Inorganic-salt efficient coolant for refrigerated products

A technology of frozen products and inorganic salts, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of phase separation, flammability and explosion, low latent heat of phase change, etc., to improve the stability of phase change cycle, cycle Good stability and high latent heat of phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A kind of inorganic salt phase change material comprises the composition of following weight percent:

[0016]

[0017] The preparation process of the cold storage agent of the present invention is simple and feasible, easy to operate, high in economic value, and good in stability. The phase transition temperature of the cold storage agent measured by DSC (differential scanning calorimetry) is -19.51°C, and the latent heat of phase transition is 273.4KJ / kg

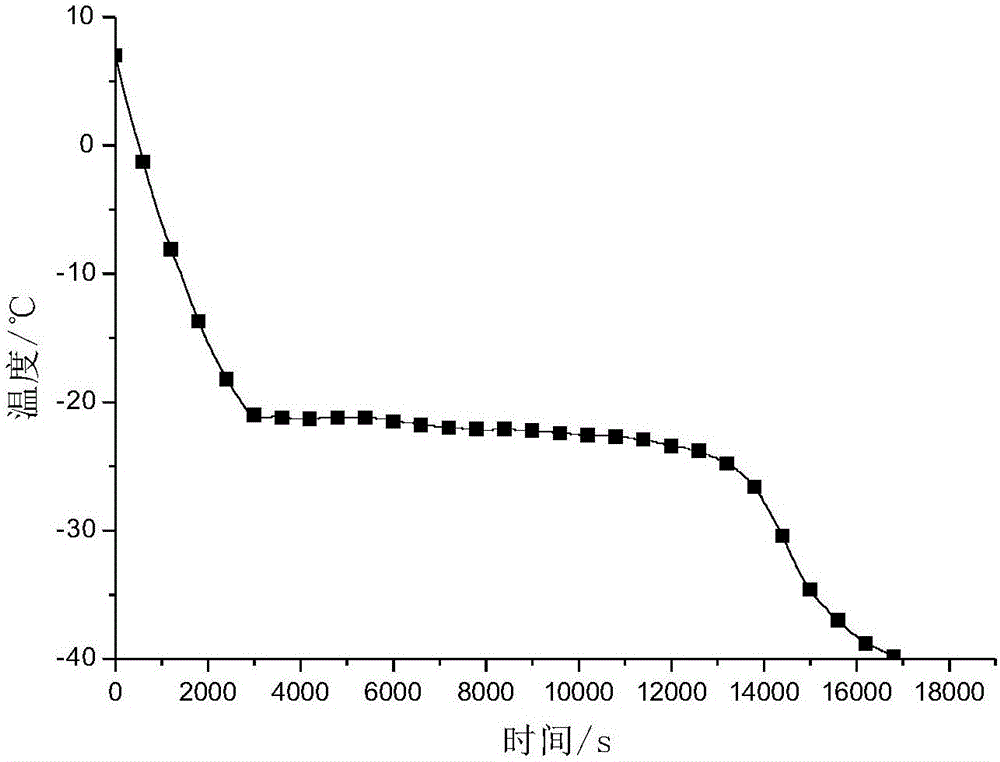

[0018] The cooling curve of this embodiment is as figure 1 As stated, the degree of subcooling is 0.1°C, basically no degree of supercooling

Embodiment 2

[0020] A kind of inorganic salt phase change material comprises the composition of following weight percent:

[0021]

[0022] The preparation process of the cold storage agent of the present invention is simple and feasible, easy to operate, high in economic value, and good in stability. The phase transition temperature of the cold storage agent measured by DSC (differential scanning calorimetry) is -20.02°C, and the latent heat of phase transition is 278.0KJ / kg

