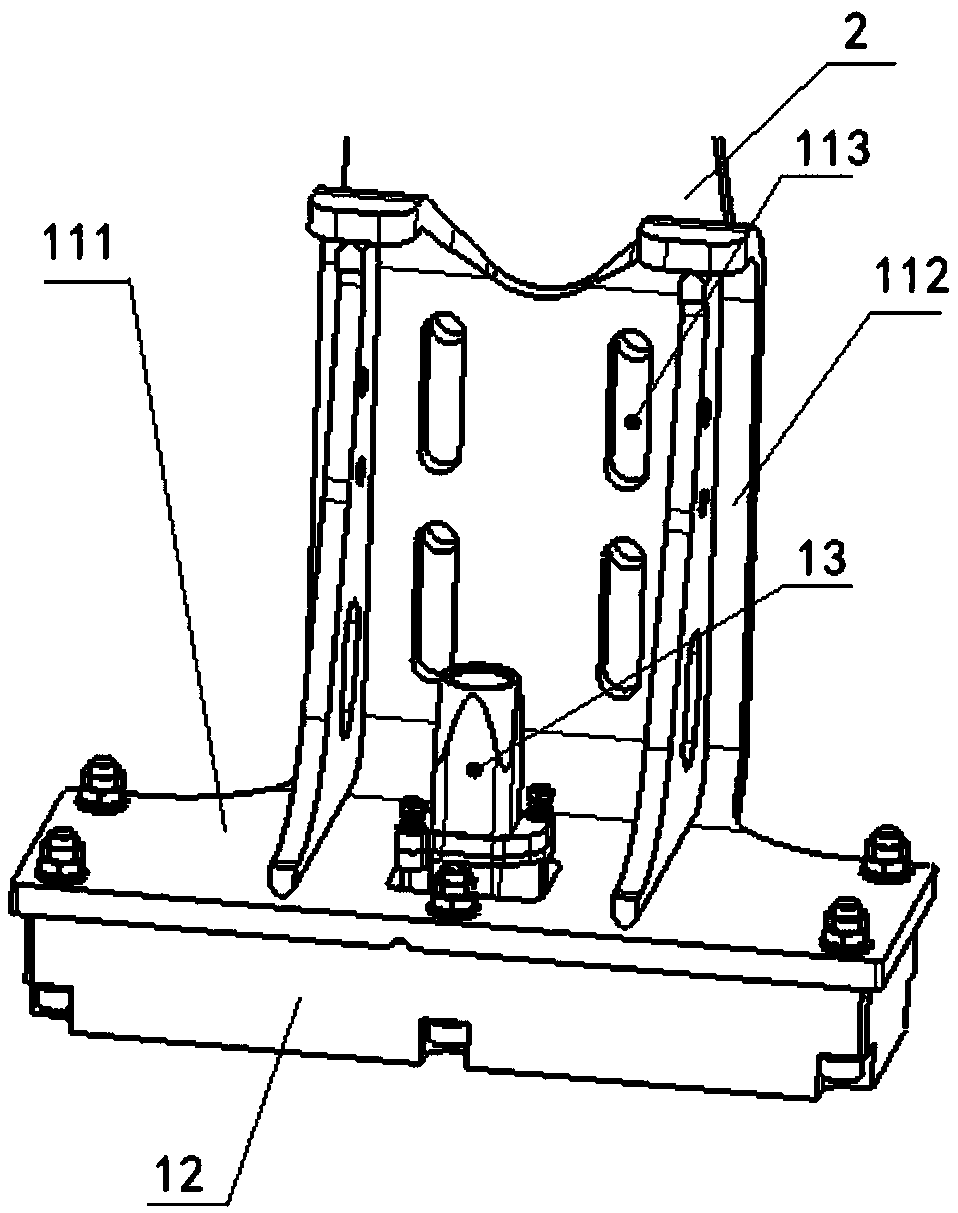

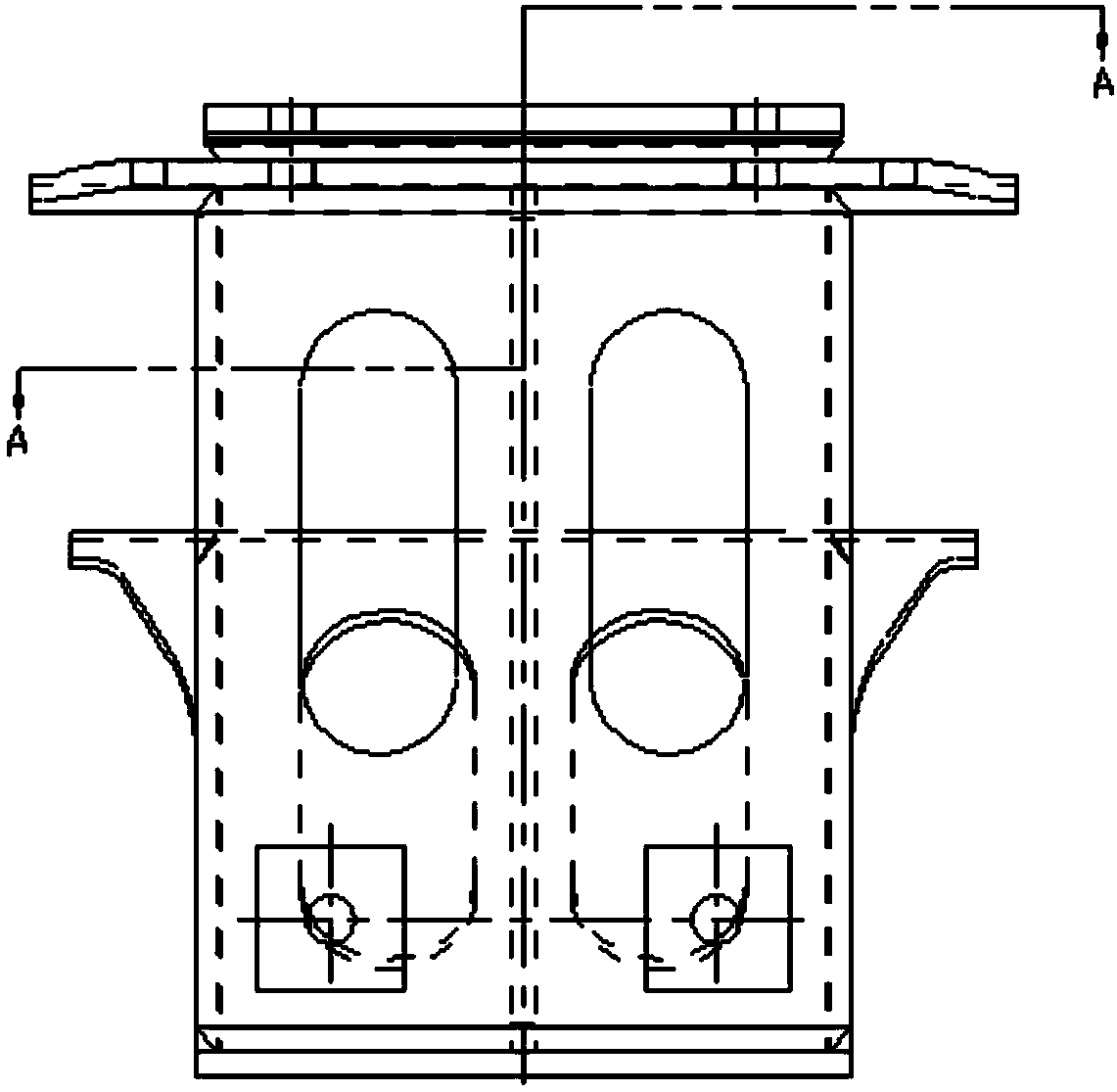

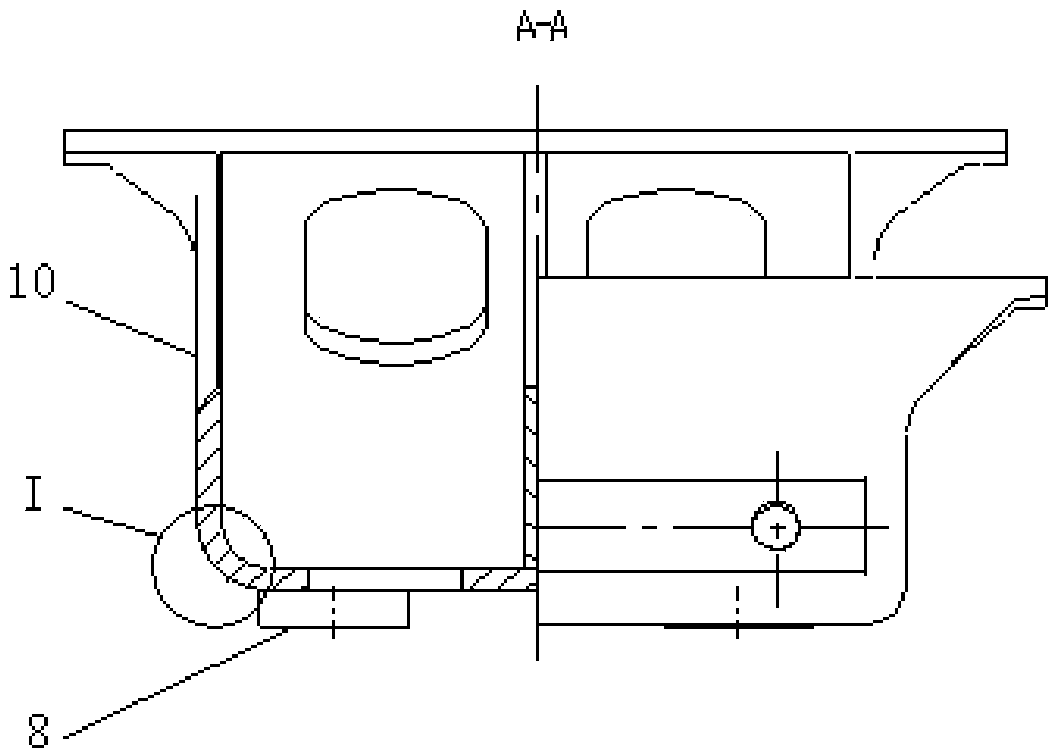

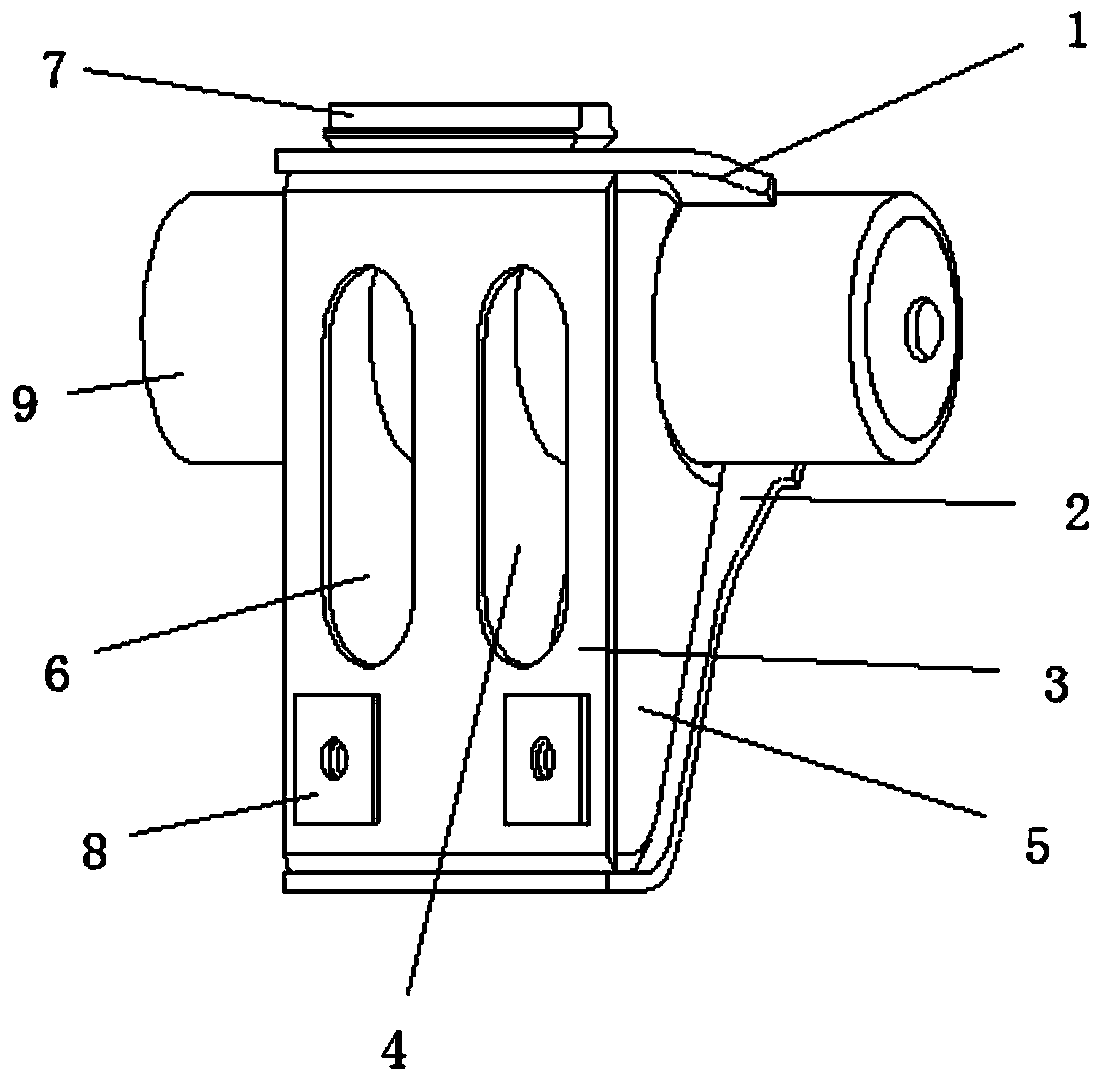

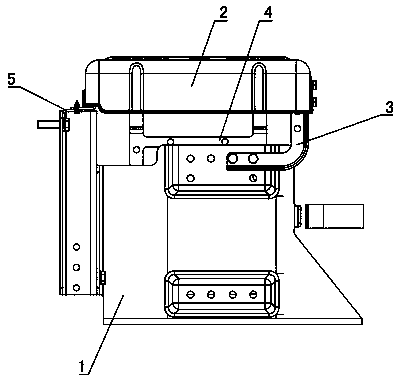

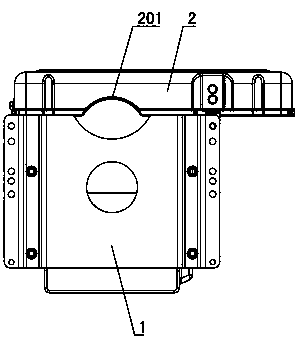

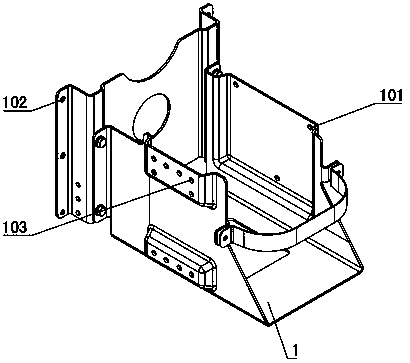

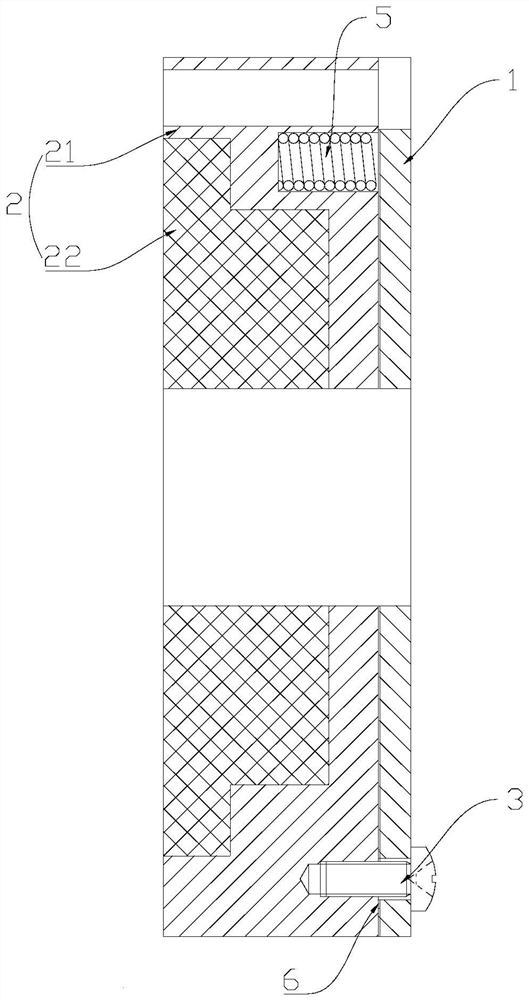

Motor suspension of urban rail vehicle

InactiveCN104044605ASave installation spaceMeet the installation space requirementsBogiesEngineeringSpace requirements

The invention provides a motor suspension of an urban rail vehicle. The motor suspension is composed of a bottom plate 2, a vertical plate 3, a rib plate 4, a riser plate 7, installation bases 8 and a cover plate 1 through installing and welding, wherein the bottom plate 2 is of a bent structure; the bottom edge of the bottom plate 2 is welded with the vertical plate 3 being provided with the installation bases 8; the rib plate 4 being provided with a circular-arc notch is welded between the bottom plate 2 and the inner side of the vertical plate 3; the cover plate 1 being provided with the riser plate 7 is welded between the vertical plate 3 and the top of the rib plate 4; inwards-retracted positions on two sides of the vertical plate 3 and the bottom plate 2 are respectively welded with a side end plate 5 and a side end plate 6 with the same shape with the rib plate. The installed and welded structure meets the space requirements on equipment installation, interference to equipment is avoided.

