Patents

Literature

448results about How to "Meet sealing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

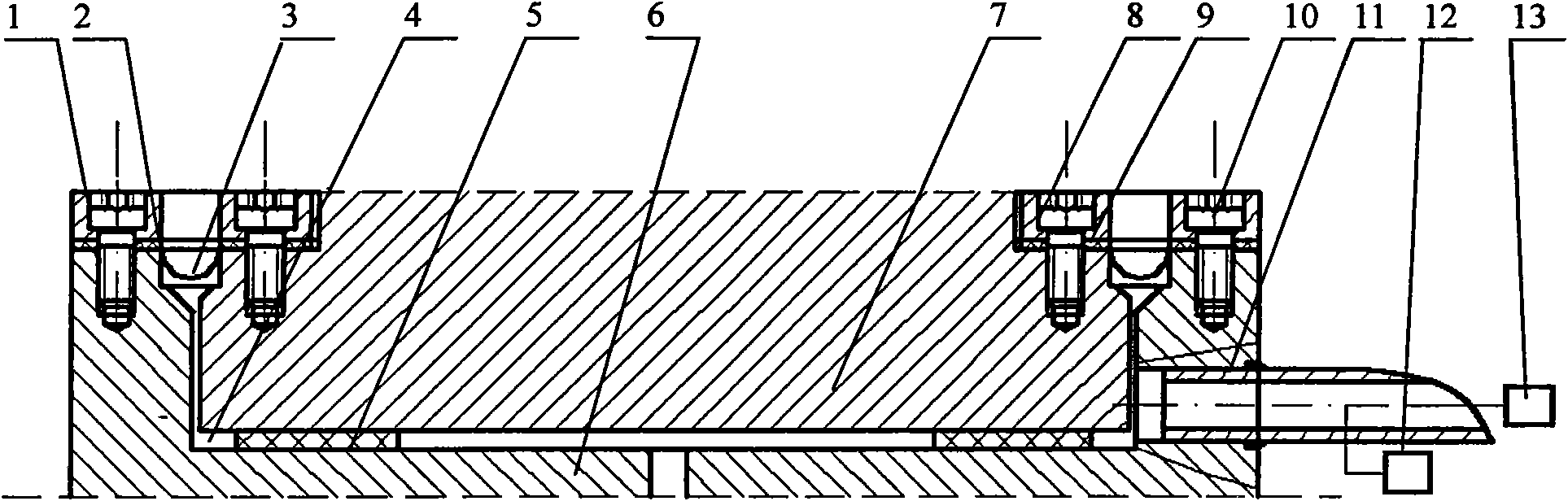

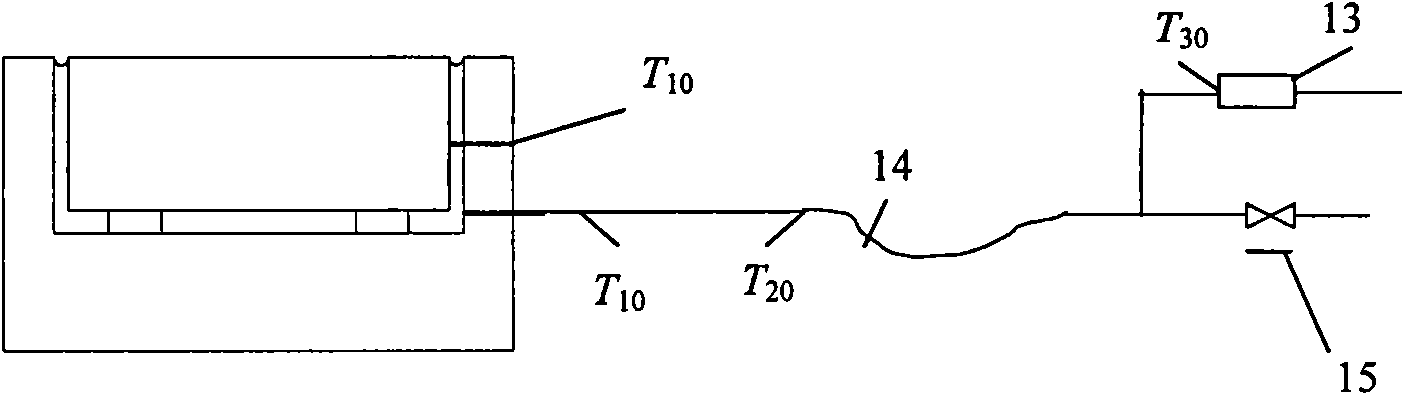

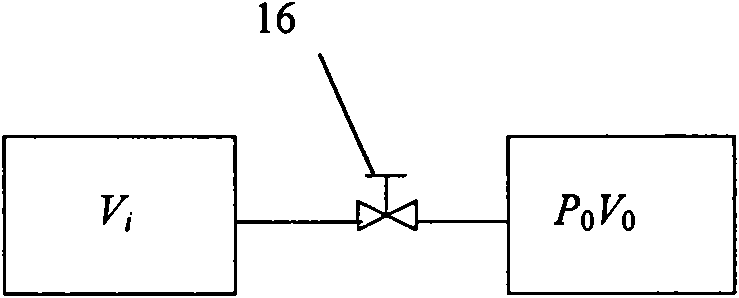

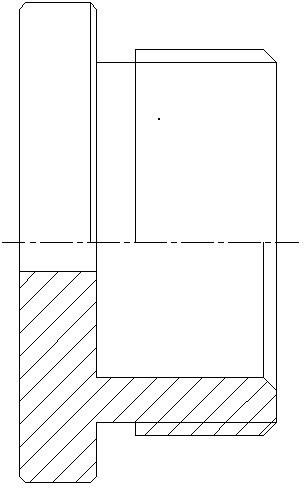

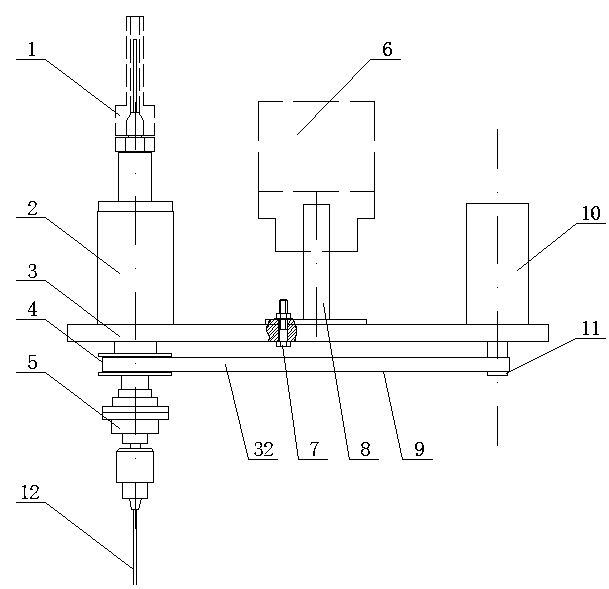

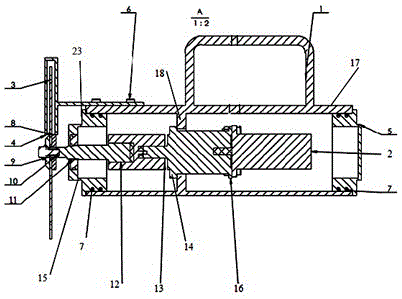

Testing method of leakage rate of high-temperature sealing gasket and testing device thereof

InactiveCN101666700AFix the leakAccurate measurementMeasurement of fluid loss/gain rateCavity pressureEngineering

The invention relates to a testing method of the leakage rate of a high-temperature sealing gasket and a testing device thereof, which establishes the corresponding testing method of the leakage rateof the high-temperature sealing gasket. The testing method and the testing device thereof perfect the testing method of the leakage rate of the high-temperature gasket, have reasonable structure, ensure the high precision in measuring the pressure of a leakage detecting cavity, and overcome the problem of large experimental error because the leakage detecting cavity is not tightly sealed, so the leakage rate test of the high-temperature gasket can be realized easily. The structure of the leakage detecting cavity is improved, and the testing method of the leakage rate of the high-temperature gasket by using a low-pressure region as the leakage detecting cavity is established. The invention plays a positive role in researching the sealing performance of the high-temperature gasket and promoting the progress of the sealing technique, and well meets the requirements of the high-speed development of the modern industry for gasket sealing.

Owner:NANJING UNIV OF TECH

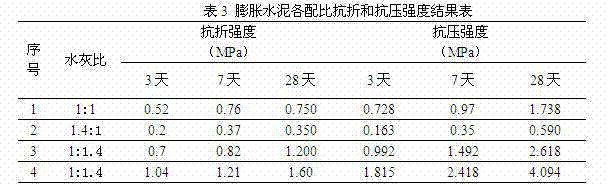

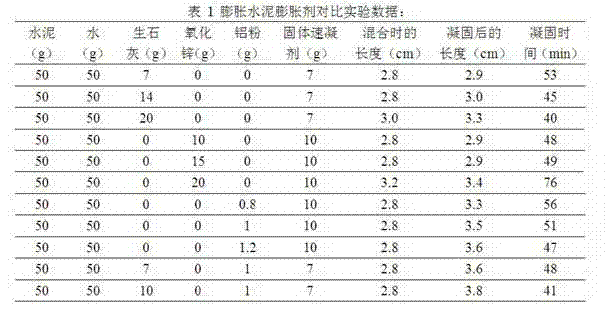

Hole sealing structure and hole sealing method as well as expansive cement for sealing hole

InactiveCN102733844AGuaranteed Extraction EffectShort setting timeGas removalSealing/packingSlurryEngineering

The invention discloses a hole sealing structure and a hole sealing method as well as expansive cement for sealing a hole. The hole sealing structure comprises a gas collecting pipe arranged in a drilled hole and a grouting pipe, wherein front and back end caps are respectively arranged on the periphery at the two end parts of the gas collecting pipe; each one of the front and back end caps comprises flexible textiles winding the outer periphery of the two end parts of the gas collecting pipe, and the expansive cement which is coated on the flexible textiles when being wetly dispersed, and then is matched with the outer wall of the gas collecting pipe and the inner wall of the drilled hole in a sealed manner after being expanded and cured; the grouting pipe is arranged on the front end cap in a penetrated manner; and the outlet of the grouting pipe is located between the front end cap and the back end cap. The front and back end caps are formed after the expansive cement coated at the two ends of a gas pumping pipe is expanded, and after the expansive cement is expanded, better expansive seal can be formed between the expansive cement and the hole wall of the drilled hole as well as between the expansive cement and the gas collecting pipe; slurry is poured into the drilled hole through the grouting pipe, and cracks on the periphery of the drilled hole can be better sealed to keep that a hole sealing cavity is at a pressure bearing state; and the condensing time of the expansive cement is shorter, the hole sealing cost is low, and high-pressure equipment does not need to be additionally purchased.

Owner:CHINA UNIV OF MINING & TECH

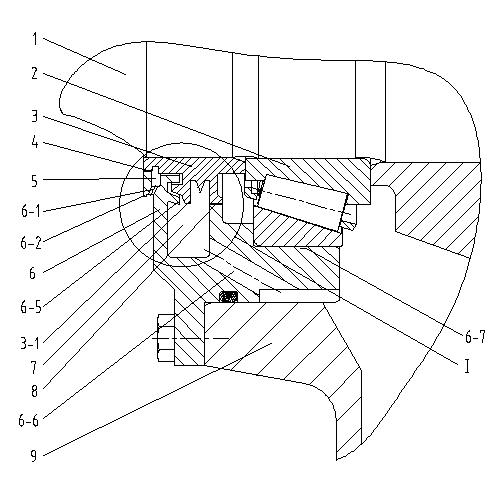

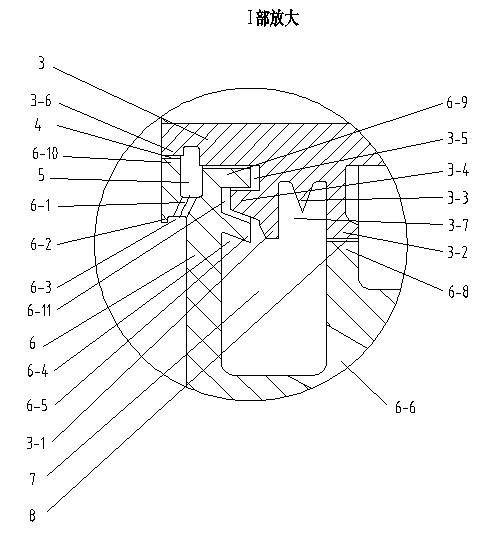

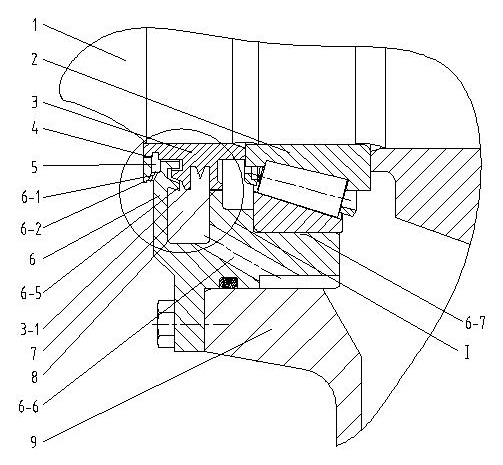

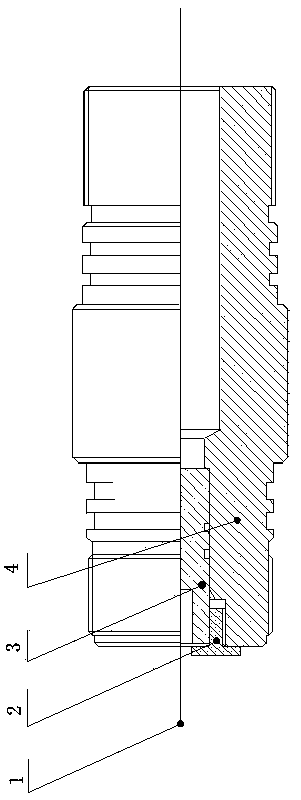

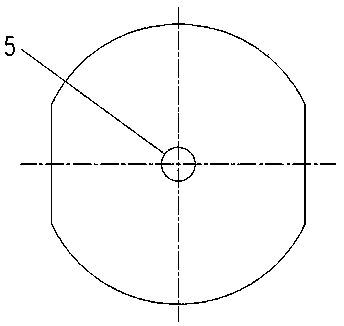

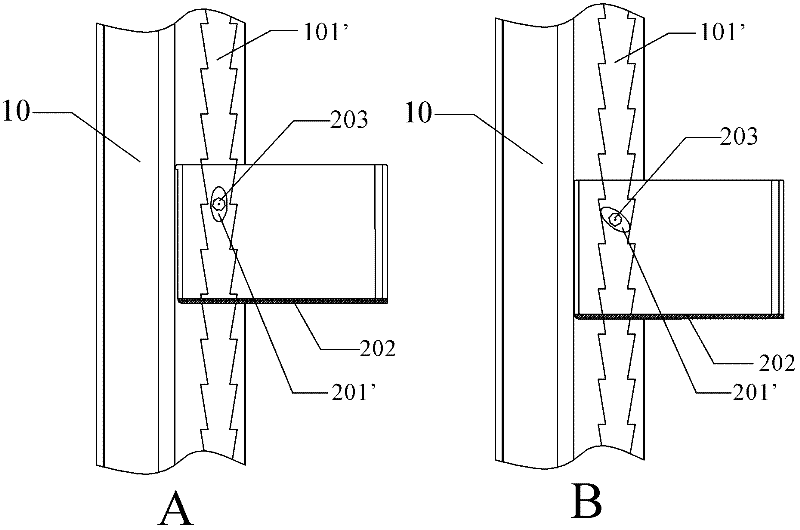

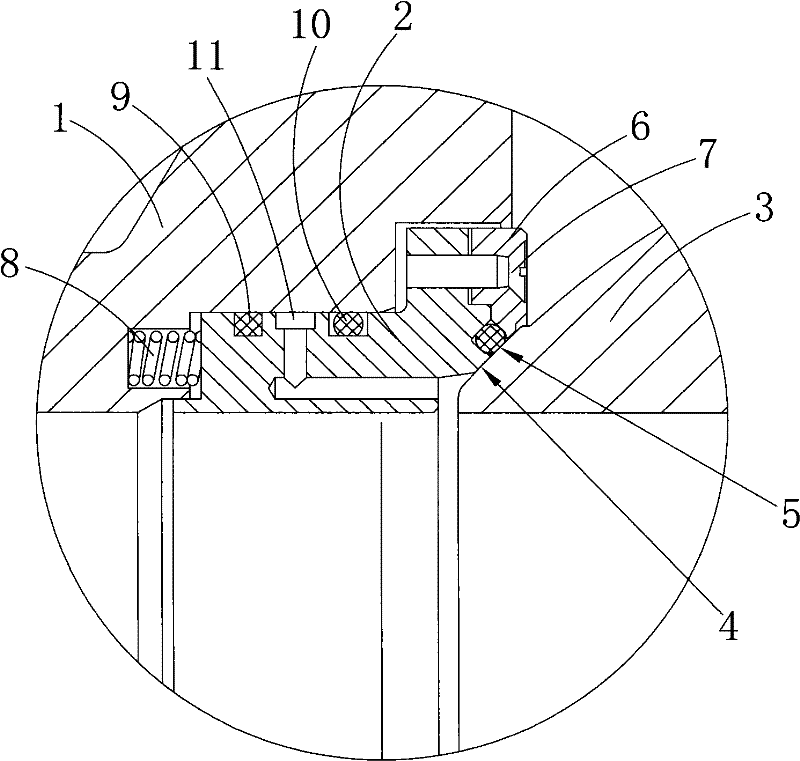

Gear case sealing structure of urban rail vehicle

ActiveCN102009663AReduce in quantityMeet the installation space requirementsEngine sealsAxle-boxesEngineeringFlange

The invention discloses a gear case sealing structure of an urban rail vehicle, comprising a bearing pedestal fixed to a case body and a sealing ring fixed on a rotation shaft, the bearing pedestal includes a matching hole for installing an outer ring of the bearing, and further includes a first sealing flange of the bearing pedestal, a second sealing flange of the bearing pedestal, a third sealing flange of the bearing pedestal and a fourth sealing flange of the bearing pedestal, the sealing ring includes a first flange of the sealing ring and a second flange of the sealing ring, a third flange of the sealing ring, a lubricating flange and a second sealing groove; the bearing pedestal and the sealing ring form a first radial clearance seal, a second radial clearance seal and a labyrinth seal; a first ring-shaped sealing chamber and a second ring-shaped sealing chamber are further formed between the bearing pedestal and the sealing ring, the bottom of the first ring-shaped sealing chamber is provided with an oil return hole, and the bottom of the second ring-shaped sealing chamber is provided with a through hole. The invention is simple in structure, reliable in sealing, and convenient in detaching and maintaining.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Fluorine rubber seal element and preparing method thereof

ActiveCN101168656AExtended service lifeGood process performanceOther chemical processesCarbon blackCalcium hydroxide

The invention provides a fluorinated rubber sealing element; the invention is characterized in that the sealing element is produced by the raw material with the following quality parts: binary fluorinated elastomer of 60 to 80 parts, tetrafluoroethlene propylene rubber of 20 to 40 parts, carbon black of 20 to 40 parts, calcium hydroxide of 3 to 5 parts, metal oxide of 3 to 6 parts, hexafluoride sonitroso propyl diphenol of 1.5 to 2 parts, benzyl triphenyl phosphorus chloride of 0.3 to 0.5 part, processing aid of 0.5 to 2 part, dicumyl peroxide of 0.5 to 1.2 parts, and triene propyl isocyan urate of 0.5 to 1.2 parts. The invention has the preparation method that sulphation for 8 to 12 minutes is molded on a compression machine under 165 to 180 DEG C through being extruded and formed after the raw material with the quality parts are added in mixing equipment to be mixed uniformly under 60 to 80 DEG C, and then the sealing element is produced after performing secondary cure for 8 to 24 hours in hot air of 200 to 250 DEG C. The fluorinated rubber sealing element produced has long service life and can be high temperature water vapor resistant and high and low impact resistant.

