Patents

Literature

35results about How to "Comply with temperature requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

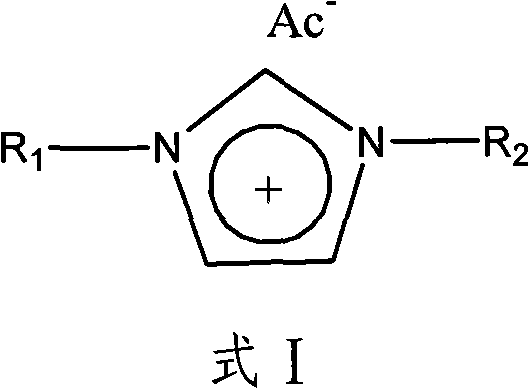

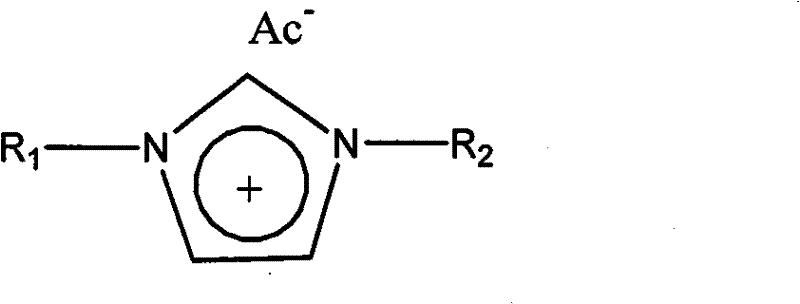

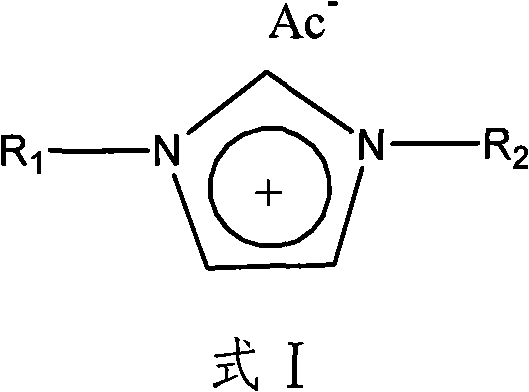

Supported ionic liquid catalyst and preparation method and application thereof

InactiveCN101773852ANot easy to loseExtended service lifeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveActive component

The invention provides a supported ionic liquid catalyst for preparing vinyl acetate in an acetylene method, the catalyst adopts mesoporous molecular sieve as a carrier and adopts zinc acetate as an active component, and the carrier and the active component are connected by imidazole acetate ionic liquid. The invention further provides a preparation method of the catalyst and an application in preparing the vinyl acetate in the acetylene method. The active component of the zinc acetate of the supported ionic liquid catalyst is bond-coupled on the surface of the carrier in a chemical method and is not easy to be lost in the reaction process; the carrier of the mesoporous molecular sieve provides suitable reaction space for catalytic reaction, and carbon deposition is not easy to be generated; the ionic liquid forms a pseudophase liquid microenvironment on the surface of the catalyst, thus improving the mass transfer and heat transfer in the reaction process; and the catalyst has good stability, long service life, high activity and good selectivity.

Owner:TSINGHUA UNIV

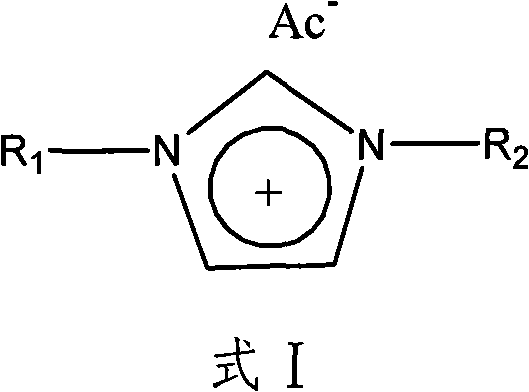

New energy automobile fuel cell system, working method, hydrogen inlet flow calculation method and efficiency evaluation method

The invention discloses a new energy automobile fuel cell system, a working method, a hydrogen inlet flow calculation method and an efficiency evaluation method, Belongs to the technical field of newenergy. Keys points of the new energy automobile fuel cell system are that the new energy automobile fuel cell system comprises an air supply system, a hydrogen supply system and a fuel cell stack, wherein the air supply system provides fresh air for the fuel cell stack, and the system comprises an air filter, a centrifugal air compressor, a gas heat exchanger, a humidifying and intercooling assembly, a throttle valve, a water segregator, a drain valve, a turbine and a back pressure valve; the hydrogen supply system provides fresh hydrogen for the fuel cell stack and comprises a hydrogen tank,a pressure reducing valve, an ejector, a water distributor, a water distribution valve, a nitrogen discharger, a nitrogen discharge valve, a first one-way valve, a circulating pump and a second one-way valve; and the fuel cell stack is a place where hydrogen and air react, and chemical energy is converted into electric energy to provide kinetic energy for accessory mechanisms and loads. The invention aims to provide the new energy automobile fuel cell system, the working method, the hydrogen inlet flow calculation method and the efficiency evaluation method, the stability of the fuel cell isimproved, and the efficiency of the fuel cell is conveniently calculated and evaluated.

Owner:擎能动力科技(苏州)有限公司

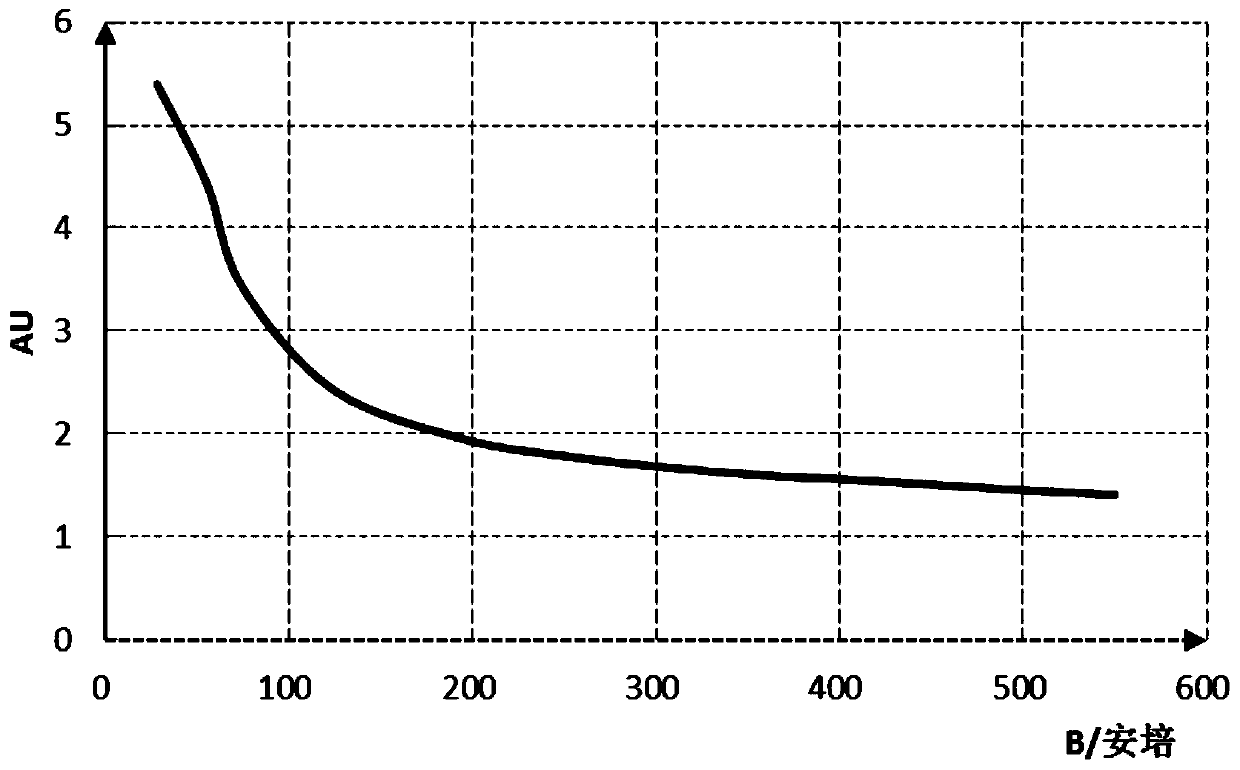

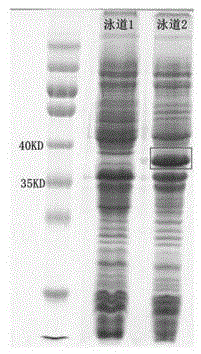

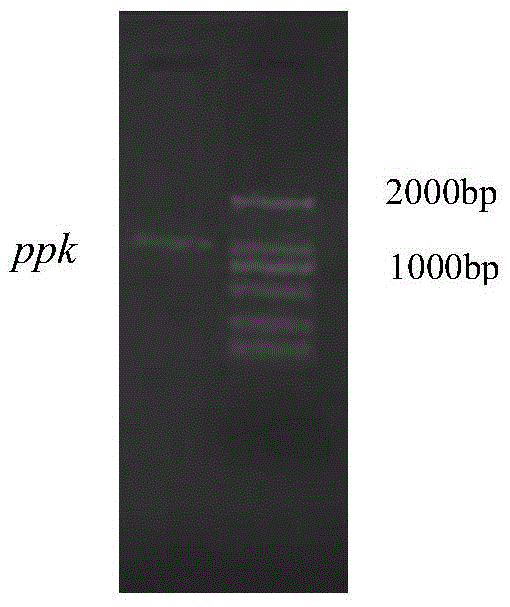

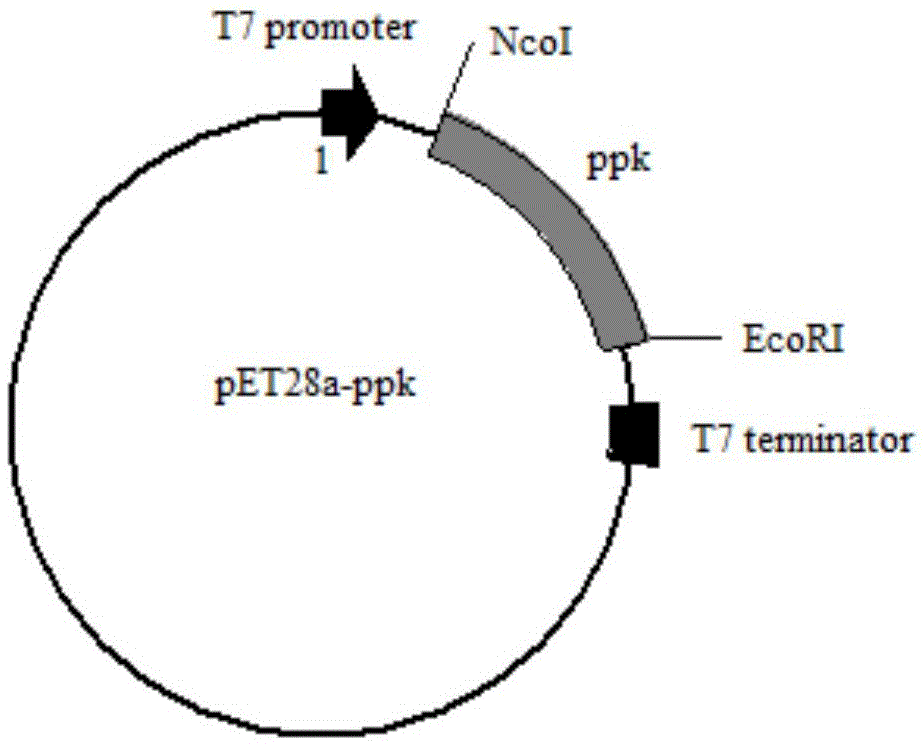

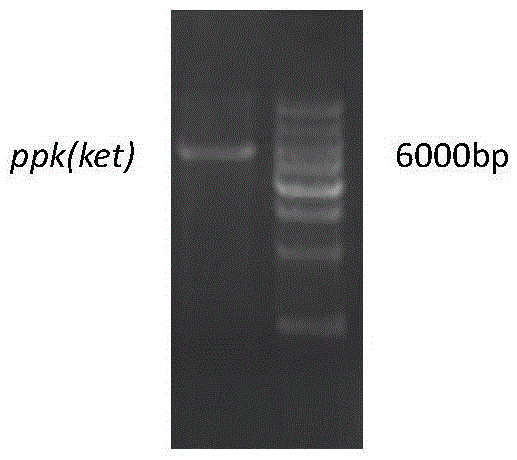

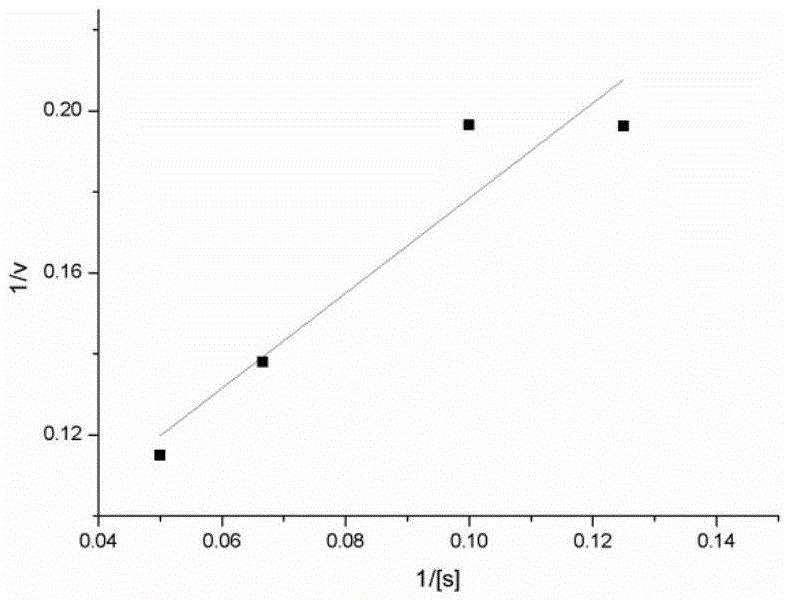

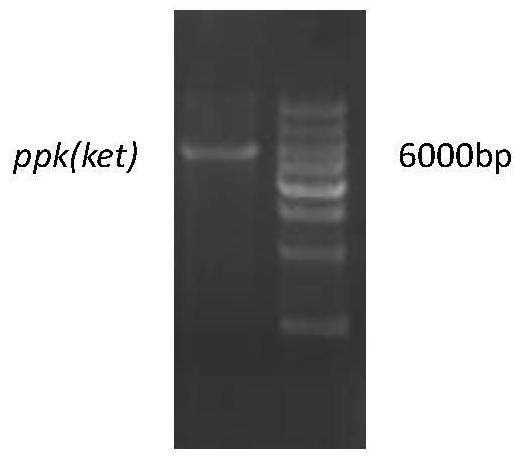

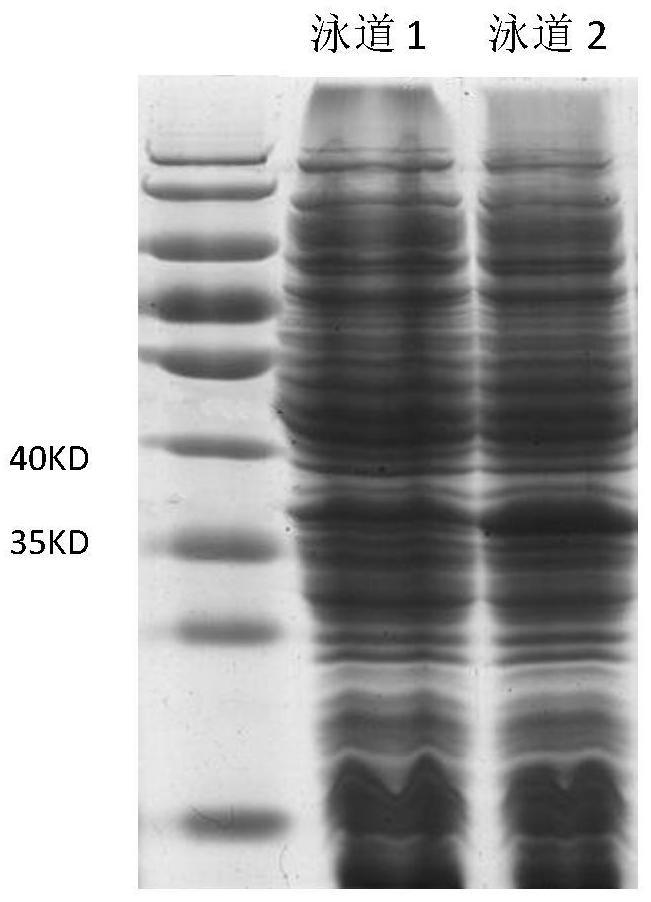

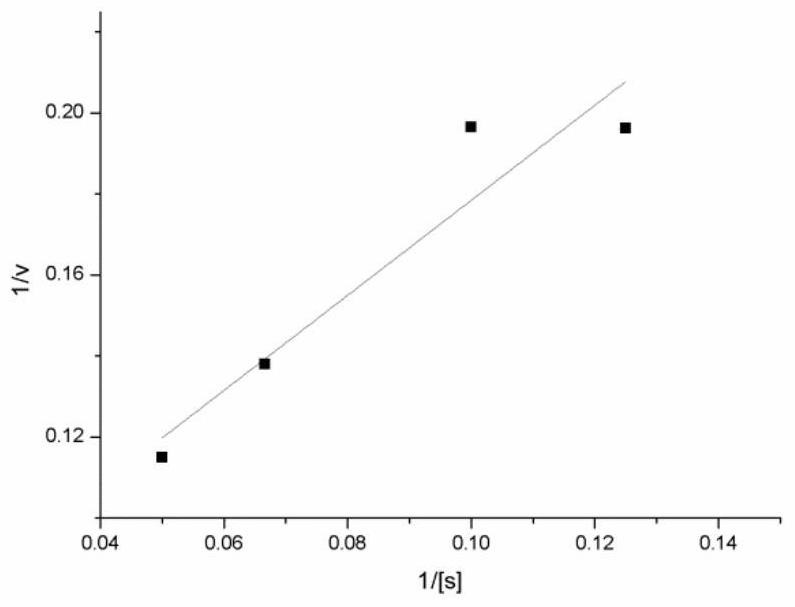

Method for regenerating ATP(adenosine triphosphate) through enzyme method

InactiveCN105463043ALow costComply with temperature requirementsTransferasesFermentationPhosphoric acidHeterogeneous source

The invention relates to a method for regenerating ATP(adenosine triphosphate). A heterogeneous source is used for expressing polyphosphate kinase, and under catalyzing of polyphosphate kinase, polyphosphates with the low polymerization degree are used as phosphoric acid donors for regenerating ATP. Compared with an existing ATP regeneration method, adopted polyphosphate kinase is a normal-temperature enzyme, can be combined with multiple enzymes for promoting reaction coupling, and adopts a tripolyphosphate, a tetrapolyphosphate and a hexametaphosphate as the phosphoric acid donors, these polyphosphates are low in polymerization degree, common, easy to obtain and low in price, on the basis of simplifying the ATP regeneration process, feasibility of ATP regeneration is improved, and the ATP regeneration cost is reduced; activity of a PPK enzyme is not inhibited by polyphosphate concentration, and possibility is provided for industrialized large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

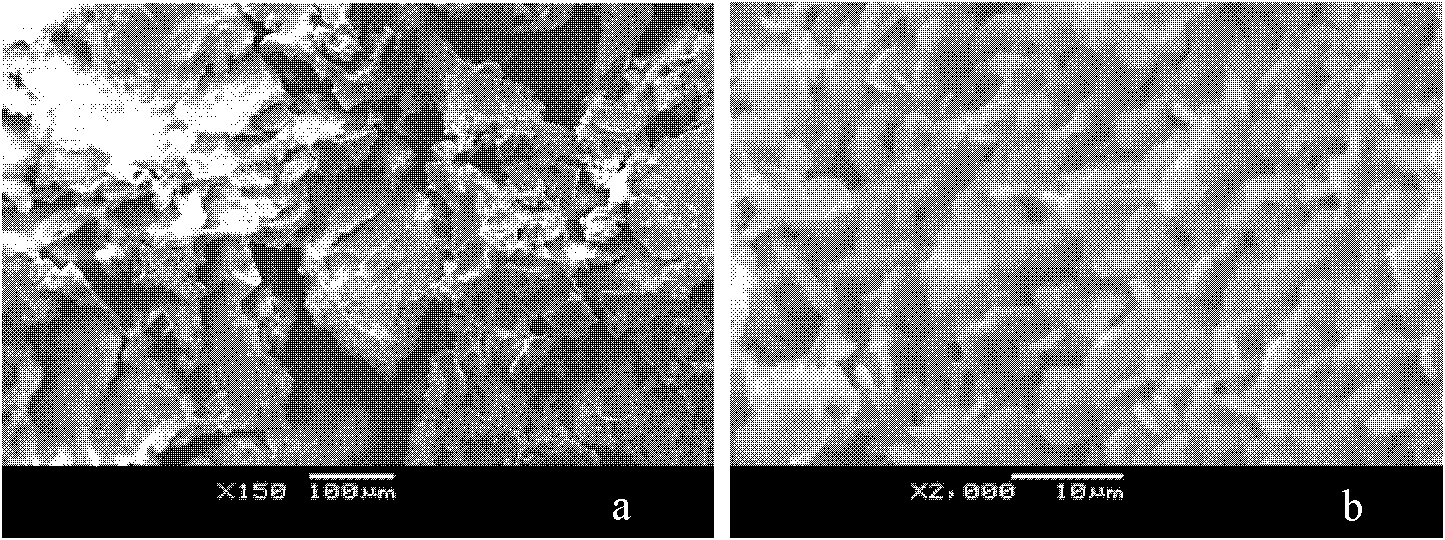

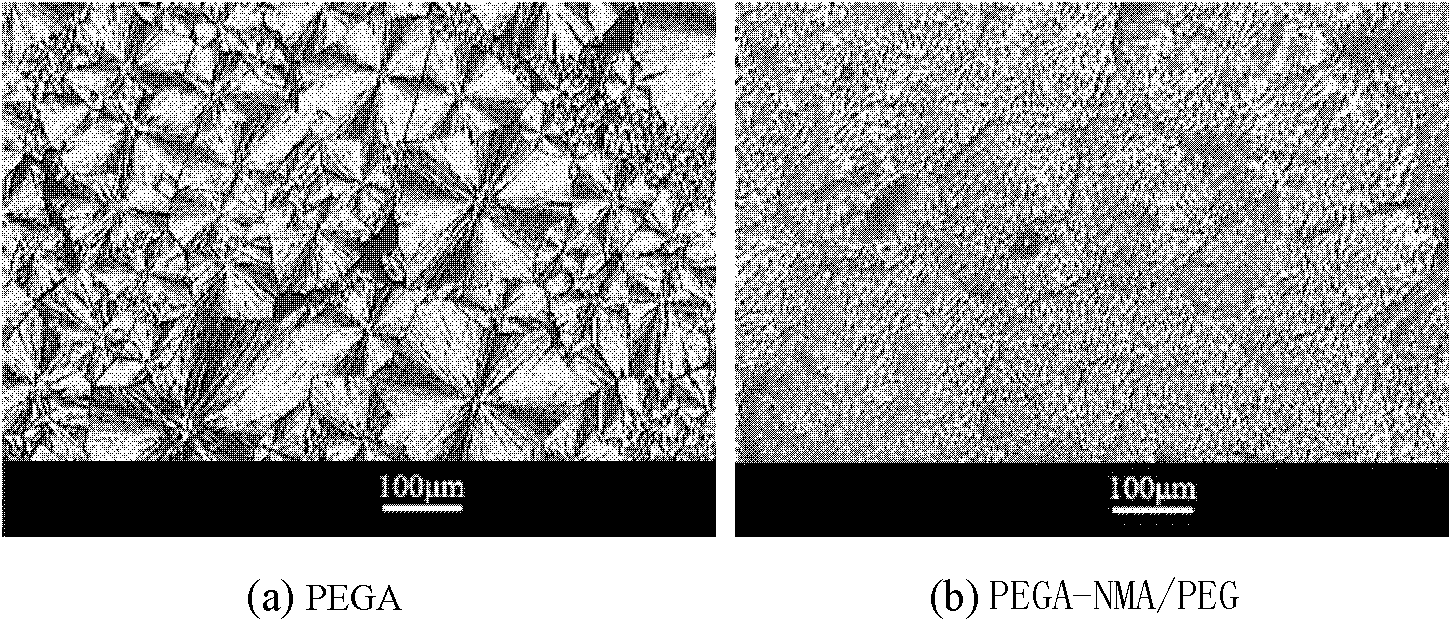

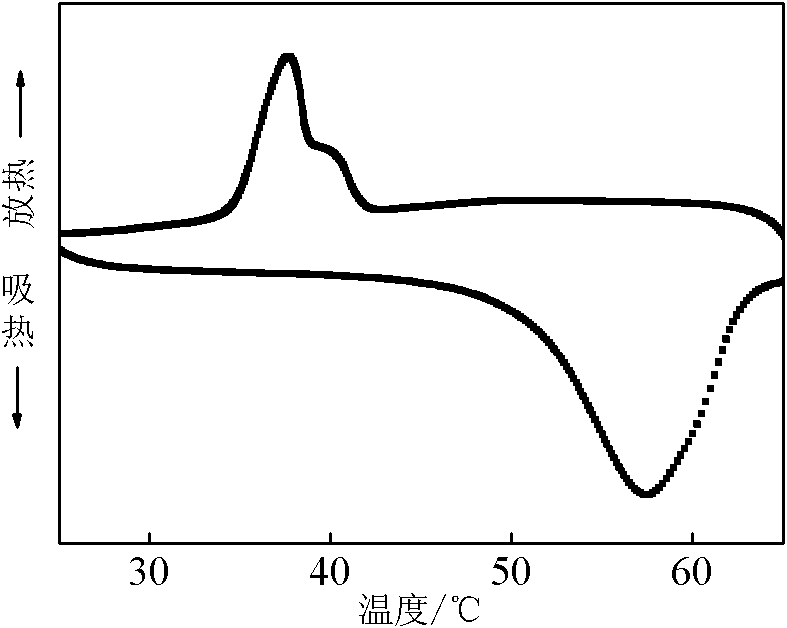

Multi-element composite solid-solid phase-change material and preparation method thereof

InactiveCN102492396AImprove thermal stabilityAlleviate the decline of phase transition performanceHeat-exchange elementsHeat resistancePolyethylene glycol

The invention discloses a preparation method of a multi-element composite solid-solid phase-change material. The preparation method comprises the following steps: dissolving polyethylene glycol acrylate (PEGA), N-hydroxylmethyl acrylamide (NMA) and polyethylene glycol (PEG) in deionized water; carrying out ultrasonic dispersion; adding a crosslinking agent and an initiator; heating to 70-80 DEG C to react for 2-5 hours, so as to form hydrogel with a crosslinking network structure; and drying the hydrogel at the temperature of 35 DEG C, so as to obtain the multi-element composite PEGA-NMA / PEG solid-solid phase-change material. According to the invention, the chemical immobilization of PEG is achieved through copolymerization reaction of PEGA and NMA, and an interpenetrating network is formed under the action of the crosslinking agent to realize the network immobilization of the blending component PEG, so as to obtain a novel composite phase-change material. By using the method, solid-solid phase-change transformation is achieved, the thermal resistance of the phase-change material is improved, and the obtained phase-change material can be used as a heat-storage functional additive for melt spinning.