Owner:CRRC DALIAN CO LTD

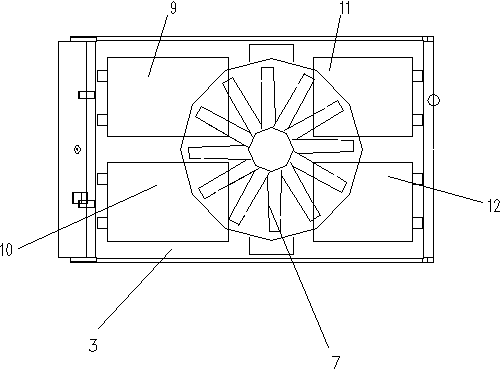

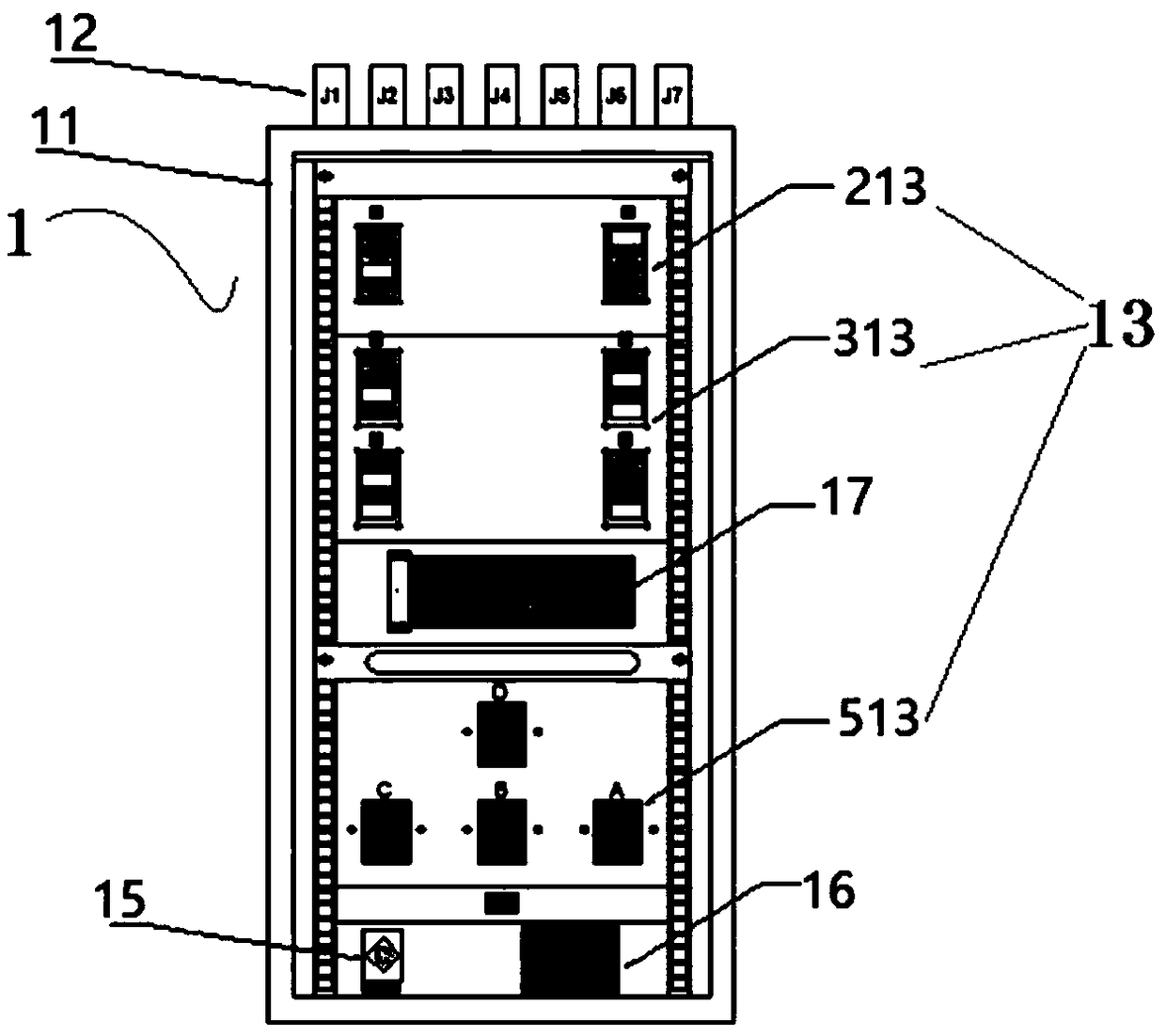

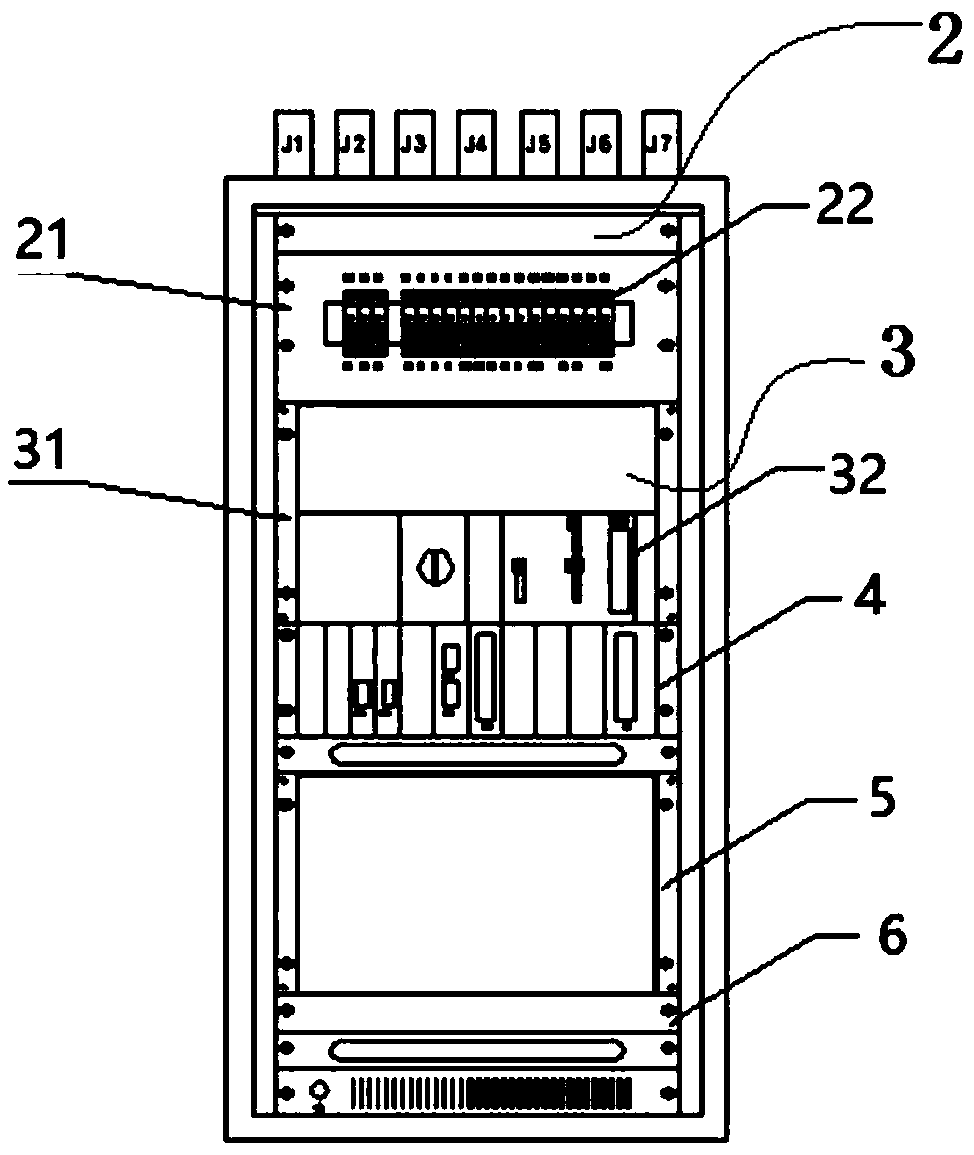

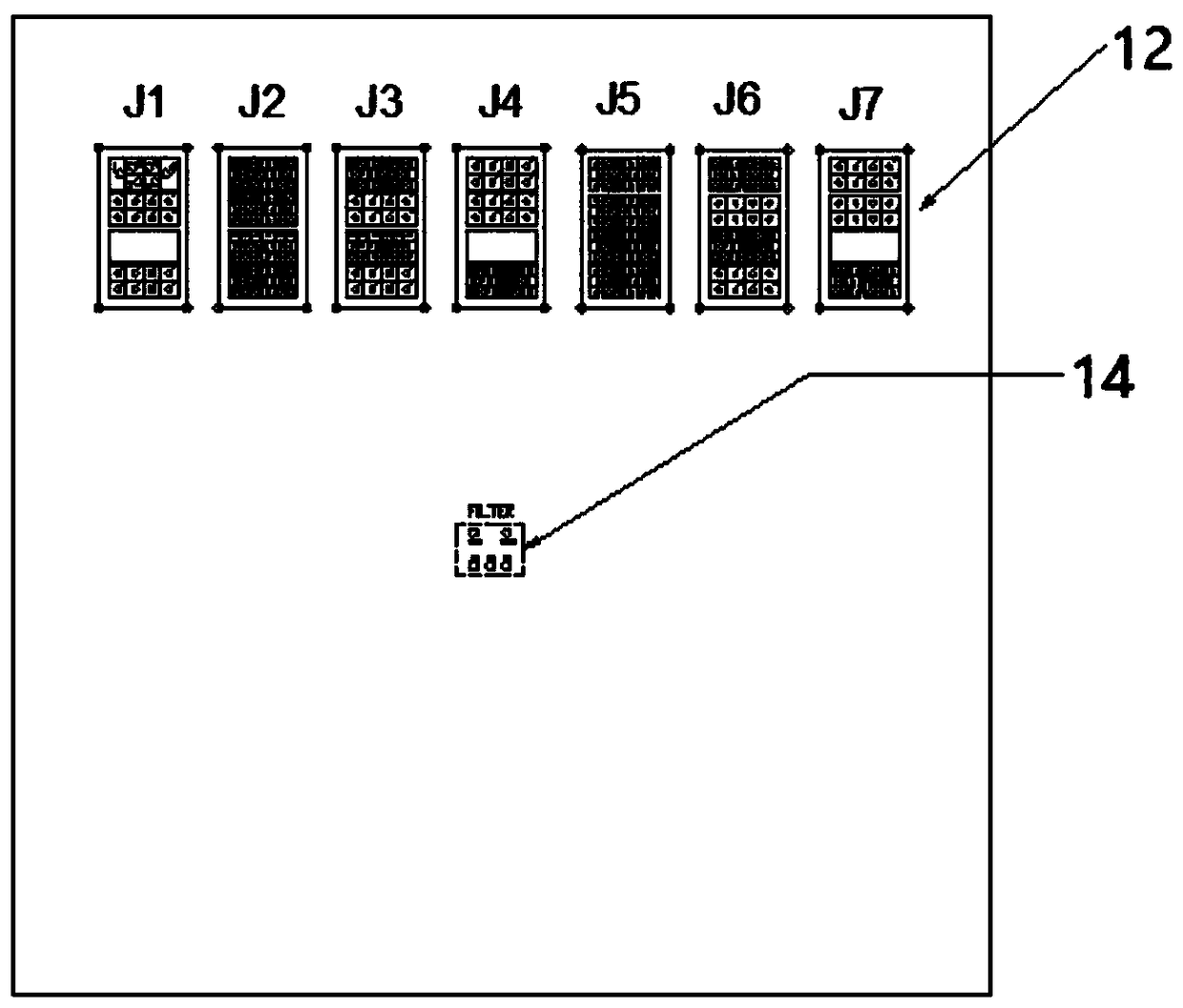

C2 train control vehicle-mounted equipment cabinet based EVC platform

PendingCN109367581ASolve matching problemsConvenient custom developmentSignalling indicators on vehicleCrateEmbedded system

The invention relates to a C2 train control vehicle-mounted equipment cabinet based an EVC platform. The equipment cabinet comprises an equipment cabinet body (1), a power source crate (2), an interface crate (3), a track circuit signal receiving unit (4), a vehicle-mounted safety computer (5) and a fan crate (6); the power source crate (2), the interface crate (3), the track circuit signal receiving unit (4), the vehicle-mounted safety computer (5) and the fan crate (6) are modules independent of one another; and the modules are detachably installed in the equipment cabinet body (1). Comparedwith the prior art, the C2 train control vehicle-mounted equipment cabinet based the EVC platform has the advantages that modularized design is achieved, and maintaining and customizing are easy andconvenient.

Owner:CASCO SIGNAL

Shell for hybrid power drive device

PendingCN107842597AMeet assembly process requirementsMeet the installation space requirementsGearboxesGear lubrication/coolingDrive motorWater jacket

The invention provides a shell for a hybrid power drive device. The shell comprises a front-end shell body, a motor end cover, a motor water jacket, a supporting type hydraulic partition plate and a rear-end shell body. The motor end cover is connected with the front-end shell body through a connecting part. The motor water jacket is arranged in a water jacket mounting hole of the front-end shellbody. The supporting type hydraulic partition plate is connected with the front-end shell body or the rear-end shell body through a connecting part. The front-end shell body and the rear-end shell body are connected through a connecting part. Inner space formed by the front-end shell body, the motor water jacket and the rear-end shell body is sequentially divided by the motor end cover and the supporting type hydraulic partition plate into a first containing cavity, a second containing cavity and a third containing cavity. According to the shell, a drive motor device at least provided with oneclutch can be integrated in a transmission, and meanwhile, the assembly process requirement of the hybrid power drive device and the mounting space requirement of an engine compartment are met.

