Graphitized graded porous carbon composite phase change energy storage material and preparation method thereof

A phase-change energy storage material and hierarchical porous technology, applied in chemical instruments and methods, carbon compounds, heat exchange materials, etc., can solve the problems of unfavorable phase-change material molecular movement, reduction of phase-change latent heat, poor energy storage effect, etc. , to achieve good heat conduction network channels, good heat storage effect, and increase energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

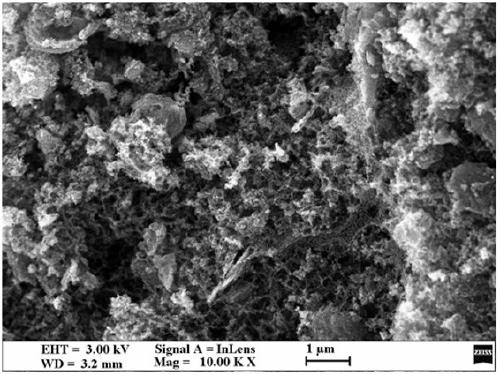

[0028] (1) Weigh phenolic resin, aluminum isopropoxide and nano-magnesium oxide according to the mass ratio of 1:2:1, and add ethanol twice the mass of the mixture, ball mill at 300r / min for 3 hours, and then put them in a drying oven at 80°C to keep warm Distill off the solvent, put it into the atmosphere furnace after cooling to room temperature, pass in nitrogen, raise the temperature to 1100°C at a rate of 5°C / min, and keep it warm for 3 hours to obtain graphitized hierarchical porous carbon, which is taken out after cooling to room temperature for later use; The prepared graphitized hierarchical porous carbon has a specific surface area of 991m 2 / g, the pore volume is 2.53cm 3 / g, the average pore diameter is 3.2nm, and the Al content is 0.56wt%;

[0029] (2) Weigh the graphitized hierarchical porous carbon and stearic acid respectively according to the mass ratio of 0.5:9.5, add the graphitized hierarchical porous carbon to absolute ethanol and sonicate for 1 hour, t...

Embodiment 2

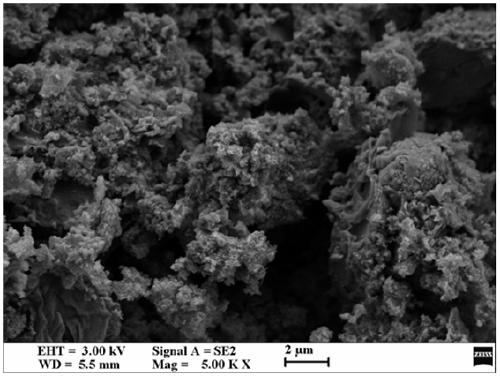

[0031] (1) Weigh coal tar pitch, ferrous sulfate and magnesium citrate according to the mass ratio of 1:1:1, and add 4 times the mass of n-butanol to the mixture, ball mill at 500r / min for 2 hours, and put them in a drying oven at 100°C Distill out the solvent by heat preservation, put it into the atmosphere furnace after cooling to room temperature, pass in argon gas, raise the temperature to 900°C at a rate of 10°C / min, and keep it warm for 4 hours to obtain graphitized hierarchical porous carbon. After cooling to room temperature, take it out for use ; The specific surface area of the obtained graphitized hierarchical porous carbon is 759m 2 / g, the pore volume is 1.93cm 3 / g, the average pore diameter is 2.6 nm, and the Fe content is 0.32wt%;

[0032] (2) Weigh the graphitized hierarchical porous carbon and paraffin wax respectively according to the mass ratio of 1:9, add the graphitized hierarchical porous carbon to absolute ethanol for 1 h, then add paraffin and heat ...

Embodiment 3

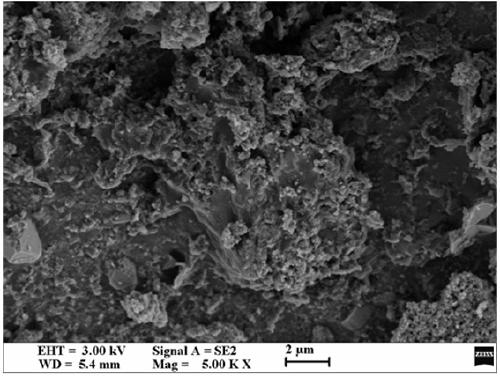

[0034] (1) Weigh lignin, iron stearate and magnesium oxide according to the mass ratio of 1:2:3, and add dichloromethane 3 times the mass of the mixture, ball mill at 450r / min for 1.5h, and put it in a 70°C drying oven The solvent was distilled out by medium heat preservation, and then put into the atmosphere furnace after cooling to room temperature, and nitrogen gas was introduced, and the temperature was raised to 1000°C at a rate of 8°C / min, and kept for 3.5h to obtain graphitized hierarchical porous carbon, which was taken out after cooling to room temperature Standby; The specific surface area of the prepared graphitized hierarchical porous carbon is 599m 2 / g, the pore volume is 2.01cm 3 / g, the average pore diameter is 3.3 nm, and the Mg content is 0.23wt%;

[0035](2) Weigh the graphitized hierarchical porous carbon and myristic acid respectively according to the mass ratio of 1.5:8.5, add the graphitized hierarchical porous carbon to absolute ethanol and sonicate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com