Patents

Literature

241results about How to "High latent heat of phase change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic salt phase-change cold accumulation material

ActiveCN103242806AHigh latent heat of phase changeImprove thermal conductivityHeat-exchange elementsHigh energyCold storage

The invention discloses an inorganic salt phase-change cold accumulation material which is prepared from the following raw materials in parts by weight: 100 parts of a 15-25% inorganic salt solution, 1-7 parts of a nucleation agent and 2-15 parts of a thickening agent. Inorganic salt is used as an inorganic phase-change material. The inorganic salt phase-change cold accumulation material has the advantages that the phase-change latent heat is high (can reach 200-400J / g); the heat conductivity coefficient is good (when being compared with an organic phase-change energy accumulation material); no toxin exists and a pH (Potential of Hydrogen) value is neutral; and the price is low. According to the inorganic salt phase-change cold storage material disclosed by the invention, compared with the prior art (the phase-change latent heat is in a range of 100-200J / g), the inorganic salt phase-change cold accumulation material has the advantages of high energy storage density, small condensate depression and good circulatory stability.

Owner:杭州鲁尔新材料科技有限公司

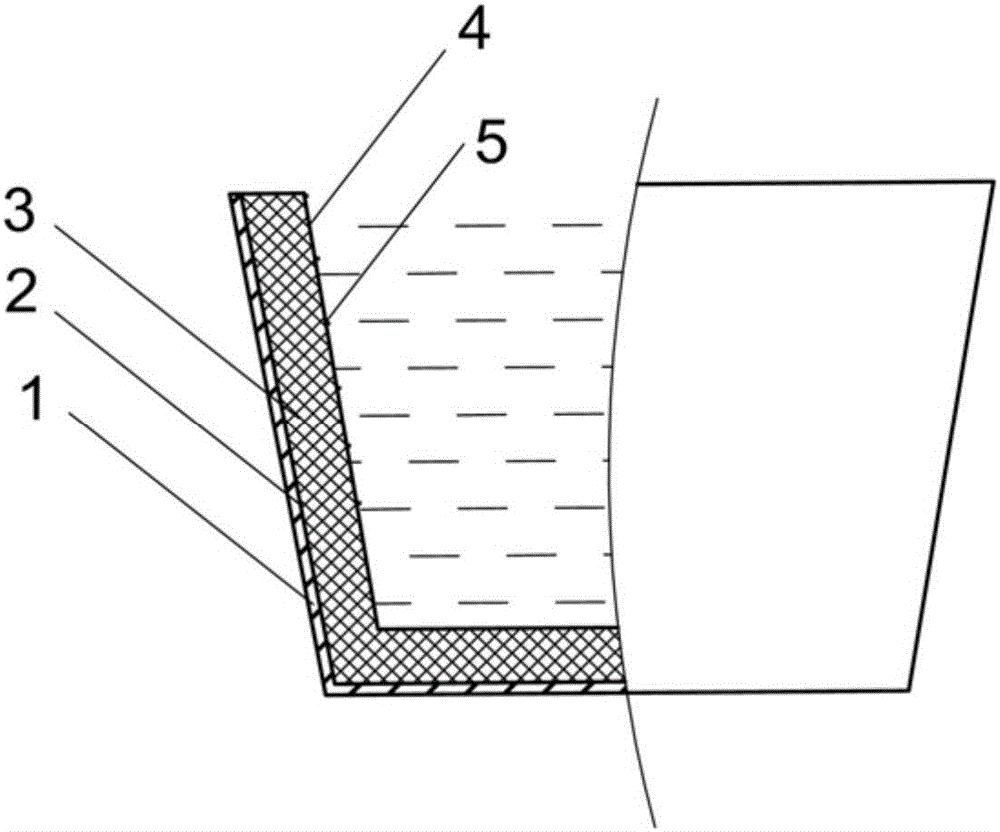

Phase-change energy storage heat-insulation solid wood and manufacturing method thereof

ActiveCN106625930ALow viscosityFacilitated Diffusion MigrationPressure wood treatmentWood treatment detailsSolid woodCell cavity

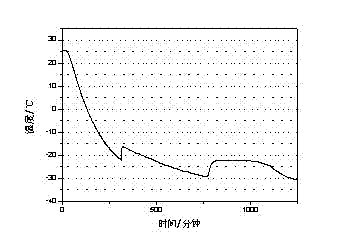

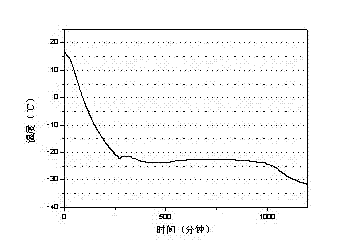

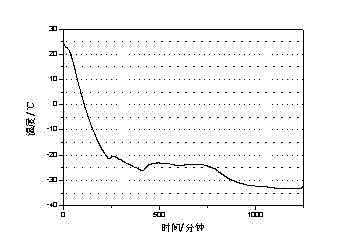

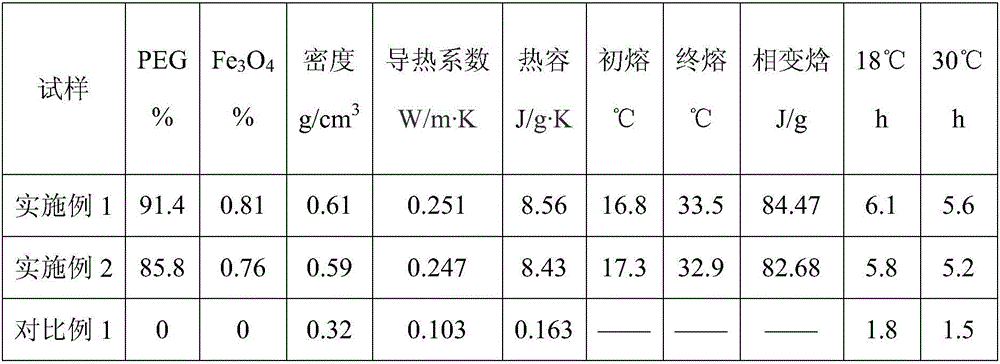

The invention provides phase-change energy storage heat-insulation solid wood. The wood comprises a solid wood component, wherein magnetic Fe3O4 nanoparticles are formed in a conduit and a cell cavity of the solid wood component through in-situ attached growth, and the conduit and the cell cavity are filled with composite phase-change energy storage materials of polyethylene glycol 600 and polyethylene glycol 800; and a protective coating is painted on the surface of the heat-insulation solid wood. The heat-insulation solid wood is capable of absorbing heat to withstand excessive rise of an indoor temperature during the day, releasing phase-change latent heat for thermal retention and cold dispelling during the night, and maintaining a human body within a comfort temperature range. The invention further provides a manufacturing method of the heat-insulation solid wood. The method comprises the steps of firstly processing the solid wood component according to the required dimension; carrying out degreasing and drying pretreatment on the solid wood component, forming the magnetic Fe3O4 nanoparticles in the solid wood component through in-situ attached growth and then impregnating and filling the composite phase-change energy storage material of the polyethylene glycol 600 and the polyethylene glycol 800; and finally carrying out sanding shaping and painting the protecting coating. According to the manufacturing method, the process is simple and the cost is low.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