Owner:CHINA FIRST AUTOMOBILE

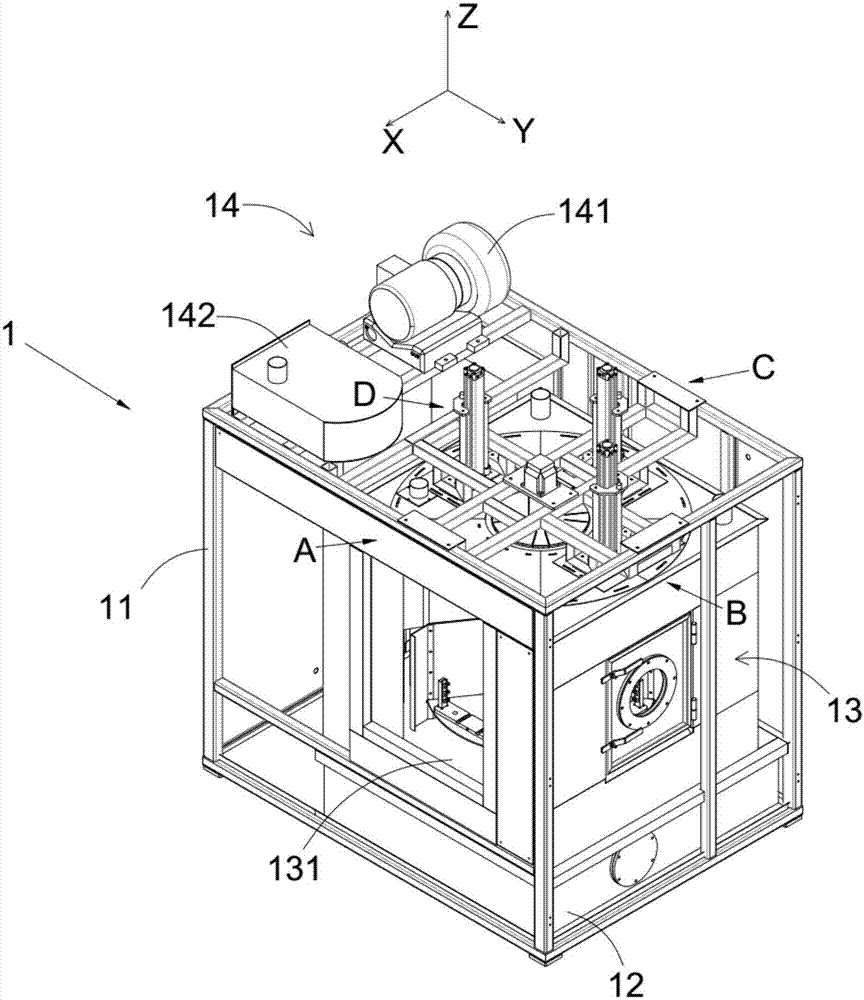

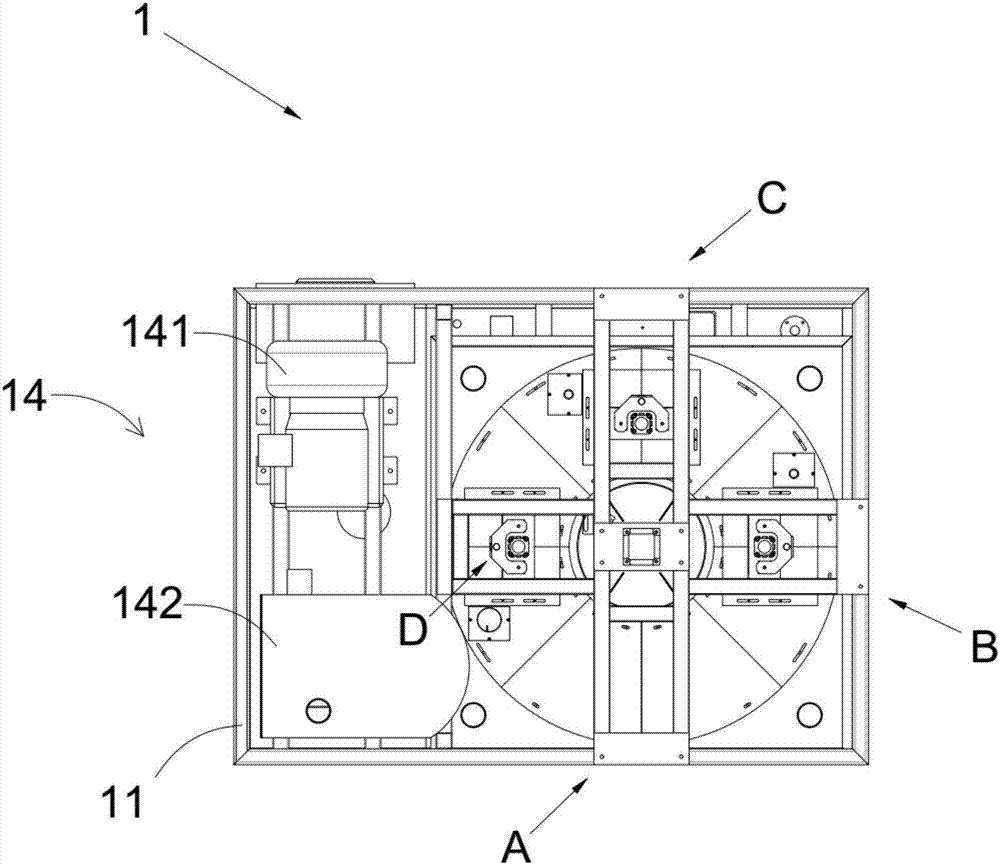

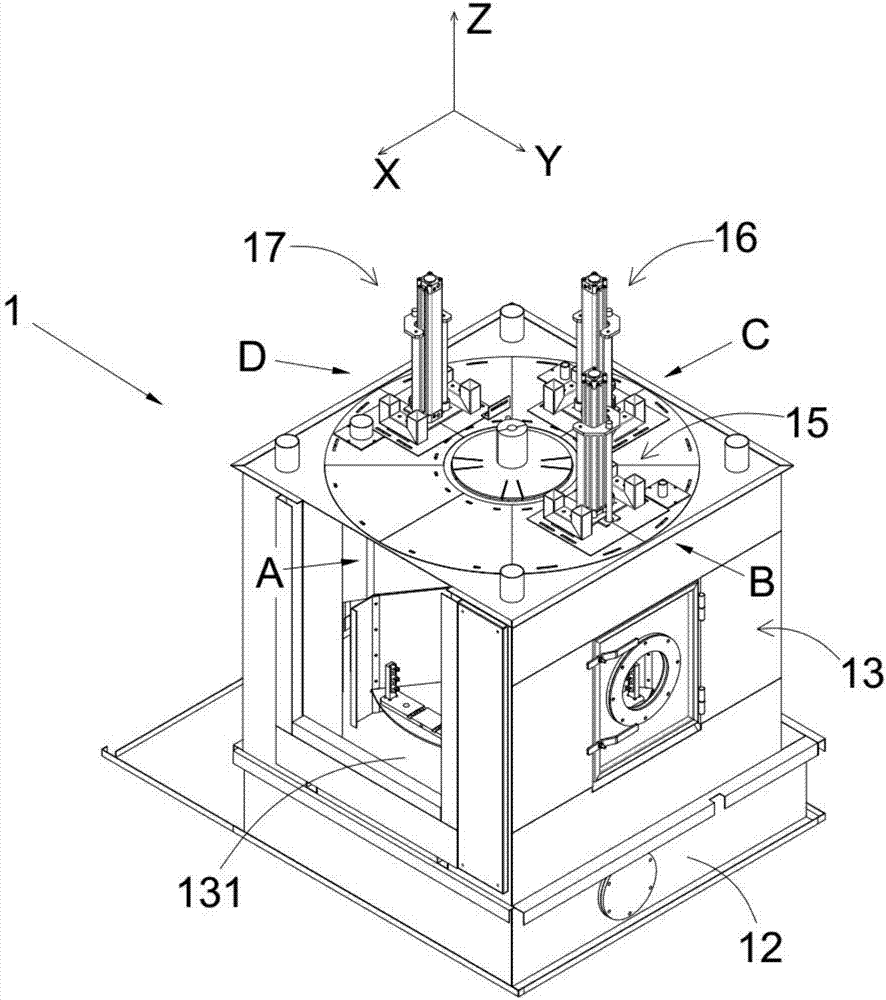

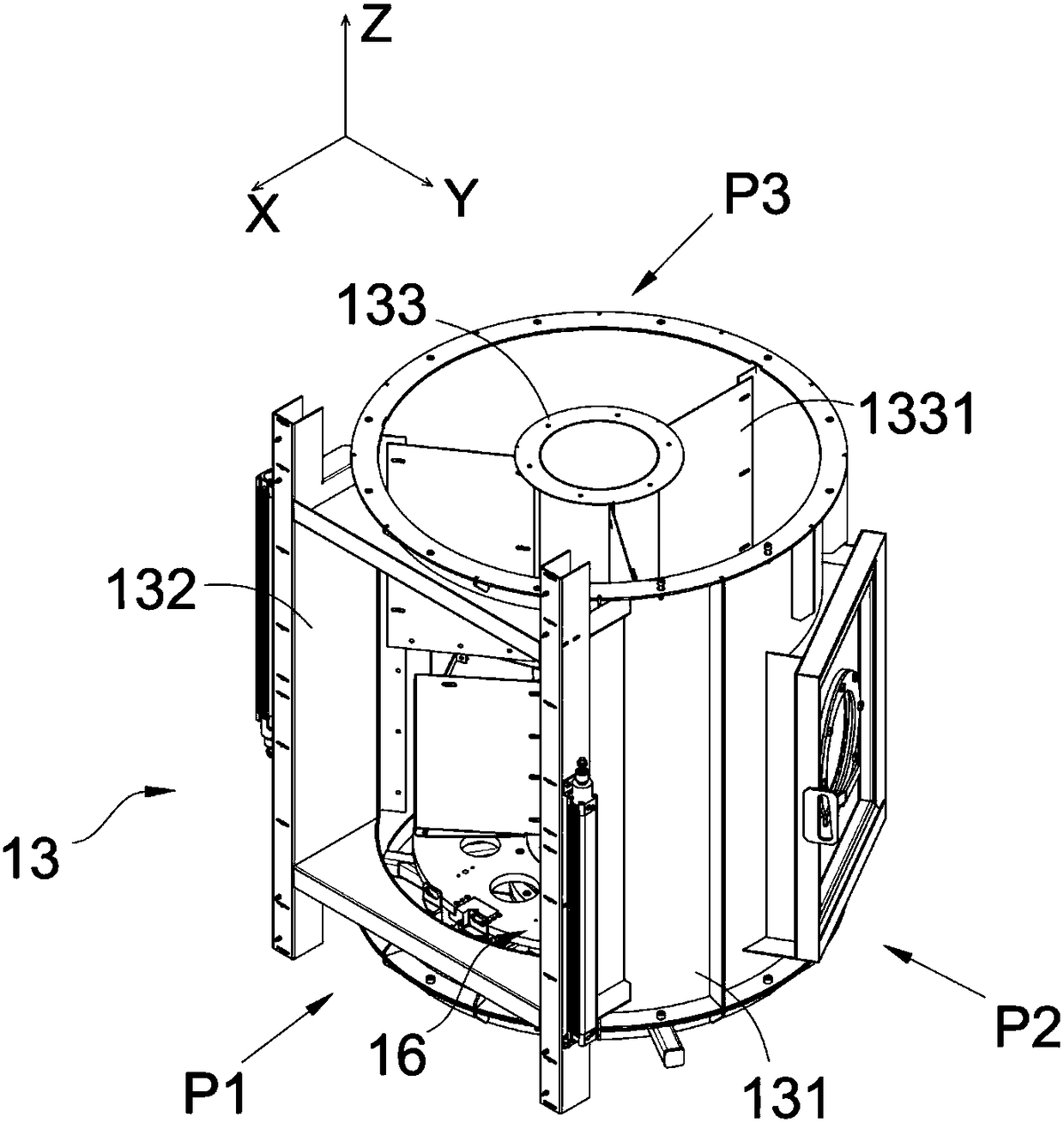

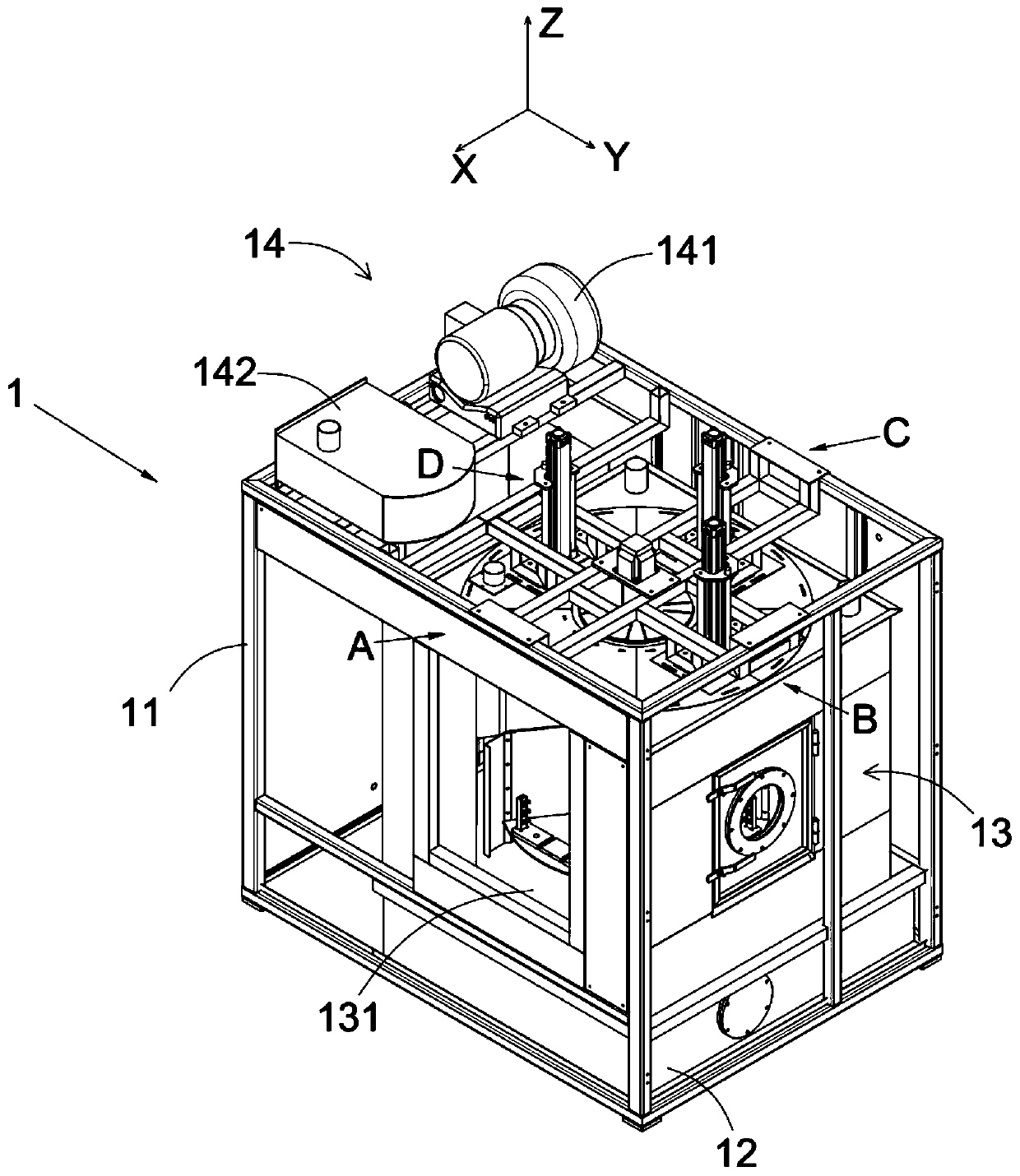

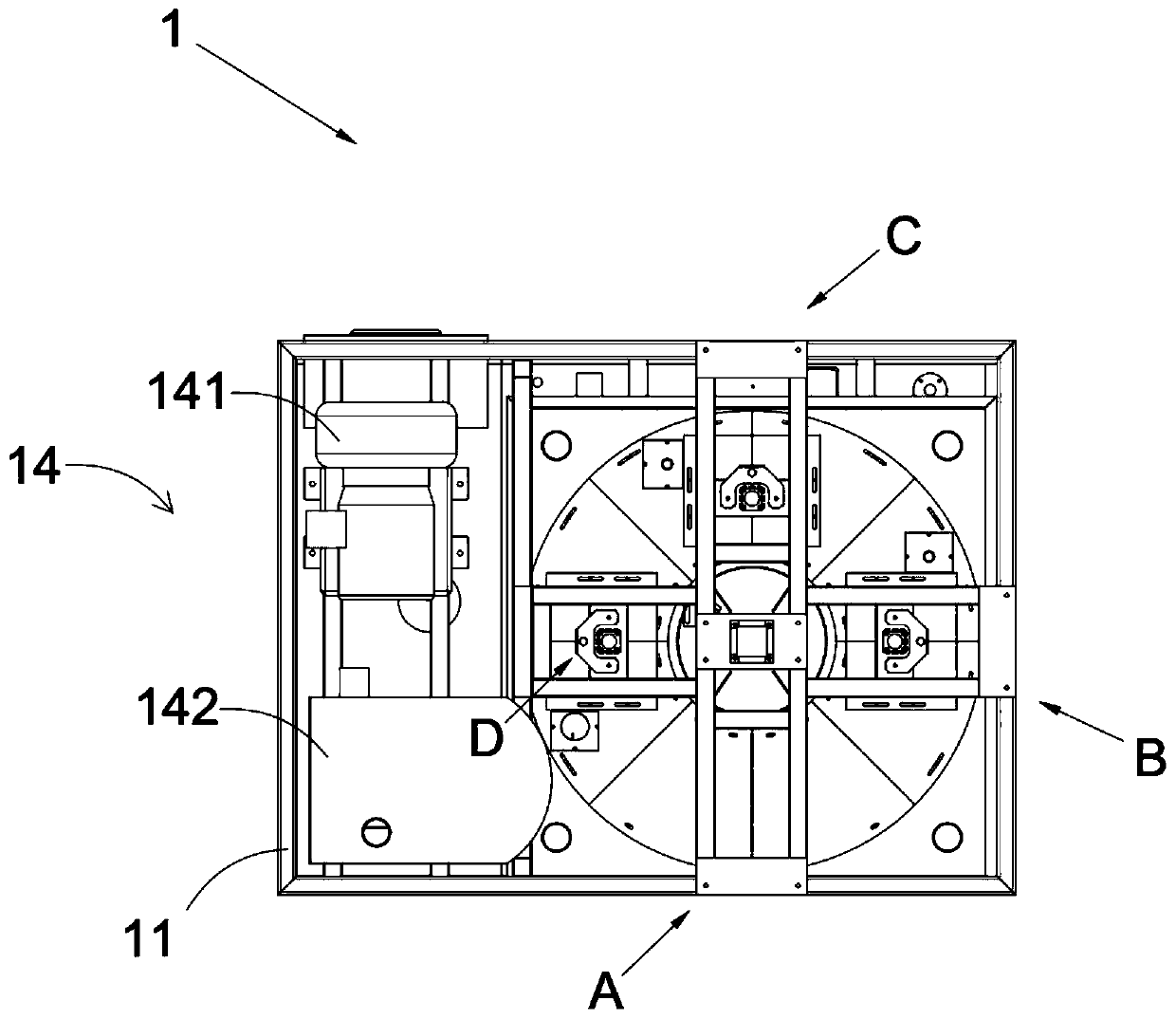

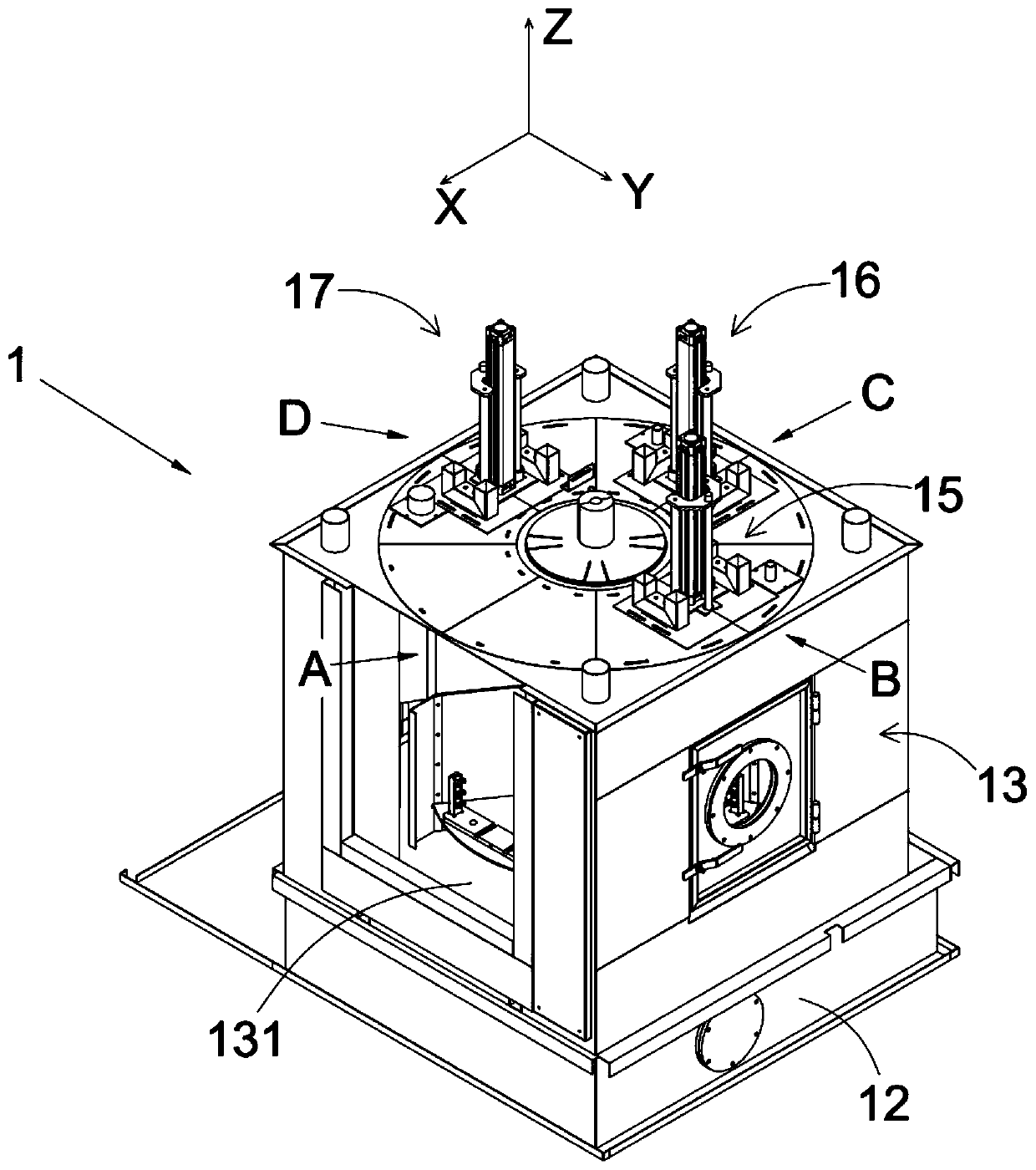

Four-station rotary table type spraying cleaning machine

ActiveCN107962025AReduced external volumeLarge internal spaceDrying gas arrangementsCleaning using gasesSpace requirementsWater tanks

The invention discloses a four-station rotary table type spraying cleaning machine. The four-station rotary table type spraying cleaning machine comprises a rack with a certain internal space, a containing box and a circulating water tank which are arranged in the rack and a hot air supplying mechanism arranged on the top of the rack; and the circulating water tank communicates with the bottom ofthe containing box, the containing box comprises a box body which is hollow in interior and a rotary supporting table arranged in the box body, and a cleaning device is arranged in the box body. According to the four-station rotary table type spraying cleaning machine, the four-station rotary table type spraying cleaning machine has the small external size and the large internal space, the floor area is small while the installing space requirements of the cleaning device are met, and therefore operation of an operator is convenient; in addition, all cleaning stations are partitioned clearly, all cleaning procedures are connected compactly, mutual interference among the stations is small, and the cleaning effect and the cleaning efficiency are both significantly improved.

Owner:SUZHOU RS TECH

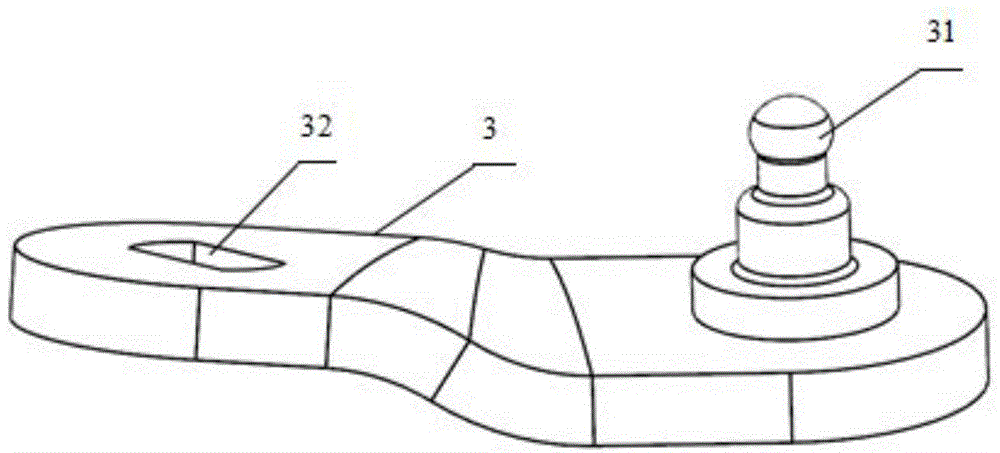

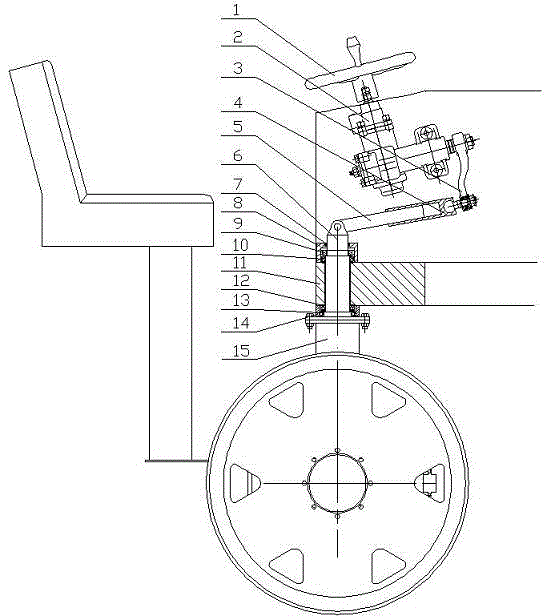

Steering mechanism of articulated type engineering vehicle

InactiveCN106143584AMeet the installation space requirementsCompact structureSteering linkagesSteering columnsSteering wheelBall bearing

The invention designs a steering mechanism of an articulated type engineering vehicle. The steering mechanism comprises a steering wheel (1), a steering gear (2), a steering rocker arm (3), a steering loop bar (4), a steering knuckle arm (5), a steering shaft (6), a dust ring (7), an upper flange cover (8), a circular nut (9), a tapered roller bearing (10), an upper vehicle body (11), a thrust ball bearing (12), a deep groove ball bearing (13), a lower flange cover (14) and a lower vehicle body (15). During working, an output shaft of the steering gear (2) can be driven to rotate through rotating the steering wheel (1), so that the steering rocker arm (3) is driven to rotate, the steering rocker arm (3) can drive the steering shaft (6) to rotate through the steering loop bar (4) and the steering knuckle arm (5), the lower vehicle body is driven to rotate, and the steering function of the vehicle is completed. The whole steering mechanism does not need hydraulic power, and is compact in structure, and requirements for mounting space of a small-scale engineering vehicle can be met.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Containing barrel used for three-station rotary table type spraying washing machine

