Testing method of leakage rate of high-temperature sealing gasket and testing device thereof

A technology of high-temperature sealing and testing methods, which is applied in the direction of liquid-tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the test error of leak detection cavity, old structure, high-temperature pad Difficulty in testing chip leakage rate, etc., to avoid leakage problems and achieve accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

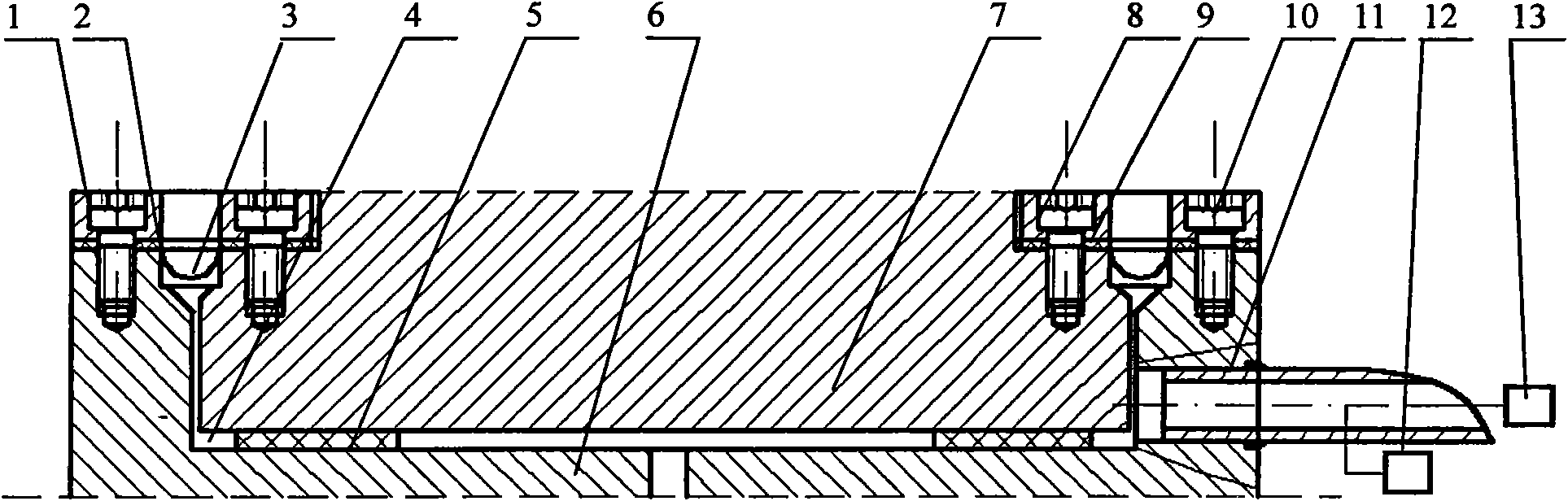

[0067] A method for testing the leakage rate of a high-temperature sealing gasket, comprising the following steps:

[0068] Load the test gasket 5 between the upper flange 7 and the lower flange 6, and seal the "Ω" annular sealing ring 3 of the upper flange 7 and the lower flange 6, the test gasket 5 and the upper flange 7, The lower flange 6 and the medium outlet pipe 11 on the lower flange 6 form a closed leak detection cavity 4;

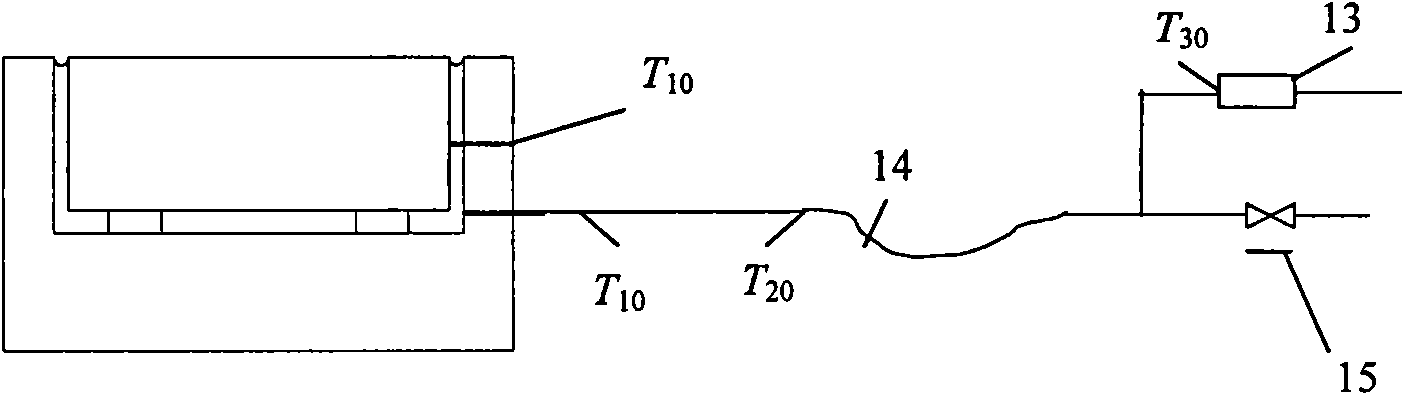

[0069] Open the valve 15, inject a gas medium with a predetermined temperature and pressure into the leakage cavity 4, and keep the medium pressure stable;

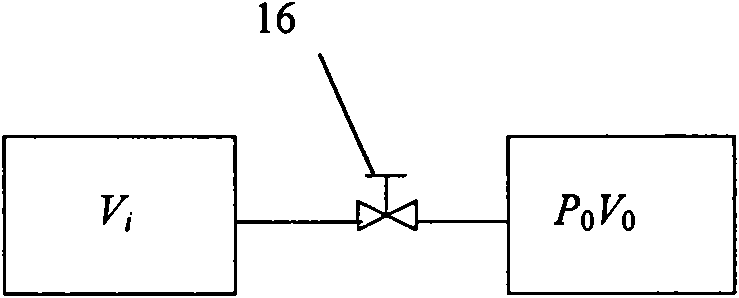

[0070] Measure the pressure difference, temperature and volume in the leakage cavity 4 within a specified time interval, and calculate the leakage rate according to the gas state equation;

[0071] The pressure difference in the leakage cavity 4 within the specified time interval is the pressure difference between the two ends of the micro pressure sensor 14 connected to the medium outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com