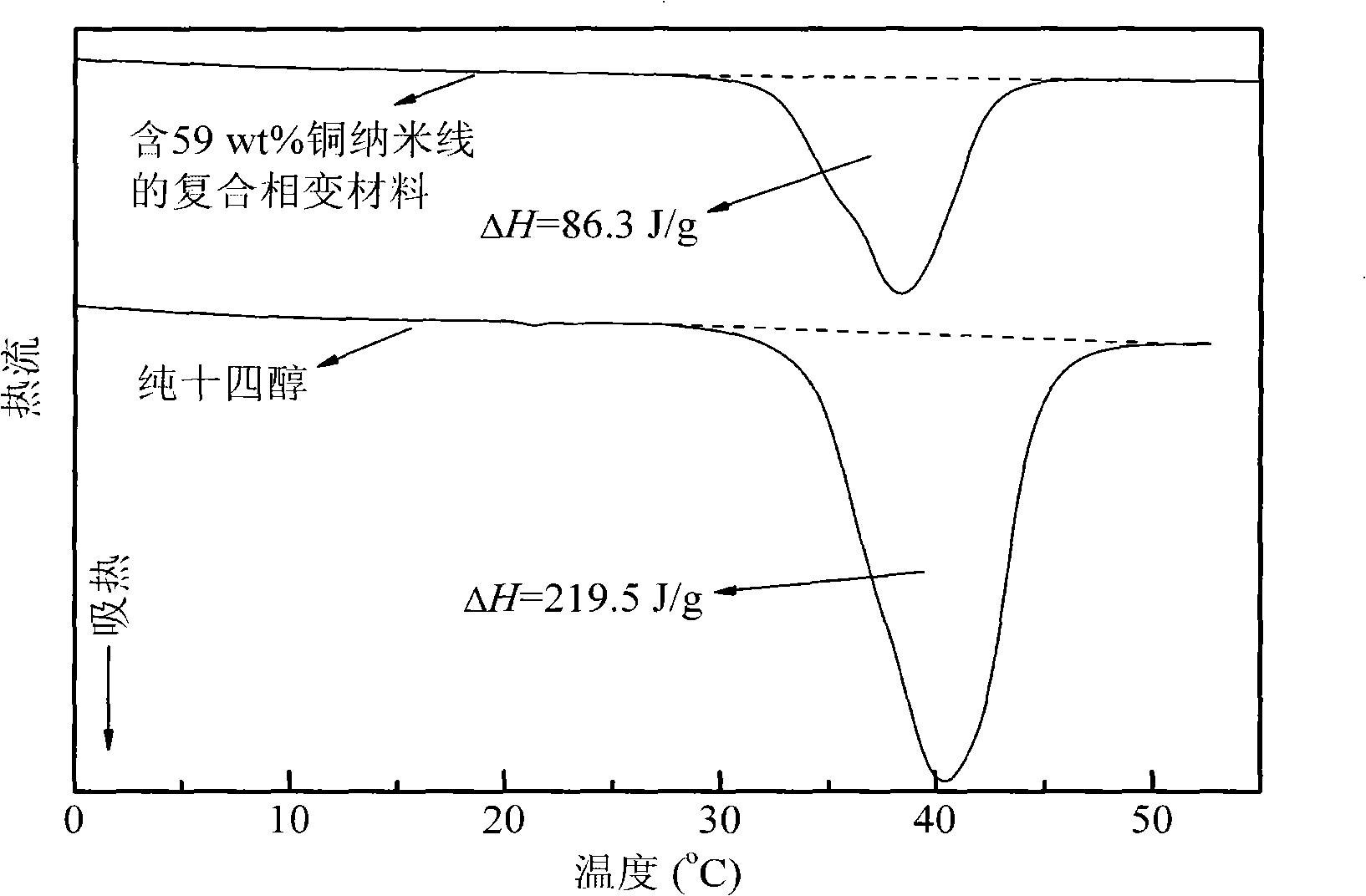

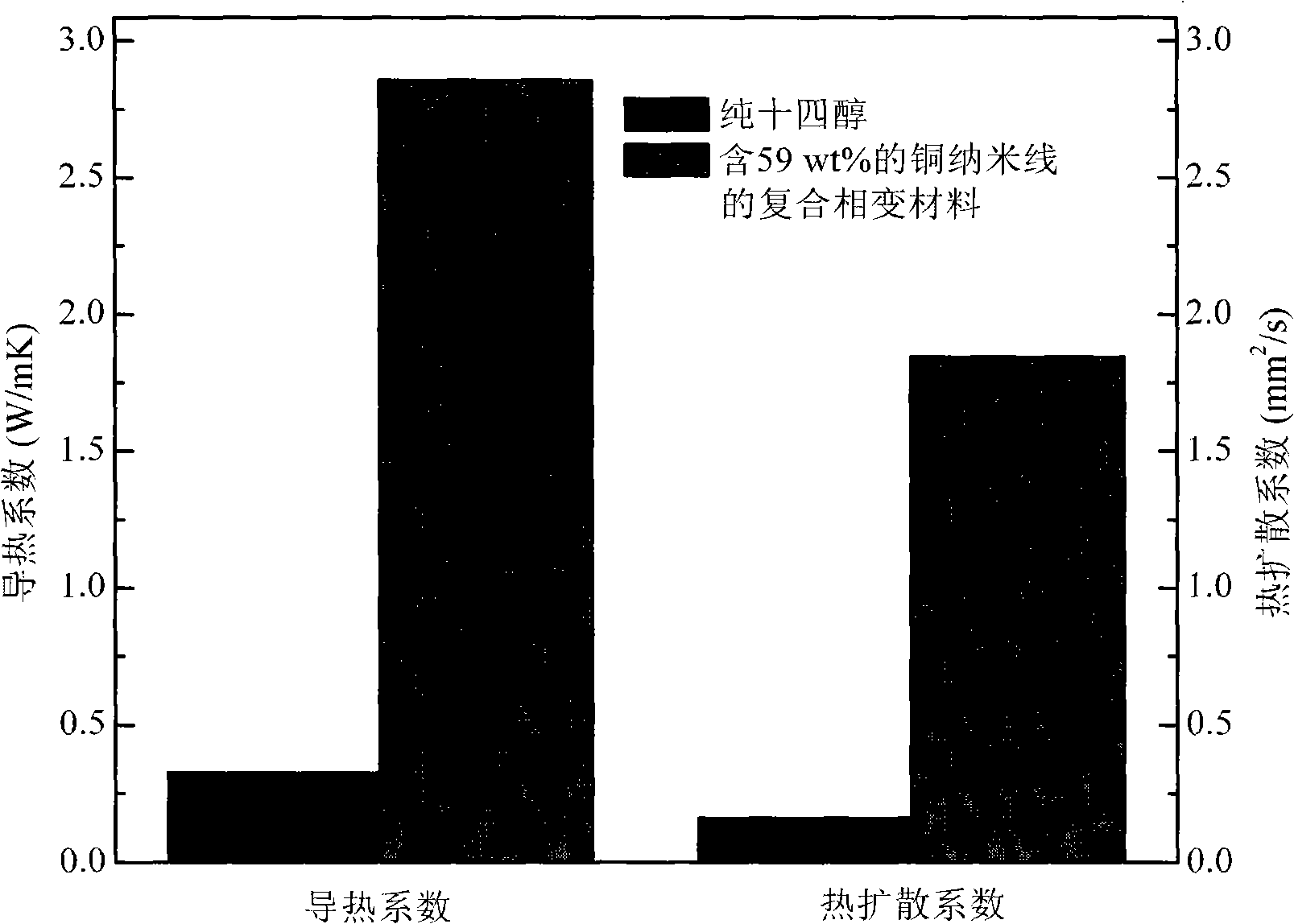

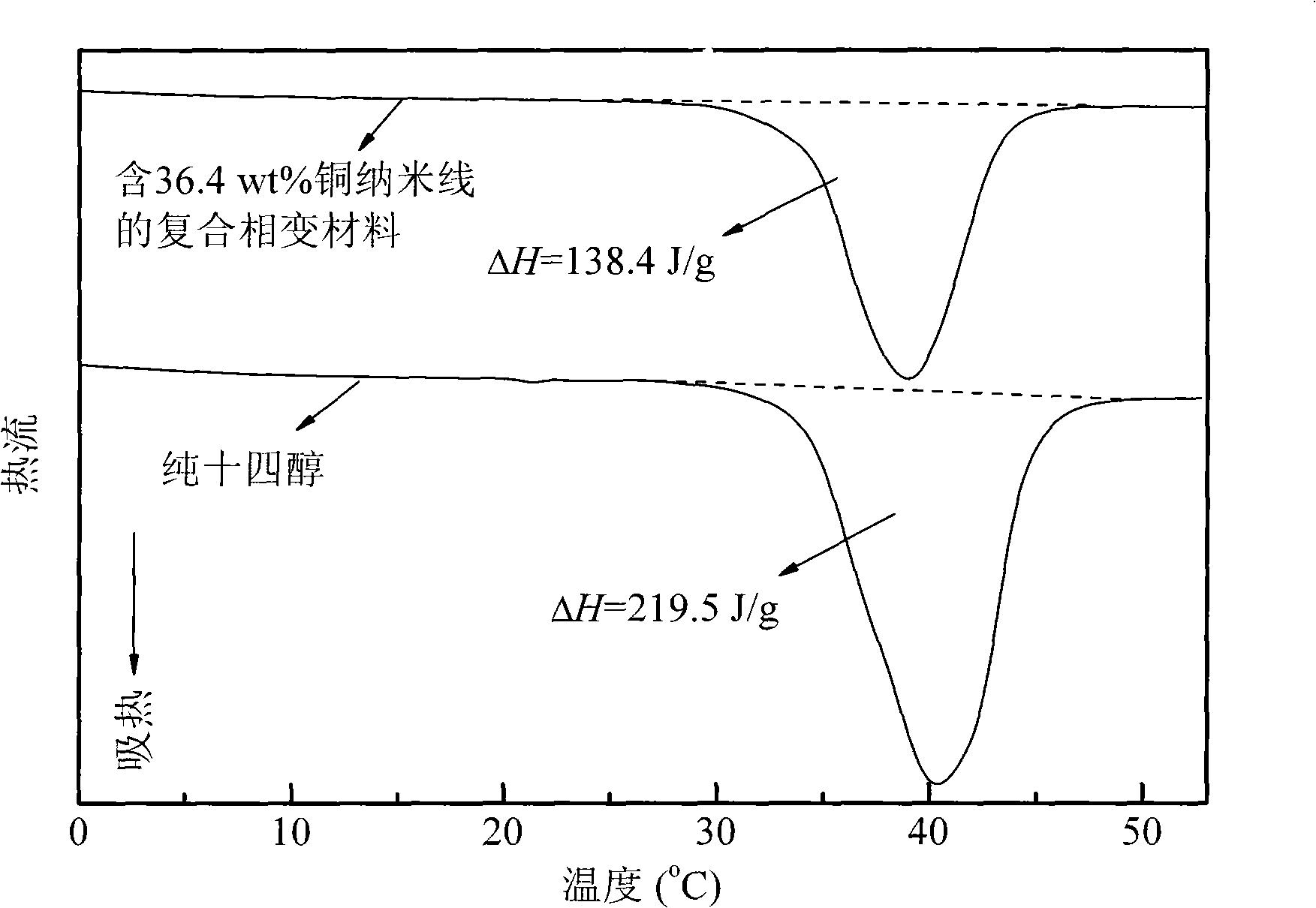

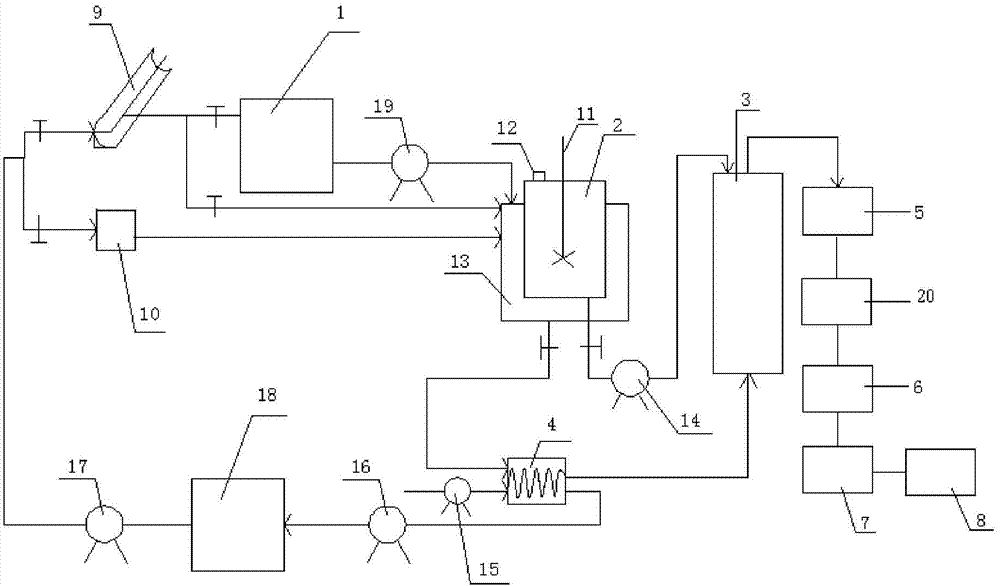

Method for preparing composite phase-changing material

The invention relates to a preparation method of the phase change material, in particular to a preparation method of the compound phase change material which has a higher latent heat of phase change and a high thermal conductivity under the solid and the liquid states. The preparation steps are as follows: firstly, metal nanowires are prepared; secondly, the metal nanowires are dispersed into an organic solvent; thirdly, an organic phase change material and the mixture are mixed; fourthly, the mixture is dispersed by ultrasonic under the condition of heating, and the organic solvent is removed. The phase change material prepared by the method has the advantages that the art is simple, the cost is low, and the thermal conductivity of the organic phase change material is enhanced greatly while the latent heat of phase change is maintained, thus the performance of the organic phase change material is improved effectively, and the application scope is greatly developed.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Molten nano-carbonate heat transfer and accumulation medium, and preparation method and application thereof

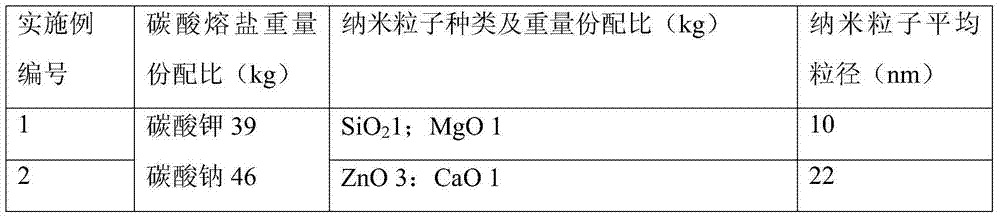

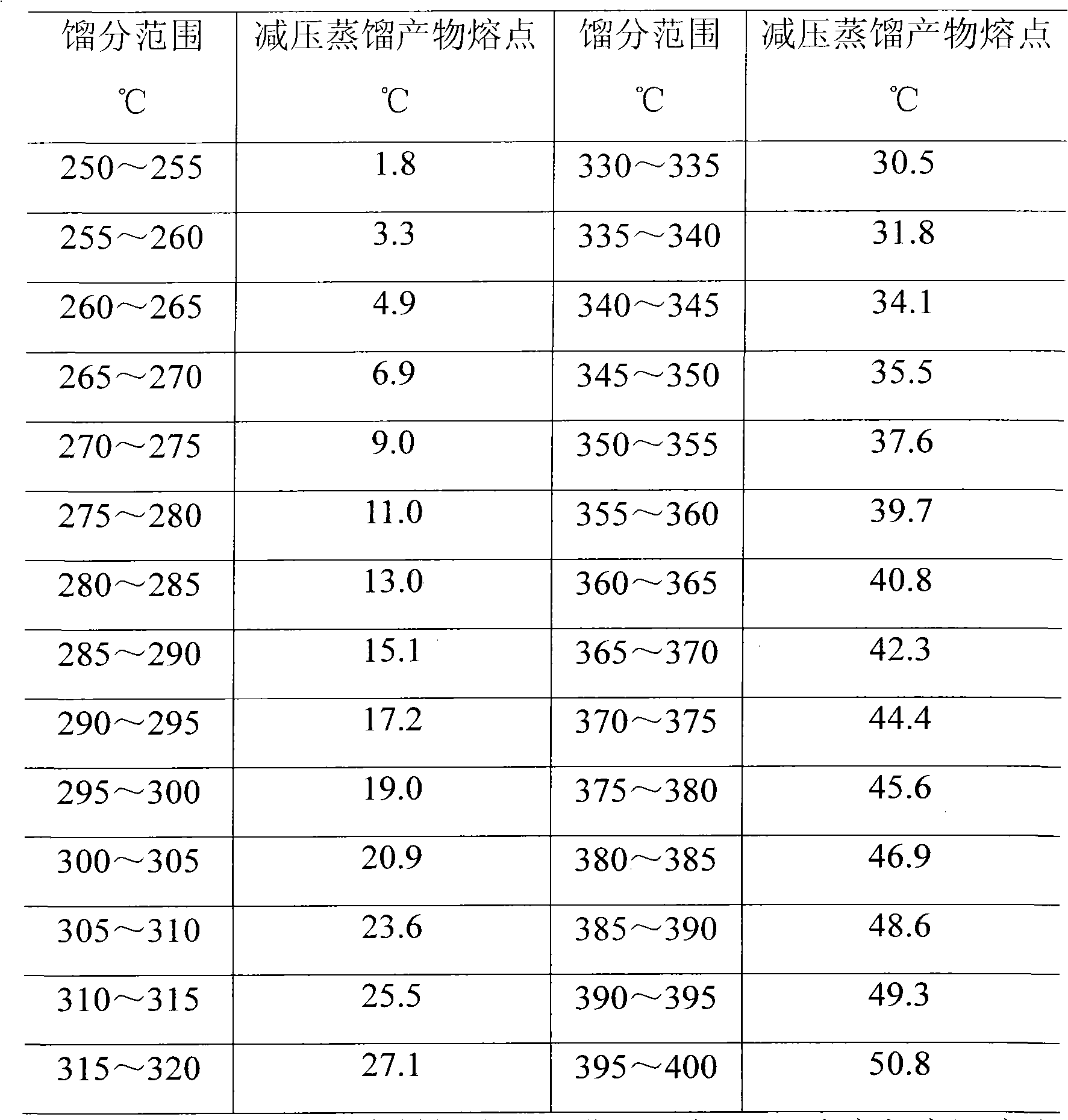

ActiveCN103923619AHigh safe use upper limit temperatureReduce volume shrinkage ratioHeat-exchange elementsHeat stabilityNanoparticles dispersion

The invention provides a molten nano-carbonate heat transfer and accumulation medium, and a preparation method and an application thereof, and belongs to the technical field of heat storage and transmission. The molten nano-carbonate heat transfer and accumulation medium contains a molten carbonate system formed by potassium carbonate, sodium carbonate, lithium carbonate and sodium chloride, nanoparticles are added into the molten carbonate system, and the nanoparticles are metal oxide and / or nonmetal oxide; and the nanoparticles are dispersed into the molten carbonate system, and the molten nano-carbonate heat transfer and accumulation medium is formed through compounding. The melting point of molten nano-carbonate is low, so the molten nano-carbonate heat transfer and accumulation medium has an upper limit use temperature of 800DEG C, has a good heat stability and a high heat conductivity, and is very suitable for the heat accumulation and transfer systems of industrial energy accumulation and solar photo-thermal power generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

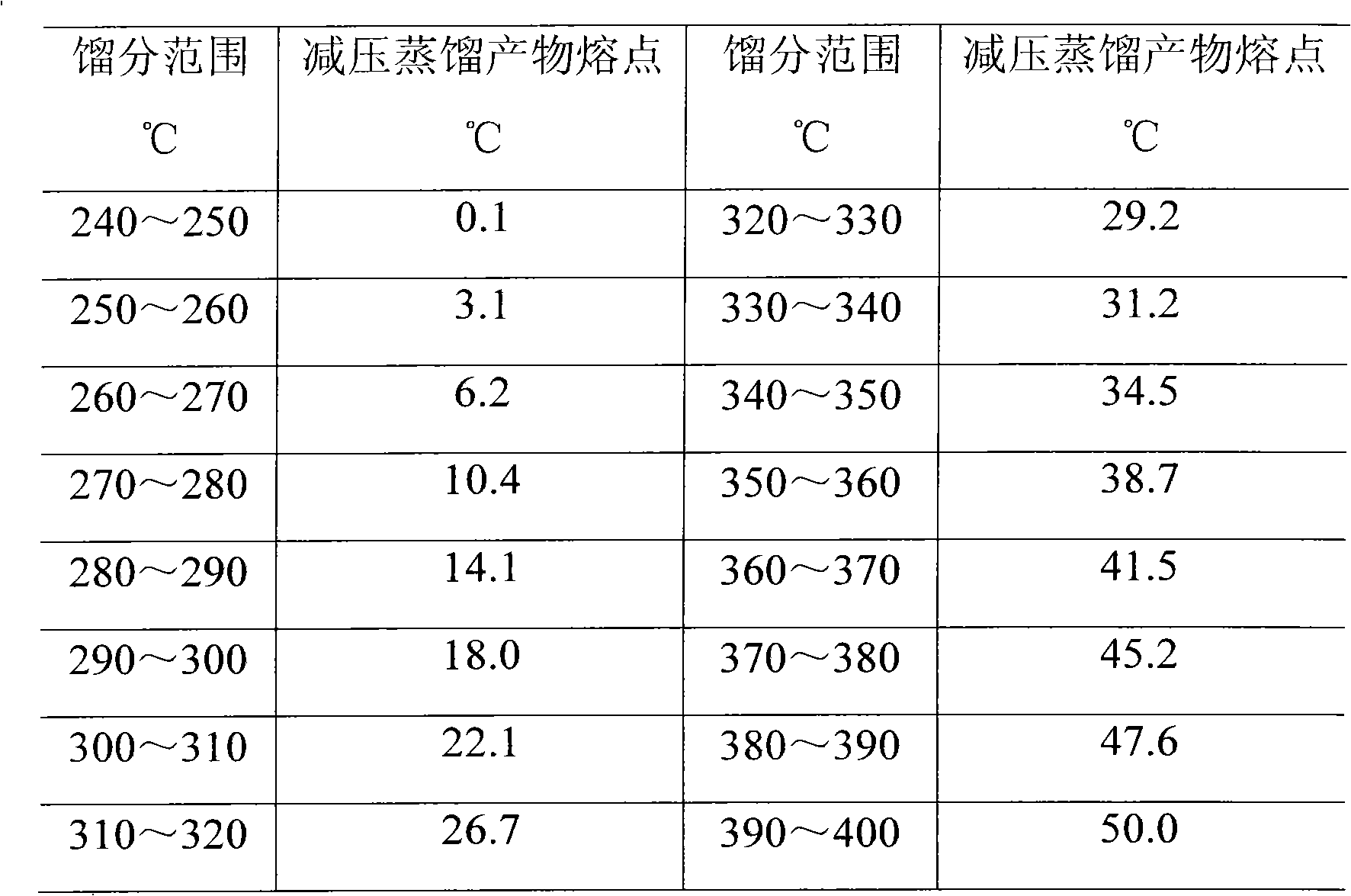

Method for preparing phase-change materials from Fischer-Tropsch (F-T) synthesis product

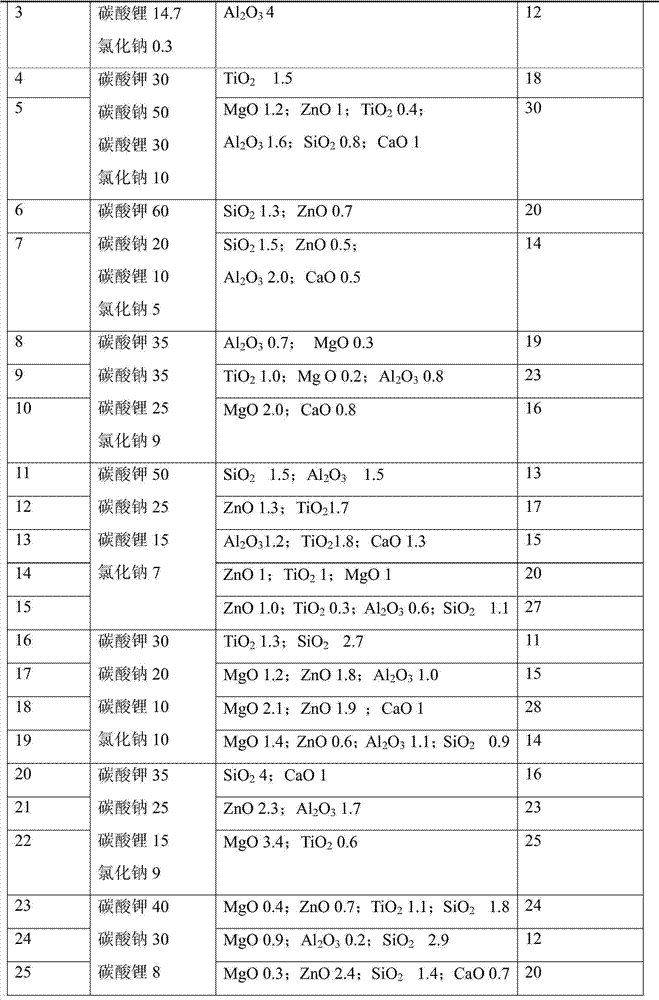

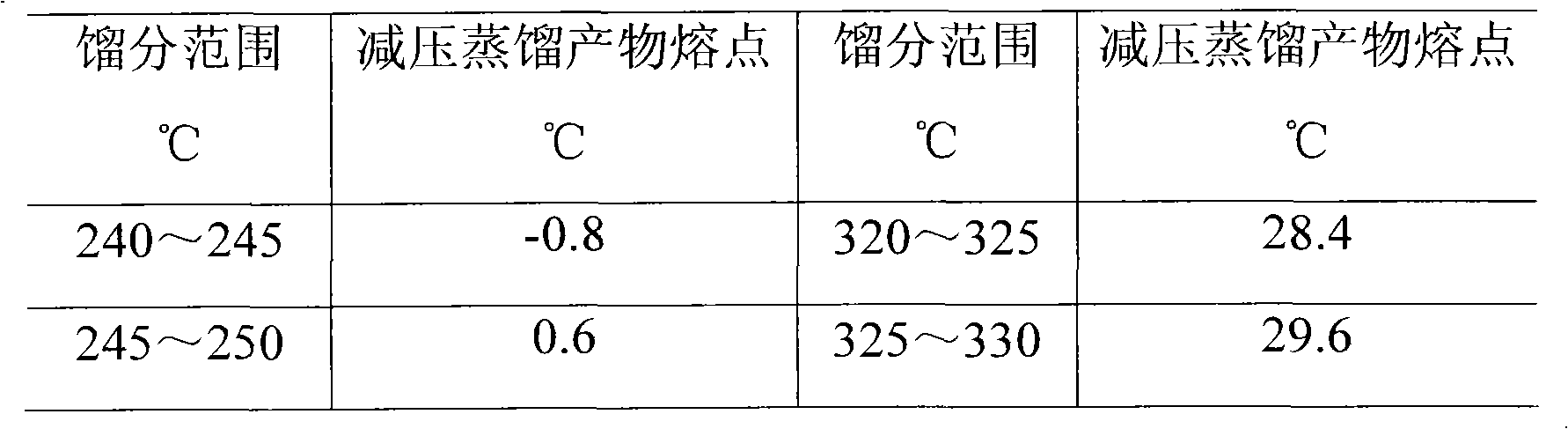

ActiveCN102041090AImprove performanceHigh latent heat of phase changeHydrocarbon distillationTreatment with hydrotreatment processesFiberOxygen