InactiveCN108405438AReduce mutual interferenceMeet the installation space requirementsCleaning using liquidsMaintainance and safety accessoriesEngineeringMechanical engineering

The invention discloses a containing barrel used for a three-station rotary table type spraying washing machine. The containing barrel comprises a hollow barrel body and a separating assembly arrangedat the upper half section of the barrel body, the upper and lower ends of the barrel body are opened to form upper and lower openings, and feeding and discharging windows are arranged on the side wall of the barrel body. The containing barrel is compact in structure, the small external size and the large internal space are achieved, while the washing device installing space need is met, the occupied land area is small, operation by an operator is facilitated, all washing stations are clearly separated, mutual interference between the stations is small, and the washing effect is obvious.

Owner:SUZHOU RS TECH

Railway vehicle driving system and bogie

ActiveCN113830112AMeet the installation space requirementsRealize the hanging methodElectric motor propulsion transmissionRailway transportBogieGear wheel

The invention discloses a railway vehicle driving system and a bogie. The device comprises a traction motor, a gear transmission device, an axle, a coupling sleeved on the axle, and a suspension cross beam; the gear transmission device comprises a small gear box body, a large gear box body, a small gear, an idle gear, an idle gear shaft, a large gear and a gear hub; the idle gear shaft is supported in the small gear box body, and the idle gear is supported on the idle gear shaft; the idle gear shaft is of a hollow structure, the large end of the idle gear shaft is fixedly connected with one side end of the small gear box body, and the small end of the idle gear shaft is inserted into the blind hole structure on the other side of the small gear box body; the bull gear is fixedly connected with the gear hub, and the bull gear and the gear hub are supported on the bull gear box body; and the small gear is in meshing transmission with the idle gear, and the idle gear is in meshing transmission with the large gear. The problems of fast steel rail abrasion, line deformation, sleeper breakage, abnormal wheel abrasion and the like caused by the conditions of the prior art can be solved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

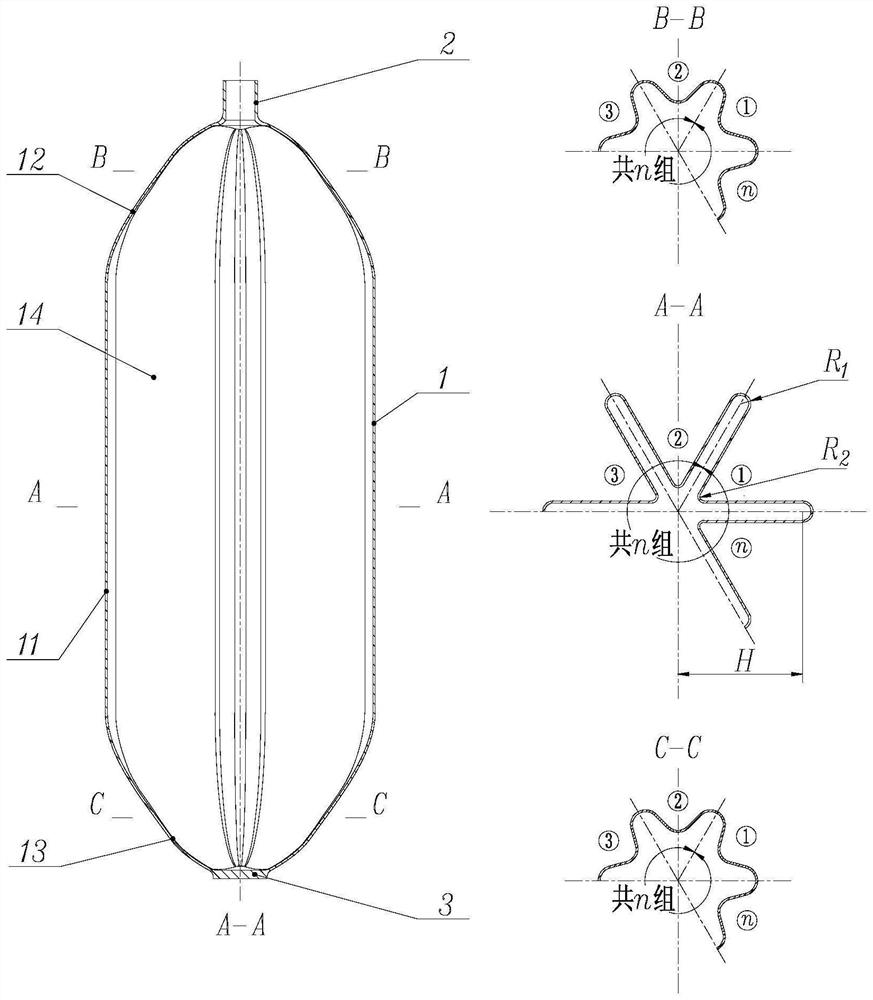

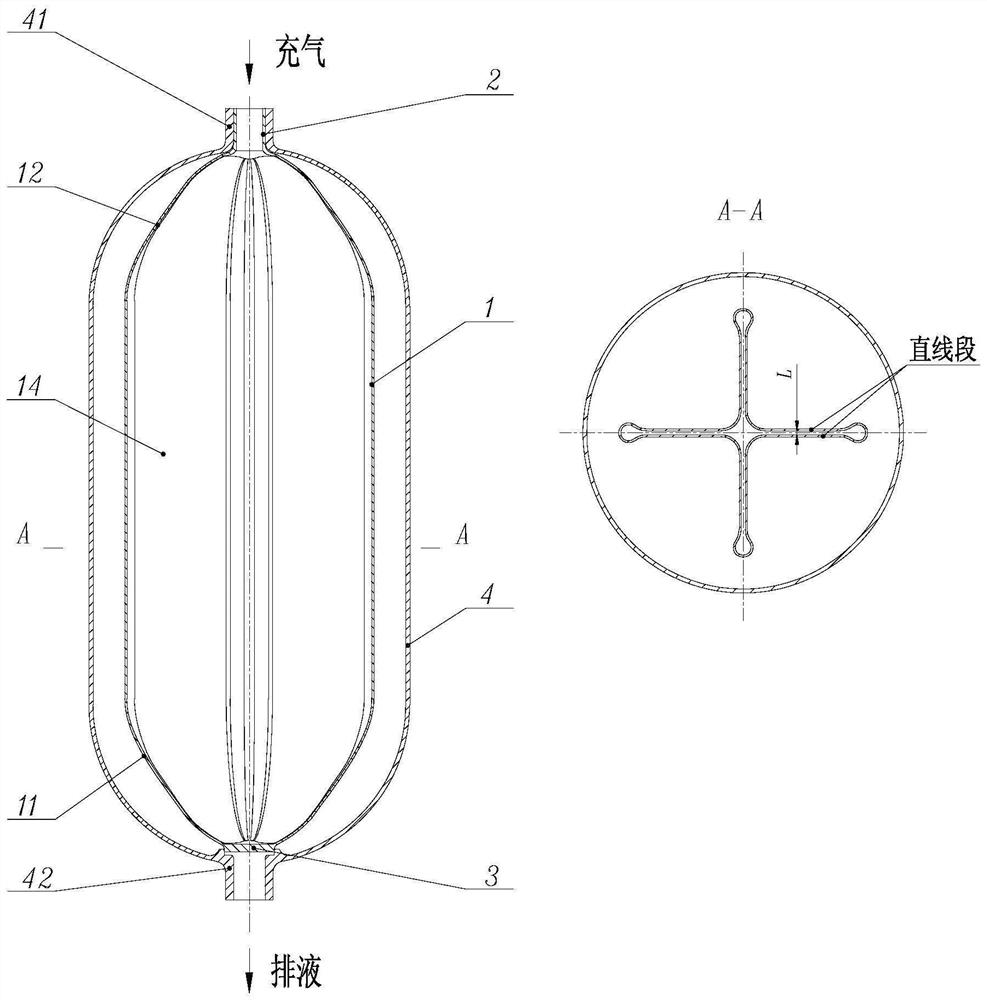

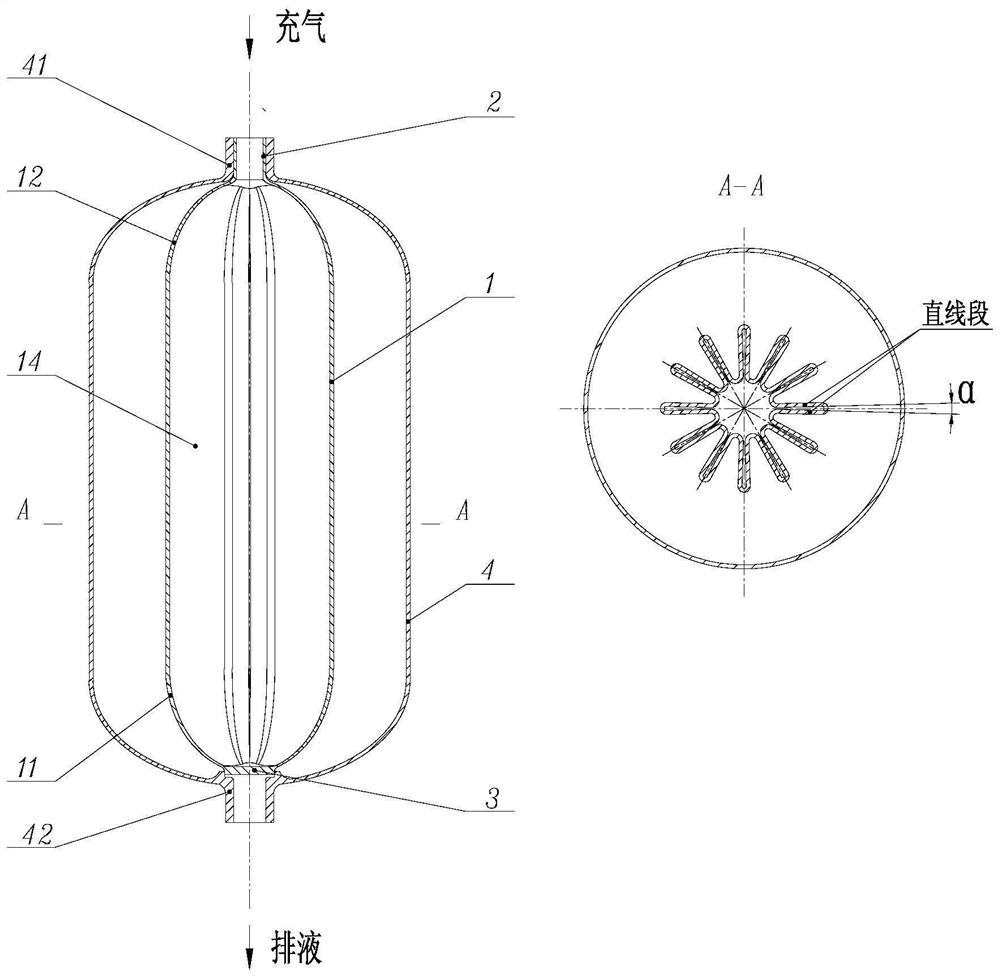

Cylindrical diaphragm

ActiveCN113247311AMeet the installation space requirementsImprove regularityCosmonautic vehiclesCosmonautic propulsion system apparatusFlight vehicleMechanical engineering