Owner:广州国机智能橡塑密封科技有限公司

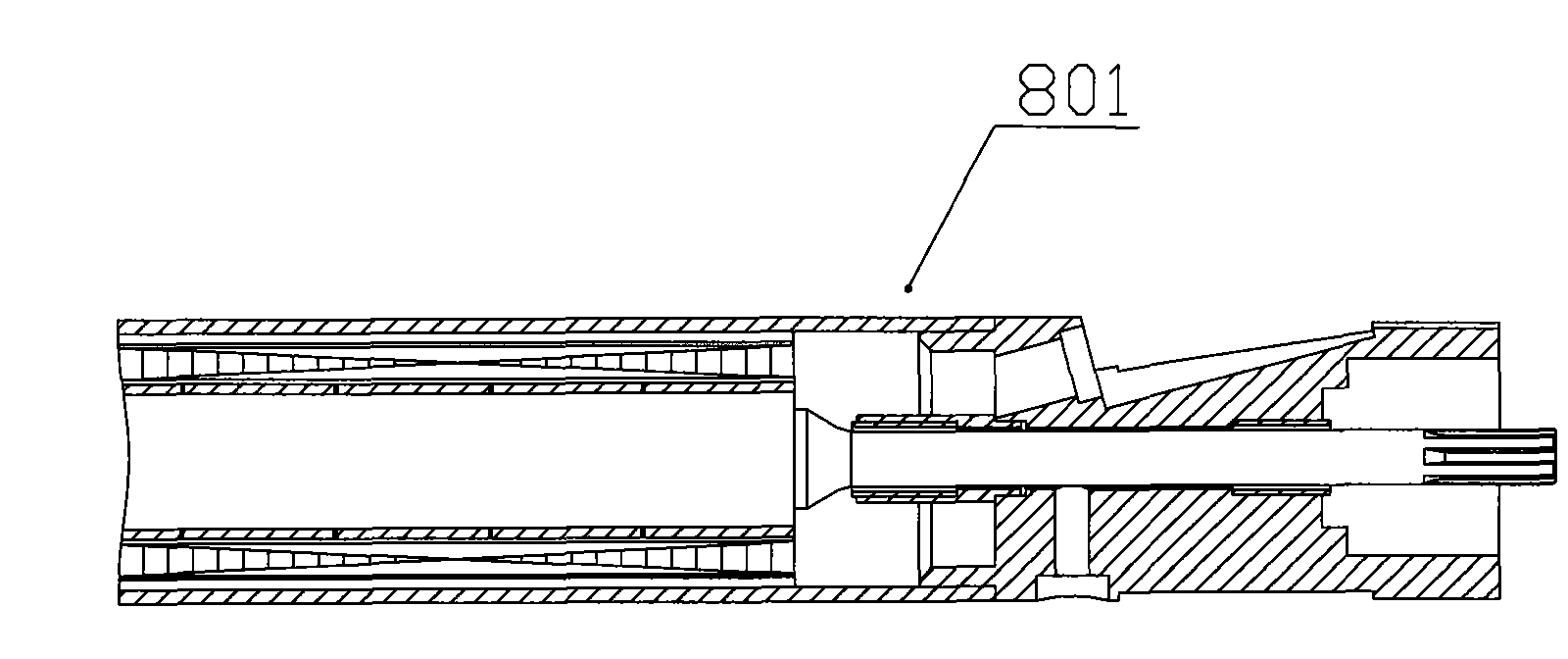

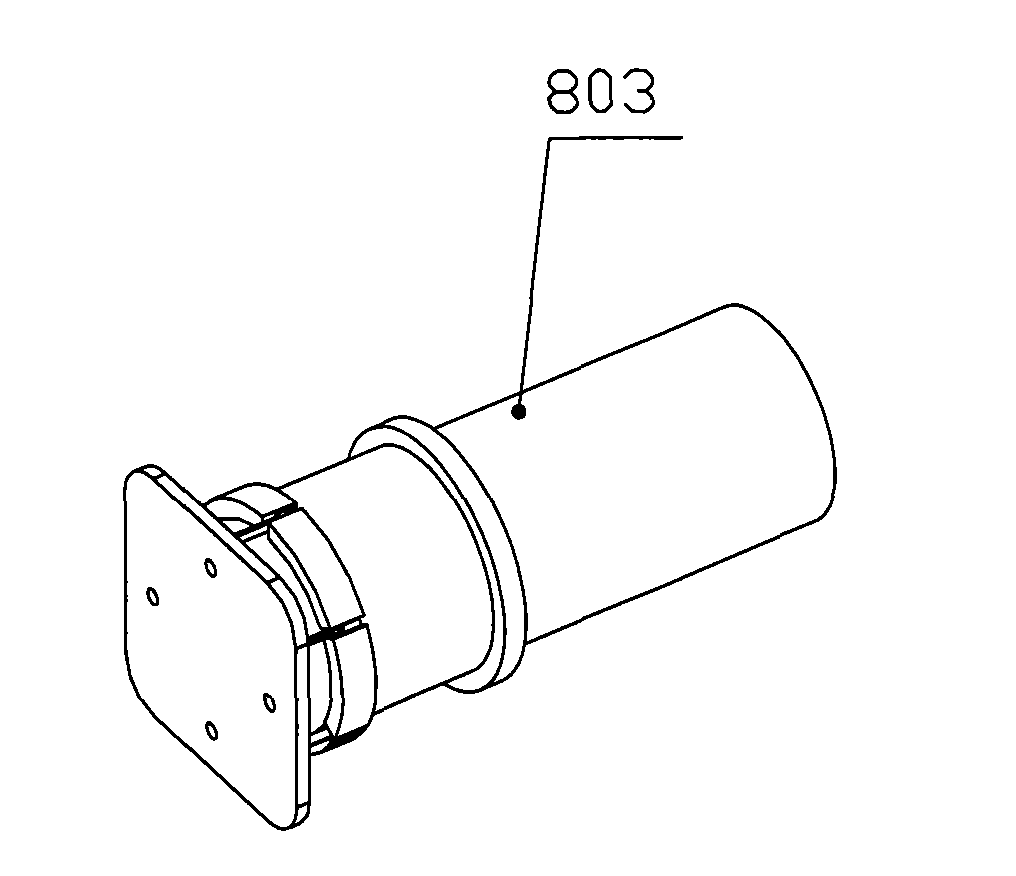

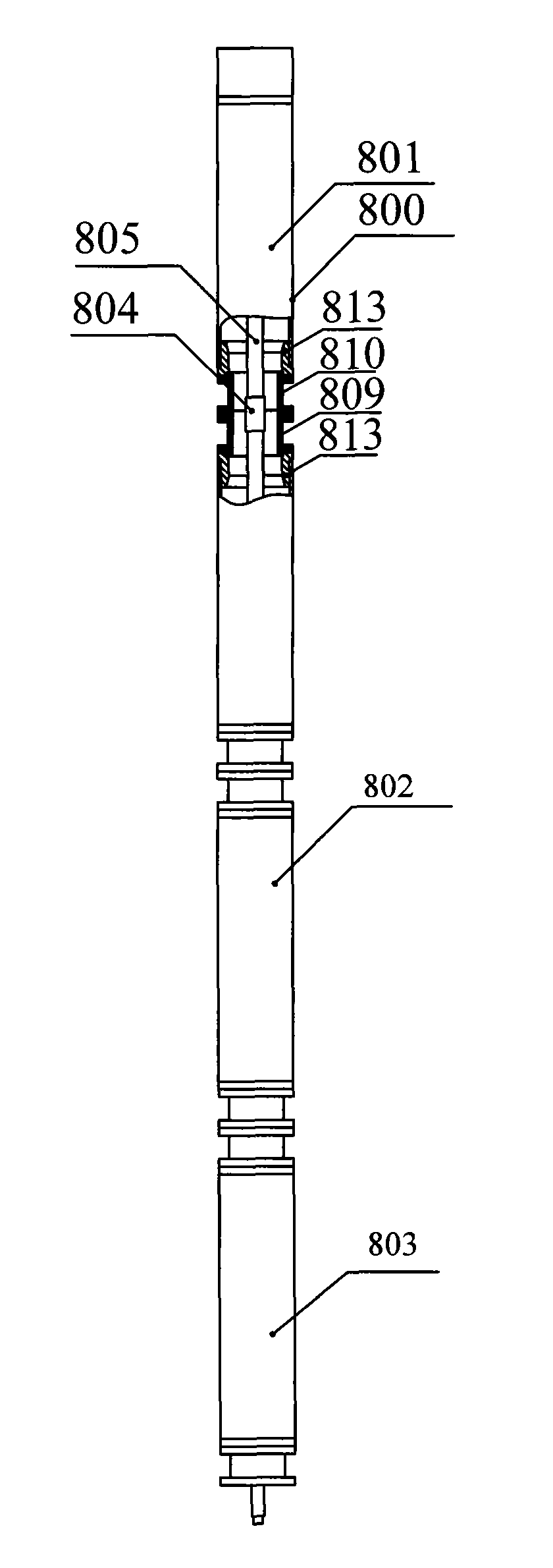

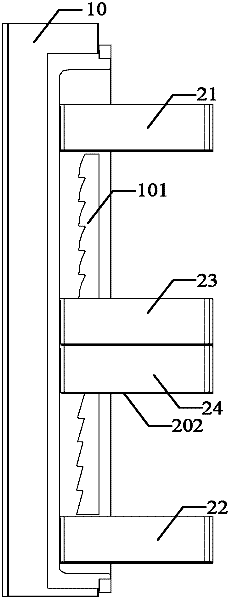

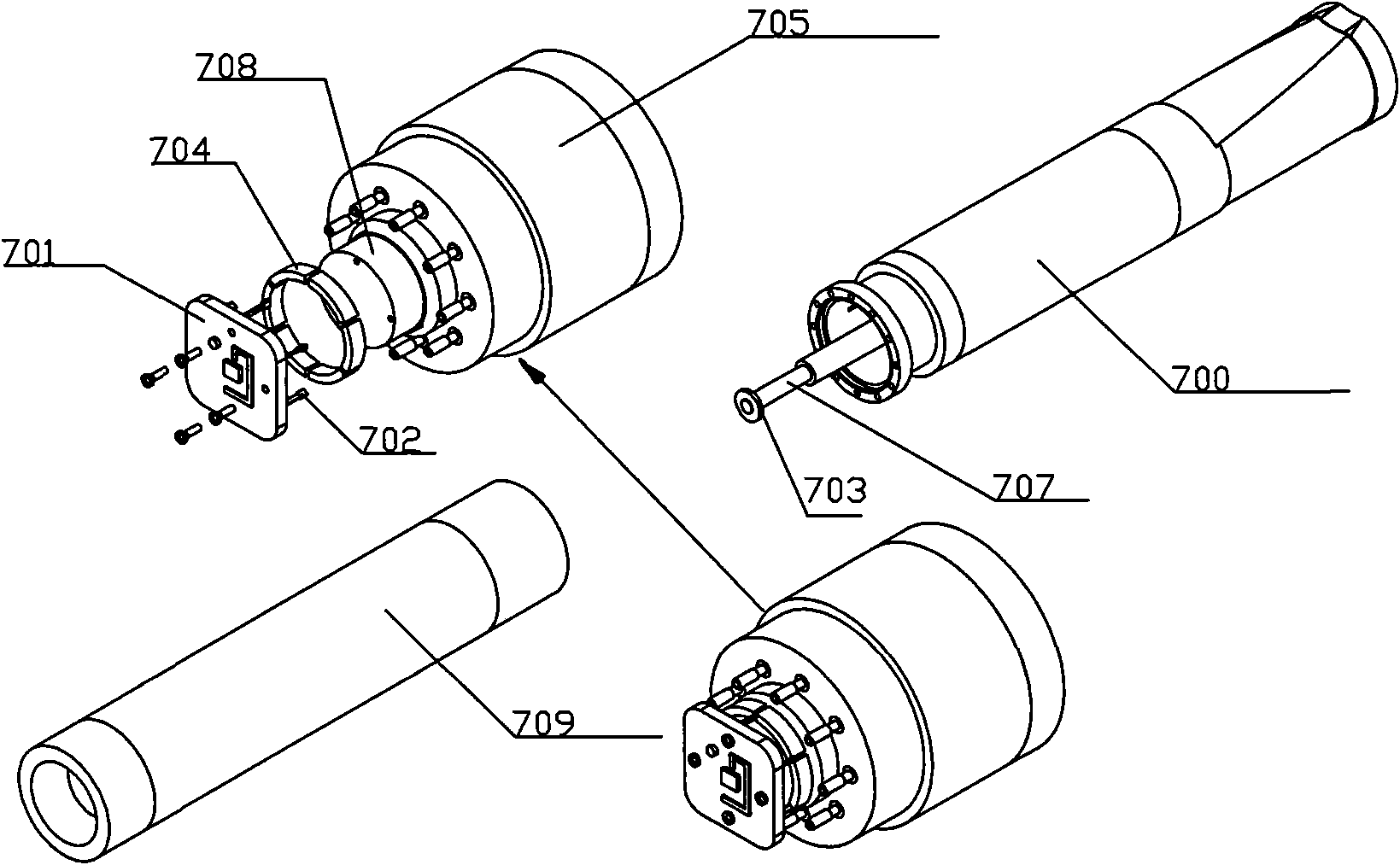

Multi-section servo submersible motor

InactiveCN101877521ASimple installation structureEasy to operateStructural associationConverting sensor outputCouplingControl theory

The invention relates to a multi-section servo submersible motor which mainly comprises a motor body, wherein a motor housing at the head of the motor body is connected with a head flange, the head of a motor shaft convexly extends out of the head flange, the motor shaft is fixed in the head flange and is connected with other devices through the head flange, the motor body internally comprises multiple sections of motors, the motor housing of each section of motor internally mainly comprises a stator and a rotor, the rotor is a permanent magnet, a winding is arranged in a stator iron core, rotor shafts of two adjacent sections of motors are connected through a coupler; the motor housings of two adjacent sections of motors are connected through a connecting device; N poles of the rotors arranged on two adjacent sections of motors correspond in a straight line and S poles correspond in a straight line; and U, V and W phase windings of the rotors respectively correspond in a straight line. The servo submersible motor has simple installation structure, easy operation and capability of providing higher power.