The invention relates to a method for preparing phase-change materials from a Fischer-Tropsch (F-T) synthesis product. The comprises the following steps: in the presence of catalyst, carrying out hydrogenation transformation on the F-T synthesis product in which the weight content of normal paraffin hydrocarbons is greater than 85%, thereby transforming olefins and oxygen-containing compounds in the F-T synthesis product into the proper components of the phase-change materials; and distilling the hydrogenated product, and preparing the fraction within the range of 240-400 DEG C according to the fraction width of 5-20 DEG C, wherein the mixture of all the fractions or any fraction is the phase-change material. The method has the advantages of simple process and low production cost, and is especially suitable for preparing serial phase-change materials; and the prepared phase-change materials have the characteristics of high phase-change latent heat, continuously adjustable phase-change temperature and the like. The phase-change materials can be used in the fields of fiber fabrics, architectural energy conservation, electric appliance protection and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

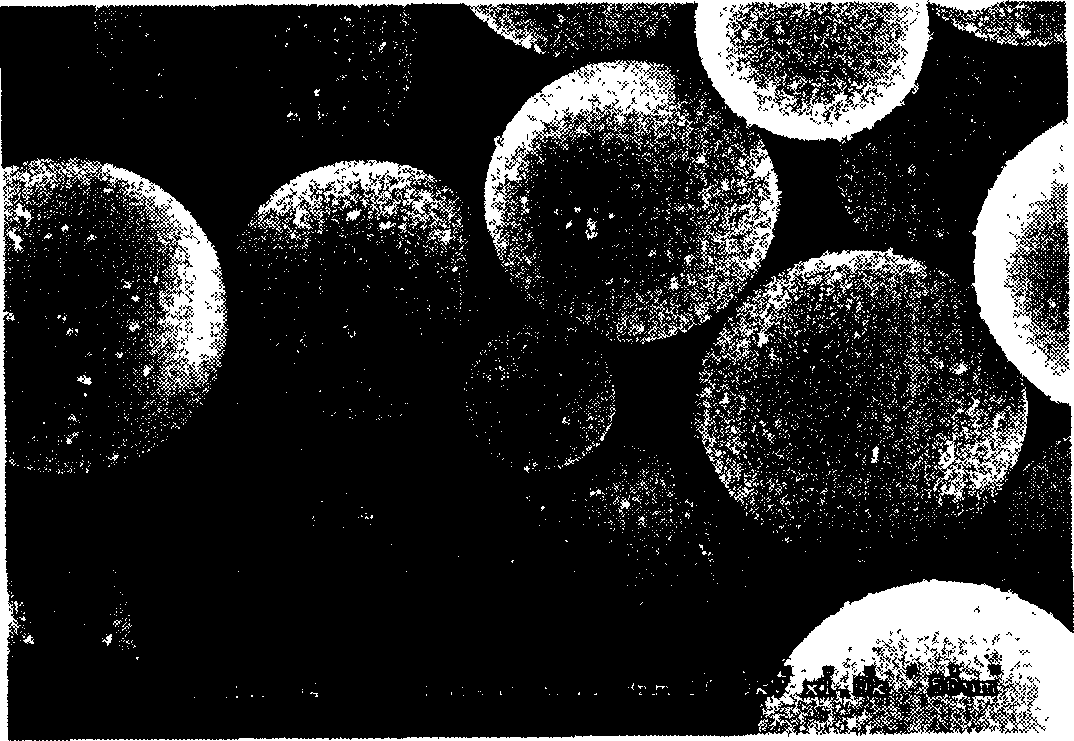

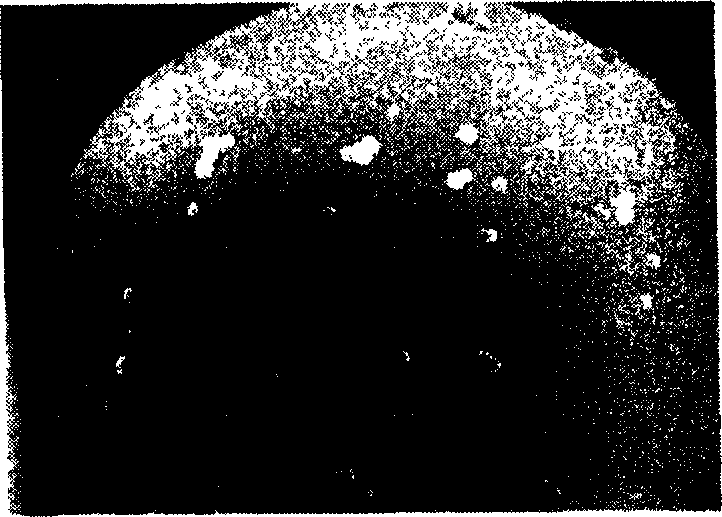

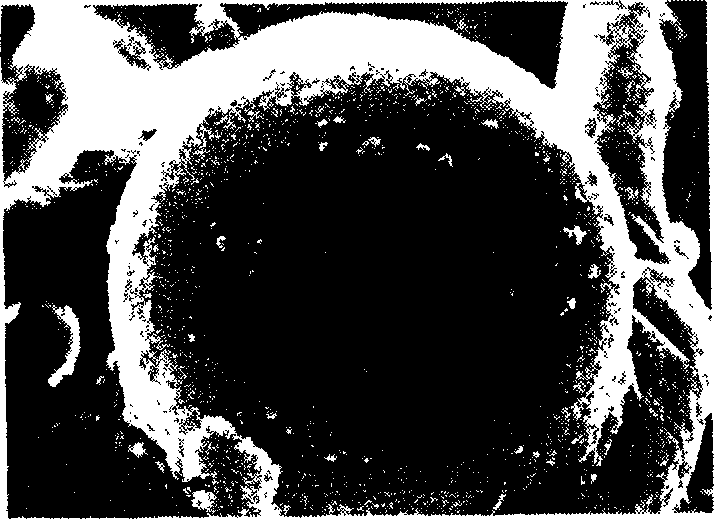

Phase change energy storage microcapsule of composite shell and its making method

InactiveCN1570014ASmooth and dense surfaceComplete appearanceHeat-exchange elementsMicroballoon preparationHexadecaneComposite construction

The invention discloses a phase change energy storage microcapsule of composite shell and its making method, wherein the core material of the microcapsule employs tetradecane, pentadecane or hexadecane, the shell layer has a composite construction, the inner layer is melamine resin, the outer layer is PEG200 modified melamine resin, or PEG200 modified melamine, or copolycondensation resin of methyl poultry manure amine, acetyl poultry manure amine or benzene substituted melamine.

Owner:TIANJIN UNIV

Medium-temperature phase-change heat storage material and preparation method thereof

ActiveCN104559936AHigh latent heat of phase changeImprove heat resistanceHeat-exchange elementsHeat conductingAdhesive

The invention relates to a medium-temperature phase-change heat storage material and a preparation method thereof. The medium-temperature phase-change heat storage material is composed of the following components in percentage by weight: 80-90% of adipic acid, 5-10% of rare-earth oxide, 5-10% of graphene and adhesive which accounts for 3 wt% of the sum of adipic acid, rare-earth oxide and graphene. The preparation method comprises the following steps: (1) weighing the raw materials of the medium-temperature phase-change heat storage material according to the weight percentage; (2) mechanically mixing the adipic acid, rare-earth oxide and graphene uniformly, adding into a crucible, putting in a vacuum drying oven, and carrying out melt adsorption at 150-160 DEG C for 6 hours; and (3) doping the adhesive, and carrying out pelleting forming to obtain the medium-temperature phase-change heat storage material. The simple technique for preparing the medium-temperature phase-change heat storage material has the advantage of short production cycle; and the prepared phase-change heat storage material has favorable heat-conducting property and heat stability.