The invention relates to a liquid propellant extrusion-isolation device of an aircraft power system, and discloses a cylindrical diaphragm which comprises a diaphragm barrel, an inflation connector and an assembly connector. The diaphragm cylinder is composed of a cylinder body, a first end socket and a second end socket which are in seamless connection, and an inner cavity formed by the inner surface of the diaphragm cylinder is used for being filled with pressurized gas. The gas charging connector is connected with the first end socket of the diaphragm cylinder at the polar hole, is communicated with the inner cavity of the diaphragm cylinder and is used for assembling the diaphragm and charging and discharging gas; and the assembly joint is connected with the second end socket of the diaphragm cylinder at the polar hole and is used for assembling the diaphragm. The problems that a metal diaphragm cannot achieve a cylindrical structure, and several existing cylindrical extrusion-isolation devices are large in deformation randomness, poor in sealing performance, large in weight and the like are solved, and the cylindrical diaphragm the beneficial effects of being wide in application range, high in reliability, good in safety and the like are achieved.

Owner:SHANGHAI INST OF SPACE PROPULSION

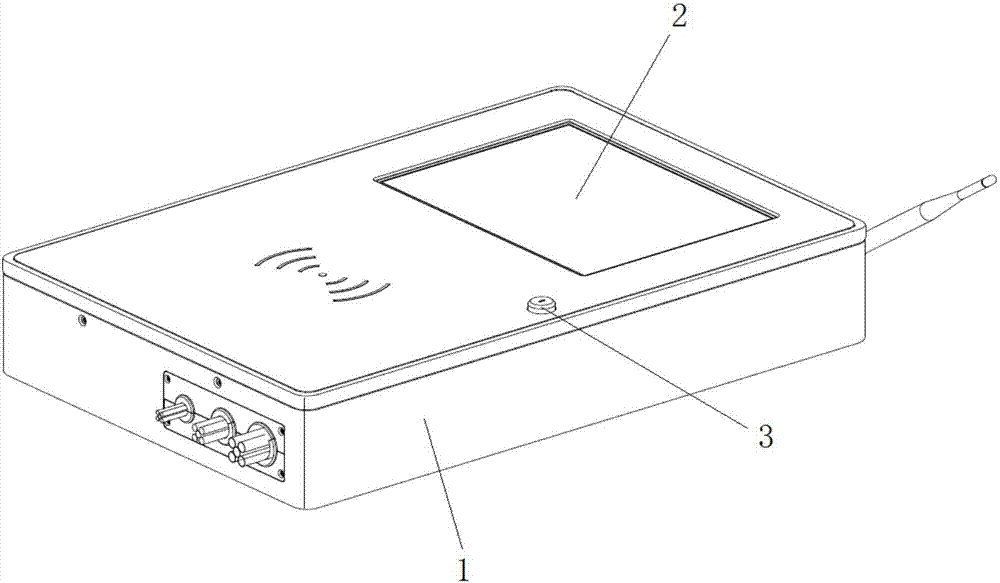

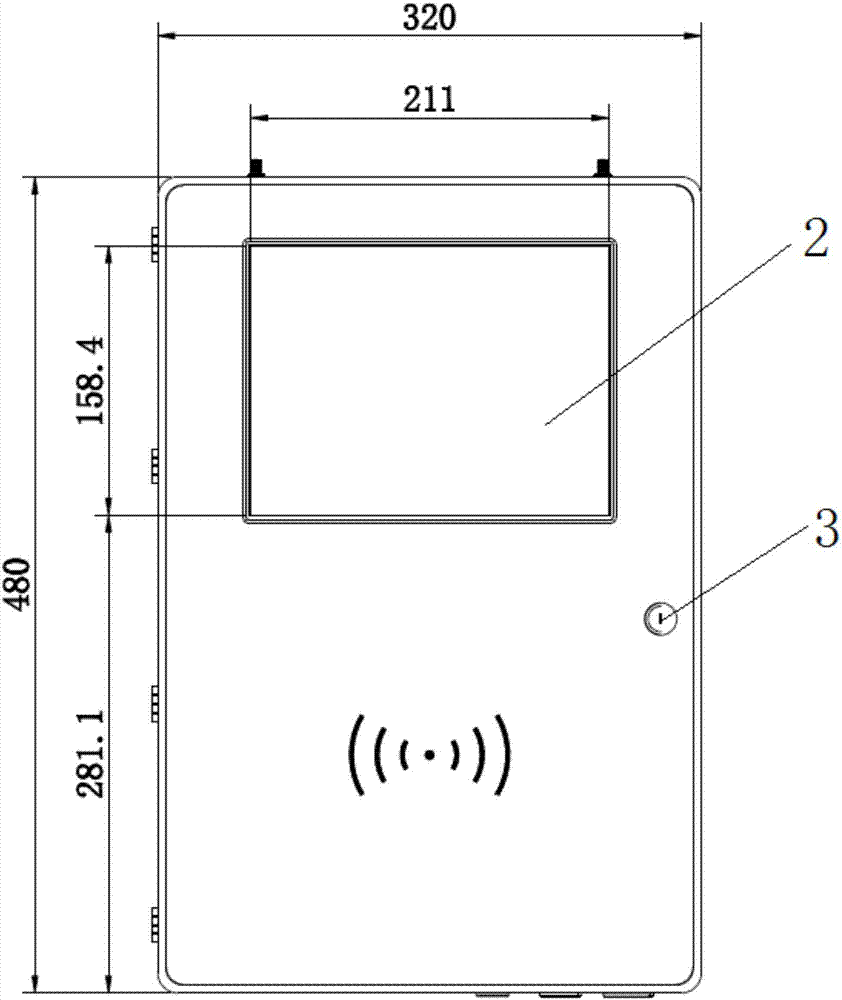

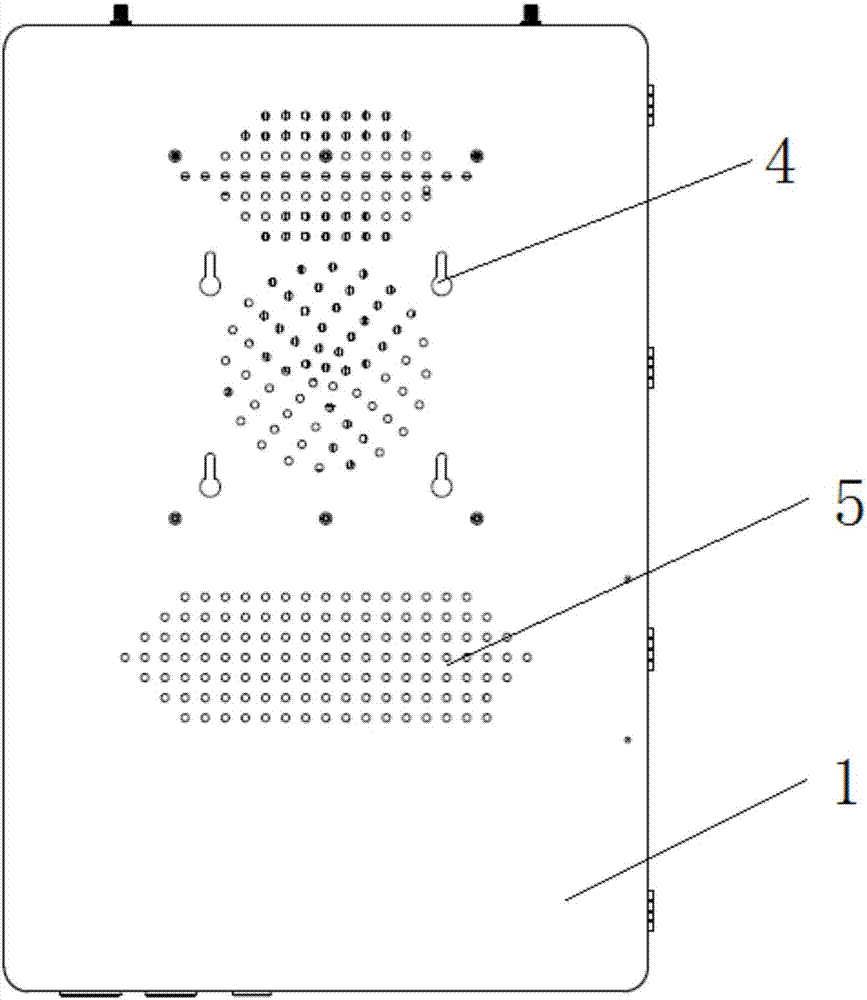

Basic total amount monitor

InactiveCN107544374ACompact structureMeet functional requirementsProgramme controlTransmission systemsCommunication interfaceCharge and discharge

The invention discloses a basic total amount monitor which includes a housing, a display, a housing lock and a control system. The front end of the housing is provided with the display and the housinglock. The back side of the housing is provided with a wall-mounted mechanism. The control system is installed inside the housing and includes a control terminal, a card reader, a switch power supply,a storage battery, a charging and discharging panel, at least one interface board, a micro camera. The control terminal is provided with a plurality of communication interfaces, and is in separate connection to the card reader, the charging and discharging panel, the interface board and the micro camera through the plurality of communication interfaces. The switch power supply and the storage battery are in separate and electrical connection to the charging and discharging panel. According to the invention, the basic total amount monitor has the characteristic of compact structure, and meetsrequirements for functions and installation space.