Owner:杭州坤泽采油设备有限公司

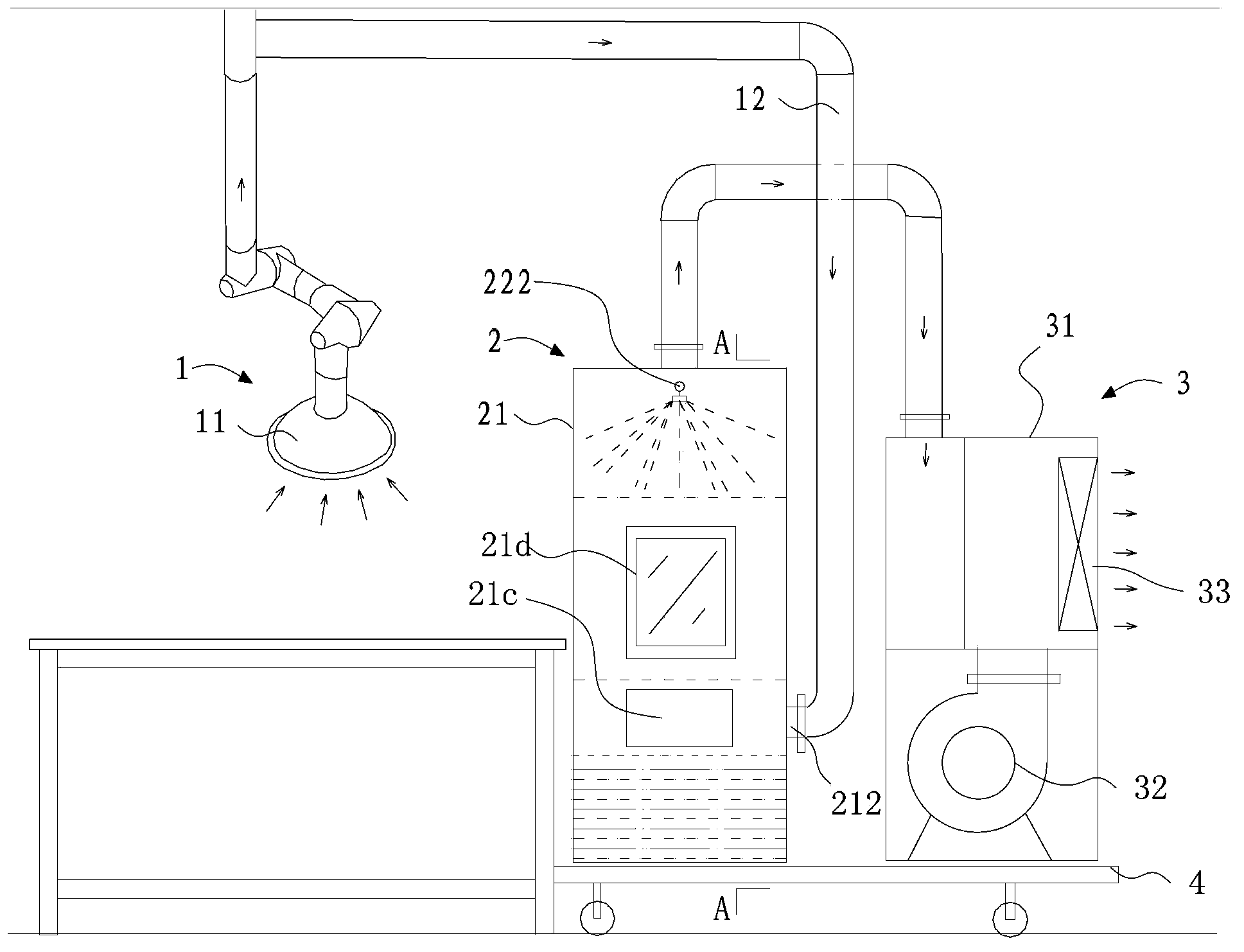

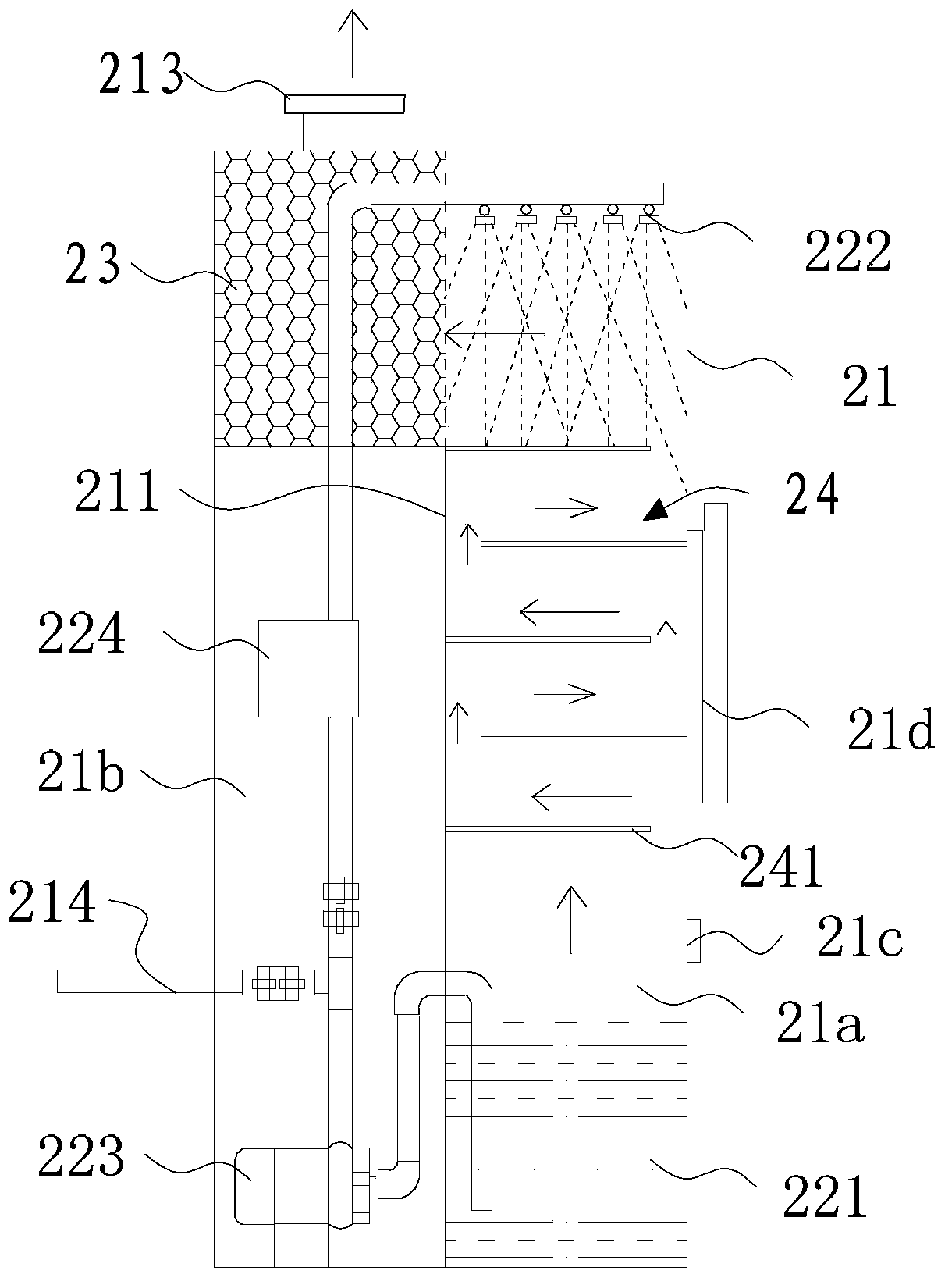

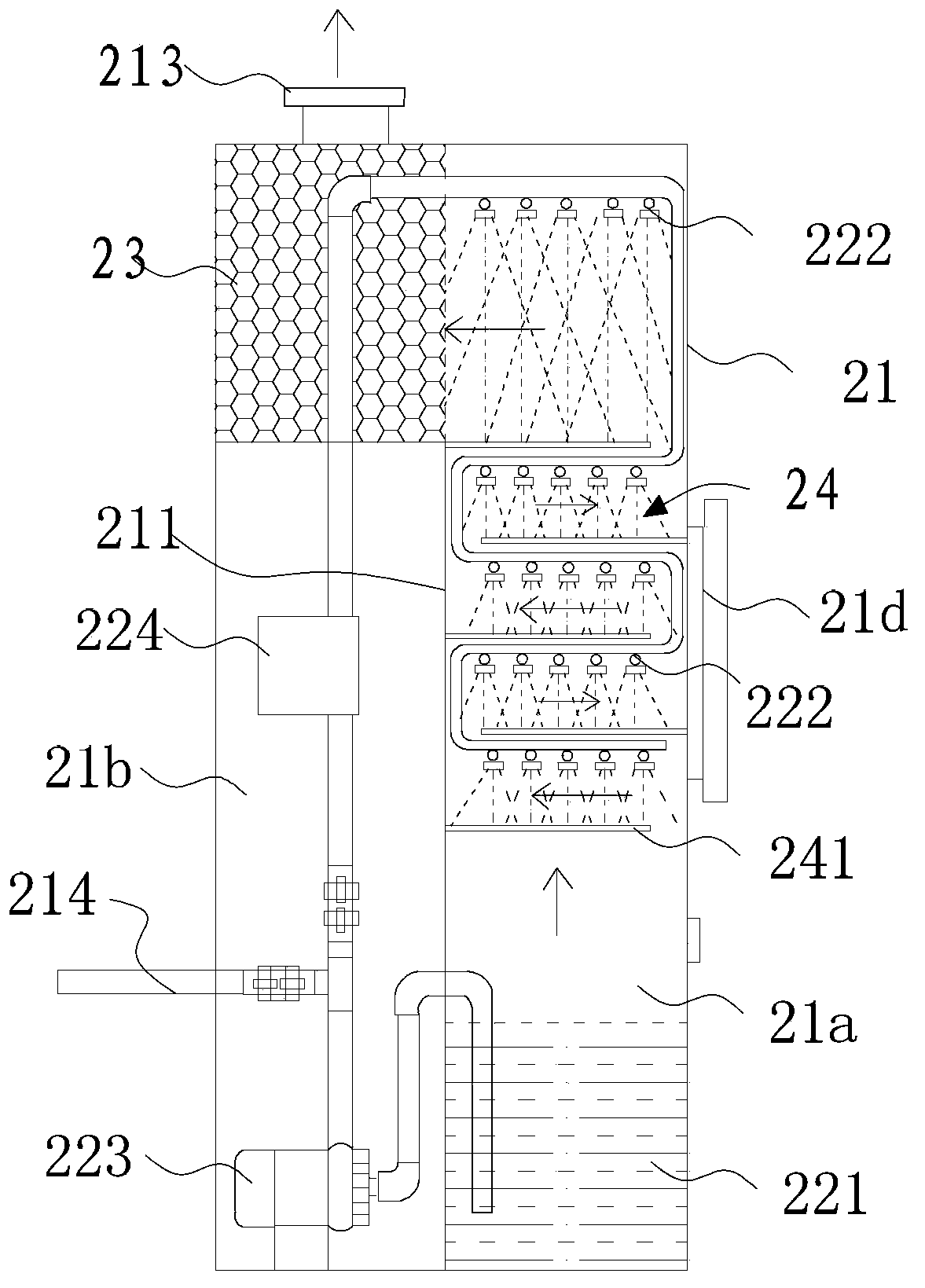

Waste gas and dust treating device

InactiveCN103505969ASimple structureMeet cleanliness requirementsUsing liquid separation agentAfter treatmentEmission standard

The invention provides a waste gas and dust treating device. The waste gas and dust treating device comprises a gas collecting device, a purification treatment device and a discharging device, wherein the gas collecting device is used for collecting waste gas and dust; the purification treatment device for purifying waste gas and dust collected by the gas collecting device is communicated with the gas collecting device and comprises a spraying device for spraying a washing liquid for washing the waste gas and the dust collected by a dust collecting device and a defogging device for dewatering and defogging gas which is obtained after the washing liquid sprayed by the spraying device is treated; the discharging device is used for discharging the gas treated by the purification treatment device and is communicated with the purification treatment device. The waste gas and dust treating device is simple in structure, and capable of effectively treating waste gas and dust and enabling the waste gas and the dust to achieve emission standards, thereby reducing pollution to workshop environment as well as harms to human bodies; the gas discharged after treatment of the waste gas and dust treating device can meet the cleaness requirement of the workshop environment and can be directly discharged into the workshop environment, so that both the cleaness requirement and the sealing requirement of the workshop environment are met.

Owner:BEIJING SKYWING TECH CO LTD

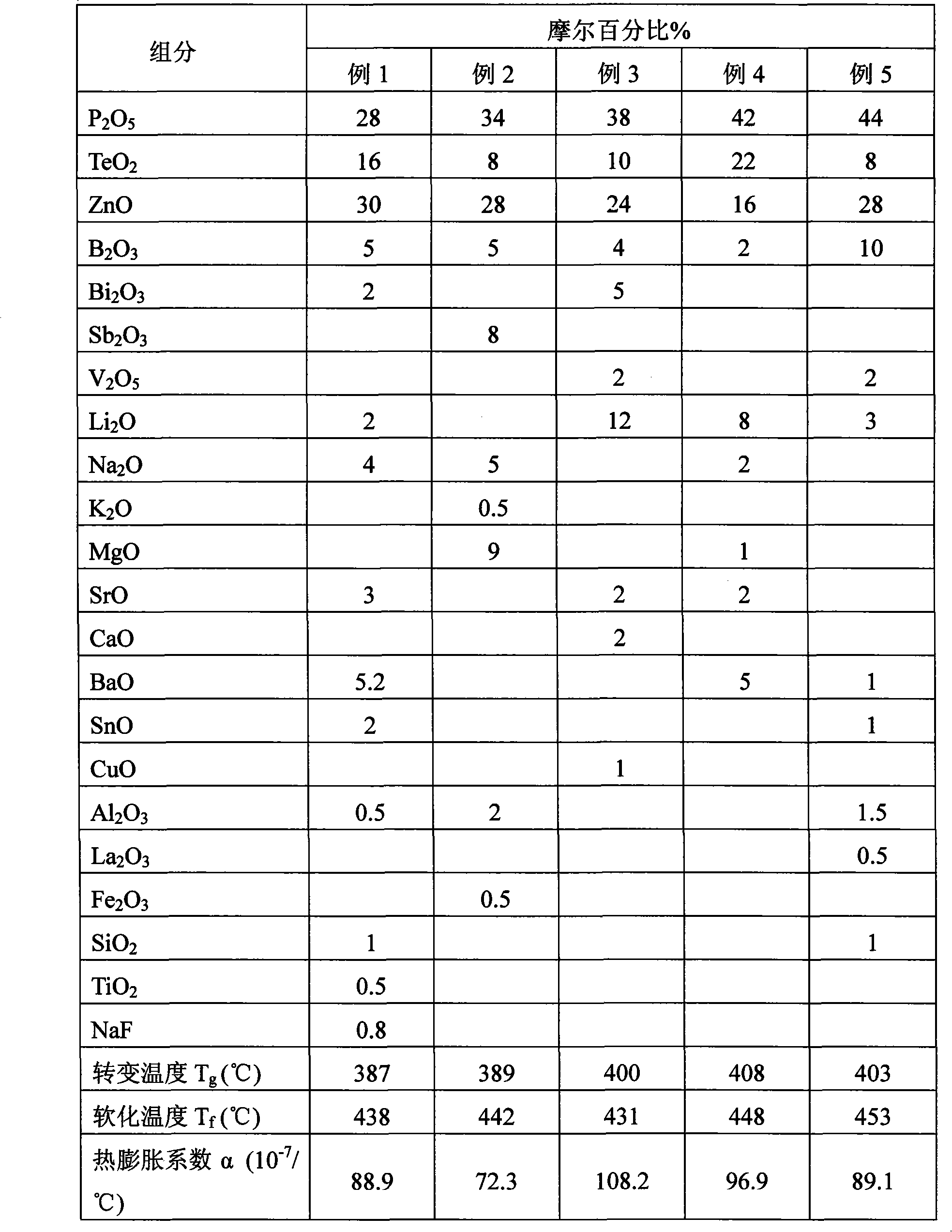

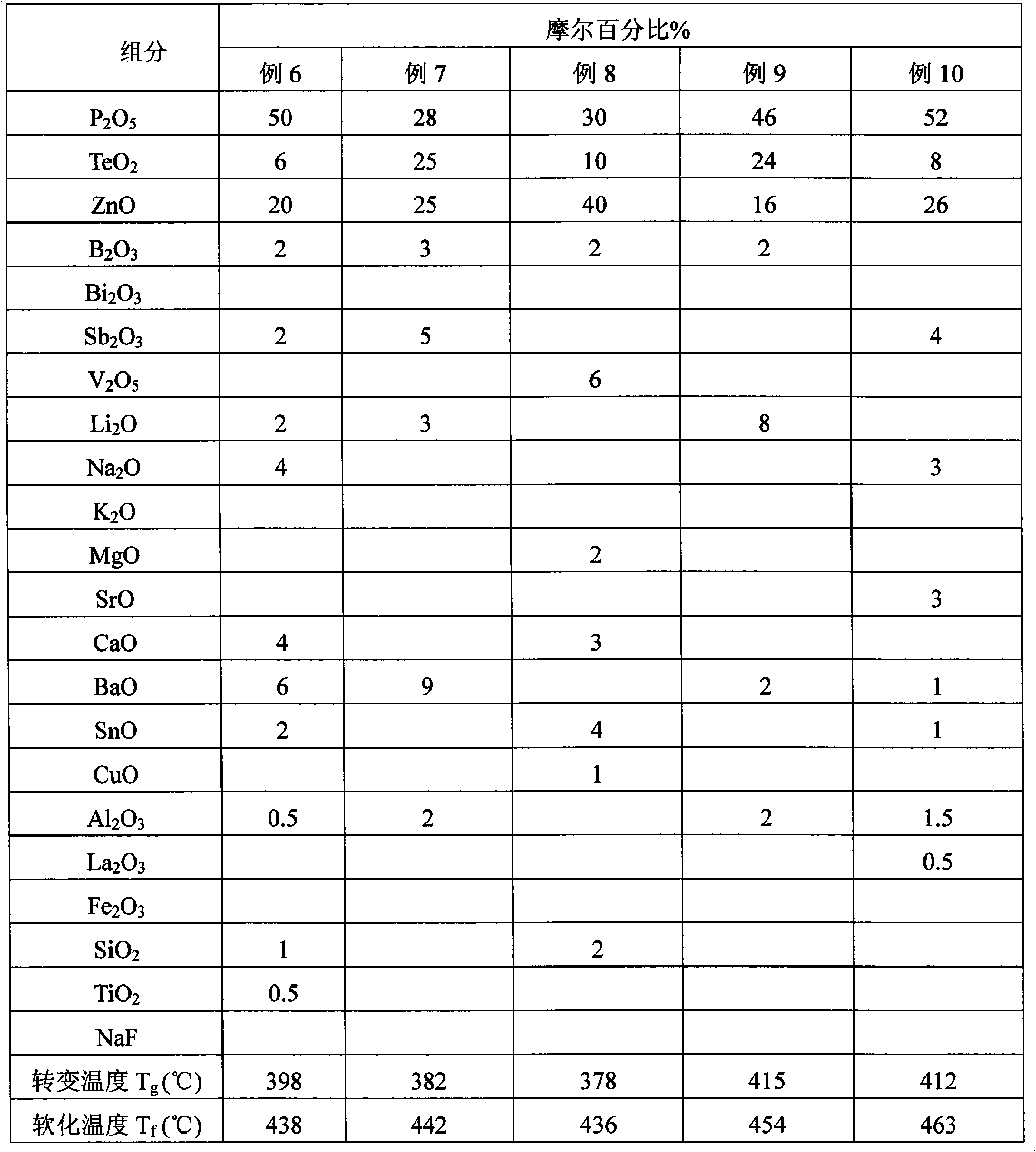

Lead-free low-melting sealing glass and preparation method thereof

InactiveCN101597136AScientific and reasonable componentsThe ratio is scientific and reasonableThermal expansionOperability

The invention discloses lead-free low-melting sealing glass and a preparation method thereof. The glass comprises the following raw materials in percentage by mol: 20 to 55 percent of P2O5, 5 to 30 percent of TeO2, 0 to 55 percent of ZnO and additives with the content not more than 30 percent of that of total compositions of the glass. The lead-free low-melting sealing glass has the advantages that the compositions and composition proportioning of the glass are scientific and reasonable, and the compositions do not contain lead which pollutes the environment or poisons human body; meanwhile, the glass is environment-friendly and low toxic and has wide softening temperature and thermal expansion coefficient ranges; therefore, the glass can be used in low-temperature packaging among different electronic components. Moreover, the simple and reasonable preparation method has strong operability and high qualified rate of finished products and is suitable for continuous large-scale industrialized production.

Owner:苏州恒仓红外光学材料研发中心有限责任公司

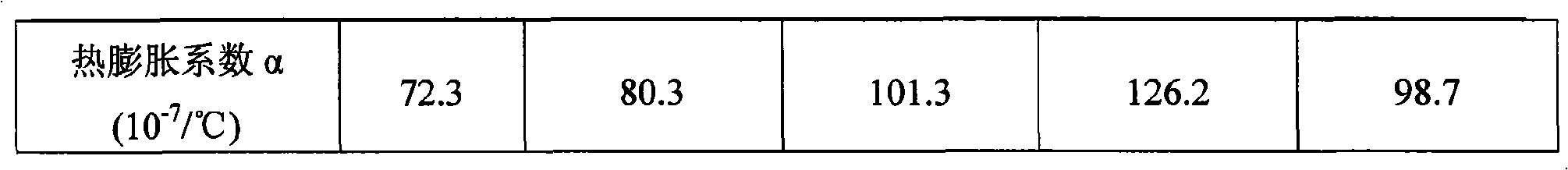

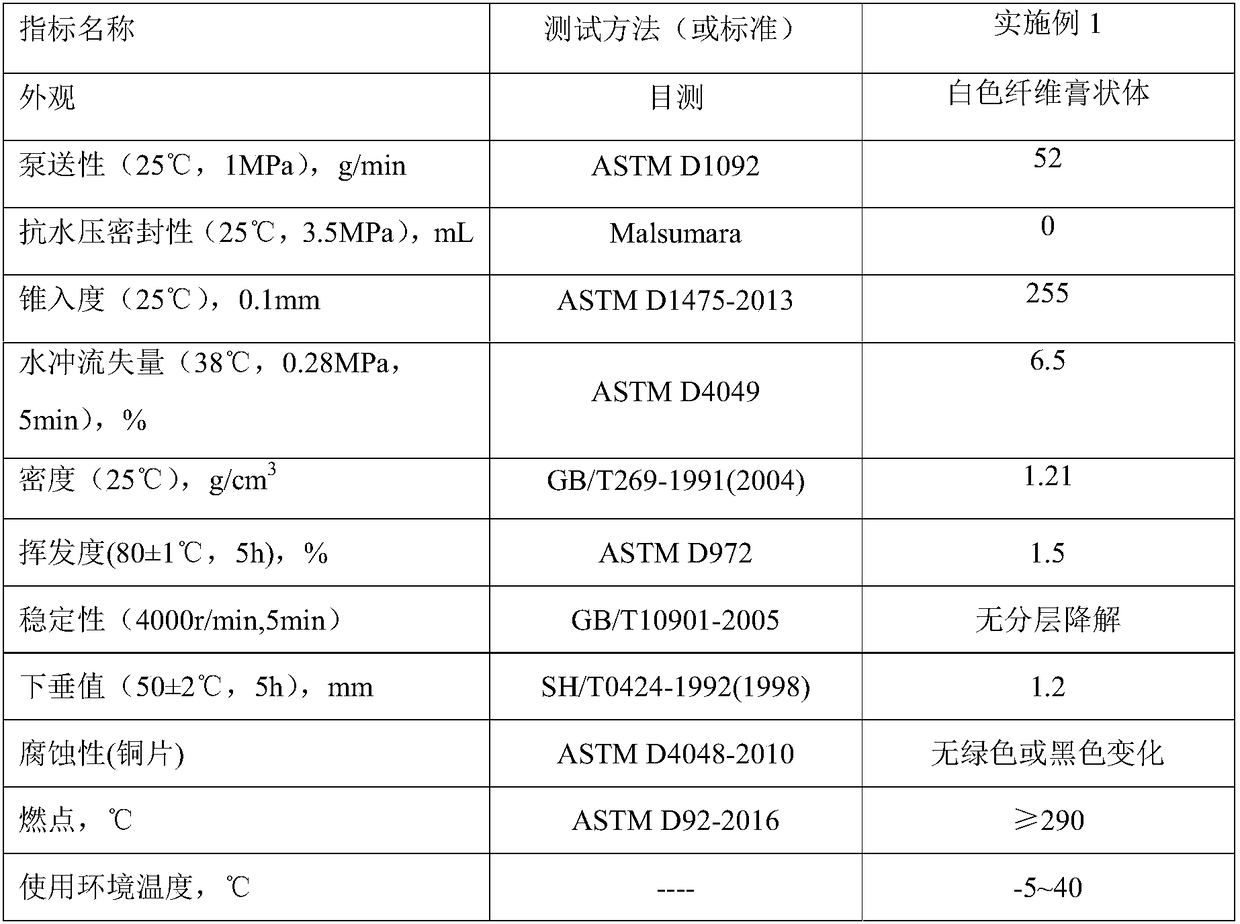

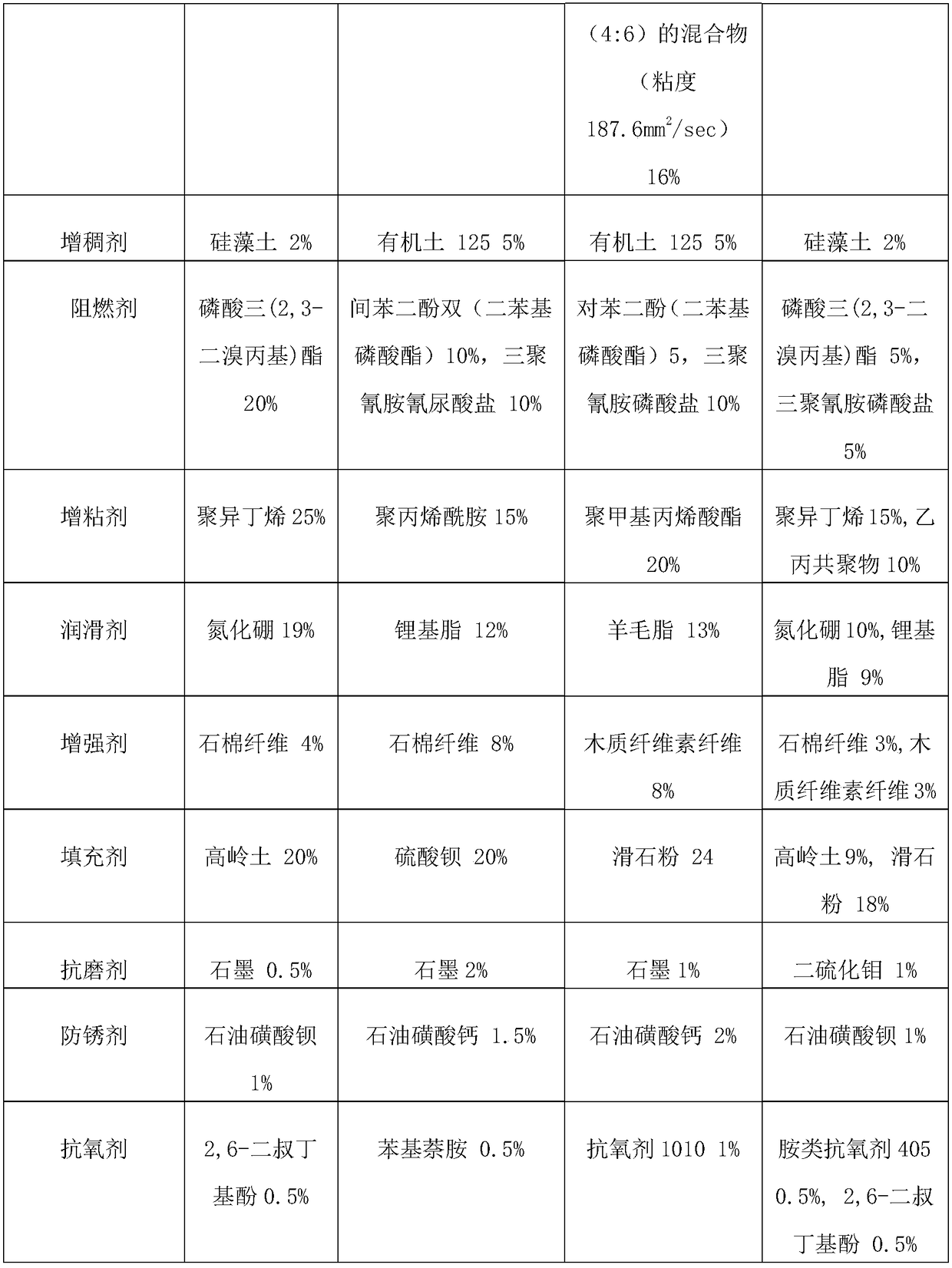

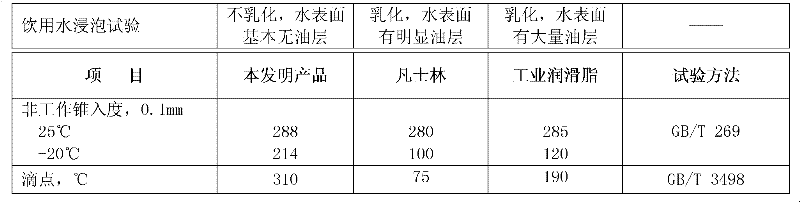

Special main bearing sealing grease for shield tunneling machine as well as preparation method and application thereof