Owner:WUHAN UNIV OF TECH

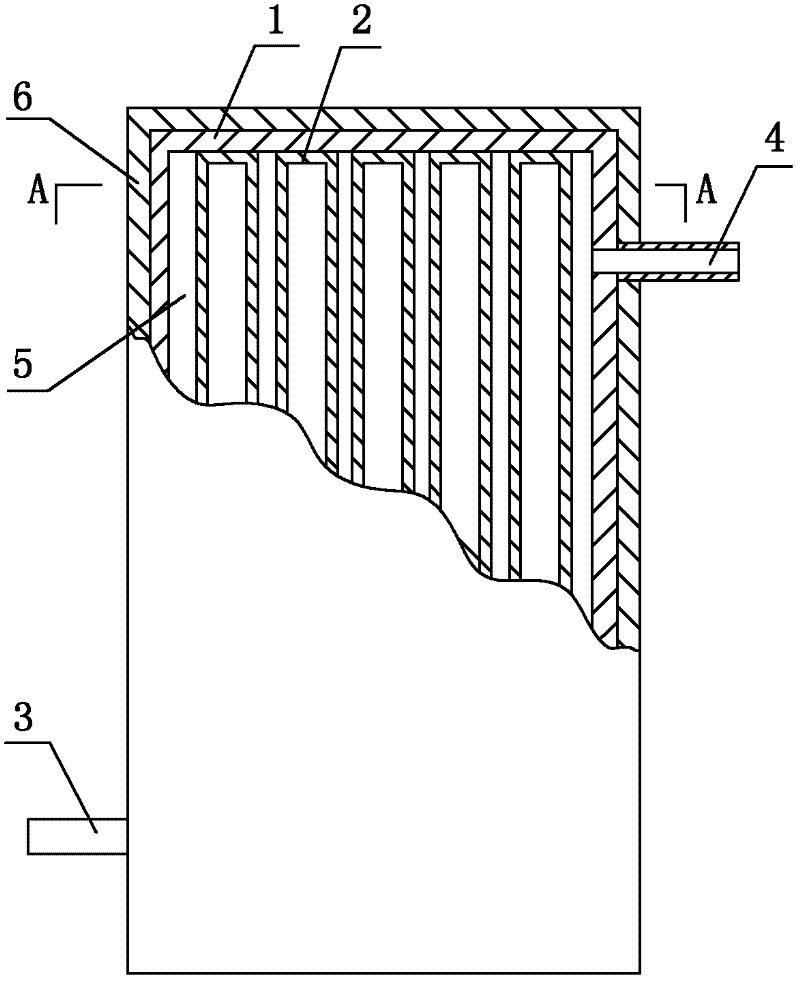

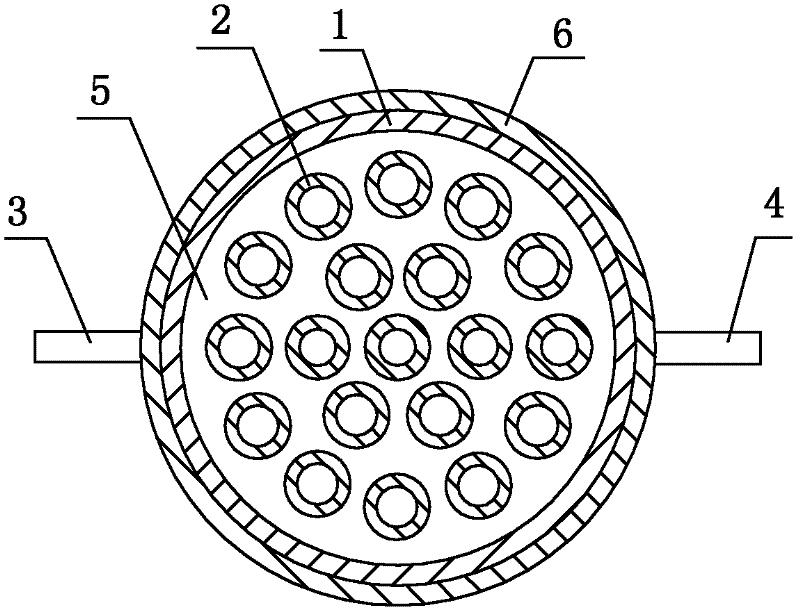

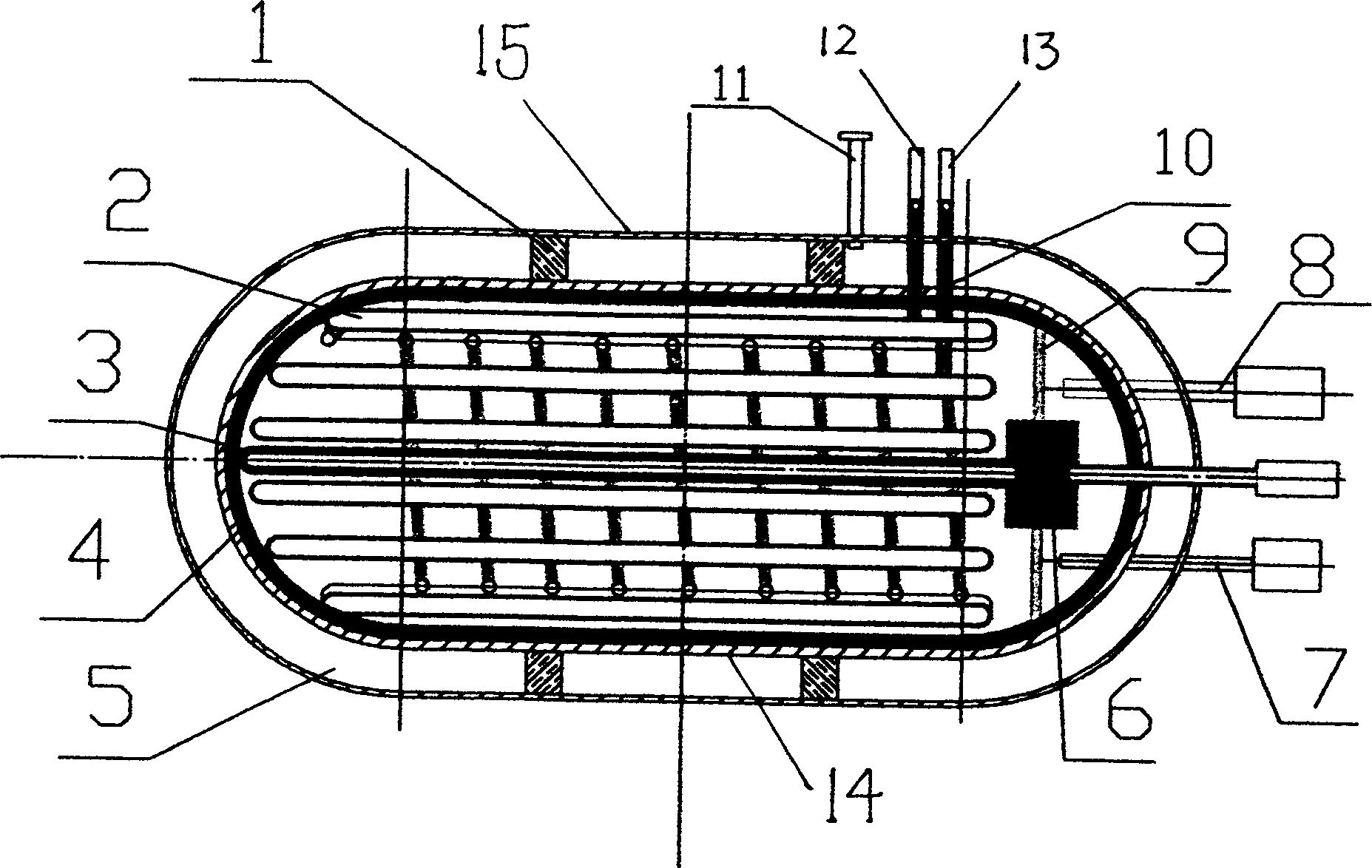

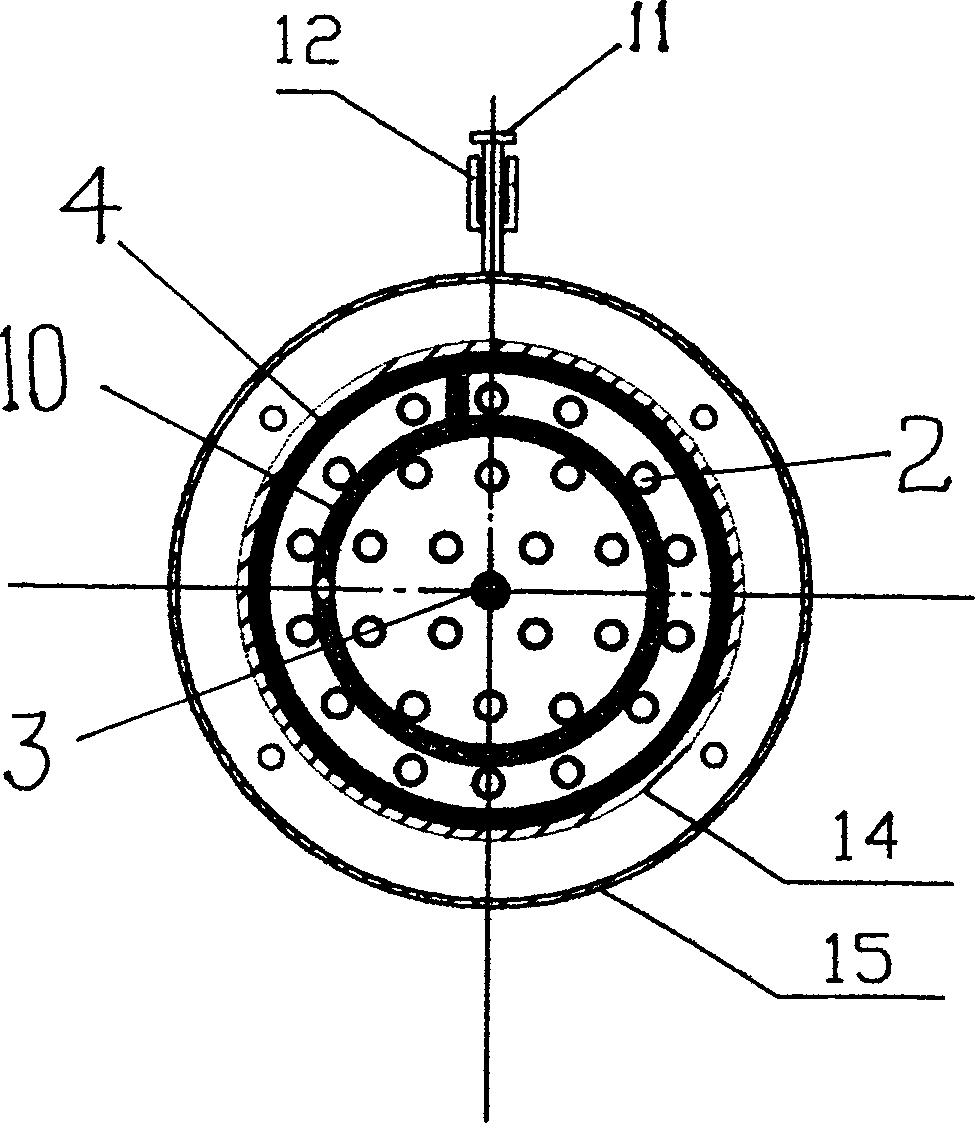

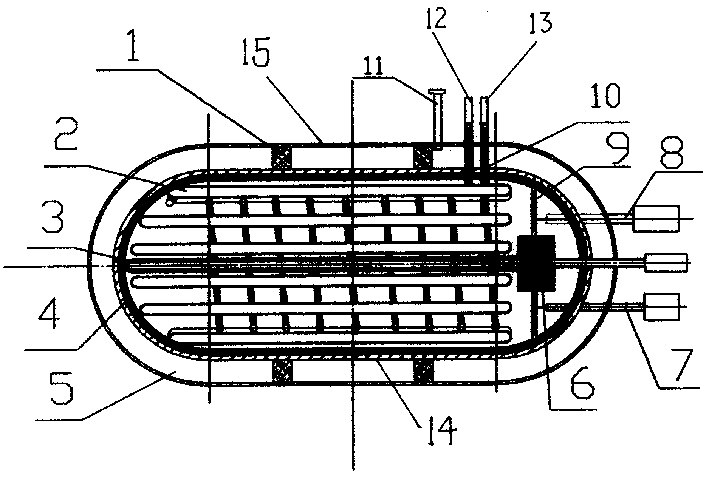

Fused salt phase change heat storage device applied to solar air conditioner

InactiveCN102252545AImprove heat transfer efficiencyGuarantee safety and reliabilityHeat storage plantsEnergy storageHeat conductingHeat storage material

The invention relates to a fused salt phase change heat storage device applied to a solar air conditioner. The fused salt phase change heat storage device applied to the solar air conditioner is characterized by comprising a heat storage chamber box, heat storage material accommodating pipelines, a heat storage material and heat conducting oil; a heat storage space is formed in the heat storage chamber box, the heat storage chamber box is provided with an oil inlet and an oil outlet, the oil inlet and the oil outlet are communicated with the heat storage space respectively, 2 to 200 heat storage material accommodating pipelines are arranged in the heat storage space of the heat storage chamber box, the heat storage material accommodating pipelines are fixed with the heat storage chamber box, and the heat storage material is filled in the heat storage material accommodating pipelines; and a heat transfer medium between the outer walls of the heat storage material accommodating pipelines and the inner wall of the heat storage chamber box is the heat conducting oil. The fused salt phase change heat storage device has the characteristics of simple structure, safety, reliability and high heat exchange efficiency.

Owner:WUHAN UNIV OF TECH

Graphitized graded porous carbon composite phase change energy storage material and preparation method thereof

ActiveCN109321211AImprove adsorption capacityHigh latent heatCarbon compoundsHeat-exchange elementsHeat conductingPorous carbon

The invention discloses a graphitized graded porous carbon composite phase change energy storage material and a preparation method thereof. A carbon precursor with a low price, a graphitization catalyst and a pore-forming agent are used as raw materials and are treated through technologies including ball milling and mixing, carbonization and the like to prepare graphitized graded porous carbon; then the prepared graphitized graded porous carbon is used as a supporting material and is compounded with a phase change material to obtain the graphitized graded porous carbon composite phase change energy storage material. The porous carbon material prepared by the invention has a three-dimensional intercommunication graded porous network structure and a high graphitization degree; the sizing andpackaging of the phase change material are easy to realize; meanwhile, a good heat-conducting network channel can be provided and the heat transferring performance is enhanced; the porous carbon material is prepared by adopting an additive containing metal salt; in a preparation process, part of metal substances can be reduced by utilizing carbothermal reduction reaction and the heat conduction performance of the material is further increased, so that the composite phase change energy storage material with high heat conduction performance and good chemical stability is obtained.

Owner:FUZHOU UNIV

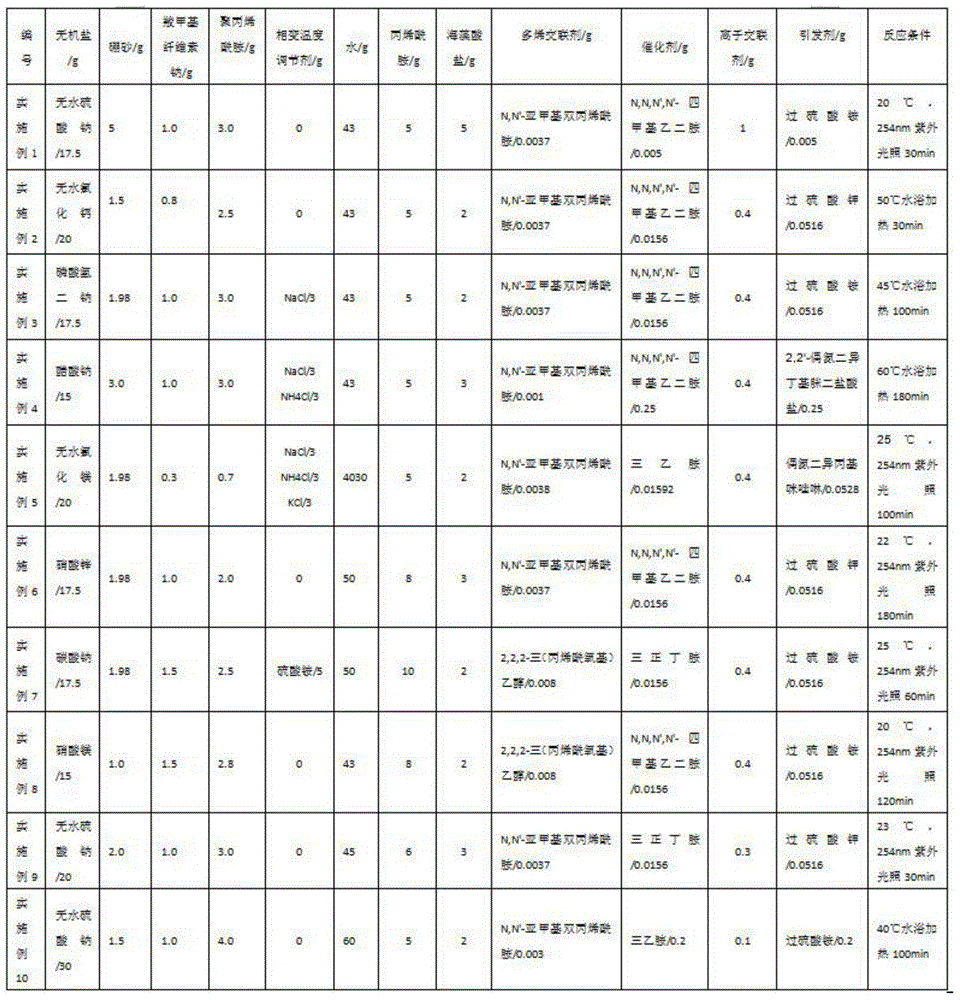

Solid-solid phase change energy storage hydrogel with stable shape and preparation method thereof

The invention discloses a solid-solid phase change energy storage hydrogel with a stable shape. The hydrogel is prepared from the following components in parts by weight: 15-30 parts of inorganic salt, 1-5 parts of nucleating agent, 1-5 parts of thickening agent, 0-15 parts of phase change temperature conditioning agent, 30-60 parts of distilled water, 5-10 parts of acrylamide, a polyene crosslinking agent, an initiator, a catalyst, 2- parts of alginate and an ionic crosslinking agent, wherein the mass of the polyene crosslinking agent is 0.02-0.15 percent of the mass of the acrylamide; the mass of the initiator is 0.1-5 percent of the mass of the acrylamide; the mass of the catalyst is 0.1-5 percent of the mass of the acrylamide; the mass of the ionic crosslinking agent is 5-20 percent of the mass of the alginate. The hydrogel is a solid-solid phase change energy storage hydrogel having a multiple network with a stable shape, and has good toughness and elasticity and good mechanical performance, and the material keeps an excellent solid state before and after phase change.

Owner:SOUTHEAST UNIV

High-phase-change thermoset phase change material and preparation method thereof

The invention discloses a high-phase-change thermoset phase change material. The high-phase-change thermoset phase change material is prepared form expandable graphite of which the expansion multiplying power is 100-500mL / g and erythritol which is adsorbed into gaps of the expandable graphite, wherein the weight of the expandable graphite accounts for 10-20 percent of the total weight, and the balance is erythritol. The method comprises the following steps of: heating erythritol in an oil bath of 125-135 DEG C according to a certain proportion till the erythritol is fully molten for later use; putting expandable graphite into a vacuum drying oven; drying at the temperature of 65-75 DEG C under the vacuum degree of -0.09MPa for 8-12 hours; taking out, and putting into a muffle furnace of which the temperature is 700-800 DEG C for calcining for 30-90 seconds to form expansion graphite with a microcellular structure for later use; stirring the two kinds of materials in the oil bath for 1-1.5 hours; and naturally cooling to obtain a product. The high-phase-change thermoset phase change material is simple in structure; and according to the porous adsorption characteristic of the expansion graphite and the high-phase-change potential heat value of the erythritol, the product has higher phase change potential heat value than a phase change material prepared in the prior art.

Owner:HENAN UNIV OF SCI & TECH

Phase change heat storage material as well as preparation method and application thereof and phase change heat storage device

ActiveCN105086948AHigh latent heat of phase changeLow toxicityHeat storage plantsEnergy storageHeat conductingCollector device

The invention discloses a phase change heat storage material as well as a preparation method and application thereof and a phase change heat storage device. The phase change heat storage material comprises the following raw materials in parts by mass: 60-75 parts of hydrous salt, 0.5-3 parts of nucleating agents, 1-3 parts of anti-supercooling agent, 1-3 parts of phase splitting preventing agent, 1-5 parts of heat conducting reinforcing materials and 1-5 parts of rare earth compound. The preparation method is characterized by mixing various raw materials, melting, uniformly mixing and cooling the mixture and then grinding the mixture into powder, thus obtaining the phase change heat storage material. The phase change heat storage material is applied to a heat collector. The phase change heat storage device comprises a shell and the phase change heat storage material arranged in the shell. The phase change heat storage material has the beneficial effects that the phase change heat storage material has higher phase change latent heat, low toxicity and weak corrosivity; the phase change heat storage material is encapsulated in the shell and then the shell is placed in the heat collector, thus avoiding the problem of corrosion or scaling caused because the phase change heat storage material comes into direct contact with the wall of the heat collector; the phase change heat storage material has a better application prospect in the field of solar power generation.

