Silicon boron tackifier, preparation method thereof and application thereof in double-component LED packaging gel

A technology of LED packaging and tackifier, which is applied in the direction of adhesives, polymer adhesive additives, adhesive additives, etc., can solve the problems of poor bonding performance of LED substrates, increased costs and workload, and achieve industrialization. Strong, less dangerous, and the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

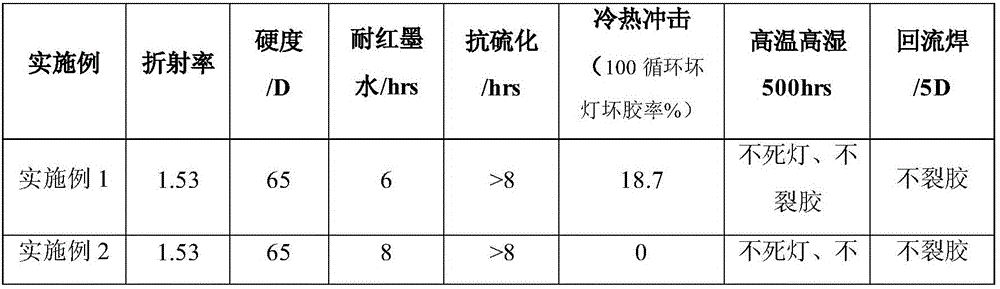

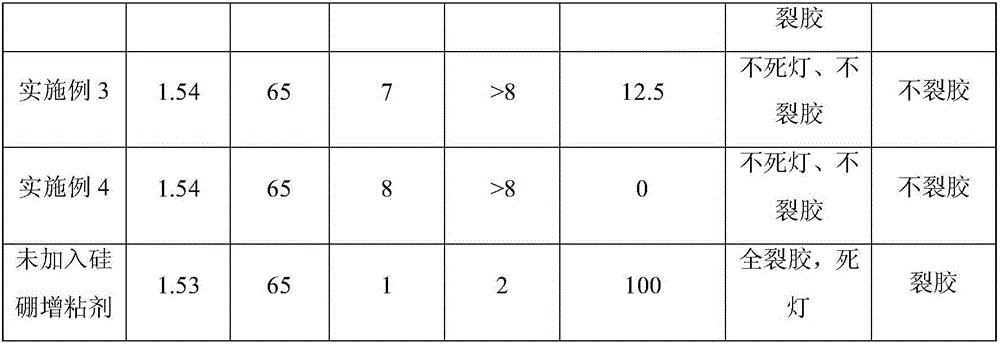

Examples

Embodiment 1

[0031] (1) Preparation of epoxy-modified polysiloxane: Add 114.2 g of allyl glycidyl ether and 100.0 g of hydrogen-containing silicone oil to a 500-ml three-necked flask. The hydrogen value of the hydrogen-containing silicone oil is 0.8%, and 120 ppm chlorine The platinum acid catalyst and 80.0 g of toluene solvent were reacted at 80° C. for 6 hours, and the low boilers were removed at 110° C. under low pressure to obtain epoxy-modified polysiloxane.

[0032] (2) Preparation of phenylpolysiloxane prepolymer: Add 104.0g ethyl orthosilicate, 198.0g phenyltrimethoxysilane, 558.0g divinyltetramethyldisiloxane to a 1000ml three-necked flask Alkanes and 150.0g toluene solvent, add 160.0g of 1.0% sulfuric acid solution dropwise at 70°C, react for 4 hours and then heat up to 100°C for distillation until no fractions are distilled out, wash with water until neutral, and remove low boiling substances under low pressure to obtain Phenyl polysiloxane prepolymer.

[0033] (3) Mix 100.0 g ...

Embodiment 2

[0035] (1) Preparation of epoxy-modified polysiloxane: Add 248.0 g of 4-vinyl epoxycyclohexane and 110.0 g of high hydrogen-containing silicone oil into a 500 ml three-necked flask, and the hydrogen content of the hydrogen-containing silicone oil is 1.6%. , 240ppm chloroplatinic acid catalyst and 160.0g toluene solvent were reacted at 85°C for 5 hours, and low boilers were removed at 110°C under low pressure to obtain epoxy-modified polysiloxane.

[0036] (2) Preparation of phenylpolysiloxane prepolymer: Add 104.0g ethyl orthosilicate, 198.0g phenyltrimethoxysilane, 558.0g divinyltetramethyldisiloxane to a 1000ml three-necked flask Alkanes and 150.0g toluene solvent, add 160.0g of 1.0% sulfuric acid solution dropwise at 70°C, react for 4 hours and then heat up to 100°C for distillation until no fractions are distilled out, wash with water until neutral, and remove low boiling substances under low pressure to obtain Phenyl polysiloxane prepolymer.

[0037] (3) Mix 100.0 g of t...

Embodiment 3

[0039] (1) Preparation of epoxy-modified polysiloxane: Add 114.2 g of allyl glycidyl ether and 100.0 g of hydrogen-containing silicone oil to a 500-ml three-necked flask. The hydrogen value of the hydrogen-containing silicone oil is 0.8%, and 120 ppm chlorine The platinum acid catalyst and 80.0 g of toluene solvent were reacted at 80° C. for 6 hours, and the low boilers were removed at 110° C. under low pressure to obtain epoxy-modified polysiloxane.

[0040] (2) Preparation of phenylpolysiloxane prepolymer: add 122.2g of diphenyldimethoxysilane, 396.0g of phenyltrimethoxysilane, 184.0g of divinyltetramethyl in a 1000ml three-necked flask Disiloxane and 160.0g of toluene solvent, add 120.0g of 1.5% sulfuric acid solution dropwise at 80°C, react for 4 hours and then raise the temperature to 100°C for distillation until no fractions are distilled out, wash with water until neutral, and remove the low boiling point under low pressure products to obtain phenylpolysiloxane prepolym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com