Owner:DALIAN POLYTECHNIC UNIVERSITY

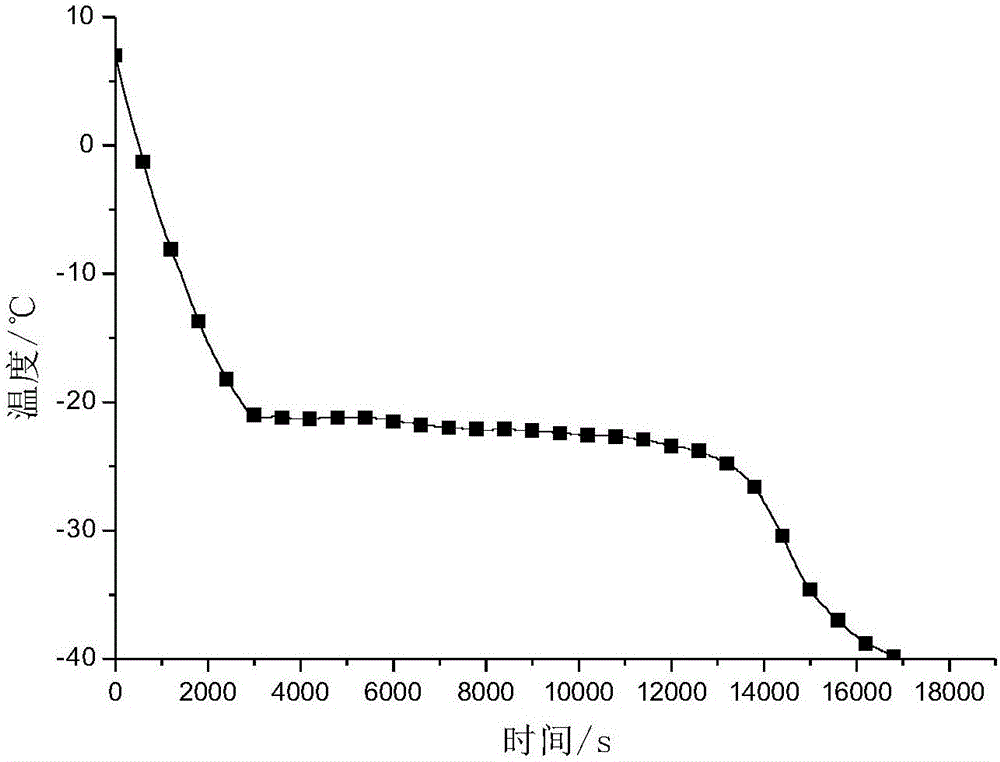

Inorganic-salt efficient coolant for refrigerated products

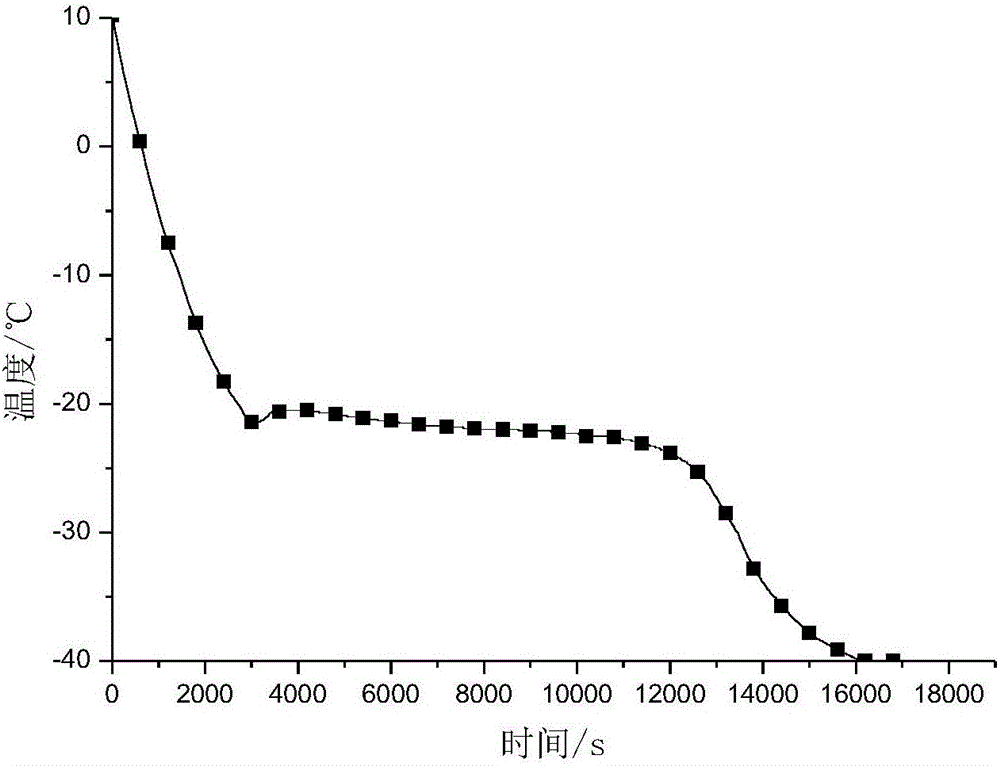

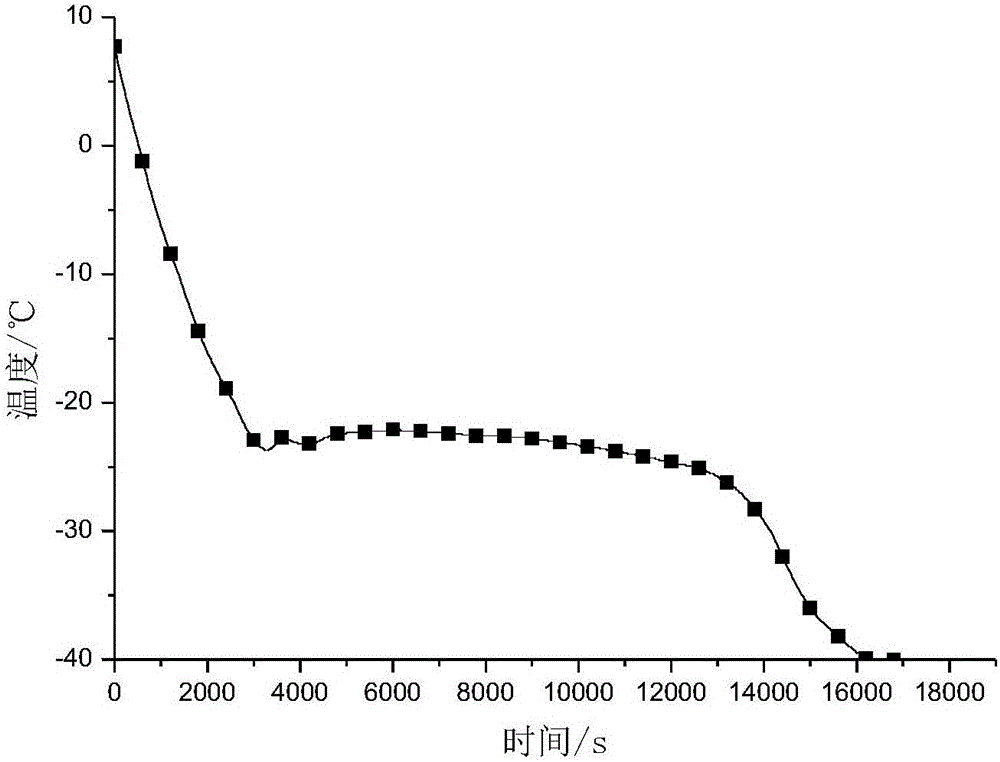

InactiveCN106566480AImproving Phase Change Cycling StabilityHigh latent heat of phase changeHeat-exchange elementsInorganic saltsPhase change temperature

The invention discloses an inorganic-salt efficient coolant for refrigerated products. The inorganic-salt efficient coolant is prepared from the following raw materials by mass percent: 20% to 35% of main energy storage agent, 5% to 10% of nucleating agent and 1% to 5% of thickener. The main energy storage agent is an inorganic-salt mixture of ammonium bromide (NH4Br) and a cooling agent, i.e., ammonium chloride (NH4Cl). The nucleating agent is one of strontium chloride (SrCl2), magnesium sulfate (MgSO4), sodium metaphosphate (Na2P2O7.10H2O) and potassium sulfate (K2SO4). The thickener is xanthan gum, and the xanthan gum, serving as the thickener, has a remarkable effect on the phase separation of inorganic-salt phase-change cold storage materials. The inorganic-salt phase-change coolant provided by the invention has the advantages that the latent heat of phase change is about 280KJ / kg, the degree of supercooling is low, and the cycle stability is good. The phase change temperature of the coolant is -18 DEG C to -22 DEG C, thereby meeting the requirements of frozen foods and frozen drugs on temperature.

Owner:JIANGNAN UNIV

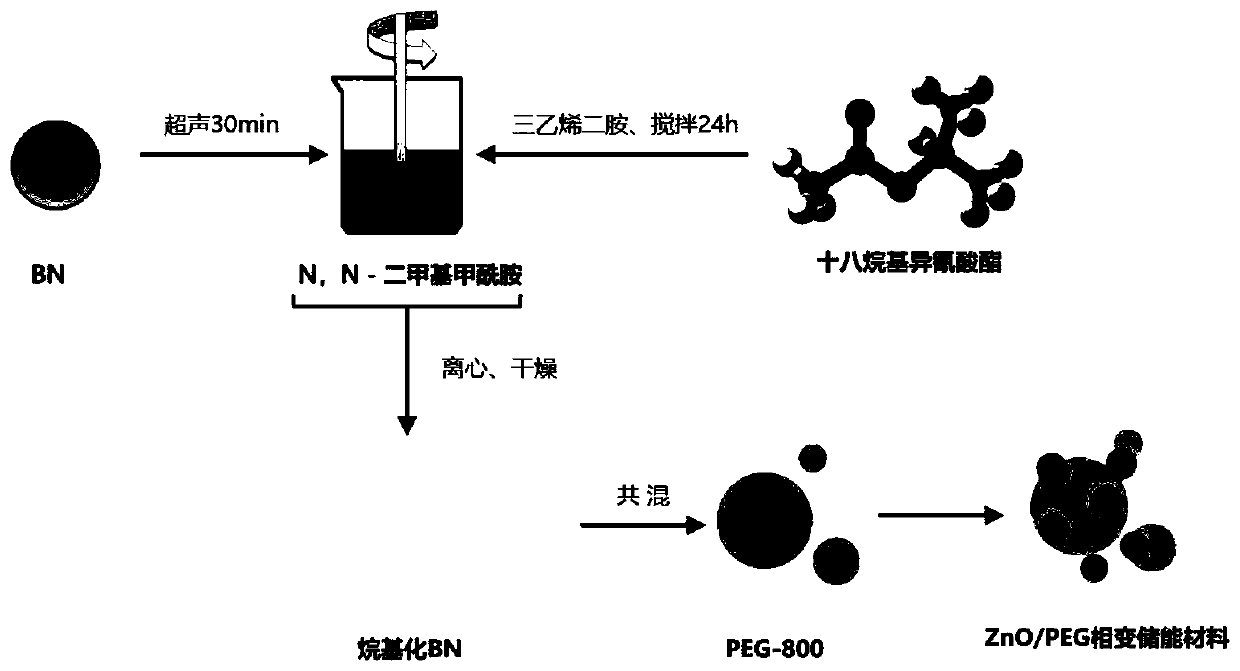

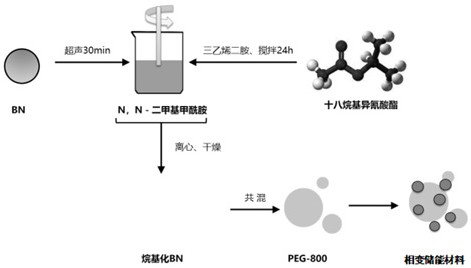

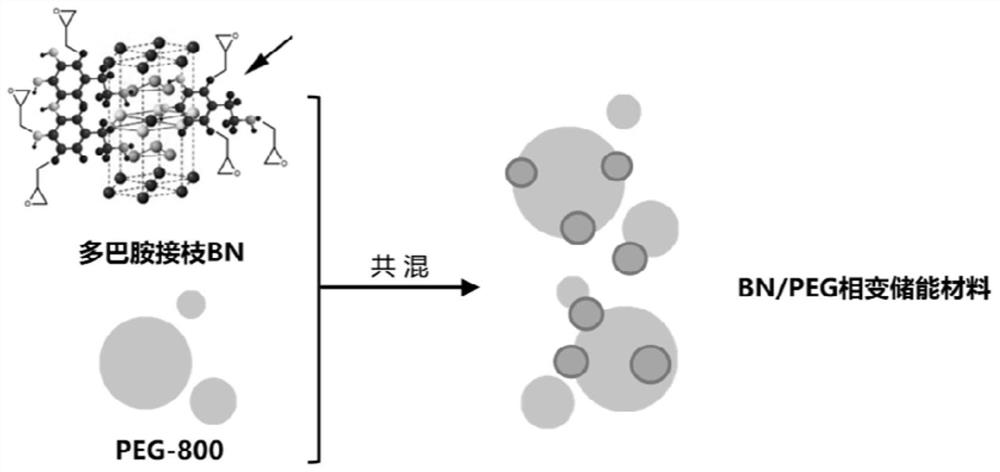

Energy storage wood material using alkylated boron nitride as filler

InactiveCN110405883AHigh photothermal conversion efficiencyComply with temperature requirementsWood treatment detailsThermal wood treatmentGlycidyl methacrylateBoron nitride

The invention discloses an energy storage wood material using alkylated boron nitride as a filler. The main steps of the method comprise: (1) carrying out lignin removing treatment on a wood materialto increase energy storage space; (2) copolymerizing glycidyl methacrylate and polyethylene glycol 400, and blending with glycidyl methacrylate to prepare an organic solvent; (3) dispersing boron nitride in a buffer solvent, adding dopamine hydrochloride, carrying out a reaction for a certain time at a room temperature to graft boron nitride onto dopamine, dispersing dopamine-modified boron nitride in N,N-dimethyl formamide, adding octadecyl isocyanate, and grafting boron nitride onto the alkyl chain under the action of a catalyst; (4) blending the alkylated boron nitride, the organic solventand polyethylene glycol 800 to prepare a phase change energy storage material; and (5) immersing the phase change energy storage material in the wood material by using a vacuum pressurizing full cellmethod to obtain a phase change energy storage wood material.

Owner:BEIJING FORESTRY UNIVERSITY

Method for regenerating ATP using rationally designed enzyme

ActiveCN105624238ALow costComply with temperature requirementsTransferasesFermentationPhosphoric acidTetra

The invention relates to a method for regenerating ATP using a rationally designed enzyme. Through rational design after sequence alignment, polyphosphate kinase from sinorhizobium meliloti is mutated and heterologously expressed; and under the catalysis of the polyphosphate kinase, the regeneration of ATP is realized by adopting polyphosphate with low polymerization degree as a phosphoric acid donor. Compared with existing ATP regeneration method, the polyphosphate kinase used in the invention is a normal-temperature enzyme which can react for coupling with multiple enzymes; the enzyme can take tetra-polyphosphate as a phosphoric acid donor; compared with phosphoric acid with high polymerization rate, the tetra-polyphosphoric acid is more common and easily available; and the feasibility of ATP regeneration is increased on the basis of simplifying the ATP regeneration process, and the cost of ATP regeneration is reduced. The activity of PPK enzyme is not inhibited by the polyphosphate concentration, and industrial large-scale production is possible.