Owner:苏州天一信德环保科技有限公司

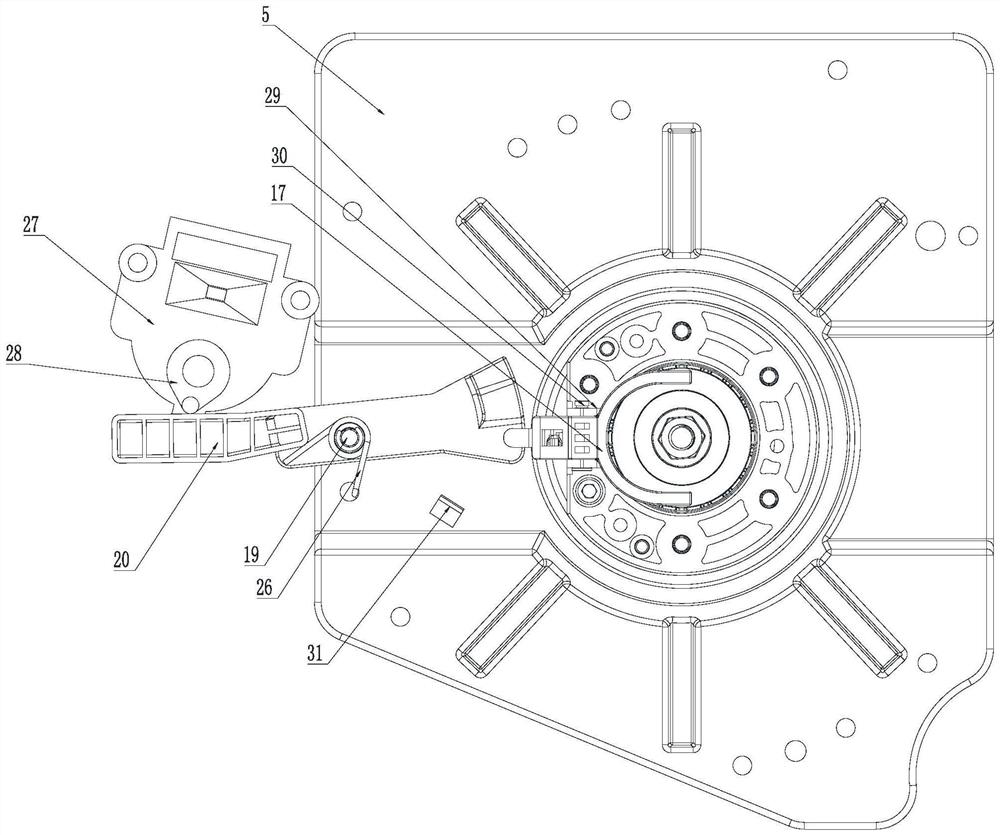

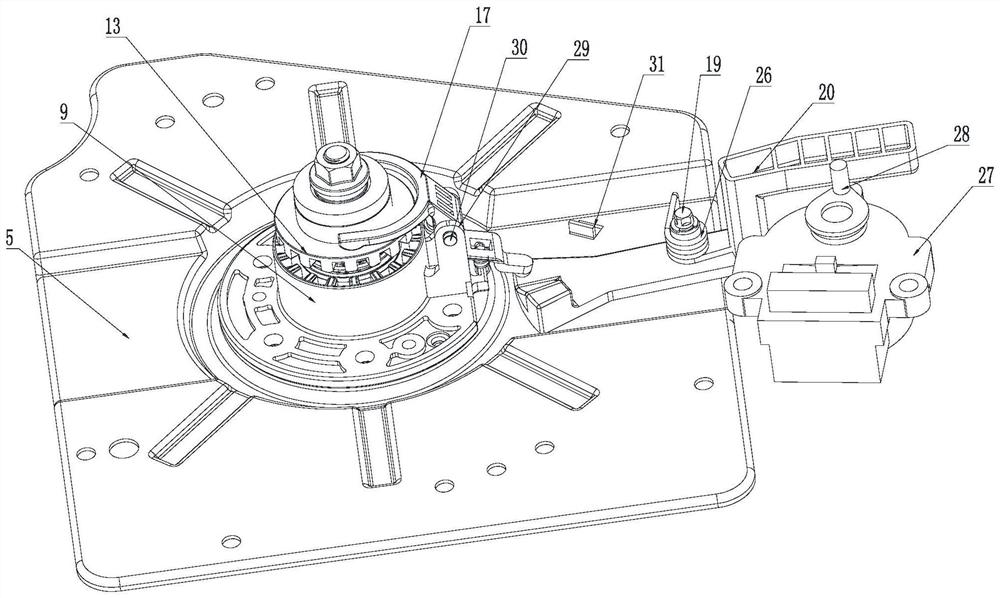

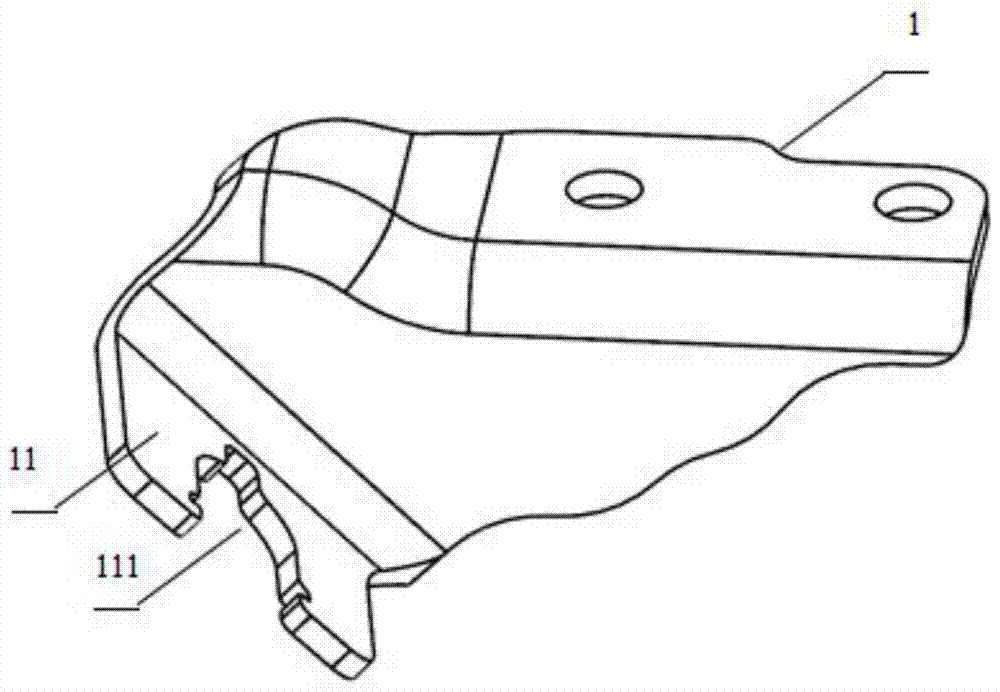

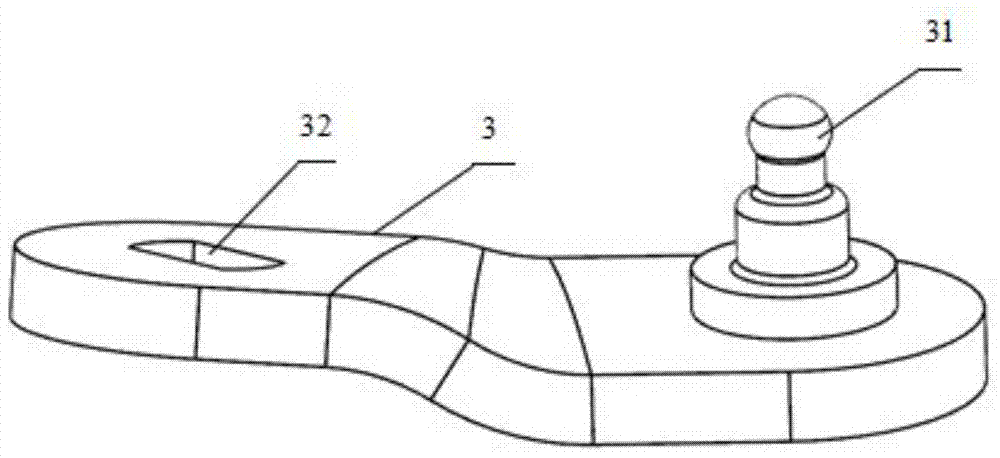

Washing machine speed reduction clutch device, washing machine and control method of washing machine

PendingCN114635266AStay fully lockedPrevent follow-upOther washing machinesControl devices for washing apparatusImpellerLaundry washing machine

The invention discloses a speed reduction clutch device of a washing machine. The inner barrel shaft is rotatably arranged on the periphery of the impeller shaft in a sleeving manner; one end of the impeller shaft is in transmission connection with the speed reduction gear train; one end of the input shaft is in transmission connection with the speed reduction gear train; the input shaft sleeve is rotatably arranged on the periphery of the input shaft in a sleeving mode, and the inner barrel shaft is fixedly connected with the input shaft sleeve; the clutch sleeve is arranged on the input shaft sleeve in a sleeving mode in an axial sliding mode, and the clutch sleeve and the input shaft sleeve are matched in a limiting mode in the circumferential direction; the fixed disc is fixedly arranged above the clutch sleeve, and the clutch sleeve is arranged on the fixed disc; and the clutch sleeve is controlled to slide upwards to be meshed and fixed with the fixed disc so as to limit the circumferential rotation of the input shaft sleeve and the inner barrel shaft. According to the speed reduction clutch device of the washing machine, the inner barrel can be completely locked in the washing process, follow-up rotation of the inner barrel in the washing process is avoided, the washing ratio of clothes is increased, and energy consumption is reduced.

Owner:ZHEJIANG SANXING MECHANICAL & ELECTRONICSAL STOCK

A shift cable device and an automatic transmission shift system

ActiveCN104613168BReduce installationEasy to fixGearing controlControl devicesAutomatic transmissionEngineering

The invention provides a gear shifting inhaul cable device, and belongs to the field of parts of a car gear shifting system. The gear shifting inhaul cable device comprises an inhaul cable and an inhaul cable support, a notch is formed in the contact face of the inhaul cable support and the inhaul cable, the inhaul cable is connected to the notch of the inhaul cable support in a sleeving mode, an elastic piece is arranged at the connecting position of the inhaul cable and the inhaul cable support, and a gear-shaped clamping structure is arranged on the inhaul cable to be matched with the notch in the inhaul cable support. By means of the gear shifting inhaul cable device, in limited space, the requirements for simpleness and firmness are met, the assembling space is reduced, the number of the parts is decreased, the assembling efficiency is improved, and the cost is better optimized.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Urea tank cover

ActiveCN108252781AMeet support needsAvoid cross-bundling situationsExhaust apparatusSilencing apparatusBiochemical engineeringUrea

The invention provides a urea tank cover, and belongs to the technical field of urea tanks. The urea tank cover is characterized by comprising a tank cover (2), the tank cover (2) is detachably connected to a urea tank bracket (1) through a strutting piece, one side of the urea tank bracket (1) is provided with a urea pump, the tank cover (2) covers the upper sides of the urea tank bracket (1) andurea pump at an interval, the strutting piece is provided with a plurality of preformed holes, and the wires or pipelines can penetrate through the preformed holes; the strutting piece comprises an end portion support (4), a first central support (3) and a second central support (5), the end portion support (4) is arranged on one side, away from the urea pump, of the tank cover (2), and the firstcentral support (3) and the second central support (5) are arranged at the two sides of the urea pump. The urea tank cover has the advantages that the wires and pipelines can pass through the different preformed holes respectively, the pipelines and the wires are arranged through the preformed holes, thereby avoiding the situation that cross-bundling of lines still occurs on the pipelines and line arrangement, and the pipelines and the wires are laid on the lower side of the tank cover so that the tank cover is attractive in appearance.

Owner:SHANDONG TANGJUN OULING AUTOMOBILE MFG

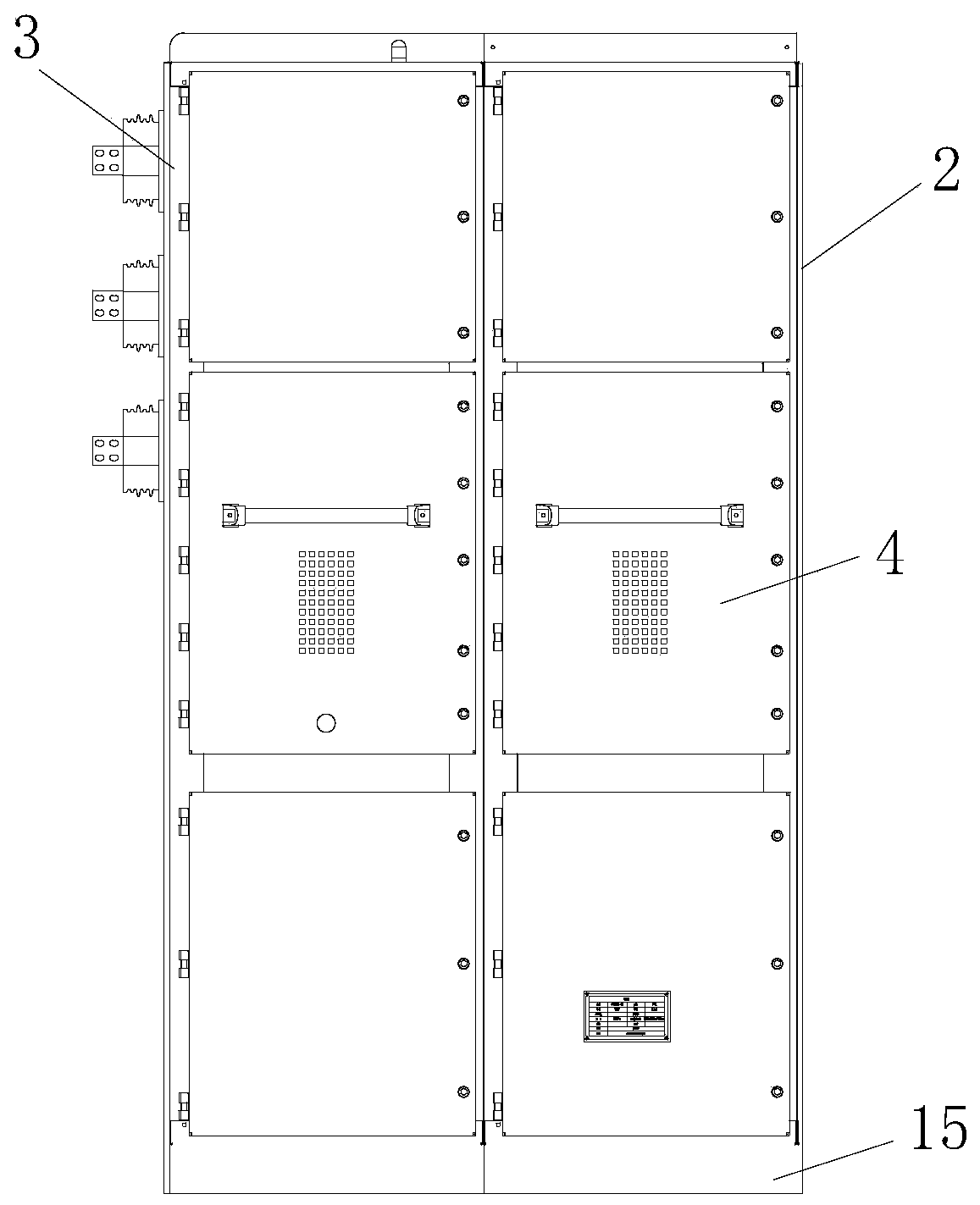

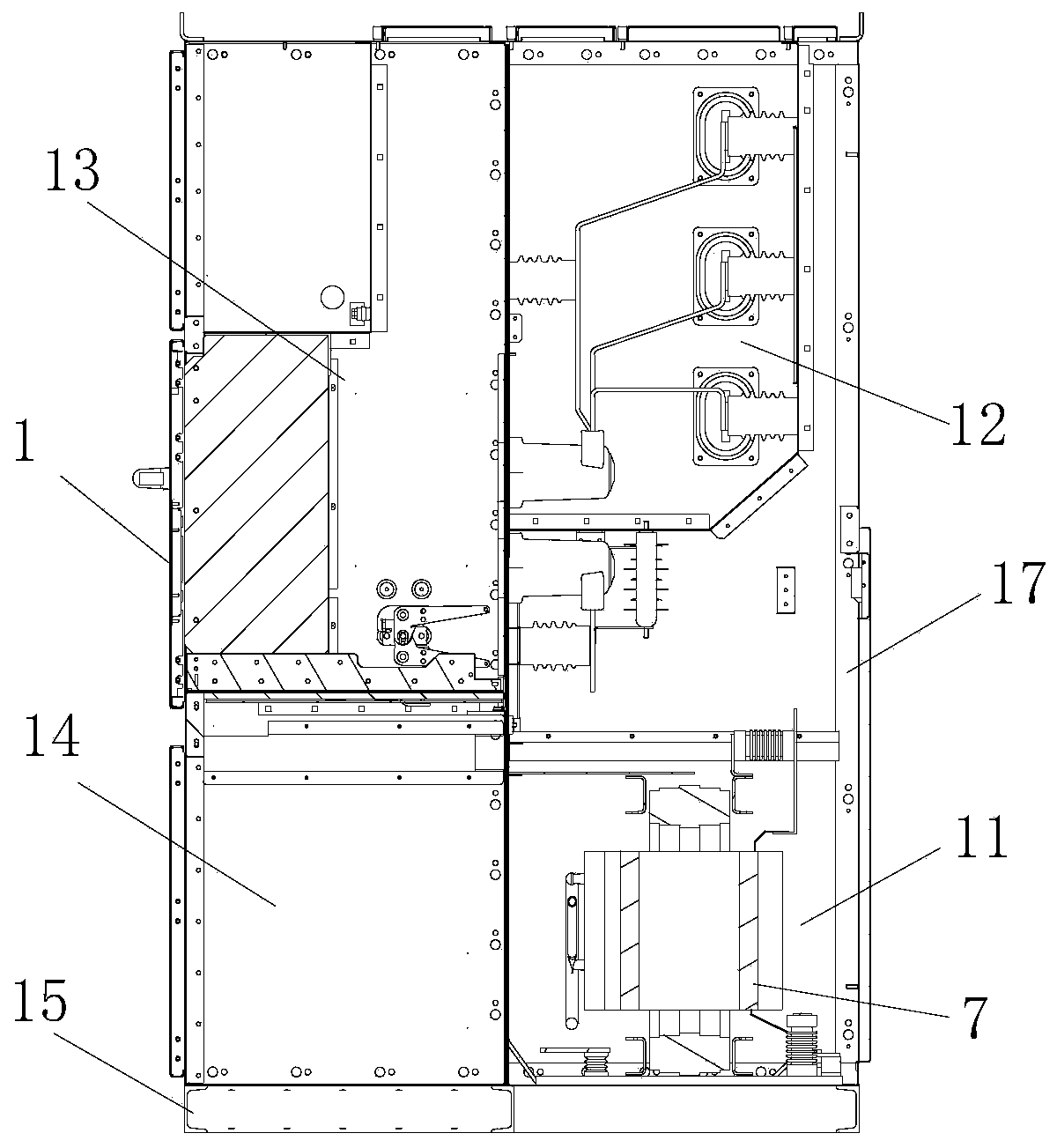

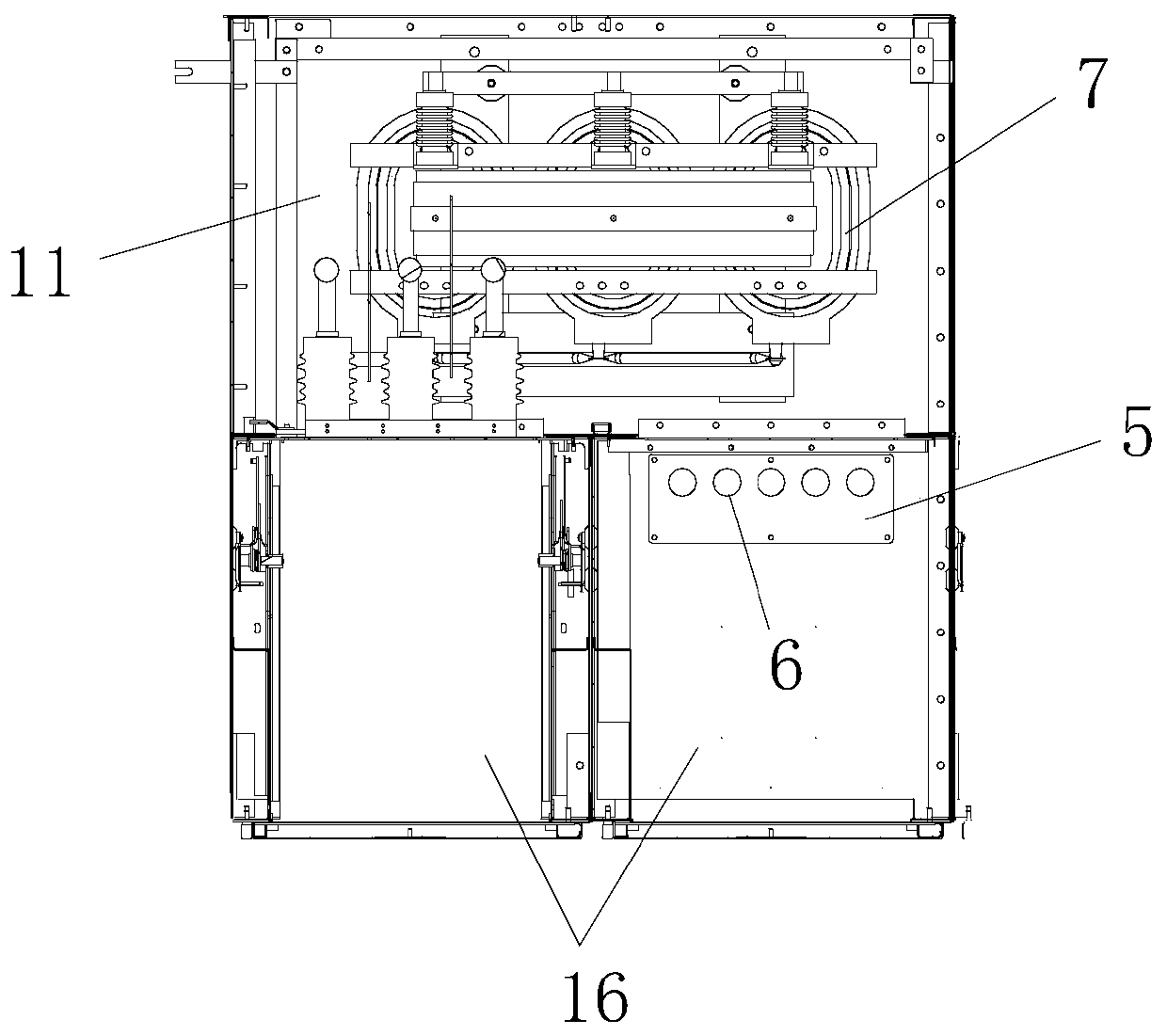

Large-scale transformer installation switch cabinet

PendingCN111293597AHigh strengthMeet the installation space requirementsBus-bar/wiring layoutsSubstation/switching arrangement casingsTransformerStructural engineering

The invention relates to the technical field of switch cabinets, and particularly relates to a large-scale transformer installation switch cabinet. The switch cabinet comprises a first switch cabinetand a second switch cabinet, wherein one side of the first switch cabinet is fixedly connected with one side of the second switch cabinet. The first switch cabinet and the second switch cabinet are respectively provided with a cabinet body. The cabinet body comprises a base, a supporting structure, a transformer chamber and a plurality of equipment chambers, wherein the supporting structure is fixed on the base, the transformer chamber and the plurality of equipment chambers are arranged in the supporting structure, the transformer chamber is arranged at one end, close to the base, of the cabinet body, a cross beam is arranged at the bottom of the transformer chamber, and the cross beam is fixed on the base; and the transformer chamber of the first switch cabinet is communicated with the transformer chamber of the second switch cabinet. The transformer chamber of the large-scale transformer installation switch cabinet can meet the installation space requirement of a large-scale transformer, the cabinet widths of all cabinets are consistent, the cabinets are placed orderly and attractively, and the space utilization rate is high.