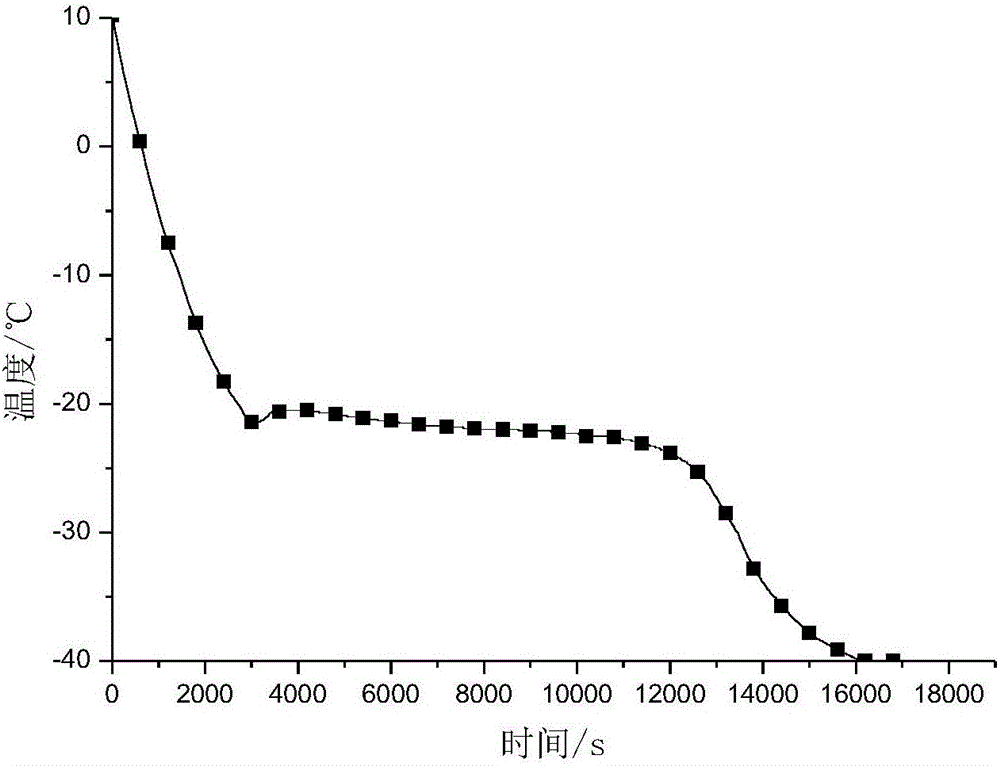

[0023] The cooling curve of this embodiment is as figure 2 As stated, the degree of supercooling is 0.7°C, which is very small.

Embodiment 3

[0025] A kind of inorganic salt phase change material comprises the composition of following weight percent:

[0026]

[0027] The preparation process of the cold storage agent of the present invention is simple and feasible, easy to operate, high in economic value, and good in stability. The phase transition temperature of the cold storage agent measured by DSC (differential scanning calorimetry) is -21.78°C, and the latent heat of phase transition is 282.3KJ / kg

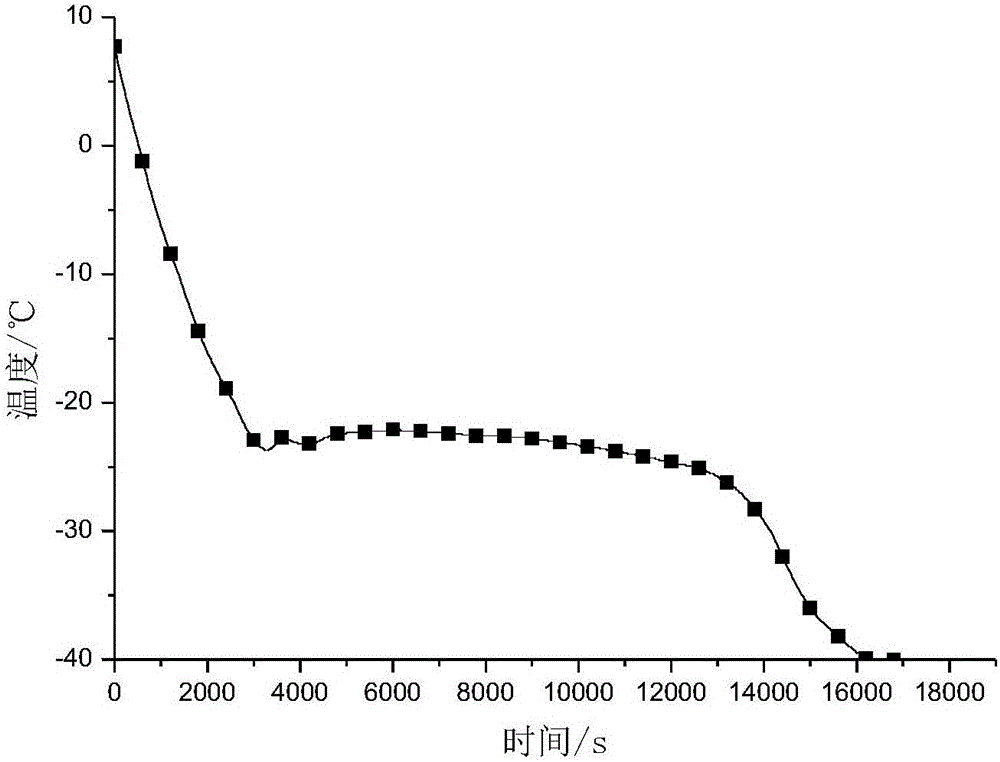

[0028] The cooling curve of this embodiment is as image 3 As stated, the degree of supercooling is 1.0°C, which is very small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com