Owner:BEIJING UNIV OF CHEM TECH

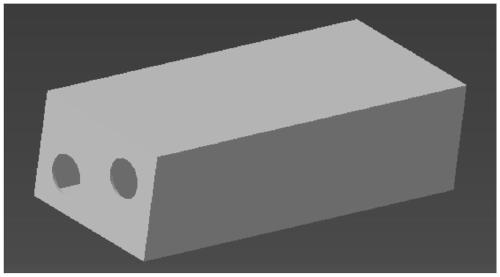

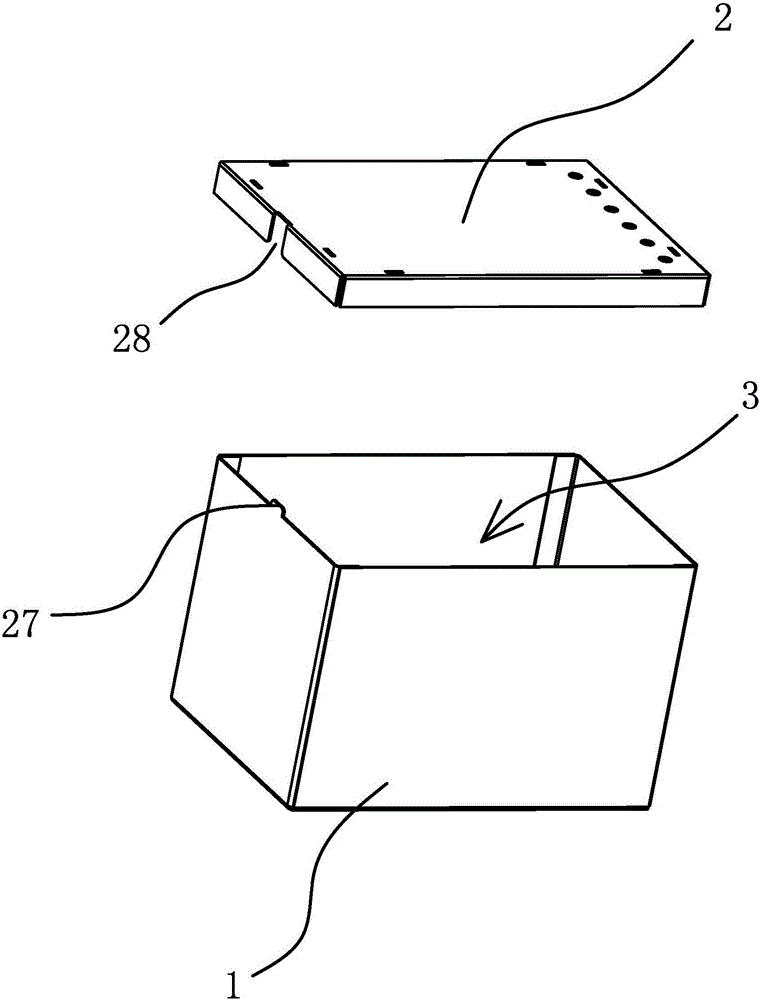

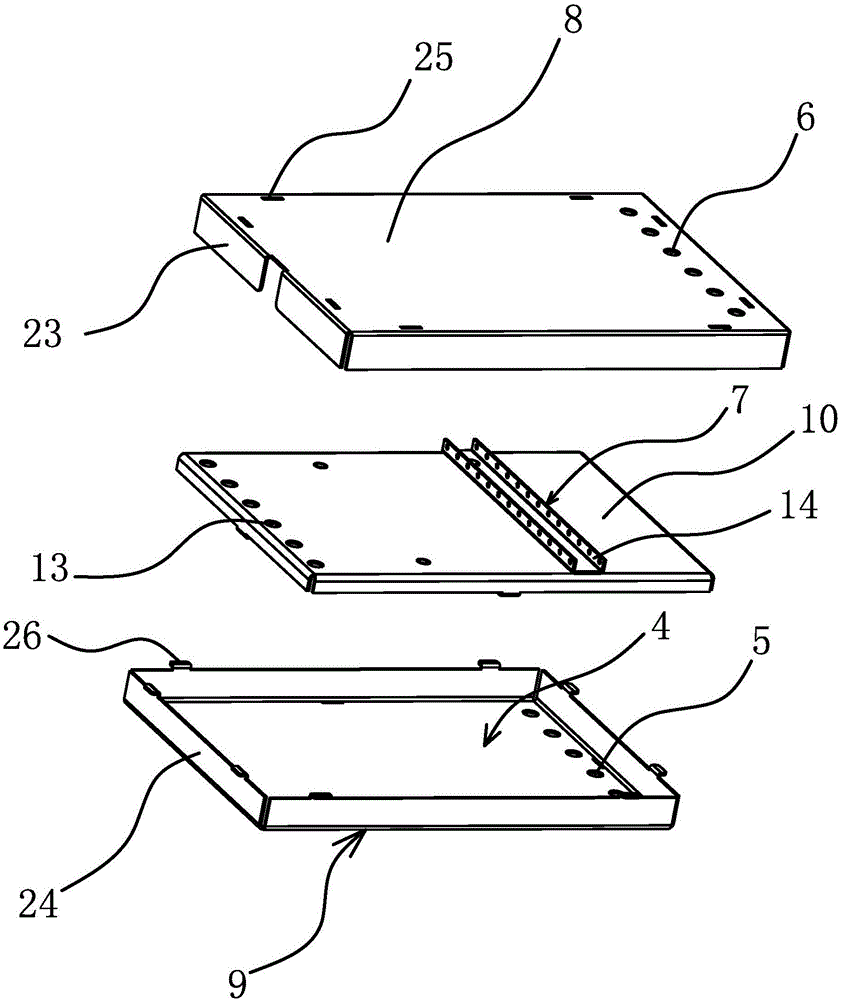

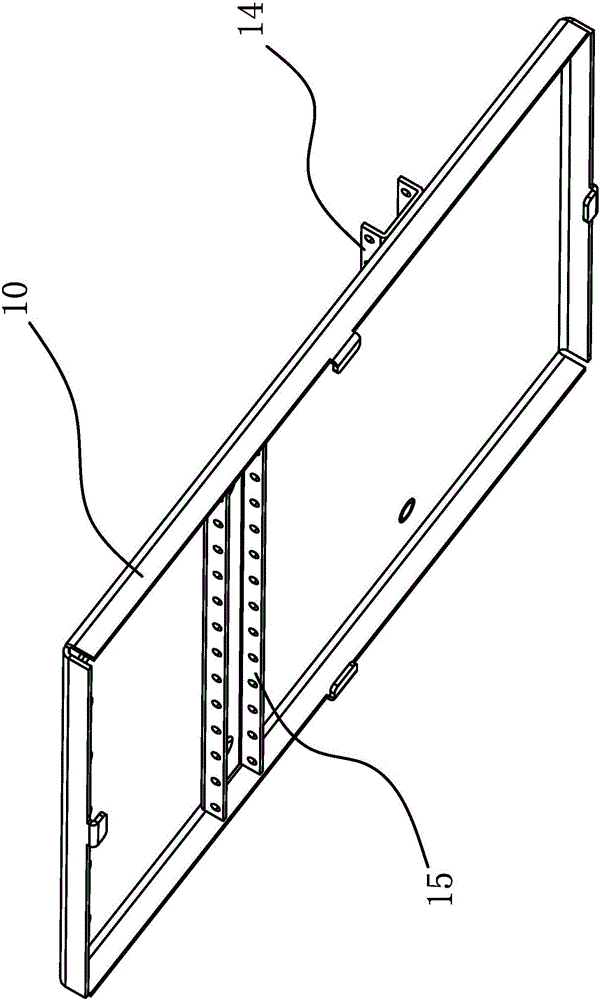

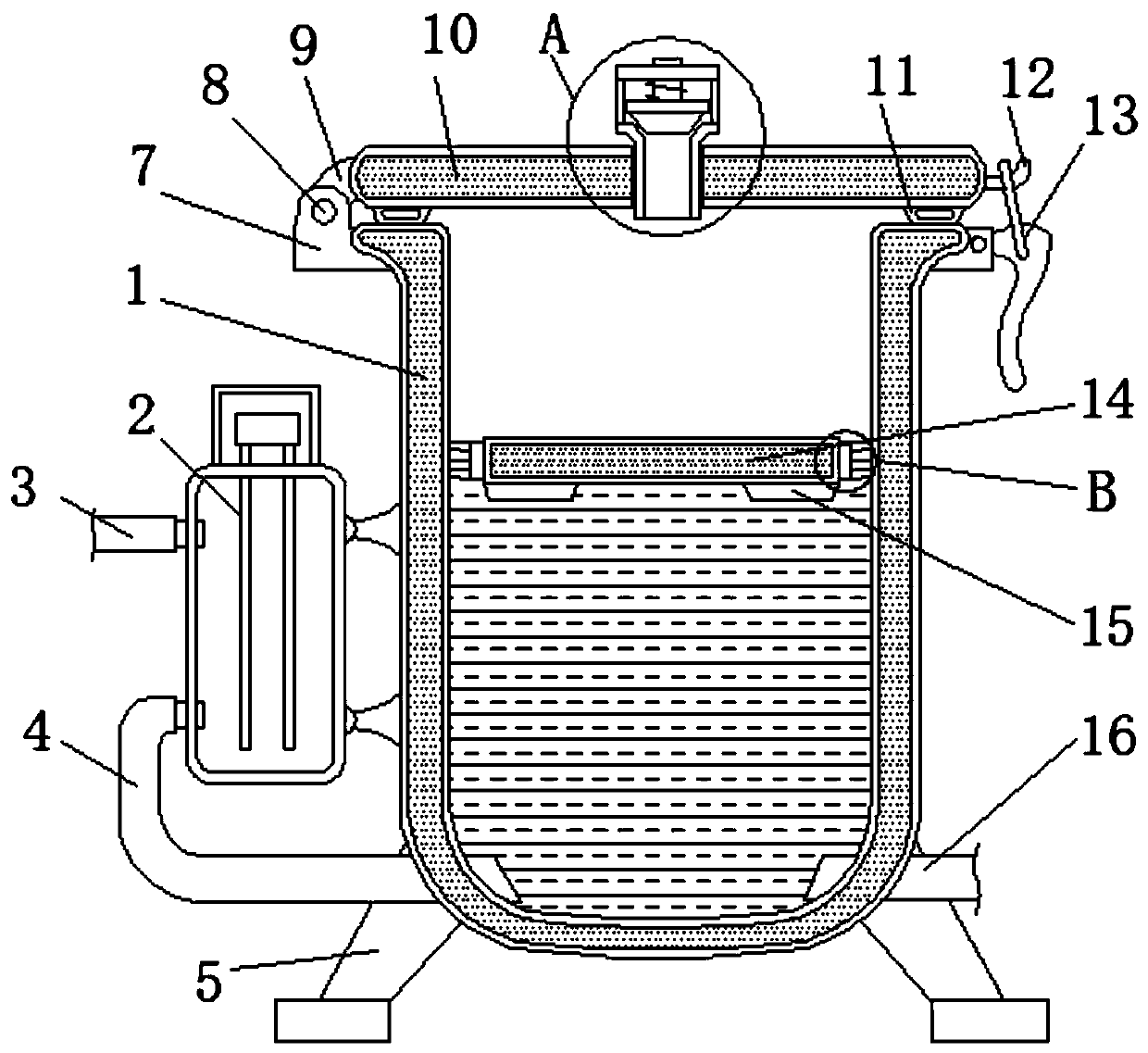

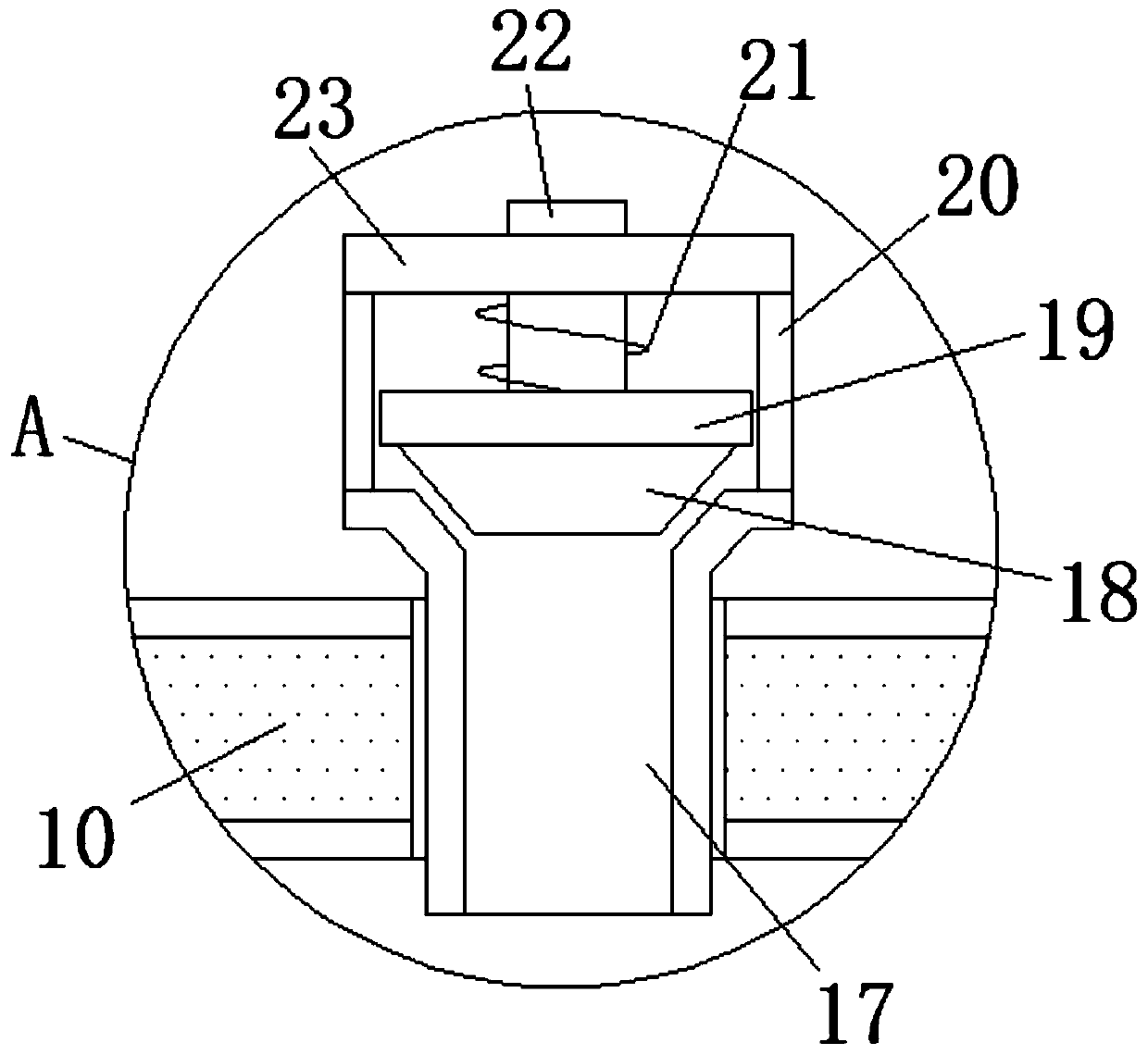

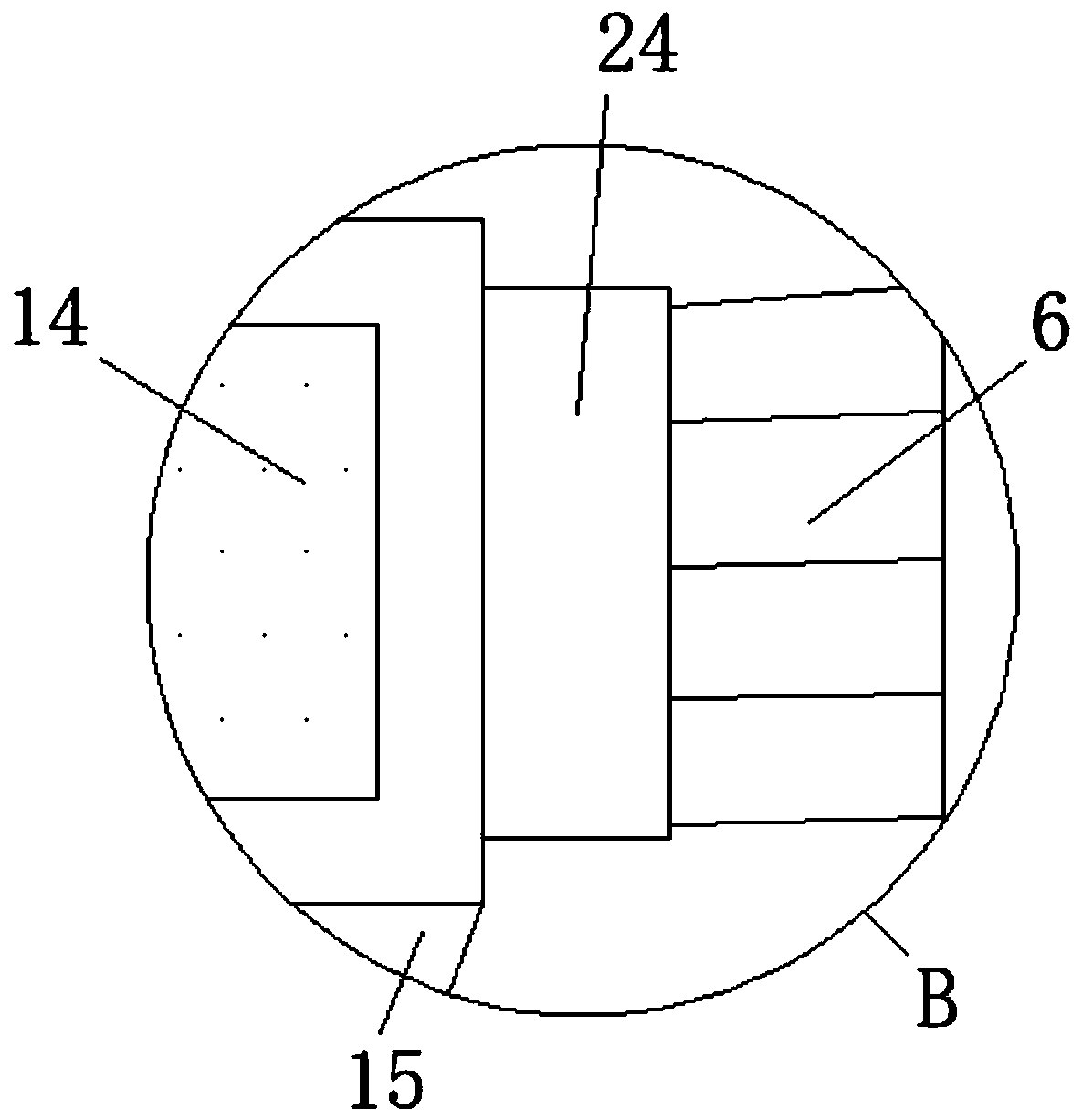

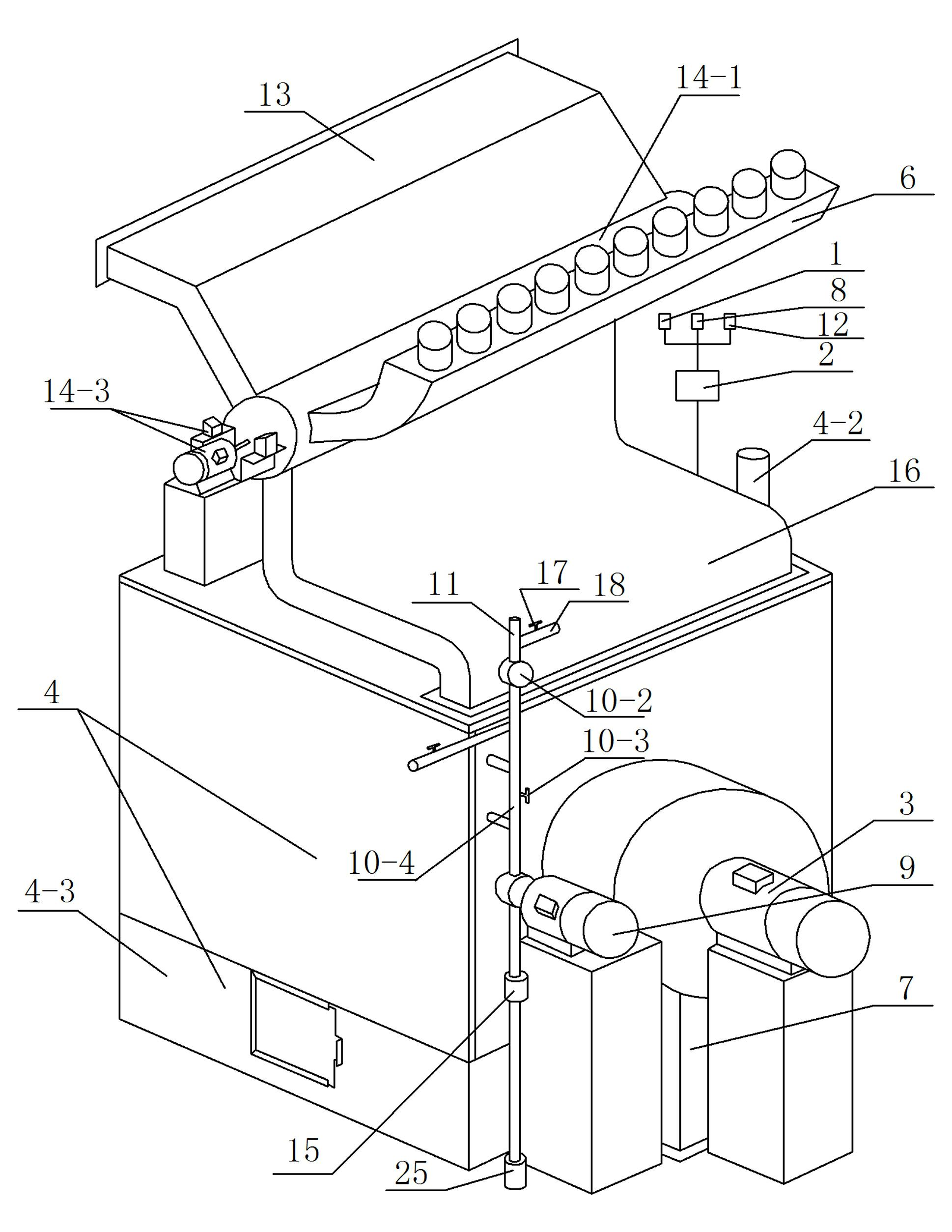

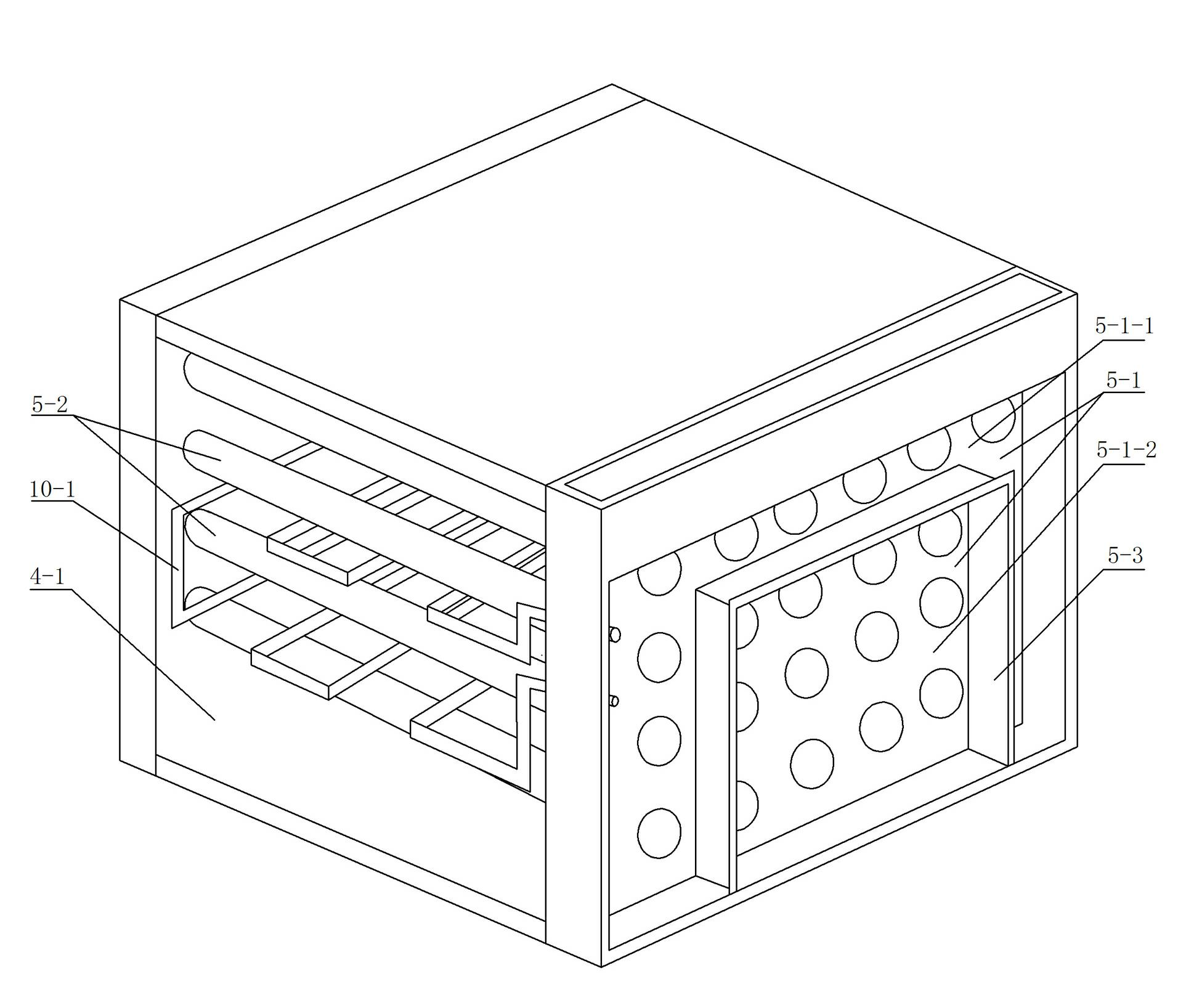

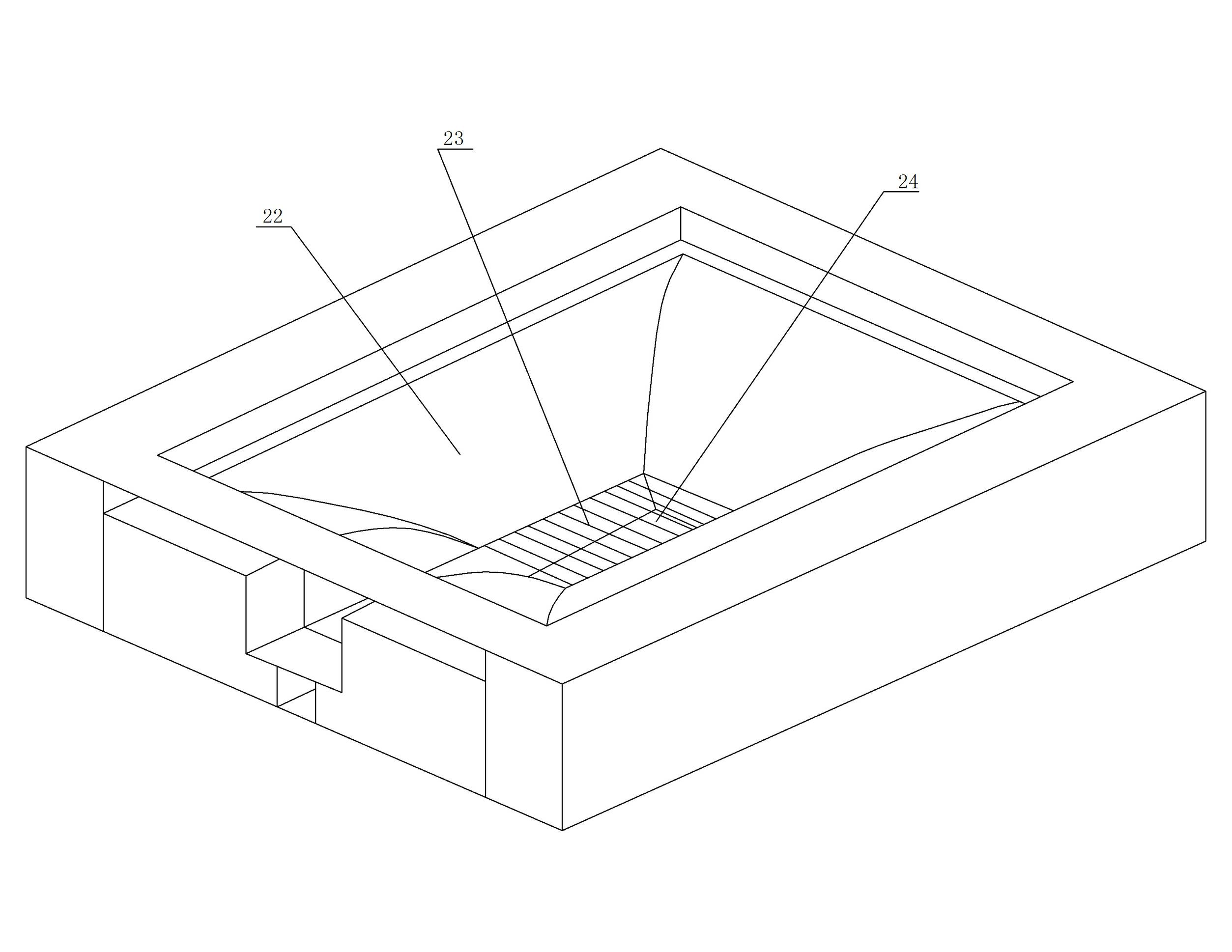

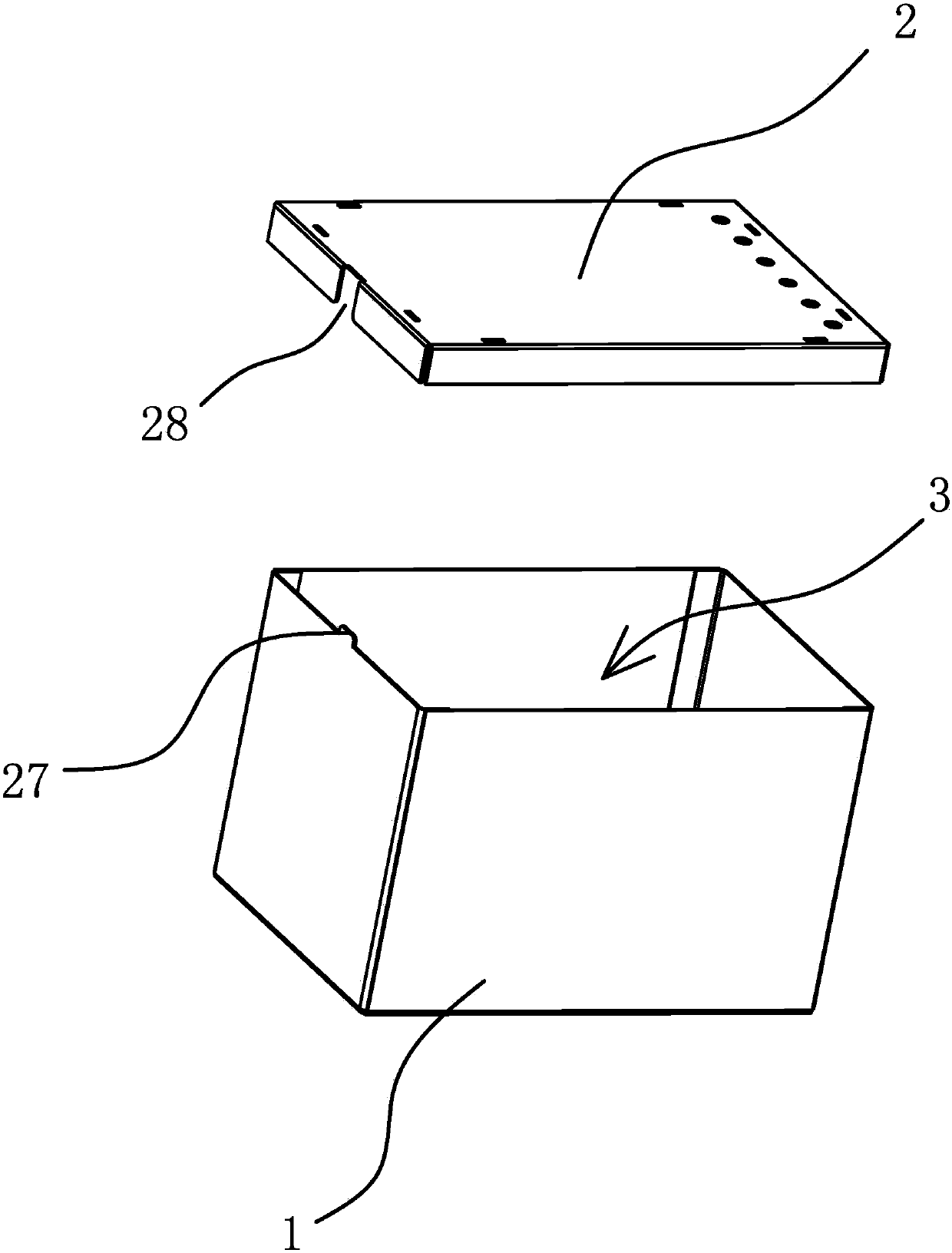

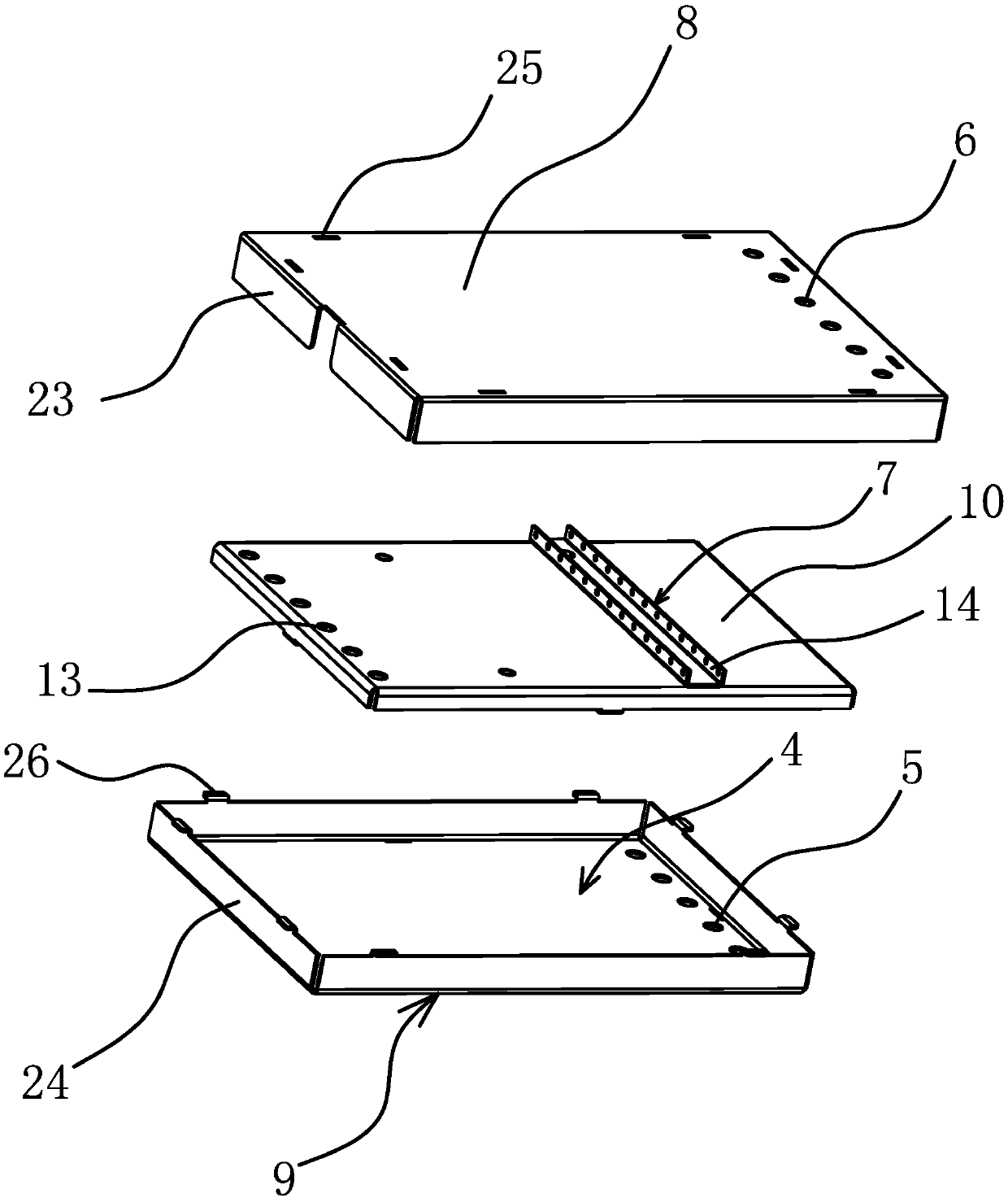

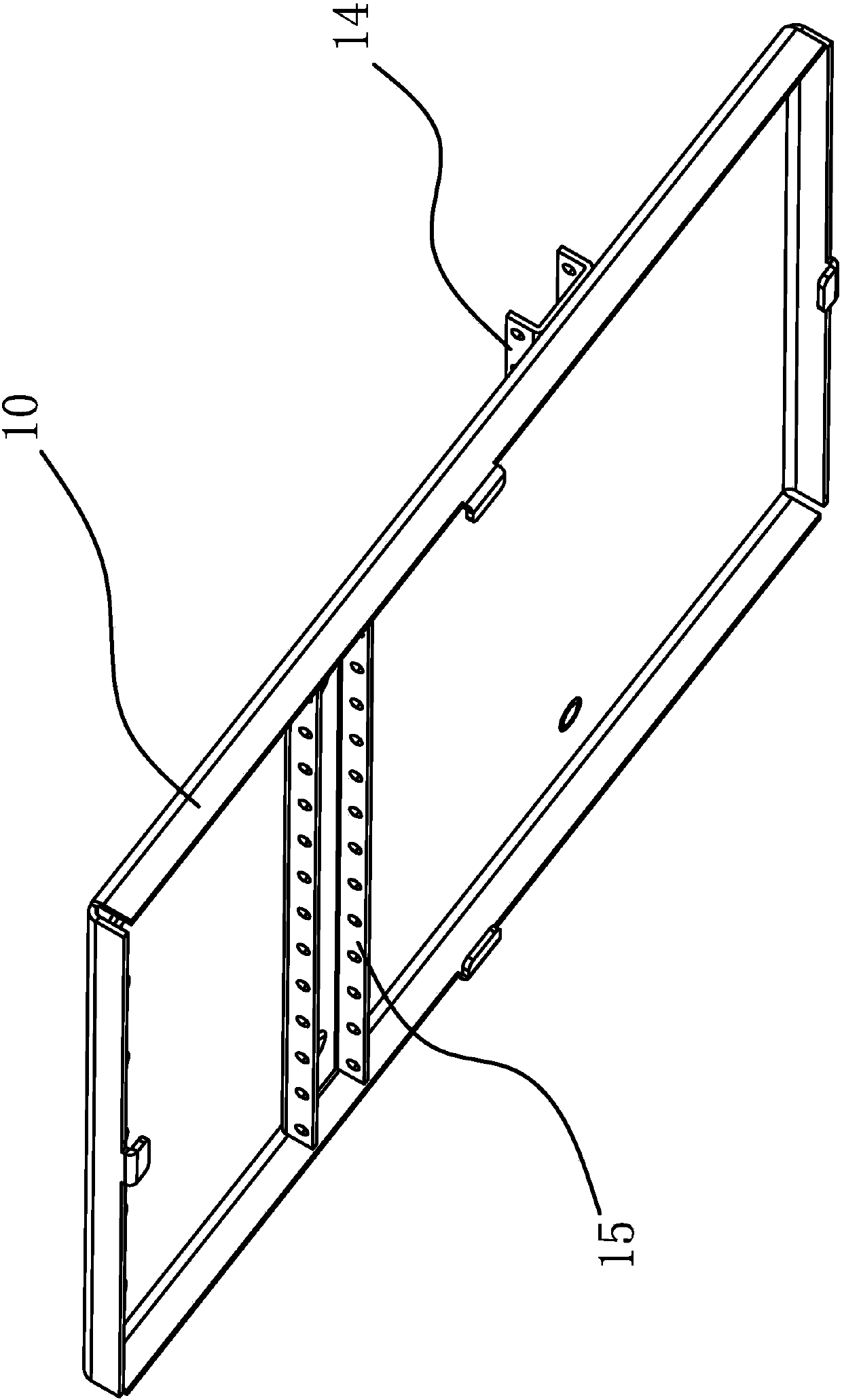

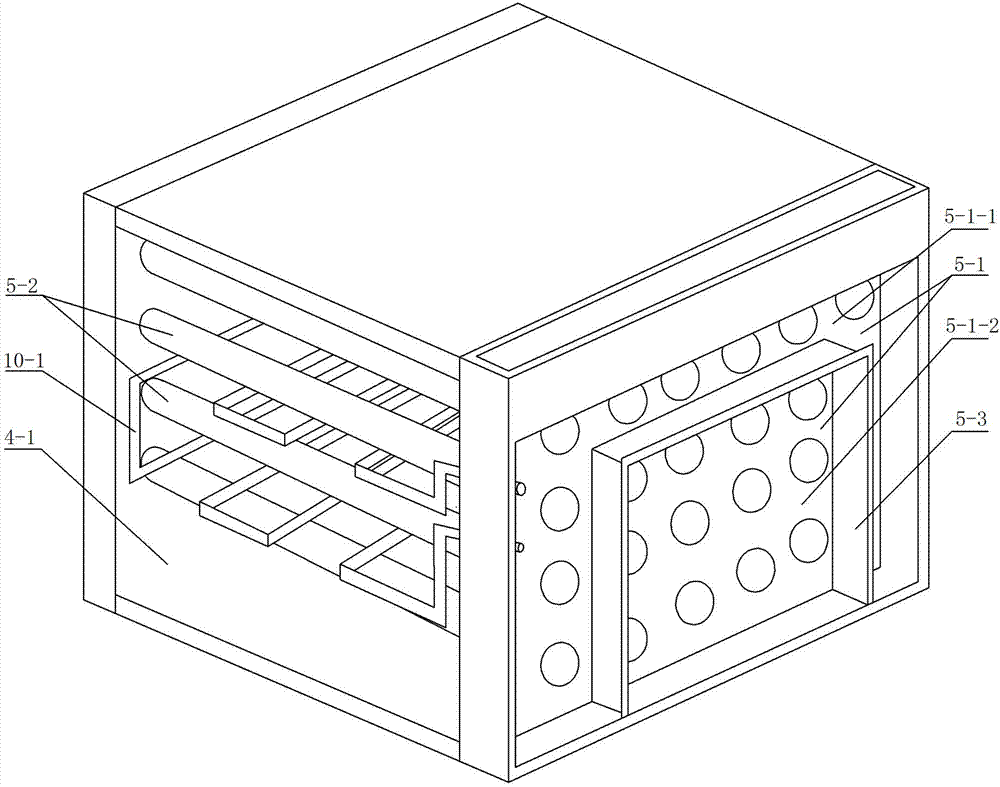

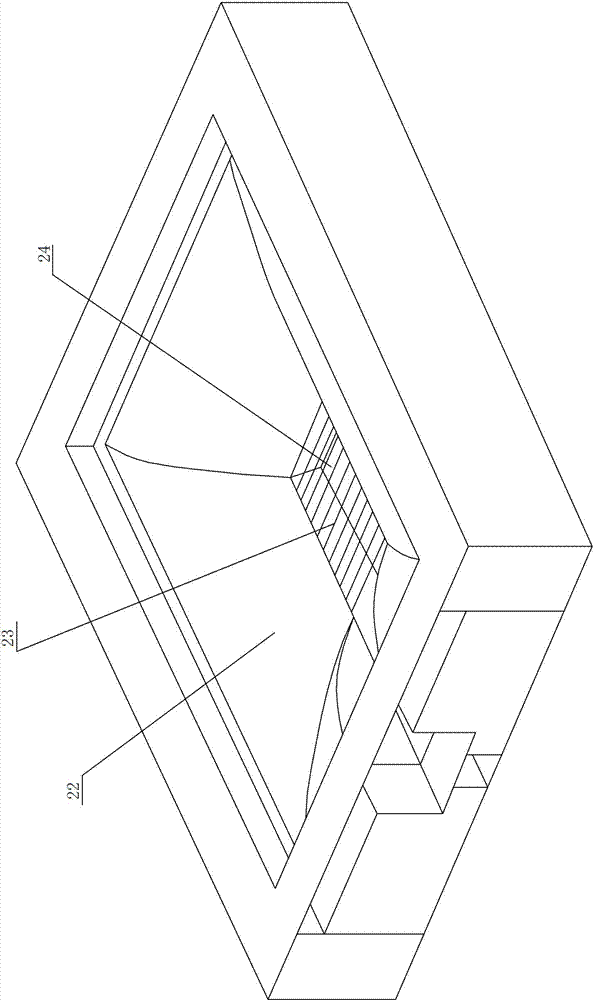

Fumigating box and electric fumigating oven with fumigating box

ActiveCN105662170AEvenly dehydratedImprove the heating effectRoasters/grillsEngineeringUtilization rate

The invention provides a fumigating box and an electric fumigating oven with the fumigating box, belongs to the technical field of electric fumigating ovens, and aims to solve the technical problems that the fume supply time is shortened, a relatively great amount of materials can be consumed, and the like as the flowing speed of fume generated from a fume generator of a conventional fumigator is too high. The fumigating box comprises a box body and a box cover, wherein a material storage cavity for accommodating a fume generating material is formed inside the box body; the top surface of the box body is opened; the box cover is detachably connected onto the top of the box body and is used for sealing the opening of the box body; a fume storage cavity is formed inside the box cover; fume inlets for communicating the fume storage cavity with the material storage cavity are formed in the bottom surface of the box cover; fume outlets communicated with the fume storage cavity are formed in the top surface of the box cover; a fume baffle structure for retarding fume in the fume storage cavity from being discharged out is arranged inside the box cover. By adopting the fumigating box and the electric fumigating oven, the utilization rate of a fume generating material can be effectively increased.