InactiveCN108641794AGood sealing against water pressureEnhanced pumpabilityLubricant compositionAntioxidantEngineering

The invention discloses special main bearing sealing grease for a shield tunneling machine. According to the formula, the special main bearing sealing grease is prepared from the ingredients, in percentage by weight: 8-16% of base oil, 2-5% of thickener, 10-20% of fire retardant, 15-25% of tackifier, 12-20% of lubricating agent, 4-8% of reinforcing agent, 20-30% of filler, 0.5-3% of antiwear agent, 1-3% of antirust agent and 0.5-1% of antioxidant. The invention further provides a preparation method of the special main bearing sealing grease for the shield tunneling machine. The special main bearing sealing grease for the shield tunneling machine can resist the water pressure as high as 3.5MPa at the temperature of 25 DEG C in a lab, and has good water pressure resistance and airtightness.The pumping property of the special main bearing sealing grease is 30-60g / min at the temperature of -5-40 DEG C and under the pressure of 1MPa, the pumping property is excellent and not affected by the environmental temperature, and thus the construction problems that the pumping property in winter is poor, and pipes are blocked and the like. In addition, the product has the outstanding fire resistance, abrasive resistance and demulsibility.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP +1

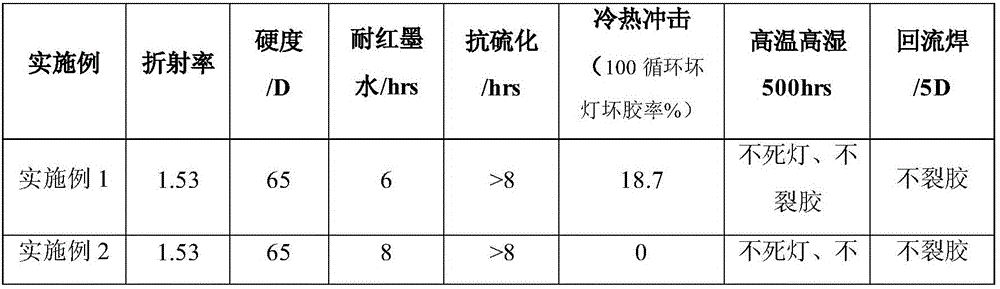

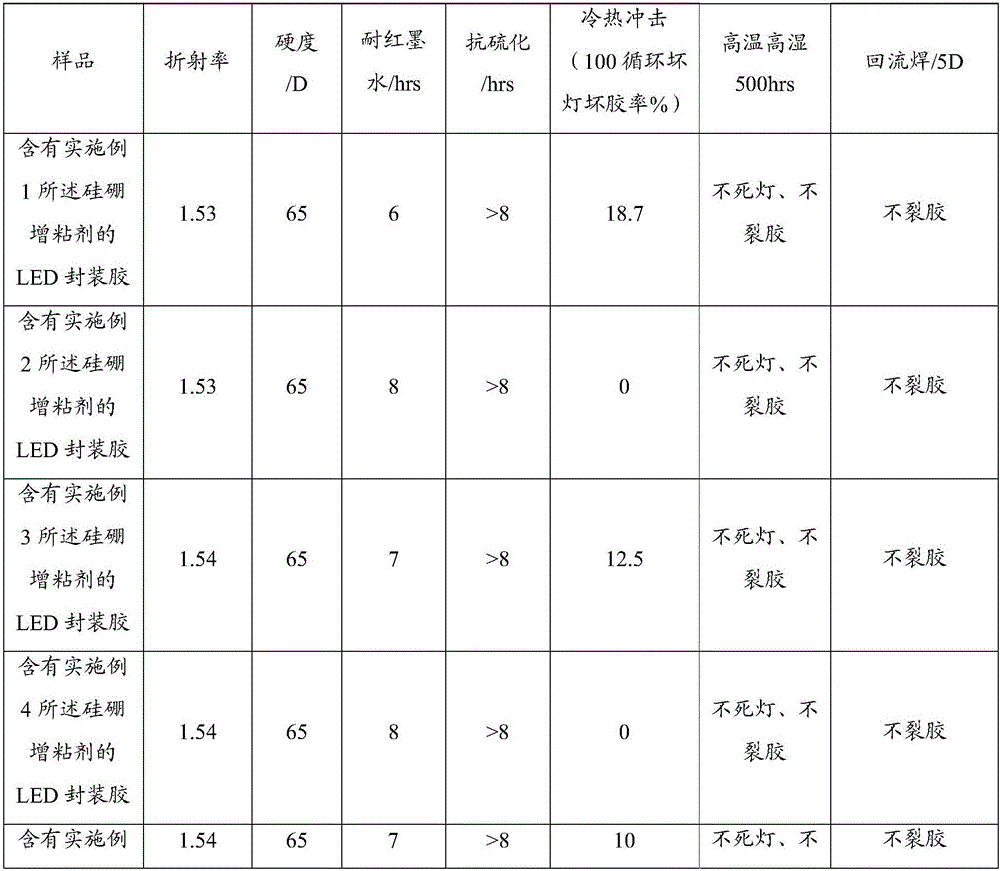

Silicon boron tackifier, preparation method thereof and application thereof in double-component LED packaging gel

ActiveCN105802532AImprove adhesionHigh refractive indexMacromolecular adhesive additivesPrepolymerChemistry

The invention belongs to the field of organosilicon materials and discloses a silicon boron tackifier, a preparation method thereof and application thereof in double-component LED packaging gel. The preparation method includes: subjecting unsaturated monomer with epoxy group and polysiloxane with hydrogen group to hydrosilylation to obtain epoxy modified polysiloxane; subjecting silane monomers R1Me2SiOR, PhR2Si(OR)2, R4Si(OR)3 and Si(OR)4 to hydrolytic condensation under an acidic condition to obtain a phenyl polysiloxane prepolymer; mixing the epoxy modified polysiloxane with the phenyl polysiloxane prepolymer, adding borate, and allowing reaction under action of alkaline catalysis to obtain the silicon boron tackifier. The silicon boron tackifier can be directly added into an LED packaging silica gel system, adhesion between the LED packaging silica gel and lamp beads is improved, requirements on sealing the lamp beads are met, and the silicon boron tackifier has high refractive rate and good yellowing resistance.

Owner:清远市美佳乐环保新材股份有限公司

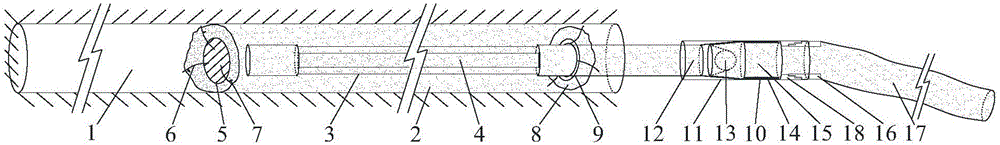

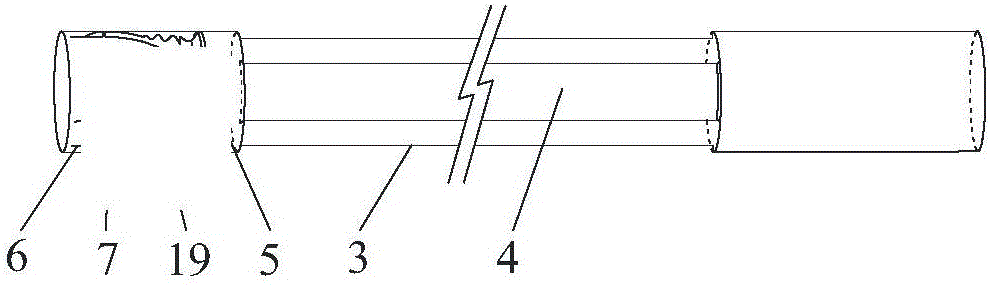

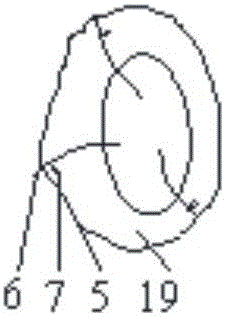

Intermediate connector device for multistage ignition perforating

InactiveCN103485750ARealize transmissionTroubleshoot isolated technical issuesFluid removalMaterial PerforationElectrical and Electronics engineering

The invention discloses an intermediate connector device for multistage ignition perforating. The intermediate connector device comprises an interstage isolator and a side junction device connected with the same. The interstage isolator comprises an intermediate connector, an isolating spindle and a gland. One end of the intermediate connector is used for being connected to an upper-stage perforating gun, and the other end of the intermediate connector is used for being connected to the side junction device. The intermediate connector is provided with a through stepped hole. The isolating spindle is disposed inside the stepped hole. The intermediate connector is provided with an inner threaded hole fitting the gland. The gland and the inner threaded hole fit so that the isolating spindle is pressed to a step of the stepped hole. The intermediate connector device has the advantages that signals of detection, ignition and the like can be transmitted among the multiple stages of ignition perforation; after the previous stage of ignition and initiating perforation, subsequent tools and devices to be used for ignition perforation are isolated and sealed; the problem that the common perforating gun connector is unable to meet the junction requirements is overcome, and the sealing requirements of descent strings can be met.

Owner:WELL LOGGING OF CNPC CHUANQING DRILLING ENG

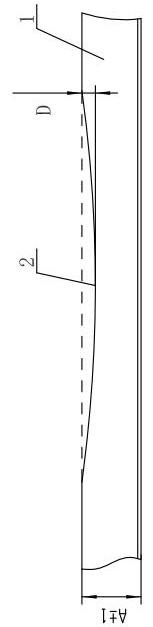

Mounting mechanism for bottle seat of refrigerator

ActiveCN102313433AEasy to adjust up and down positionMeet sealing requirementsLighting and heating apparatusSupportEngineeringBottle

The invention discloses a mounting mechanism for a bottle seat of a refrigerator, which comprises a groove sliding rail for supporting and a boss, wherein the groove sliding rail is arranged on the side wall of a lining of a door body of the refrigerator; the boss is arranged on the side surface of the bottle seat; the boss is embedded in the groove sliding rail; and the boss can move vertically along the groove sliding rail. Therefore, the convenient regulation of the upper position and the lower position of the bottle seat can be achieved, and the sealing requirements between bottle seats also can be met.

Owner:HAIER GRP CORP +1

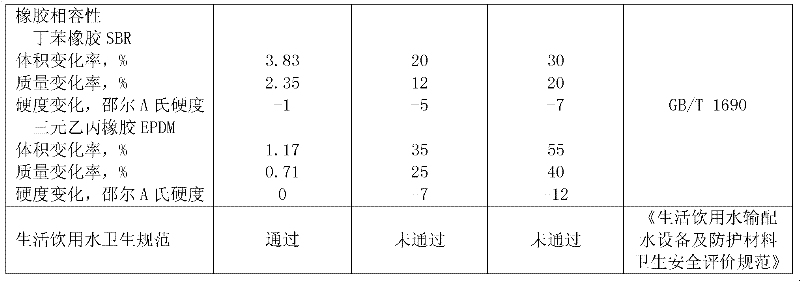

Food grade lubricating grease and its preparation method and application

ActiveCN102268320AComply with water quality sanitation and safety requirementsSealedLubricant compositionFood gradeBase oil

The invention relates to food-grade lubricating grease as well as a preparation method and application thereof. The food-grade lubricating grease comprises the following components by weight percent: 70-80% of base oil, 6-15% of thickening agent and 10-20% of antiwear agent. The preparation method comprises the following steps: adding fatty acid, aromatic acid and organic aluminum into the base oil in a proportion, mixing and heating to 60-100 DEG C, and carrying out a recombination reaction for 1-2 hours; further heating the combined material to 100-140 DEG C, adding tap water with a certain proportion and then maintaining the constant temperature for 1-2 hours, wherein water equivalent is 1-3 times that of organic aluminum; further heating the combined material to 150-180 DEG C and the nmaintaining the constant temperature for 0.5-1 hour; then adding quenching oil and evenly mixing, wherein the amount of quenching oil is about 30%-40% of that of base oil; and further cooling the material to the temperature below 140 DGE C, and adding the antiwear agent and then evenly mixing, so as to obtain the required product. In the invention, a one-step method is adopted for direct recombination reaction, thus process is simple, energy consumption is reduced, production cost is reduced, and the quality of the product produced by the process is relatively stable.

Owner:CHINA PETROLEUM & CHEM CORP

Expanded delay mining hole sealing material

The invention relates to an expanded delay mining hole sealing material which is prepared after modification of an expanding agent by microcapsules. The hole sealing material is prepared by aluminum powder microcapsules, water, cement, polycarboxylate superplasticizer, water-borne epoxy resins E-51 and T31 curing agents according to certain mass percentage. The aluminum powder microcapsules are prepared by water, gelatin, sodium alginate and aluminum powder in a mass ratio of 100: 2: 2: (4-6) (wt). According to the expanded delay mining hole sealing material, ineffective expansion of earlier stage of the cement is delayed so that the cement can reach certain strength and then is expanded, and coordinating growth of material strength and expansion can be guaranteed. Final expansion rate reaches 15%-25%, one-day compressive strength is 3.2Mpa, three-day strength is 20.8Mpa, seven-day strength is 45.8Mpa, and requirements of mine gas extraction drilling sealing and strength can be met. The hole sealing material and the microcapsules can be prepared and used on site in the environment of high temperature and high humidity of a mine, toxicity is absent, and the price is low.

