Insulating container lid capable of quickly lowering temperature and insulating container including same

A technology for thermal insulation containers and lids, applied in the field of lids for thermal insulation containers, can solve the problems of poor thermal conductivity, limited, slow cooling speed, etc., and achieve the effects of easy manufacturing and use, good cycle stability, and ensuring rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

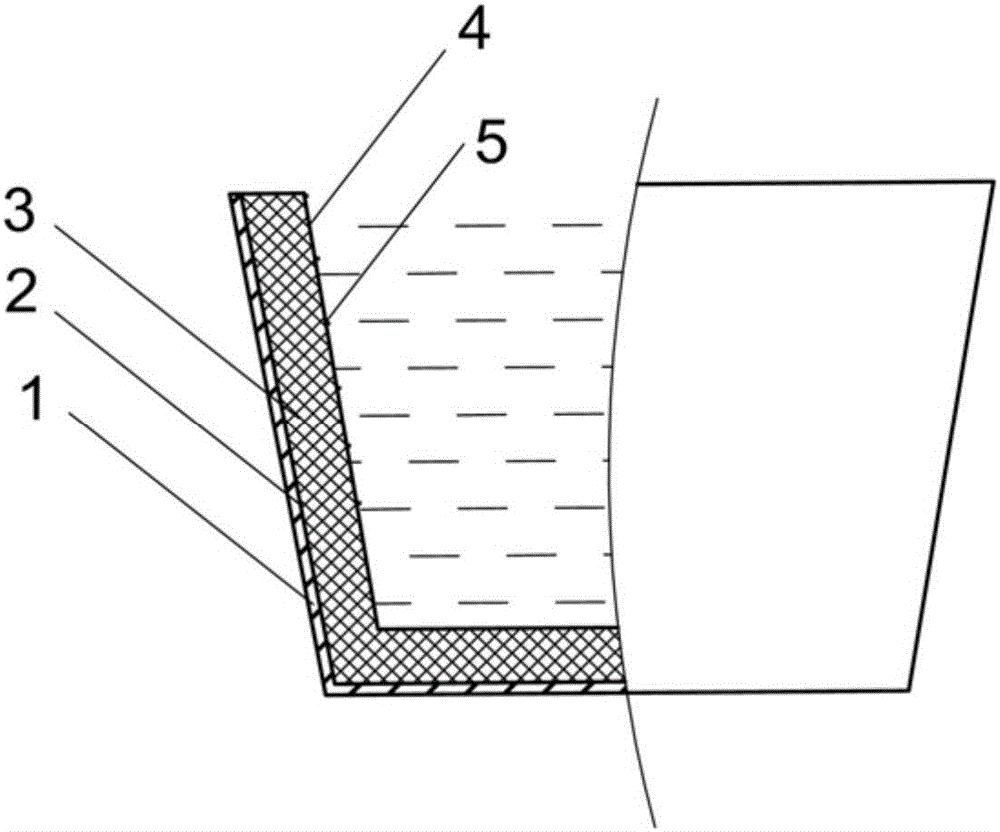

[0080] A drinking water thermos cup cover is manufactured, wherein stainless steel is used as the outer cylinder wall and the inner cylinder wall, the inner cylinder wall is close to the 2mm temperature control layer, and the outer cylinder wall is the temperature control layer. The temperature control layer material is composed of paraffin wax with a melting point of 40°C and expanded graphite according to the mass percentage of 90% and 10%, the thermal conductivity is 8W / m K, and the phase transition temperature of paraffin wax with a melting point of 40°C is 40°C. The latent heat of phase change is 210kJ / kg.

[0081] The 90°C hot water in the thermos cup is poured into the cover of the drinking water thermos cup, and the drinking temperature of 50°C is reached in less than 10 seconds. After drinking water, put the lid of the drinking water thermos cup on the thermos cup, the phase change material in the interlayer releases the absorbed heat to the environment through the ou...

Embodiment 2 to 21

[0083] Except for the content shown in the table below, use a method similar to that described in Example 1 to manufacture the thermos lid, and measure the time required for the water temperature to drop to 50°C at room temperature (25°C) after it is filled with 90°C water .