Owner:ZHEJIANG FUDEER ELECTRIC APPLIANCE

Heat storage device with supply-production balance

InactiveCN110763063AEasy inputImprove insulation effectHeat storage plantsNon-rotary device cleaningEngineeringMechanical engineering

The invention relates to the technical field of heat storage equipment, and discloses a heat storage device with supply-production balance. The heat storage device with the supply-production balance comprises a tank body, supporting rods are installed on the left side and the right side of the bottom of the tank body, a heat exchanger is fixedly installed on the left side of the tank body, the left side of the heat exchanger fixedly communicates with an outer water conveying pipe and an inner water conveying pipe, the right end of the inner water conveying pipe penetrates through the tank bodyand extends to the bottom of an inner cavity of the tank body, the bottom of the right side of the tank body fixedly communicates with a water outlet pipe, and a fixing piece is fixedly installed atthe top of the right side of the tank body. According to the heat storage device with the supply-production balance, through the cooperation among a sliding rod, a blocking block, a top plate elasticspring and a bottom plate, the sliding rod can slide up and down inside the top plate, the elastic spring provides downward pressure on the bottom plate, and when the gas pressure inside the tank bodybecomes large, the blocking block moves upwards under the action of the gas pressure, so that the internal gas pressure of the tank body is balanced with the external gas pressure, and then water ina water pump water conveying pipe is conveniently input into the tank body.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