Owner:ANHUI UNIV OF SCI & TECH

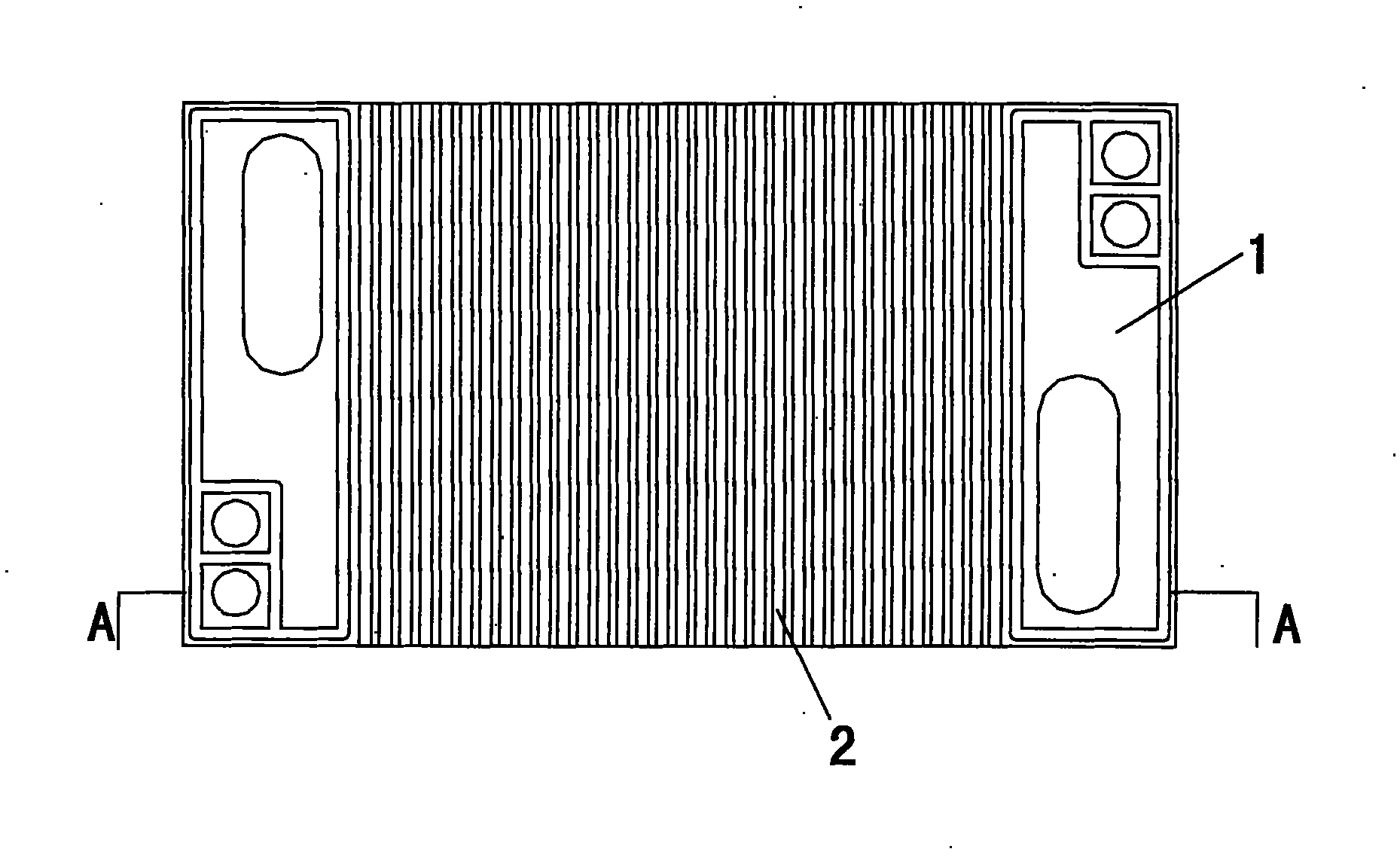

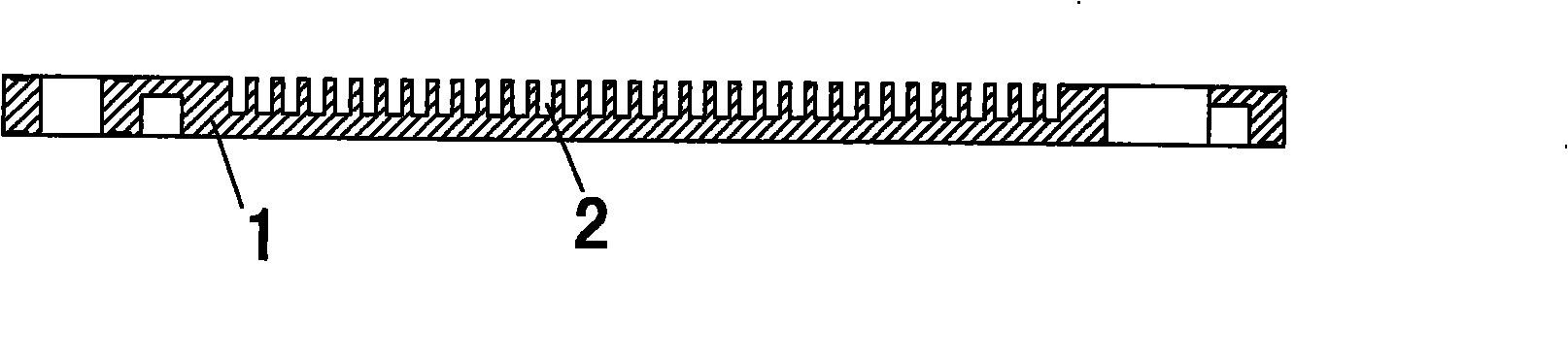

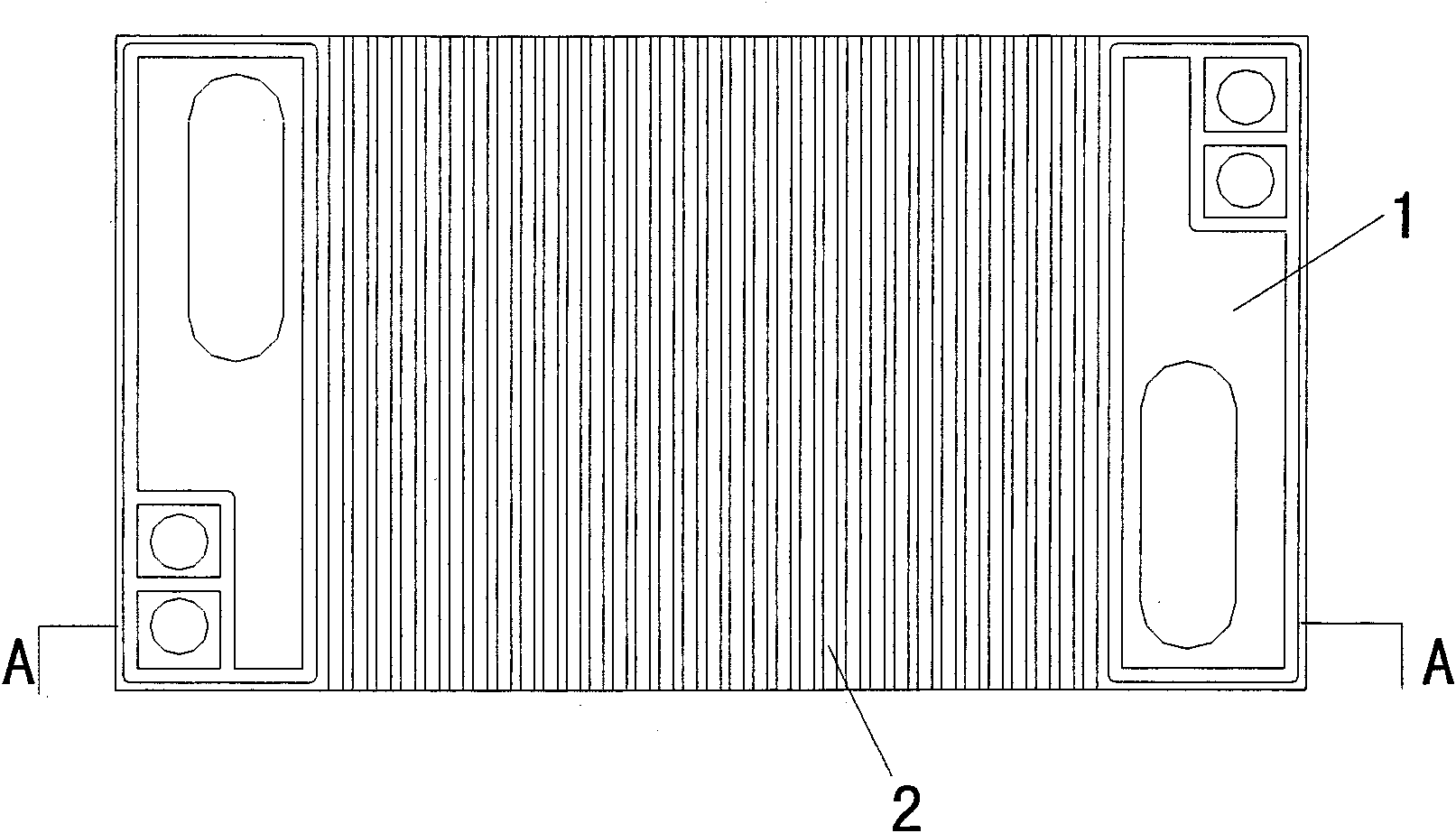

Production method for graphite bipolar plate of fuel cell

The invention provides a production method for a graphite bipolar plate of a fuel cell, which comprises the following steps of: A) taking a high-purity graphite block which is baked for one time or is soaked for one time and baked for two times as a raw material, and mechanically cutting the graphite block into bipolar plate biscuits; B) flatly grinding the bipolar plate biscuits into bipolar plate sheets; C) using a horizontal milling cutter which is formed by a plurality of parallel circular saw blades to process a straight-through flow field structure with multiple grooves which are distributed in parallel to form semi-finished bipolar plate products; and D) sealing the semi-finished bipolar plate products by using epoxy glue and conducting solidification to obtain finished bipolar plate products. Compared with the prior art, the cost of the bipolar plate of the fuel cell is greatly reduced from the aspects of the selection of the raw material, the flow field design of the graphite bipolar plate, the processing and the like, and the production method is particularly suitable for the production of the bipolar plate with deep runners.

Owner:SHANGHAI PEARL HYDROGEN POWER SOURCE TECH

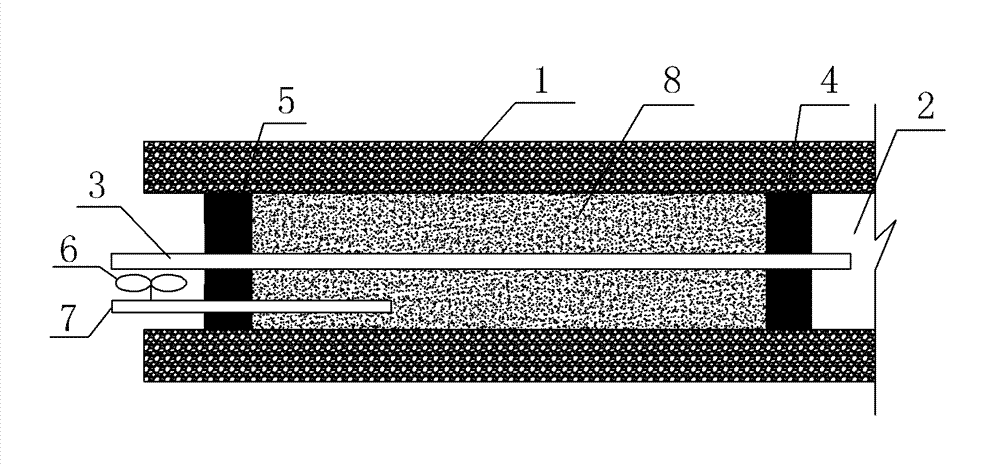

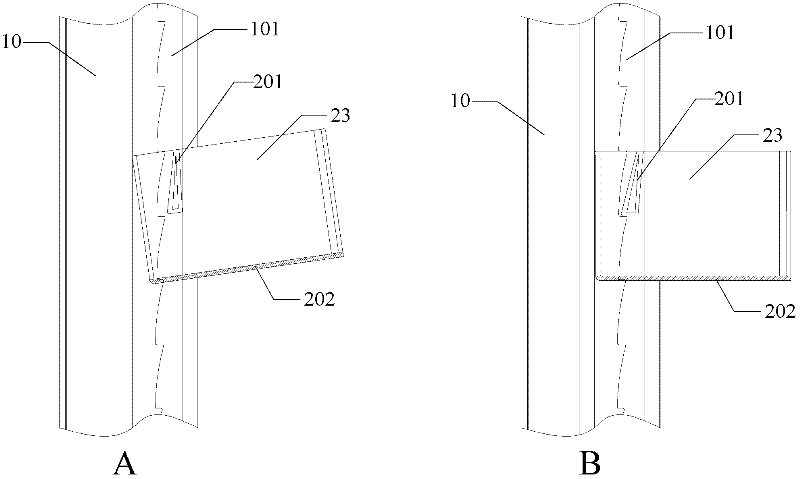

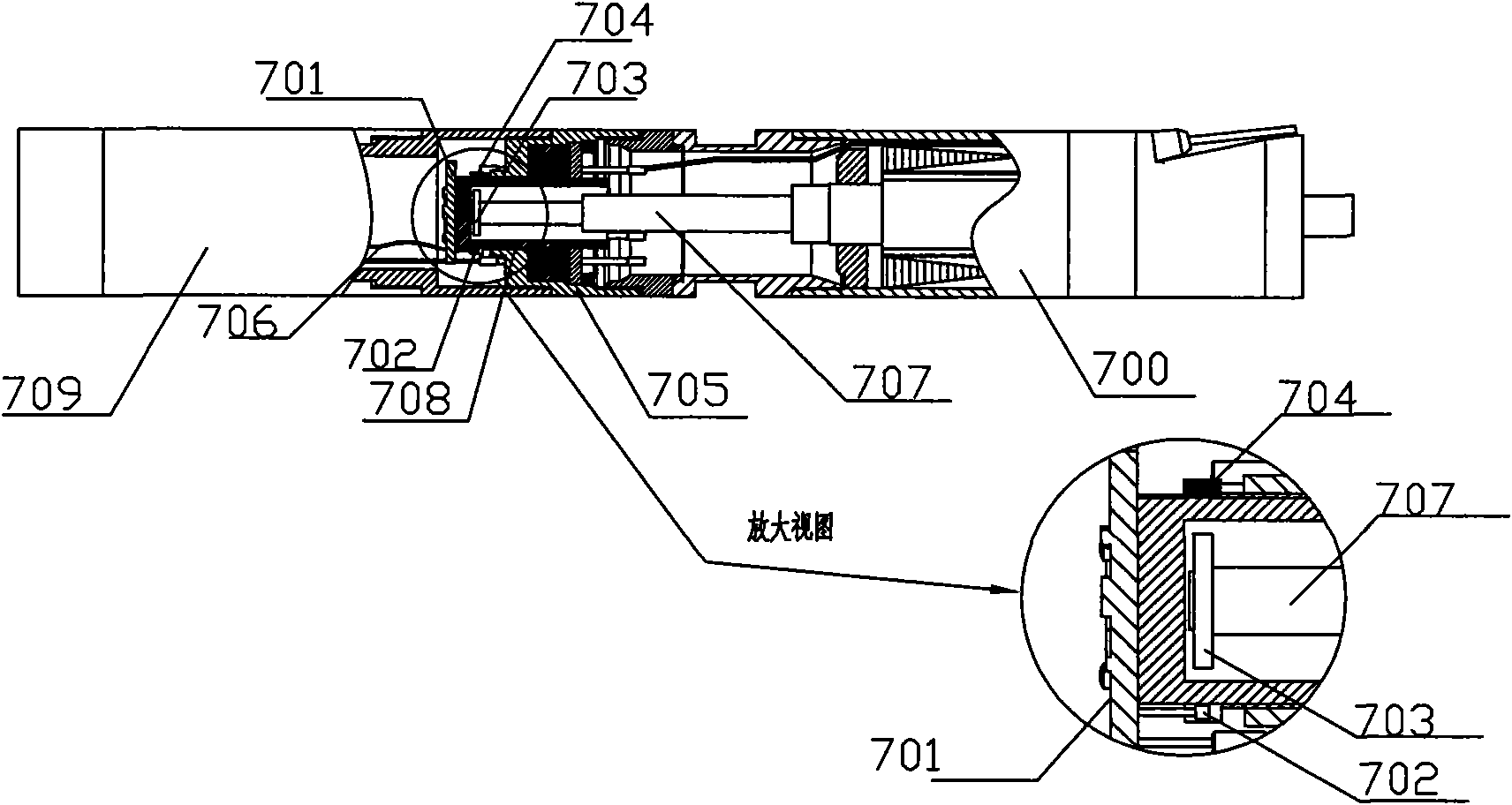

Position detector and signal processing device thereof

InactiveCN101876556AMeet sealing requirementsStrong dust abilityConverting sensor output electrically/magneticallyLocation detectionElectric machine

The invention relates to a position detector and a signal processing device thereof. The position detecting device mainly comprises a sensor body, a stainless steel shied, a sealing device and a casing, wherein the sensor body is composed of a magnetic steel ring, a conductive magnet ring and a magnetic induction element; the conductive magnet ring is arranged on the outer wall of the stainless steel shield and is formed by two or more arc segments with same radium and circle center, and a slit is reserved between two adjacent arc segments; the magnetic induction element is arranged in the slit; the magnetic steel ring is arranged in the cavity of the stainless steel shield and is fixed on a motor rotating shaft; the outside of the stainless shield is sealed and fixed with the casing via a sealing device; and when the magnetic steel ring and the conductive magnet ring are in opposite rotation, the magnetic induction element converts the sensed magnetic signals into pressure signals and transmits the pressure signals to a corresponding signal processing device. The position detector in the invention has strong vibration, oil stain and dust resistance, has high reliability, simple installation structure and easy operation and is suitable for high precision detection at a motor rotor position in a severe environment.

Owner:HANGZHOU SES MACHINERY

Silicon-boron tackifier and preparation method and application thereof

InactiveCN106008983AGood adhesionMeet the sealing requirementsMacromolecular adhesive additivesSemiconductor devicesRefractive indexStructural formula

The invention discloses a silicon-boron tackifier. The silicon-boron tackifier has the following molecular structural formula: (R 1 Me 2 SiO 1 / 2 ) a (PhR 2 SiO 2 / 2 ) b (R 3 MeSiO 2 / 2 ) c (R 4 SiO 3 / 2 ) d (SiO 4 / 2 ) e (BO 3 / 3 ) f , wherein a+b+c+d+e+f=1; R in the molecular structural formula 1 is an unsaturated group, R 2 is an alkoxy group, methyl or phenyl, R 3 is the epoxy group, R 4 is phenyl or methyl. The invention also provides a preparation method of the silicon-boron tackifier and its application in two-component LED encapsulation glue. The silicon-boron tackifier of the present invention can be directly added to the LED packaging silica gel system to improve the adhesion between the LED packaging silica gel and the lamp beads, meet the requirements for sealing the lamp beads, and have high refractive index and good anti-yellowing properties. Change performance.