Owner:汉诺威智慧能源科技(内蒙古)有限公司

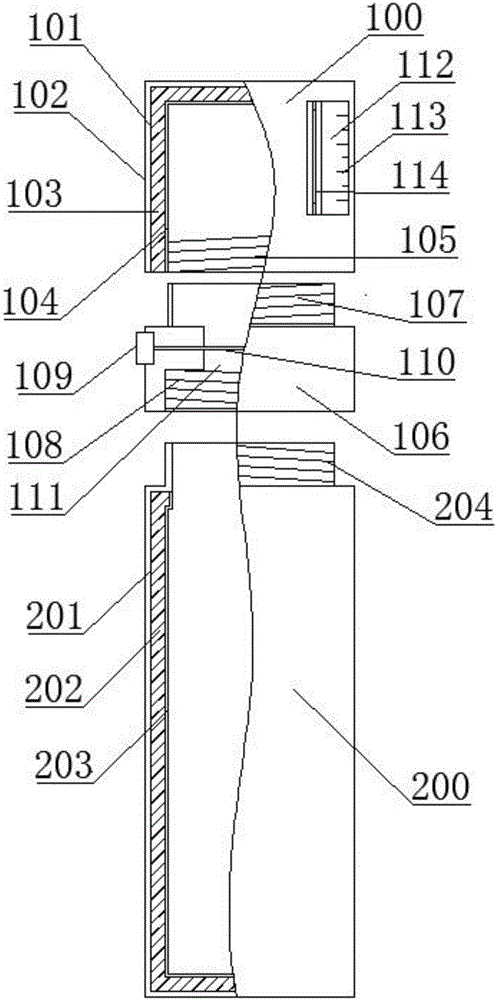

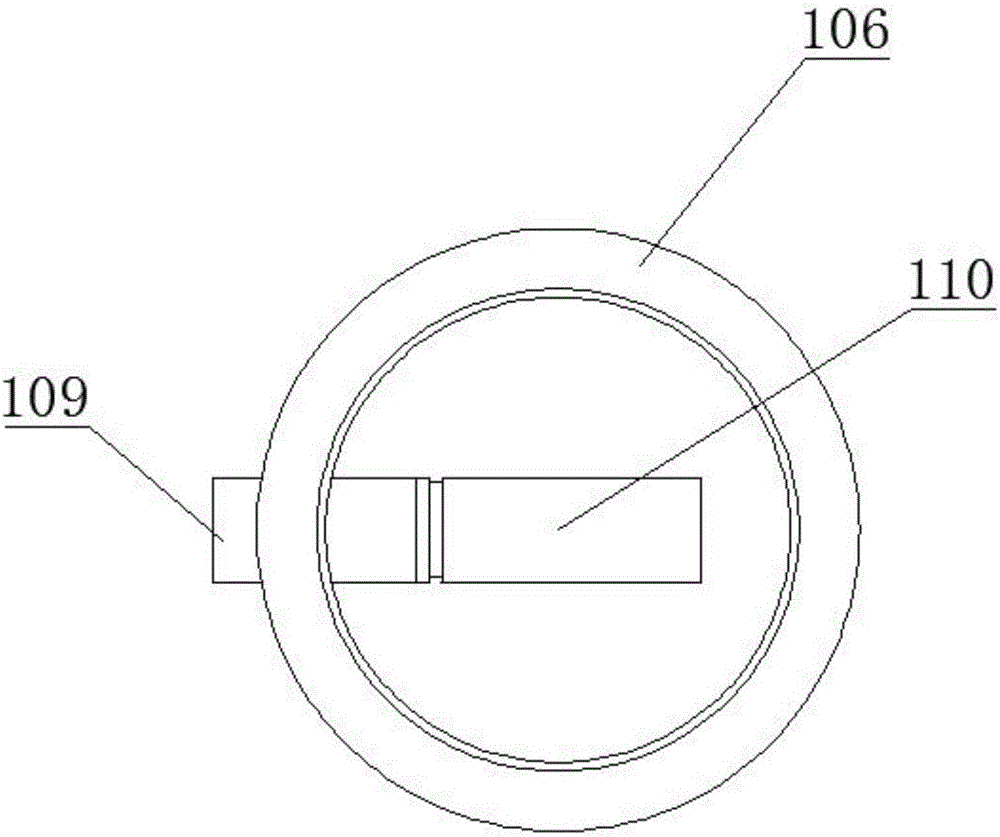

Thermal storage type high efficiency hydrogen storage apparatus used for magnesium base hydrogen storage material

InactiveCN1430010AHigh latent heat of phase changeTo offer comfortFixed capacity gas holdersHydrogen technologiesHeat transfer tubeThermal energy storage

An efficient heat-accumulated hydrogen accumulator for Mg-base hydrogen-bearing material is a cylindrical body, which is composed of external and internal shells and vacuum layer between them, insulating layer on the inner surface of internal shell, heat accumulating tubes in the insulating layer, heat transfer tube at inside of the most external heat accumulating layer, hydrogen distributing and filtering tube passing through hdyrogen filter layer and installed at central position of internal shell, and hydrogen filter layer installed on supporting plate on the internal shell. It features that the heat generated by absorbing hydrogen is accumulated for supplying it when hydrogen is released.

Owner:HARBIN INST OF TECH

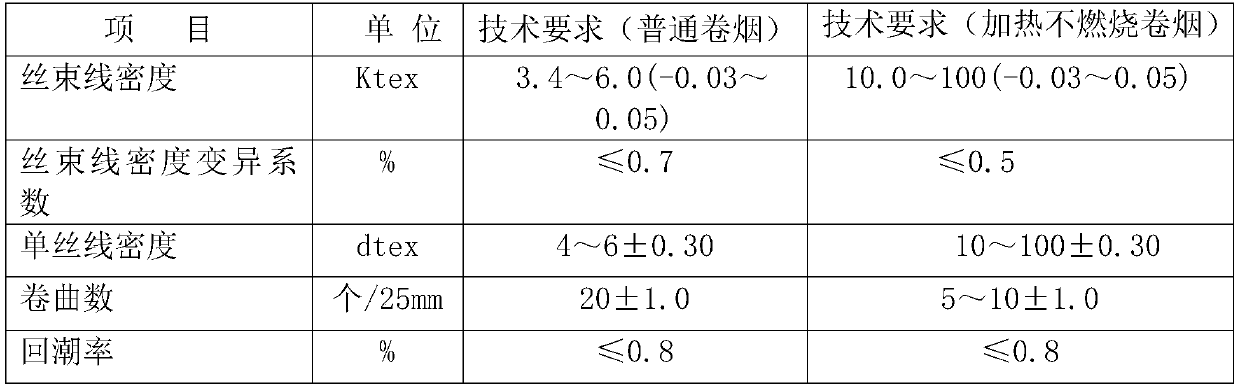

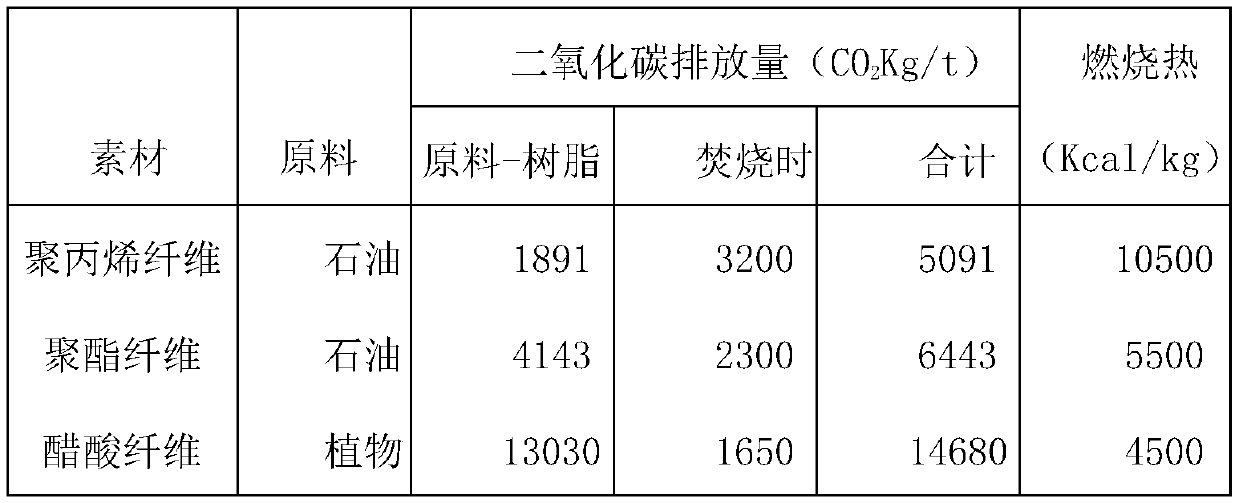

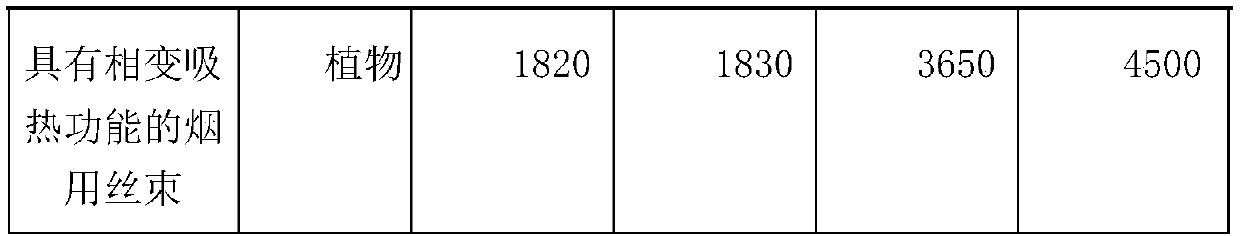

Cigarette tow with phase change heat absorption function and preparation method of cigarette tow

InactiveCN109763189AUnique smelling styleReduce the temperatureFlame-proof filament manufactureCigarette manufactureAbsorption capacityHazardous substance

The invention discloses a cigarette tow with a phase change heat absorption function. The tow is obtained as follows: microcapsules containing a phase change agent are added to a food fiber-grade polylactic acid material in a melt spinning process, and drying, melting, spinning, cooling, oiling, drafting, crimping and drying setting processes are performed. During smoking of a cigarette with a filter tip processed from fiber prepared with the preparation method, polylactic aid hollow fiber has high adsorption / absorption capacity for polar and non-polar smoke component gases; meanwhile, the temperature of smoke passing through the filter tip is increased, the polylactic acid material and the phase change material in the microcapsules absorb heat during phase state conversion, the smoke temperature is decreased, a harm reduction effect is realized, the prepared cigarette with the polylactic acid filter tip has unique smell absorption style, and harmful substances in smoke can be effectively filtered out.

Owner:云南中成道和新材料科技有限公司

High thermal conductivity medium temperature form-stable phase change material and preparation method thereof

InactiveCN104845592AHigh latent heat of phase changeImprove thermal conductivityHeat-exchange elementsActive agentAlcohol sugars

The invention relates to a high thermal conductivity form-stable phase change thermal energy storage material and a preparation method thereof. According to the form-stable phase change thermal energy storage material, carbon nano-materials are taken as heat conductive fillers, water-soluble sugar alcohol is taken as phase change thermal energy storage material, polyaniline is taken as backing material. The preparation of the form-stable phase change thermal energy storage material comprises the following steps of firstly dispersing the carbon nano-materials into ethyl alcohol through an ultrasonic dispersion method, then adding the sugar alcohol and a surfactant to form stable suspension through a method of heating, dissolving, and cooling to separate out, then adding aniline and acid and mixing uniformly, and further adding a oxidizing agent to polymerize the aniline into the polyaniline, so as to obtain the form-stable phase change material after purification and separation. The method has the advantages of simple process and low cost, the obtained form-stable phase change material has very high latent heat of phase change and heat-conducting property, is stable in performance and is no need to be packaged, the performance of a sugar alcohol phase change material is effectively improved, the application range of the sugar alcohol phase change material is expanded, and the material can be widely applied in various fields, such as medium temperature solar energy thermal utilization and recovery of industrial waste heat.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

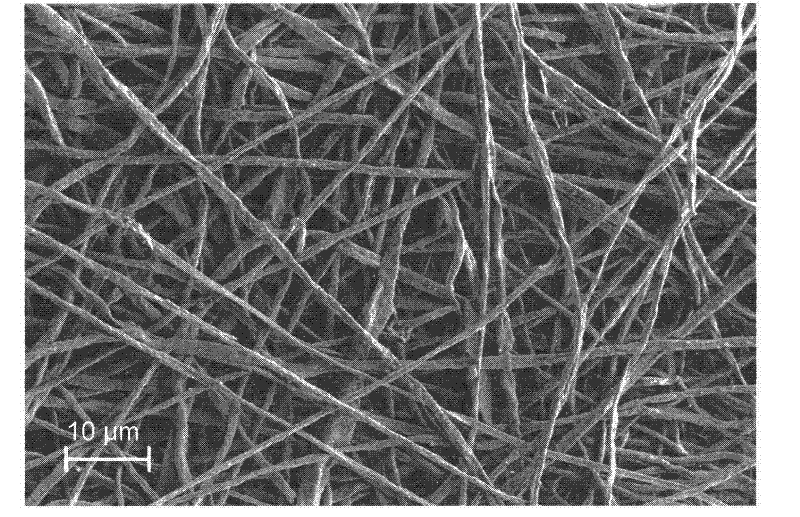

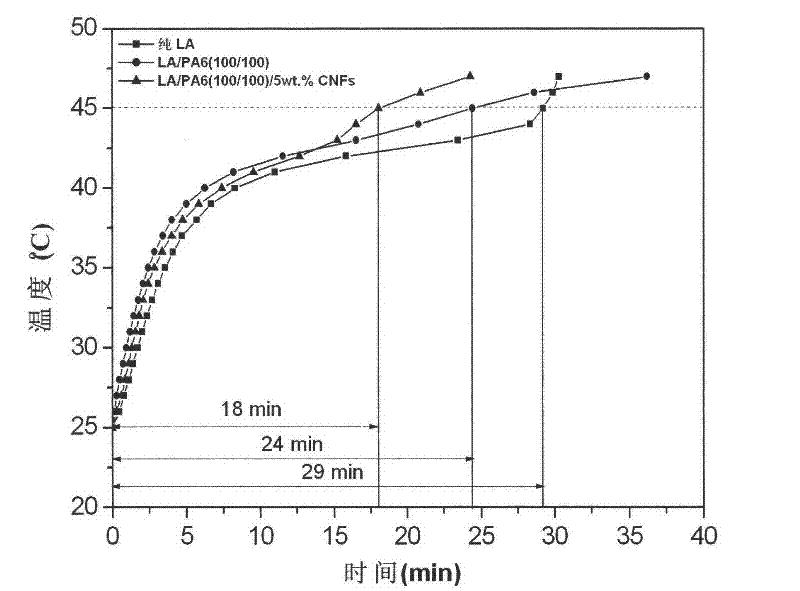

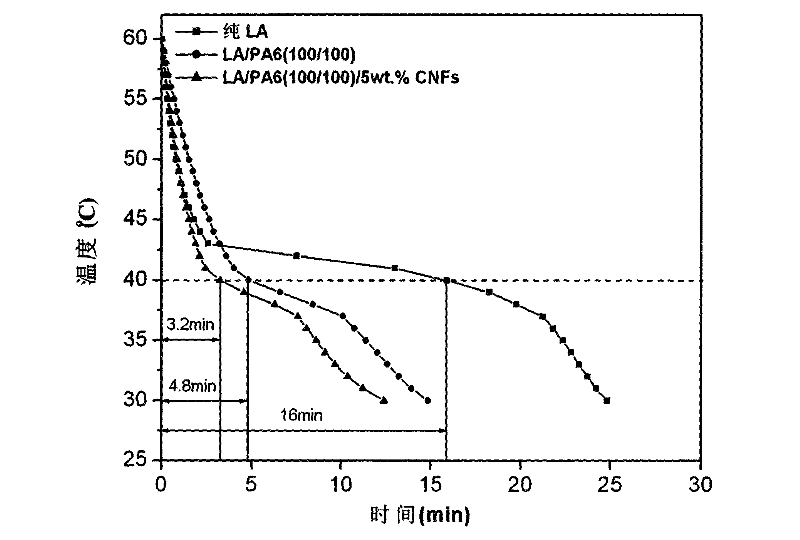

Method for enhancing thermal conductivity of phase-change energy-storage superfine composite polyamide fiber and method for producing phase-change energy-storage superfine composite polyamide fiber

InactiveCN102517793APhase transition temperature is suitableHigh latent heat of phase changeFilament/thread formingNon-woven fabricsElectrospinningCarbon nanofiber

A production method for enhancing thermal conductivity of a fatty acid / polyamide-6 nano composite phase-change material belongs to the technical fields of nanocomposites, phase change materials, electrostatic spinning and the like, and particularly relates to a method of using an electrostatic spinning device to produce a nano composite fiber membrane of fatty acid / pollyamide-6 / carbon nano fibers. The production method is simple in process and easy in control. By effectively combining the production method with the electrostatic spinning technique, the produced fiber is small in diameter and uniform in distribution, the produced nano composite phase change material is uniform, stable and less prone to leakage, and has the thermal conductivity more evident than that of the conventional phase change material. Therefore, the material is more convenient in processing and application, and more widely applicable.