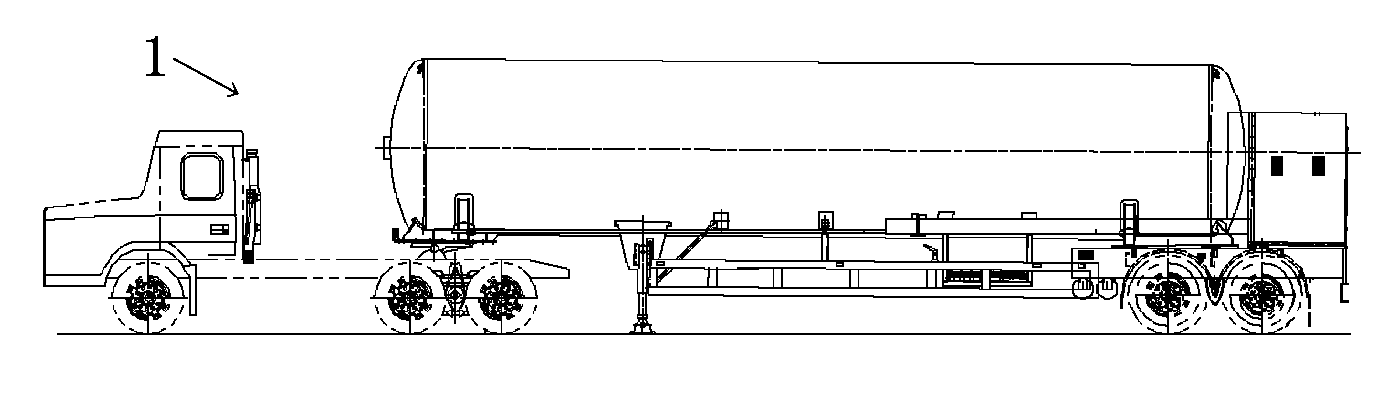

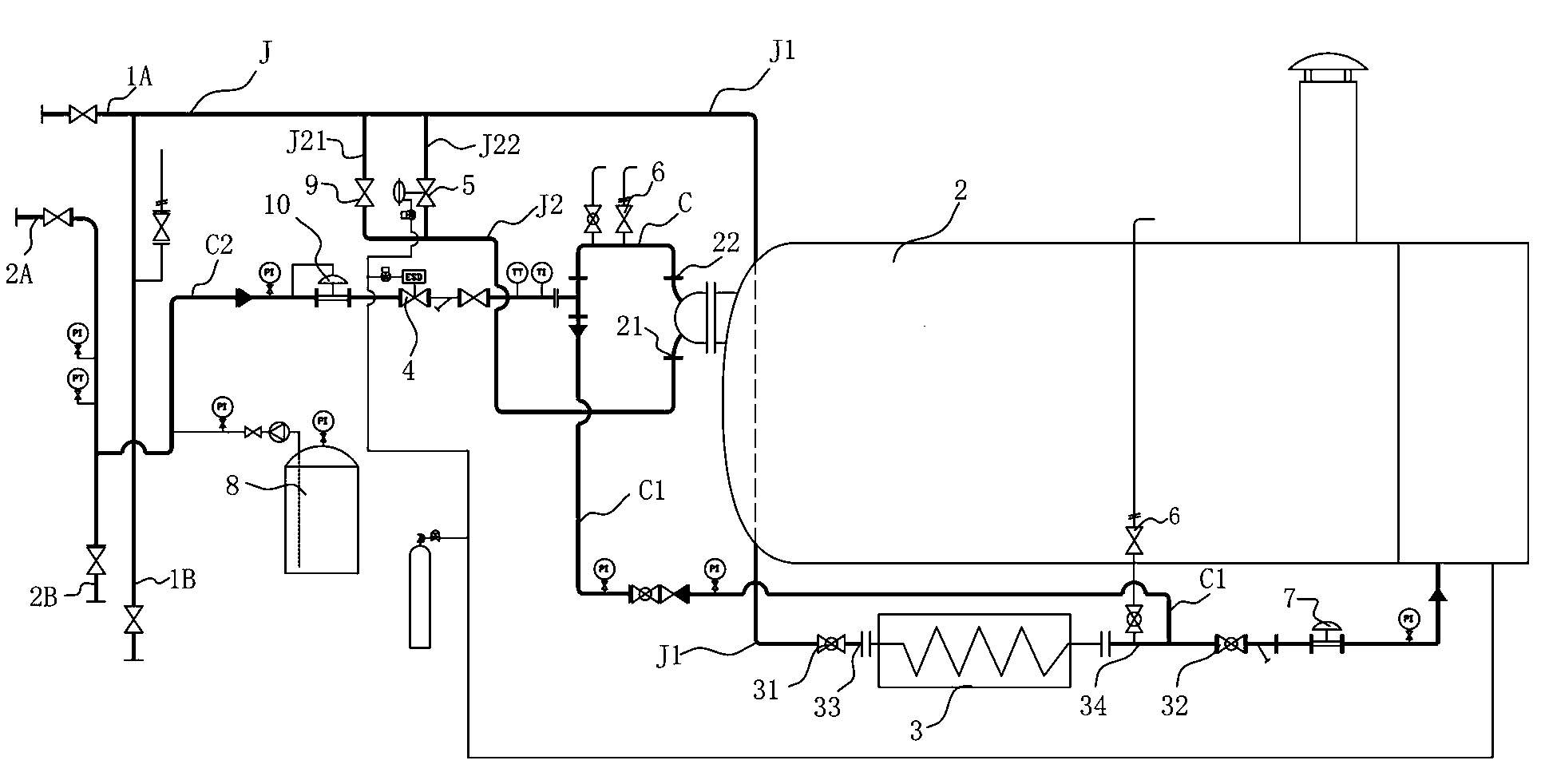

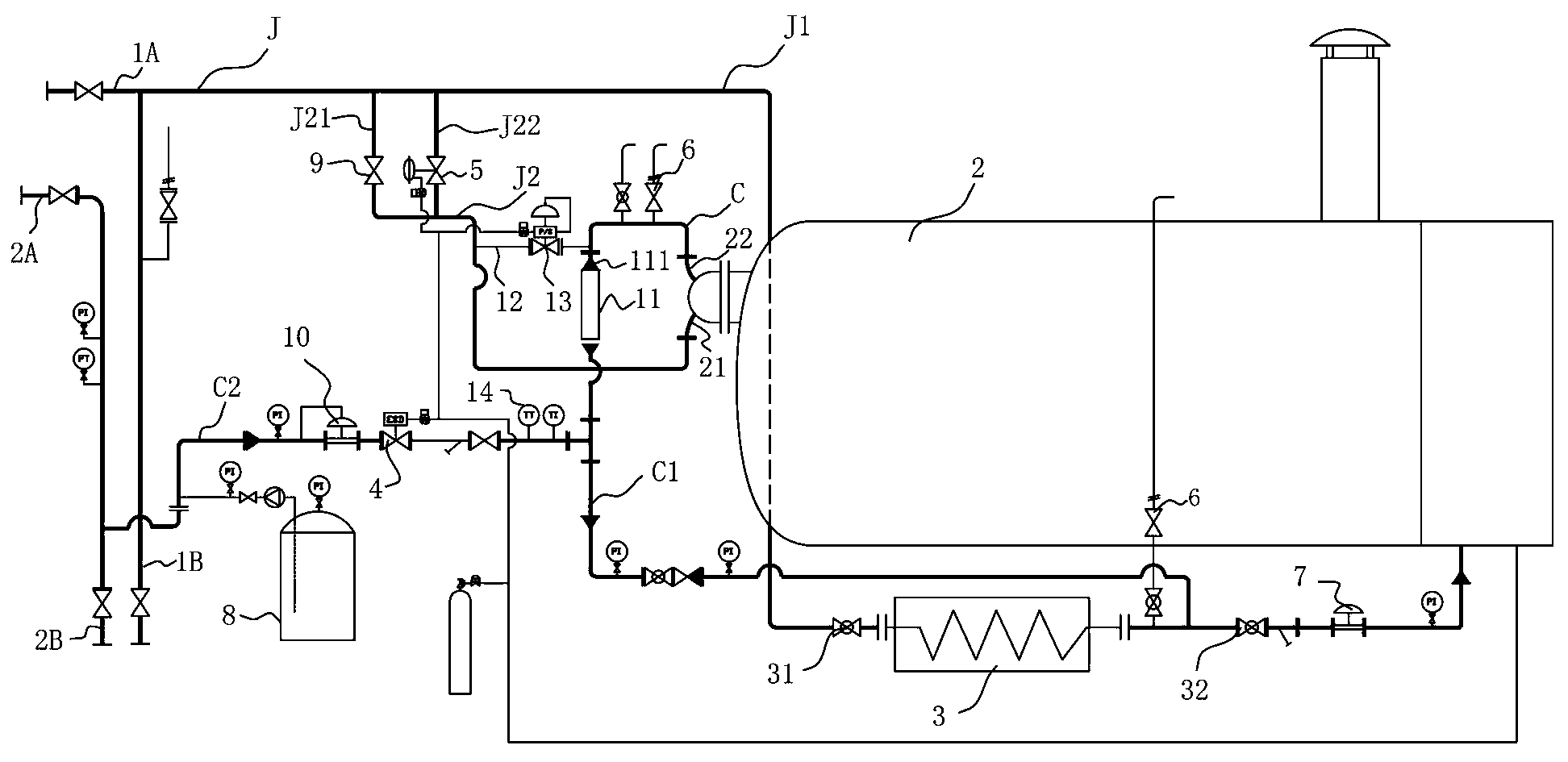

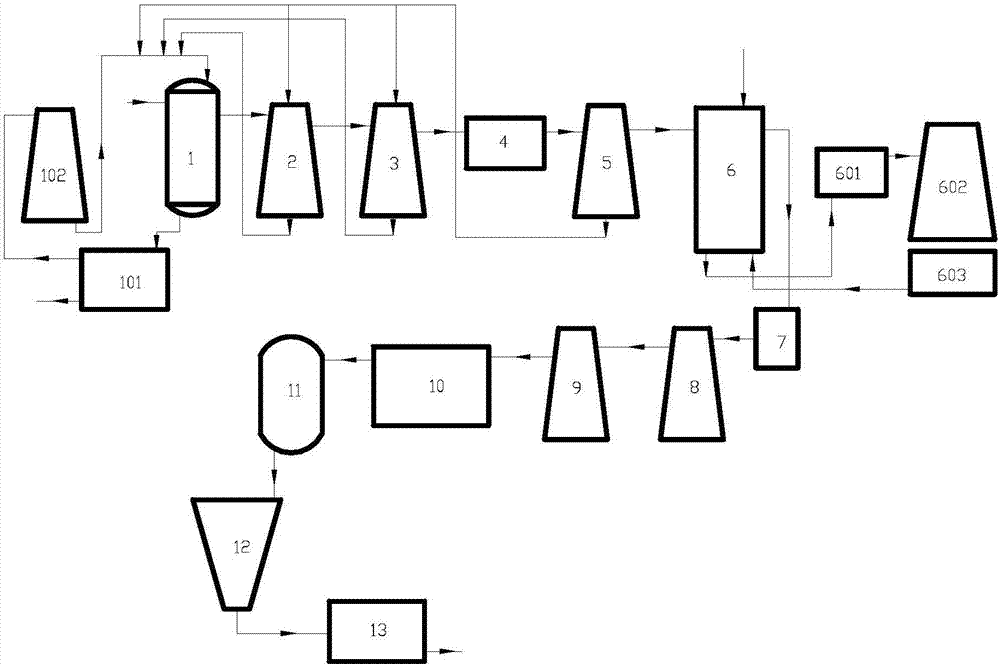

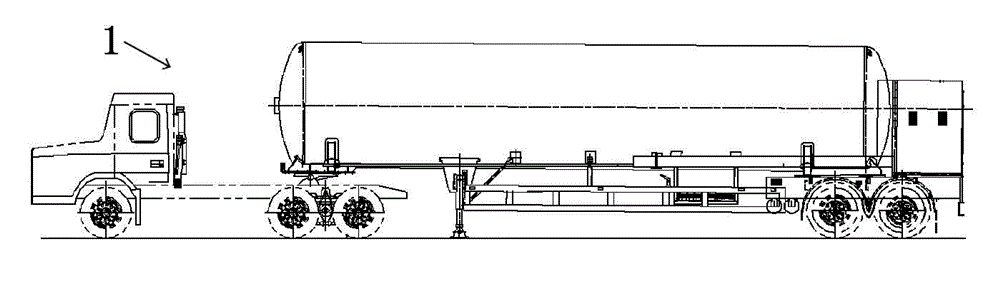

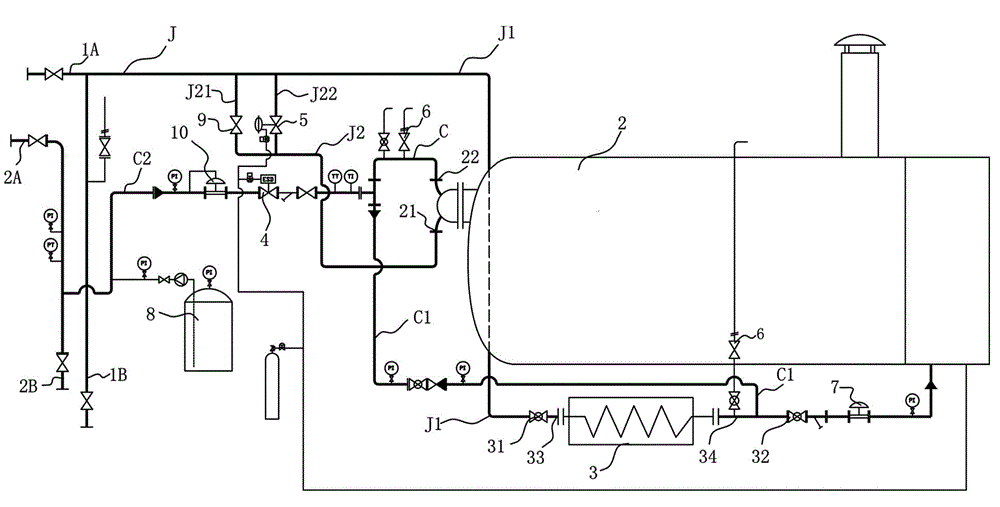

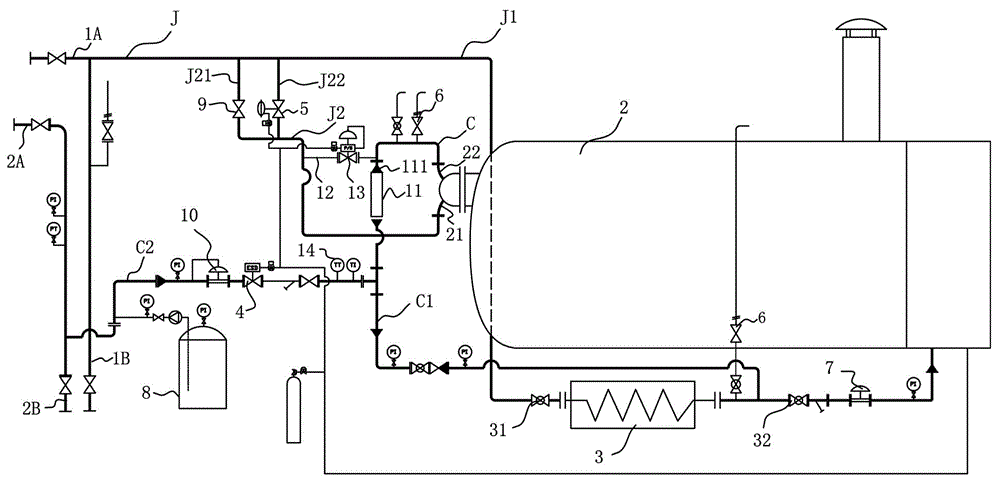

Mobile emergency natural gas supply system and mobile emergency natural gas supply method

The invention provides a mobile emergency natural gas supply system. The mobile emergency natural gas supply system comprises a water bath type vaporizer which is arranged on a skid-mounted vehicle, an ambient air vaporizer, a first liquefied natural gas inlet pipeline, a second liquefied natural gas inlet pipeline, a first gaseous natural gas outlet pipeline and a second gaseous natural gas outlet pipeline; the first liquefied natural gas inlet pipeline is connected with a liquid phase inlet end of the ambient air vaporizer; the second liquefied natural gas inlet pipeline and the second gaseous natural gas outlet pipeline are respectively connected with a fluid phase inlet end and a gaseous phase outlet end of the water bath type vaporizer; a gaseous phase outlet end of the ambient air vaporizer is connected with a combustor which is arranged inside the water bath type vaporizer; one end of the first gaseous natural gas outlet pipeline is connected with the gaseous phase outlet end of the water bath type vaporizer; and the other end of the first gaseous natural gas outlet pipeline is connected with the combustor which is arranged inside the water bath type vaporizer. The invention also provides a mobile emergency natural gas supply method using the mobile emergency natural gas supply system. The mobile emergency natural gas supply system and the mobile emergency natural gas supply method have the advantages of being large in gas supply capacity, high in temperature of the gaseous phase outlets, capable of achieving continuous gas supply, rapid in starting and capable of adapting to a mobile gas supply requirement.

Owner:SHENZHEN GAS CORP

Energy storage wood construction method using alkylated carbon black as filler

InactiveCN110587752AWide variety of sourcesMeet the requirements of low-carbon environmental protectionWood treatment detailsThermal wood treatmentModified carbonPolyethylene glycol

The invention discloses an energy storage wood construction method using alkylated carbon black as filler. The main steps of the method are as follows: (1) delignification treatment is carried out onwood to open cell wall gaps and improve energy storage space; (2) glycidyl methacrylate is selected as the basic material to prepare organic solvent, then organic solvent and polyethylene glycol 800 are blended to prepare phase change energy storage materials, (3) carbon black is dispersed in sulfuric acid solution and heated to prepare hydroxylated carbon black, then hydroxylated carbon black isdispersed in Tris buffer solution, and dopamine is added to adjust the reaction conditions to prepare dopamine modified carbon black. Dopamine modified carbon black is alkylated with octadecyl isocyanate, finally, it is dispersed in the phase change energy storage material; (4) the phase change energy storage material is immersed into the wood by vacuum pressurization full cell method to obtain the phase change energy storage wood.

Owner:BEIJING FORESTRY UNIVERSITY

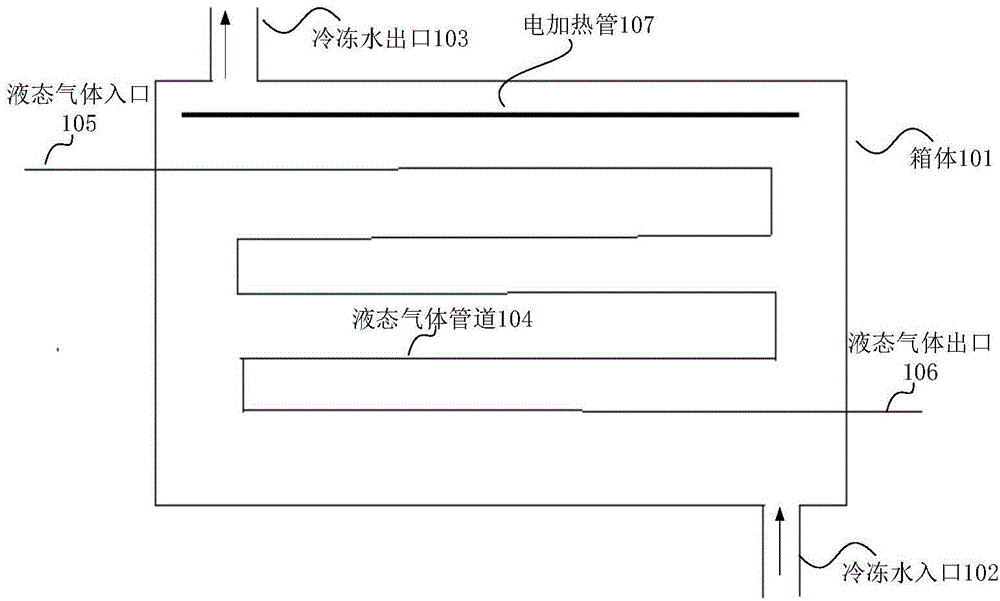

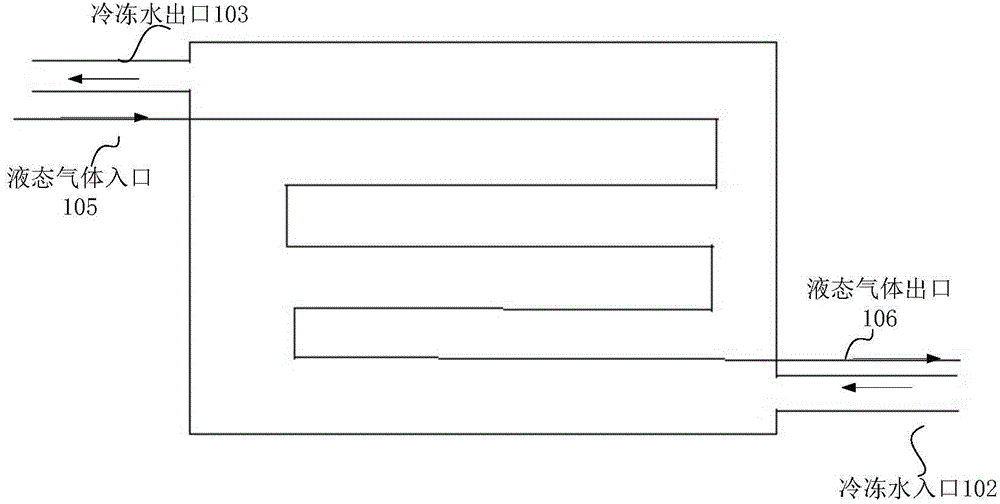

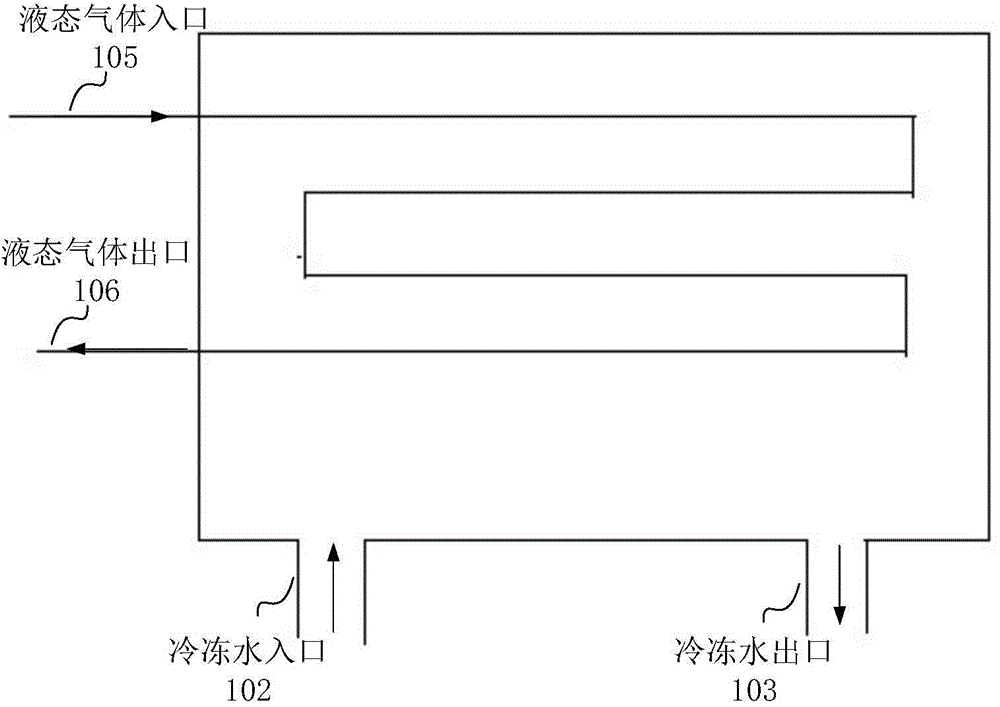

Chilled water treatment device and system

InactiveCN105333664ATo achieve the purpose of energy saving and environmental protectionPrevent freezing and even ice blockageDomestic cooling apparatusLighting and heating apparatusWater pipeWater treatment

The embodiment of the invention provides a chilled water treatment device and system. The chilled water treatment device comprises a sealed box body, and a chilled water inlet and a chilled water outlet are formed in the box body. The chilled water inlet is communicated with a chilled water returning pipe of an air conditioner system. The chilled water outlet is communicated with a chilled water supply pipe of the air conditioner system. A liquid gas pipeline is arranged in the box body and forms a liquid gas inlet and a liquid gas outlet in the wall of the box body. The chilled water treatment device and system can recycle cooling capacity released in the liquid gas gasification process to treat chilled water, the chilled water is made to carry the cooling capacity, and the purposes of saving energy and protecting the environment are realized.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Process of using calcium carbide to produce PVC

ActiveCN106967192AGuaranteed temperatureIncrease profitPreparation by halogen halide additionSlagUranium carbide

The invention discloses a process of using calcium carbide to produce PVC. The method is characterized by including: enabling calcium carbide slag slurry going out of an acetylene generator to overflow into a settling basin for settling, discharging bottom slag slurry for other use, and returning supernatant after being cooled into the acetylene generator to serve as reaction water for preparing acetylene from calcium carbide; returning wastewater used for dedusting acetylene gas and after being cooled into the acetylene generator to serve as reaction water for preparing acetylene from calcium carbide; enabling hot water going out of a converter shell layer and after exchanging heat through a heat exchanger to enter the upper portion of a steam absorption tower to absorb heat evaporated by a hot water tank and then automatically flow into the hot water tank, wherein the heat exchanger is used in other processes. By the process, effective utilization of water resources is realized fully, and environment pollution caused by wastewater discharge is avoided; conversion heat of chloroethylene is utilized reasonably, so that energy conservation and consumption reduction are realized.