Owner:广州双桃精细化工有限公司

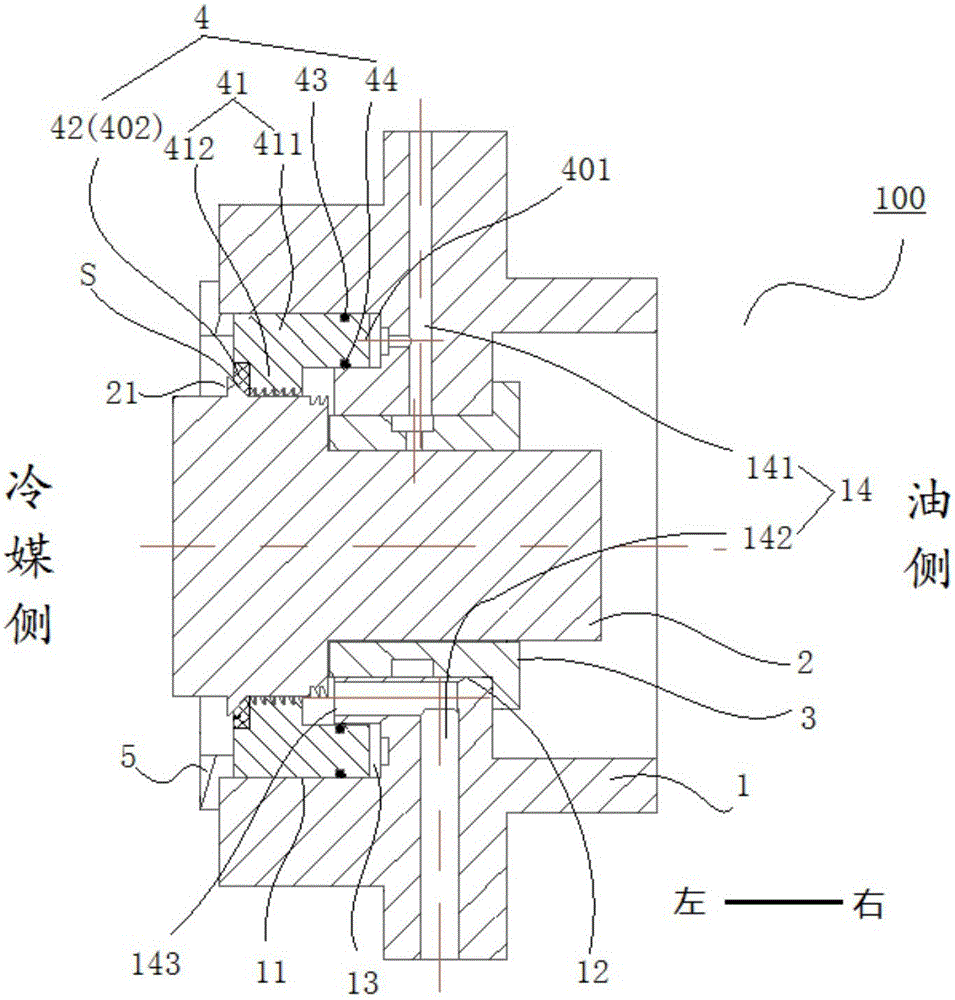

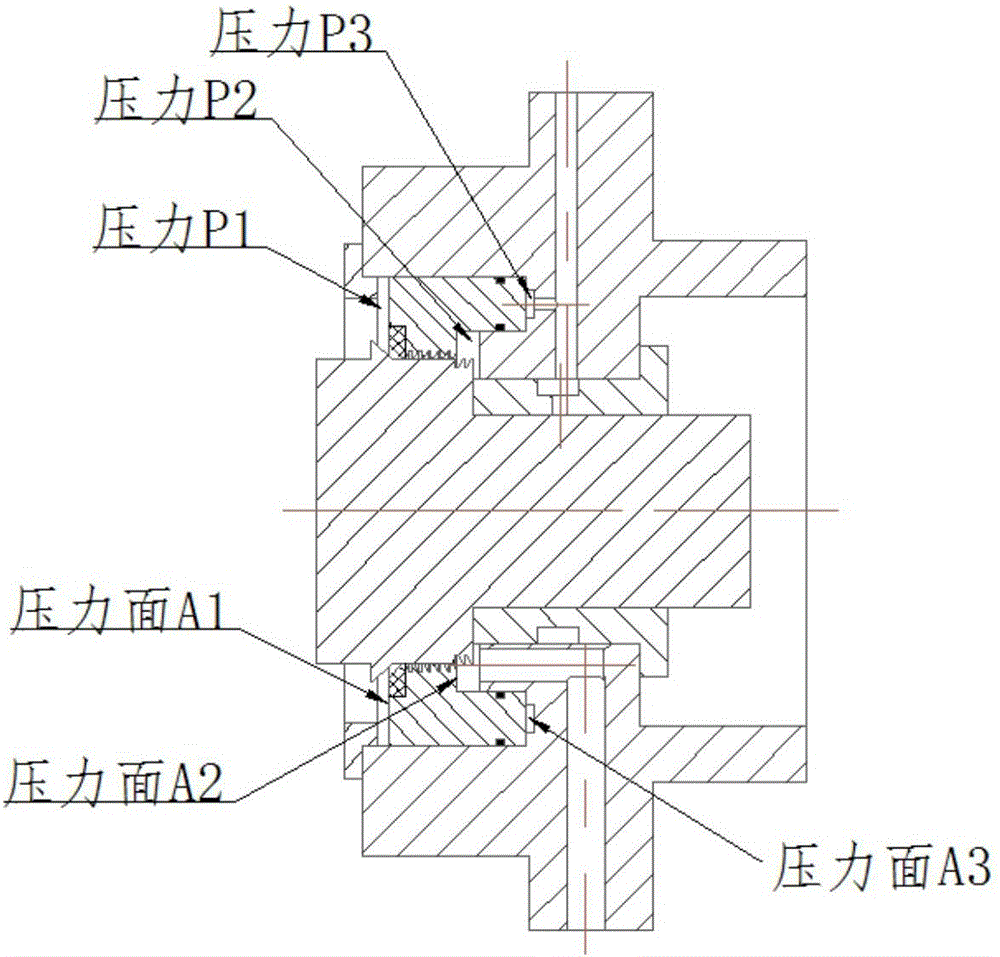

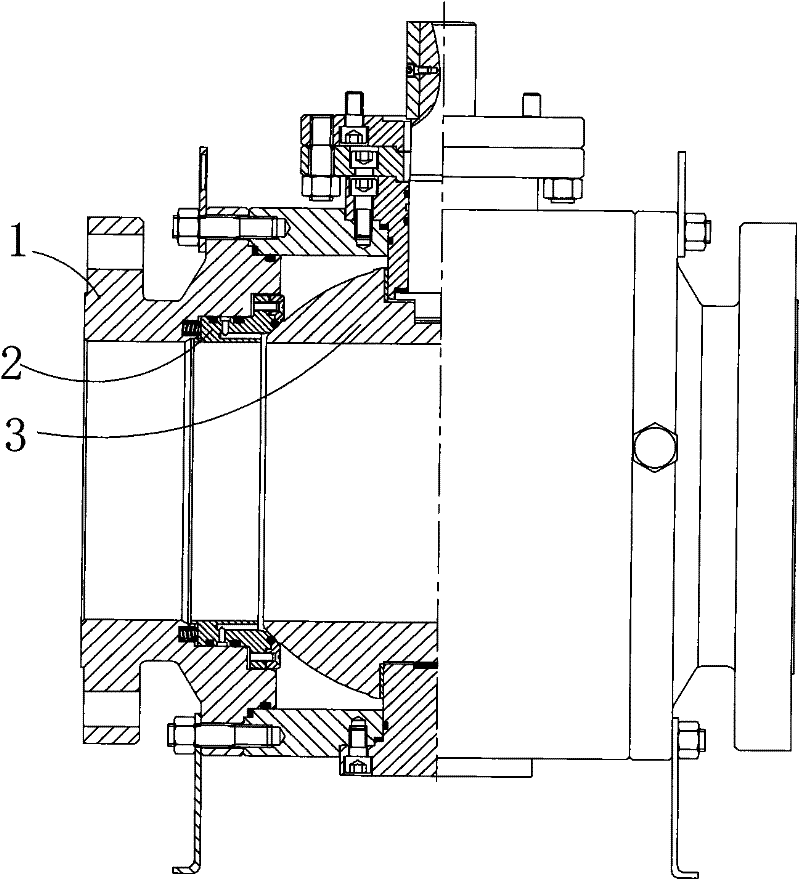

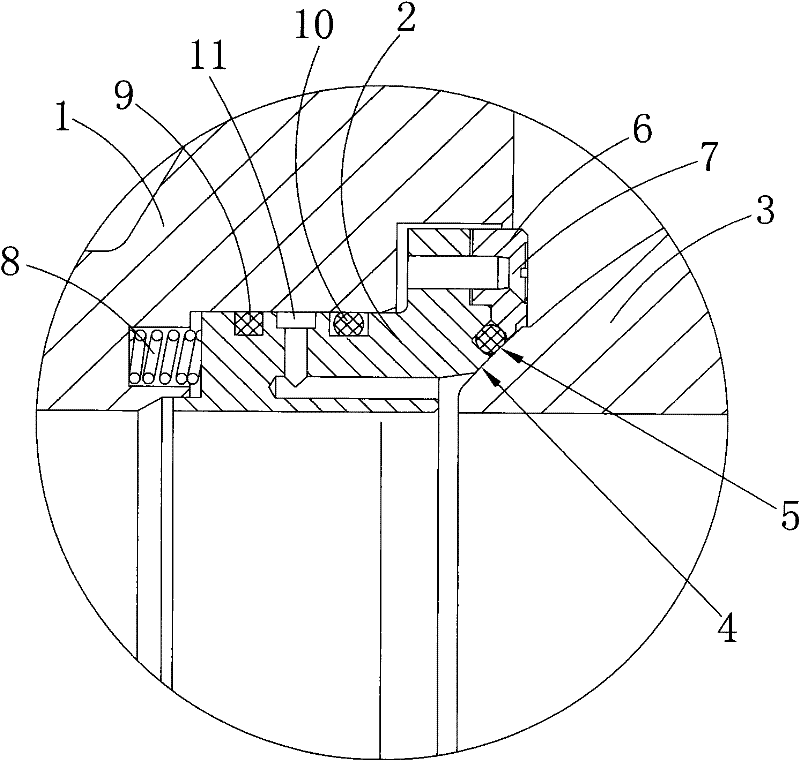

Compressor

ActiveCN106050726ASimple structureShorten the lengthSealing arrangement for pumpsPumpsEngineeringMoving parts

The invention discloses a compressor. The compressor comprises a bearing seat, a rotary shaft, a bearing and a sealing component, wherein the bearing seat is provided with a shaft hole; a coolant side and an oil side are separately arranged on two sides of the bearing seat; the surface, facing to the coolant side, of the bearing seat is provided with a matching groove which is separated from the shaft hole; an oil passage is defined in the bearing seat; the oil passage separately communicates with the shaft hole and the matching groove; the rotary shaft is arranged in the shaft hole; the outer peripheral wall, located on the coolant side, of the rotary shaft is provided with a sealing bulge; the bearing is arranged in the shaft hole and sleeves the rotary shaft; the sealing component is located on the coolant side and sleeves the rotary shaft; the sealing component is provided with a matching part and a moving part; the moving part is movably matched in the matching groove; the matching part is located between the sealing bulge and the bearing seat; and the matching part is provided with a sealing surface which can be in surface contact with the sealing bulge. According to the compressor, high sealing requirement can be met at any time during use; especially requirement of use at special working conditions can be met; meanwhile, the sealing component is simple in structure; and sealing length is shortened.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP +1

Soft and hard double seal fixed ball valve

InactiveCN102278491AAvoid damageMeet the sealing requirements of "zero leakage"Plug valvesRubber materialEngineering

The invention discloses a soft and hard double-seal fixed ball valve, which comprises a valve body, a valve seat and a spherical valve core. It is made of metal, and the valve seat has a hard sealing surface. The hard sealing surface is the surface of the valve seat in contact with the spherical valve core. The shape of the hard sealing surface is consistent with the arc surface of the corresponding spherical valve core. The hard sealing surface is the same as the spherical valve core. The contact of the core constitutes the primary hard seal, and the first O-ring of rubber material is fixed on the valve seat, and the contact between the first O-ring and the spherical valve core forms the secondary soft seal. The hard double seal combination sealing structure makes the sealing performance of the ball valve more reliable and basically meets the "zero leakage" sealing requirement. The outer surface of the first O-ring made of rubber has a polytetrafluoroethylene layer, which not only ensures the elasticity and toughness of the sealing surface, It also reduces friction, improves wear resistance, and increases the opening and closing times of the ball valve to more than ten times.

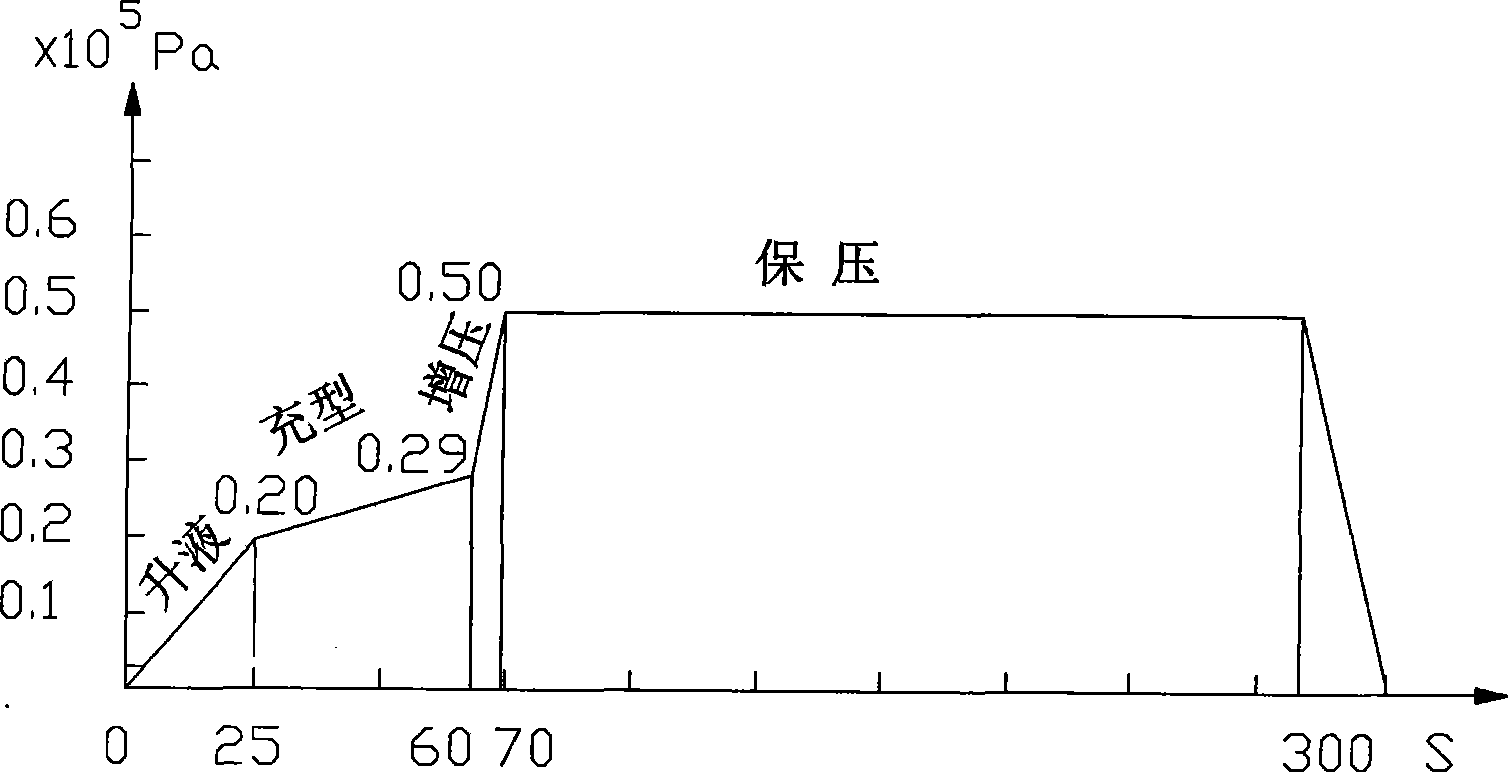

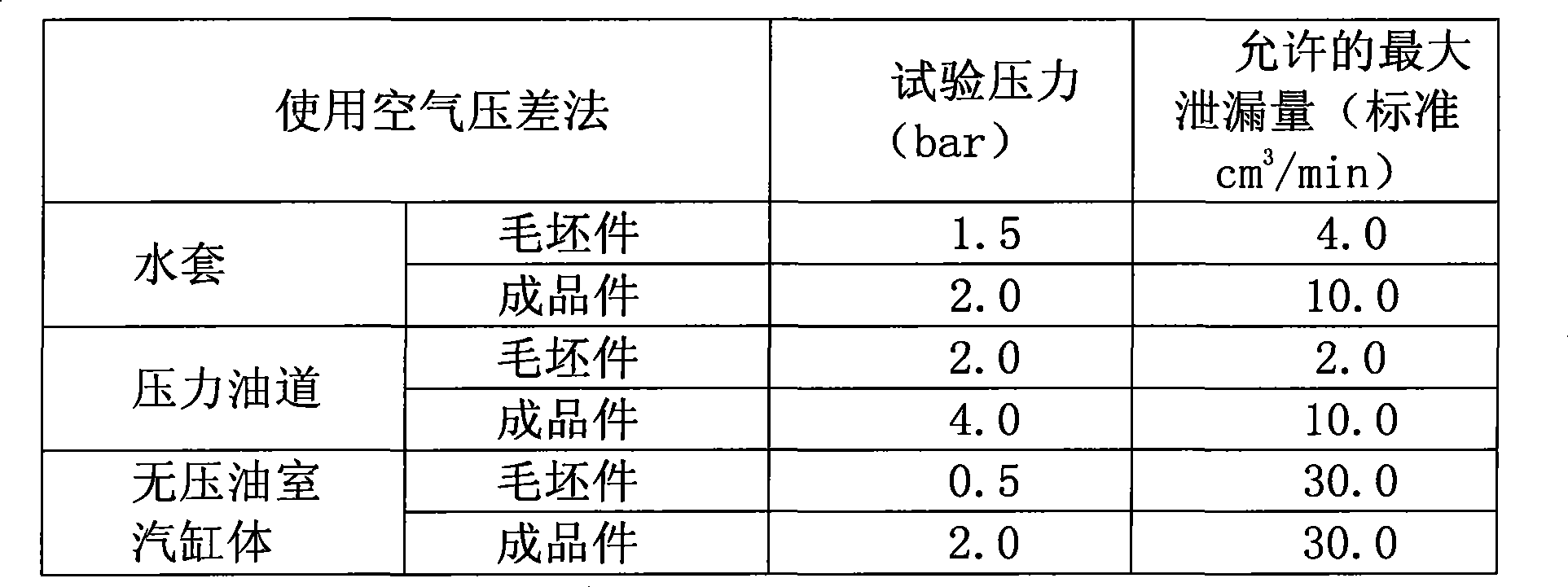

Pressurizing method of diesel motor aluminium alloy cylinder metal mould low-pressure casting

The invention discloses a pressurizing method for metal mold low-pressure casting of an aluminum alloy cylinder of a diesel engine, which comprises the following steps: step one, performing liquid-raising and pressurizing operations on an aluminum liquid; step two, performing filling type pressurizing operations on the aluminum liquid obtained in the step one; step three, pressurizing a cast obtained in the step two; step four, performing pressure-maintaining operations on the cast obtained in the step three; and step five, performing depressurizing operations on the cast obtained in the step four. The pressurizing method adopts a reasonable pressurizing specification to make the cast filled and molded smoothly and solidified sufficiently so that the structure of the cast is compact without generating hole defects to satisfy the sealing requirement, thus the method can make a high-compactness and high-strength aluminum alloy and a diesel engine cylinder body which is provided with a closed water-cooling cast-in cylinder sleeve.

Owner:SHANGHAI AISHIDA AUTOMOTIVE COMPONENTS

Method for machining aluminum alloy thin-wall cabin

InactiveCN102229048AImprove surface qualityMeet sealing requirementsOther manufacturing equipments/toolsNumerical controlMilling cutter

The invention discloses a method for machining an aluminum alloy thin-wall cabin. A position of a milling tool is changed by modifying a machine tool, and in the process of machining a long cylindrical thin-wall part, milling is replaced by turning, and complex thin-wall parts are machined in a turning and milling combined mode. Some large-size sealing grooves of the cabin are machined by a milling method, a high-quality key groove milling tool is adopted, numerical control programming is performed and a circular trace is formed; the machining method has simple machining processes, product yield is high and the products have stable quality; and in the machining process, a spindle rotating speed, feeding amount and other cutting parameters are required strictly, so high surface quality can be guaranteed, and the sealing requirement is met.

Owner:WUJIANG TIANLONG MACHINERY

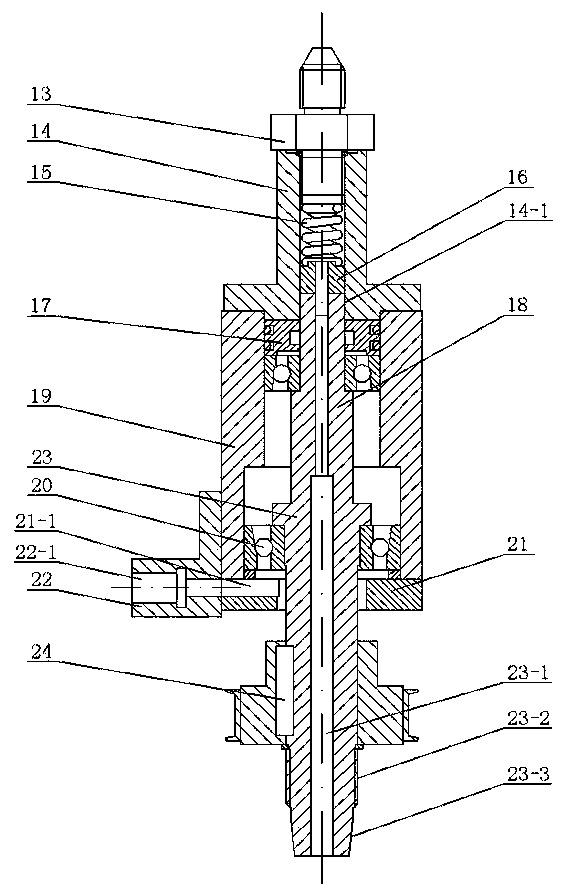

Electrode rotating and clamping device for electrosparking of insulating ceramic coated metal

The invention discloses an electrode rotating and clamping device for electrosparking of insulating ceramic coated metal, belongs to the field of electrosparking and forming technique, and solves the problem that the electrode rotating and clamping device on an EDM machine tool can not be used in an oil base working solution in the present electrosparking of the insulating ceramic coated metal. The working solution is the oil base working solution; a synchronous belt drive mechanism is connected with a DC gear motor and an electrode slewer; the positioning section of the hollow shaft of the electrode slewer is mounted in the circular truncated conical hole of the taper connecting shaft of an electrode clamping device in a matched manner; the electrode clamping device clamps an electrode and drives the electrode to rotate; the high-pressure working solution provided by an oil supply pipeline is erupted from the lower end of the electrode through the electrode; an insulation baseplate is connected with a fixed block; the fixed block is connected with the main shaft of the EDM machine tool; the main shaft of the EDM machine tool enables the whole electrode rotating and clamping device to move in the vertical direction. The electrode rotating and clamping device for electrosparking of the insulating ceramic coated metal can realize rotation of the tubular electrode and inner solution flushing of the oil base working solution during the electrosparking of the insulating ceramic coated metal.