Owner:HAINAN JINPAN INTELLIGENCE TECH CO LTD +1

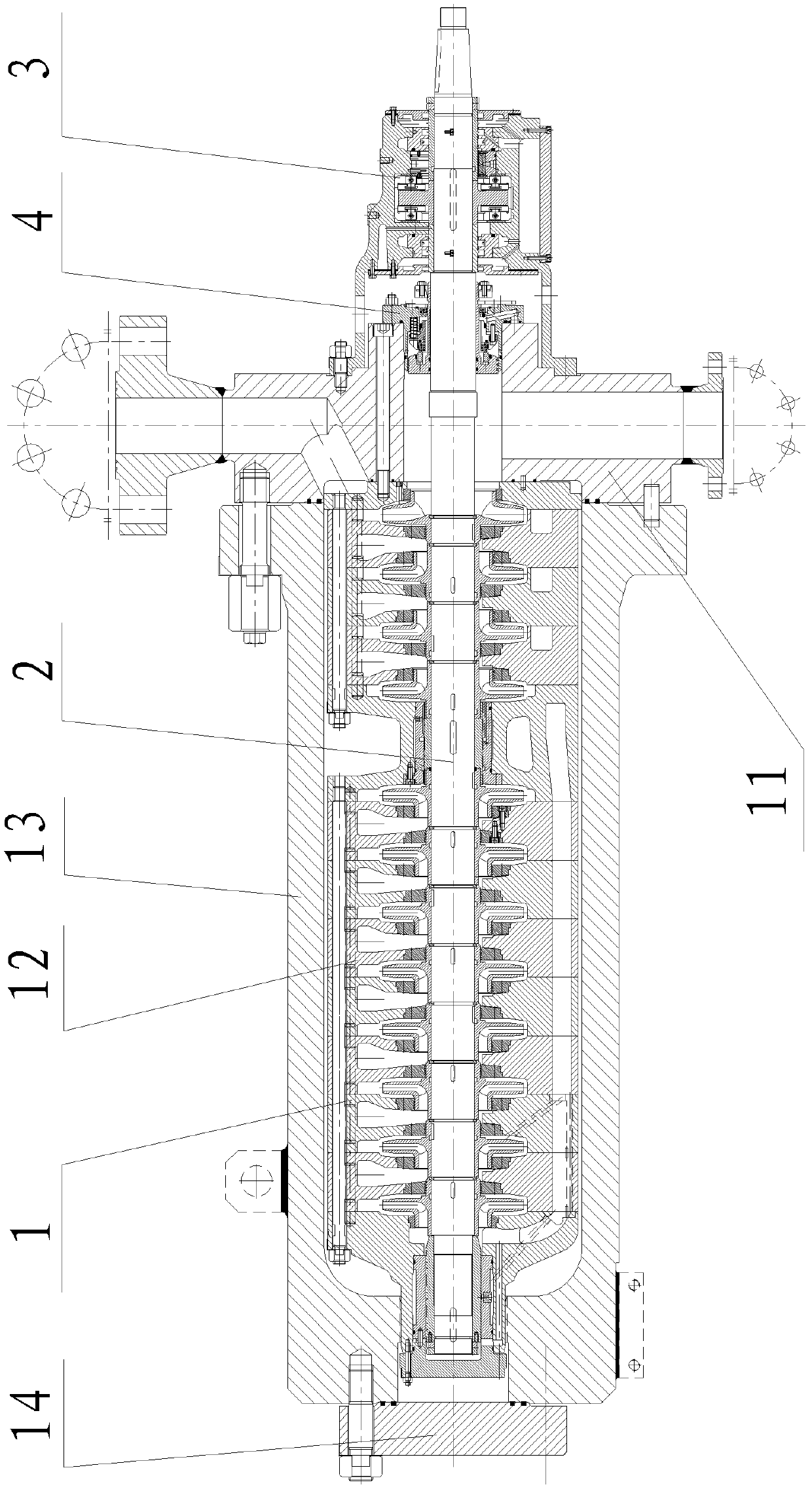

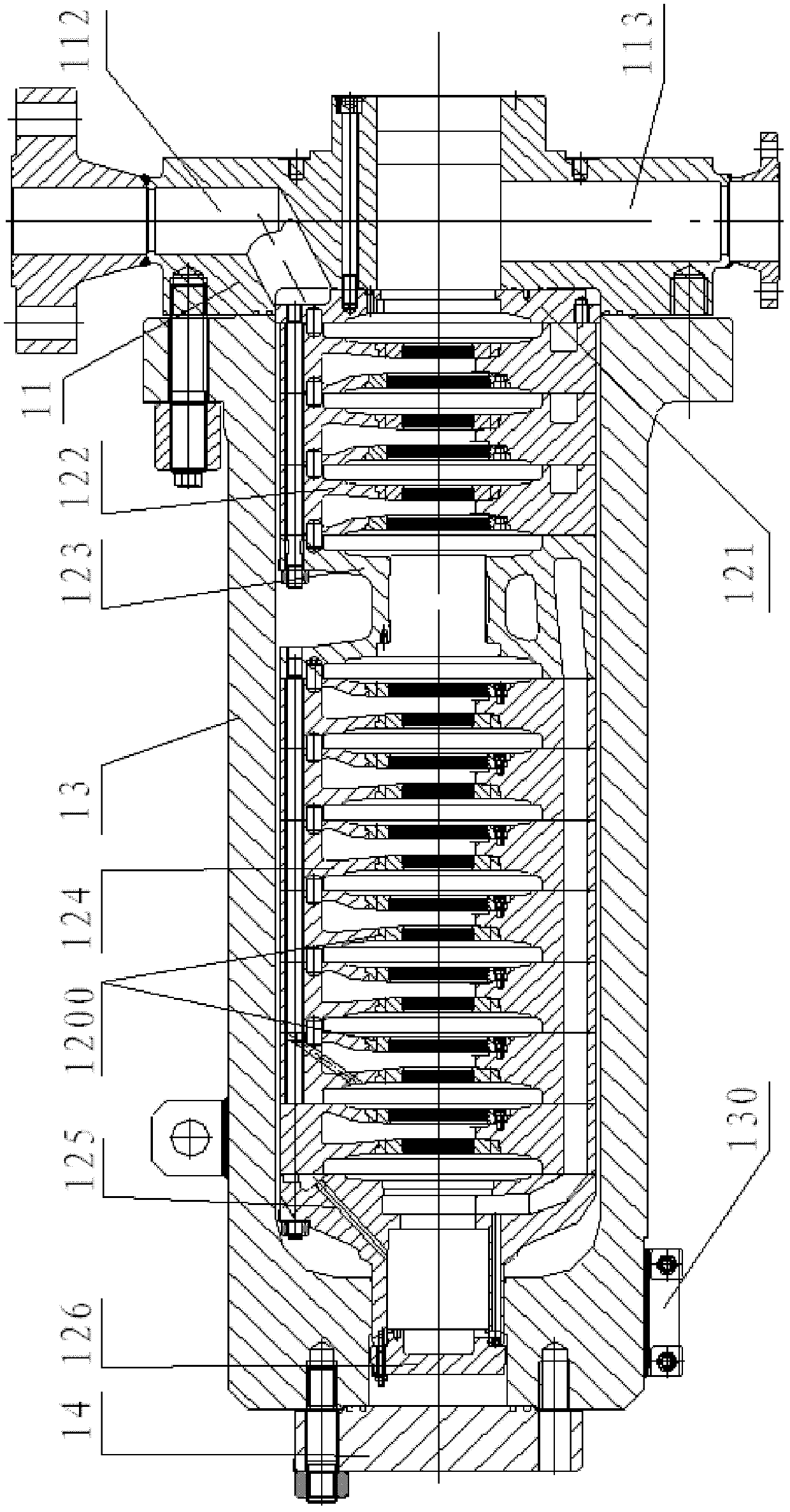

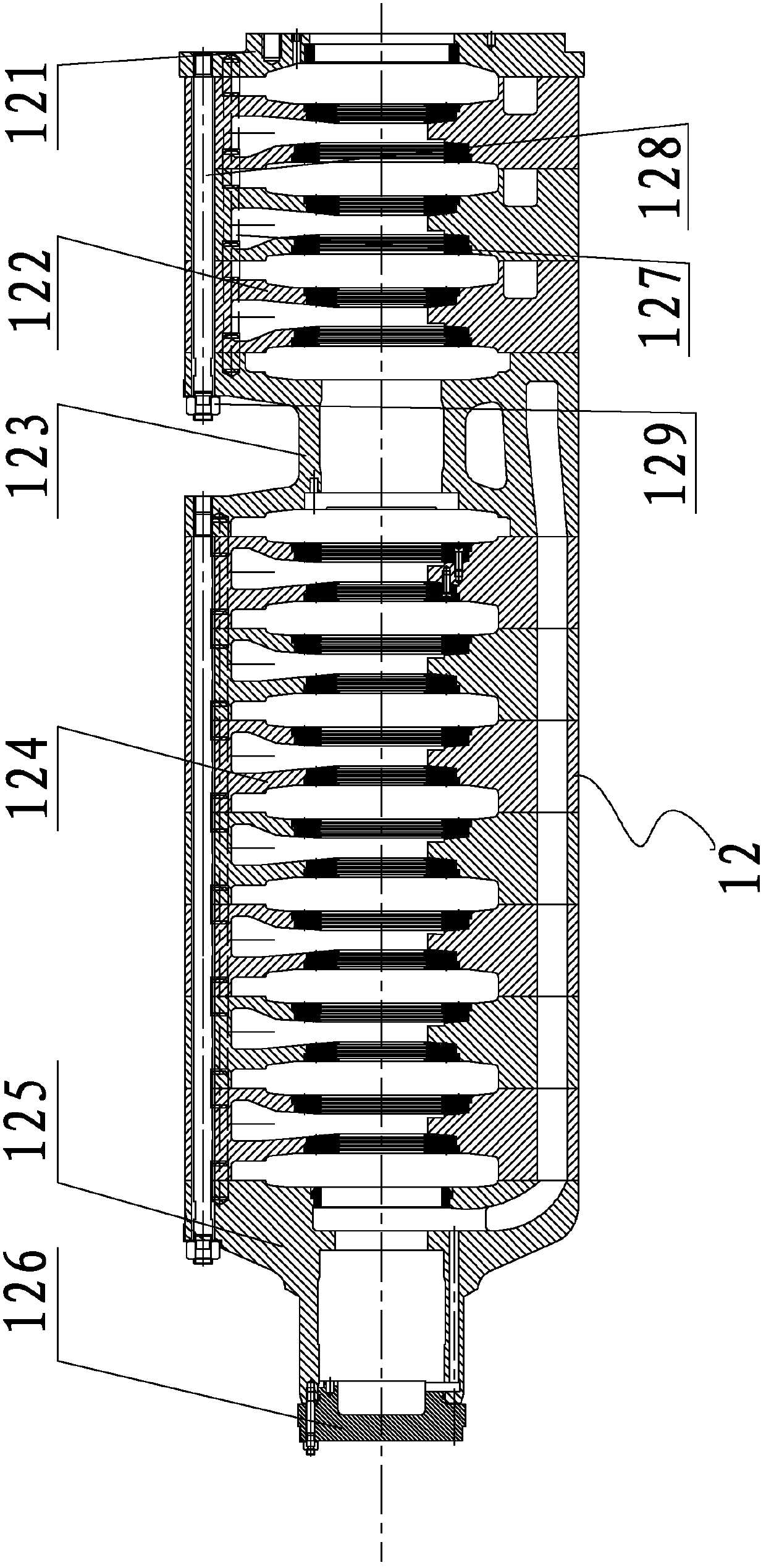

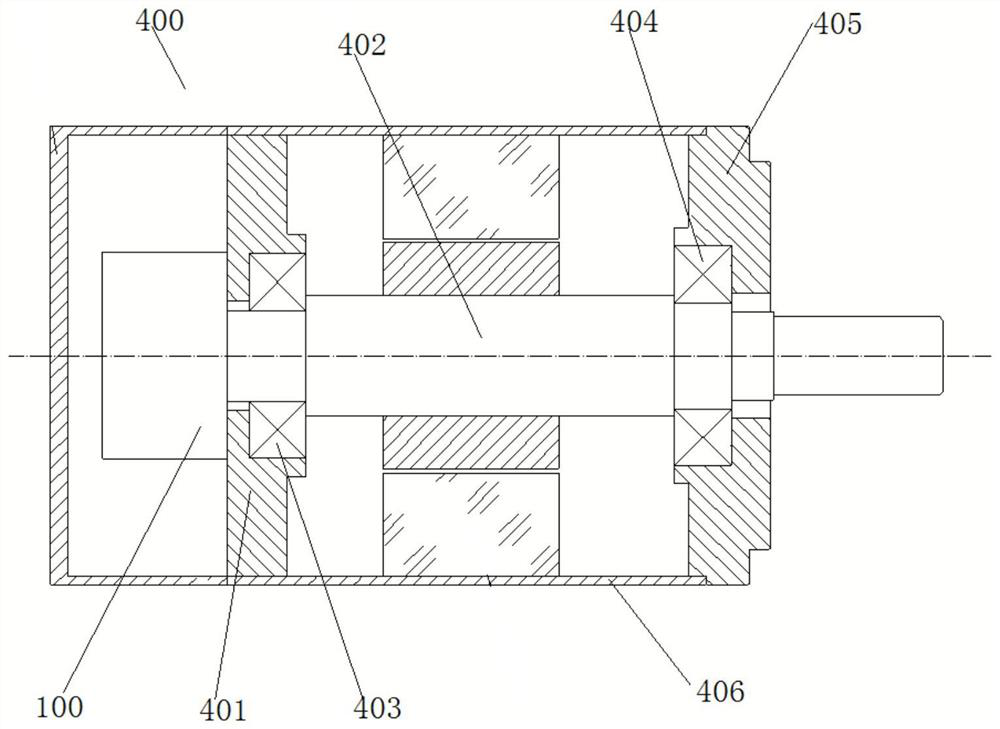

Stator component of charging pump for nuclear power station

InactiveCN102606506AImprove surface roughnessImproved surface roughness improves pump efficiencyPump componentsRadial flow pumpsImpellerCircular disc

The invention discloses a stator component of a charging pump for a nuclear power station, which comprises a pump head, a barrel and a tail plate which are sequentially connected in back and forth direction. The barrel comprises an outer casing and an inner casing. The pump head comprises a main body portion which is of a circular structure and provided with an axial hole, an inlet hole and an outlet hole. An inner cavity of the outer casing comprises an inner casing cavity and a rear bearing cavity. The inner casing is of a radial subdivision structure and comprises a head plate, pump head lateral guiding fluid, a middle section, barrel lateral guiding fluid, a tail cover and a rear bearing cover which are sequentially connected in back and forth direction. After the head plate, the pump head lateral guiding fluid, the middle section, the barrel lateral guiding fluid and the tail cover are connected, complete cavities for containing impellers are arranged at intervals. The head plate is fixed on the rear end face of the pump head to enable the head plate, the pump head lateral guiding fluid, the middle section, the barrel lateral guiding fluid and the front half portion of the tail cover to be located in the inner casing cavity of the outer casing, and the rear half portion of the tail cover and the rear bearing cover are located in the rear bearing cavity of the outer casing and enable the rear end face of the rear bearing cover to have a free space with the front end face of the tail plate.