Owner:JIANGNAN UNIV

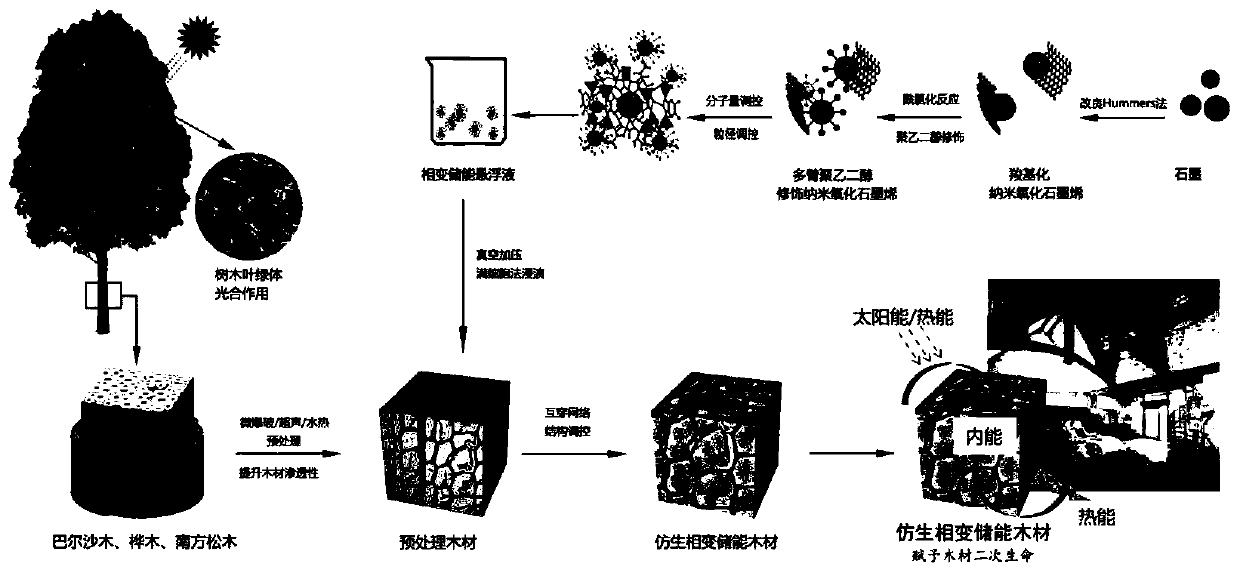

Method for preparing thermal conduction enhanced phase change energy storage wood based on photothermal response

InactiveCN110126043AImproves loss resistanceWide molecular weight rangeWood treatment detailsHeat-exchange elementsSulfite saltPolyethylene glycol

The invention discloses a method for preparing a thermal conduction enhanced phase change energy storage wood based on photothermal response. The method mainly comprises the following steps: (1) carboxylating graphene oxide to obtain carboxylated graphene oxide, performing conjugate grafting on the carboxylated graphene oxide by using ammoniated multi-arm polyethylene glycol, controlling the amount of polyethylene glycol grafted on the surface of graphene, and blending the polyethylene glycol-grafted graphene with polyethylene glycol to prepare a phase change energy storage material; and (2) preprocessing wood with a low-concentration sodium hydroxide and sodium sulfite solution, preparing a solution by using maleic anhydride as esterification agent and acetone as a solvent, impregnating the preprocessed wood in the solution, allowing the above obtained graphene / polyethylene glycol phase change energy storage suspension to infiltrate the wood by a vacuum pressurizing full-cell process,and regulating a multidimensional interpenetrating network structure to obtain the thermal conduction enhanced phase change energy storage wood. A firm amide bond can be formed between graphene and polyethylene glycol to ensure the stability of the phase change system.

Owner:BEIJING FORESTRY UNIVERSITY

Shape-stabilized composite phase change material for energy storage and preparation method thereof

ActiveCN103509525AMild experimental conditionsPrevent leakageHeat-exchange elementsSilica gelPhase change

The invention provides a shape-stabilized composite phase change material for energy storage and a preparation method thereof. The method comprises: uniformly dispersing an organic solid-liquid phase change material in silica sol by utilizing dispersibility of the organic solid-liquid phase change material in silica sol, and gelating under proper temperature and stirring condition, thereby absorbing the organic solid-liquid phase change material in a micropore structure of silica gel. Under action of capillary force and surface tension, the organic solid-liquid phase change material is firmly fixed by silica micropores when generating solid-liquid phase change without seepage, and maintains stable shape. The shape-stabilized composite phase change material for energy storage is obtained through surface hydrophobic treatment after ground to powder. The shape-stabilized composite phase change material for energy storage provided by the method has advantages of non leakage at high temperature (200 DEG C), stable shape and high phase change latent heat.

Owner:重庆中防德邦防水技术有限公司

Boron nitride/graphene double-heat-conduction-base aerogel composite phase change material and preparation method thereof

ActiveCN111662688ALow densityContinuous network structureHeat-exchange elementsFreeze-dryingPyrrolidinones

The invention discloses a boron nitride / graphene double-heat-conduction-base aerogel composite phase change material. The material is formed by compounding modified boron nitride / graphene aerogel andn-octadecane by adopting a vacuum impregnation method. The double-heat-conduction aerogel is prepared by taking graphene oxide, modified boron nitride, polyvinylpyrrolidone and ethylenediamine as rawmaterials to prepare boron nitride / graphene hydrogel, freeze-drying the boron nitride / graphene hydrogel and then calcining the boron nitride / graphene hydrogel at a constant temperature. Polyvinylpyrrolidone is used as a cross-linking agent, and ethylenediamine is used as a reducing agent. A preparation method of the composite phase change material comprises the following steps: 1) preparing modified boron nitride; 2) preparing boron nitride / graphene double-heat-conduction-base aerogel; and 3) preparing the boron nitride / graphene double-heat-conduction-base aerogel composite phase change material. When the material is applied as a phase change material, the heat conductivity coefficient is 0.9-1.6 W / (m.K); wherein the phase change temperature is 19-32 DEG C, and the phase change latent heatis 200-220 J / g. The composite phase change material has the following advantages: 1, the heat conductivity coefficient is improved by 738%; 2, the leakage problem in the phase change process is effectively solved; and 3, the phase-change latent heat and the heat stability are high;

Owner:GUILIN UNIV OF ELECTRONIC TECH

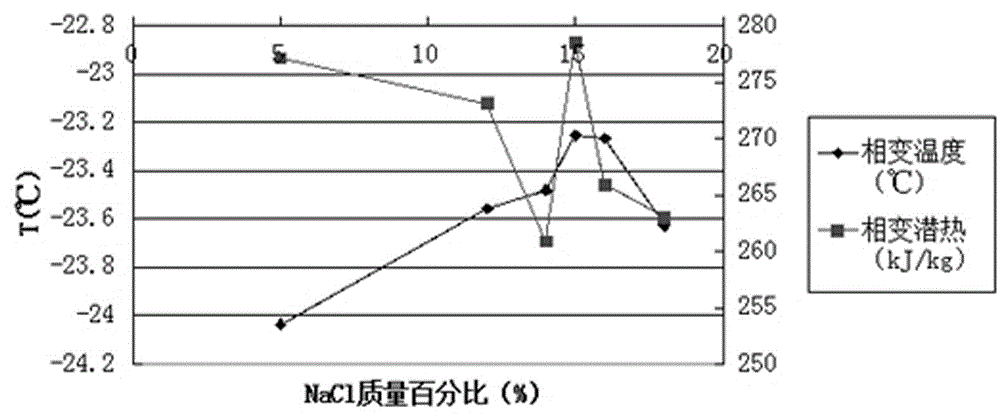

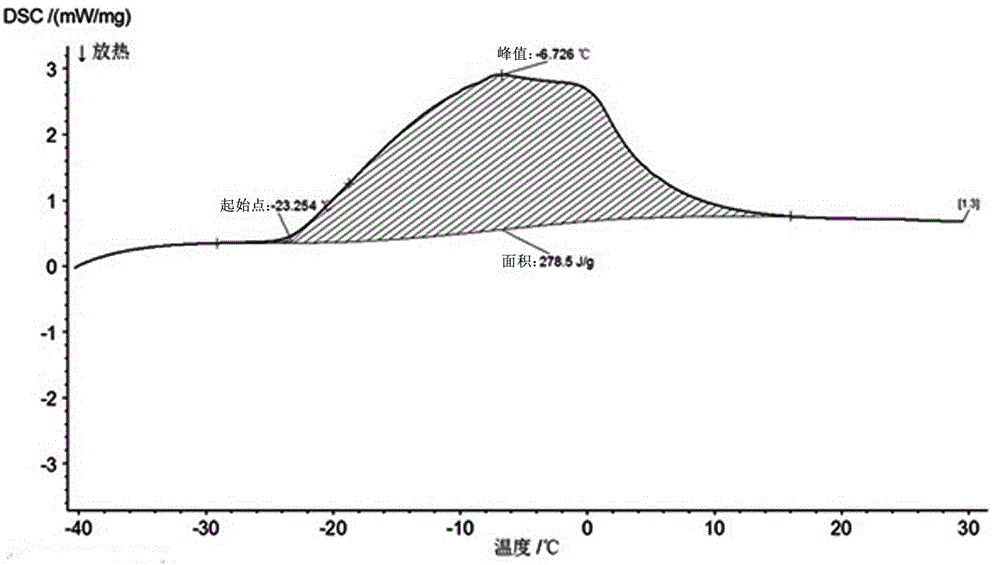

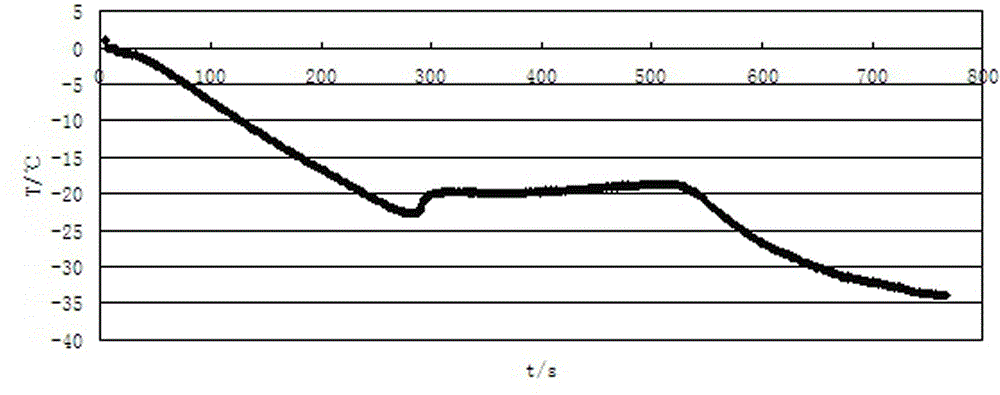

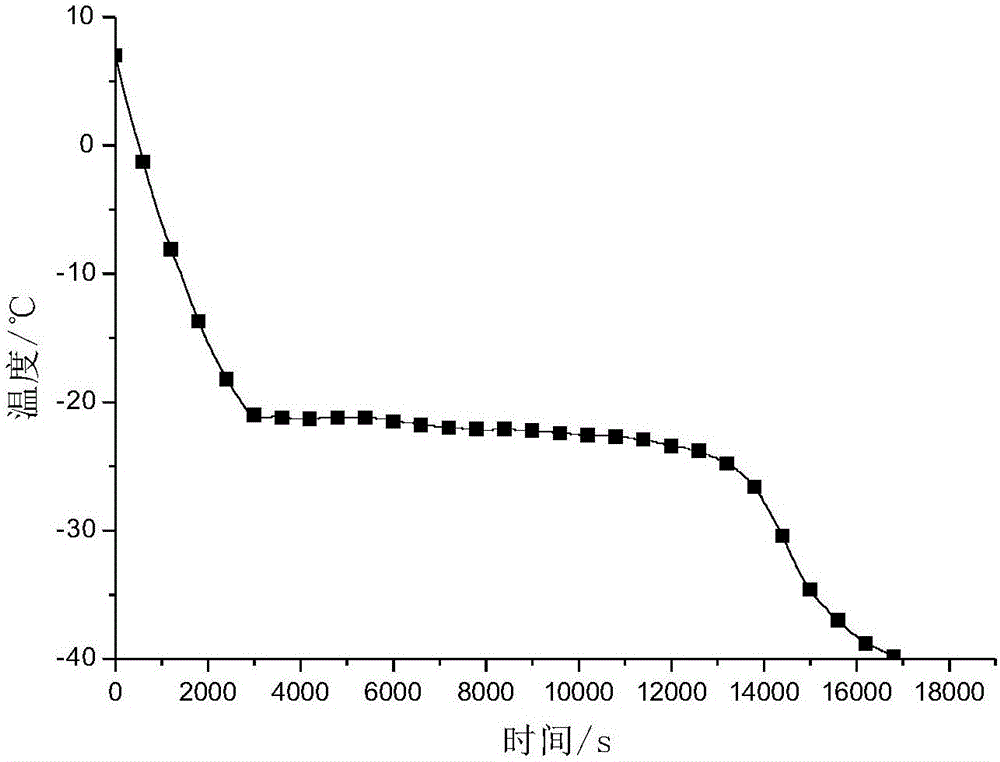

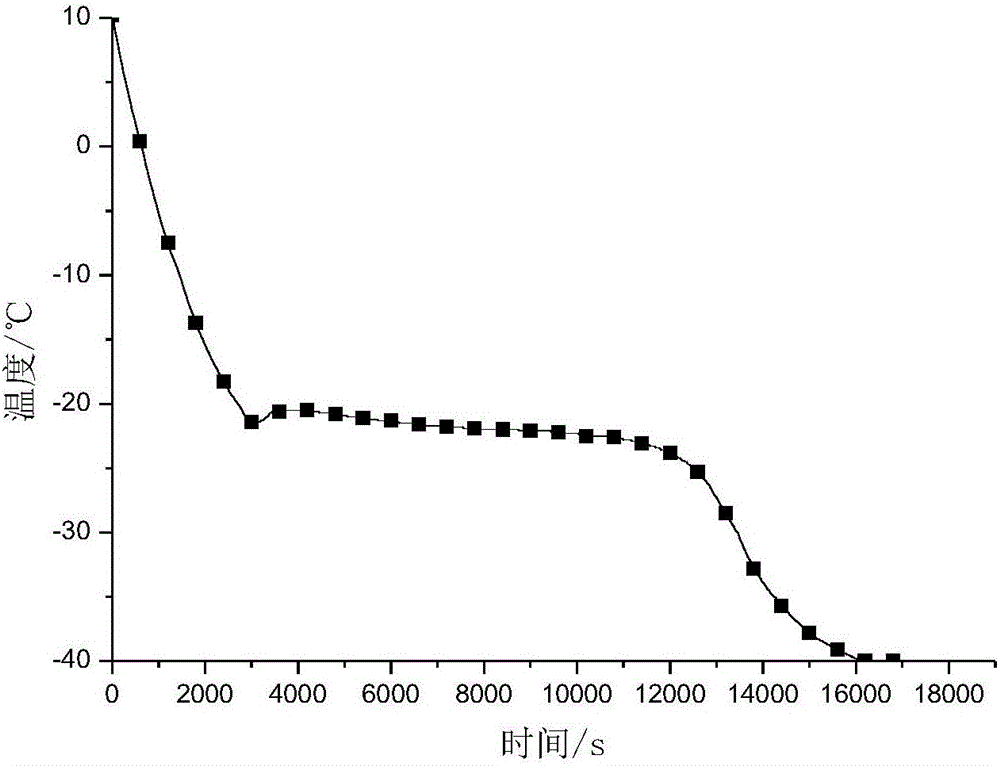

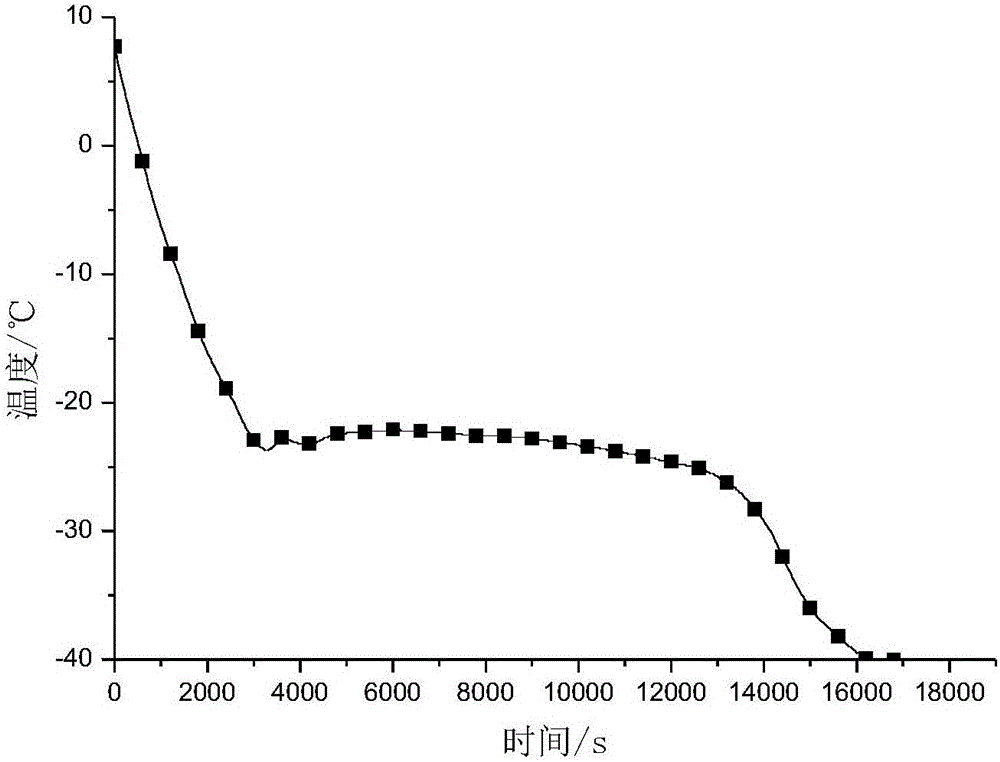

Low-temperature phase change cold storage material and production method thereof

ActiveCN104830283AImprove thermal conductivityHigh latent heat of phase changeHeat-exchange elementsPotassium nitrateTO-18

The invention discloses a low-temperature phase change cold storage material and a production method thereof. The low-temperature phase change cold storage material is made from, by weight, 5% to 18% of sodium chloride, 4% to 17% of potassium nitrate, 74% of water, 1% of sodium tetraborate, 1% of sodium benzoate, and 2% of polyvinyl alcohol. The phase change temperature of the low-temperature phase change cold storage material is -20 DEG C to -25 DEG C; the low-temperature phase change cold storage material is suitable for cold-storage transportation of frozen foods, cold storage density per unit mass is high, and latent heat of phase change is above 260kJ / kg. The low-temperature phase change cold storage material has the advantages that the matching of ingredients is simple, the range of sources is wide, and the preparing method is easy to operate and suitable for industrial popularization.

