Gear case sealing structure of urban rail vehicle

A sealing structure, the technology of urban rail vehicles, which is applied to the sealing of engines, axle boxes, railway car body parts, etc., can solve the problem of high maintenance requirements of gearboxes, inconvenient maintenance and replacement of gearboxes, and inability to meet the service life of gearbox seals. requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

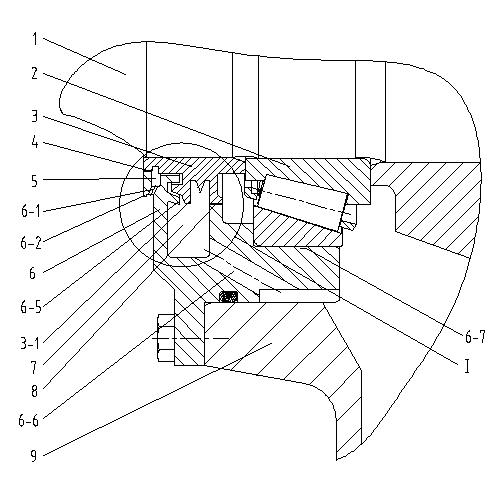

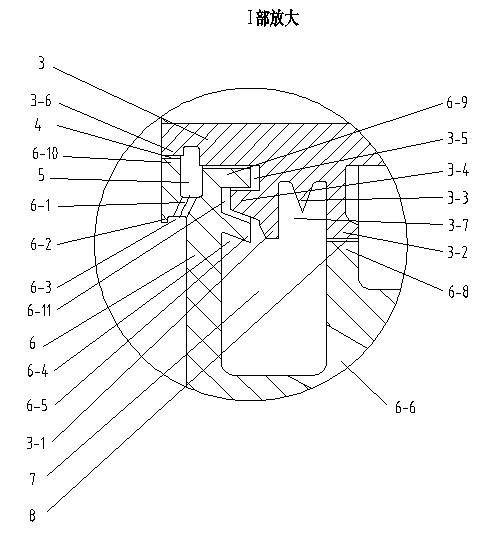

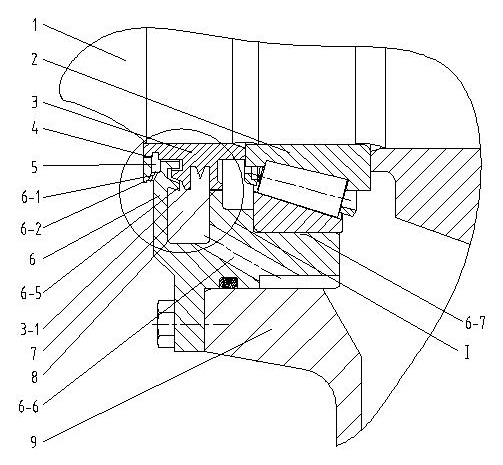

[0018] Such as figure 1 , 2 As shown, the urban rail vehicle gearbox sealing structure of the present invention includes a bearing seat 6 fixed on the casing 9 and a seal ring 3 fixed on the rotating shaft 1, and the bearing seat 6 has an outer ring of the bearing 2 Fitting hole 6-7, also has bearing housing first sealing flange 6-5, bearing housing second sealing flange 6-9, bearing housing third sealing flange 6-8 and bearing housing fourth sealing flange 6- 10. The first sealing groove 6-11 is formed between the first sealing flange 6-5 of the bearing seat and the second sealing flange 6-9 of the bearing seat; the sealing ring 3 has a first sealing ring flange 3-4 And the second flange 3-2 of the sealing ring, the third flange 3-6 of the sealing ring, the oil throwing flange 3-1 and the second sealing groove 3-5; the third sealing flange 6-8 of the bearing seat and The second flange 3-2 of the sealing ring corresponds to and forms the first radial gap seal 8; the fourth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com