Owner:SICHUAN YONGXIANG CO LTD

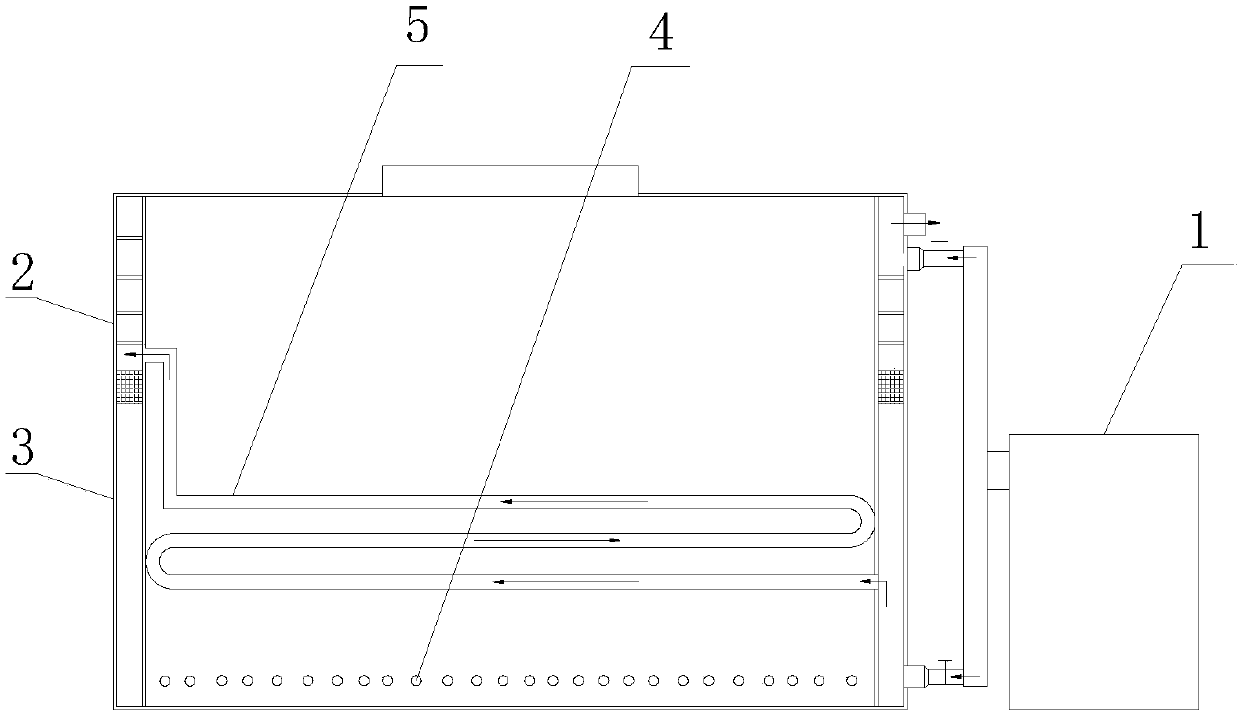

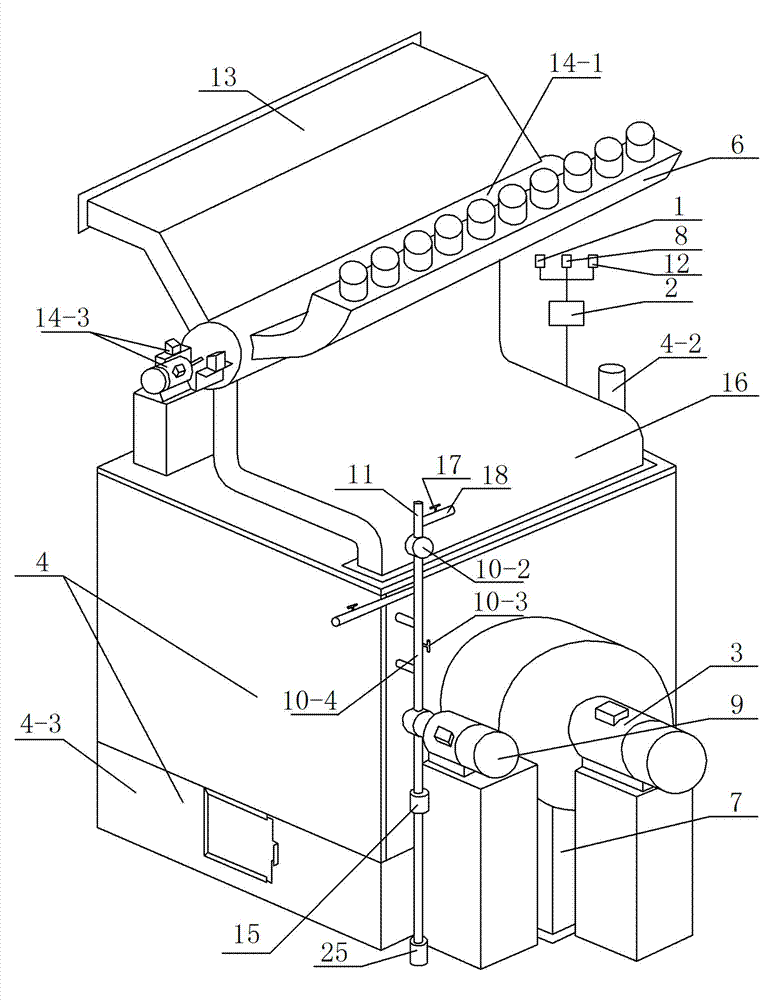

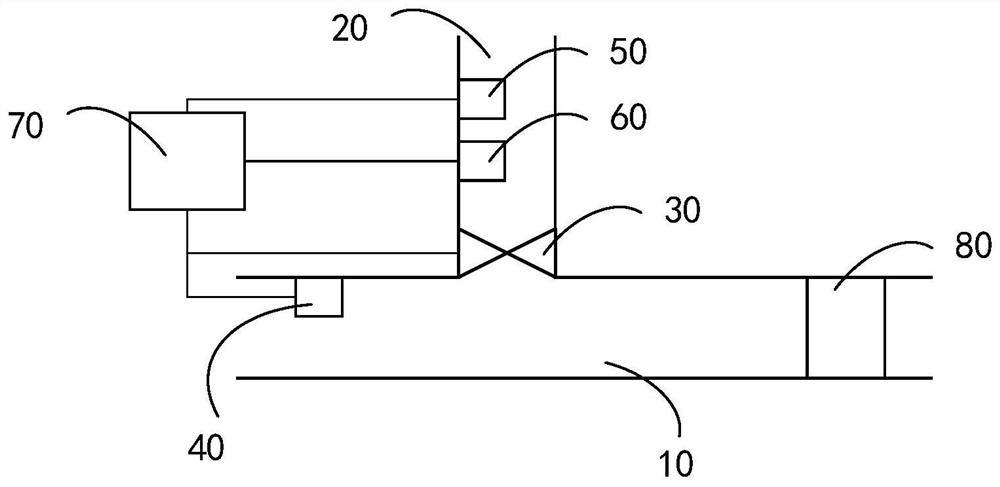

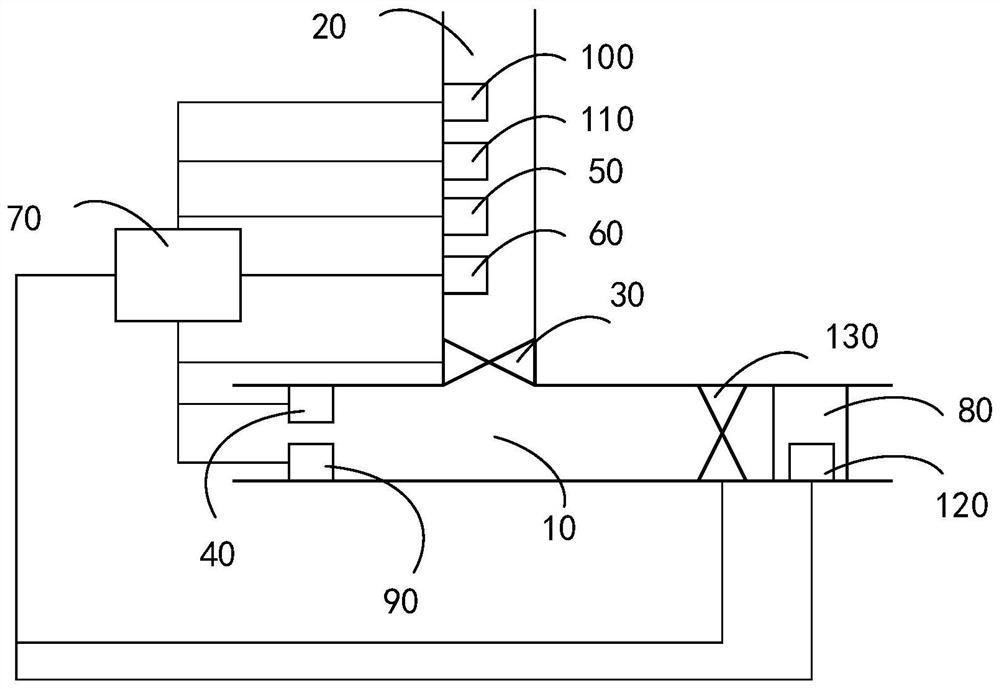

Machine for monitoring cultivation environment of edible fungi

InactiveCN102156470AComply with temperature requirementsHumidity controlProgramme total factory controlEngineeringEdible fungus

The invention relates to a machine for monitoring cultivation environment of edible fungi, which is characterized by comprising a temperature detection probe, a control device, a blasting device, a heater, a heating air duct, a circulative air inlet duct and an air outlet duct, wherein the temperature detection probe is arranged in an edible fungi cultivation room; the control device is connectedbetween the temperature detection probe and the blasting device; an inlet end of the circulative air inlet duct is arranged in the edible fungi cultivation room while an outlet end of the circulativeair inlet duct is connected with an inlet end of the heating air duct; the heating air duct passes through the heater, and an outlet end of the heating air duct is connected with an inlet end of the blasting device; and an inlet end of the air outlet duct is connected with an inlet end of the blasting device, and an outlet end of the air outlet duct is arranged in the edible fungi cultivation room. The invention aims to provide the machine for monitoring the cultivation environment of the edible fungi, which can regulate and control the temperature of the edible fungi cultivation room.

Owner:曾定金

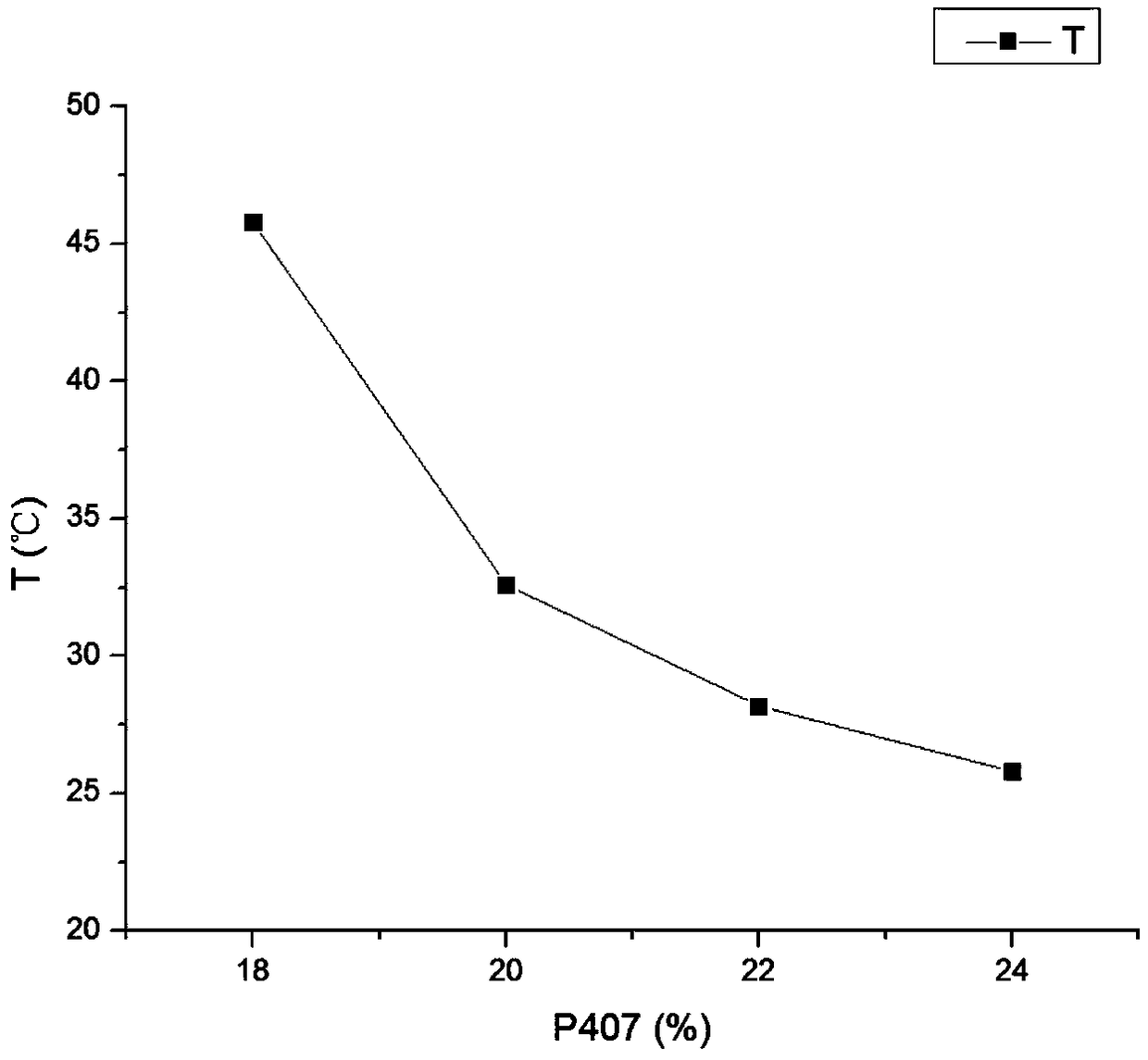

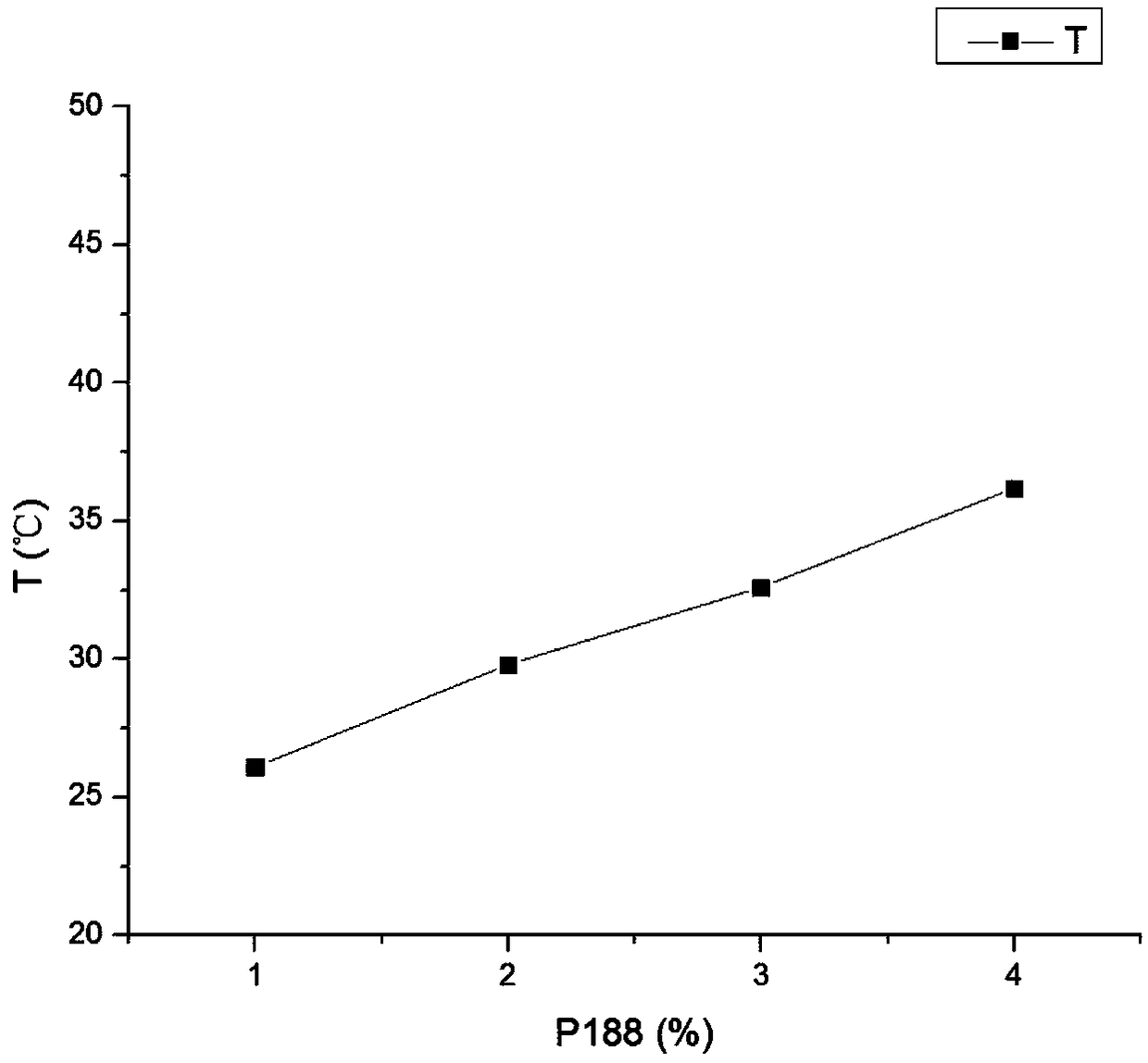

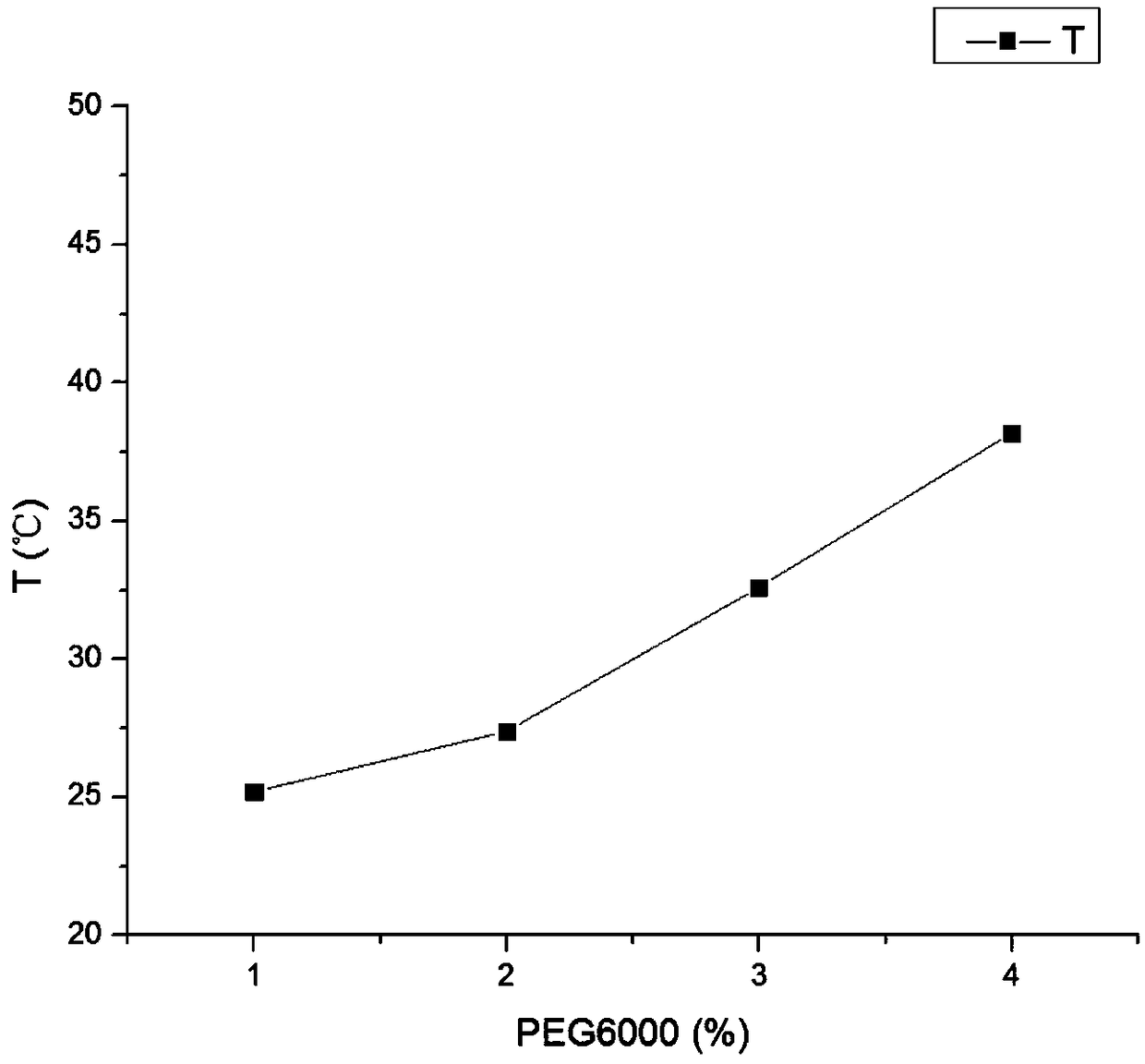

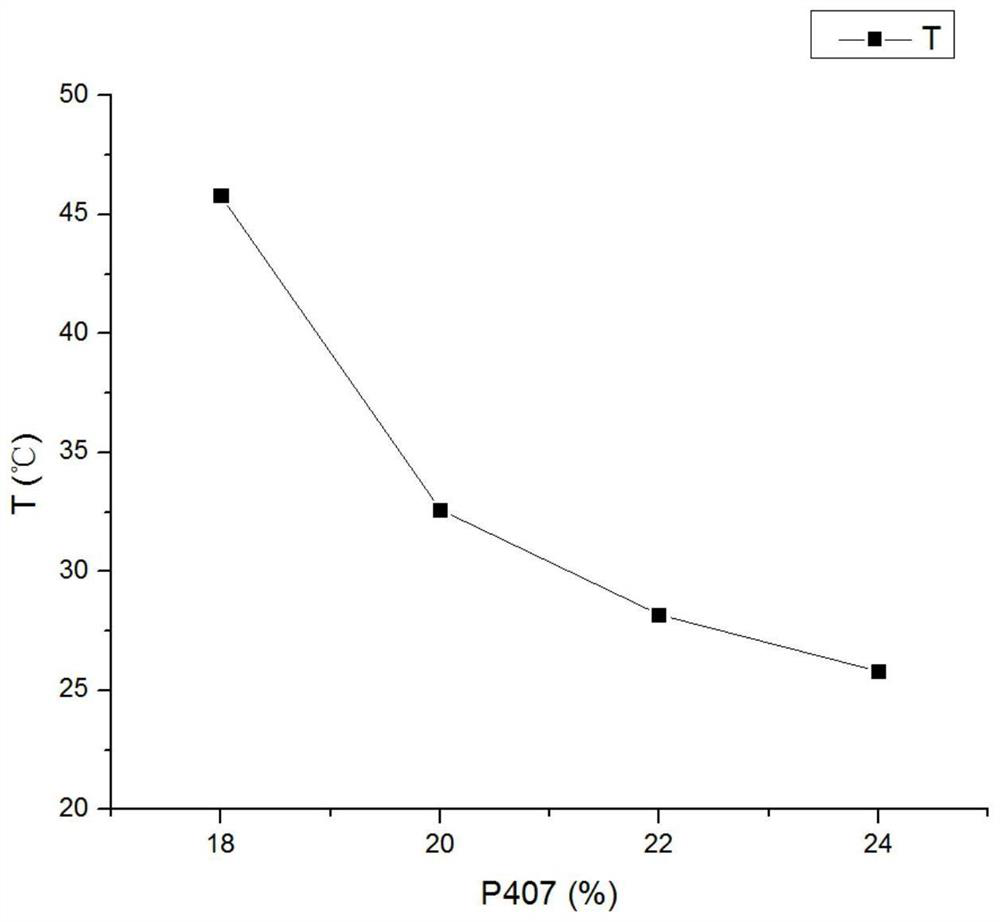

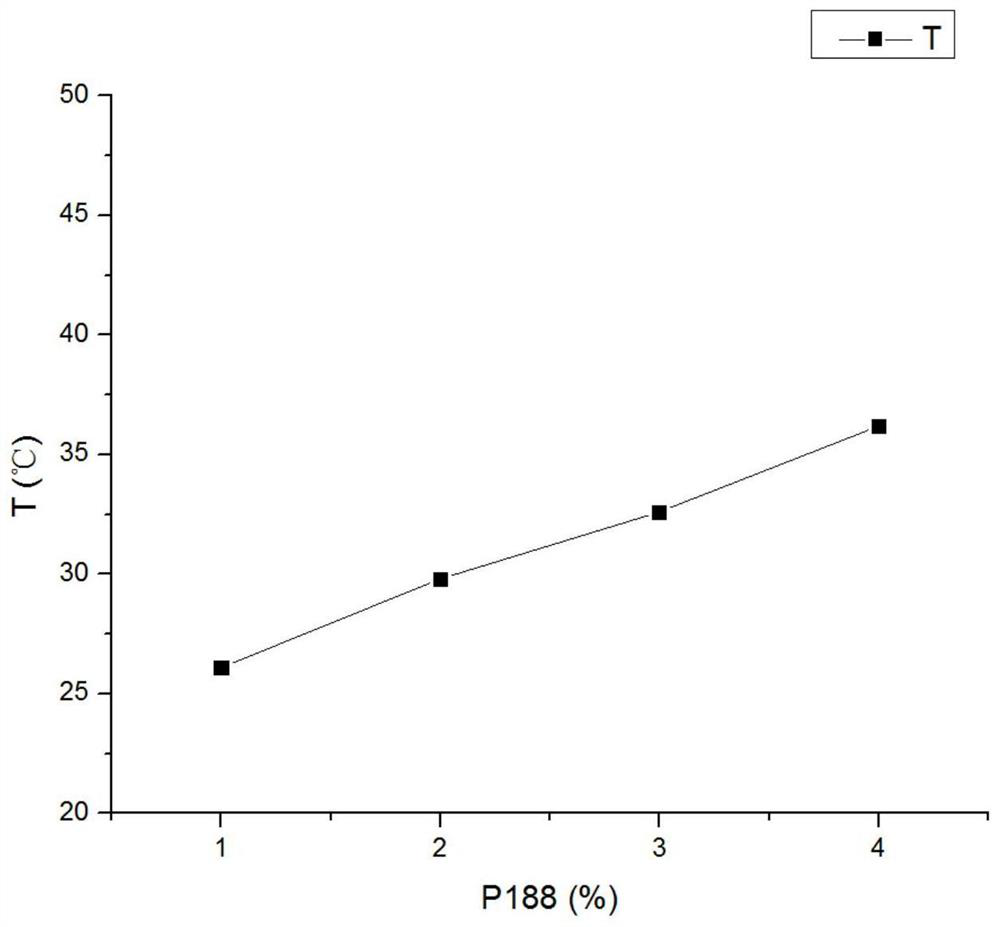

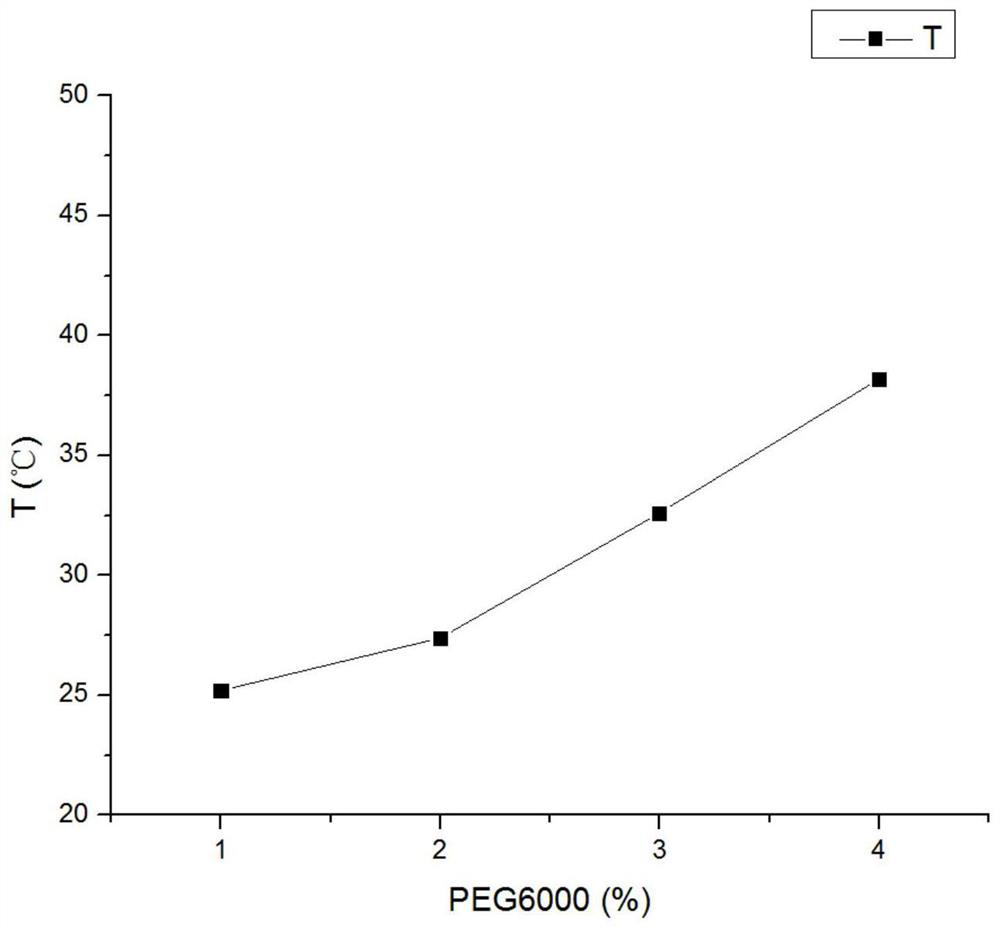

Rhizoma coptidis antidotal nasal thermo-sensitive gel and preparation method thereof

ActiveCN109453108AEasy to useSignificant effectAntibacterial agentsAntipyreticIrritationPolyethylene glycol

The invention relates to the technical field of traditional Chinese medicines, in particular to rhizoma coptidis antidotal nasal thermo-sensitive gel and a preparation method thereof. The rhizoma coptidis antidotal nasal thermo-sensitive gel is prepared by mixing concentrate of rhizoma coptidis and cortex phellodendri extraction liquid, concentrated liquid of radix scutellariae and fructus gardeniae extraction liquid, poloxamer 407, poloxamer 188, polyethylene glycol 6000 and water. According to the rhizoma coptidis detoxification nasal thermo-sensitive gel, the defects that active componentsare unstable, and can hardly reach a focus are overcome, a preparation technology is simple, the raw materials are easy to get, the medicine efficacy is explicit, irritation is small, and the rhizomacoptidis antidotal nasal thermo-sensitive gel is safe, stable, antibacterial, antiphlogistic and wide in application range.