[0084]

[0085]

Embodiment 22

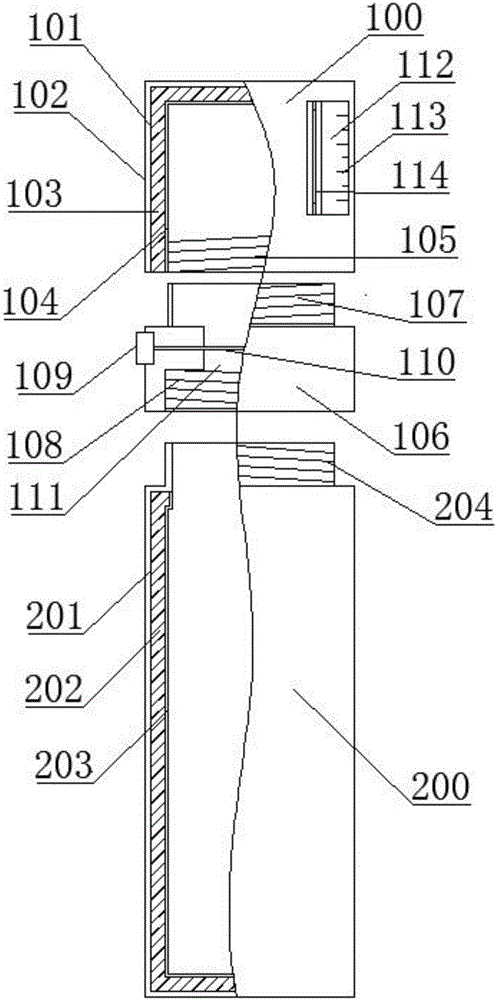

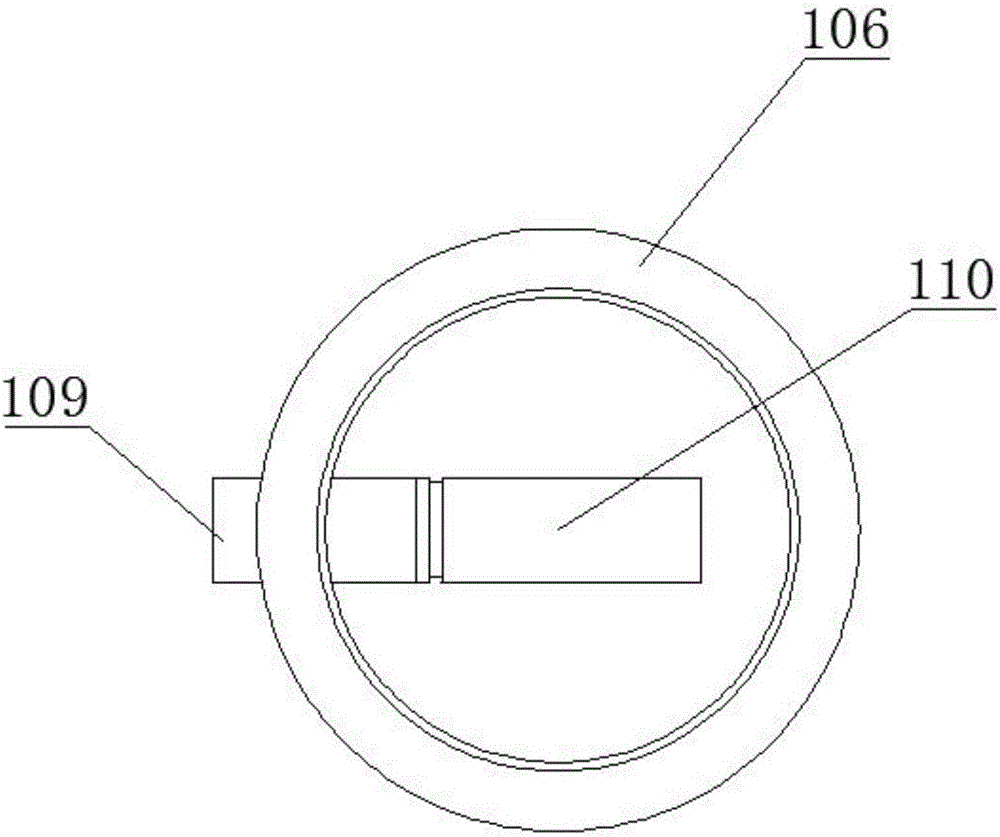

[0087] Create a thermos (see figure 2), which includes a drinking water cover 100 and a kettle body 200, the drinking water cover includes a stainless steel inner cylinder wall 104, a temperature control layer 103 formed by a temperature control layer material and a stainless steel outer cylinder wall 102 from the inside to the outside, in the inner cylinder A closed chamber is provided between the wall and the outer cylinder wall, and the temperature control layer material is placed inside the closed chamber, and the composition of the temperature control layer material is the same as that described in Example 3, with a thickness of 2mm. The drinking water cap 100 also includes a plastic protective layer 101 on the outer side of the outer cylinder wall 102 . The drinking water cap 100 has an internal thread 105 on the inner surface of the outer cylinder wall 103 of the opening, and is used for sealingly connecting with the outer thread 204 on the outer surface of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com