Owner:SHANGHAI APOLLO MACHINERY

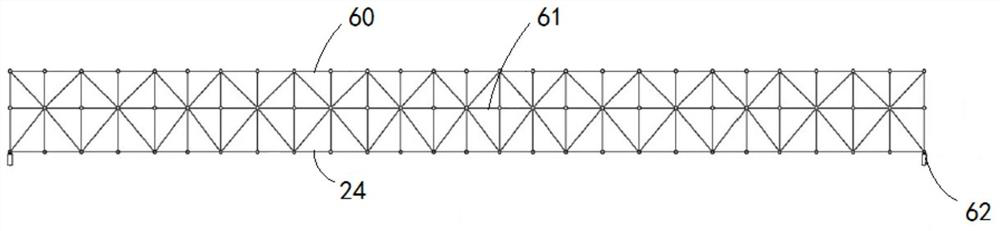

Prestressed truss end base structure and construction method

ActiveCN112095779BIncrease binding forceReduce adverse effectsBuilding constructionsParkingsPre stressClassical mechanics

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Mounting bracket, encoder connecting structure and motor

PendingCN113972793AGuaranteed to workMeet the installation space requirementsStructural associationSupports/enclosures/casingsElectric machineControl engineering

The invention provides a mounting bracket, an encoder connecting structure and a motor, belongs to the field of electromechanical equipment, and aims to solve the problem that the work of an encoder is affected due to poor perpendicularity between the encoder mounted on a motor end cover and a motor shaft. The mounting bracket comprises a base fixed with an assembly part in the motor and a mounting part with a mounting surface, a gap exists between the base and the mounting part, the mounting part is provided with a fixed position and a movable position, and the fixed position is locked with the base; and the distance between the movable position and the base can be changed by adjusting the position of the movable position, so that the mounting surface is vertical to the motor shaft. According to the mounting bracket, encoder connecting structure and motor, the distance between the fixed position and the base is not changed, and the distance between the movable position and the base can be changed by adjusting the position of the movable position, so that the inclination of the mounting surface relative to the motor shaft can be adjusted, and the mounting surface is vertical to the motor shaft; and when the encoder is fixed on the mounting surface, the encoder can be ensured to be vertical to the motor shaft, and the normal work of the encoder is ensured.

Owner:GREE ELECTRIC APPLIANCES INC

Vehicle-mounted transformer oil conservator

PendingCN114220634ASave materialRegular structureTransformers/inductances coolingIn vehicleAutomotive engineering

The invention provides a vehicle-mounted transformer oil conservator. The switch oil conservator is independently arranged on the end face of one side outside the main oil conservator, materials needed by the switch oil conservator can be saved, it is guaranteed that the internal structure of the main oil conservator is regular, and capsule sealing is facilitated. In order to facilitate an operator to maintain the oil conservator, a main oil conservator breathing channel, a vacuumizing channel and a switch cabinet breathing channel of a switch oil conservator are conducted and connected together through a pressure balance valve, and the three channels extend to the lower portion of an oil tank along the outer side of a transformer body. Respirators and valve structures at the tail ends of the channels are ensured to be located at the height positions close to maintenance personnel, and vacuumizing oil injection of the transformer, overall sealing test of the transformer and follow-up maintenance operation are more convenient. Therefore, the vehicle-mounted transformer oil conservator and the switch oil conservator can be separately and independently designed, operation of maintenance personnel is facilitated, the occupied volume of the oil conservators can be reduced, and the transformer is integrated to meet the vehicle-mounted installation space requirement.

Owner:江苏安靠智能输电工程科技股份有限公司

A four-station turntable spray cleaning machine

ActiveCN107962025BReduce mutual interferenceMeet the installation space requirementsDrying gas arrangementsCleaning using gasesInterior spaceProcess engineering

The invention discloses a four-station rotary table type spraying cleaning machine. The four-station rotary table type spraying cleaning machine comprises a rack with a certain internal space, a containing box and a circulating water tank which are arranged in the rack and a hot air supplying mechanism arranged on the top of the rack; and the circulating water tank communicates with the bottom ofthe containing box, the containing box comprises a box body which is hollow in interior and a rotary supporting table arranged in the box body, and a cleaning device is arranged in the box body. According to the four-station rotary table type spraying cleaning machine, the four-station rotary table type spraying cleaning machine has the small external size and the large internal space, the floor area is small while the installing space requirements of the cleaning device are met, and therefore operation of an operator is convenient; in addition, all cleaning stations are partitioned clearly, all cleaning procedures are connected compactly, mutual interference among the stations is small, and the cleaning effect and the cleaning efficiency are both significantly improved.

Owner:SUZHOU RS TECH

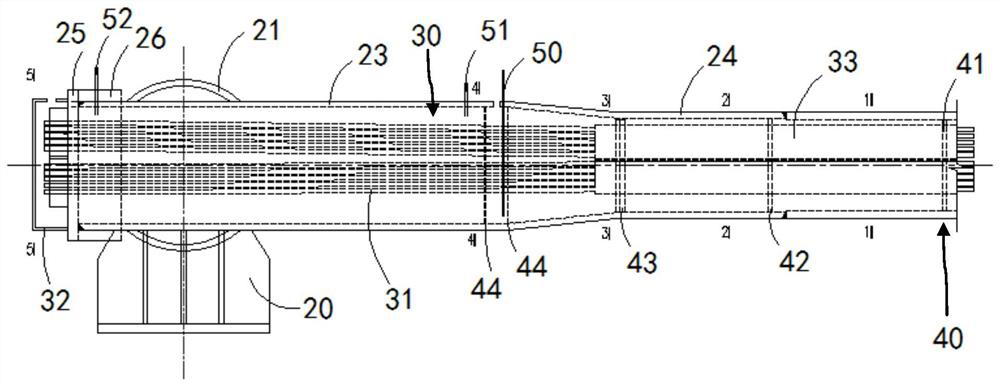

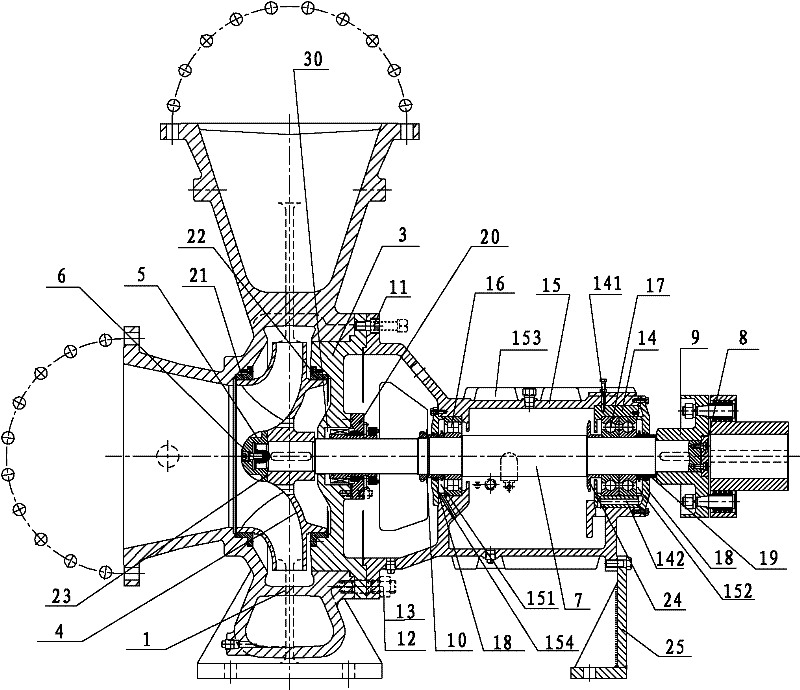

Equipment cooling water pump for nuclear power station

ActiveCN102116322BMeet the installation space requirementsSatisfy cavitation performance issuesPump componentsPumpsCavitationSingle stage

The invention discloses an equipment cooling water pump for a nuclear power station, which belongs to a single-stage single-suction hanging arm horizontal type centrifugal pump. The water pump comprises a stator assembly, a rotor assembly, a bearing assembly and a shaft seal assembly, wherein the stator assembly comprises a pump body, a pump cover and a pair of pump body sealing rings; the rotor assembly comprises a pump shaft, an impeller, an impeller nut and two bearing retaining sleeves; the bearing assembly comprises a bearing body, a bearing assembly and two bearing glands; and the shaftseal assembly comprises a bump body seal and a bearing oil seal. The equipment cooling water pump completely meets the requirement of the installation space of the nuclear power station and solves the problems of large volume, inconvenience of maintenance, low vibration resistance and the like of the equipment cooling water pump of the nuclear power station. Simultaneously, a bearing cooling modeis changed into a natural air cooling mode from a water cooling mode, the complexity of a system is further optimized, and an excellent hydraulic model is selected, so that the problem of the cavitation performance of a single-stage single-suction equipment cooling water pump can be completely solved.

Owner:SHANGHAI APOLLO MACHINERY

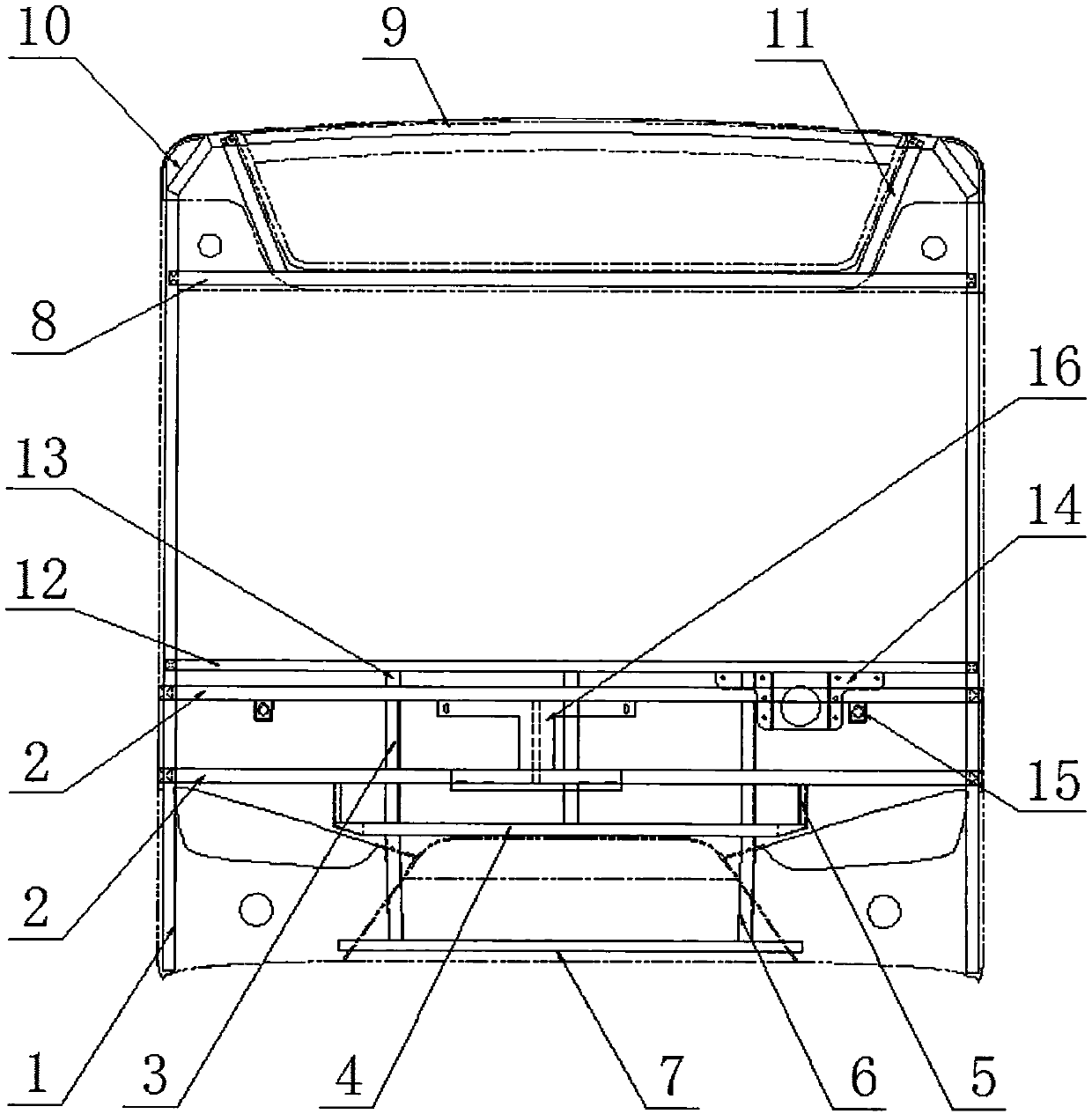

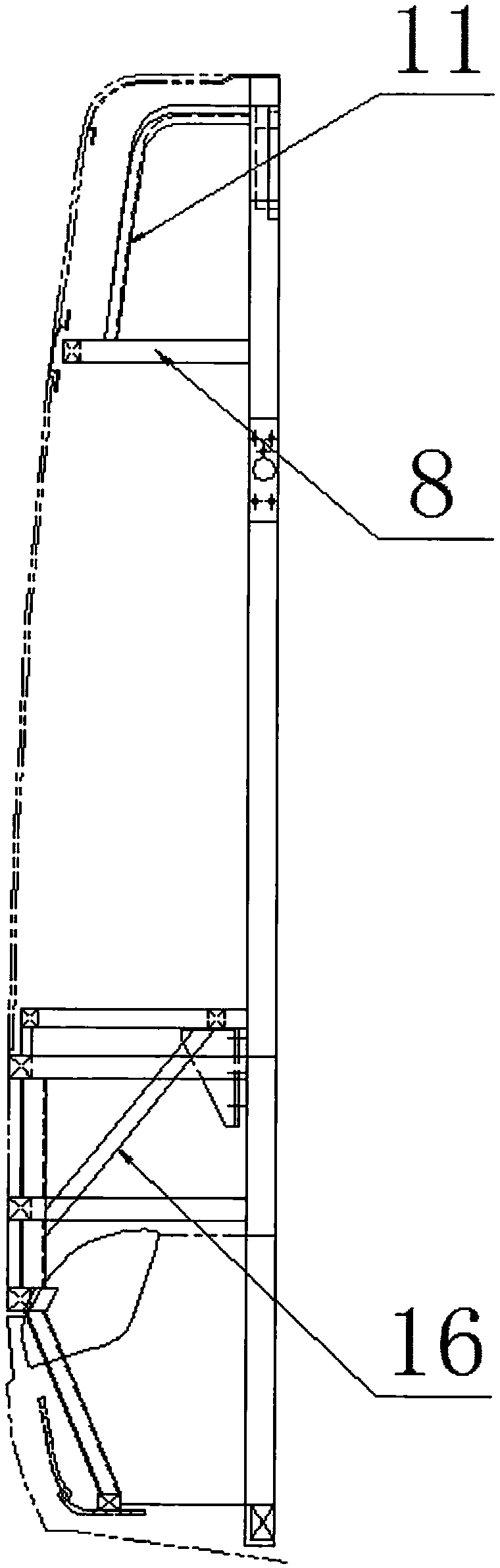

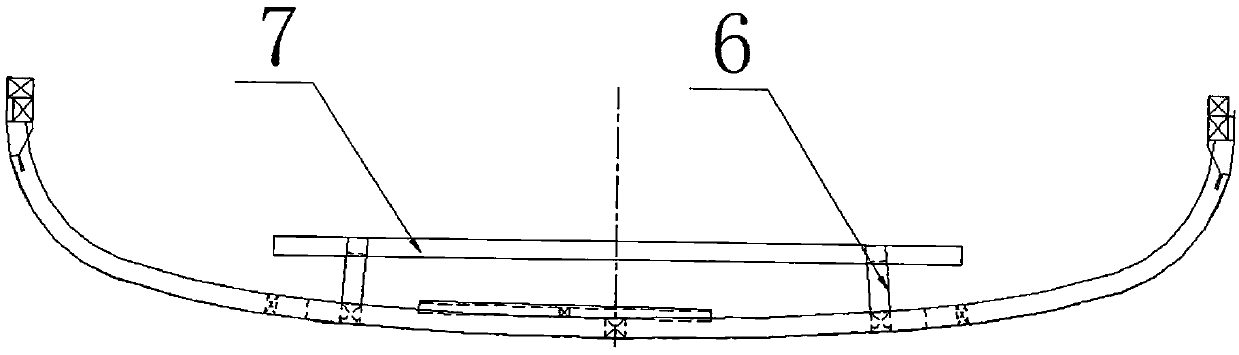

Bus front wall framework anti-collision structure

The invention relates to a bus front wall framework anti-collision structure. The bus front wall framework anti-collision structure comprises two uprights (1) which are placed on the left and on the right in parallel; two first bent arc cross beams (2) are arranged between the lower parts of the left and right uprights (1) in parallel in the up-and-down direction; a third bent arc cross beam (8) is arranged between the lower parts of the left and right uprights (1); the third bent arc cross beam (8) is opened backwards; a fourth bent arc cross beam (9) is arranged above the left and right uprights (1); the fourth bent arc cross beam (9) is is opened backwards; the left and right ends of the fourth bent arc cross beam (9) are correspondingly connected with the top ends of the left and rightuprights (1) through second diagonal bracings (10); and left and right bent arc uprights (11) are arranged between the third bent arc cross beam (8) and the fourth bent arc cross beam (9). Accordingto the bus front wall framework anti-collision structure, as an anti-collision structure is arranged between the upper parts of the left and right uprights, the bus front wall framework anti-collisionstructure can have an effect of protecting a bus body when the bus has front impact with a vehicle with a higher vehicle body, and therefore, the safety of the bus is greatly enhanced.

Owner:JIANGSU ALFA BUS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com