Owner:SHANGHAI MARITIME UNIVERSITY

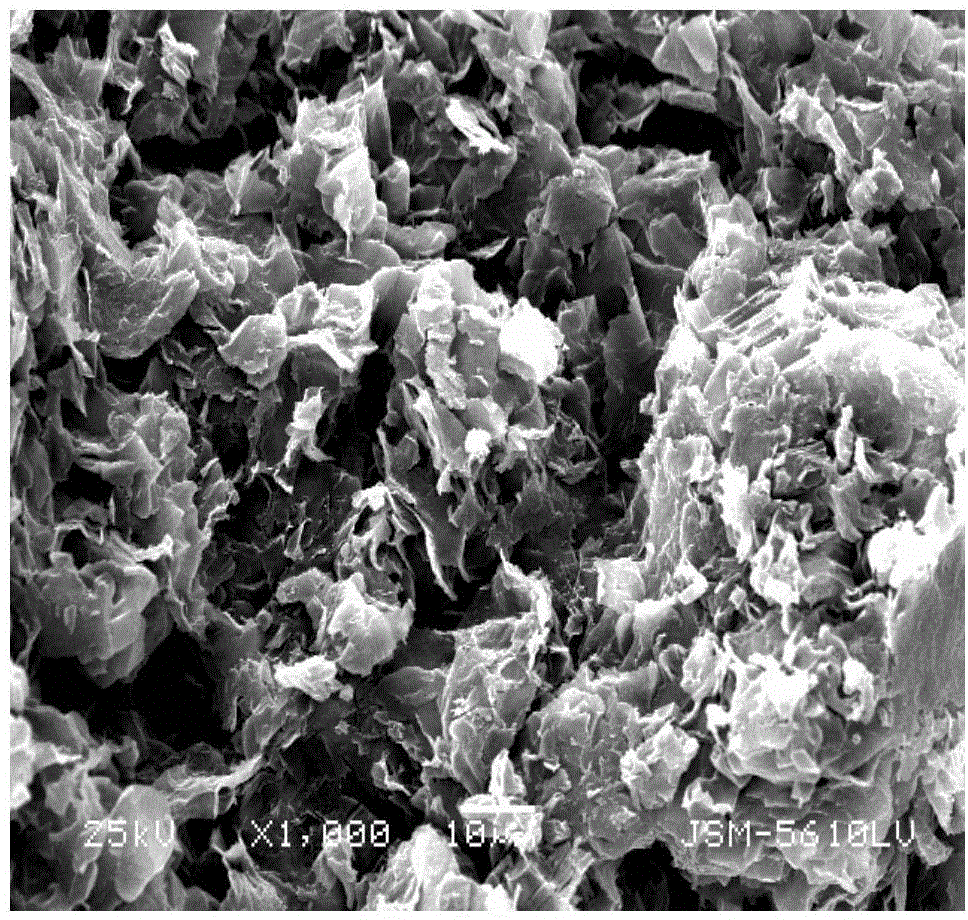

Composite phase-change energy-storage material and preparation method thereof

InactiveCN101798497AHigh latent heat of phase changeImprove leakageHeat-exchange elementsHeat conductingFiltration

The invention discloses a composite phase-change energy-storage material and a preparation method thereof and aims to provide a composite phase-change energy-storage material with high phase-change latent heat, leakage resistance, good heat-conducting performance and low cost and a preparation method thereof. The invention adopts the technical scheme that the composite phase-change energy-storage material comprises a stearic acid phase-change material and nerchinskite as a material combined with the stearic acid phase-change material. The preparation method comprises the following steps of: (1) drying the nerchinskite in vacuum at 150-250 DEG C for 1-3h and cooling to a room temperature; (2) adding an ethanol solution of sulphuric acid to the nerchinskite, stirring at 30-50 DEG C for 3-5h, filtering, washing with the ethanol solution to be neutral and carrying out suction filtration; (3) drying at 70-90 DEG C and grinding to prepare a stearic acid phase-change material carrier; (4) preparing an ethanol solution of the stearic acid; and (5) putting the ethanol solution of the stearic acid into the dispersion liquid of the nerchinskite and the ethanol and drying at 80 DEG C to have constant weight so as to obtain a stearic acid / nerchinskite composite phase-change energy-storage material. The invention is used for heat-storage materials.

Owner:HENAN NORMAL UNIV

Preparation method of composite phase-change material

InactiveCN102040949AHigh latent heat of phase changeImprove thermal stabilityOther chemical processesHeat-exchange elementsWater bathsComposite phase change material

The invention relates to a preparation method of a composite phase-change material, belonging to the technical field of application of a new material. In the method, nano SiO2 powder having high adsorption property and nano TiO2 powder having an infrared shielding effect are used as substrates to adsorb paraffin so as to prepare a composite phase-change energy storage material. The preparation method comprises the following steps: A. placing a phase-change material in a beaker, heating the beaker in a thermostatic water bath, adding distilled water and emulsifying agent to the phase-change material, and carrying out high-speed shearing and emulsification with a high-shear emulsifying machine; B. uniformly mixing nano SiO2 and nano TiO2, and then, heating the mixture in a beaker; and C. pouring the phase-change material obtained after emulsification in the step A into the oxide powder in the step B, uniformly mixing, drying in an oven to obtain lumpish solids, and grinding the lumpish solids into powder. The invention has the advantages of simple process and low cost, can effectively solve the problem of leakage in the solid-liquid phase change process and can greatly improve the phase-change temperature, latent heat of phase change, thermal stability and heat storage effect of phase-change materials such as paraffin and the like.

Owner:沈阳临德陶瓷研发有限公司

Form-stable phase change material with multilevel package structure and preparation method thereof

InactiveCN108048043AImprove stabilityPrevent leakageSecondary cellsHeat-exchange elementsAdditive ingredientGraphite

The invention discloses a form-stable phase change material with a multilevel package structure. The form-stable phase change material is prepared from ingredients by mass percent: 38 to 70% of phasechange material, 5 to 20% of first-stage package porous graphite, 20 to 50% of second-stage package thermoplastic polymer. According to the form-stable phase change material, the phase change material, the porous graphite and the thermoplastic polymer are utilized as materials, the porous graphite is utilized to perform first-stage package on the phase change material, the thermoplastic polymer isutilized to perform second-stage package on the phase change material in a melting and blending process, and the form-stable phase change material can be prepared by twice package. The form-stable phase change material disclosed by the invention has the advantages of good heat conductivity coefficient, phase change latent heat and mechanical property.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