Owner:HARBIN INST OF TECH

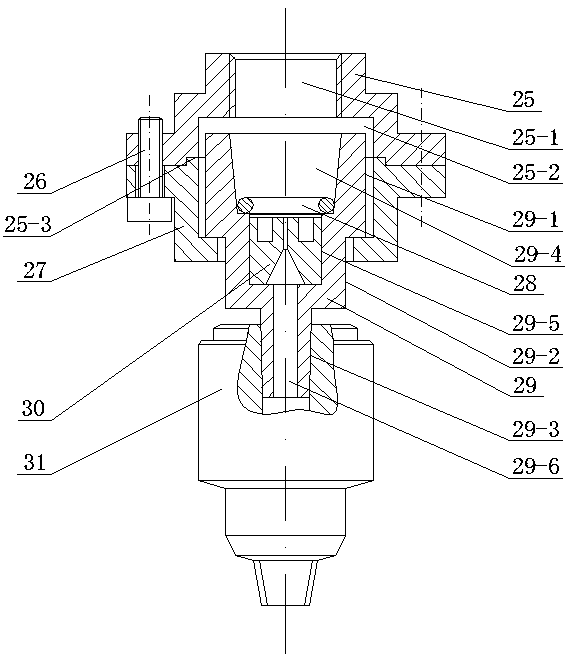

Manufacturing process of metal seated ball valve nickel-based tungsten carbide wear-proof coating

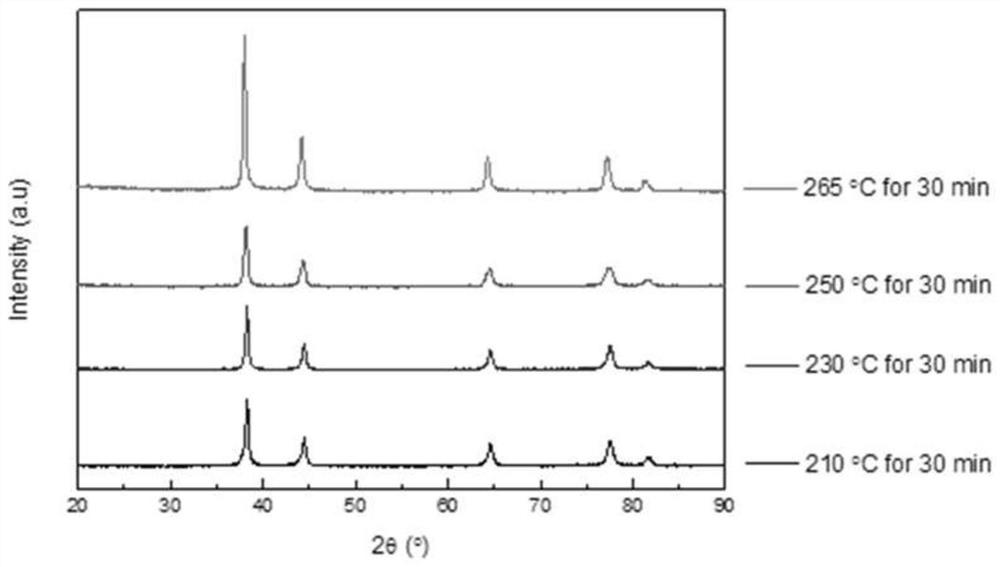

InactiveCN111455306AAvoid crackingImprove compactnessMolten spray coatingSurface cleaningWear resistance

The invention discloses a manufacturing process of a metal seated ball valve nickel-based tungsten carbide wear-proof coating. The manufacturing process includes the following steps that S1, the surfaces of workpieces are pre-treated, wherein a machined ball body and a machined valve seat are subjected to surface cleaning and coarsening; S2, a wear-proof coating is sprayed, wherein a wear-proof coating powder material is evenly sprayed to the surfaces of the ball body and the valve seat through a hypersonic flame spraying process; S3, heating and remelting are carried out, wherein the sprayedball body and the sprayed valve seat are put in a vacuum furnace in batches for heating and remelting, and the ball body and the valve seat are metallurgically bound with the wear-proof material; S4,cooling is carried out, wherein after being remelted, the ball body and the valve seat are slowly cooled along with the vacuum furnace; and S5, grinding is carried out, wherein the cooled ball body and the cooled valve seat are precisely ground in sequence through a grinding device. The strength of the wear-proof coating on the sealing face of a ball valve can be improved, then the wear-proof performance of the sealing face of the ball valve is enhanced, and the service life of the ball valve is prolonged.

Owner:CHAODA VALVE GRP

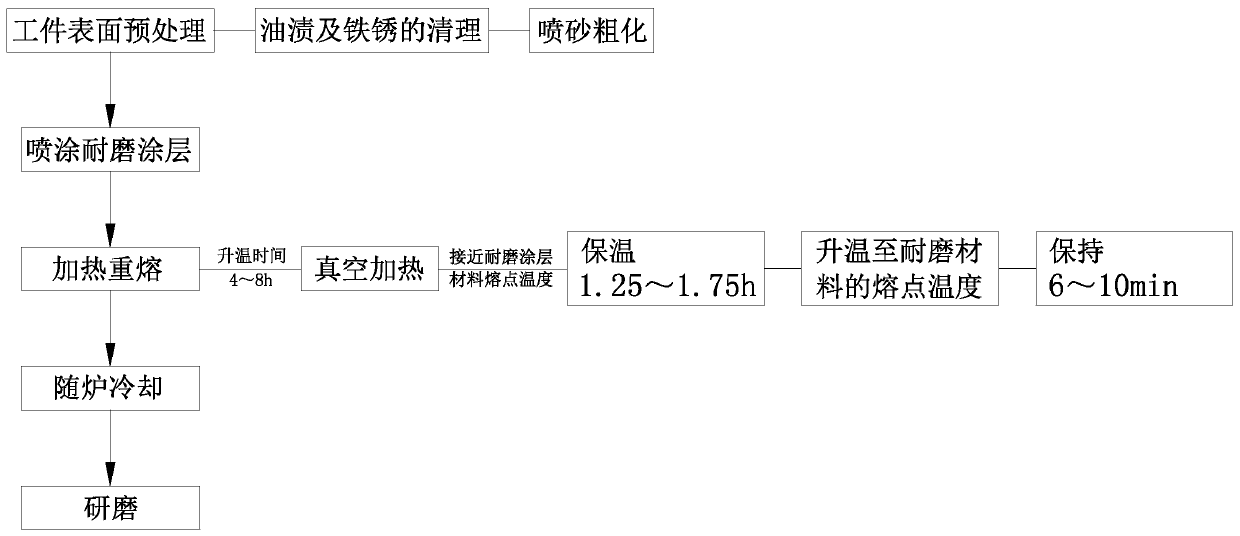

Micro-nano compound silver-copper alloy welding paste used for low-temperature sintering and interconnection and production method

ActiveCN112756841AEnsure replacementFully integratedWelding/cutting media/materialsSoldering mediaMicro nanoOrganic solvent

The invention provides micro-nano compound silver-copper alloy welding paste used for low-temperature sintering and interconnection and a production method. The production method comprises the following steps: evenly mixing an organic solvent, a thickener, a dispersant, a coupling agent and a defoamer according to a certain ratio to produce an organic carrier of the micro-nano compound silver-copper alloy welding paste; and then evenly mixing silver-copper nano-alloy particles and silver microparticles which are produced through a chemical reduction method, and a certain amount of the organic carrier to obtain the micro-nano compound silver-copper alloy welding paste used for low-temperature sintering and interconnection. According to the micro-nano compound silver-copper alloy welding paste used for low-temperature sintering and interconnection and the production method, by adopting a solid solution alloy principle to dope a silver phase with copper atoms, the single-phase silver-copper alloy particles are obtained; the problem of oxidation of copper is solved, meanwhile, due to doping of the copper atoms, the atom diffusion rate is reduced, the problem of massive volume shrinkage of pure nanometer welding paste in sintering processes is solved, and meanwhile, cost reduction and yield raising are facilitated, so that the micro-nano compound silver-copper alloy welding paste used for low-temperature sintering and interconnection and the production method are suitable for mass production; and the micro-nano compound silver-copper alloy welding paste can be substituted for traditional Sn-based solder and pure nano-Ag paste in low-temperature connection of third-generation semiconductors, and has higher reliability.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

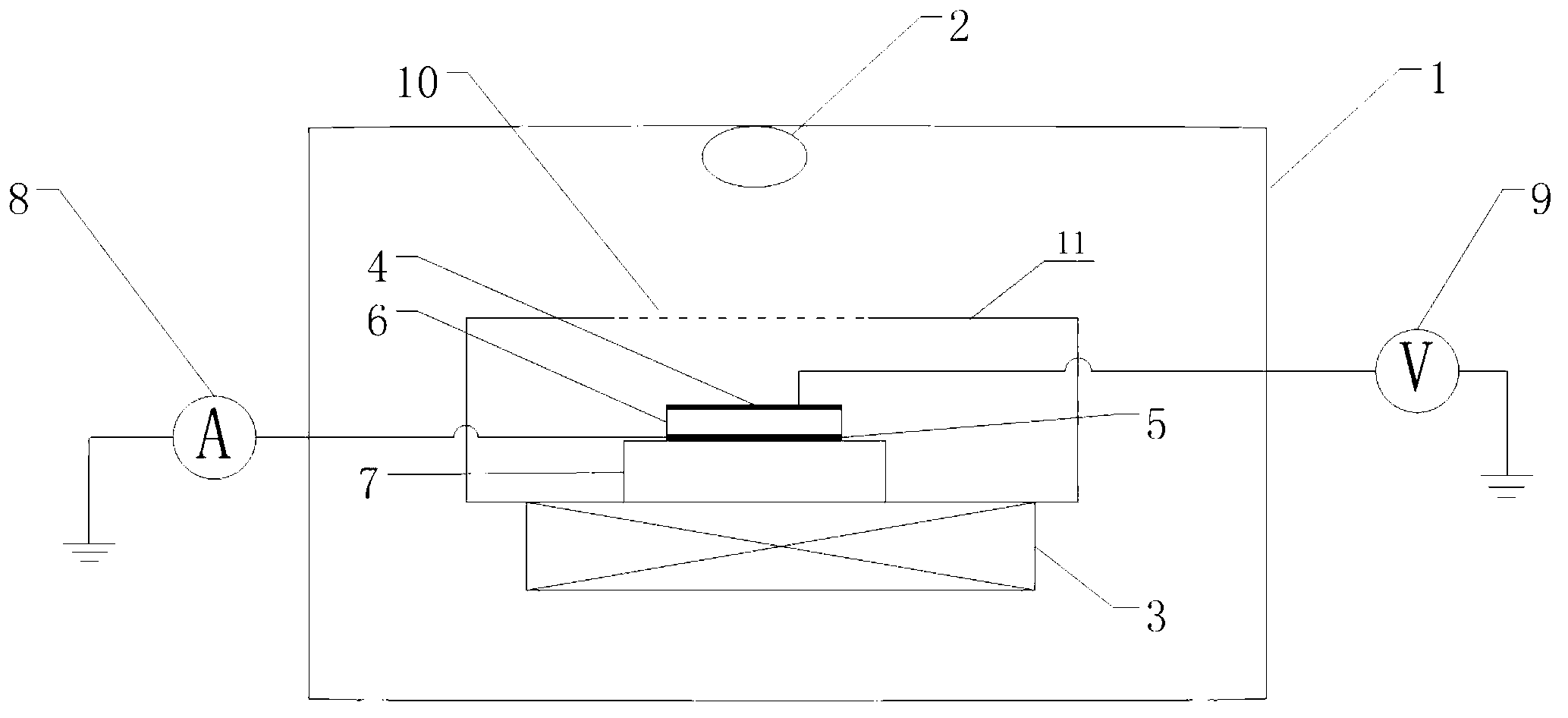

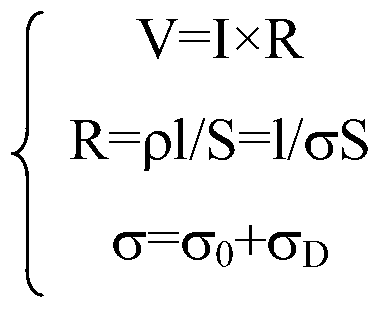

Device and method for testing medium material radiation induction conductivity for satellite

The invention relates to a device and method for testing medium material radiation induction conductivity for a satellite, and belongs to the field of testing. The device and method for testing the medium material radiation induction conductivity for the satellite is applicable to a test on thicker medium material radiation induction conductivity in an electrification effect evaluation inside the satellite. The device comprises a shielding box body, a 60Co irradiation source, a vacuum-pumping system, an upper electrode plate, a lower electrode plate, a sample table, an electrometer, a stabilized voltage source, a titanium window and a vacuum box. The method comprises the steps of utilizing the 60Co irradiation source to generate gamma ray irradiation medium materials, meanwhile utilizing the stabilized voltage source to exert voltage on electrodes on the medium materials, testing a leakage current of the lower electrode plate through the electrometer, obtaining a voltage value V and a current value I of the surface of the medium materials, and further calculating to obtain radiation induction conductivity of the medium materials. The device and method for testing the medium material radiation induction conductivity for the satellite is applicable to the test on the thicker medium material radiation induction conductivity in the electrification effect evaluation inside the satellite.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

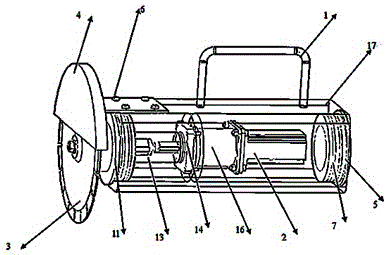

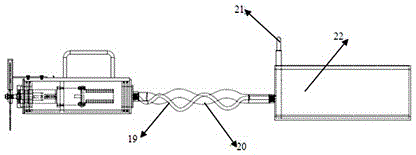

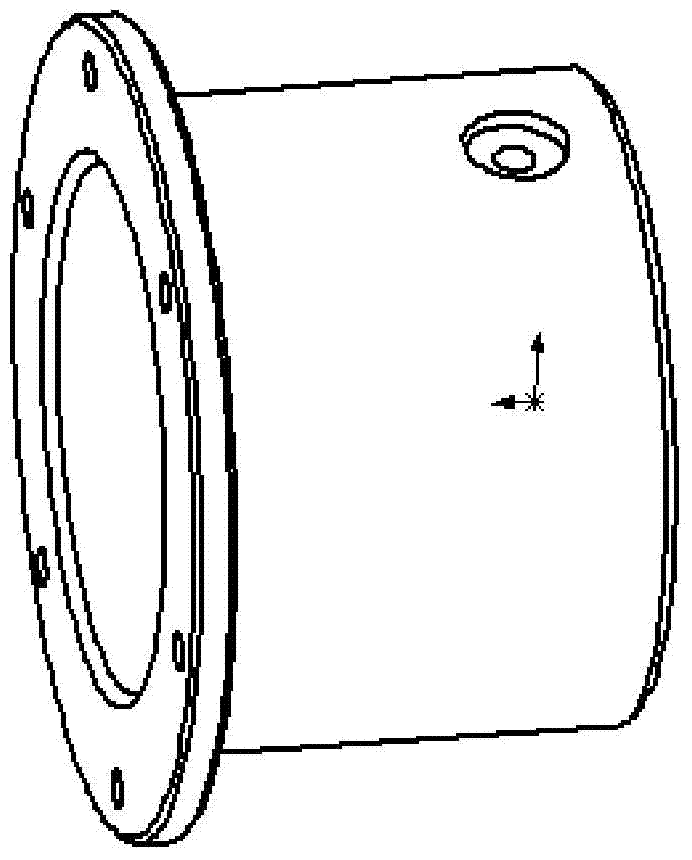

Great-depth seabed portable electric cutting device based on submersible

InactiveCN105034176ASatisfy the cutting torqueFulfil requirementsWithdrawing sample devicesStone-like material working toolsRubber ringRotational axis

The invention provides a great-depth seabed portable electric cutting device which can be loaded onto a 7000-meter manned submersible and conducts cutting and sampling on underwater ore. The device comprises a direct current motor and a reducer, the direct current motor and the reducer are fixed to an output shaft through a coupling and a bearing, and an oil charge cavity is formed in a shell body of a shell. The static sealing design is adopted between a front end cap of the shell and the shell, and one or more O-shaped rubber rings are arranged at the contact part between the front end cap and the shell; a rotating combination sealing ring is arranged at the contact part between a revolving shaft and the front end cap, the double-acting rotating seal is adopted for the rotating combination sealing ring, and the sealing pressure can reach 30 MP; the same static sealing design is adopted at a rear end cap of the shell, and one or more O-shaped rubber rings are arranged at the contact part between the rear end cap and the shell. By means of the device, the problems that existing great-depth underwater rock sampling mechanisms are difficult to sample or load, complex in structure, high in fabrication cost, hard to maintain and the like are solved, and the device has the advantages of being simple in fabrication, high in efficiency, safe and reliable.

Owner:NAT DEEP SEA CENT

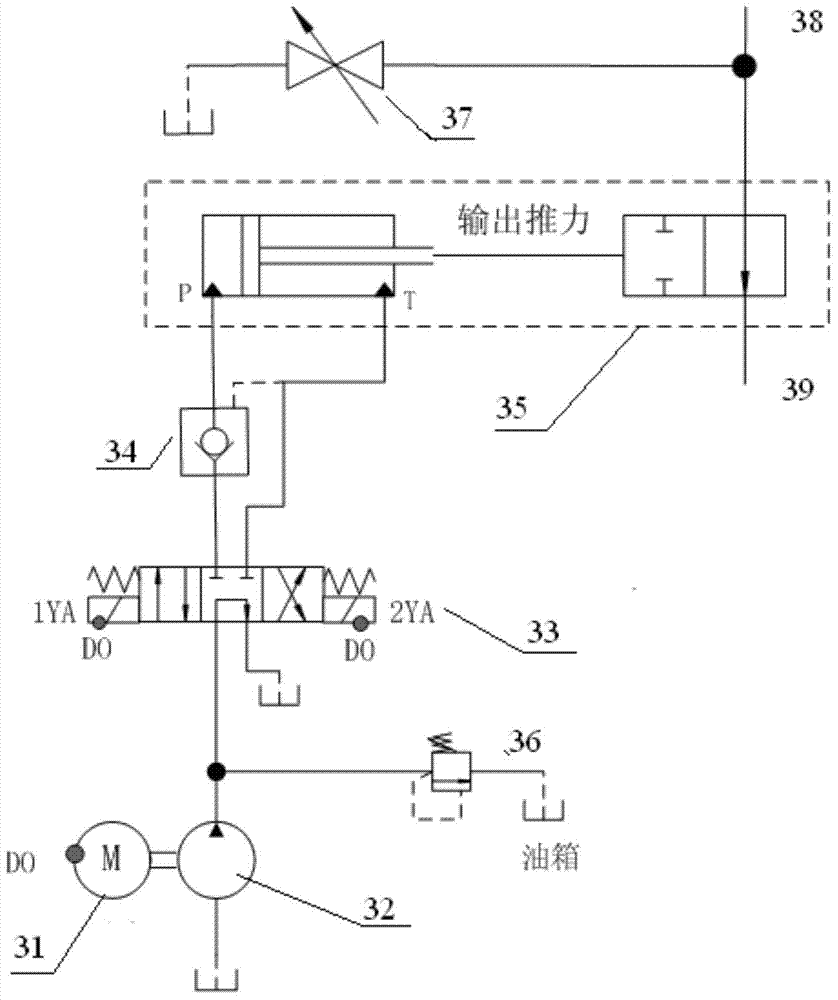

Ultrahigh-pressure large-flow-rate supercharged hydraulically controlled stop valve and application thereof

ActiveCN103573732AImprove sealingMeet the intensityServomotor componentsUltra high pressureEngineering

The invention relates to an ultrahigh-pressure large-flow-rate supercharged hydraulically controlled stop valve and the application thereof. The stop valve comprises a valve base, a low-pressure valve body and an ultrahigh pressure valve body; the valve base is hermetically connected with one end of the low-pressure valve body, and the other end of the low-pressure valve body is connected with the ultrahigh pressure valve body; a piston penetrates through the valve base and the low-pressure valve body, and divides a cavity defined by the valve base and the low-pressure valve body into an oil chamber I and an oil chamber II; the ultrahigh pressure valve body is internally provided with a piston rod which is connected with the piston; the valve base is provided with an oil inlet; the low-pressure valve body is provided with an oil return opening; the front end of the ultrahigh pressure valve body is provided with an oil chamber III; the front part of the ultrahigh pressure valve body is provided with a system oil outlet; one side of the oil chamber III is provided with an unloading port. The invention discloses the ultrahigh-pressure large-flow-rate supercharged stop valve which can bear pressure of 125 MPa; a hydraulic system is used for outputting pressure and the flow so as to control the ultrahigh-pressure large-flow-rate supercharged stop valve, so that the opening and closing of the stop valve are realized, the pressure can be maintained, the requirements of large flow rate and ultrahigh pressure can be met.