Owner:ZHANG ZHOU HALTH VOCATIONAL COLLEGE

Supported ionic liquid catalyst and preparation method and application thereof

InactiveCN101773852BNot easy to loseExtended service lifeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveSurface reaction

The invention provides a supported ionic liquid catalyst for preparing vinyl acetate in an acetylene method, the catalyst adopts mesoporous molecular sieve as a carrier and adopts zinc acetate as an active component, and the carrier and the active component are connected by imidazole acetate ionic liquid. The invention further provides a preparation method of the catalyst and an application in preparing the vinyl acetate in the acetylene method. The active component of the zinc acetate of the supported ionic liquid catalyst is bond-coupled on the surface of the carrier in a chemical method and is not easy to be lost in the reaction process; the carrier of the mesoporous molecular sieve provides suitable reaction space for catalytic reaction, and carbon deposition is not easy to be generated; the ionic liquid forms a pseudophase liquid microenvironment on the surface of the catalyst, thus improving the mass transfer and heat transfer in the reaction process; and the catalyst has good stability, long service life, high activity and good selectivity.

Owner:TSINGHUA UNIV

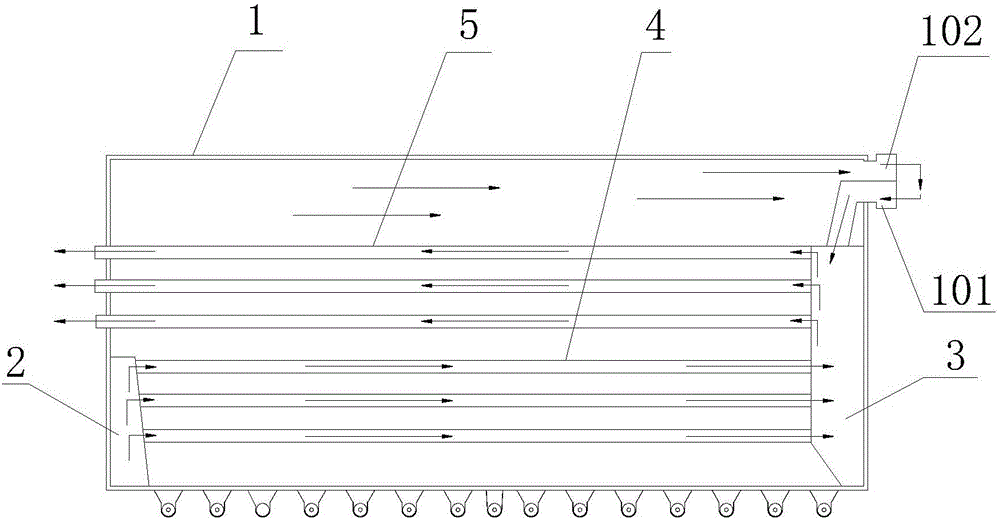

Extinguishment preventing garbage processing device

InactiveCN106838912AAccelerate the reduction of carbonization effectReduce absorptionIncinerator apparatusEngineeringAuxiliary heating

The invention discloses an extinguishment preventing garbage processing device comprising a furnace body used for processing garbage. An inner cavity of the furnace body has the length direction and the width direction, wherein the width direction is smaller than the length direction. A heating chamber and a flow guiding chamber are arranged in the interior, on the two sides, close to the bottom, of the inner cavity of the furnace body. The heating chamber is provided with an inlet communicating with the outside world and used for introducing a high-temperature medium. An energy balancer is arranged in the inner cavity of the furnace body and comprises first pipes and second pipes which extend in the length direction of the inner cavity of the furnace body. The two ends of the first pipes communicate with the heating chamber and the flow guiding chamber correspondingly. The second pipes are located above the first pipes, one ends of the second pipes communicate with the flow guiding chamber, and the other ends of the second pipes communicate with the outside world. The extinguishment preventing garbage processing device can conduct auxiliary heating to enable the interior of the furnace body to be in a high-temperature state all the time, and the problem that extinguishment occurs due to insufficient heat in a furnace is avoided.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

A kind of process of calcium carbide producing pvc

ActiveCN106967192BGuaranteed temperatureIncrease profitPreparation by halogen halide additionSlagSlurry

The invention discloses a process of using calcium carbide to produce PVC. The method is characterized by including: enabling calcium carbide slag slurry going out of an acetylene generator to overflow into a settling basin for settling, discharging bottom slag slurry for other use, and returning supernatant after being cooled into the acetylene generator to serve as reaction water for preparing acetylene from calcium carbide; returning wastewater used for dedusting acetylene gas and after being cooled into the acetylene generator to serve as reaction water for preparing acetylene from calcium carbide; enabling hot water going out of a converter shell layer and after exchanging heat through a heat exchanger to enter the upper portion of a steam absorption tower to absorb heat evaporated by a hot water tank and then automatically flow into the hot water tank, wherein the heat exchanger is used in other processes. By the process, effective utilization of water resources is realized fully, and environment pollution caused by wastewater discharge is avoided; conversion heat of chloroethylene is utilized reasonably, so that energy conservation and consumption reduction are realized.

Owner:SICHUAN YONGXIANG CO LTD

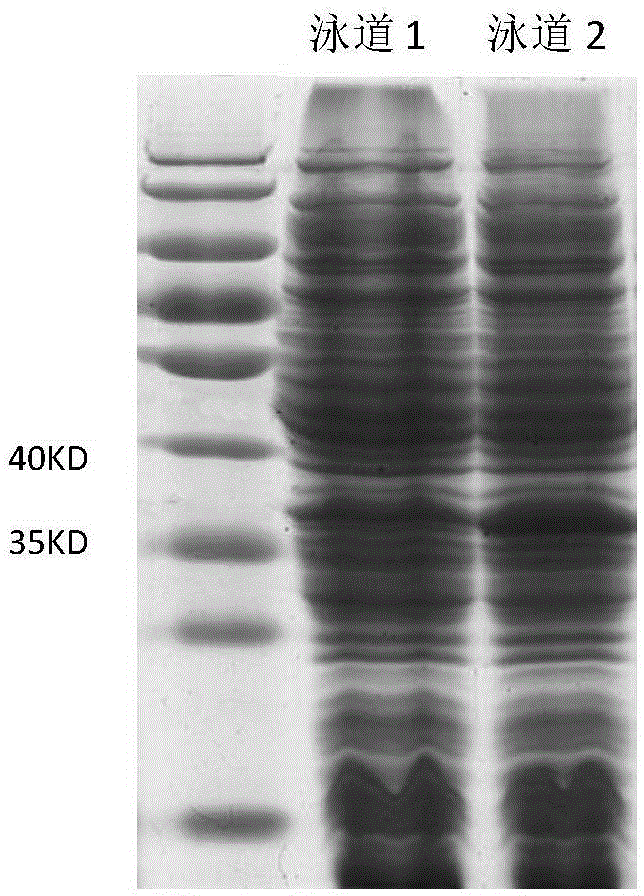

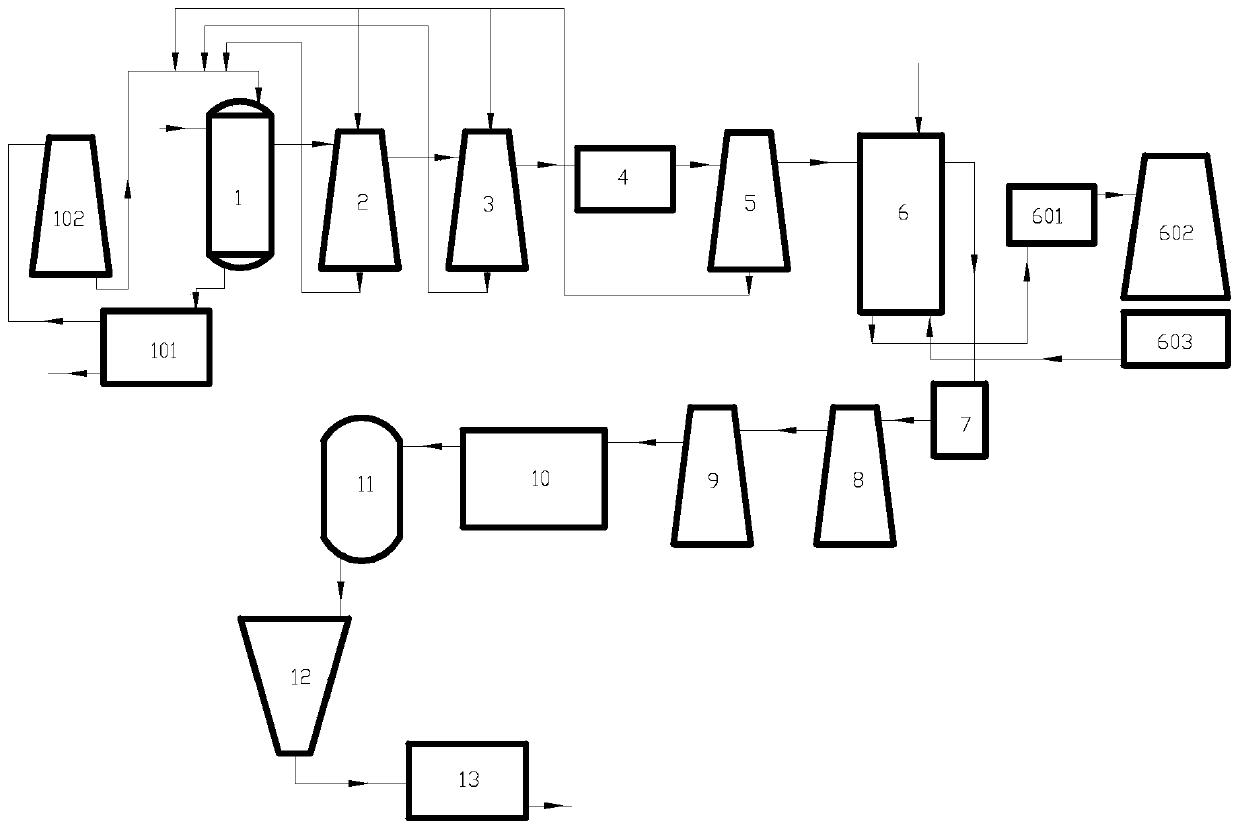

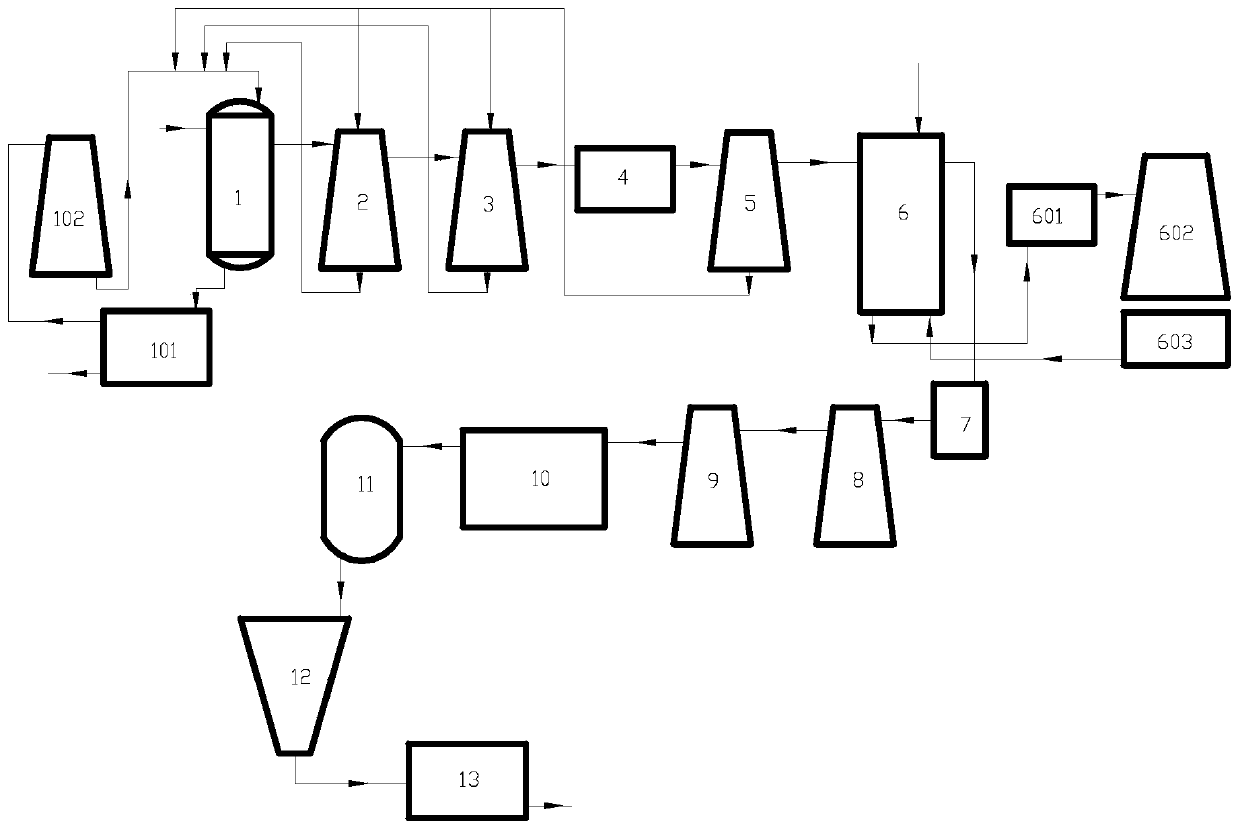

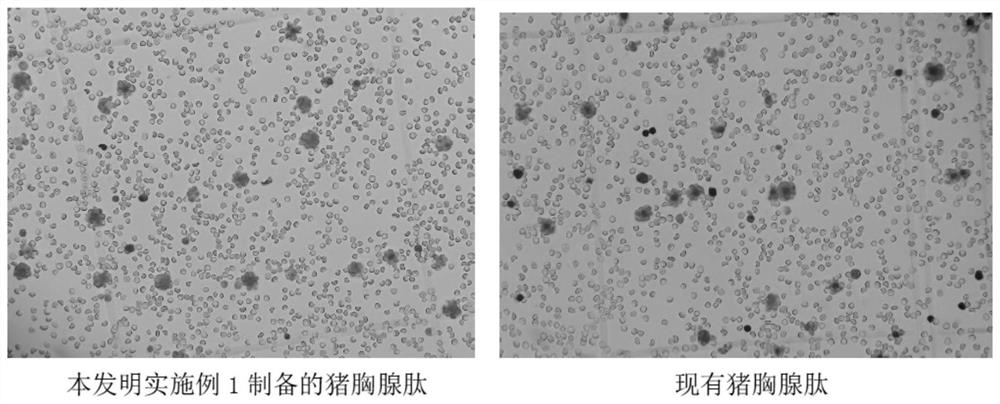

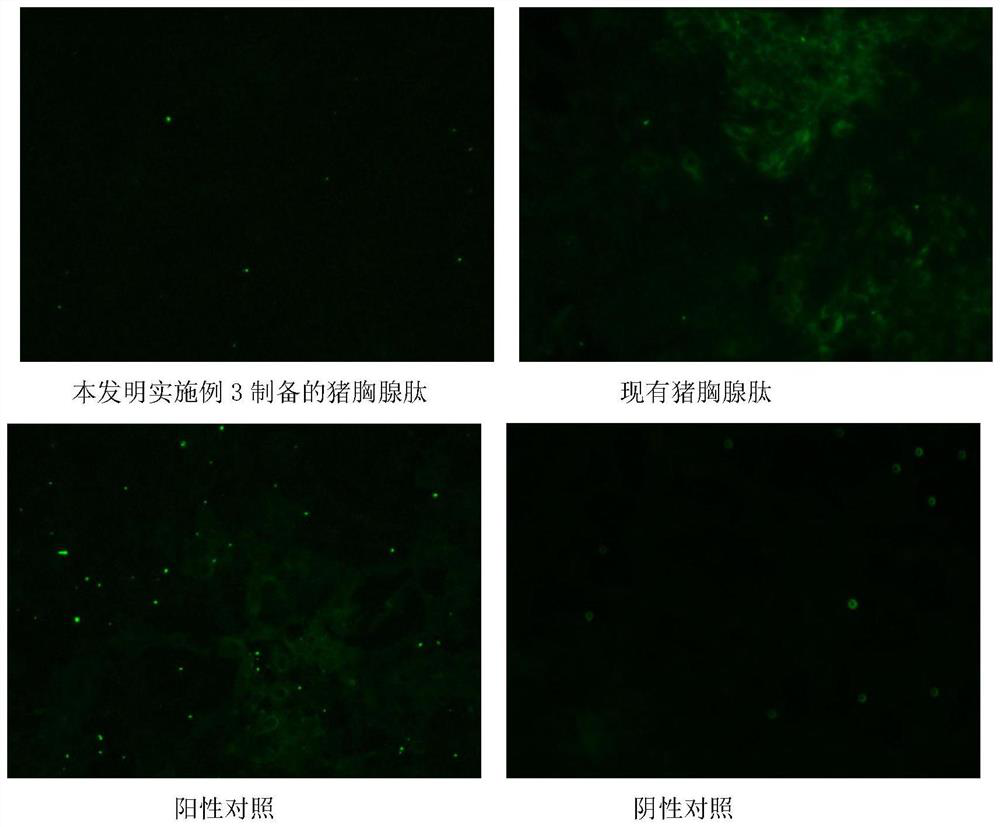

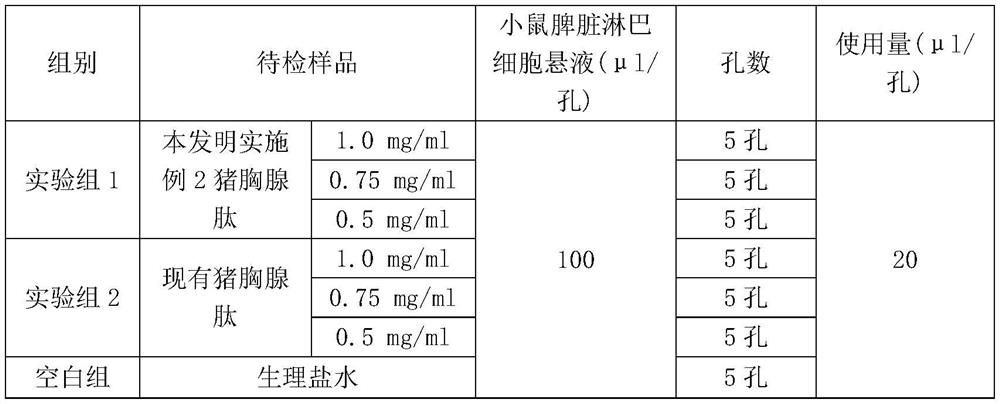

Preparation method of pig thymosin

PendingCN114805541AAccurate and effective separation and concentration technologyDifferent biological activitiesThymosin peptidesPeptide/protein ingredientsThymus GlandsVirus

The invention discloses a preparation method of pig thymosin, which comprises the following steps: 1) mixing water for injection or water for injection of which the pH value is adjusted to 1.5-6.5 by hydrochloric acid with minced pig thymus, and homogenizing by a colloid mill to obtain homogenate; 2) carrying out cell disruption and water insulation and heat preservation on the homogenate, and centrifuging and collecting a centrifugal supernatant; (3) carrying out tangential flow filtration on the harvested centrifugal supernate by adopting a filter membrane, and collecting permeate; 4) carrying out tangential flow filtration on the permeate step by step by using filter membranes with different interception pore diameters and molecular weights, and collecting the permeate to obtain a pig thymosin crude product in a required molecular weight range; 5) mixing the thymosin crude products in at least one molecular weight range in the step 4) to obtain a thymosin primary product; and 6) removing viruses from the pig thymosin primary product, adjusting the pH value and osmotic pressure, filtering and sterilizing to obtain the pig thymosin. According to the method, step-by-step tangential flow filtration is adopted, an accurate and effective pig thymosin separation and concentration technology and a small molecule purification technology are established, and the pig thymosin in the required molecular weight range can be prepared by selecting filter membranes with different cut-off pore diameters and molecular weights according to different technological processes.

Owner:福建农业职业技术学院 +4

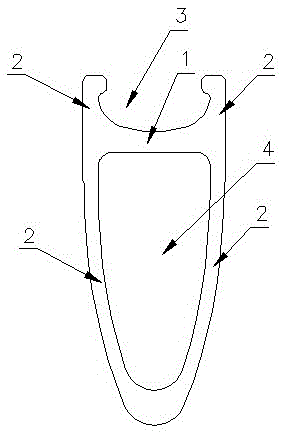

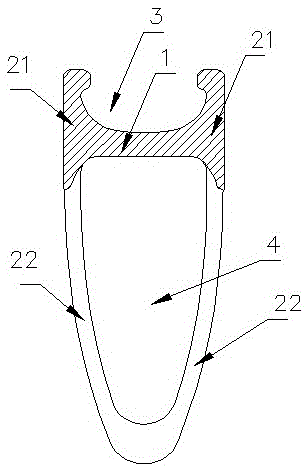

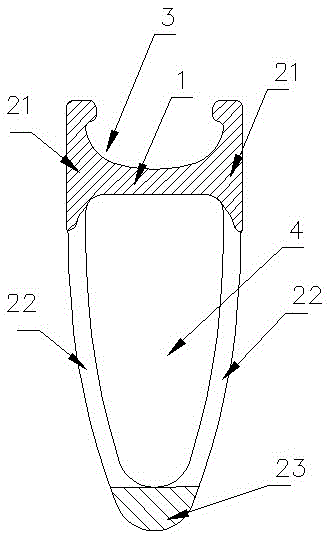

Multi-tg carbon fiber rim and preparation method thereof

ActiveCN103722977BReduce the risk of frame burntImprove securityRimsNon-metallic wheel bodyFiberEpoxy

The invention discloses a multi-TG (glass transition temperature) carbon fiber wheel rim as well as a manufacturing method thereof. The wheel rim is manufactured from carbon fiber composite materials, and comprises two crossed side walls and a connecting axle; a tire position hole slot for placing an inner tire and a 'V'-shaped inner cavity body are formed in two border areas of the connecting axle in a spacing manner, and the tire position hole slot and the 'V'-shaped inner cavity body are ranked up and down; side walls, corresponding to and close to the tire position hole slot and the connecting axle, are braking sides; the braking sides and the connecting axle combine to form a structure with an 'H'-shaped cross section; two kinds or more than two kinds of epoxy resin carbon fiber materials with different TGs are adopted for the 'H'-shaped structure and the side wall corresponding to the inner cavity body. According to the multi-TG carbon fiber wheel rim disclosed by the invention, epoxy resin carbon fiber materials with high-TG higher than 180 DEG C are adopted for the braking area for bearing tire pressure, and the frame burning hazard of the rim is reduced effectively; not only is the safety of the rim improved, but also the requirements at two aspects of light weight and safety are considered; at the non-braking part, epoxy resin carbon fiber materials with low-TG lower than 180 DEG C are adopted, and thus the rim has favorable rigidity and toughness, and the impact strength of the rim is improved.