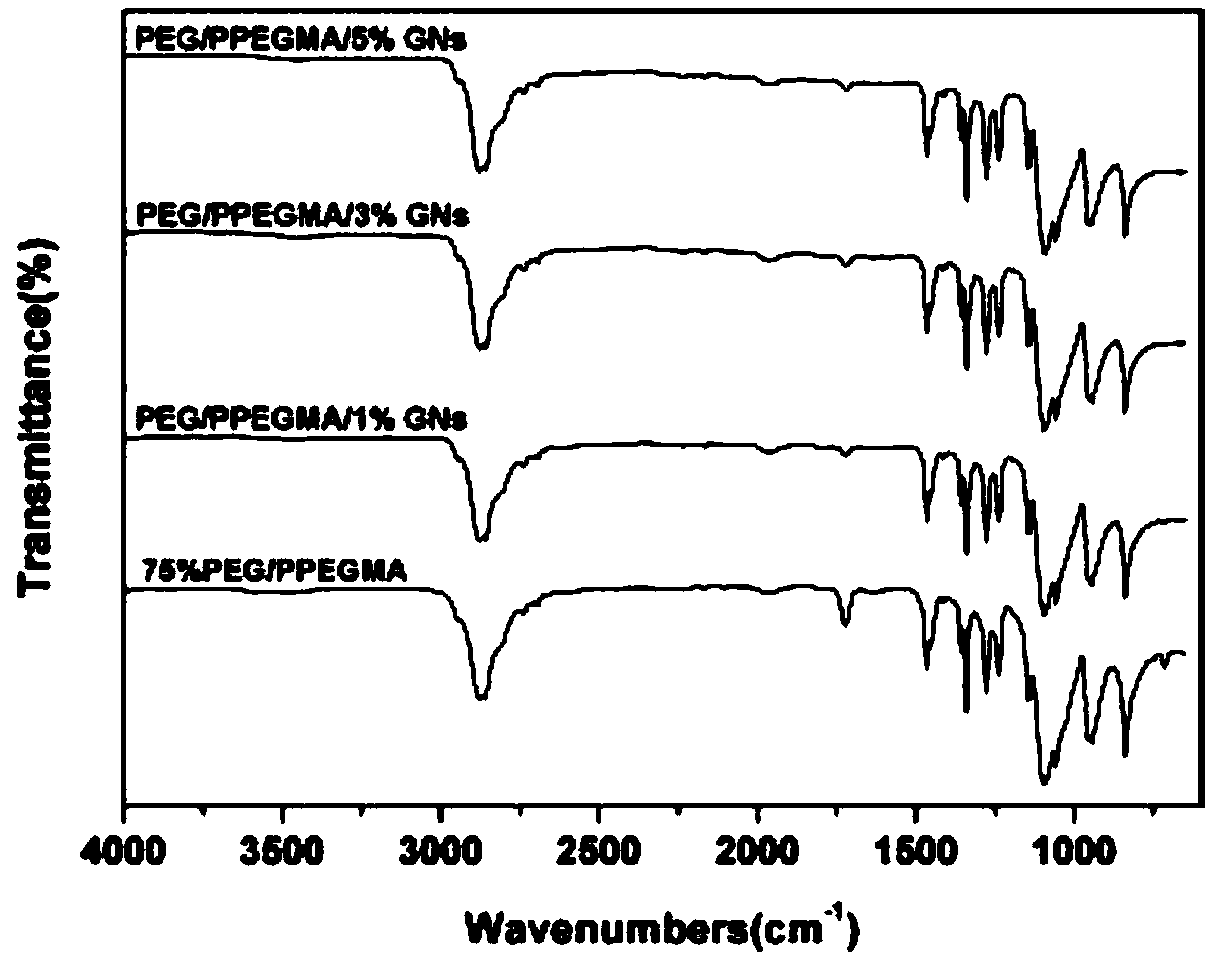

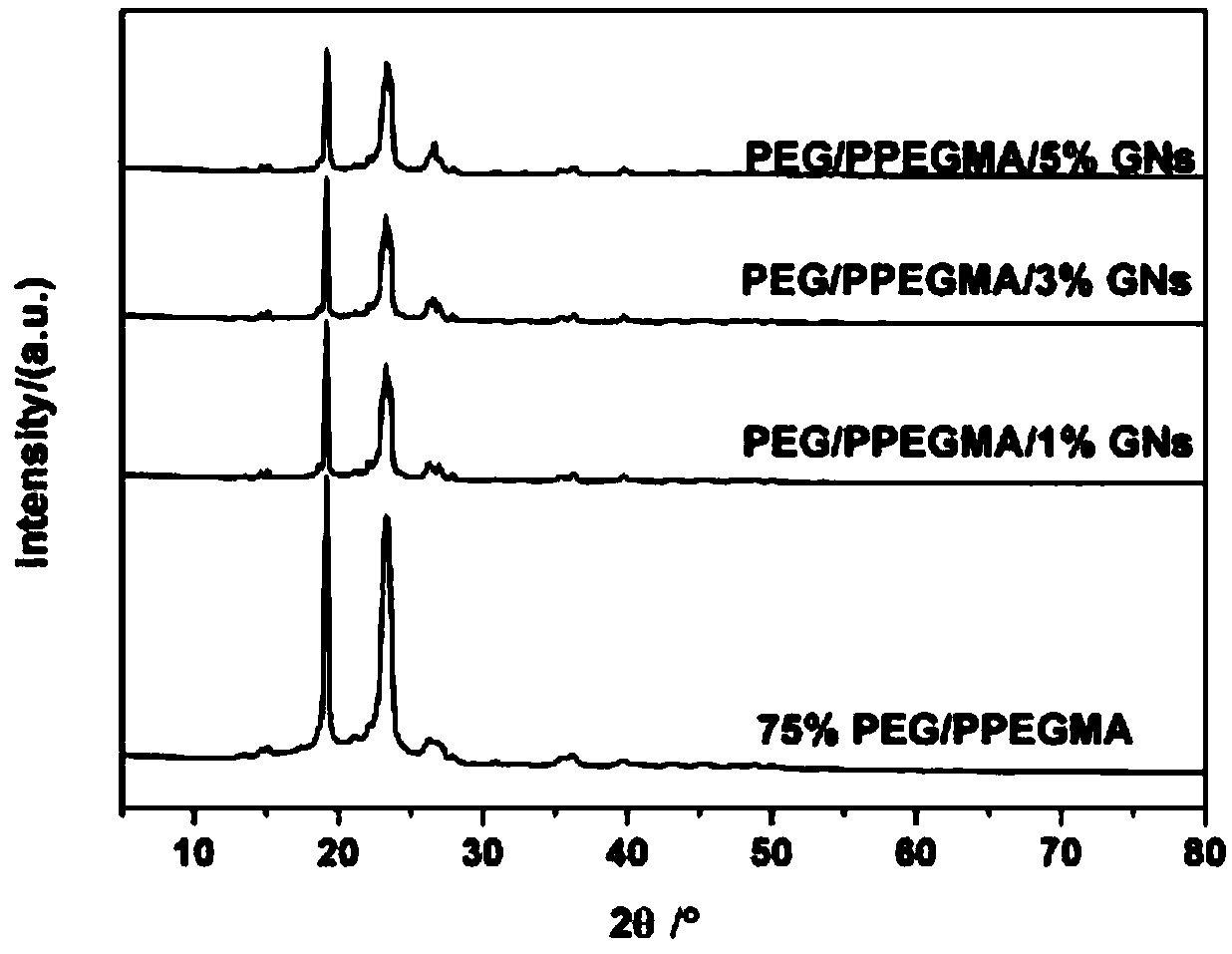

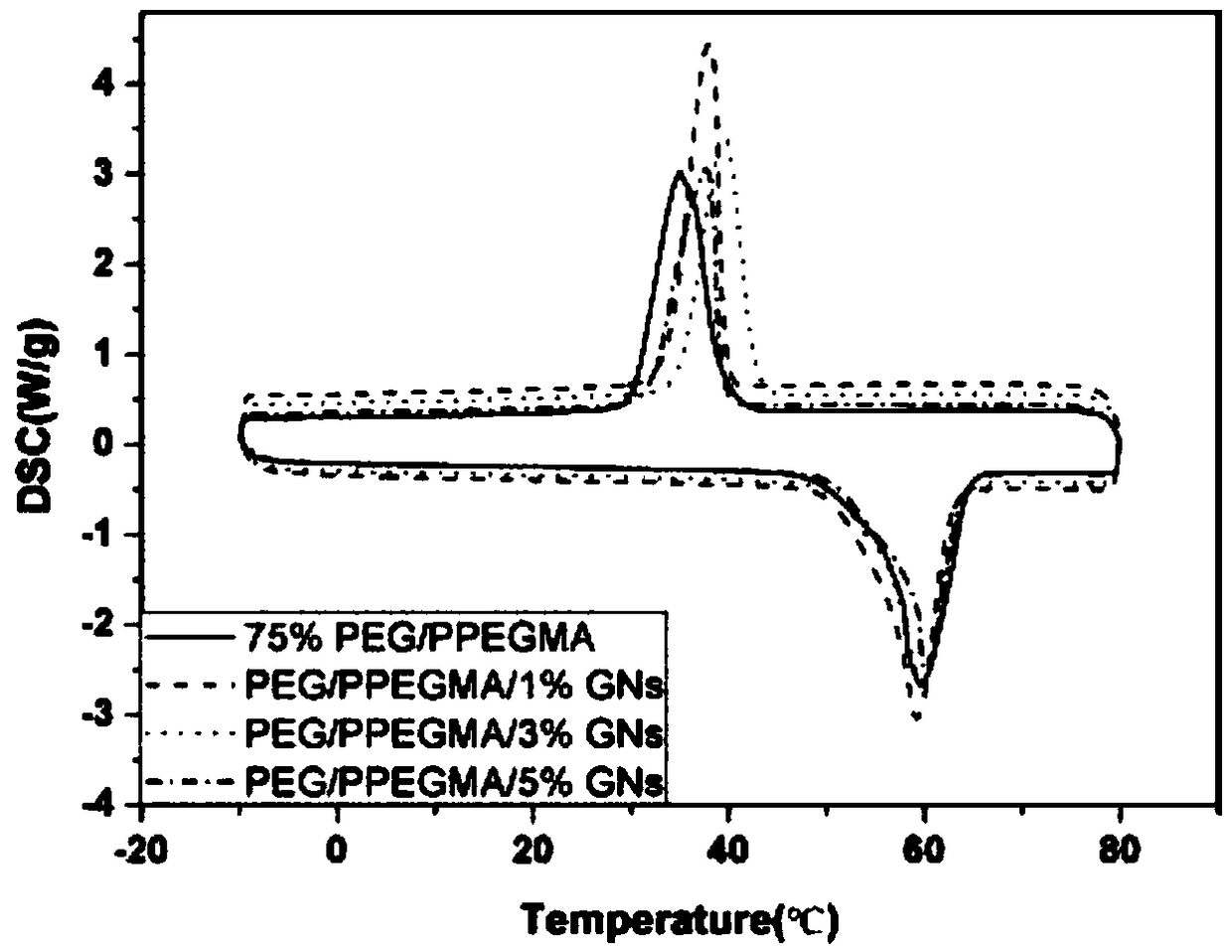

Polyether-based composite phase change energy storage material and preparation method thereof

ActiveCN109504351AHigh thermal conductivityImprove thermal conductivityHeat-exchange elementsPolymer sciencePolyethylene glycol

The invention relates to a polyether-based composite phase change material and a preparation method thereof, and belongs to the technical field of novel materials. The polyether-based composite phasechange material comprises the following components in percent by mass: 23-70% of a phase change supporting material, 1-7% of a carbon material and 30-75% of polyethylene glycol, wherein the phase change supporting material is a polyacrylate polymer, and a monomer structure of the olyacrylate polymer is as shown in the specification, wherein n is 5-90, m is 50-1000, R1 is -H or -CH3, and R2 is -CH3or -CH2CH3; and the carbon material is graphene or graphene oxide. The novel heat storage material is high in energy storage density, high in heat conductivity coefficient, good in heat stability, simple in synthesis technology and good in shaping performance, so that the novel heat storage material has very strong practicability.

Owner:DALIAN UNIV OF TECH

Preparation method of wood-based functional magneto-thermal composite phase change heat storage material

InactiveCN110358504AImprove controllabilityHigh latent heat of phase changeHeat-exchange elementsHeat storage materialPhase change

The invention provides a preparation method of a wood-based functional magneto-thermal composite phase change heat storage material. Magnetic Fe3O4 particles are anchored to the surface of a poplar fiber matrix through a hydrothermal process by using hemicellulose and lignin partially-removed poplar fiber as a matrix, and a phase change material is impregnated in the poplar fiber matrix by a vacuum impregnation process. The method improves the anchoring ability of the poplar fiber matrix to the magnetic Fe3O4 particles and the ability of the matrix to accommodate the phase change material by removing hemicellulose and lignin from poplar, releasing a part of active hydroxyl groups and expanding the pore structure of the poplar fiber, provides the novel green packaging material with the advantages of wide sources, low price, simplicity in processing, safety, environmental protection and wide application range for the phase change material, realizes magneto-thermal conversion by using themagneto-thermal effect of the magnetic Fe3O4 particles, realizes the functional enhancement of the composite phase change heat storage material, and develops new direction for magneto-thermal utilization.

Owner:BEIJING FORESTRY UNIVERSITY

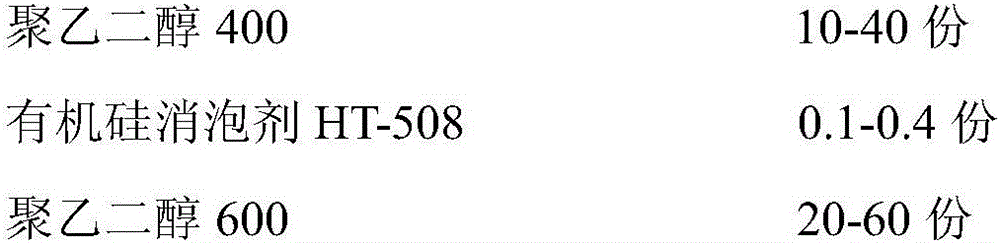

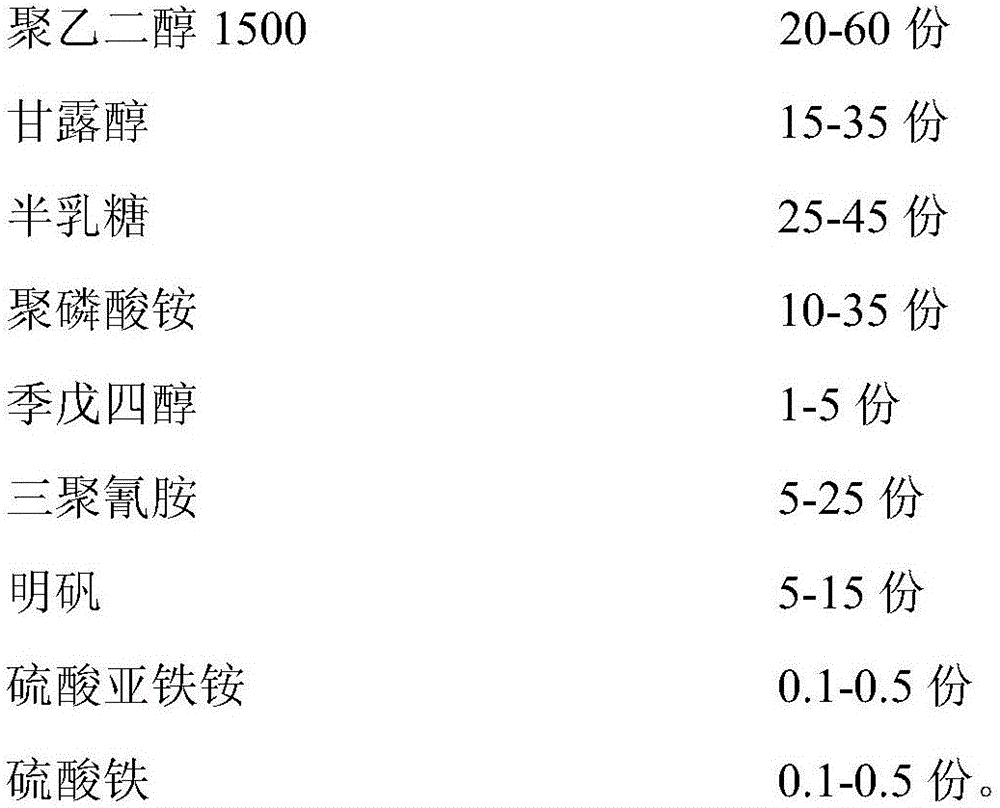

Method for manufacturing phase-change heat absorption swelling fire-retardant wood and swelling fire-retardant wood

ActiveCN106738149AAvoid spreadingIt has the function of filling and densifyingWood treatment detailsPressure impregnationSolid woodCarbon layer

The invention discloses a method for manufacturing phase-change heat absorption swelling fire-retardant wood and the swelling fire-retardant wood. The manufacturing method includes the following steps that the wood is processed and manufactured according to the dimensions required, so that a solid wood component is obtained; the solid wood component is subjected to degreasing and duct dredging pretreatment, and accordingly the pretreated solid wood component can be obtained; the pretreated solid wood component is put into phase-change heat absorption swelling fire-retardant steeping liquor for conducting vacuum pressure impregnation treatment, and then drying is performed, so that the solid wood component filled with a phase-change heat absorption swelling fire-retardant material is obtained; the solid wood component filled with the phase-change heat absorption swelling fire-retardant material is subjected to sanding shaping and surface closing protective treatment, and accordingly the phase-change heat absorption swelling fire-retardant wood is obtained. The swelling fire-retardant wood obtained through the manufacturing method achieves phase-change heat absorption in the heating process of the wood and forms a swelling foam carbon layer under the fire condition, the change of fires can be lowered and fire losses are reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

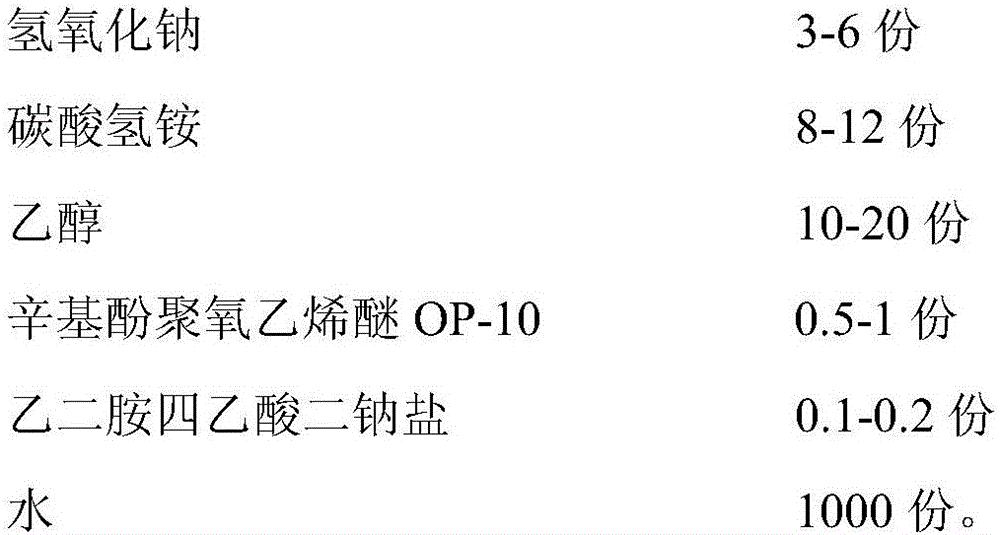

Inorganic-salt efficient coolant for refrigerated products

InactiveCN106566480AImproving Phase Change Cycling StabilityHigh latent heat of phase changeHeat-exchange elementsInorganic saltsPhase change temperature

The invention discloses an inorganic-salt efficient coolant for refrigerated products. The inorganic-salt efficient coolant is prepared from the following raw materials by mass percent: 20% to 35% of main energy storage agent, 5% to 10% of nucleating agent and 1% to 5% of thickener. The main energy storage agent is an inorganic-salt mixture of ammonium bromide (NH4Br) and a cooling agent, i.e., ammonium chloride (NH4Cl). The nucleating agent is one of strontium chloride (SrCl2), magnesium sulfate (MgSO4), sodium metaphosphate (Na2P2O7.10H2O) and potassium sulfate (K2SO4). The thickener is xanthan gum, and the xanthan gum, serving as the thickener, has a remarkable effect on the phase separation of inorganic-salt phase-change cold storage materials. The inorganic-salt phase-change coolant provided by the invention has the advantages that the latent heat of phase change is about 280KJ / kg, the degree of supercooling is low, and the cycle stability is good. The phase change temperature of the coolant is -18 DEG C to -22 DEG C, thereby meeting the requirements of frozen foods and frozen drugs on temperature.

Owner:JIANGNAN UNIV

Insulating container lid capable of quickly lowering temperature and insulating container including same

InactiveCN106343847ARealize instant drinkingRapid coolingTravelling sacksDrinking vesselsTemperature controlEngineering

The invention provides an insulating container lid capable of quickly lowering the temperature and an insulating container including the same. The lid comprises an inner cylinder wall, a temperature control layer made from temperature control layer materials and an outer cylinder wall, wherein the temperature control layer materials comprise a phase-change material and / or a heat conduction material. The invention further provides the insulating container including the lid. The lid such as a lid of a drinking insulating cup or an insulating kettle has the advantage of quickly lowering the temperature to the needed temperature and can achieve the effect that poured hot water is immediately drunk. The insulating container can quickly enable the temperature of contents to be lowered to the needed temperature through the lid while the temperature of the contents is kept, is especially suitable for achieving the purpose that people carry hot water in the outdoor travel process and can meet the requirement that the hot water is immediately drunk when being poured out.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Solid-solid phase change material and preparation method thereof

ActiveCN110669475AHigh latent heat of phase changeLow costHeat-exchange elementsFiberInorganic salts

The invention relates to a solid-solid phase change material and a preparation method thereof, and belongs to the field of phase change energy storage materials. The solid-solid phase change materialcomprises a component A and a component B, wherein the addition amount of the component A is 50-97% and the addition amount of the component B is 3-50% according to the percentage of the total mass ofthe raw materials, wherein the component A is a phase change material component, and comprises the following components in percentage by mass: 0-30% of an inorganic salt, 41-96.8% of water, 1-8% of fiber, 0.1-2% of a dispersant, 0.5-5% of a nucleating agent, 1-8% of a thickening agent and 0.5-6% of a heat conducting medium, wherein the component B is a curing component and comprises the followingcomponents in percentage by mass: 3-25% of isocyanate, 75-97% of hydrophilic polyether polyol and 20 ppm-200 ppm of A retarder accounting for the total mass of the component B. Compared with the existing water-based phase change material, the solid-solid phase change material provided by the invention not only furthest retains the characteristics of high phase change latent heat and low cost of the water-based phase change material, but also has no leakage risk and better heat conductivity.

Owner:SHANDONG ANLENG NEW MATERIAL TECH CO LTD

Preparation method of carbonized wood-based composite phase- change energy storage material

ActiveCN112391149AImprove controllabilityHigh latent heat of phase changeChemical industryHeat-exchange elementsFiber matrixPore diameter

The invention provides a preparation method of a carbonized wood-based composite phase-change energy storage material, which comprises the following steps: using a balsa woodblock from which part of lignin is removed as a matrix and SiO2 aerogel as a reinforcing phase to support a fiber matrix, and impregnating a phase-change material into the carbonized wood- SiO2 aerogel matrix by a vacuum impregnation method. According to the method, the pore channel structure of the balsa wood is reinforced by using the SiO2 aerogel, so that the volume shrinkage of the balsa wood fiber matrix in the carbonization process is reduced, and the original multi-stage pore structure of the wood is maintained; and the SiO2 aerogel further enhances the specific surface area of the packaging substrate material while reinforcing the pore structure of the carbonized wood, the SiO2 aerogel improves the accommodating capacity of the whole substrate to the phase-change material by means of the unique pore diameter and pore structure, and the packaging rate exceeds 90%. The problem of leakage of the phase-change energy storage material in use is solved, the heat storage and release efficiency of the packaged phase-change energy storage material is improved, and a new direction is developed for research of a frame matrix of the phase-change energy storage material.

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com