Owner:SHANDONG UNIV

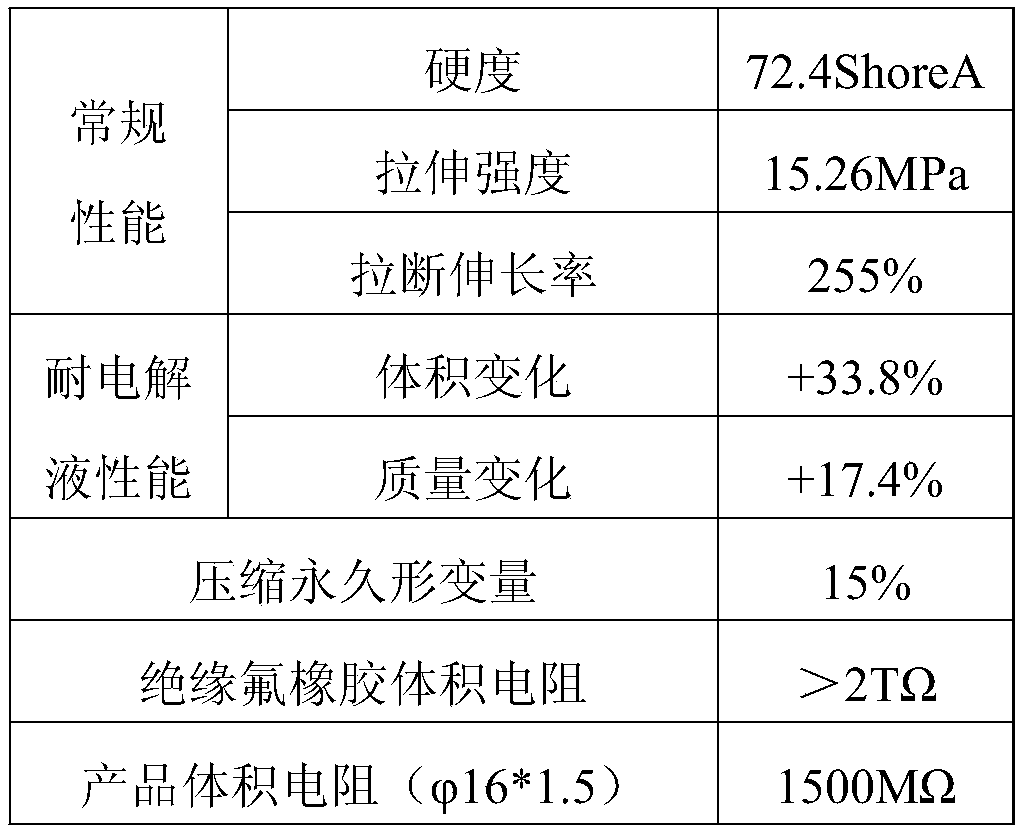

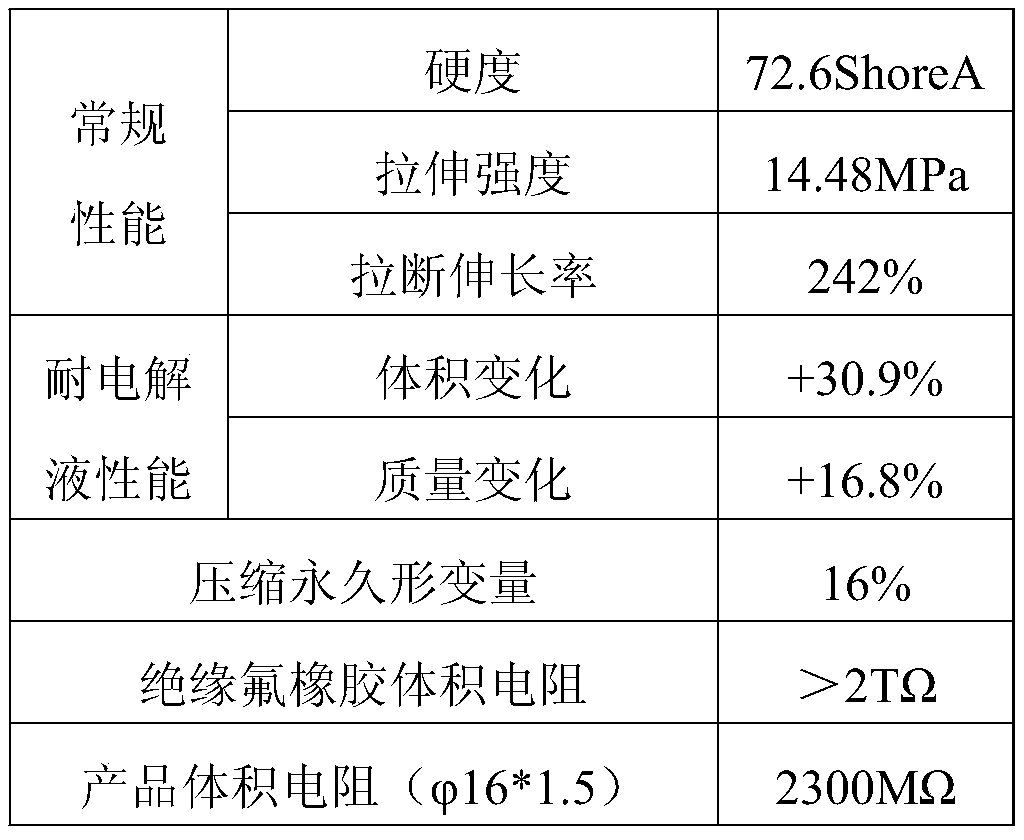

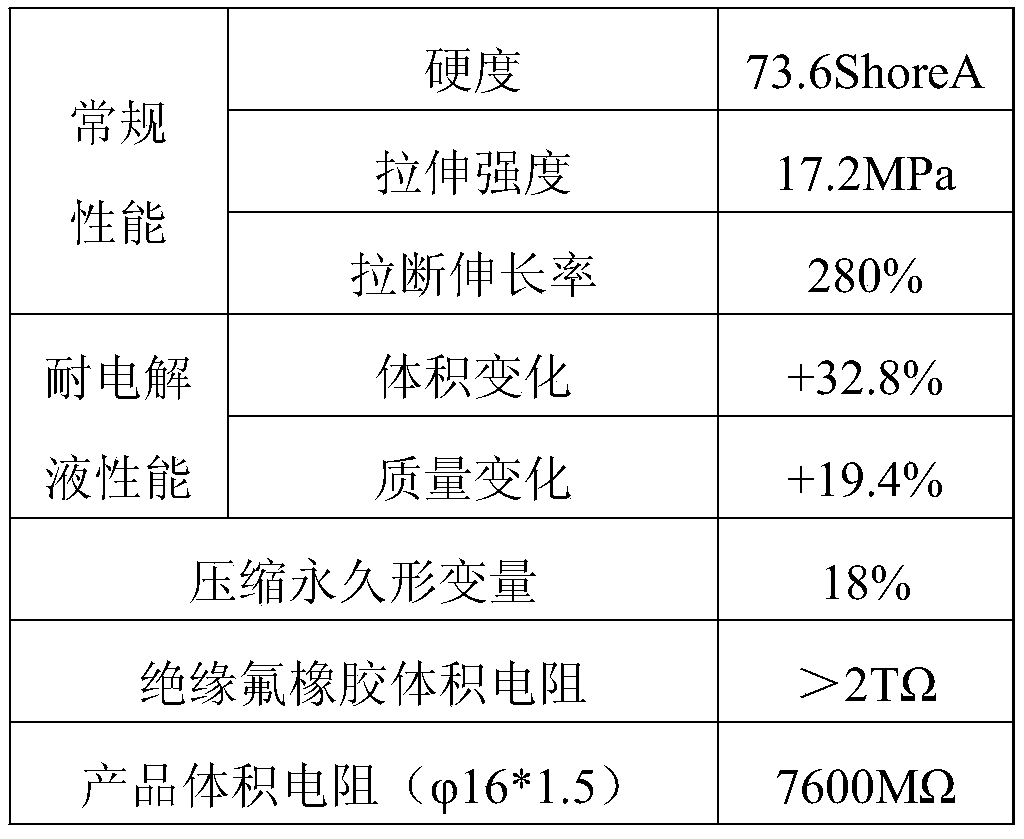

Insulating fluororubber material for sealing lithium battery and preparation method thereof

InactiveCN111269511AExcellent electrolyte resistanceMeet sealing requirementsElectrolytic agentPhysical chemistry

The invention discloses an insulating fluororubber material for sealing a lithium battery and a preparation method thereof. The insulating fluororubber material comprises the following components in parts by weight: 100 parts of fluororubber, 5-15 parts of an insulating material, 12-30 parts of a reinforcing filler, 0.75-2.5 parts of a peroxide vulcanizing agent, 1.5-3 parts of a vulcanizing aid and 0.8-6 parts of a processing aid. The fluororubber material has excellent electrolyte resistance, volume expansion is less than 35% after the fluororubber material is soaked in an electrolyte, and mass expansion is less than 20%. Meanwhile, the material has good insulating property; the volume resistance of the material is more than 2 * 10 < 12 > omega.cm, the volume resistance is more than 1000M omega (1000V voltage, delayed reading is tested for 3 seconds) after the material is assembled into the sealing material of the lithium battery, the high-temperature compression set is below 20% (200 DEG C * 70 hours), and the sealing and insulating requirements of the lithium ion battery are met.

Owner:江苏中煜橡塑科技有限公司

Flexible plastic quick grouting hole sealing device and method

ActiveCN106401522ARaise the initial pressureFlexibleDrilling rodsWell/borehole valve arrangementsSlurryMechanical engineering

The invention discloses a flexible plastic quick grouting hole sealing device and method. The device is mainly composed of an umbrella buckle type plugging device, a slotting flexible plastic grouting pipeline and a double-cone pipe connector device. The initial grout pressure in pipes is positively stored in a sealed mode through the differential flow of grout fed into and discharged out of the grouting pipes, and the processes of automatic pushing out, spreading and plugging of a convex angle umbrella buckle are completed. A flexible plastic pipe capable of being coiled is adopted to be inserted into a drill hole at a time, and the primary quick hole sealing operation requirement is met. According to the flexible plastic quick grouting hole sealing device and method, the process of traditional hole sealing operation is simplified, operation is convenient and quick, the cost is low, and the device and the method are novel hole sealing device and method which have wide application and popularization value.

Owner:CHINA UNIV OF MINING & TECH

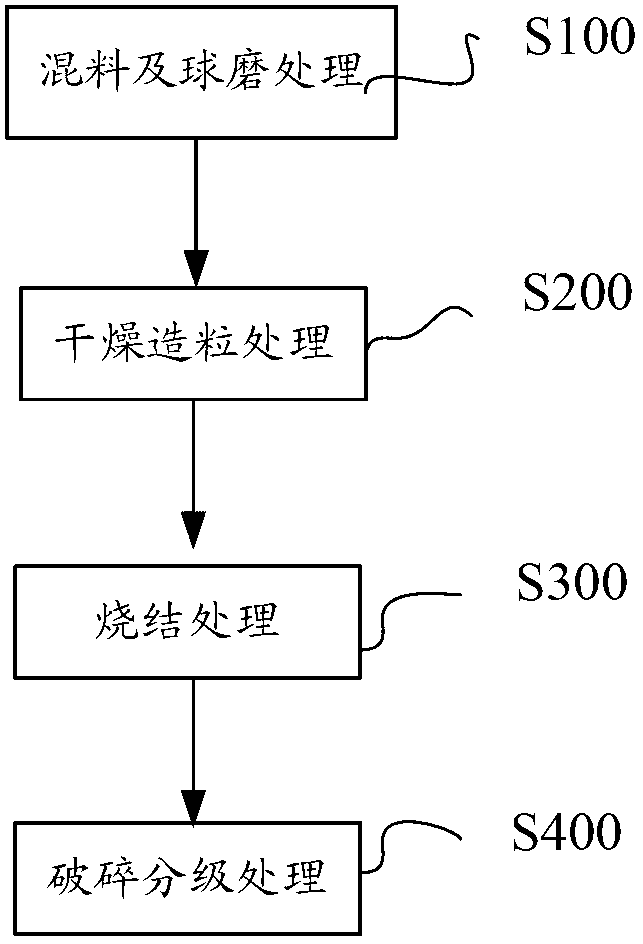

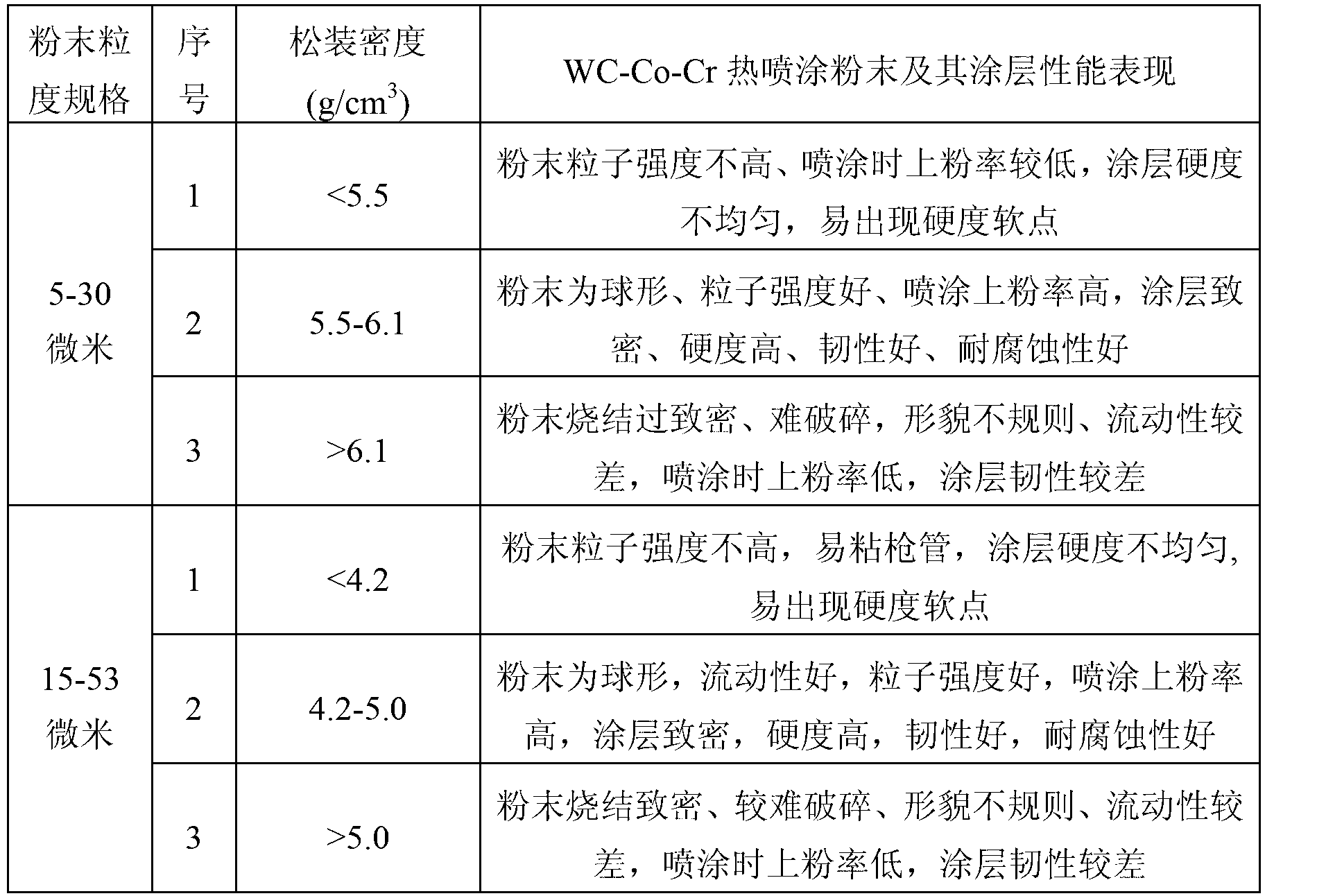

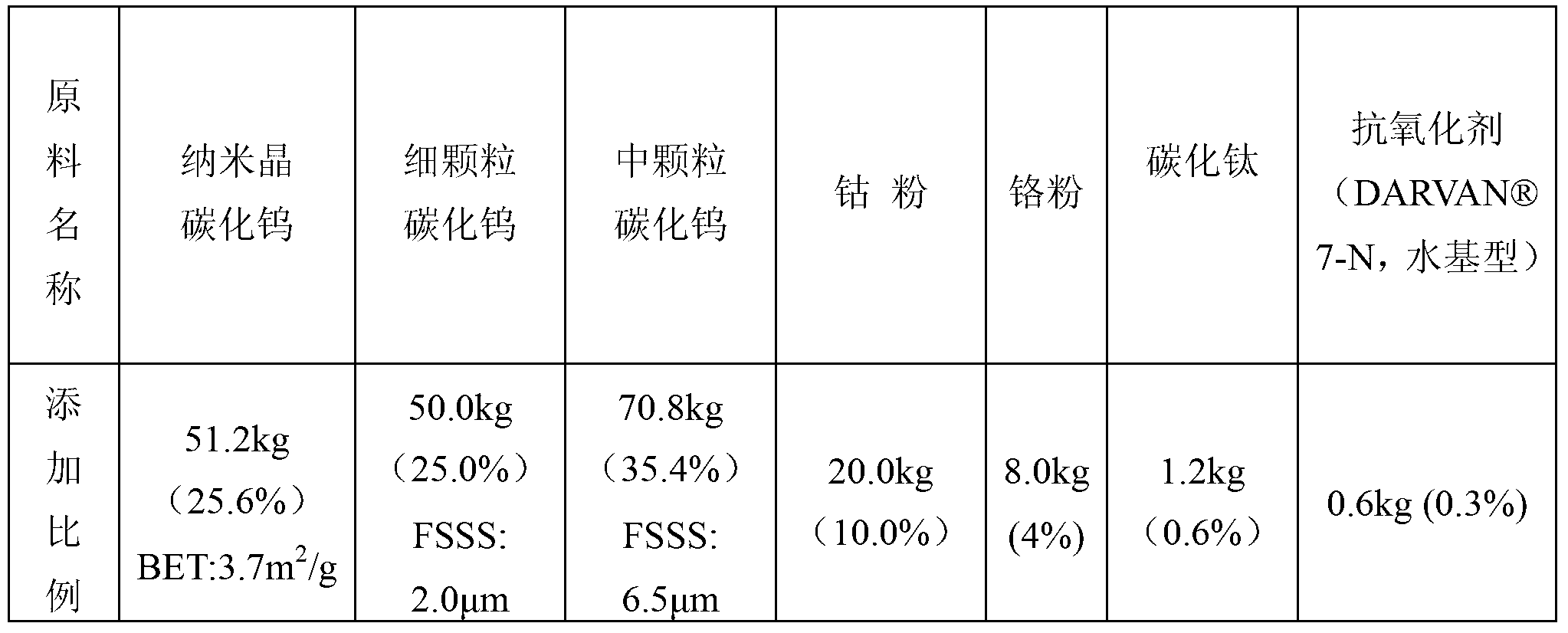

WC-Co-Cr thermal spraying powder and its preparation method and application

ActiveCN103225053AImprove corrosion resistanceImprove toughnessMolten spray coatingThermal sprayingTitanium carbide

The utility model discloses a WC-Co-Cr thermal spraying powder and its preparation method and an application thereof. The WC-Co-Cr thermal spraying powder comprises: by weight, 86 parts of a tungsten carbide mixture, 9.8-10.2 parts of cobalt, 4.0 parts of chromium, 0.3-0.6 parts of titanium carbide and 0.3 parts of an anti-oxidant, wherein the tungsten carbide mixture comprises: by weight, 13.2-25.6 parts of tungsten carbide with the granularity of 0.05-0.2 micrometer, 15.0-31.5 parts of tungsten carbide with the granularity of 1.0-2.5 micrometer and 24.5-65 parts of tungsten carbide with the granularity of 4.5-9.0. The WC-Co-Cr thermal spraying powder provided by the invention has excellent toughness and corrosion resistance and can be used to effectively improve compactness of a coating which has been undergone thermal spraying. Thus, the WC-Co-Cr thermal spraying powder can be effectively used in preparation of a super-high pressure sealing and corrosion-resistant coating.

Owner:GANZHOU ACHTECK TOOL TECH +1

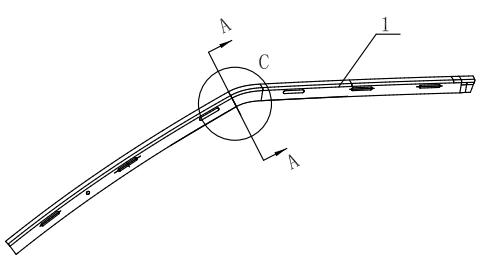

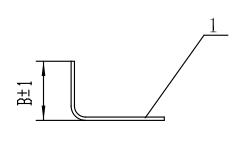

Molding equipment for controlling cross-section deformation of glass guide groove of automobile

InactiveCN102615157AReduce warping and dent problemsReduce distortionProgrammable logic controllerMachining

The invention discloses molding equipment for controlling the cross section deformation of a glass guide groove of an automobile. A form-following material pressing device is added on one side of the periphery of a fixed profile die; a gear of the axis of rotation of a rotary plate is meshed with racks; the rotary plate can be deflected around the axis of the fixed profile die; the outer side of the rotary plate is fixedly provided with an oil cylinder; the front end of a piston rod of the oil cylinder is fixedly provided with a movable profile die; the movable profile die can slide back and forth on the rotary plate; and a workpiece butts against the periphery of the fixed profile die when operated. According to the molding equipment, the form-follow material pressing device is added on the basis of the conventional die, the bending speed and the material pressing force are controlled by a programmable logic controller (PLC), and continuous pressing force is applied to the place of a deformation material when the horizontal planes of products are subjected to round bending, so that the problems of deformation and depression of the material can be favorably solved, the deformation D of the size of a machined guide groove piece at the depression is less than 1mm according to actual machining tests, and the requirements of assembled glazing tapes and sealing of automobile bodies can be completely met.

Owner:无锡华尔斯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com