Owner:XIAMEN CARBONKING COMPOSITES TECH

A kind of energy storage wood with alkylated boron nitride as filler

InactiveCN110405883BWide variety of sourcesMeet the requirements of low-carbon environmental protectionWood treatment detailsThermal wood treatmentPolymer scienceGlycidyl methacrylate

The invention discloses an energy storage wood material using alkylated boron nitride as a filler. The main steps of the method comprise: (1) carrying out lignin removing treatment on a wood materialto increase energy storage space; (2) copolymerizing glycidyl methacrylate and polyethylene glycol 400, and blending with glycidyl methacrylate to prepare an organic solvent; (3) dispersing boron nitride in a buffer solvent, adding dopamine hydrochloride, carrying out a reaction for a certain time at a room temperature to graft boron nitride onto dopamine, dispersing dopamine-modified boron nitride in N,N-dimethyl formamide, adding octadecyl isocyanate, and grafting boron nitride onto the alkyl chain under the action of a catalyst; (4) blending the alkylated boron nitride, the organic solventand polyethylene glycol 800 to prepare a phase change energy storage material; and (5) immersing the phase change energy storage material in the wood material by using a vacuum pressurizing full cellmethod to obtain a phase change energy storage wood material.

Owner:BEIJING FORESTRY UNIVERSITY

Smoker box and electric smoker with smoker box

The invention provides a fumigating box and an electric fumigating oven with the fumigating box, belongs to the technical field of electric fumigating ovens, and aims to solve the technical problems that the fume supply time is shortened, a relatively great amount of materials can be consumed, and the like as the flowing speed of fume generated from a fume generator of a conventional fumigator is too high. The fumigating box comprises a box body and a box cover, wherein a material storage cavity for accommodating a fume generating material is formed inside the box body; the top surface of the box body is opened; the box cover is detachably connected onto the top of the box body and is used for sealing the opening of the box body; a fume storage cavity is formed inside the box cover; fume inlets for communicating the fume storage cavity with the material storage cavity are formed in the bottom surface of the box cover; fume outlets communicated with the fume storage cavity are formed in the top surface of the box cover; a fume baffle structure for retarding fume in the fume storage cavity from being discharged out is arranged inside the box cover. By adopting the fumigating box and the electric fumigating oven, the utilization rate of a fume generating material can be effectively increased.

Owner:ZHEJIANG FUDEER ELECTRIC APPLIANCE

Auxiliary heat garbage disposal equipment

InactiveCN106813245BKeep burningTo achieve the purpose of self-heatingIncinerator apparatusCombustionMetallurgy

The invention discloses an auxiliary heating type garbage treatment device. The auxiliary heating type garbage treatment device comprises a furnace body and a heat supply device; the furnace body comprises an upper furnace body and a lower furnace body which are arranged up an down, the heat supply device is used for conveying high-temperature gas, the upper furnace body is communicated with a furnace cavity of the lower furnace body, the upper furnace body is provided with an upper clamping cavity, an exhaust opening is formed in the upper clamping cavity, the lower furnace body is provided with a lower clamping cavity, and the lower clamping cavity is provided with an air inlet; a feeding opening is formed in the top of the upper furnace body, an air inlet pipe bundle is arranged in the lower furnace body, an auxiliary heating pipe is arranged above the air inlet pipe bundle and is provided with an air inlet end and an air exhaust end, the air inlet end of the auxiliary heating pipe is communicated with the lower clamping cavity, the air outlet end of the auxiliary heating pipe is communicated with the upper clamping cavity, and the heat supply device is communicated with the air inlet of the lower clamping cavity and is used for conveying high-temperature gas to the interior of the lower clamping cavity. According to the device, it can be effectively ensured that garbage in a combustion layer can be continuously combusted, the air outlet end of the auxiliary heating pipe is communicated with the upper clamping cavity, and the middle-low-temperature gas exhausted from the auxiliary heating pipe enters the upper clamping cavity so as to achieve heat preservation in the upper furnace body.

Owner:SINOBIOWAY DINGHE ENVIRONMENTAL PROTECTION CO LTD

A kind of energy storage wood and semi-interpenetrating network regulation method using boron nitride as filler

ActiveCN110394871BWide variety of sourcesMeet the requirements of low-carbon environmental protectionWood treatment detailsPressure impregnationPolymer scienceGlycidyl methacrylate

Owner:BEIJING FORESTRY UNIVERSITY

A method for rationally designed enzymes to regenerate ATP

ActiveCN105624238BComply with temperature requirementsLow priceTransferasesFermentationHeterologousO-Phosphoric Acid

The present invention relates to a method of rationally designed enzymes for the regeneration of ATP. Through rational design after sequence comparison, polyphosphate kinase derived from Sinorhizobium meliloti was mutated and heterologously expressed, and under its catalysis, polyphosphate with a low degree of polymerization was used as a phosphate donor to regenerate ATP. Compared with the existing ATP regeneration method, the polyphosphate kinase used in the present invention is an enzyme at room temperature, which can be coupled with various enzymatic reactions. Compared with polyphosphoric acid, tetrapolyphosphoric acid is more common and easy to obtain, which increases the feasibility of ATP regeneration and reduces the cost of ATP regeneration on the basis of simplifying the ATP regeneration process. The activity of PPK enzyme is not inhibited by the concentration of polyphosphate, which provides the possibility for industrial large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

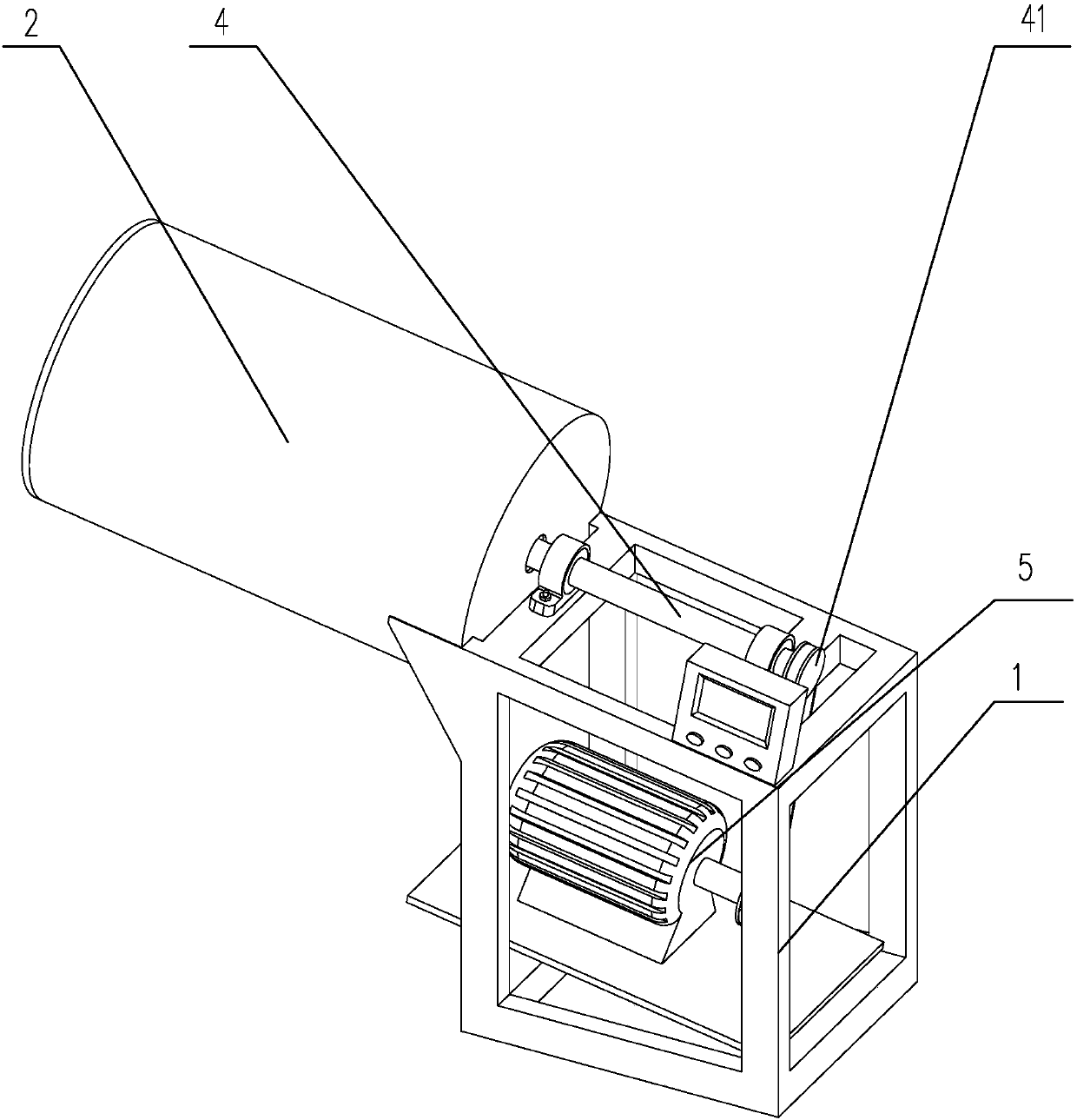

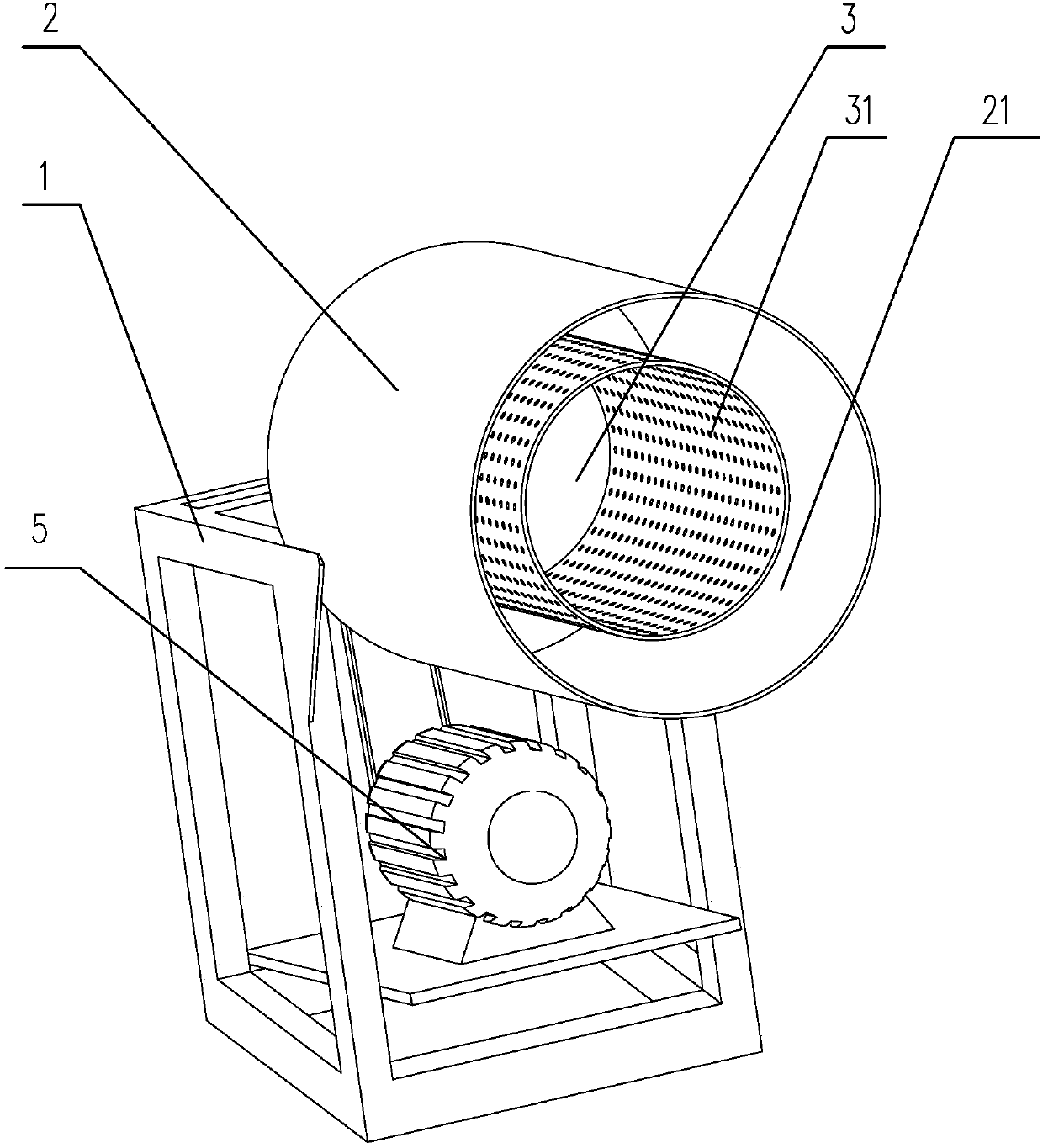

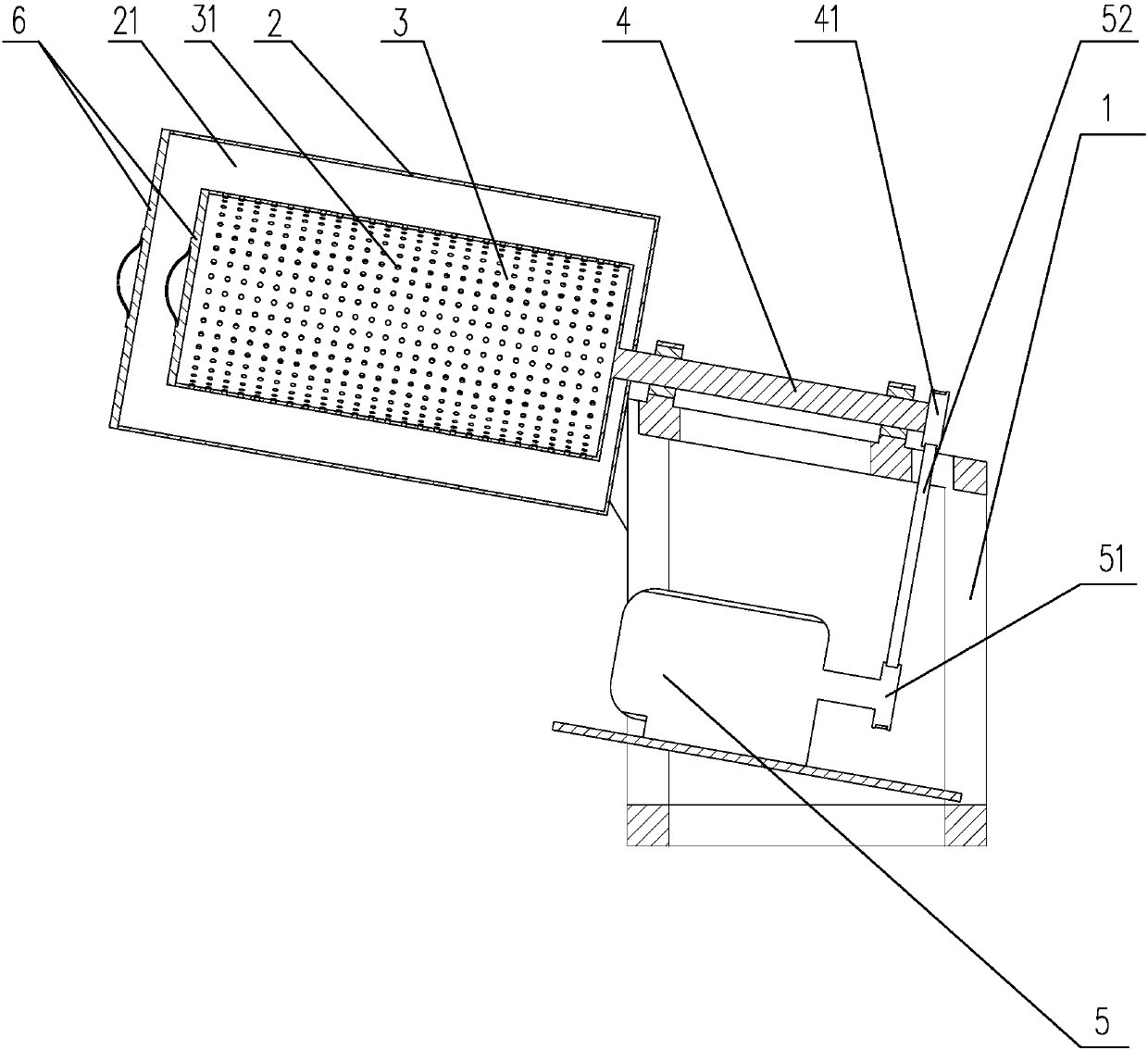

Peeling processing method of dendrobium officinale and processing device for realizing the method

PendingCN107736629AAvoid contaminationImprove cleanlinessPharmaceutical product form changeVegetable peelingEngineeringMechanical engineering

The present invention discloses a peeling processing method of dendrobium officinale. The method comprises five steps of dendrobium officinale screening, washing, peeling, peel screening and shearing,wherein the peeling step comprises the following steps: dendrobium officinale stalks are heated at a heating temperature of 80-140 DEG C, and at the same time, the dendrobium officinale stalks are stirred and turned at a stirring and turning frequency of 40-60 rpm / min for 100-130 min. At the same time, the present invention discloses a processing device for realizing the method. The processing device comprises a bracket, a heating barrel, a roller and a driving member used for driving a rotation of the roller, the heating barrel is arranged on the bracket, a heating chamber is formed in the heating barrel, the roller is rotatably arranged in the heating chamber, and the roller and the driving member are in a transmission connection via a transmission member. The processing device can effectively strip the peels on the dendrobium officinale stalks, so that the obtained fresh dendrobium officinale strips are better in appearance. The use of the device can effectively increase productionefficiency and reduce labor costs.

Owner:陈恩平

Coptis rhizome detoxification nasal temperature-sensitive gel and preparation method thereof

ActiveCN109453108BEasy to useSignificant effectAntibacterial agentsAntipyreticNosePolyethylene glycol

Owner:ZHANG ZHOU HALTH VOCATIONAL COLLEGE

Machine for monitoring cultivation environment of edible fungi

InactiveCN102156470BComply with temperature requirementsHumidity controlProgramme total factory controlEngineeringEdible fungus

The invention relates to a machine for monitoring cultivation environment of edible fungi, which is characterized by comprising a temperature detection probe, a control device, a blasting device, a heater, a heating air duct, a circulative air inlet duct and an air outlet duct, wherein the temperature detection probe is arranged in an edible fungi cultivation room; the control device is connectedbetween the temperature detection probe and the blasting device; an inlet end of the circulative air inlet duct is arranged in the edible fungi cultivation room while an outlet end of the circulativeair inlet duct is connected with an inlet end of the heating air duct; the heating air duct passes through the heater, and an outlet end of the heating air duct is connected with an inlet end of the blasting device; and an inlet end of the air outlet duct is connected with an inlet end of the blasting device, and an outlet end of the air outlet duct is arranged in the edible fungi cultivation room. The invention aims to provide the machine for monitoring the cultivation environment of the edible fungi, which can regulate and control the temperature of the edible fungi cultivation room.

Owner:曾定金

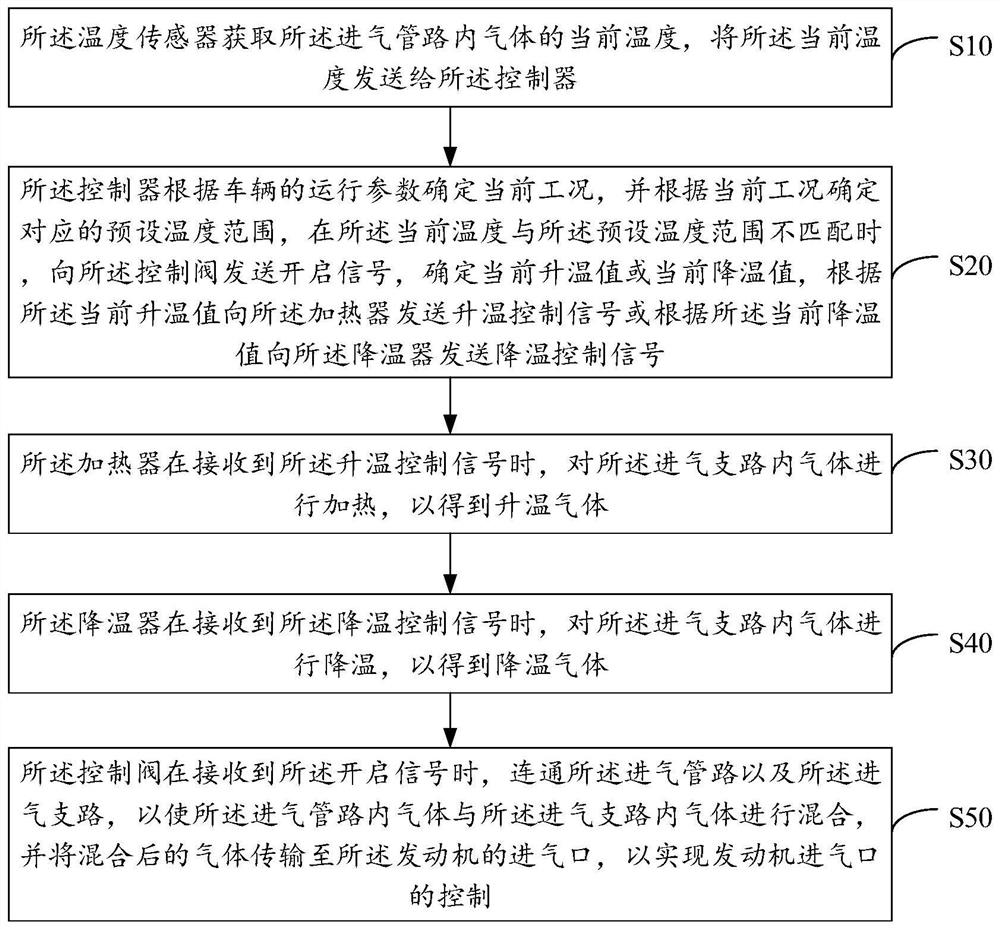

Engine air inlet control system and method

ActiveCN113250865AEasy to controlRealize transmissionElectrical controlInternal combustion piston enginesControl systemControl valves

The invention discloses an engine air inlet control system and method. The system comprises an air inlet pipeline communicated with an air inlet of an engine, an air inlet branch communicated with the air inlet pipeline through a control valve, a temperature sensor arranged at an inlet of the air inlet pipeline, a heater, a cooler and a controller connected with the control valve, the heater, the cooler and the temperature sensor, wherein the heater and the cooler are arranged in the air inlet branch; and the controller receives the current temperature detected by the temperature sensor, determines a preset temperature range corresponding to the current working condition, and controls the control valve to be opened, controls the heater to heat or controls the cooler to cool when the current temperature is not matched with the preset temperature range so as to communicate the air inlet pipeline with the air inlet branch. Air in the air inlet pipeline and the air inlet branch is mixed and conveyed to the air inlet of the engine. The temperature of the air in the air inlet branch is controlled according to the current working condition, so that the mixed air meets the temperature requirement of the current working condition, the actual air inlet temperature of the engine is monitored and controlled, and the working efficiency of the engine is improved.

Owner:WUHAN FINEMEMS

A mobile emergency natural gas supply system and mobile emergency natural gas supply method

Owner:SHENZHEN GAS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com